Air foil bearing having a porous foil

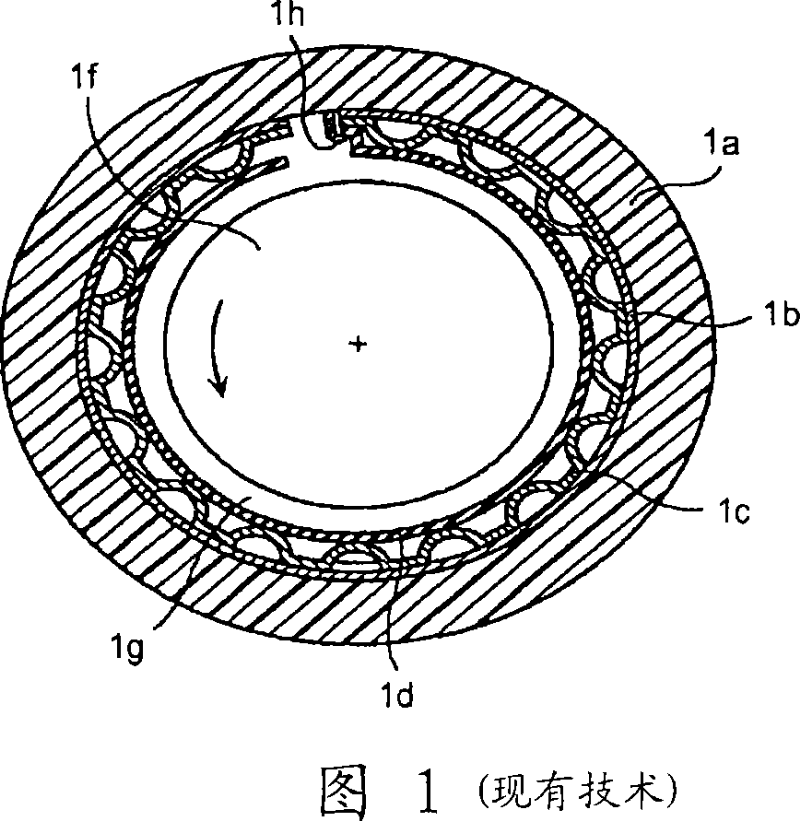

A foil bearing and foil technology, which is applied in the field of air foil bearings, can solve the problems of difficult performance, insufficient vibration damping capacity of air foil bearings, and the reduction of the maximum rotational speed of rotating bodies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, we describe in detail preferred embodiments of the present invention with reference to the accompanying drawings.

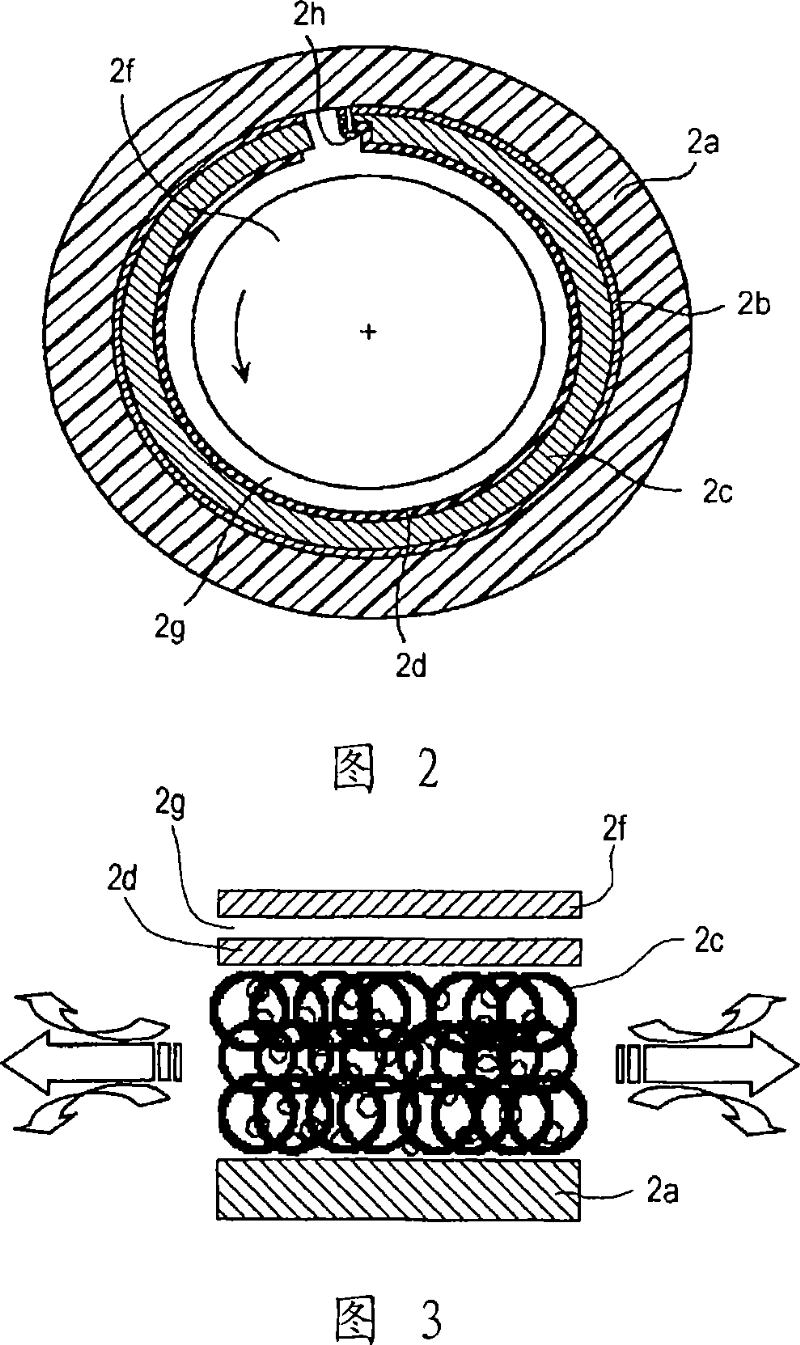

[0019] Figure 2 illustrates a cross-sectional view of an air foil bearing constructed in accordance with the present invention.

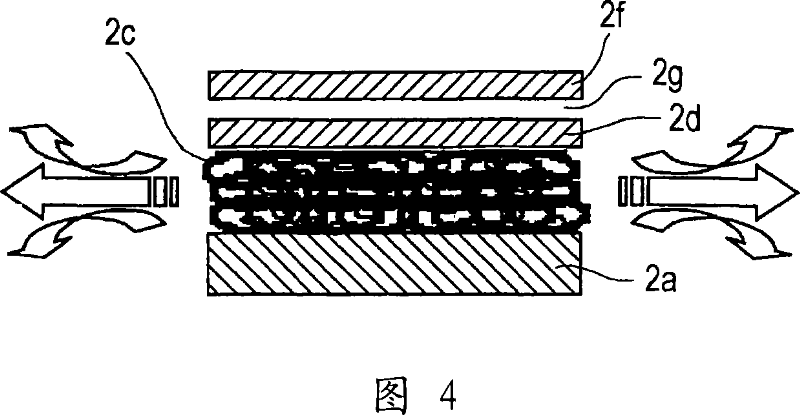

[0020] Referring to Fig. 2, the air foil bearing constructed according to the present invention includes: a bearing housing 2a, a top foil 2d, a porous foil 2c and a backing foil 2b.

[0021] The top foil 2d is arranged on the innermost side of the bearing housing 2a, positioned relative to the rotary shaft 2f, with an air lubricating film 2g in between. The upper surface of the top foil 2d facing the rotary shaft 2f is formed with a coated surface for body lubrication to minimize friction between it and the rotary shaft 2f during start and stop of the rotary shaft 2f. Those skilled in the art know that the purpose of this surface coating treatment is to increase the friction between the foils in an air foil bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com