Patents

Literature

262 results about "Foil bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

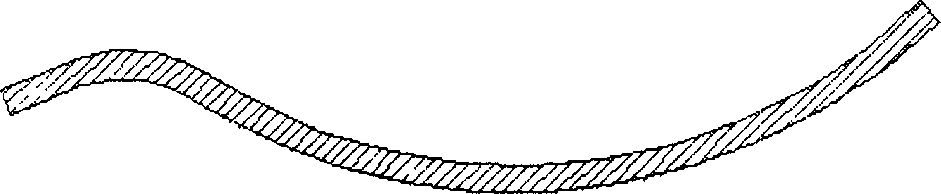

A foil bearing, also known as a foil-air bearing, is a type of air bearing. A shaft is supported by a compliant, spring-loaded foil journal lining. Once the shaft is spinning fast enough, the working fluid (usually air) pushes the foil away from the shaft so that no contact occurs. The shaft and foil are separated by the air's high pressure, which is generated by the rotation that pulls gas into the bearing via viscosity effects. A high speed of the shaft with respect to the foil is required to initiate the air gap, and once this has been achieved, no wear occurs. Unlike aerostatic or hydrostatic bearings, foil bearings require no external pressurisation system for the working fluid, so the hydrodynamic bearing is self-starting.

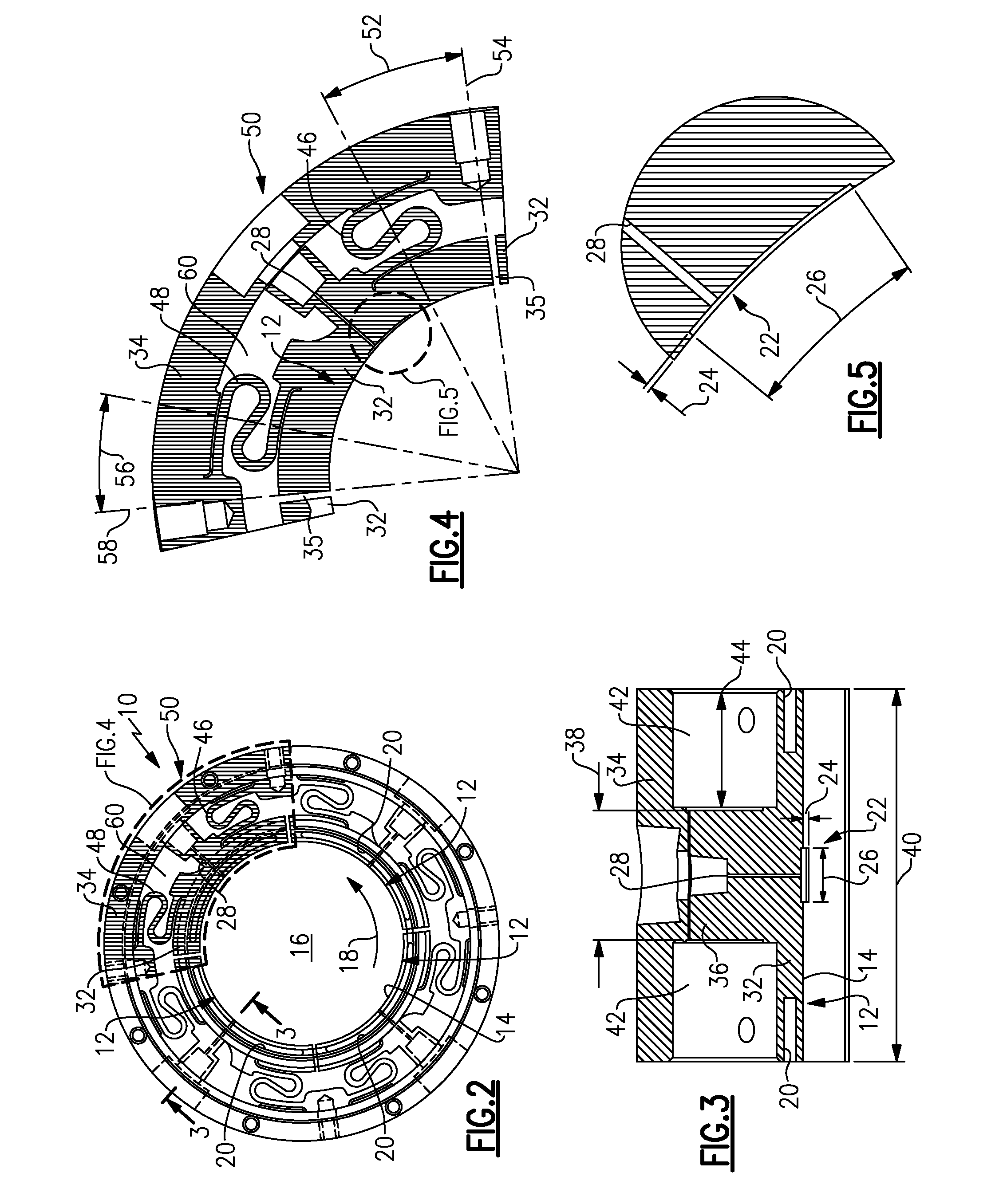

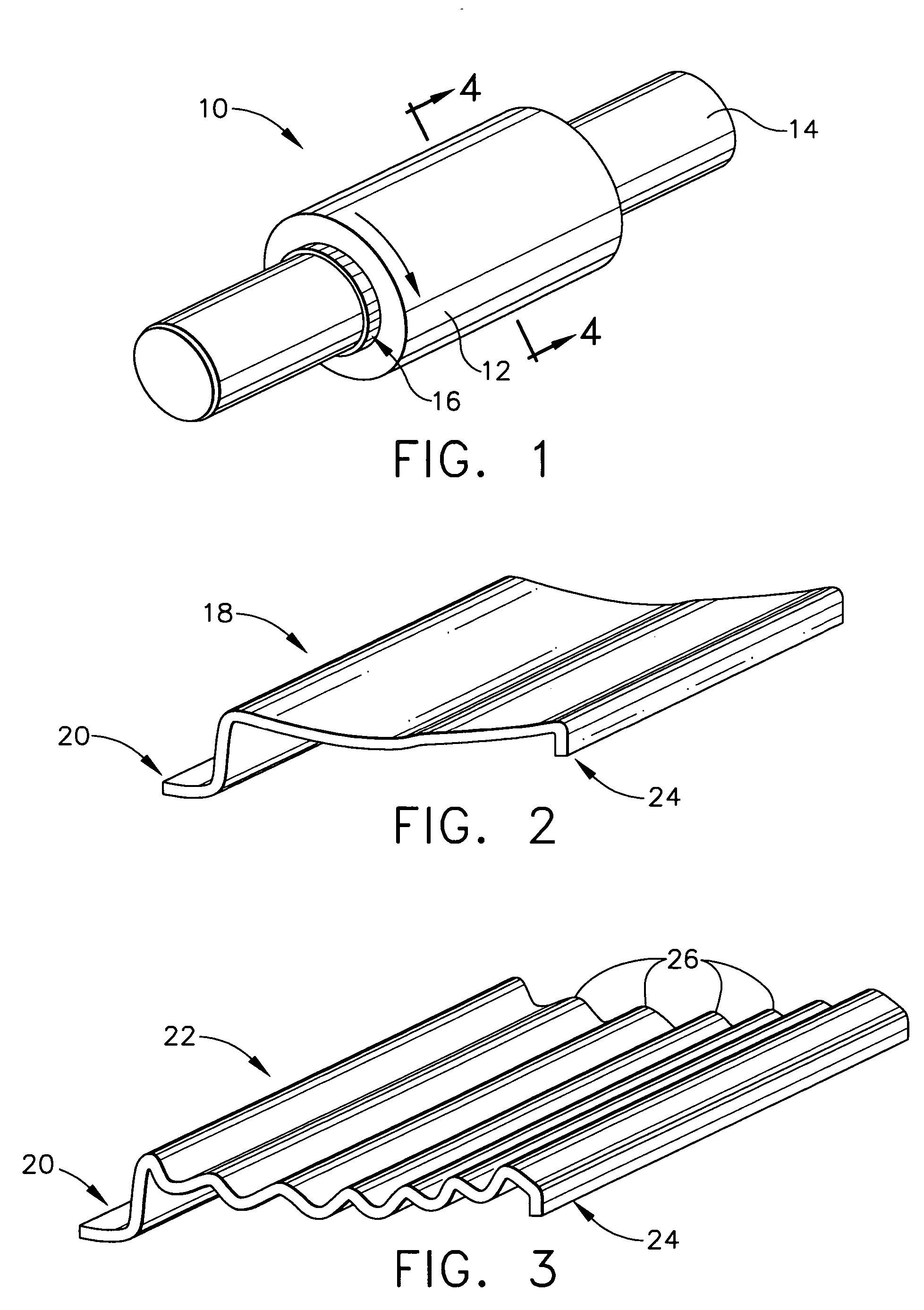

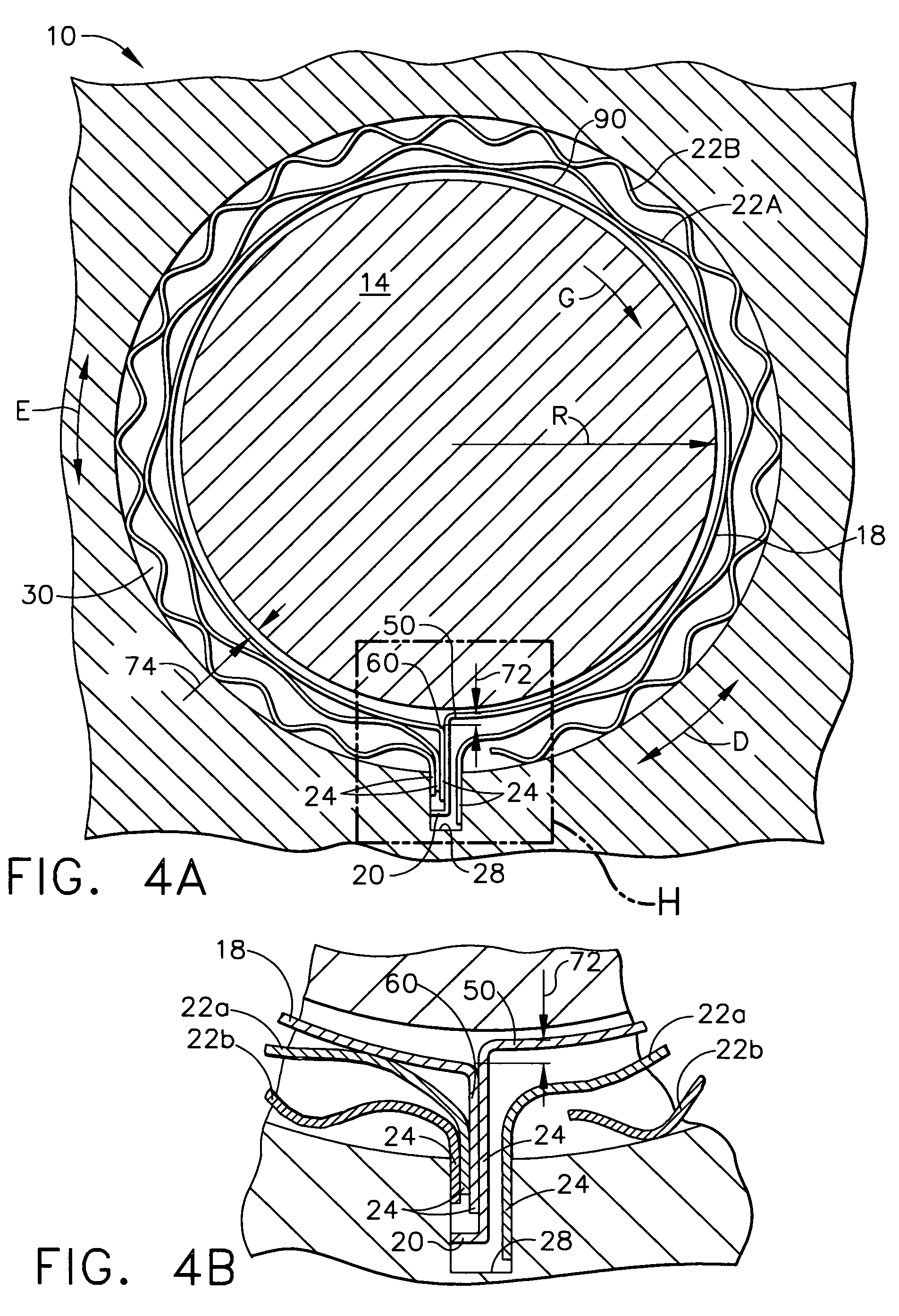

Hydrodynamic journal foil bearing system

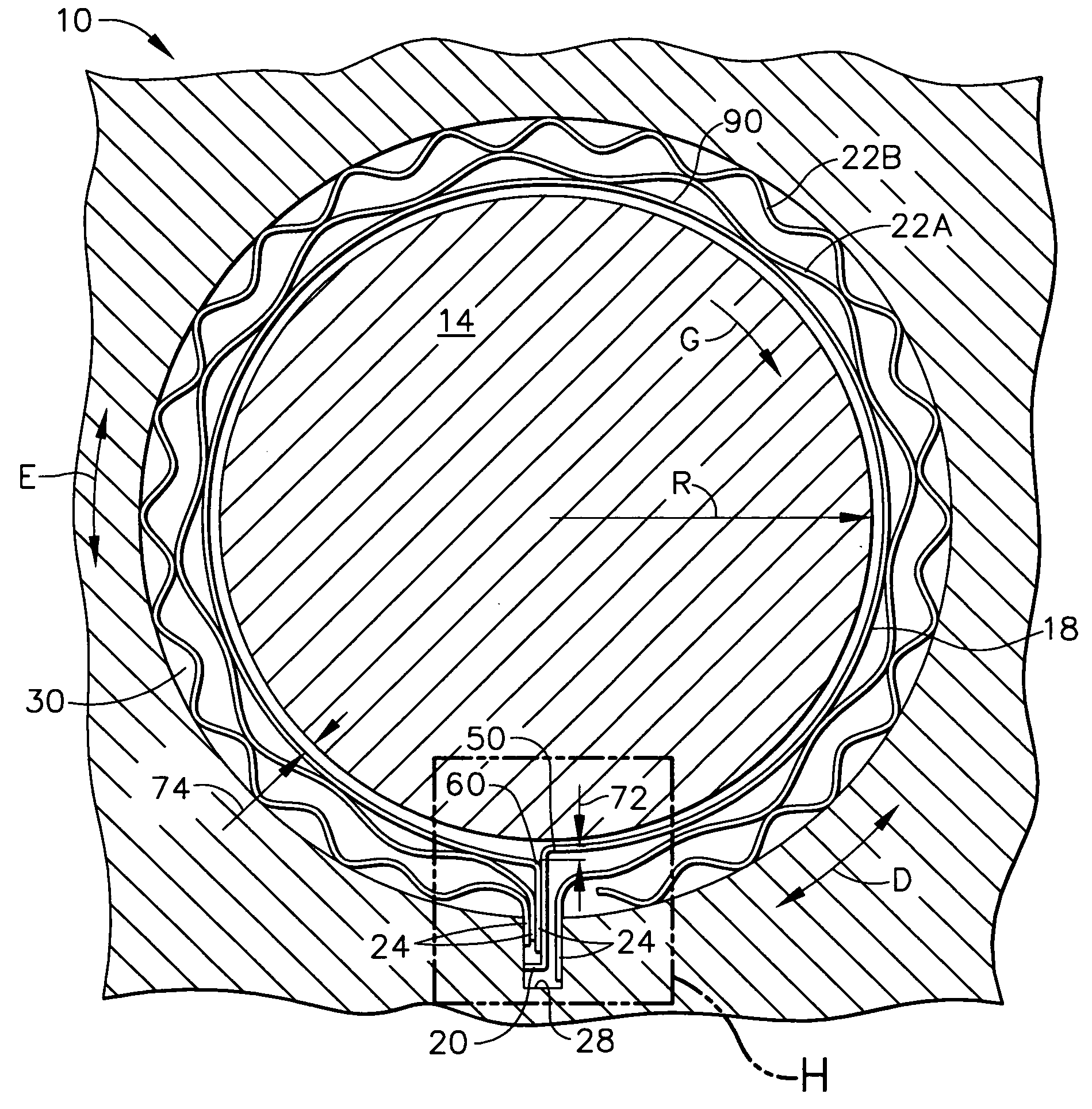

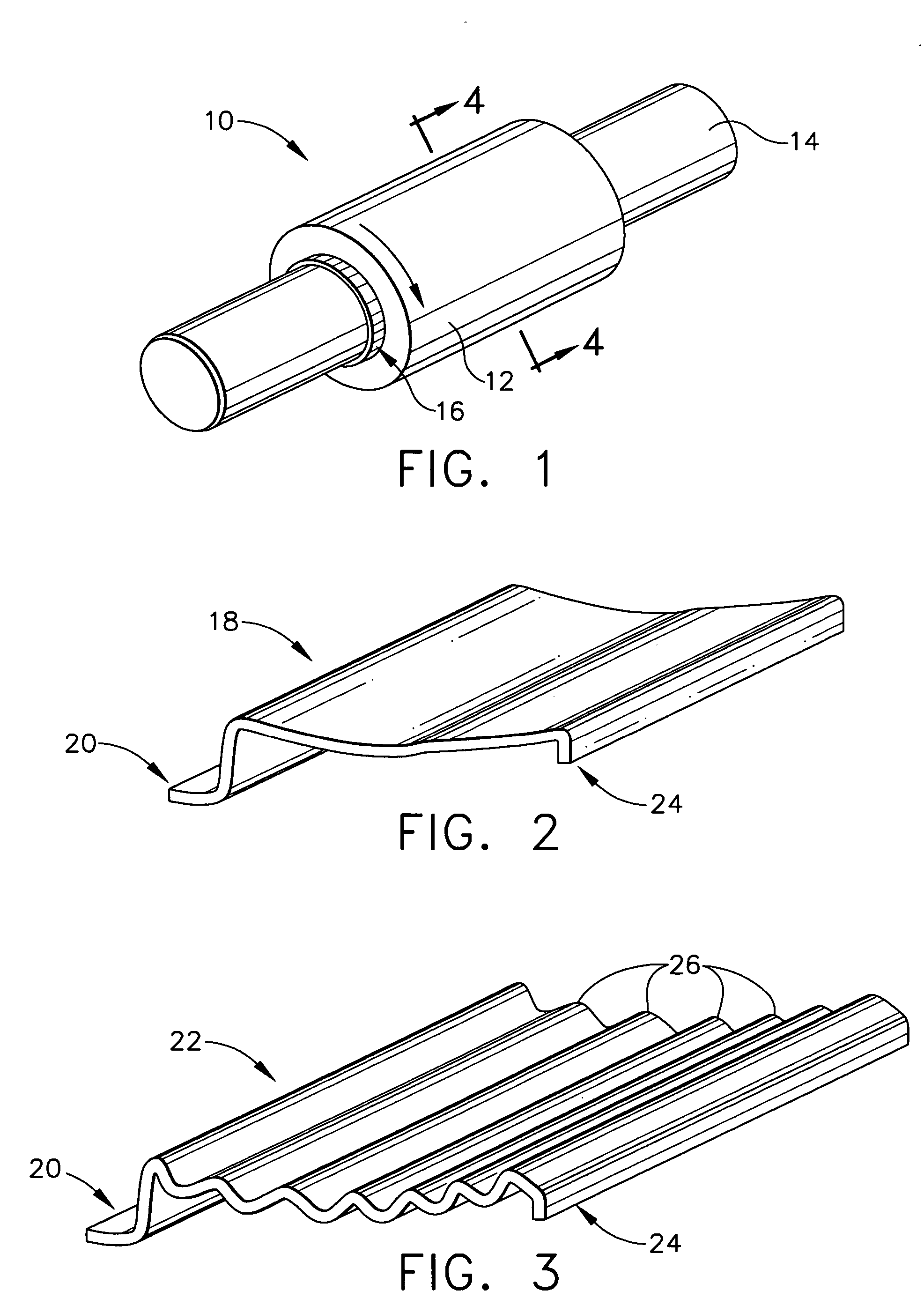

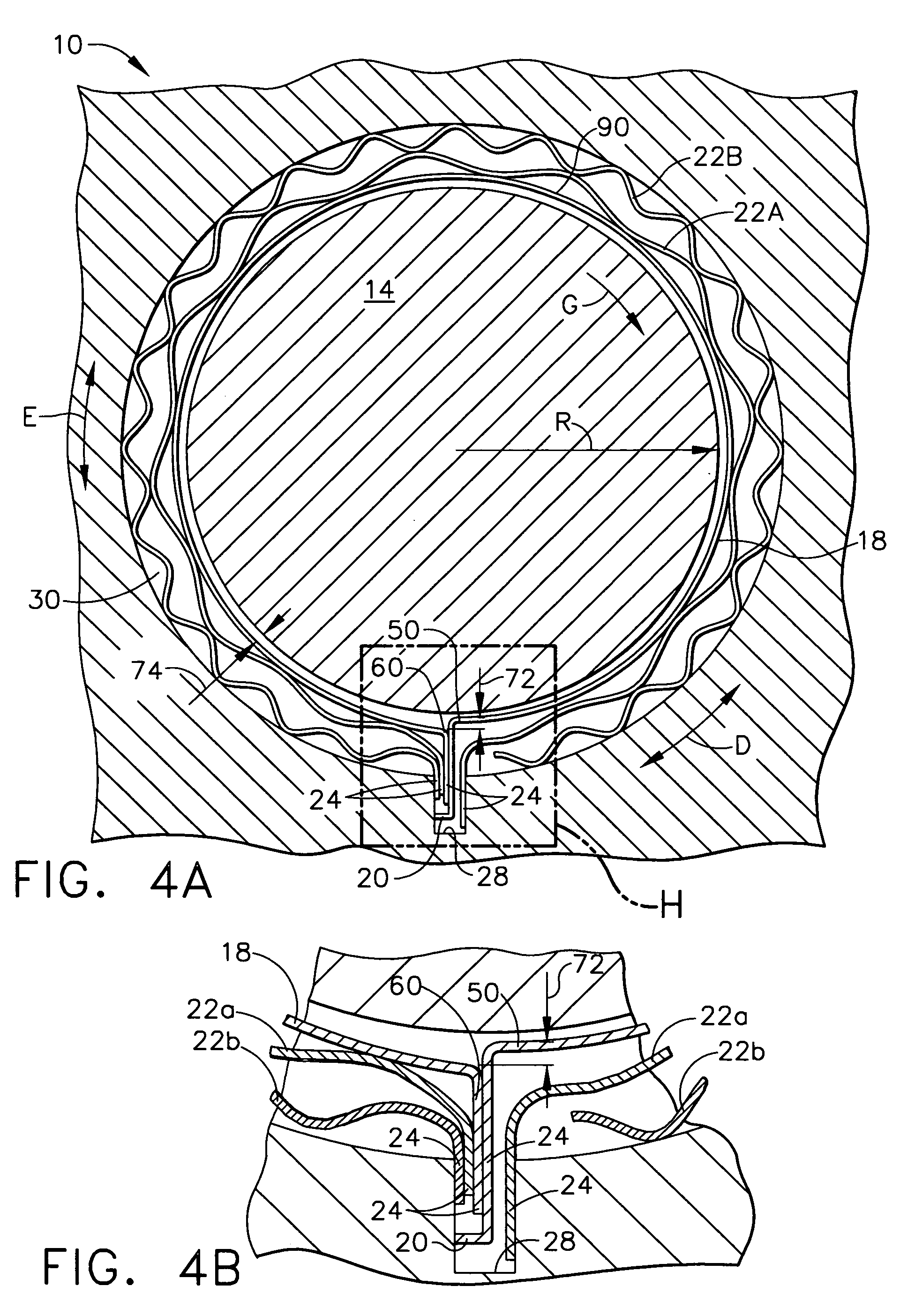

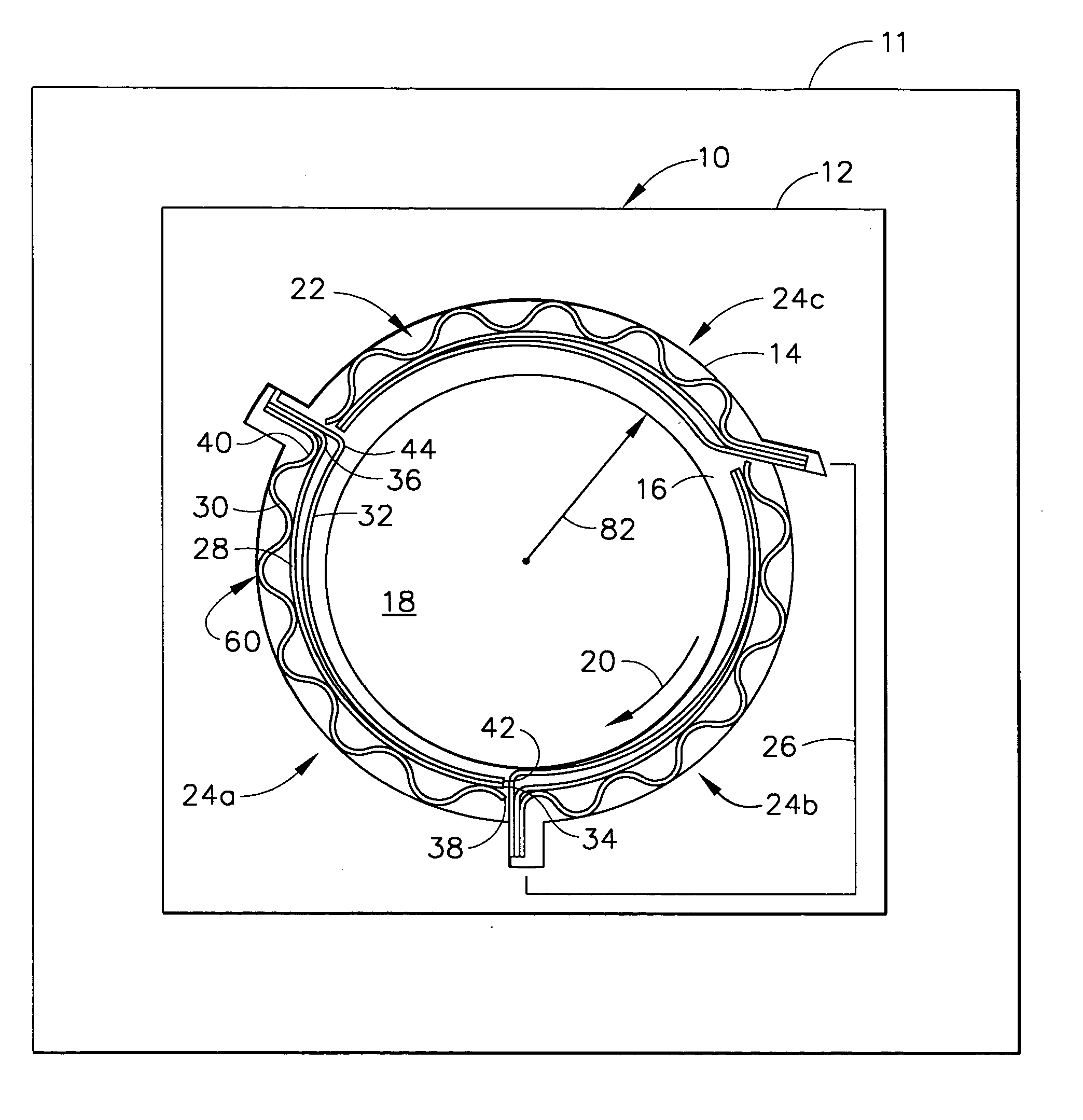

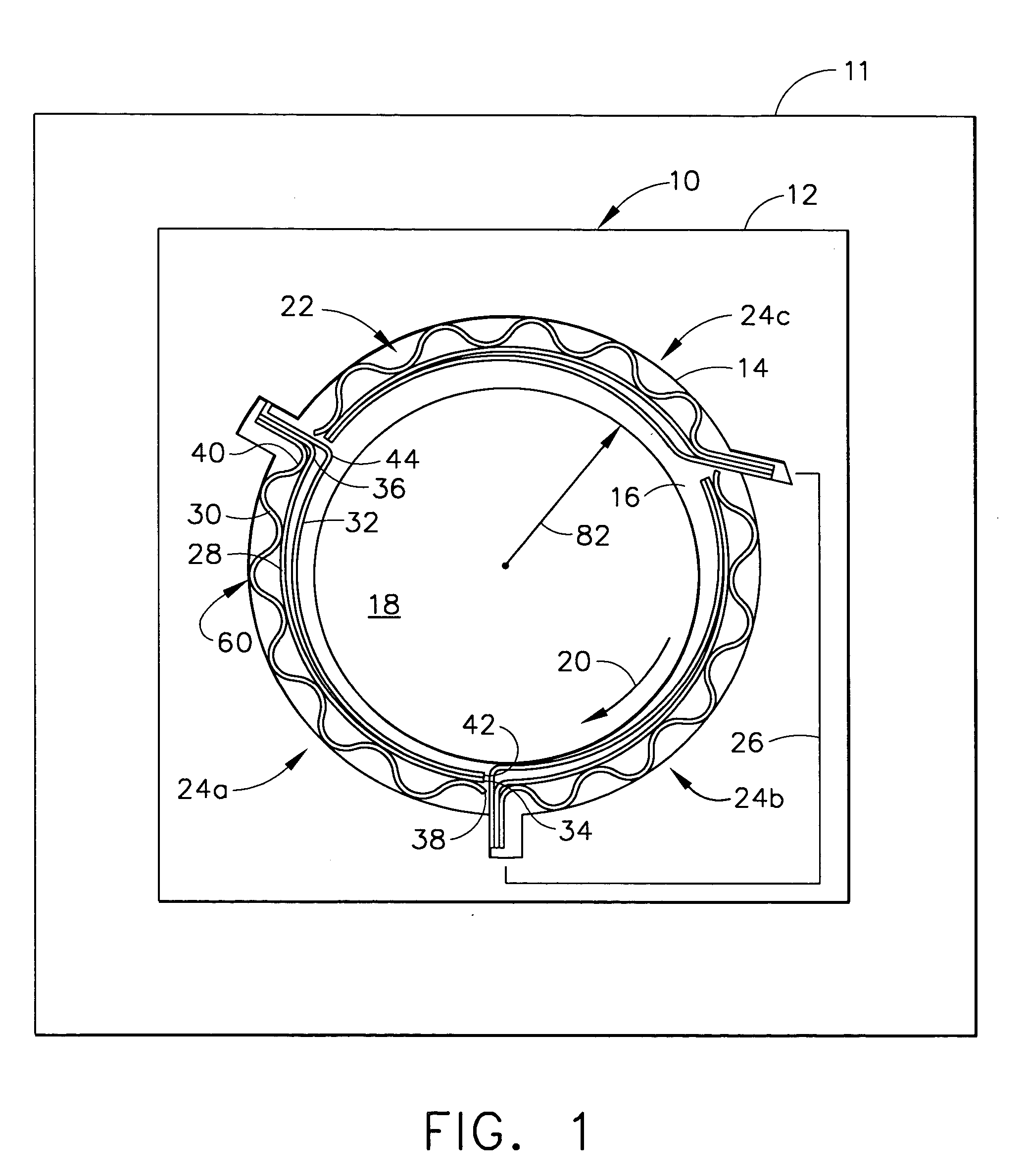

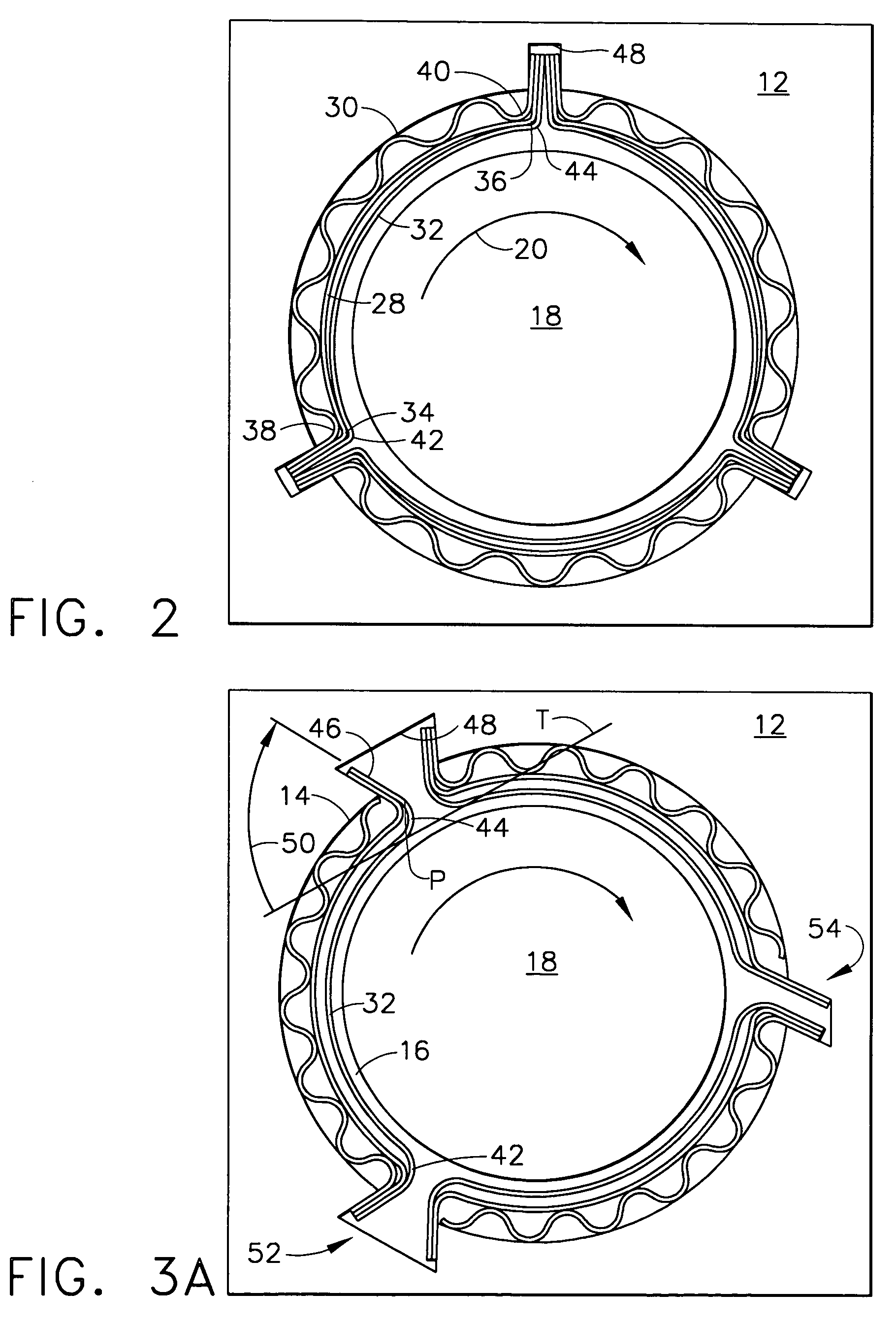

A high load capacity hydrodynamic journal foil bearing system is disclosed, which comprises a top foil and a plurality of undersprings. Preload forces are transferred from the undersprings to internal circumferential compressive forces within a top foil, resulting in low preload forces against the shaft, allowing the shaft to expand at high speeds without increasing the preload forces or overloading the fluid film. One underspring may have a different spring rate than another underspring. The top foil may be normalized to shaft shape and dimensions. These features may be accomplished with using less mechanical parts than other journal foil bearing system designs.

Owner:HONEYWELL INT INC

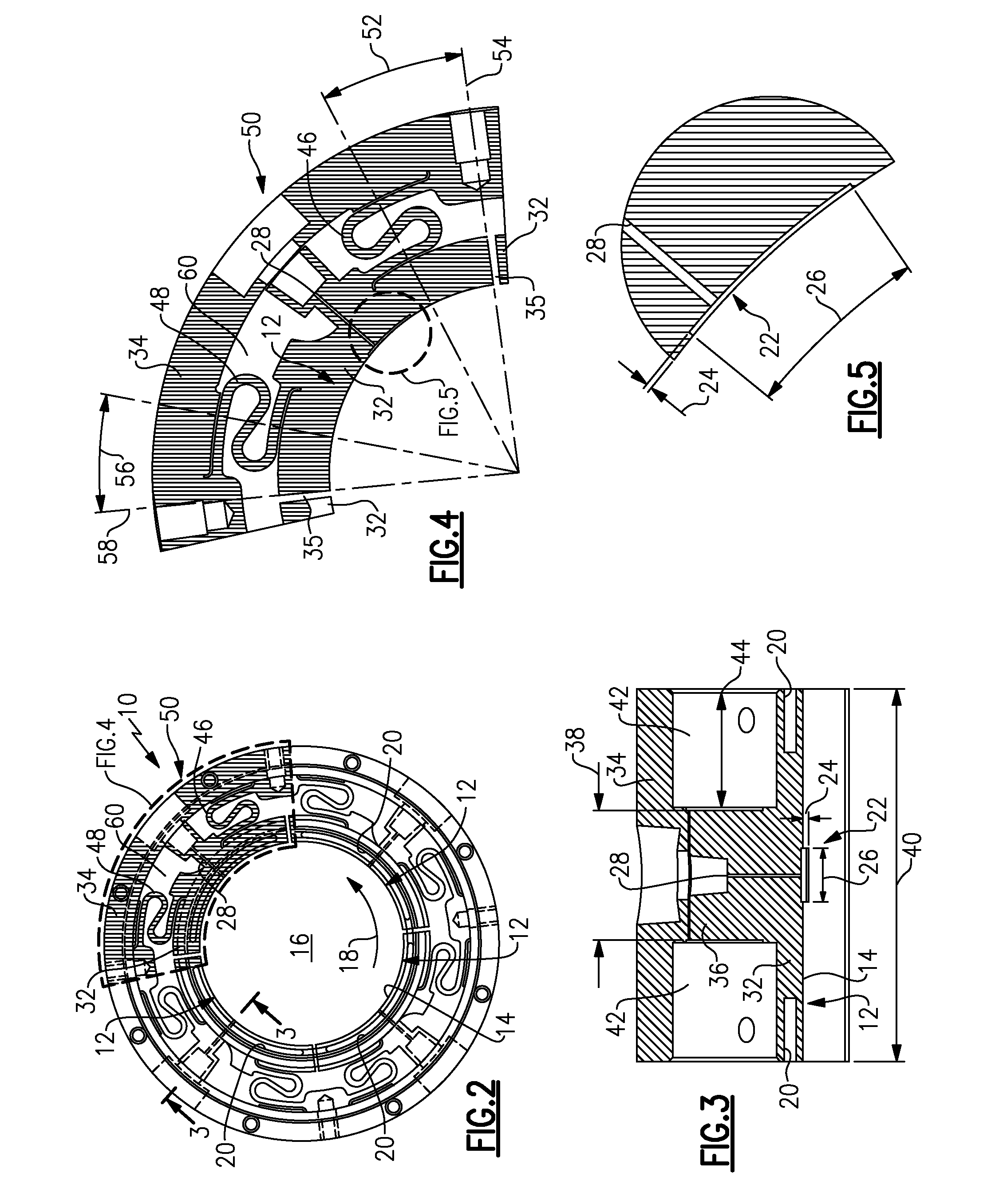

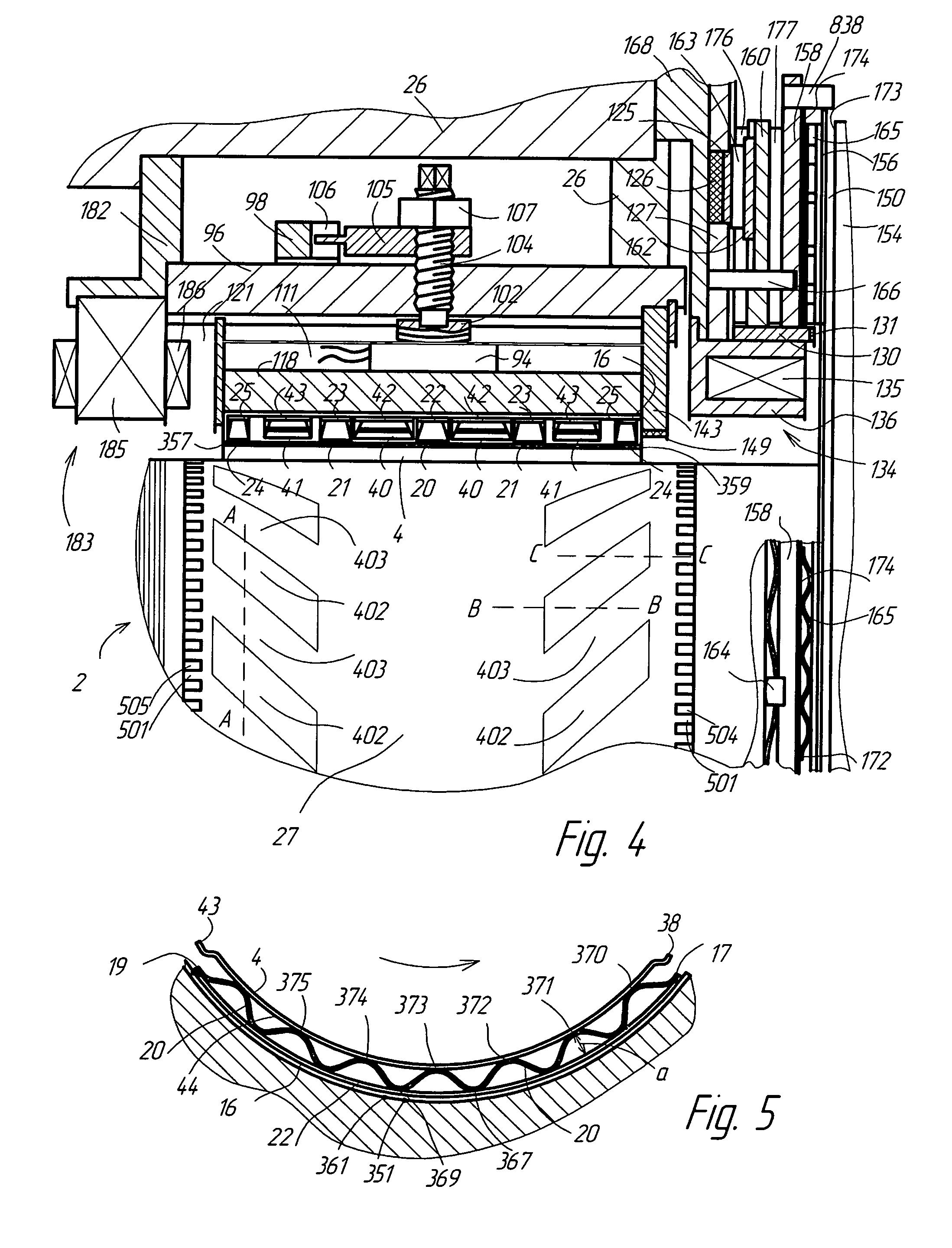

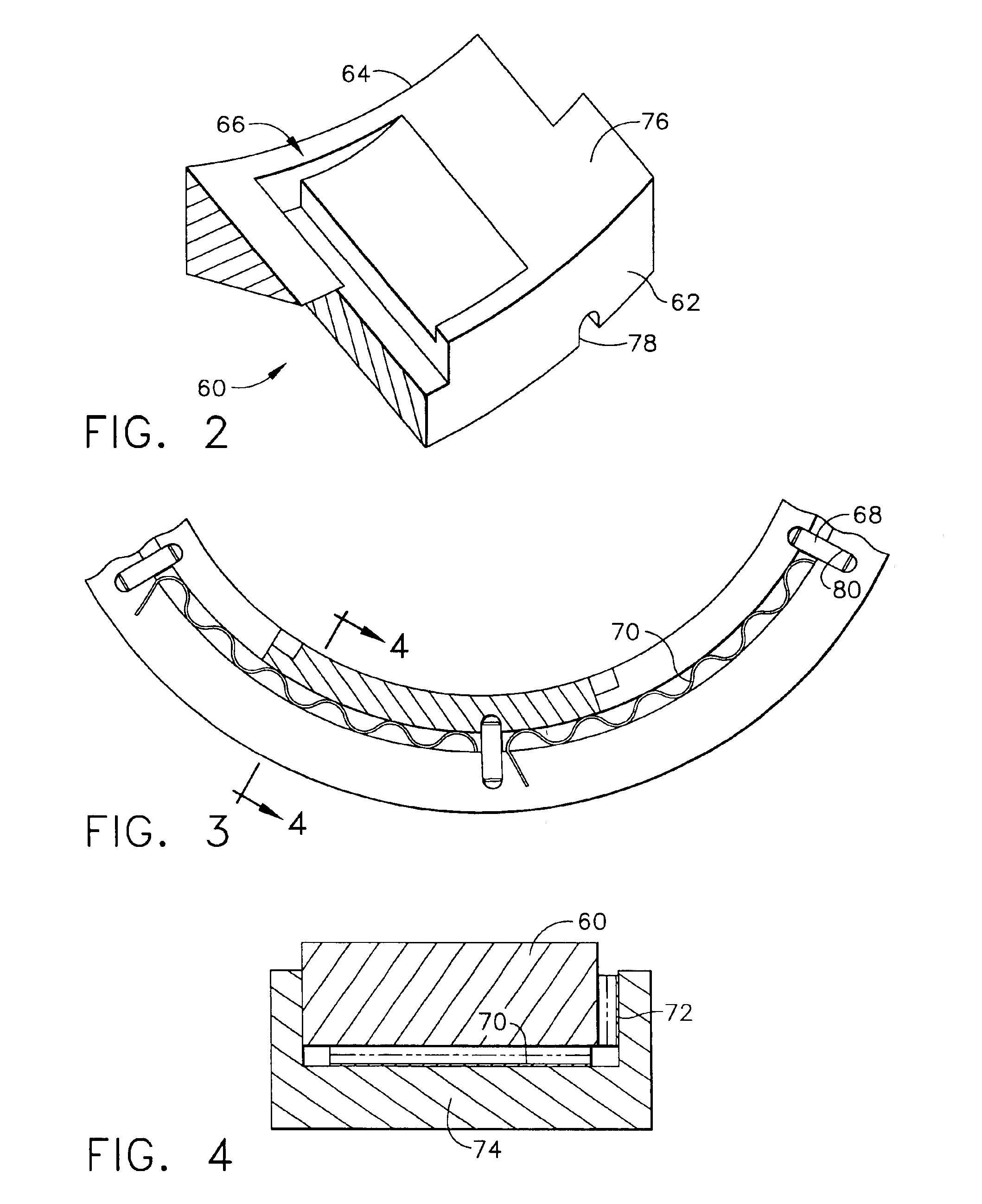

Compliant hybrid gas journal bearing using integral wire mesh dampers

A compliant hybrid gas journal bearing includes compliant hybrid bearing pads having a hydrostatic recess and a capillary restrictor for providing a flow of pressurized gas to the bearing. The bearing also includes an inner rim adjacent the bearing pads, an outer rim and a damper bridge between the inner and outer rims. The damper bridge has an axial length that is less than an axial length of the bearing pads and the outer rim to form a damper cavity on each side of the damper bridge. An integral wire mesh damper is situated within the damper cavity on each side of the damper bridge. Integral centering springs are located between the inner and outer rims to provide radial and rotational compliance to the bearing pads. The oil-free bearing design addresses the low damping and low load capacity characteristics that are inherent in present day compliant air foil bearing designs, while retaining the compliance to changes in rotor geometry.

Owner:GENERAL ELECTRIC CO

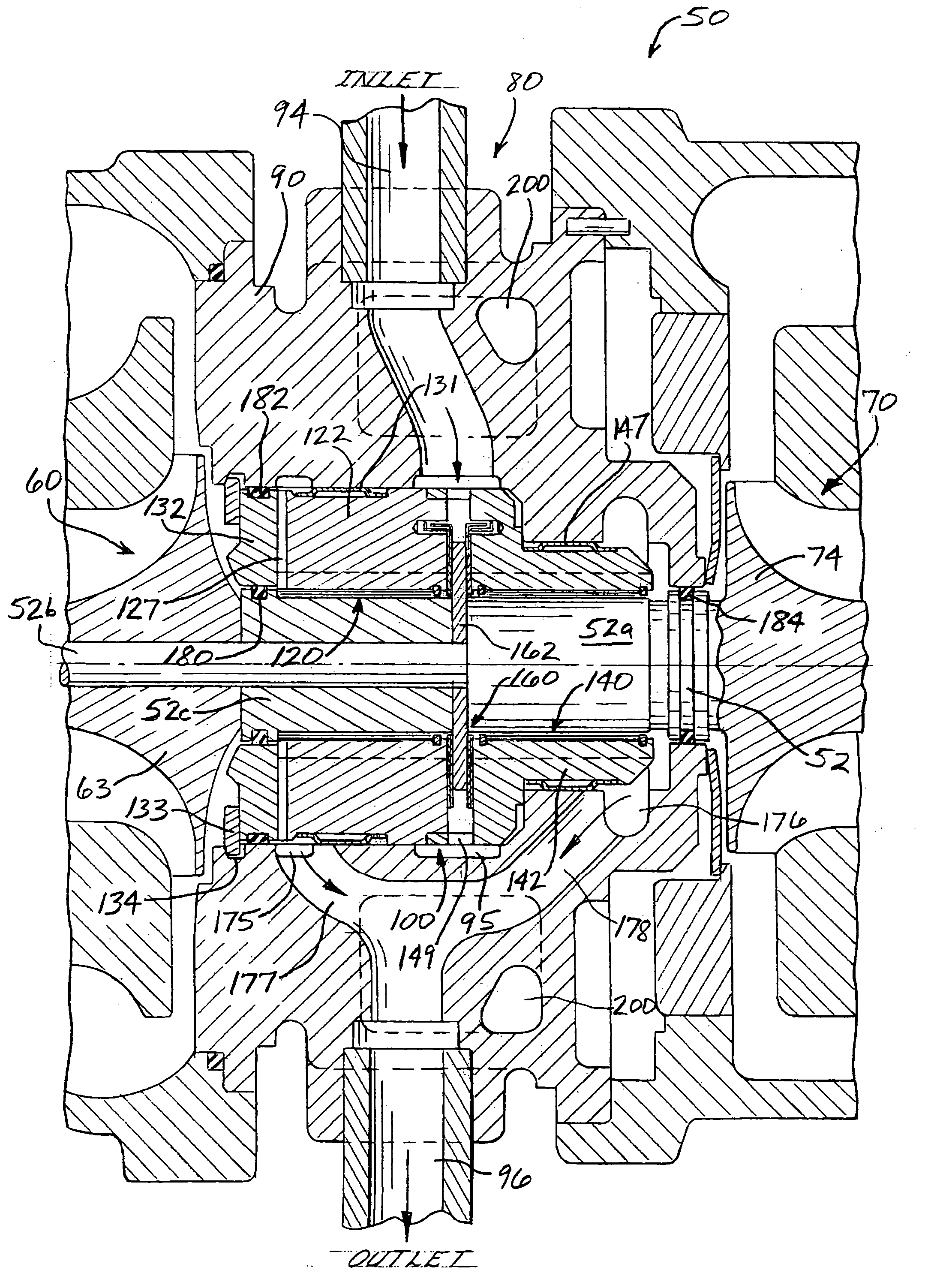

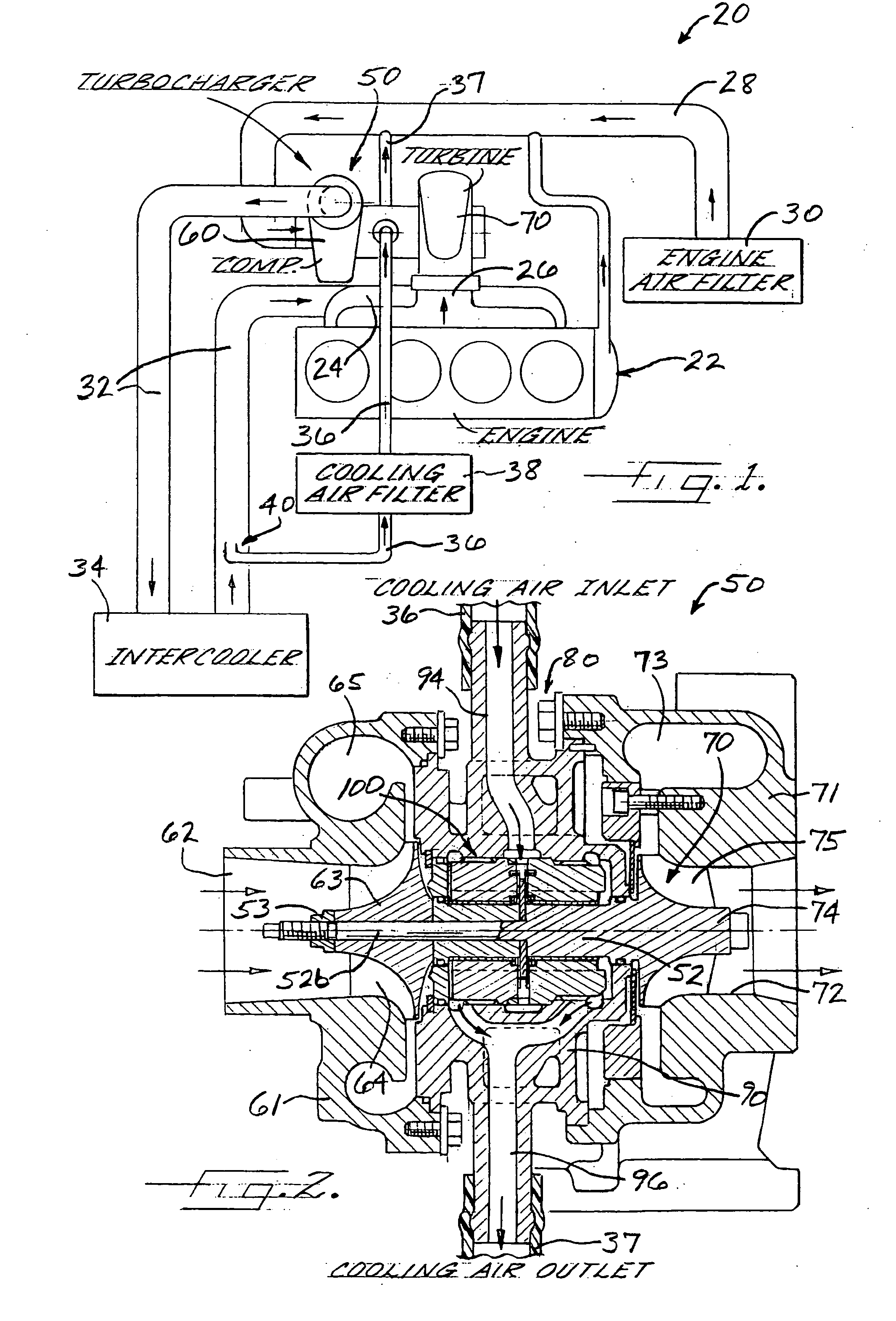

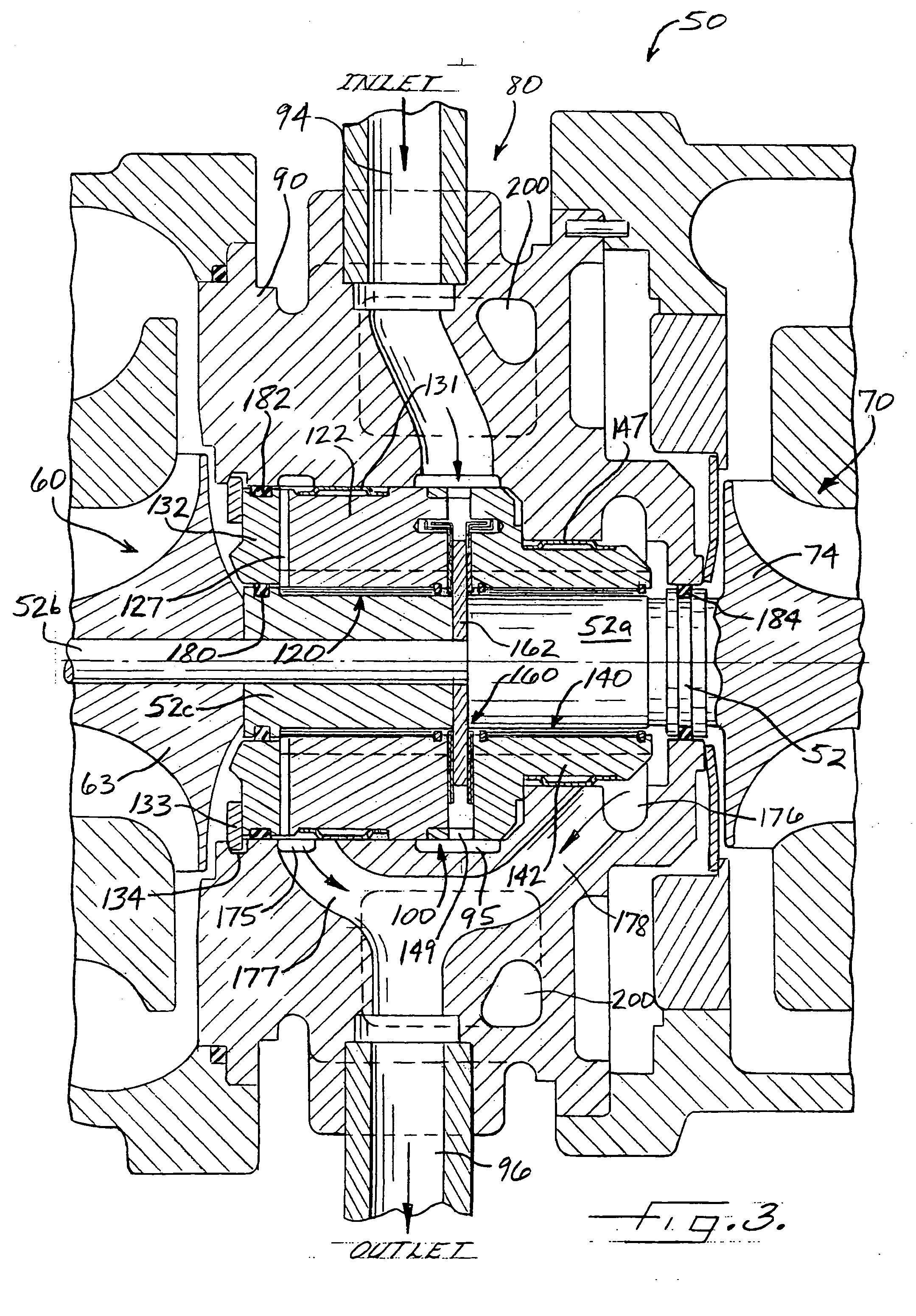

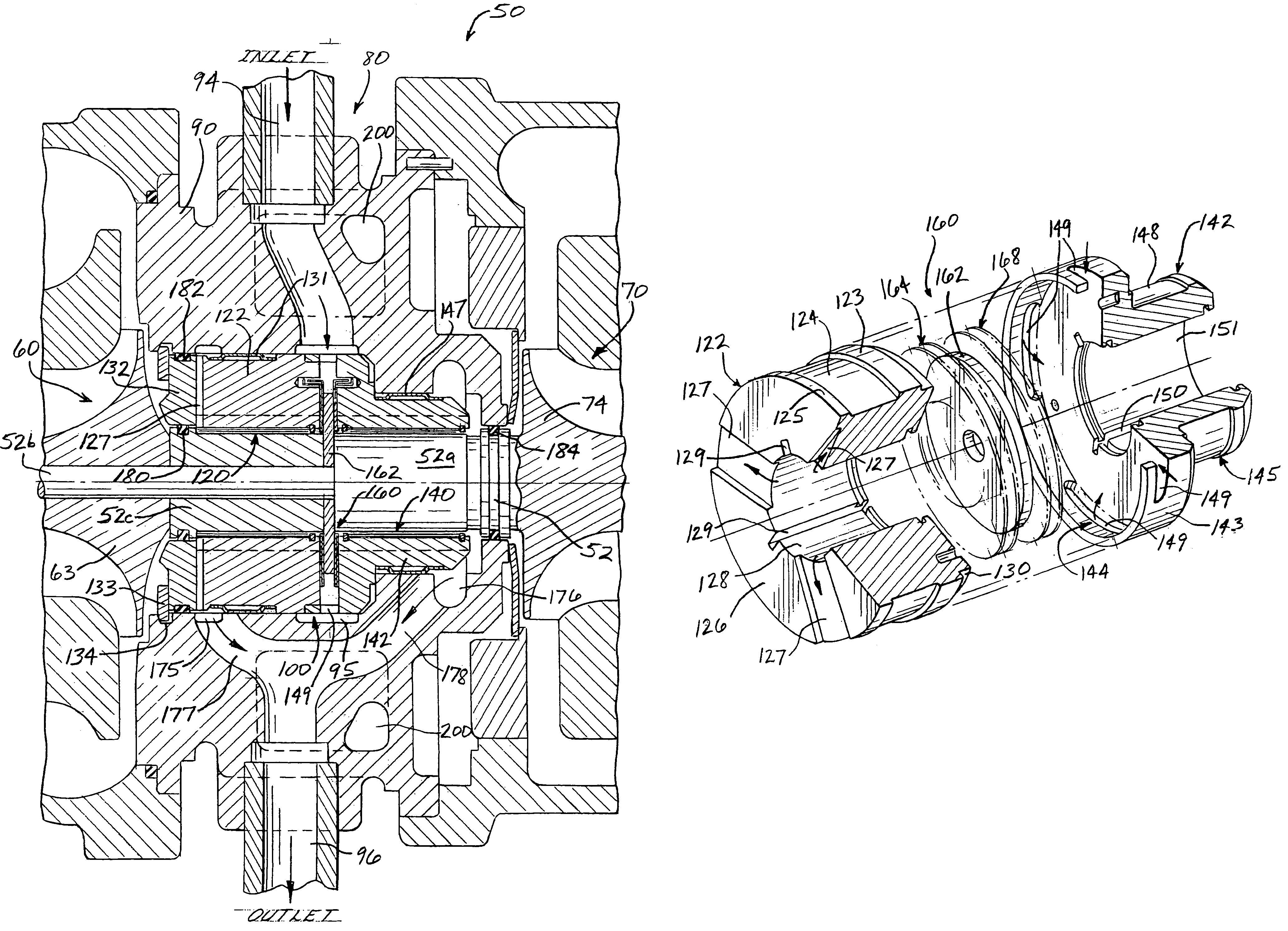

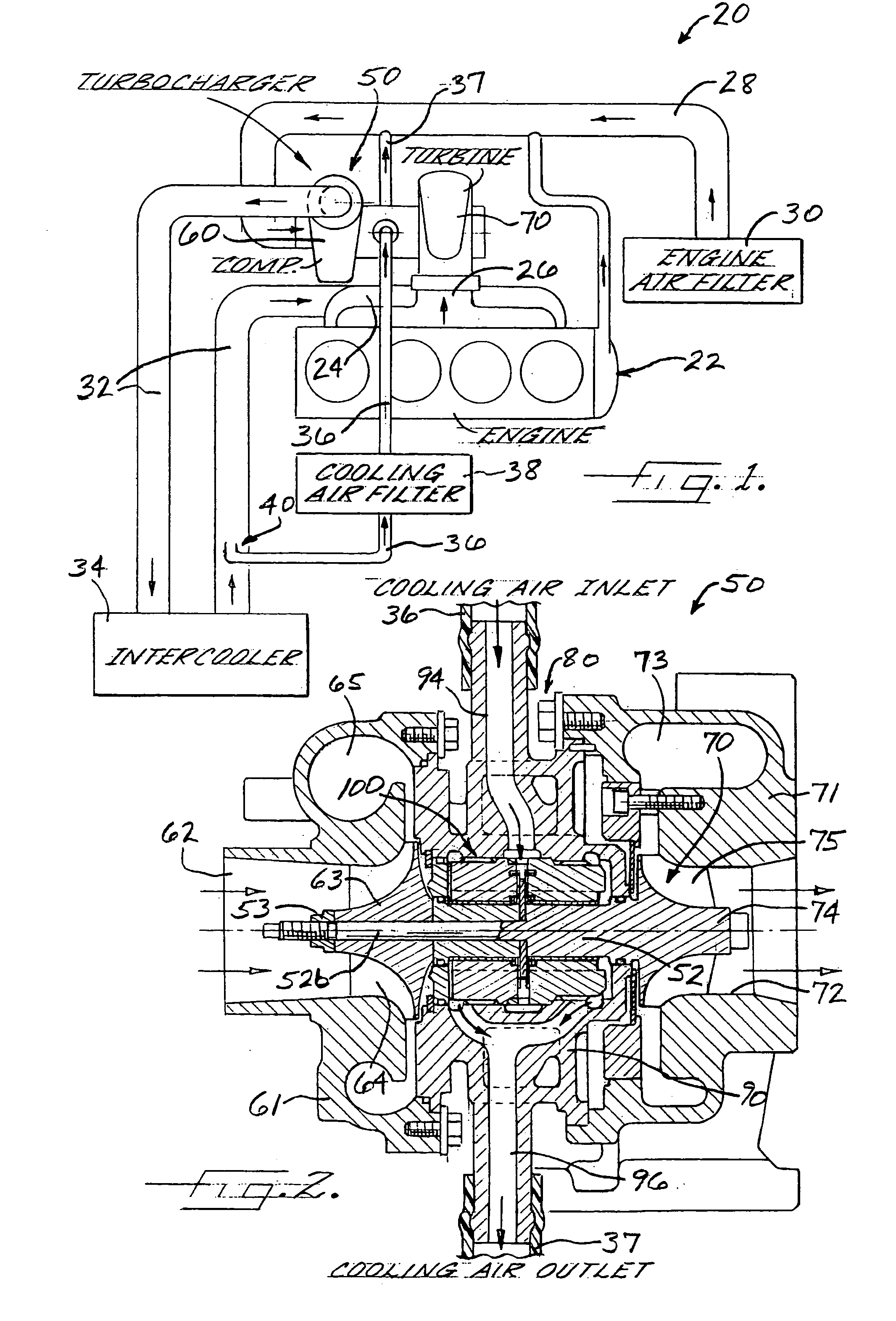

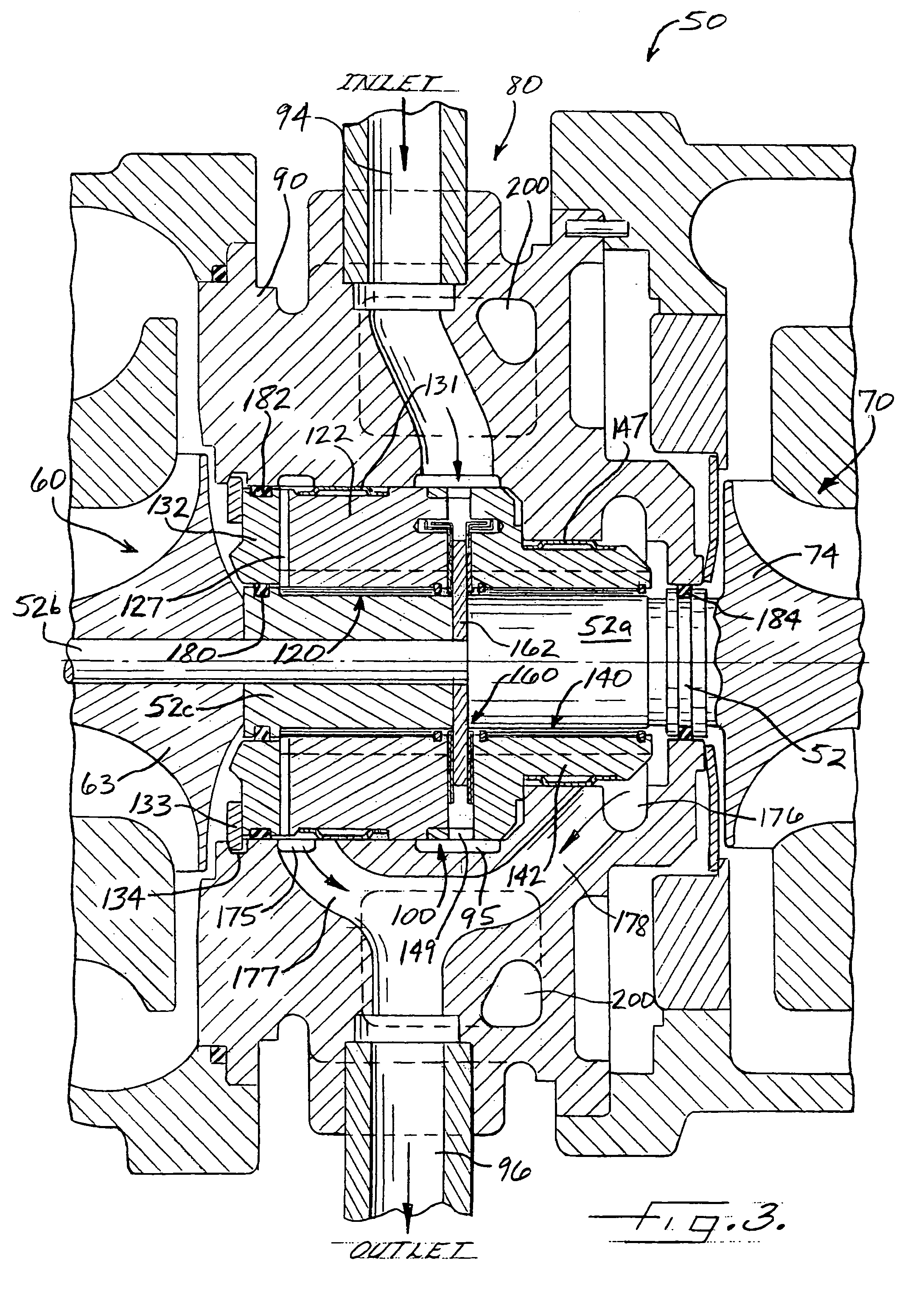

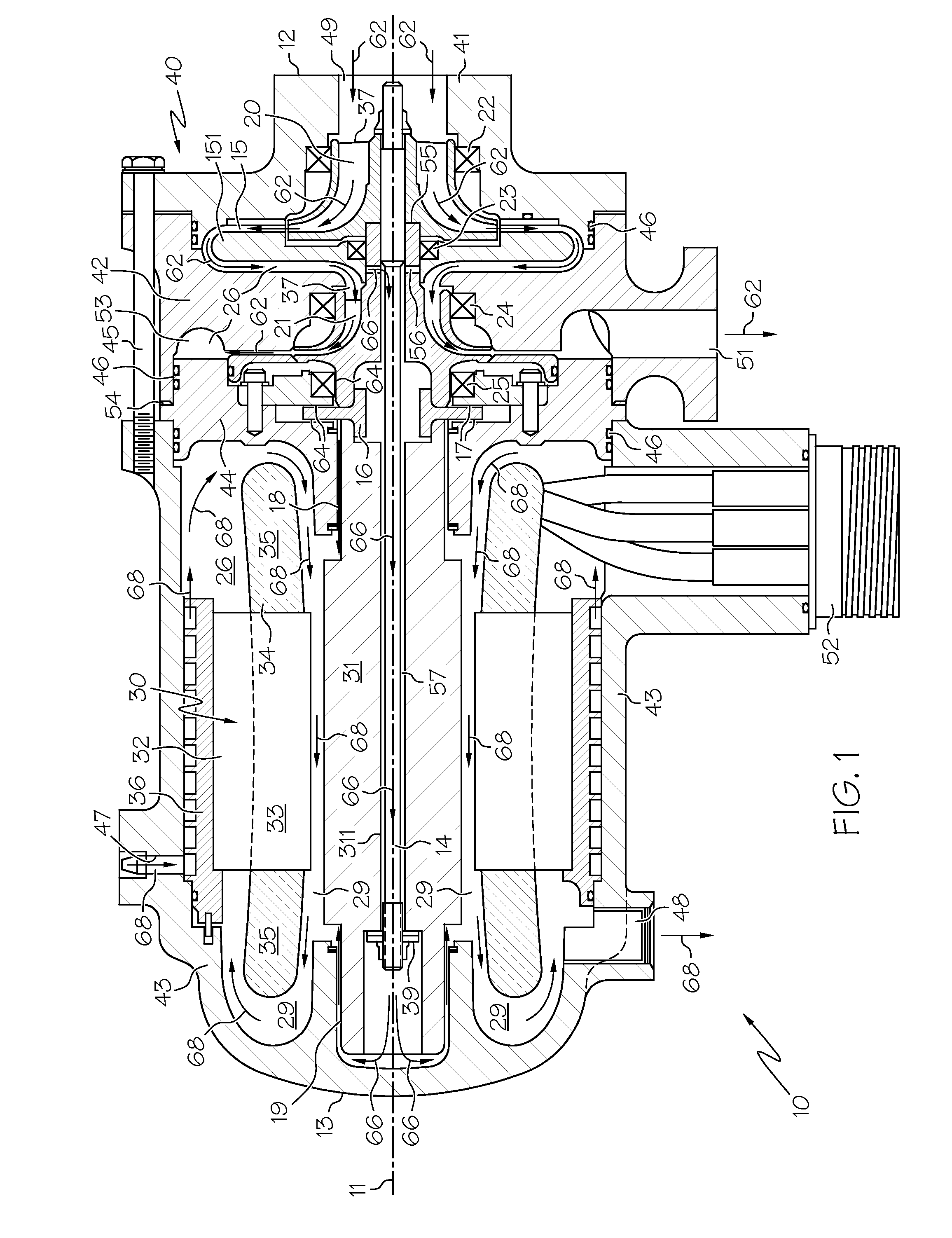

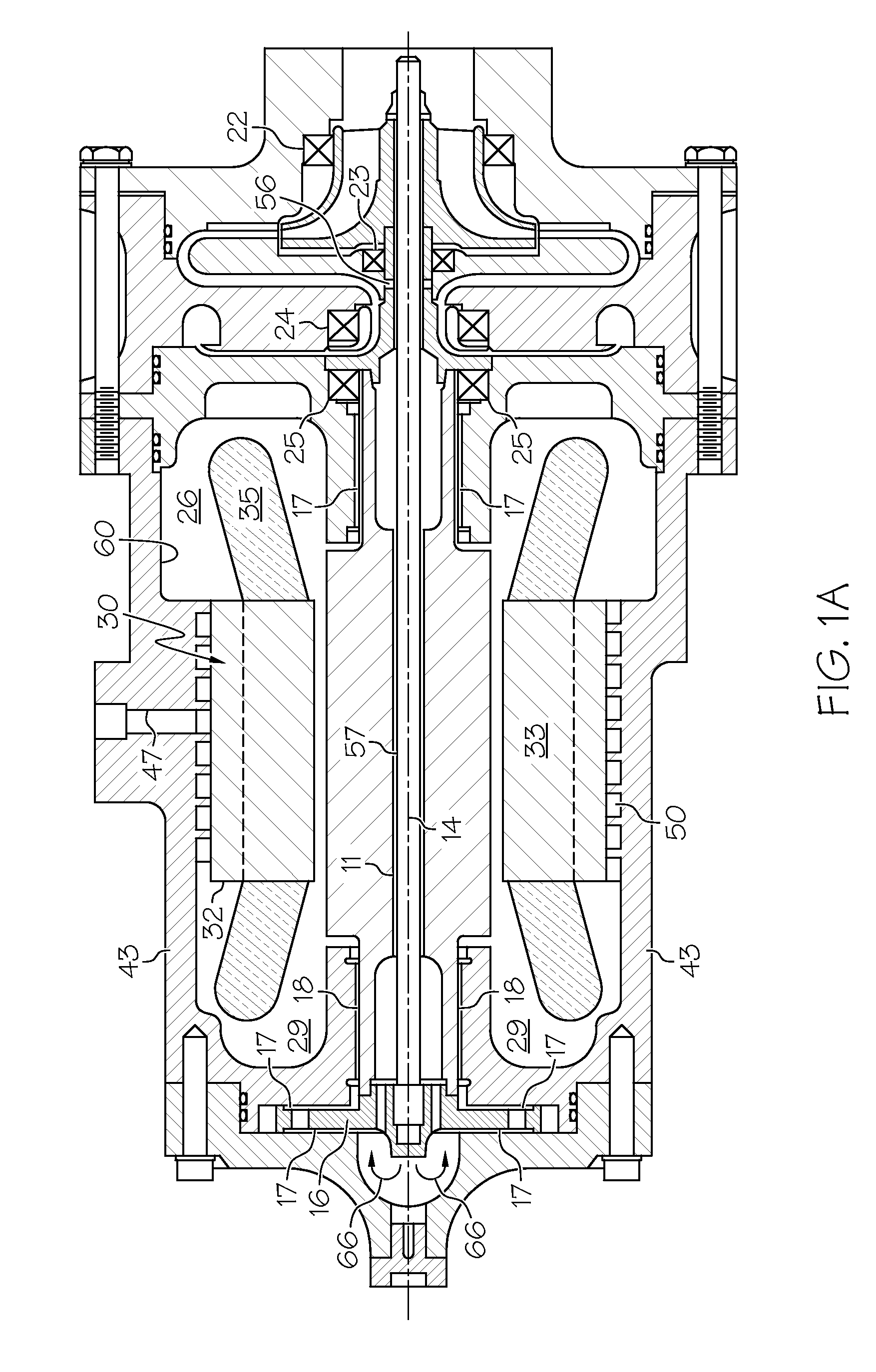

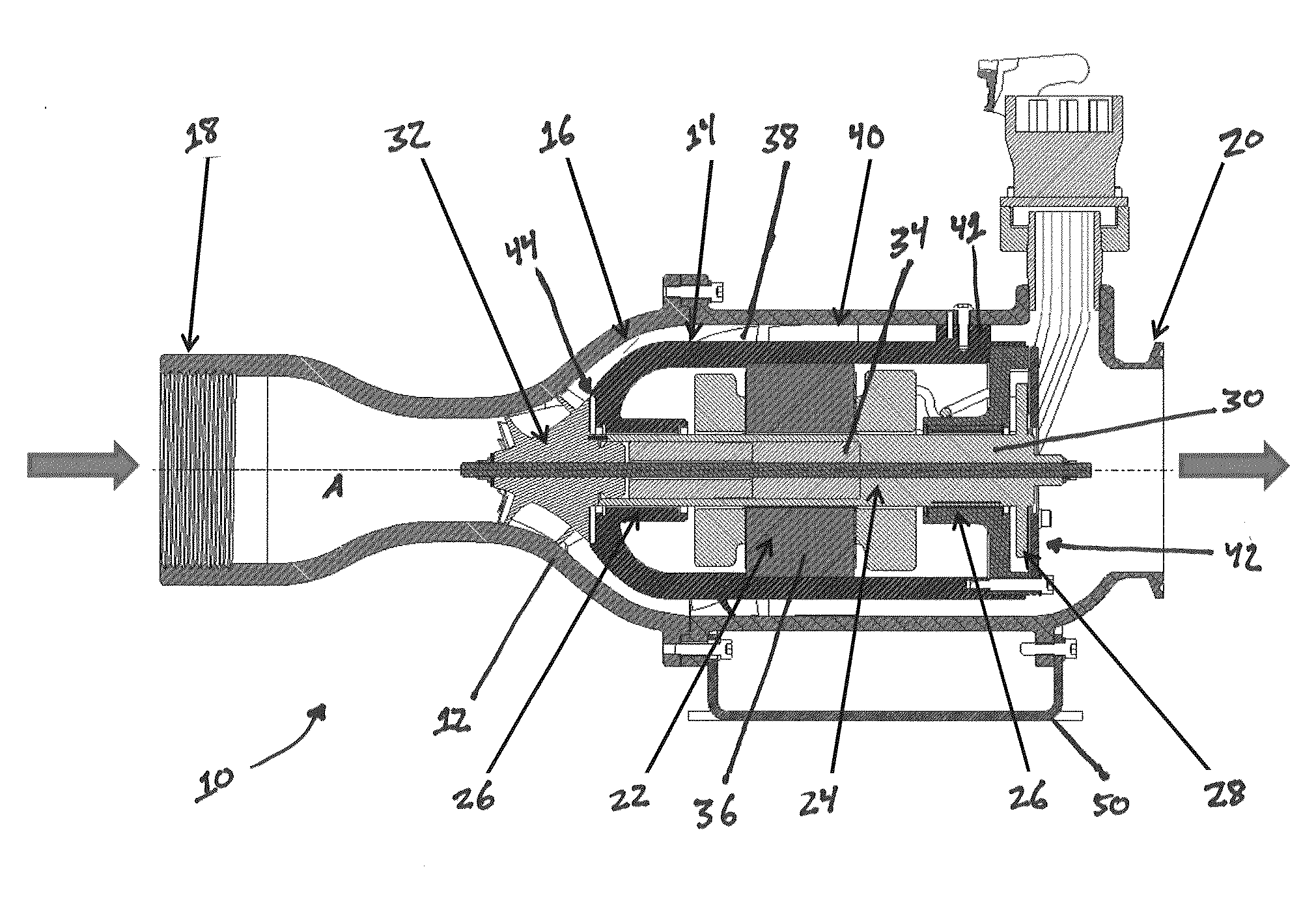

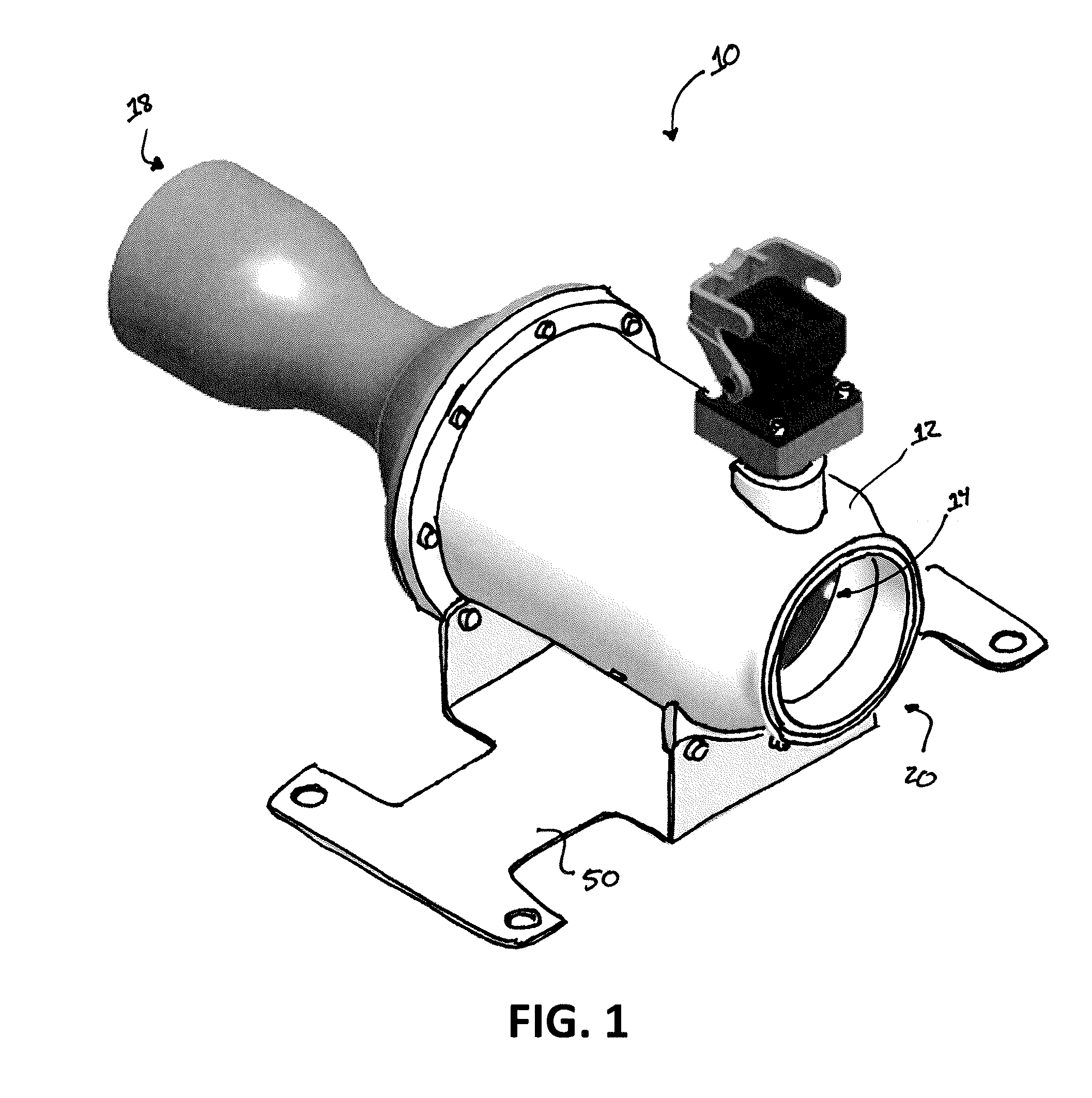

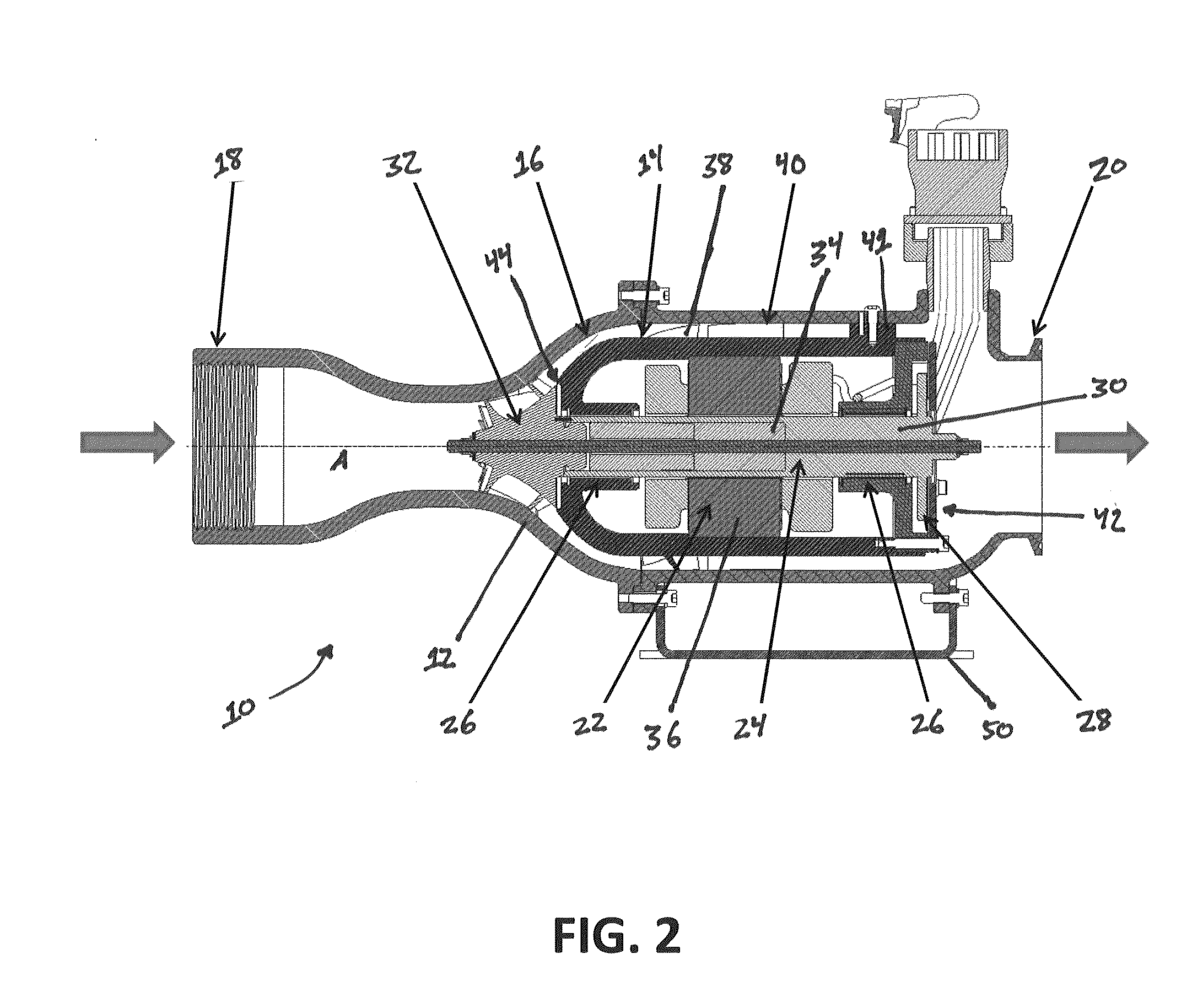

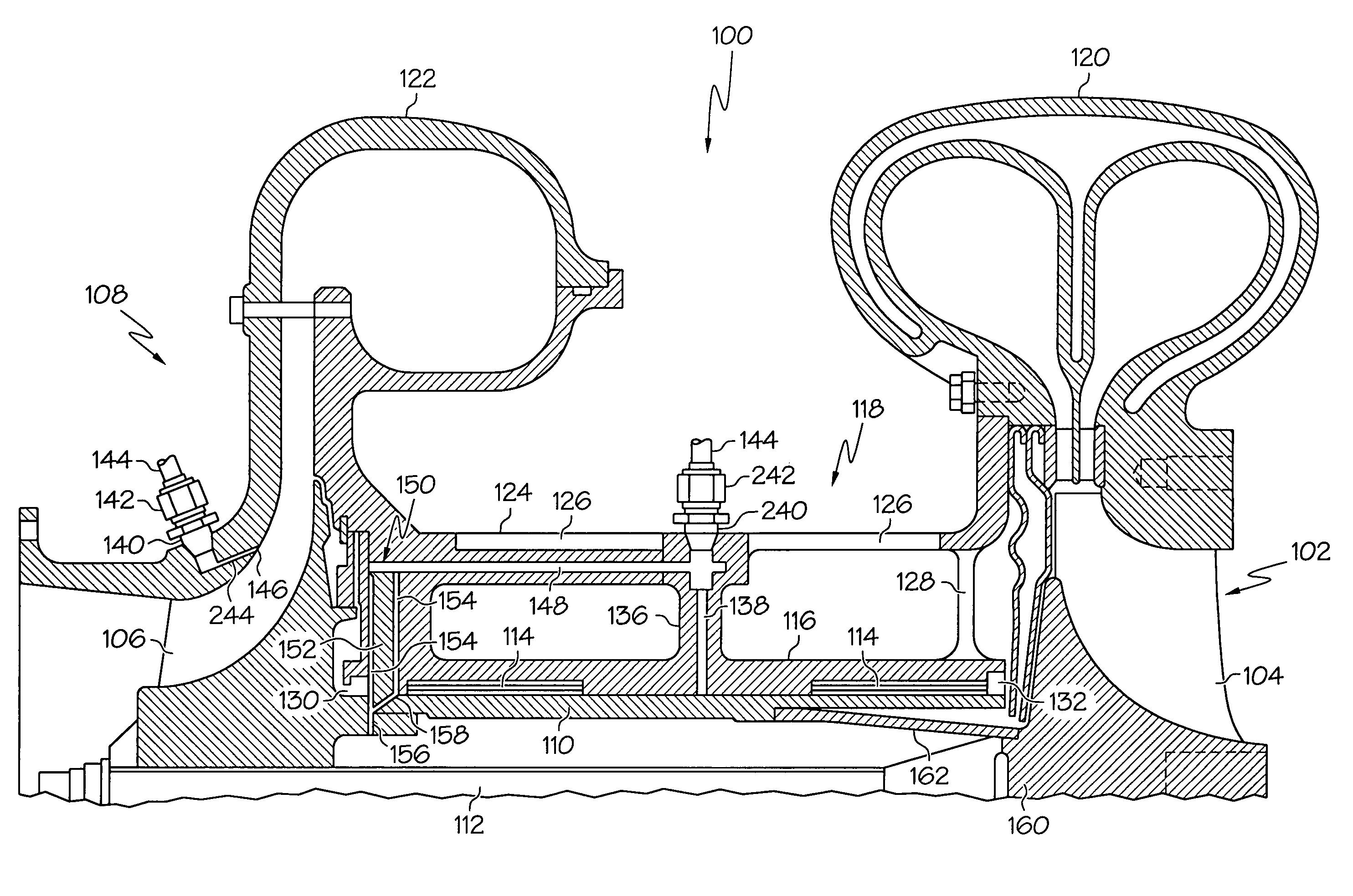

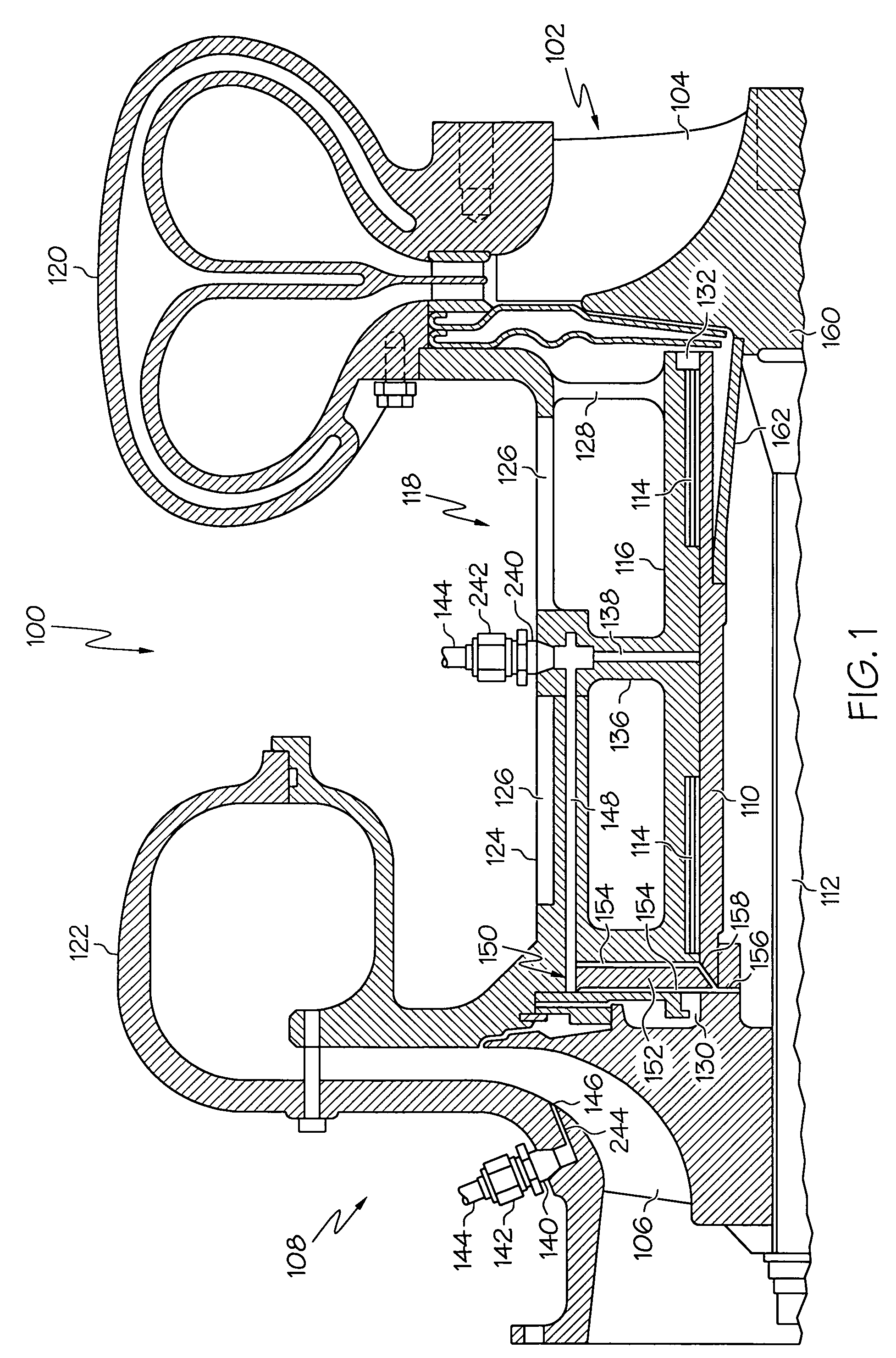

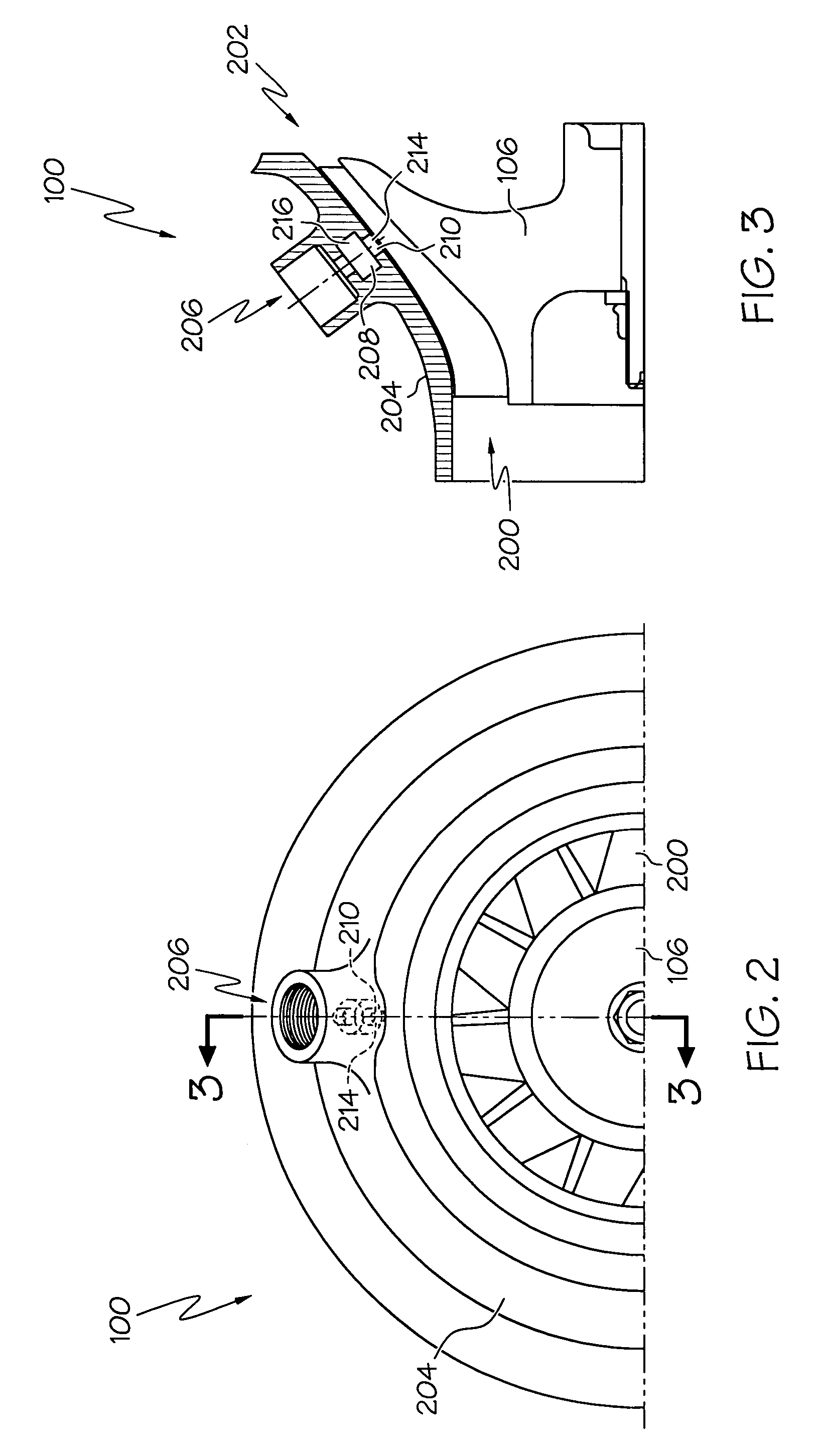

Turbocharger with hydrodynamic foil bearings

A turbocharger includes a foil bearing assembly mounted in a center housing between a compressor and a turbine of the turbocharger. The bearing assembly forms a unit installable into the center housing from one end thereof, and the center housing is a one-piece construction. The bearing assembly includes a foil thrust bearing assembly disposed between two foil journal bearings. The journals foils are mounted in annular bearing carriers fixedly mounted in the center housing. A radially inner portion of a thrust disk of the thrust bearing assembly is captured between a shaft and a shaft sleeve of the turbocharger. The center housing defines cooling air passages for supplying cooling air to the foil bearings, and optionally includes a water jacket for circulating engine coolant through the center housing.

Owner:GARRETT TRANSPORATION I INC

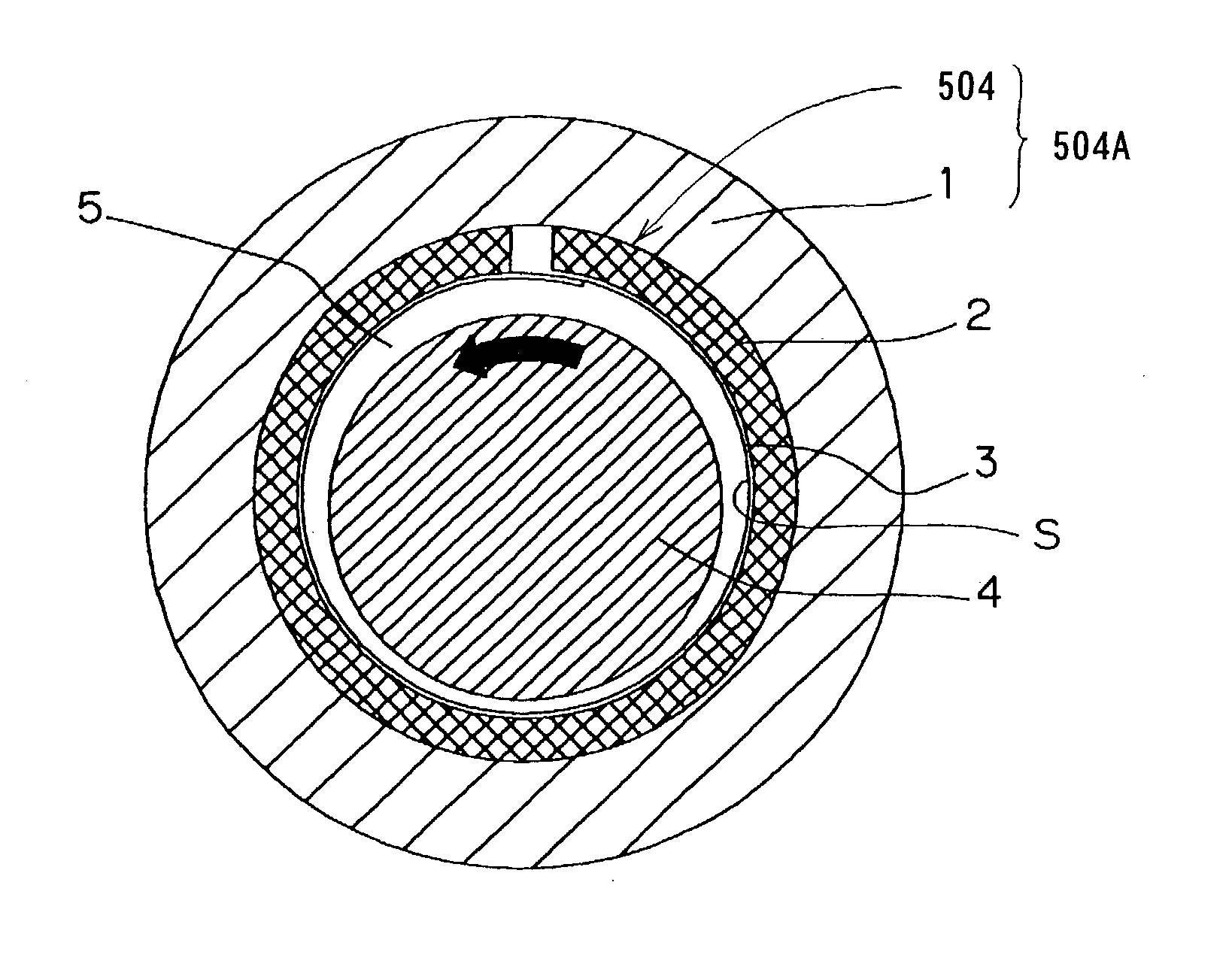

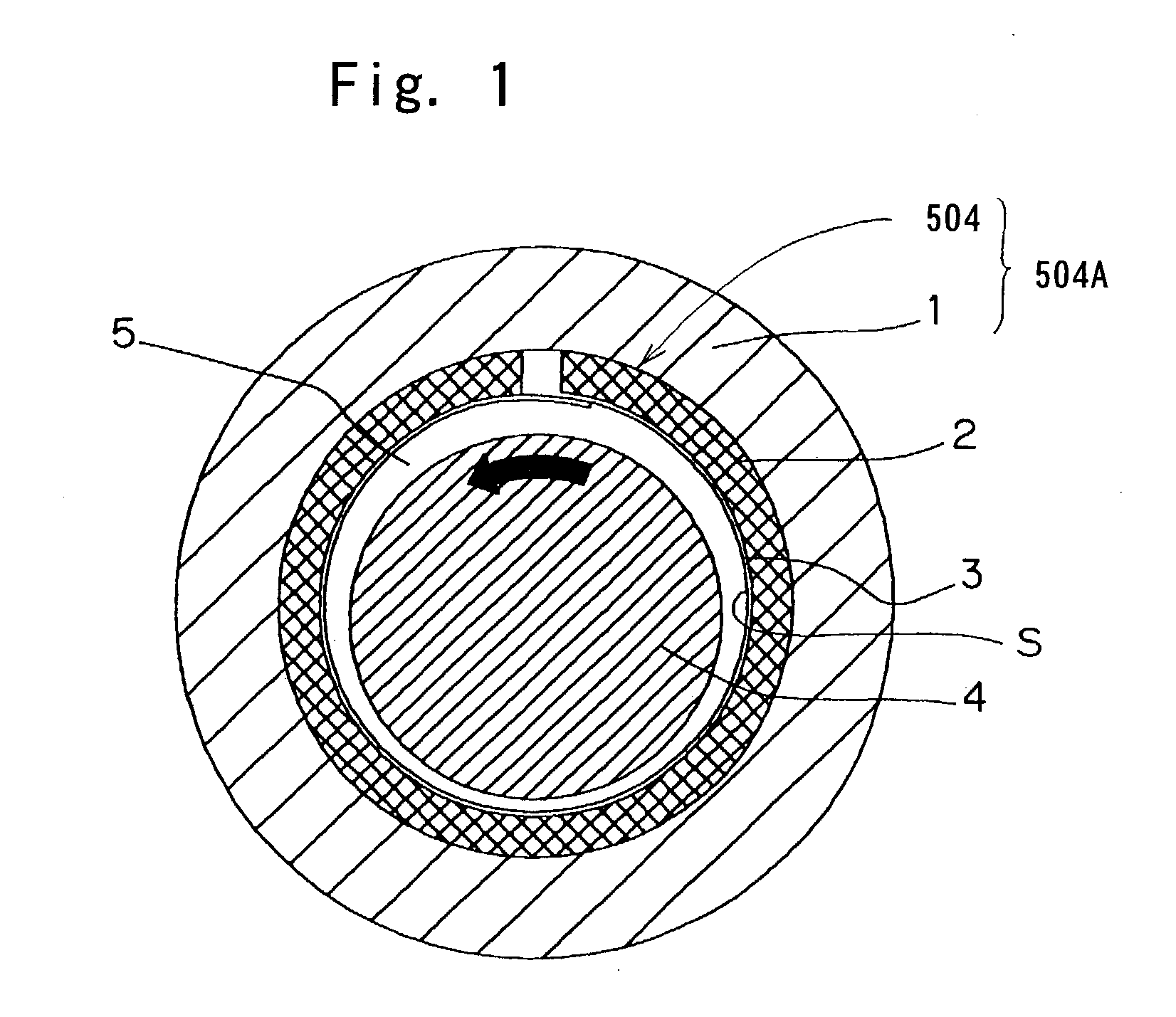

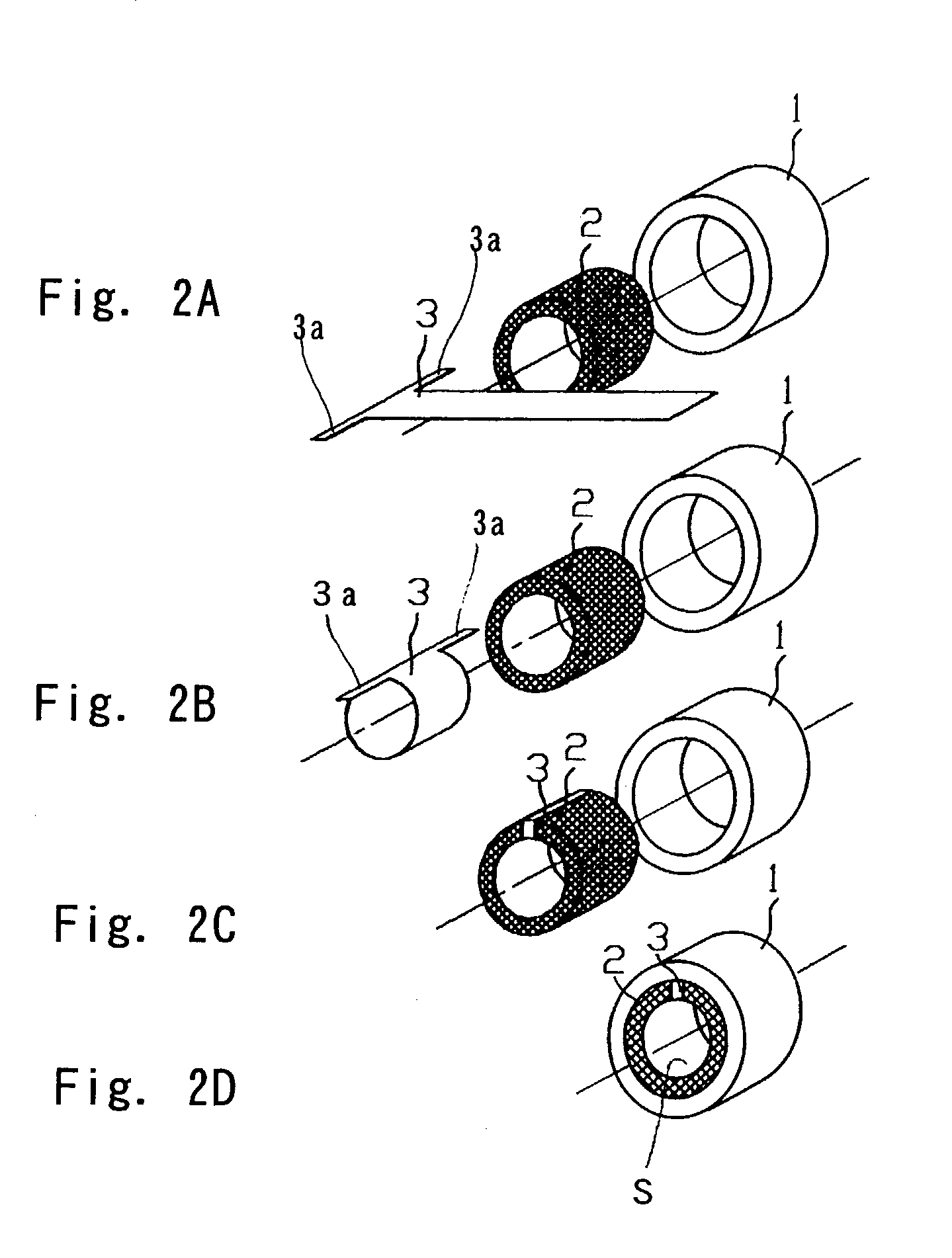

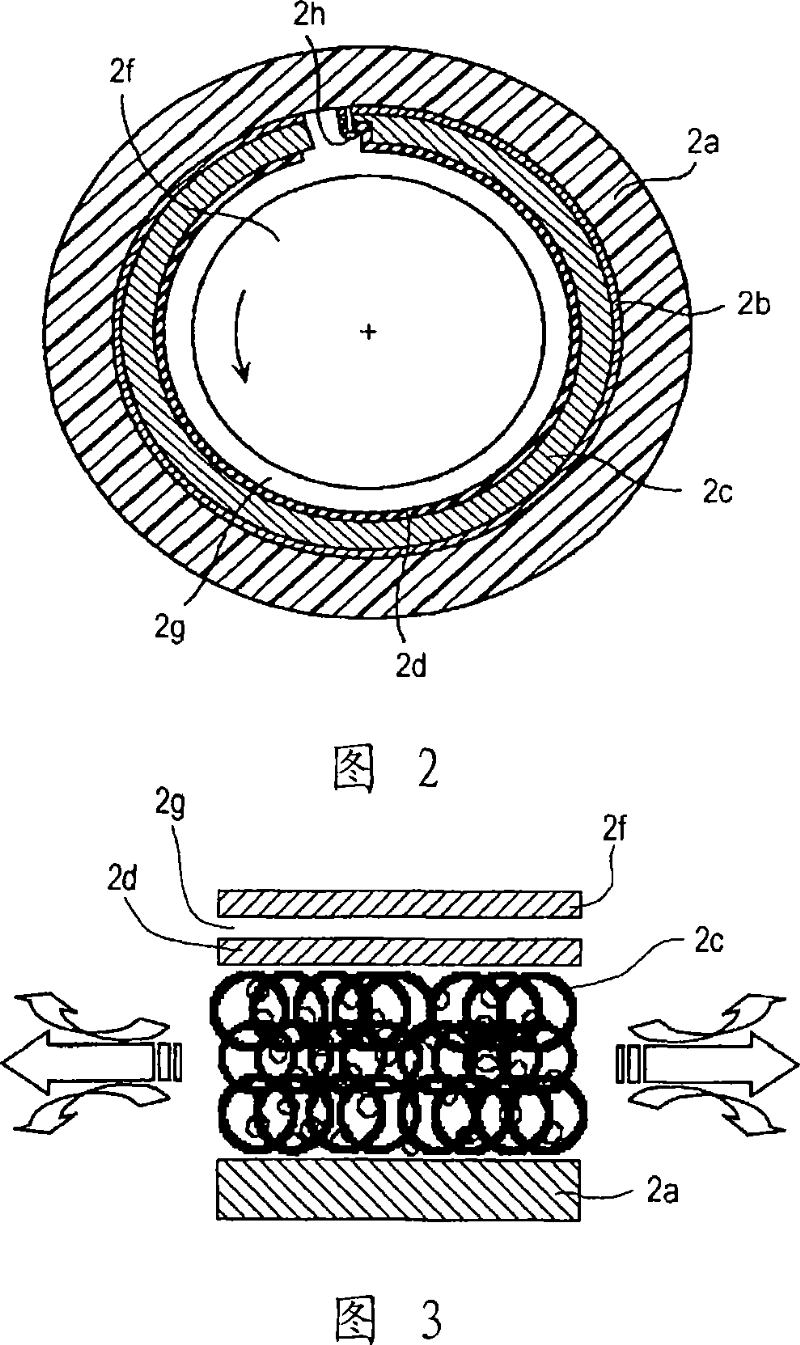

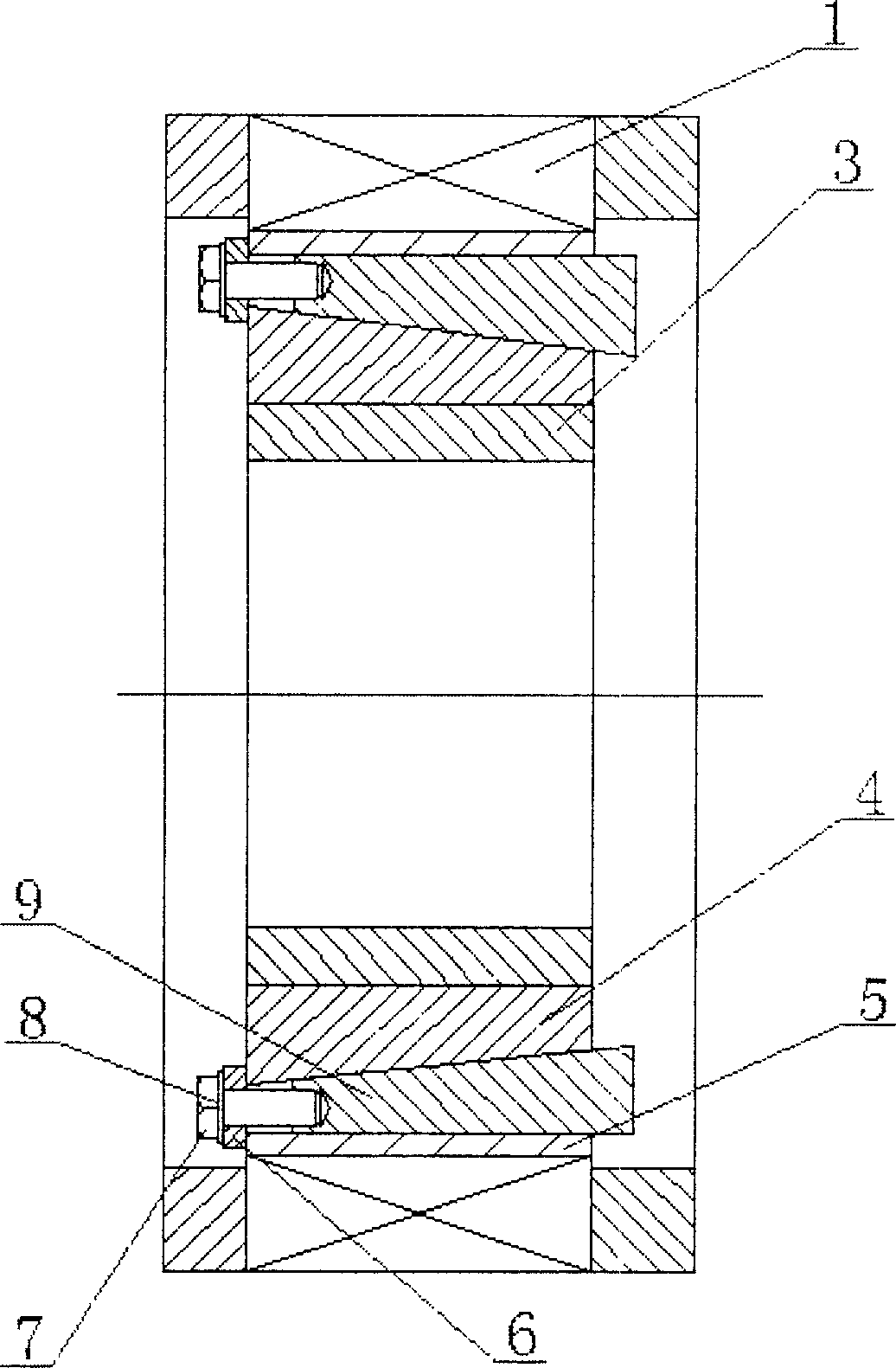

Foil bearing and spindle device using the same

InactiveUS20030169951A1Liquid spraying apparatusSliding contact bearingsThrust bearingBearing surface

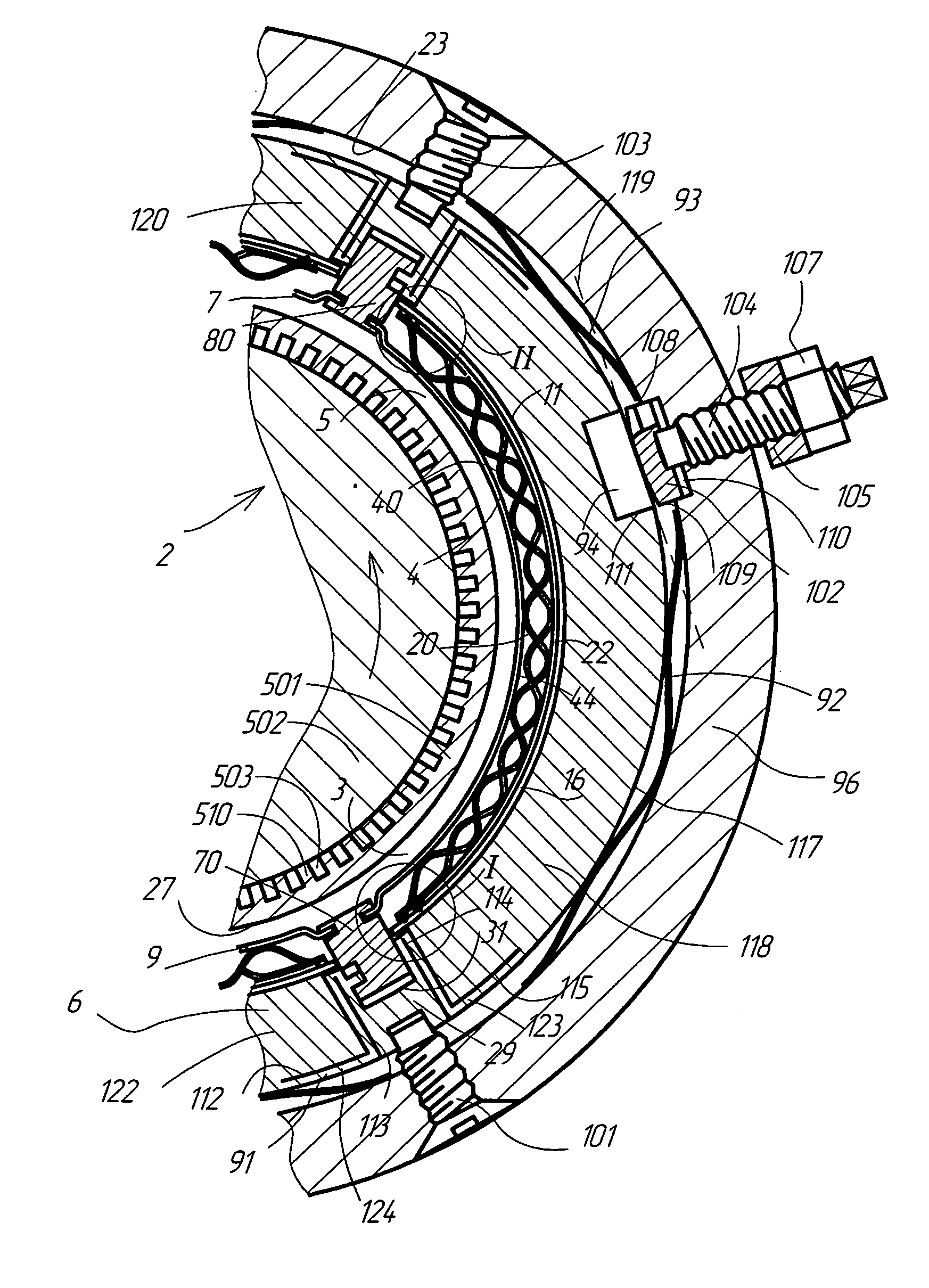

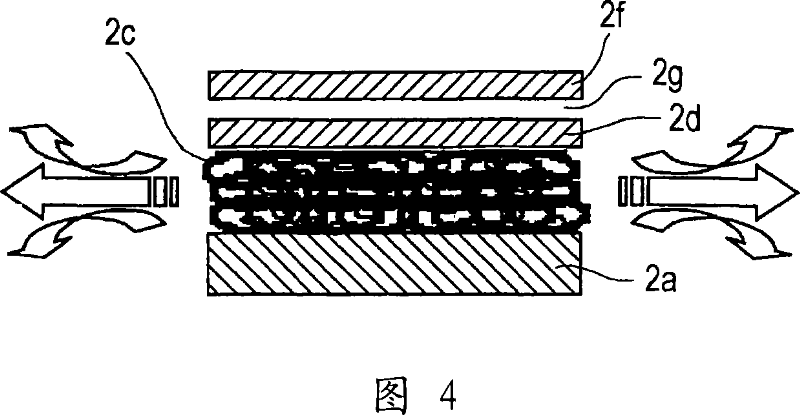

A foil bearing is provided, which is simple in structure, has a large load capacity and a large damping capability and can therefore allow a rotary shaft having a large unbalance as compared with the conventional bearing to be driven stably at a high speed. A spindle device utilizing such foil bearing is also provided, which is designed to increase the permissible amount of unbalance and also to have a light-weight feature. Each of the foil bearings 504 and 505 includes an elastic member 2 prepared from a wire net formed by braiding wires, and a thin bearing foil 3 supported by the elastic member 2 and defining an elastic bearing surface S. The respective foil bearing 504 and 505 is used at least as a radial bearing 504 in the spindle device including a rotary shaft 4 having a head mount 501a, on which an atomizer head is mounted, and the radial and thrust bearings 504 and 505 for rotatably supporting the rotary shaft 4.

Owner:NTN CORP

Compliant hybrid gas journal bearing using integral wire mesh dampers

A compliant hybrid gas journal bearing includes compliant hybrid bearing pads having a hydrostatic recess and a capillary restrictor for providing a flow of pressurized gas to the bearing. The bearing also includes an inner rim adjacent the bearing pads, an outer rim and a damper bridge between the inner and outer rims. The damper bridge has an axial length that is less than an axial length of the bearing pads and the outer rim to form a damper cavity on each side of the damper bridge. An integral wire mesh damper is situated within the damper cavity on each side of the damper bridge. Integral centering springs are located between the inner and outer rims to provide radial and rotational compliance to the bearing pads. The oil-free bearing design addresses the low damping and low load capacity characteristics that are inherent in present day compliant air foil bearing designs, while retaining the compliance to changes in rotor geometry.

Owner:GENERAL ELECTRIC CO

Turbocharger with hydrodynamic foil bearings

A turbocharger includes a foil bearing assembly mounted in a center housing between a compressor and a turbine of the turbocharger. The bearing assembly forms a unit installable into the center housing from one end thereof, and the center housing is a one-piece construction. The bearing assembly includes a foil thrust bearing assembly disposed between two foil journal bearings. The journals foils are mounted in annular bearing carriers fixedly mounted in the center housing. A radially inner portion of a thrust disk of the thrust bearing assembly is captured between a shaft and a shaft sleeve of the turbocharger. The center housing defines cooling air passages for supplying cooling air to the foil bearings, and optionally includes a water jacket for circulating engine coolant through the center housing.

Owner:GARRETT TRANSPORATION I INC

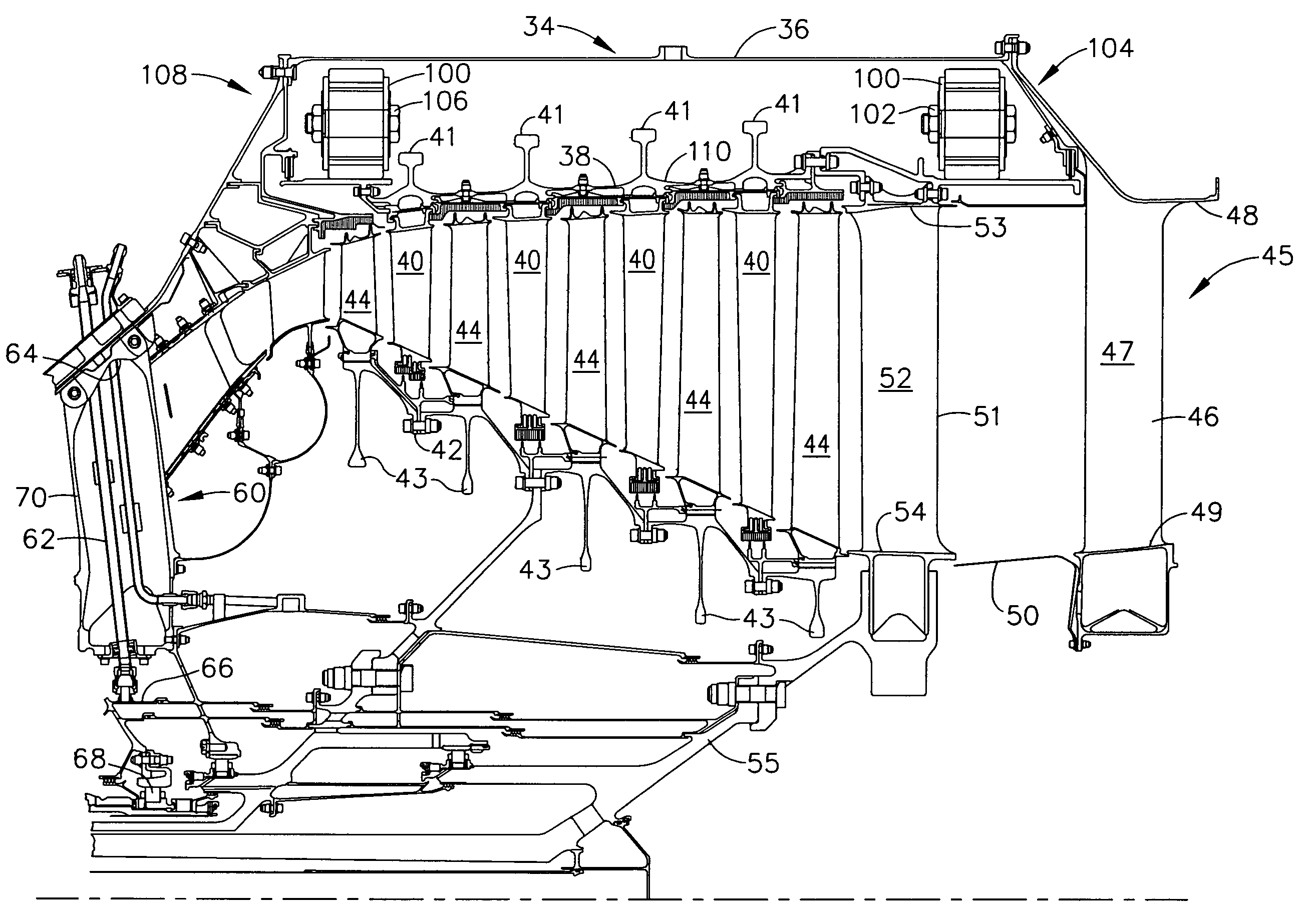

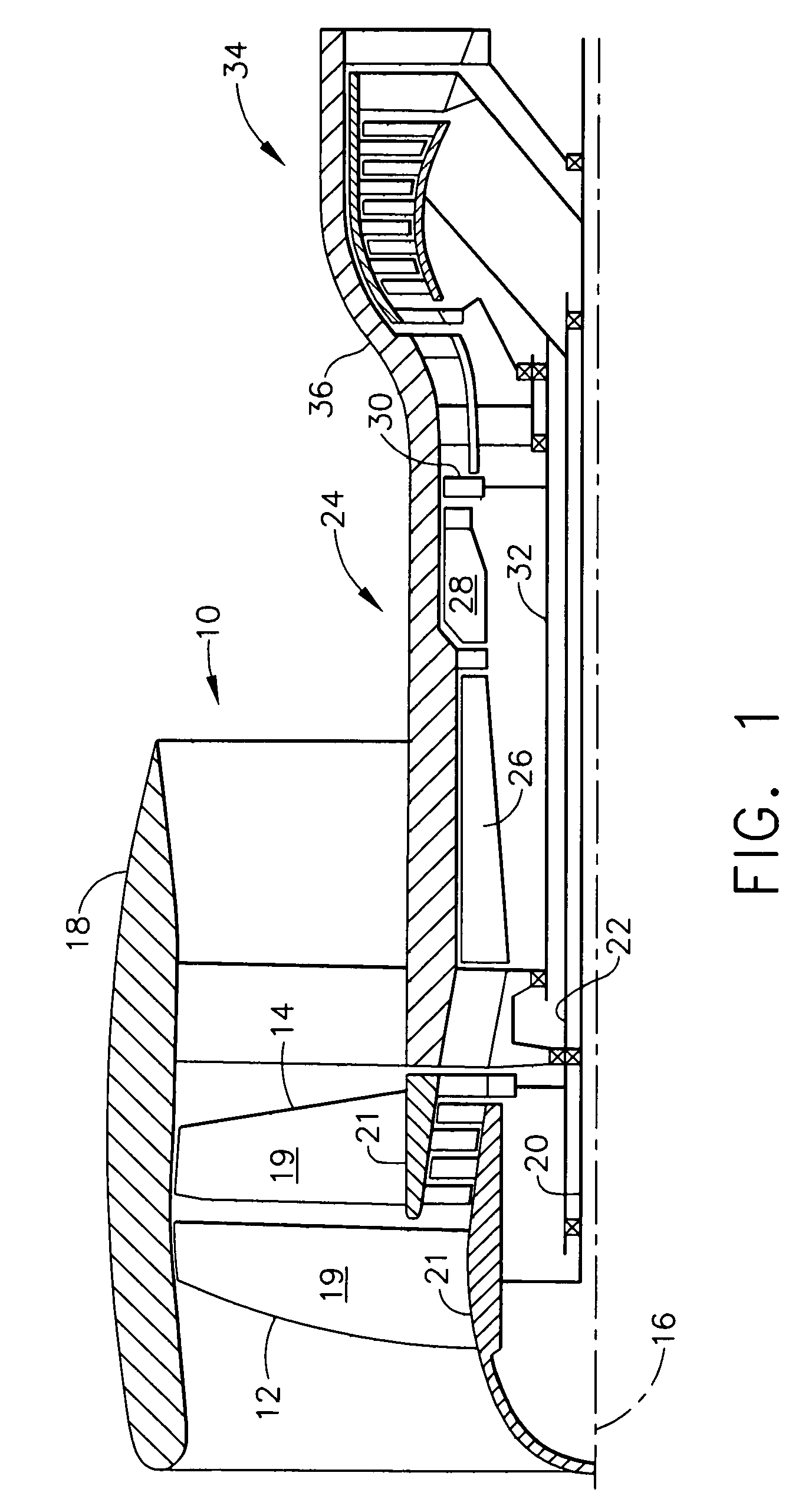

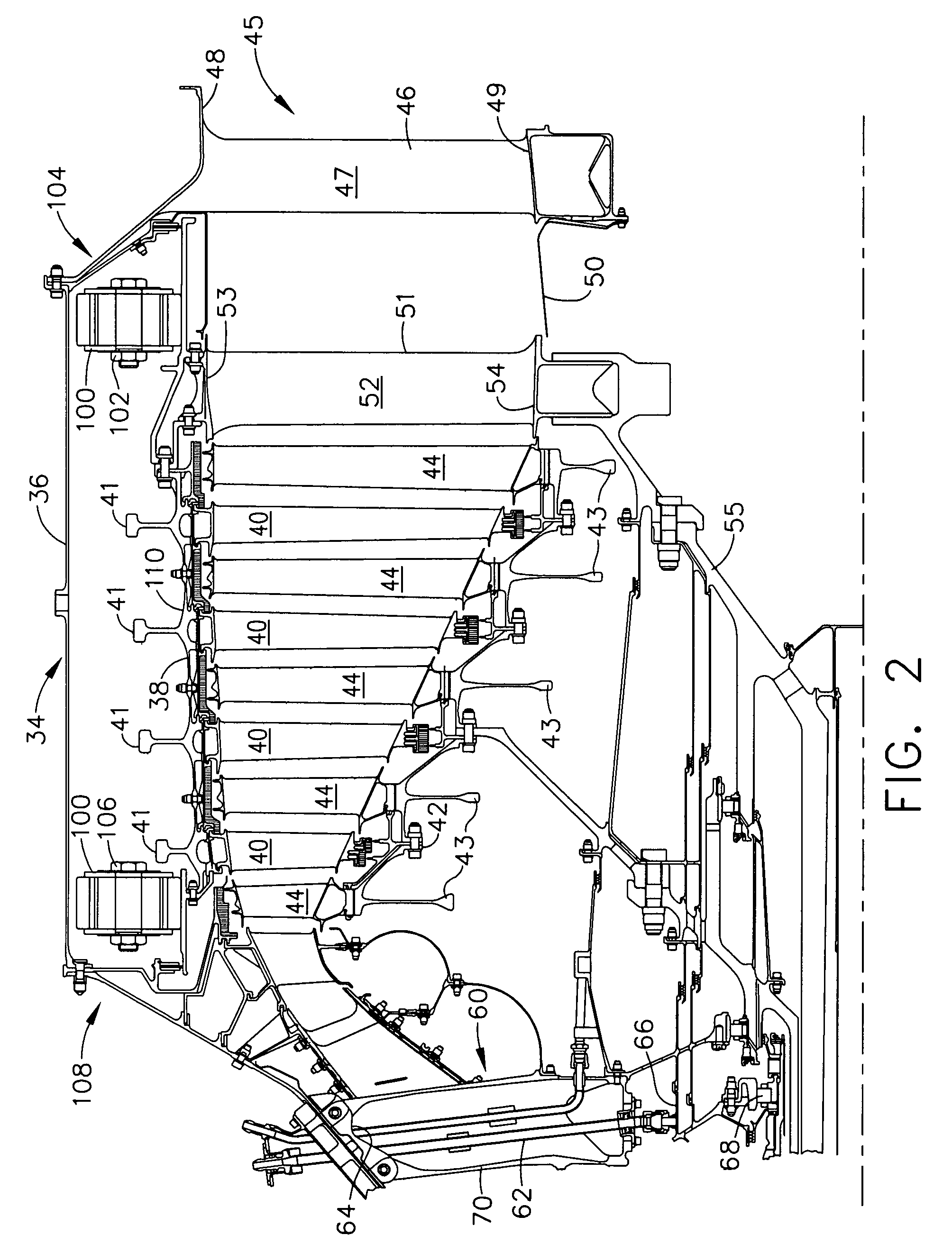

Counter-rotating turbine engine and method of assembling same

A method for assembling a gas turbine engine that includes providing a low-pressure turbine inner rotor configured to rotate in a first direction, providing a low-pressure turbine outer rotor configured to rotate in a second direction that is opposite the first rotational direction, and coupling at least one foil bearing to at least one of the inner and outer rotors to facilitate improving clearance control between a first rotating component and at least one of a second rotating component and a non-rotating component.

Owner:GENERAL ELECTRIC CO

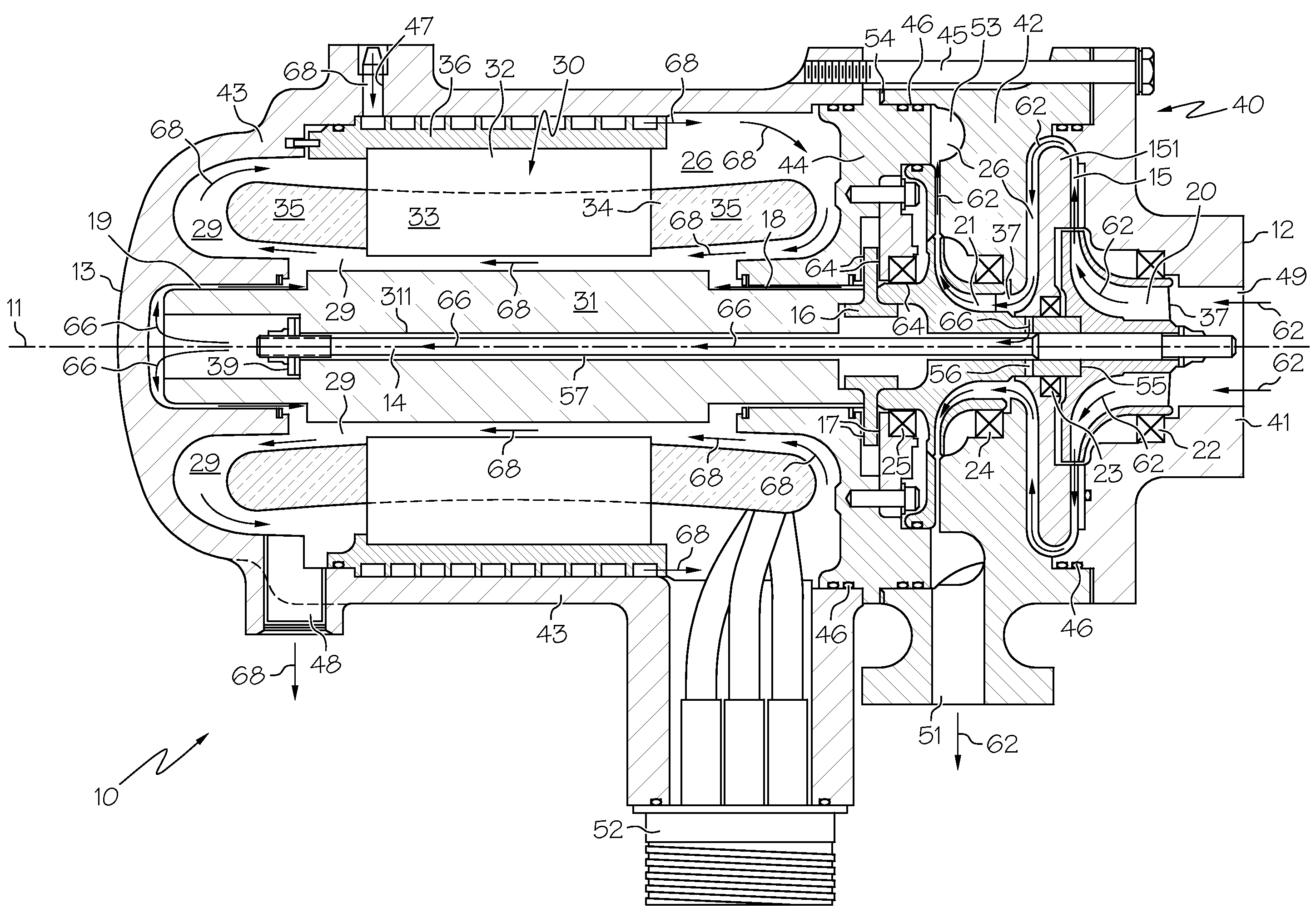

Two-stage vapor cycle compressor

A two-stage vapor cycle compressor includes a first stage impeller, a second stage impeller situated adjacent to the first stage impeller, an electric motor running on a pair of foil bearings, a thrust disk including two foil bearings and being positioned between the second stage impeller and the electric motor, and a compressor housing enclosing the first and second stage impeller and the electric motor. A refrigerant vapor compressed by the first stage and second stage impeller flows through an internal passageway formed by the compressor housing and cools the foil bearings and the electric motor. The compressor may be a gravity insensitive, small, and lightweight machine that may be easily assembled at low manufacturing costs. The two-stage vapor cycle compressor may be suitable for, but not limited to, applications in vapor compression refrigeration systems, such as air-conditioning systems, for example, in the aircraft and aerospace industries.

Owner:HONEYWELL INT INC

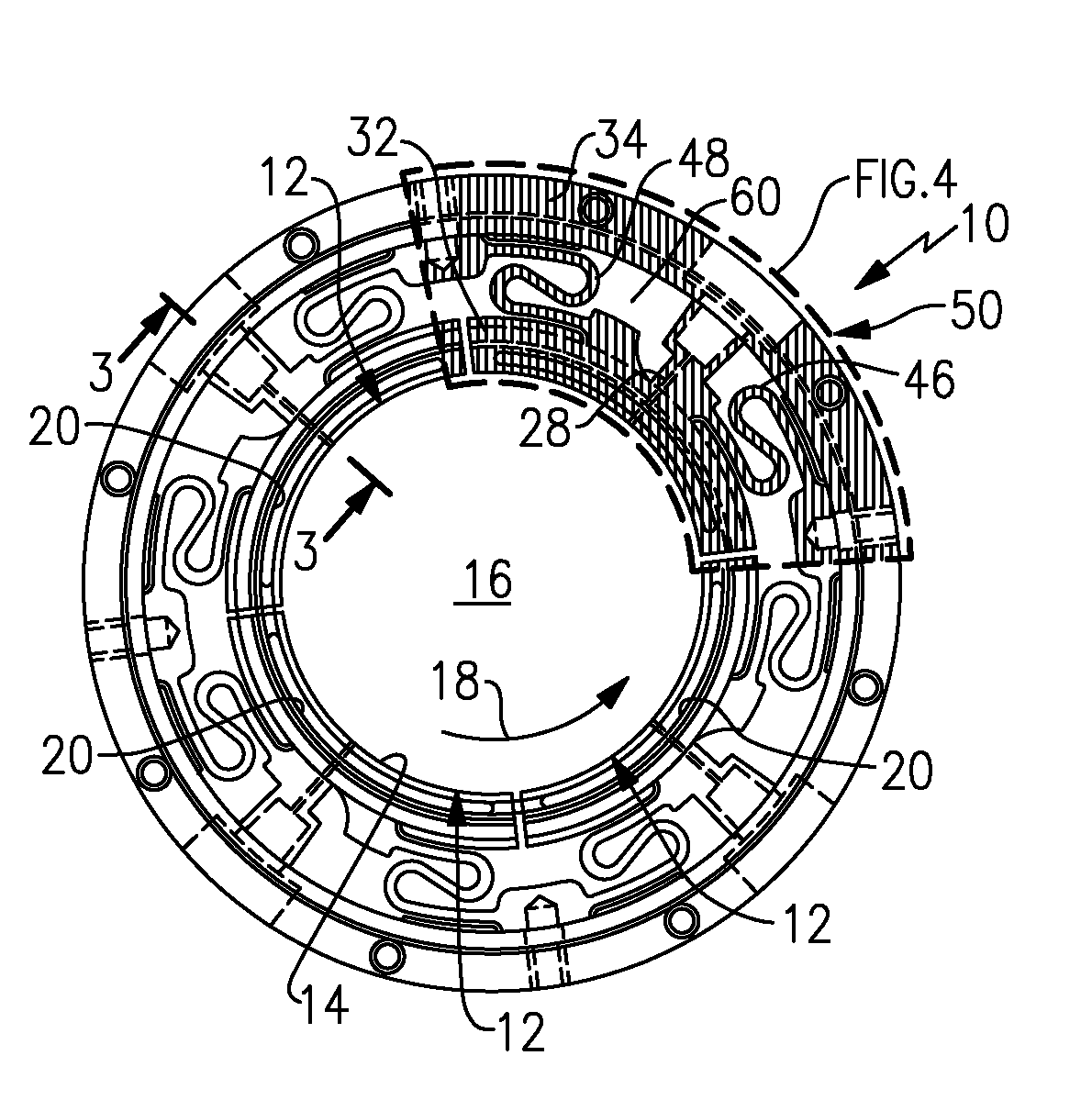

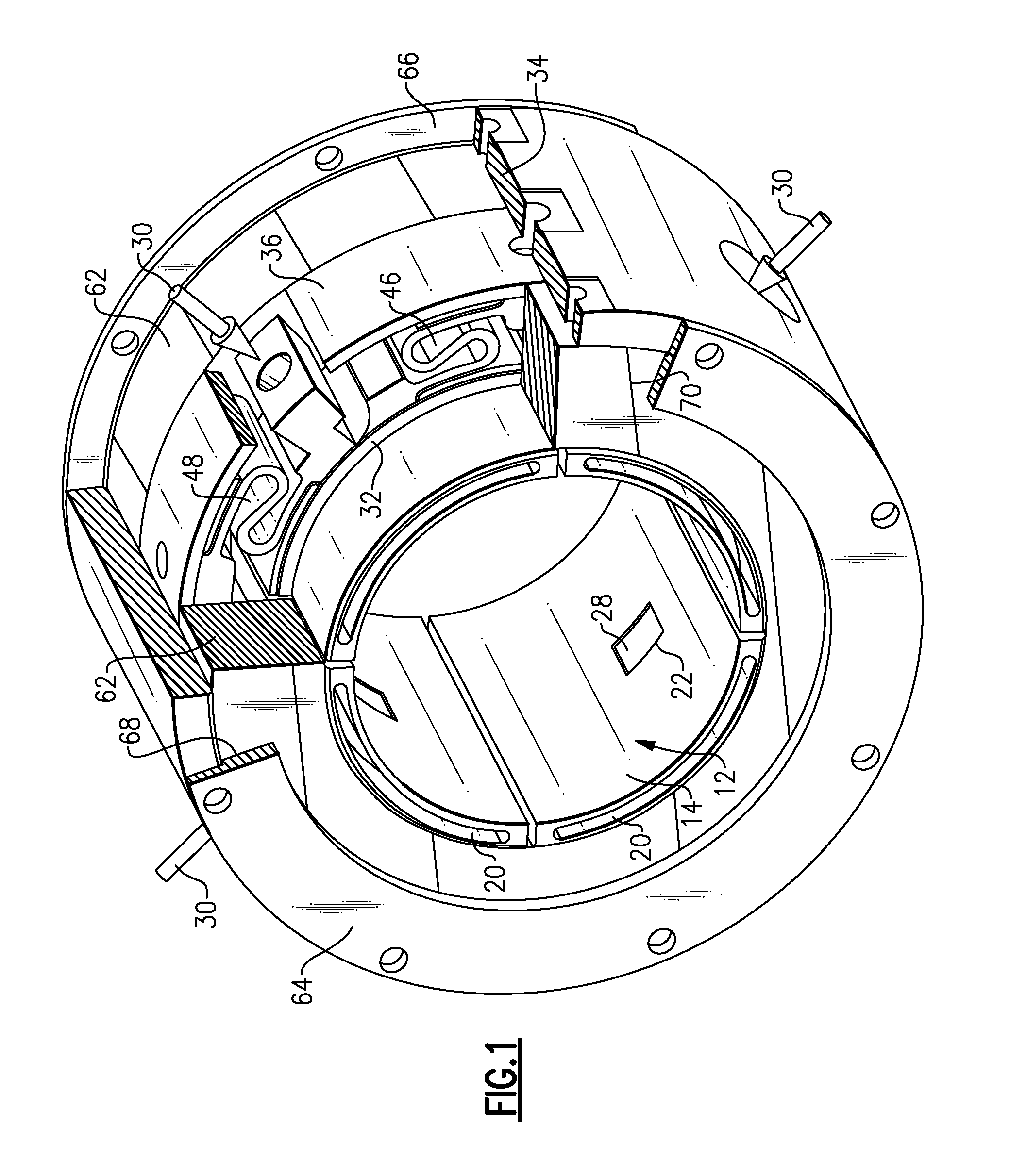

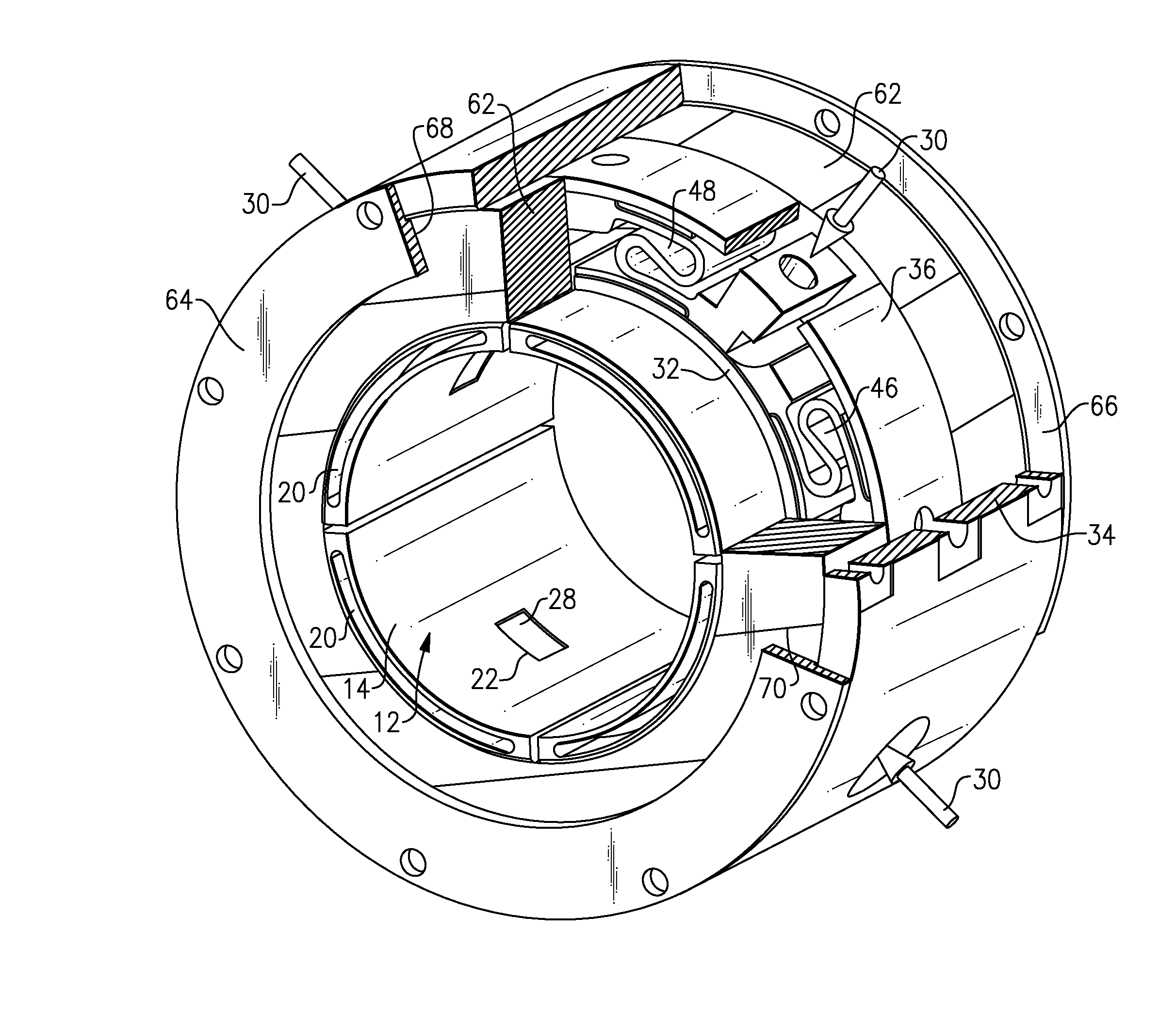

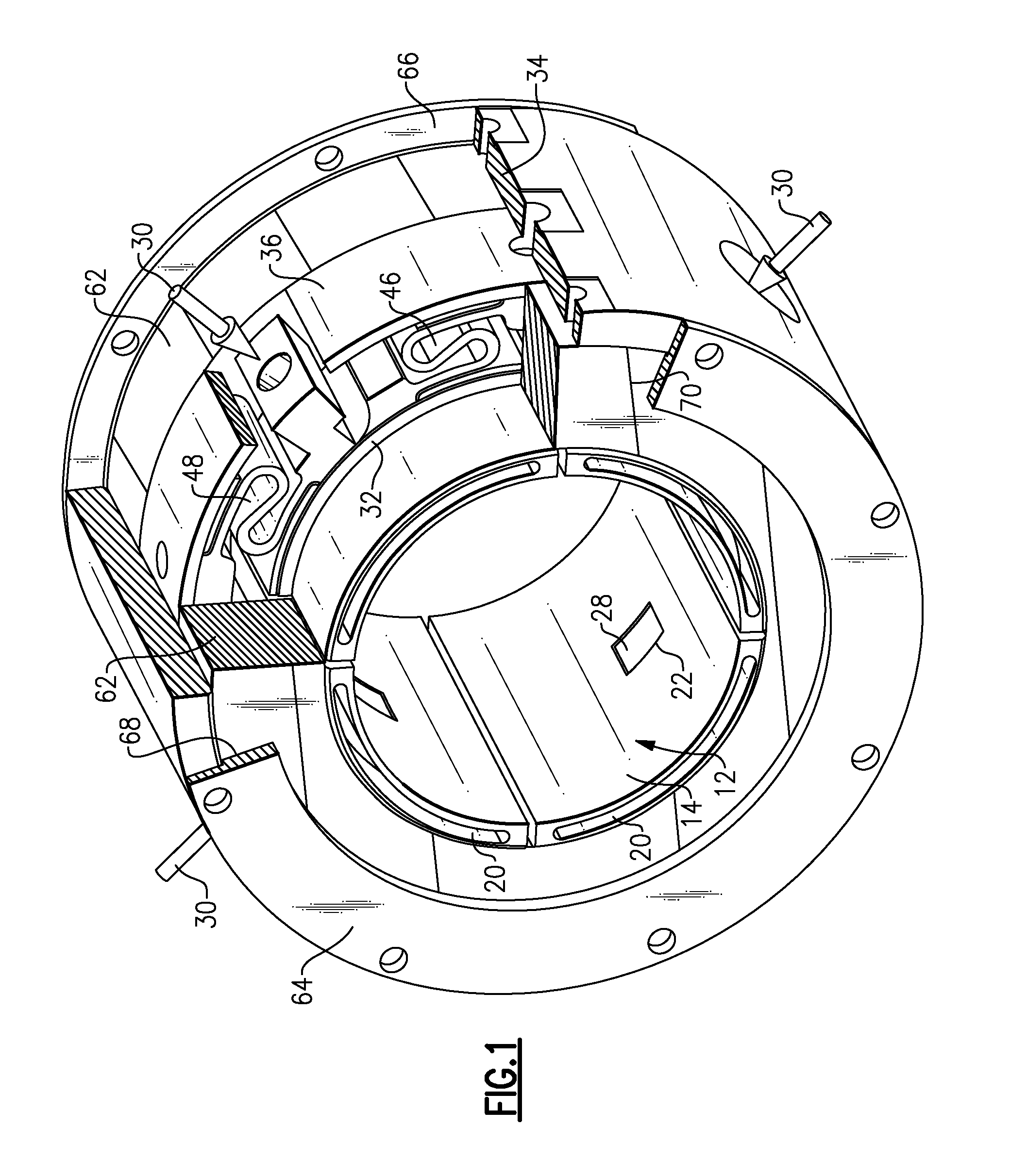

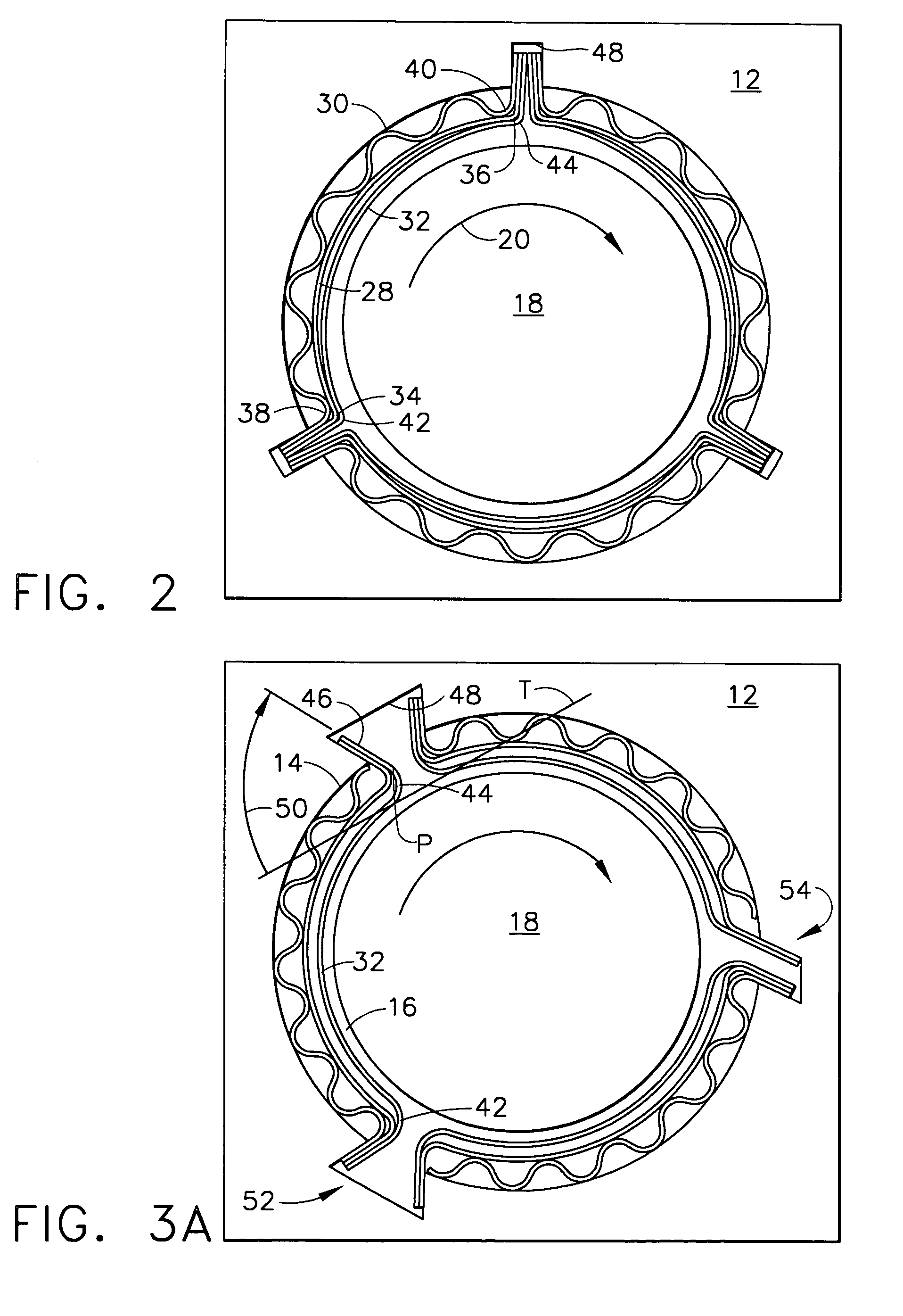

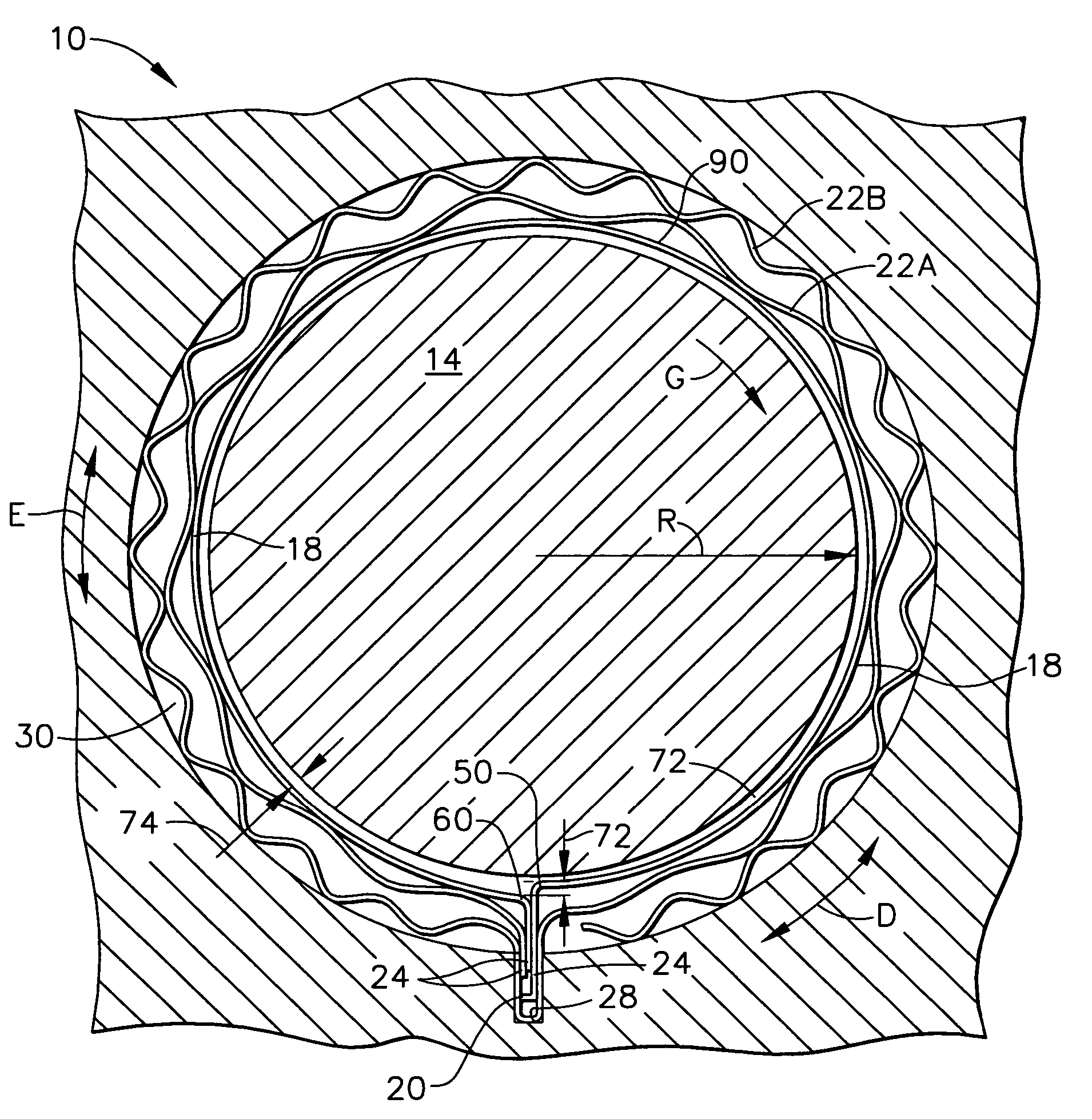

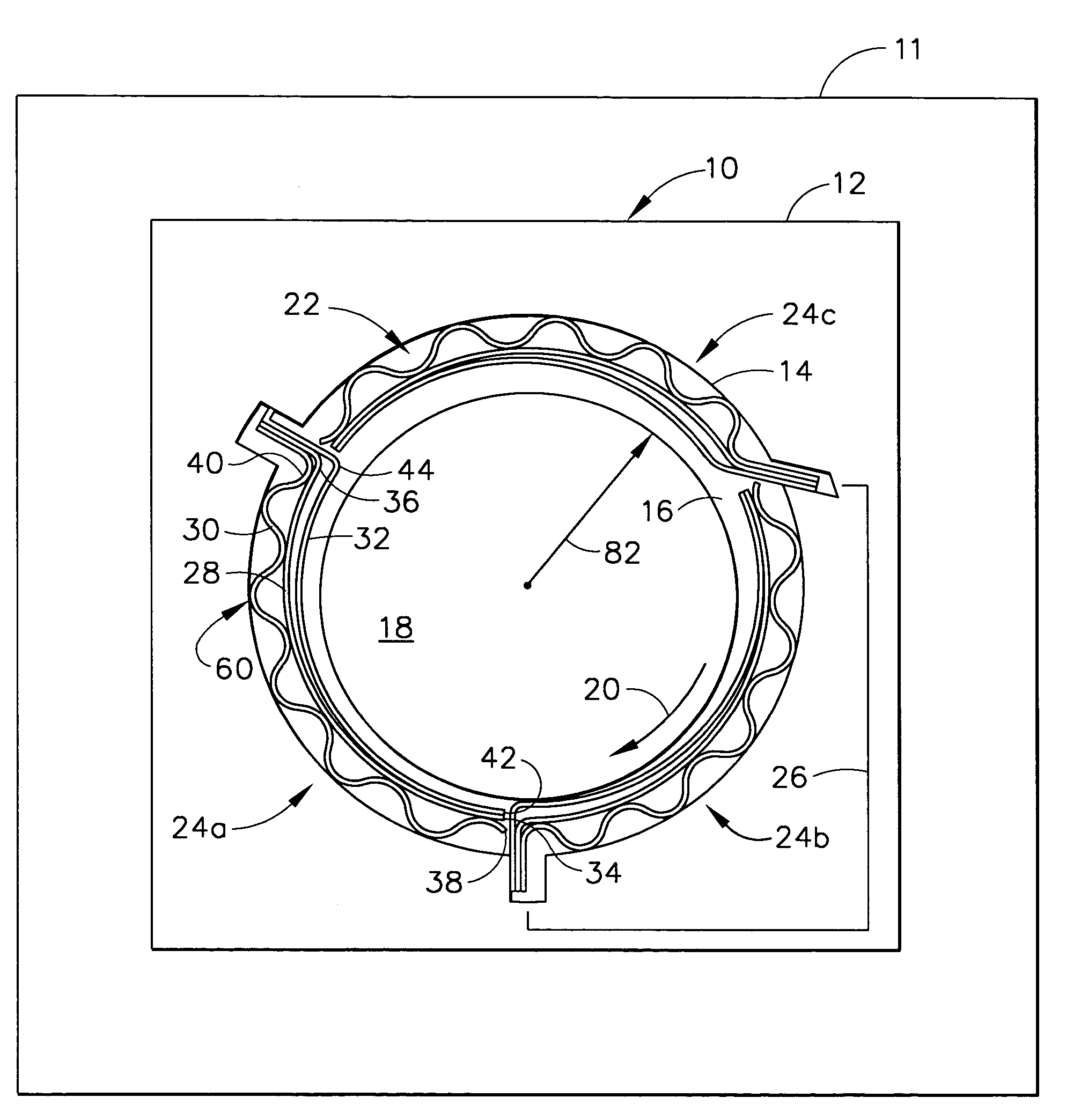

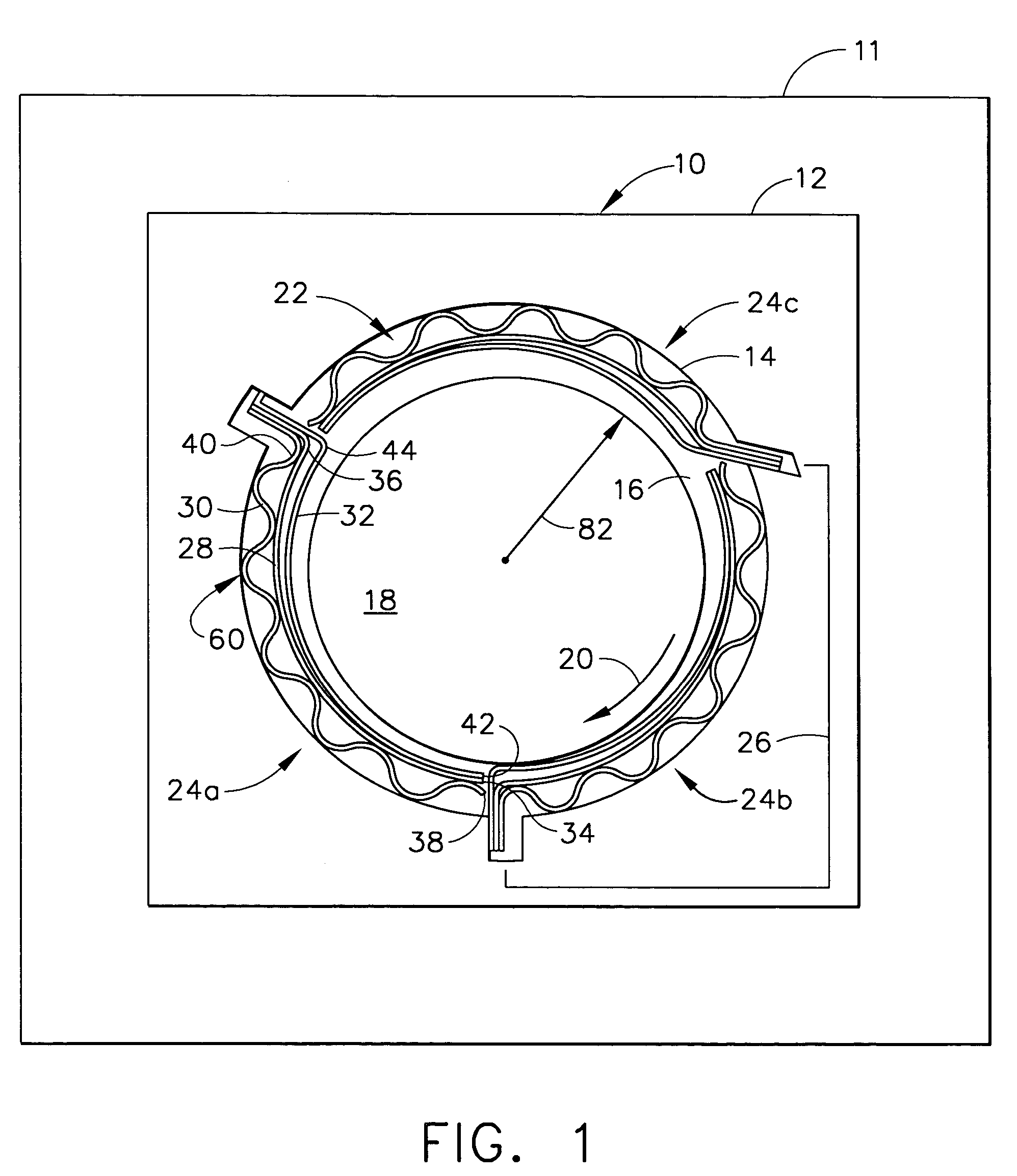

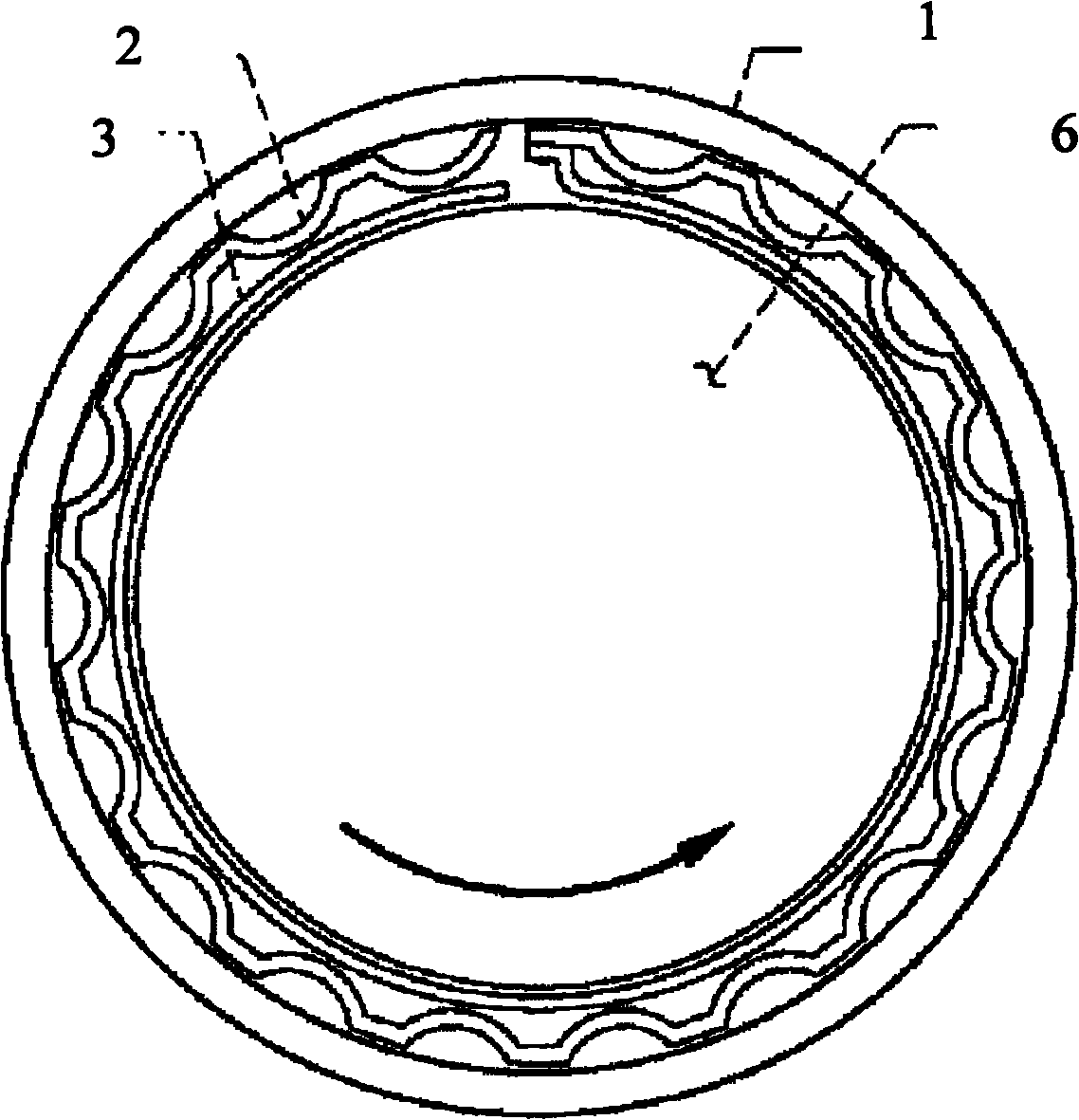

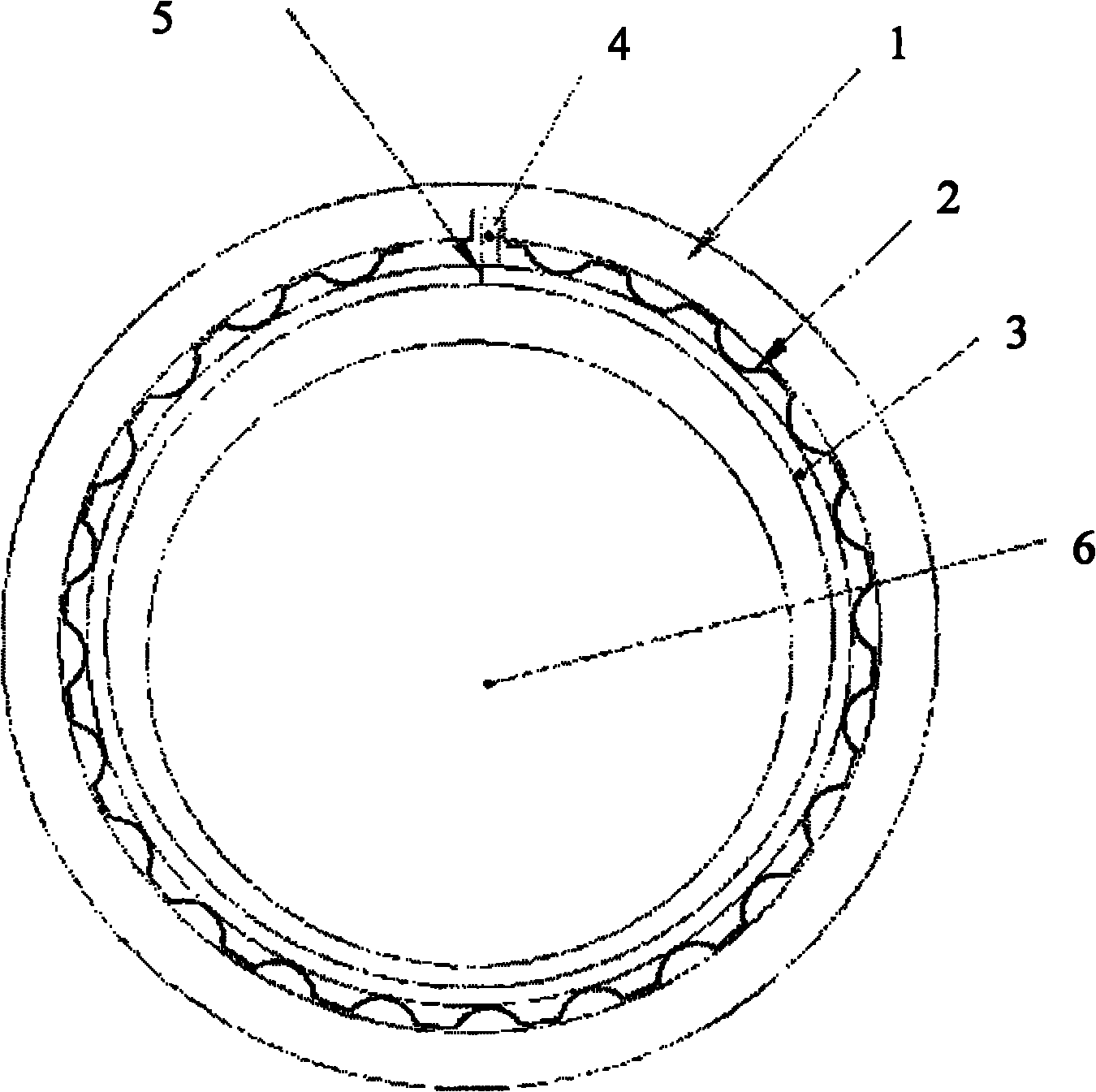

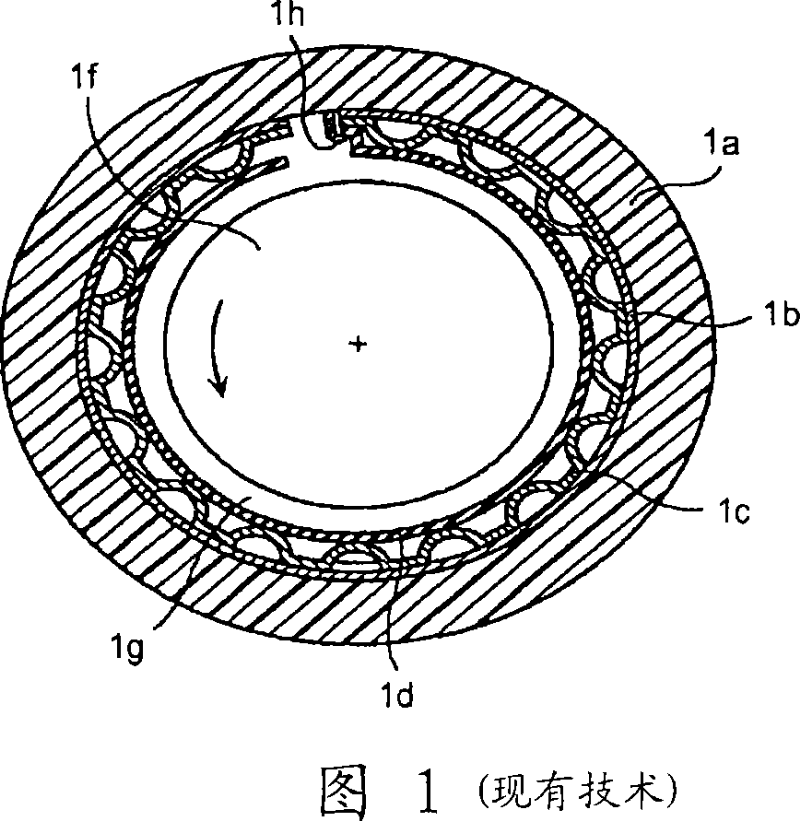

Hydrodynamic journal bearing

A journal foil bearing comprising a retaining member having an inner surface which defines a shaft opening within which a rotatable shaft is receivable for rotation; and a foil assembly affixed to and lining the inner surface and comprising a plurality of foil sub-assemblies each subtending a circumferential segment, of the inner surface. Each of the foil sub-assemblies may comprise an under foil sandwiched between a spring foil disposed radially outwardly of the under foil, and a top foil disposed radially inwardly of the under foil, the under foil, the top foil, and the spring foil each having a leading edge distal from a trailing edge in a direction of rotation of the rotatable shaft, and each of the under foil, the top foil, and the spring foil being affixed to the retaining member along their respective leading edge, their respective trailing edge, or both their respective leading edge and their respective trailing edge, wherein a radius of curvature of the top foil is less than a radius of curvature of the under foil. A method of supporting a rotating shaft is also disclosed.

Owner:HONEYWELL INT INC

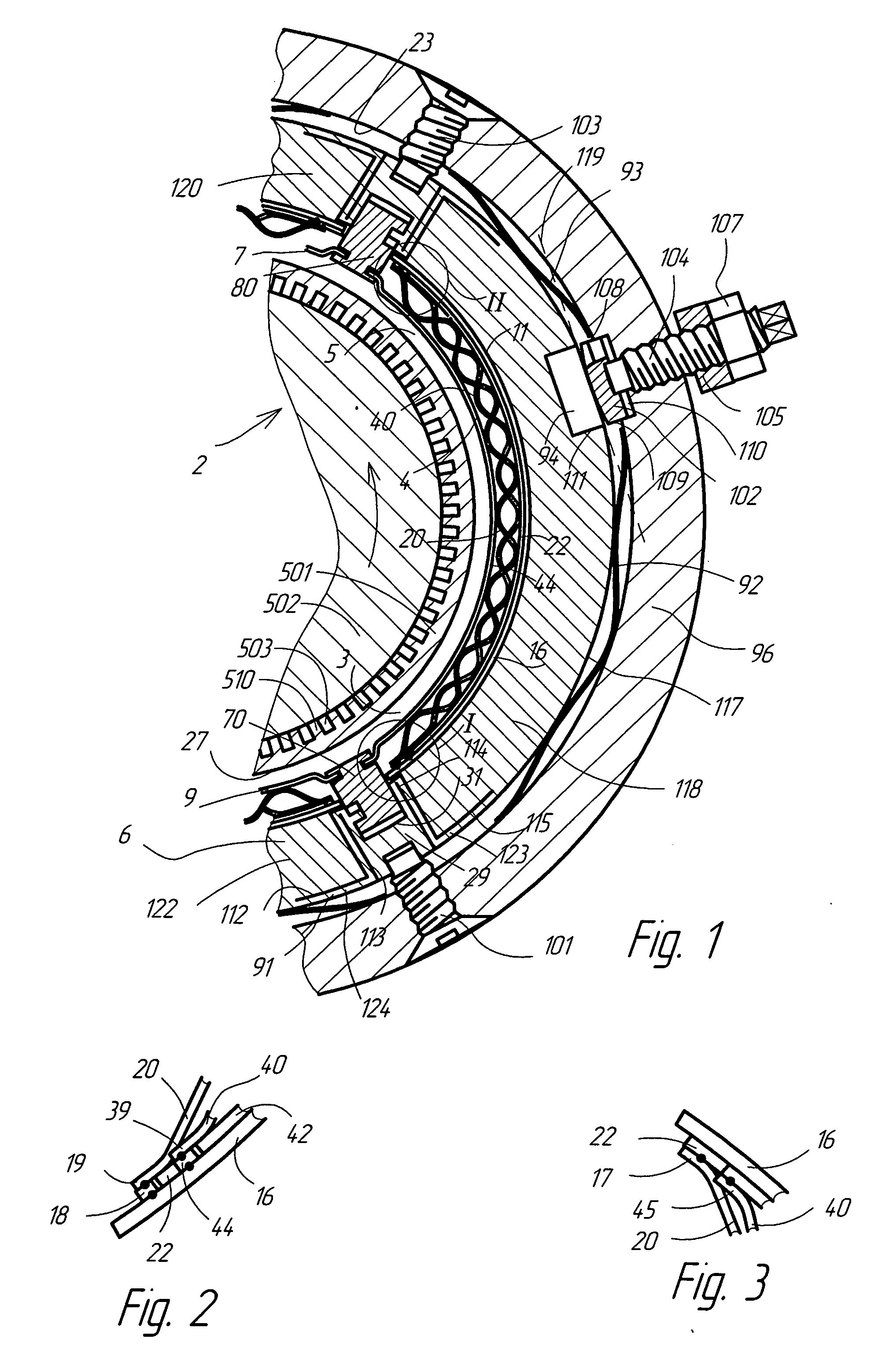

Foil bearing assembly

InactiveUS20150362012A1Reduce stiffnessConstant elastic member stiffnessRotary combination bearingsMagnetic bearingsEngineeringMechanical engineering

The bearing assembly comprises a radial foil bearing and an axial foil bearing, a control bearing preload device for controlling stiffness of the bearing under normal operating conditions, an electromagnetic unloading device for decreasing amplitude of rotor oscillations and an unloading means for increasing the ultimate bearing load without damaging bump foils. The radial foil bearing comprises a bushing 6 providing accommodating bearing misalignment with respect to the journal, an elastic member in the form of an elastic damping unit for increasing damping, which consists of a bump foil 20 and two smooth foils 16 and 22. The bump foils in the bearing have different heights and alternate in the axial direction to decrease wear under start / stop. A top foil 4 of the bearing is weldlessly retained within slots of mounting bars 70 and 80. The axial bearing has the bump foil with ridges circumferentially extended in order for the bearing to work in sealing mode. The top foils of the bearing are provided with circumferential slits in order to decrease thermal stress.

Owner:ERMILOV YURY IVANOVICH

Hydrodynamic journal foil bearing system

A high load capacity hydrodynamic journal foil bearing system is disclosed, which comprises a top foil and a plurality of undersprings. Preload forces are transferred from the undersprings to internal circumferential compressive forces within a top foil, resulting in low preload forces against the shaft, allowing the shaft to expand at high speeds without increasing the preload forces or overloading the fluid film. One underspring may have a different spring rate than another underspring. The top foil may be normalized to shaft shape and dimensions. These features may be accomplished with using less mechanical parts than other journal foil bearing system designs.

Owner:HONEYWELL INT INC

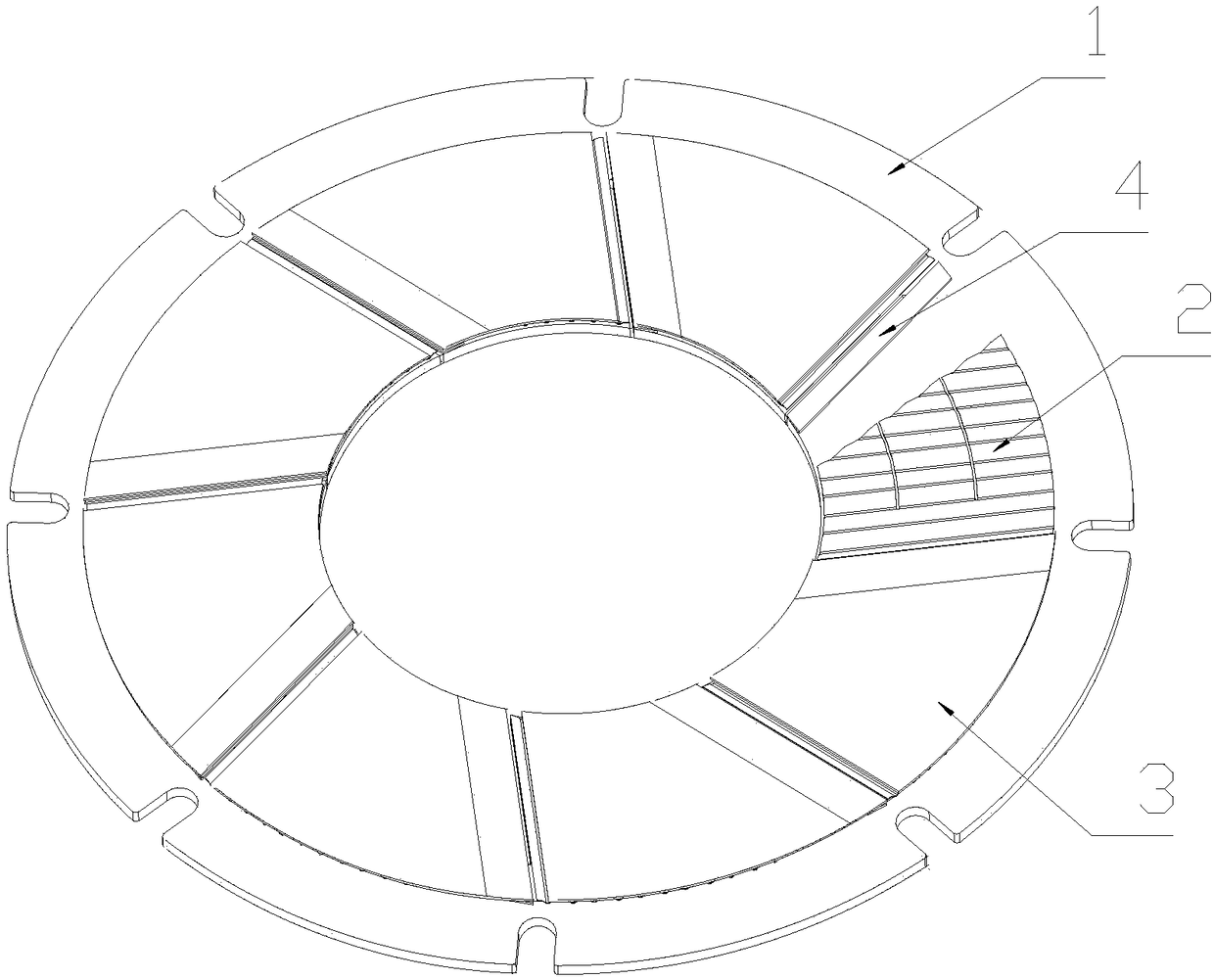

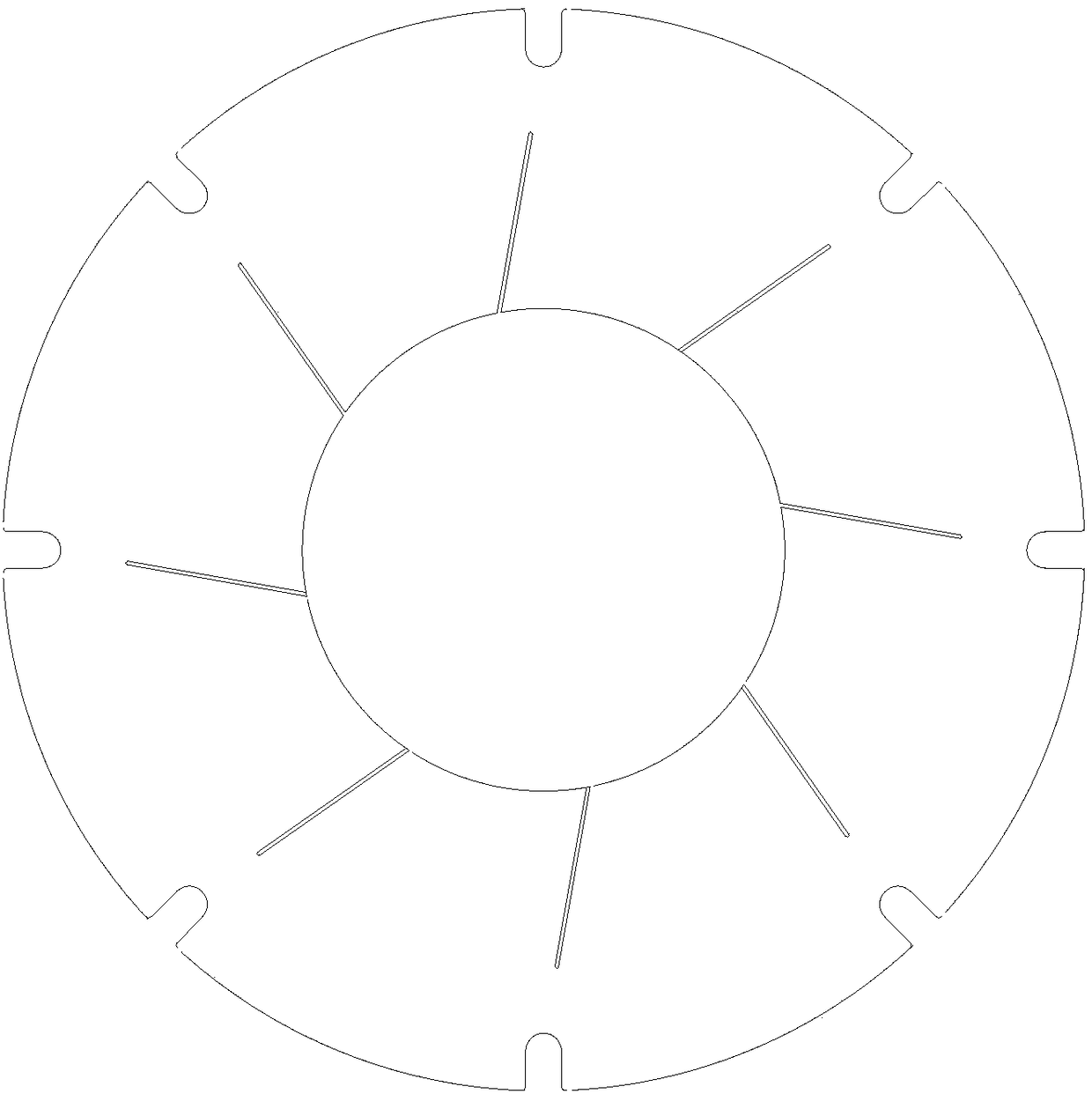

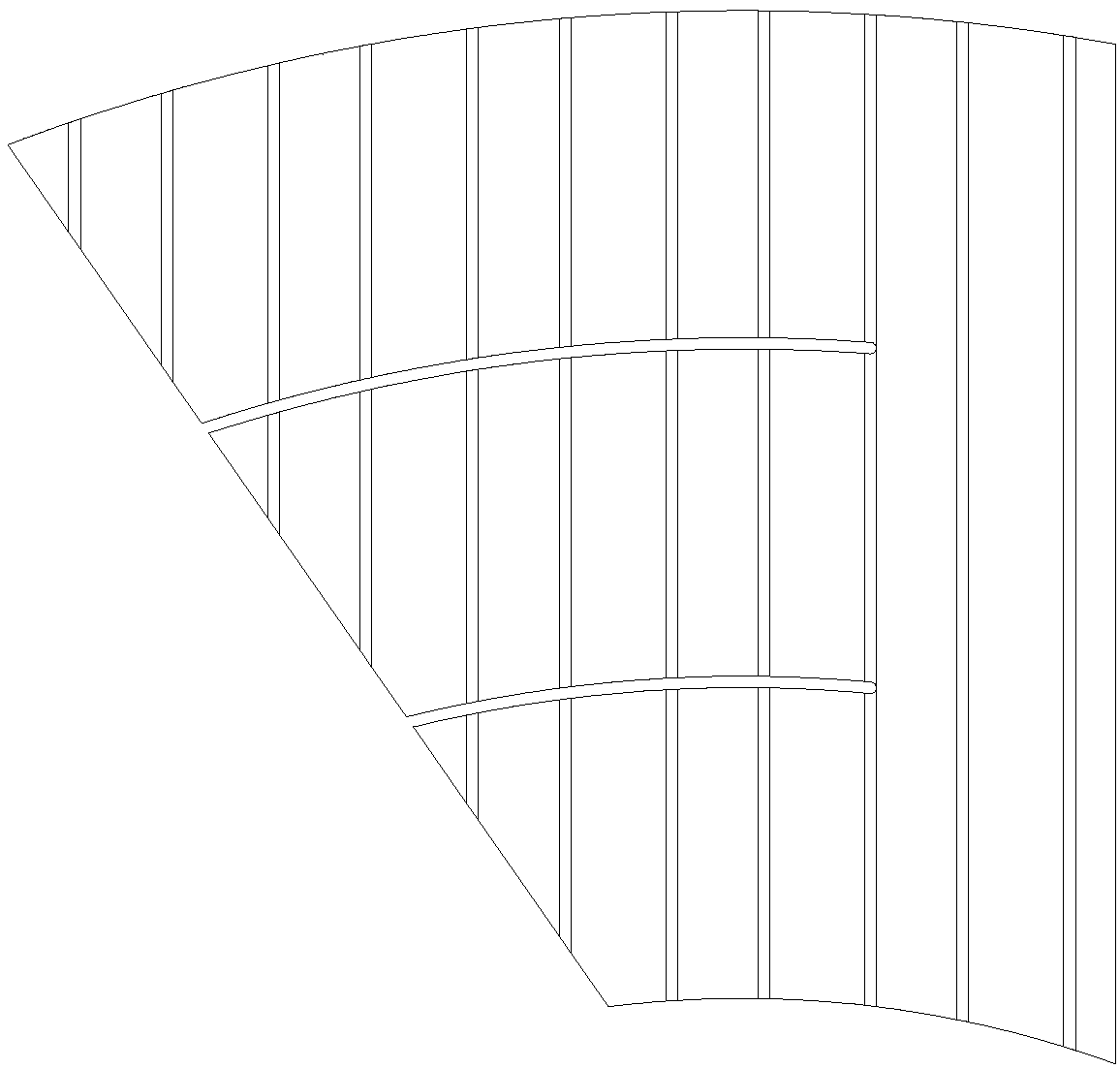

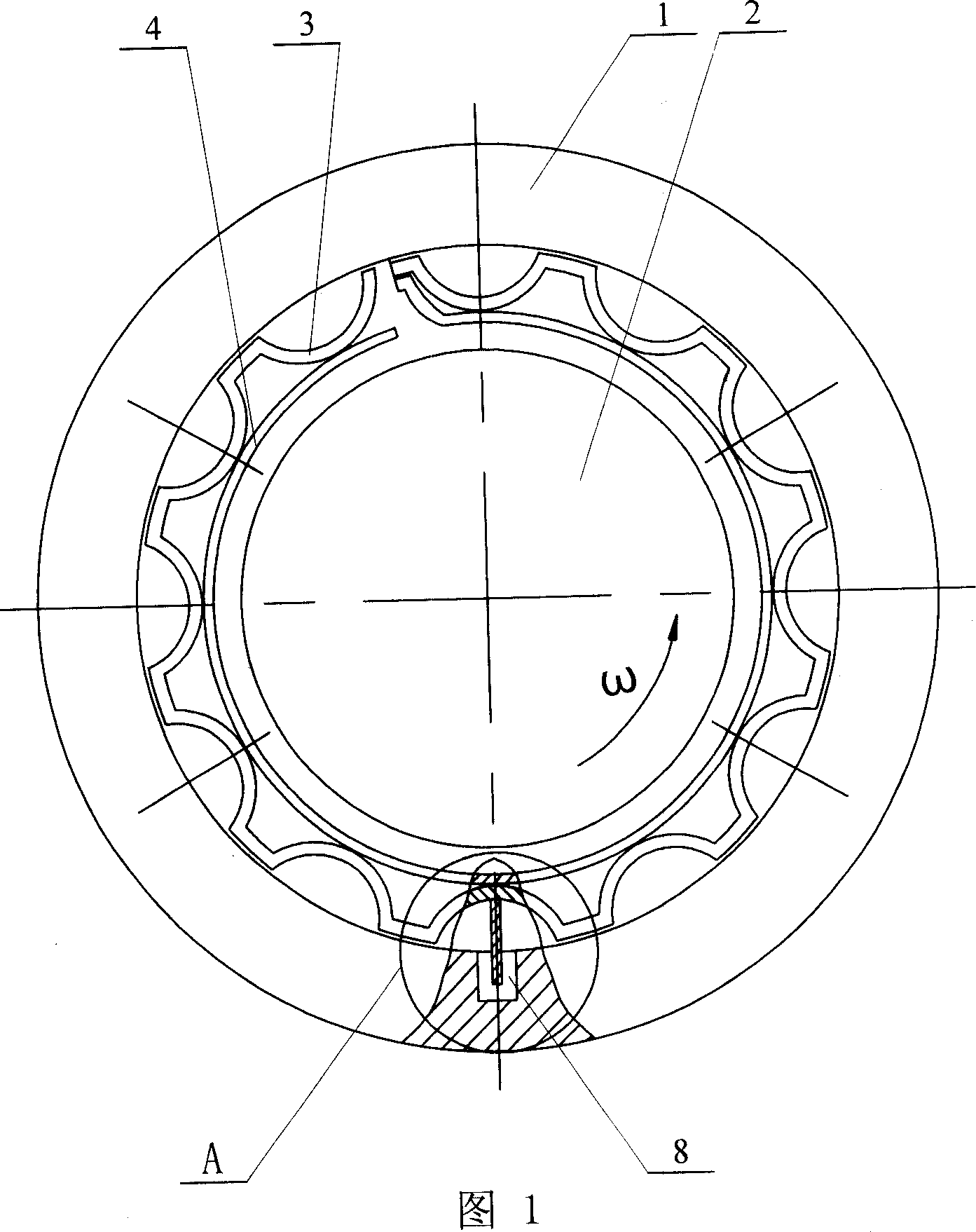

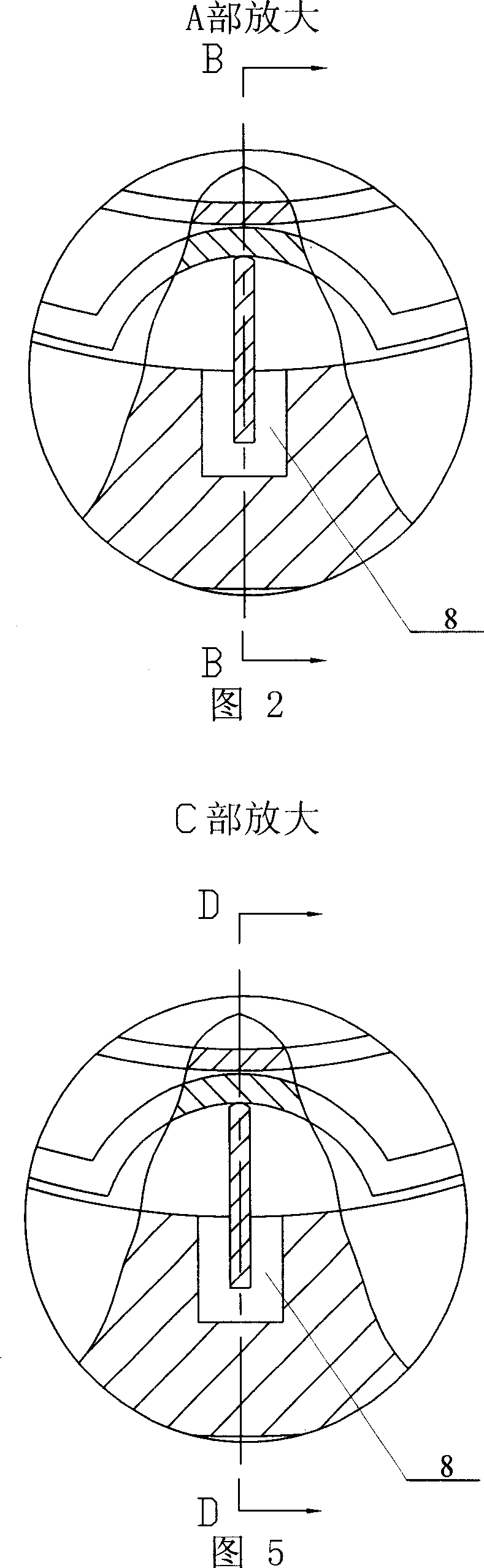

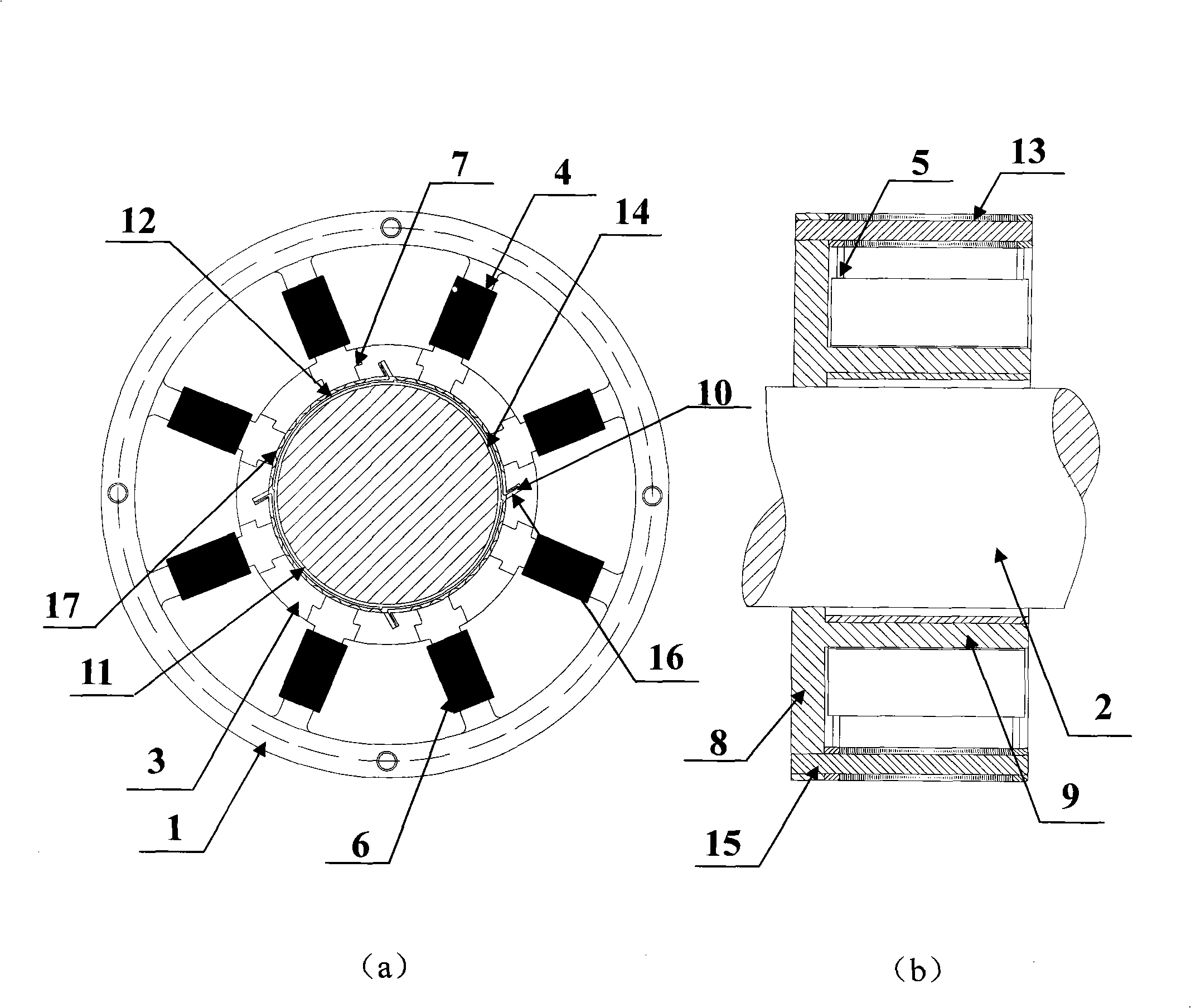

Thrust foil dynamic pressure air bearing with thick top foil structure

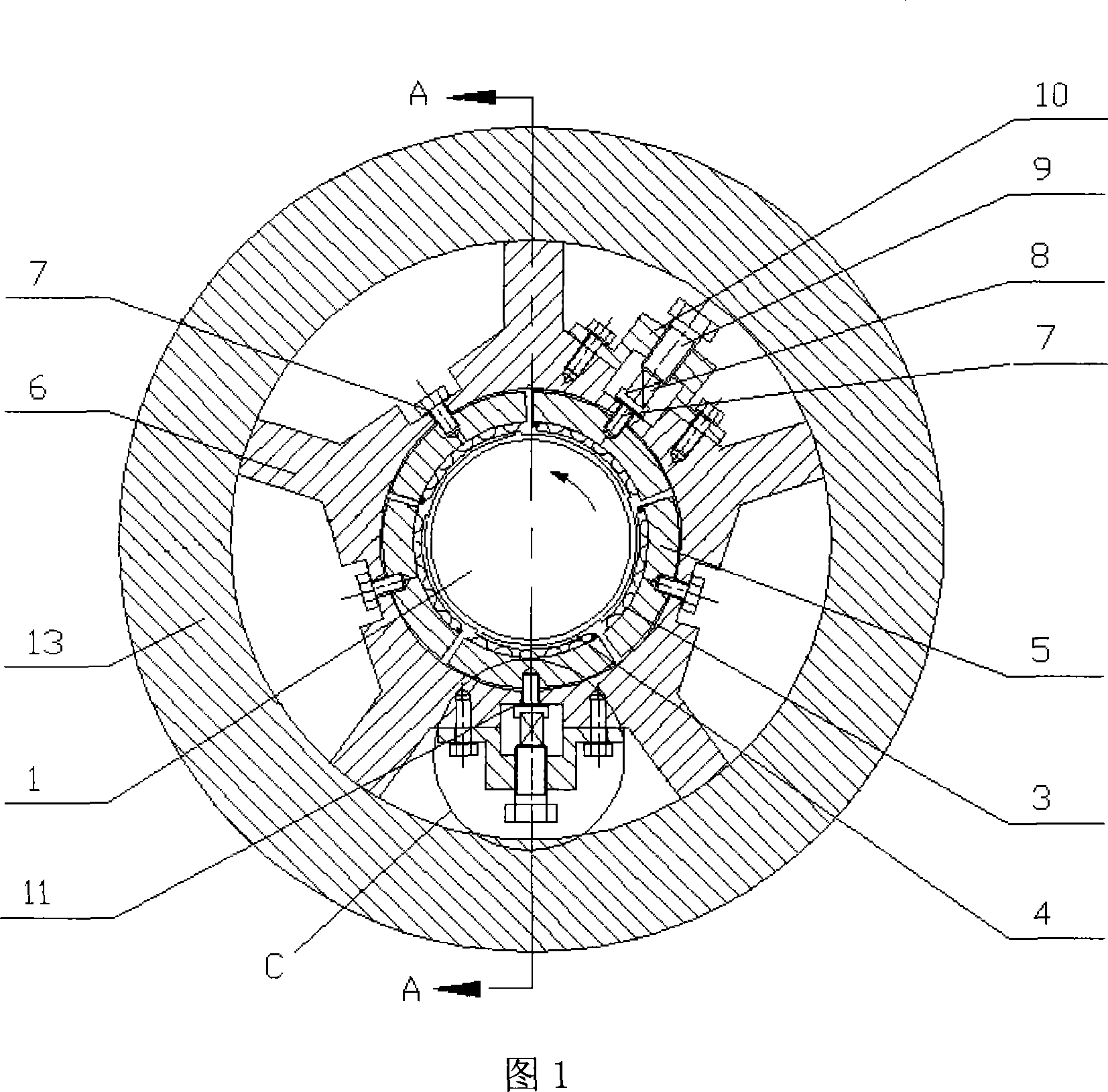

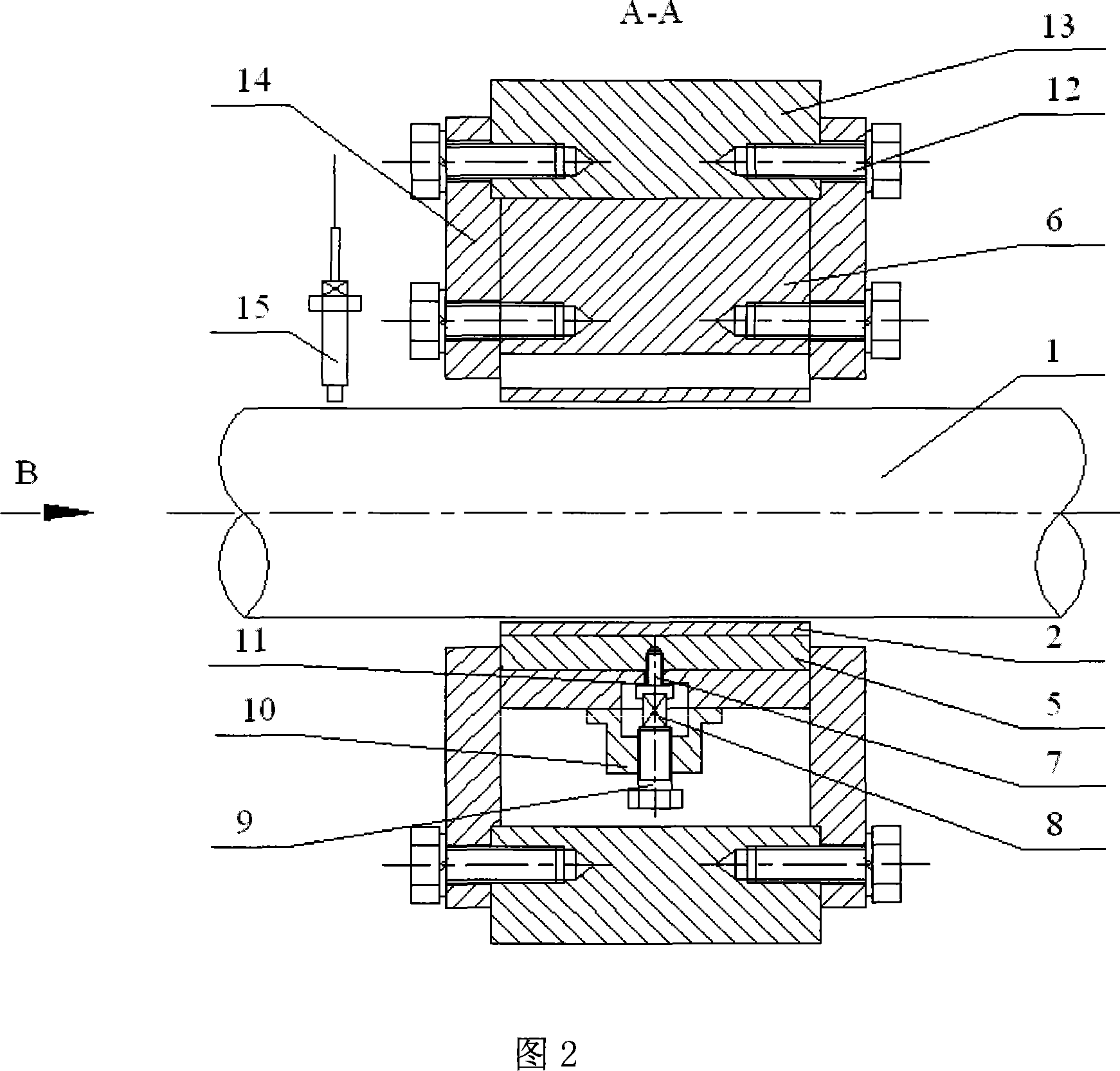

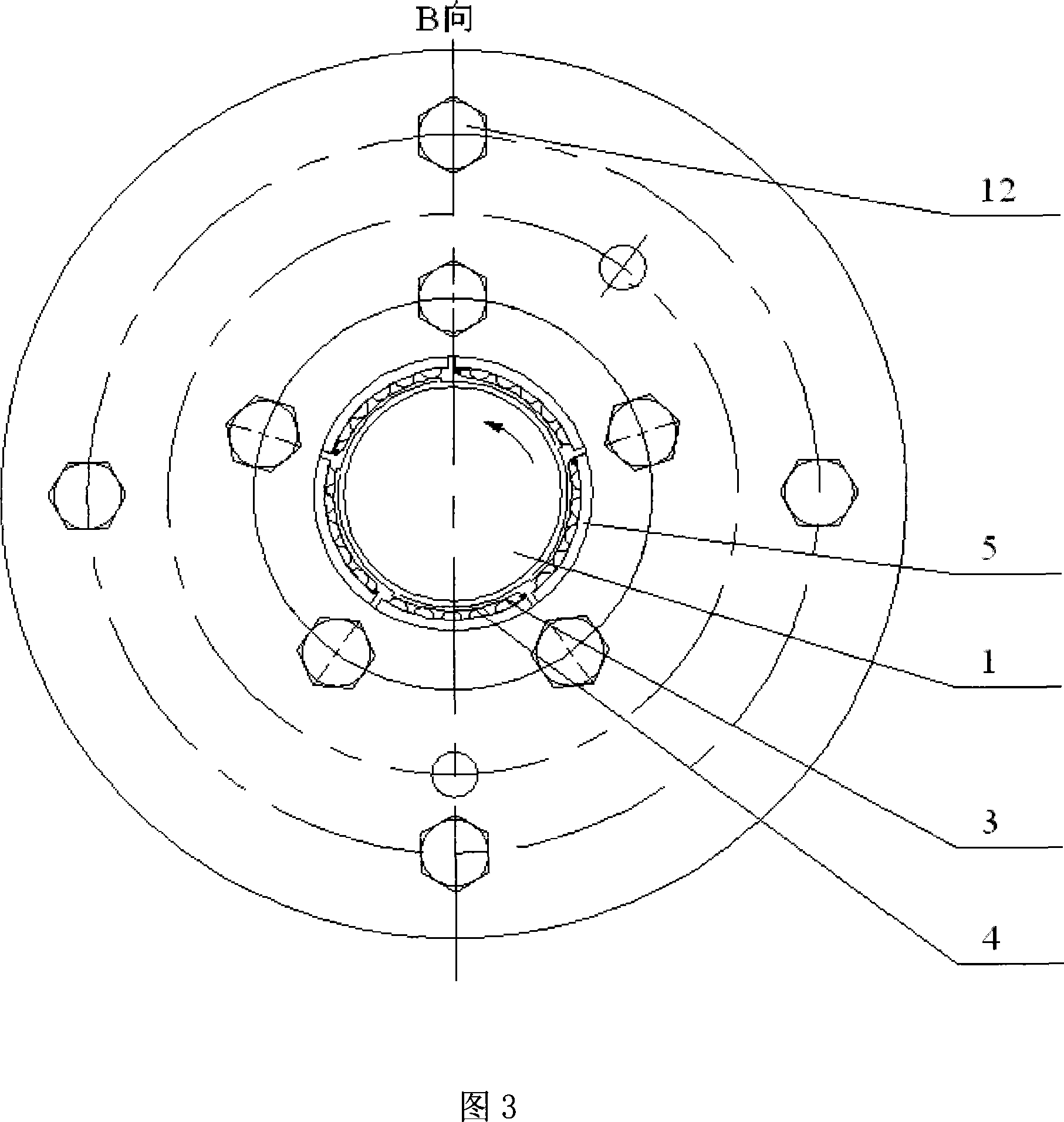

ActiveCN108286567AReduced Consistency Accuracy RequirementsImprove bearing capacityBearing componentsSliding contact bearingsAir bearingThrust bearing

The invention relates to a thrust foil dynamic pressure air bearing with a thick top layer foil structure. The thrust foil dynamic pressure air bearing comprises a bottom plate (1), supporting wave foils (2) and top foil sheets (3), wherein the round bottom plate (1) are arranged on the lower part, the plurality of fan-shaped top foil sheets (3) are fixed above the bottom plate, and the supportingwave foils (2) are assembled on the bottom plate (1) and the top foil sheets (3); the bearing is characterized by further comprising inlet section gaskets (4) are arranged on one side in the radial direction of the joint of the top foil sheets (3) and the bottom plate (1), and the thickness of the inlet section gaskets (4) is adjustable; and the thickness of the top foil sheets is 0.5 mm to 1 mm,the support wave foils (2) and the top foil sheets are assembled in a pre-tightening mode, and the shape variable of the supporting wave foils is 0.01 mm-0.02mm. On one hand, the requirement for theconsistency precision of the foil bearing on the support wave foils is lowered, and meanwhile, the problem of foil deformation of the inlet sections of the top foil sheets of the thrust bearing is solved, so that the thickness shape of the gas film of the inlet section is basically unchanged, and the bearing capacity of the bearing is improved.

Owner:SHIJIAZHUANG KINGSTON BEARING TECH

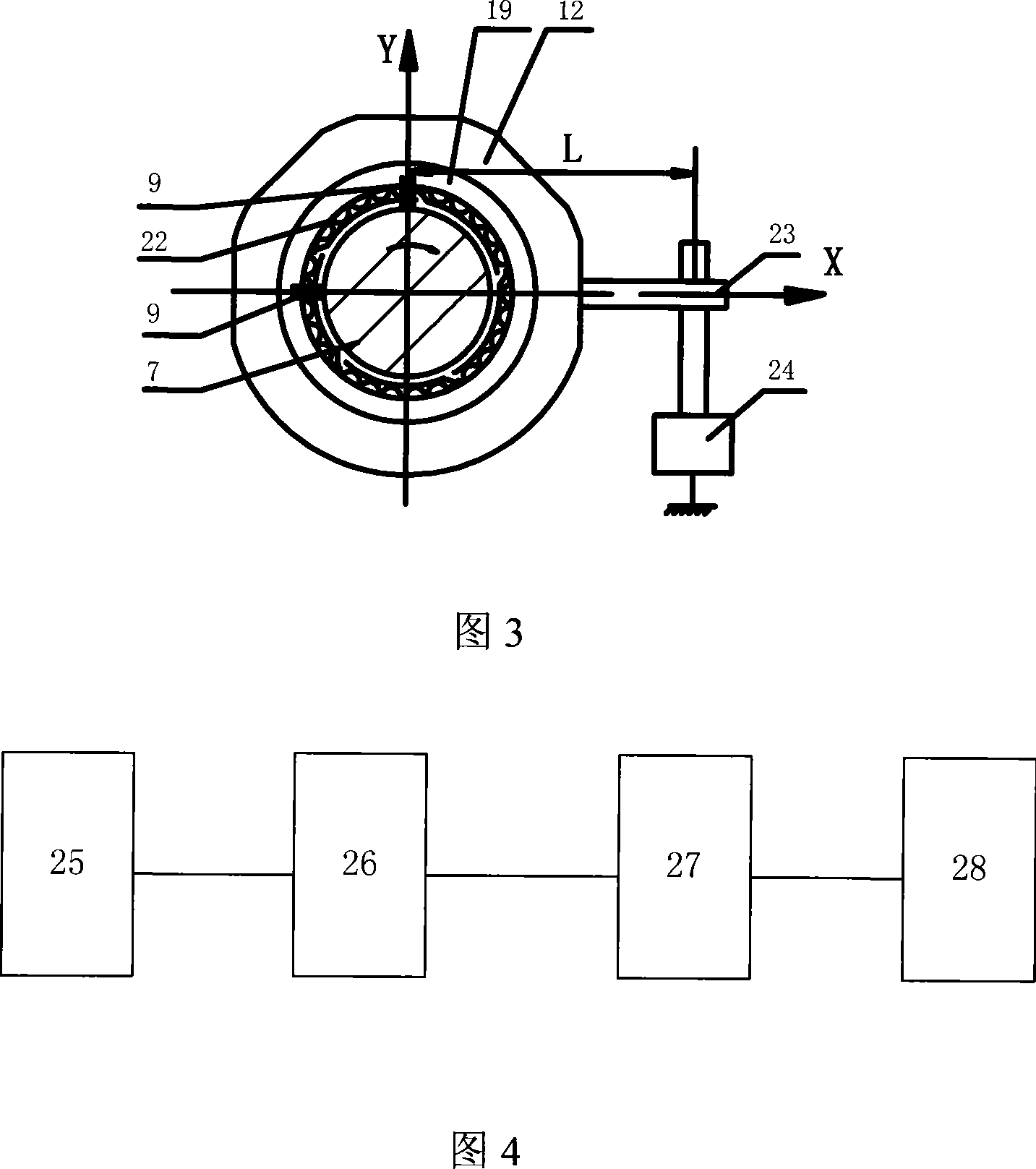

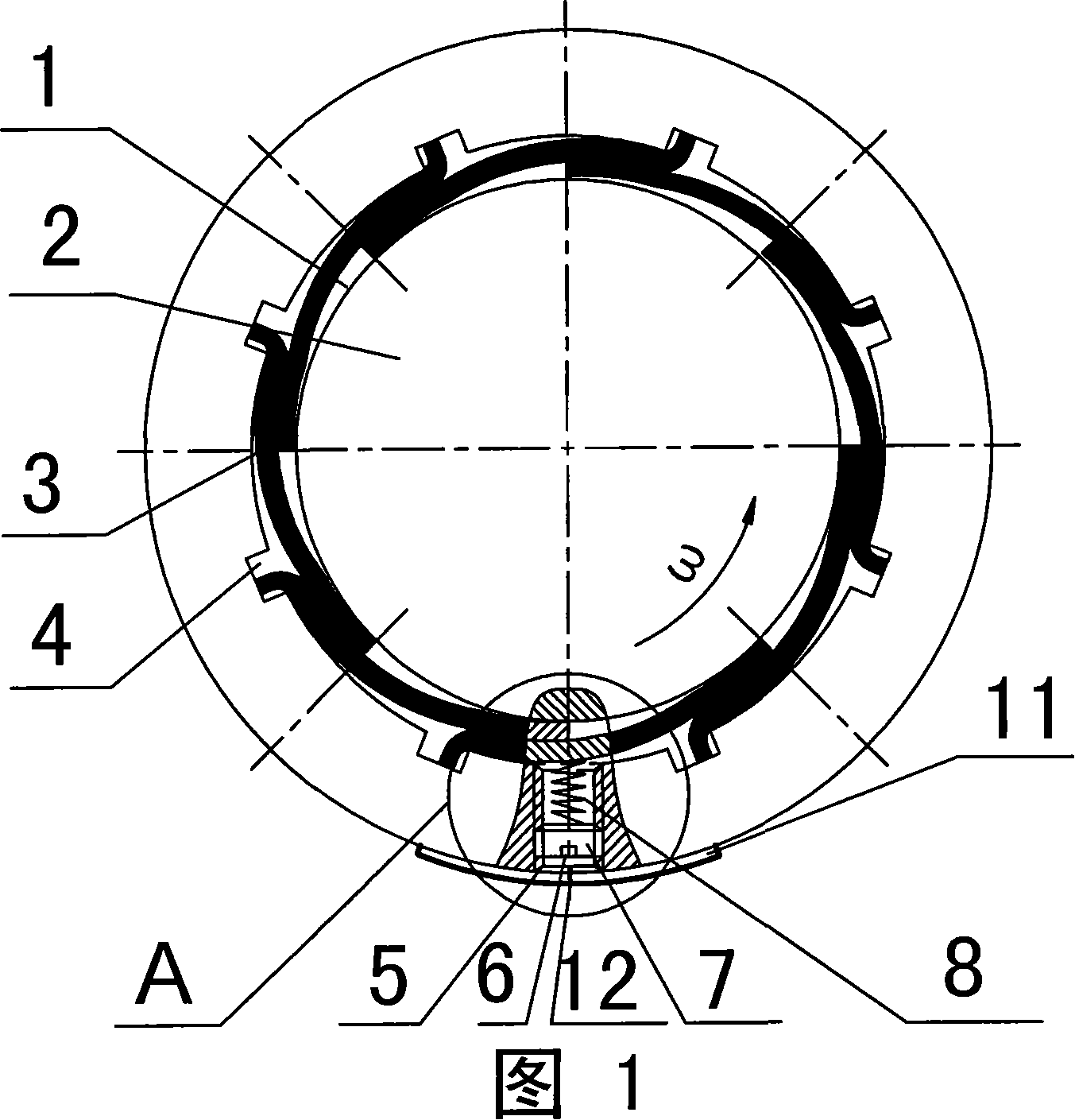

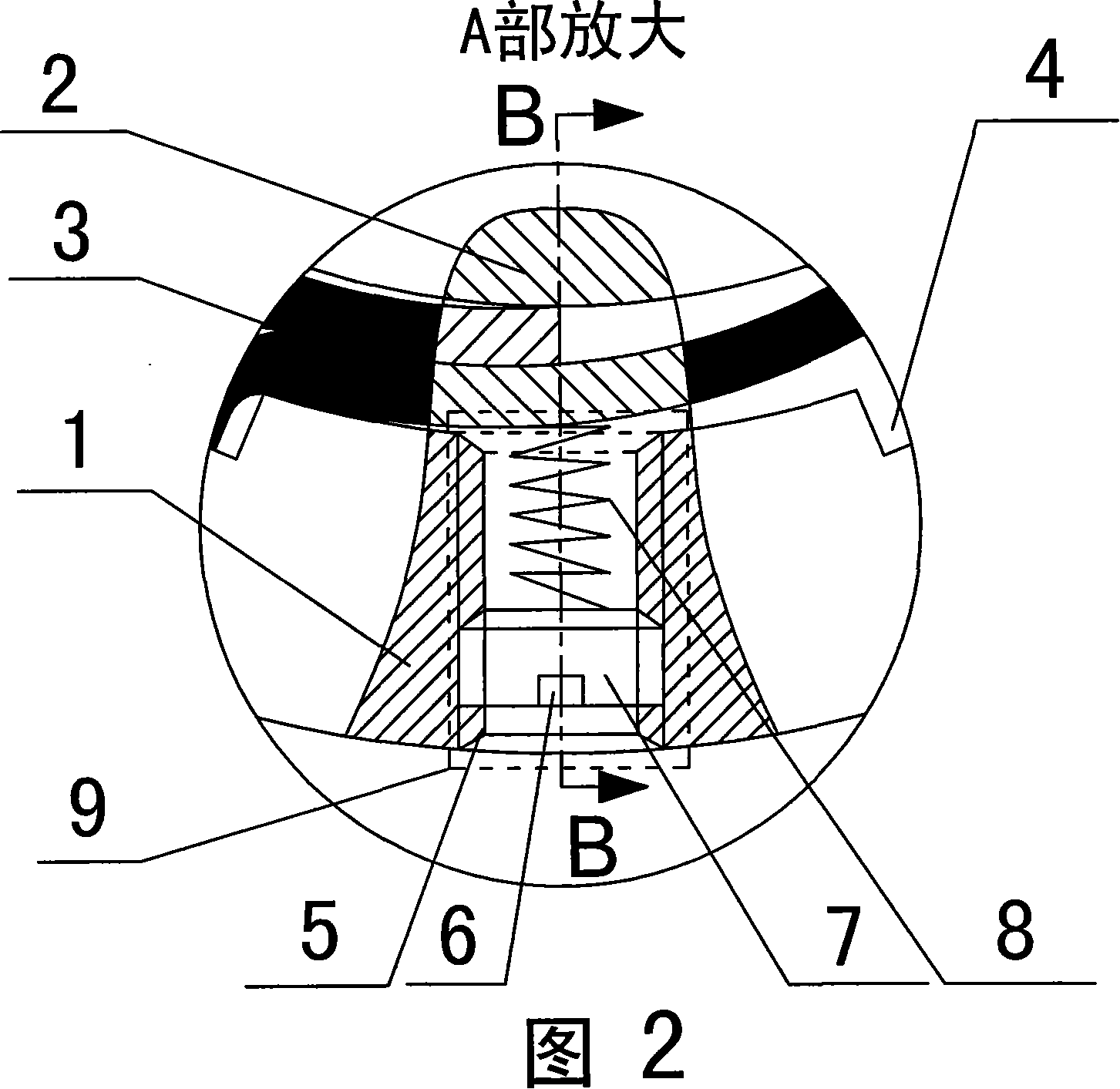

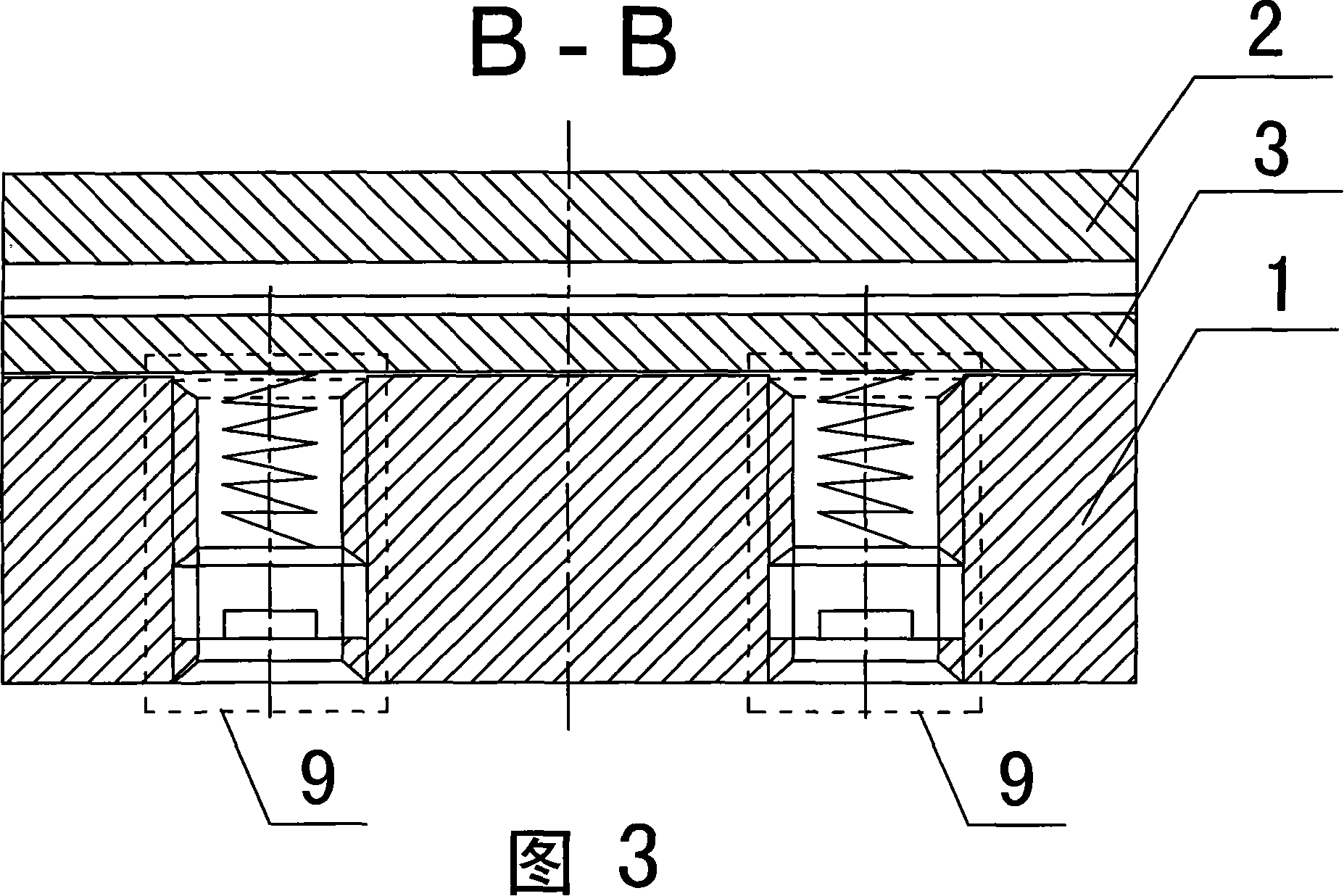

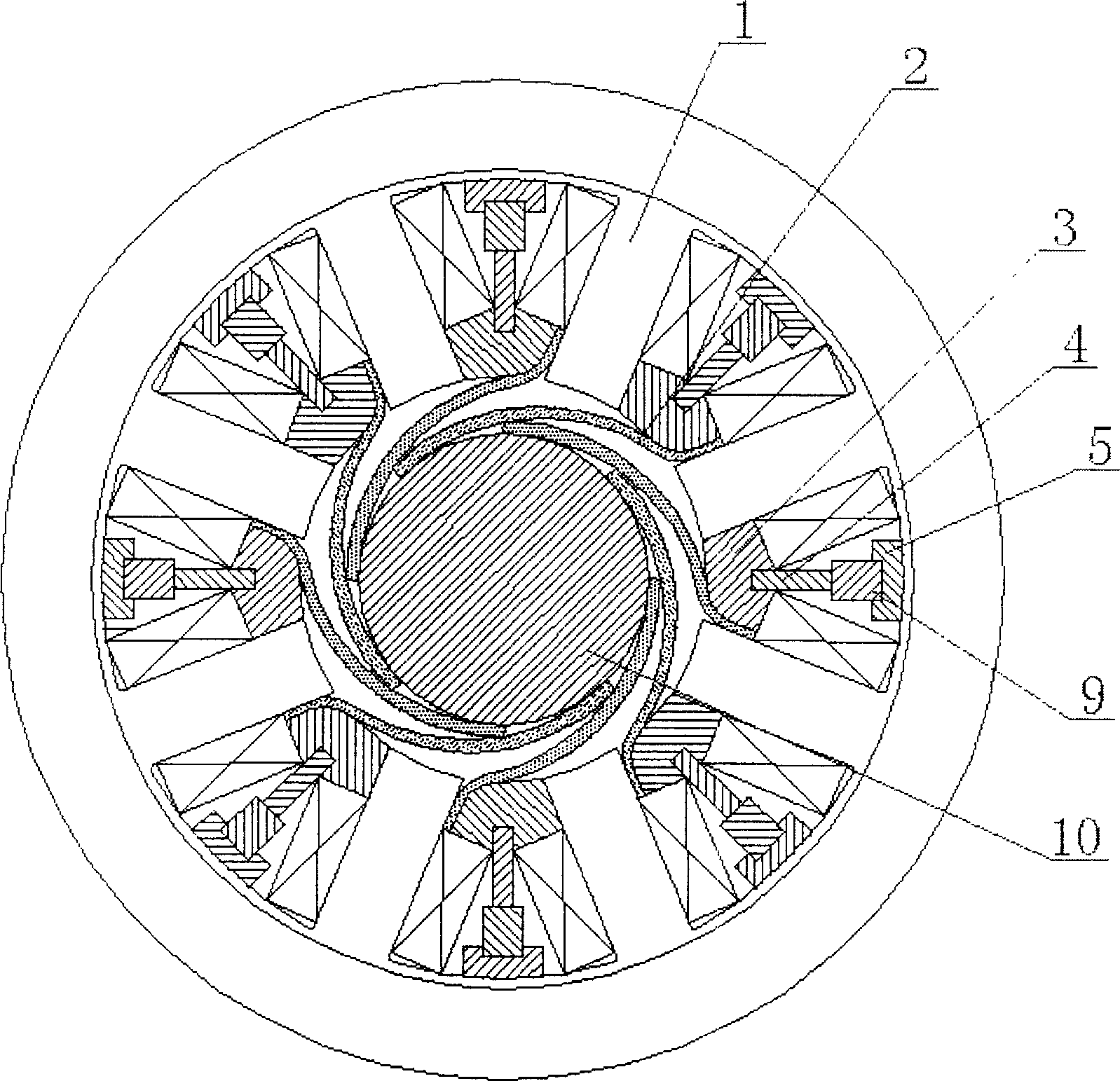

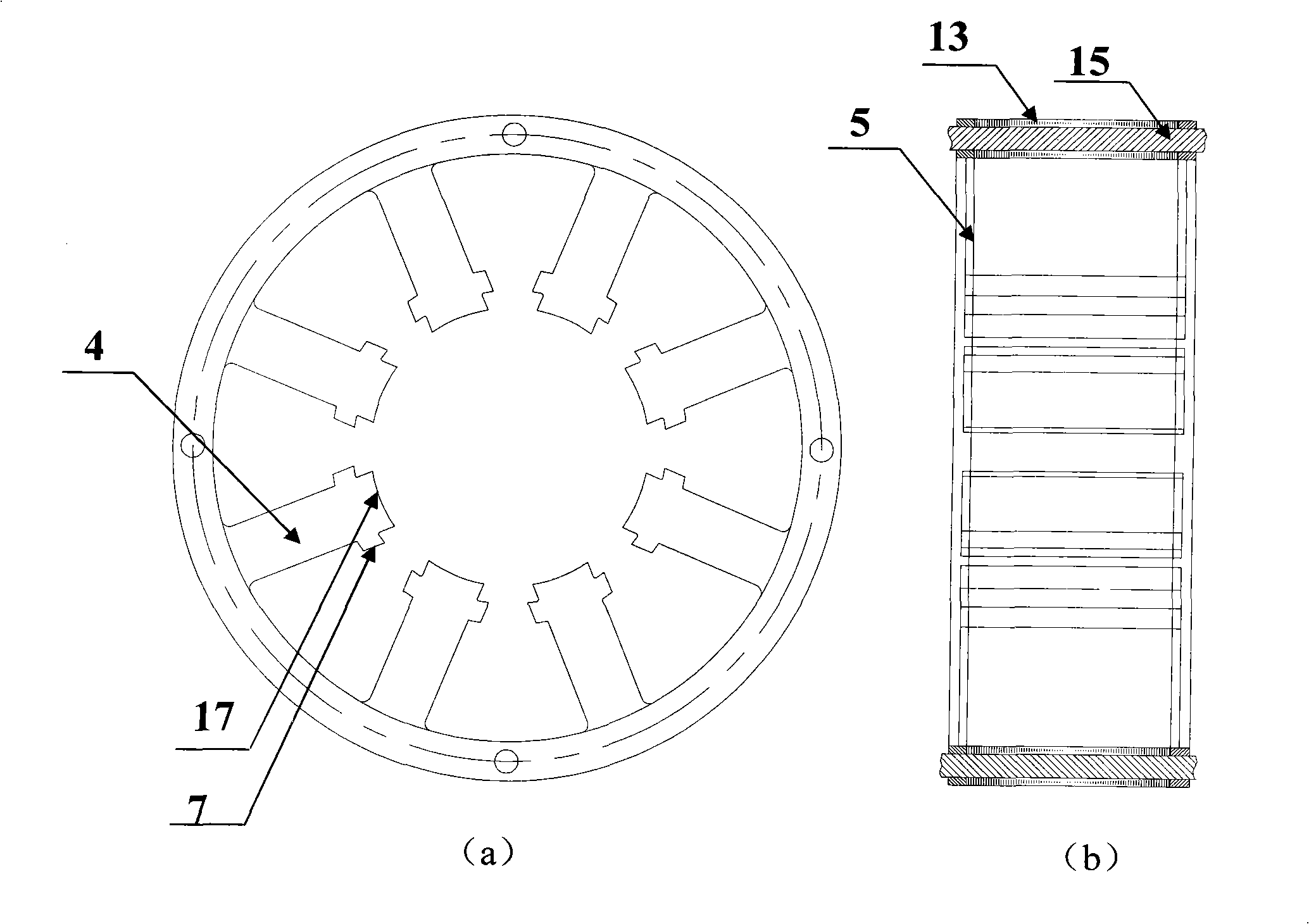

Dynamical pressure gas elasticity foil tablet bearing with stability self-adaptive control function

InactiveCN101225853ARealize micro-displacement control requirementsImprove displacement control accuracyNon-rotating vibration suppressionBearingsDisplacement controlEngineering

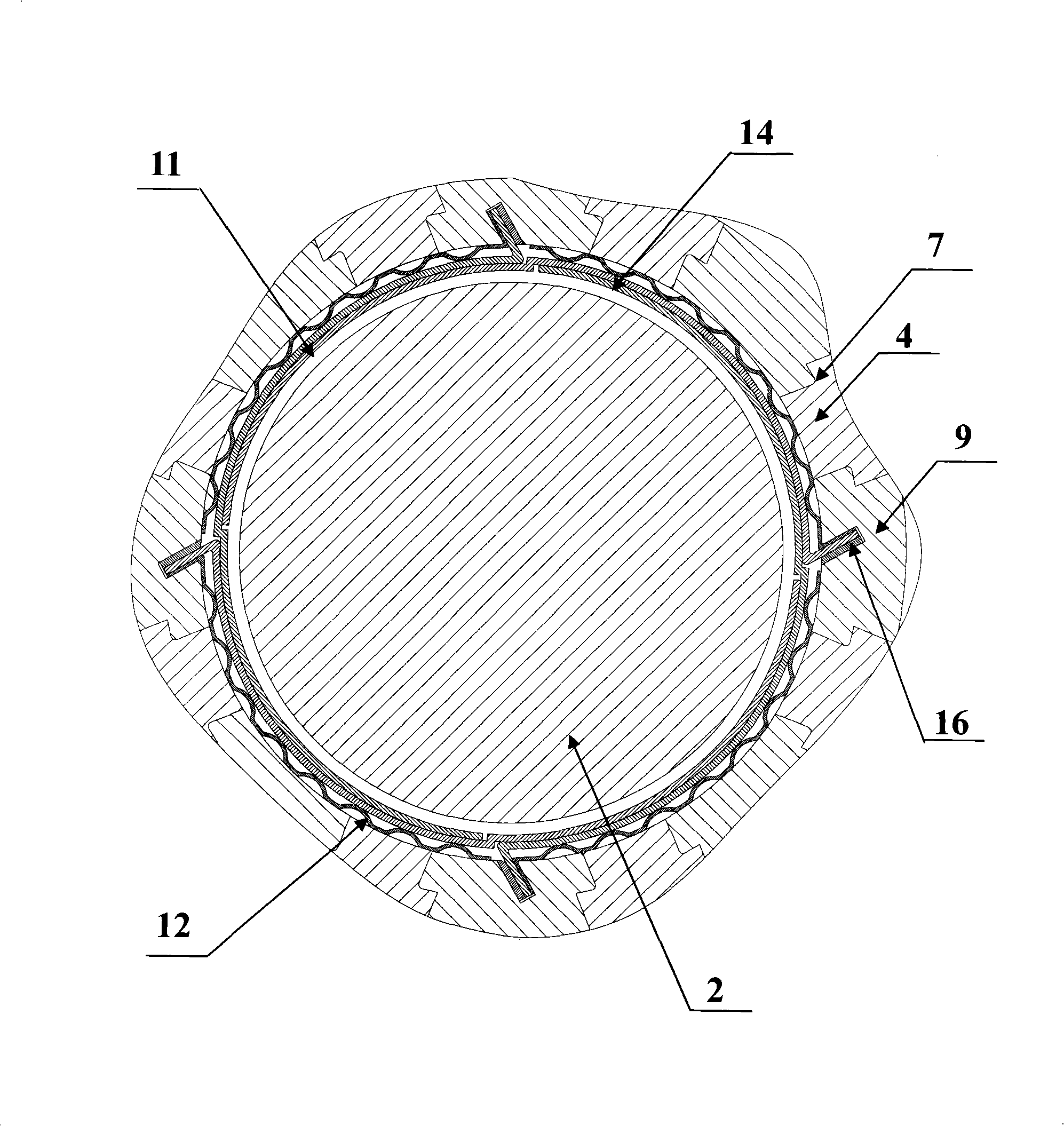

The invention relates to a dynamic gas elastic foil bearing with stability and adaptive control functions, comprising a bearing casing, a plurality of bearing pads, an elastic foil, and a piezoelectric ceramics micro displacement actuator. The dynamic gas elastic foil bearing is characterized in that the bearing pads are uniformly distributed along the inner wall of the bearing casing; the bearing pads are welded with a bottom bump foil and one end of a top foil; the other end of the top foil is lapped over an adjacent top foil, wherein the piezoelectric ceramics micro displacement actuator with one end fixed on a set screw and the other end arranged on a jig is connected with two bearing pads; the piezoelectric ceramics micro displacement actuator is connected with a feedback controller PID; an input of the feedback controller PID is connected with an eddy current displacement sensor. The dynamic gas elastic foil bearing with stability and adaptive control functions has the advantages of strengthened equivalent rigidity and equivalent damping of the elastic foil, restrained vibration of rotor system, improved bearing capacity and stability of the bearing, reduced size and structure, increased control precision of displacement, and quickened response speed.

Owner:XI AN JIAOTONG UNIV

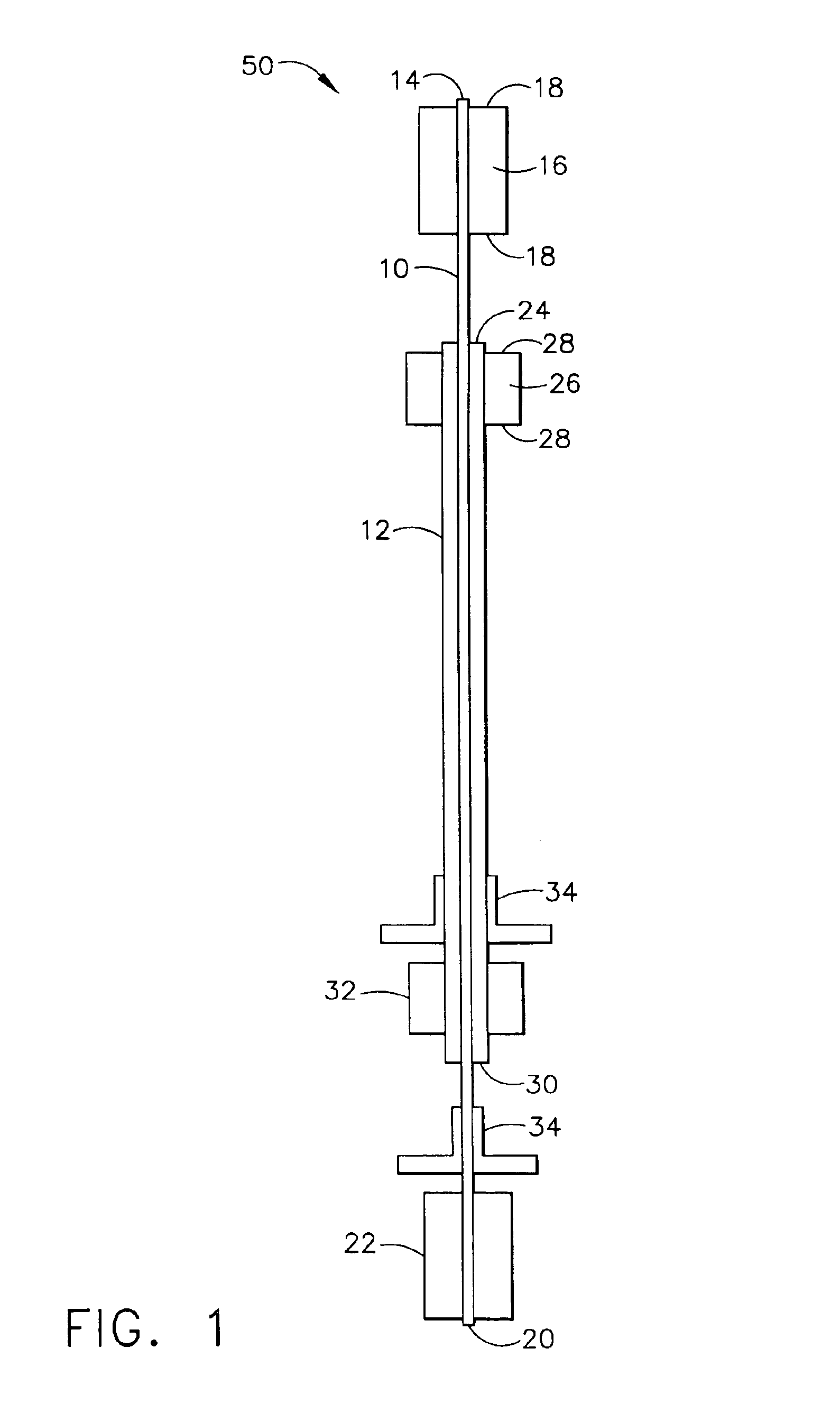

Gearless/oilless gas turbine engine

InactiveUS6881027B2Increase operating pressureIncrease capacityEngine sealsPump componentsMagnetic bearingLubrication

The complex mechanical gear trains and lubrication systems of conventional engine configurations are eliminated by using combinations of hydrodynamic air foil bearings, hydrodynamic solid geometry carbon seals / bearings, magnetic bearings, and electrical starter / generators that can also act as bearings to support the high speed shafts of gas turbine engines. The various bearing types and the starter / generators are arranged in such a way as to share peak loads experienced by the engine shaft during maximum aircraft maneuvers. This results in a minimal bearing and engine size.

Owner:HONEYWELL INT INC

Hydrodynamic journal bearing

A journal foil bearing comprising a retaining member having an inner surface which defines a shaft opening within which a rotatable shaft is receivable for rotation; and a foil assembly affixed to and lining the inner surface and comprising a plurality of foil sub-assemblies each subtending a circumferential segment, of the inner surface. Each of the foil sub-assemblies may comprise an under foil sandwiched between a spring foil disposed radially outwardly of the under foil, and a top foil disposed radially inwardly of the under foil, the under foil, the top foil, and the spring foil each having a leading edge distal from a trailing edge in a direction of rotation of the rotatable shaft, and each of the under foil, the top foil, and the spring foil being affixed to the retaining member along their respective leading edge, their respective trailing edge, or both their respective leading edge and their respective trailing edge, wherein a radius of curvature of the top foil is less than a radius of curvature of the under foil. A method of supporting a rotating shaft is also disclosed.

Owner:HONEYWELL INT INC

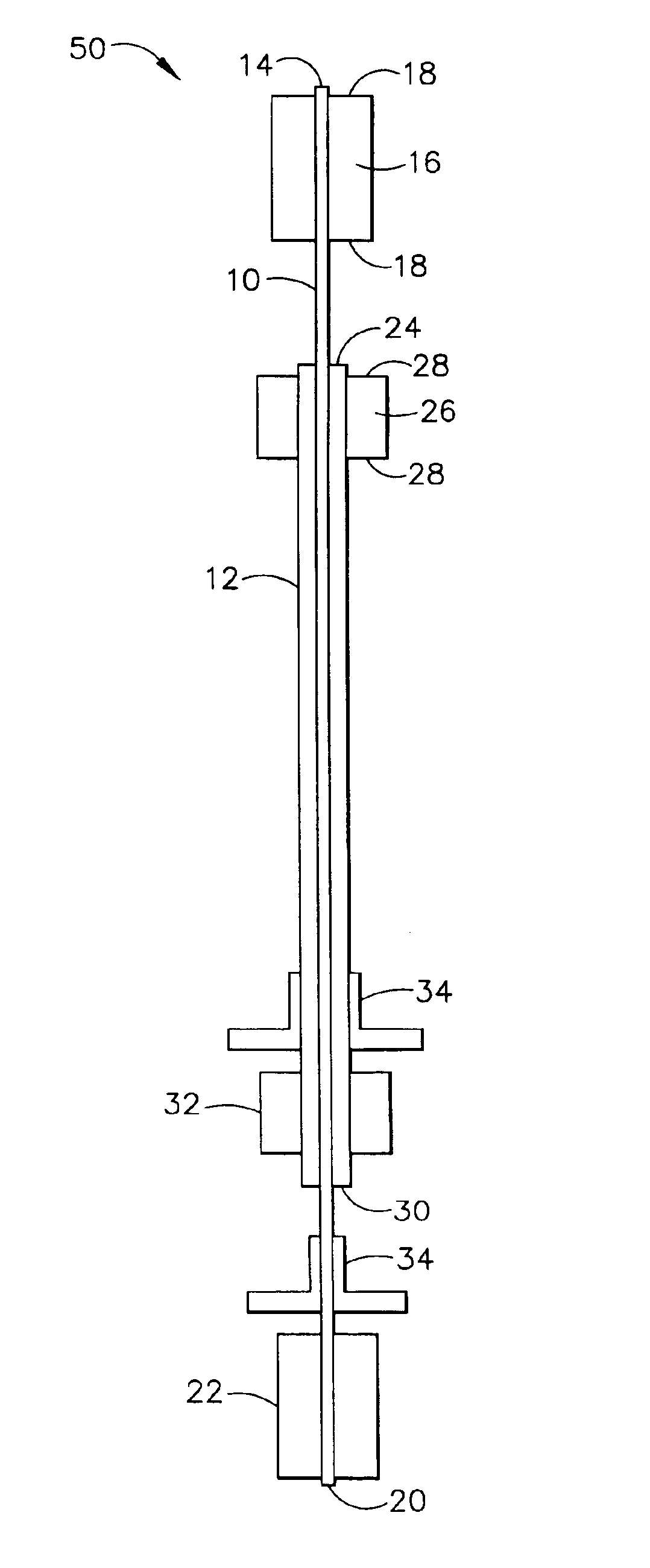

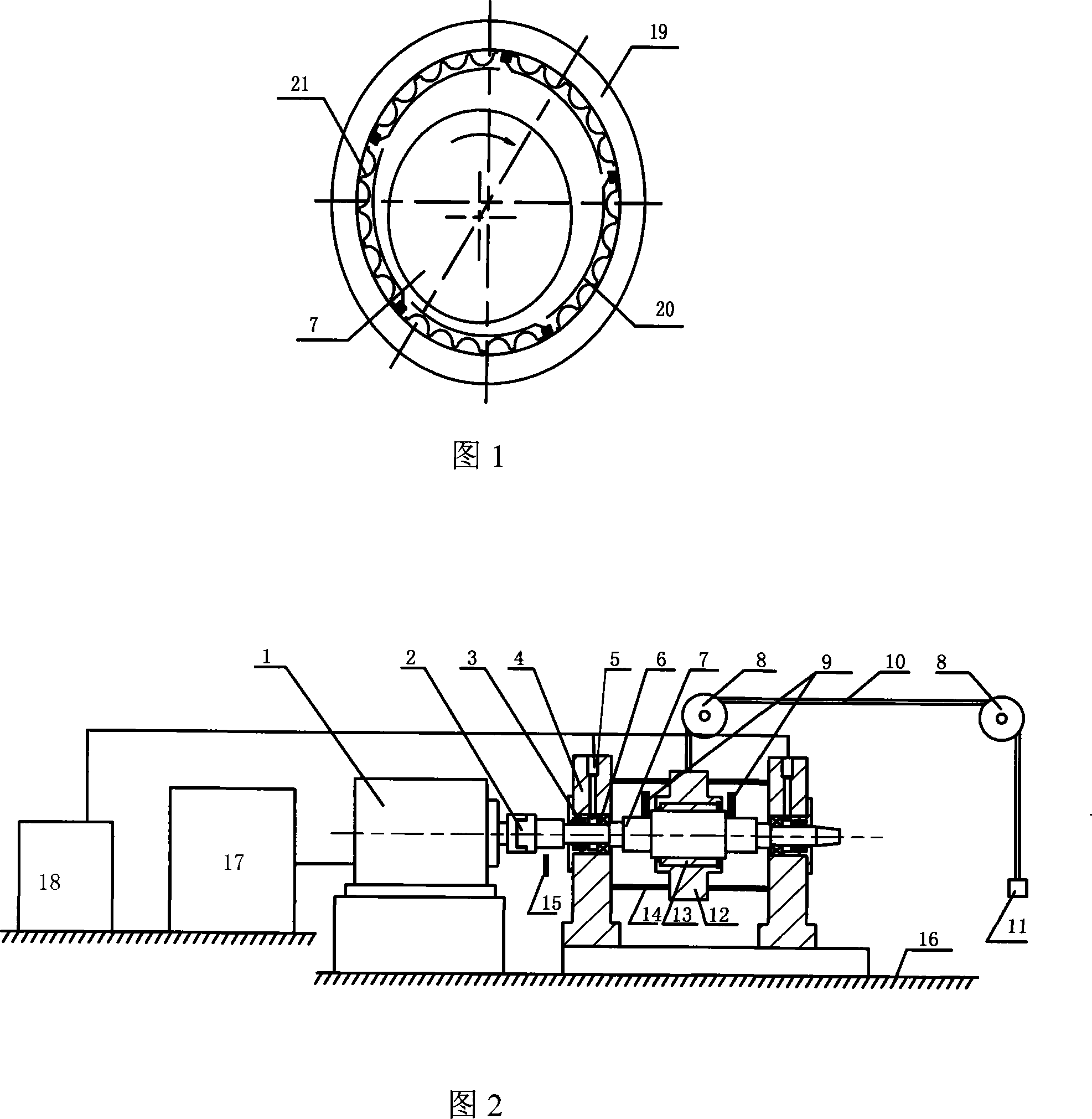

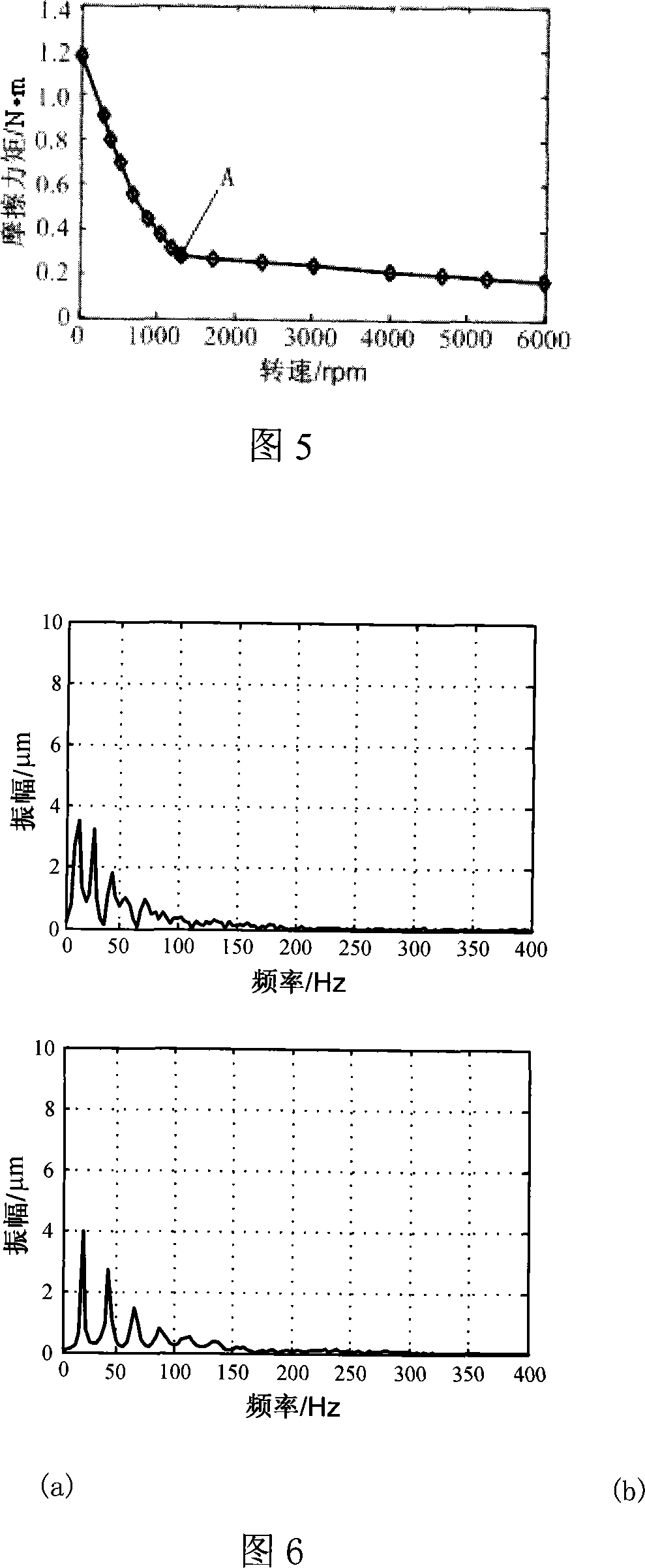

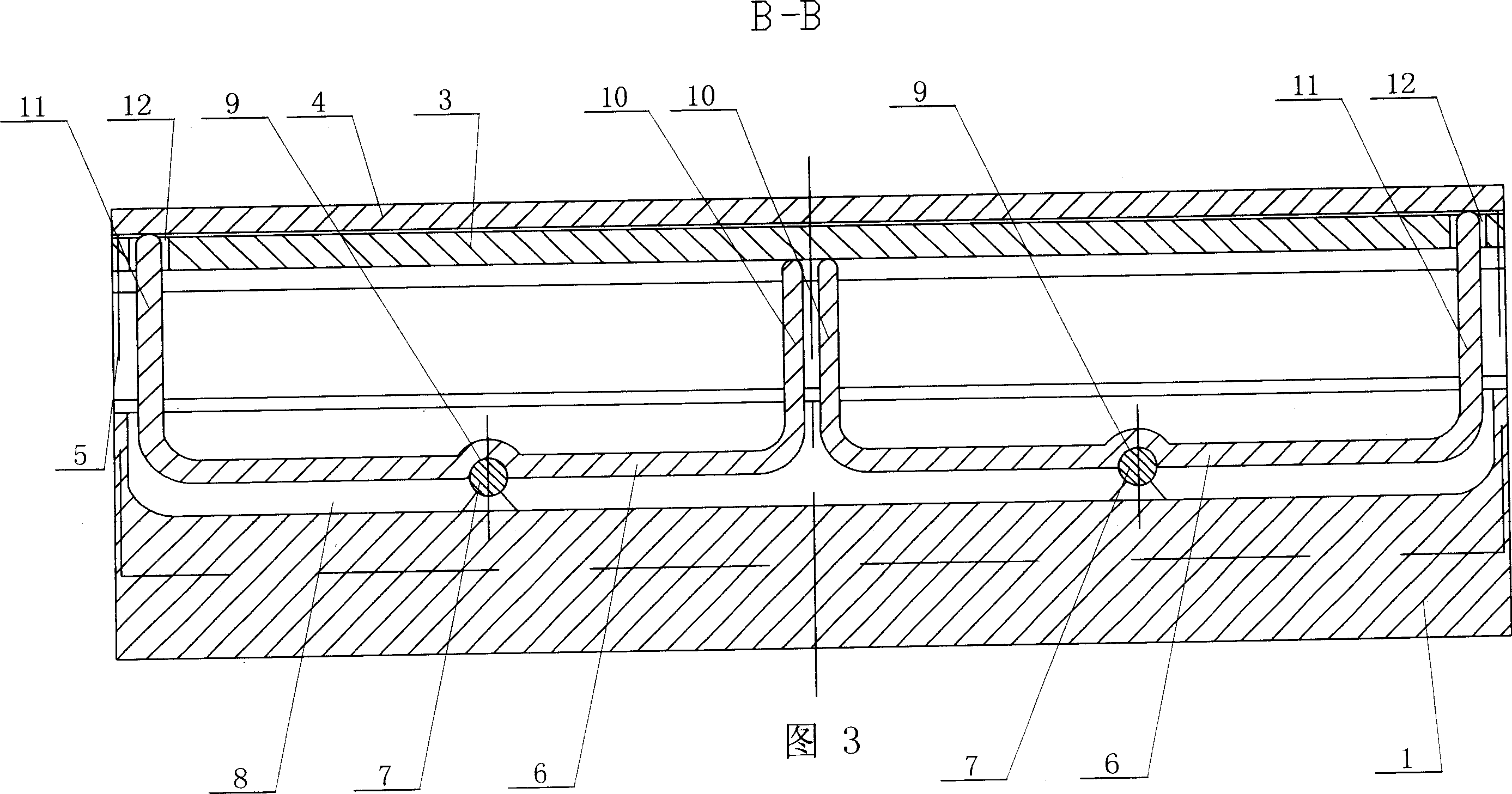

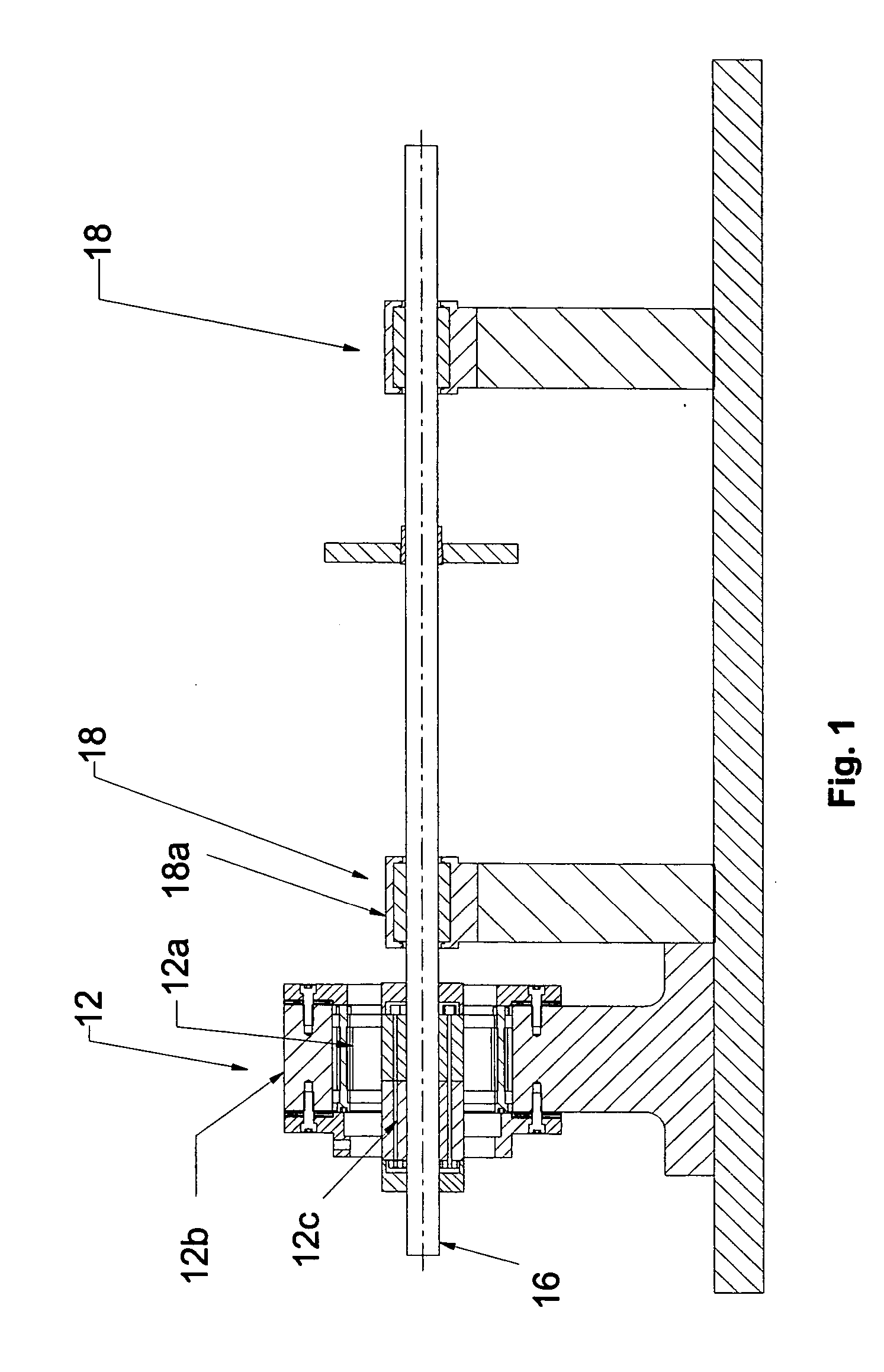

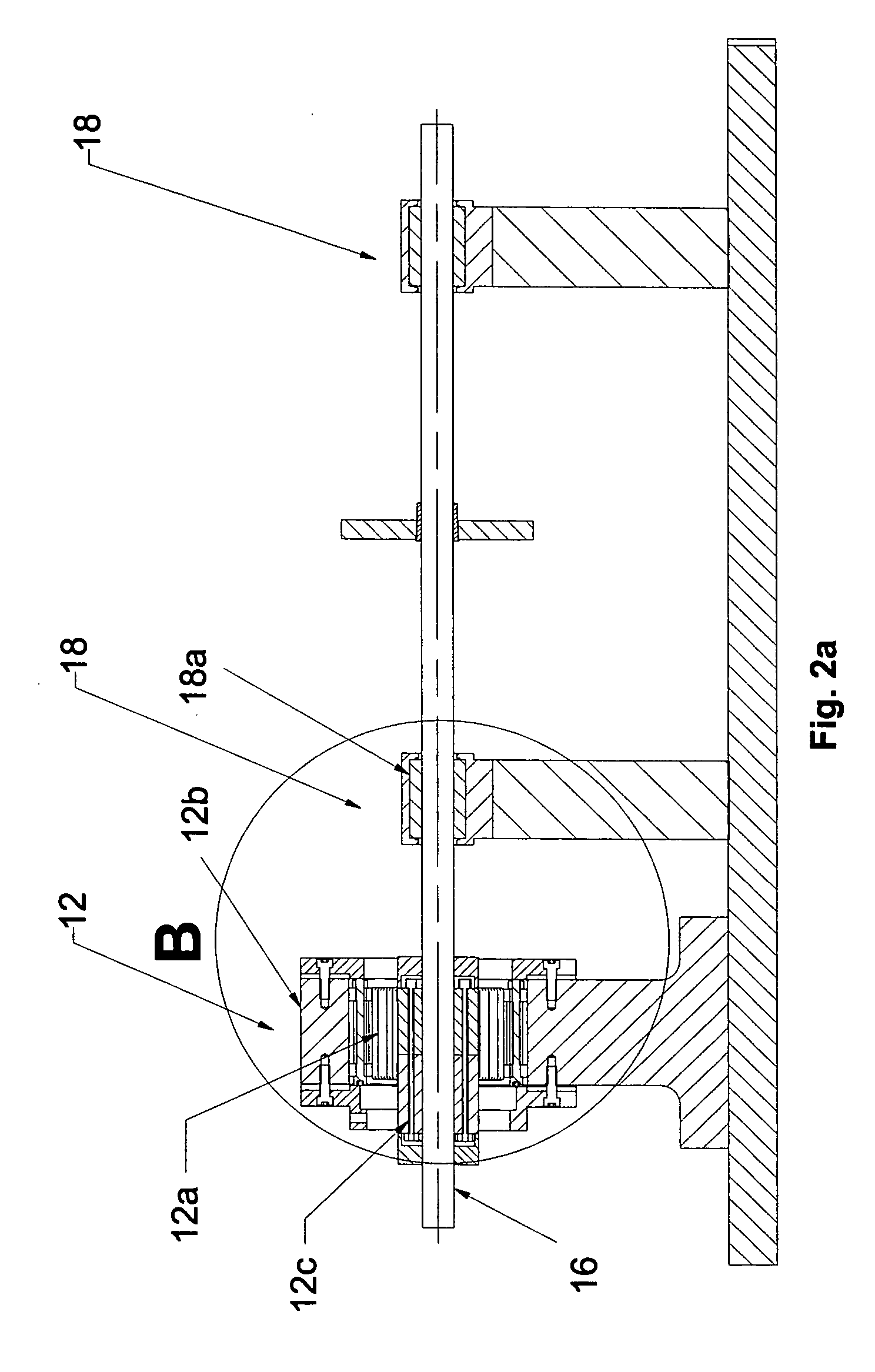

Device for testing elastic foil tablet transverse bearing departure rotary speed

InactiveCN101226103ADetermination of takeoff speedMachine bearings testingDevices using electric/magnetic meansFrequency changerAudio power amplifier

The invention relates to a device for measuring the takeoff rotating speed of the elastic foil radial bearing, which comprises a drive system, a shaft journal part and a lubricating system, and a data acquisition system; the drive system is composed of an asynchronous motor and a frequency converter; the asynchronous motor is connected with one end of the shaft journal through a high-speed flexible shaft coupling; the shaft journal utilizes two rolling bearing holders to implement lubrication on the rolling bearing through an oil gas lubricating coupler; the data acquisition system is composed of a sensor, an amplifier and a computer; the data measured by the sensor can be collected by an acquisition card and be input in the computer for storage; the rotor is driven by a motor; the static load of the bearing can be changed by a charger, thereby the takeoff rotating speed of the foil bearing in different loads can be measured.

Owner:XI AN JIAOTONG UNIV

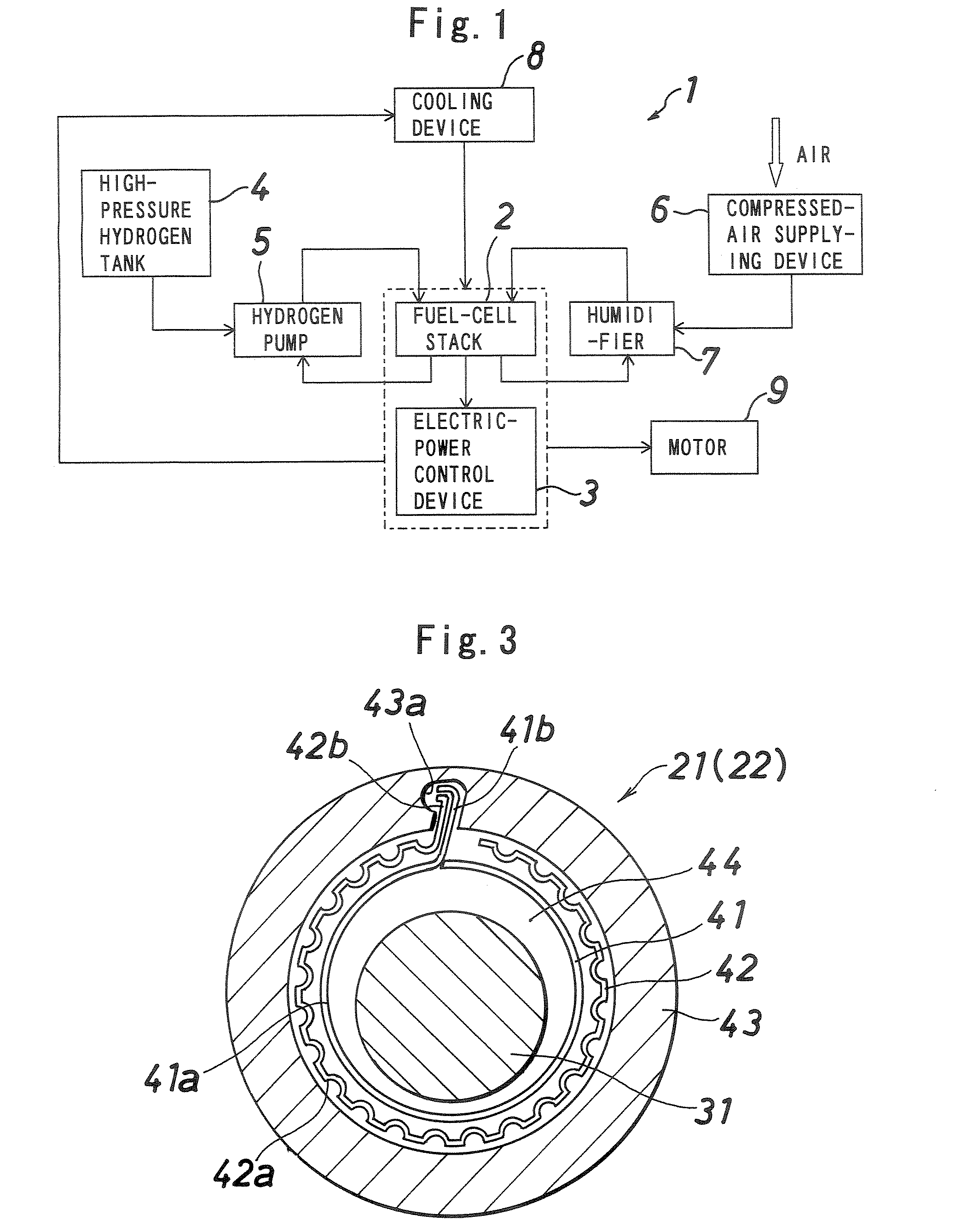

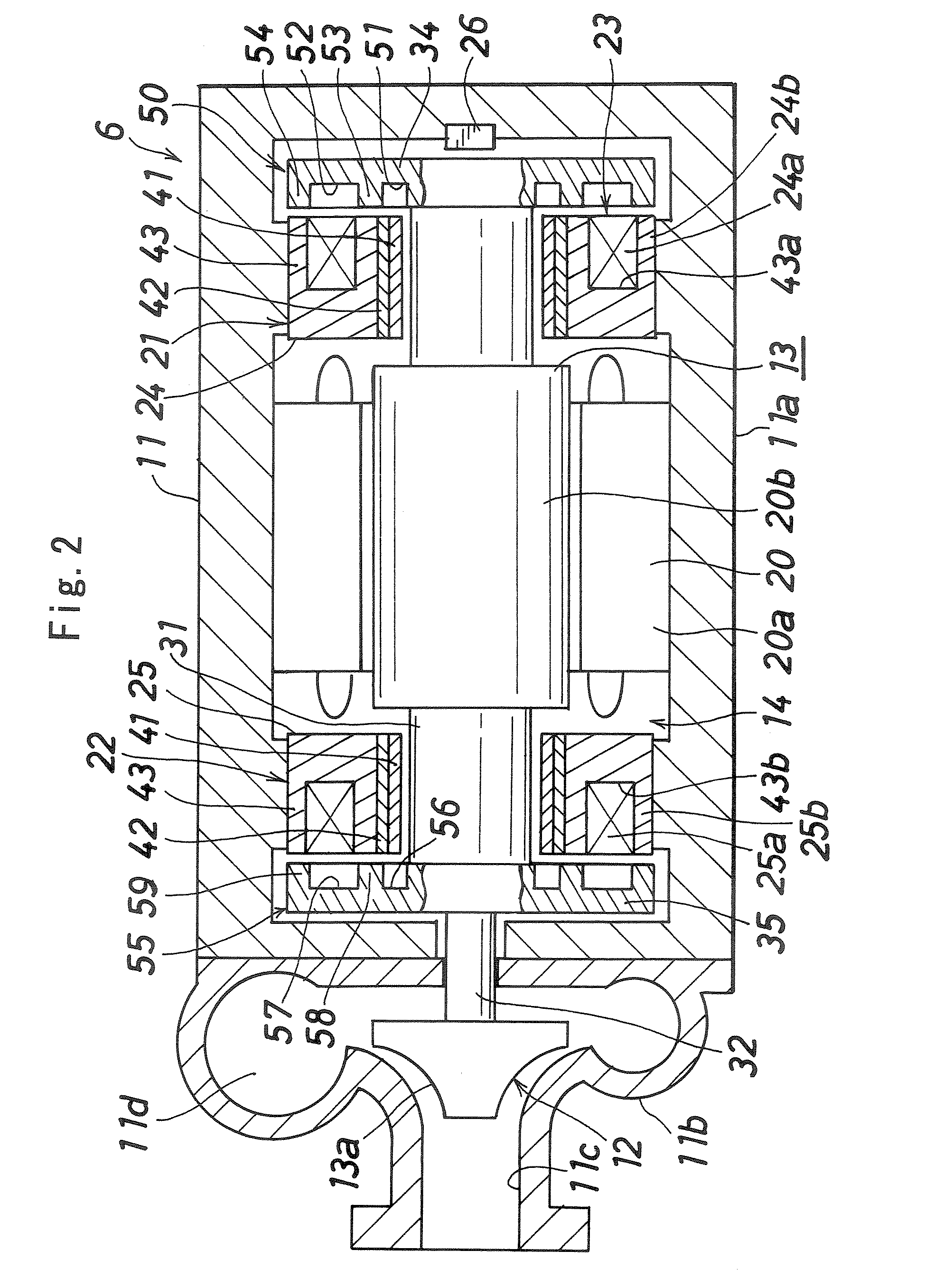

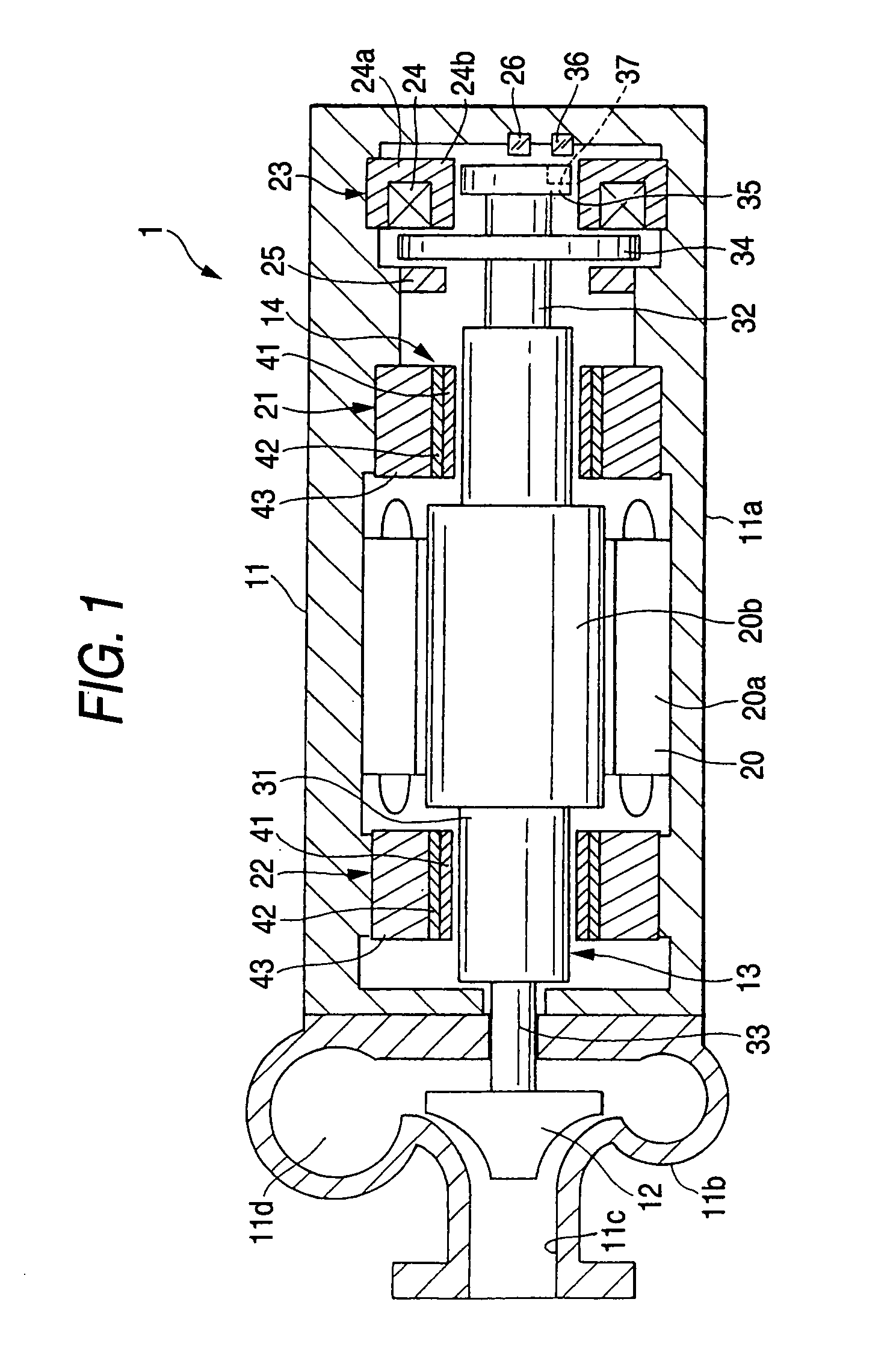

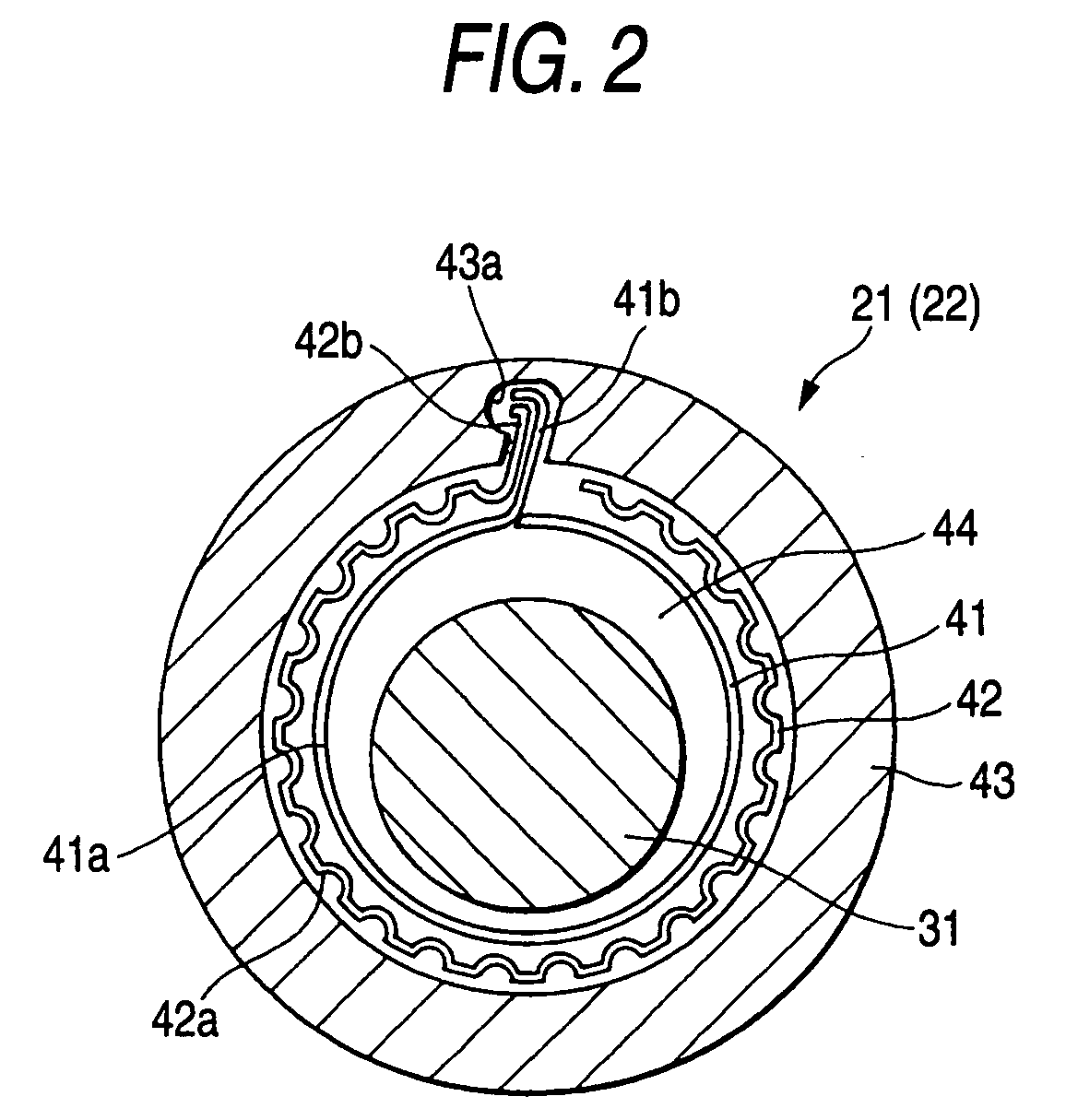

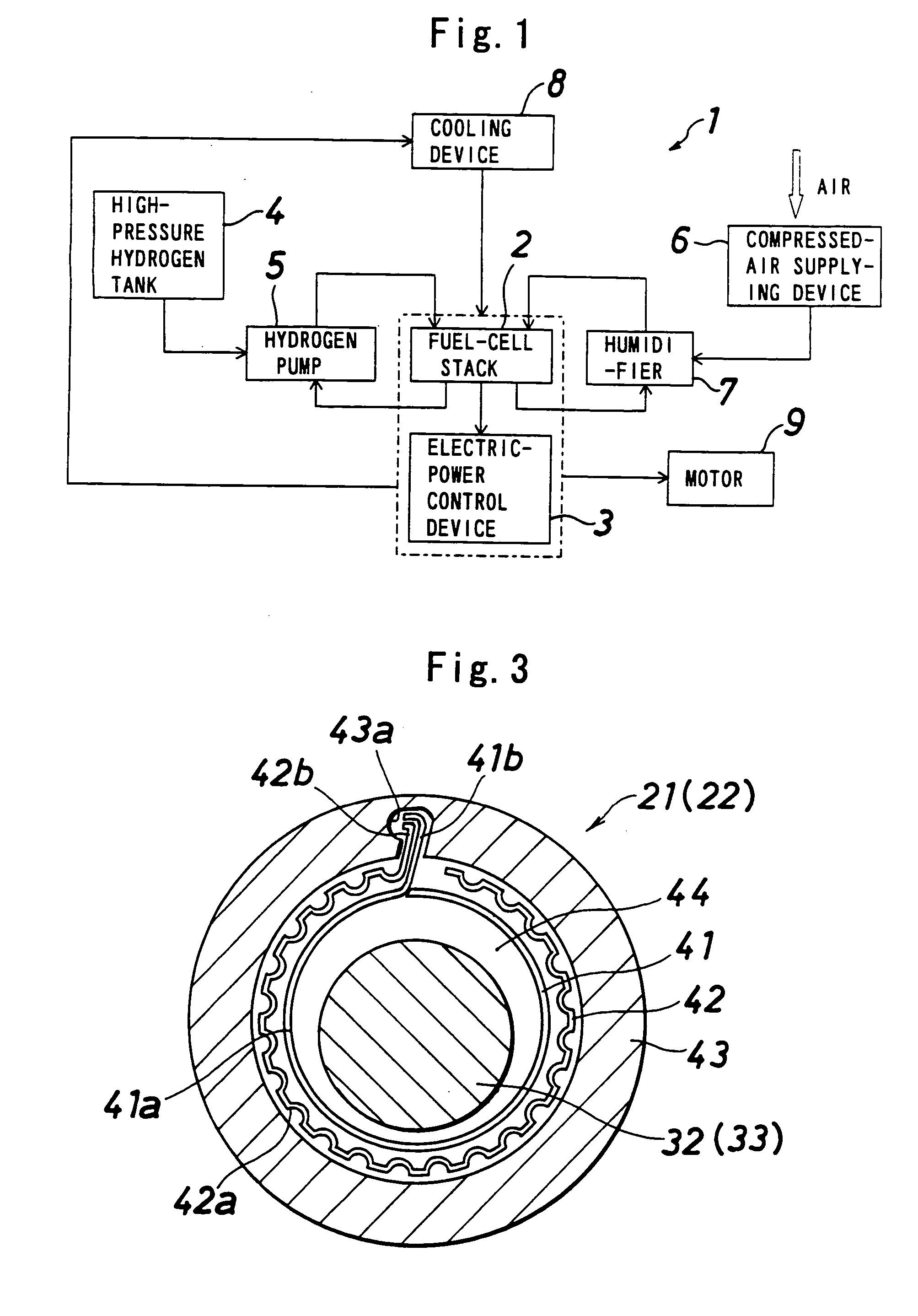

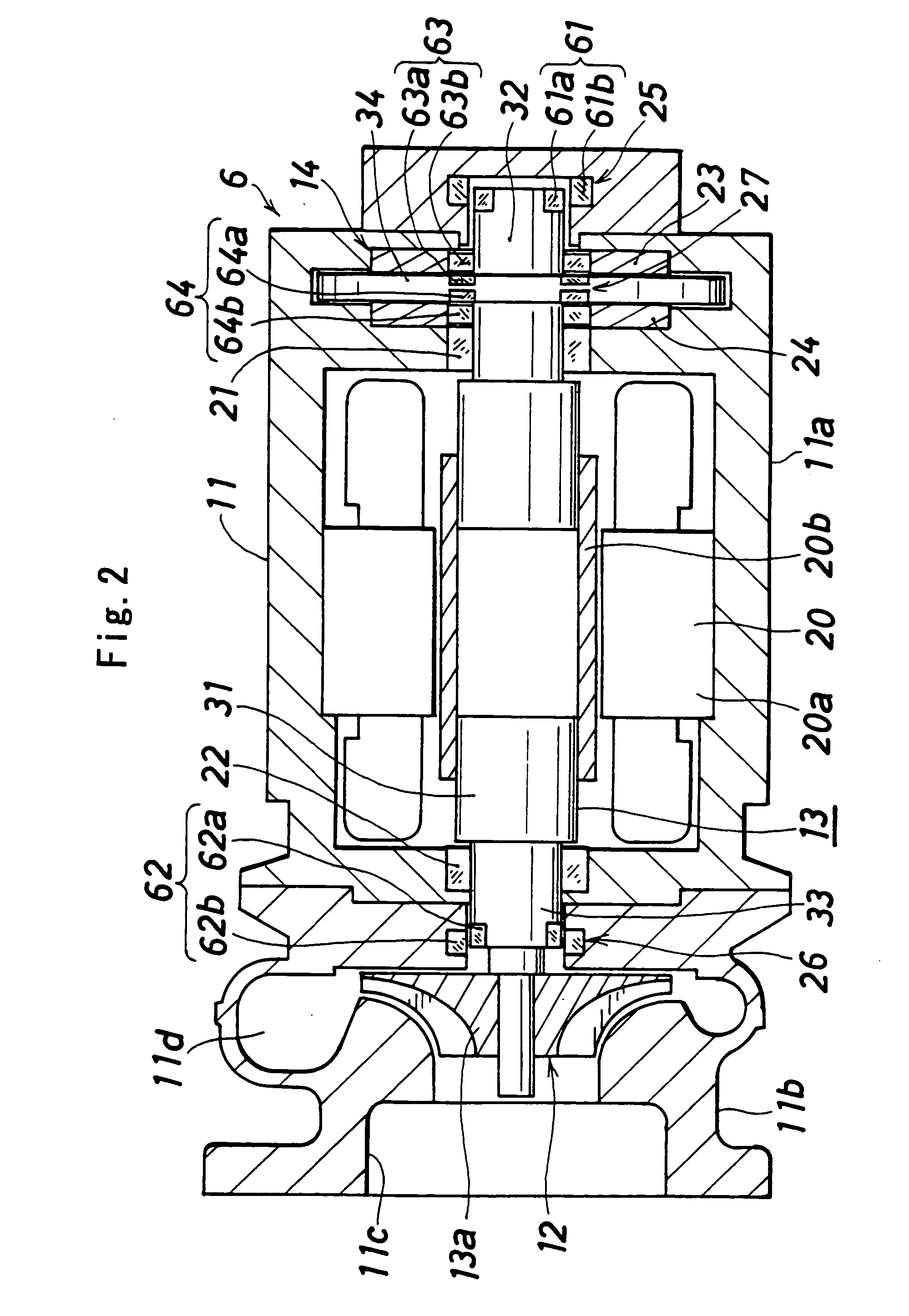

Fuel-cell compressed-air supplying device

A fuel-cell compressed-air supplying device 6 includes a centrifugal compressor 12 provided in a casing 11, and a bearing device 14 for supporting a rotation shaft 13 of the compressor 12. The bearing device 14 includes a pair of radial foil bearings 21 and 22 provided coaxially with the rotation shaft 13 for supporting the rotation shaft 13 in the radial direction, and an axial magnetic bearing 23 facing to the rotation shaft 13 in the axial direction for supporting the rotation shaft 13 in the axial direction. Axial electromagnets 24 and 25 of the axial magnetic bearing 23 are integrated with the radial foil bearings 21 and 22, respectively.

Owner:JTEKT CORP

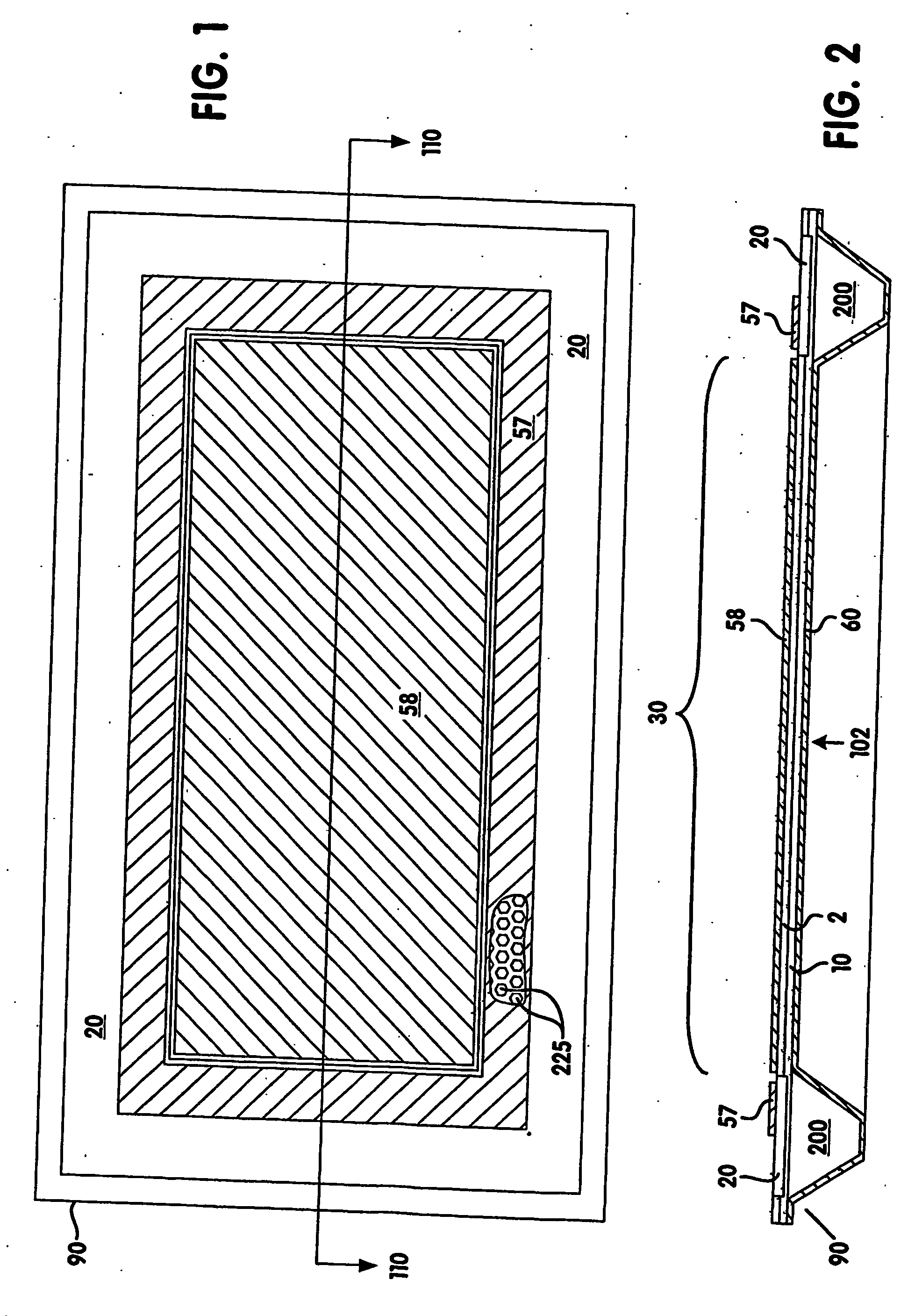

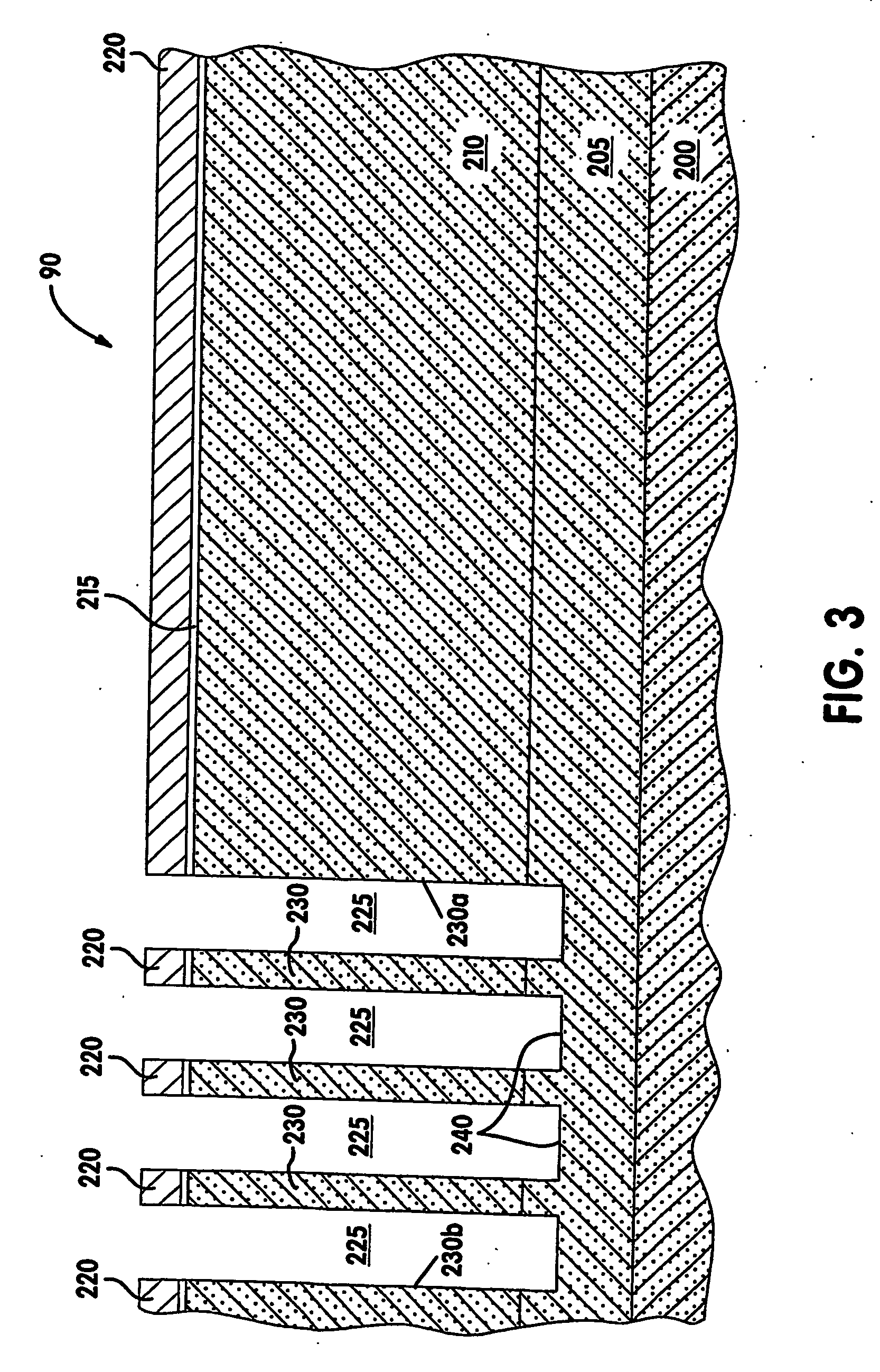

Foil bearing supported motor-driven blower

InactiveUS20130129488A1Save energyEasy to adaptEngine manufacturePump componentsMotor driveMixed flow

A high-speed blower designed to move and circulate dry process gas includes an axial or mixed-flow compressor driven by a brushless permanent magnet synchronous motor utilizing a remotely mounted variable frequency drive. The blower uses foil gas bearings which enable high-speed, low-power loss, and oil-free operation. The blower comprises an outer blower housing and an inner blower housing defining an annular cavity therebetween. A cooling flow of process gas may be leaked through the inner blower housing to cool the internal operational components of the blower, including the motor and the bearings, and to capture heat therefrom, which can be added to the process gas flow moving through the blower. Diffuser vanes and flow-straightening vanes are provided on the outer surface of the inner blower housing to improve the fluid dynamics of the process gas flow through the blower and heat transfer from the inner blower housing.

Owner:R & D DYNAMICS

Radial foil bearing with sealing function

The present invention provides a radial foil bearing having a sealing function, comprising a top end foil (3) which has a thickness t of more than or equal to 0.1.D0.33, and a plug (7) which is capable of preventing a bearing component from falling off and shielding a space of the gas as a lubricating oil to pass through raised foils (2), wherein t is the thickness (mm), D is a shaft diameter (mm). According to the radial foil bearing, the plug (7) which is capable of shielding the space between the raised foils (2) is arranged so that a slight gap is kept between a shaft (6) and the top end foil (3), and a high-performance sealing function with a least gap is provided.

Owner:科特博公司

Bottle with internal advertisement

InactiveUS20020029501A1Easy to packMinimize contaminationStampsAdvertisingTectorial membraneEngineering

A package for a liquid includes a bottle having a transparent wall and a hologram unit received in the bottle and consisting of a carrier foil bearing the hologram and a pair of transparent protective foils sandwiching the hologram between them.

Owner:BRAUN MANFRED

Self-regulating type hydrodynamic gas elastic foil bearing

InactiveCN101000071AImprove carrying capacityCarrying capacity will not be reducedBearingsHigh pressureMembrane configuration

The invention is a self-adjusting aerodynamic foil bearing, relating to an aerodynamic foil bearing, comprising casing, ripple foil and plane foil, where the plane foil is arranged in the casing, and the ripple foil is arranged between the casing and the plane foil and contacts with them; and the invention also comprises a self-adjustor, arranged in the casing and located between the casing and the ripple or plane foil. By adding a self-adjustor to the original aerodynamic foil bearing, the highest pressure of lubricating air membrane is transferred through the self-adjustor to the two sides of the plane foil to deform it so as to largely reduce leakage of lubricating airflow from two side edges of the plane foil, improving bearing capability of the bearing.

Owner:HARBIN INST OF TECH

Methods of controlling the instability in fluid film bearings

InactiveUS20050275300A1Large load carrying capacityImprove reliabilityMeasurement/indication equipmentsSliding contact bearingsMagnetic bearingInstability

A method of controlling the instability in fluid film bearings by using a magnetic bearing in combination with a fluid film bearing (whether it is a cylindrical journal bearing, an elliptic bearing, an offset-half bearing, a multi-lobe bearing, foil bearing or a tilting-pad bearing, does not really matter), wherein the fluid film bearing serves as the primary load carrying bearing and the magnetic bearing controls the instability of the fluid film bearing. This efficient combination results in bearings that can be used at high speeds without having neither stability nor reliability problems. An alternative method of controlling the instability in fluid film bearings is to disturb the flow in the axial direction, for example, a sleeve journal) bearing can be manufactured such that the bearing axis is skewed with the shaft axis or a variable geometry bearing can be manufactured to allow for bearing angular misalignment.

Owner:EL SHAFEI ALY

Compressor ported shroud for foil bearing cooling

A compressor ported shroud takes compressed air from the shroud of the compressor before it is completely compressed and delivers it to foil bearings. The compressed air has a lower pressure and temperature than compressed outlet air. The lower temperature of the air means that less air needs to be bled off from the compressor to cool the foil bearings. This increases the overall system efficiency due to the reduced mass flow requirements of the lower temperature air. By taking the air at a lower pressure, less work is lost compressing the bearing cooling air.

Owner:HONEYWELL INT INC

Adjustable cantalever type dynamic pressure gas elastic foil bearing

InactiveCN101054995AIncrease equivalent stiffnessAdd equivalent dampingBearing componentsSliding contact bearingsEngineeringScrew thread

A new type adjustable cantalever type aerodynamic elastic foil bearing relates to an aerodynamic foil bearing. The present invention solves the problems that the existing cantalever type aerodynamic foil bearing will leak bearing lubricate gas, and has low bearing force and bad stability in high speed. The elastic foil (3) is mounted on the inner wall of a bearing housing (1) and is uniformly distributed along the inner wall of the bearing housing (1), one end of the elastic foil (3) is fixed in a longitudinal groove (4) disposed on the inner wall of the bearing housing (1), and another end of the elastic foil (3) is superposed on an adjacent elastic foil. It is characterized in that the bearing also includes an adjustable mechanism (9) which is mounted in a screw thread through hole (5) on the housing (1) and is connected with the elastic foil (3). The present invention improves the equivalent rigidity and equivalent damping of the elastic foil by the adjustable mechanism and thereby greatly improves the bearing ability and stability of the bearing.

Owner:HARBIN INST OF TECH

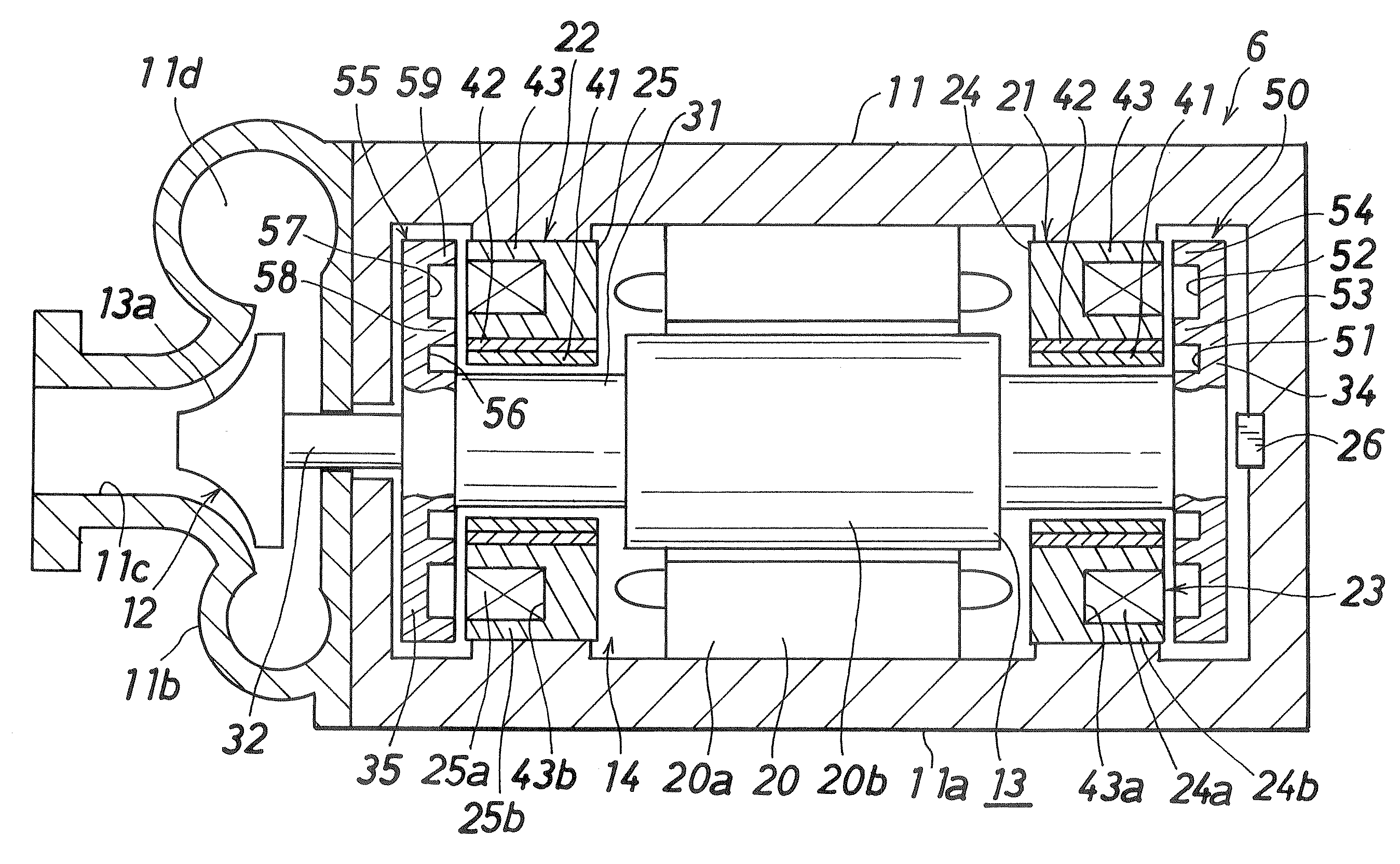

Compressor for fuel cell

InactiveUS20070246002A1Increased durabilityInternal combustion piston enginesPump componentsFuel cellsMagnetic bearing

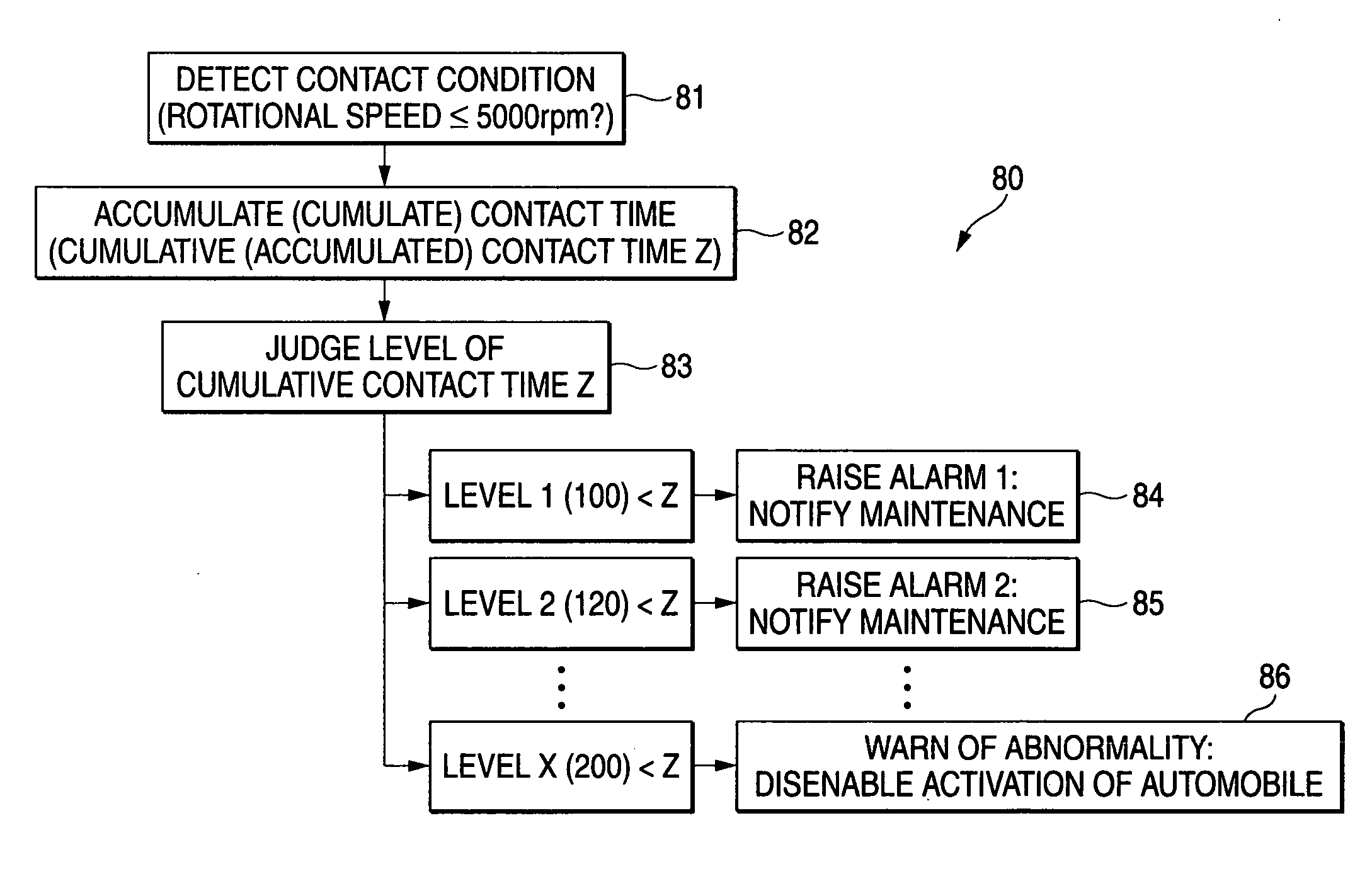

A bearing device supporting a rotation shaft of a fuel cell compressor includes a pair of radial foil bearings and mounted in concentric relation to the rotation shaft and supporting the rotation shaft in a radial direction, and an axial magnetic bearing opposed to the rotation shaft in an axial direction and supporting the rotation shaft in the axial direction. A control device includes bearing life diagnostic unit for accumulating times during which a rotational speed of the rotation shaft has been below a predetermined value, so as to obtain a cumulative contact time, thereby judging a bearing lifetime.

Owner:JTEKT CORP

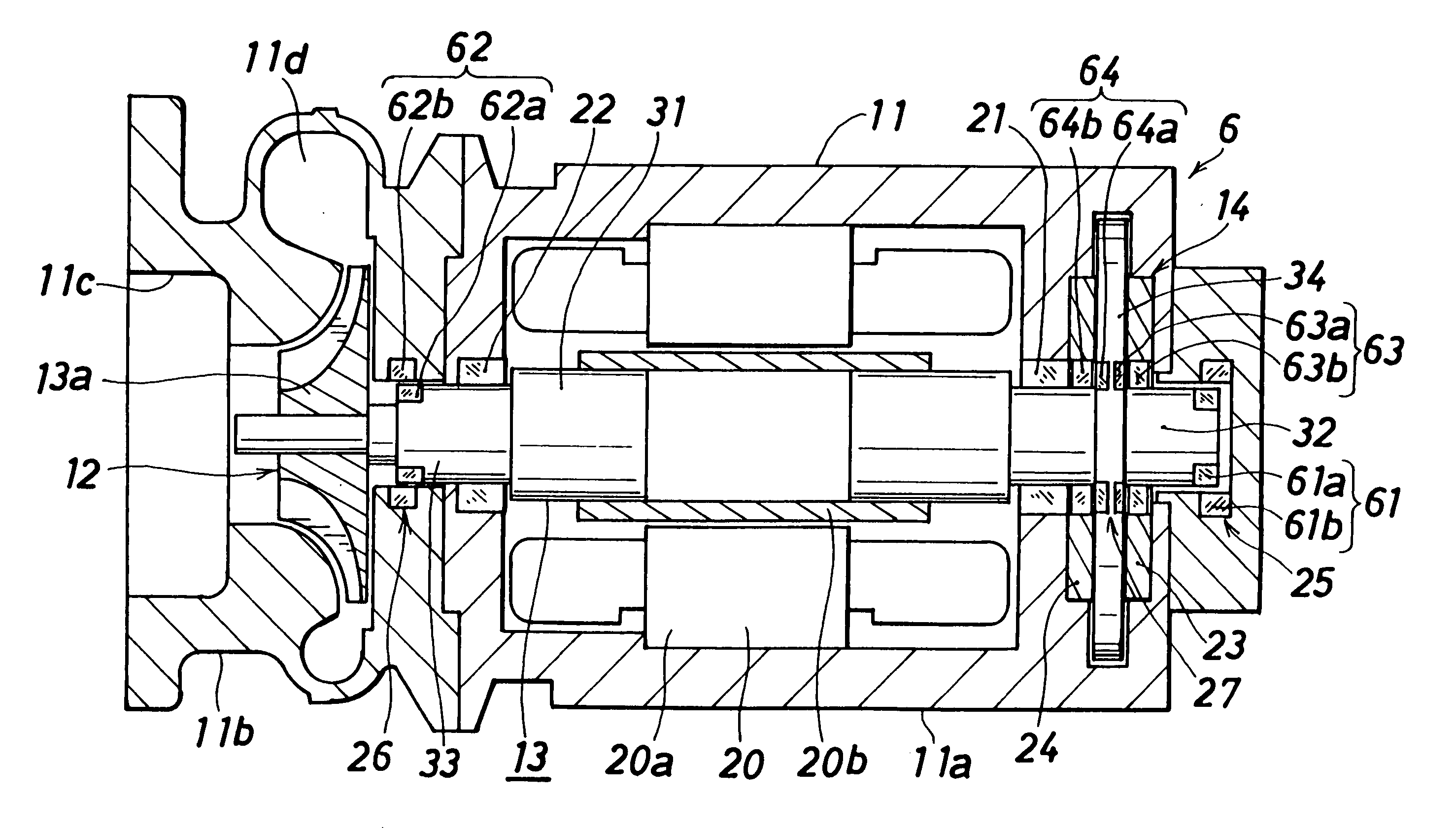

Fuel-cell compressed-air supplying device

A fuel-cell compressed-air supplying device 6 includes a centrifugal compressor 12 provided in a casing 11 and a bearing device 14 for supporting a rotation shaft 13 of the compressor 12. The bearing device 14 includes a pair of radial foil bearings 21 and 22 provided coaxially with the rotation shaft 13 for supporting the rotation shaft 13 in the radial direction, a pair of axial foil bearings 23 and 24 facing to the rotation shaft 13 in the axial direction for supporting the rotation shaft 13 in the axial direction, and a secondary bearing means 25 which is constituted by a combination of plural permanent magnets 61a, 61b, 62a, 62b, 63a, 63b, 64a and 64b and holds the rotation shaft 13 in a non-contact manner at static states.

Owner:JTEKT CORP

Air foil bearing having a porous foil

There is provided an air foil bearing. The air foil bearing comprises a bearing housing and a first foil, wherein a first end of the first foil is fixed with respect to the bearing housing and a second end of the first foil is extended along a peripheral surface of a rotating shaft while maintaining a predetermined clearance with respect to the rotating shaft to thereby become a free end. The air foil bearing also comprises a second foil fabricated from a porous metallic material and extended along the first foil between the first foil and the bearing housing.

Owner:KOREA INST OF SCI & TECH

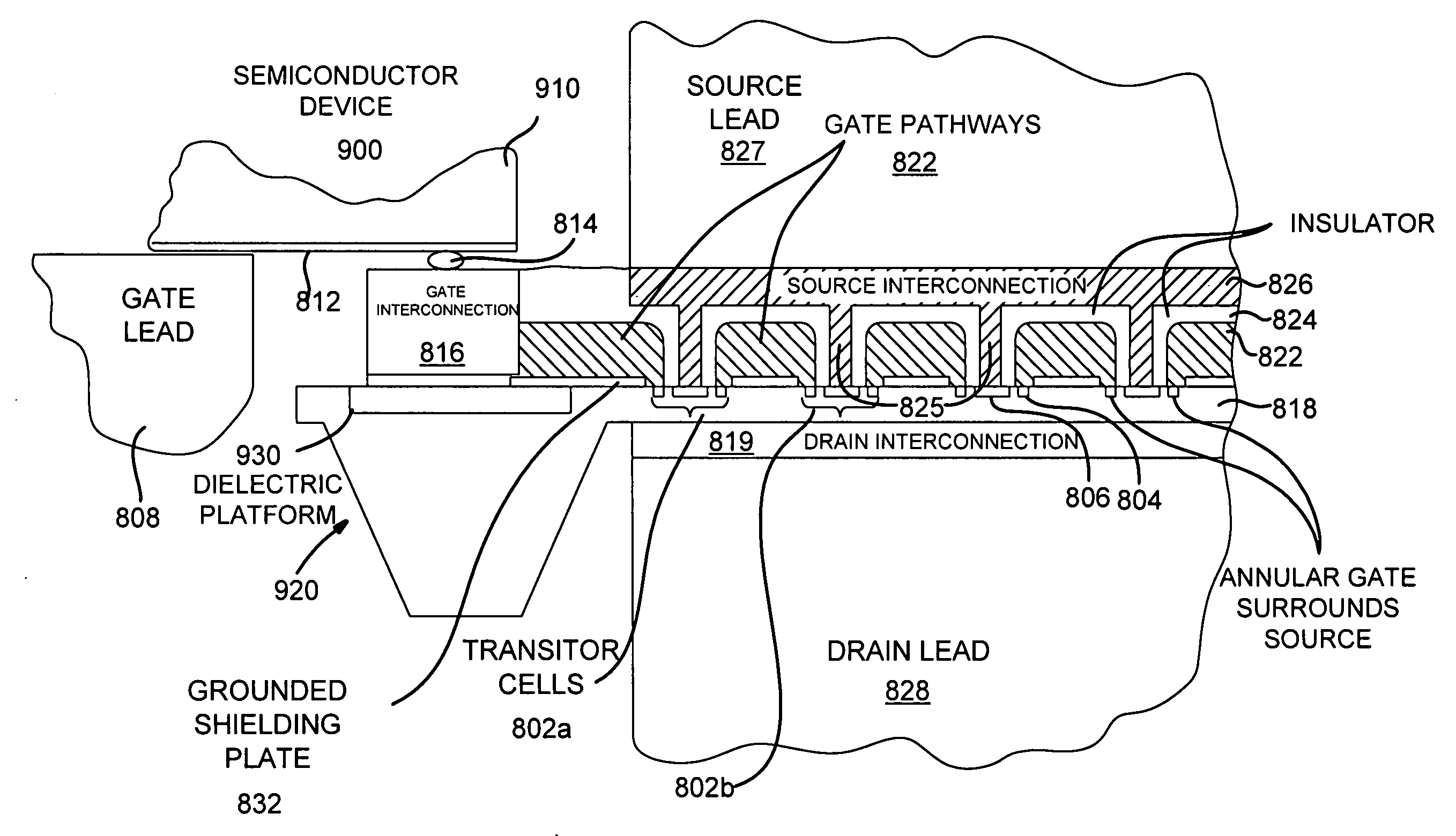

Power semiconductor device and method therefor

InactiveUS20070057289A1Semiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceAir bearing

Owner:HVVI SEMICON

Magnetic-gas bearing and method for making compliant foil

InactiveCN1730959AShorten the axial lengthImprove performanceBearing componentsMagnetic bearingsMagnetic tension forceMagnetic poles

The mixed magnetic air journal bearing is mixed bearing of active magnetically suspension bearing and dynamic pressure air journal bearing, and includes active magnetically suspension radial bearing, elastic foil embedded between magnetic poles of the magnetically suspension radial bearing, and locking mechanism comprising locking wedge block, inclined blocks, bearing block, gag, screw and stop washer. The elastic foil with pre-wedged angle, has one end held onto the magnetic pole and has higher static and dynamic performance than rigid bearing. Owing to the magnetic force to suspend the rotor in the balance position and fluid force to deform the foil for coupling the interval of the air film, the rotor-bearing reaches ultimate stable balance. The bearing has simple structure, has the advantages of both active magnetically suspension bearing and foil bearing, excellent damping characteristic and improved structure rigidity and dynamic characteristic.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Pre-tightening electromagnetic-elastic foil gas combination bearing

The invention discloses a gas combination bearing provided with a pretension electromagnetic-elastic foil; the gas combination bearing comprises an electromagnetic bearing and an elastic foil bearing which is nested between the electromagnetic bearing and a rotor journal; the inner wall of the electromagnetic bearing is provided with a magnetic pole and an end cover is arranged at the axial direction thereof; a boss is arranged on the magnetic pole; an extension part is arranged on a bearing seat component of the foil bearing; a groove is arranged on the inner wall of the bearing seat component at the extension part which is evenly distributed along the circumference direction; a top-layer elastic foil and a bottom-layer elastic wave foil are arranged in the groove by pretension; when a coil is electrified, an electromagnetic field is formed between a pole shoe and the rotor journal; the pole shoe generates an attraction force to the rotor journal; and when the rotating speed is increased to a certain value, a pretension force which is formed between the top-layer elastic foil and the rotor journal and offsets the top-layer elastic foil causes the rotor to float. The gas combination bearing has the advantages of small volume, appropriate damp, low cost, low power consumption and high bearing capacity.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com