Insulated wire coded by entity color bars and preparation method thereof

A technology of insulated wires and color stripes, applied in the direction of insulated cables, insulated conductors, marking conductors/cables, etc., can solve problems such as limited wiring density, difficult color stripes, and limited total amount of color codes, and achieves simple preparation methods and high production efficiency High, the effect of increasing the total amount of color codes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

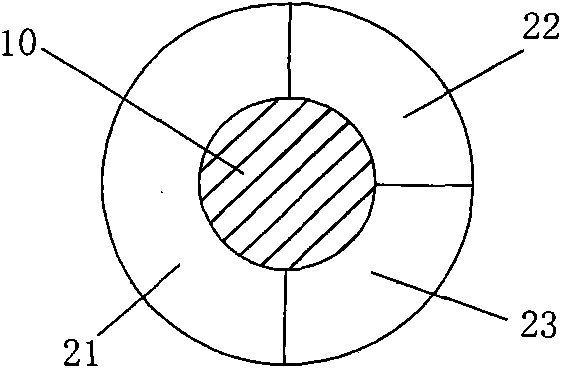

[0037] see figure 2 , in this embodiment, on the cross-section of the electric wire, the sub-regions of the outermost rubber sleeve are set as fan-shaped solid regions of different colors, as shown in the figure, they are respectively white fan-shaped solid region 21, blue fan-shaped solid region 22 and red fan-shaped The solid area 23 ; the fan-shaped solid areas of different colors are in a spiral shape in the axial direction of the electric wire, forming a spiral color strip around the electric wire. In the specific implementation, in the helical color strip around the wire, the white solid area as the primary color body is set to twice the width of other color strips; the helical color strip around the wire is set to rotate to the left axis, so that the wire can be rotated in any position and direction Can clearly identify the color code of the wire.

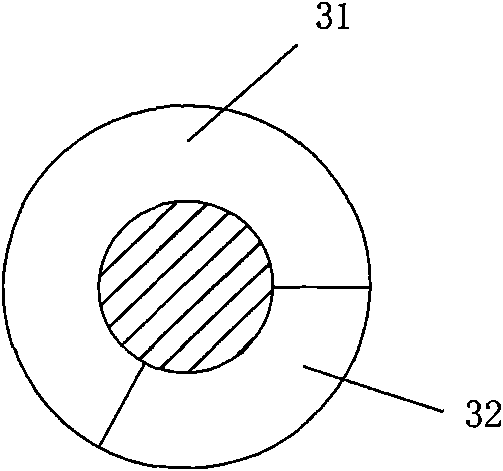

[0038] Figure 3a and Figure 3b Shown is the electric wire structure that coding is 92, is primary color body 31 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com