Radial foil bearing with sealing function

A technology of foil bearings and foils, applied in the field of radial foil bearings, can solve the problems of deformed top foils not acting as bearings, not trying foil bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

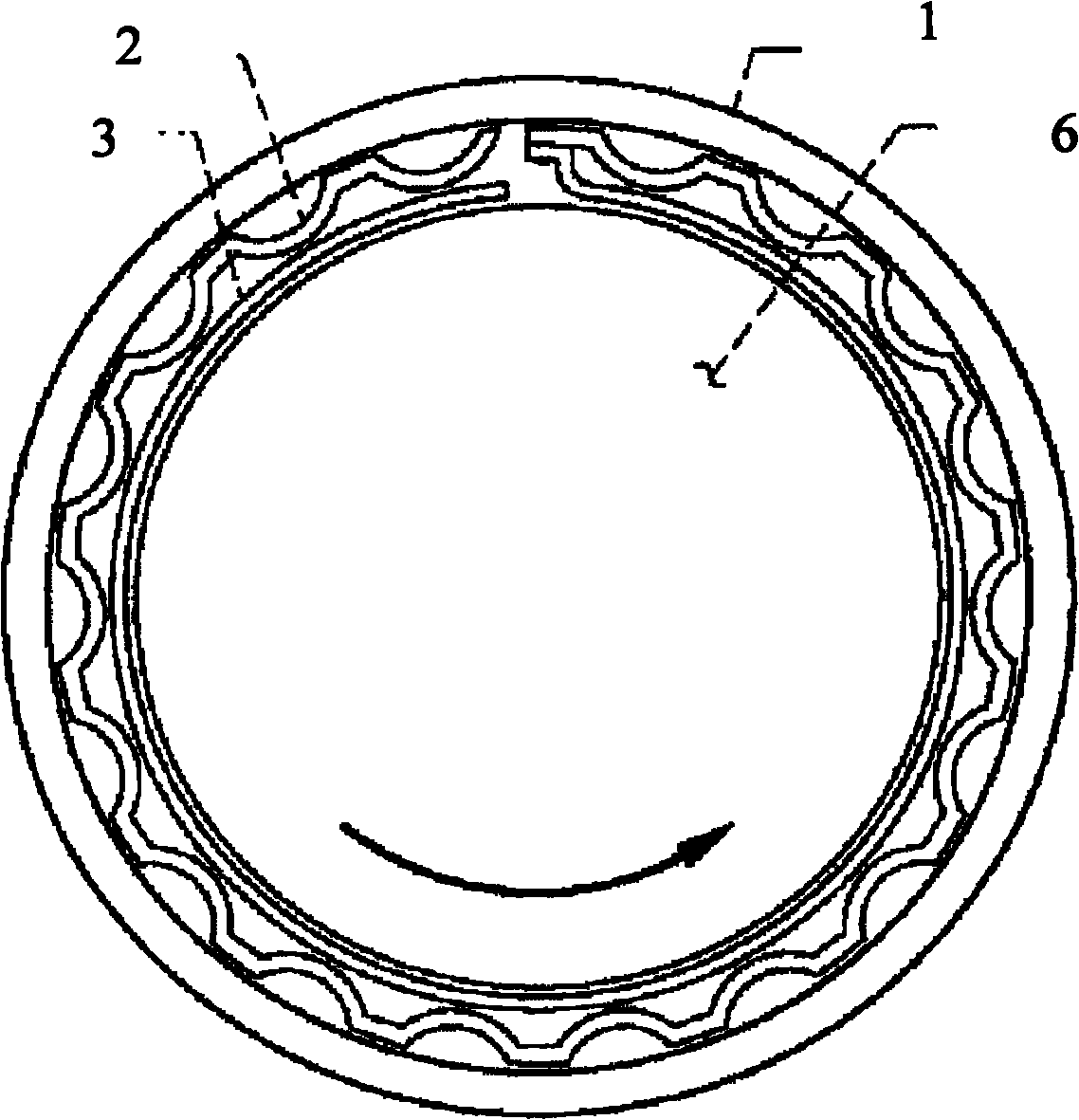

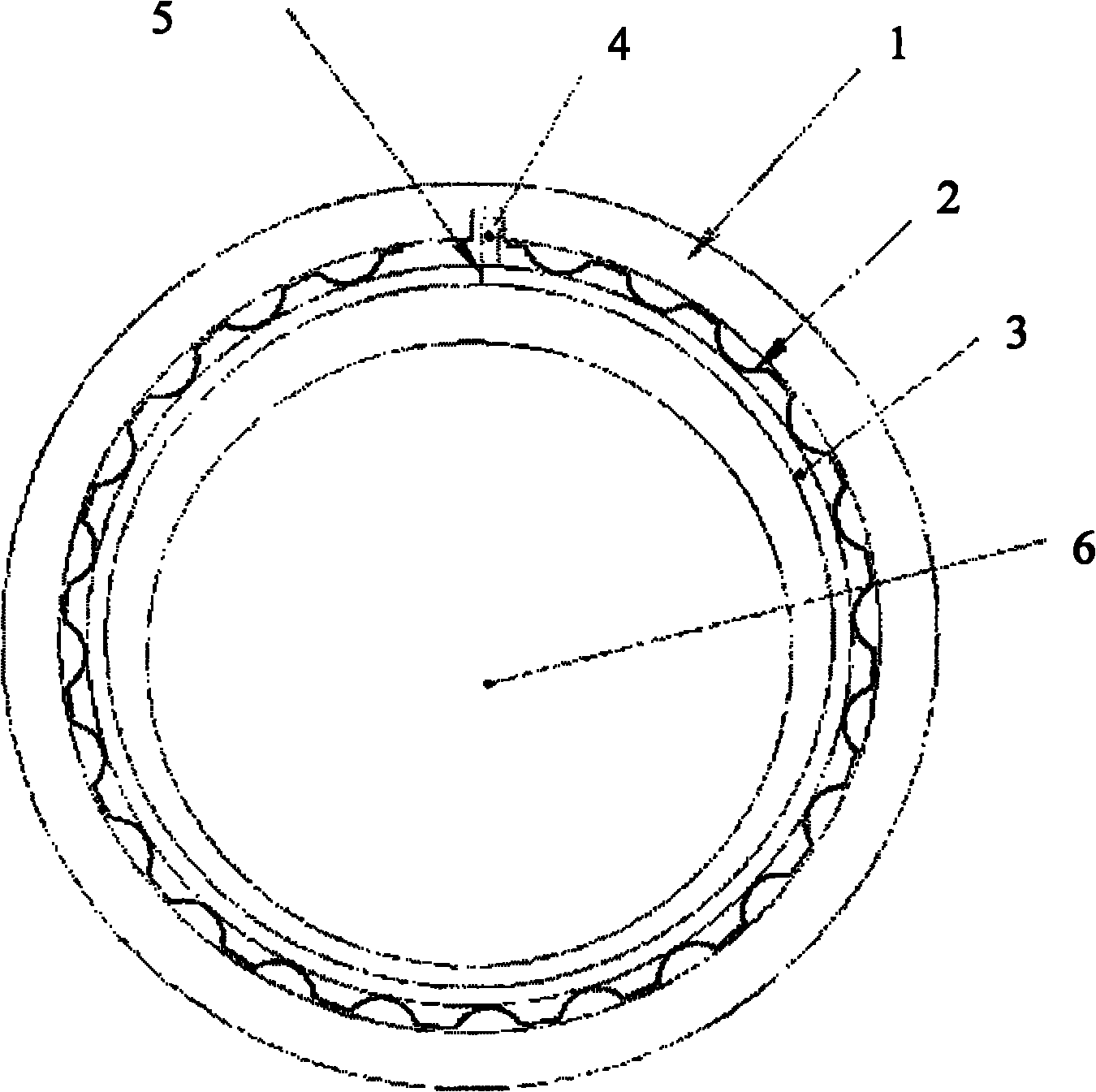

[0018] figure 1 Shown is a typical form of foil bearings used so far, figure 2 Shown is a version of the foil bearing with a thickened tip foil 3 . Since the surrounding gas acting as lubricating oil can flow to the place with the raised foil 2, it is difficult to add a seal, and the performance of the seal is greatly reduced due to the movement of the shaft 6.

[0019] Thus, the foil bearing can be made to seal with only a slight gap between the shaft 6 and the top foil 3 , thus giving it the function of a seal.

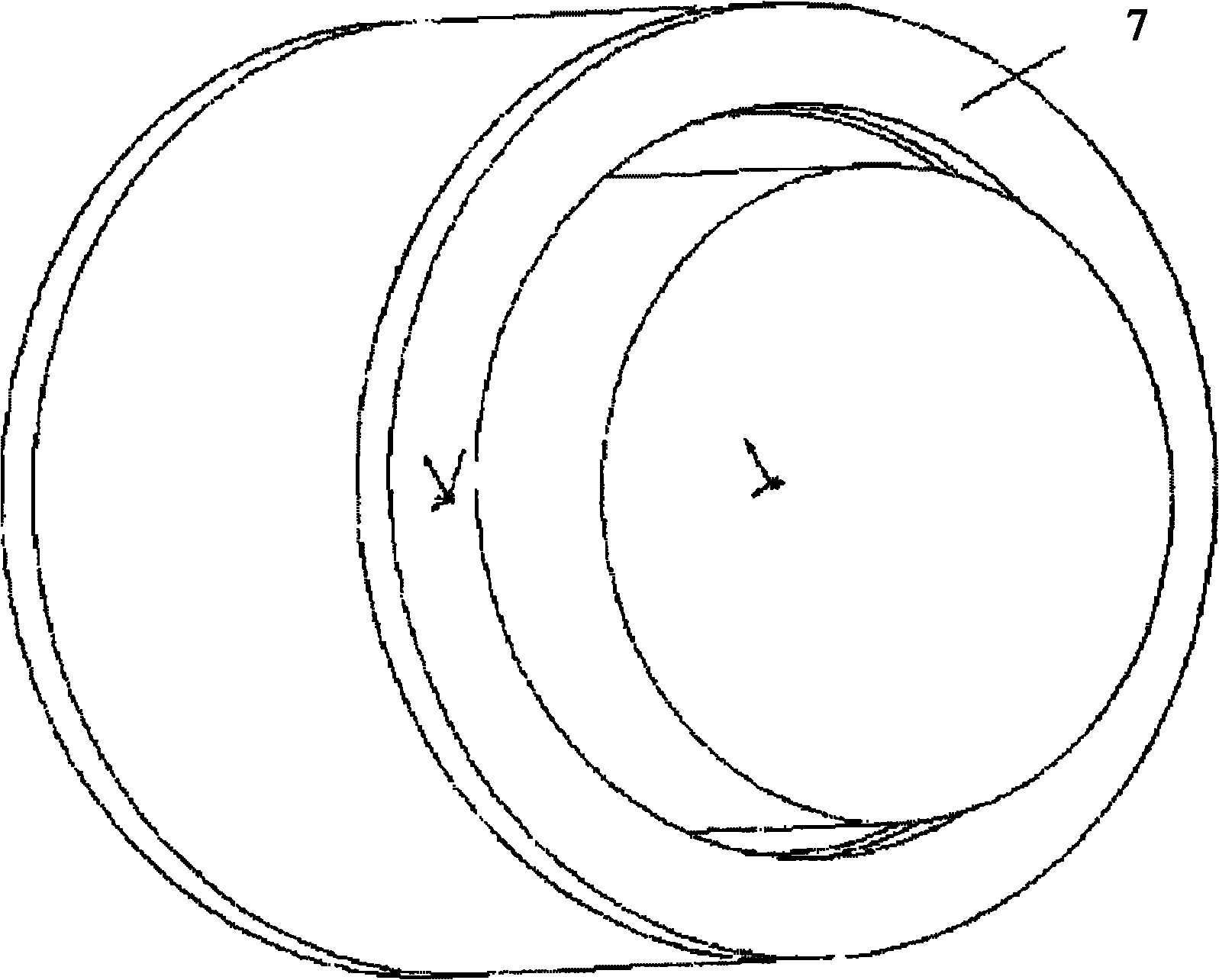

[0020] The present invention is to figure 2 The structure of the raised radial foil bearing shown is modified so that it functions as a seal. Such as image 3 , Figure 4 As shown, by using a lathe-machined top foil 3 of sufficient thickness and a plug 7 capable of covering the gap between the raised foils 2, only a tiny gap exists between the shaft 6 and the bearing and all others are removed. The flow gap can provide high performance sealing function.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com