Pre-tightening electromagnetic-elastic foil gas combination bearing

A technology of elastic foils and electromagnetic bearings, applied in the direction of bearings, shafts, bearings, mechanical equipment, etc., can solve the problems of large wear, low damping and stiffness, and low bearing capacity, and achieve improved bearing capacity, high dynamic stiffness, and improved The effect of damping and degree of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

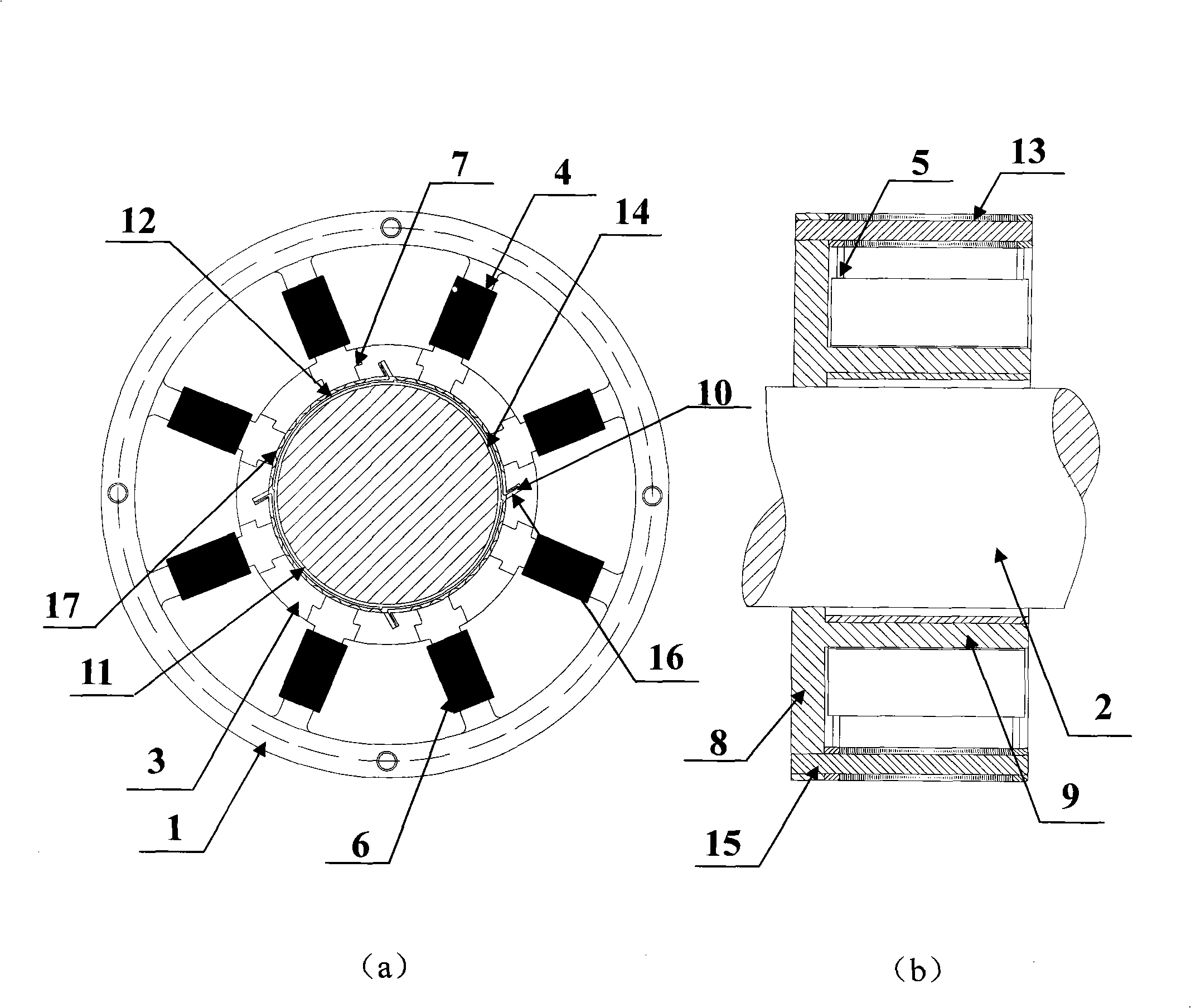

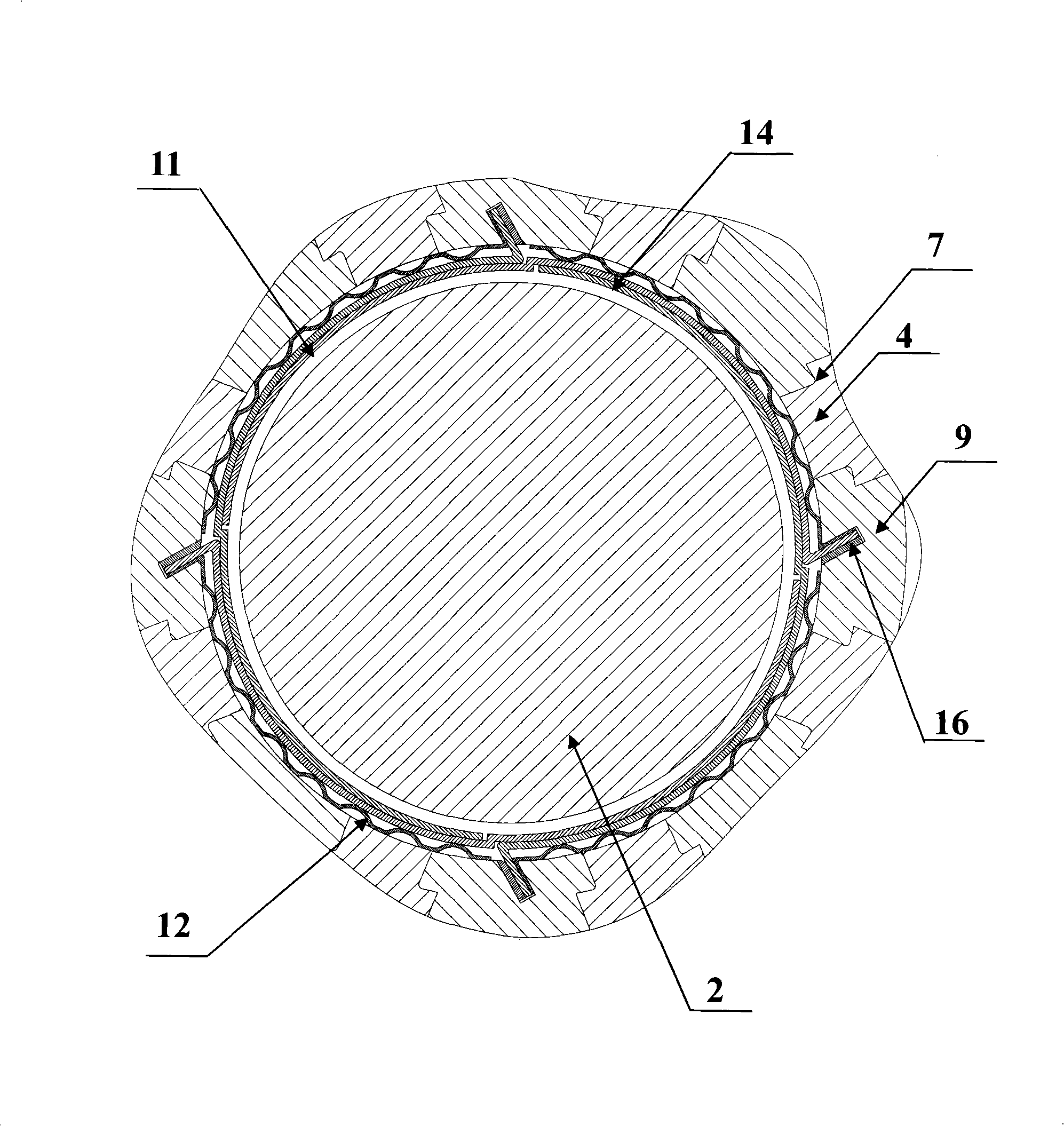

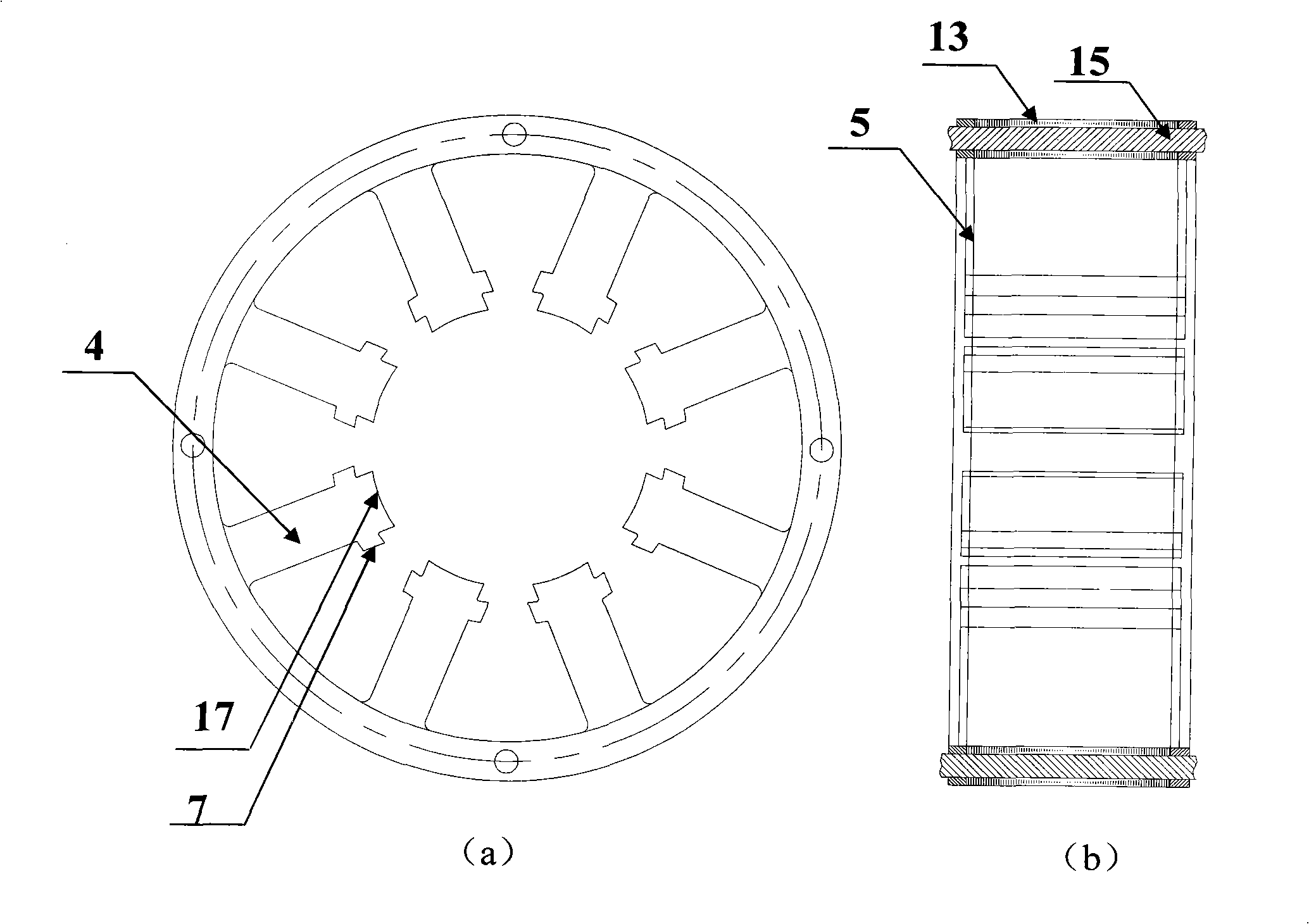

[0028] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] see figure 1 , figure 2 , image 3 , Figure 4 , a preloaded electromagnetic-elastic foil gas combined bearing, including an electromagnetic bearing 1 and an elastic foil bearing 3 nested between the electromagnetic bearing 1 and the rotor journal 2, wherein the inner wall of the electromagnetic bearing 1 is set There are n (n=4, 6, 8, 10, 12) magnetic poles 4 and end caps 5 that compress the magnetic poles 4 in the axial direction, and the magnetic poles 4 are provided with coils 6, and the coils 6 are dipped in paint and placed on them. Both ends are bonded with insulating paper for fixing, and a boss 7 is set radially outward 5 mm at the pole shoe 17 of the magnetic pole 4 close to the end of the elastic foil bearing 3 . The structure of the combined bearing magnetic pole 4 of the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com