Patents

Literature

169results about How to "Increase the critical speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

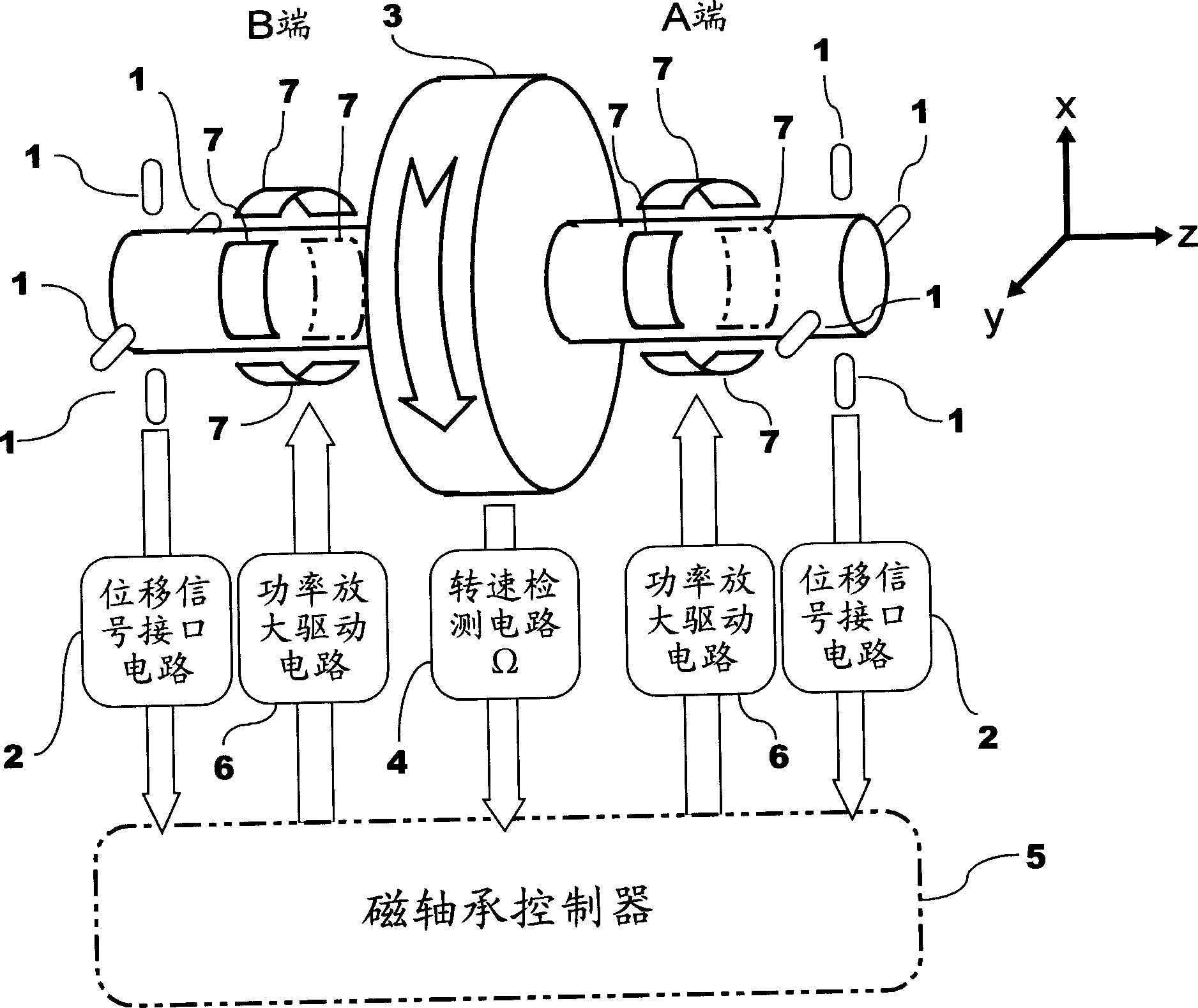

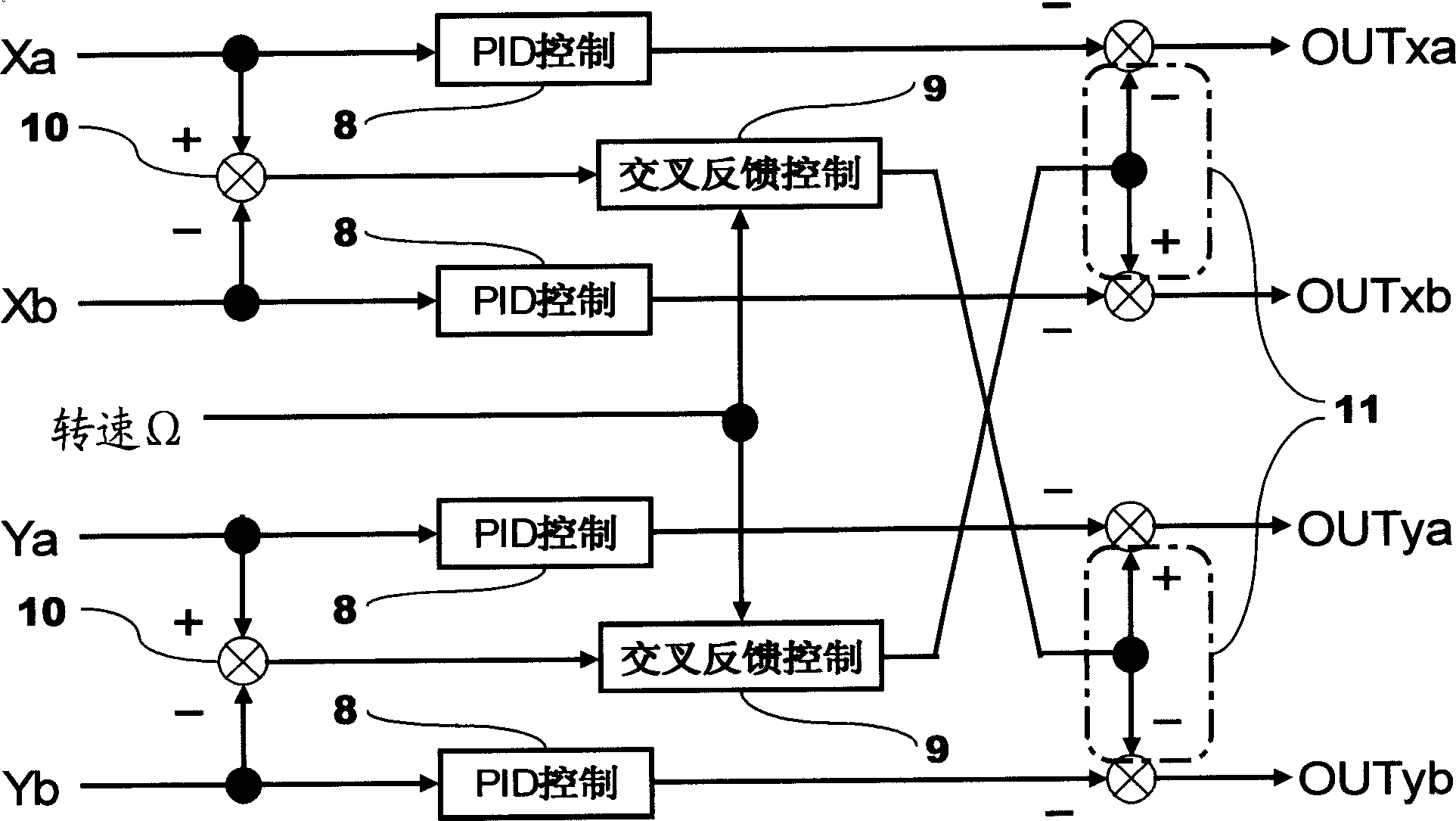

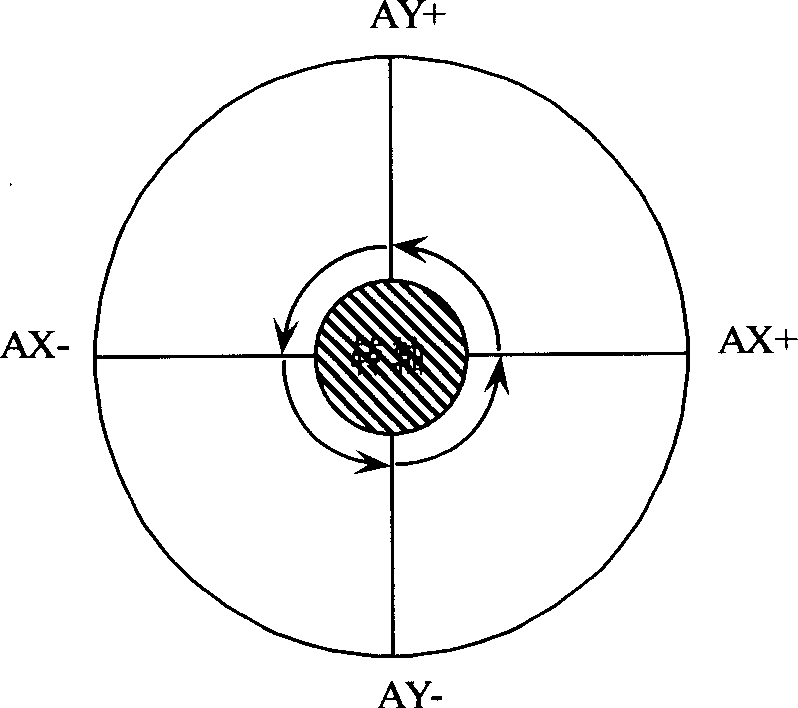

High-speed magnetic levitation flywheel stabilization control system

InactiveCN1738183ASimple designEasy to set upIgnition automatic controlBearingsMagnetic bearingStabilization control

Disclosed a high speed magnetic levitation flywheel stability control system, comprises a displacement sensor, a displacement signal interface circuit, a rotary speed detect circuit, a magnetic bearing controller, and a magnetic bearing power amplifying drive circuit. Wherein, the magnetic bearing controller comprises a axial magnetic bearing controller and a radial magnetic bearing controller, while the radial one is formed by decentralized PID control module and a cross feedback control module whose outputs are connected by the feedback method in cross and parallel. Said invention utilizes the cross feedback control formed by forward whirling motion filter and backward whirling motion filter based on the decentralized PID control; it reaches the phase lead compensation to the forward and backward whirling motion by using the difference of their frequency and whirling motion directions, their variation rule of rotary speed, and the signal of rotary speed of flywheel. So the breakdown speed of flywheel is improved while the stable operation of magnetic levitation flywheel in whole rising and falling process is confirmed too.

Owner:BEIHANG UNIV

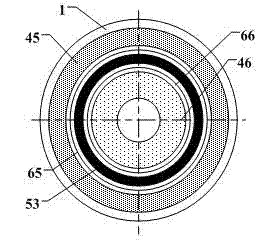

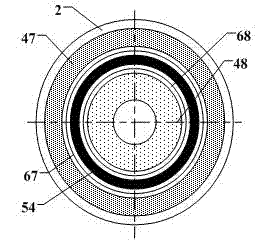

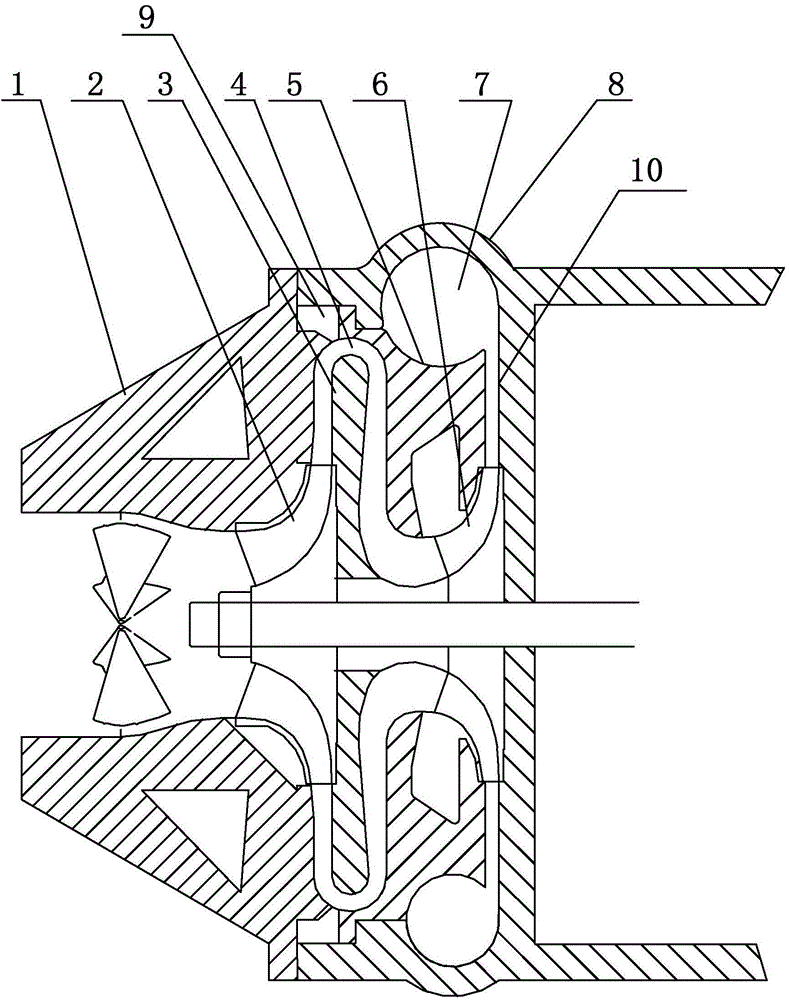

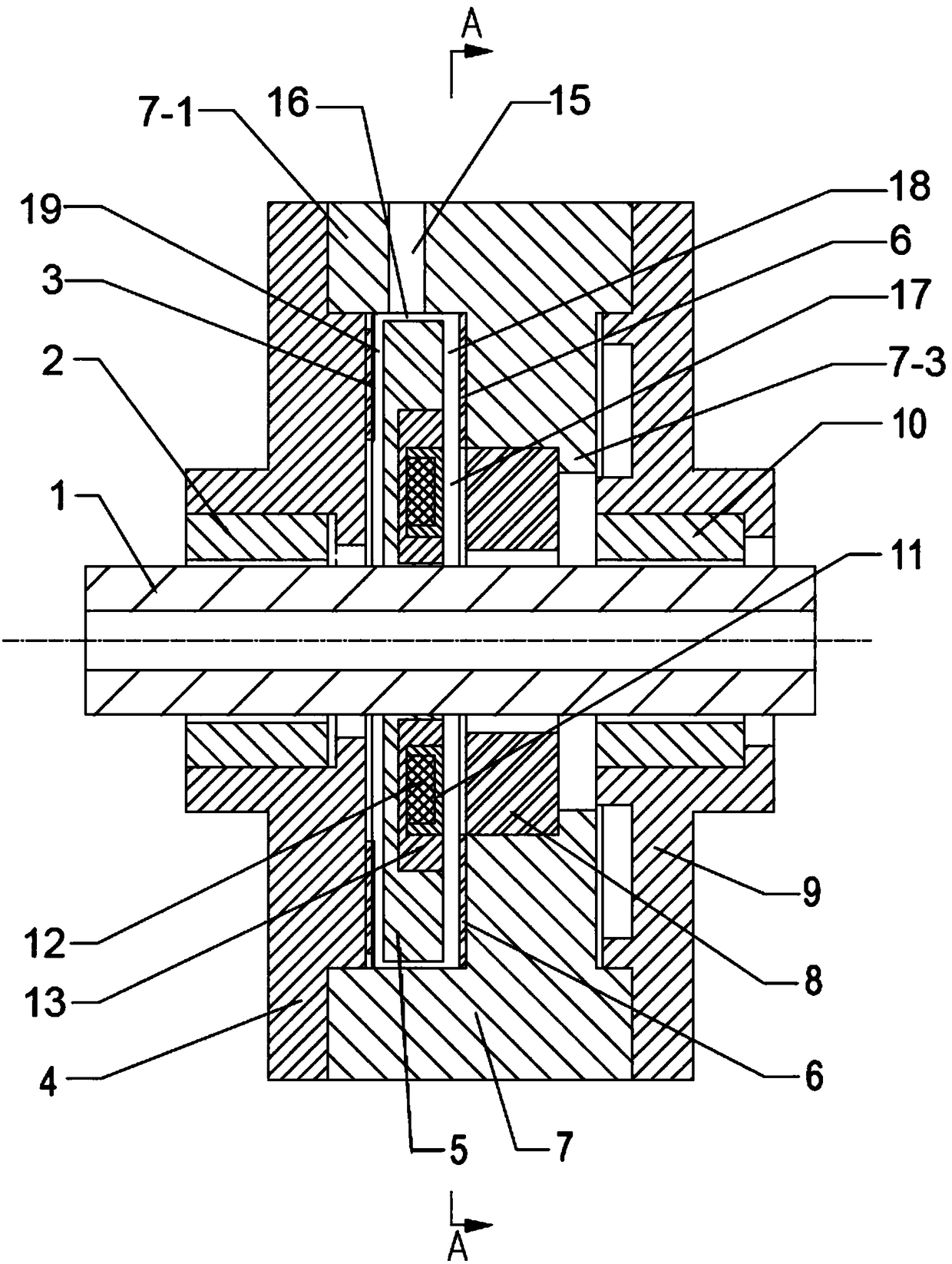

Radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing

The invention discloses a radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing used for non-contact suspension bearing. An axial control coil is arranged between a radial stator core and an axial stator core; an axial air gap is formed between the axial stator core and the end face of a rotor in the axial direction; three same stator core magnetic poles uniformly distributed in the circumferential direction extend from the wall of an inner cavity of the radial stator core to the axle center; same radial control coils are wound on the three stator core magnetic poles, and radial air gaps are formed between the stator core magnetic poles and the outer wall of the rotor in the radial direction; same axially magnetized annular permanent magnets are arranged between two axial sides of the radial stator core and the axial stator core; and S poles of the permanent magnets face the radial stator core, and N poles of the permanent magnets face the axial stator core. The radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing integrates axial and radial functions, is only driven by a three-phase alternating current power inverter, is provided with two axially magnetized annular permanent magnets, controls the magnetic flux not to pass magnetic poles where the permanent magnets are positioned, and has the advantages of low power consumption, small volume, light weight and high bearing capacity.

Owner:JIANGSU UNIV

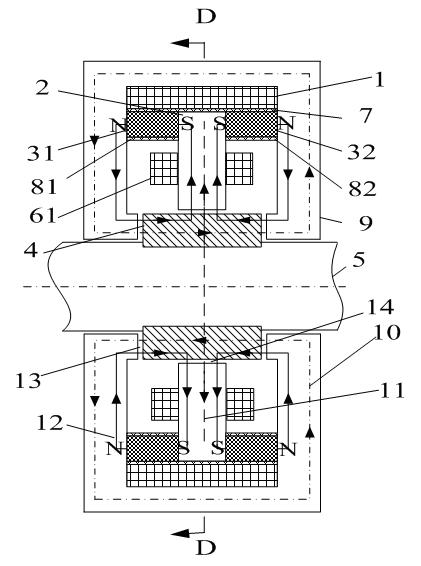

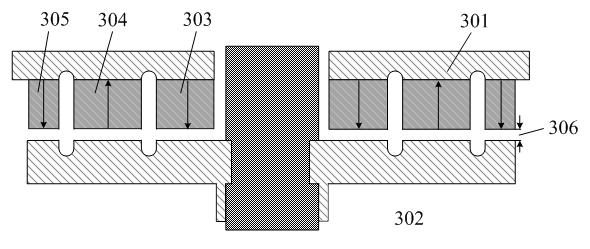

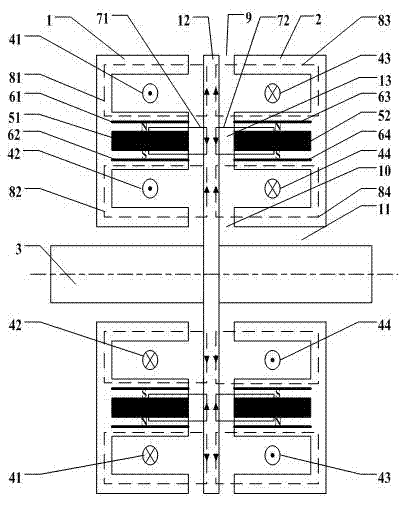

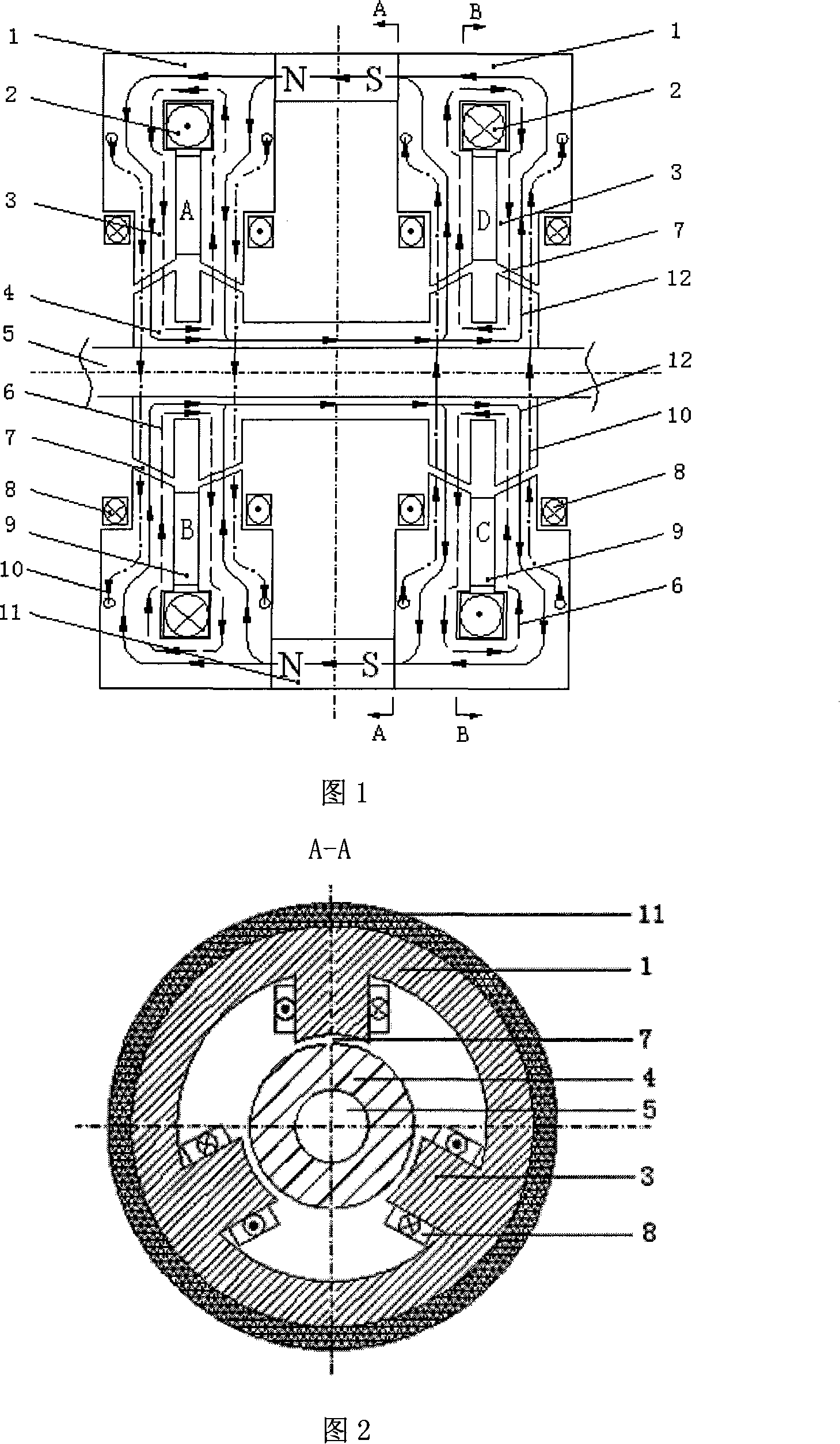

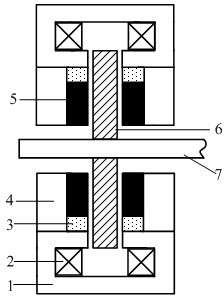

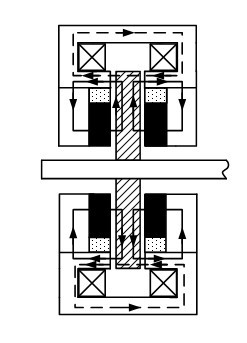

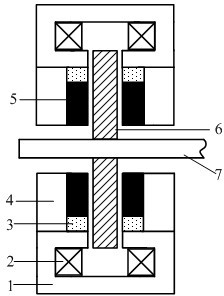

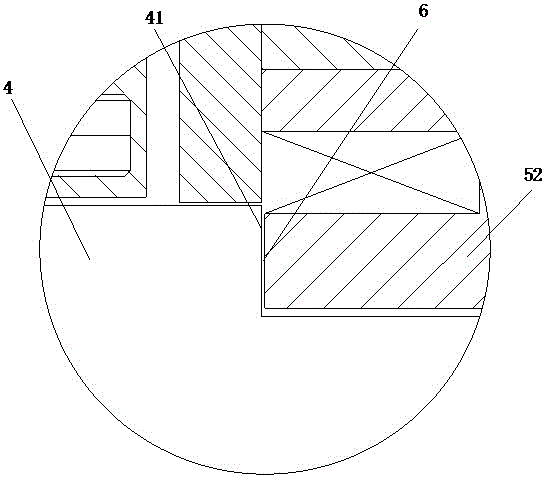

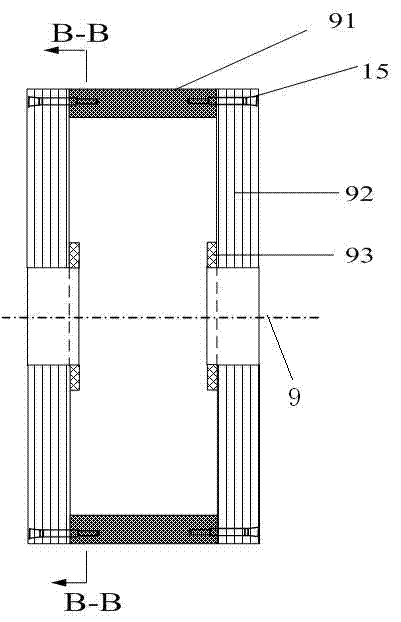

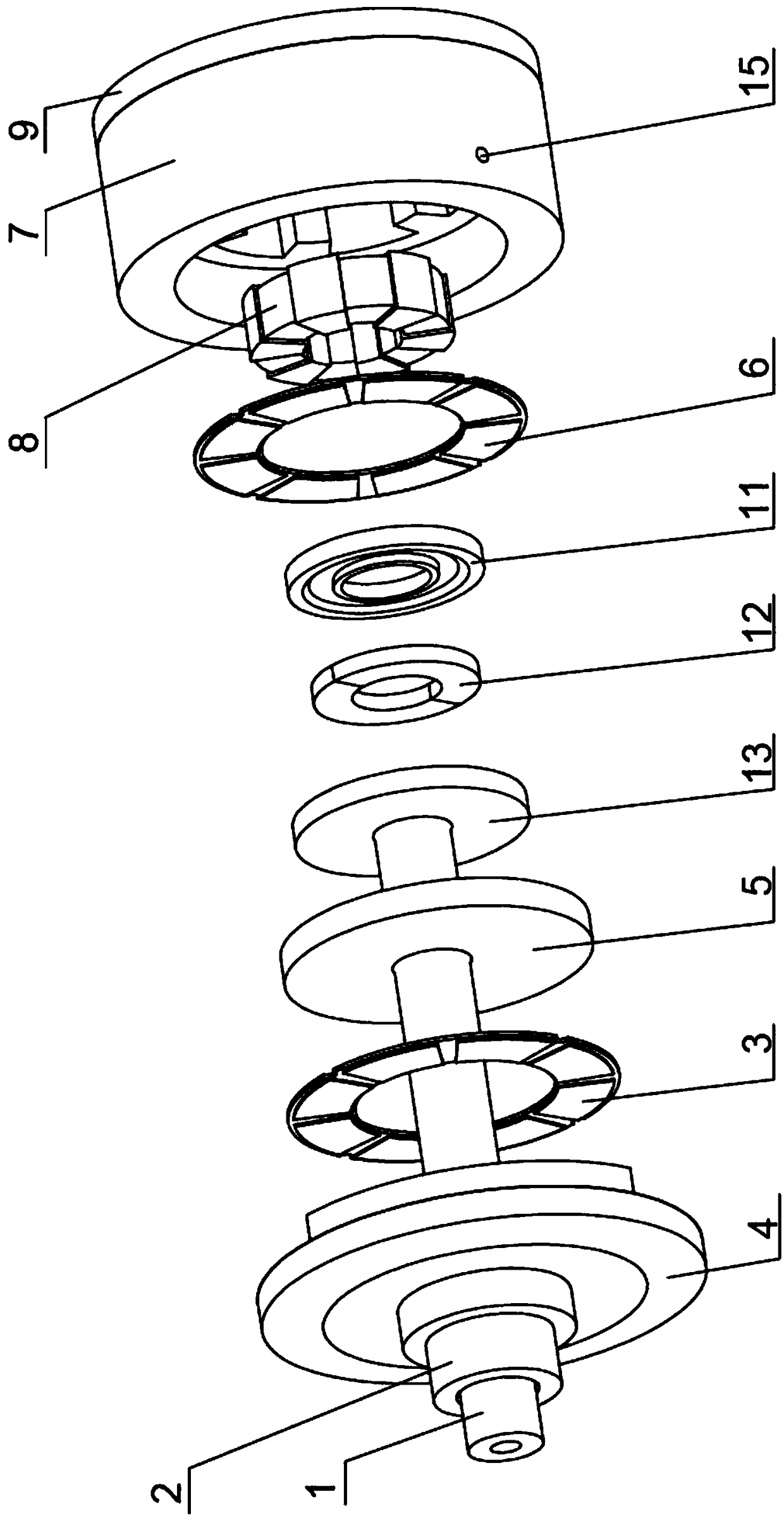

Permanent-magnetic biased axial radial magnetic bearing

The permanently magnetic biased axial and radial magnetic bearing as one mixed magnetic bearing includes one axial stator, one axial control winding, two radial magnetized ring permanent magnets, two radial stator with three poles, one radial control winding, and one rotor with jacketed iron core. The permanently magnetic biased axial and radial magnetic bearing has one static bias magnetic field established with two radial magnetized ring permanent magnets, one closed magnetic path formed with one external axial magnetic pole iron core, one rotor iron core and one radial stator, one axial suspension controlled by the axial superposed magnetic flux, and one two freedom suspension controlled by the radial superposed magnetic flux. The present invention has simple structure, high critical rotation speed, low power consumption, and broad application foreground in energy storing flywheel, air conditioner compressor and other high speed application fields.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

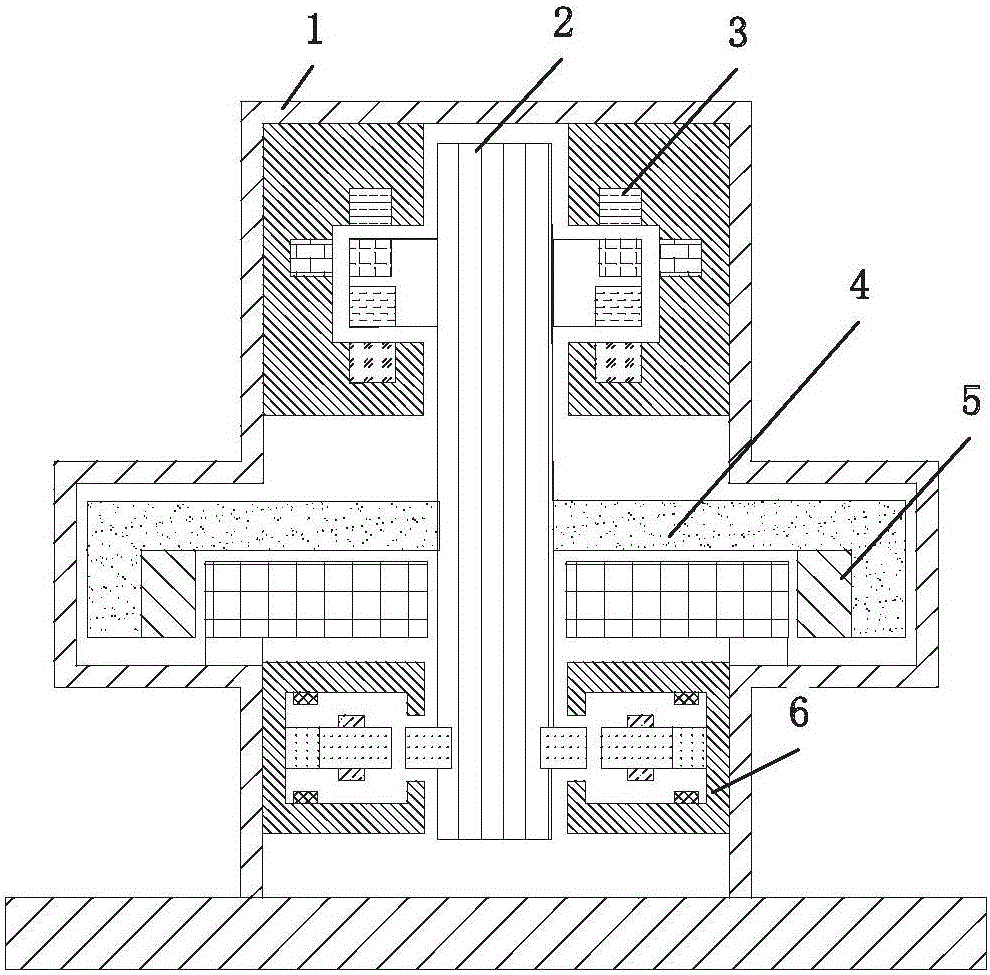

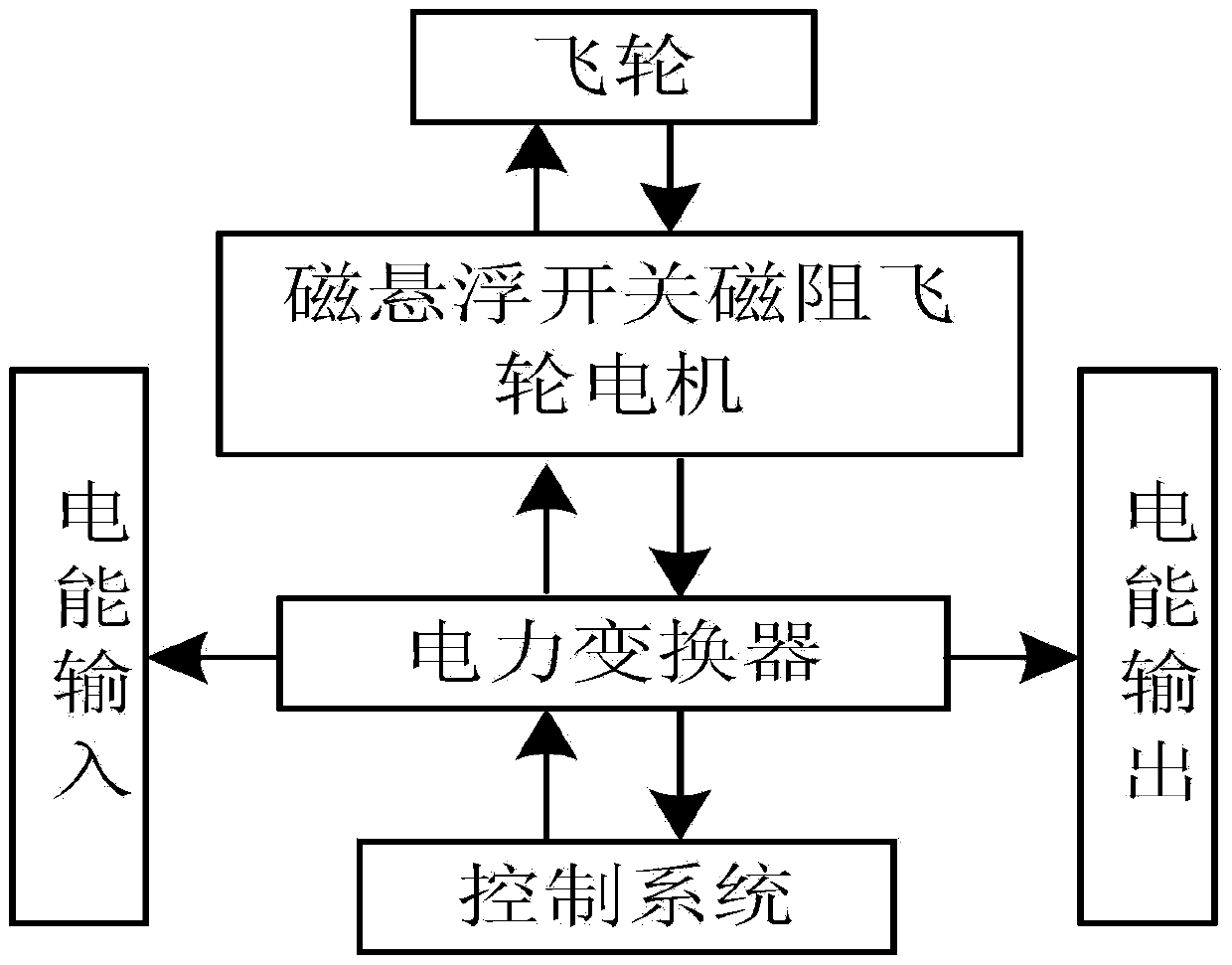

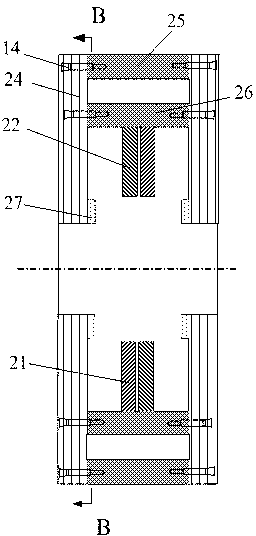

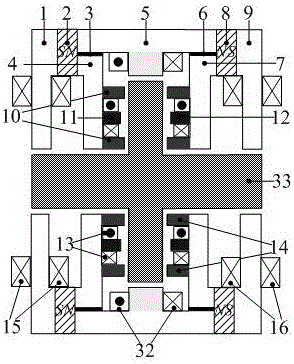

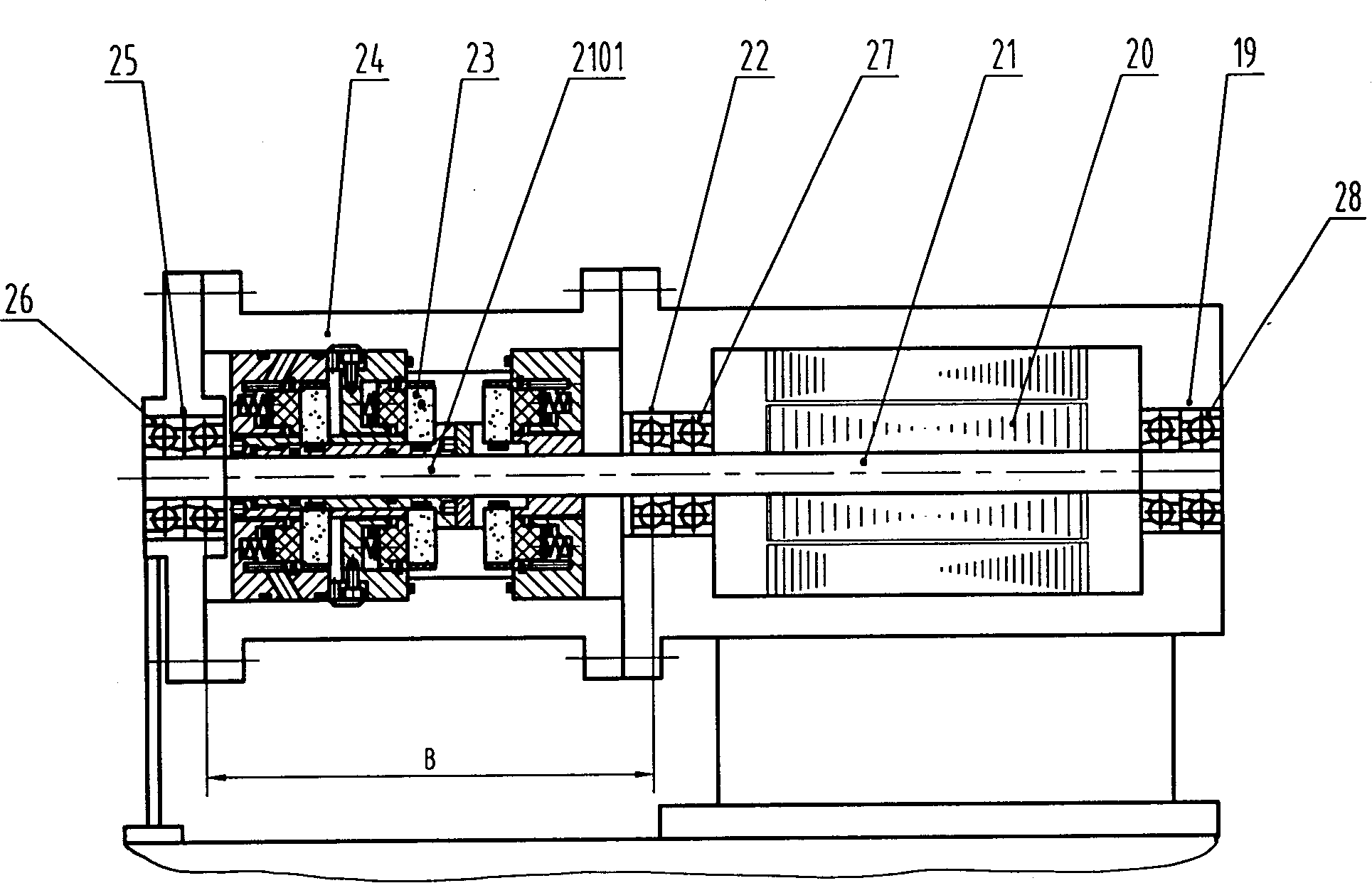

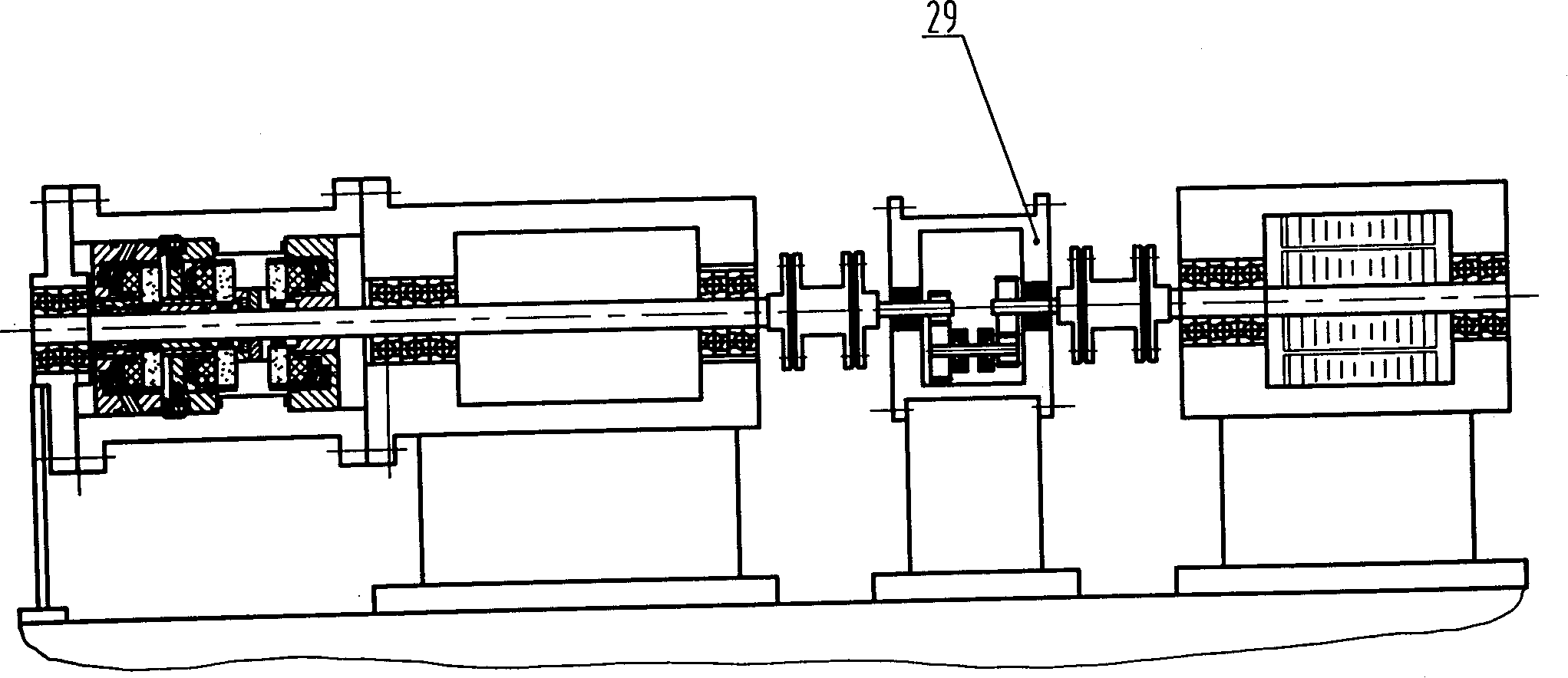

Flywheel energy storage device adopting bearingless switched reluctance motor

InactiveCN102684365AShorten the axial lengthIncrease the critical speedMechanical energy handlingMagnetic holding devicesMagnetic bearingFlywheel energy storage

The invention discloses a flywheel energy storage device adopting a bearingless switched reluctance motor. A permanent magnetic unloading bearing, a bearingless switched reluctance motor, a flywheel rotor and a mixed magnetic bearing are sequentially sleeved between the upper end and the lower end of a flywheel rotating shaft, wherein the permanent magnetic unloading flywheel carries the axial weight of the flywheel rotating shaft; the mixed magnetic bearing on the lower end overcomes the residual weight and the dynamic load of the flywheel rotating shaft, so that the flywheel rotating shaft is guaranteed to be stably suspended in the axial direction, simultaneously two-degree-of-freedom suspension bearing in the radial direction is provided for the flywheel rotating shaft, and the other two-degree-of-freedom suspension and electric function / power generation function in the axial direction are completed by the bearingless switched reluctance motor; and by adopting the high-speed electromotion / power generation running advantage and the self-suspension function of the bearingless switched reluctance motor, the strong unloading characteristic and the controllable suspension characteristic of the permanent magnetic unloading bearing and the mixed magnetic bearing are reasonably combined, so that the five-degree-of-freedom suspension of a flywheel with low loss and high reliability is realized, the running speed of the flywheel is improved, and the system power consumption and the size are reduced.

Owner:JIANGSU UNIV

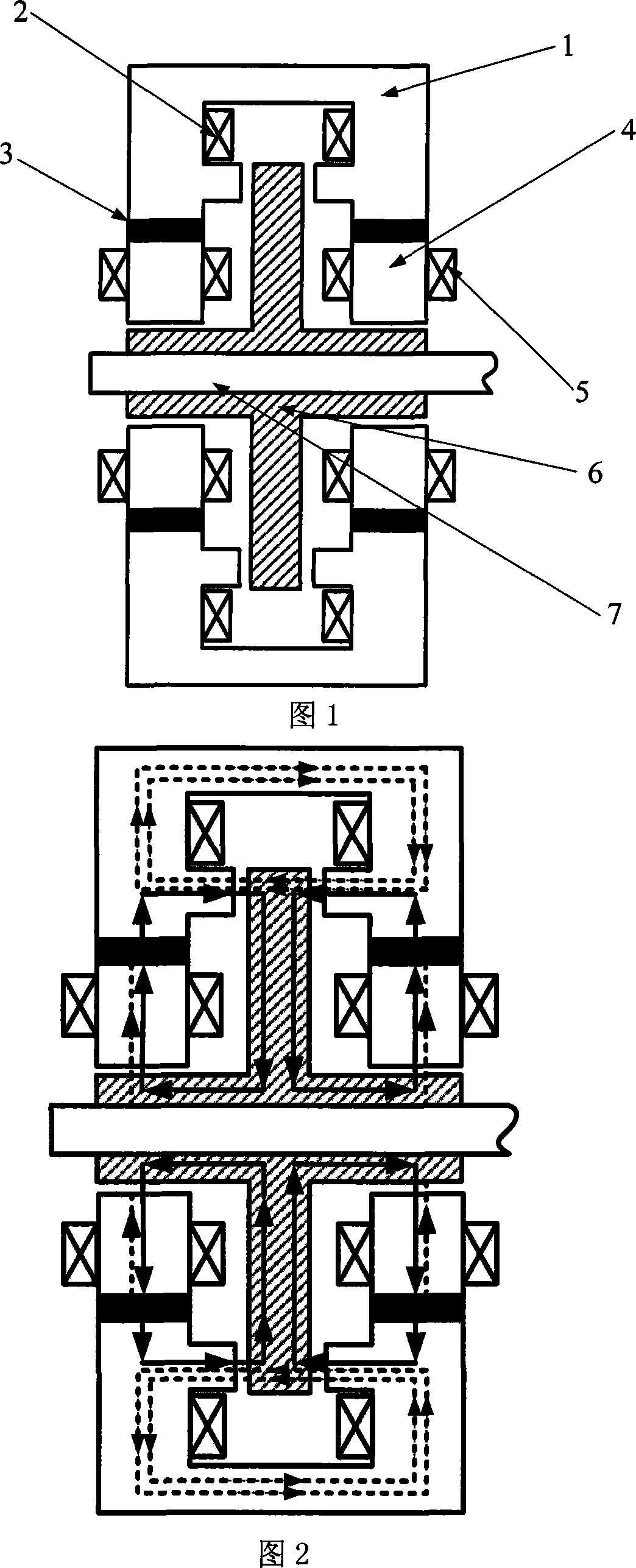

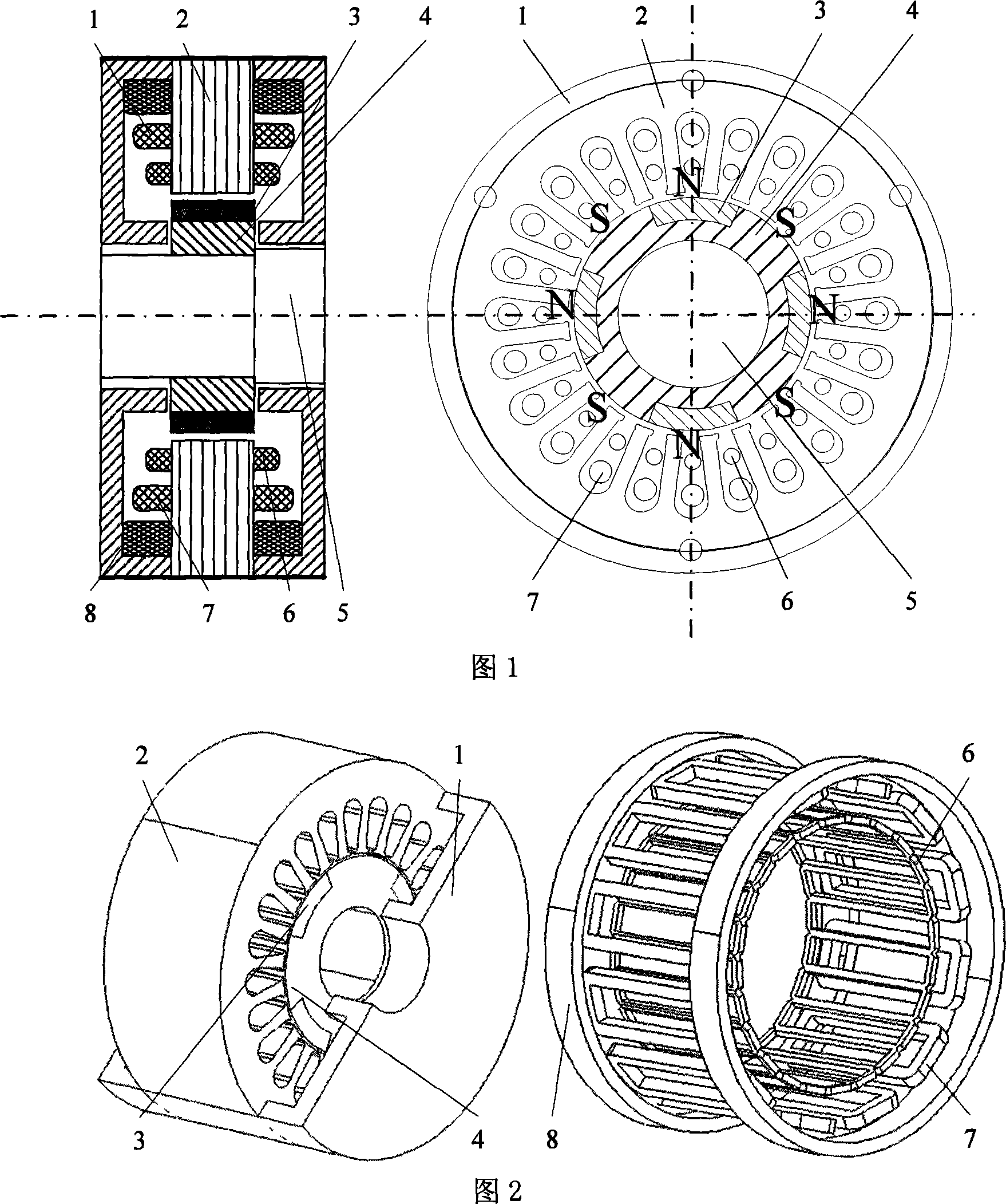

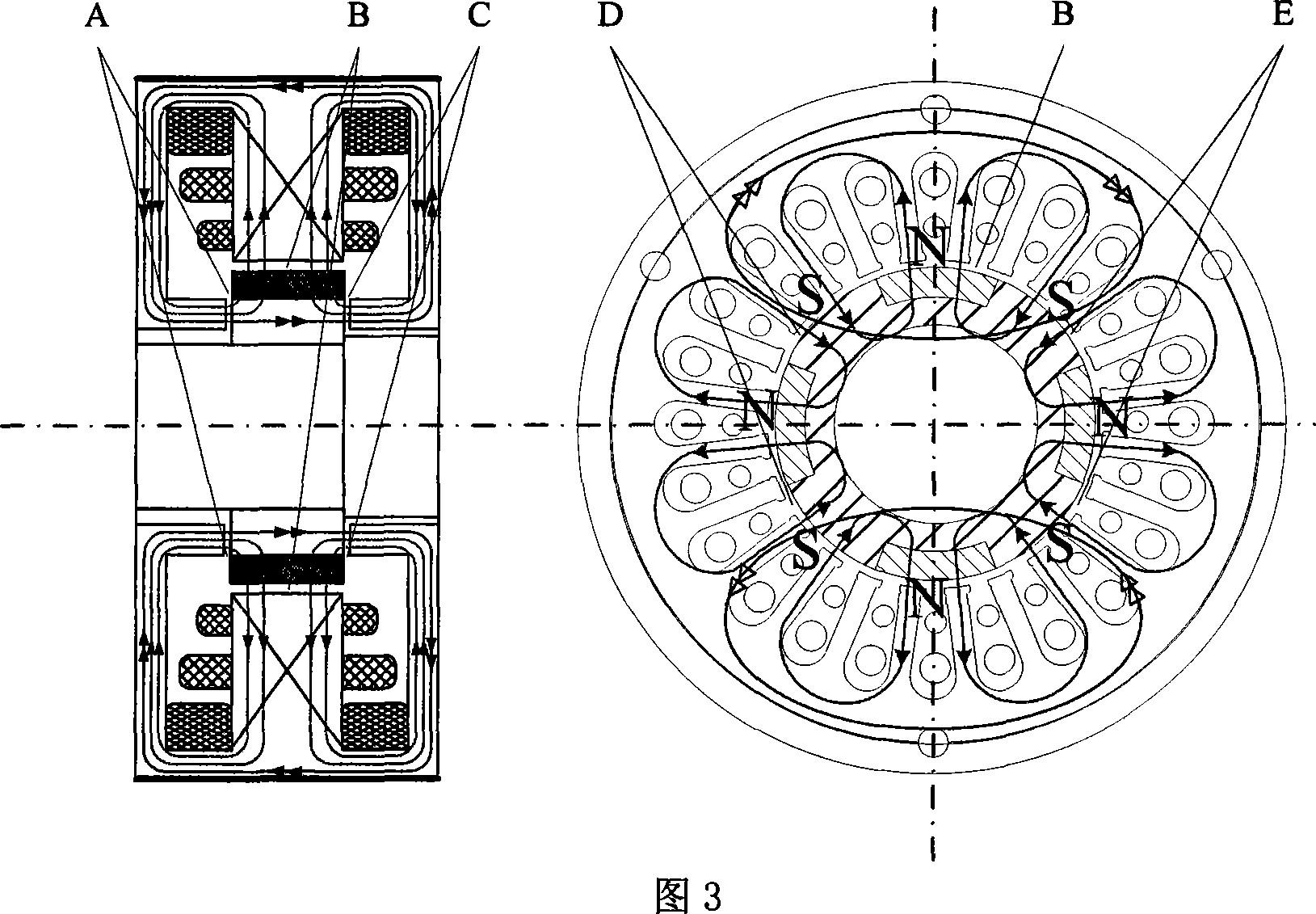

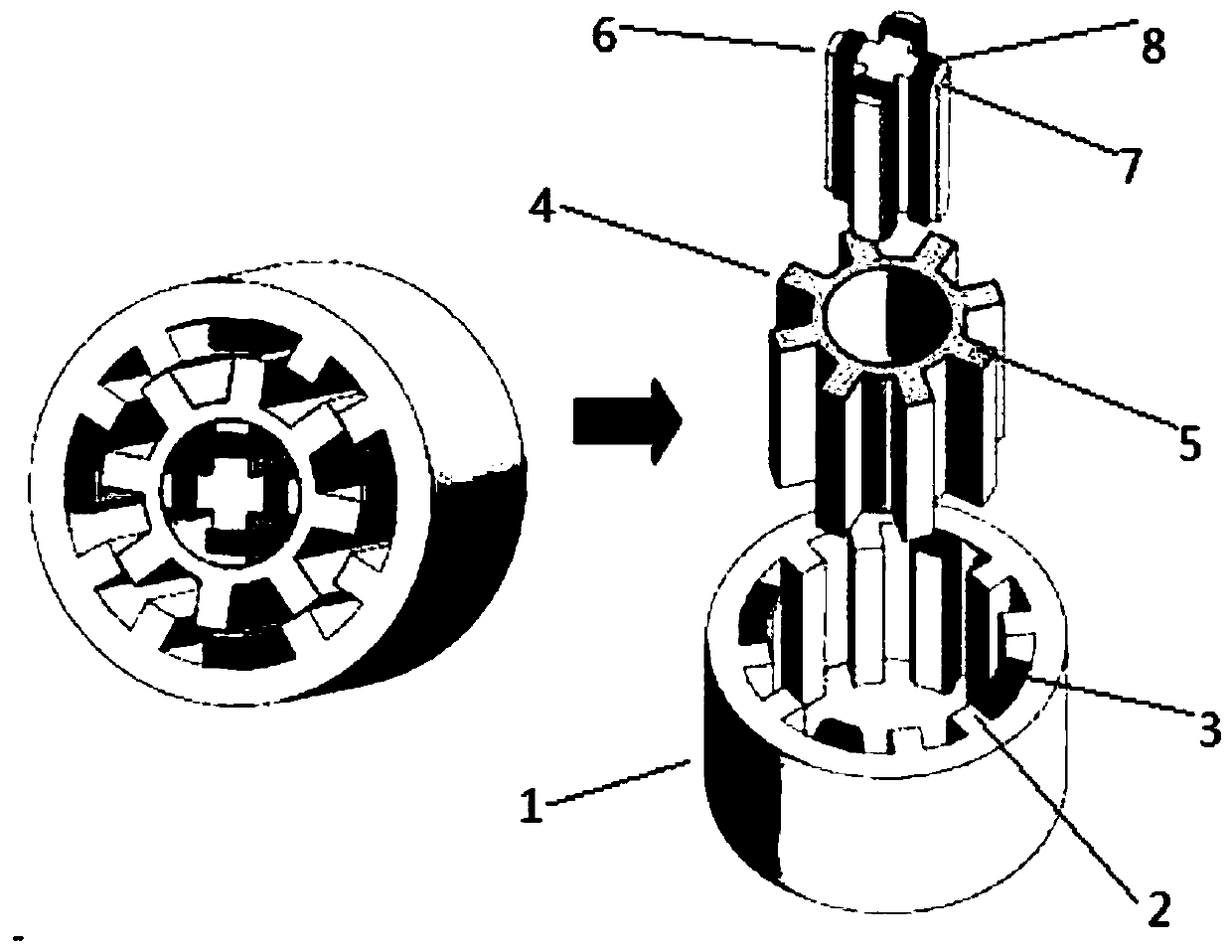

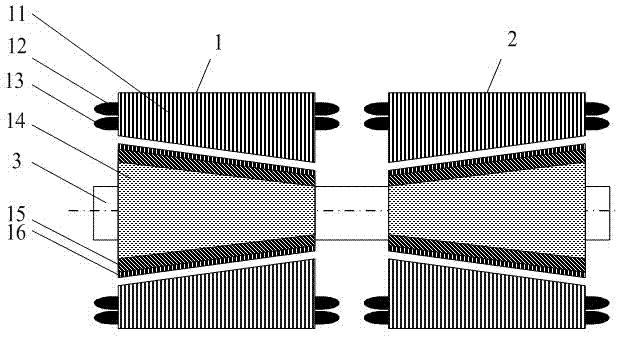

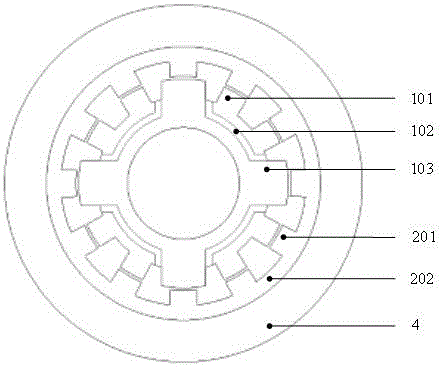

Three-freedom consequent pole permanent magnet motor without bearing of axial direction initiative suspending

InactiveCN101207310AMagnetic Control EasyLevitation current is smallMechanical energy handlingMagnetic holding devicesMagnetic bearingPermanent magnet motor

The invention relates to an axial initiative-suspension three-dimensional bearing-free alternative-pole permanent-magnetic machine, which belongs to a bearing-free magnetic-suspension motor. The machine comprises two axial stator cores (1) that are provided with axial suspension controlling windings (8) that are serially connected with each other, a radial stator core (2) that is provided with a set of four-pair-pole torque controlling windings (7) and a set of one-pair-pole radial suspension controlling windings (6), a rotor core (4) that is provided with four homo-polar magnetizing permanent-magnets (3) and a rotor rotating shaft (5) that is enclosed with the rotor core (4). The motor has simple and compact structure, is free from additional axial magnetic bearing, integrates the motor rotation and axial and radial simultaneous-suspension functions of the rotor, has high integration, enlarges the suspension freedom of the bearing-free motor, simplifies the system structure, reduces the volume, the weight and the cost of the system, and has broad application prospect and important significance in different high-speed magnetic-suspension motor systems.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Flywheel energy storing device

ActiveCN105024479AShorten the axial lengthCompact structureMechanical energy handlingBearingsFlywheel energy storagePower consumption

The invention discloses a flywheel energy storing device. The device includes a vacuum container arranged on the outer layer. A rotary shaft is arranged in the center of the vacuum container. A radial-axial permanent magnetic bearing is nested in the upper end of the rotary shaft. The lower end of the rotary shaft is sleeved with a flywheel, a single-winding outer rotor magnetic suspension switch reluctance motor, and a permanent magnetic bias radial-axial magnetic bearing successively from top down. The rotary shaft penetrates through the center of the flywheel and is connected with the flywheel. The flywheel is nested in an outer rotor of the single-winding outer rotor magnetic suspension switch reluctance motor. According to the invention, by combining that the single-winding outer rotor magnetic suspension switch reluctance motor can drive the flywheel directly and has a high-speed suspension function with that the radial-axial magnetic bearing and a hybrid magnetic shaft have characteristics of controllable suspension in forced uninstallation, five degree of freedom and high-reliability suspension of the flywheel are realized. Besides, operation speed of the flywheel is increased and system power consumption and size are reduced.

Owner:JIANGSU UNIV

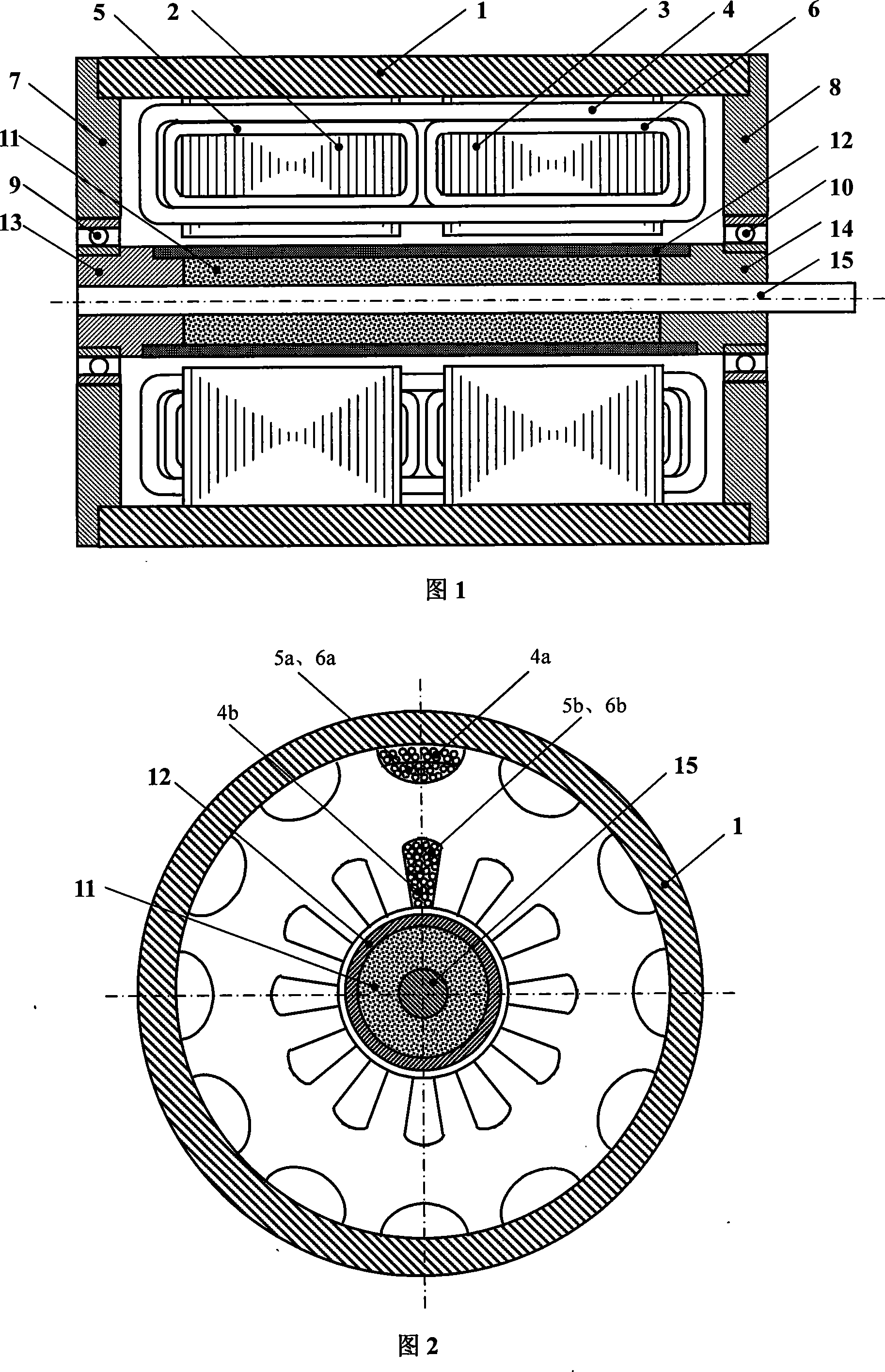

Low consumption permanent magnetism biased axial radial magnetic bearing

InactiveCN101235848AReduce lossSimple structureShaftsEngine componentsMagnetic bearingFlywheel energy storage

The invention relates to a low loss permanent magnet biased axial radial magnetic bearing, which belongs to a mixed magnetic bearing, which comprises an axial stator (1), an axial control winding (2), a radial magnetizing ring permanent magnet (7), a radial stator (3), a radial control winding (4) and a rotor (5) which is sleeved with an iron core (6). The low loss permanent magnet biased axial radial magnetic bearing uses the radial magnetizing ring permanent magnet to build a static bias magnetic field, a closed magnetic circuit is formed through an external axial pole core, a rotor iron core and a radial stator, and the axial control winding produces a controlling flux and a bias flux which are stacked to control axial suspension. A control winding is surrounded on a radial stator of a four-tooth two-antipode structure which is not retained gaps between magnetic poles, the windings on the two corresponding teeth are connected in series, and the superposition of the controlling flux and the bias flux are produced to achieve radial two freedom suspension. The structure is simple, the critical speed is high, the power consumption is low, and the low loss permanent magnet biased axial radial magnetic bearing has wide application prospect in high speed application fields which are flywheel energy storage, air conditioning compressors and turbomolecular pumps and the like.

Owner:NANJING COLLEGE OF CHEM TECH

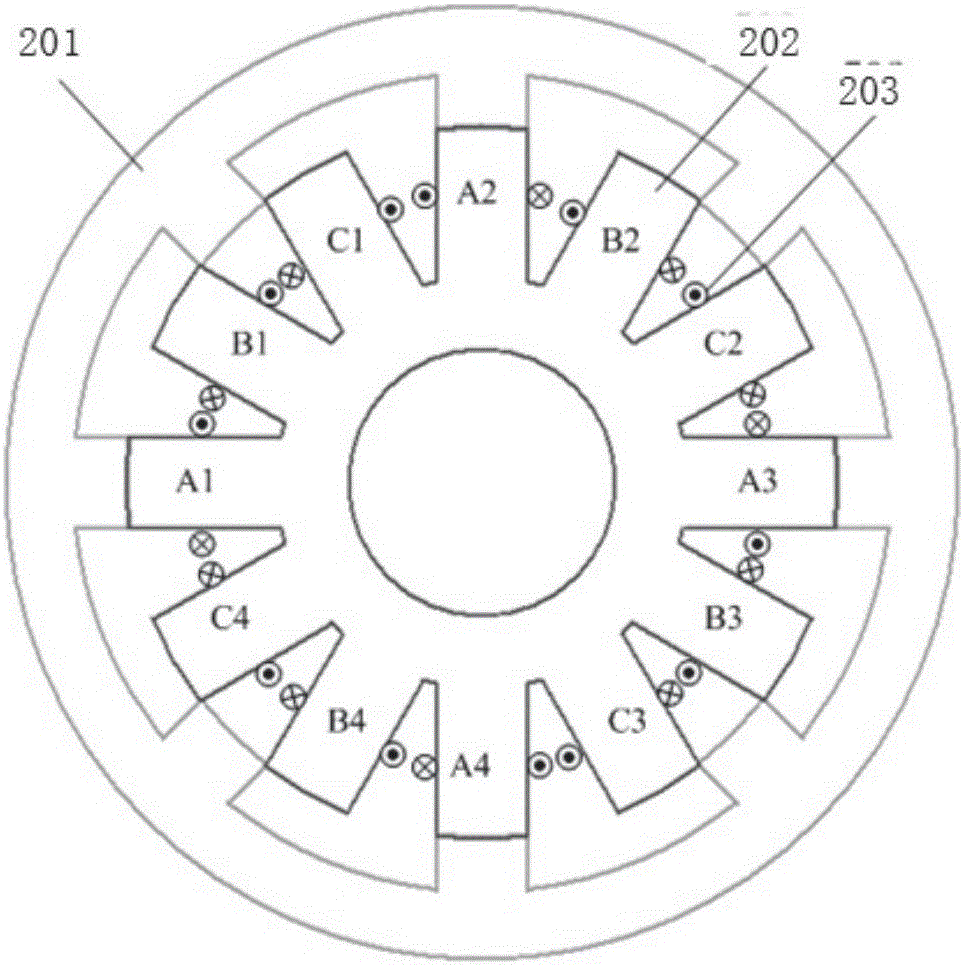

Single-winding non-bearing magnetic flux switching permanent magnetic motor

InactiveCN103825418AThere is no problem of sheddingImprove structural stabilityMagnetic circuit stationary partsElectric machineOperation mode

The invention belongs to the technical field of a motor, and relates to a single-winding non-bearing magnetic flux switching permanent magnetic motor. The single-winding non-bearing magnetic flux switching permanent magnetic motor comprises a stator iron core, a rotator iron core, permanent magnets embedded in the middle of stator teeth, and concentrated windings. A stator and a rotor are both of double-salient pole structures. The single-winding non-bearing magnetic flux switching permanent magnetic motor is characterized in that the stator iron core is composed of six U-shaped laminations; a permanent magnet capable of tangential alternative magnetizing is embedded between every two laminations so that a stator tooth which is axisymmetric is formed; the stator teeth are provided with the concentrated windings, the end portions of the windings are quite small, and the windings, which are opposite to each other in terms of space, on two stator teeth form a phase so that a three-phase winding is formed; and the excitation of winding currents is of a radial excitation mode, each winding is independently controlled, the winding currents can perform bidirectional flow in positive and negative directions, the current size can be controlled according to needs, and the currents has the same phase as a back electromotive force. The single-winding non-bearing magnetic flux switching permanent magnetic motor has the advantages of high speed, large power, high efficiency, high power density, high operation stability, high reliability, and adaptability to an AC operation mode.

Owner:TIANJIN UNIV

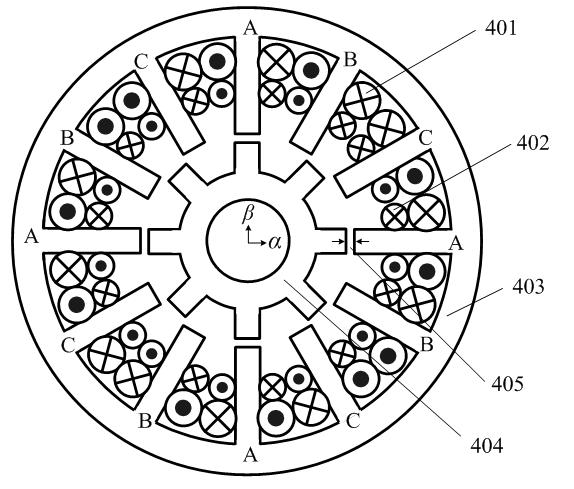

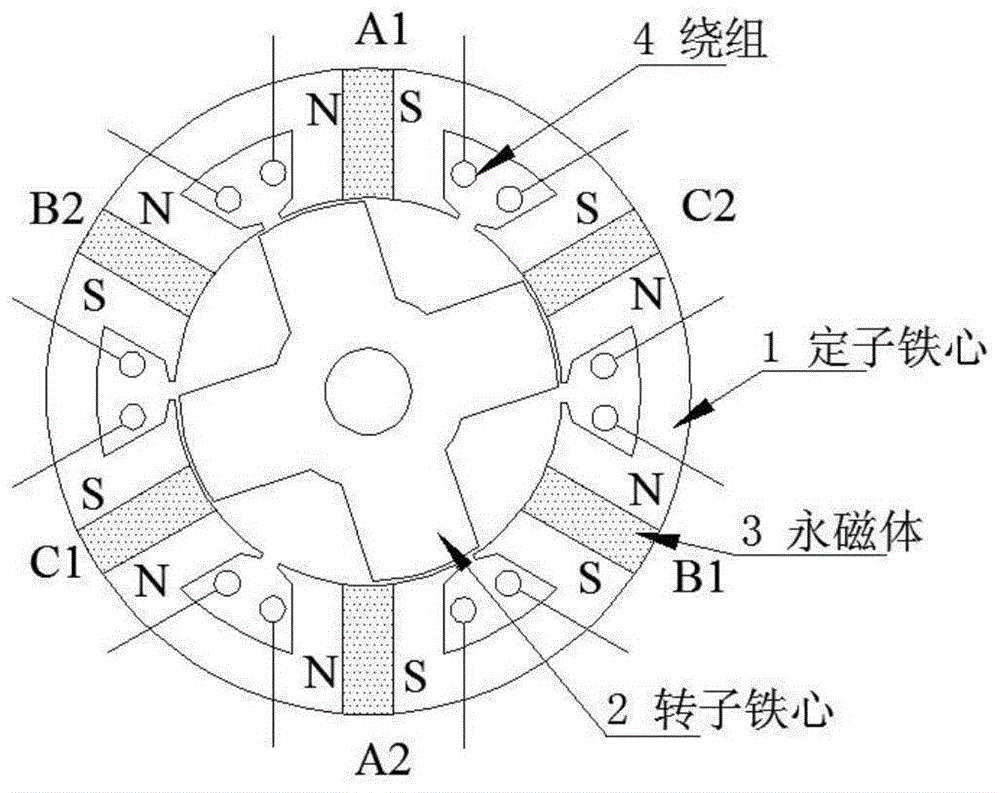

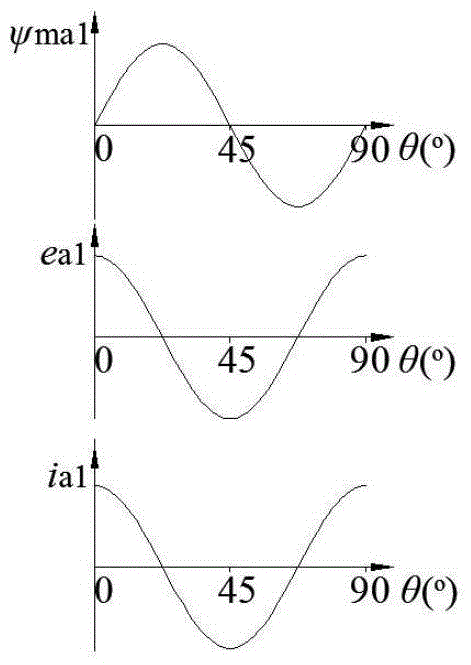

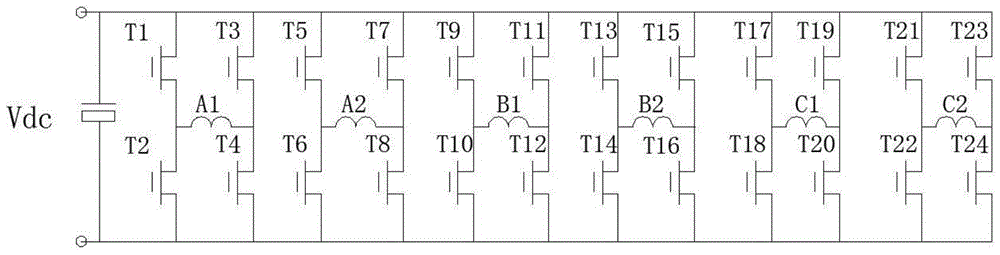

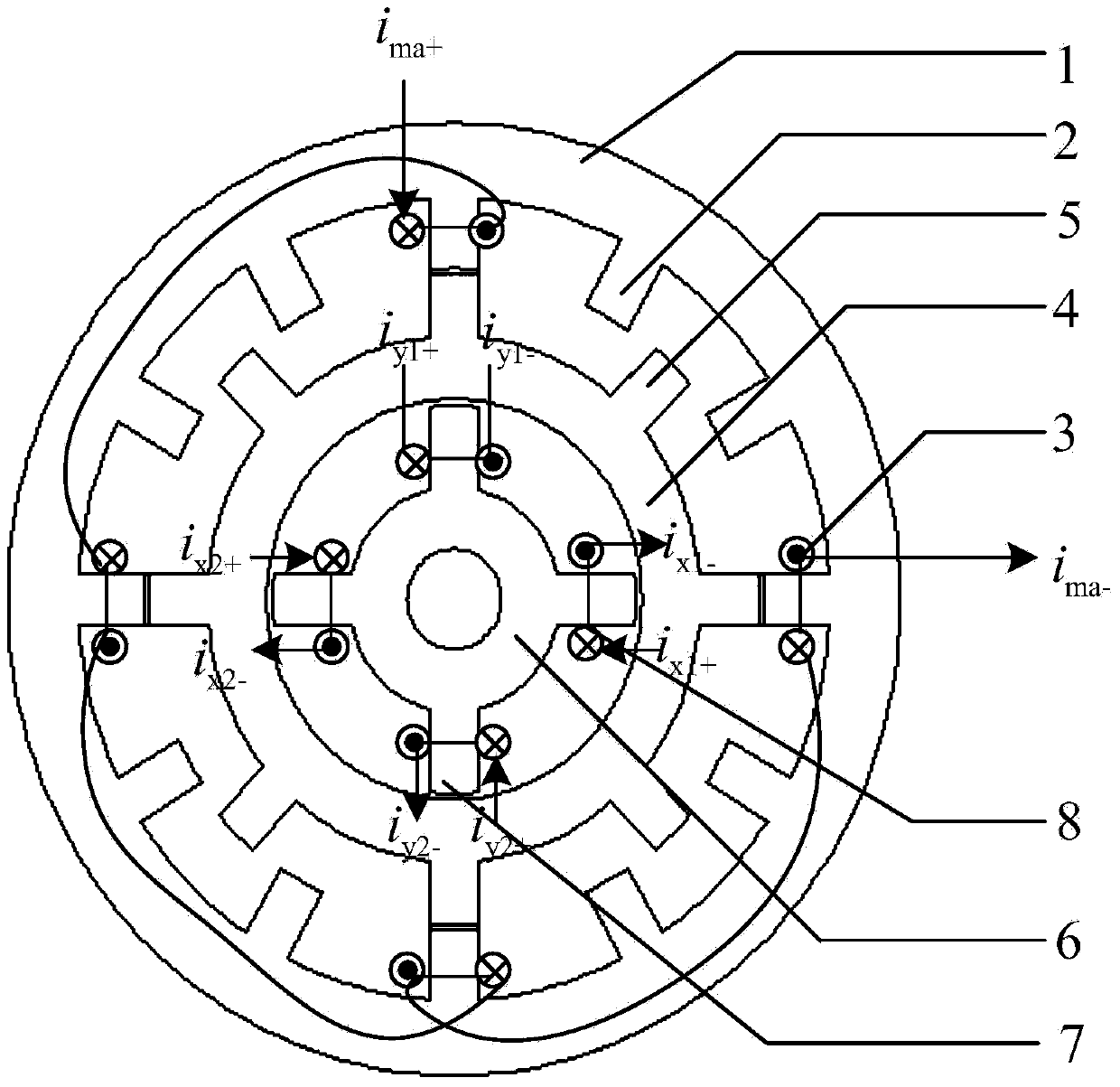

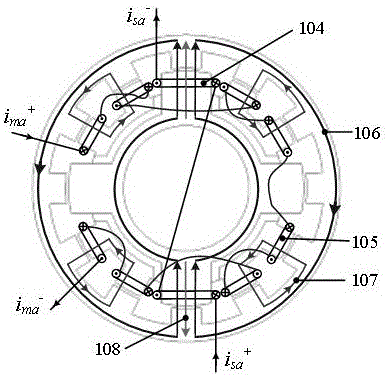

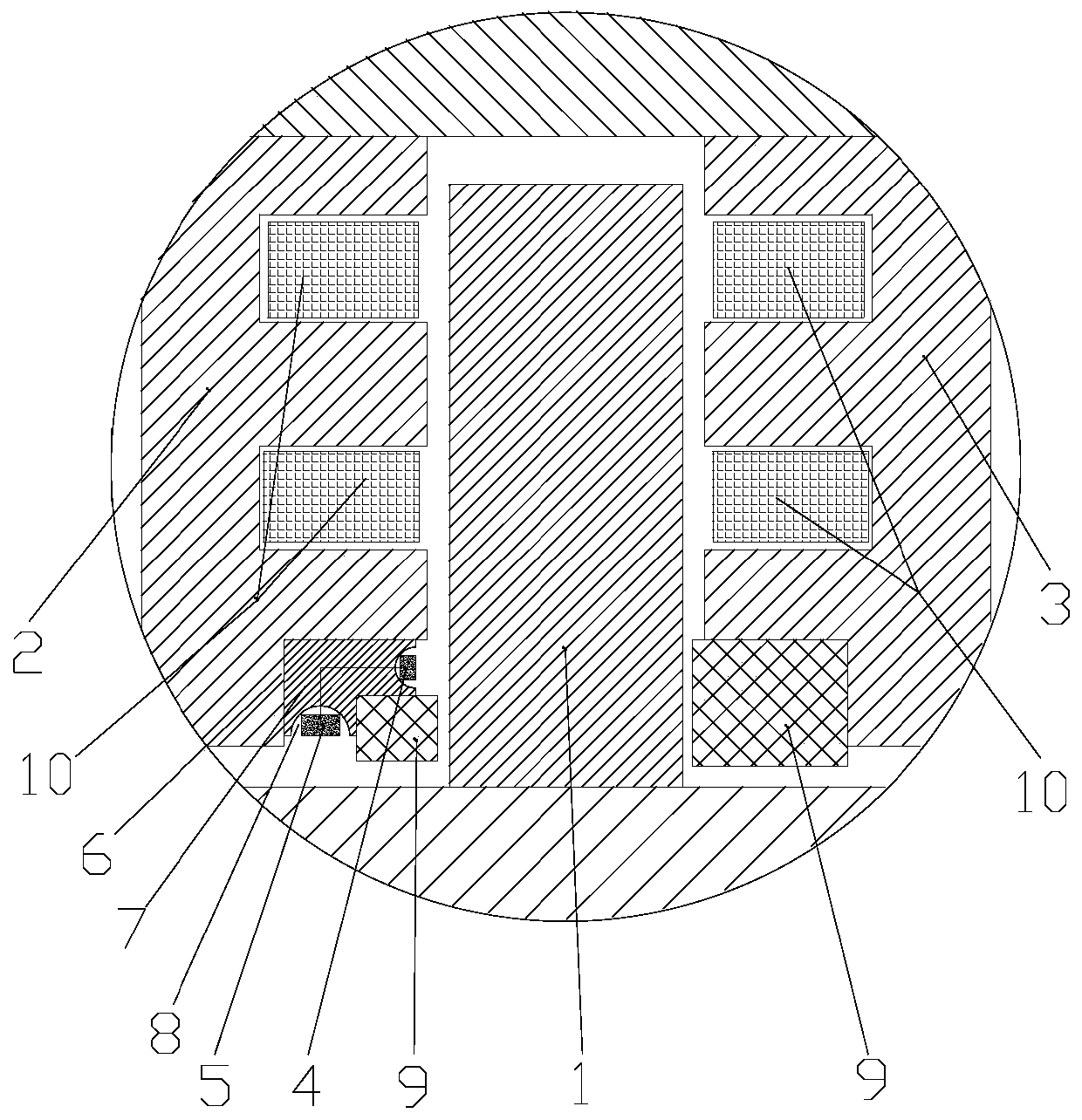

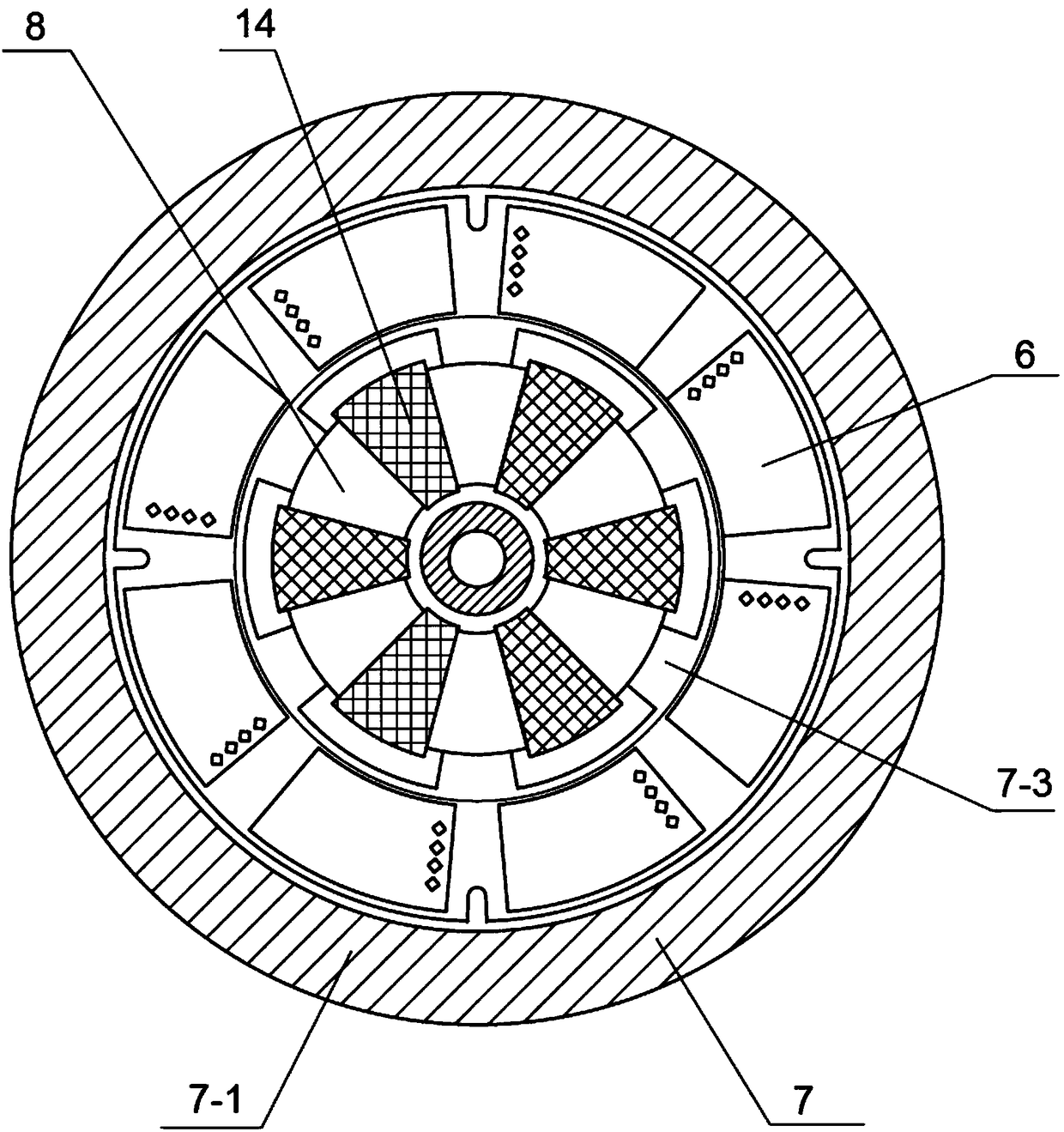

Magnetic suspension switch magnetic resistance flywheel motor and control method

InactiveCN104184286AIncrease radial load capacitySolve the problem of nonlinear strong couplingSingle motor speed/torque controlDynamo-electric machinesControl theoryConductor Coil

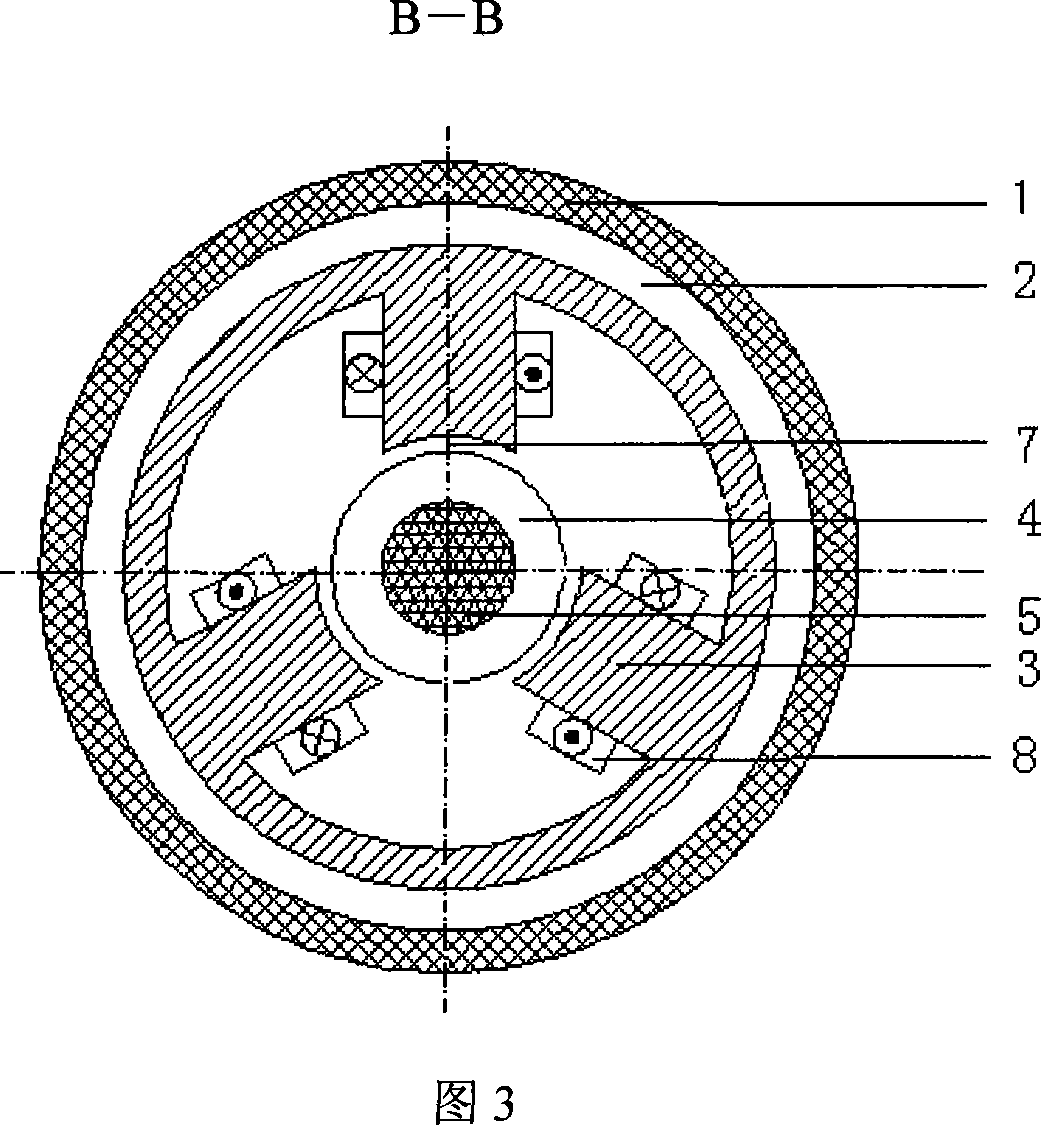

The invention discloses a magnetic suspension switch magnetic resistance flywheel motor and a control method. The magnetic suspension switch magnetic resistance flywheel motor comprises an inner stator, a rotor and an outer stator. The inner stator (6), the rotor (4) and the outer stator (1) are successively nested in a concentric mode, 12 torque poles (2) are arranged on the inner wall of the outer stator (1) at equal intervals, and the torque poles are wound by main windings (3); eight rotor salient poles (5) are arranged on the outer wall of the rotor (4) at equal intervals; and four suspension poles (7) are arranged on the outer wall of the inner stator (6) at equal intervals, and the suspension poles (7) are wound by suspension force windings (8). According to the invention, the problem of incapability of effectively generating suspension forces when a stator and a rotor are not aligned by use of a conventional magnetic suspension switch magnetic resistance motor is overcome, the radial force and the torque decoupling effect are good, the radial load capability is improved, the suspension force windings are individually controlled simply according to a needed radial suspension force, each main winding on the outer stator is also controlled simply according to needed electromagnetic torque, the control is easy, and a control algorithm is simpler and is more easily realized.

Owner:NANJING INST OF TECH

High speed magnetic suspension permanent magnet motor without bearing

InactiveCN101207309ASimple structureIncrease axial lengthMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet motorEngineering

The invention relates to a high-speed magnetic-suspension bearing-free permanent-magnetic machine, which comprises a shell, a stator core, a stator winding, a permanent-magnetic rotor, a rotating shaft, a left terminal cover, a right terminal cover, a left standby bearing and a right standby bearing. The stator core is divided into a right section and a left section and is provided with a groove that is used for holding the stator winding on the radial inner side and the radial outer side. The stator winding consists of a set of double-pole torque windings that are used for producing the electromagnetic torque and two sets of four-pole magnetic-suspension windings that are used for producing the rotor suspension force. The permanent-magnetic rotor consists of a permanent-magnet of a radial magnet-charging integral structure, a high-strength magnetic-conductive sheath and a fastening piece. The standby bearings are used for supporting the rotor when the high-speed motor is not powered on. The invention integrates the magnetic-suspension bearing and the permanent-magnetic machine, so that the stator and the rotor of the machine not only can produce the electromagnetic torque that drives the rotation of the motor, but also can produce the magnetic-suspension force that supports the weight of the rotor, thereby simplifying the structure of the machine, shortening the axial length of the machine, increasing the stiffness and the critical rotating speed of the rotor of the high-speed machine, and improving the stability of the operation.

Owner:SHENYANG POLYTECHNIC UNIV

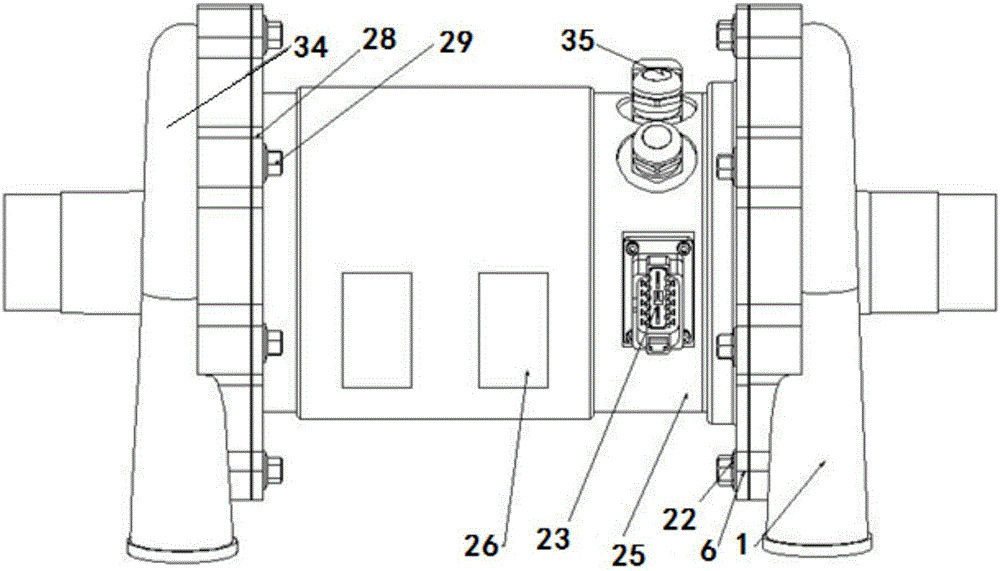

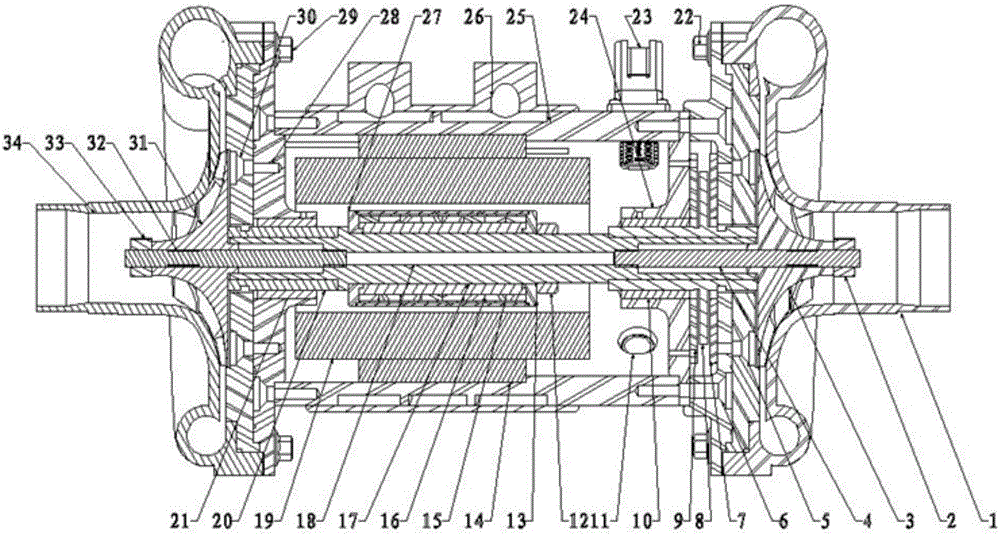

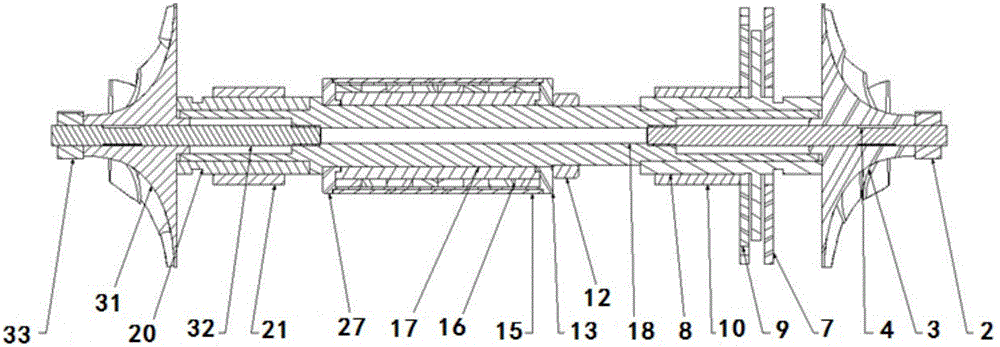

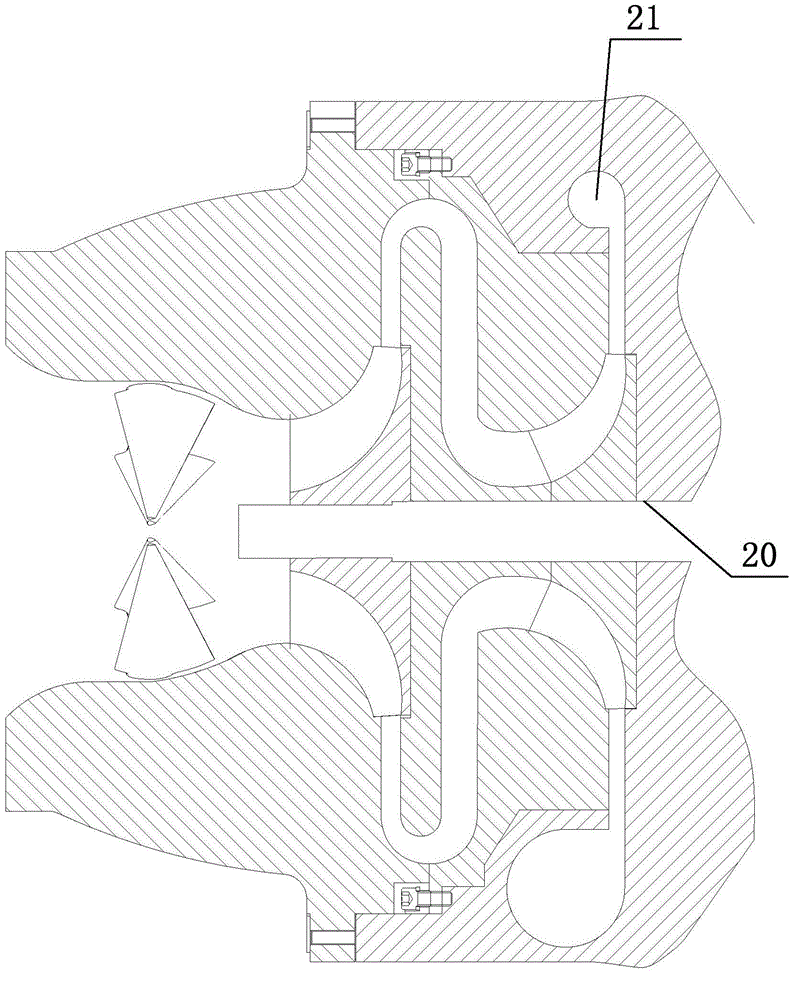

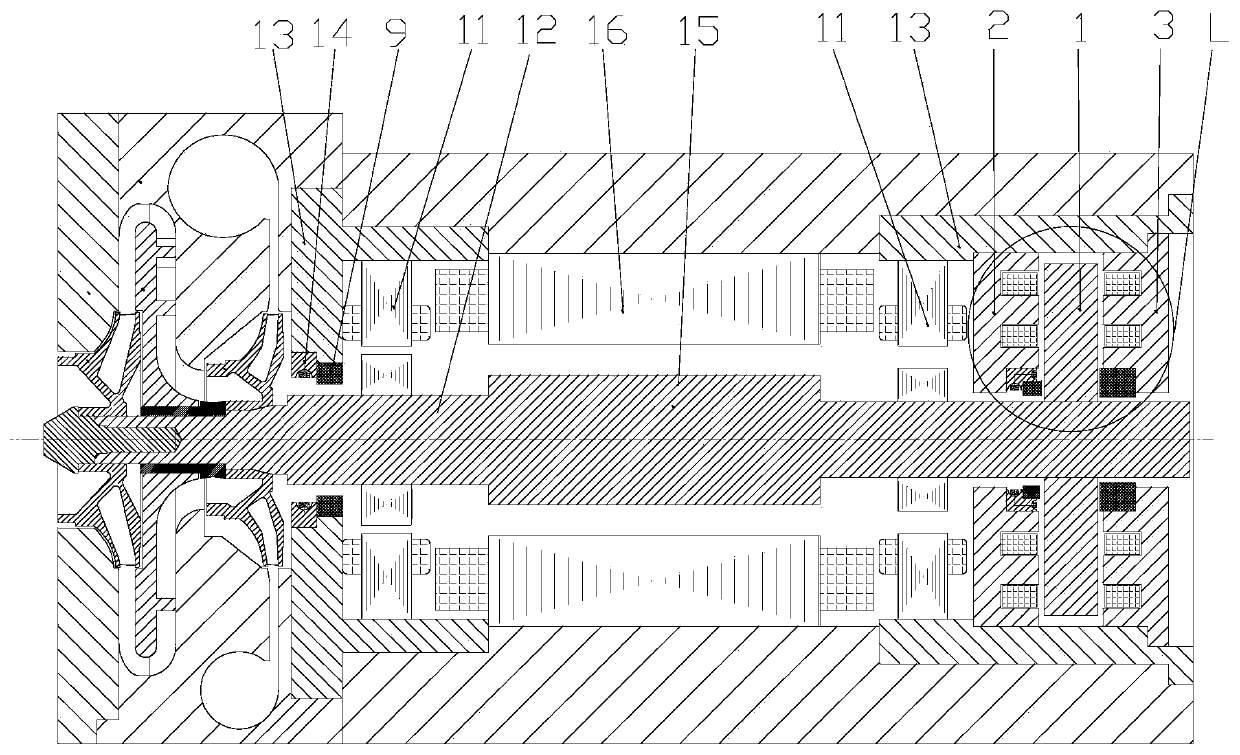

Two-stage series pressurization direct-driven centrifugal air compressor of fuel cell engine

ActiveCN105889096AImprove reliabilityReduce volumeMagnetic circuit rotating partsPump componentsImpellerStator

The invention relates to a two-stage series pressurization direct-driven centrifugal air compressor of a fuel cell engine. The two-stage series pressurization direct-driven centrifugal air compressor comprises end covers, a spindle, volutes, impellers, a rotor, a stator and a driver. The spindle is supported by a left-end radial supporting air foil bearing, a left-end radial supporting air foil bearing bush, an air foil axial thrust bearing and a right-end radial supporting air foil bearing, wherein the left-end radial supporting air foil bearing and the left-end radial supporting air foil bearing bush are arranged on the left side, and the air foil axial thrust bearing and the right-end radial supporting air foil bearing are arranged on the right side of the spindle. The left-end radial supporting air foil bearing bush is arranged on the outer side of the spindle in a surrounding manner. The left-end radial supporting air foil bearing is fixed to the outer side of the left-end radial supporting air foil bearing bush. The air foil axial thrust bearing is fixed to the outer side of the spindle in a bush form. The right-end radial supporting air foil bearing is fixed to the outer side of the air foil axial thrust bearing. Compared with the prior art, the two-stage series pressurization direct-driven centrifugal air compressor is more suitable for the air inlet pressurization scene of the fuel cell engine with the high oilless air inlet requirement, and the durability and reliability of the air compressor of the fuel cell engine can be improved.

Owner:TONGJI UNIV

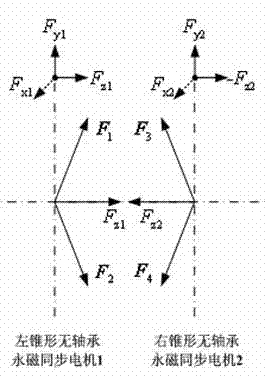

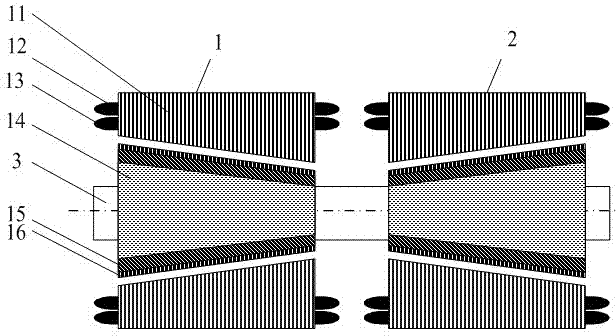

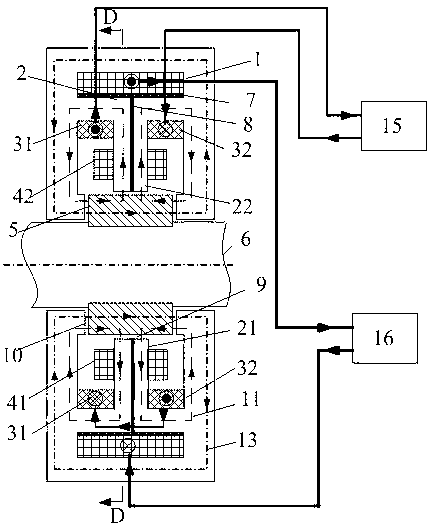

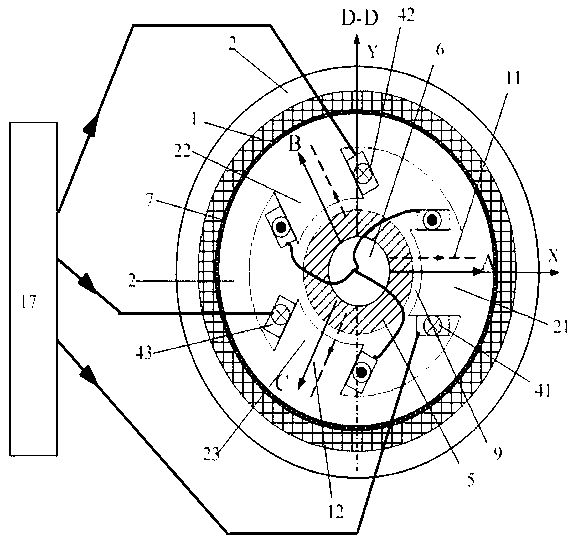

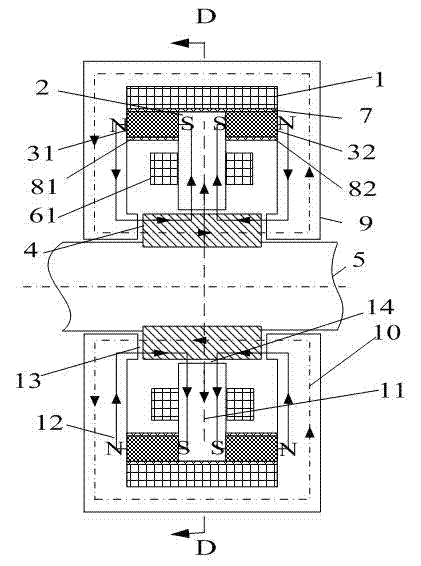

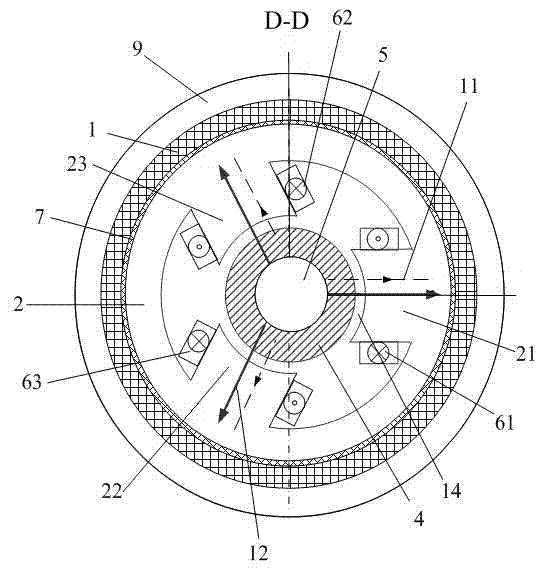

Five-degree-of-freedom (five-DOF) bearing-free permanent magnet synchronous motor

ActiveCN102377298AAchieve levitationSimple structureDynamo-electric machinesMagnetic holding devicesSynchronous motorMagnetic bearing

The invention discloses a five-degree-of-freedom (five-DOF) bearing-free permanent magnet synchronous motor. Left and right conical bearing-free permanent magnet synchronous motors respectively arranged at the left and right ends of a motor shell are symmetrically connected to a mechanical rotating shaft; each conical bearing-free permanent magnet synchronous motor consists of a conical stator, atorque winding, a suspension force winding and a conical rotor; and a permanent magnet is mounted on the outer surface of the conical rotor, a jacket is fixedly sleeved outside the permanent magnet, the conical rotor is fixedly arranged on the mechanical rotating shaft, the conical stator is provided with a plurality of through slots in the axial direction, each through slot is divided into an inner layer and an outer layer in the radial direction, the suspension force winding and the torque winding are respectively placed in the inner layer and the outer layer, the pole number of the torque winding is as same as that of the permanent magnet, and the difference between the pole number of the suspension force winding and the pole number of the torque winding is 2. The five-DOF bearing-freepermanent magnet synchronous motor can simultaneously realize radial and axial five-DOF suspension of the rotor without an additional magnetic bearing, has the advantages of high integration, reducedvolume and high critical rotating speed, and is easy to realize high-power ultrahigh-speed operation.

Owner:ZHENJIANG YUANDONG ELECTRIC MOTOR

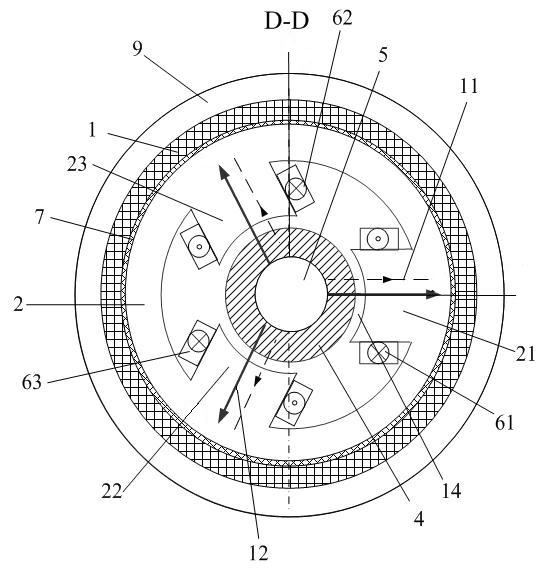

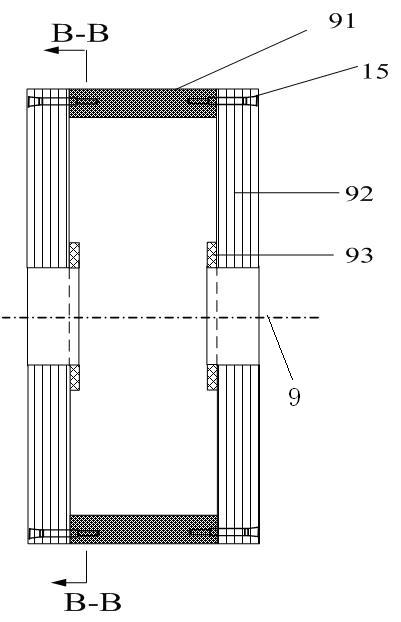

Constant current biased radial-axial magnetic bearing

ActiveCN103016525AImprove work efficiencyReduce power consumptionBearingsMagnetic bearingMagnetic poles

The invention discloses a constant current biased radial-axial magnetic bearing. The magnetic bearing comprises a rotating shaft, a rotor and a stator core which are mounted coaxially, wherein the stator core is formed by connection of two identical disks, an outer ring, an inner ring, two identical small rings and three stator core magnetic poles; the outer wall of the inner ring is tightly sleeved with a peripheral magnet-isolating aluminum ring; an internal magnet-isolating aluminum sheet is embedded in the axial middle inside each stator core magnetic pole; an axial control coil connected with a power amplifier is arranged between the peripheral magnet-isolating aluminum ring and the outer ring; a radial control coil is wound on each stator core magnetic pole, and three radial control coils are connected to a three-phase AC power inverter after star connection; a constant current biased coil is arranged in each of two axial cavity formed by the disks, the inner ring and the three stator core magnetic poles; and the two constant current biased coils are connected in series and then connected with the constant current. The magnetic bearing is good in heat dissipation, low in cost, small in power consumption and large in bearing force.

Owner:JIANGSU UNIV

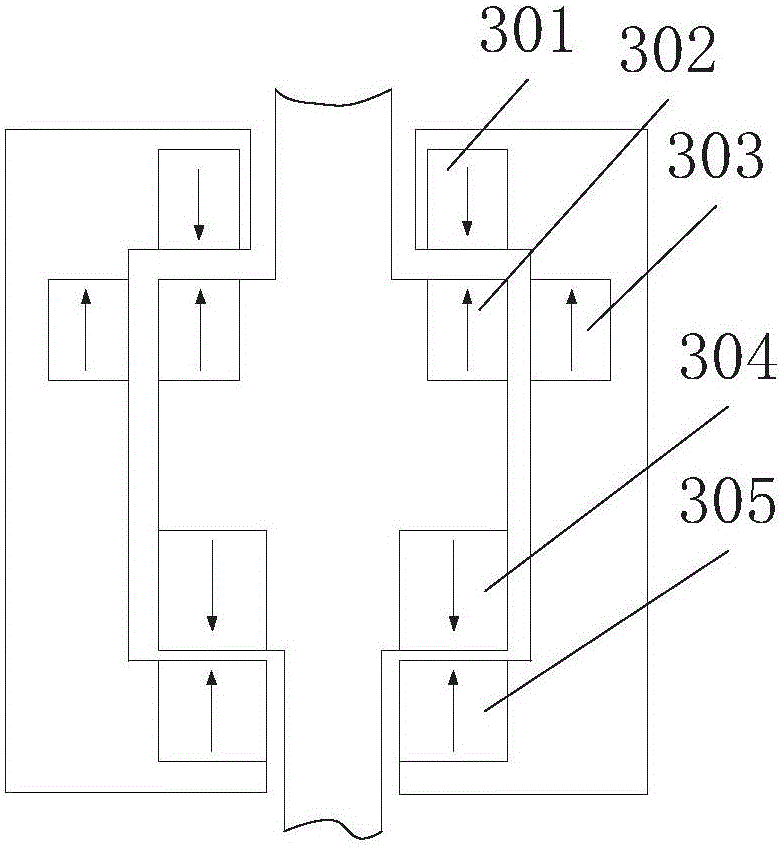

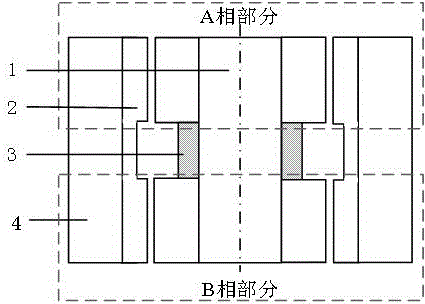

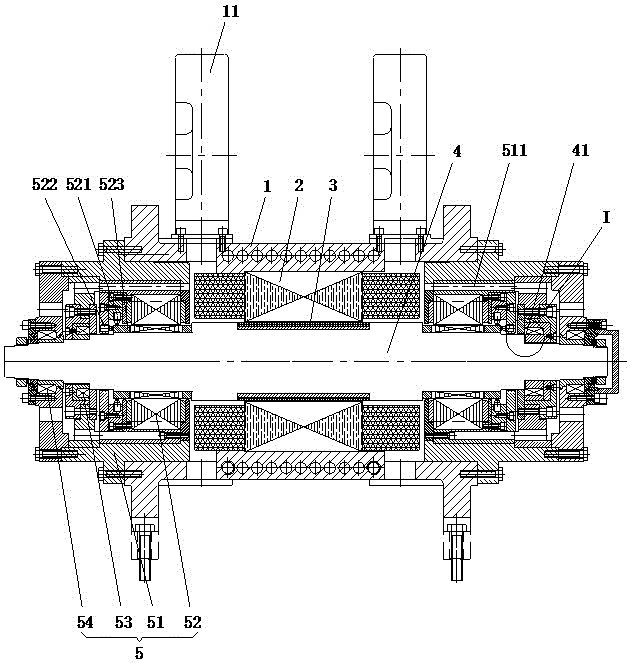

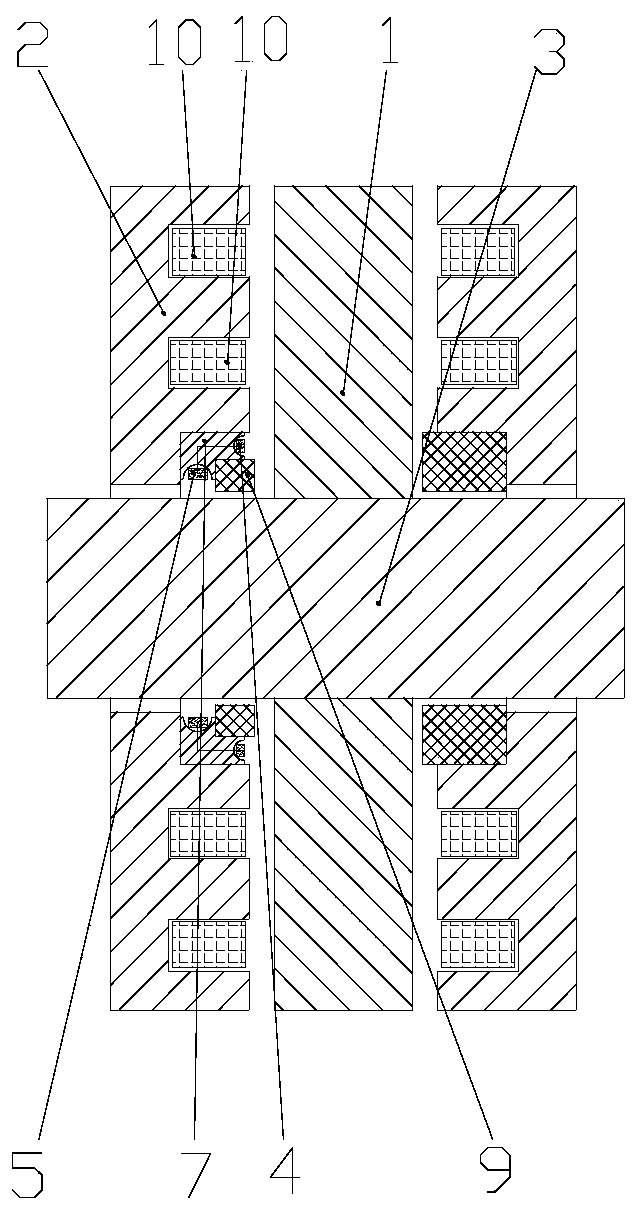

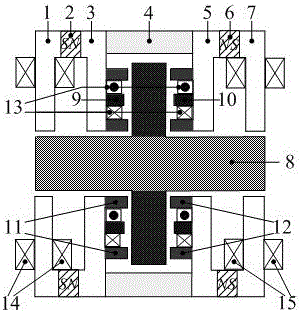

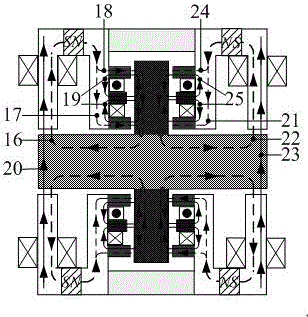

Axial split-phase internal stator permanent magnet biased magnetic suspension switched reluctance flywheel motor

ActiveCN106385203AIncrease the critical speedReduce lossMagnetic circuit stationary partsMechanical energy handlingFreewheelMagnetic poles

The invention provides an axial split-phase internal stator permanent magnet biased magnetic suspension switched reluctance flywheel motor comprising an external rotor, a flywheel and an internal stator. The external rotor is packaged at the internal side of the flywheel in a laminating way. An internal stator iron core and an external rotor iron core are divided into m segments along the axis according to the phase number. The internal side of each segment of external rotor is equidistantly provided with 12 rotor poles along the circumference. The internal stator iron core is provided with 8 narrow tooth main magnetic poles and 4 wide tooth suspension poles. Main pole control coils and suspension control coils are respectively wound on the narrow tooth main magnetic poles and the wide tooth suspension poles. The coils on each narrow tooth main magnetic pole are interconnected in series to form a main pole winding. Every two of the control coils on each segment of wide tooth suspension pole are connected in series so as to form two sets of suspension windings in an orthogonal direction. The size of the system can be reduced and the critical speed of rotation can be enhanced; the suspension supporting loss can be reduced and the operation efficiency can be enhanced; and the stator poles are separately provided with the suspension poles, the main magnetic poles and magnetic isolating rings so that the control algorithm can be simplified and the suspension performance and the decoupling effect can be enhanced.

Owner:NANJING INST OF TECH

Permanent magnet biased axial hybrid magnetic bearing

The present invention discloses a permanent magnet biased axial hybrid magnetic bearing, which comprises two stator discs having the same structure, wherein the two stator discs are arranged relative to a suction disc in an axially symmetric manner, the disc surface of every stator disc is provided with an outer annular coil groove, two annular magnetic isolation ring grooves, an annular permanent magnet groove and an inner annular coil groove along a radial direction from outside to inside, the two annular magnetic isolation ring grooves are respectively positioned on both radial sides of the annular permanent magnet groove, control coils are arranged inside every inner annular coil groove and every outer annular coil groove, a magnetic isolation ring is intercalated inside each annular magnetic isolation ring groove, an annular permanent magnet is pressed into each annular permanent magnet groove, and every annular permanent magnet is radially magnetized. According to the present invention, a static bias magnetic field is generated by the permanent magnet material so as to reduce magnetic bearing volume, lower power amplifier power consumption, and improve carrying capacity of the magnetic bearing; and the annular permanent magnet is embedded in the middle of the stator disc so as to ensure suction disc stiffness and upper-lower symmetry and left-right equality of the provided bias magnetic field.

Owner:江阴智产汇知识产权运营有限公司

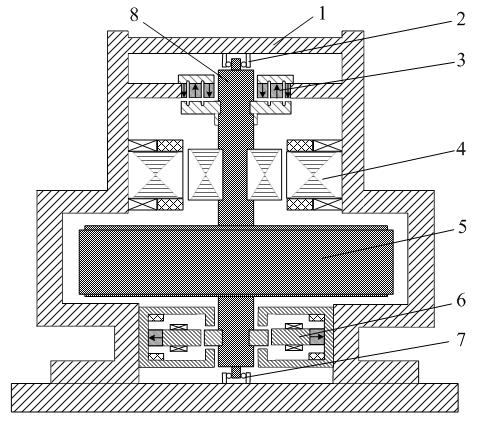

Permanent magnet biased five-degree-of-freedom integrated magnetic suspension supporting system

ActiveCN106050918AUniform air gapSuspension support is stableShaftsMagnetic bearingsSupporting systemMagnetic bearing

The invention discloses a permanent magnet biased five-degree-of-freedom integrated magnetic suspension supporting system. A stator comprises a left side radial magnetic bearing iron core, a right side radial magnetic bearing iron core, a left side annular permanent magnet, a right side annular permanent magnet, a left side axial control iron core and a right side axial control iron core; a radial control iron core is arranged between the left side annular permanent magnet and the right side annular permanent magnet; a radial control winding is wound on stator teeth; a right side magnetism dividing aluminum ring is arranged between the left side axial control iron core and the radial control iron core, and a left side magnetism dividing aluminum ring is arranged between the right side axial control iron core and the radial control iron core; a left side radial control winding is correspondingly wound on the left side radial magnetic bearing iron core in a stator groove, and a right side radial control winding is correspondingly wound on the right side radial magnetic bearing iron core in the stator groove; and the left side axial control iron core and the right side axial control iron core are each of an E-shaped structure, and axial control windings are correspondingly wound in the stator groove. The supporting system is small in axial length, high in critical rotating speed, simple in structure, easy to manufacture and assemble, and capable of generating larger axial and radial suspension force, and the axial control magnetic flux and the radial control magnetic flux do not pass through the permanent magnets.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Volute structure, centrifugal compressor and refrigeration equipment

ActiveCN104454652ASmall footprintReduce Articulation FixationPump componentsPump installationsEngineeringRefrigeration

The invention discloses a volute structure, a centrifugal compressor and refrigeration equipment, and relates to the field of refrigeration equipment. An existing centrifugal compressor structure is optimized. The volute structure comprises a box body, a volute body and a return device. The volute body comprises an inner volute and an outer volute independent from the inner volute. A fluid channel is formed between the inner volute and the outer volute. The inner volute and the return device are arranged together. According to the technical scheme, the length of the section of a primary pressure expander can be increased so that the pressure expansion effect of gas entering the primary pressure expander can be improved, and then the unit performance of the centrifugal compressor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

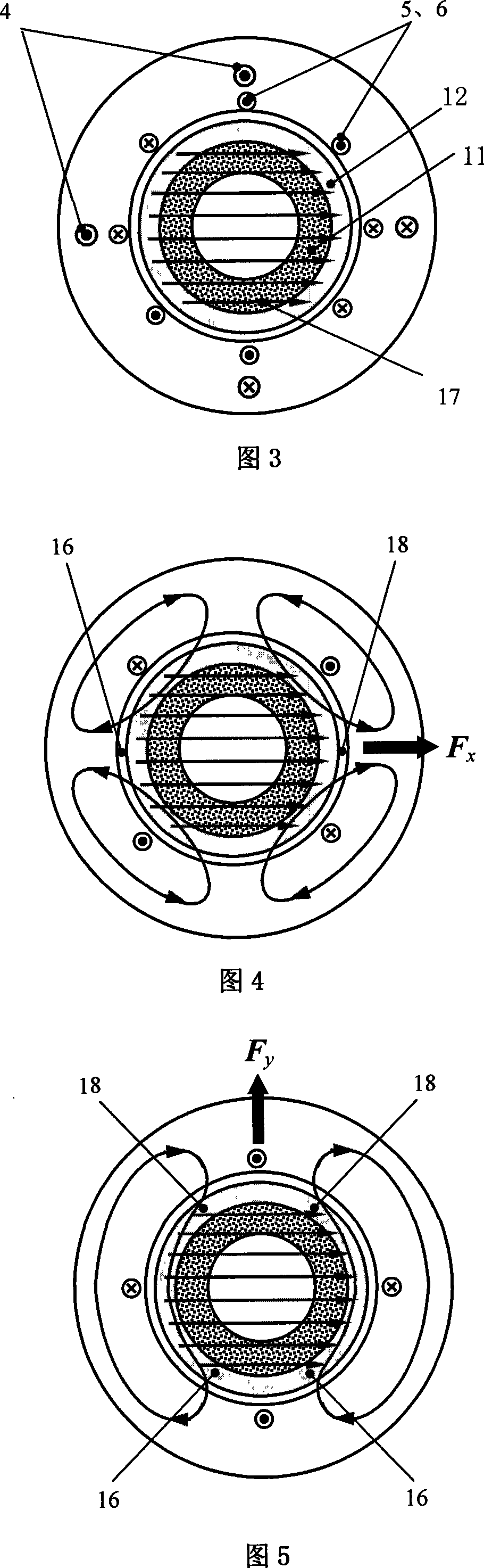

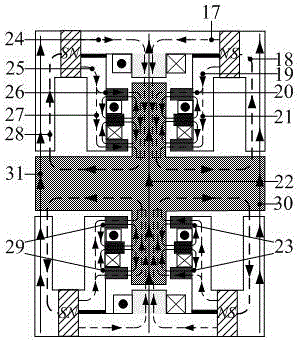

Three freedom degree conical rotor AC-DC hybrid magnetic bearing

InactiveCN101169160ASuspension stabilityShorten the axial lengthBearingsMagnetic bearingThree degrees of freedom

The invention discloses a three-degree-of-freedom conical stator-rotor AC-DC hybrid magnetic bearing. Three silicon steel laminations are evenly distributed on the inner side of the stator and along the radial circumference. The separated conical magnetic poles are separated from each other. The mirror is symmetrically distributed, and the magnetic isolation aluminum ring is installed in the middle for spatial isolation; the three-phase radial control coil is wound on three separate conical magnetic poles, and the axial control coil is located in the inner cavity of the stator; the rotor is arranged to be in phase with the conical magnetic poles. Correspondingly, a working air gap is formed between the conical rotor and the conical magnetic pole. The stator of the invention adopts a double-piece six-pole (2×3) structure, the axial stator and the radial stator are shared, and the radial and axial control currents are input independently, realizing the use of the axial magnetic circuit and the radial magnetic circuit to share the same work. The air gap simultaneously controls the suspension of the conical rotor in three degrees of freedom in the axial and radial directions; the magnetic bearing structure is further simplified; the control is simple and the power loss is reduced.

Owner:JIANGSU UNIV

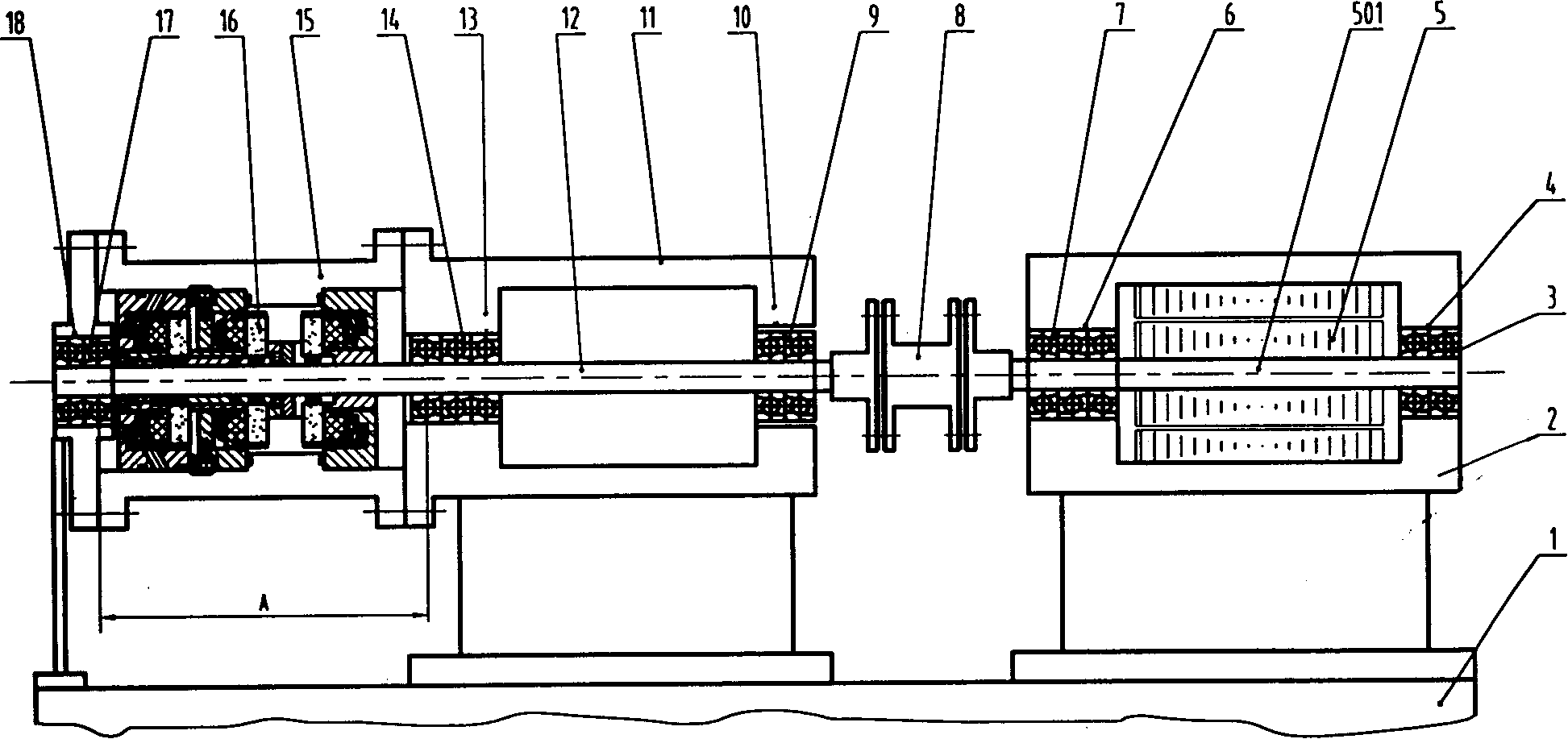

Mechanical seal test device for nuclear main pump

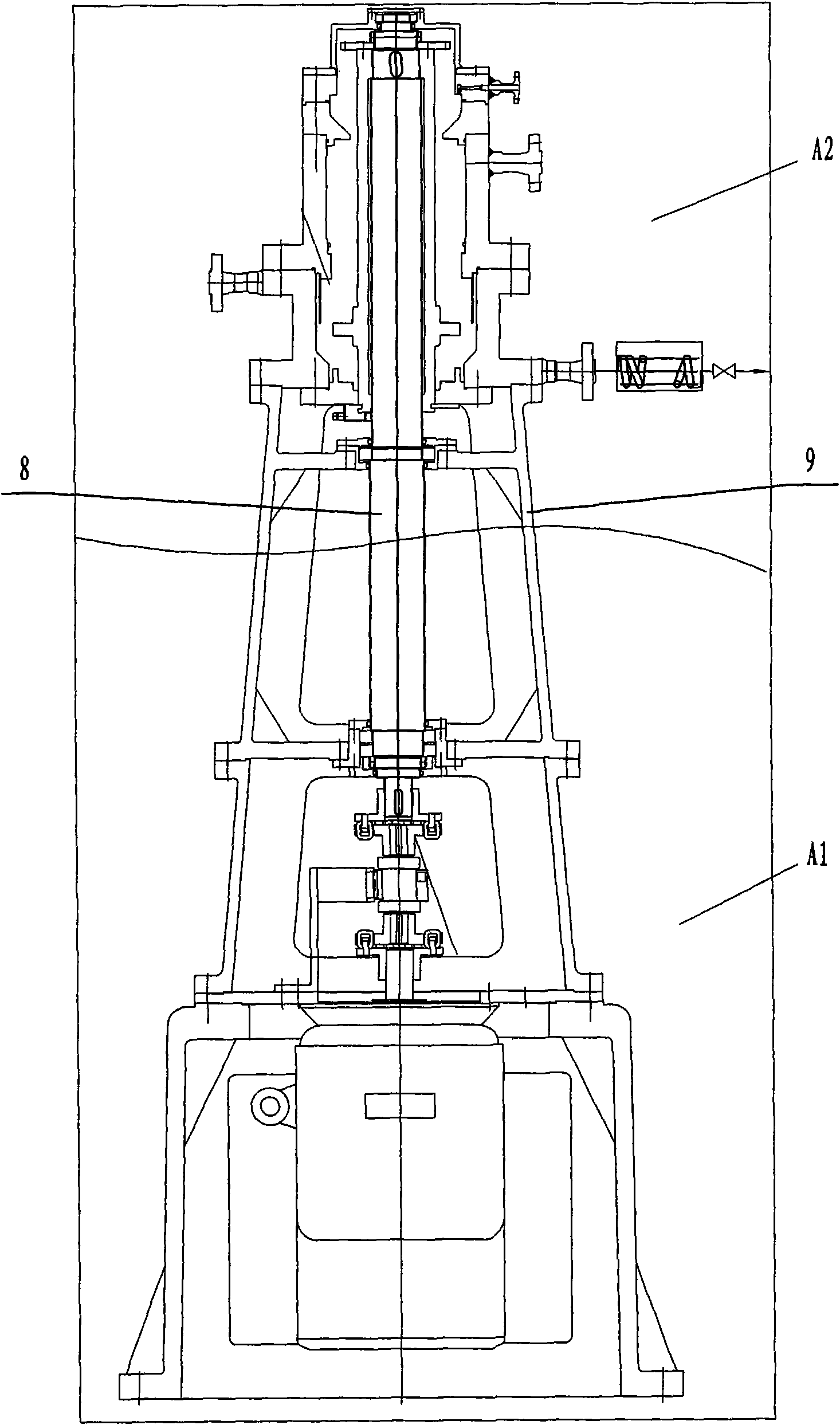

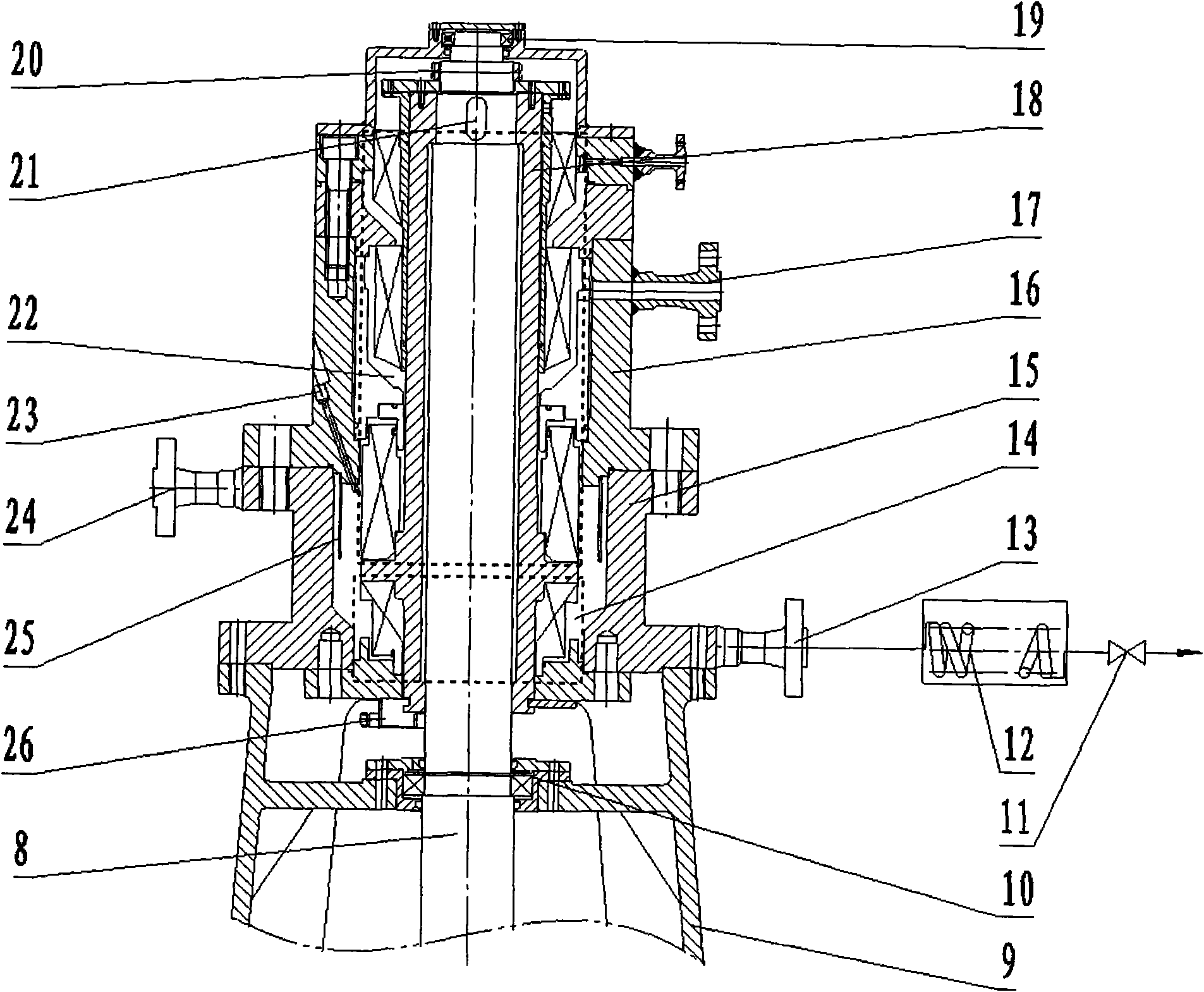

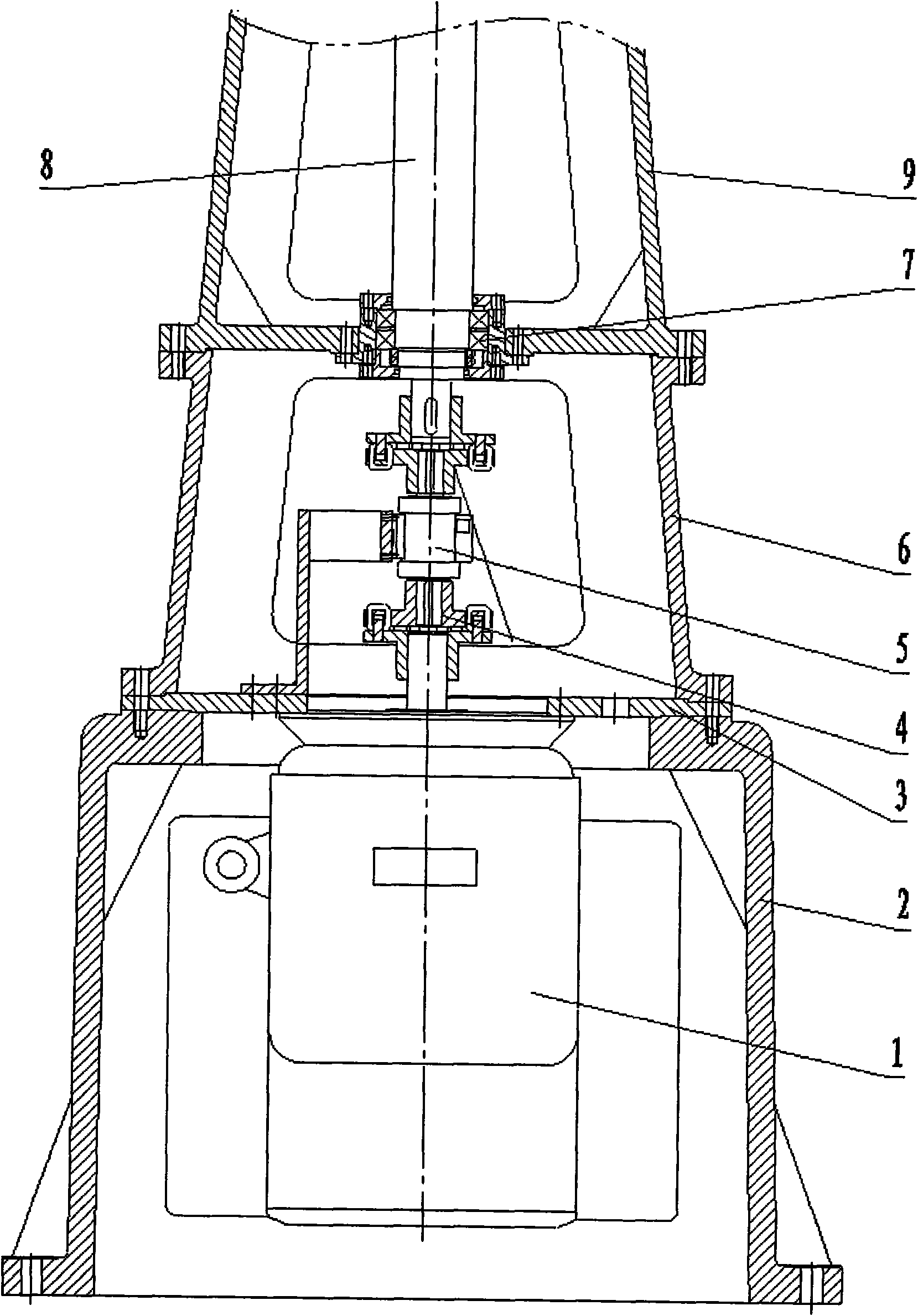

ActiveCN101649833AEasy to installEasy to disassemblePump testingPositive-displacement liquid enginesCouplingEngineering

The invention relates to a mechanical seal test device for a nuclear main pump, which is characterized by adopting a vertical structure of bottom transmission, which is driven by a motor; a speed-torque sensor is connected between a motor shaft and a main shaft through a flexible coupling; the main shaft is supported by a lower support and an upper support which are installed in an upper stand; the main shaft extends upward, and the extending part of the main shaft is sleeved with a testing shaft sleeve for installing a bench seal and a mechanical seal used in the tested nuclear main pump; thebench seal is arranged at the bottom of a lower seal cavity, and the mechanical seal for the tested nuclear main pump is arranged at the top of an upper cavity; the testing shaft sleeve is replaceable; a flow guiding sleeve is arranged in the lower seal cavity; a long tube throttling cooler and a back pressure valve are arranged at the position of the seal liquid outlet of the lower seal cavity;and an auxiliary support is matched at the top end of the main shaft. The mechanical seal test device can simulate hydrostatic mechanical seal tests for the nuclear main pump, can simulate hydrodynamic mechanical seal tests for the nuclear main pump and can simulate hydrostatic and hydrodynamic combined type mechanical seal tests for the nuclear main pump.

Owner:HEFEI GENERAL MACHINERY RES INST

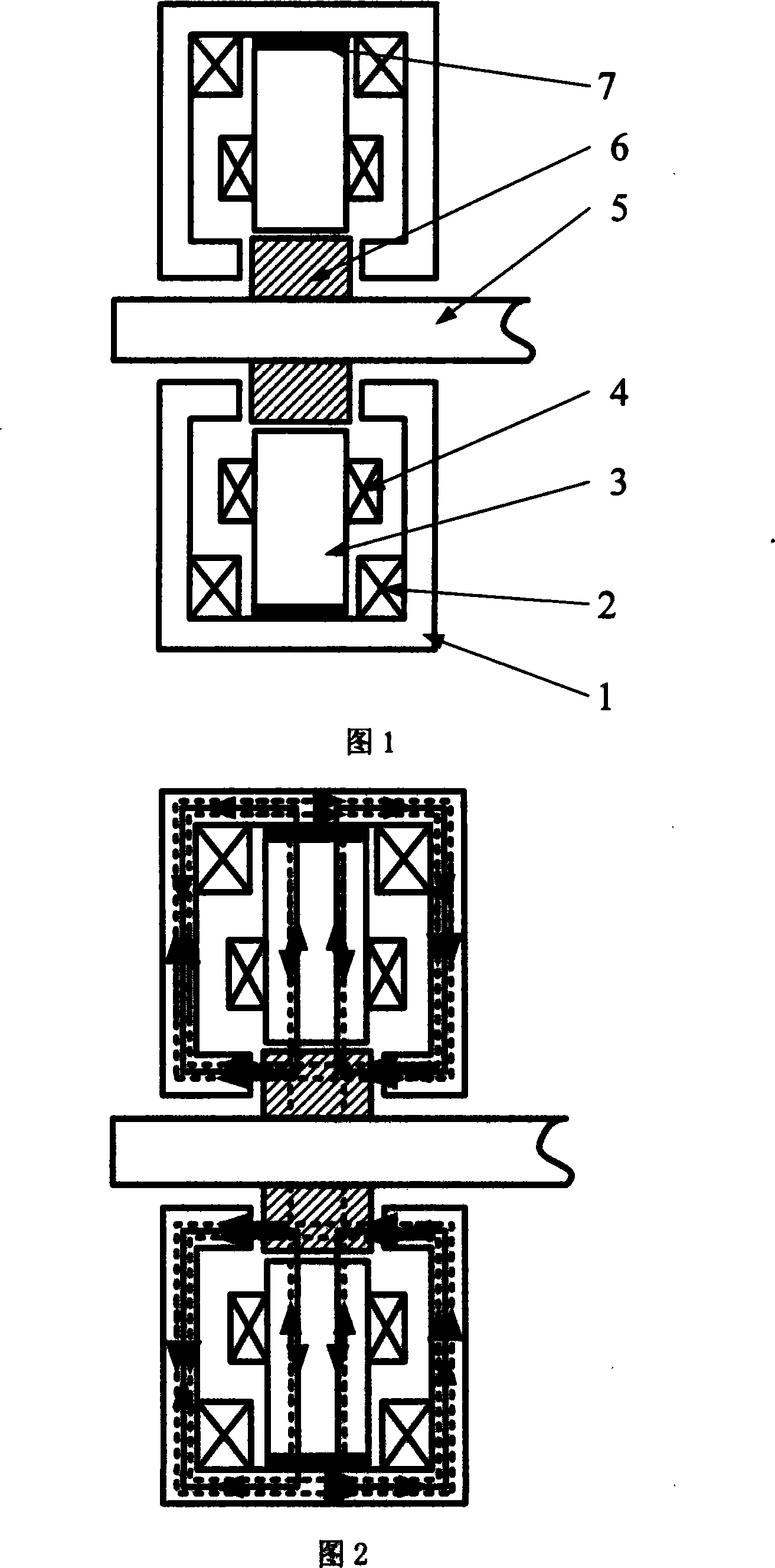

Permanent-magnet-biased axial magnetic bearing

InactiveCN102562800ASimple structureEasy to controlShaftsEngine componentsMagnetic bearingMagnetic poles

The invention discloses a permanent-magnet-biased axial magnetic bearing in the technical field of magnetic bearings. The permanent-magnet-biased axial magnetic bearing comprises a stator assembly and a rotor assembly; the stator assembly comprises an axial stator, an axial control winding, a septum magnet, a magnetizer and a permanent magnet; the rotor assembly comprises a rotation shaft and a rotor core; the axial control winding is wound on a magnetic pole of the axial stator; the rotor core is sleeved on the rotation shaft; the magnetizer is arranged in the axial stator, and the external end of the magnetizer is connected with the internal end of the axial stator; the septum magnet is arranged in the axial stator, the external end of the septum magnet is connected with the internal end of the axial stator; the permanent magnet is adhered to one side of the magnetizer, and the external end of the permanent magnet is contacted with the inner end face of the septum magnet; and the rotor core is arranged in the axial stator. The permanent-magnet-biased axial magnetic bearing has a simple structure, and is high in critical rotation speed, and low in power consumption; and magnetic flux flows in an axial direction and is decoupled with the radial suspension force completely, so the permanent-magnet-biased axial magnetic bearing is convenient to control.

Owner:NANJING COLLEGE OF CHEM TECH

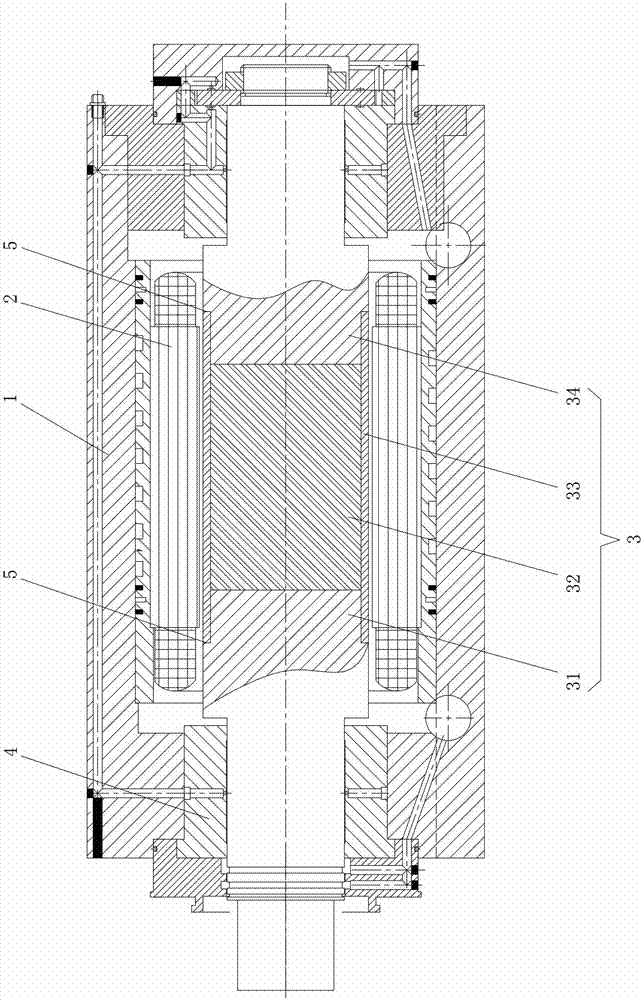

Magnetic suspension permanent-magnet direct-drive high-speed motor

PendingCN106505780AReduce quality problemsCompact structureMechanical energy handlingSupports/enclosures/casingsPermanent magnet rotorMagnetic bearing

The invention discloses a magnetic suspension permanent-magnet direct-drive high-speed motor, which comprises a shell, a stator, a permanent-magnet rotor, a main shaft and two groups of bearing assemblies, wherein the two groups of bearing assemblies are arranged at the front end and the rear end of the main shaft respectively; the stator is fixed in the shell; the permanent-magnet rotor is arranged on the main shaft and emptily sleeved with the stator; each bearing assembly comprises a bearing block, a radial magnetic bearing, a thrust magnetic bearing and an auxiliary bearing; the radial magnetic bearings, the thrust magnetic bearings and the auxiliary bearings are sequentially arranged from the middle part of the main shaft to two ends of the main shaft; the main shaft is provided with a thrust shaft shoulder; and a thrust magnetic gap is arranged between the end surface of the thrust shaft shoulder and the thrust magnetic bearings. The magnetic suspension permanent-magnet direct-drive high-speed motor disclosed by the invention has the advantages that the mass and the rotational inertia of a motor rotor shaft system are small, the critical rotating speed of the shaft system is high, the strength and the security risk are low and the magnetic suspension permanent-magnet direct-drive high-speed motor is convenient to disassemble, assemble and adjust.

Owner:NANTONG JINCHI MECHANICAL ELECTRIC

Magnetic suspension bearing and magnetic suspension centrifugal compressor and air conditioner

PendingCN109763994AHigh control reliabilityIncrease the critical speedPump componentsPump controlAxial displacementThrust bearing

The invention provides a magnetic suspension bearing, a magnetic suspension centrifugal compressor and an air conditioner. The magnetic suspension bearing comprises an axial thrust bearing (1), a first axial bearing stator (2) and a second axial bearing stator (3), wherein the first axial bearing stator (2) and the second axial bearing stator (3) are correspondingly arranged at two axial ends of the axial thrust bearing (1) and are used for adjusting the axial position of the axial thrust bearing (1); and at least one of the first axial bearing stator (2), the second axial bearing stator (3) and the axial thrust bearing (1) is provided with an axial displacement sensor (4) for detecting the axial displacement of the axial thrust bearing (1). The magnetic suspension bearing improves the accuracy of axial displacement detection of the thrust bearing; and the control accuracy is improved.

Owner:GREE ELECTRIC APPLIANCES INC

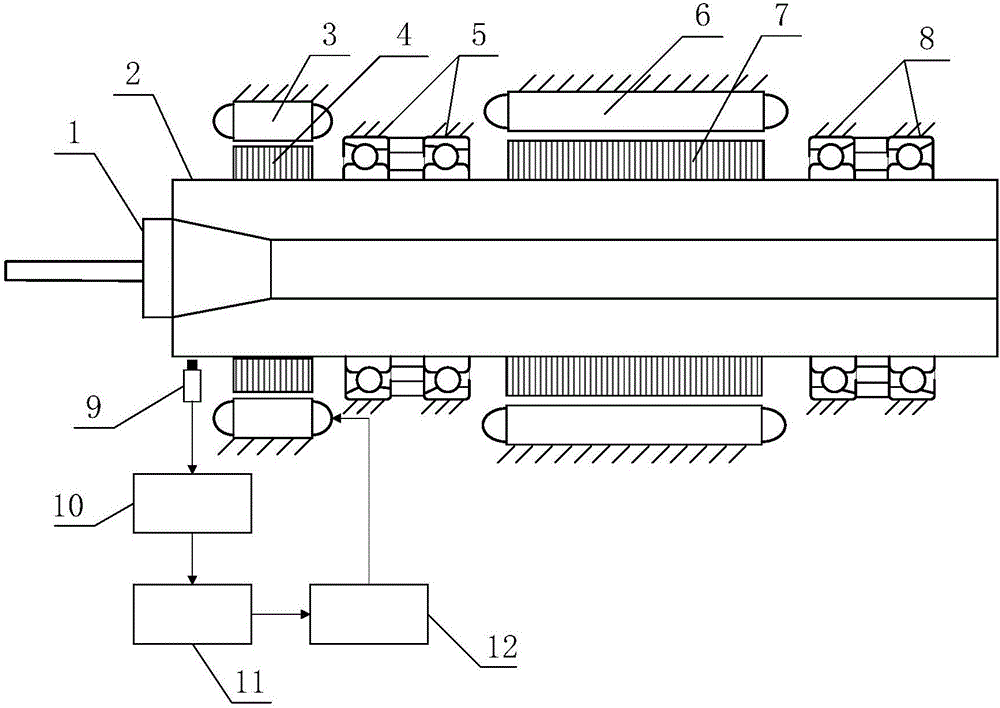

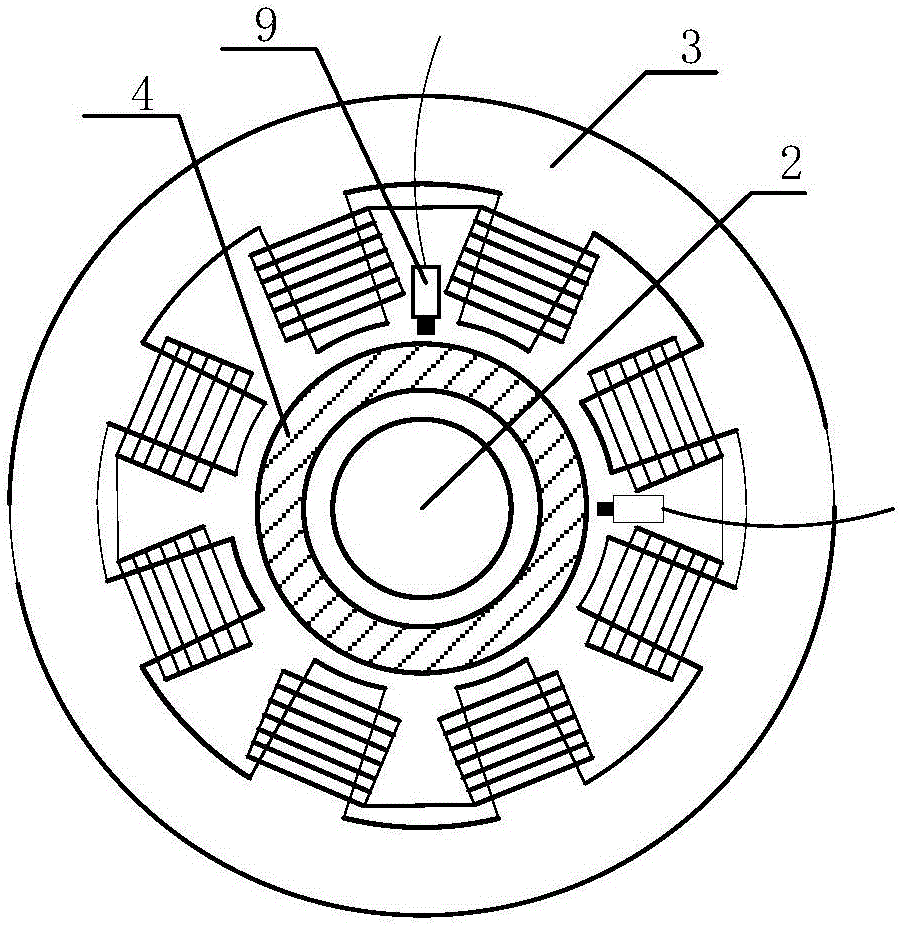

Online active type cutting chatter restraining system and method for intelligent milling motorized spindle

ActiveCN106392753ARealize intelligenceIncrease the critical speedMaintainance and safety accessoriesAxial displacementMagnetic bearing

The invention provides an online active type cutting chatter restraining system and method for an intelligent milling motorized spindle. The online active type cutting chatter restraining system for the intelligent milling motorized spindle comprises a sensing portion, a controller and a chatter restraining adjustment and control device, wherein the sensing portion, the controller and the chatter restraining adjustment and control device are sequentially connected. The sensing portion comprises a non-contact type eddy current displacement sensor and a signal collector, wherein the non-contact type eddy current displacement sensor is installed at the front end of the spindle and used for measuring the axial displacement of the spindle, and the signal collector is used for collecting displacement signals of the non-contact type eddy current displacement sensor and converting the displacement signals to acceleration signals. The controller is used for outputting voltage control signals to the chatter restraining adjustment and control device according to the acceleration signals output by the signal collector. The chatter restraining adjustment and control device comprises a power amplifier and an active type electromagnetic bearing. The active type electromagnetic bearing comprises a rotor core and a stator core, wherein the rotor core is installed at the front end of the spindle, and a copper coil is wound around the stator core. The power amplifier is used for converting the received voltage signals into current control signals. The output end of the power amplifier is connected with the copper coil. The online active type cutting chatter restraining method for the intelligent milling motorized spindle comprises the steps of identifying and restraining chatter in the machining process.

Owner:XI AN JIAOTONG UNIV

Low-power-consumption permanent-magnet bias five-degree-of-freedom integrated magnetic bearing

ActiveCN106015331AUniform air gapSuspension stabilityShaftsMagnetic bearingsMagnetic bearingEngineering

The invention discloses a low-power-consumption permanent-magnet bias five-degree-of-freedom integrated magnetic bearing which comprises a stator and a rotor iron core, wherein the stator iron core comprises an axial part and a radial part; the stator comprises a left radial magnetic bearing iron core and a right radial magnetic bearing iron core as well as a left ring-shaped permanent magnet, a right ring-shaped permanent magnet, a left axial magnetic bearing iron core and a right axial magnetic bearing iron core; and a magnetism-isolated aluminum ring is arranged between the left axial magnetic bearing iron core and the right axial magnetic bearing iron core. The invention effectively solves the defects of a current five-degree-of-freedom magnetic suspension system and provides the low-power-consumption permanent-magnet bias five-degree-of-freedom integrated magnetic bearing which is small in size, is light in mass, is short in axial length, is high in clinical rotation speed, is high in iron core utilization rate, is simple in structure, is simple to manufacture and assemble, controls magnetic flux without the permanent magnets in the axial direction and in the radial direction, and can generate greater axial suspension force and radial suspension force.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

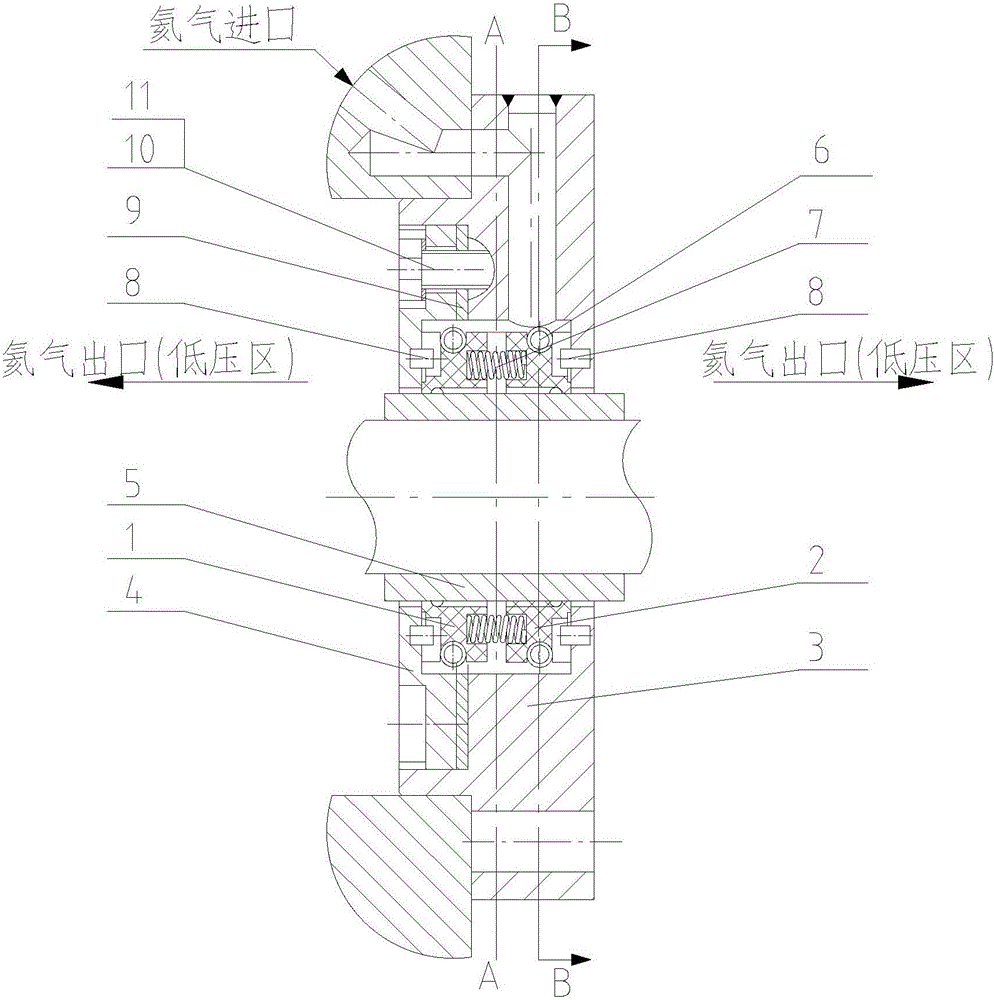

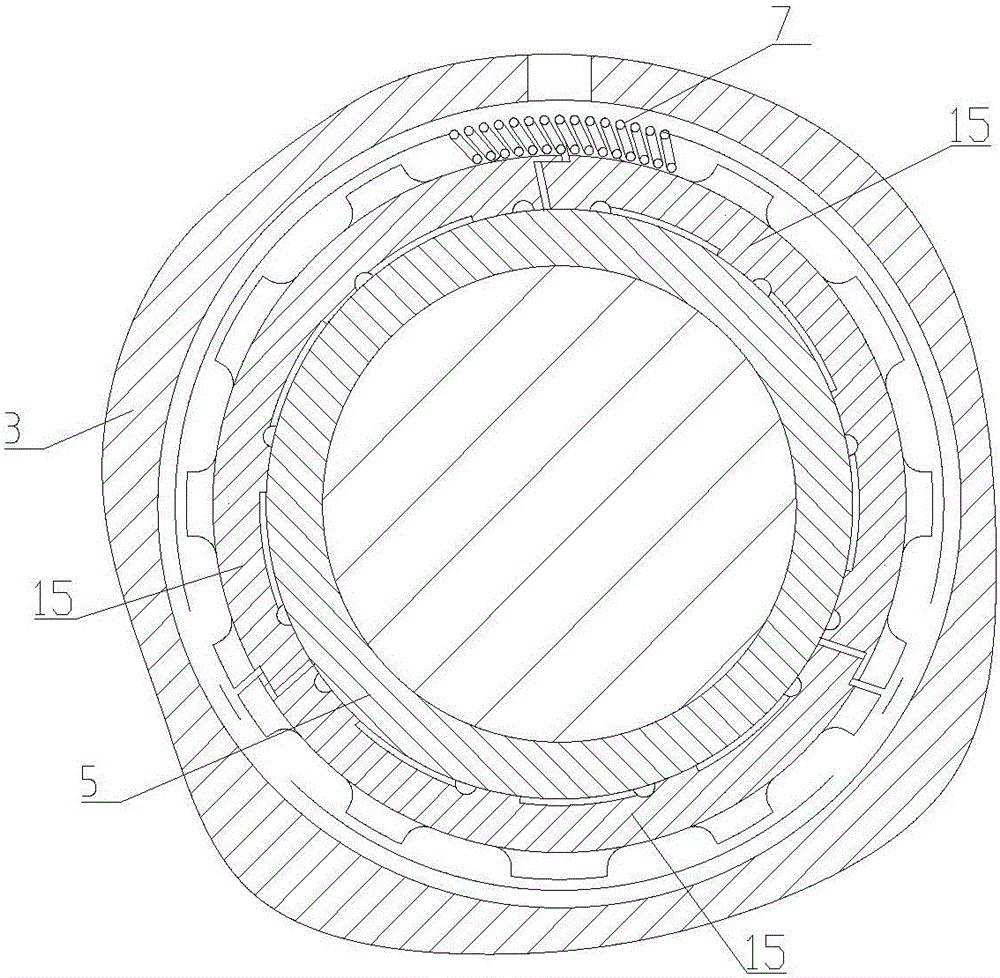

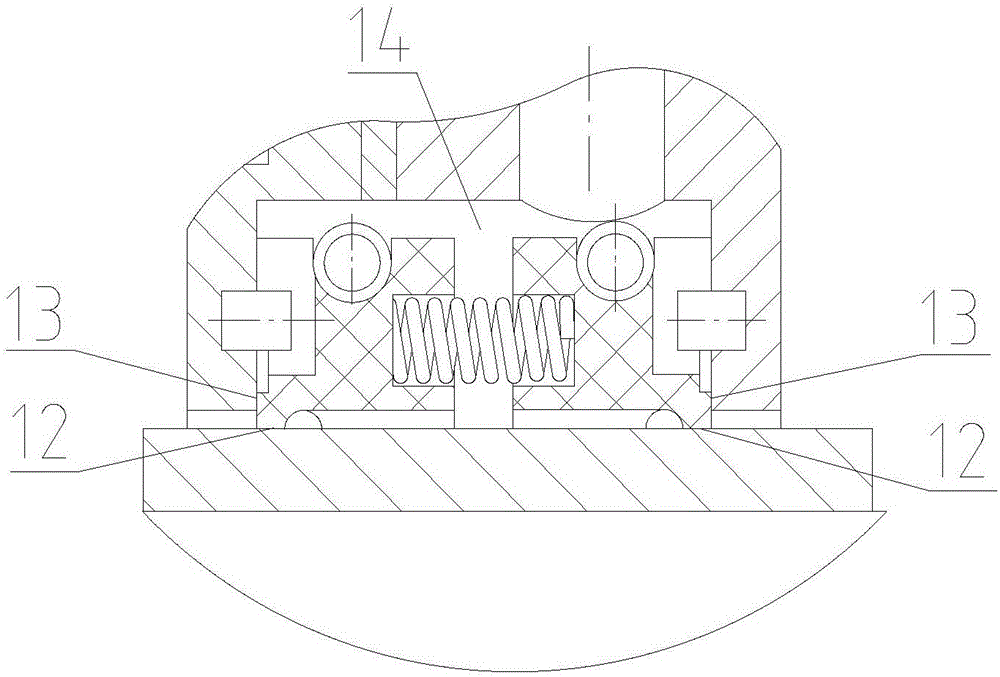

Circumferential sectioned helium sealing device for oxygen turbine pump of hydrogen oxygen engine

The invention discloses a circumferential sectioned helium sealing device for an oxygen turbine pump of a hydrogen oxygen engine. According to the circumferential sectioned helium sealing device, a circumferential sectioned sealing ring I and a circumferential sectioned sealing ring II are placed in a cavity formed by a cover plate and a sealing shell; sealing shaft sleeves are placed in rings of the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II; the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II are oppositely placed and pre-tensioned by virtue of pre-tensioning springs; and each of the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II is formed by connecting a plurality of fan-shaped arc sections with the same structure end to end, and constrained on an excircle surface through garter springs. According to the circumferential sectioned helium sealing device, each sealing ring is composed of the plurality of fan-shaped arc sections, a hydrodynamic groove structure is introduced, and a hydrodynamic effect of a sealing clearance fluid is adequately utilized, thus the helium sealing device reliably works under an extremely small clearance, and a low leakage amount is maintained.

Owner:BEIJING AEROSPACE PROPULSION INST

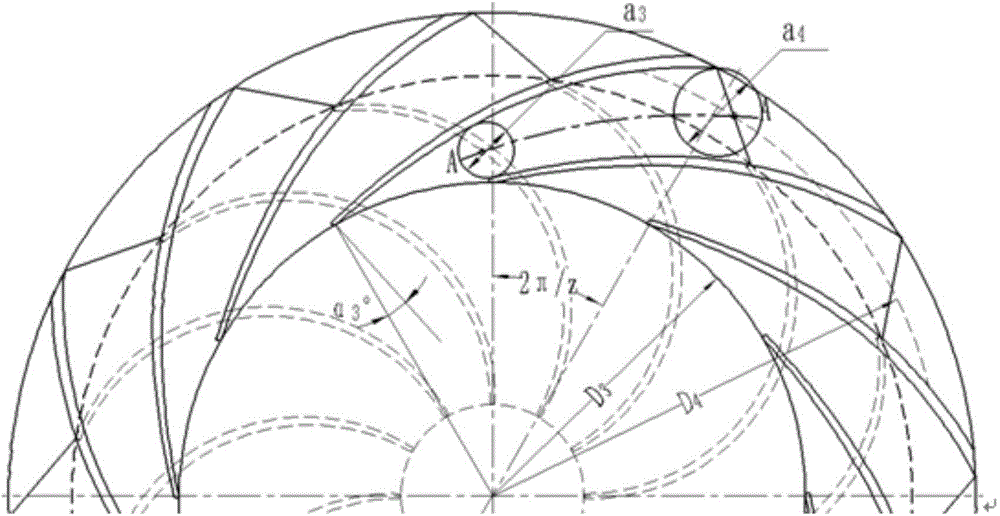

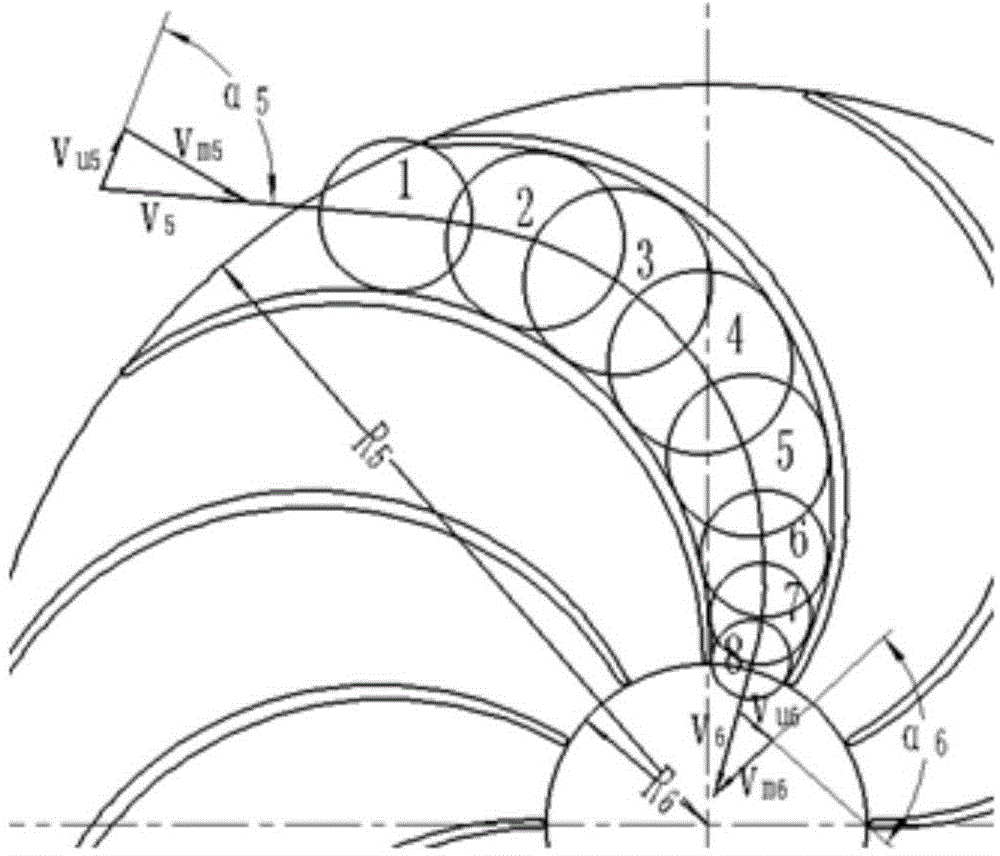

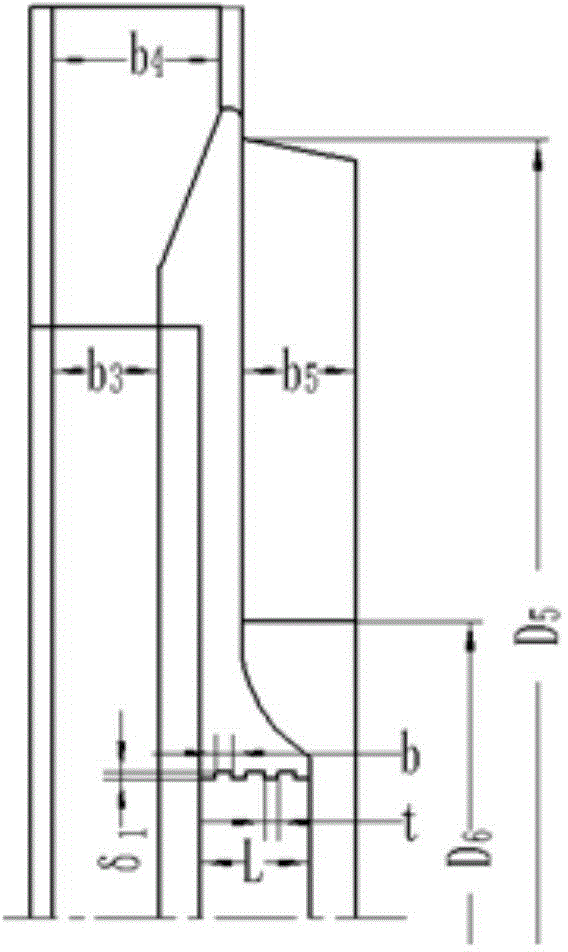

Guide vane designing method for improving stability of multistage pump

InactiveCN104879323AImprove stabilityIncrease the critical speedPump componentsPumpsControl engineeringProcess engineering

The invention provides a guide vane designing method for improving stability of a multistage pump. The guide vane designing method includes the following steps: determining geometric parameters of guide vanes, acquiring a basic guide vane model from three-dimensional modeling software according to the geometric parameters, and arranging multiple groove structures at guide vane hubs of the guide vane basic model to acquire a final guide vane model; acquiring final guide vanes by means of die opening and casting according to the final guide vane model. According to the guide vane designing method, the guide vanes in a proper number are selected in the process of designing the guide vanes, and maximum 2, 3 or 4 common divisor exists between the proper number and number of impeller vanes, so that flowing inside the multistage pump can present obvious regularity, and the objective of lowering vibrating amplitude of the multistage pump is achieved; the groove structures are arranged at the guide vane hubs, so that large radial water power is generated at the guide vane hubs of the multistage pump, good supporting effect is realized, and stability of the multistage pump is improved.

Owner:JIANGSU UNIV

Radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing

The invention discloses a radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing used for non-contact suspension bearing. An axial control coil is arranged between a radial stator core and an axial stator core; an axial air gap is formed between the axial stator core and the end face of a rotor in the axial direction; three same stator core magnetic poles uniformly distributed in the circumferential direction extend from the wall of an inner cavity of the radial stator core to the axle center; same radial control coils are wound on the three stator core magnetic poles, and radial air gaps are formed between the stator core magnetic poles and the outer wall of the rotor in the radial direction; same axially magnetized annular permanent magnets are arranged between two axial sides of the radial stator core and the axial stator core; and S poles of the permanent magnets face the radial stator core, and N poles of the permanent magnets face the axial stator core. The radial-axial three-degree-of-freedom alternating current-direct current hybrid magnetic bearing integrates axial and radial functions, is only driven by a three-phase alternating current power inverter, is provided with two axially magnetized annular permanent magnets, controls the magnetic flux not to pass magnetic poles where the permanent magnets are positioned, and has the advantages of low power consumption, small volume, light weight and high bearing capacity.

Owner:JIANGSU UNIV

Three-pivot seal testing device

InactiveCN1354332AImprove rigidityIncrease the critical speedEngine sealsFluid-tightness measurementFixed bearingEngineering

The present invention relates to a three-fulcrum type seal test device, on the seal test main shaft a three-fulcrum type structure is placed for supporting said shaft. The described three-fulcrum type structure is characterized by that three groups of bearings which are mutually spaced at a certain distance are mounted on the seal test main sahft, in which two groups of bearings are respectively mounted into two fixed bearing seats; another group of bearing of mounted in a removable bearing seat, between the removable beairng seat and its adjacent fixed bearing seat, the tested seal cavity and tested seal are mounted. Said invention possesses the folloiwng advantages: good rigidity of test seal main shaft, high critical rotating speed, and said device is suitable for testing various gas seals.

Owner:JOHN CRANE TECH TIANJIN

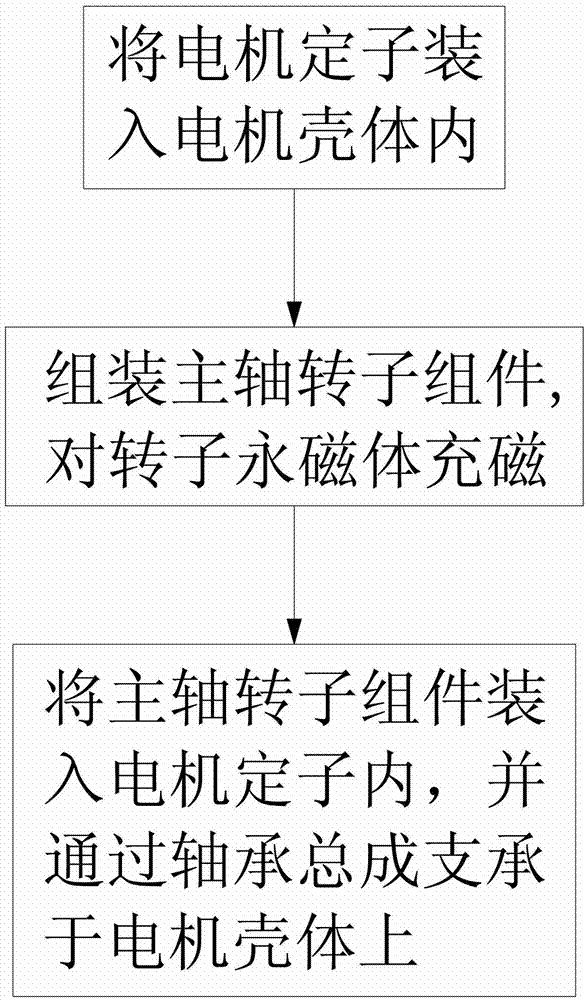

High-speed permanent magnet synchronous motor and assembly method thereof

InactiveCN103117633AIncrease speedImprove efficiencyMagnetic circuit rotating partsManufacturing dynamo-electric machinesPermanent magnet synchronous motorPermanent magnet synchronous generator

Disclosed are a high-speed permanent magnet synchronous motor and an assembly method thereof. The motor comprises a motor shell, a motor stator, a spindle rotor component and a pair of bearing assemblies, the bearing assemblies are separately arranged at the front end and the rear end of the shell, the motor stator is fixed into the motor shell, the spindle rotor component is sleeved in the motor stator, two ends of the spindle rotor component are supported on the motor shell through the bearing assemblies, the spindle rotor component comprises a front rotor half shaft, a rotor permanent magnet, a rotor sleeve and a rear rotor half shaft, the rotor permanent magnet is sleeved in the rotor sleeve, one end of the rotor sleeve is fixedly connected with the front rotor half shaft, and the other end of the rotor sleeve is fixedly connected with the rear rotor half shaft. The high-speed permanent magnet synchronous motor is compact in structure, sufficient in space usage, small in radial dimension and particularly suitable for meeting the requirement on high rotation speed. The assembly method includes the steps: 1) mounting the motor stator into the motor shell; 2) assembling the spindle rotor component and magnetizing the rotor permanent magnet in the spindle rotor component after the spindle rotor component is assembled; and 3) mounting the spindle rotor component into the motor stator, and supporting the spindle rotor component on the motor shell through the bearing assemblies.

Owner:HUNAN UNIV

Ultrahigh-speed disc type permanent magnet synchronous motor

PendingCN108233656AIncrease the critical speedShorten the axial lengthSupports/enclosures/casingsSynchronous machines with stationary armatures and rotating magnetsUltra high speedPermanent magnet synchronous motor

The invention provides an ultrahigh-speed disc type permanent magnet synchronous motor. The motor comprises a rotor, a stator, a thrust disc and a case, wherein the rotor consists of a rotary shaft and a rotor disc; the rotor disc consists of an aluminum sheath, a permanent magnet and a protection jacket; the rotary shaft is sleeved with the thrust disc and in clearance fit with the thrust disc; afirst annular groove is formed in the thrust disc, the aluminum sheath is embedded in the first annular groove, a second annular groove is formed in the aluminum sheath, and the permanent magnet is embedded in the second annular groove; the stator consists of a stator core and a coil winding which winds around the stator core, and the rotary shaft is sleeved with the stator core in a hollow manner. The rotor disc adopts a disc structure and is embedded on the thrust disc, the axial length of the motor is greatly reduced, so that the size of the whole motor is reduced, the clearance between the rotator disc and the thrust disc which are combined together and surrounding parts is increased, and the cooling effect is improved remarkably; the stator adopts the annularly concentrated winding,the stator core is inlaid in the case, and the size of the whole motor is reduced greatly.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com