Discontinuous contact incremental forming method and product of sheet metal driven by equal-diameter spiral trajectory

A progressive forming and discontinuous technology, which is applied in the field of discontinuous contact progressive forming and products driven by equal-diameter spiral trajectory, can solve the problems of forming limit angle, increasing external force of sheet forming, and large frictional resistance, etc., to achieve The effect of reducing the degree of thinning and improving formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

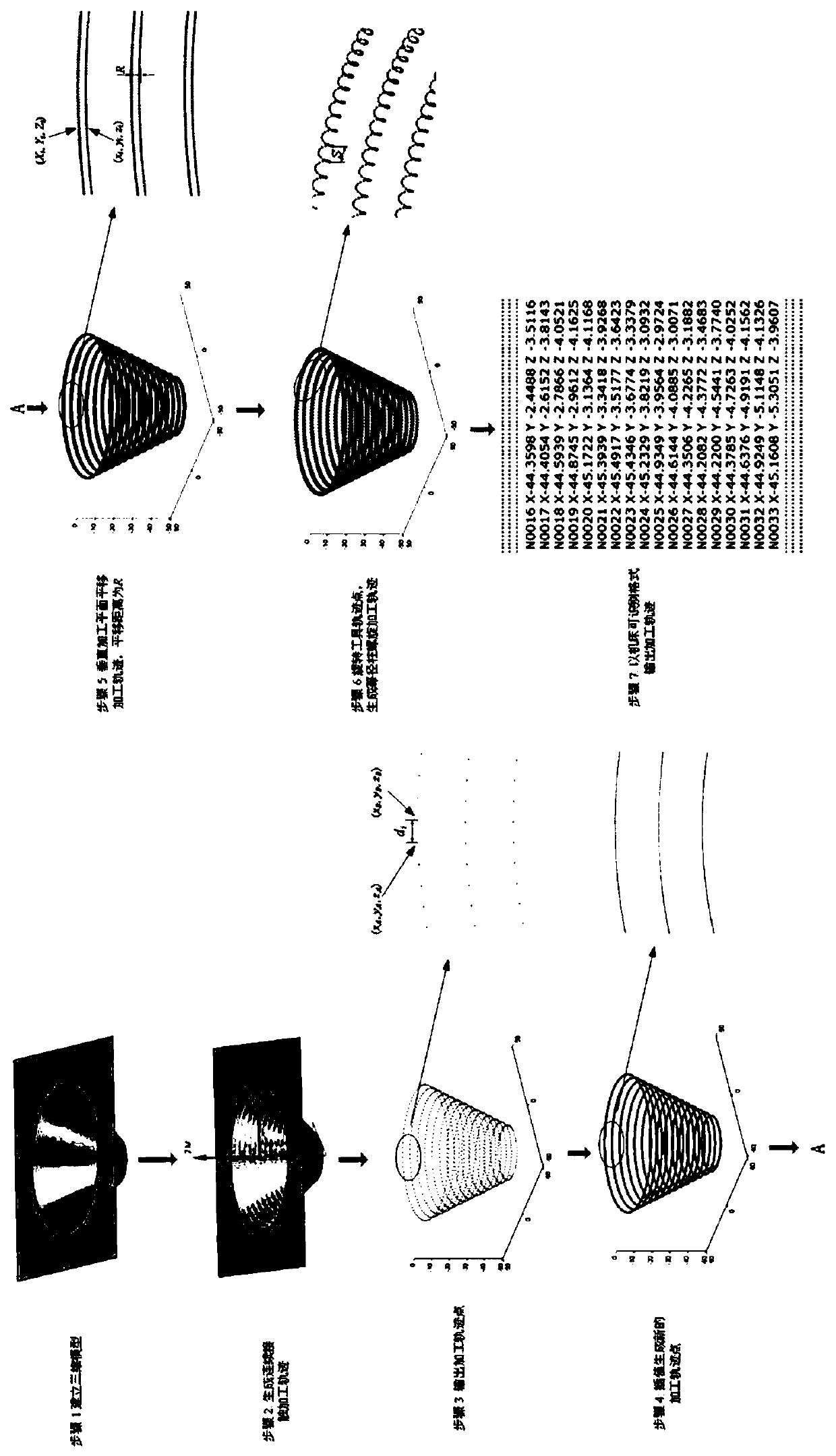

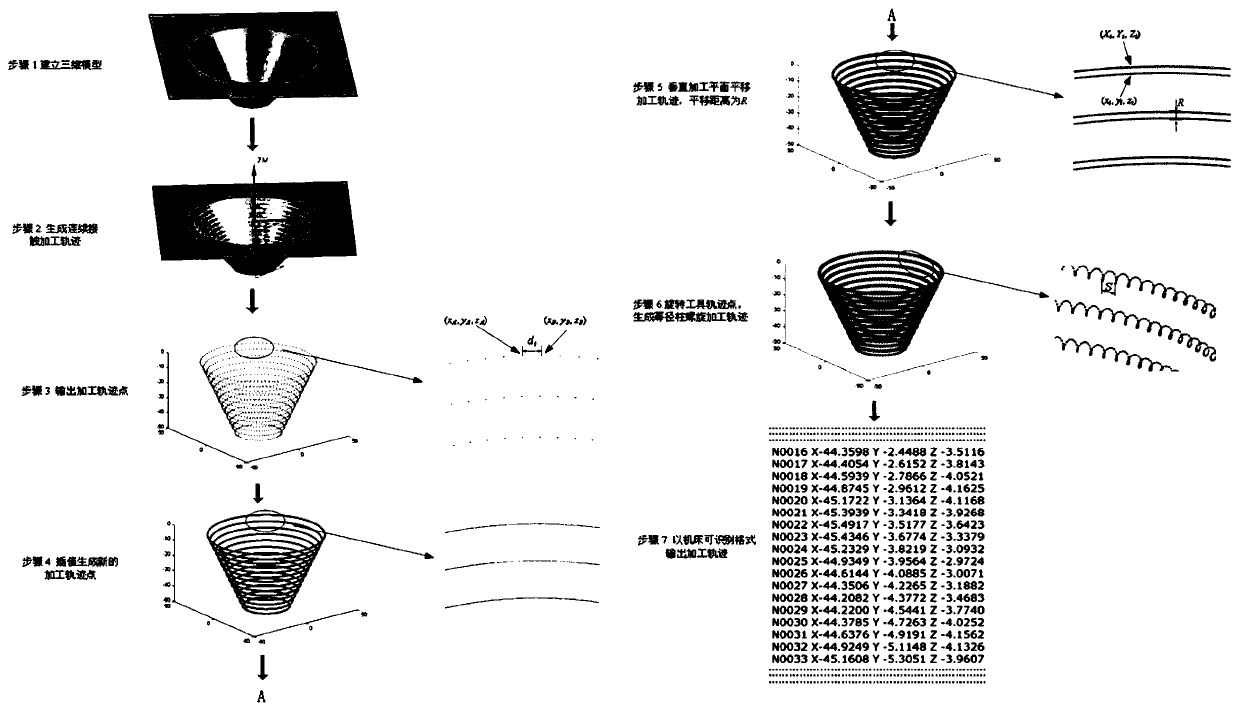

[0068] The implementation process of discontinuous contact incremental forming driven by equidiametric spiral trajectory is as follows: figure 1 As shown, as follows:

[0069] (1) Establish a three-dimensional CAD model of a conical cup with a side wall inclination angle of 60°, a radius of 100 m, and an opening size of 100 mm in UGNX8.0 software.

[0070] (2) The machining module in UGNX8.0 software generates the machining trajectory of continuous contact incremental forming.

[0071] (3) Set the accuracy of the incremental forming processing trajectory to 0.02 mm, and output the continuous processing trajectory in the form of discrete points through calculation.

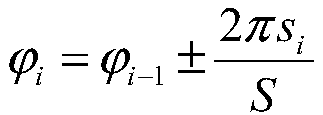

[0072] (4) Interpolate the processing trajectory points output in step (3), and set the number of trajectory points that each helical lead should meet to be 18, and obtain the space of the new processing trajectory point i through the Lagrange linear interpolation method The coordinates are (x i ,y i ,z i ); ...

Embodiment 2

[0083] A sheet-shaped formed part, that is, the above-mentioned product, is obtained by using the non-continuous contact sheet metal incremental forming method driven by the equal-diameter spiral trajectory described in Implementation 1. After using steps (1)-(8) to obtain the corresponding program, then use an industrial pure aluminum 1060 plate with a thickness of 1mm to cut the plate into 230×230mm, so that the geometric center of the plate coincides with the geometric center of the forming fixture , press the plate around 15mm and clamp it; the forming tool is gradually formed point by point according to the equal-diameter spiral trajectory data generated in step (8) under the control of the machine tool; the final product is obtained.

[0084] The parameters mentioned in the above embodiments are only given as a specific embodiment and are not limited thereto. In other embodiments, those skilled in the art can adjust according to the parameters of the processed products or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com