Road lamp electric ballast

A technology for electronic ballasts and street lamps, applied in electric light sources, electrical components, lighting devices, etc., can solve the problems of damaging discharge lamps, affecting traffic, burning electronic ballasts, etc., so as to solve the problem of acoustic resonance and save social energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention is described below:

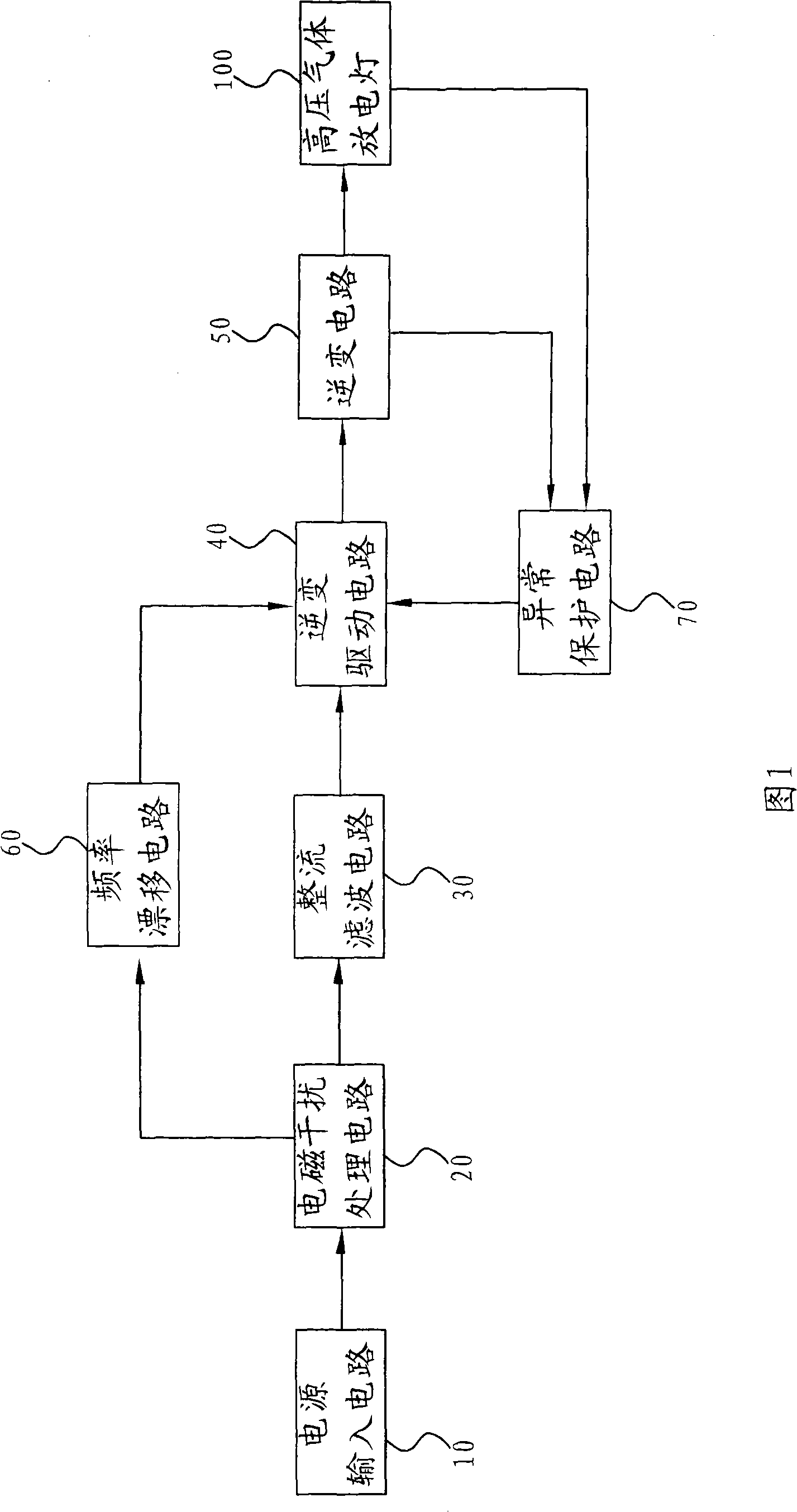

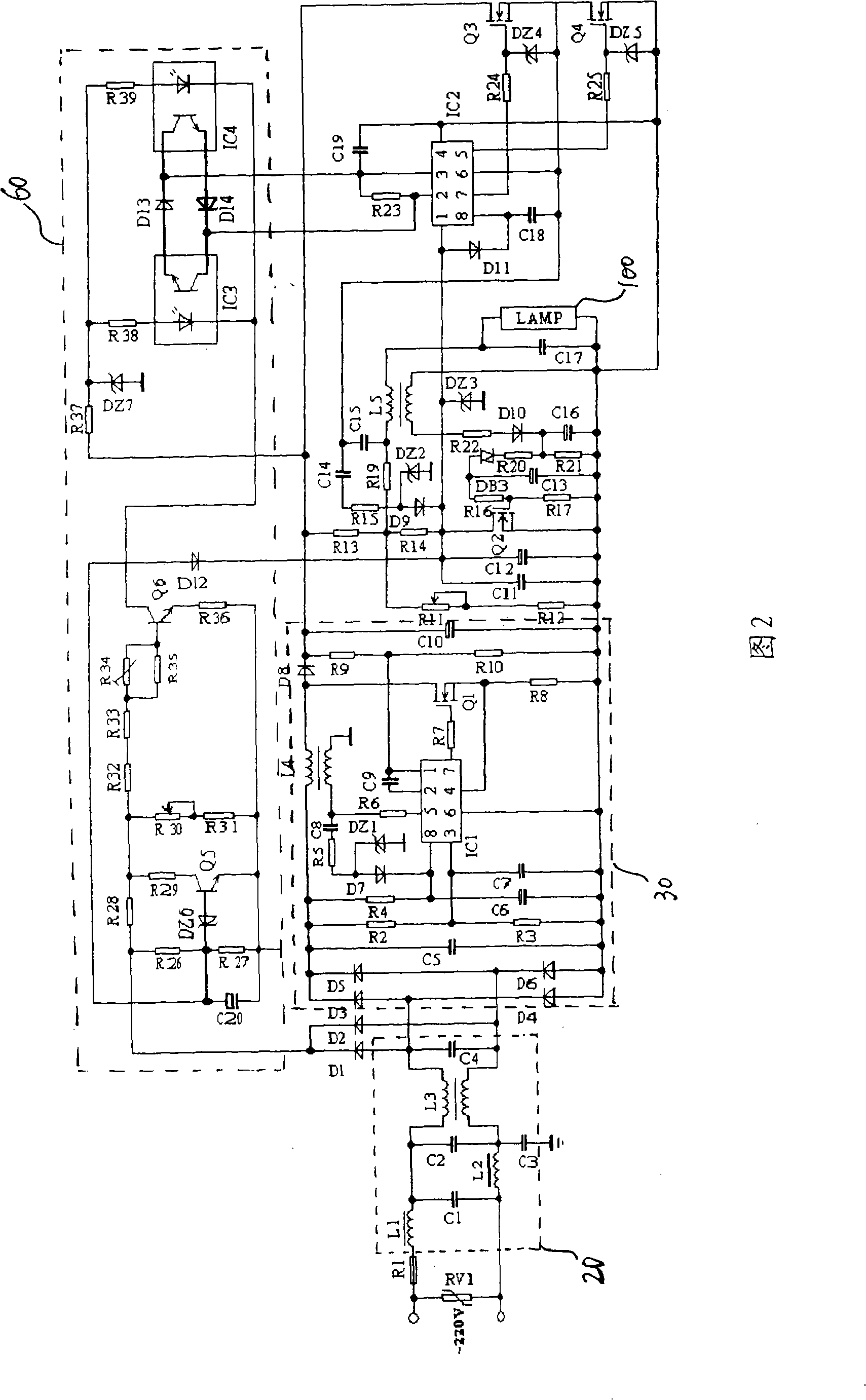

[0019] The electronic ballast shown in Figure 1 includes a power input circuit 10, an electromagnetic interference processing circuit 20, a rectification filter circuit 30, an inverter drive circuit 40, an inverter circuit 50, and a frequency drift circuit 60, wherein the power input circuit 10 The input end of the input terminal is connected with the AC mains (usually 220V), so that in the case of the AC mains power supply, the AC is input to the electromagnetic interference processing circuit 20, and the electromagnetic interference processing circuit 20 is used to prevent high-frequency electromagnetic interference, so that the electronic The degree of electromagnetic interference of the ballast is reduced to the minimum; the input end of the rectification filter circuit 30 is electrically connected with the output end of the electromagnetic interference processing circuit 20, and the rectification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com