Electromagnetic double-mode type vibration absorber for transmission shaft

A vibration absorber and drive shaft technology, applied in the directions of magnetic springs, springs/shock absorbers, springs, etc., can solve the problems of reducing the durability of the drive shaft and the wear durability of the drive shaft assembly, so as to avoid wear and durability problems. , fast response, energy-saving adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

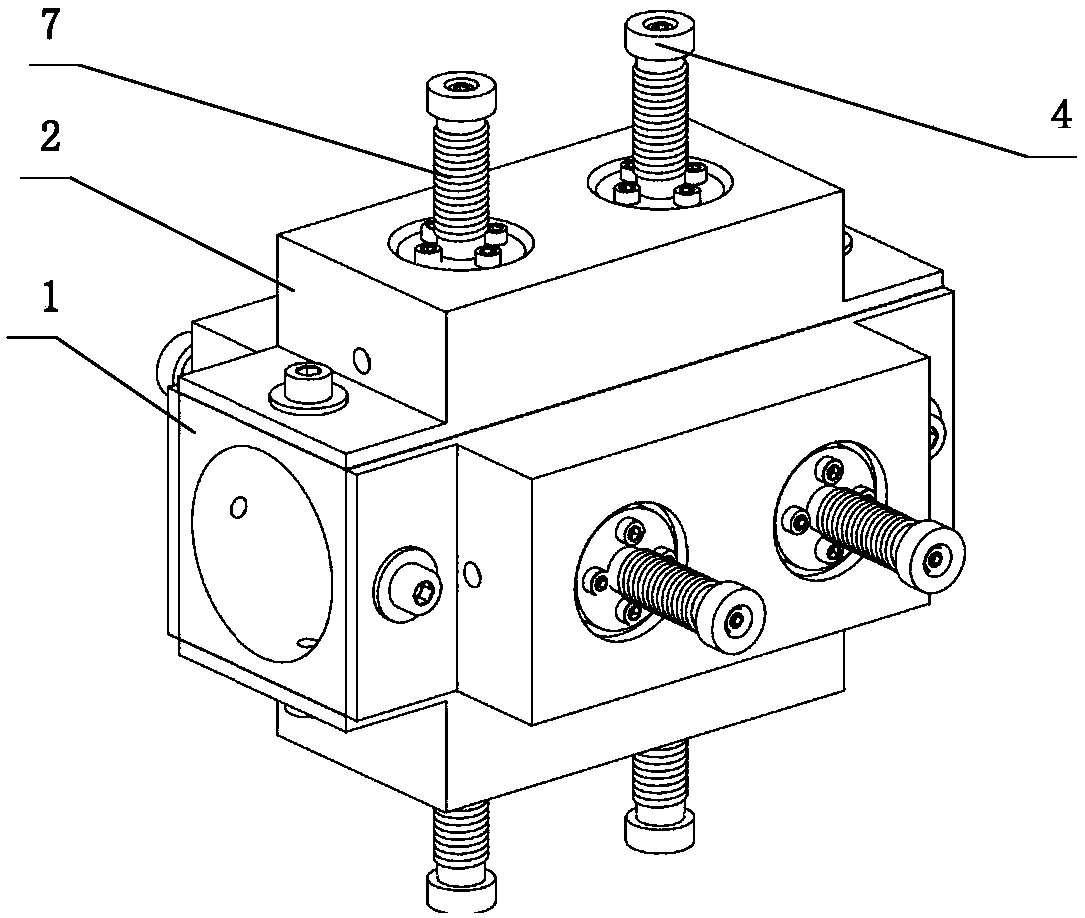

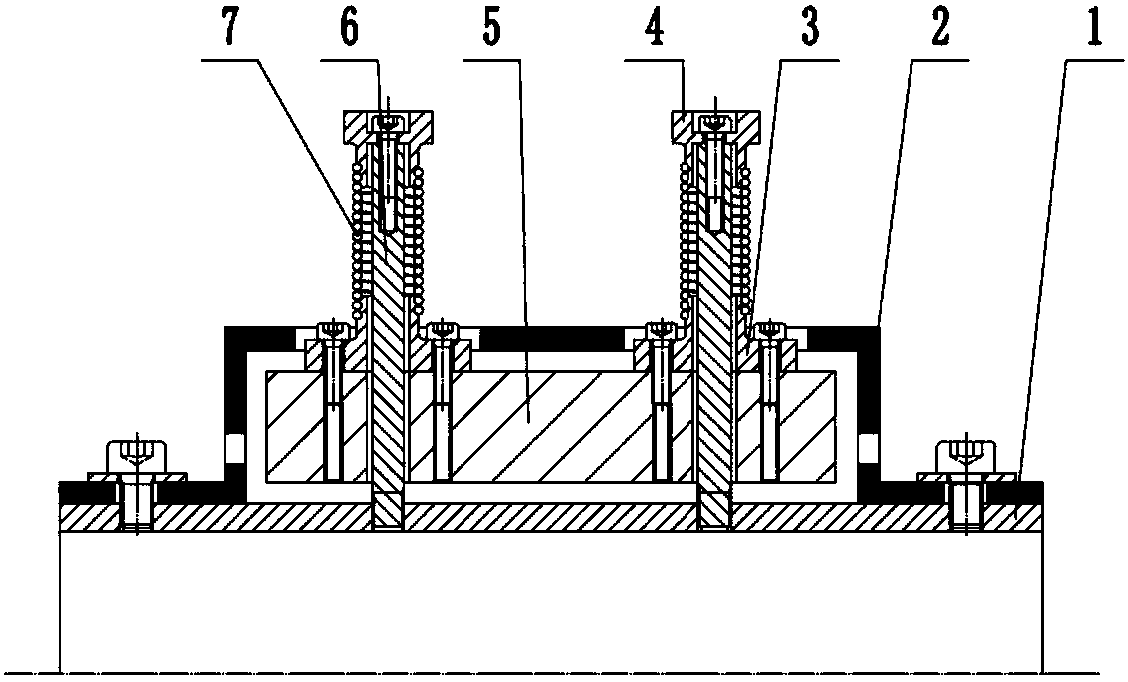

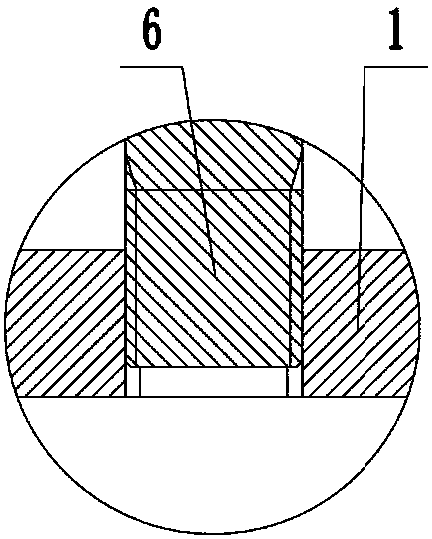

[0030] like figure 1 and figure 2 As shown, a transmission shaft electromagnetic dual-mode shock absorber includes a cubic metal sleeve 1 with a central hole, and four symmetrically fixed four outer walls on the upper, lower, left and right outer walls of the metal sleeve 1. An electromagnetic vibration absorber mode conversion unit, the metal sleeve 1 is directly set on the transmission shaft, and the electromagnetic vibration absorber mode conversion unit is connected with the ECU circuit, and is used for real-time The electromagnet is switched on and off, so that the electromagnetic vibration absorber mode conversion unit is switched between the dynamic vibration absorber mode and the mass block mode.

[0031] like figure 2 As shown, the electromagnetic vibration absorber mode conversion unit includes an electromagnet 5 and tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com