A Side Pushing Device for Electromagnetic Tube Bending

A bending forming and electromagnetic technology, which is applied in the field of electromagnetic pipe bending and forming side pusher, can solve the problems of thinning wall thickness of the outer material of the bending section, springback of pipe fittings, cross-sectional distortion, and cracking, etc., to achieve reduction Small degree of thinning, high flexibility, and the effect of alleviating distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

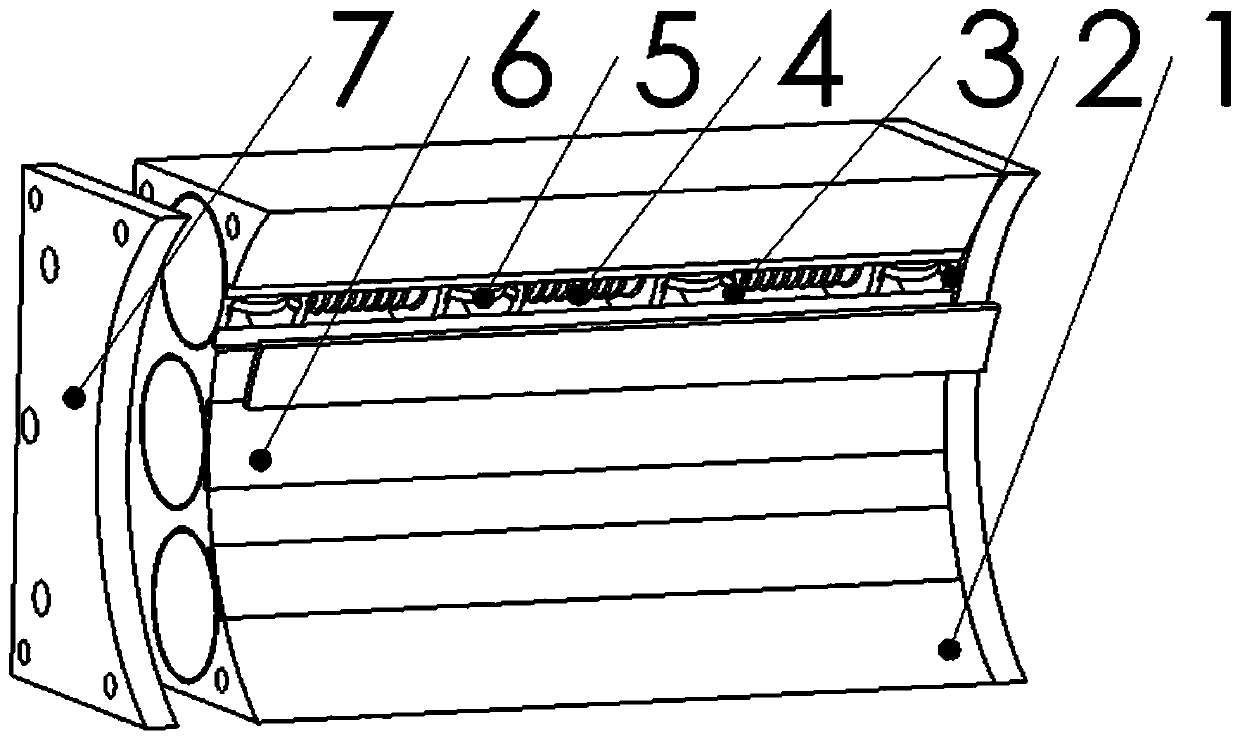

[0029] Such as figure 1 As shown, the specific implementation of the present invention includes a side push block 1, an electromagnetic briquetting unit and a rubber sheet 6; There are several strip-shaped through grooves arranged at intervals in the circumferential direction. The notch of each strip-shaped through-groove is attached with a rubber sheet 6. The rubber sheet 6 is placed between the two sides of the strip-shaped through-groove. The rubber sheet 6 covers the strip. In the notch of the shaped through groove, the inside of the side push block 1 is equipped with a number of electromagnetic briquetting units arranged in parallel along the circumferential direction of the concave arc cylindrical surface.

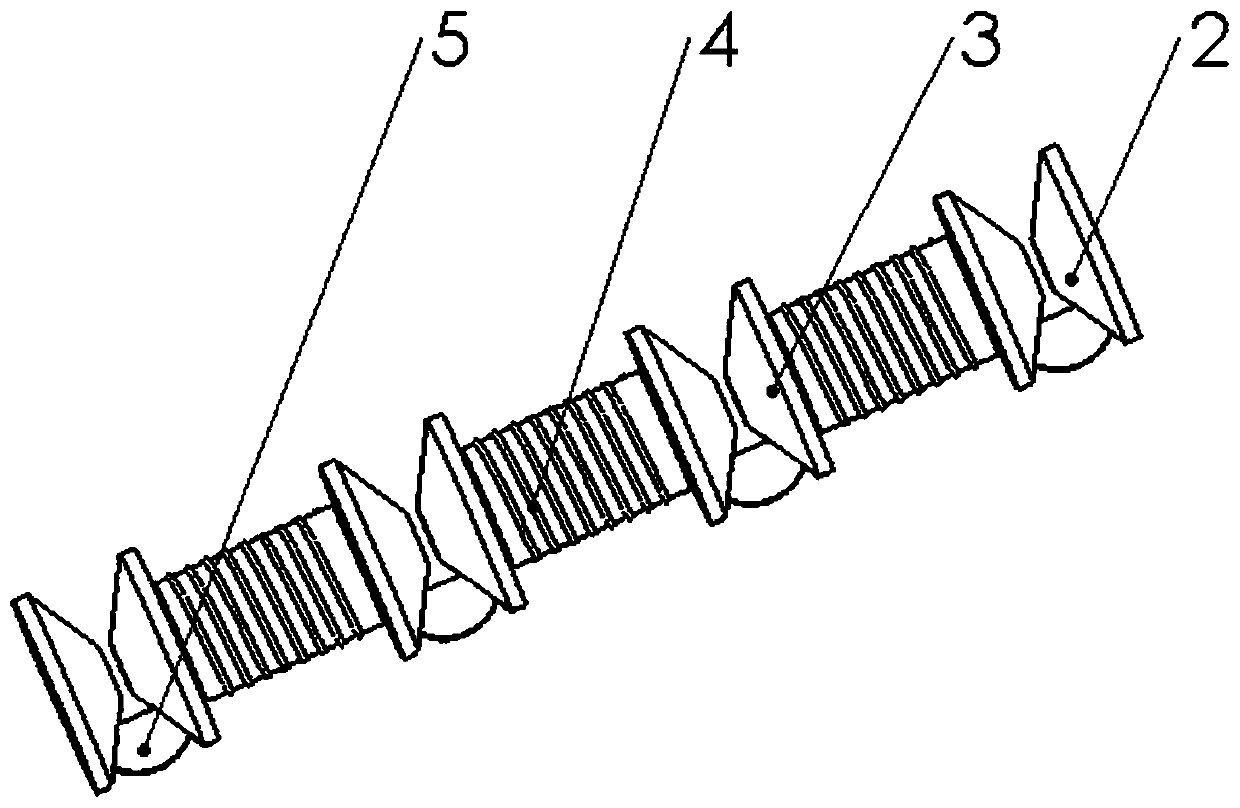

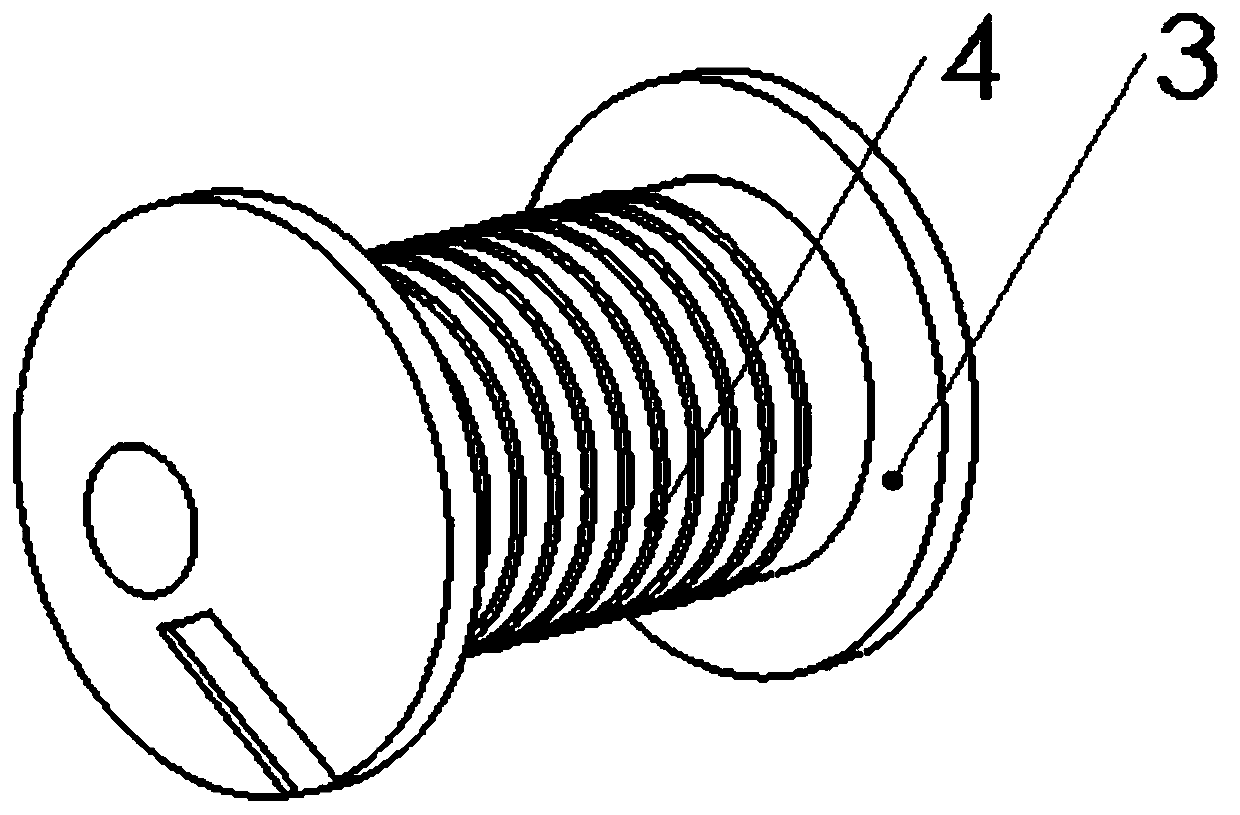

[0030] Such as figure 1 and Figure 4 As shown, each electromagnetic briquetting unit corresponds to each bar-shaped through groove, and the electromagneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com