Magnetic-gas bearing and method for making compliant foil

A hybrid bearing and elastic foil technology, which is applied in the mechanical field, can solve the problems of reducing the dynamic performance of the rotor and the foil gas bearing occupying a large axial space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The mechanism principle and working principle of the present invention will be described in further detail below in conjunction with the accompanying drawings.

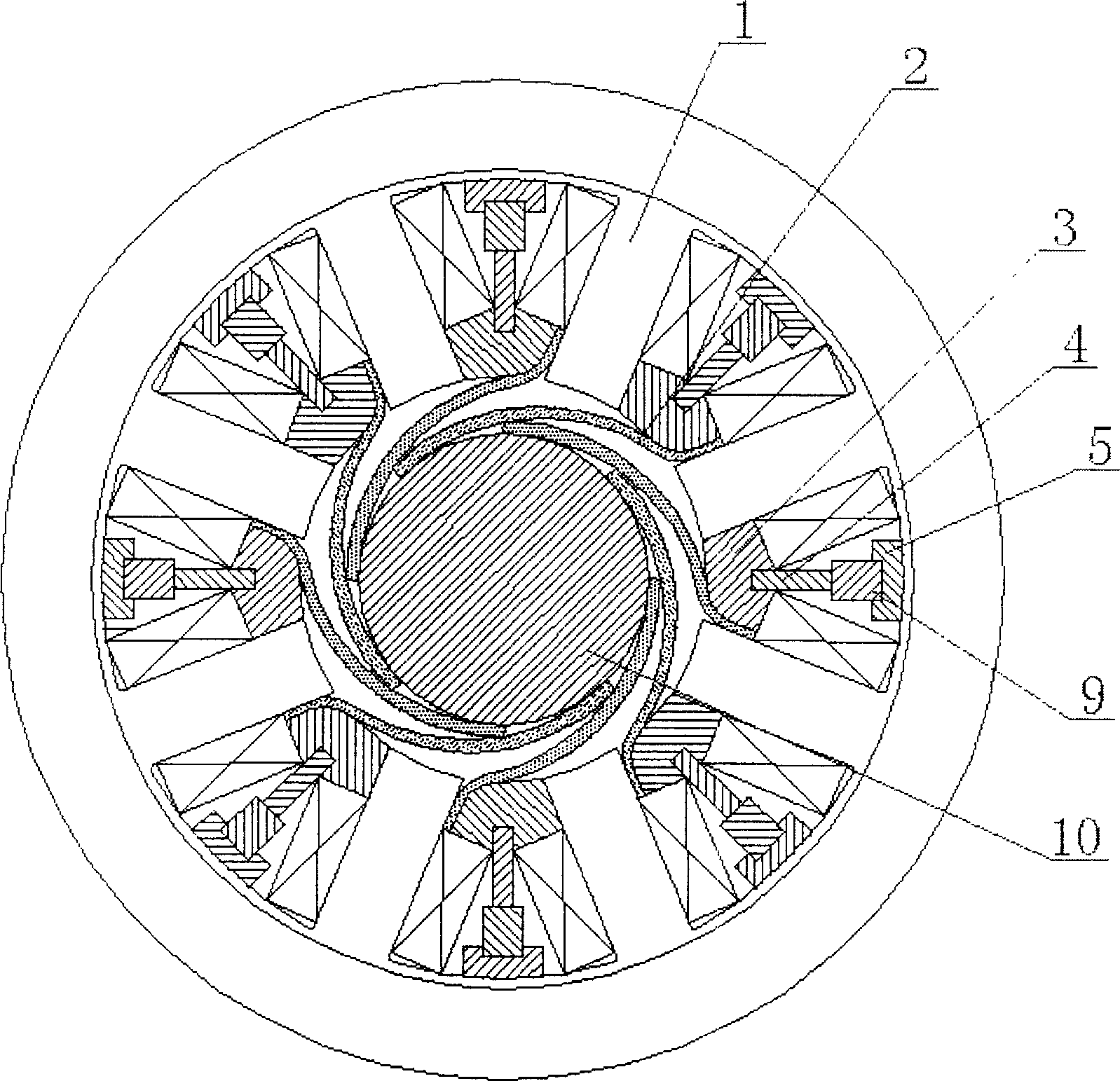

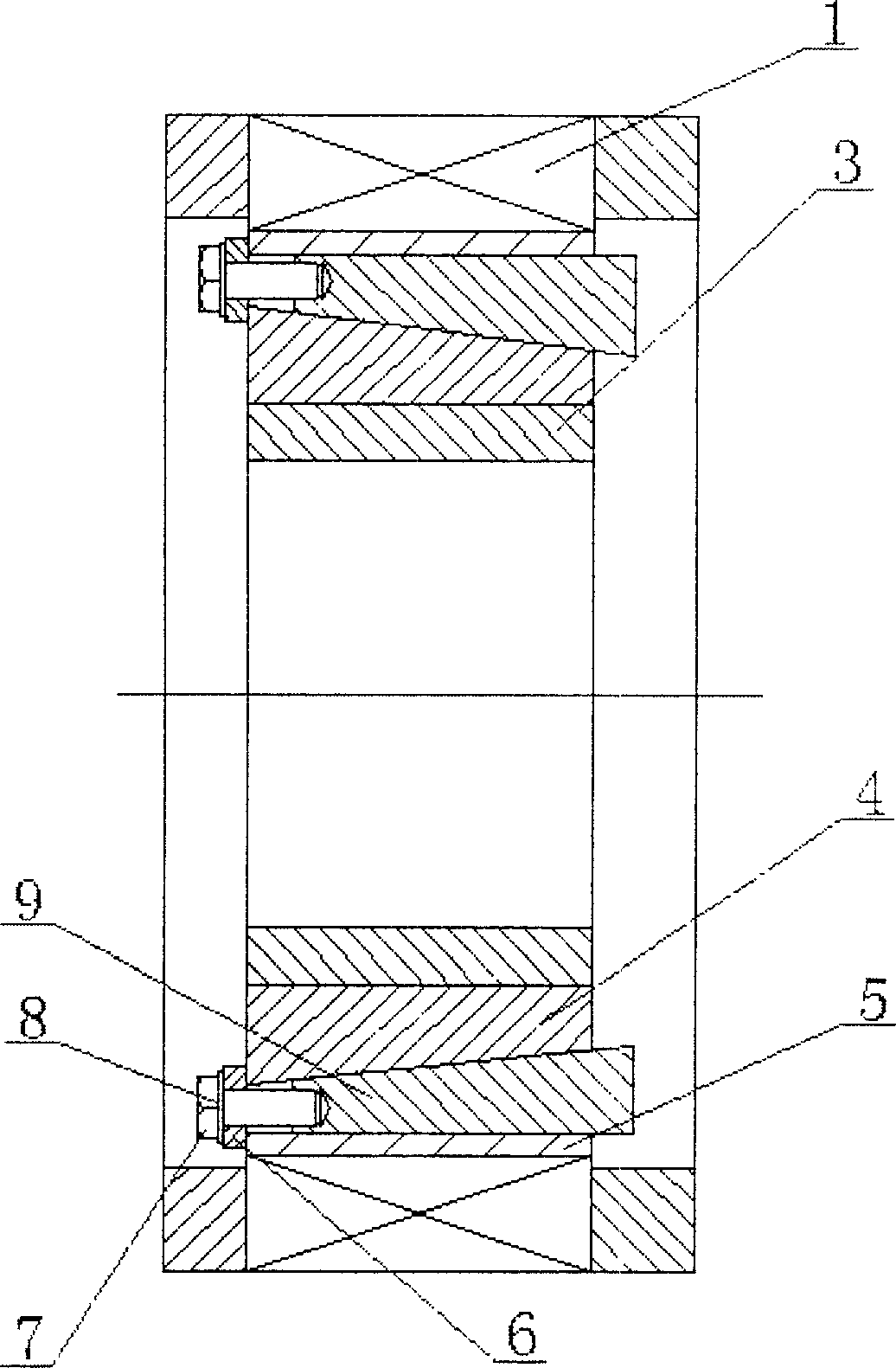

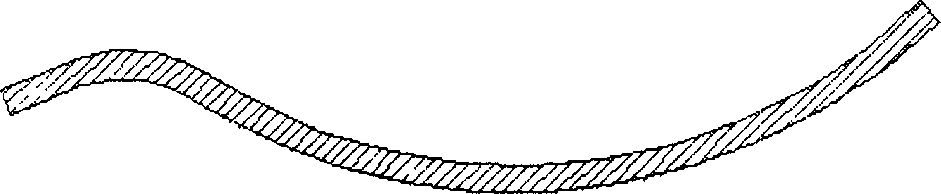

[0010] see figure 1 , 2, 3 The composition of the present invention includes the active magnetic suspension radial bearing 1, and the elastic foil 2 is fixed in the extremely small air gap between the active magnetic suspension bearing magnetic pole and the shaft through the locking mechanism integrated in the active magnetic suspension bearing magnetic pole. The elastic foil dynamic pressure gas bearing can adopt various forms, such as flat foil type, cantilever type, corrugated foil type, etc. The key is to fix the position of the elastic foil in the extremely small air gap between the active magnetic levitation radial bearing and the shaft, Due to the spatial structure characteristics of the active magnetic suspension radial bearing, the locking device of the elastic foil can only be integrated between the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com