A motor suspension structure of a new energy vehicle

A new energy vehicle, suspension technology, applied in the substructure, electric power unit, power unit and other directions, can solve the problems affecting the ride comfort of the whole vehicle, such as the service life of the motor, insufficient stiffness, and motor whistle, etc., to achieve light weight, Improve ride comfort and solve the effect of motor whistle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

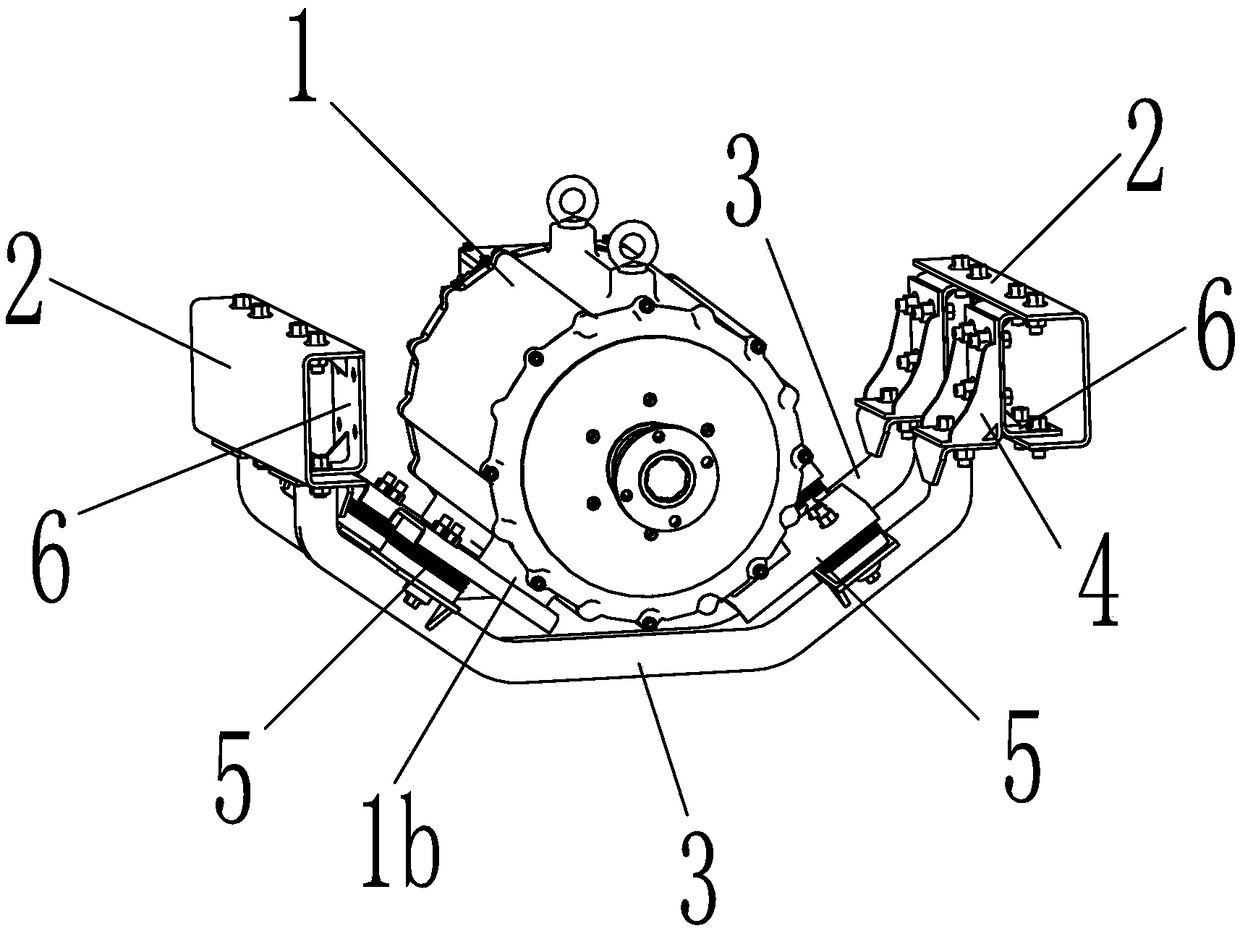

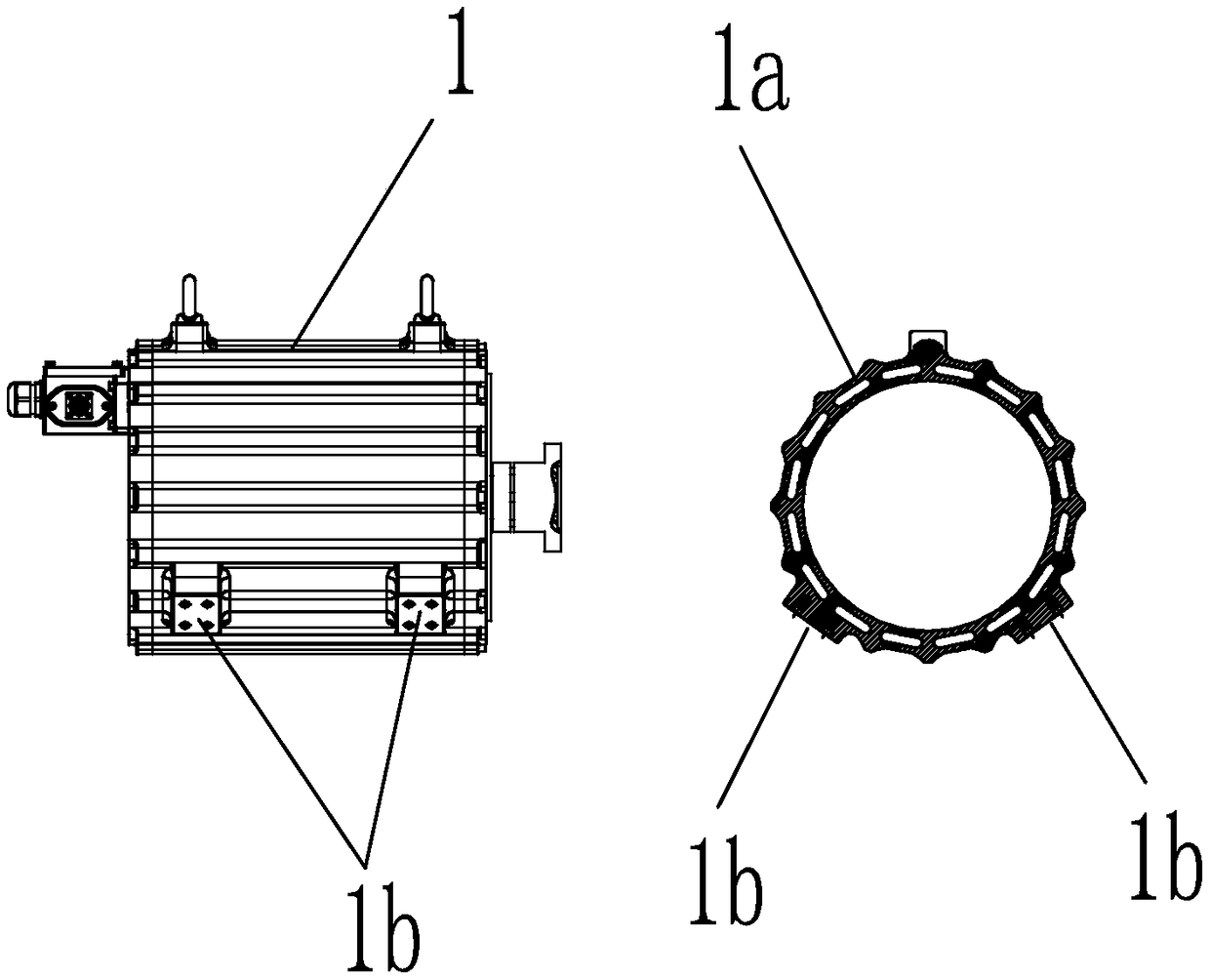

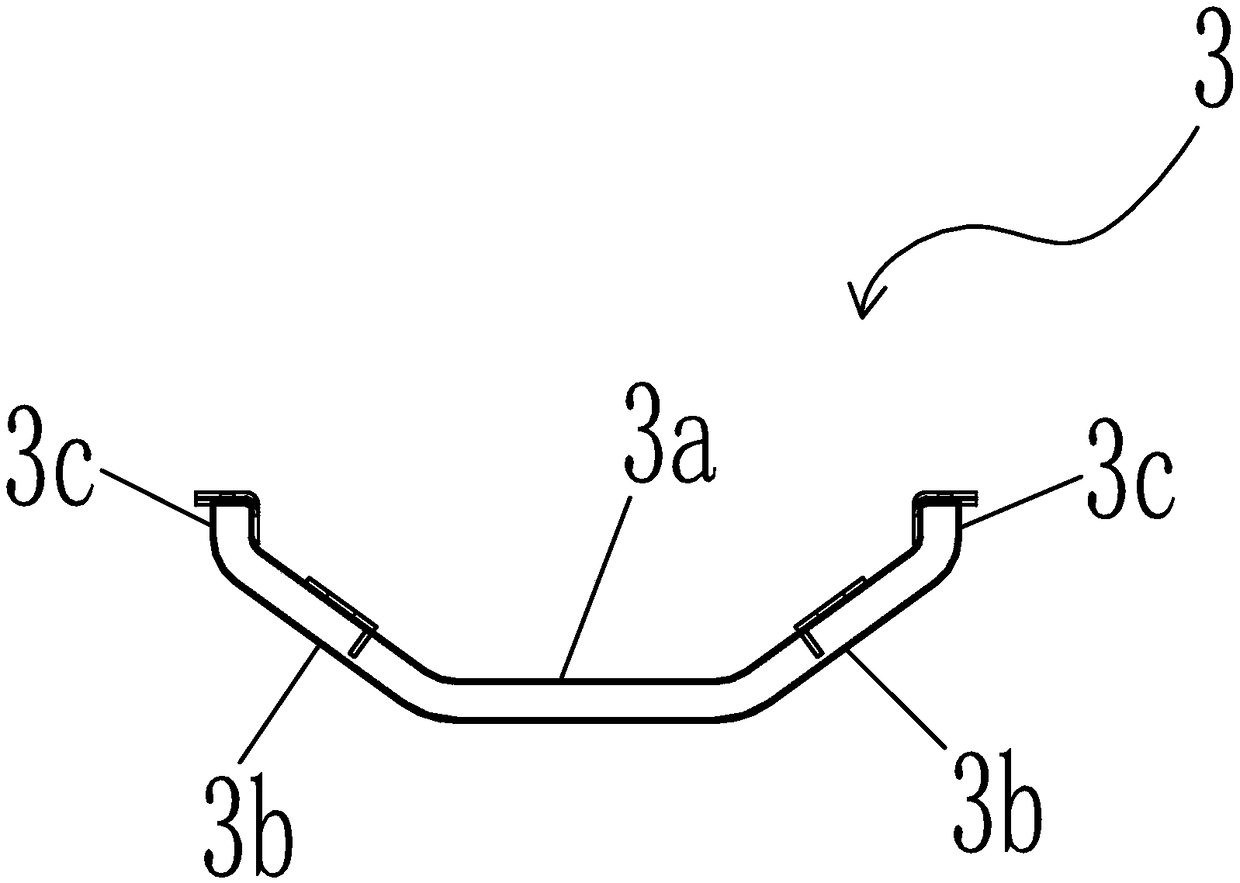

[0018] like figure 1 The motor suspension structure of a new energy vehicle shown includes a drive motor 1, two frame longitudinal beams 2 and two suspension beams 3 for mounting the drive motor 1, and the housing 1a of the drive motor 1 There are a plurality of mounting bosses 1b on the top, and the two suspension beams 3 are arranged in parallel on the front and rear sides, and also include a bias bracket 4 for making the output shaft of the drive motor 1 correspond to the input shaft of the rear axle and a plurality of respectively The shock absorbing device 5 connected with each installation boss 1b, a plurality of the installation bosses 1b are arranged obliquely downward and symmetrically on both sides of the bottom of the housing 1a, each of the suspension pocket beams 3 includes a beam 3a 1. A V-shaped structure formed by two sections...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com