Numerical control one-column composite vertical lathe

A vertical lathe and column technology, applied in the field of CNC one-column composite vertical lathe, can solve the problems of poor static balance and dynamic balance, uneven single arm and resonance, affecting machining accuracy, etc., to improve the precision and automation level, Powerful functions and the effect of improving equipment rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

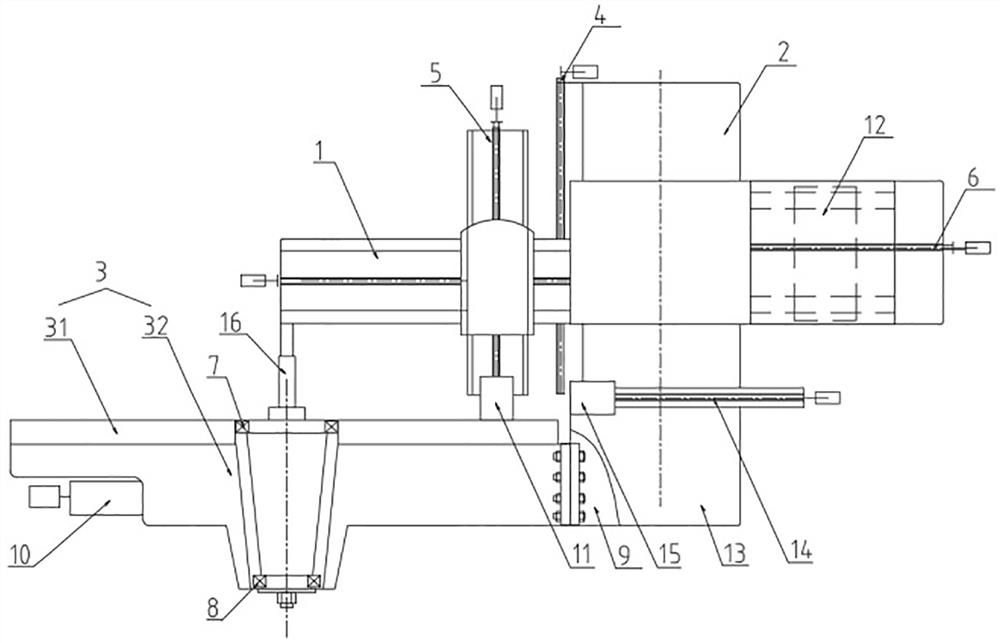

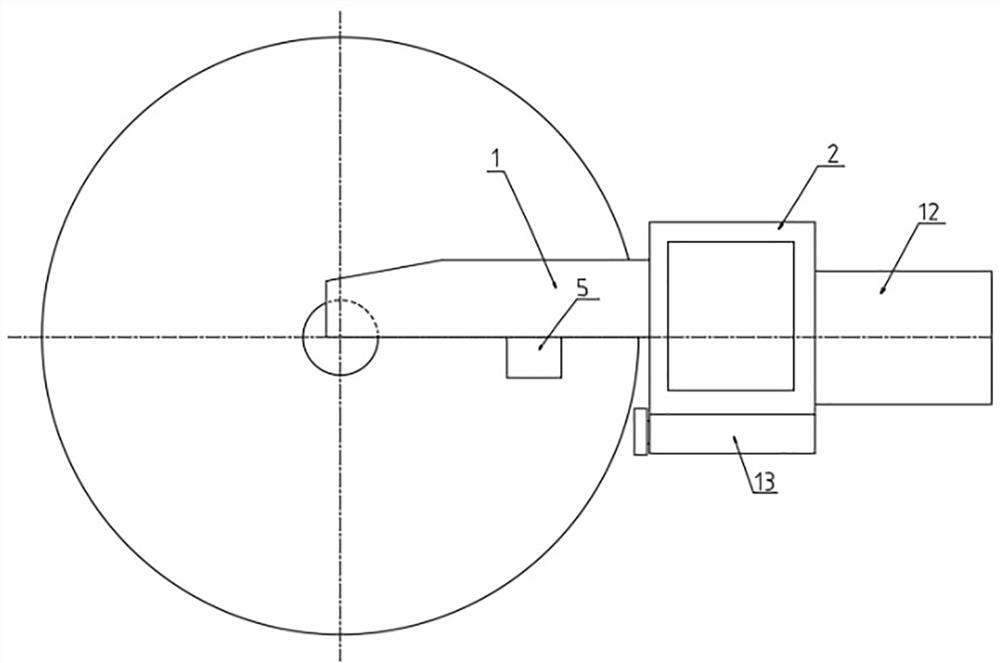

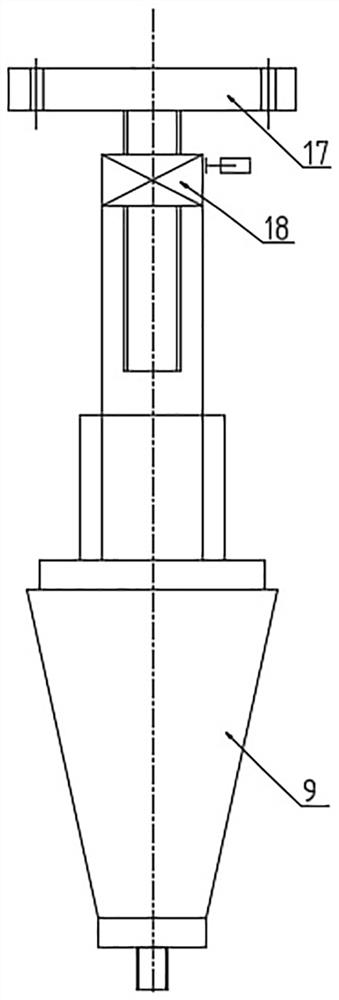

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

[0022] In the following embodiments, the beam 1, the column 2, the workbench 3, the lifting assembly 4, the square ram assembly 5, the counterweight ball screw 6, the main gearbox assembly 10, the square ram boring and milling head 11, the horizontal The counterweight 12, the side tool rest 13, the side tool rest square ram 14, the end milling head 15, the worm gear screw lifting mechanism 18 and the numerical control system are all exist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com