Self-regulating type hydrodynamic gas elastic foil bearing

An elastic foil, self-adjusting technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of dynamic pressure gas elastic foil bearing load capacity reduction, air leakage, etc., to improve load capacity, reduce leakage, The effect of enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

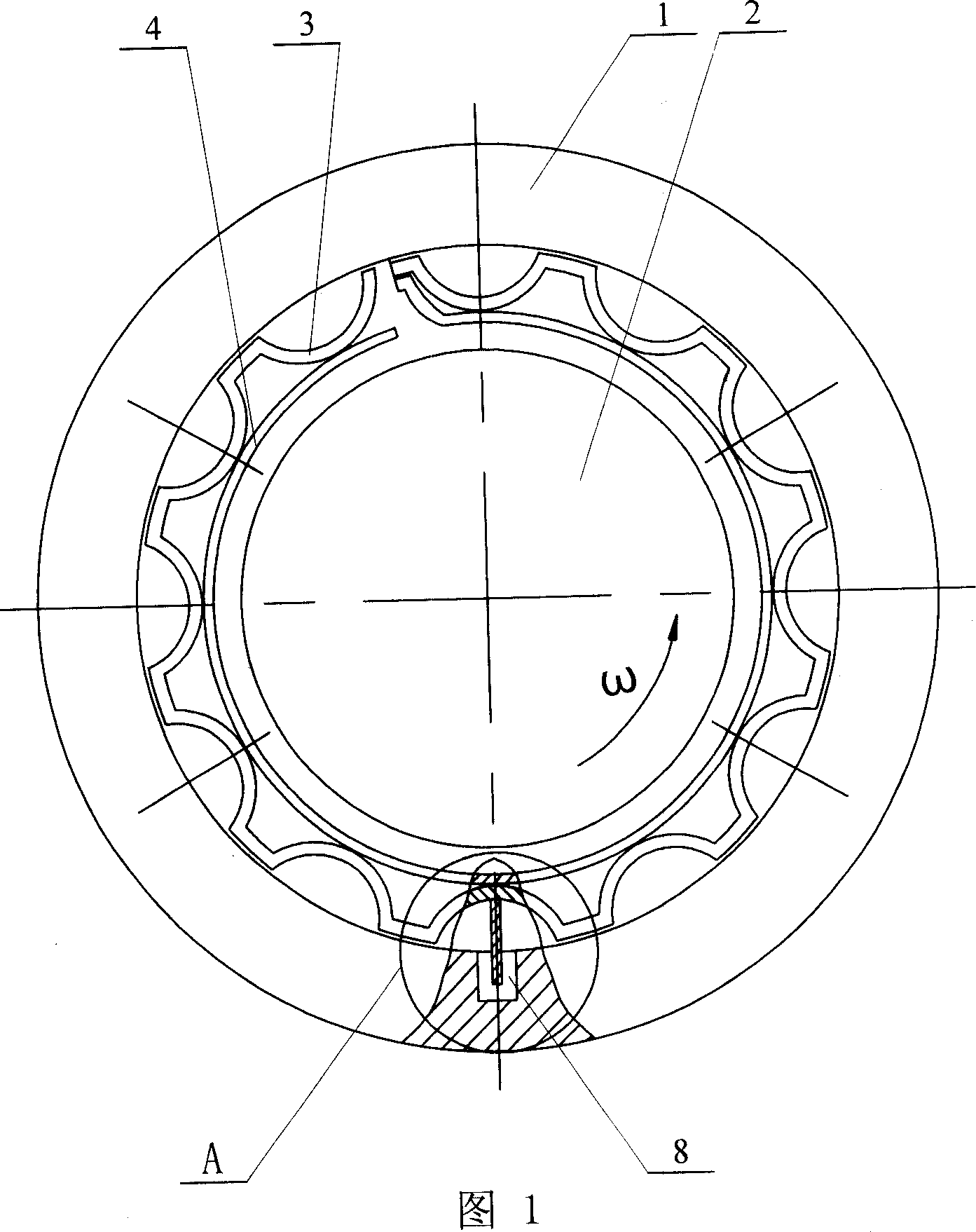

[0007] Specific embodiment 1: This embodiment is described in conjunction with Fig. 1 to Fig. 18. This embodiment is composed of a housing 1, a corrugated foil 3, a flat foil 4 and a self-regulator 5; the flat foil 4 is installed in the housing 1, between the housing 1 and the flat foil 4, there are corrugated foils 3 that are respectively in contact with the housing 1 and the flat foil 4; the self-regulator 5 is installed in the housing 1 and located in the housing 1 and the corrugated foil 3 or between the shell 1 and the flat foil 4, the number of self-regulators 5 is determined according to actual production needs, and the self-regulators 5 are distributed along the inner wall of the shell 1 to ensure the bearing capacity .

[0008] When in use, the bearing is mounted on the rotating shaft 2 to ensure the clearance fit between the flat foil 4 and the rotating shaft 2 .

specific Embodiment approach 2

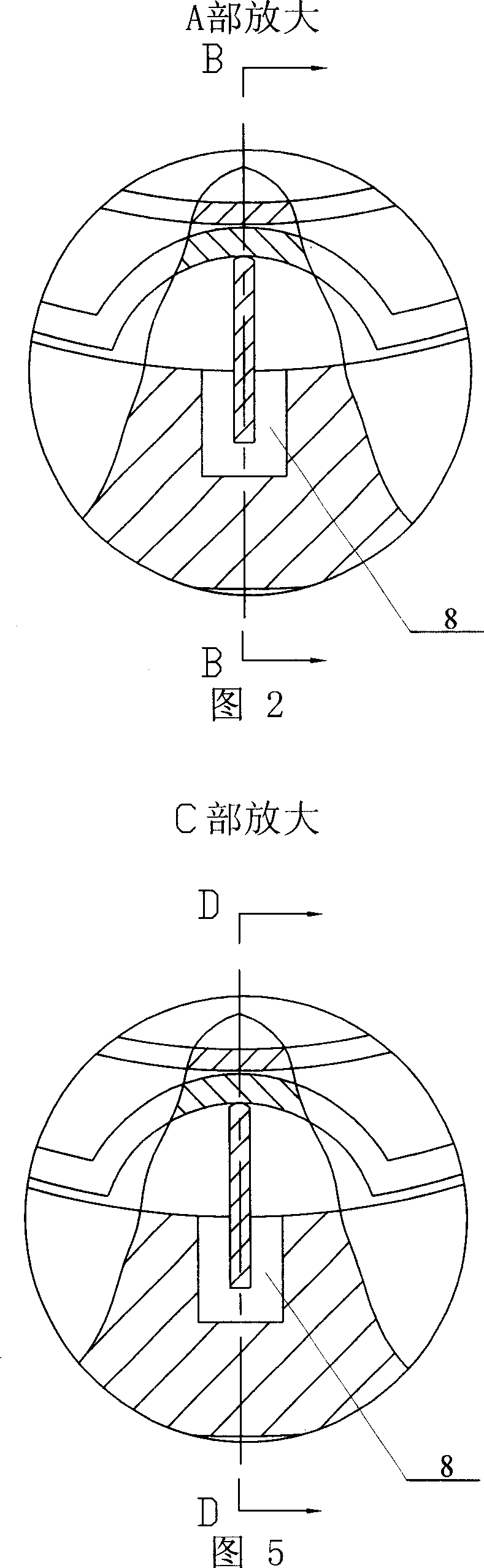

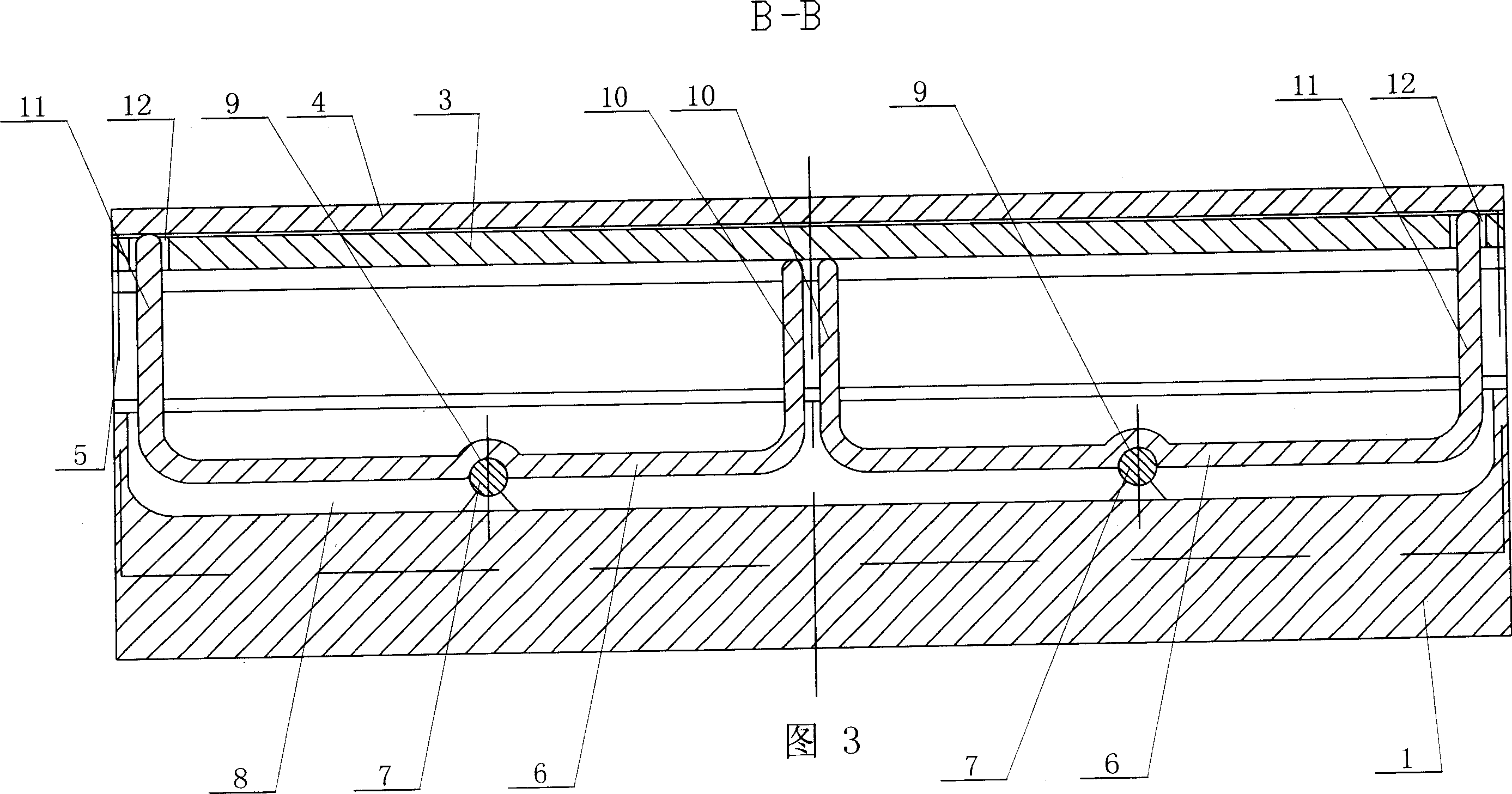

[0009] Specific Embodiment 2: This embodiment is described with reference to FIGS. 1 to 3. The self-regulator 5 of this embodiment is located between the housing 1 and the flat foil 4. The self-regulator 5 is composed of two first U-shaped rods 6 and Composed of two first cylindrical hinge supports 7, the inner wall of the housing 1 is provided with a first long slot 8 in the axial direction, and two first U-shaped rods are installed in the first long slot 8 in the axial direction 6. The lower end of each first U-shaped bar 6 corresponds to a first cylindrical hinge support 7 respectively, and the upper end of the first cylindrical hinge support 7 is installed on the first circle at the lower end of the corresponding first U-shaped bar 6. In the arc-shaped pit 9, the lower end of the first cylindrical hinge support 7 is affixed to the bottom end surface of the first long groove 8, and the ends of the two radial rods 10 adjacent to the two first U-shaped rods 6 are respectively ...

specific Embodiment approach 3

[0010] Specific Embodiment 3: This embodiment is described in conjunction with FIGS. 4 to 6. The self-regulator 5 of this embodiment is located between the housing 1 and the corrugated foil 3. The self-regulator 5 is composed of two second U-shaped rods 14 and Composed of two second cylindrical hinge supports 15, the inner wall of the housing 1 has a second long slot 16 in the axial direction, and the second long slot 16 is equipped with two second U-shaped rods in the axial direction 14. The lower end of each second U-shaped bar 14 corresponds to a second cylindrical hinge support 15, and the upper end of the second cylindrical hinge support 15 is mounted on the second circular arc at the lower end of the corresponding second U-shaped bar 14. In the pit 17, the lower end of the second cylindrical hinge support 15 is affixed to the bottom end surface of the second long groove 16, and the ends of the two radial rods 18 of each second U-shaped rod 14 are respectively connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com