Molybdenum disulfide coating and preparation method and application thereof

A technology of molybdenum disulfide and coating, which is applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc. It can solve the problem of not being able to have both heat resistance and wear resistance, and achieve both heat resistance And wear resistance, the effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

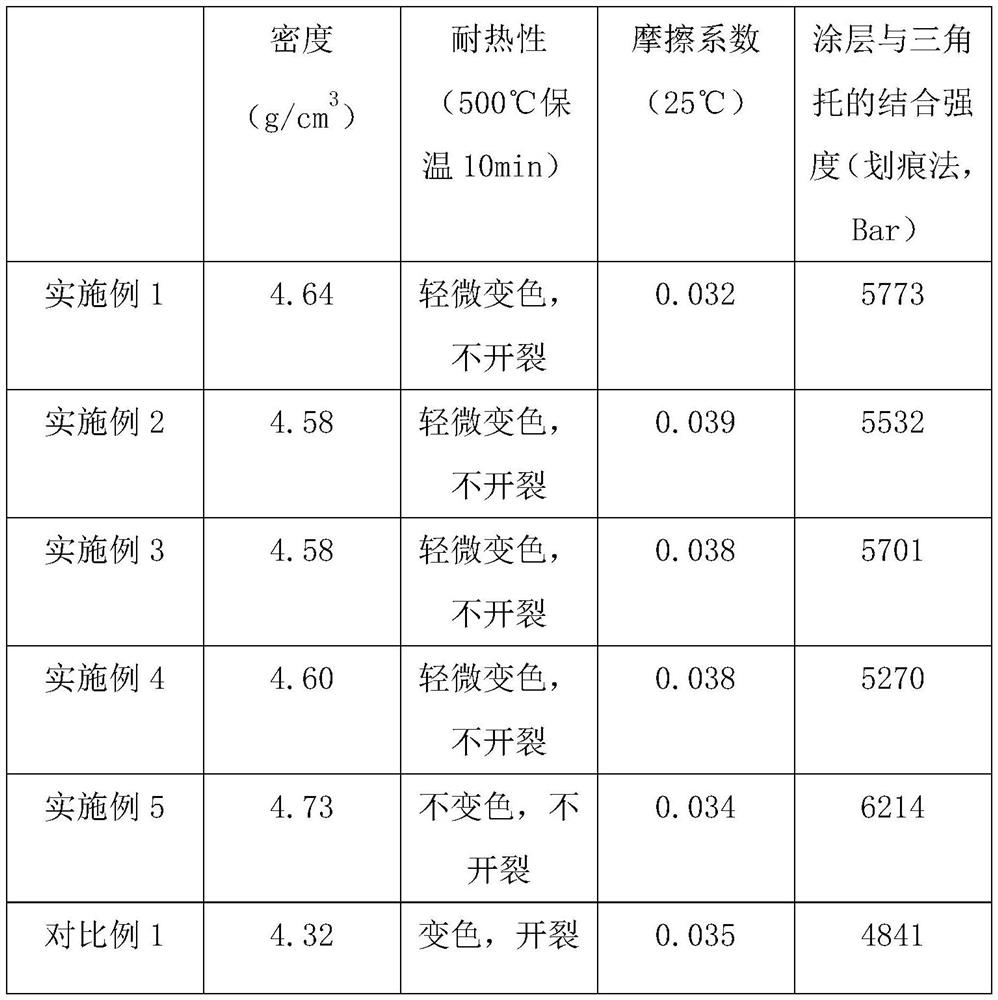

Examples

Embodiment 1

[0034] This embodiment provides a surface treatment method for the triangular bracket in the powder metallurgy brake pads of a high-speed train, which includes the following steps:

[0035] 1) Preparation of molybdenum disulfide coating: add 3kg of phenolic resin to 97kg of absolute ethanol, stir and mix to obtain a phenolic resin in absolute ethanol solution, add 100kg of molybdenum disulfide to the phenolic resin in absolute ethanol solution, and then Then add 1 kg of graphite and stir well to obtain the molybdenum disulfide coating;

[0036] 2) Ultrasonic cleaning the surface of the triangle holder for 20 minutes to remove impurities on the surface of the triangle holder. After cleaning, put the triangle holder into the oven for preheating, the preheating temperature is 50℃, and the preheating time is 15min; When preheating, put the molybdenum disulfide paint described in step 1) into the spray gun, and after the preheating of the triangle holder is completed, take the triangle ...

Embodiment 2

[0039] This embodiment provides a surface treatment method for the triangular bracket in the powder metallurgy brake pads of a high-speed train, which includes the following steps:

[0040] 1) Preparation of molybdenum disulfide paint: add 2kg of phenolic resin to 95kg of absolute ethanol, stir and mix to obtain a phenolic resin in absolute ethanol solution, add 105kg of molybdenum disulfide to the phenolic resin in absolute ethanol solution, and then Then add 0.8 kg of boron nitride and stir fully to obtain the molybdenum disulfide coating;

[0041] 2) Ultrasonic cleaning the surface of the triangle holder for 20 minutes to remove impurities on the surface of the triangle holder. After cleaning, put the triangle holder into the oven for preheating, the preheating temperature is 45℃, and the preheating time is 20min; When preheating, put the molybdenum disulfide paint described in step 1) into the spray gun, and after the preheating of the triangle holder is completed, take the tri...

Embodiment 3

[0044] This embodiment provides a surface treatment method for the triangular bracket in the powder metallurgy brake pads of a high-speed train, which includes the following steps:

[0045] 1) Preparation of molybdenum disulfide coating: add 5kg of phenolic resin to 100kg of absolute ethanol, stir and mix to obtain a phenolic resin in absolute ethanol solution, add 95kg of molybdenum disulfide to the phenolic resin in absolute ethanol solution, and then Then add 1.1 kg of graphite and fully stir to obtain the molybdenum disulfide coating;

[0046] 2) Ultrasonic cleaning the surface of the triangle holder for 20 minutes to remove impurities on the surface of the triangle holder. After cleaning, put the triangle holder into the oven for preheating, the preheating temperature is 55℃, and the preheating time is 10min; When preheating, put the molybdenum disulfide paint described in step 1) into the spray gun, and after the preheating of the triangle holder is completed, take the triang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com