Two-stage series pressurization direct-driven centrifugal air compressor of fuel cell engine

A technology of centrifugal air compressors and fuel cells, which is applied in liquid fuel engines, engine components, machines/engines, etc., can solve the problems of rotor-spindle speed reduction, support component damage, and increased friction loss, etc., to avoid gears Effects of meshing vibration noise, avoiding accuracy changes, and suppressing axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

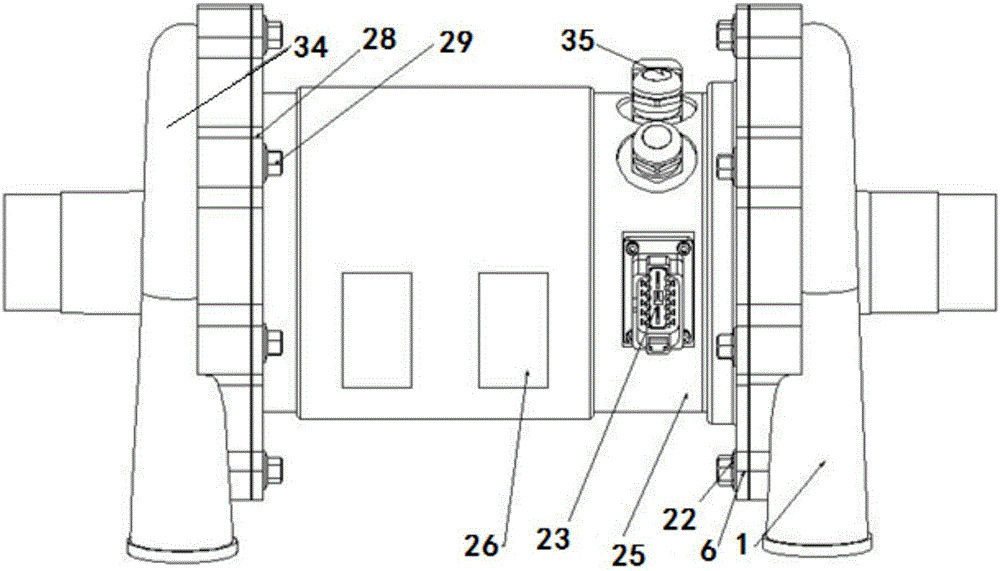

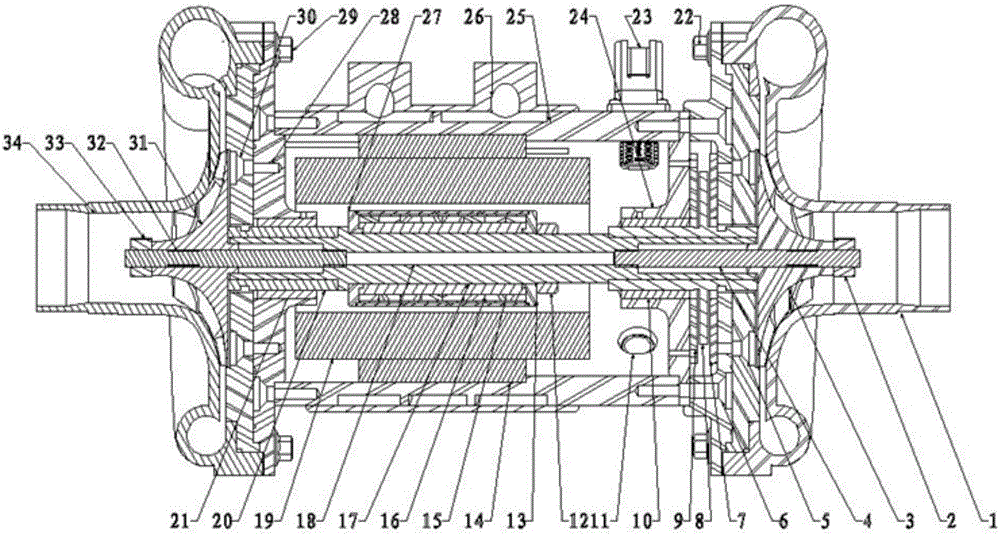

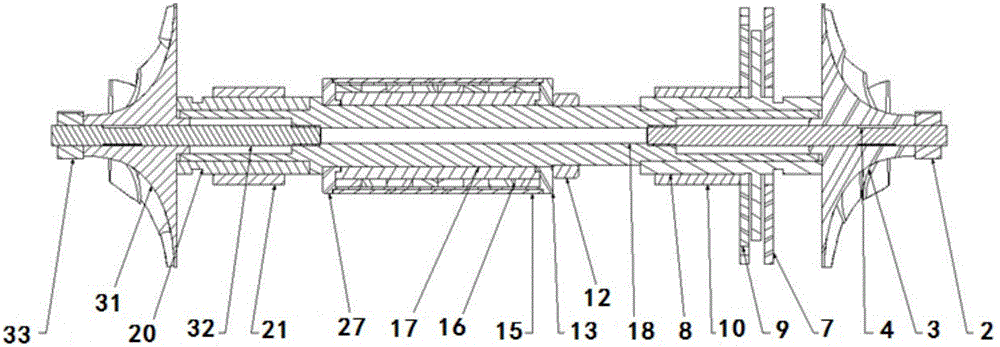

[0039] A high-power (10kW) high-speed (50,000rpm) high-speed two-stage series supercharged direct-drive centrifugal air compressor that meets the full working condition of a vehicle fuel cell engine. Its structure is as follows: figure 1 and figure 2 As shown, the air compressor is driven by a motor to rotate. The air compressor is provided with a left volute 34 and a right volute 1. The left volute 34 is provided with an air inlet, an air outlet, and a left volute end cover 30. The right volute 1 An air inlet, an air outlet and a right end volute cover 5 are arranged on the top, and the air outlet of the left volute 34 is connected to the air inlet of the right volute 1 during operation. The left and right sides of the air compressor are also provided with a left end motor end cover 28 and a right end motor end cover 6, the left end volute end cover 30 and the left end motor end cover 28 are connected and fixed by the left end connecting bolt 29, the right end volute end cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com