Adjustable cantalever type dynamic pressure gas elastic foil bearing

An elastic foil and cantilever type technology, applied in the field of dynamic pressure gas elastic foil bearings, can solve the problems of low bearing capacity, poor bearing stability, bearing lubrication gas end leakage, etc., to improve the bearing capacity and improve the equivalent Stiffness, effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

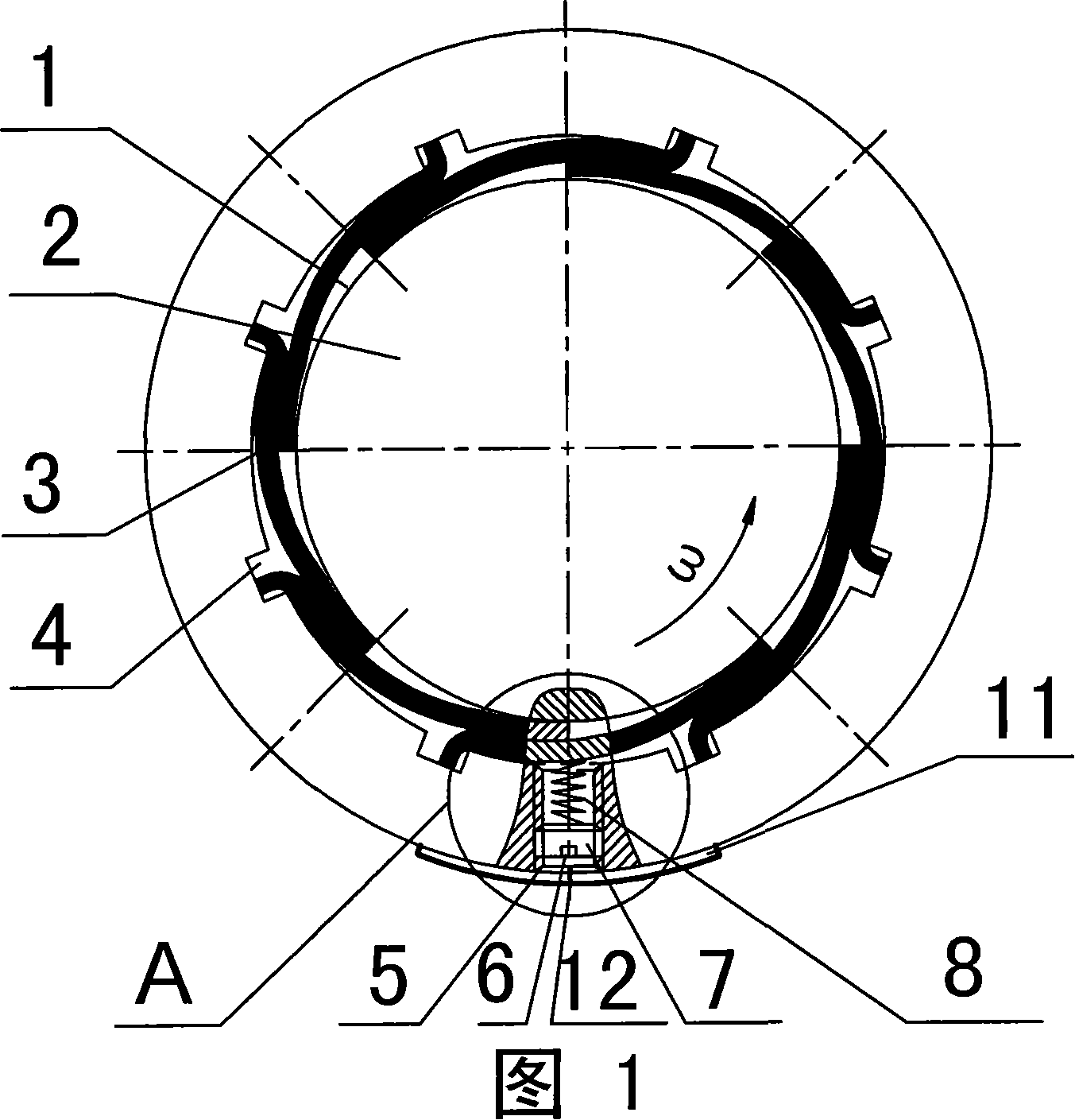

[0007] Specific embodiment one: As shown in Figure 1, the new adjustable cantilever type dynamic pressure gas elastic foil bearing of this embodiment is composed of a bearing housing 1, an elastic foil 3, and an adjustable mechanism 9; the elastic foil described 3 is mounted on the inner wall of the bearing housing 1 and evenly arranged along the inner wall of the bearing housing 1. One end of the elastic foil 3 is fixedly installed in the longitudinal groove 4 provided on the inner wall of the bearing housing 1. The elastic foil 3 The other end of the other end is overlapped on the adjacent elastic foil; the adjustable mechanism 9 is installed in the internal threaded through hole 5 of the housing 1 and screwed with the threaded through hole 5, and the adjustable mechanism 9 is in contact with the elastic foil 3 . During use, journal 2 is contained on the bearing.

specific Embodiment approach 2

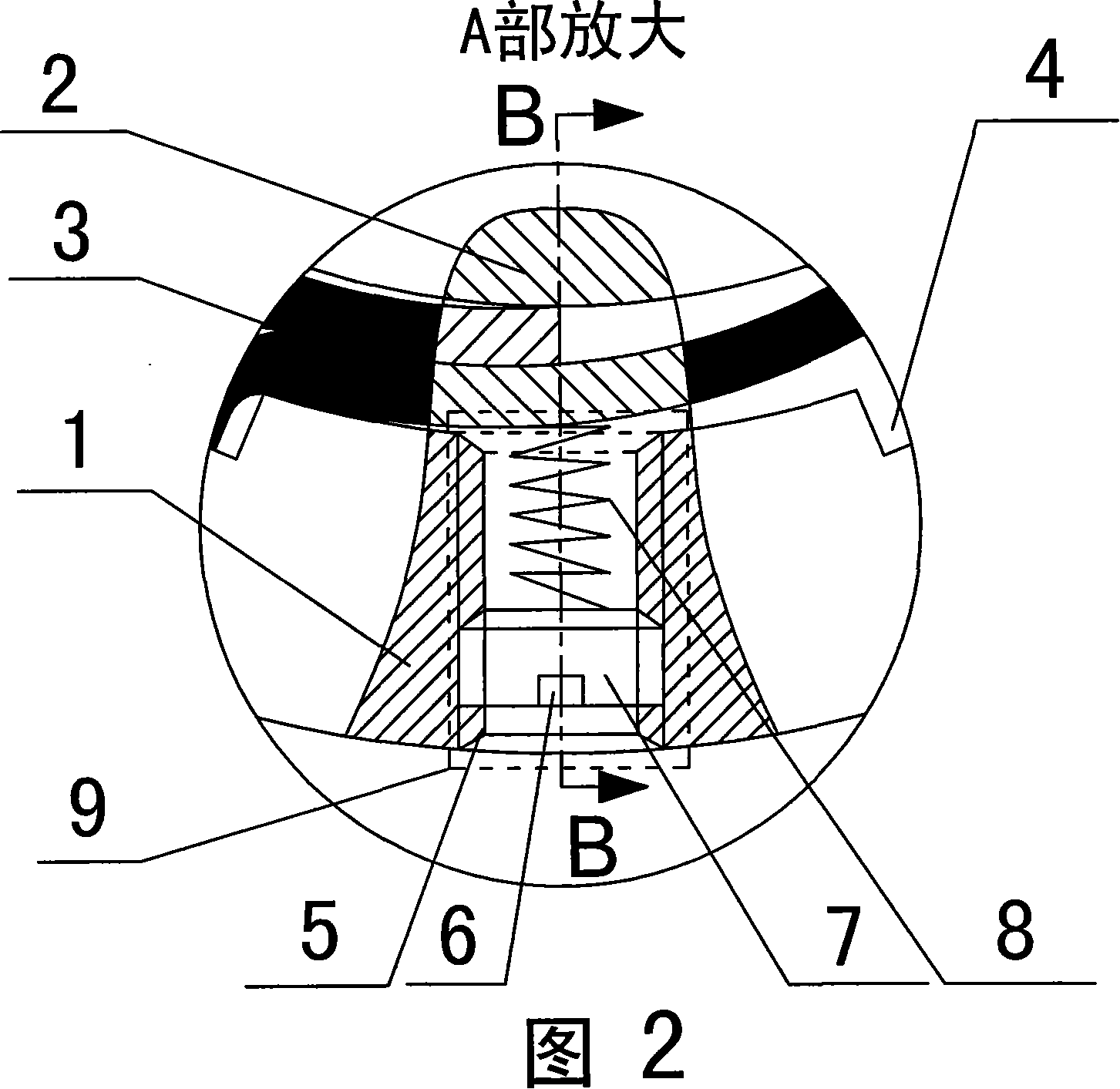

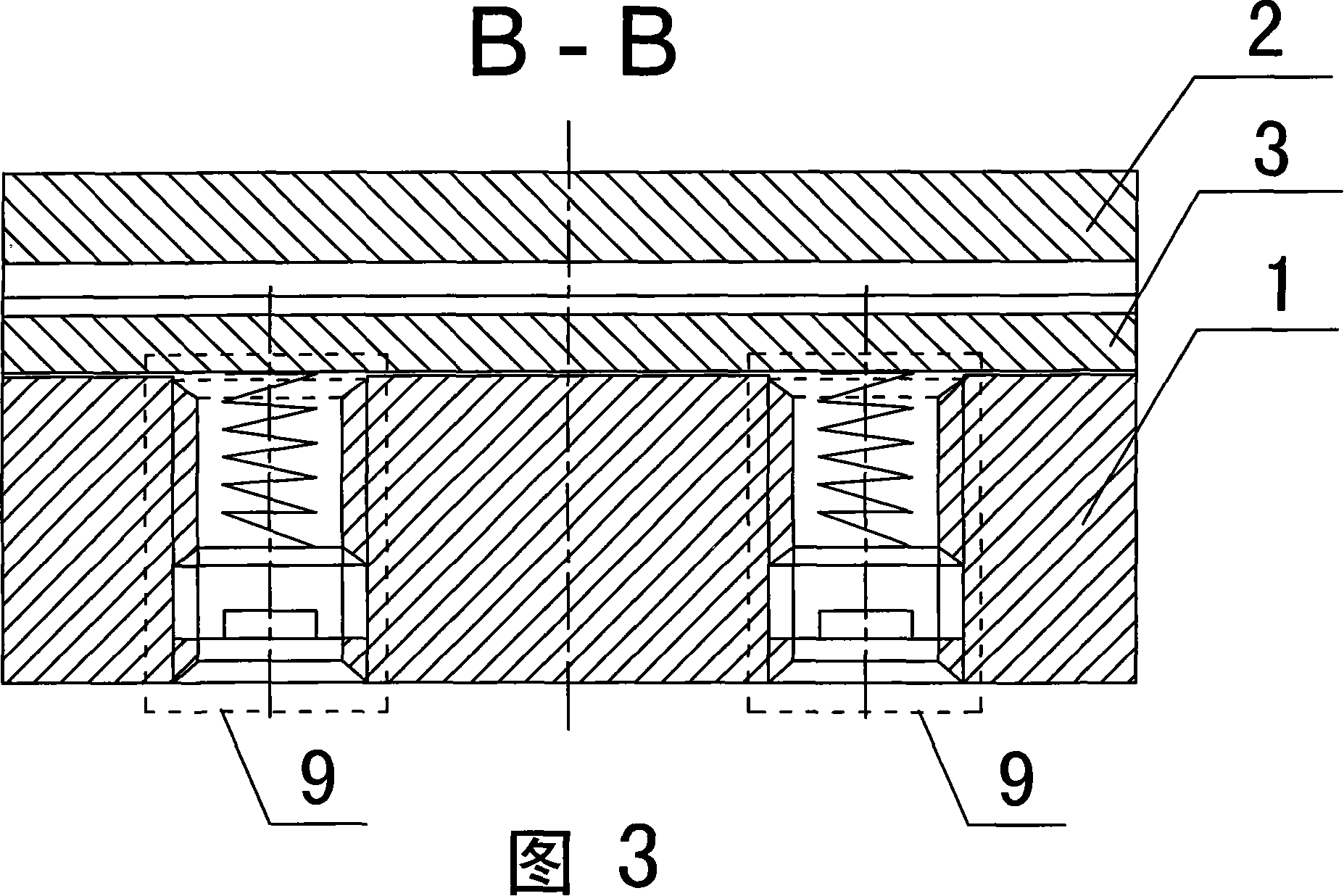

[0008] Specific embodiment two: as shown in Figure 2, the adjustable mechanism 9 described in this embodiment is composed of a cylindrical plug 7 and a cylindrical spring 8, the inner end of the cylindrical plug 7 is in contact with the outer end of the cylindrical spring 8, and the cylindrical The outer end surface of the plug 7 is provided with a square groove 6, and the square groove 6 is convenient for the adjustment of the cylindrical plug 7 in and out. This structure is simple and easy to process. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific embodiment three: the adjustable mechanism 9 described in this embodiment is composed of a cylindrical long wire plug 10, a thin steel wire rod 13 and a cylindrical spring 8, the inner end of the cylindrical long wire plug 10 is in contact with the outer end of the cylindrical spring 8, The cylindrical long screw plug 10 is radially provided with a first locking through hole 10-1 and a second locking through hole 10-2 perpendicular to each other, and a thin steel wire rod 13 is inserted into the radial first locking hole. In the tight through hole 10 - 1 or the second locked through hole 10 - 2 , a first square groove 14 is provided on the outer end surface of the cylindrical long thread plug 10 . This structure can effectively adjust the compression amount of the cylindrical spring 8 and has a first locking through hole 10-1 and a second locking through hole 10-2. The structure is simple and compact, and the locking effect is good. Other components and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com