Cantilever beam electric field detection device

A technology of detection device and cantilever beam, applied in the field of electric field detection, can solve the problem of low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

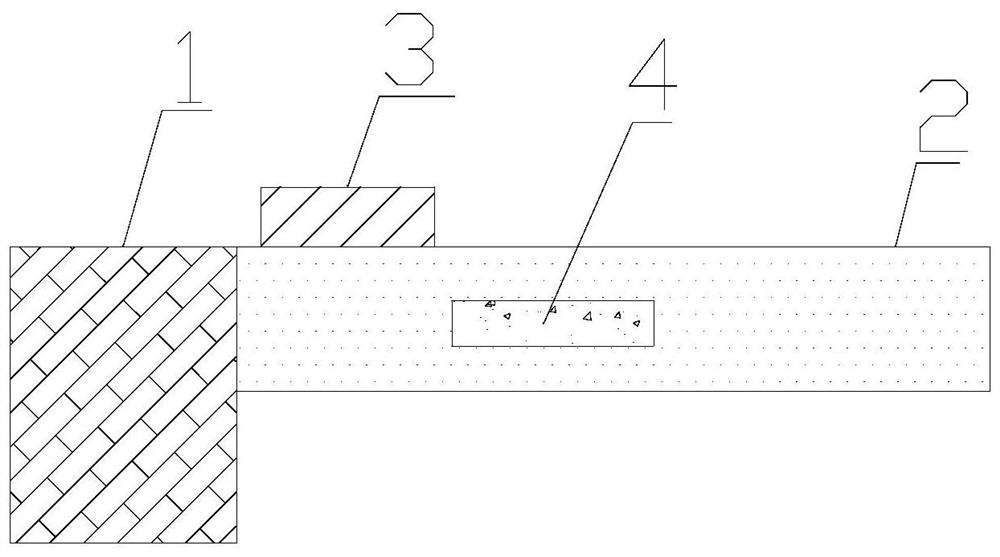

[0022] The invention provides a cantilever beam electric field detection device. like figure 1 As shown, the cantilever beam electric field detection device includes a vibration source 1, a cantilever beam 2, a piezoelectric material block 3, a cavity 4, and an organic conjugated polymer material. The cantilever beam 2 is fixed on the vibration source 1 . The material of the cantilever beam 2 is aluminum alloy, silicon, semiconductor material, diamond. The piezoelectric material block 3 is arranged on the top surface of the cantilever beam 2 near the fixed end, and the piezoelectric material block 3 is connected to an external circuit. The piezoelectric material block 3 is made of piezoelectric ceramics or polyvinylidene fluoride. A cavity 4 is arranged in the cantilever beam 2 , and the organic conjugated polymer material fills the cavity 4 . The organic conjugated polymer material is poly-3-hexylthiophene. When heated, the microscopic morphology of poly-3-hexylthiophene...

Embodiment 2

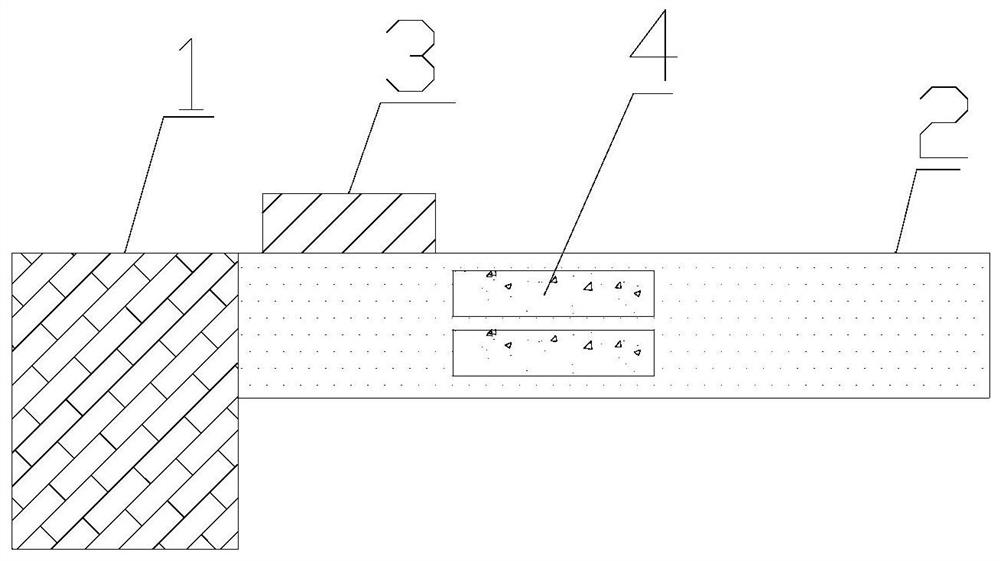

[0025] On the basis of Example 1, such as figure 2 As shown, the number of cavities 4 is two. The two cavities 4 are parallel. Specifically, the direction of the line connecting the two cavities 4 is perpendicular to the direction of the cantilever beam 2 . In this way, when the molecular chain direction of the organic conjugated polymer material changes, the stress in the cantilever beam 2 changes more, thereby changing the resonant frequency of the cantilever beam 2 more, thereby achieving higher sensitivity electric field detection.

Embodiment 3

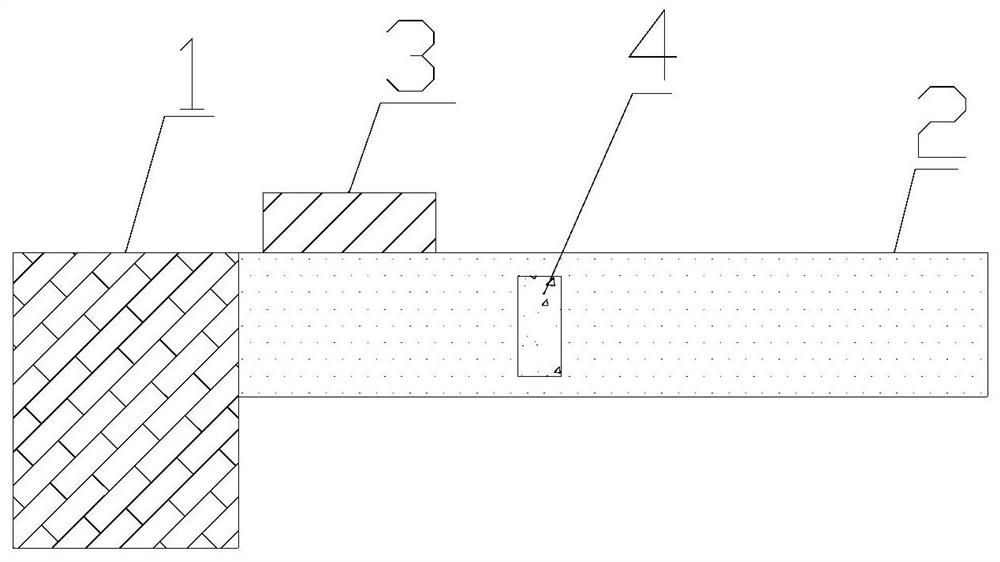

[0027] On the basis of Example 1, such as image 3 As shown, the cavity 4 is a cuboid. The long side of the cavity 4 is perpendicular to the direction of the cantilever beam 2 . The length of the long sides of the cuboid is greater than 1 / 2 of the thickness of the cantilever beam 2 . Since the cantilever beam 2 is driven by the fixed end to vibrate, along the direction of the cantilever beam 2, the force of adjacent structural units has a serious impact on the resonant frequency of the cantilever beam 2. Therefore, along the direction of the cantilever beam 2, the force between adjacent structural units A change in the applied force will severely change the resonant frequency of the cantilever beam 2 . In this embodiment, the long side of the cuboid is perpendicular to the direction of the cantilever beam 2, and the length of the long side of the cuboid is greater than that of the cantilever beam 2 at image 3 In this way, the molecular chain direction of the organic conjug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com