Piezoelectric film bulk wave resonator electric field sensor

A technology of electric field sensor and piezoelectric film, which is applied in the field of electric field sensing, can solve the problem of low sensitivity and achieve the effect of high sensitivity of electric field measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

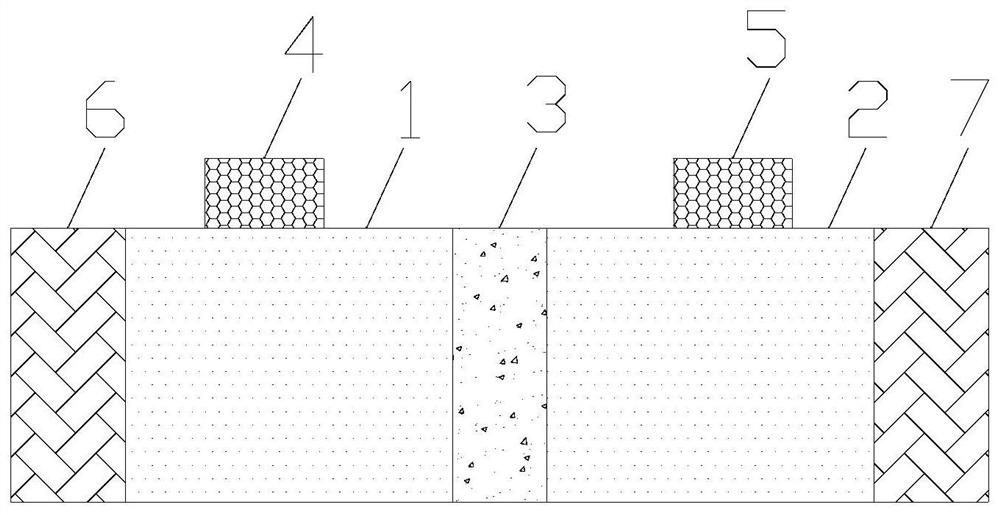

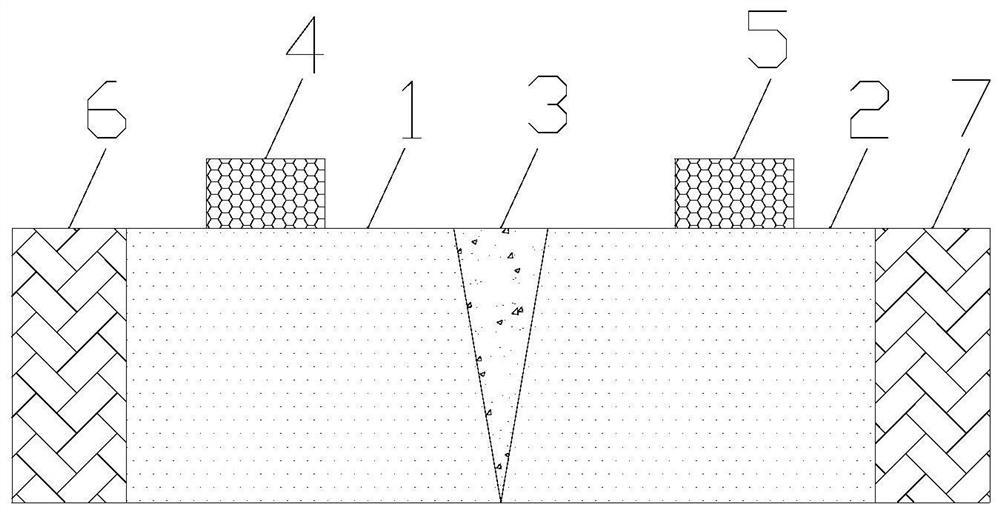

[0018] The invention provides a piezoelectric film bulk wave resonator electric field sensor, such as figure 1 As shown, it includes a first piezoelectric body 1 , a second piezoelectric body 2 , a first electrode 4 , a second electrode 5 , a first force applying part 6 , a second force applying part 7 , and an organic conjugated polymer material. A gap 3 is provided between the first piezoelectric body 1 and the second piezoelectric body 2 , and the gap 3 is rectangular. An organic conjugated polymer material fills the gap 3 . The organic conjugated polymer material is poly-3-hexylthiophene. When heated, the microscopic morphology of poly-3-hexylthiophene is more easily regulated by the electric field to be measured. The materials of the first piezoelectric body 1 and the second piezoelectric body 2 are aluminum nitride, zinc oxide, or lead zirconate titanate piezoelectric ceramics. In the present invention, the first piezoelectric body 1, the organic conjugated polymer ma...

Embodiment 2

[0021] On the basis of Embodiment 1, the first piezoelectric body 1 and the second piezoelectric body 2 are the same. The first piezoelectric body 1 and the second piezoelectric body 2 are arranged mirror-symmetrically with respect to the gap 3 . The first electrode 4 and the second electrode 5 are arranged mirror-symmetrically with respect to the gap 3 . That is, the entire device is mirror-symmetric about the gap 3, that is, at figure 1 , the device is left-right symmetrical. In this way, when the bulk acoustic wave resonates in the composite structure, the energy of the bulk acoustic wave will be concentrated in the gap 3; that is, in the gap 3, the vibration of the bulk acoustic wave is strong. When the molecular chain direction of the organic conjugated polymer material is changed, the resonant frequency of the bulk acoustic wave will be changed more, thereby achieving higher sensitivity electric field detection.

[0022] The width of the gap 3 is smaller than the wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com