Thrust foil dynamic pressure air bearing with thick top foil structure

An air bearing and foil technology, which is applied in the field of thrust foil dynamic pressure air bearings, can solve the problems of weakening the wedge-shaped air film compression effect, reducing the bearing capacity, and insufficient thickness of the top layer of foil, etc., and achieves the requirement of reducing the consistency accuracy , Improve the bearing capacity and solve the effect of foil deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

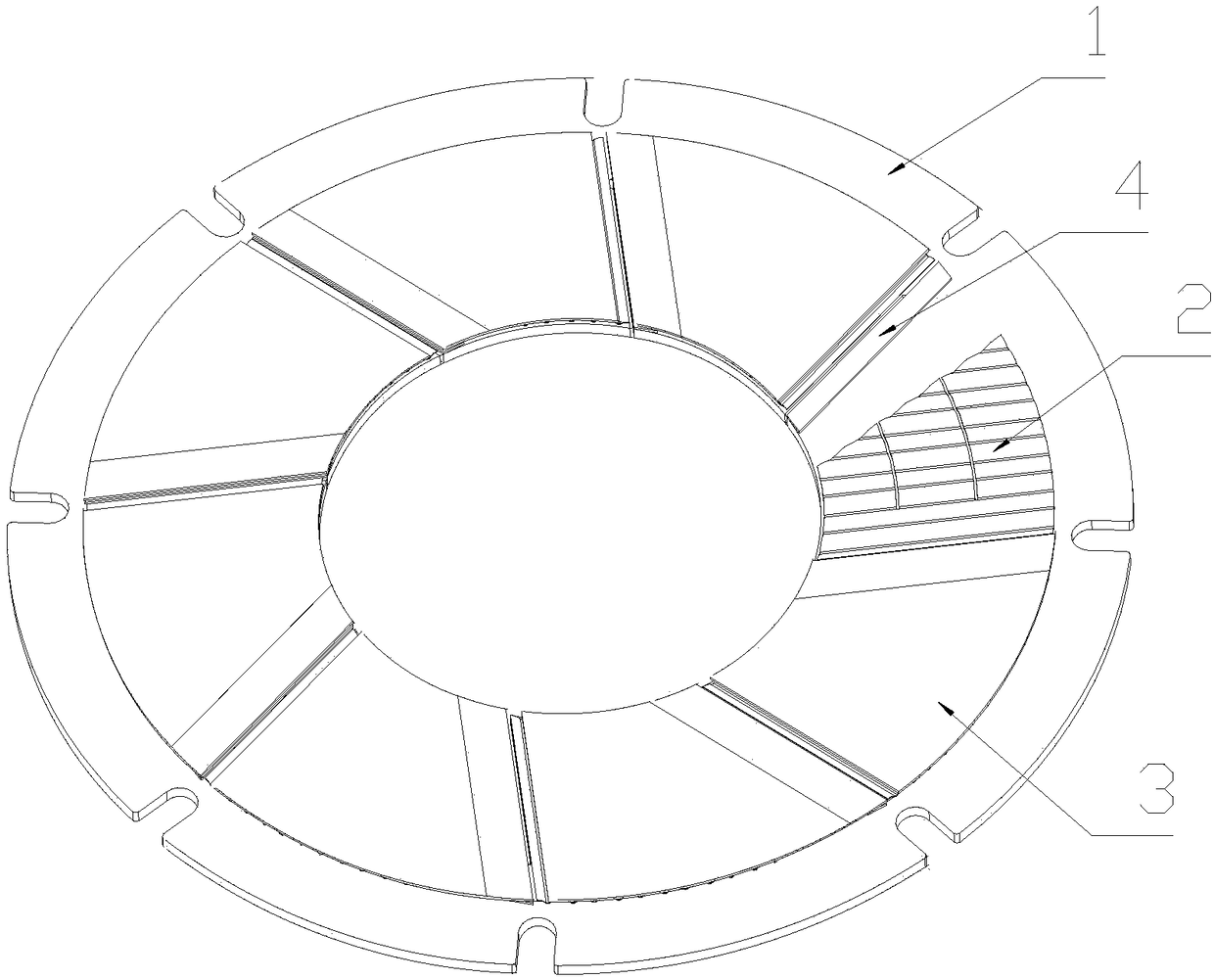

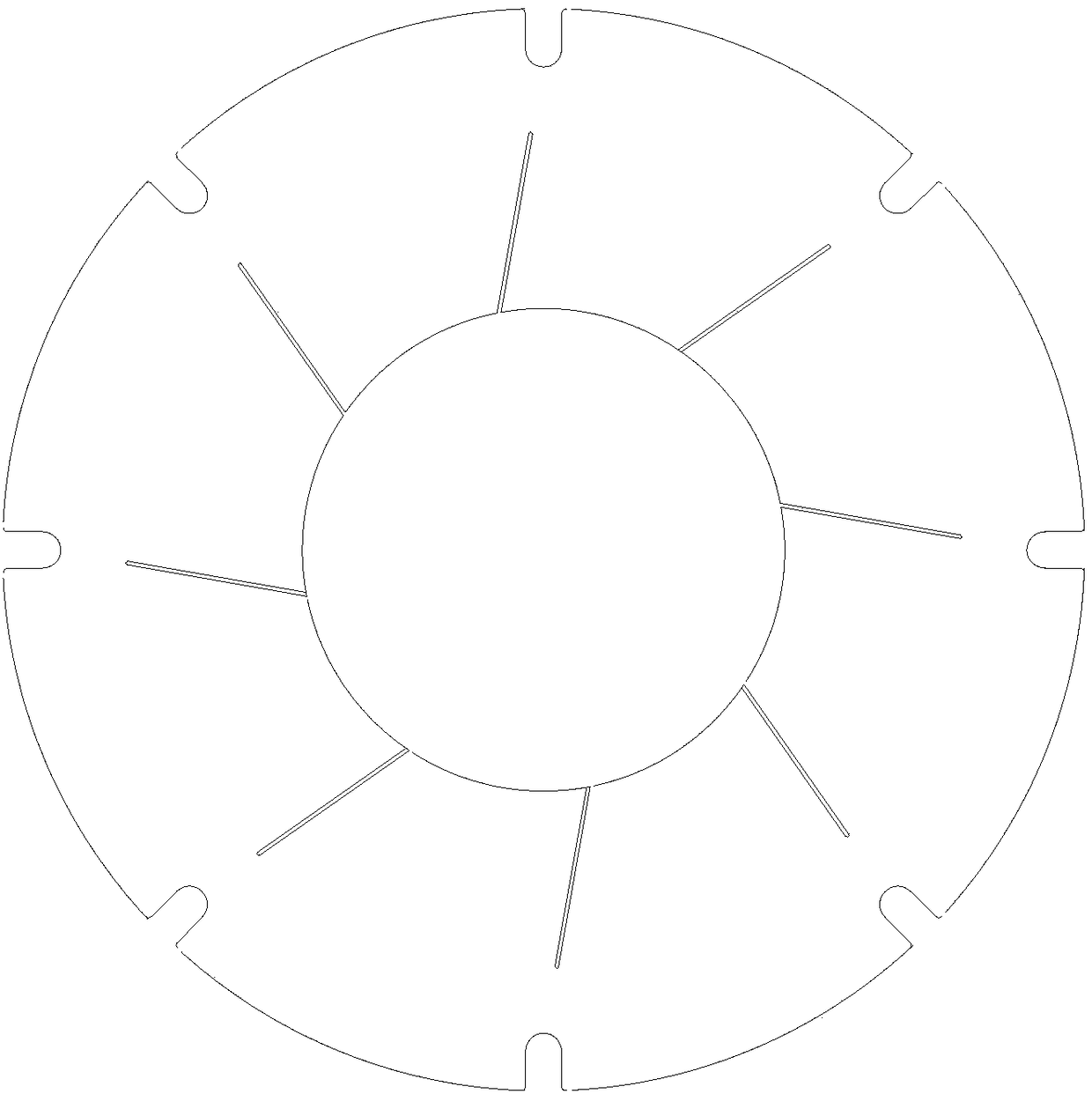

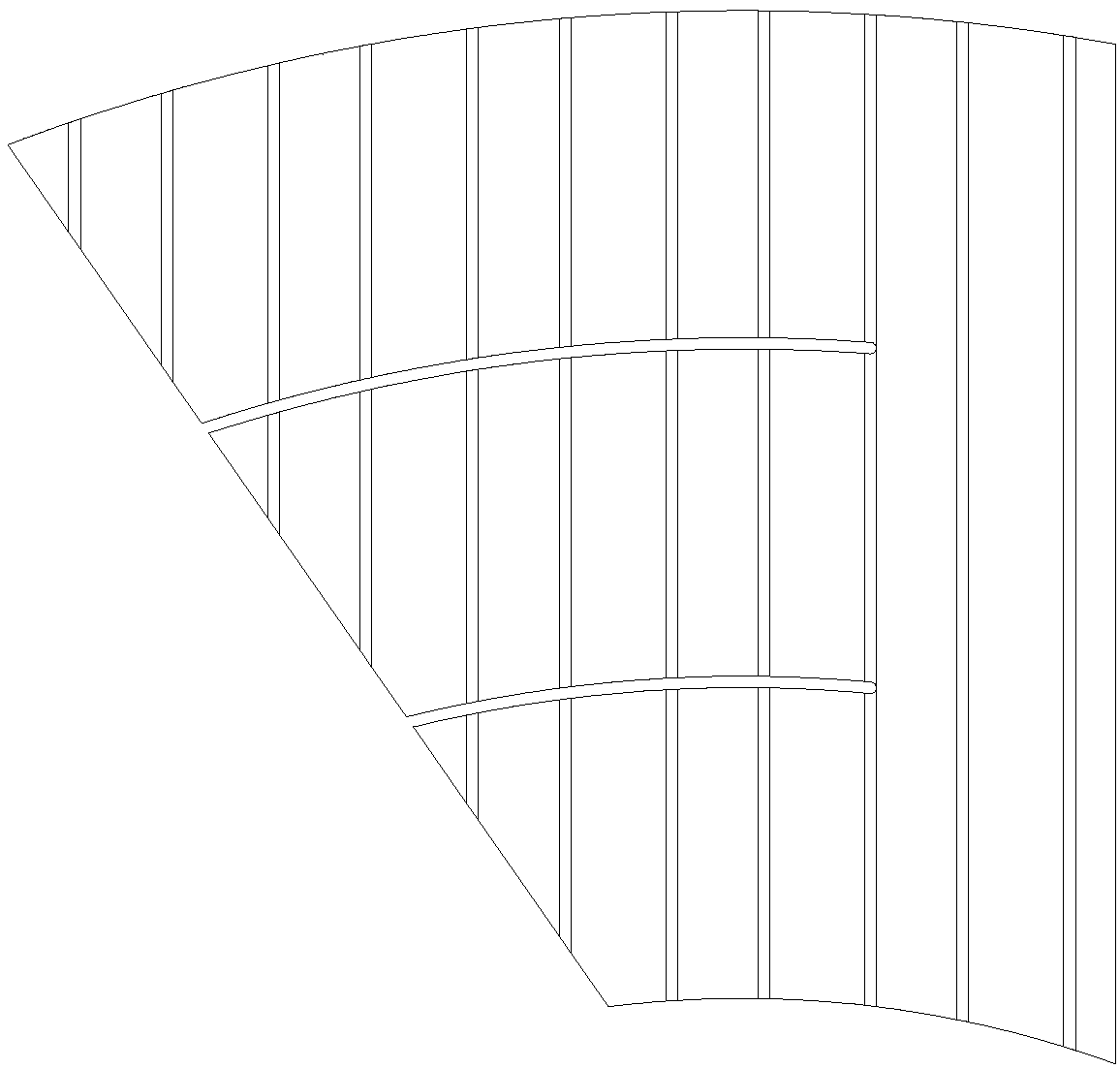

[0017] Specific examples, such as Figure 1 to Figure 4 As shown, a thrust foil dynamic pressure air bearing with a thick top-layer foil structure includes a bottom plate 1, a supporting corrugated foil 2 and a top-layer foil 3. The circular bottom plate 1 is arranged below, and multiple fan-shaped top-layer foils The sheet 3 is fixed above the bottom plate 1, and the supporting corrugated foil 2 is assembled between the bottom plate 1 and the top layer foil 3, and also includes an inlet segment gasket 4 arranged on the radial side of the junction of the top layer foil 3 and the bottom layer 1, and the inlet The thickness of the segment gasket 4 is adjustable, the thickness of the top layer foil 3 is 0.5mm-1mm, and it is processed by mold hydroforming. The deformation is 0.01mm-0.02mm, the inlet section gasket 4 and the bottom plate 1, the top...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Deformation | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com