Single-winding non-bearing magnetic flux switching permanent magnetic motor

A magnetic flux switching, permanent magnet motor technology, applied in electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of increasing motor loss, reducing winding utilization, motor power density, reducing efficiency, etc., to increase the load ability, avoid high temperature demagnetization, improve the effect of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

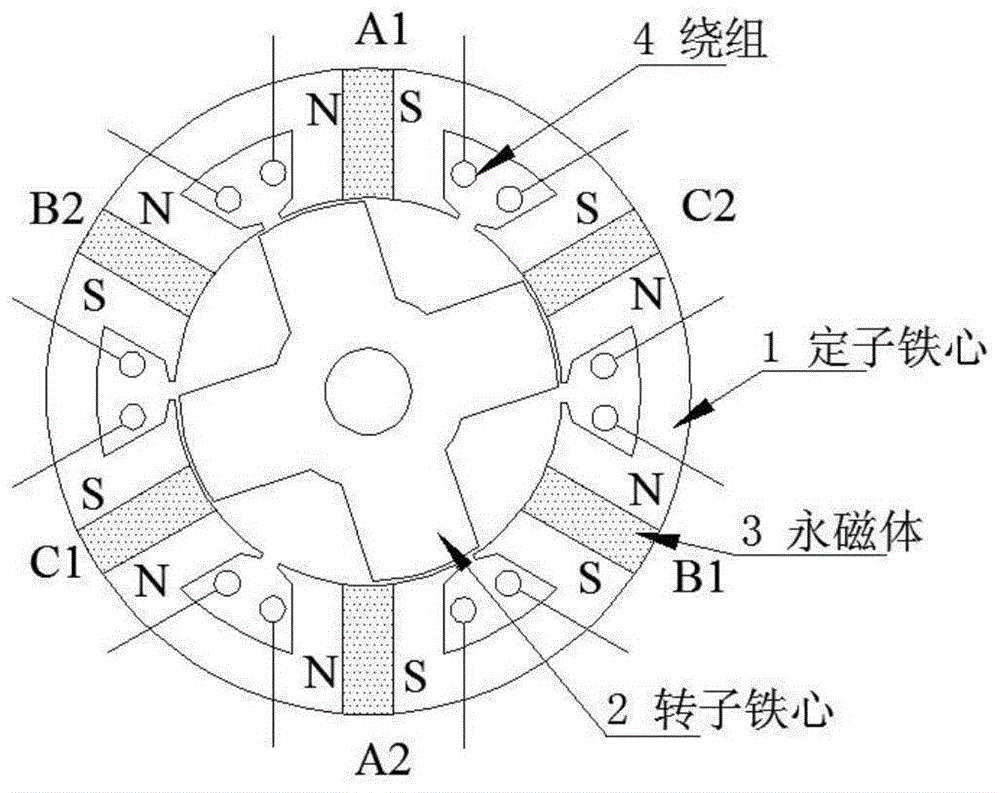

[0028] Integrating the excellent characteristics of the magnetic flux switching permanent magnet motor and the magnetic bearing motor, the present invention proposes a new type of single-winding non-bearing flux switching permanent magnet motor. Its basic structure is as figure 1 As shown, the main motor is composed of a stator core 1, a rotor core 2, a permanent magnet 3 embedded in the middle of the stator teeth, and a single-layer winding 4. Both the stator and the rotor are double-salient pole structures with axial symmetry, and the cores of the stator and rotor are made of laminated silicon steel sheets. The rotor is similar to the switched reluctance motor, without windings and permanent magnets on it, easy to manufacture, low in cost, simple and firm in structure, suitable for high-speed rotation. The stator core is composed of 6 U-shaped laminations, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com