Patents

Literature

91results about How to "Solving resonance problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

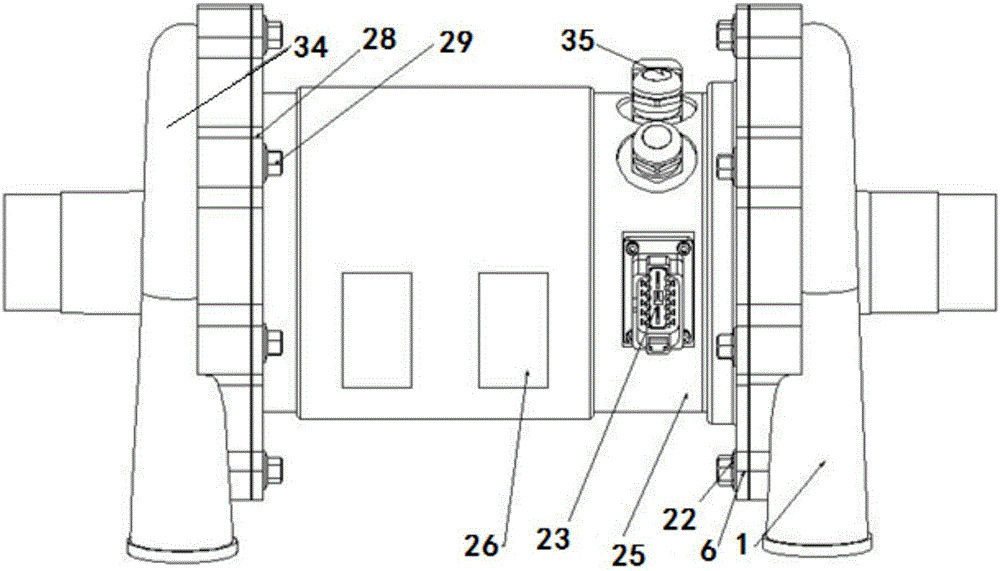

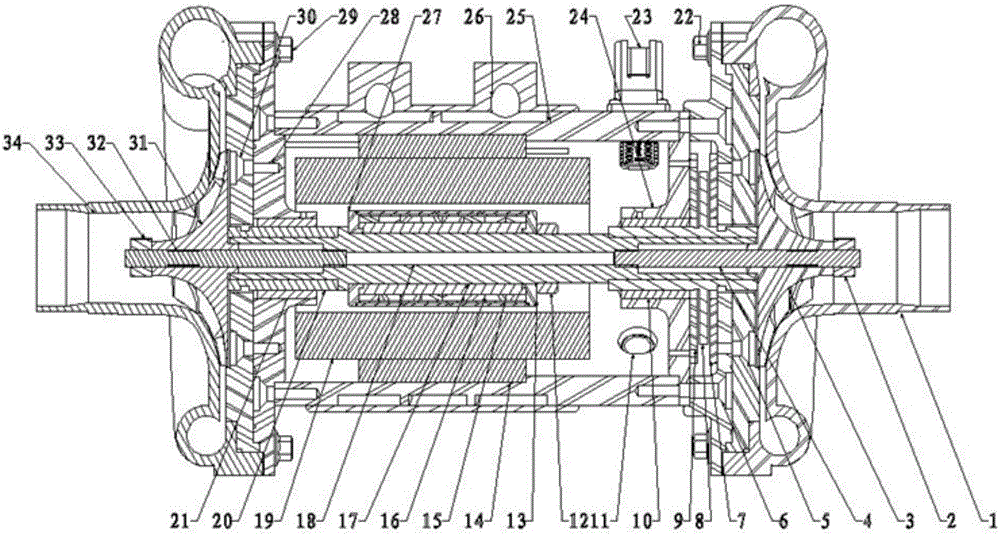

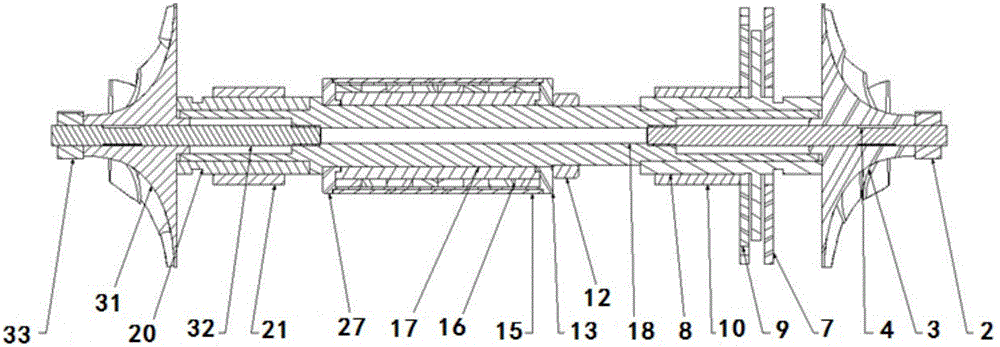

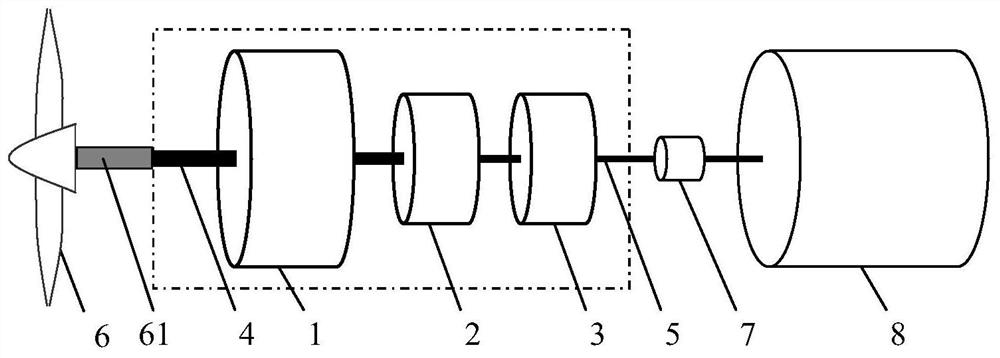

Two-stage series pressurization direct-driven centrifugal air compressor of fuel cell engine

ActiveCN105889096AImprove reliabilityReduce volumeMagnetic circuit rotating partsPump componentsImpellerStator

The invention relates to a two-stage series pressurization direct-driven centrifugal air compressor of a fuel cell engine. The two-stage series pressurization direct-driven centrifugal air compressor comprises end covers, a spindle, volutes, impellers, a rotor, a stator and a driver. The spindle is supported by a left-end radial supporting air foil bearing, a left-end radial supporting air foil bearing bush, an air foil axial thrust bearing and a right-end radial supporting air foil bearing, wherein the left-end radial supporting air foil bearing and the left-end radial supporting air foil bearing bush are arranged on the left side, and the air foil axial thrust bearing and the right-end radial supporting air foil bearing are arranged on the right side of the spindle. The left-end radial supporting air foil bearing bush is arranged on the outer side of the spindle in a surrounding manner. The left-end radial supporting air foil bearing is fixed to the outer side of the left-end radial supporting air foil bearing bush. The air foil axial thrust bearing is fixed to the outer side of the spindle in a bush form. The right-end radial supporting air foil bearing is fixed to the outer side of the air foil axial thrust bearing. Compared with the prior art, the two-stage series pressurization direct-driven centrifugal air compressor is more suitable for the air inlet pressurization scene of the fuel cell engine with the high oilless air inlet requirement, and the durability and reliability of the air compressor of the fuel cell engine can be improved.

Owner:TONGJI UNIV

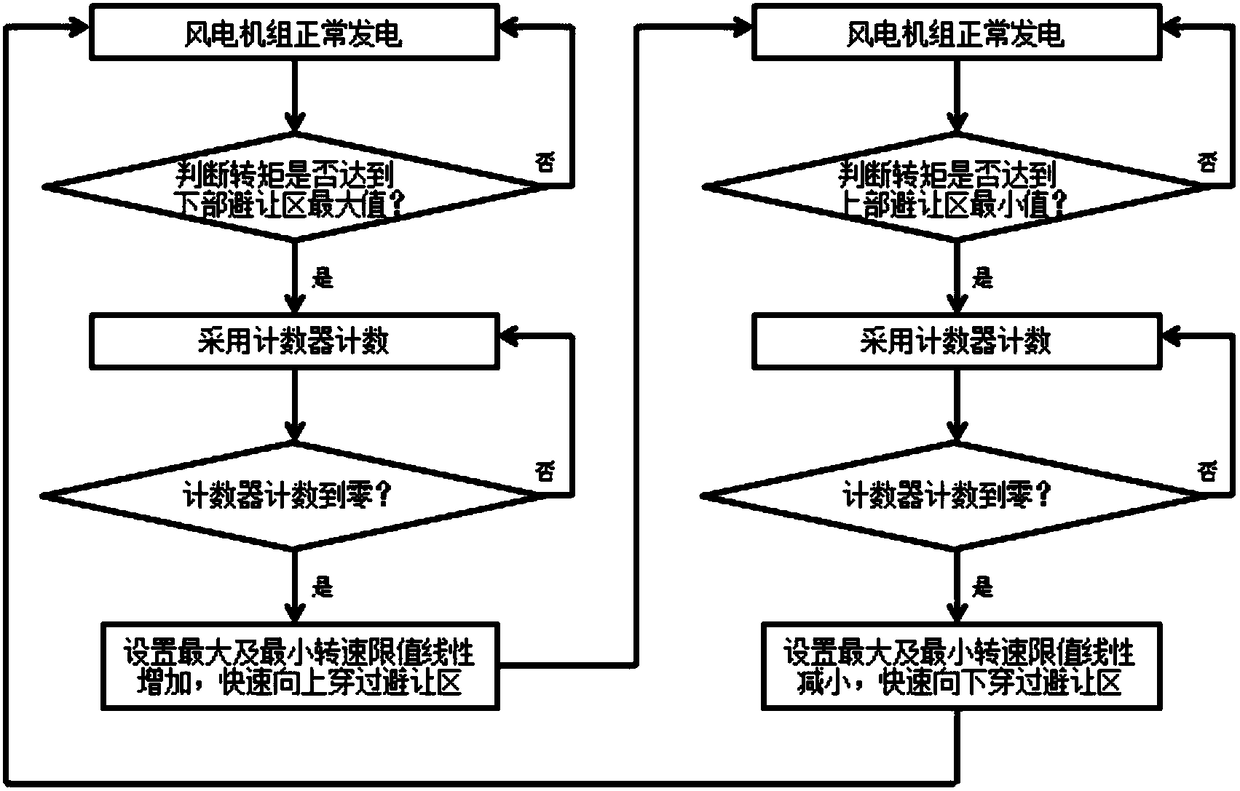

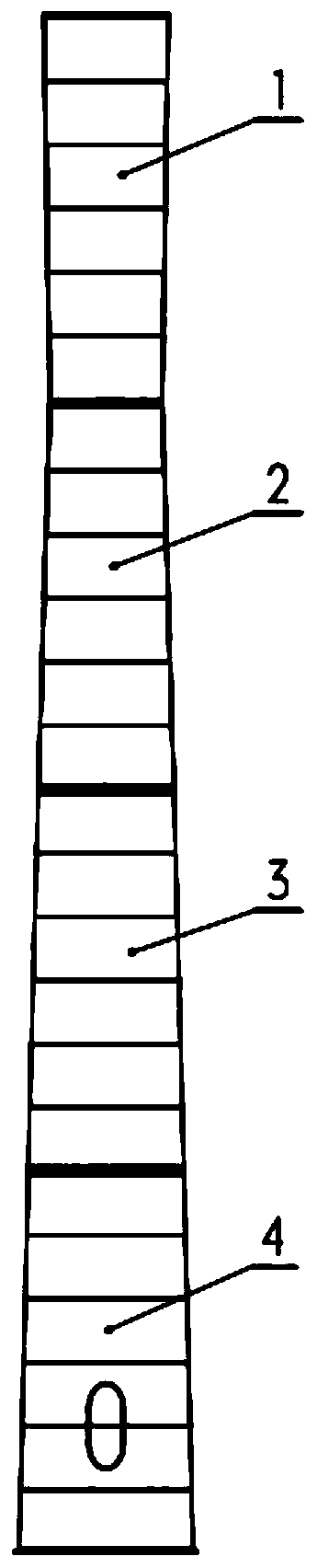

Tower drum resonance avoiding and crossing control method of wind turbine generator and wind turbine generator

InactiveCN108590956AEnsure safetyResonance does not appearWind motor controlMachines/enginesLower limitElectricity

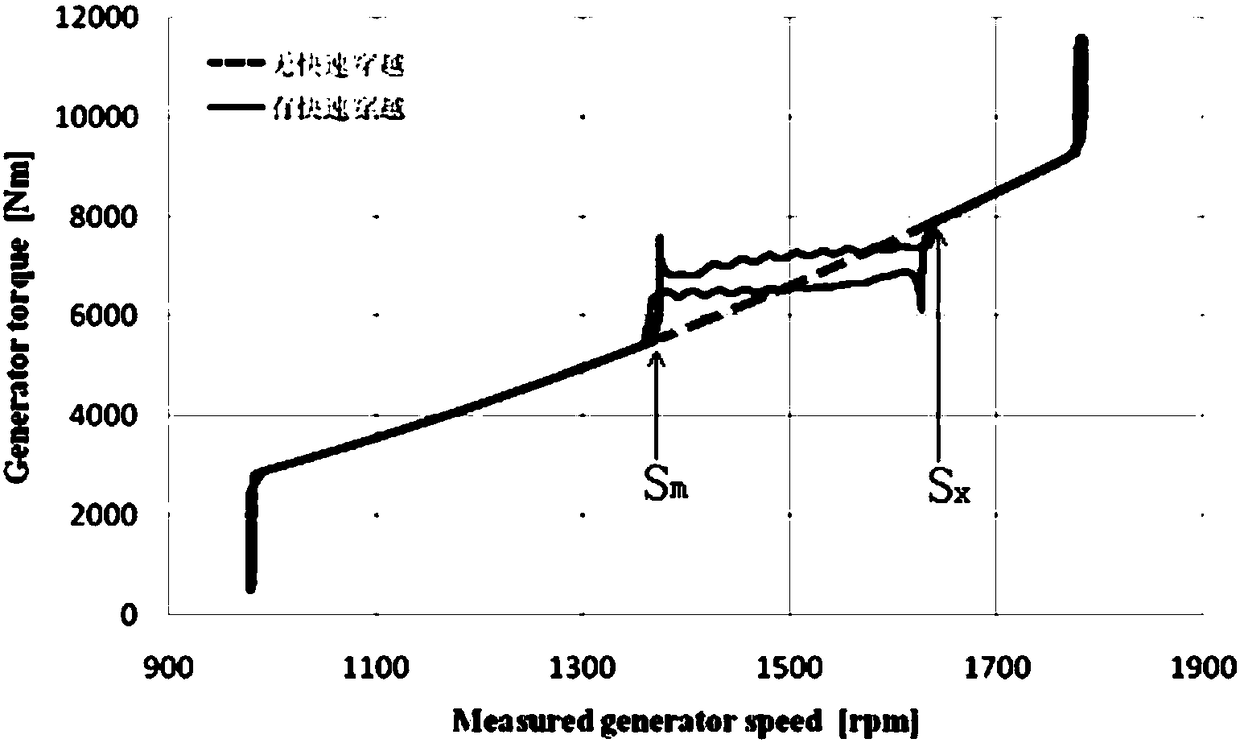

The invention discloses a tower drum resonance avoiding and crossing control method of a wind turbine generator and the wind turbine generator, and belongs to the field of wind turbine generator control. The tower drum resonance avoiding and crossing control method comprises the following steps of: monitoring wind wheel rotation frequency f, and comparing the wind wheel rotation frequency f with apreset rotation speed resonance region; setting the rotation speed resonance region as follows: setting a rotation speed resonance region according to inherent frequency ft of a tower drum, wherein the rotation speed resonance region comprises rotation speed lower limit, rotation speed upper limit and a rotation speed area between the rotation speed lower limit and the rotation speed upper limit;and converting ft into rotation speed St, wherein the size of the rotation speed St is within a range from the rotation speed lower limit value Sm and the rotation speed upper limit value Sx; and when the wind wheel rotation frequency is within the rotation speed resonance region, controlling wind wheel rotation speed to quickly rise or drop to pass through the rotation speed resonance region according to a current state of the wind turbine generator. A rotation speed resonance region is set near a crossed joint of wind wheel rotation speed and tower drum inherent frequency, reasonable rotation speed resonance region upper and lower limits are set, and the rotation speed of the wind turbine generator is controlled to quickly rise or drop, so that the wind turbine generator passes throughthe rotation speed resonance region, and therefore, the tower drum resonance problem is solved.

Owner:GUODIAN UNITED POWER TECH

Method for preventing resonance of motor and vibrator and mobile terminal

ActiveCN107800821ASolving resonance problemsAvoid problems that damage the mid-mounted camera motorTelevision system detailsCurrent supply arrangementsMotor driveResonance

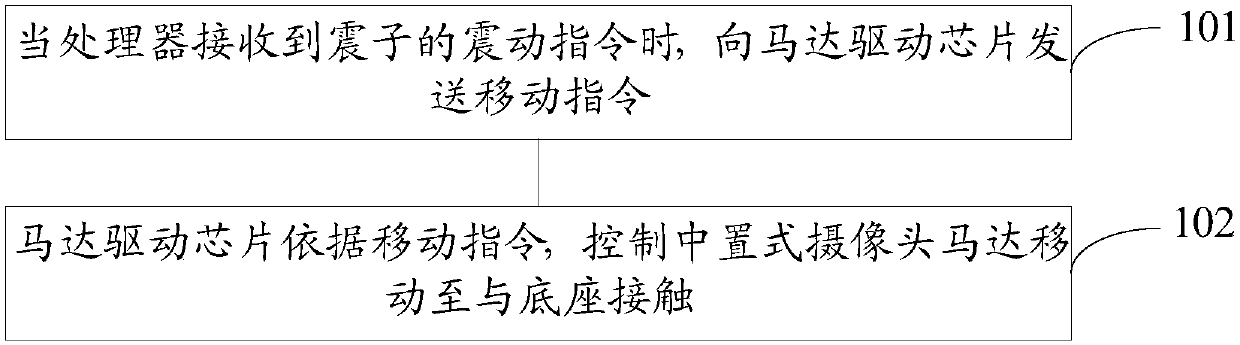

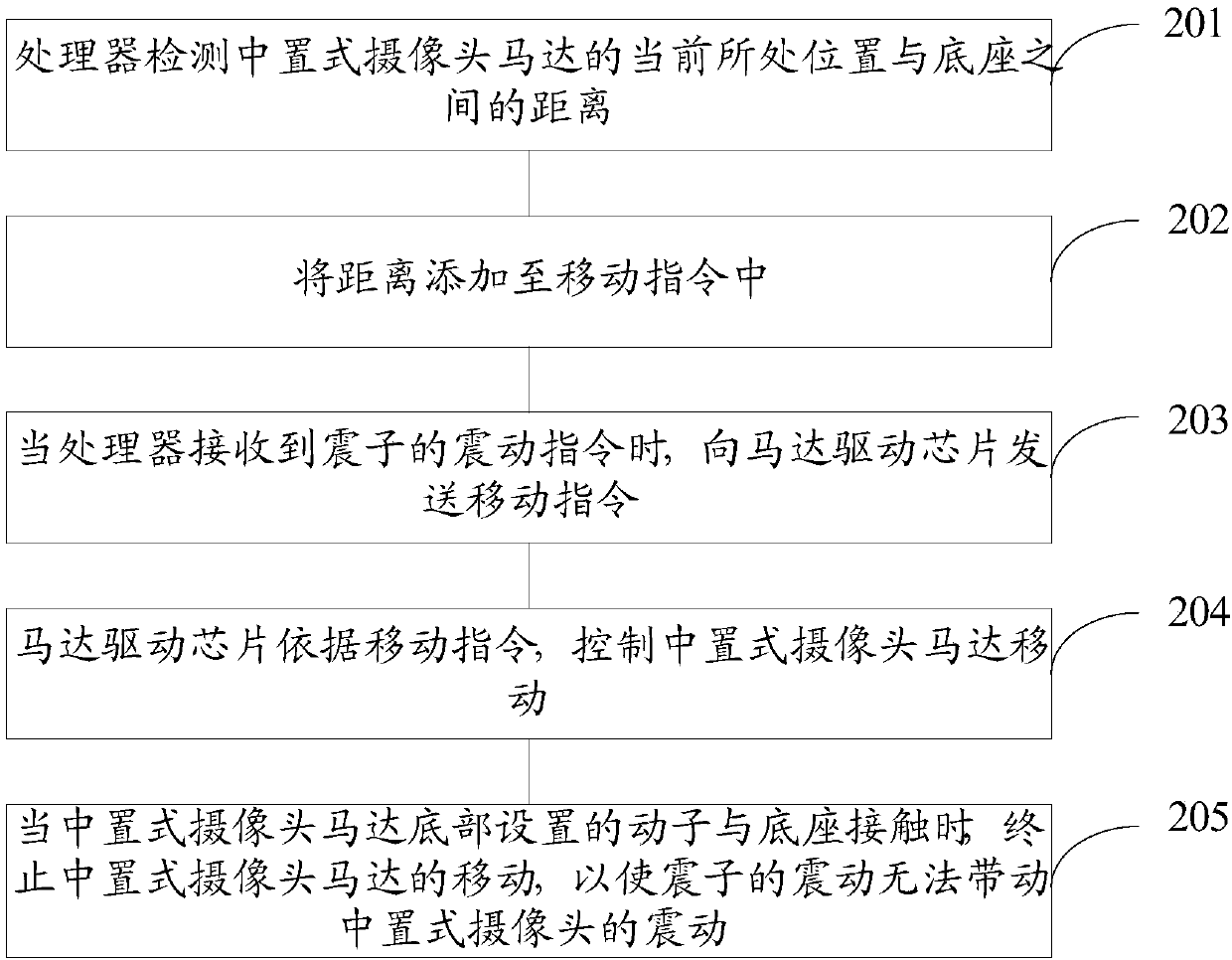

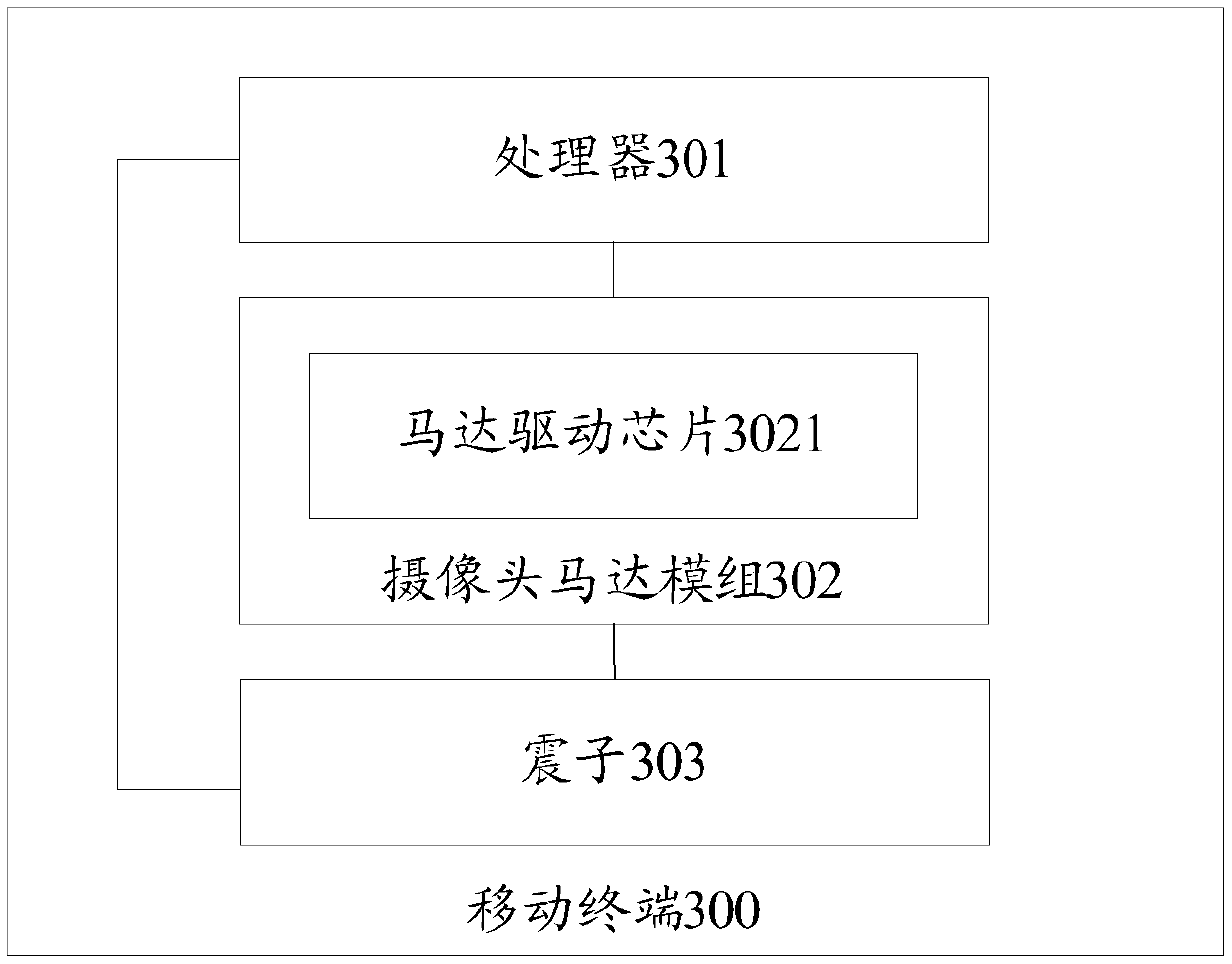

The embodiment of the invention provides a method for preventing resonance of a motor and a vibrator and a mobile terminal. The mobile terminal includes a processor, a camera motor module and a vibrator, wherein the camera motor module includes a motor driving chip, a center-mounted camera motor and a base, characterized in that the method includes the following steps: when receiving a vibration instruction of the vibrator, the processor sends a movement instruction to the motor driving chip; and the motor driving chip controls the center-mounted camera motor to move to contact the base according to the movement instruction. By moving the center-mounted camera motor to contact the base before the vibrator vibrates, the problem that the center-mounted camera motor and the vibrator have resonance due to the vibration of the vibrator can be prevented, and thus the problem that the center-mounted camera motor and the side wall of the mobile terminal collide to generate an abnormal sound ordamage the center-mounted camera motor due to the resonance can be further avoided.

Owner:VIVO MOBILE COMM CO LTD

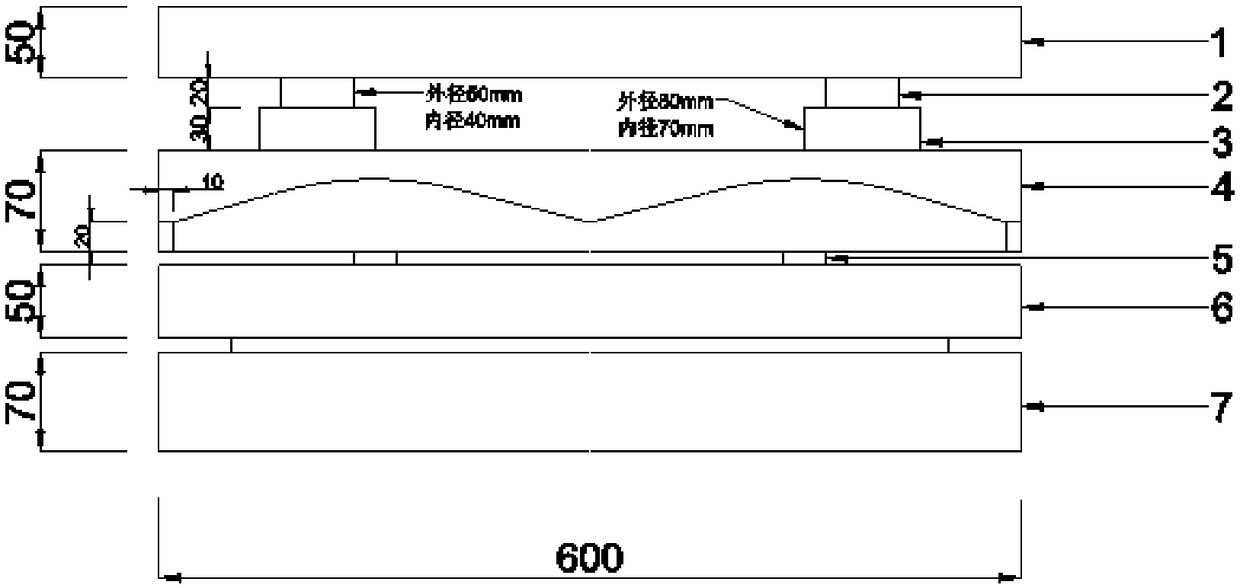

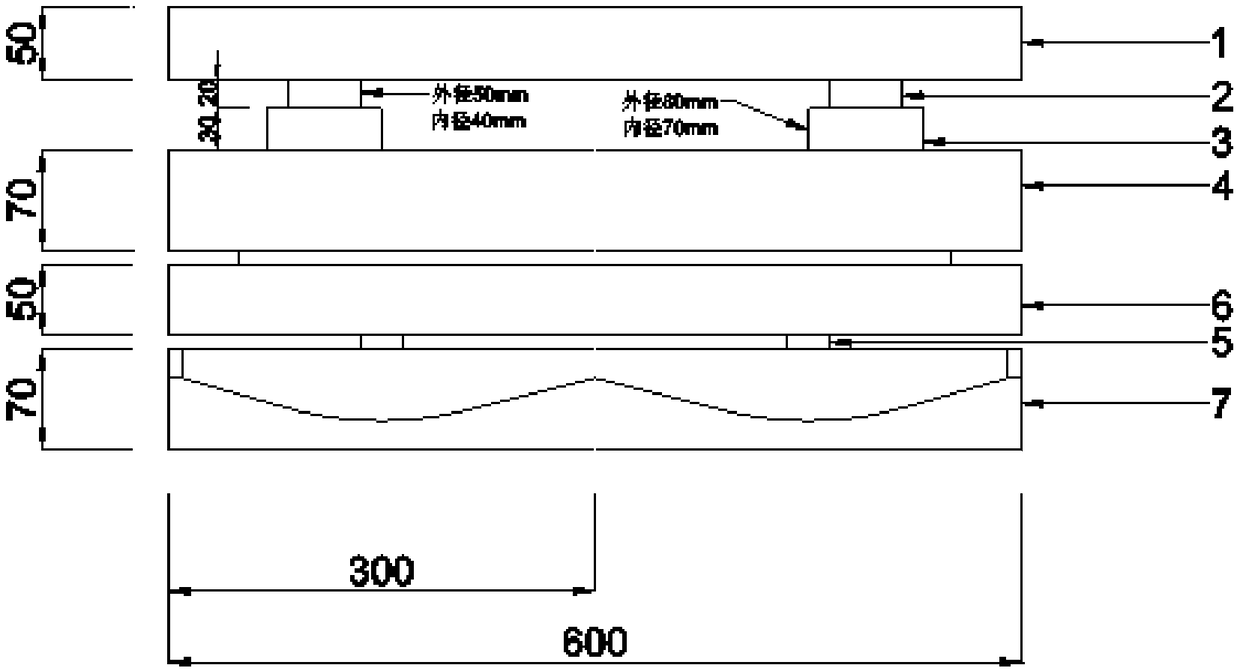

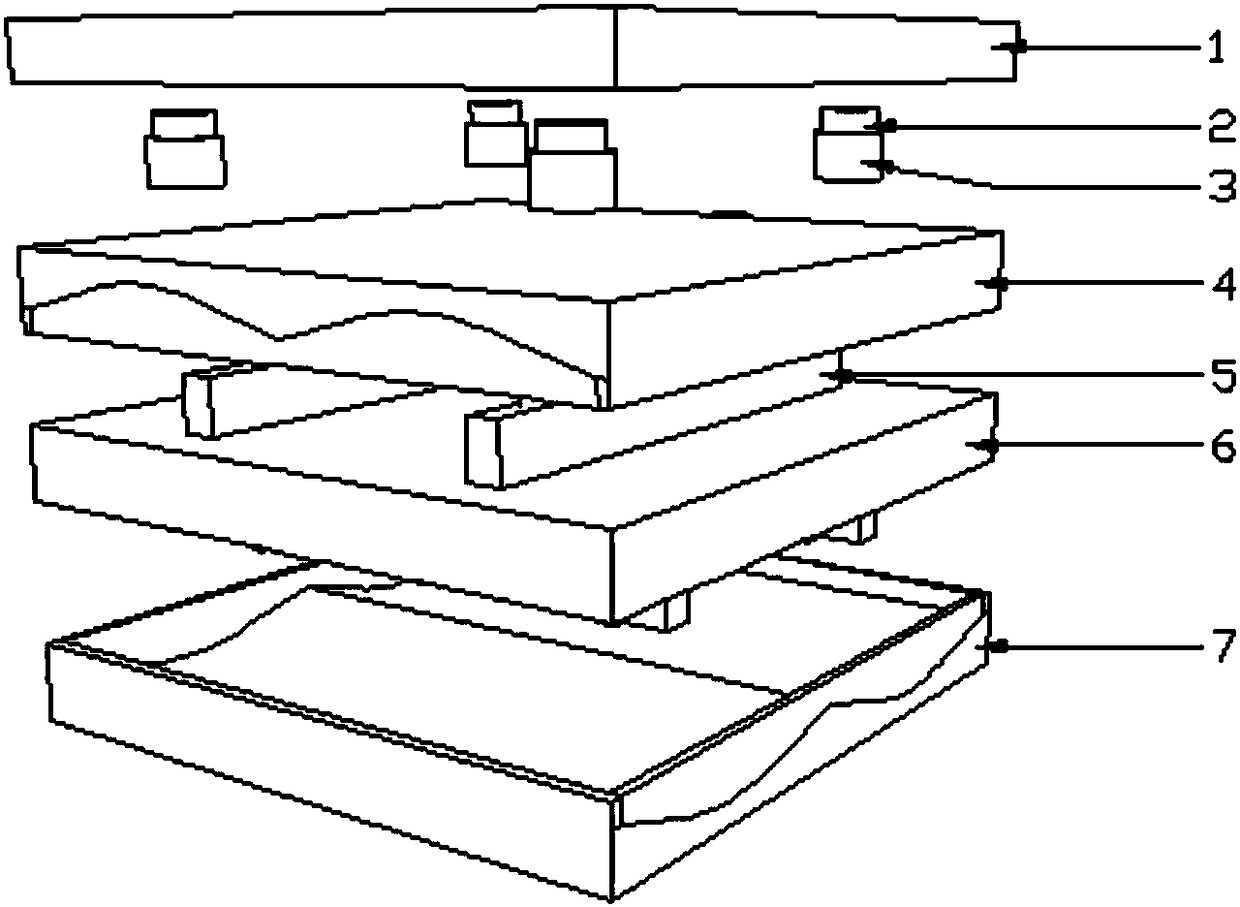

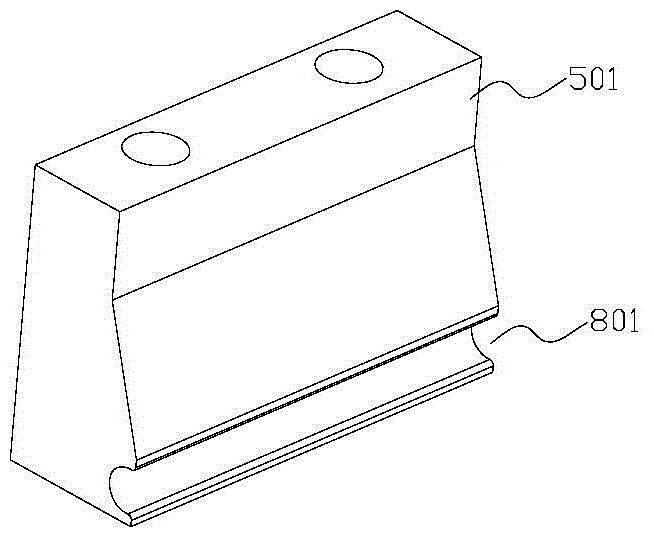

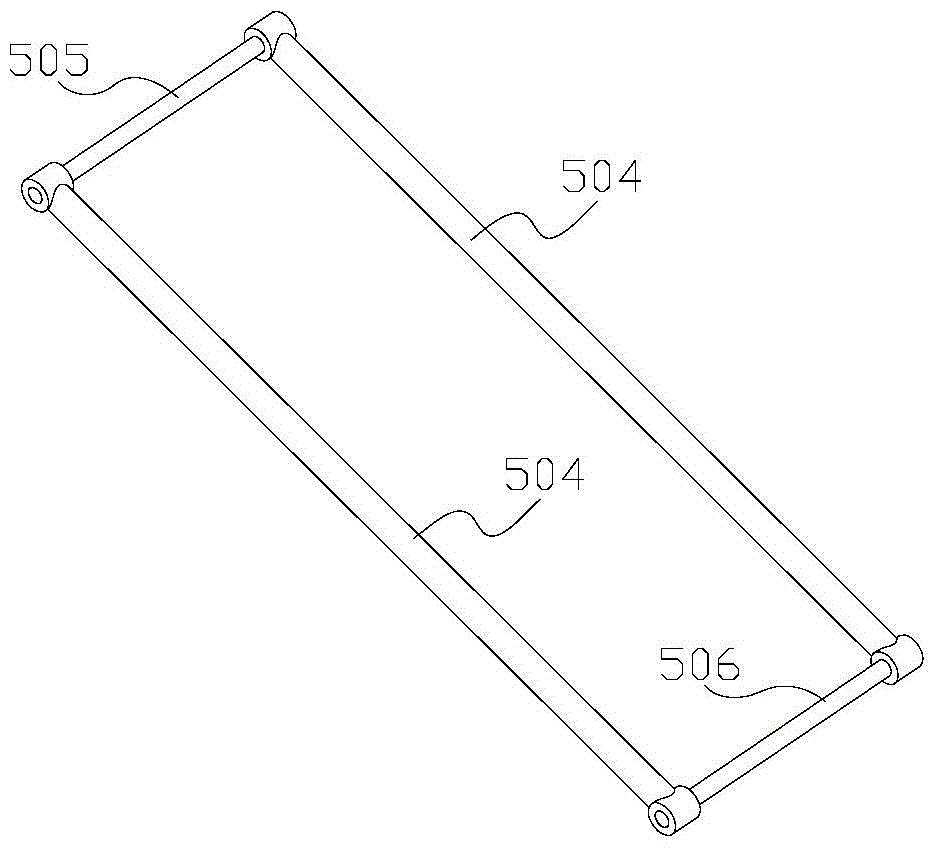

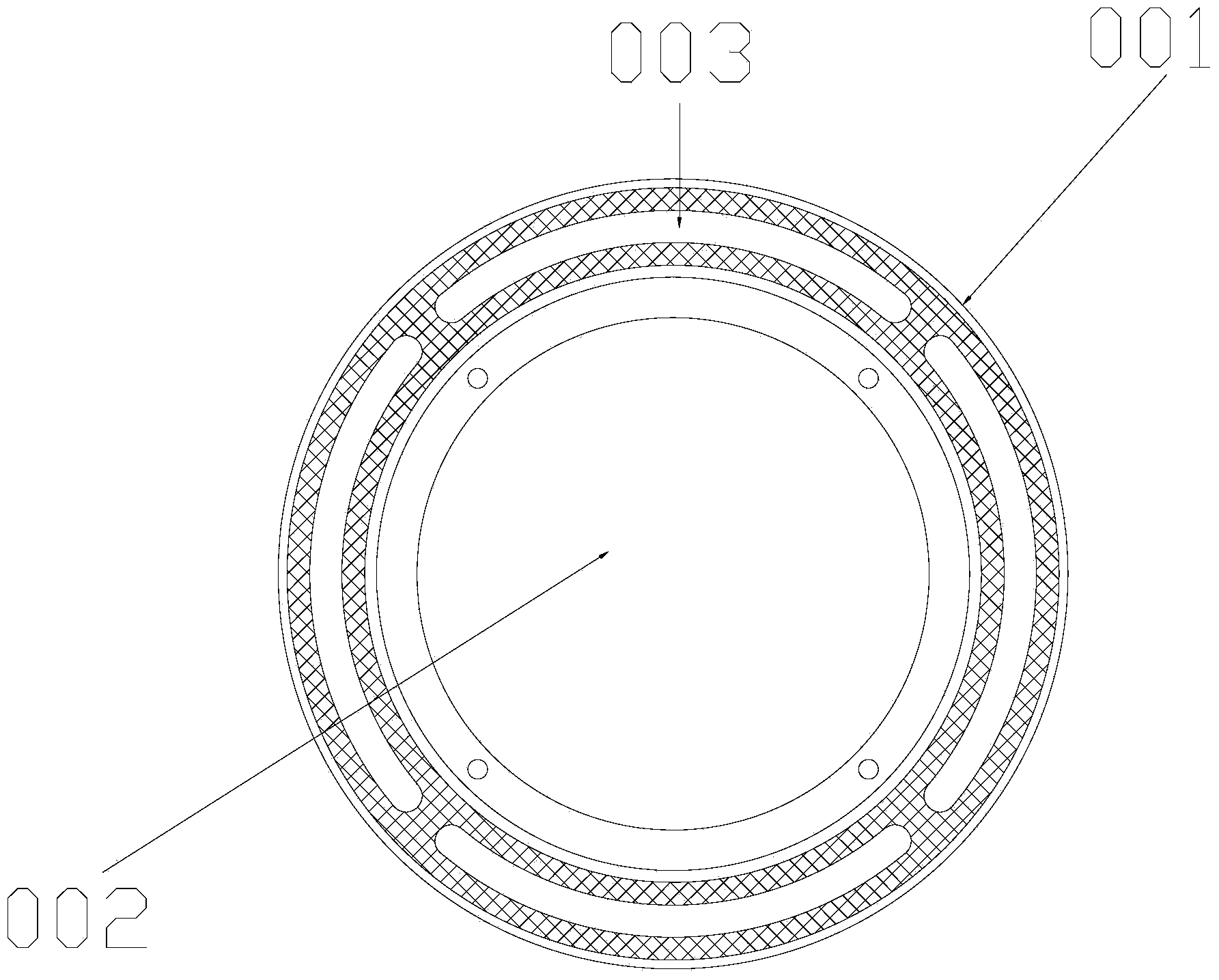

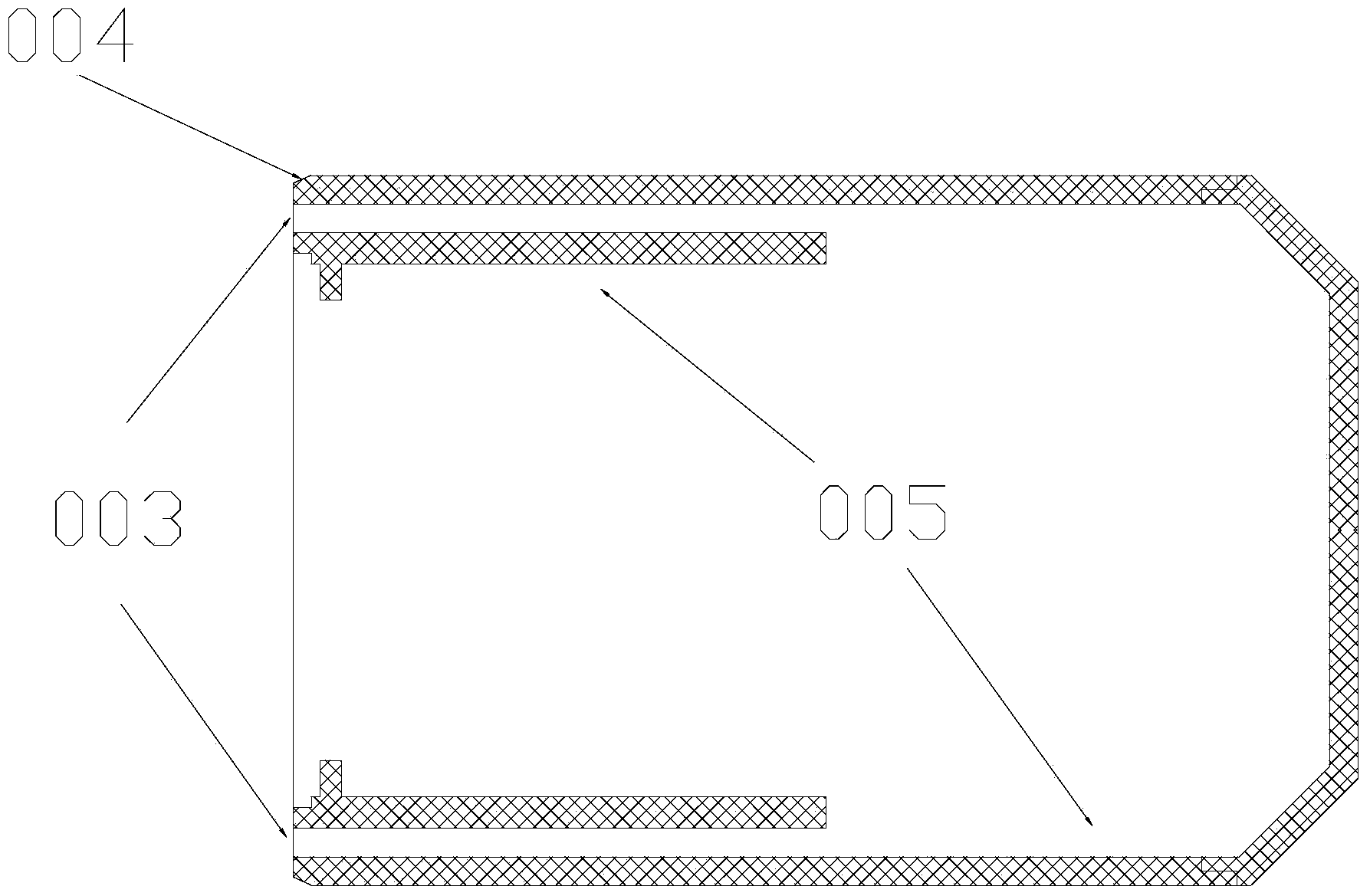

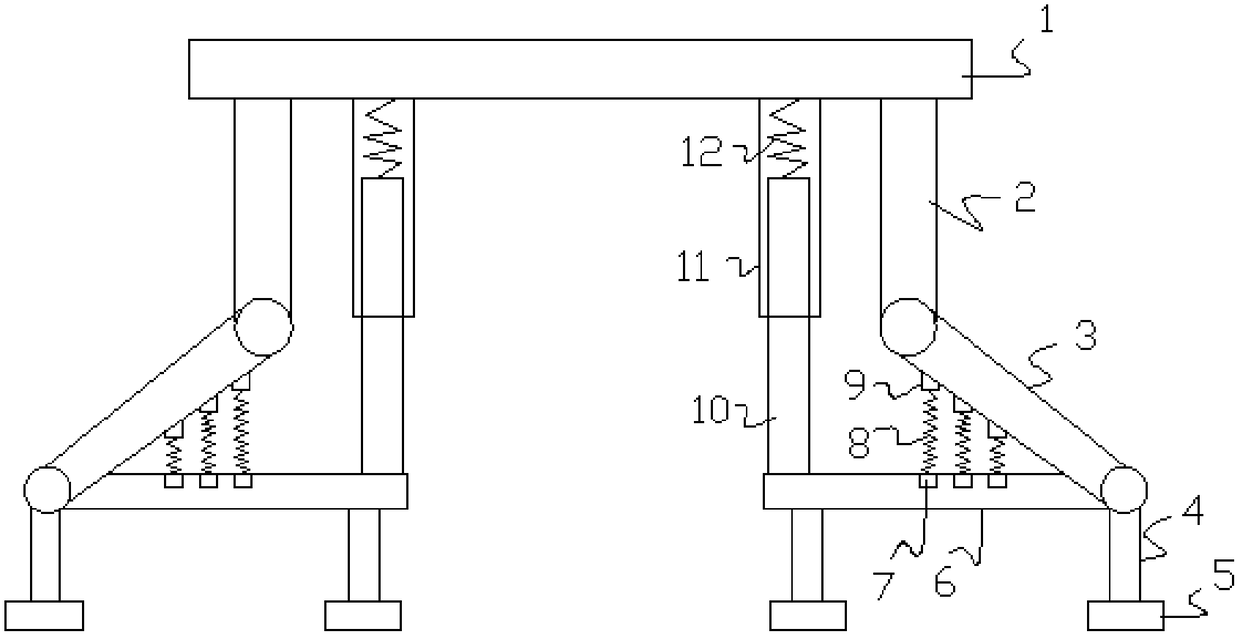

Three-dimensional friction pendulum isolation bearing

PendingCN108266611AGood stabilityOvercoming resonance problemsNon-rotating vibration suppressionStands/trestlesEngineeringPendulum

The invention discloses a three-dimensional friction pendulum isolation bearing which comprises a bottom double-slideway plate, an upper-side double-slideway plate, a bearing plate, a middle slider, aplurality of spring sleeves and springs, wherein the upper-side double-slideway plate is arranged above the bottom double-slideway plate; the bearing plate is arranged above the upper-side double-slideway plate; the middle slider is arranged between the bottom double-slideway plate and the upper-side double-slideway plate; a sliding block is arranged on each of the upper surface and the lower surface of the middle slider; the spring sleeves are connected between the upper-side double-slideway plate and the bearing plate; the springs are separately arranged in the corresponding spring sleeves;and the springs are connected with the bearing plate and the upper-side double-slideway plate. The three-dimensional friction pendulum isolation bearing realizes the decoupling of horizontal earthquake and vertical earthquake, and vertical isolation is performed by the springs with good isolation reduction effects. The bearing has necessary isolation capacity, the structure gravity is used as restoring force to enable the bearing to be reset. Position limitation protection is considered, three-way isolation parameters can be amended according to different cultural relics, and the three-dimensional friction pendulum isolation bearing has high practicability. Compared with a traditional friction pendulum, the sliding effect of rolling balls is better, and the isolation effect in the horizontal direction is excellent.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

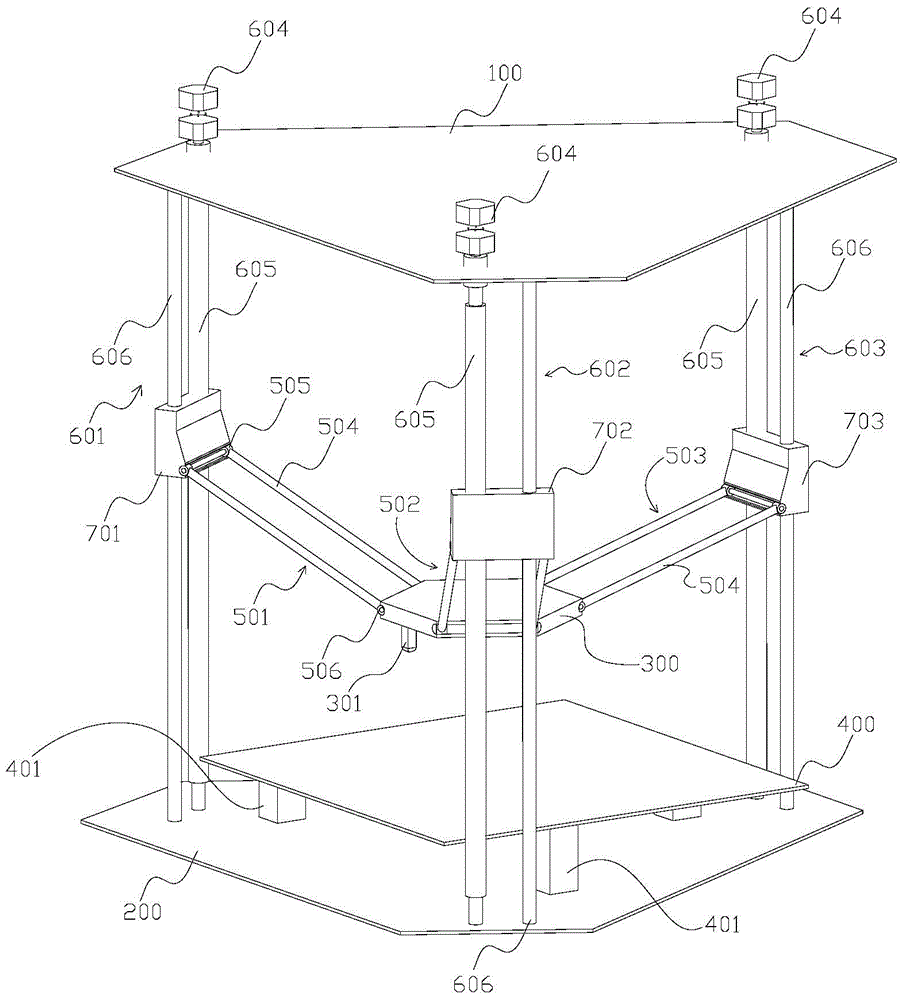

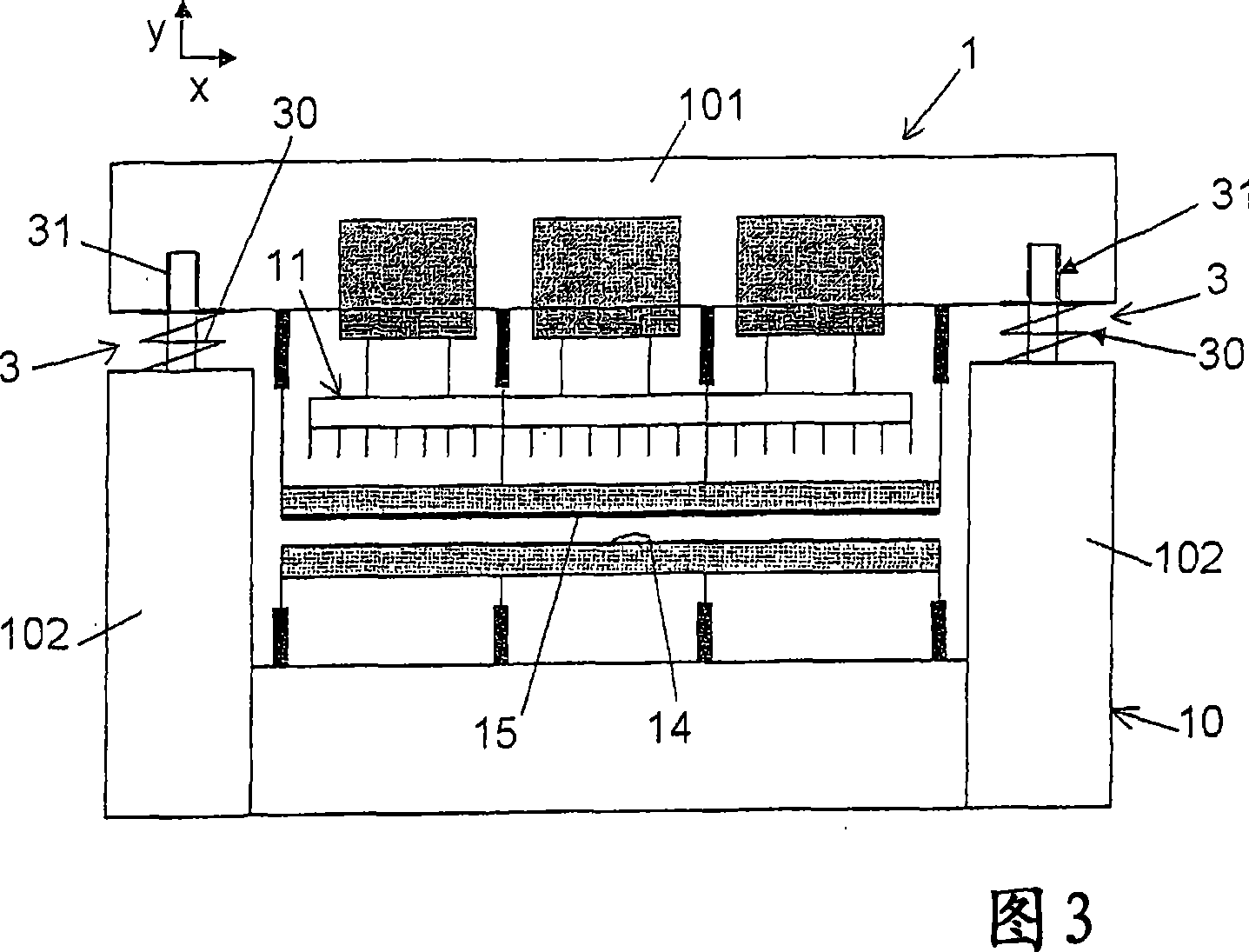

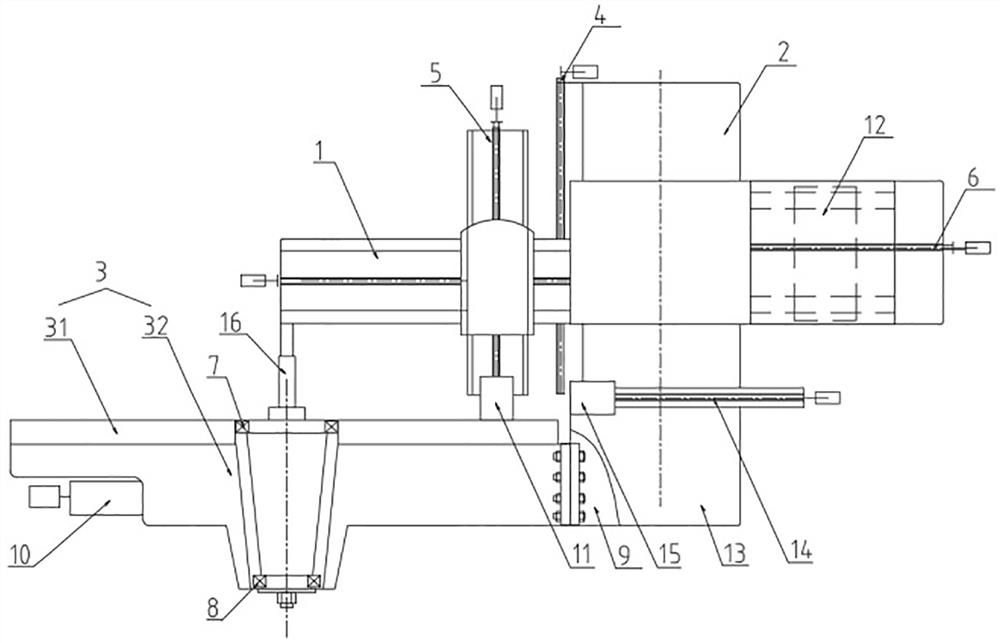

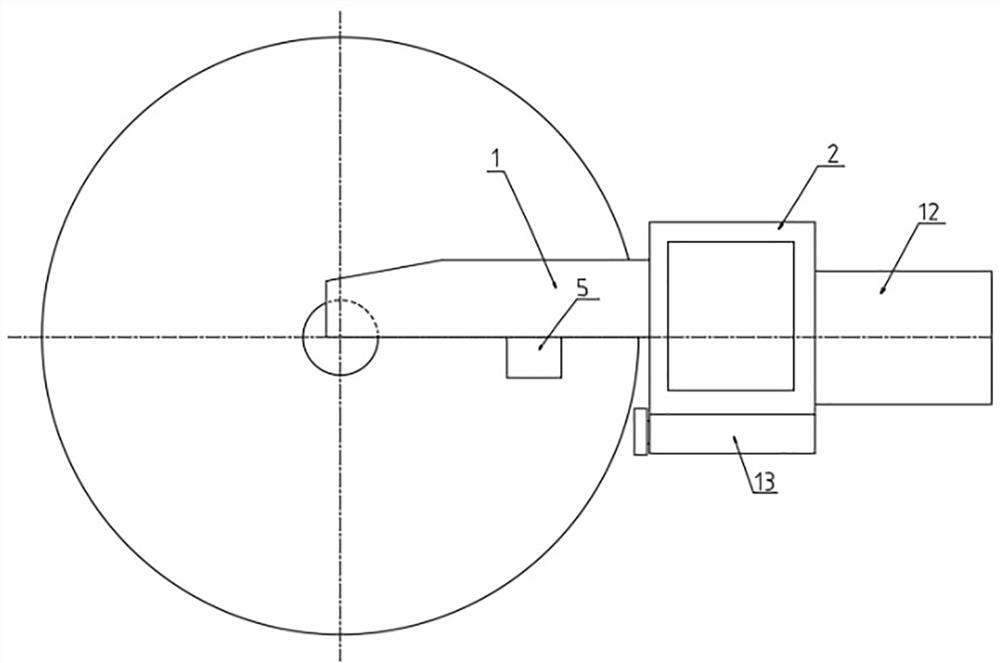

Universal movement mechanism of 3D printer

InactiveCN103552386AIncrease printing speedReduce axial movementPower drive mechanismsResonanceEngineering

The invention discloses a universal movement mechanism of a 3D printer. The universal movement mechanism of the 3D printer comprises a mechanism top, a mechanism bottom, a material extrusion device and a workbench. The workbench is arranged between the mechanism top and the mechanism bottom, and the material extrusion device is placed above the upper surface of the workbench. Three sets of universal rotating components and three sets of transmission components are further included, and the transmission components are sleeved with sliding blocks which can slide up and down. The three sets of transmission components are installed between the mechanism top and the mechanism bottom at intervals. The sliding blocks are connected with the material extrusion device through the universal rotating components and the material extrusion device. According to the universal movement mechanism of the 3D printer, only the Z-axis direction is reserved, by the aid of the scheme, the printing speed can be increased substantially, and moreover due to the fact that two axial movements are reduced, the problems of resonance and noise are solved.

Owner:JIANGXI WOXIANG INDUSTRAL CO LTD

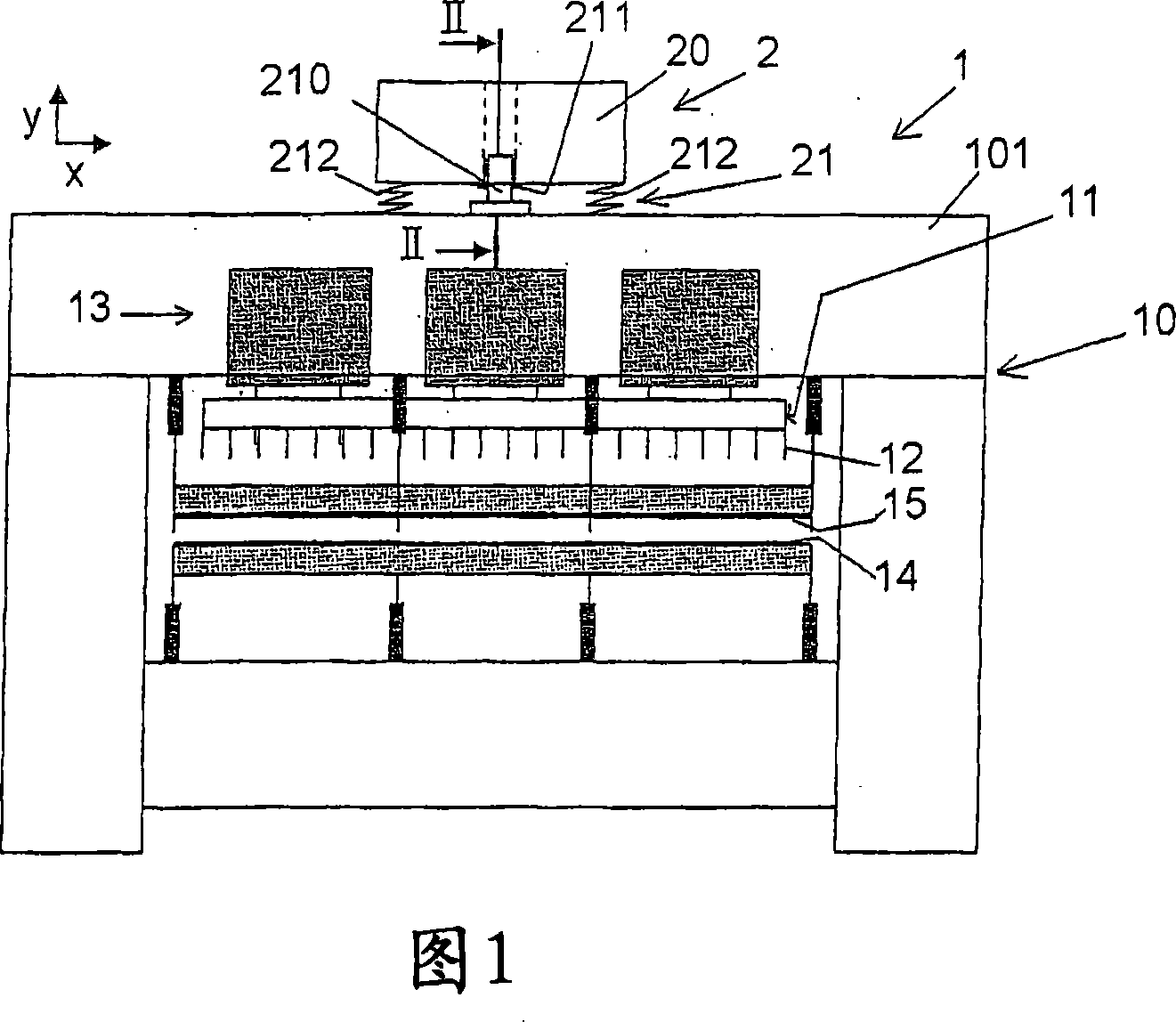

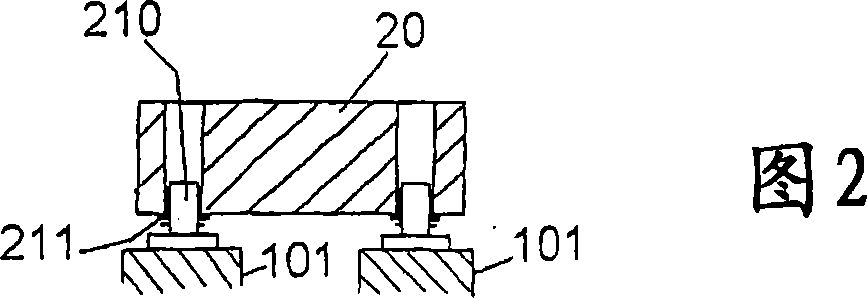

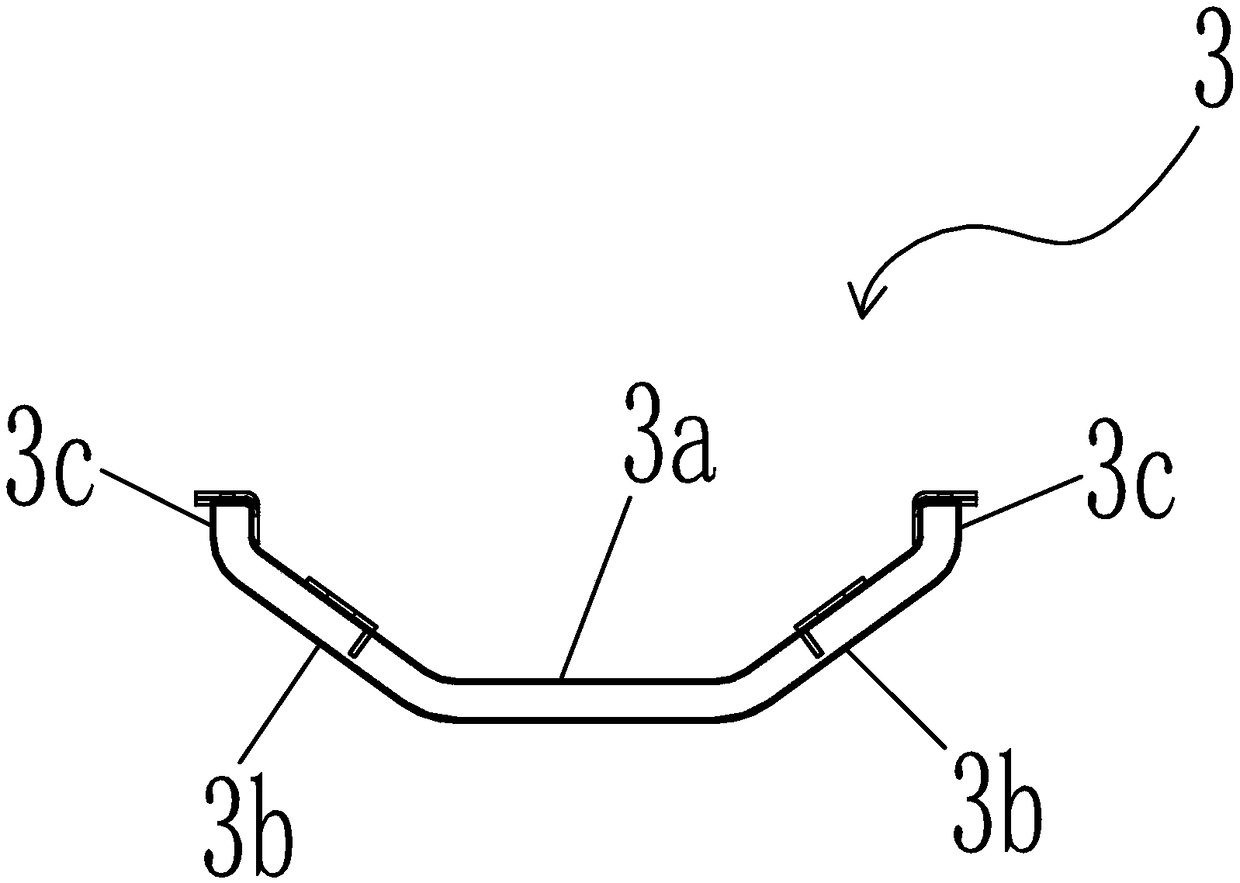

Needle loom in which the frequency of at least one of its vibration modes can be adjusted

InactiveCN101078152ASolving resonance problemsReduce use costNeedling machinesEdible oils/fats with aqeous phaseEngineeringMechanical engineering

The invention provides a needle loom in which the frequency of its natural vibration modes can be manually or automatically adjusted based on needle velocity. The said adjustment is obtained desirably by changing the quality or rigidity of the needle loom, or by changing the rotation inertia of the axis series of the needle loom.

Owner:ASSELIN THIBEAU

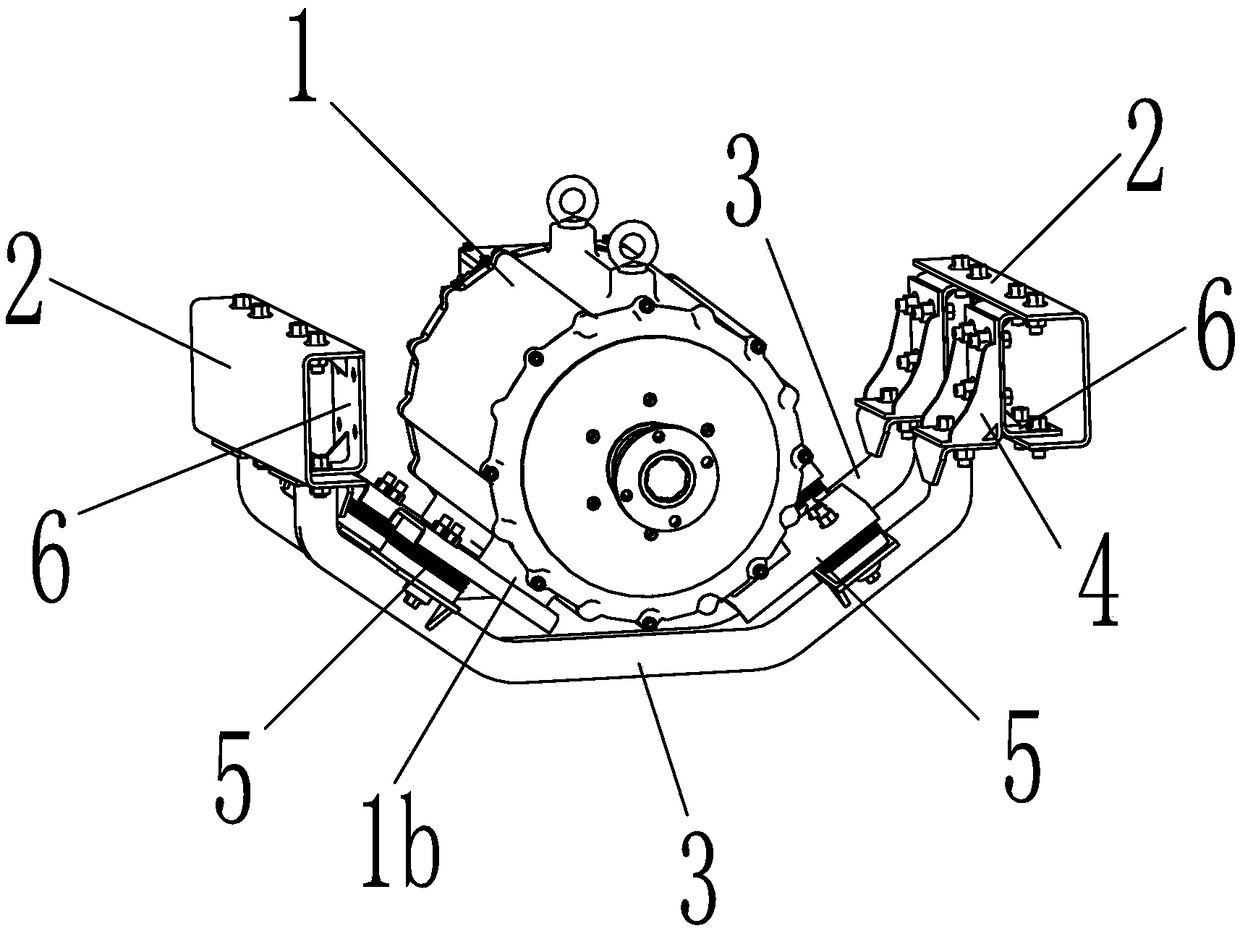

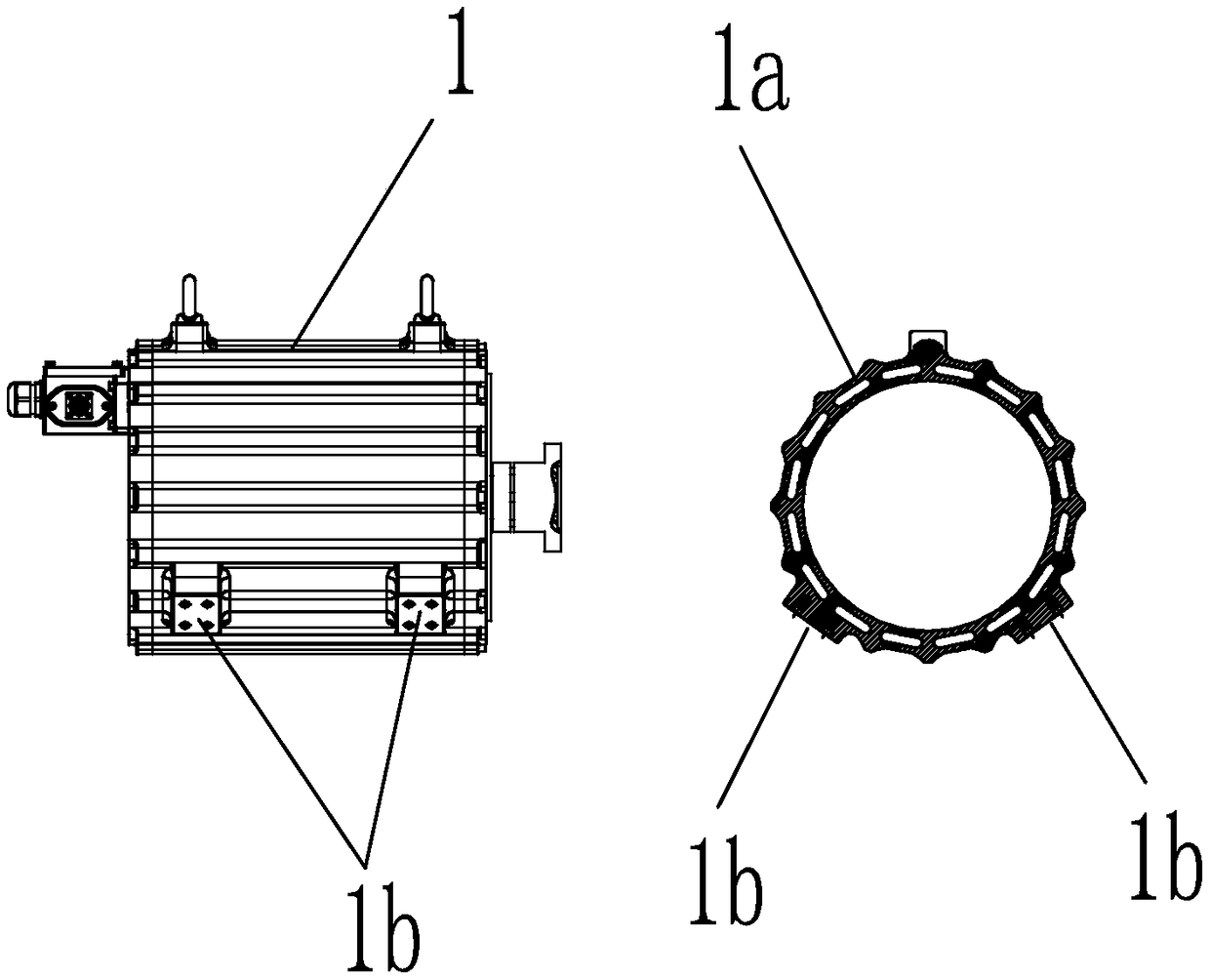

A motor suspension structure of a new energy vehicle

InactiveCN109080704ASimple structureEasy to manufactureElectric propulsion mountingUnderstructuresVehicle frameDrive motor

A suspension structure of a motor of a new energy vehicle includes drive motors, two frame rails and two suspension pocket rails for mounting drive motors, the housing of the driving motor is providedwith a plurality of mounting bosses, The two suspension pocket beams are arranged in parallel on the front and rear sides, further comprising a biasing bracket for making the output shaft of the drive motor correspond to the input shaft of the rear axle and a plurality of shock absorbing devices respectively connected with the respective mounting bosses, the two suspension pocket beams are both arranged in a rearward inclined manner, and the height of the cross member located on the rear side is greater than that of the cross member located on the front side. The advantage of that invention are simple structure, Easy to manufacture, lighter weight, cost saving, strong adaptability to different rear axle elevation angles and motor models, and can solve the problems of vehicle resonance andmotor whistling caused by traditional horizontal suspension due to vibration isolation rate difference, greatly improve the noise level and ride comfort of the vehicle, and at the same time can prolong the service life of the motor.

Owner:DONGFENG XIANGYANG TOURING CAR

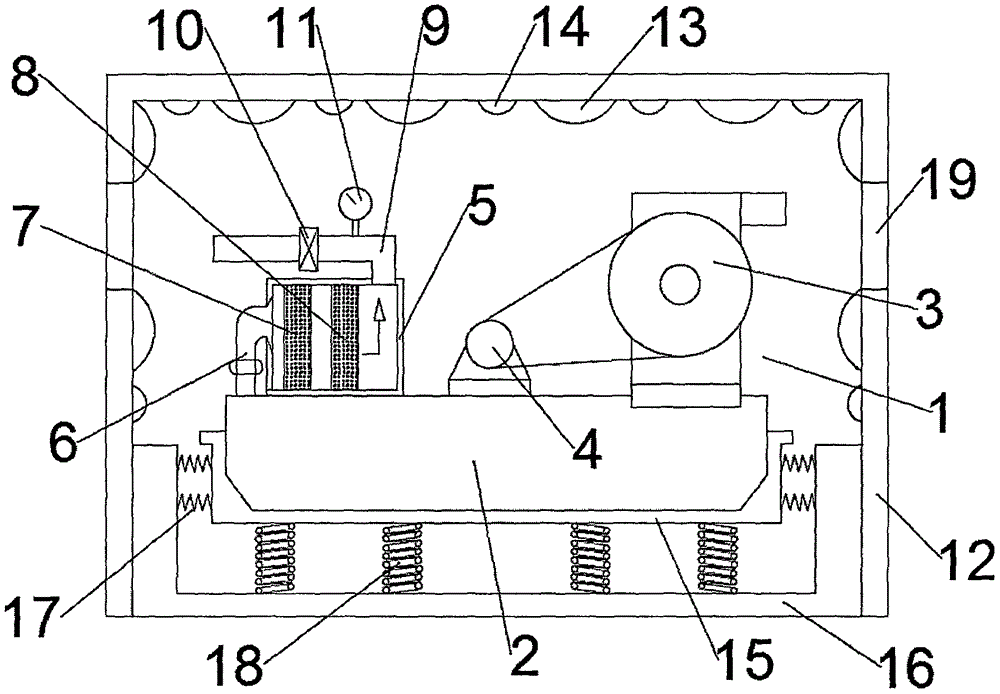

Cushioning protective decontaminable air compressing equipment

InactiveCN106640595ADoes not affect workDoes not affect stable workPump testingGas treatmentResonanceAir treatment

The invention discloses cushioning protective decontaminable air compressing equipment. The cushioning protective decontaminable air compressing equipment comprises an air compressor body, wherein a compressed air outlet tube is arranged at the position of the left side of a side wall of the top of a tank body of an air storage tank; the other end of a tube body of a compressed air outlet tube communicates with an air treatment box; the lower part of the tank body of the air storage tank is accommodated on a seat body of a cushioning inner seat; a cushioning outer seat is arranged under the cushioning inner seat; a safe protective cover further covers the air compressor body and the outside of the cushioning outer seat; and a plurality of large noise-reduction cotton balls and a plurality of small noise-reduction cotton balls are arranged on the inner side wall of a shell body of the safe protective shell. Oily impurities and odor in air can be fully filtered and screened, gas does not have lampblack odor, meanwhile, the shortcoming of affecting use due to resonance between a traditional air compressor and the ground is overcome, and the generated noises can be eliminated and weakened.

Owner:WUXI WOYO SUPERDO COMPRESSOR

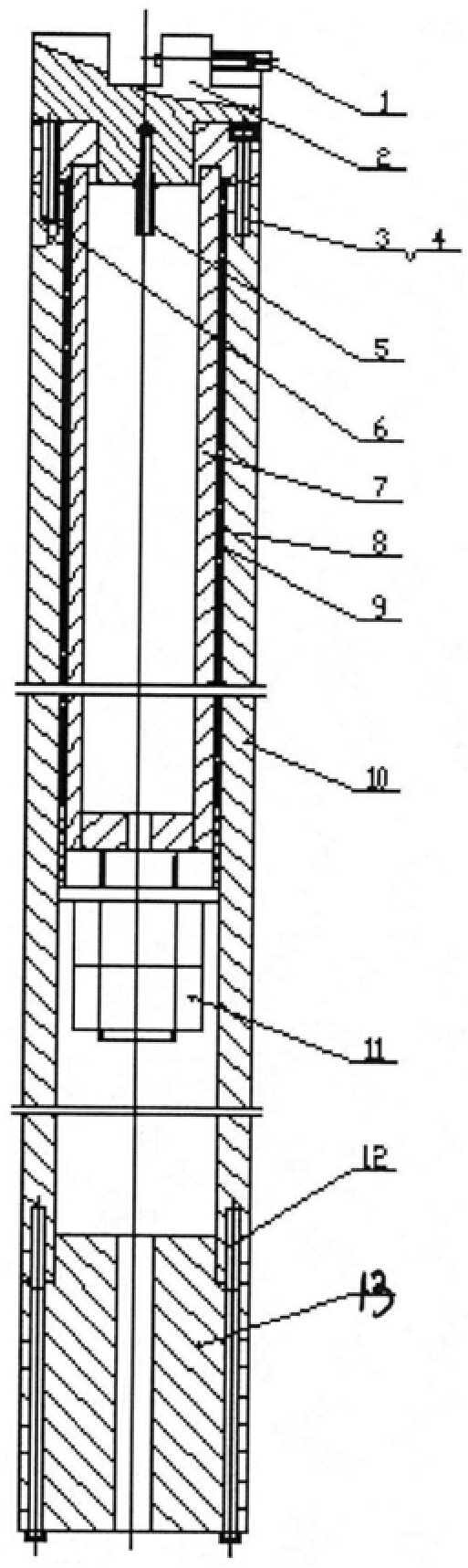

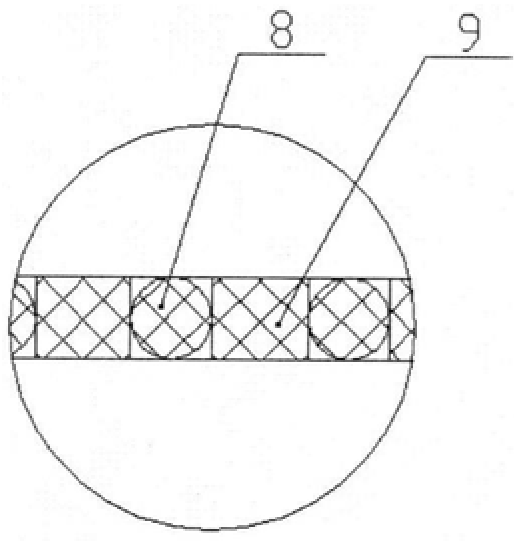

Vibration-absorbing tool holder

InactiveCN106507721BSolving resonance problemsChange the resonant frequencyBoring barsBoring/drilling machinesResonanceEngineering

The invention relates to a damping tool holder suitable for deep hole boring. The vibration-damping cutter bar includes an outer jacket and an inner sleeve. A tool seat and a nozzle connected to the coolant pipeline are arranged on the top of the cutter bar. An O-ring and an O-ring are arranged between the outer jacket and the inner sleeve. The vibration-damping layer formed by the flat washer 1 is connected with the adjustment nut 1 at the end of the vibration-damping layer formed by the O-ring 1 and the flat washer 1, and the adjustment nut 1 is placed in the jacket, which is a regular octagonal structure, at the end of the tool bar. The end is equipped with a counterweight, and the tool holder can be replaced with an extended tool holder. The vibration-damping tool rod of the present invention effectively solves the problem of the resonance of the tool rod, and the resonance frequency can be changed by adjusting the deformation of the vibration-damping layer by adjusting the nut, thereby reducing the resonance and improving the dimensional accuracy and surface quality of the product; the regular octagon of the jacket The structure greatly improves the rigidity of the tool holder. The invention adopts ordinary materials, has simple structure and low price, and can fully meet the complex damping requirements.

Owner:CAPITAL AEROSPACE MACHINERY

Loudspeaker structure based on ring shaft phase-reversing tube application

InactiveCN103957495ASolving resonance problemsReduce positive front reflexElectrical transducersReflected wavesEngineering

The invention relates to a loudspeaker structure based on ring shaft phase-reversing tube application. The loudspeaker structure comprises a loudspeaker body structure body which is composed of an outer panel and an inner installation panel, wherein a plurality of ring shaft phase-reversing tubes are arranged between the installation panel and a loudspeaker body structure. A voice coil center serves as the virtual axis, and the two or more phase-reversing tubes are mirrored based on the axis or surround the loudspeaker. High voice, medium voice and low voice are restored by approaching to a point acoustic source. A cylindrical or regular polygon cavity structure is adopted, the problem of loudspeaker body resonance caused by a weak center of a panel is solved, and the purpose of eliminating resonance can be achieved relatively with quite thin materials. Due to the fact that the combination of the phase-reversing tubes and the loudspeaker body is organically utilized, two cylindrical inner cavities which are communicated in a front-and-rear mode and integrated but are not equal in diameter are formed, the bordering length is just set in the middle segments, where standing waves are extremely prone to generation, of the inner cavities, and the formation of the standing waves is effectively damaged. The installation panel of the loudspeaker is in the shape of a chamfered cone frustum, the area of the panel is larger than the loudspeaker, and right ahead reflecting of reflected waves and superimposed interference of diffraction sound waves are evenly and effectively relieved.

Owner:郑润柏

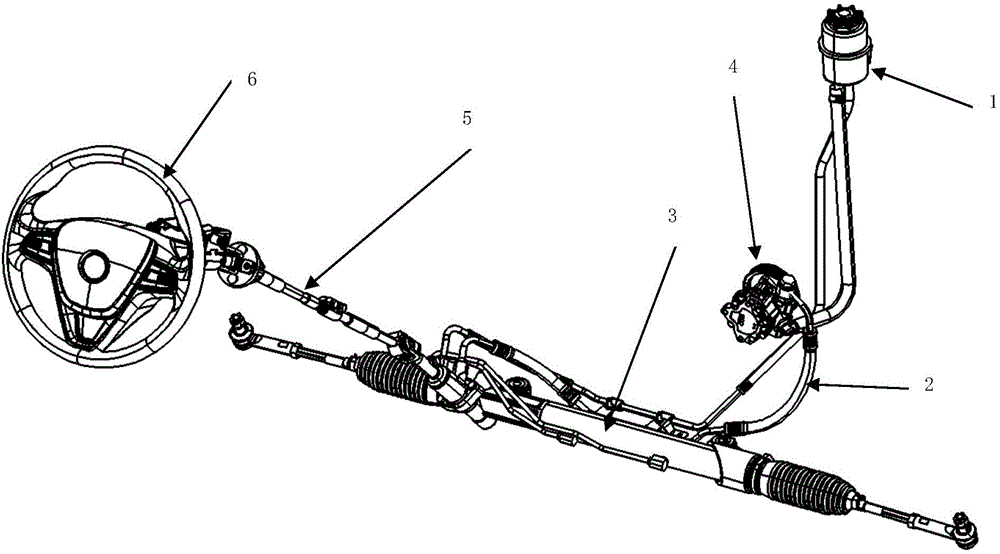

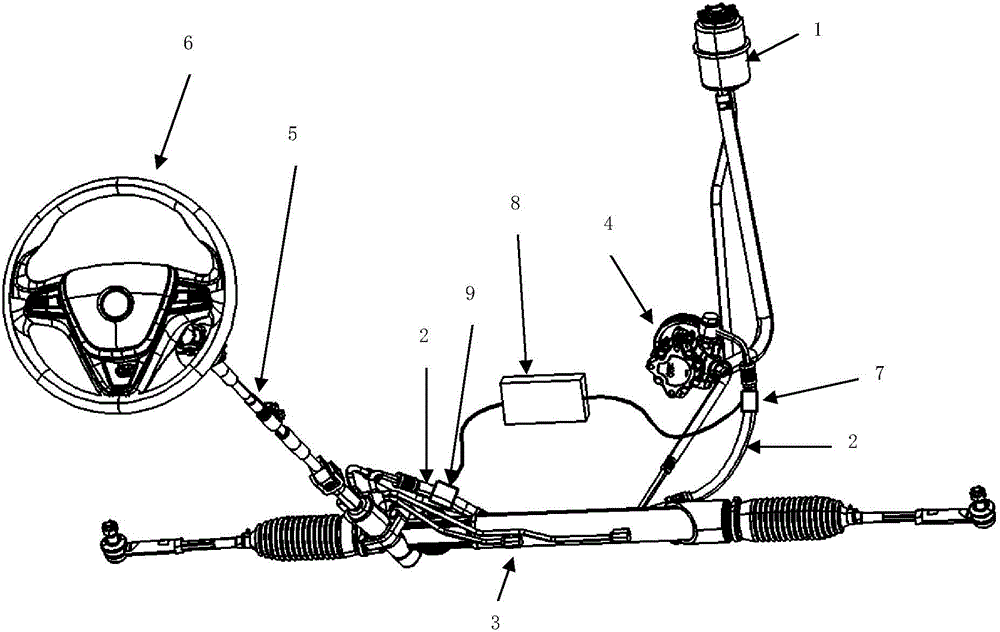

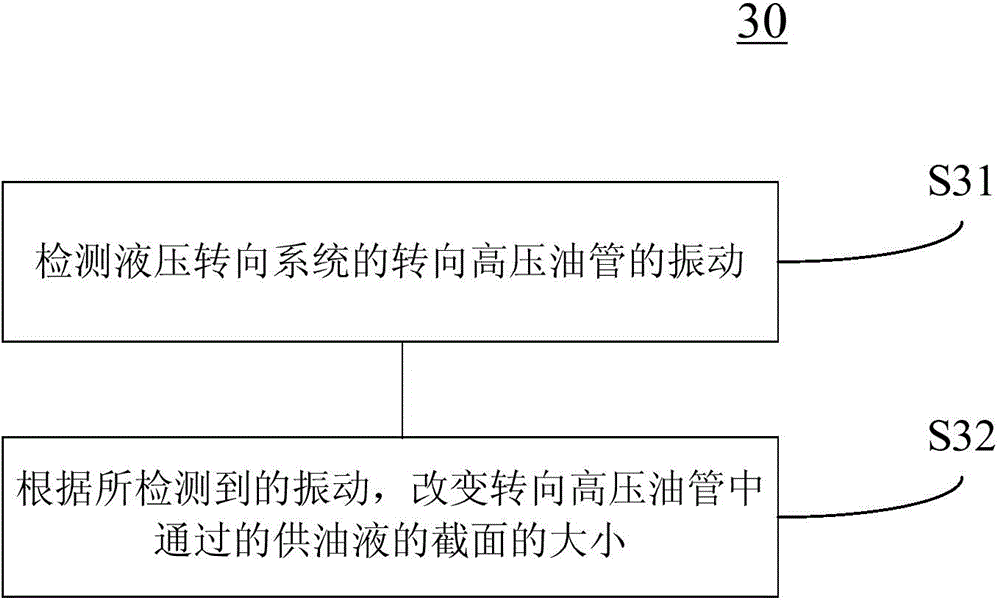

Noise and vibration reduction device for steering system

InactiveCN104908807ASolving resonance problemsShorten the lengthFluid steeringElectricityHigh pressure

The invention relates to a noise and vibration reduction device for a steering system, a car including the device and a noise and vibration reduction method for the system. The device is arranged on a hydraulic steering system. The device comprises a vibration sensor, a control unit and a steering oil tube valve. The vibration sensor is arranged on a steering high-pressure oil tube of the hydraulic steering system to detection the vibration situation of the steering high-pressure oil tube. The control unit is electrically connected with the vibration sensor which sends detected vibration signals to the control unit. A steering oil tube valve is arranged on the steering high-pressure oil tube and is electrically connected with the control unit which controls the steering oil tube valve to change the oil passing section size according to the vibration signals, and accordingly, the steering liquid flowing speed is changed, and the liquid flow frequency is changed.

Owner:BEIQI FOTON MOTOR CO LTD

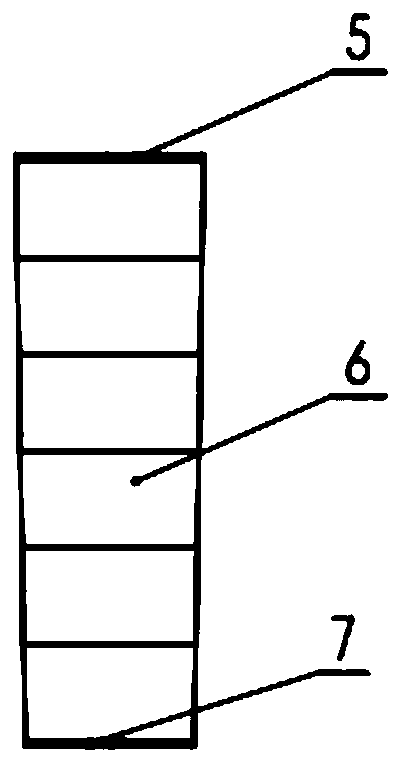

Wind turbine generator hyperbolic type tower design method based on frequency control and tower

ActiveCN109707571ASolving resonance problemsStructure frequency controllableWind motor supports/mountsWind energy generationElectricityMaximum diameter

The invention discloses a wind turbine generator hyperbolic type tower design method based on frequency control and a tower. The method comprises the following steps that the total height, wall thickness and maximum diameter of the hyperbolic type tower are determined; a plurality of groups of hyperbolic focal points and a half-real axis length are initialized, frequency and intensity requirementsserve as constraint conditions, optimization is carried out on the basis of a particle swarm multi-objective optimization method, and the optimal solution of the hyperbolic focal points and the semi-real axis length is obtained; and the number of tower sections of the tower is set, and the size of each tower section is obtained based on the optimal solution and the number of the tower sections. The external shape of the wind power tower meeting various frequency requirements can be designed, and the lightweight design of the weight of the tower can be guaranteed.

Owner:CRRC WIND POWER(SHANDONG) CO LTD

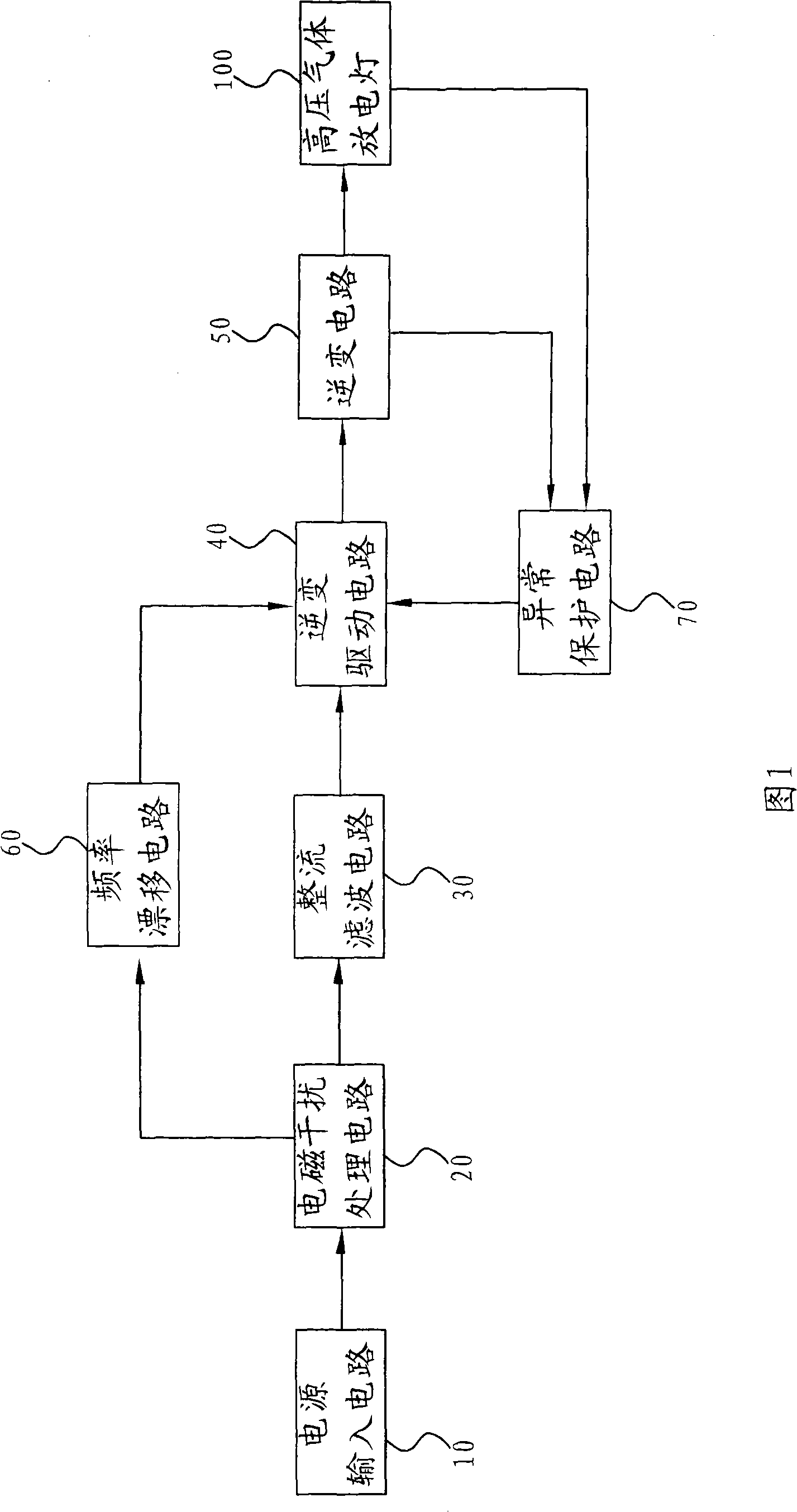

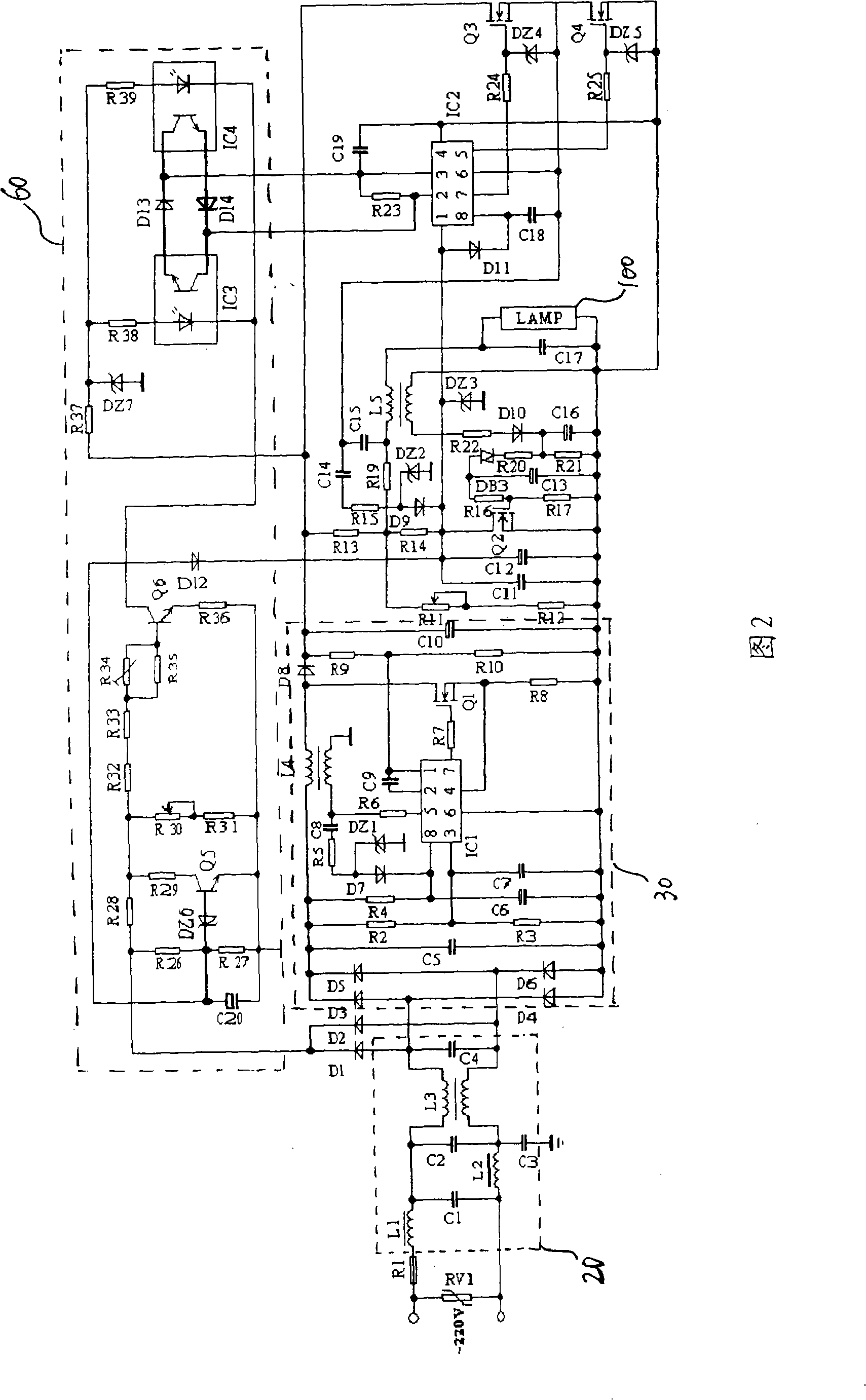

Road lamp electric ballast

InactiveCN101321423ASolving resonance problemsSave social energyElectrical apparatusElectric lighting sourcesResonance problemElectromagnetic interference

The invention provides an electronic ballast of street lamps, comprising: a power input circuit, an electromagnetic interference process circuit, a rectifier filter circuit, an inversion driving circuit, an inversion circuit and a frequency drift circuit. The frequency drift circuit is used for adjusting output frequency of the inversion driving circuit so as to put the working frequency of the inversion circuit in a periodical changeable state. The output frequency of the inversion driving circuit is adjusted by the frequency drift circuit as the frequency drift circuit is installed in the electronic ballast to solve the resonance problem of lamp and sound of high pressure gas discharging. Thus, the high pressure gas discharging lamps using the electronic ballast are able to be widely applied in street lamps such that social energy is greatly saved.

Owner:苏州金三元照明电器有限公司

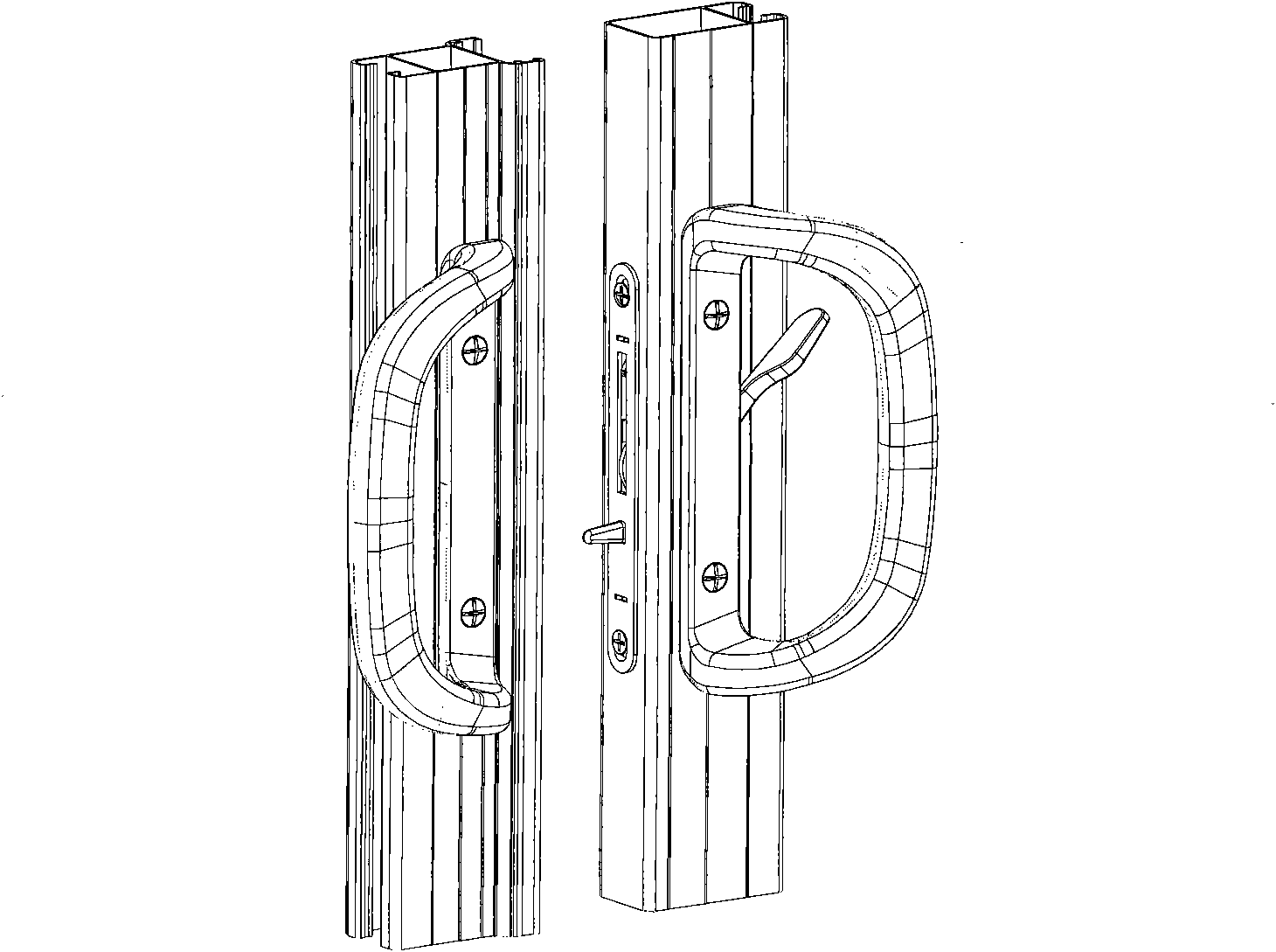

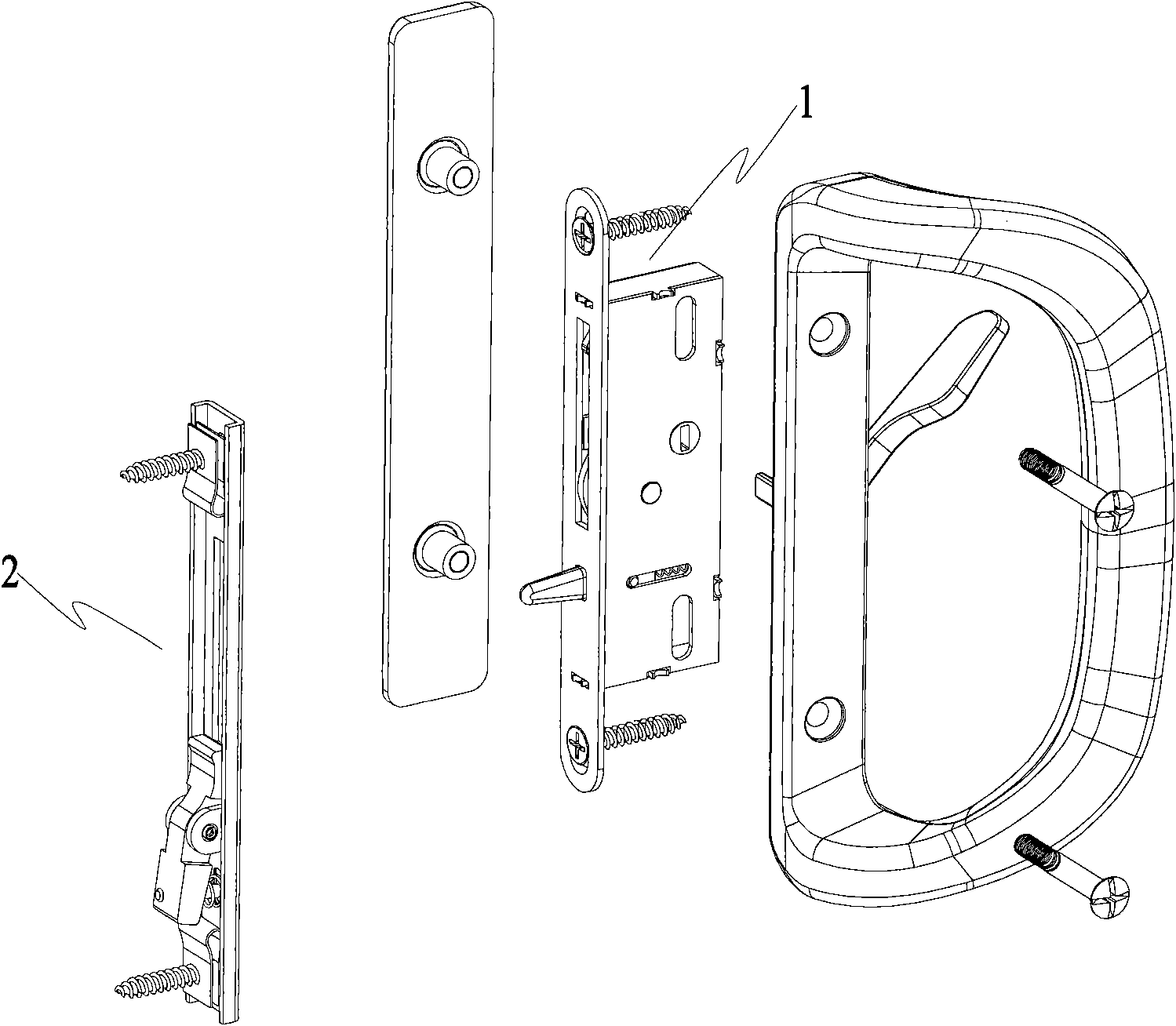

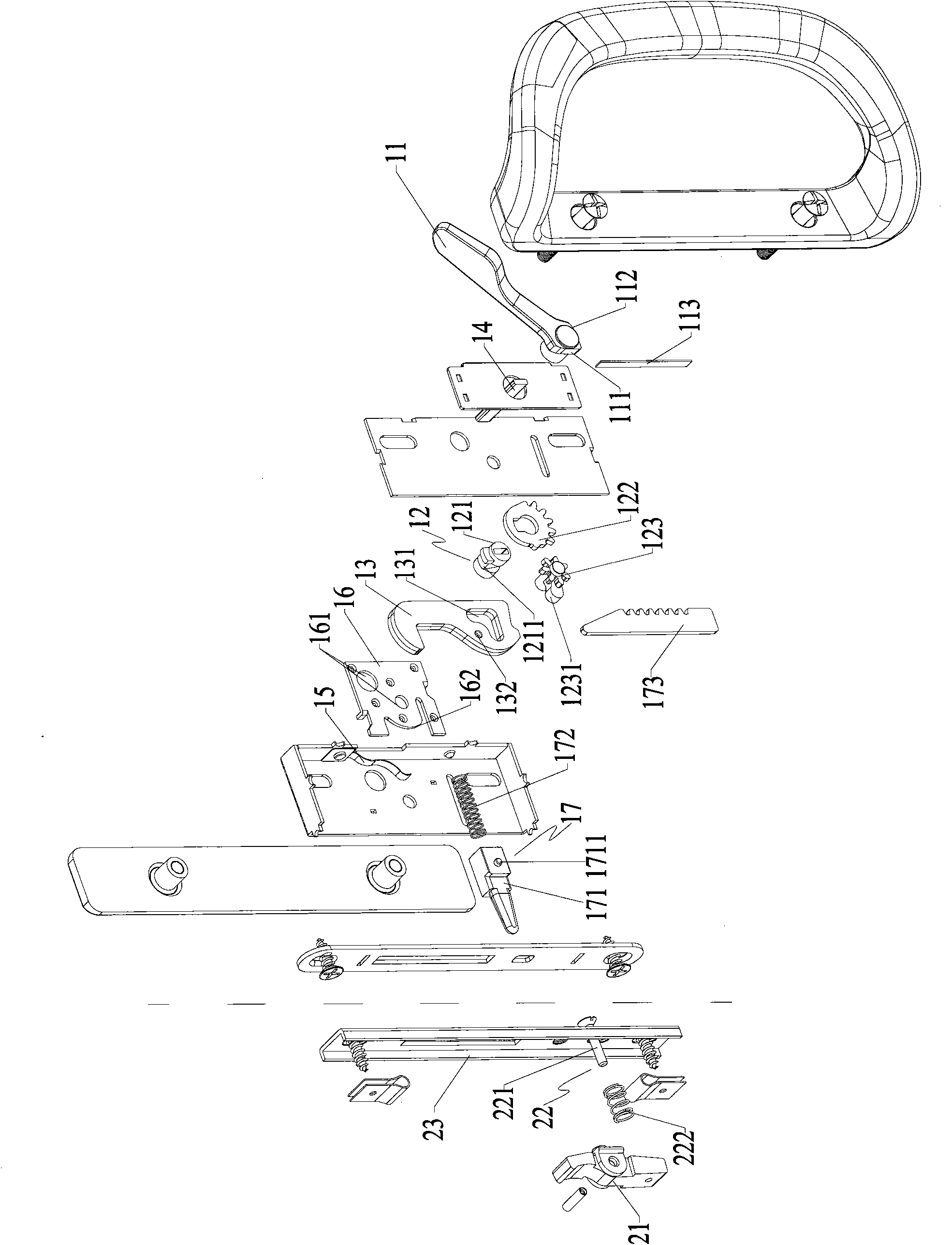

Door window hook lock with telescopic locking function

InactiveCN101892780ACompact and reasonable structureSmall form factorWing fastenersResonanceCore component

The invention discloses a door window hook lock with the telescopic locking function, comprising a lock body and a cam part which are matched for use, wherein the lock body is provided with a control handle placed outside the lock body, a lock core component in transmission connection with the control handle and a lock hook which is driven by the lock core component to rotate and extend out of the lock body; the cam part is provided with a cam adjusting block which is matched with a lock buckle of the lock hook; and the lock core component is provided with a cam structure, an L-shaped through groove which is in transmission and matching with the cam structure is arranged at the connecting end of the lock hook, and the cam structure is matched with the actions of the L-shaped through groove for driving the lock hook to rotate and maintaining that the lock hook has a certain horizontal progression amount in the lock body during the locking state. The door window hook lock has the benefits that, 1) the overall structure is compact and reasonable, the shape is small, and the door window hook lock can be matched with grips in various forms and styles for use; 2) the mounting is convenient and fast, the operation is easy, and the practicality is good; and 3) the lock hook has the telescopic function, and the cam adjusting block also has the adjusting function, thereby effectively solving the shortcoming of poor sealing property of a push-pull door window, reducing outdoor noise and solving the problem of door window resonance caused by wind.

Owner:CMECH (GUANGZHOU) INDUSTRIAL LTD

Three-kind-force sieving machine for superfine powder

InactiveCN1876253AWork hard and smoothResolve resonance and noiseSievingScreeningMechanical forceEngineering

The disclosed ultra-micro-powder three-force sieve machine comprises: a travel frame to hang whole sieve body assembly, assisting by an eccentric shaft and a movable frame to transfer the gear inertial force and the mechanical force of the eccentric shaft to the inertial connection rack, and then the sieve assembly; using the vibration source on the assembly to generate up-down vibration with some amplitude and high frequency both sent to the sieve assembly. This invention is simple and convenient, and fit to different classification request.

Owner:江苏省牧羊集团有限公司

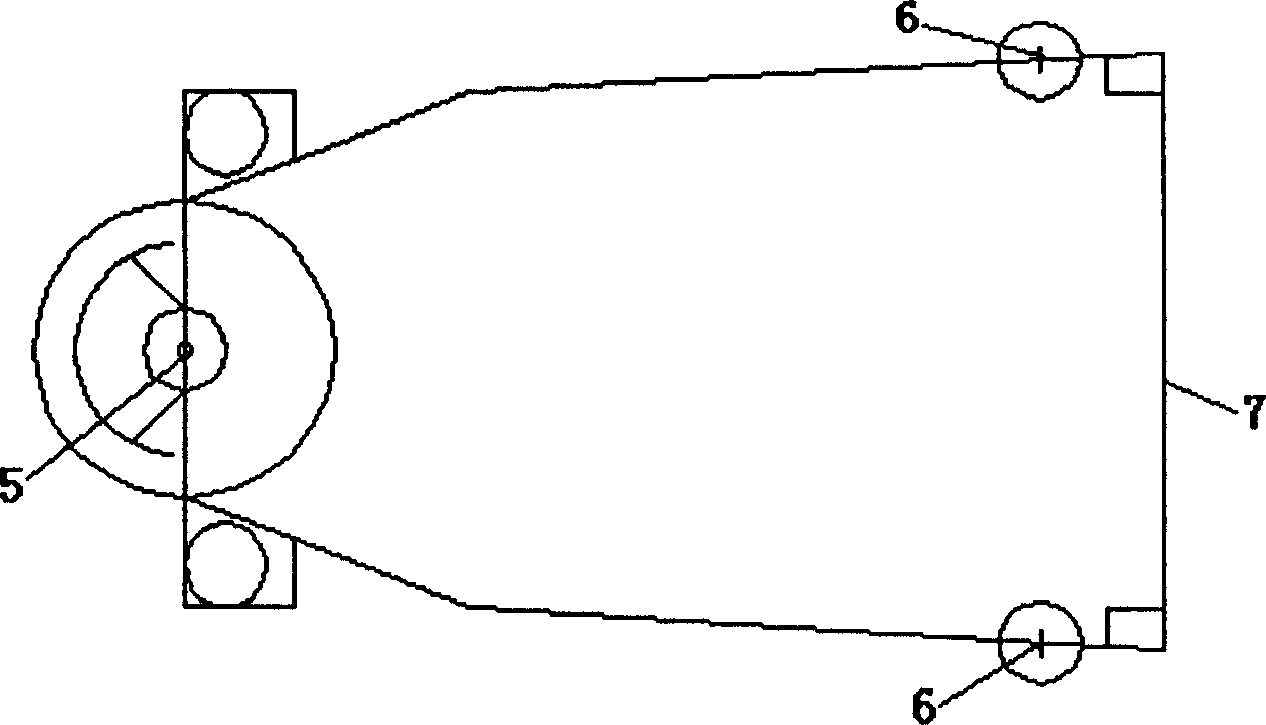

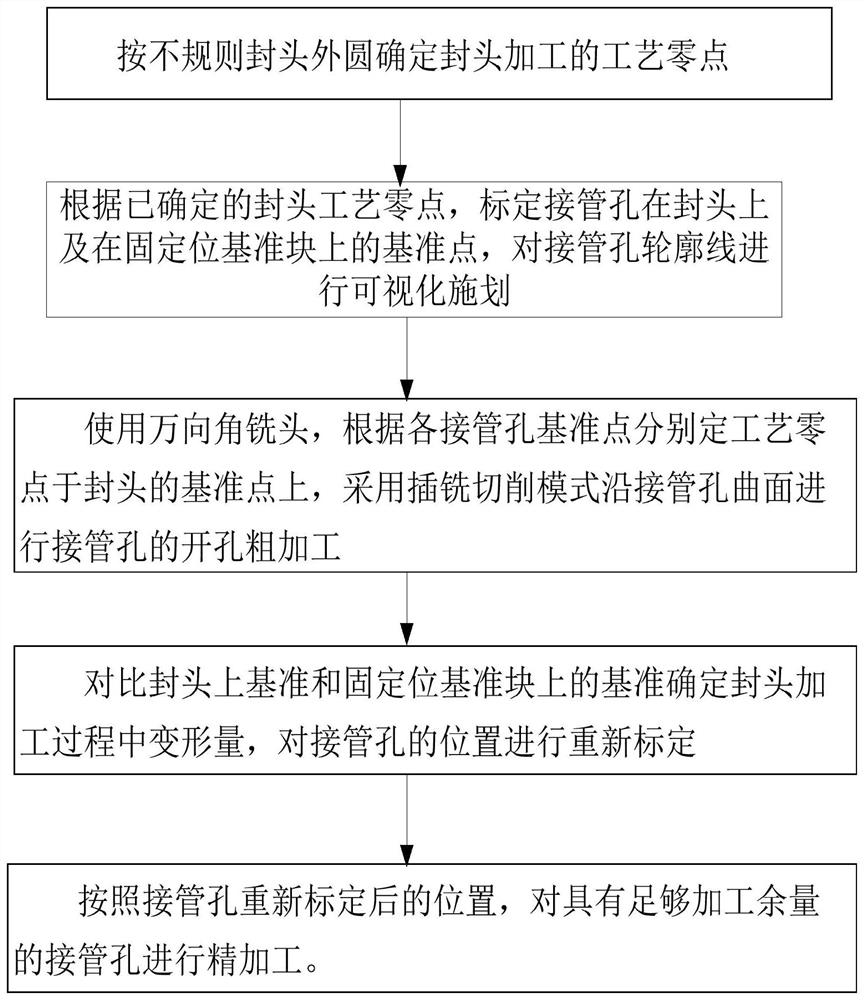

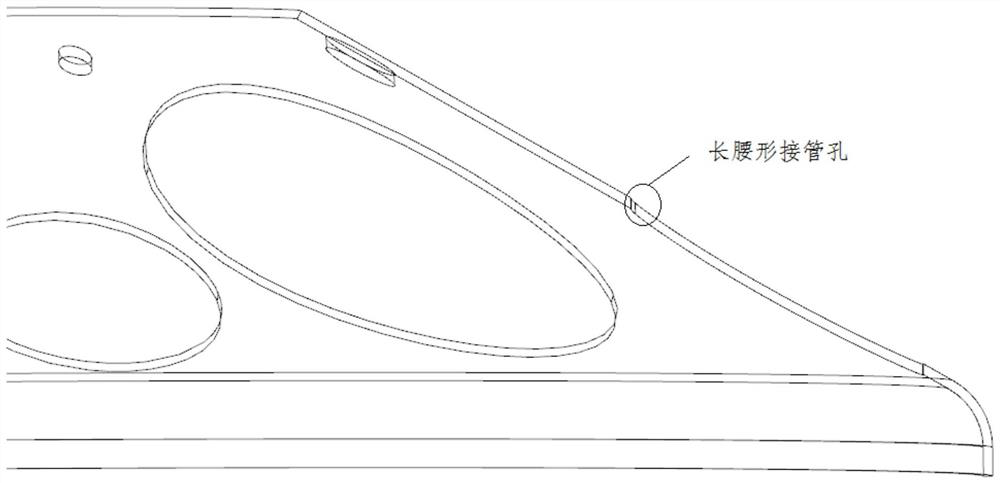

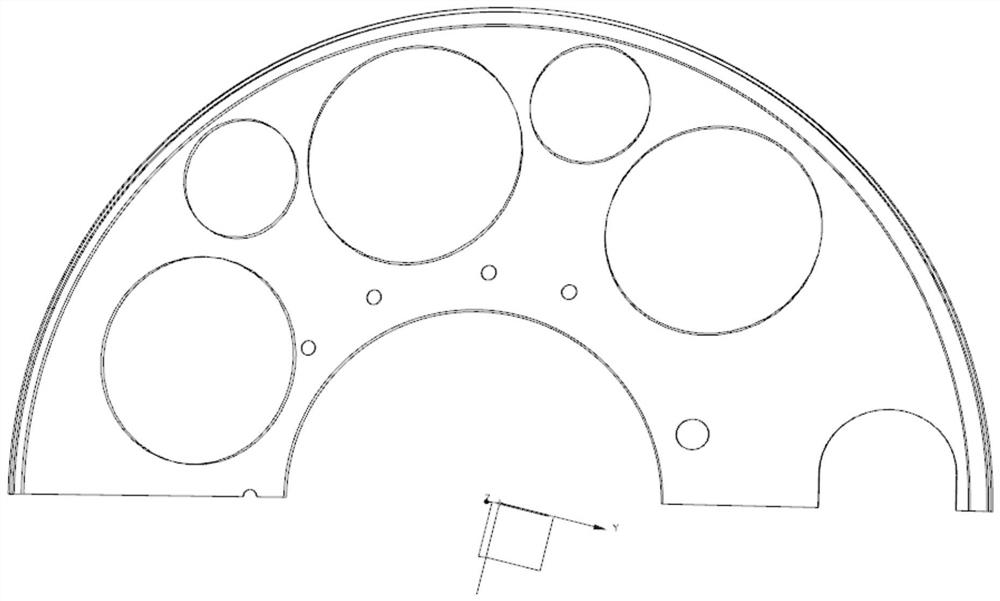

Numerical control machining method for multi-type large-diameter space pipe connecting holes in ultra-large type end socket

ActiveCN114131093ASolve the technical problem of detectable deformationSolve the problem of insufficient machining allowanceMilling equipment detailsNumerical controlPipe

The invention discloses a numerical control machining method for multi-type large-diameter space pipe connecting holes in an ultra-large type end socket, and belongs to the field of numerical control machining. The method comprises the steps that the machining process zero point of the end socket is determined according to the outer circle of the irregular end socket; according to the determined process zero point of the end socket, the datum points of the connecting pipe hole on the end socket and the fixed datum block are calibrated, and the contour line of the connecting pipe hole is visually marked; a universal angle milling head is used, a process zero point is set on the datum point of the seal head according to the datum point of each connecting pipe hole, and rough tapping machining of the connecting pipe holes is conducted along the curved surfaces of the connecting pipe holes in a plunge milling cutting mode; comparing the benchmark on the end socket with the benchmark on the fixed position benchmark block to determine the deformation in the machining process of the end socket, recalibrating the position of the connecting pipe hole, and performing finish machining on the connecting pipe hole with enough machining allowance according to the recalibrated position of the connecting pipe hole. The method is suitable for machining various large-diameter holes in workpieces which have the advantages of being oversized, thin in wall, prone to deformation, made of stainless steel materials and the like.

Owner:CFHI DALIAN HYDROGENANT REACTOR +1

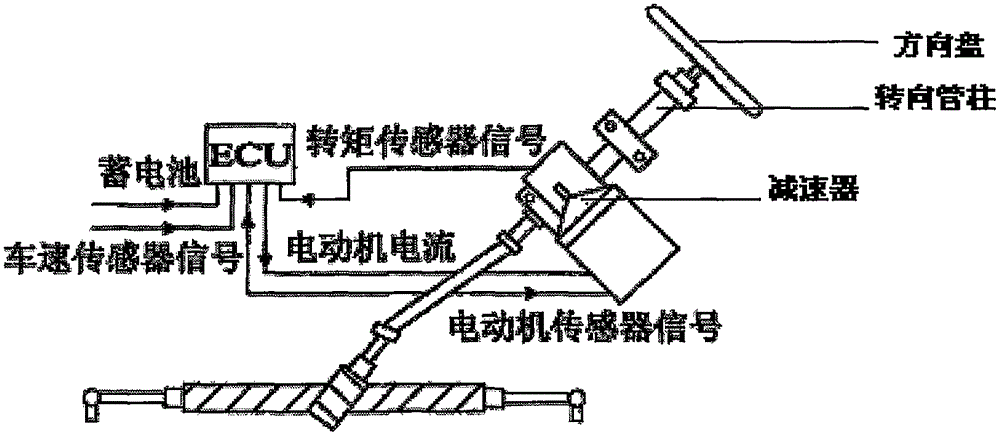

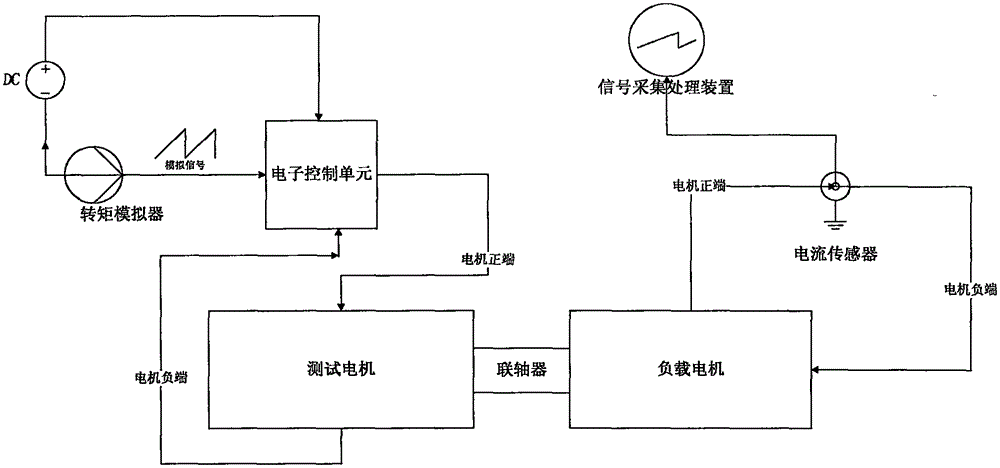

Simple function testing device for electronic power-assisted control unit

InactiveCN106681297AResistance torque increases with speedZero power consumptionElectric testing/monitoringVehicle steering/rolling behaviourMean squareElectric machine

The invention provides a simple and cheap testing device for an electronic power-assisted control steering control unit. The simple function testing device is mainly applied in a batch production testing step of electronic power-assisted steering controllers. The simple and cheap testing device can be used for testing batch characteristic consistency of electronic control units in electronic power-assisted steering systems. A motor with a characteristic which is same with that of a testing motor is used as a loading motor. The anode of the loading motor is connected with the cathode of the loading motor in a shortcircuit manner. Through driving the testing motor to drag the loading motor for rotating and acquiring an induced current value of the loading motor, a force characteristic consistency result of the product is finally acquired through a mean square deviation between the current value and a standard value.

Owner:田洪亮

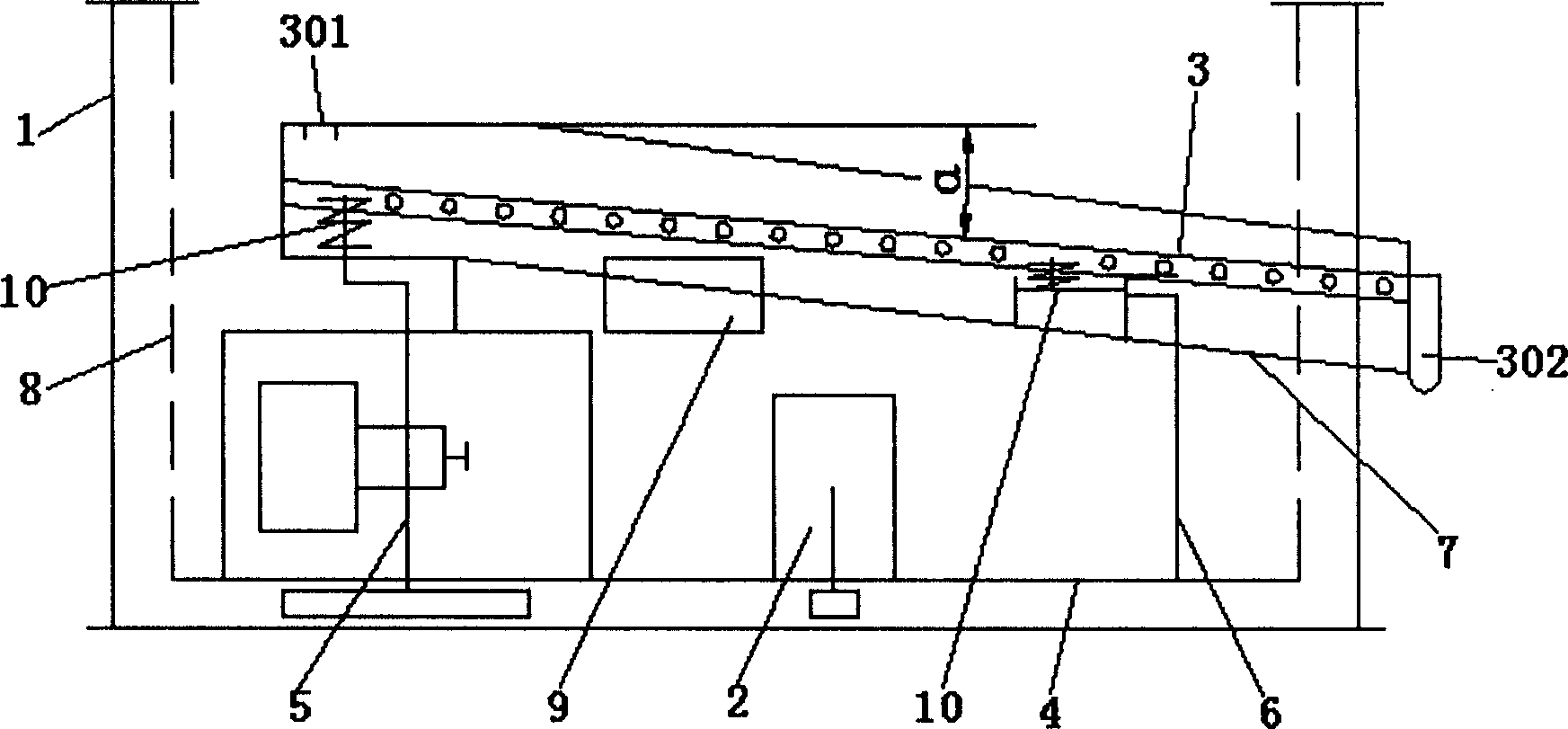

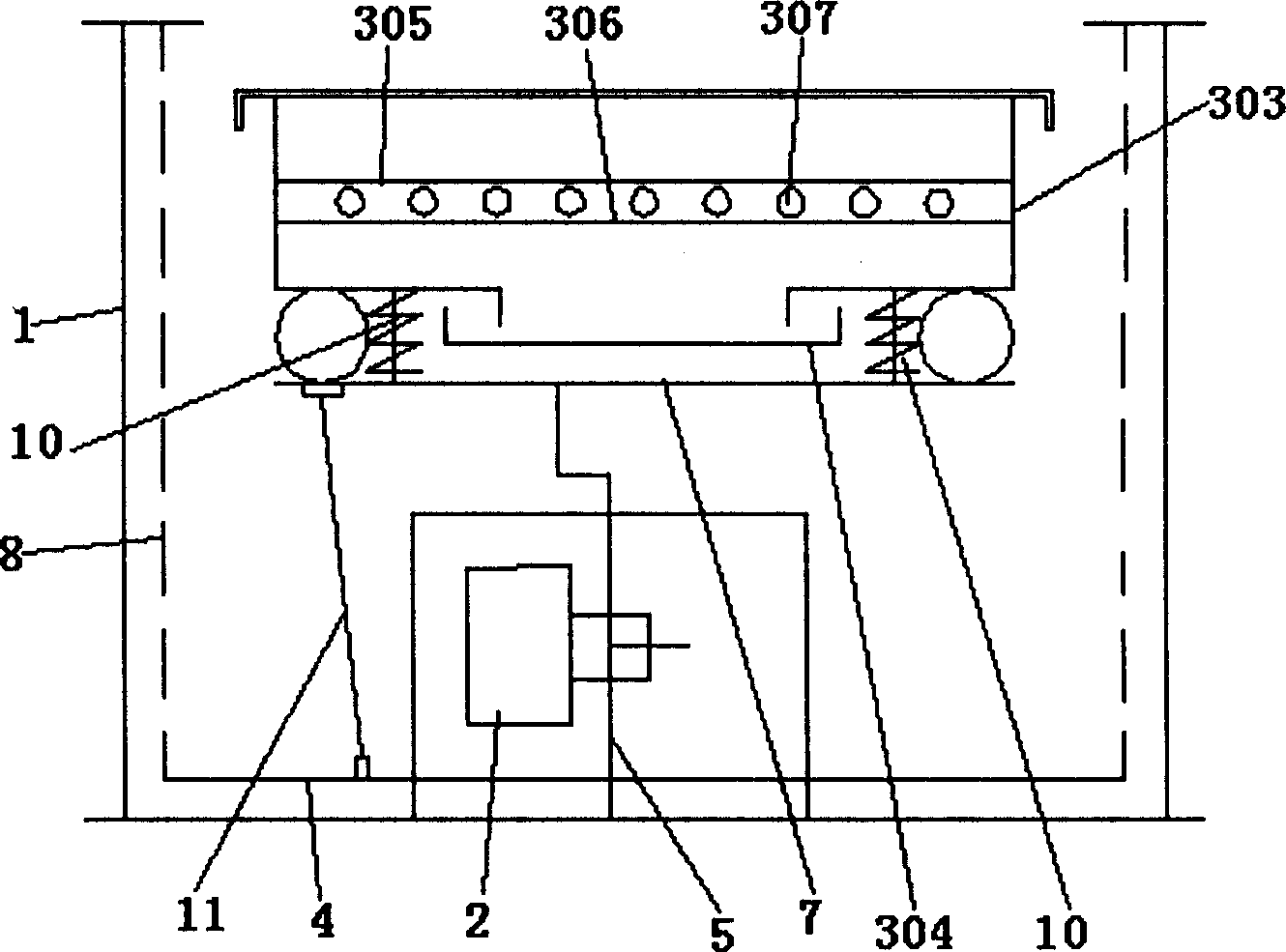

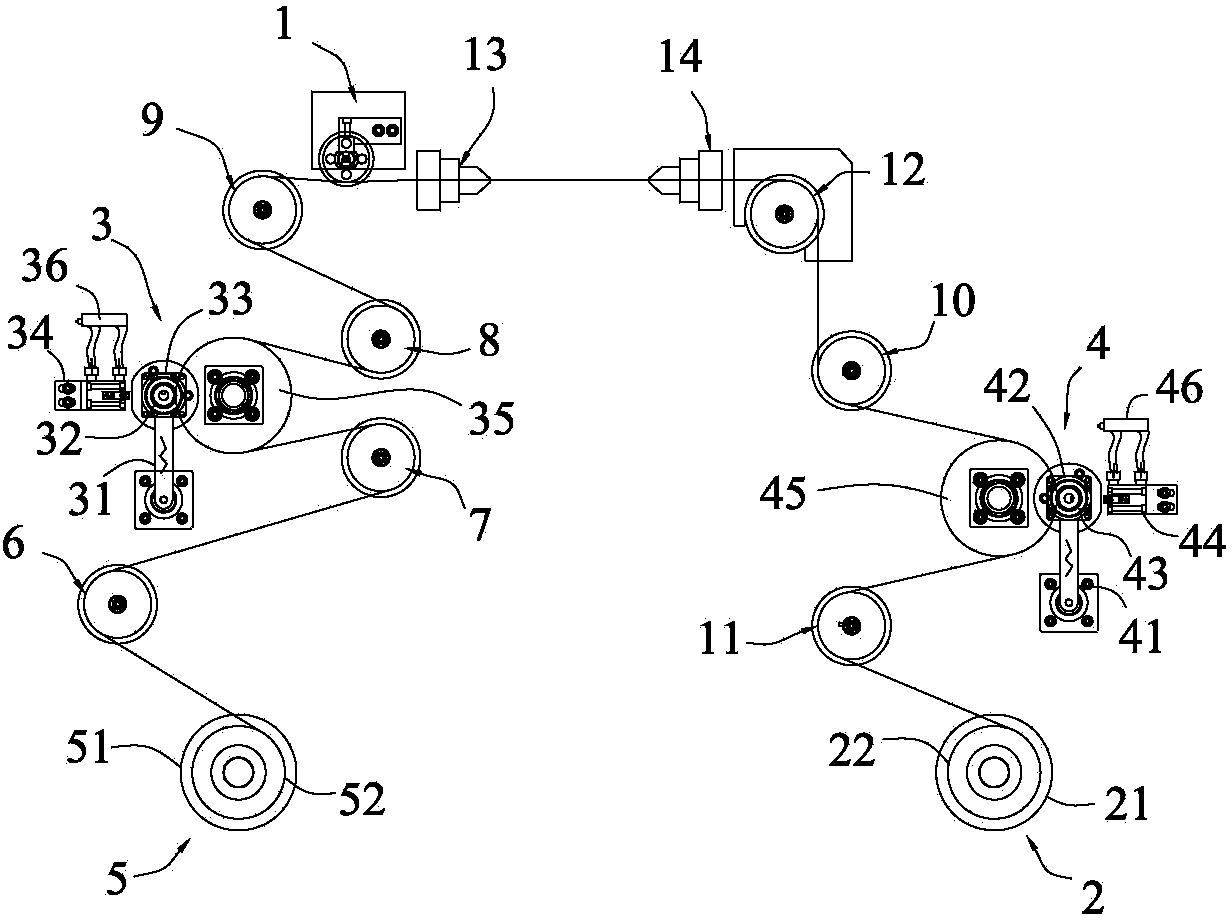

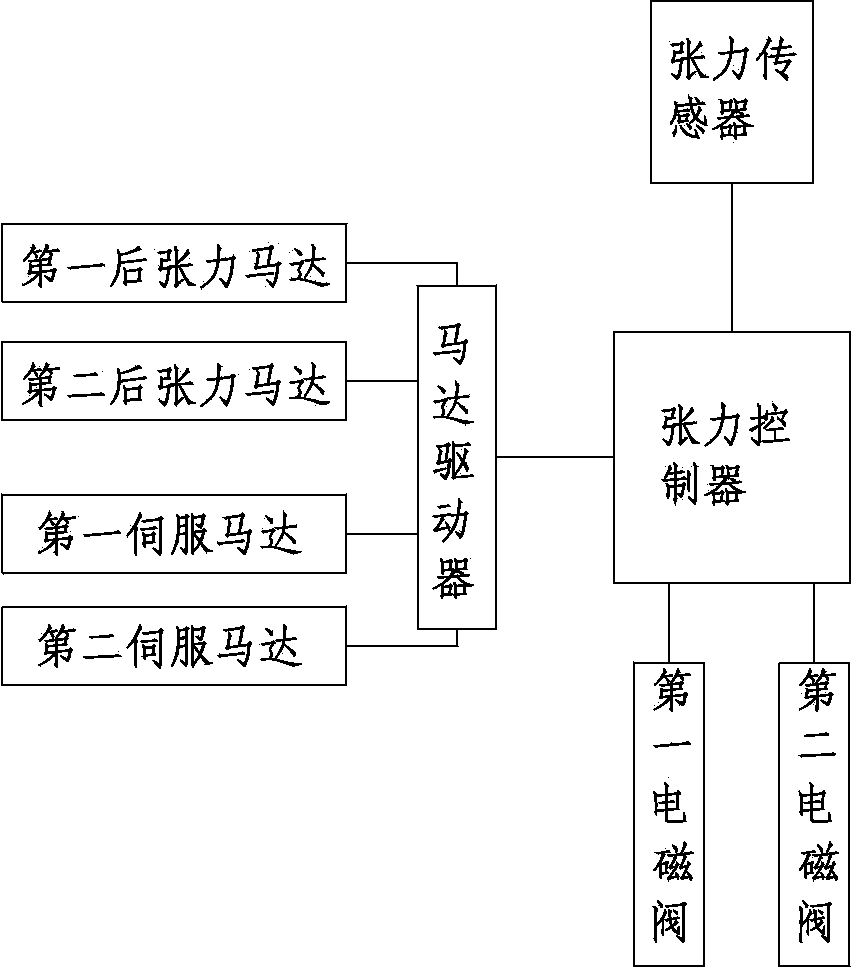

Static constant-tension control system for reciprocation high-speed wire traveling

ActiveCN104028865ASolving resonance problemsFix jitterElectrical-based machining electrodesControl systemEngineering

The invention discloses a static constant-tension control system for reciprocation high-speed wire traveling. The system comprises first guiding wire wheels A-D, second guiding wire wheels A-B, a wire entering guiding pulley, a tension controller, a tension sensor, a first wire feeding wheel taking-up and paying-off device, a second wire feeding wheel taking-up and paying-off device, a first constant tension adjusting device and a second constant tension adjusting device, wherein the tension sensor, the first wire feeding wheel taking-up and paying-off device, the second wire feeding wheel taking-up and paying-off device, the first constant tension adjusting device and the second constant tension adjusting device are respectively connected with the tension controller. The structural design is ingenuous and reasonable, the wire feeding wheel structure is adopted for replacing traditional wire winding drums, the problem that because the wire drums are not concentric, a wire electrode resonates and shakes is solved, it is effectively guaranteed that the tension of the wire electrodes is constant, and machining efficiency is improved; moreover, original positions of a tension wheel and the wire electrode do not need to be adjusted, people only need to control rotation speed of a servo motor, and therefore operation is easy; meanwhile, a symmetrical structure design is adopted, so that matched wire loosening and reciprocation operation on the two sides are achieved, the problem that because single-side wire loosening and reciprocation operation are adopted, the tension is not constant is effectively solved, constancy of the tension is further kept, and machining precision is improved.

Owner:广州静粤态科技有限公司

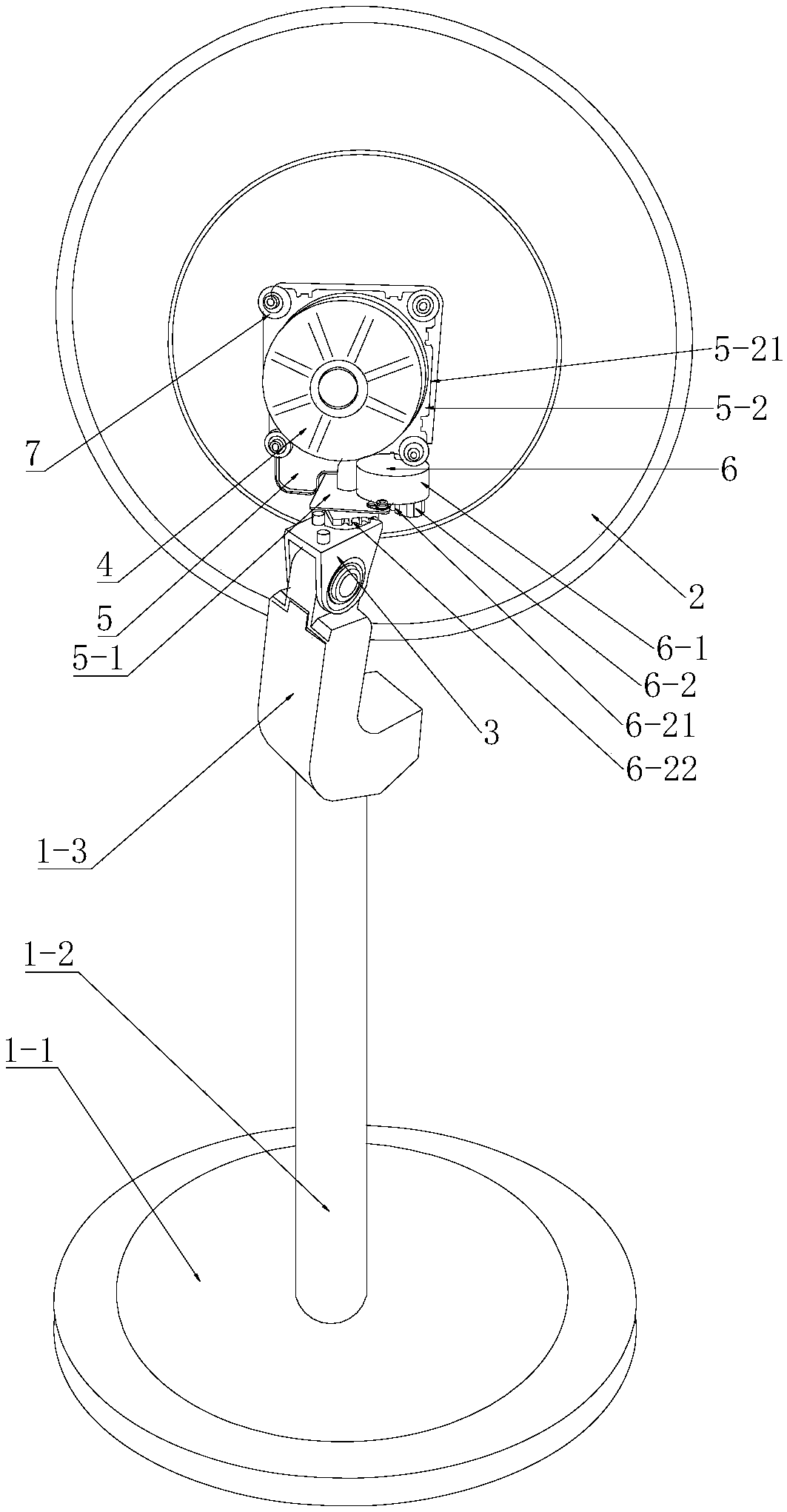

Fan

PendingCN108661937ASolving resonance problemsPump componentsPump installationsHead shakingElectric machinery

The invention discloses a fan. The fan is characterized by comprising a fan support frame, front and back net covers, fan blades, a main motor, a motor bracket, a head shaking device and a main control device; the fan blades are mounted on a rotating shaft of the main motor; and the motor bracket is movably arranged on the fan support frame. The fan is characterized in that the head shaking deviceis arranged between the motor bracket and the fan support frame; an elastic buffer support is arranged on the motor bracket; and the motor is fixed on the elastic buffer support. The fan is simple instructure and convenient to use.

Owner:佛山勤顺科技有限公司

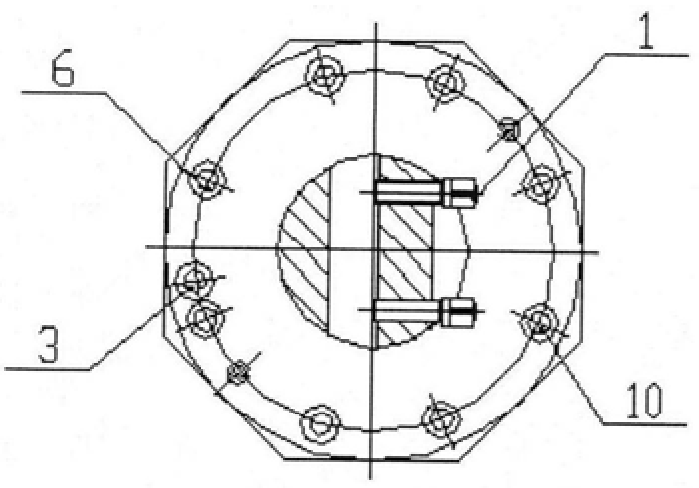

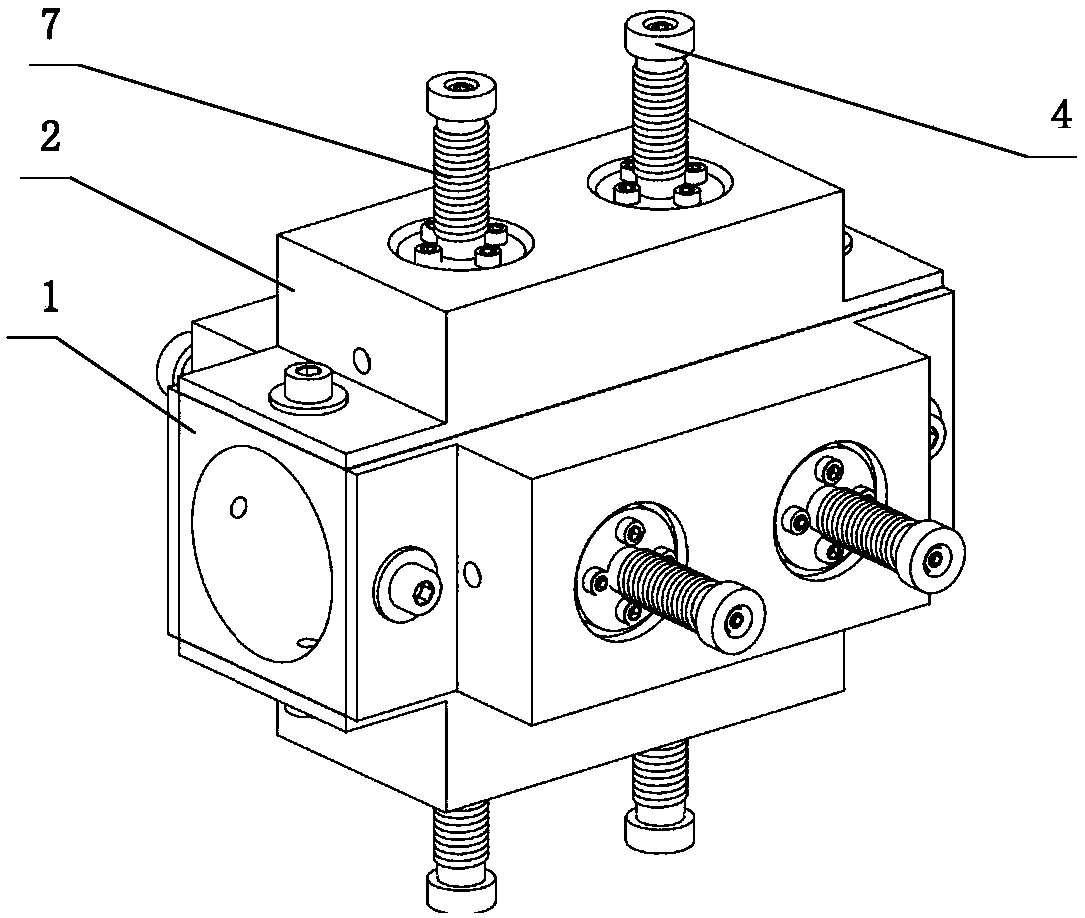

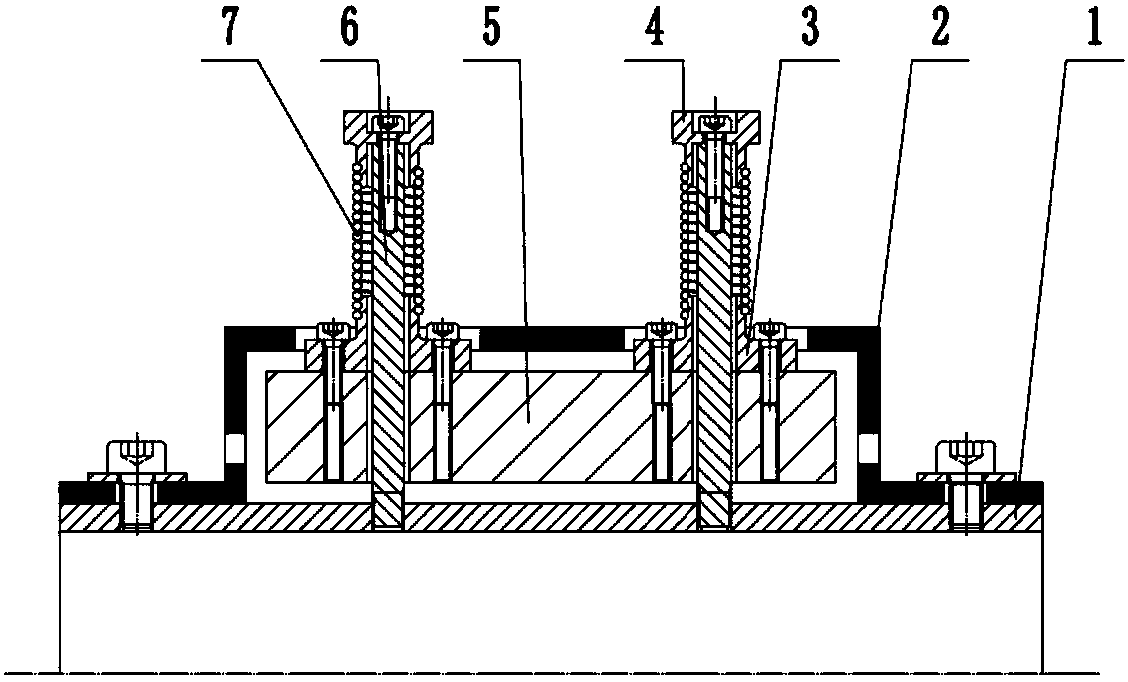

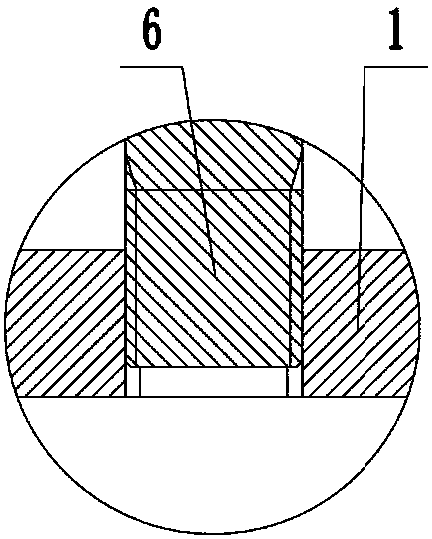

Electromagnetic double-mode type vibration absorber for transmission shaft

PendingCN108443383AAvoid wear and durability issuesQuick responseMagnetic springsInternal combustion piston enginesElectronic control unitElectromagnetic vibration

The invention provides an electromagnetic double-mode type vibration absorber for a transmission shaft. The electromagnetic double-mode type vibration absorber for the transmission shaft comprises a cubical metal sleeve which his provided with a round center hole, and four electromagnetic vibration absorber mode switching units which are symmetrically fixedly arranged on the upper outer wall, thelower outer wall, the left outer wall and the right outer wall of the metal sleeve, wherein the electromagnetic vibration absorber mode switching units are connected to an ECU circuit (Electronic Control Unit) and are used for supplying power or cutting off power supply of an electromagnet based on the transmission shaft vibration frequency acquired by the ECU, so that the electromagnetic vibration absorber mode switching units can be switched between a kinetic vibration absorber mode and a mass block mode. Compared with a traditional transmission shaft vibration absorbing method, the electromagnetic double-mode type vibration absorber for a transmission shaft has the advantages that the problem of resonance of a transmission shaft under high- and low-frequency exciting can be synchronously solved; and meanwhile, the durability of the transmission shaft is not influenced while solving the resonance problem of the transmission shaft. The electromagnetic double-mode type vibration absorber for the transmission shaft has the advantages of being fast to respond, energy saving, and high in adsorbing force.

Owner:SOUTH CHINA UNIV OF TECH

Pile type offshore embankment, design method and application

ActiveCN113255050ASimple structural designSolving resonance problemsGeometric CADDesign optimisation/simulationFrequency spectrumStructural engineering

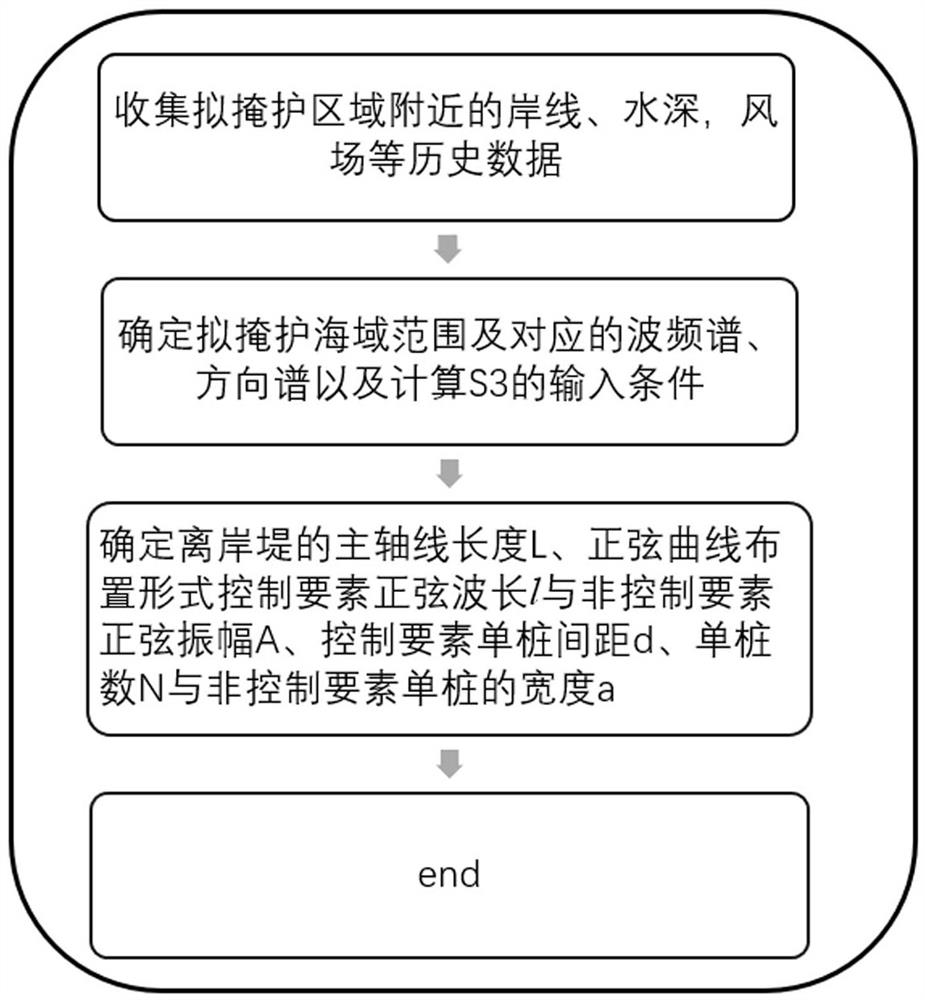

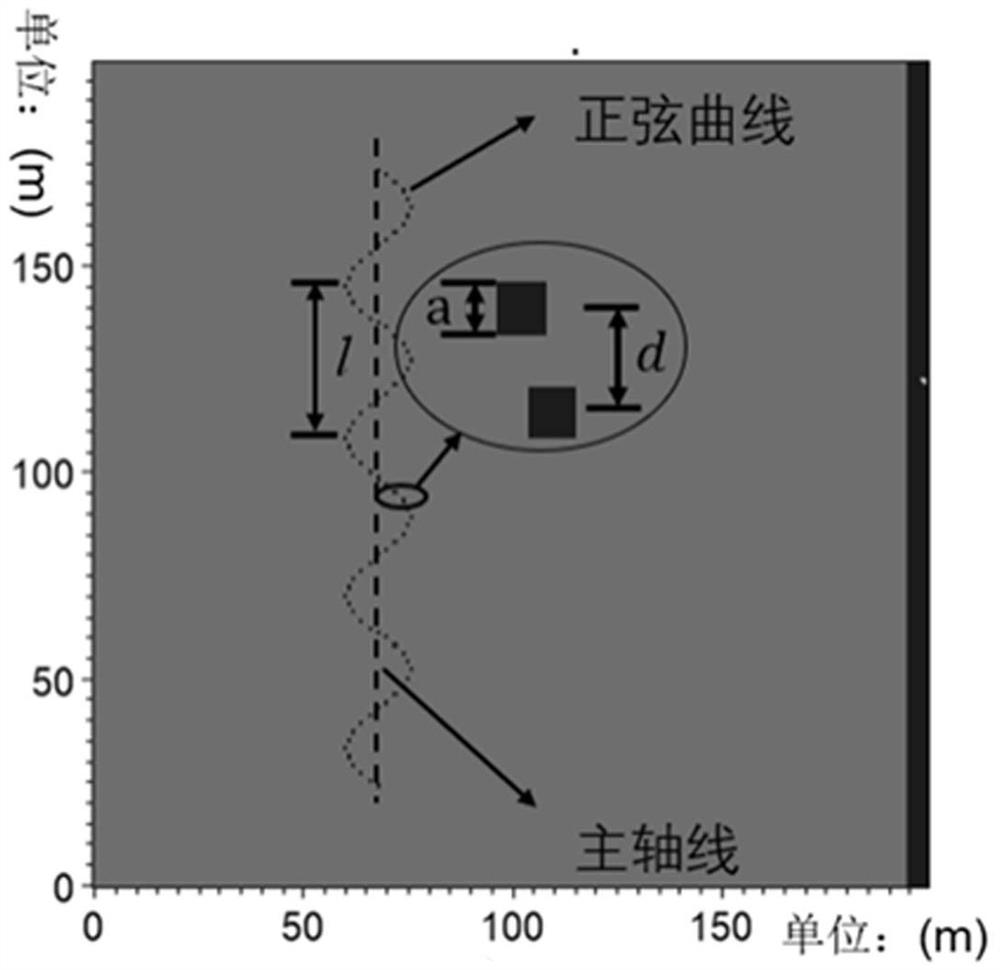

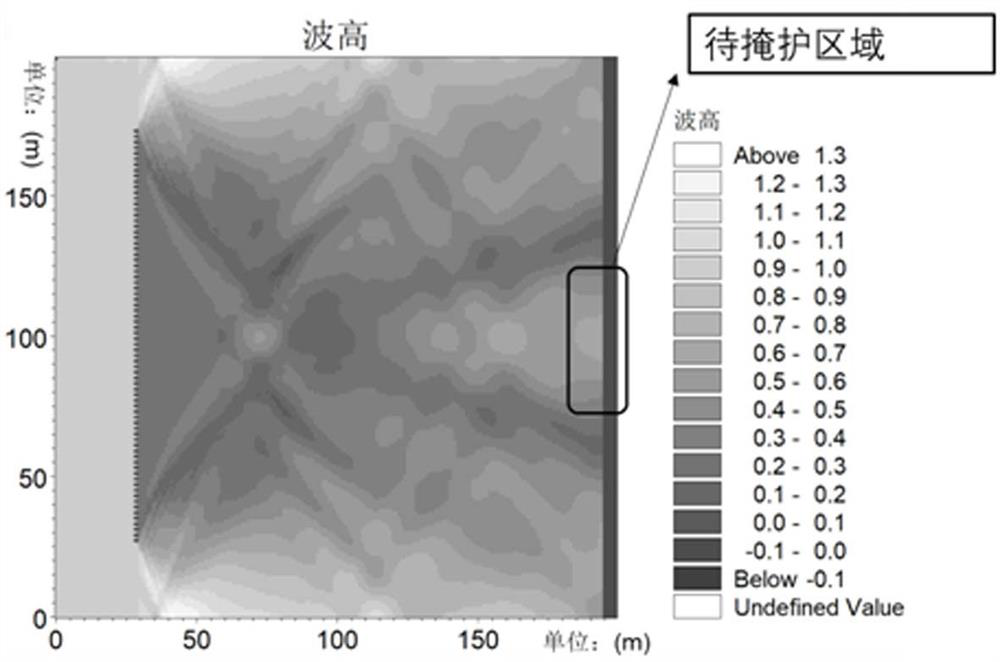

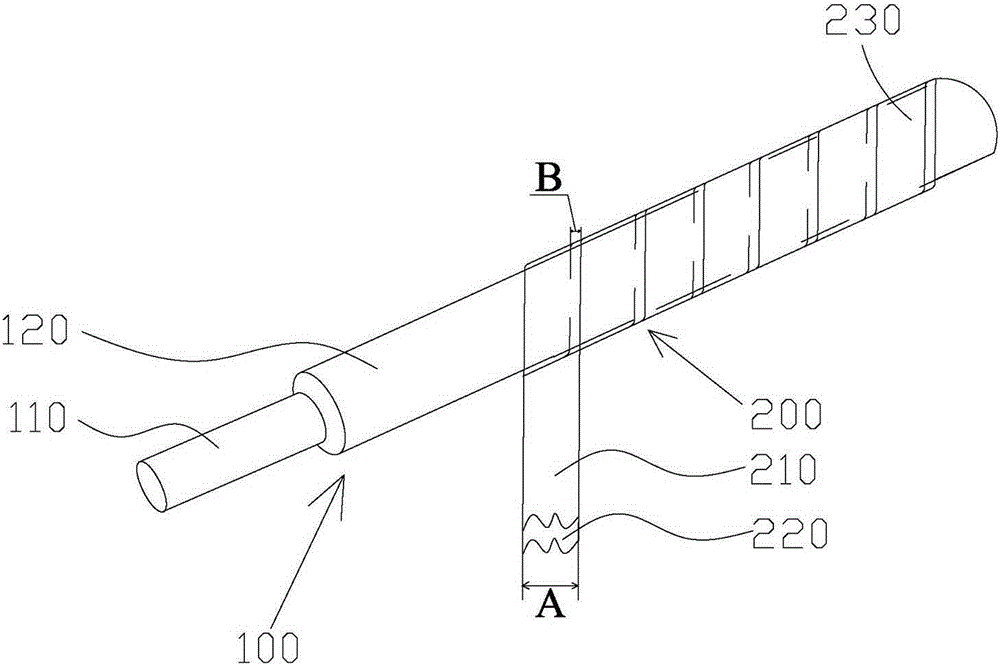

The invention discloses a pile type offshore embankment, a design method and application, and belongs to the technical field of coast engineering. The arrangement structure of the pile type offshore embankment is in a sine curve form. The design method comprises: collecting historical data such as a shoreline, water depth and a wind field near a to-be-shielded area; determining a to-be-shielded sea area range, a corresponding wave frequency spectrum and a direction spectrum, and calculating an input condition of S3; and determining the length L of the main axis of the offshore embankment, the sine wave length (m) of a control element in a sine curve arrangement form, the sine amplitude A of a non-control element, the spacing d of single piles of the control element, the number N of the single piles and the width a of the single piles of the non-control element. The interference of long-period waves can be effectively blocked through sinusoidal array arrangement, wave resonance of a to-be-shielded area is avoided, meanwhile, the interference of short waves can be effectively blocked through the single piles arranged in an array mode, the wave dissipation frequency is expanded from the narrow bandwidth to the wide bandwidth, and then the wave blocking efficiency of the pile type offshore embankment is improved.

Owner:OCEAN UNIV OF CHINA

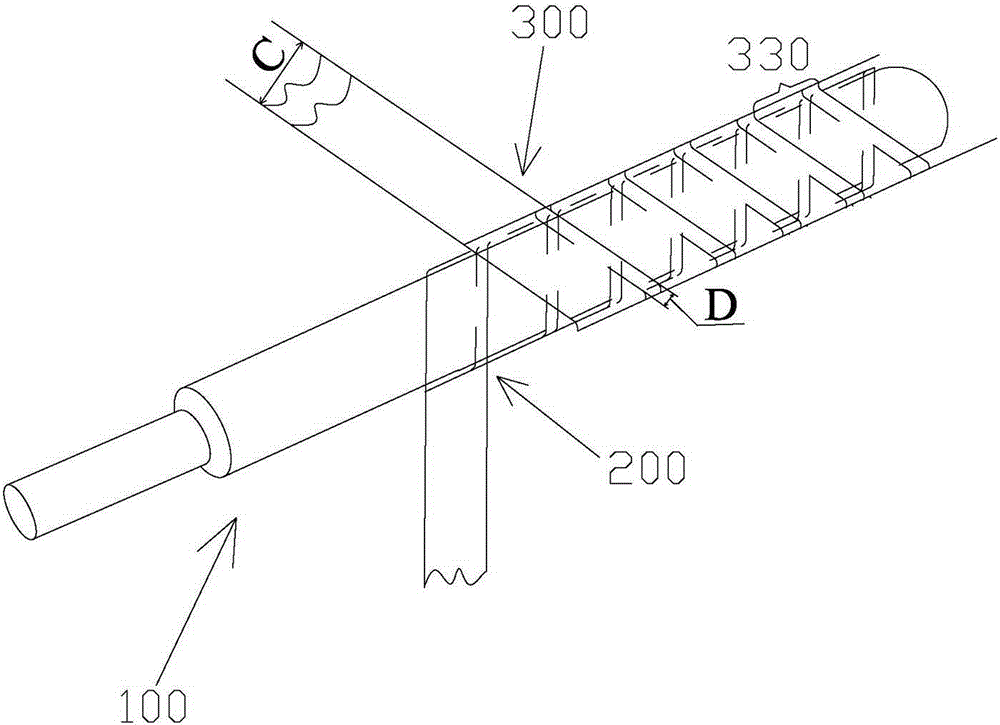

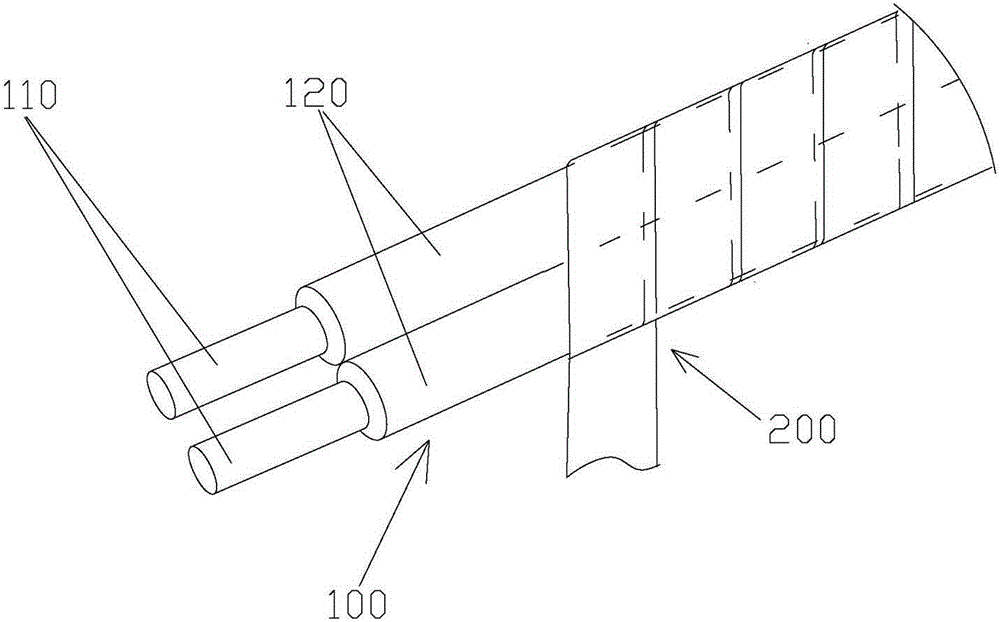

Novel shielding cable

InactiveCN105225738ATightly boundGuaranteed continuityInsulated cablesCommunication cablesCapacitanceShielded cable

Provided is a novel shielding cable comprising at least one signal line and two metallic conductive shielding tapes covering the periphery of the signal line. The metallic conductive shielding tape is formed by a metallic foil covering a side of a plasticity base material. The metallic foil of the first metallic conductive shielding tape faces outwardly, is spirally wound around the signal line, and defines a plurality of first spiral coils. The metallic foil of the second metallic conductive shielding tape faces inwardly, reversely spirally wound around the first metallic conductive shielding tape, and defines a plurality of second spiral coils. Continuous electrical contact is formed between the first metallic conductive shielding tape and the second metallic conductive shielding tape. The two metallic conductive shielding tapes are wound in a crossed manner such that the metallic foils of the two metallic conductive shielding tapes can be completely and tightly combined and cannot generate periodic breakpoints, thereby guaranteeing continuity of a conductive surface. Thus, a resonance problem generated by periodic fluctuation of shielding conductive surface capacitance is solved and an effect of solving a high-frequency point abrupt attenuation.

Owner:通盈电业(深圳)有限公司

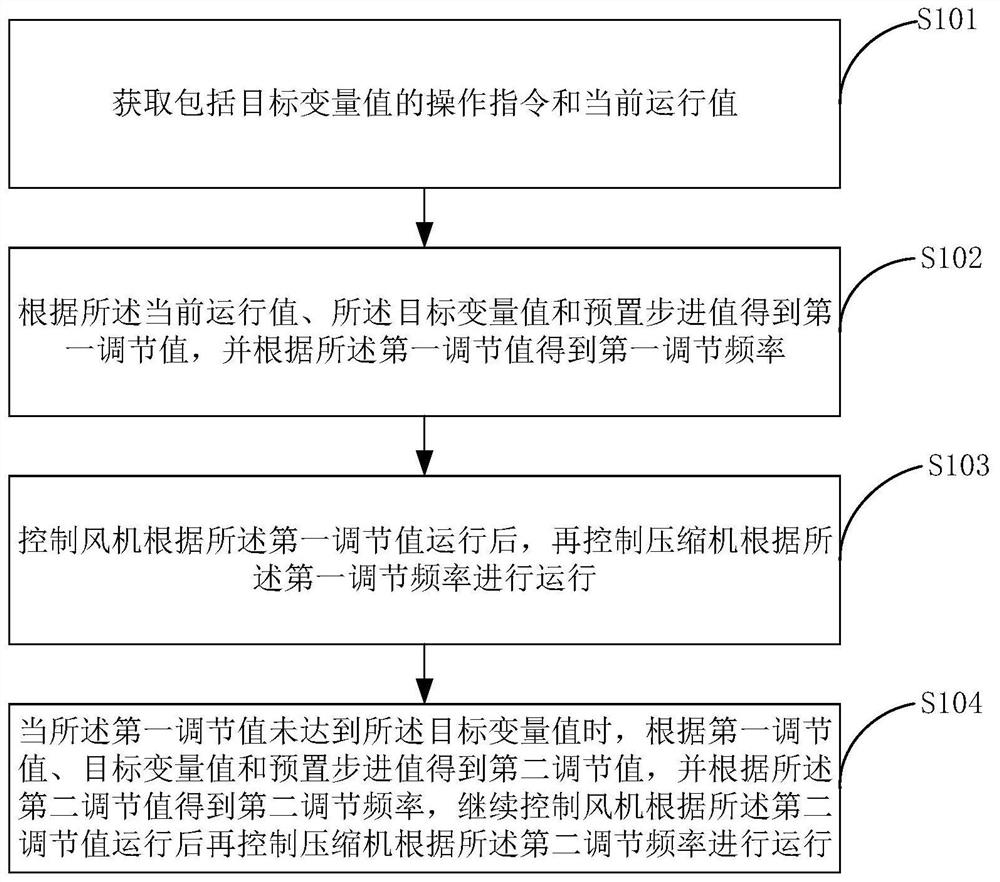

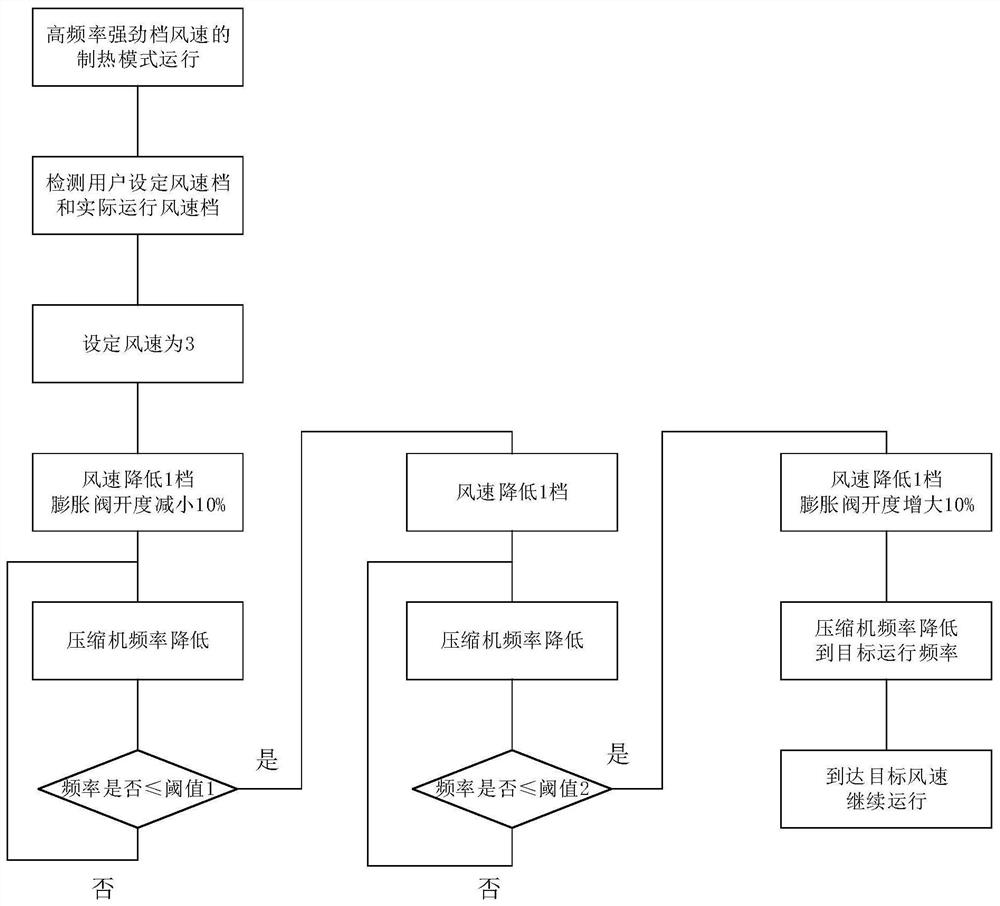

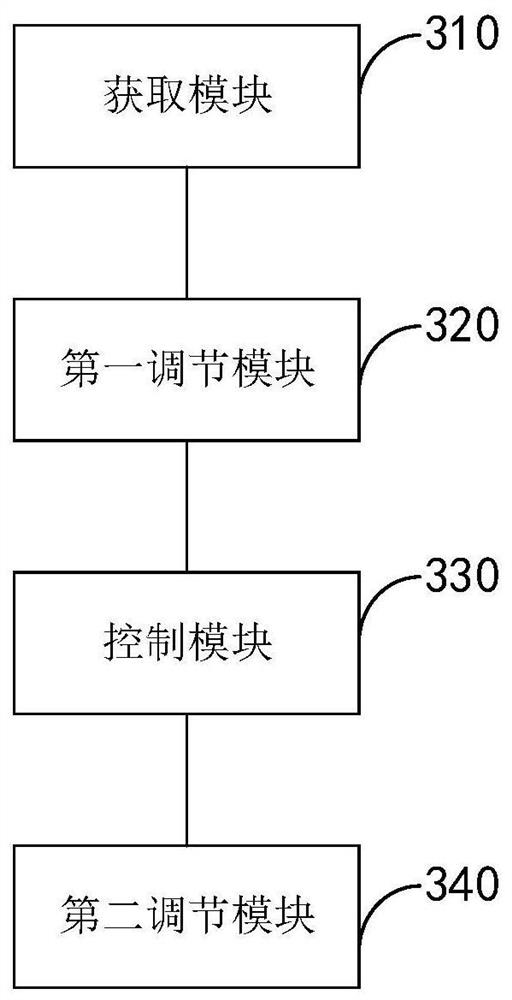

Air conditioner control method and system, computer equipment and storage medium

ActiveCN113757937ASolving resonance problemsSolve the noiseMechanical apparatusSpace heating and ventilation safety systemsAir velocityControl engineering

The invention provides an air conditioner control method and device, computer equipment and a storage medium. The method comprises the steps that an operation instruction comprising a target variable value and a current operation value are obtained; a first adjusting value is obtained according to the current operation value, the target variable value and a preset stepping value, and a first adjusting frequency is obtained according to the first adjusting value; after a fan is controlled to operate according to the first adjusting value, a compressor is controlled to operate according to the first adjusting frequency, a second adjusting value is obtained according to the first adjusting value, the target variable value and the preset stepping value, a second adjusting frequency is obtained according to the second adjusting value, the fan is continuously controlled to operate according to the second adjusting value, and then the compressor is controlled to operate according to the second adjusting frequency; and the problems of resonance, noise and the like of an indoor unit in the prior art are solved, the air speed is reduced firstly, then the frequency of the compressor is reduced, the air outlet temperature of the indoor unit cannot be obviously reduced, and therefore the user experience is not affected.

Owner:四川长虹空调有限公司

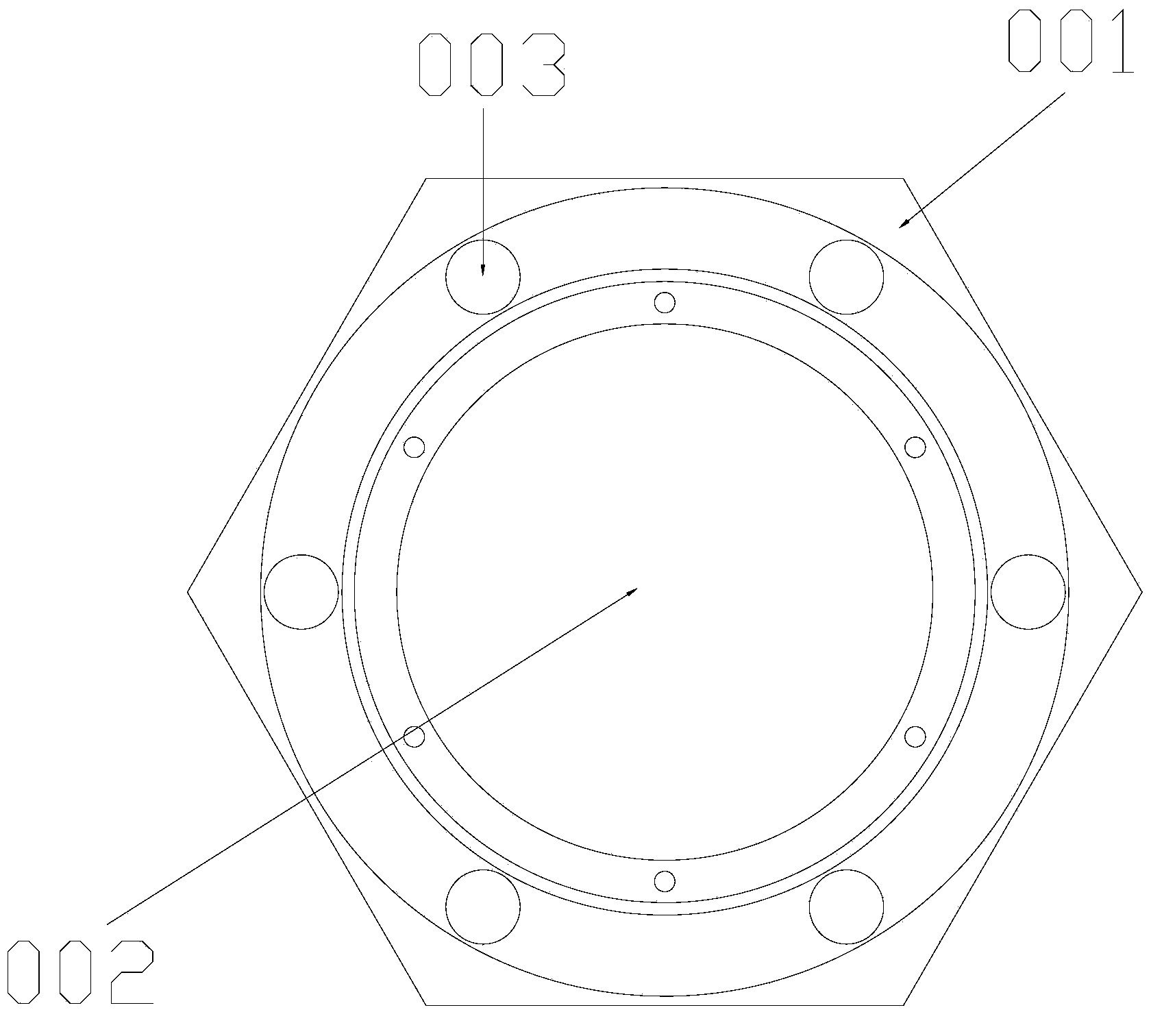

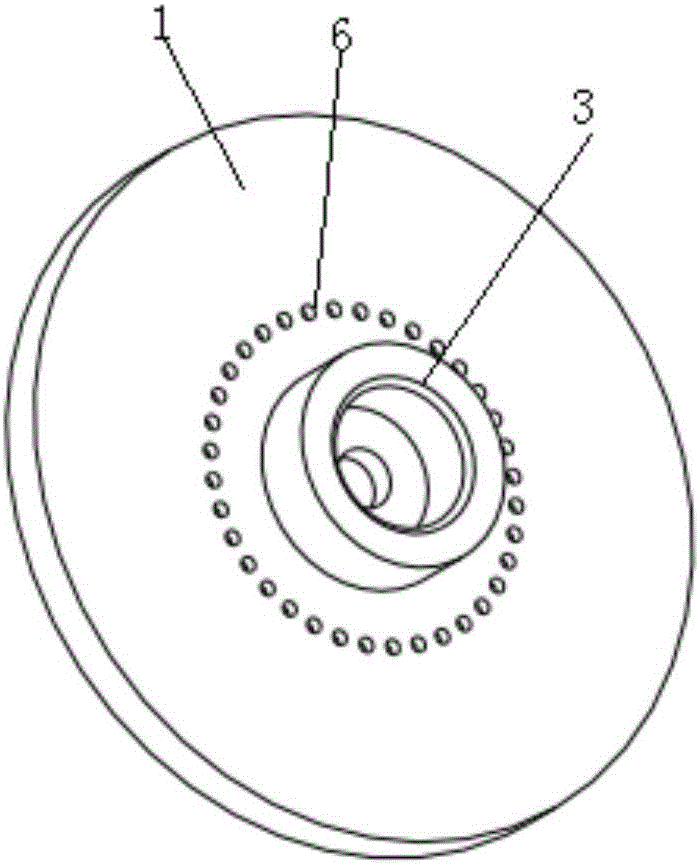

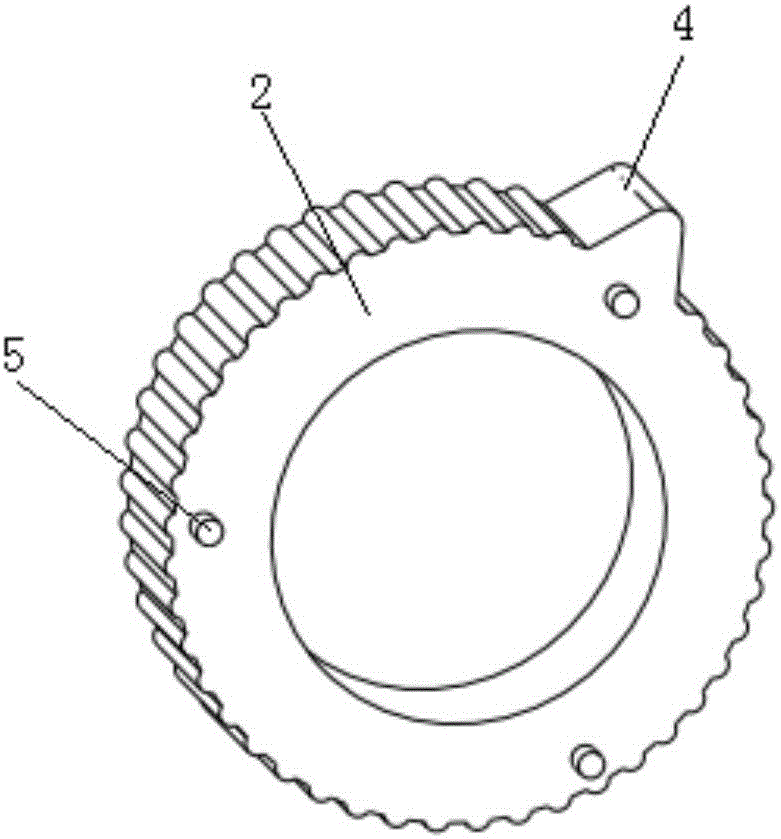

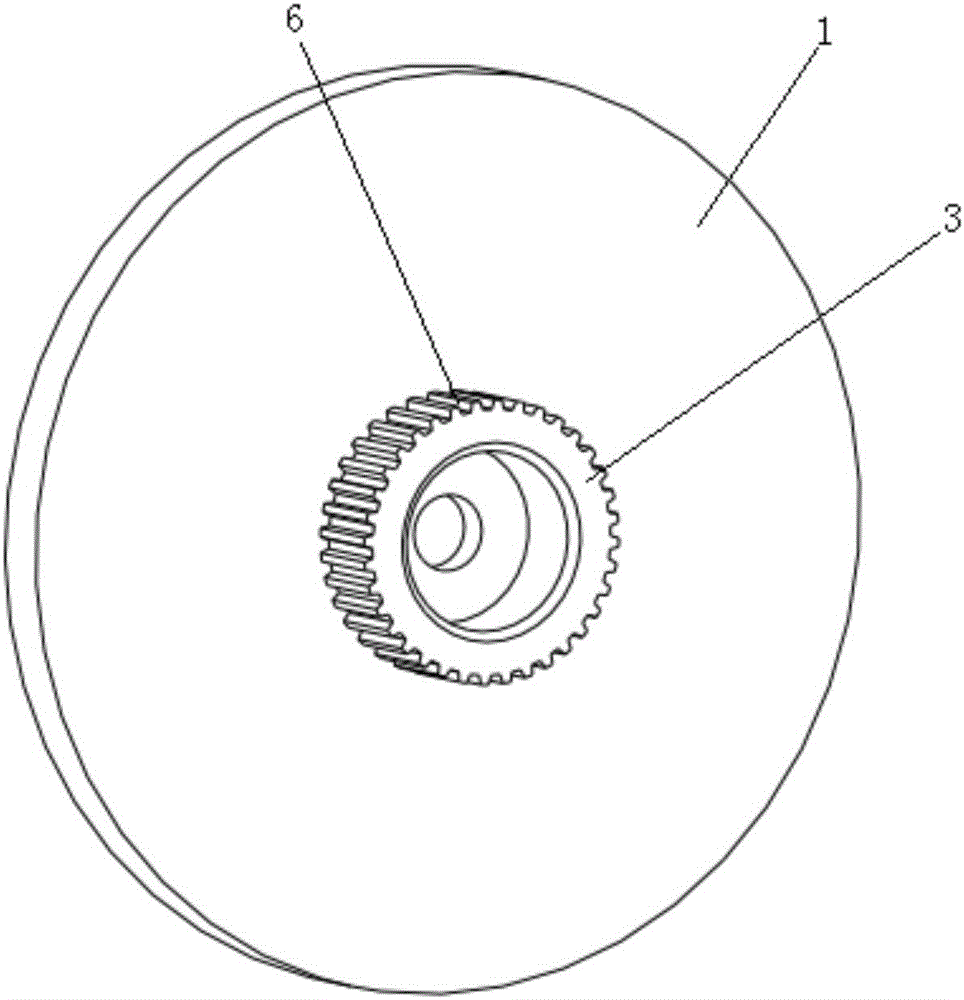

Motor end cover positioning structure and motor

InactiveCN106571711AImprove stabilityImprove reliabilitySupports/enclosures/casingsRubber ringEngineering

The invention discloses a motor end cover positioning structure and a motor. The motor end cover positioning structure comprises an end cover body (1) and a rubber ring (2), wherein a mounting bulge (3) is arranged on the end cover body (1); the rubber ring (2) sleeves the mounting bulge (3); the periphery of the rubber ring (2) is provided with a positioning groove or a positioning bulge (4); circumferential concave-convex positioning match is formed between the rubber ring (2) and the end cover body (1); the number of convex parts (5) is smaller than that of concave parts (6); the number of the concave parts (6) is integer multiple of that of the convex parts (5); and the convex parts (5) can be embedded in the concave parts (6) at the same time. According to the motor end cover positioning structure of the invention, relative rotation between the motor and the rubber ring can be effectively avoided, the stability of the motor mounting structure is improved, and the motor noise is reduced.

Owner:QINGDAO HAIER JIAOZHOU AIR CONDITIONER

Numerical control one-column composite vertical lathe

InactiveCN111993087AGuaranteed levelnessShorten the lengthFeeding apparatusOther manufacturing equipments/toolsClassical mechanicsCantilever

The invention relates to the field of vertical lathes, in particular to a numerical control one-column composite vertical lathe. The numerical control one-column composite vertical lathe is characterized in that a cross beam, a stand column and a workbench are included; the cross beam is of a horizontally arranged cantilever structure, a square sliding ram assembly is perpendicularly arranged on the cross beam, and the square ram assembly moves relative to the length direction of the cross beam through a cross beam lead screw; the bottom of the stand column is fixedly connected with the workbench; a square ram boring and milling head is arranged on the lower portion of the square ram assembly; and lifting motion of the cross beam, horizontal motion of a square ram along the cross beam, lifting feeding of the square ram boring and milling head and rotation of the workbench are controlled through a numerical control system. Compared with the prior art, the numerical control one-column composite vertical lathe has the following advantages that 1) machining is focused on milling, turning is complementary, and multiple functions of drilling, boring and grinding are achieved through thesquare ram; 2) compared with a dual-column vertical lathe, the manufacturing cost is obviously reduced; and 3) the worldwide problem of the low levelness and resonance of the large and heavy single-arm structure vertical lathe is solved.

Owner:徐绍波

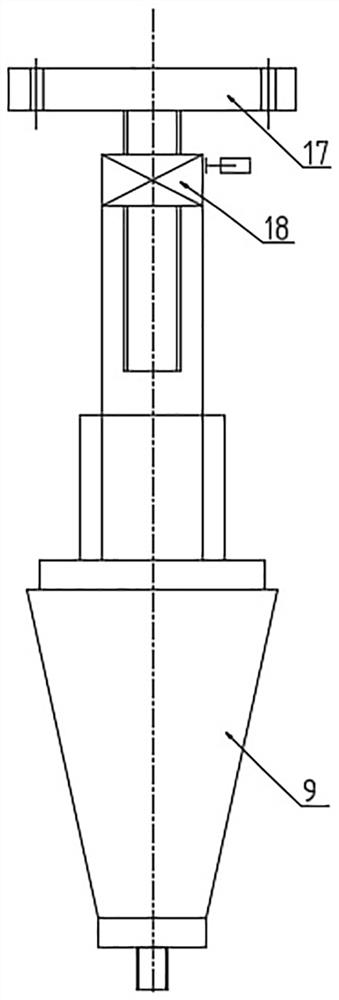

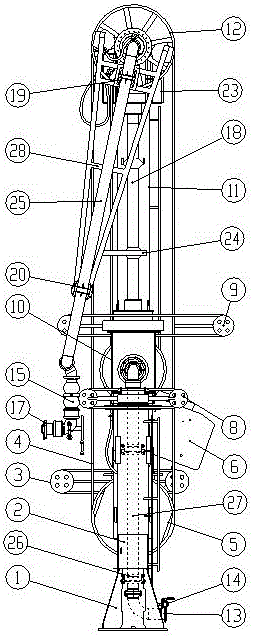

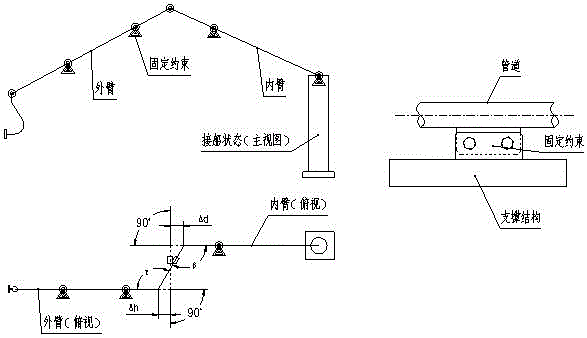

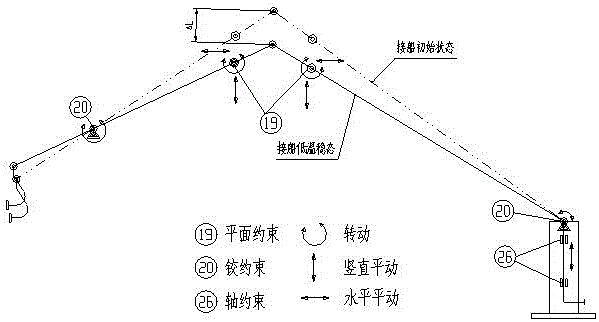

Single pipe loading and unloading arm for low-temperature ship

ActiveCN105858584ASolving resonance problemsIngenious designLiquid transferring devicesNitrogen gasInternal stress

The invention relates to a single pipe loading and unloading arm for a low-temperature ship. The single pipe loading and unloading arm comprises a supporting structure, a pipe system, a hydraulic drive system, a maintenance platform, a nitrogen gas blowing and sweeping system, an emergency escaping system, a hydraulic substation, an upper rope pulley, a steel wire rope and a lower rope wheel; the steel wire rope is arranged between the upper rope wheel and the lower rope wheel, the maintenance platform is arranged on the upper portion of the loading and unloading arm, the nitrogen gas blowing, sweeping and distributing system is arranged near an inlet flange of the loading and unloading arm, and the hydraulic substation is arranged on the side face of a stand column. The pipe system comprises a stand column pipe, an inner arm pipe and an outer arm pipe, the upper end and the lower end of the stand column pipe are constrained with a shaft, and it is guaranteed that the stand column pipe stretches out and contracts back freely in the axial direction and rotates freely in the axial direction; one end of the inner arm pipe is constrained with a hinge, and the other end of the inner arm pipe is constrained with a plane; one end of the outer arm pipe is constrained with a hinge, and the other end of the outer arm pipe is constrained with a plane. By means of the single pipe loading and unloading arm, the pipe system can stretch and contract freely under an environmental temperature as well as an ultra-low temperature working condition, and thus internal stress generated by temperature deformation is eliminated.

Owner:优必得流体科技设备(江苏)有限公司

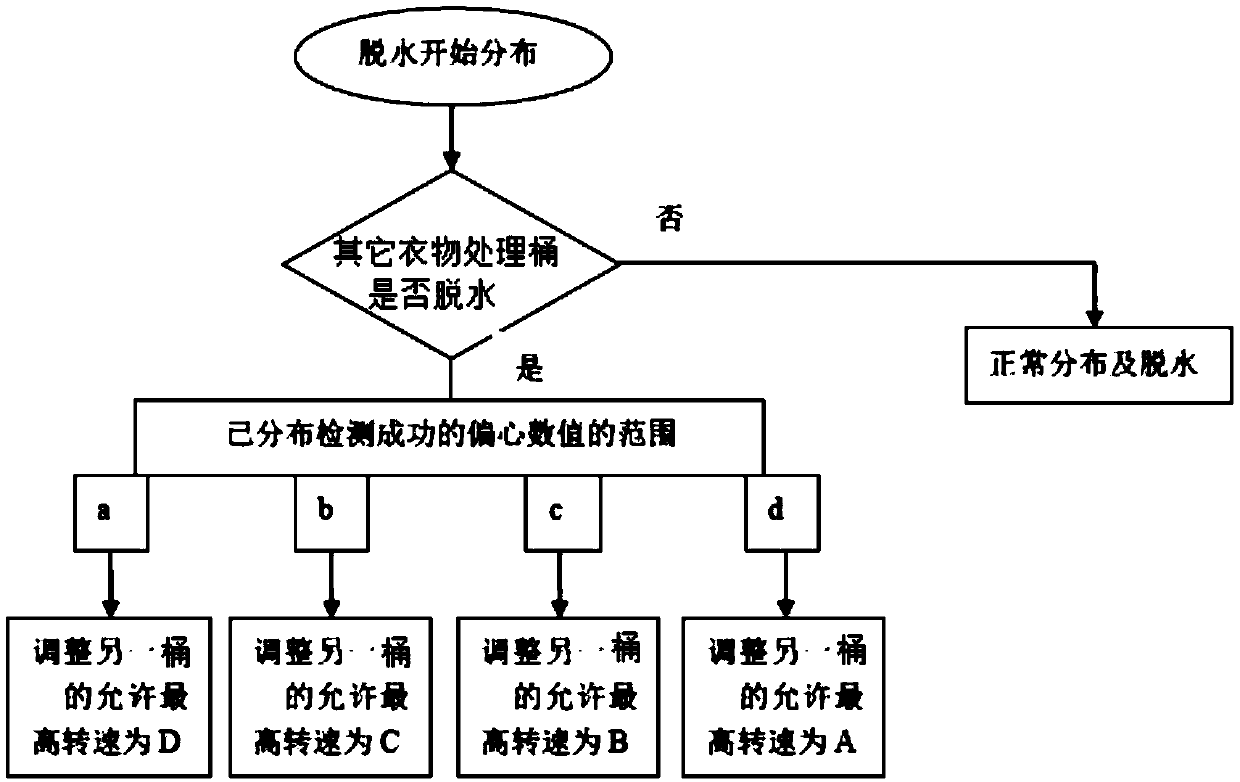

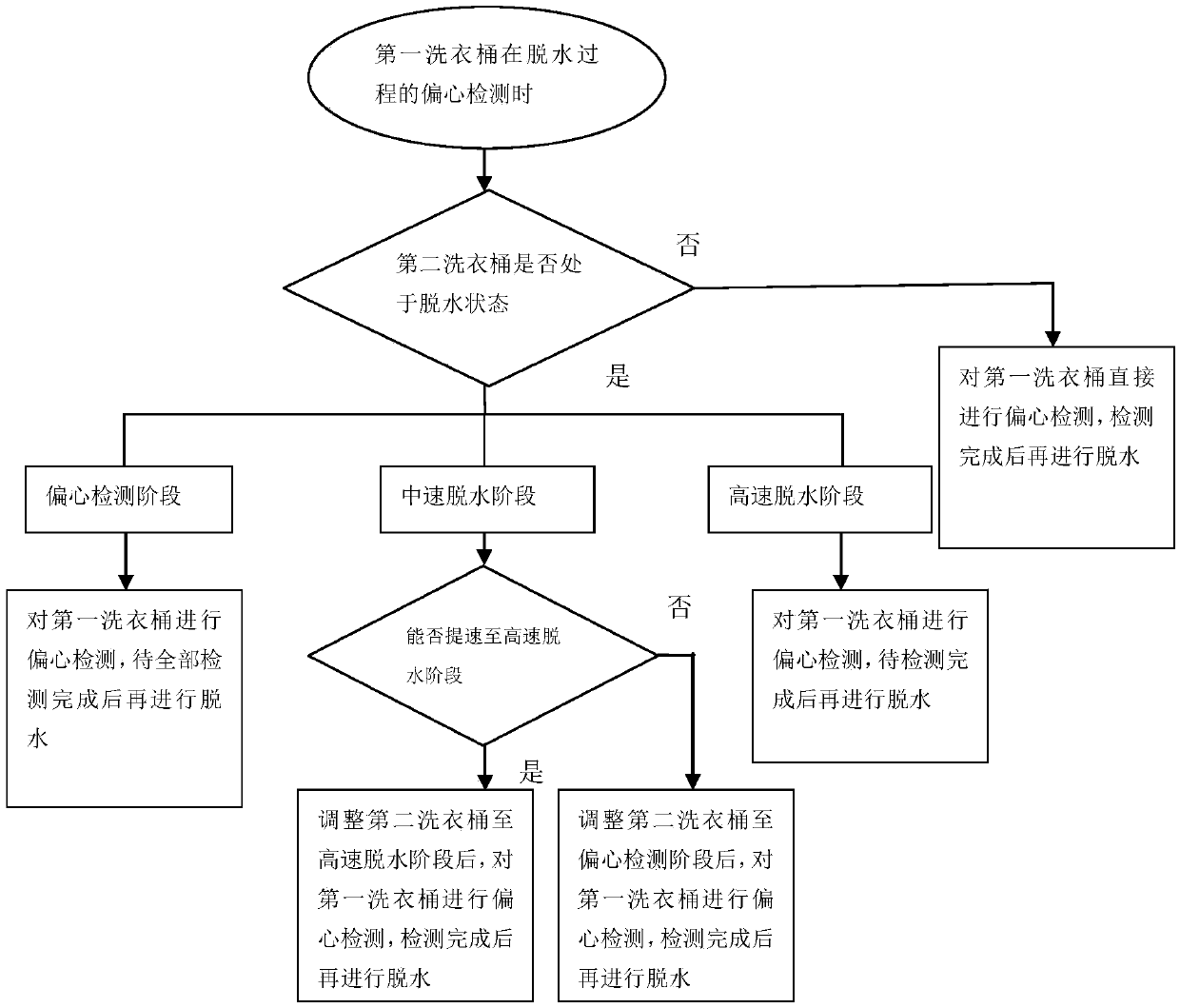

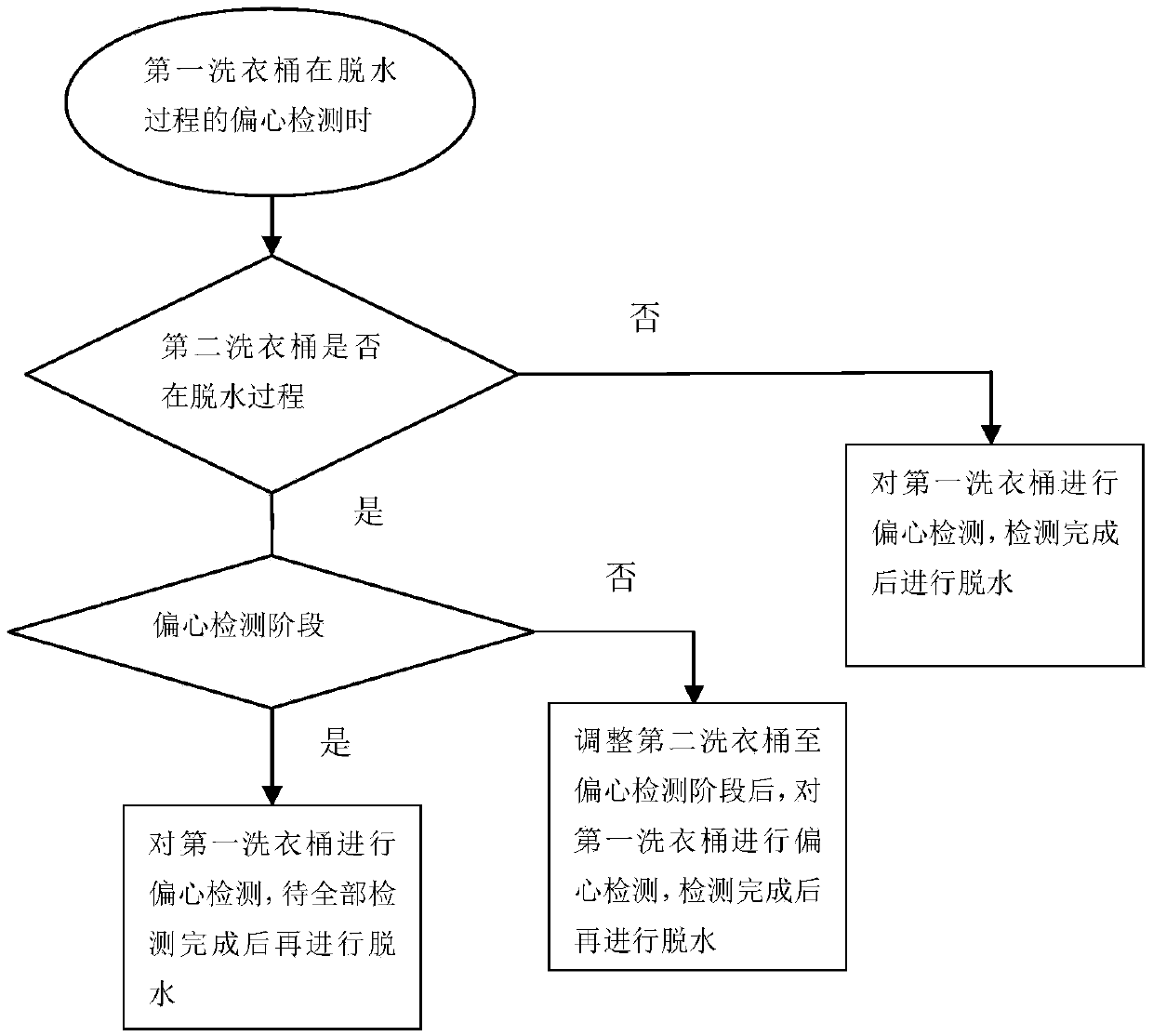

Clothes treating device and control method thereof

PendingCN110438727AAvoid resonanceReduce resonanceControl devices for washing apparatusTextiles and paperEngineeringResonance

The invention discloses a clothes treating device and a control method thereof. The clothes treating device at least comprises two clothes treating drums in independent operation. The control method includes that when any of the clothes treating drums executes eccentricity detection in a dewatering process, the clothes treating device controls a maximum dewatering rotating speed of the current clothes treating drum according to operating states of other clothes treating drums. Aiming at the clothes treating device with the multiple clothes treating drums, the problem of resonance of the multiple clothes treating drums in dewatering is solved. The dewatering eccentricity detection of the clothes treating drums are divided into several grades corresponding to different dewatering rotating speeds, and the clothes treating device controls the maximum dewatering rotating speed of the clothes treating drum which is about to execute dewatering according to the operating states of other clothes treating drums, so that the clothes treating drums are enabled to execute dewatering at different rotating speeds to avoid integral resonance.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

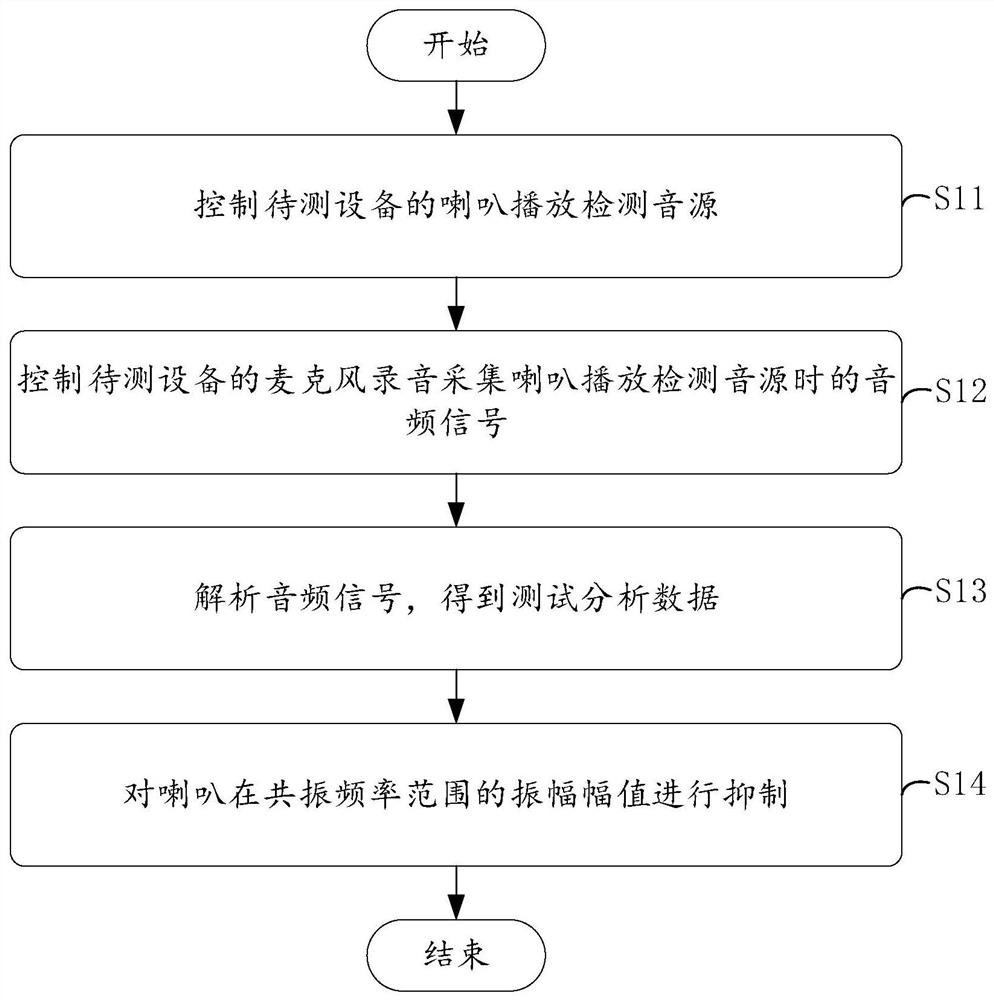

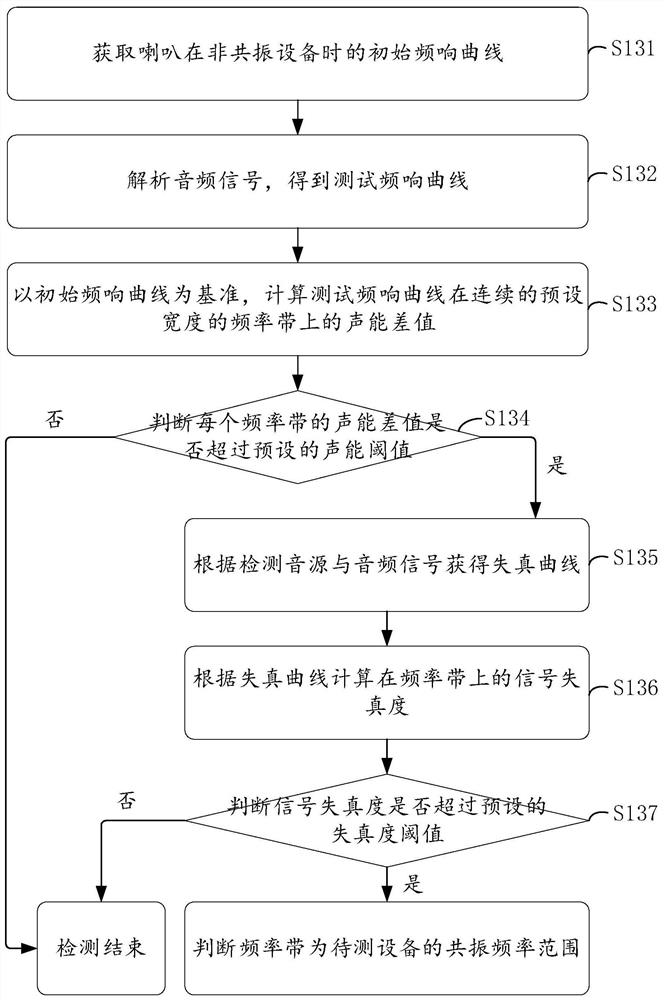

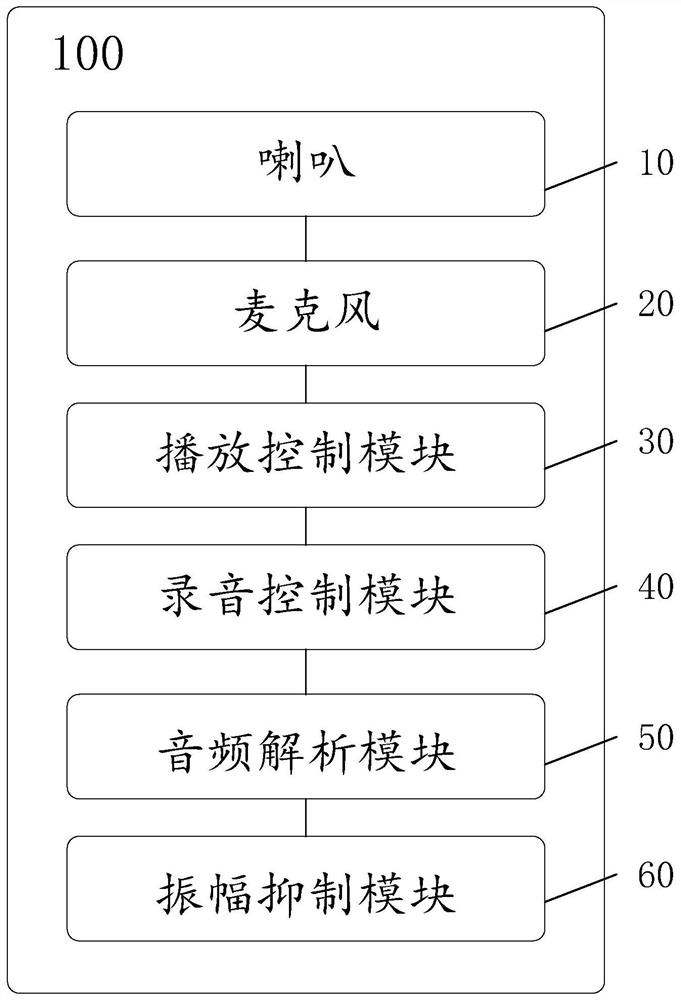

Closed-loop automatic detection vibration reduction method and system, terminal and storage medium

PendingCN113068100ASolving resonance problemsEnhance listening experienceFrequency/directions obtaining arrangementsVibration amplitudeSound sources

The invention discloses a closed-loop automatic detection vibration reduction method. The method comprises the following steps: controlling a loudspeaker of equipment to be detected to play a detection sound source; controlling a microphone of the to-be-tested device to record and collect an audio signal when a loudspeaker plays the detection sound source; analyzing the audio signal to obtain test analysis data; and suppressing the amplitude of the loudspeaker in the resonant frequency range according to the test analysis data. According to the closed-loop automatic detection vibration reduction method provided by the invention, the resources of the electronic equipment are fully utilized, closed-loop detection is realized, and the obtained audio signal is more real; meanwhile, the real resonance state of the equipment is determined according to the audio signals of the loudspeaker on the electronic equipment, then resonance noise is correspondingly suppressed according to different resonance frequency ranges of the electronic equipment, the resonance problem of the electronic equipment is solved in a targeted mode, and better sound listening experience is brought to a user.

Owner:SHANGHAI WINGTECH INFORMATION TECH CO LTD

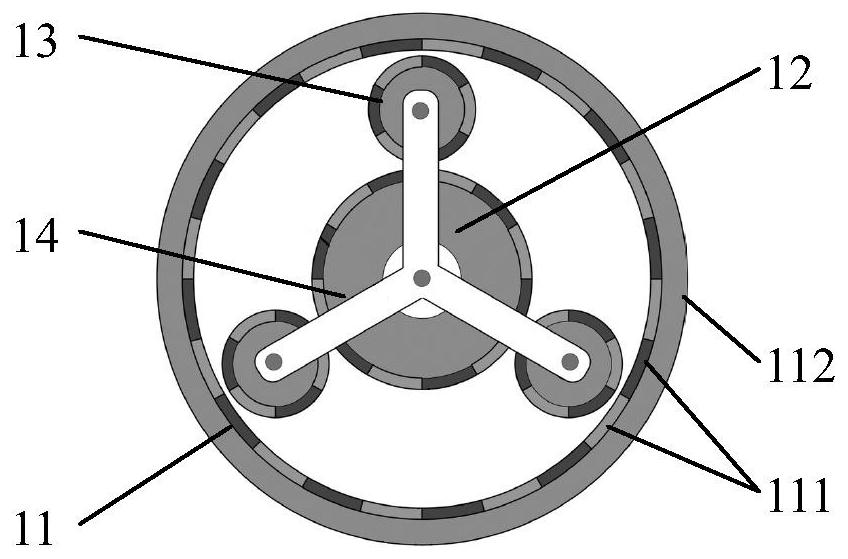

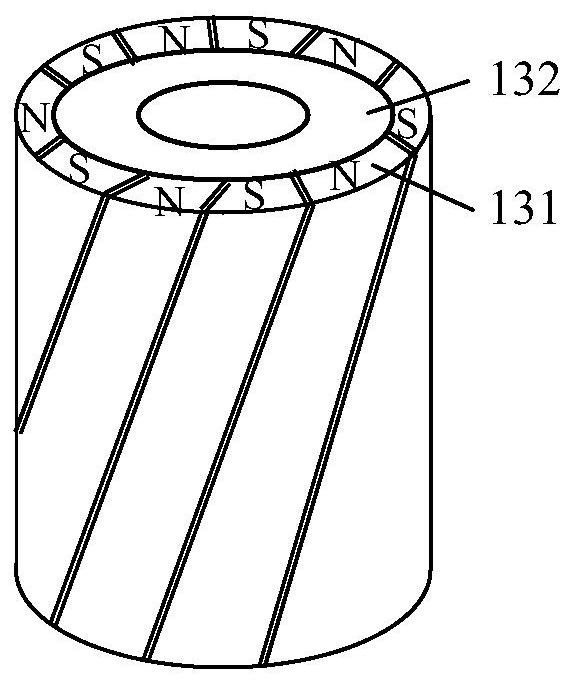

Electromagnetic gearbox for doubly-fed wind driven generator and control method of electromagnetic gearbox

PendingCN112865484AAchieve mechanical isolationSolving resonance problemsDynamo-electric gearsConstant powerGear wheel

The invention relates to an electromagnetic gearbox for a doubly-fed wind driven generator and a control method of the electromagnetic gearbox, and belongs to the field of wind power. The electromagnetic gearbox comprises a first-stage planetary electromagnetic gear, a second-stage coaxial magnetic gear and a third-stage coaxial magnetic gear. The first-stage planet electromagnetic gear comprises an electromagnetic gear ring, a planet magnetic gear, a planet carrier, a sun magnetic gear and the like; and the electromagnetic gear ring is composed of an iron core and a winding. The control method comprises the following steps that the polarity of the electromagnetic gear ring winding is controlled, so that the number of pole pairs of the electromagnetic gear ring during starting is half of the rated number of pole pairs, and the number of pole pairs of the electromagnetic gear ring after starting is the rated number of pole pairs; when the wind speed is greater than the rated wind speed, the winding current of the electromagnetic gear ring is adjusted so as to adjust the output torque of the first-stage planetary electromagnetic gear, and constant power control is achieved; and when the wind speed is great than the cut-out wind speed, a winding power supply of the electromagnetic gear ring is cut off, decoupling of the wind wheel and the generator is achieved, and braking force of the generator is reduced. The operation and maintenance cost can be reduced; and the speed increasing ratio can be adjusted in real time, and the system operation flexibility can be improved.

Owner:QUFU NORMAL UNIV

A textile machine support with shock-absorbing function

InactiveCN105570625BSolving resonance problemsPlay a shock absorbing roleNon-rotating vibration suppressionStands/trestlesBlind holeFlat panel

The invention relates to the field of textile, in particular to a textile machine supporting frame with a shock absorption function. The textile machine supporting frame can effectively prevent shocking of a textile machine frame and guarantee the safety of a workshop. The textile machine supporting frame structurally comprises a machine frame body. Supporting rods are vertically fixed to the bottom of the machine frame body. The bottom of each supporting rod is hinged to one end of a connecting rod, and the other end of each connecting rod is hinged to the outer end of a horizontal plate. A plurality of blind holes are embedded in the upper surface of each horizontal plate. Cylindrical barrels provided with lower openings and matched with the blind holes are arranged on the lower surfaces of the connecting rods; first springs are arranged between the blind holes and the cylindrical barrels; supporting legs are arranged at the bottoms of the horizontal plates, and rubber blocks are arranged at the bottoms of the supporting legs. The textile machine supporting frame with the shock absorption function is easy to operate, convenient to use and suitable for different types of textile equipment.

Owner:SUZHOU DELOO TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com