Three-kind-force sieving machine for superfine powder

A technology of ultrafine powder and screening machine, which is applied in the field of screening machine, can solve the problems of indistinguishable impurities and uneven separation of particles, achieve the effect of intense and stable work, and solve the effect of resonance and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

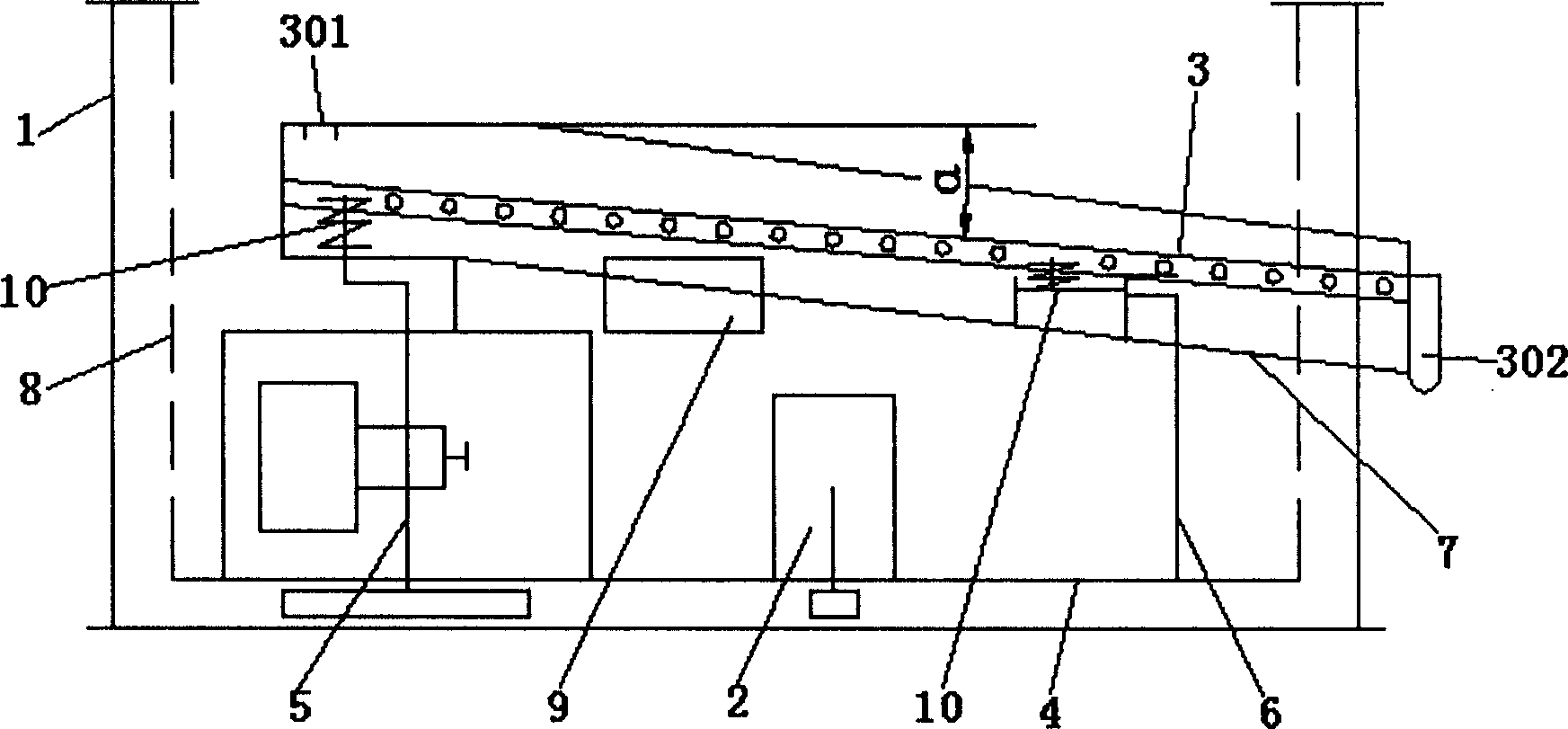

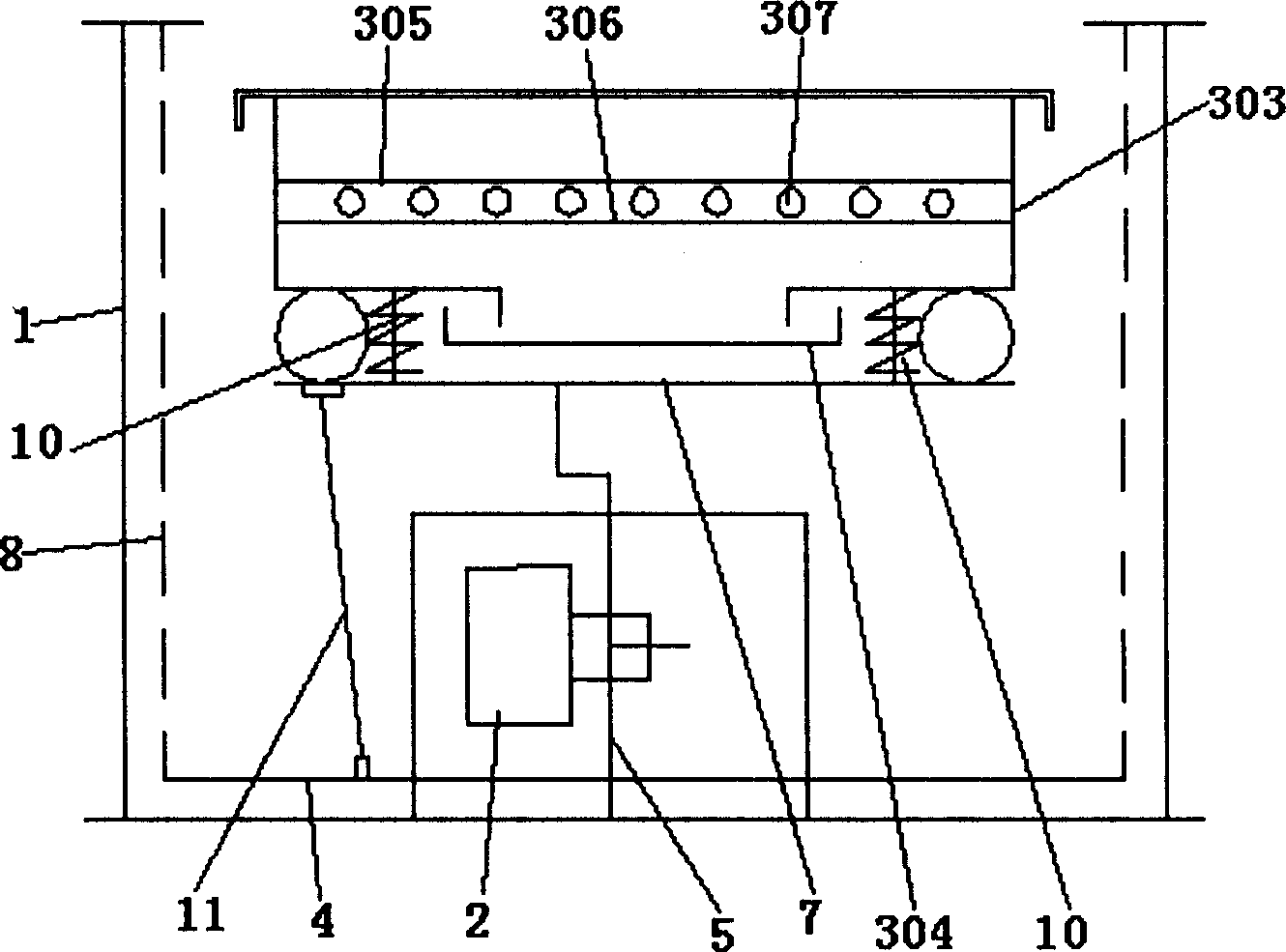

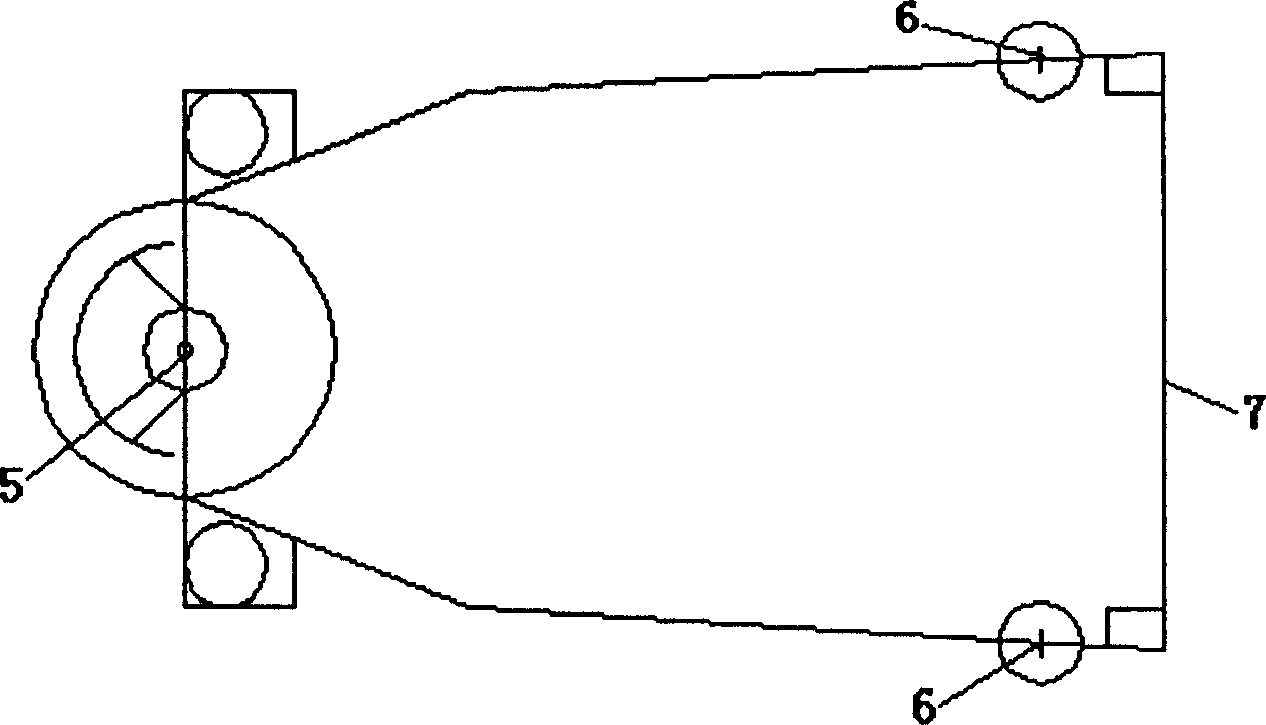

[0021] Such as figure 1 , figure 2 and Figure 4 As shown, the superfine powder three-force screening machine of the present invention includes a support frame 1, a driving device 2 and a sieve boat assembly 3, and the sieve boat assembly 3 is provided with a material inlet 301 and a material outlet 302, and also includes: a swimming chassis 4. The eccentric shaft 5, the movable support frame 6 and the inertial connection frame 7; the floating bottom frame 2 is suspended on the support frame 1 through the sling 8; the driving device 2 is fixedly arranged on the floating bottom frame 4 to drive The eccentric shaft 5 rotates; the upper end of the eccentric shaft 5 is fixedly connected to the inertial connection frame 7; the sieve boat assembly 3 is elastically connected to the inertial connection frame 7 through the vibration-proof connection seat 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com