Patents

Literature

784results about "Artistic surface treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

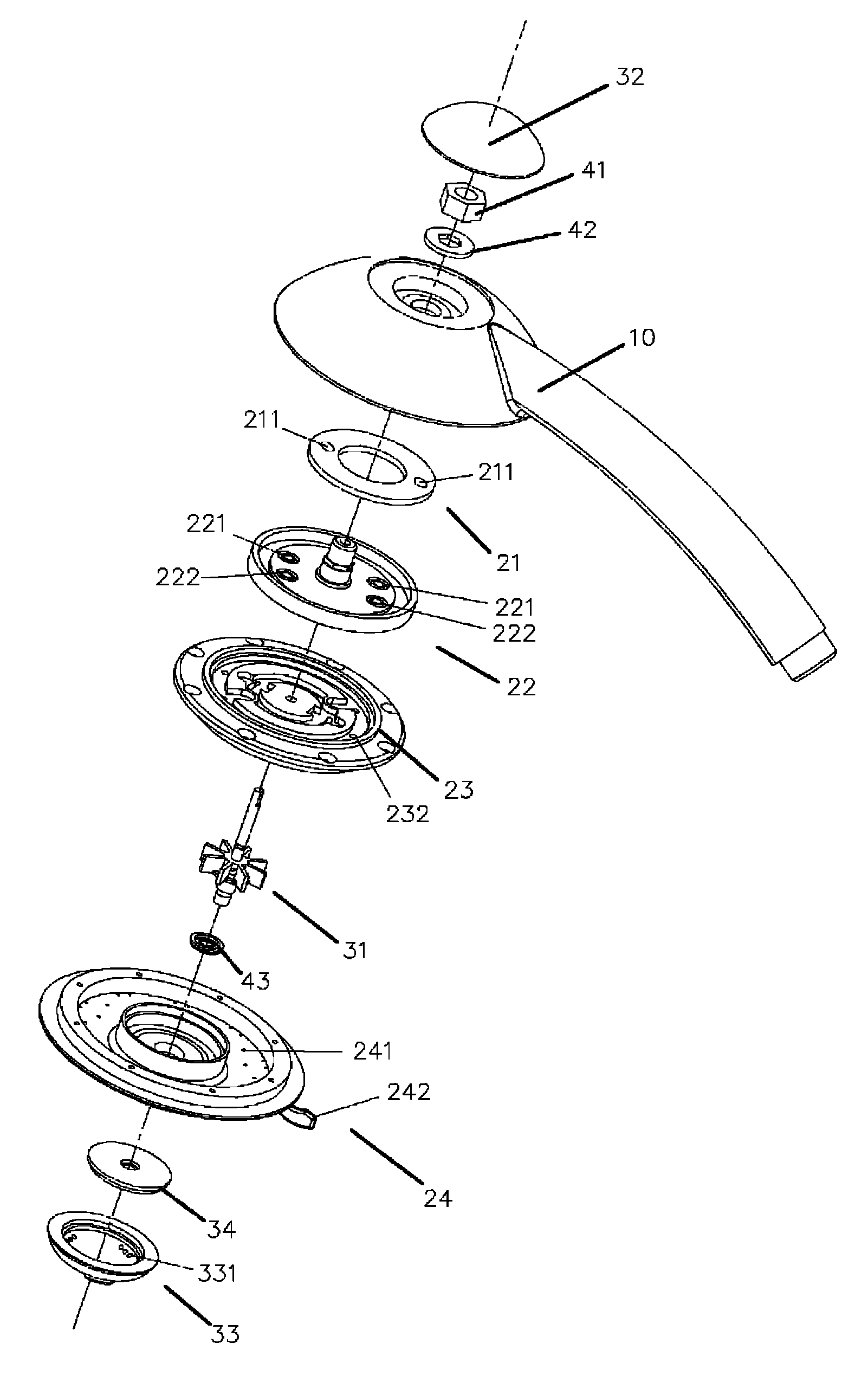

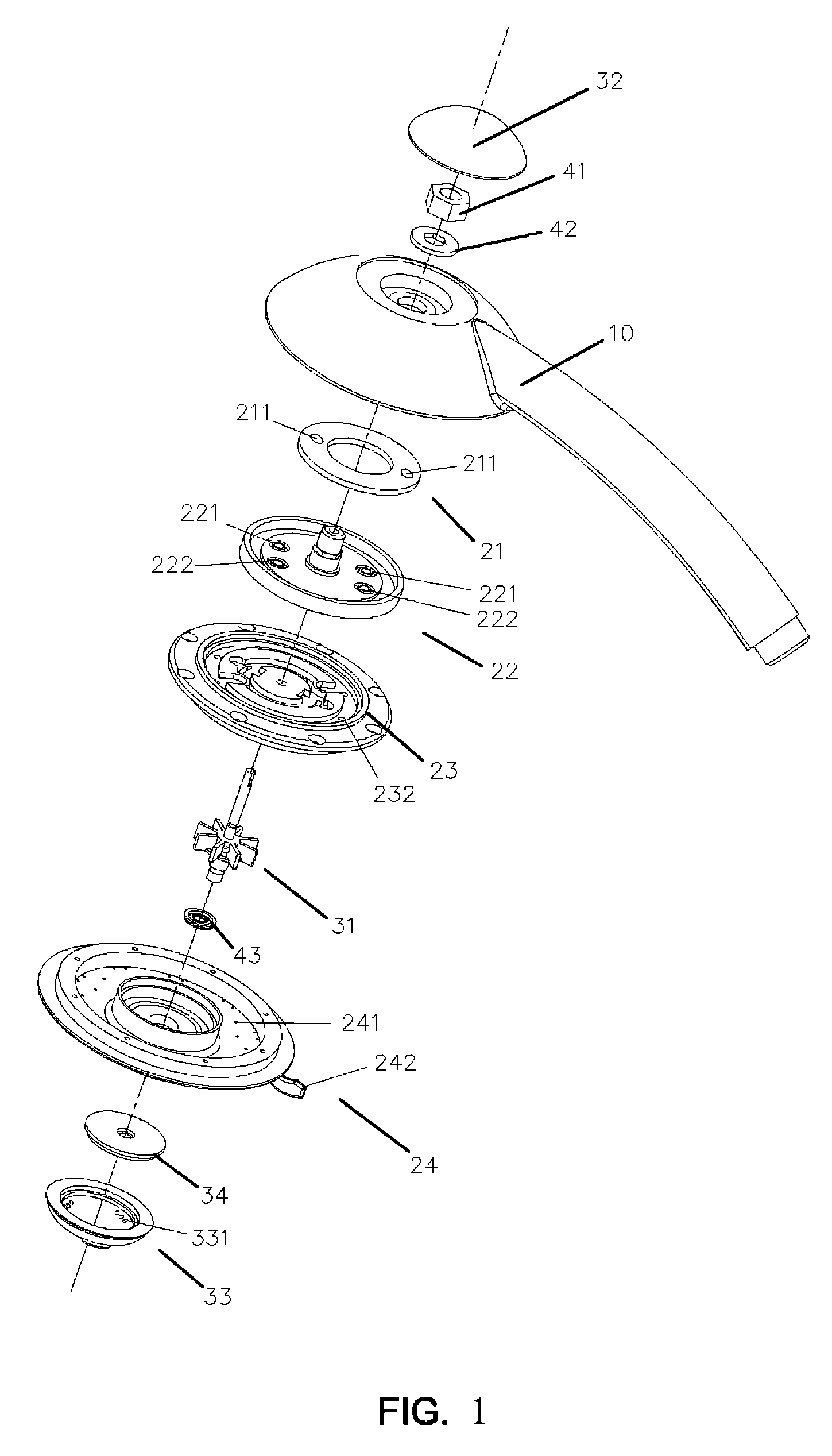

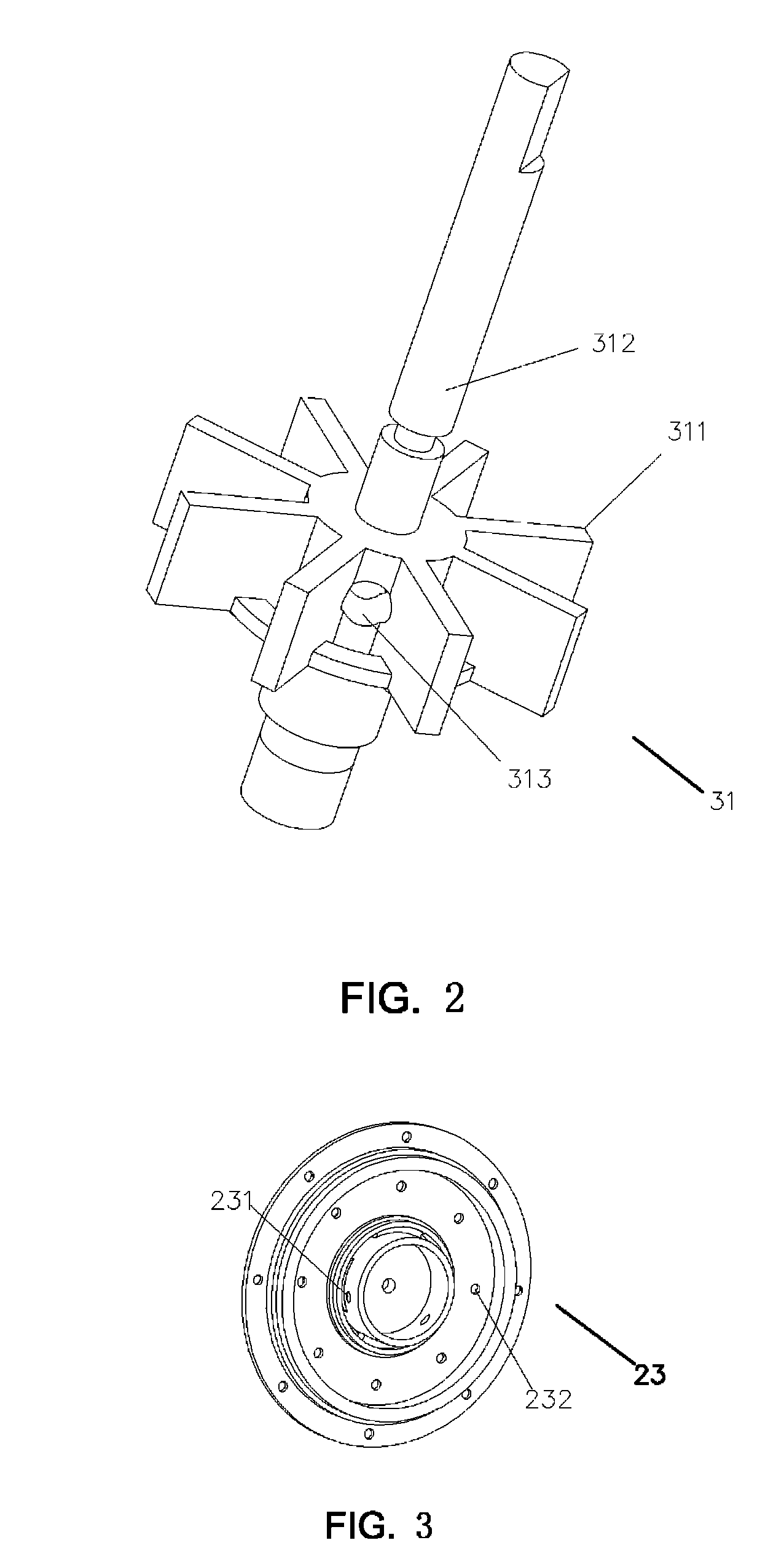

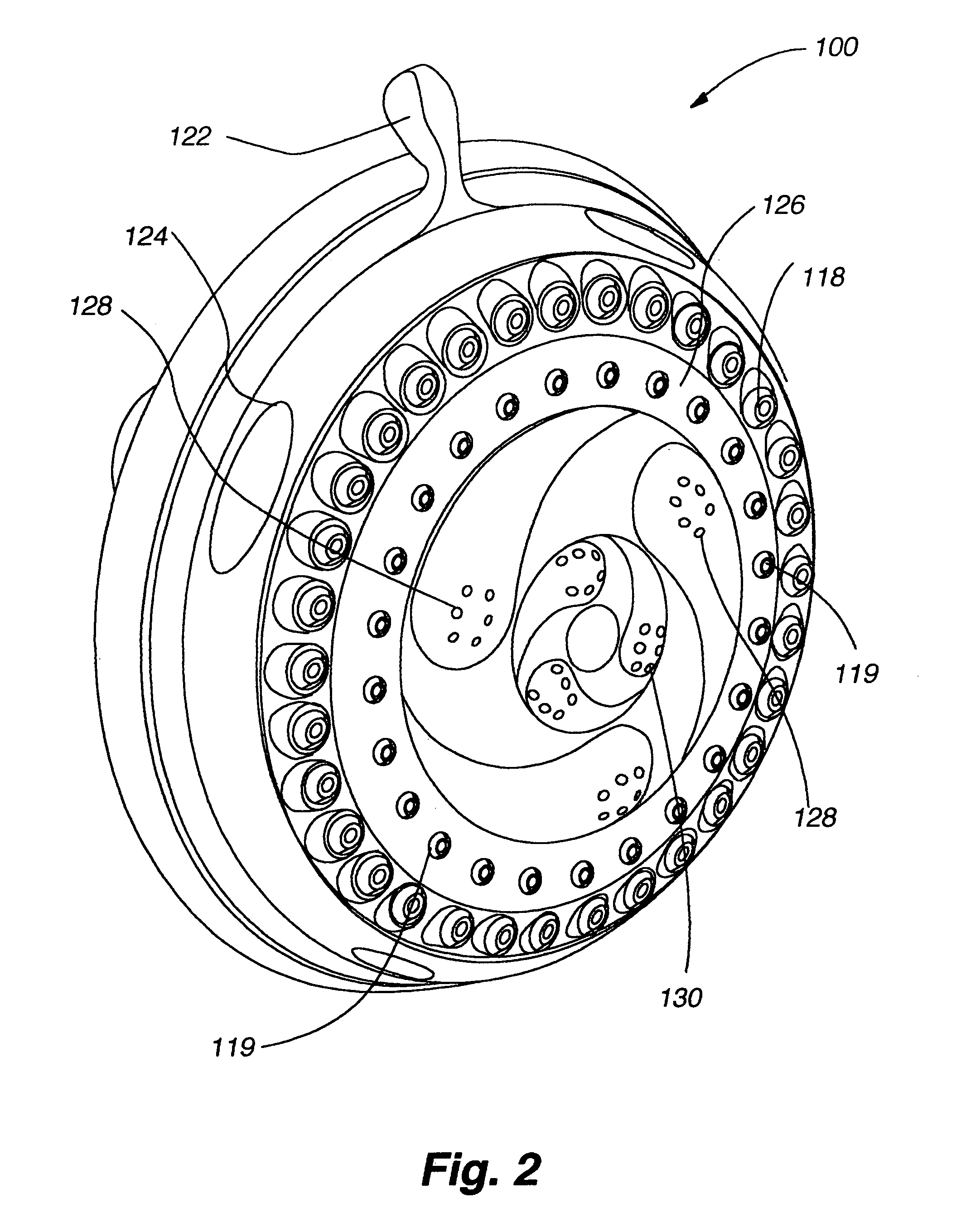

Shower with rotatable top and bottom rotating covers

InactiveUS8297534B2Dramatic watering functionImprove visual effectsBurnersMovable spraying apparatusImpellerWater flow

A shower with rotatable top and bottom rotating covers and a rotatable watering function, comprising: a shower housing, a watering unit having a tilted hole, an impeller set beneath the tilted hole and axially located between the shower housing and the watering unit, a top rotating cover protruding on the shower housing and fixed on the top of the impeller, and a bottom rotating cover protruding under the watering unit and fixed beneath the impeller. The top and bottom rotating covers rotate with the impeller around the same axis. The bottom cover contains an off-center outlet. The water stream from the tilted hole of watering unit will strike the impeller, rotating the top and bottom rotating cover around the same axis. The off-center outlet of the bottom rotating cover then generates a rotating spray.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

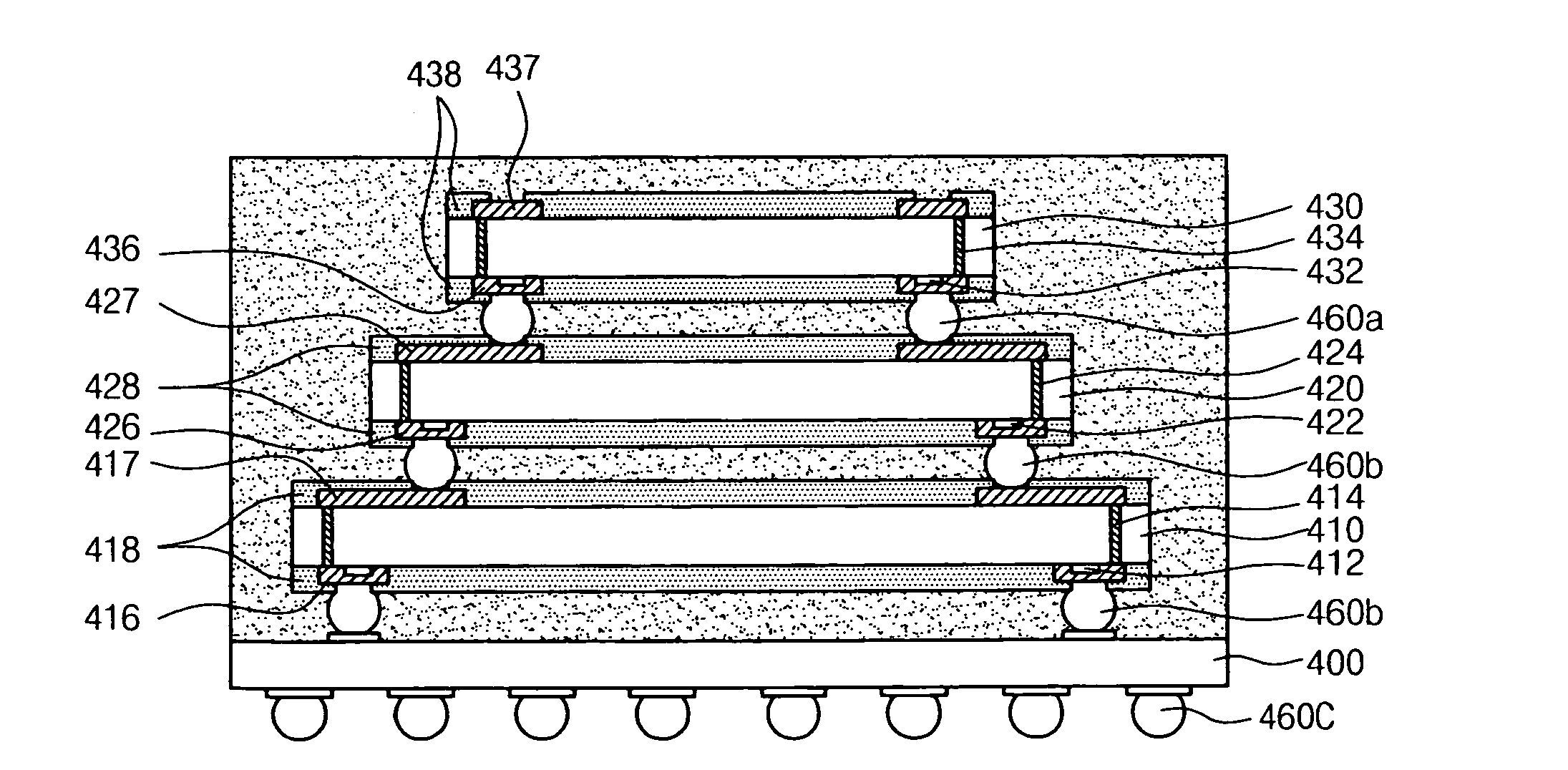

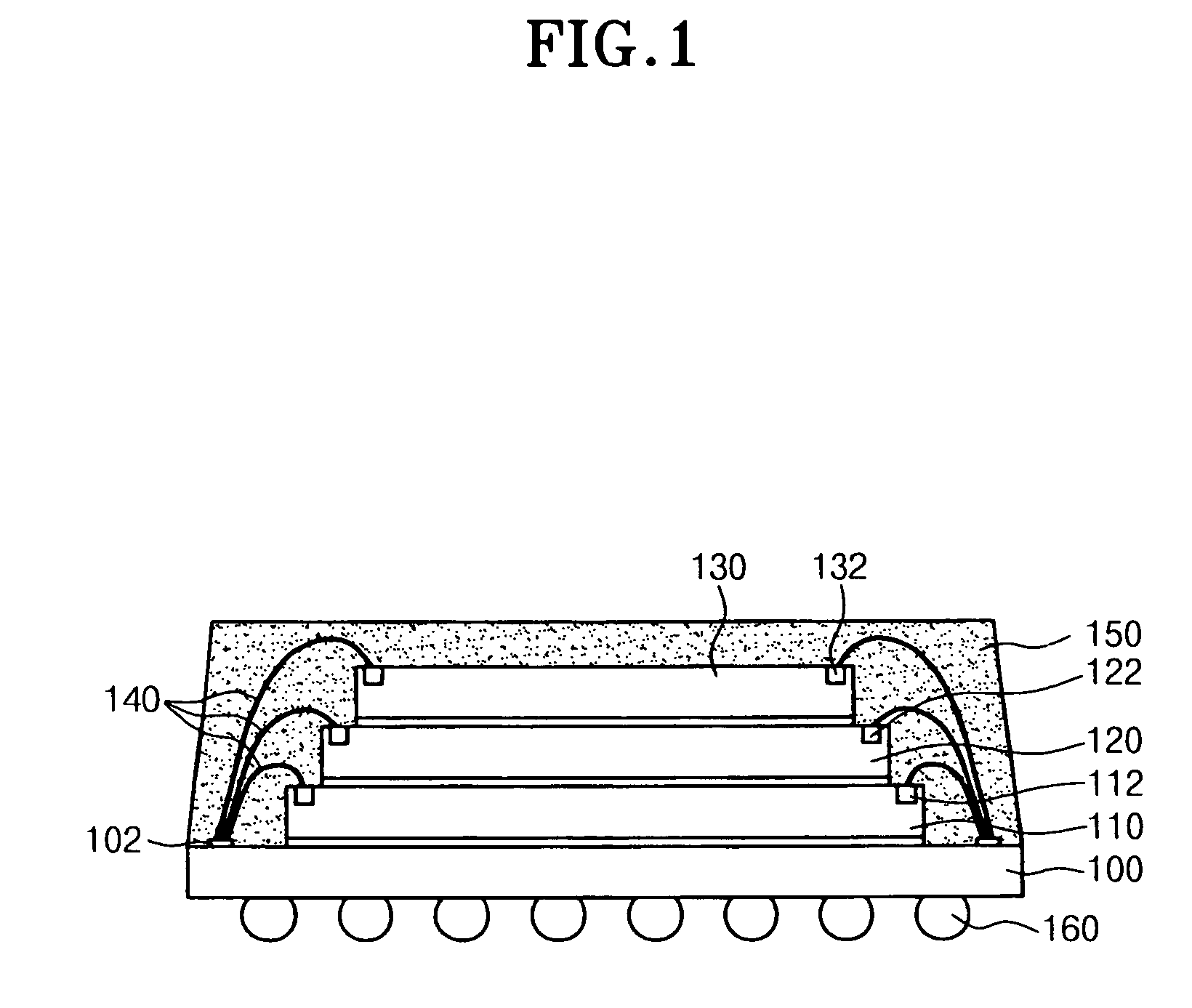

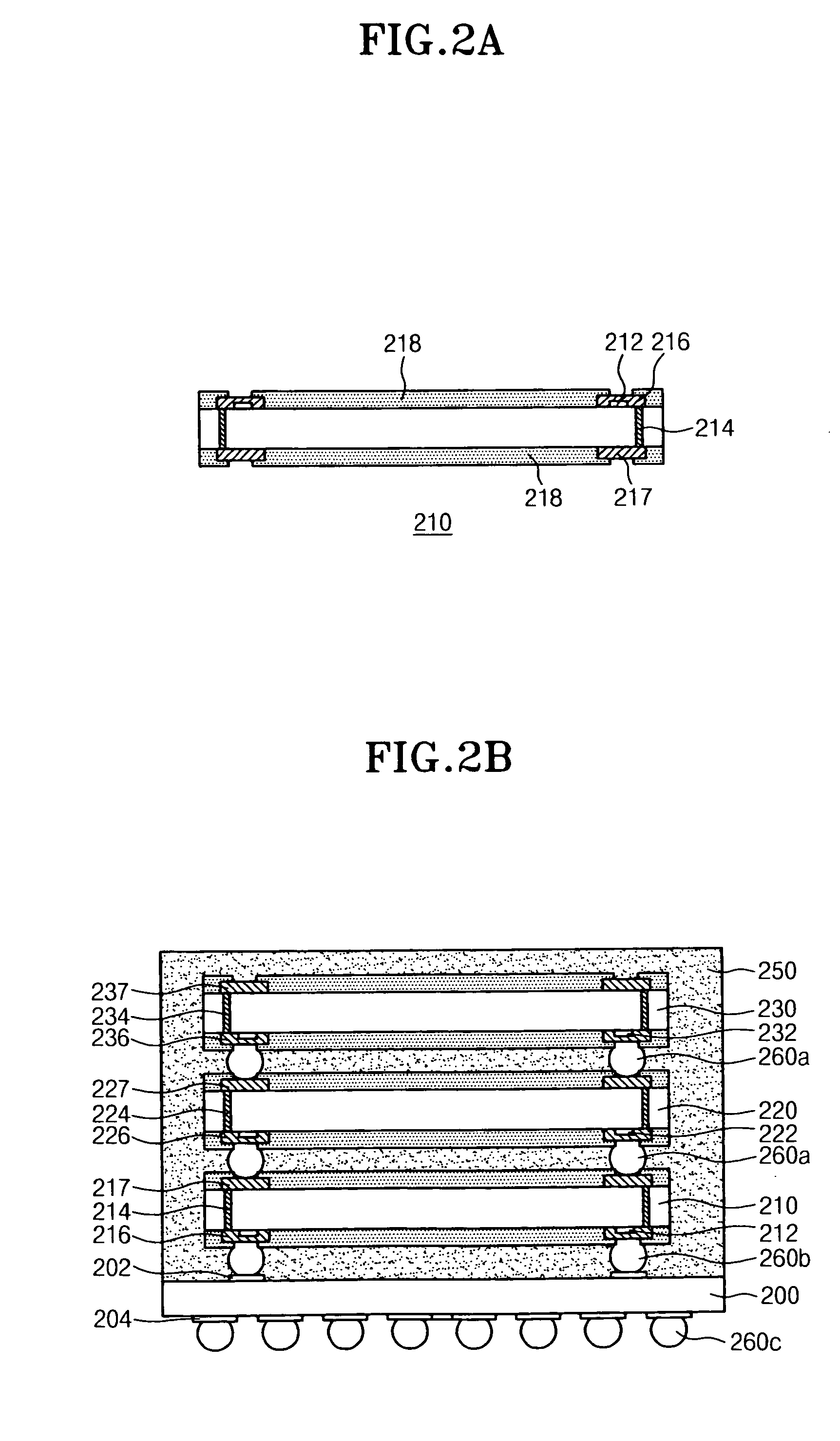

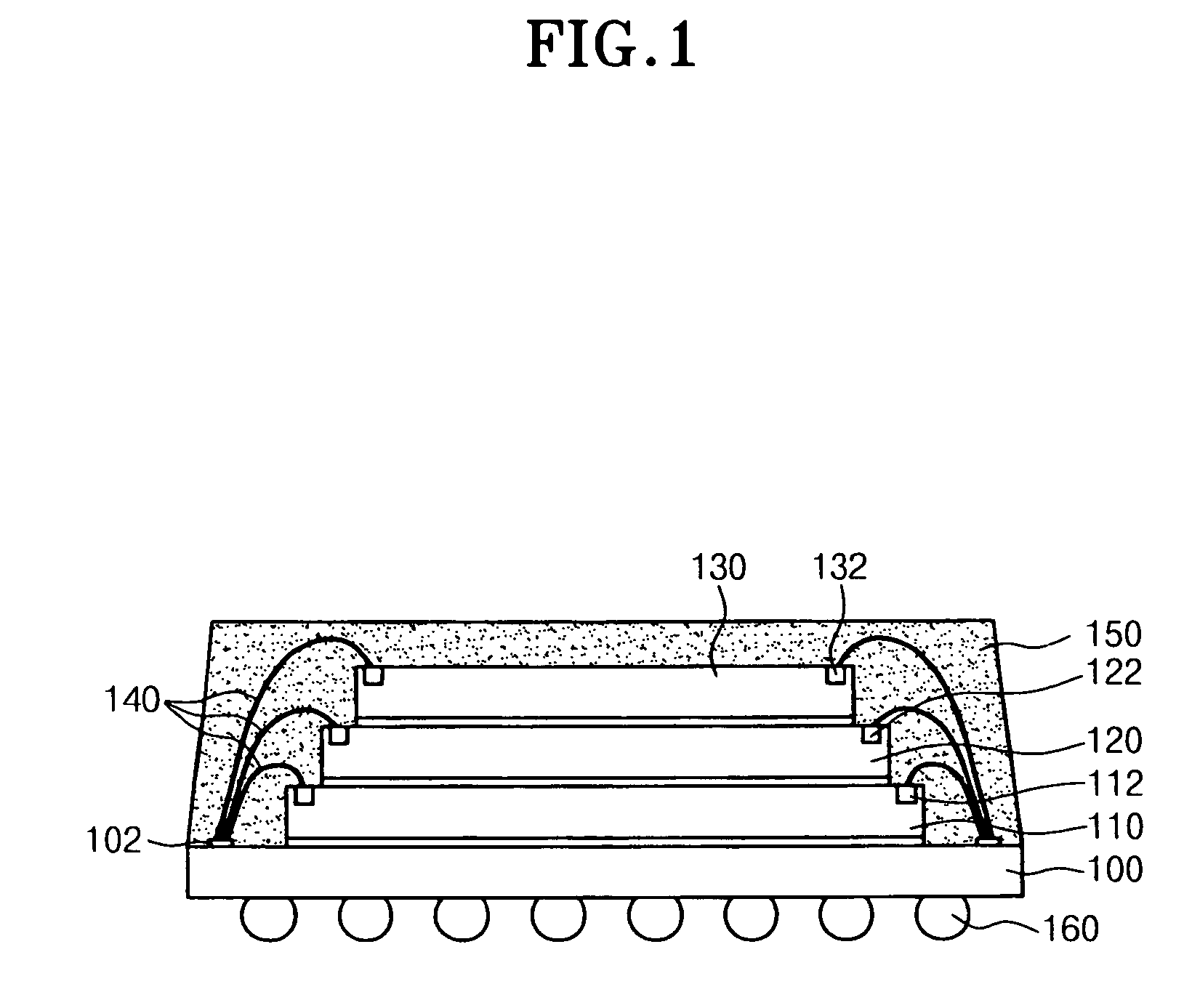

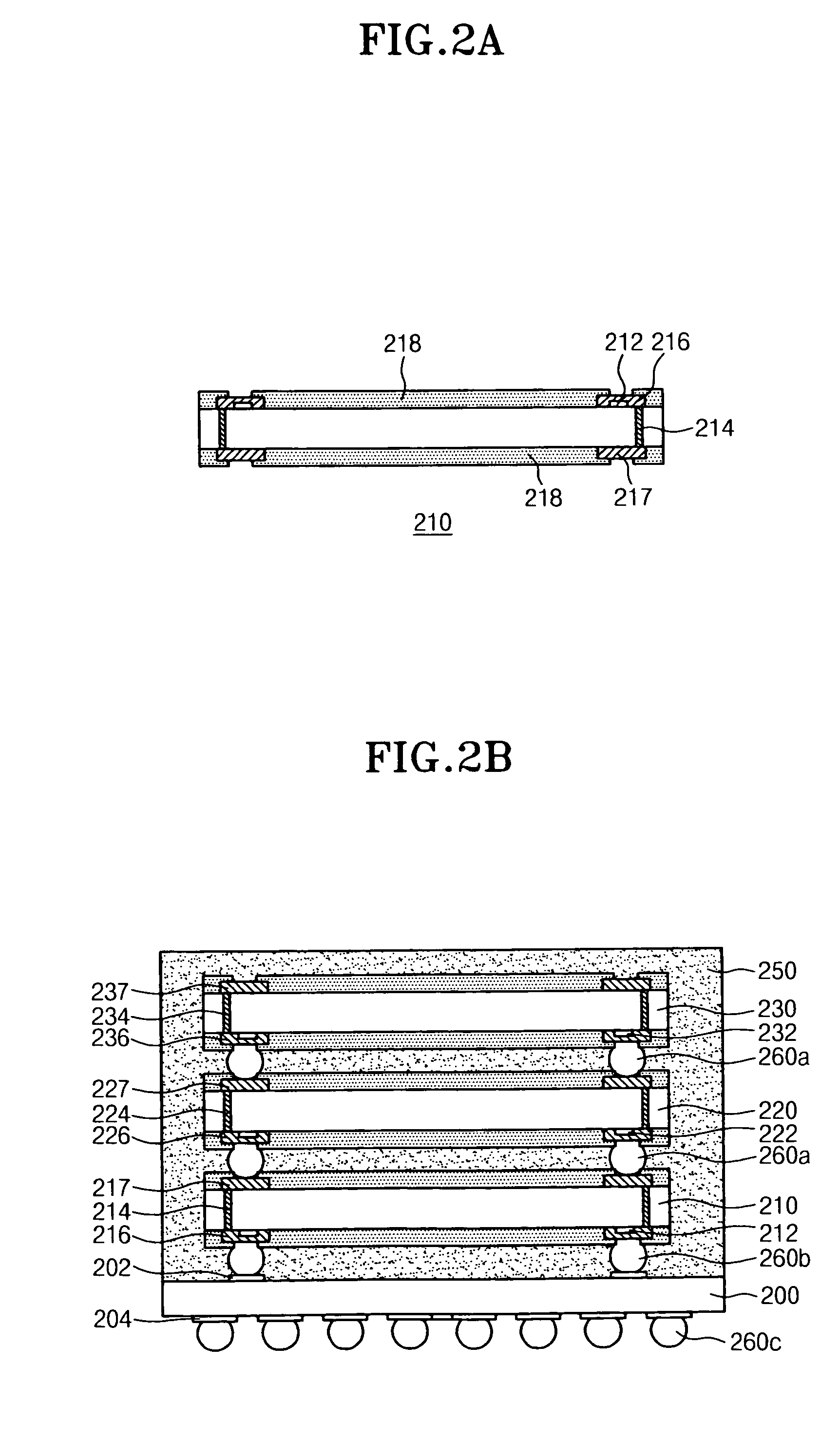

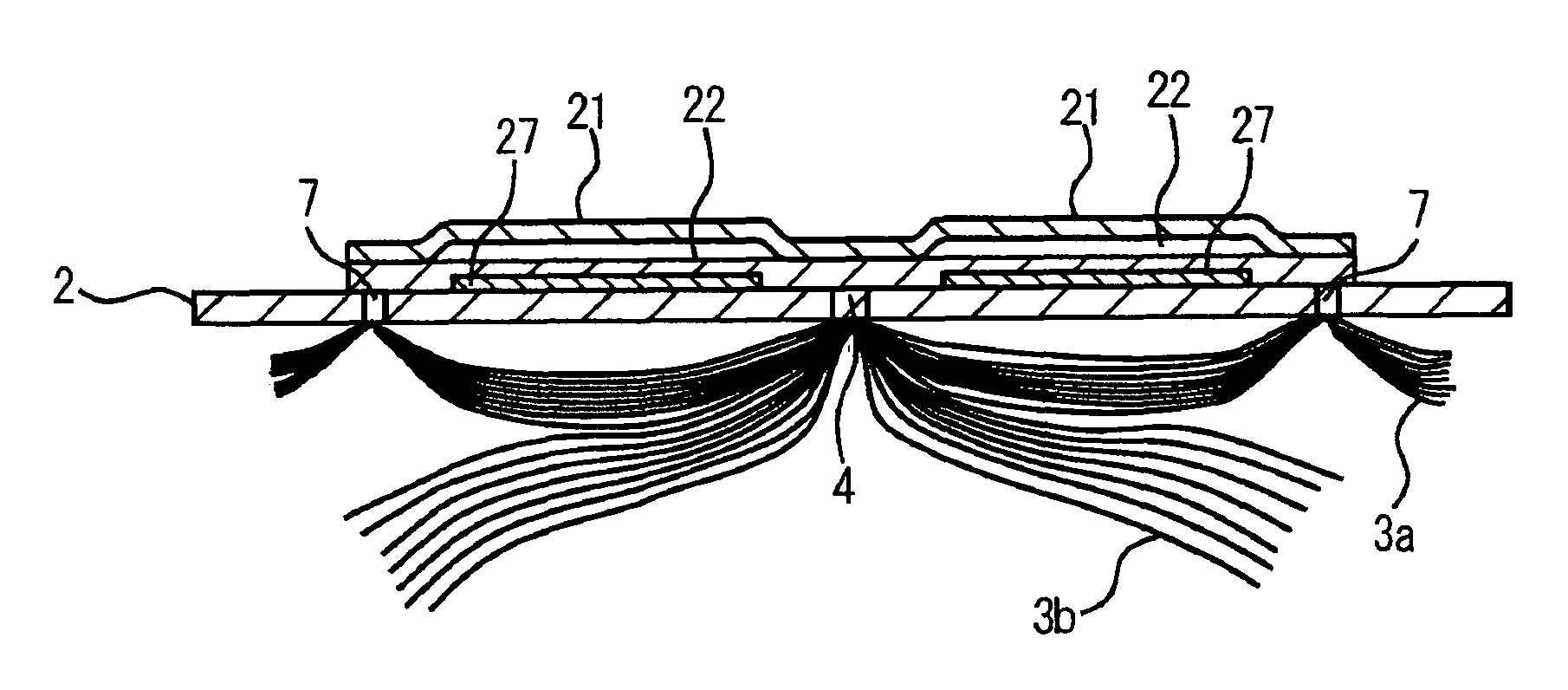

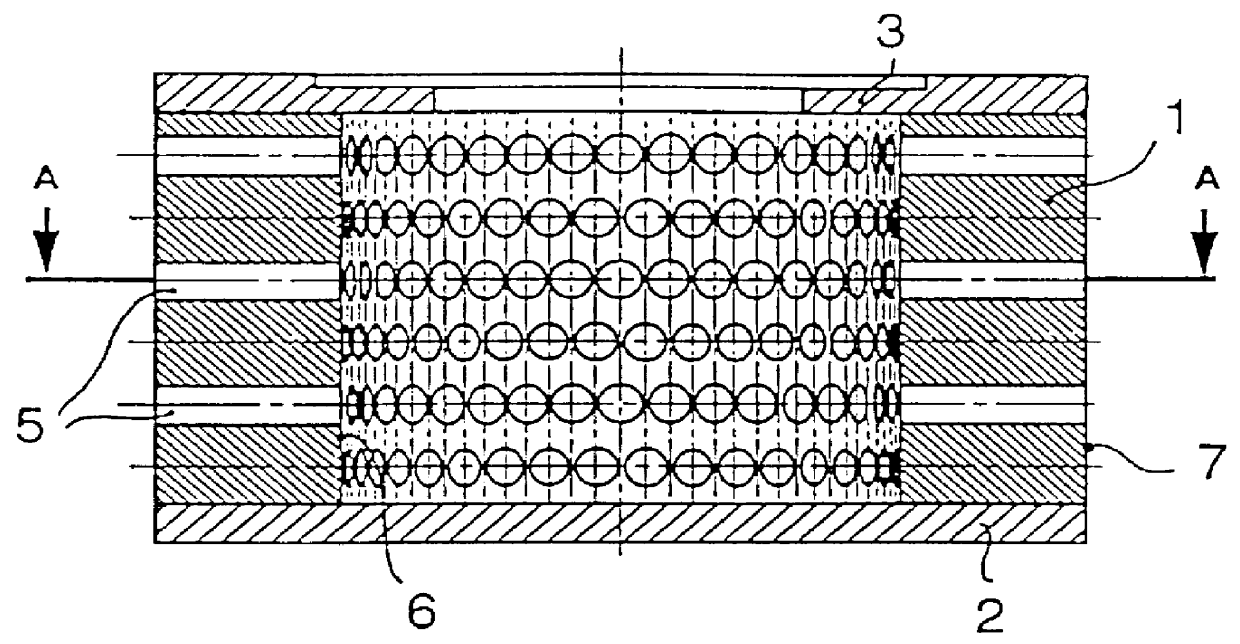

Stack package utilizing through vias and re-distribution lines

ActiveUS20070222050A1Easily applied to high-speed productSemiconductor/solid-state device detailsSolid-state devicesSolder ballSemiconductor chip

A stack package includes a printed circuit board; at least two semiconductor chips stacked on the printed circuit board, each having first re-distribution lines formed on the upper surface thereof and connected to bonding pads, through silicon vias which are formed therethrough and connected to the first re-distribution lines, and second re-distribution lines formed on the lower surface thereof and connected to the through silicon vias; first and second solder balls interposed between the first and second re-distribution lines which face each other and between the first re-distribution lines of the lowermost semiconductor chip and electrode terminals of the printed circuit board; a molding material for molding the upper surface of the printed circuit board including the stacked semiconductor chips; and third solder balls attached to ball lands formed on the lower surface of the printed circuit board.

Owner:SK HYNIX INC

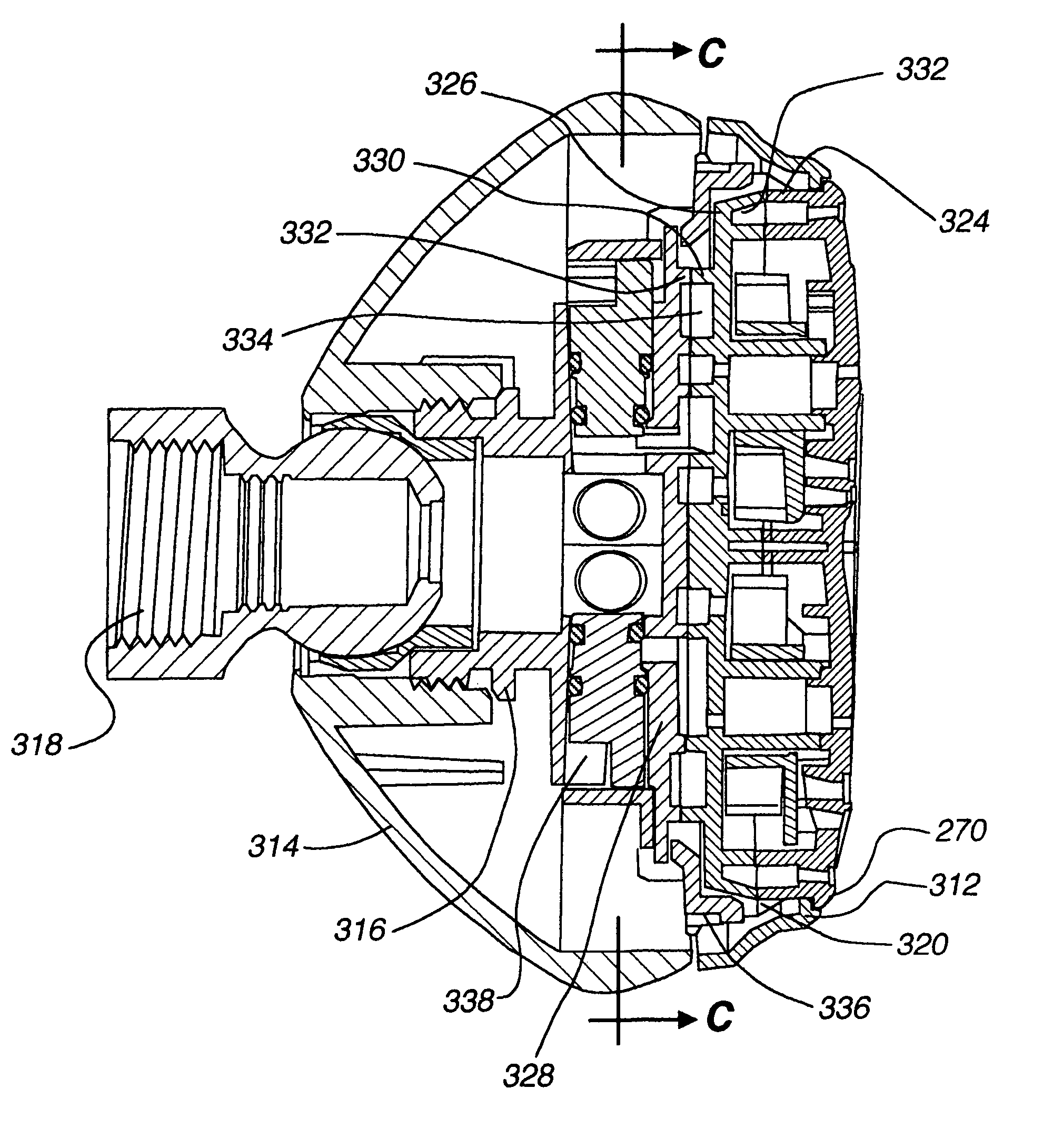

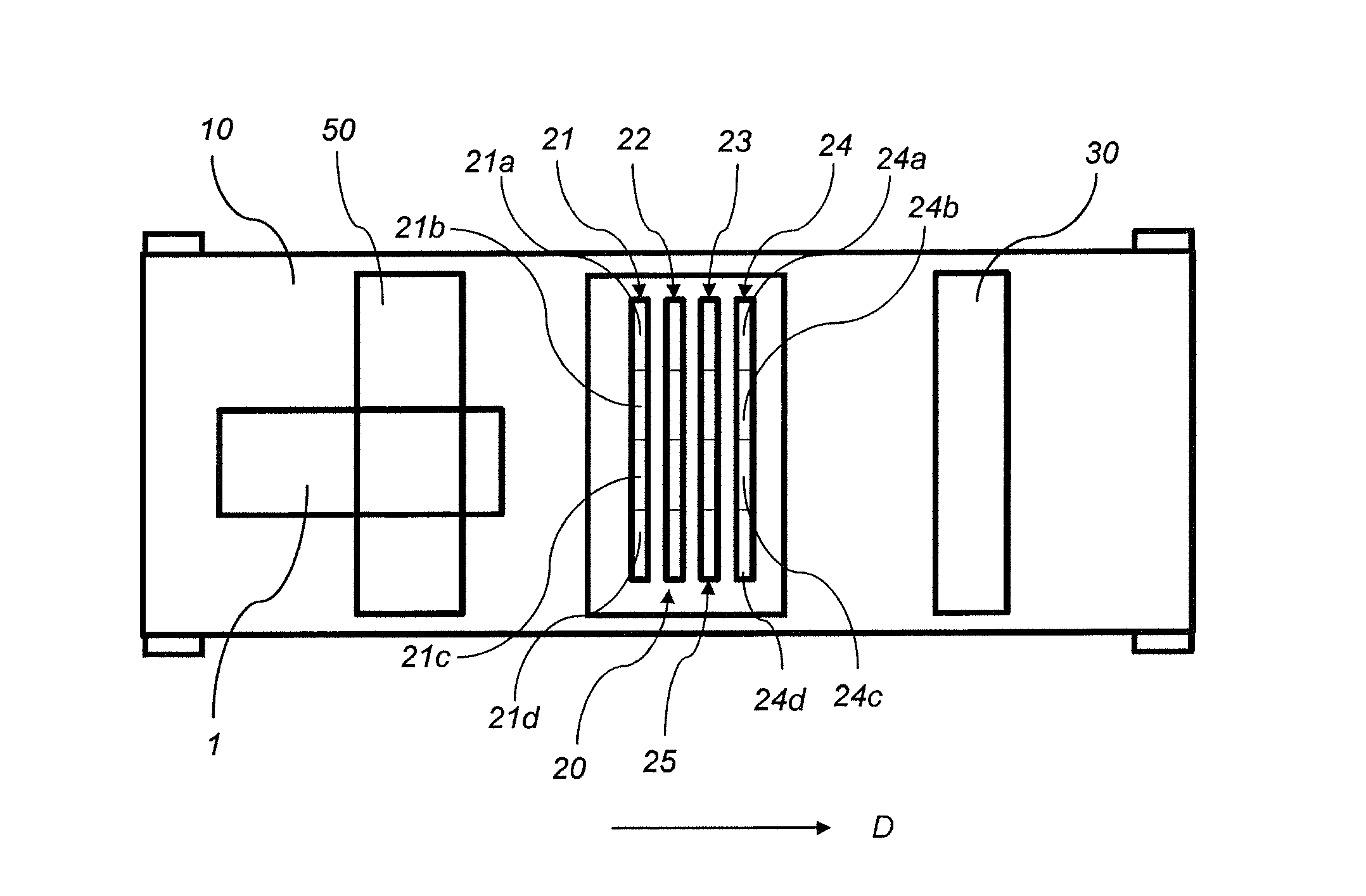

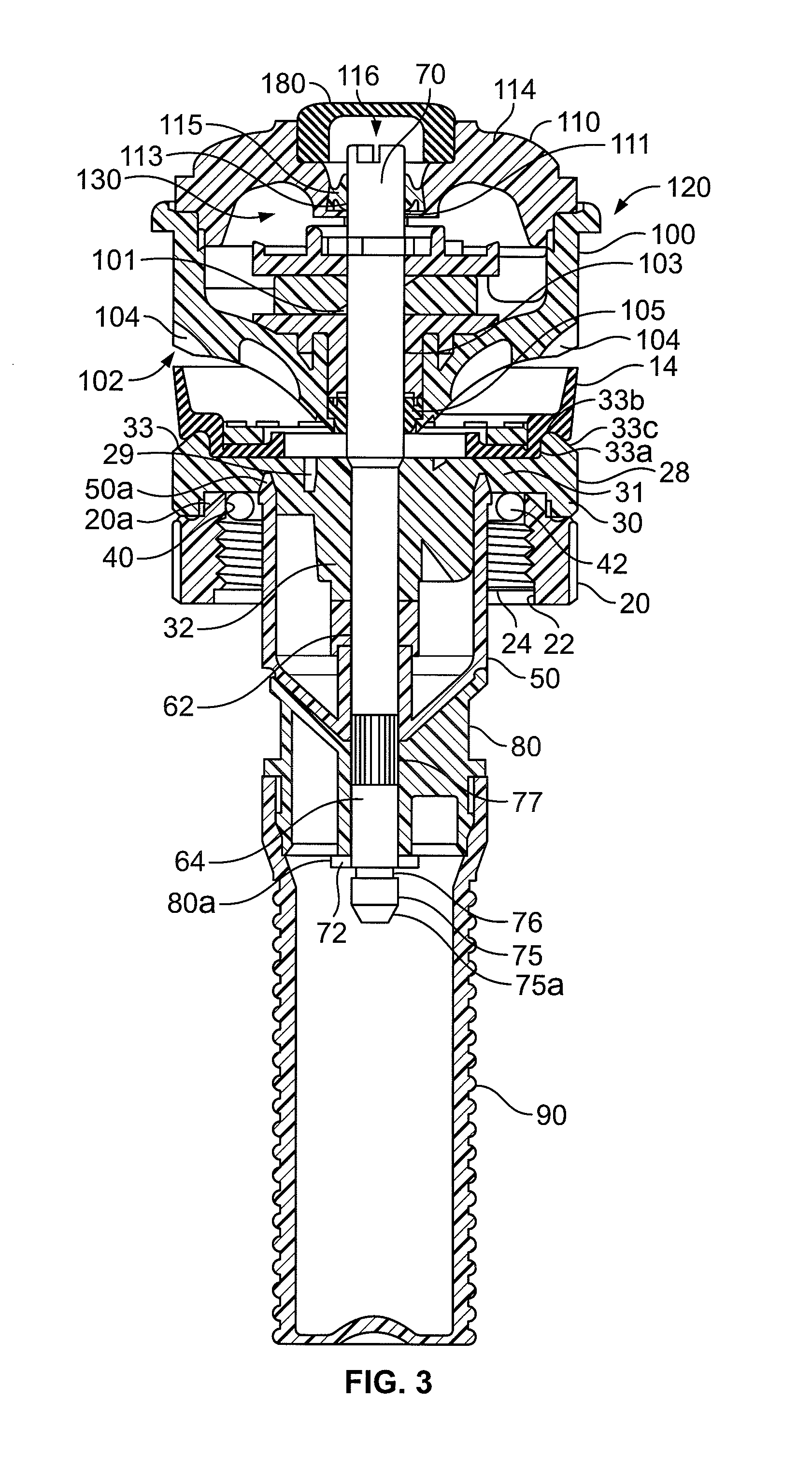

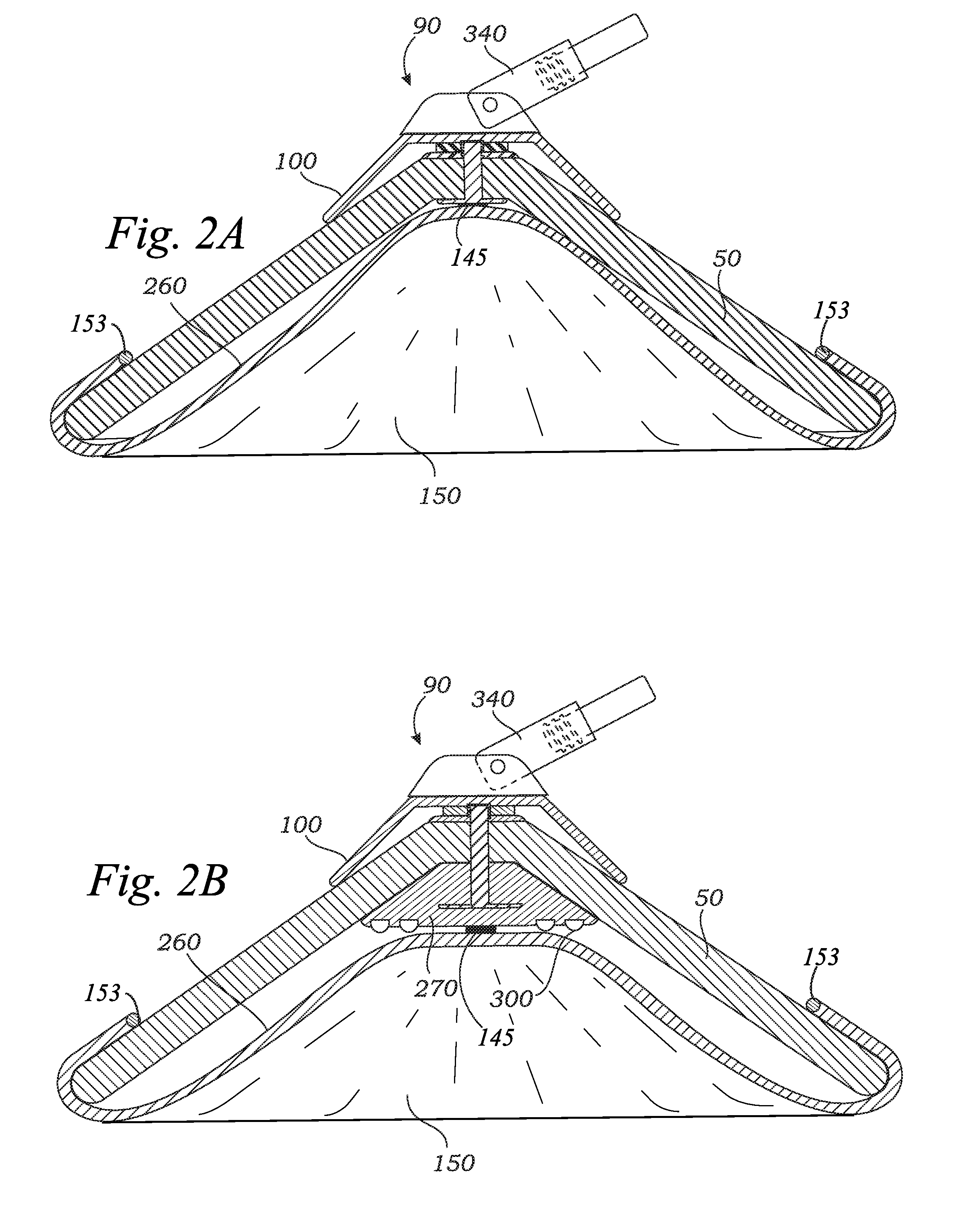

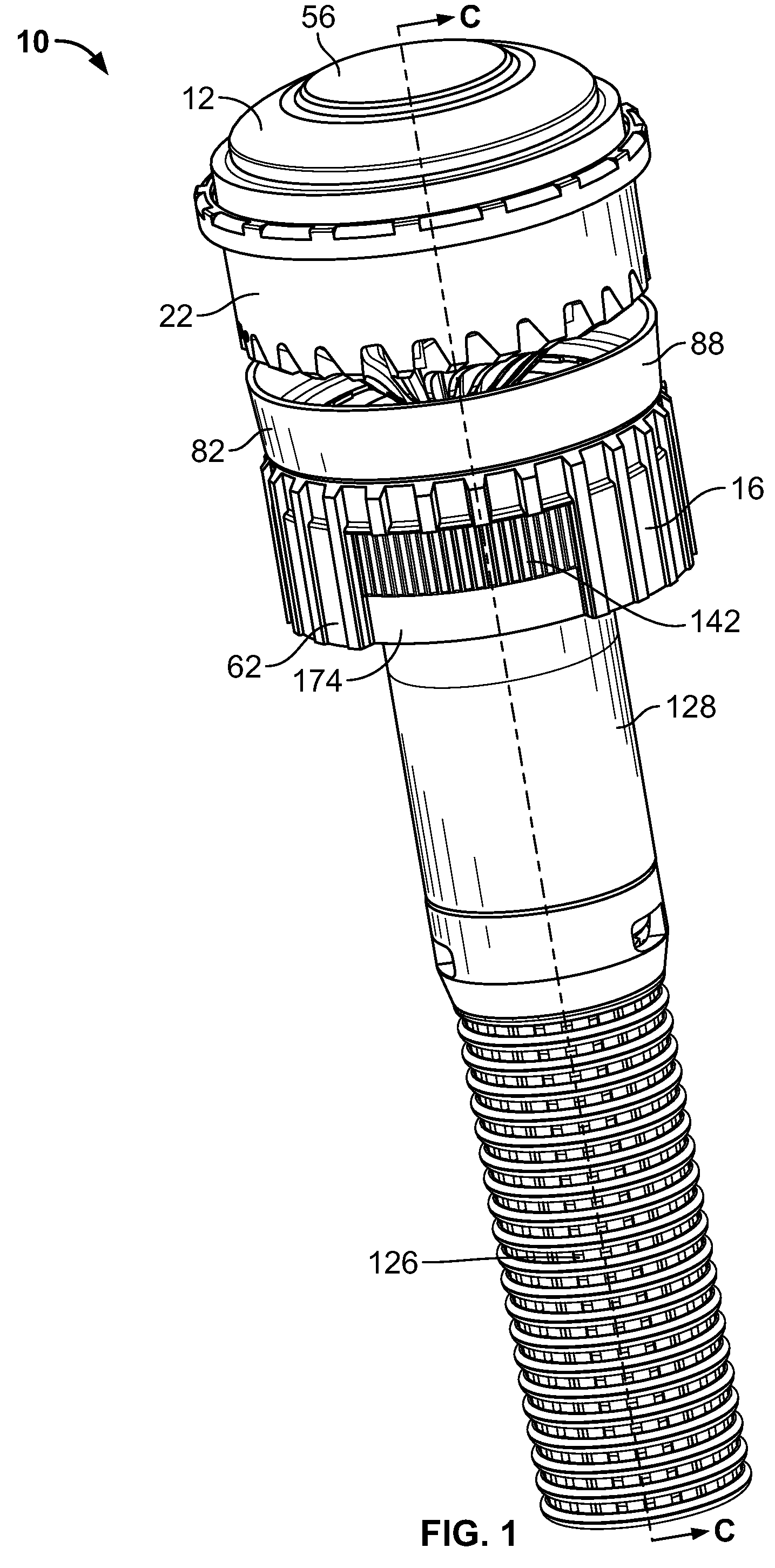

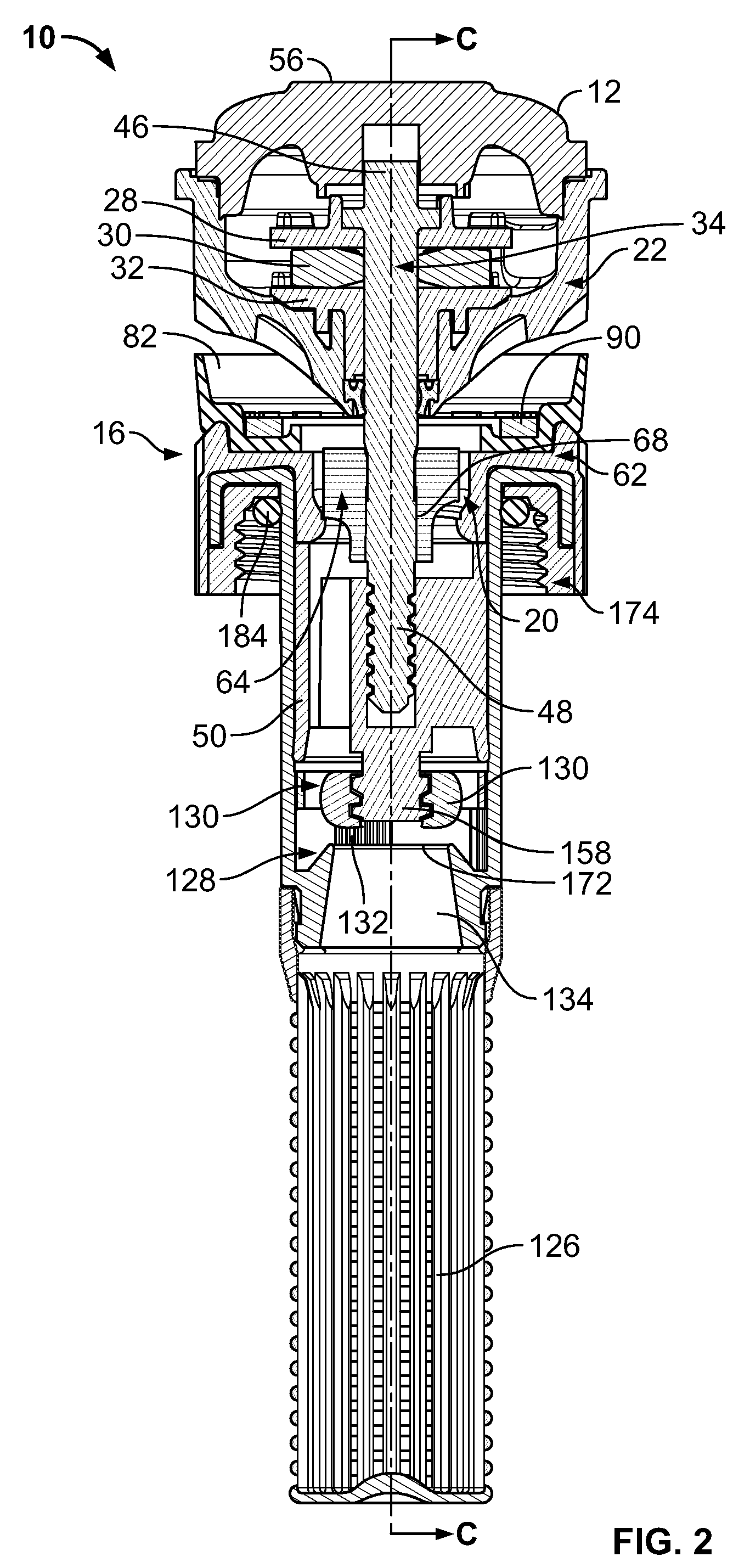

Dual massage shower head

A shower head having dual turbines. The shower head includes a body having an inlet for connection to a water conduit, a first outlet nozzle formed on the body, a second outlet nozzle formed on the body, a first turbine operably connected to the first outlet nozzle, and a second turbine operably connected to the second outlet nozzle. The shower head may include a flow actuation system taking the form of an actuator ring, a valve connected to the actuator ring and forming a flow channel, a first actuation point defined on the actuator ring, a second actuation point defined on the actuator ring, and a plunger situated within the flow channel. The plunger extends radially outwardly from a center of the valve when aligned with one of the first and second actuation points.

Owner:WATER PIK INC

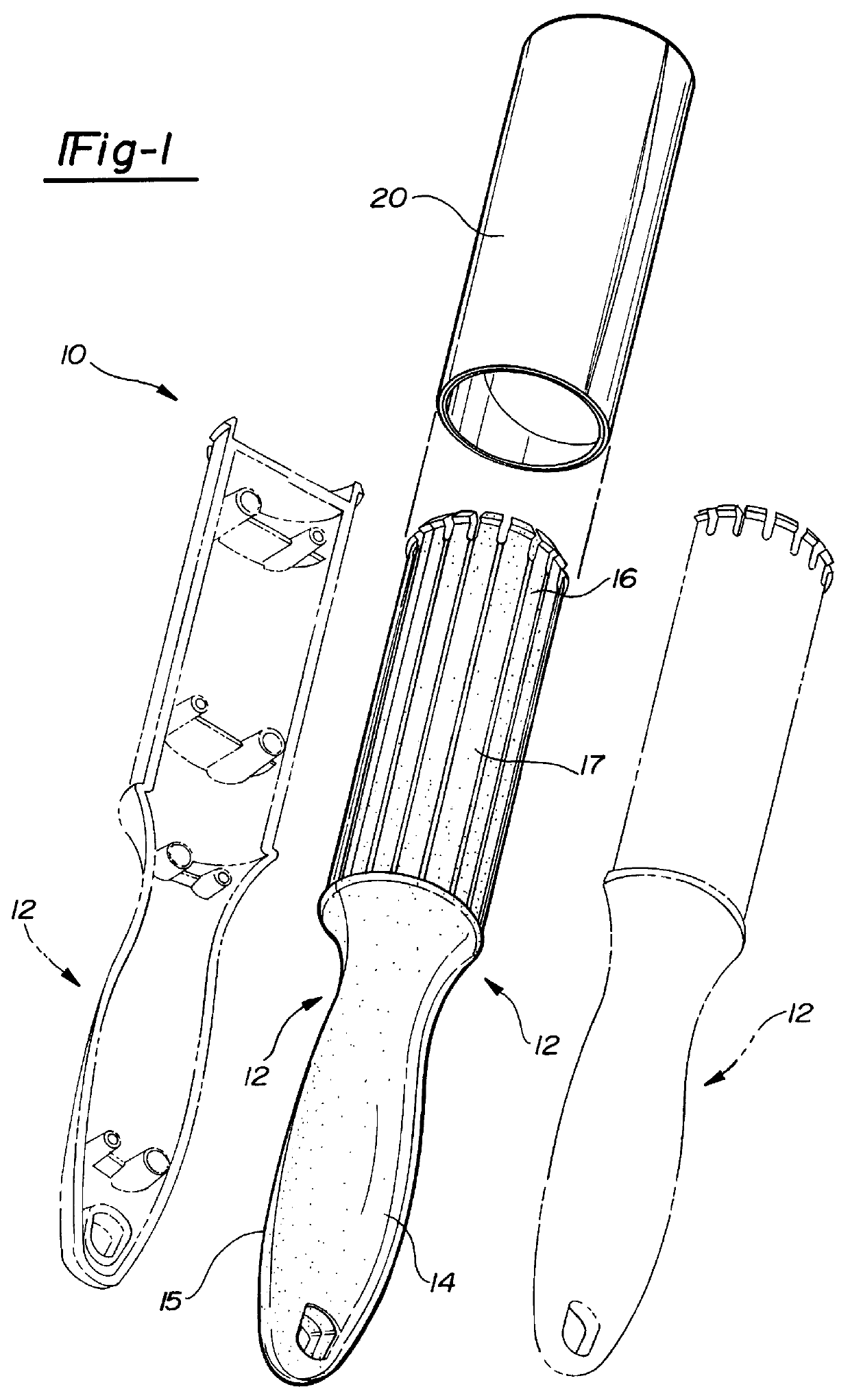

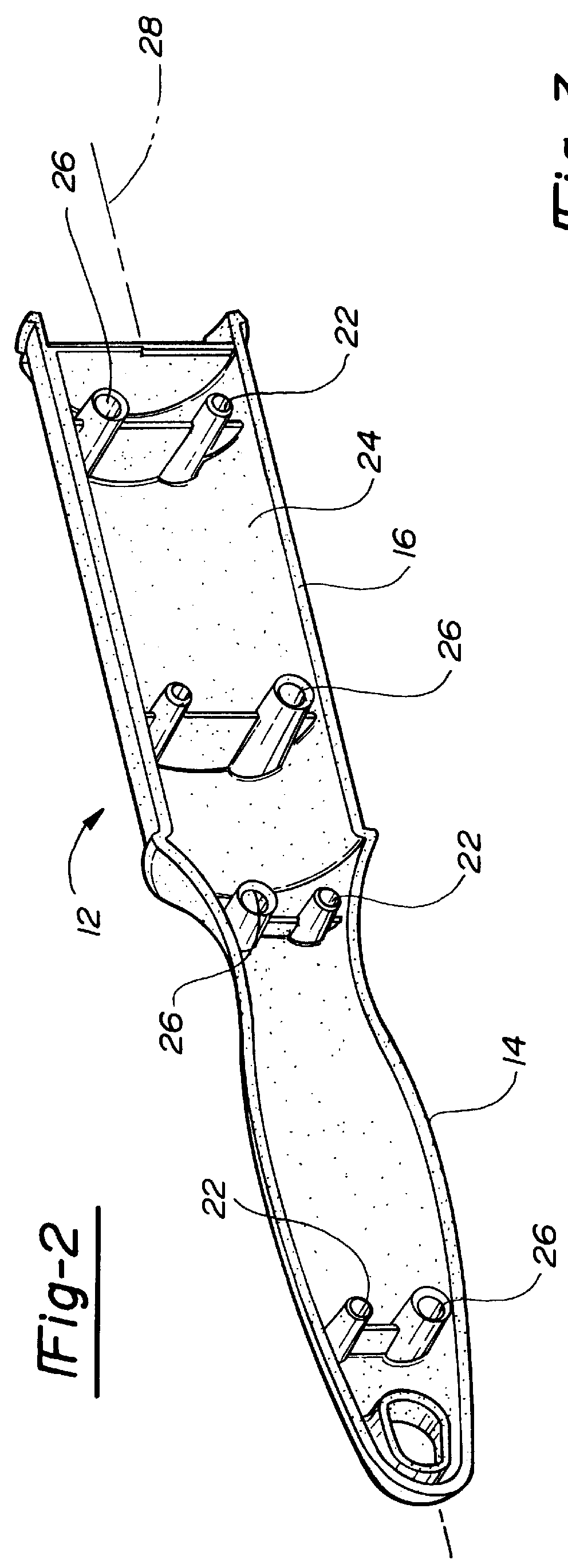

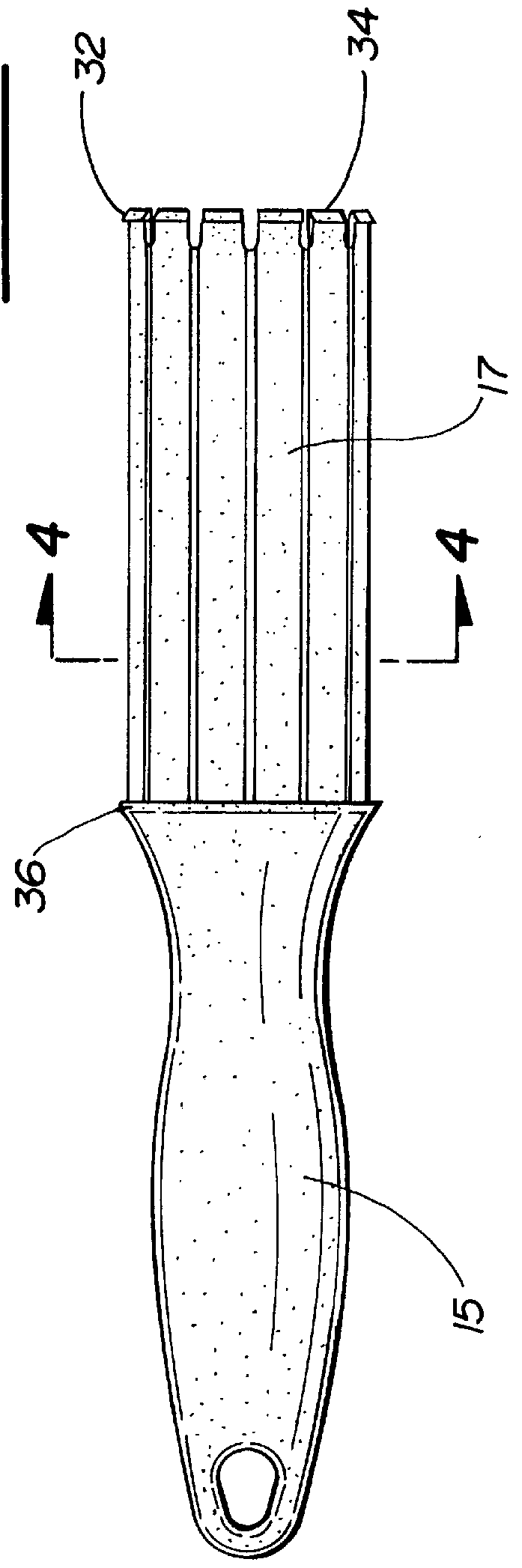

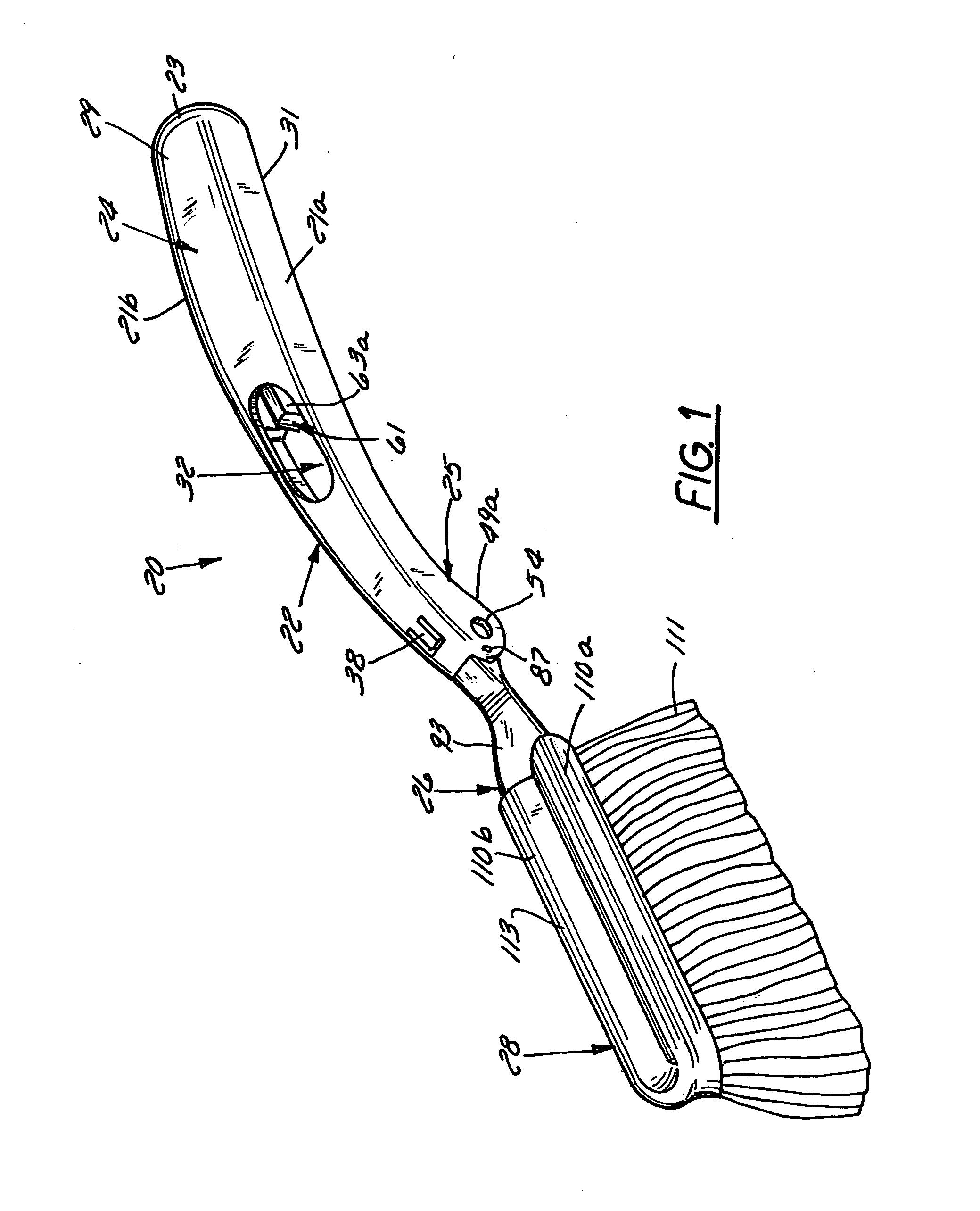

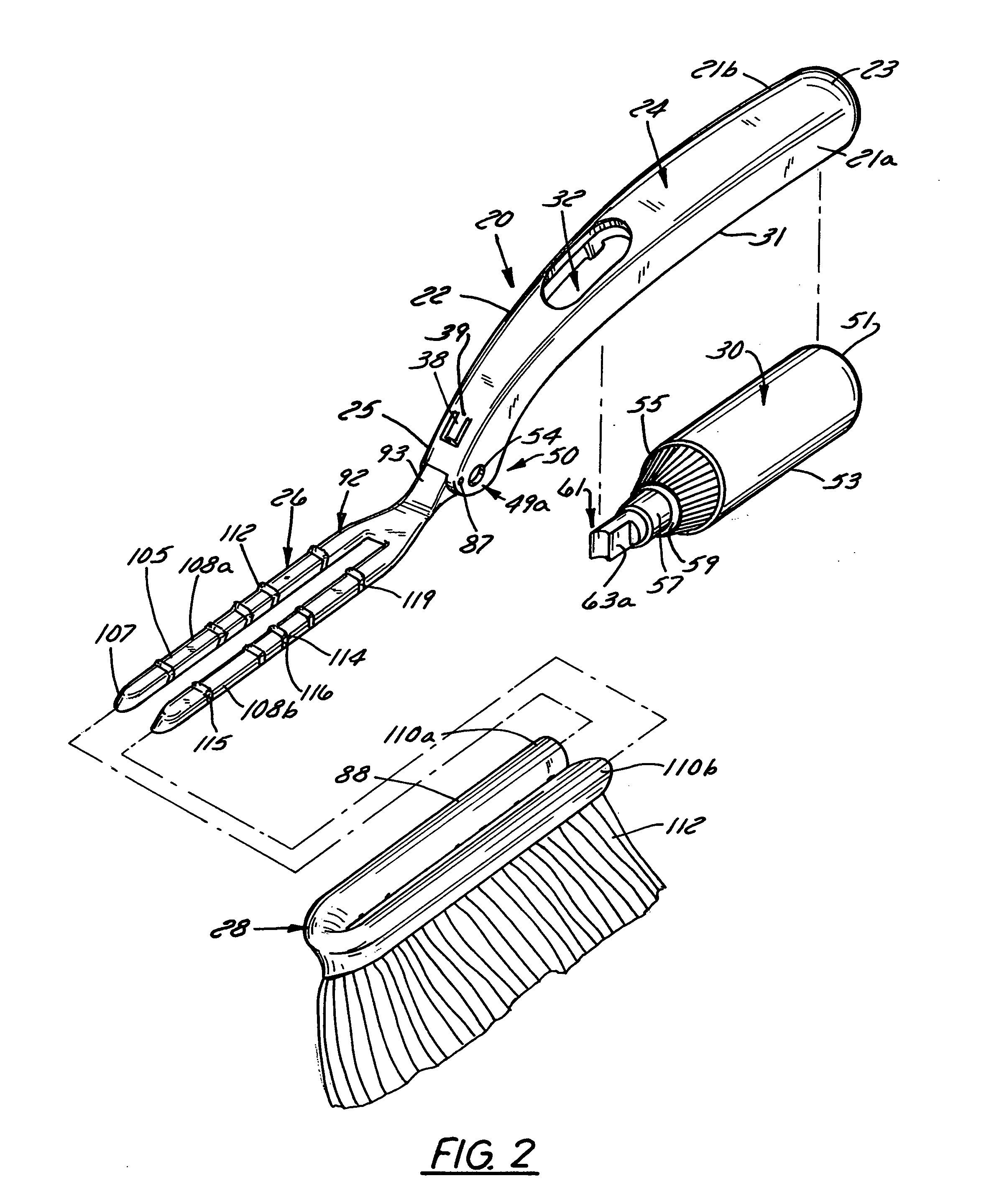

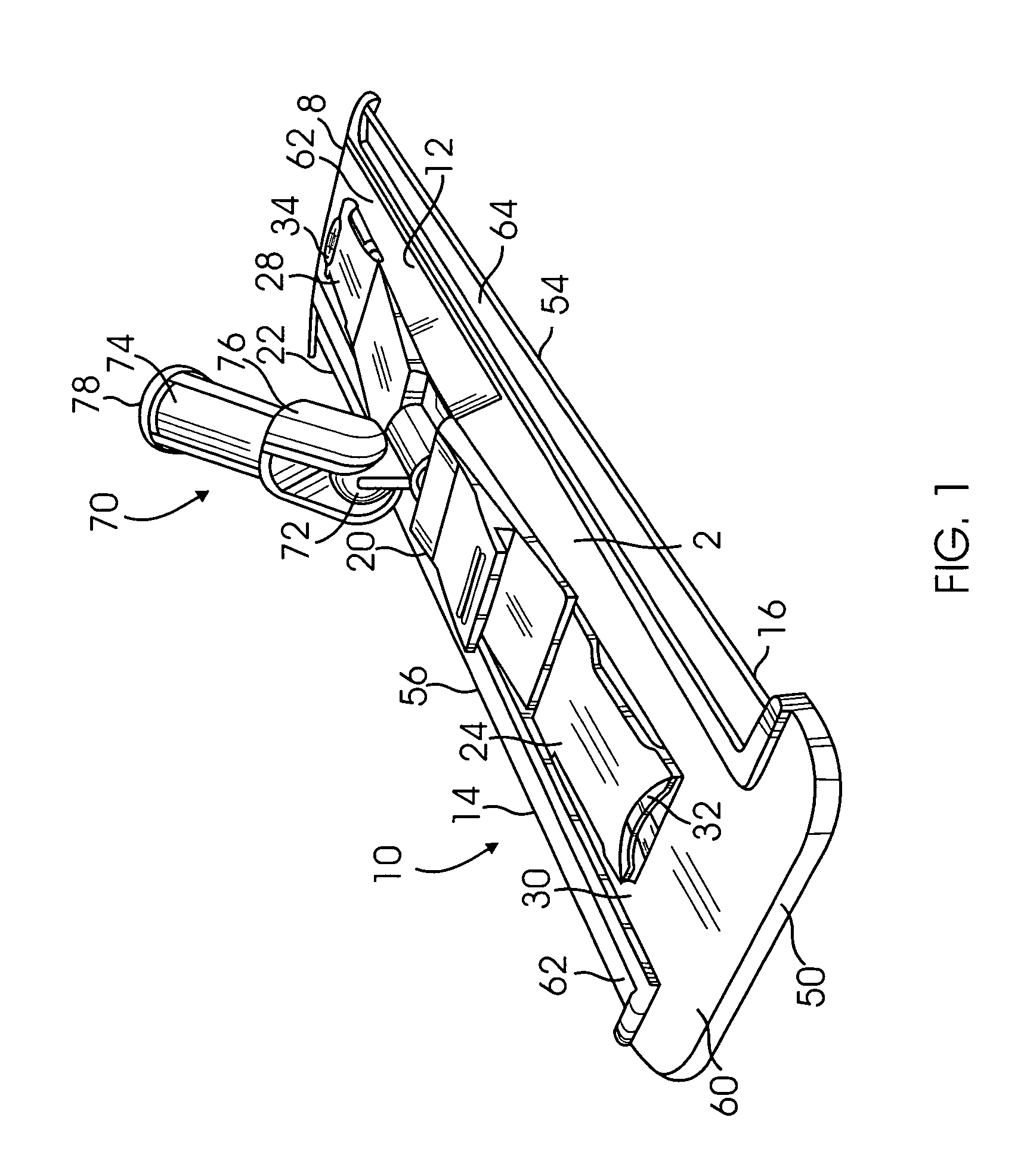

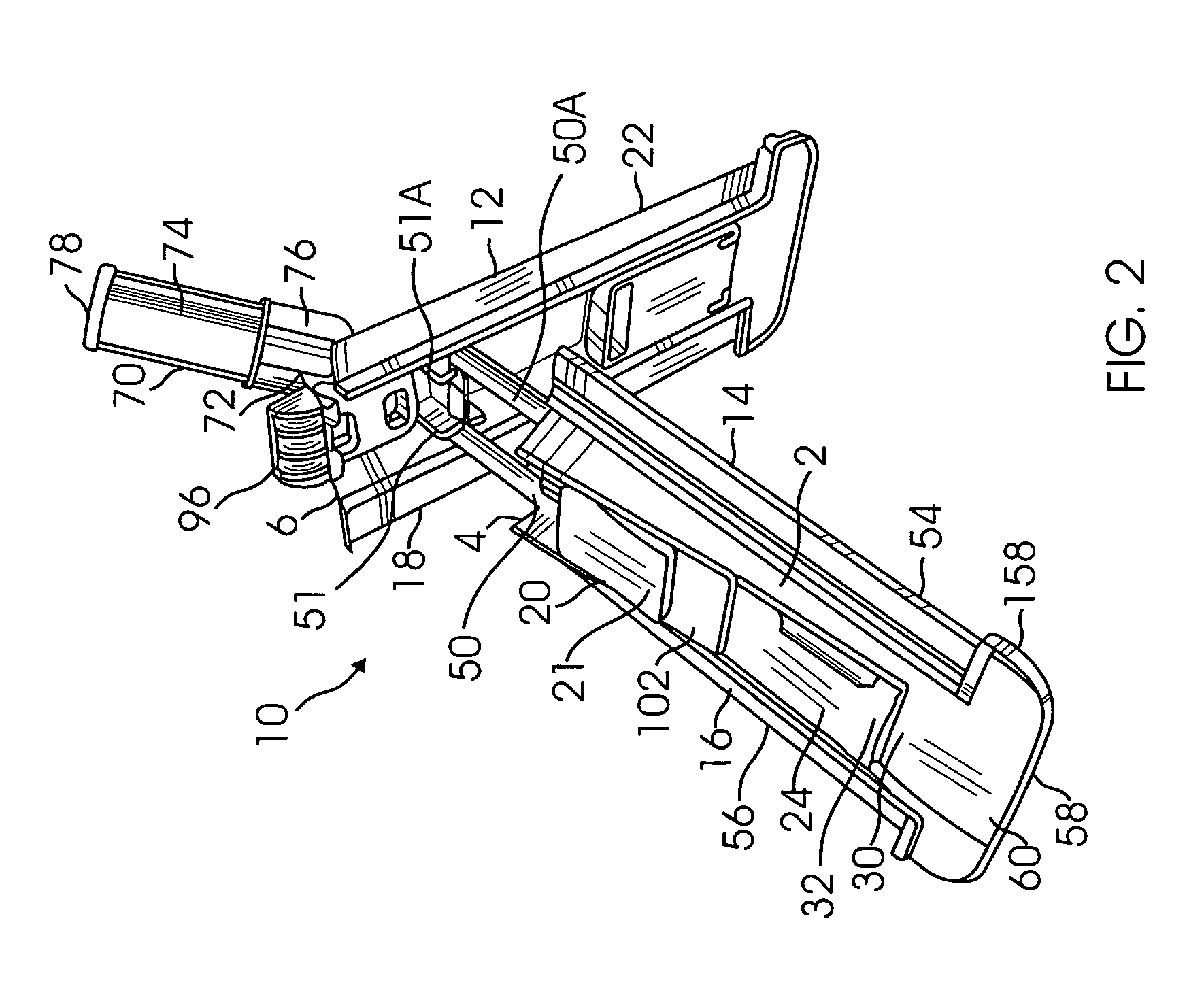

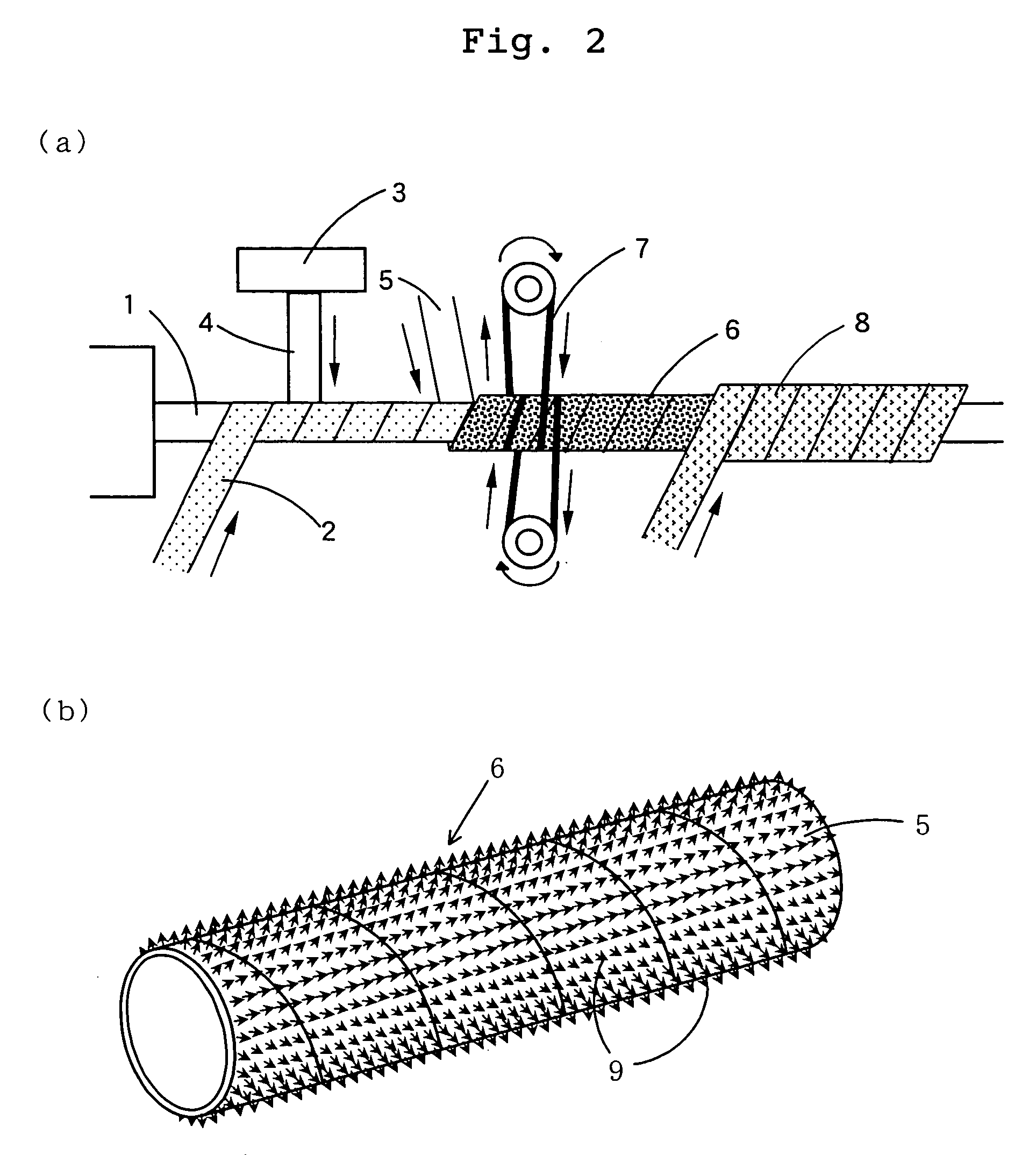

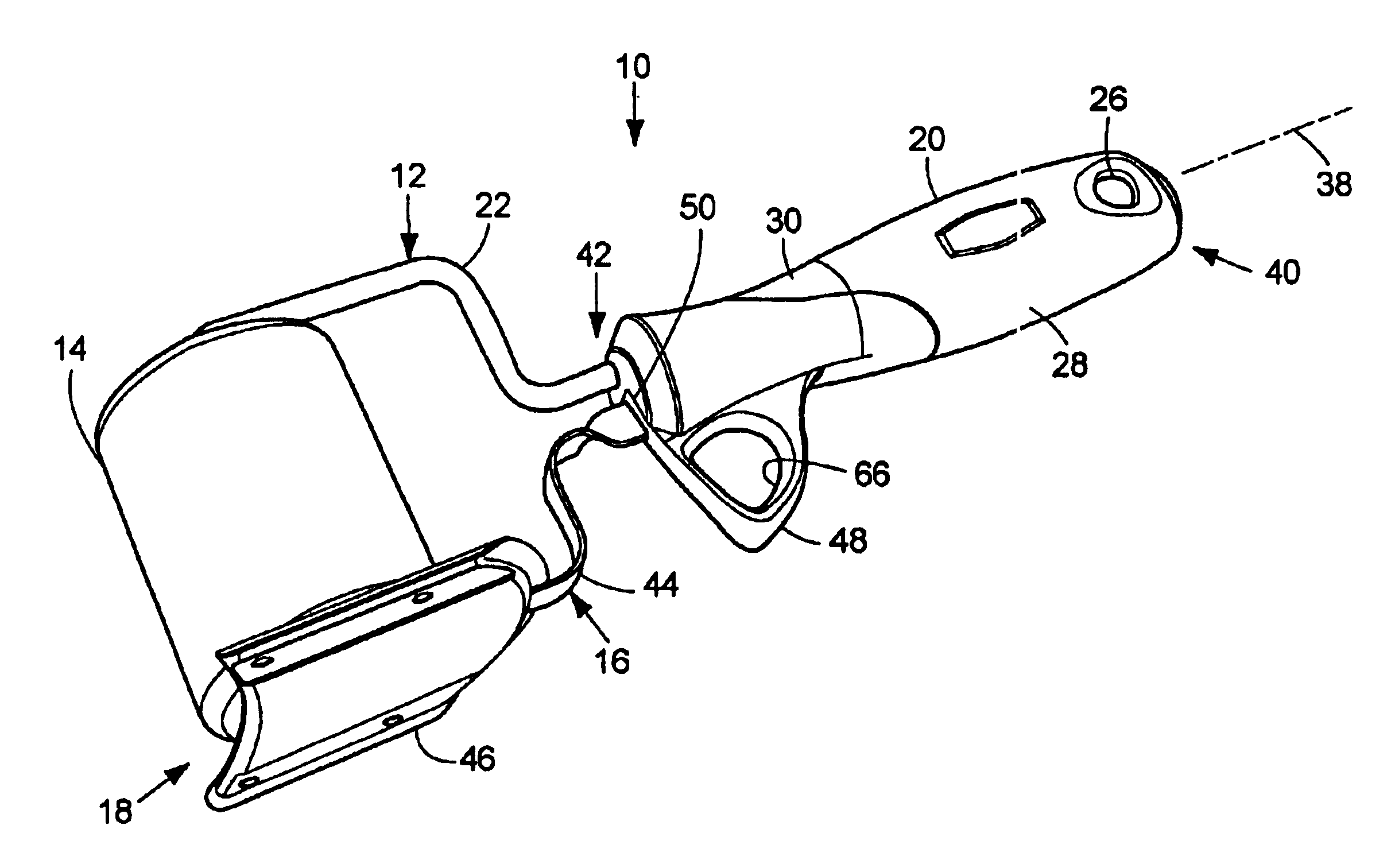

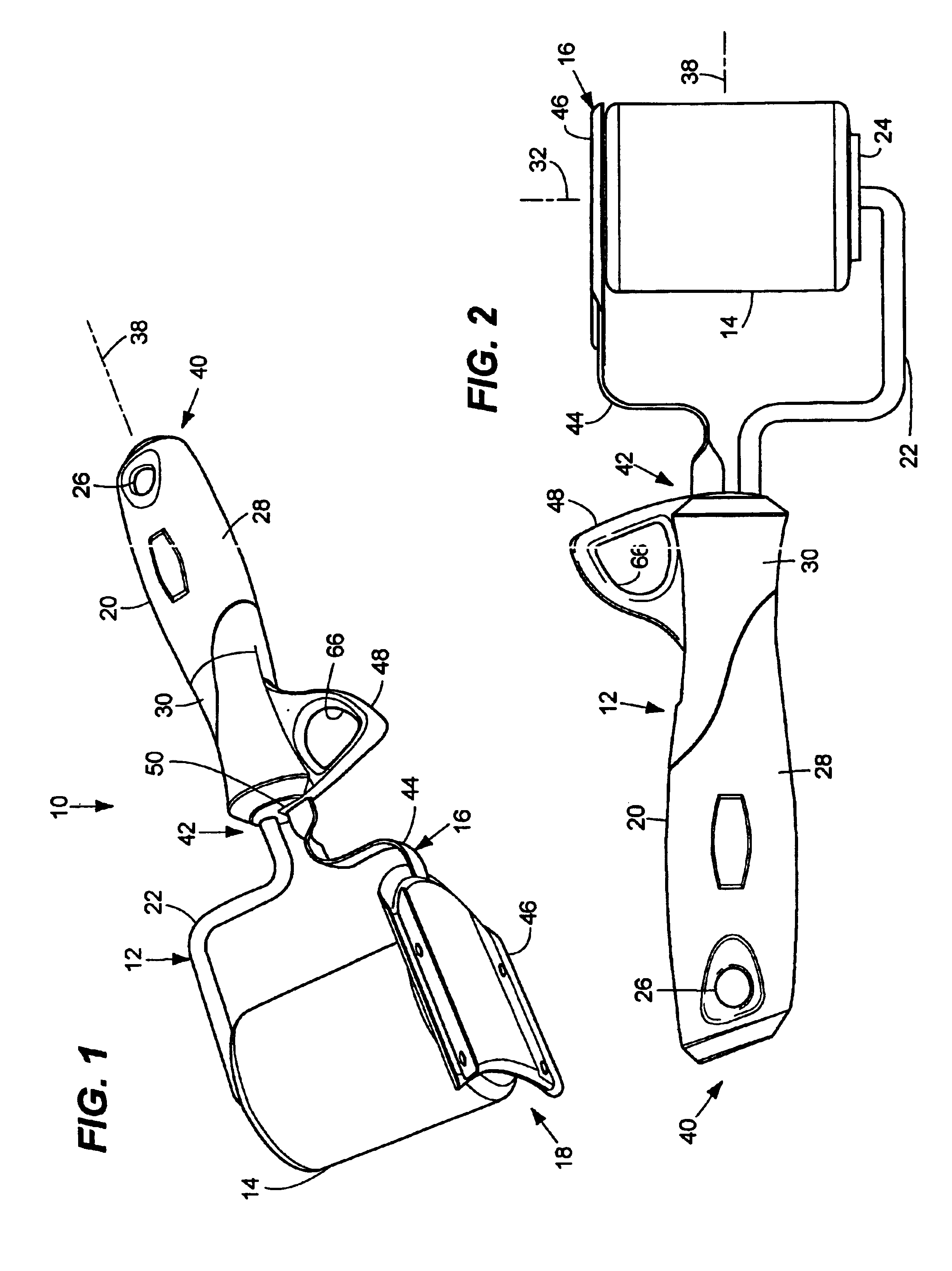

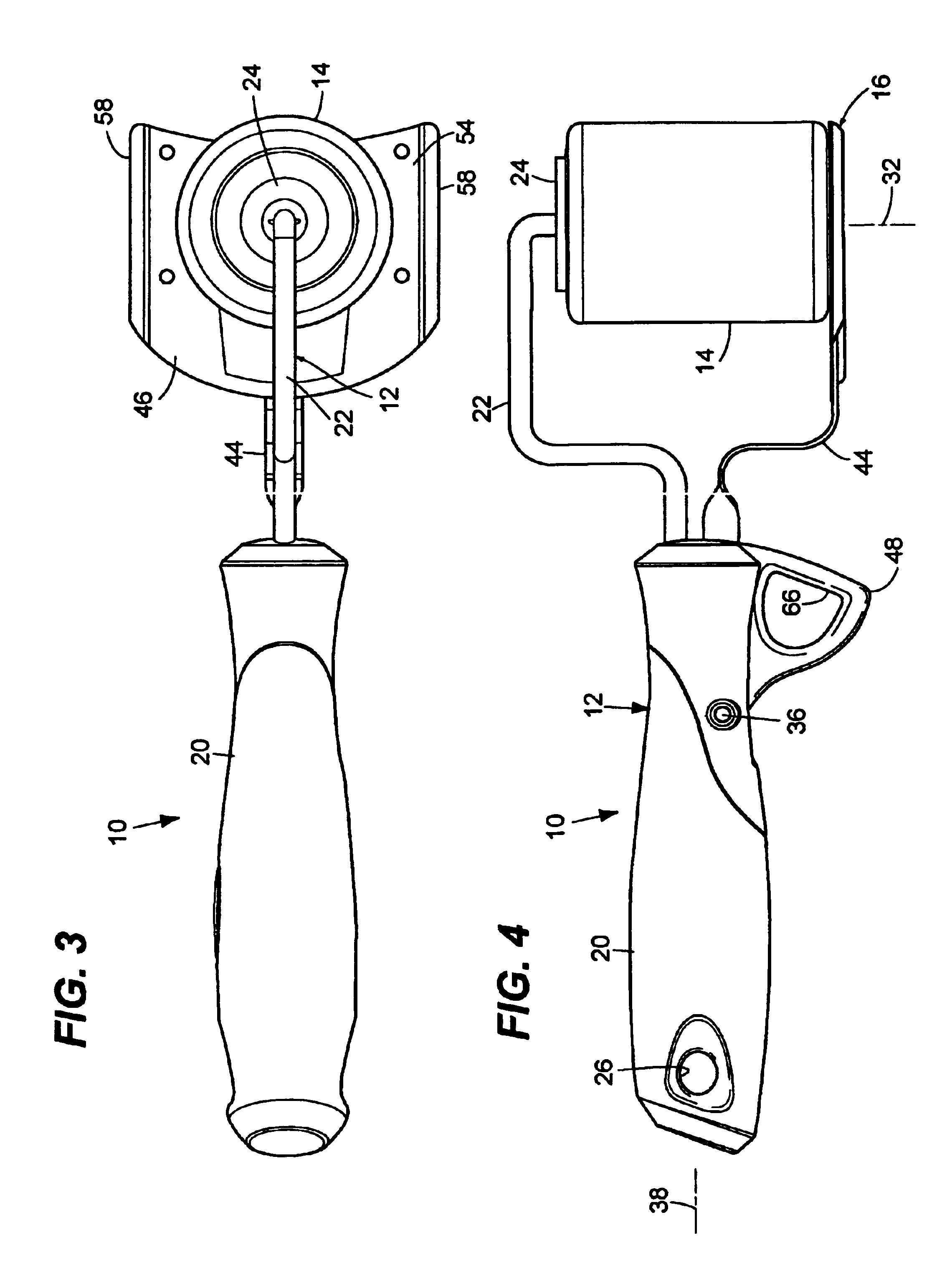

Lint roller assembly

InactiveUS6055695AMinimize frictional contactFacilitate free rotationLiquid surface applicatorsHousehold cleanersEngineeringMechanical engineering

A lint roller assembly is disclosed for rotatably supporting a tubular and cylindrical adhesive lint remover roller. The assembly includes a pair of elongated housing parts which are substantially identical to each other. Each housing part includes an elongated handle section and a semi-cylindrical lint roller support section longitudinally adjacent the handle section. The lint roller support section has an outer diameter less than the diameter of the adhesive roller. The housing parts are secured together in a facing relationship by registering pins and sockets formed on the housing parts. In doing so, the lint roller support sections form a cylindrical lint roller support for the adhesive roller while the handle sections abut against each other to form a handle.

Owner:THE EVERCARE

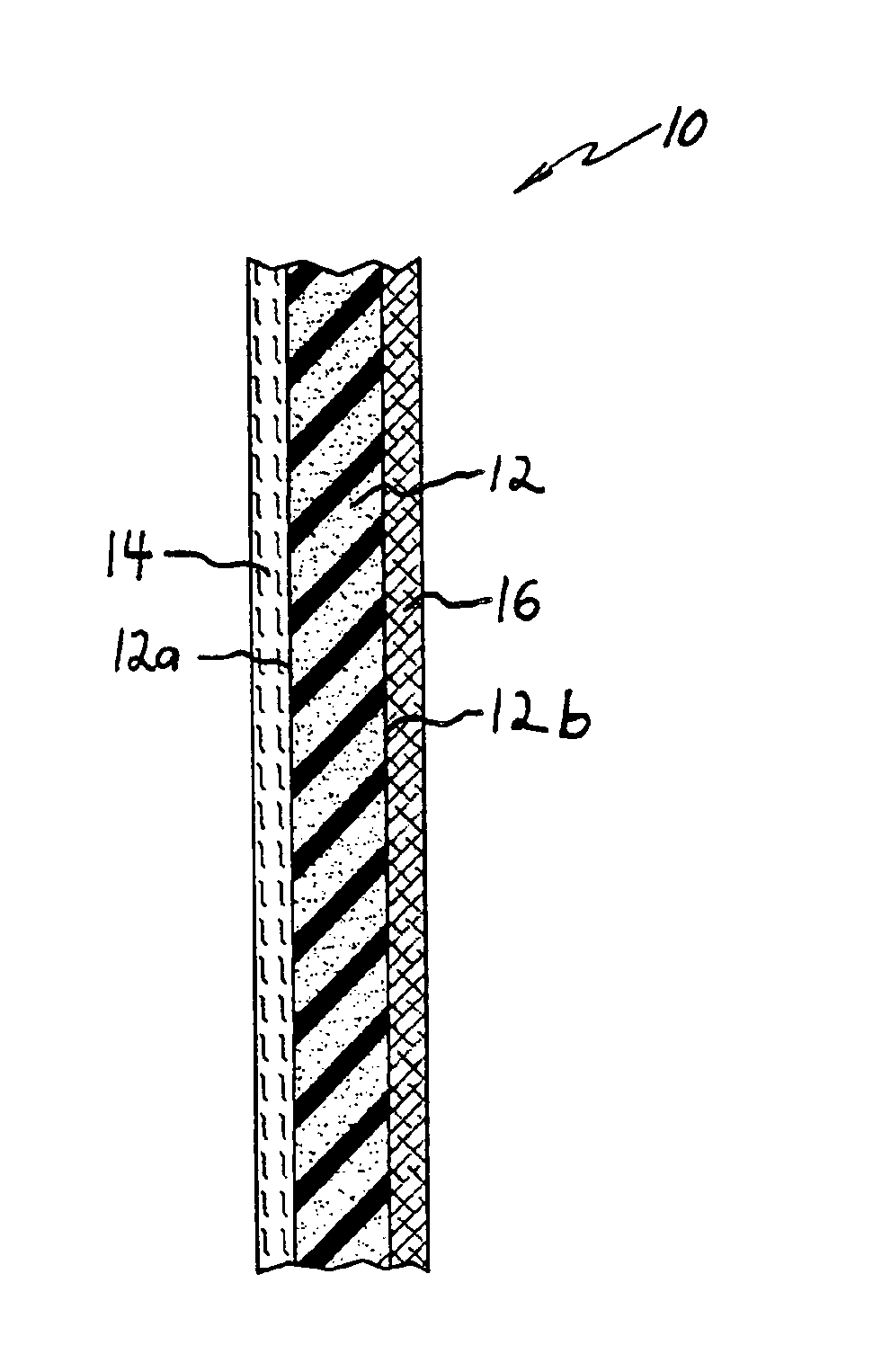

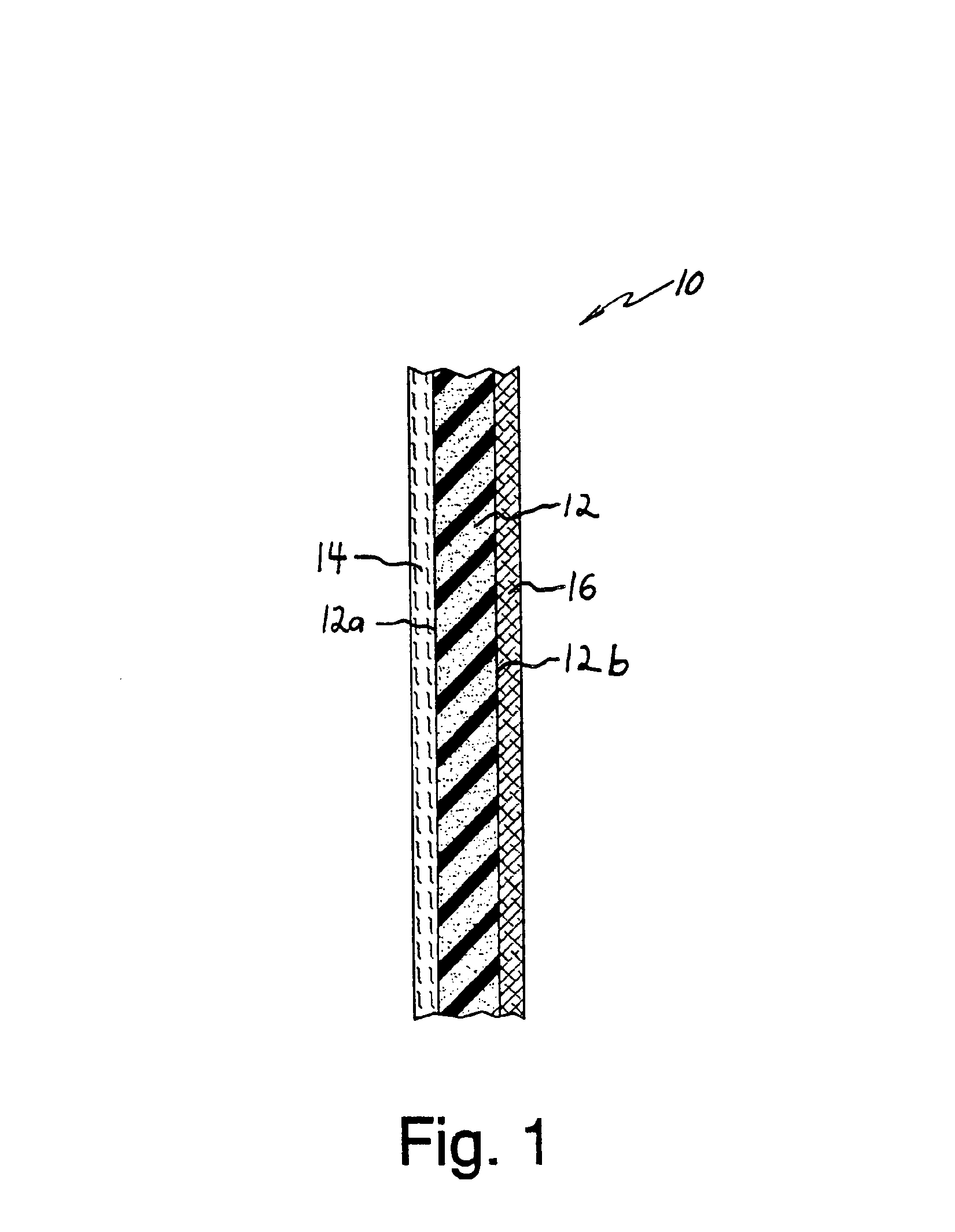

Breathable neoprene substitute

A tri-laminate material is disclosed which provides a breathable, non-irritating, four-way stretchable substitute for neoprene-based materials. The material of the present invention comprises a layer of resiliently stretchable open-celled foam which has been compressed 4 to 1; an outer layer of resiliently stretchable loop fabric, and an inner layer of resiliently stretchable wicking fabric. The fabric layers are fixed to opposite surfaces of the foam layer by flame lamination, either in two passes or in one pass.

Owner:RESMED LTD

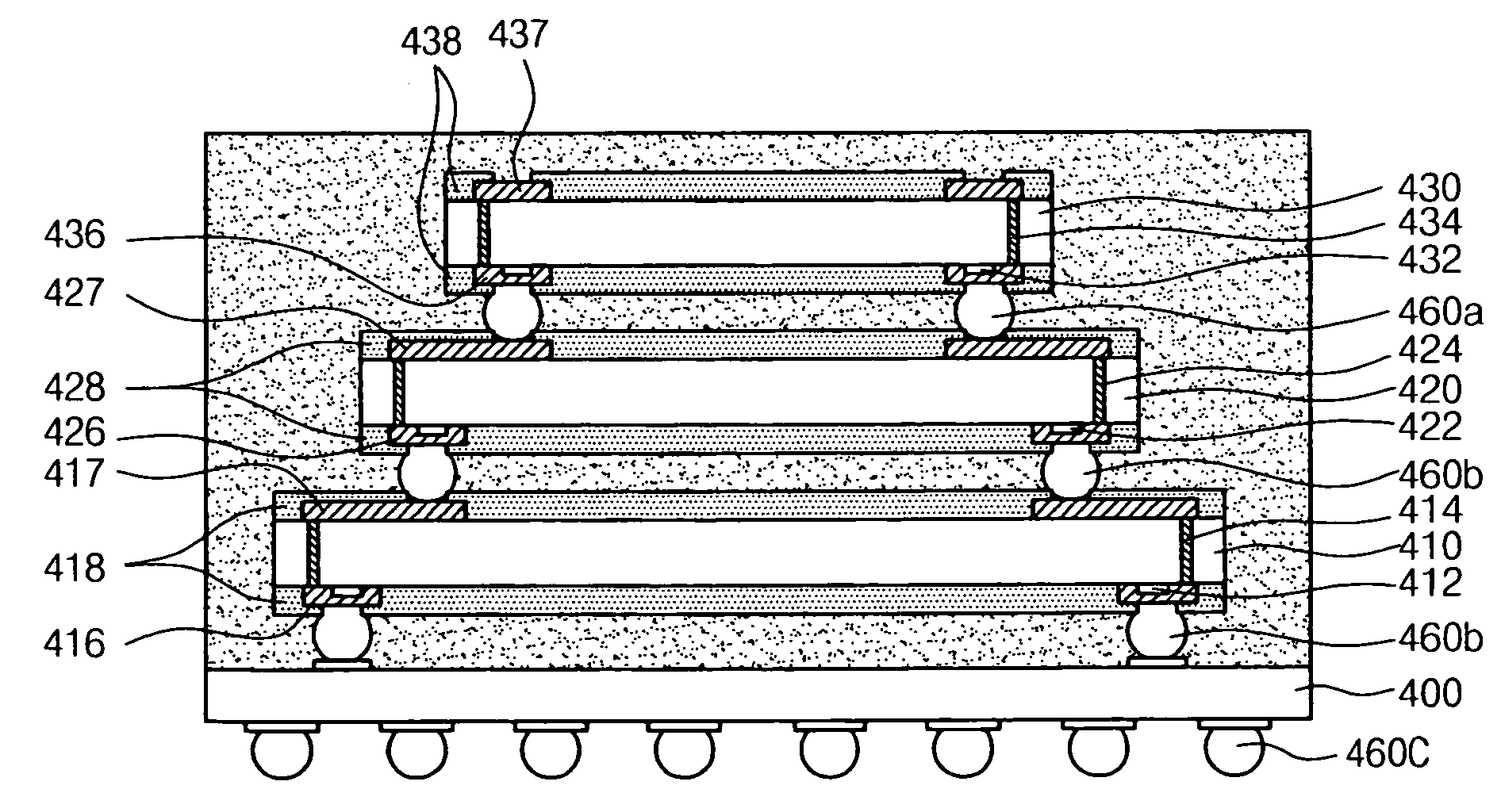

Stack package utilizing through vias and re-distribution lines

ActiveUS7598617B2Easily applied to high-speed productSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSolder ball

A stack package includes a printed circuit board; at least two semiconductor chips stacked on the printed circuit board, each having first re-distribution lines formed on the upper surface thereof and connected to bonding pads, through silicon vias which are formed therethrough and connected to the first re-distribution lines, and second re-distribution lines formed on the lower surface thereof and connected to the through silicon vias; first and second solder balls interposed between the first and second re-distribution lines which face each other and between the first re-distribution lines of the lowermost semiconductor chip and electrode terminals of the printed circuit board; a molding material for molding the upper surface of the printed circuit board including the stacked semiconductor chips; and third solder balls attached to ball lands formed on the lower surface of the printed circuit board.

Owner:SK HYNIX INC

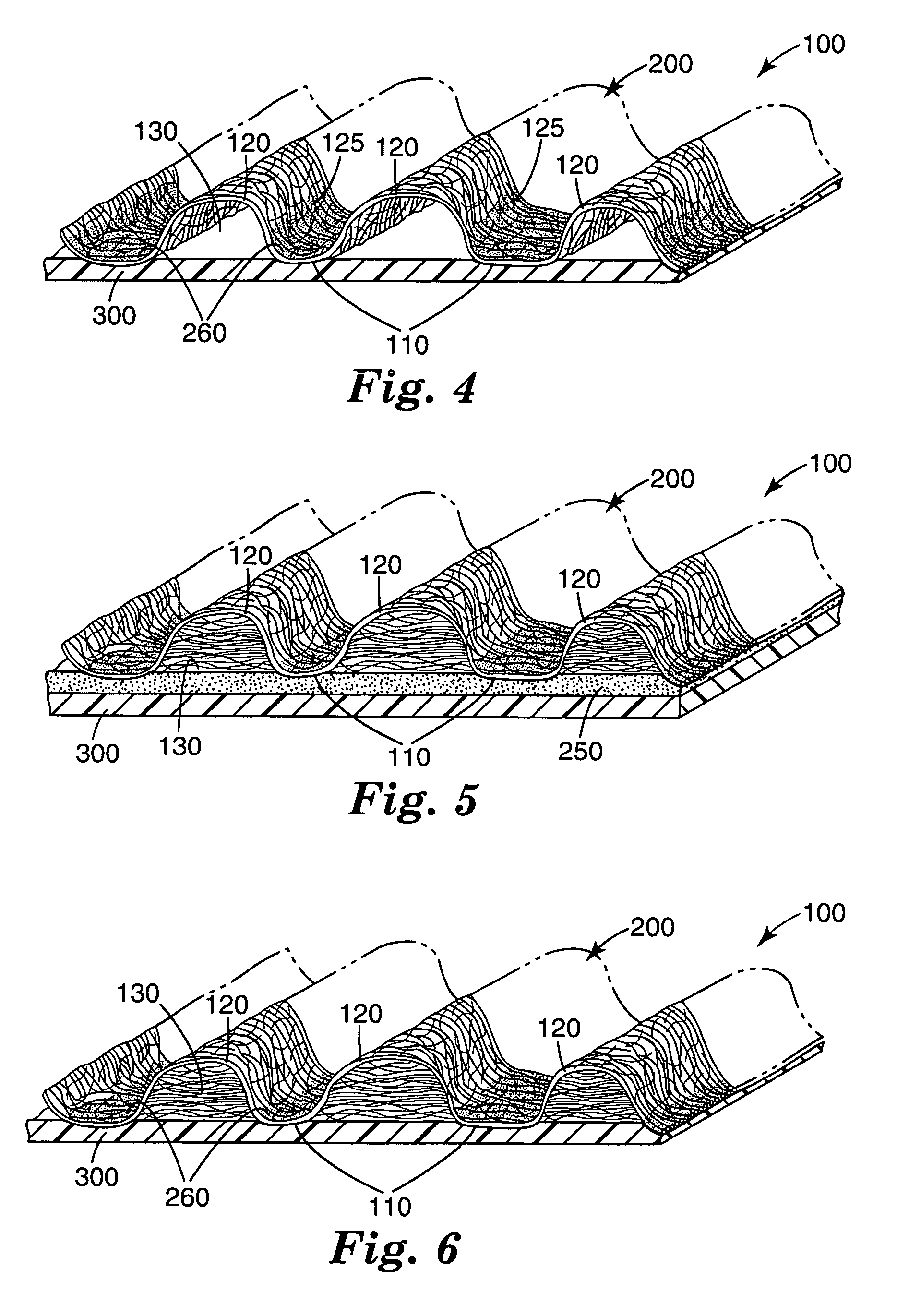

Cleaning pad for wet, damp or dry cleaning

ActiveUS20060171764A1Improved dust retentionImproved debris retentionCarpet cleanersFloor cleanersFiberEngineering

A cleaning pad (28) is disclosed. The cleaning pad (28) includes a base sheet (202) bonded to a fiber mat (203) and exhibits improved debris retention when a liquid is applied to the pad (28) or the surface to be cleaned. The pad (28) is preferably used with a cleaning system that includes a fluid source (30) in communication with a cleaning tool (22) such that fluid may be selectively applied to a surface to be cleaned or directly to the fiber mat (203) of the cleaning pad (28).

Owner:SC JOHNSON & SON INC

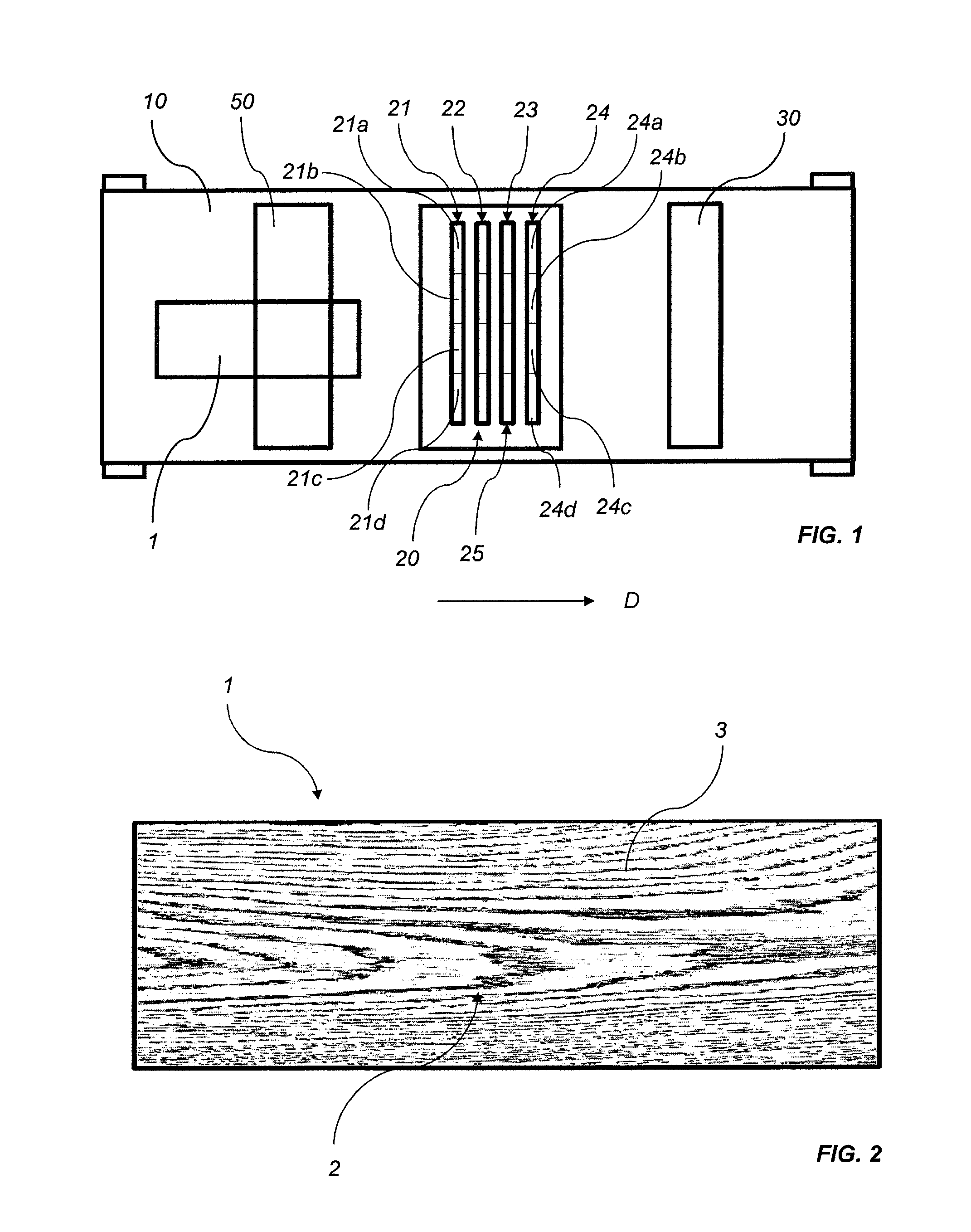

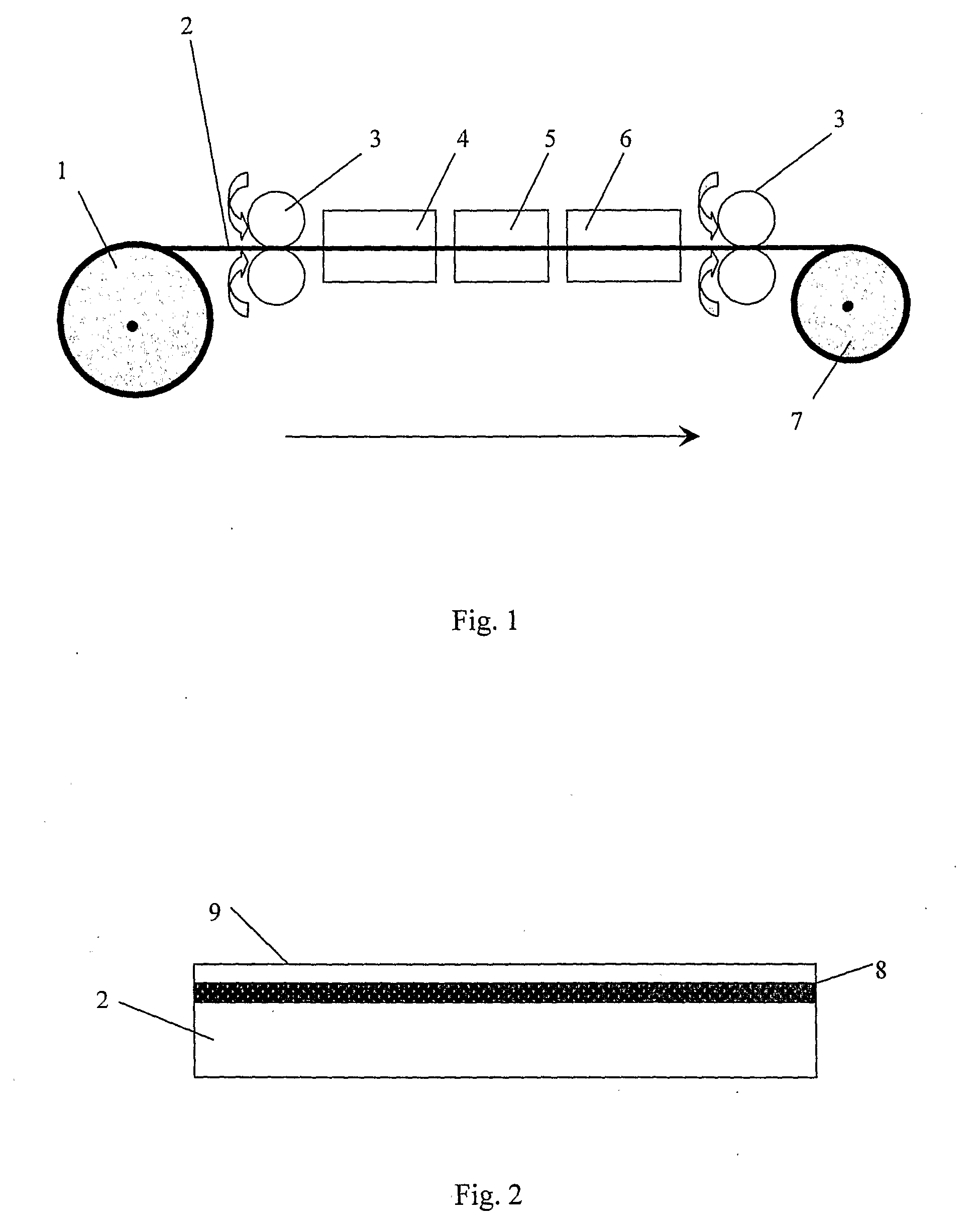

Method for forming a decorative design on an element of a wood-based material

ActiveUS20130286088A1Reduce curingNatural patternsDecorative surface effectsEngineeringDigital printing

A method for forming a decorative design (2) on an element (1) of a wood-based material, including providing an element (1) of a wood-based material having a surface (3), said surface (3) being solid and being formed of said wood-based material, and printing a decorative design (2) with an aqueous ink on at least a portion of said surface (3) by means of a digital printing device. Also, a building element including such an element.

Owner:VÄLINGE INNOVATION AB

Coated Metal Product, Method to Produce It and Use of the Method

InactiveUS20090181262A1High quality finishResistant to damageDecorative surface effectsPretreated surfacesLacquerMetallic substrate

Owner:SANDVIK INTELLECTUAL PROPERTY AB

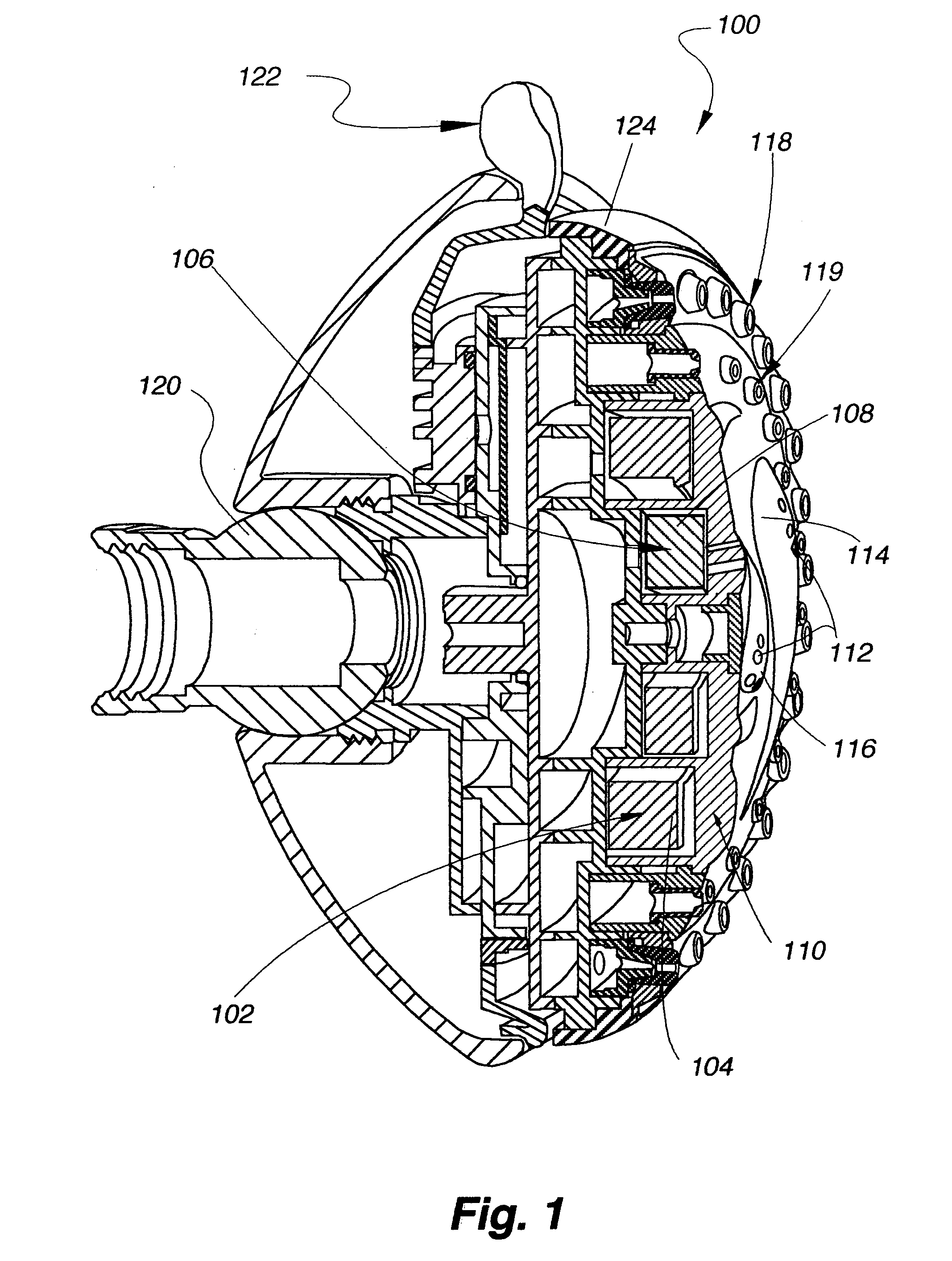

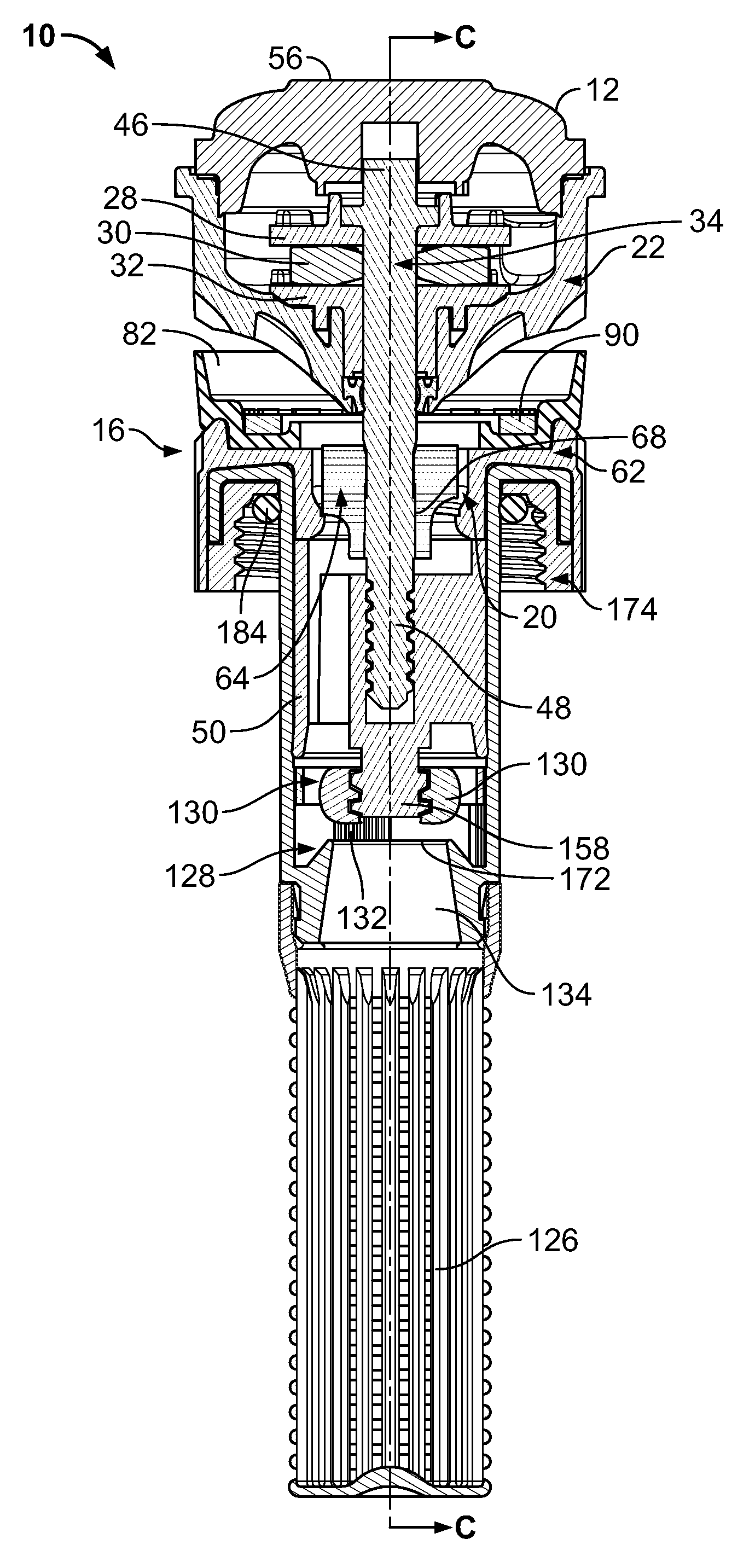

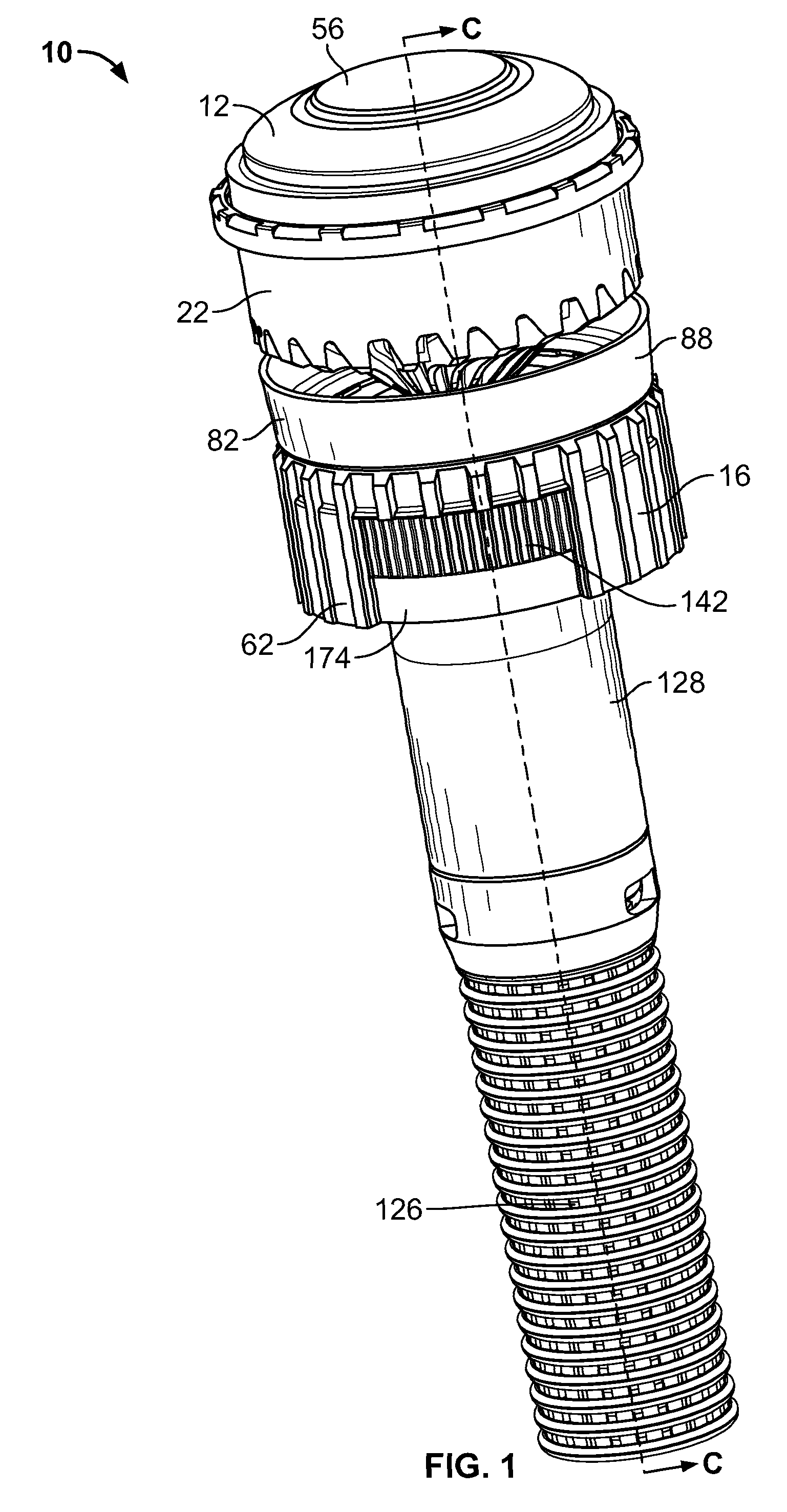

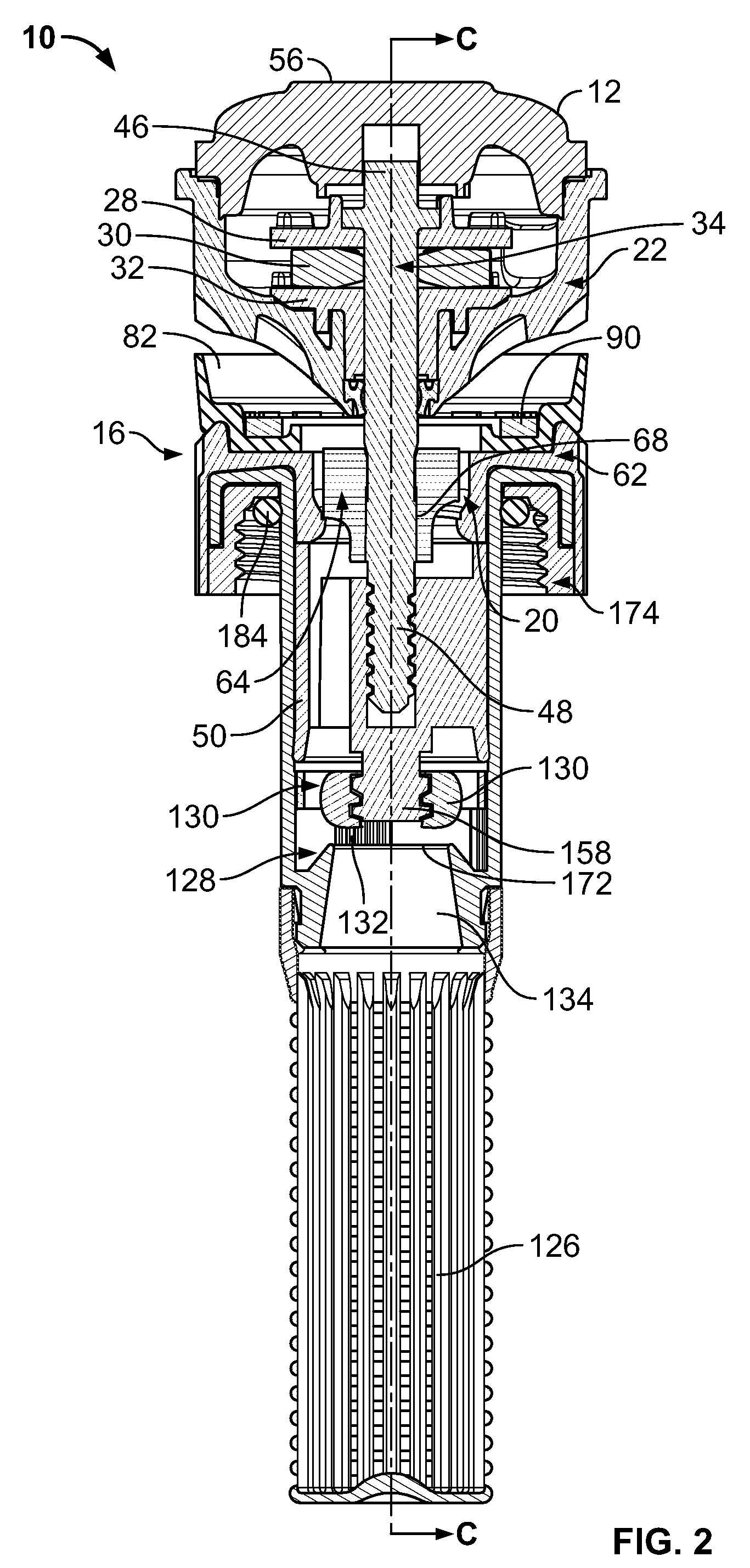

Sprinkler with variable arc and flow rate

Owner:RAIN BIRD CORP

Wipe

A wipe is provided that includes a first wiping member bonded to a backing member along valleys, whereby the wiping member includes a plurality of discrete peaks, and an adhesive is provided, in one embodiment, in the valleys and not on the peaks.

Owner:3M INNOVATIVE PROPERTIES CO

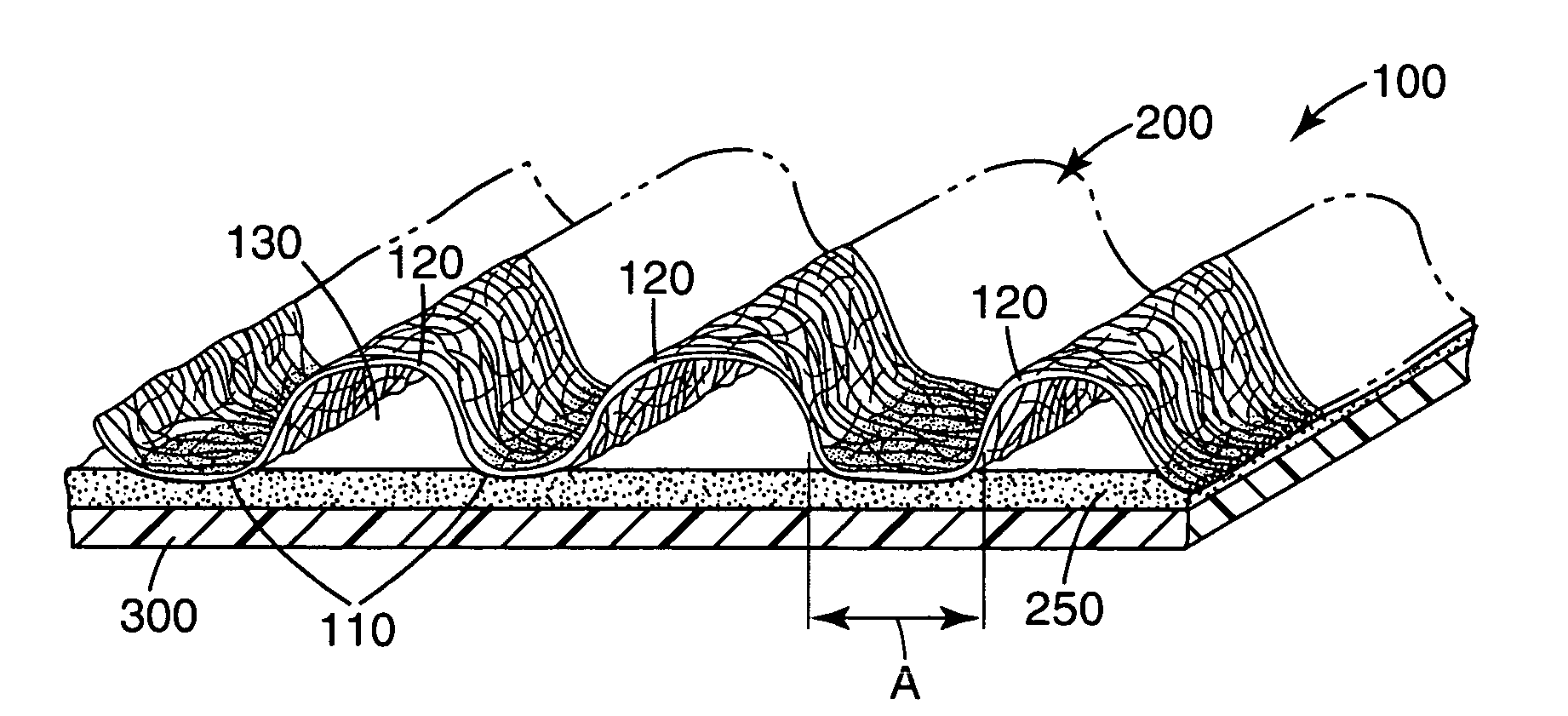

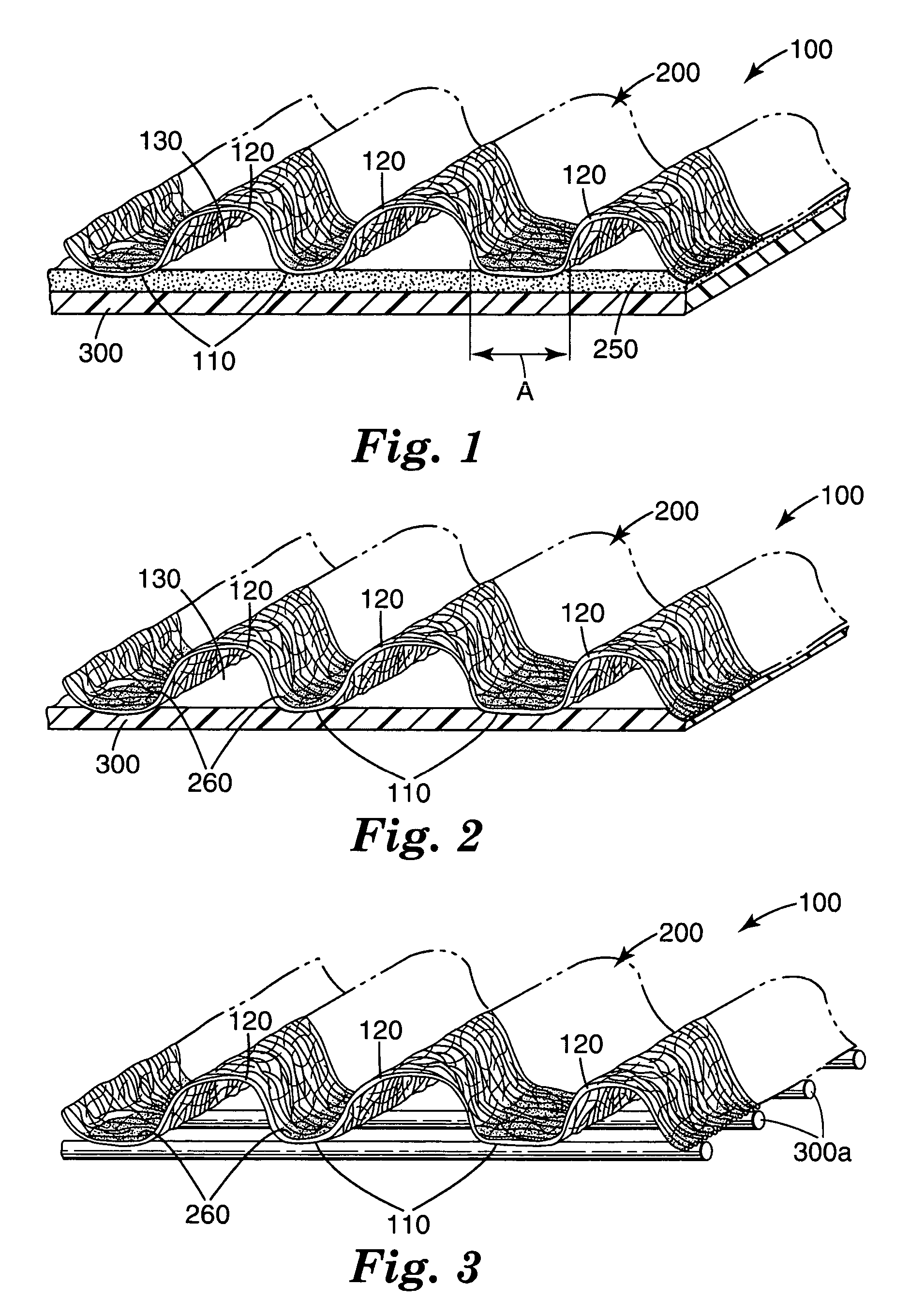

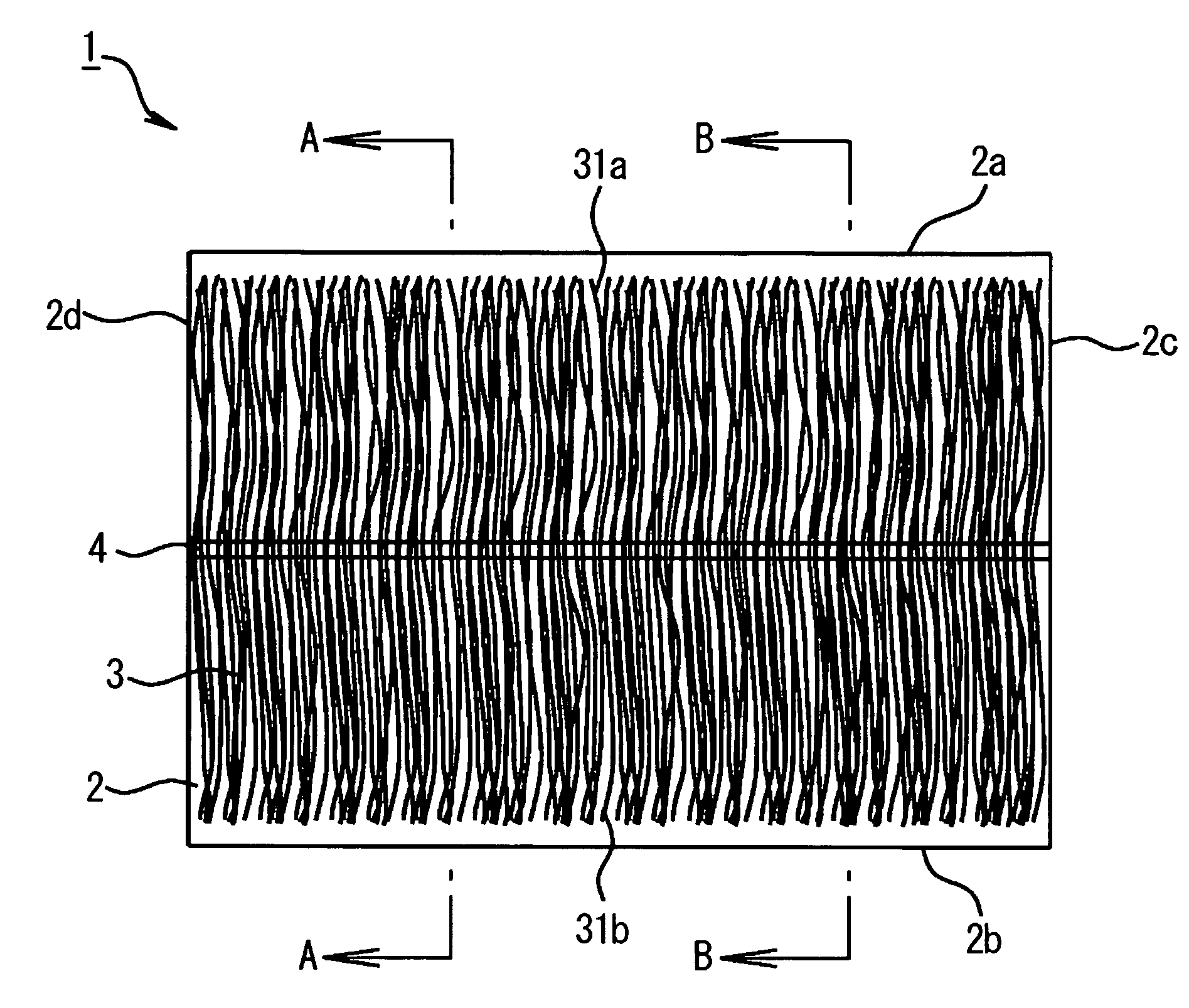

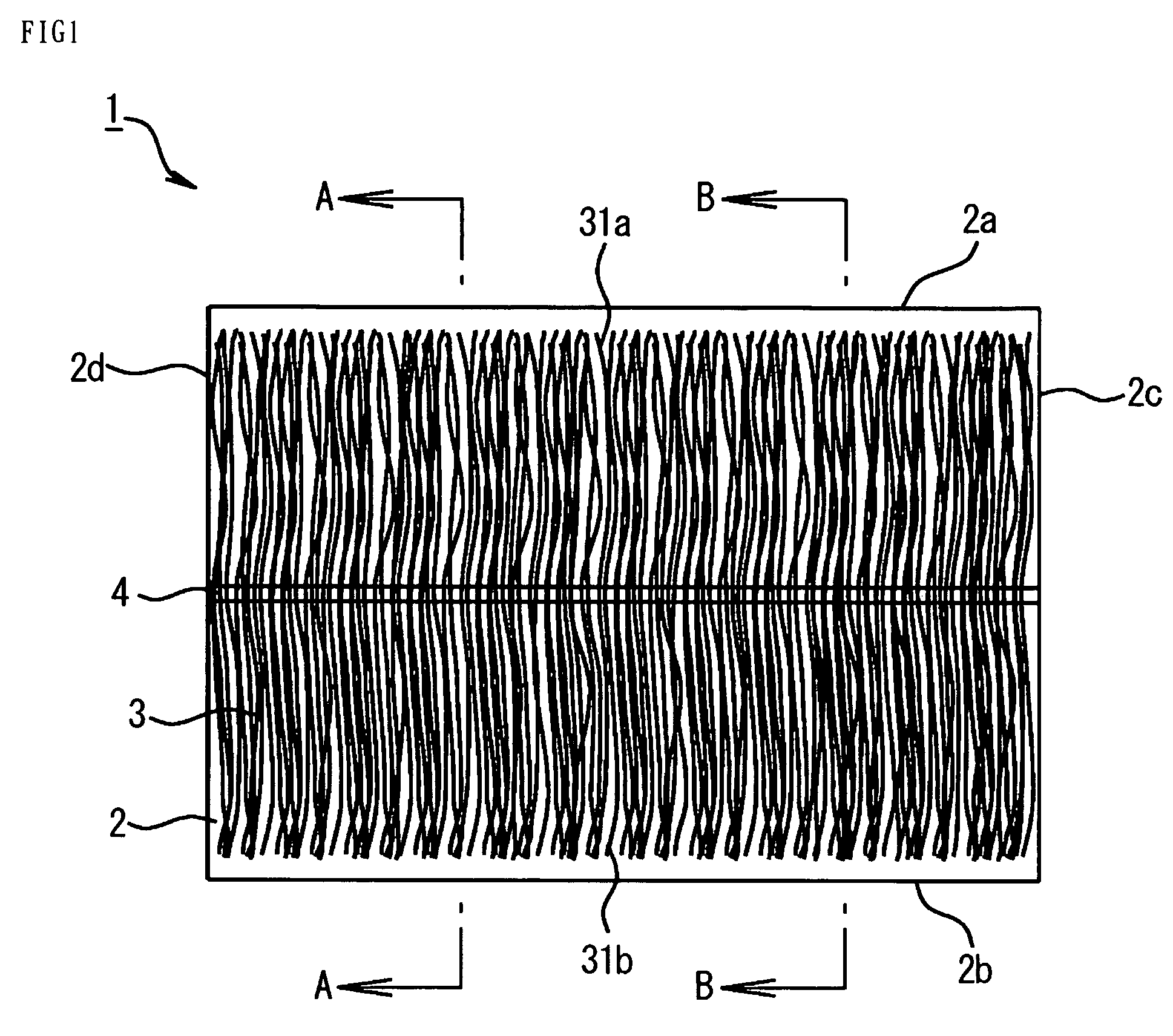

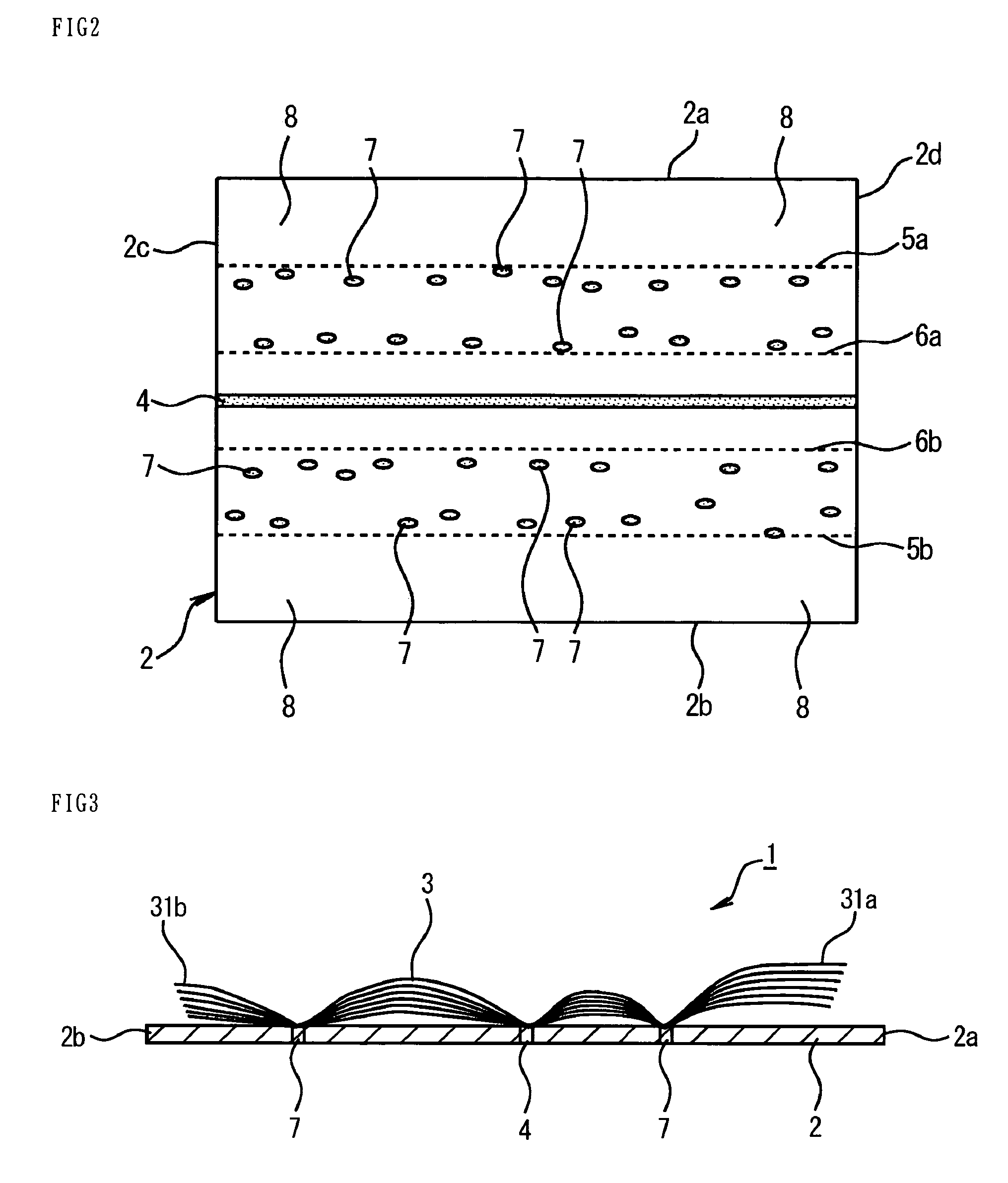

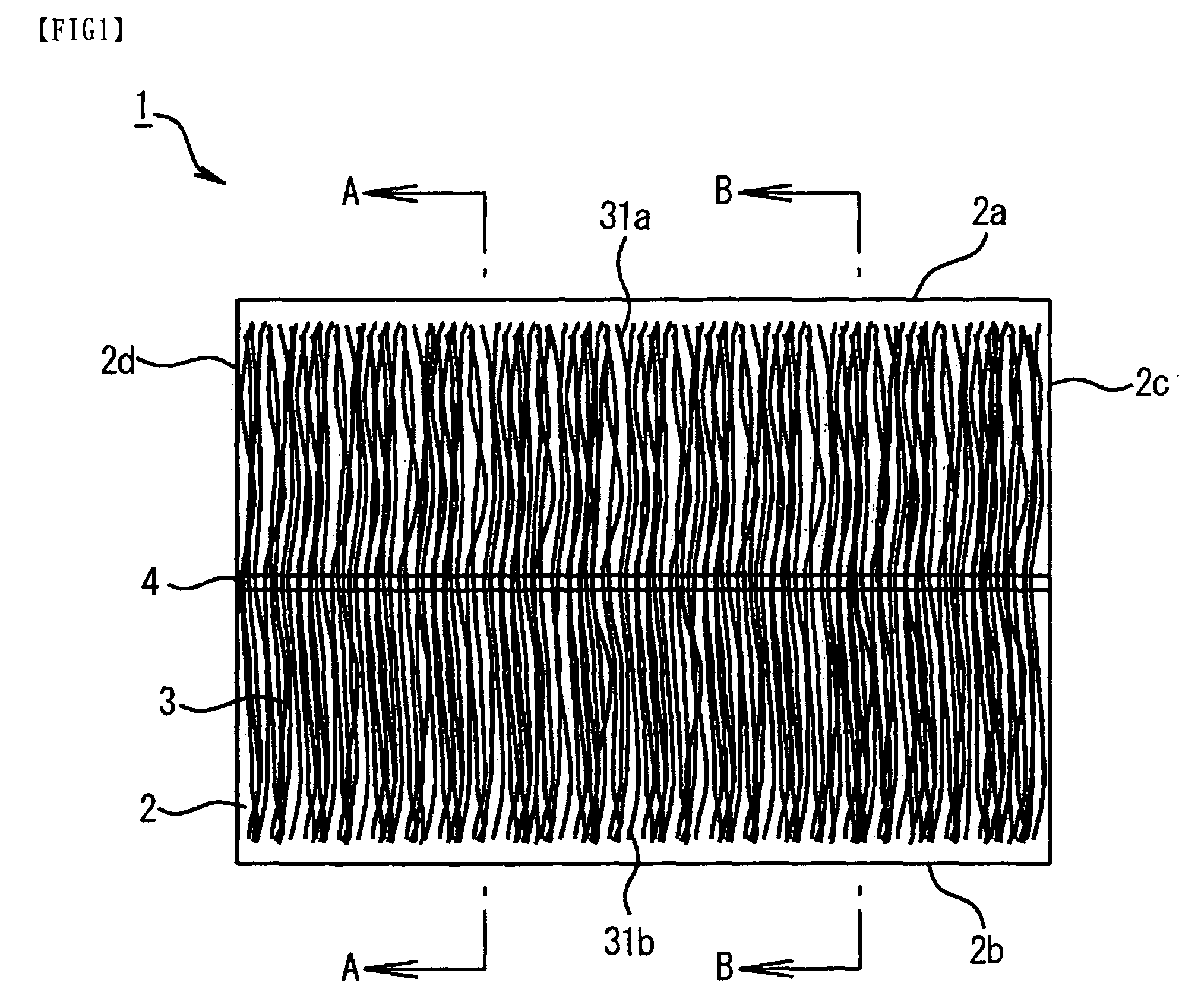

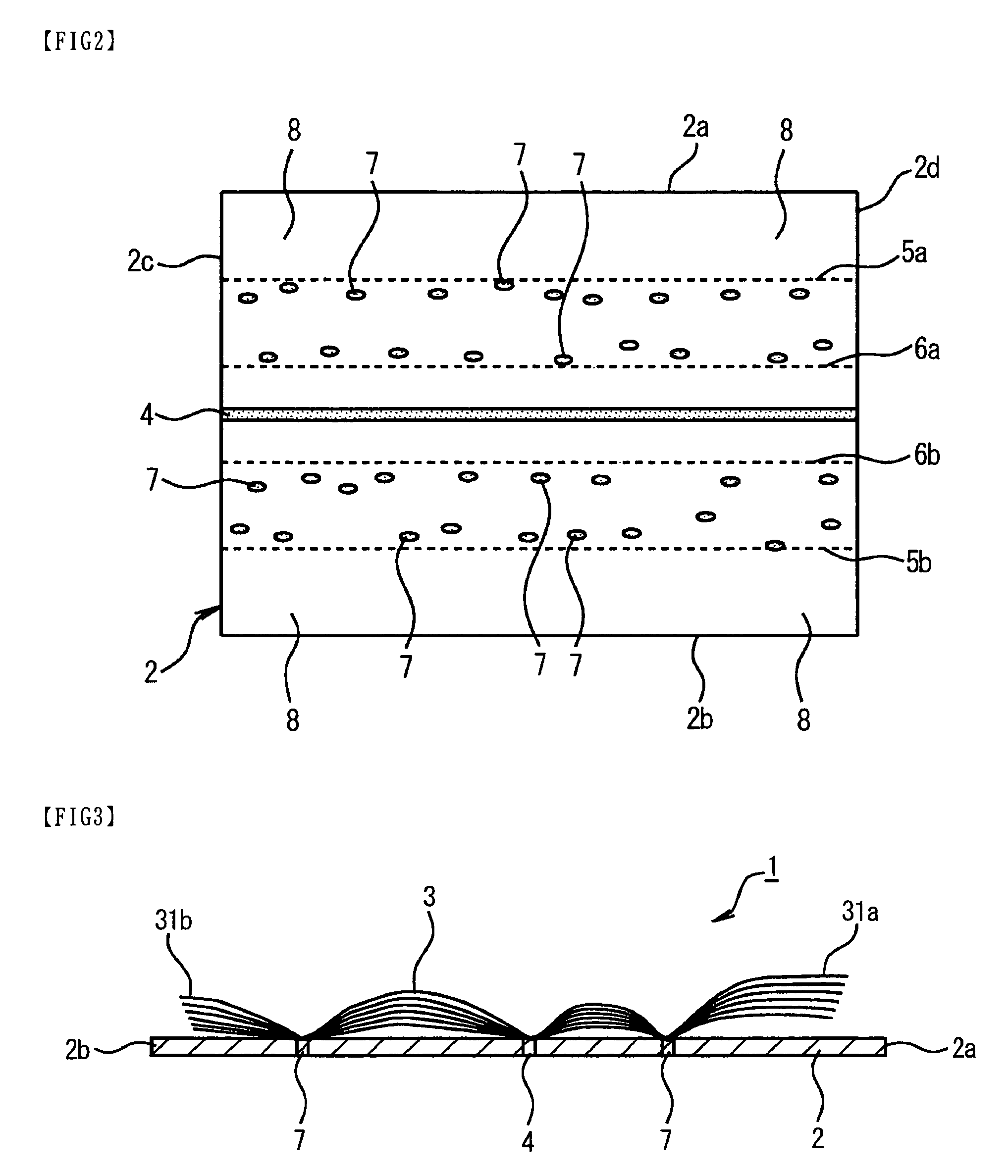

Cleaning tool sheet and cleaning tool

ActiveUS7712178B2Increase in sizeEfficient use ofBoard cleaning devicesLiquid surface applicatorsFiber bundleEngineering

The present invention relates to a cleaning tool sheet and a cleaning tool capable of use for wiping cleaning by contacting the surface of objects to be cleaned in various locations. In a cleaning tool sheet (1), fiber bundles (3) are laminated on one side face of a base sheet (2); the central parts in the direction of flow of the fibers constituting the fiber bundles (3) are joined by a central joining part (4) continuously formed in the central part of the base sheet (2) and joined at a spot-form joining part (7) formed intermittently on a parallel line between the central joining part (4) and two end edges (2a, 2b) parallel therewith. The two ends (31a, 31b) in the direction of flow of the fibers of the fiber bundles (3) are not joined to the base sheet (2). An attaching part (8) for attaching onto a holding member is provided at both ends of the base sheet (2).

Owner:SELF SETTLED TRUST OF YAMADA KIKUO YAMADA KIKUO SETTLOR & TRUSTEE

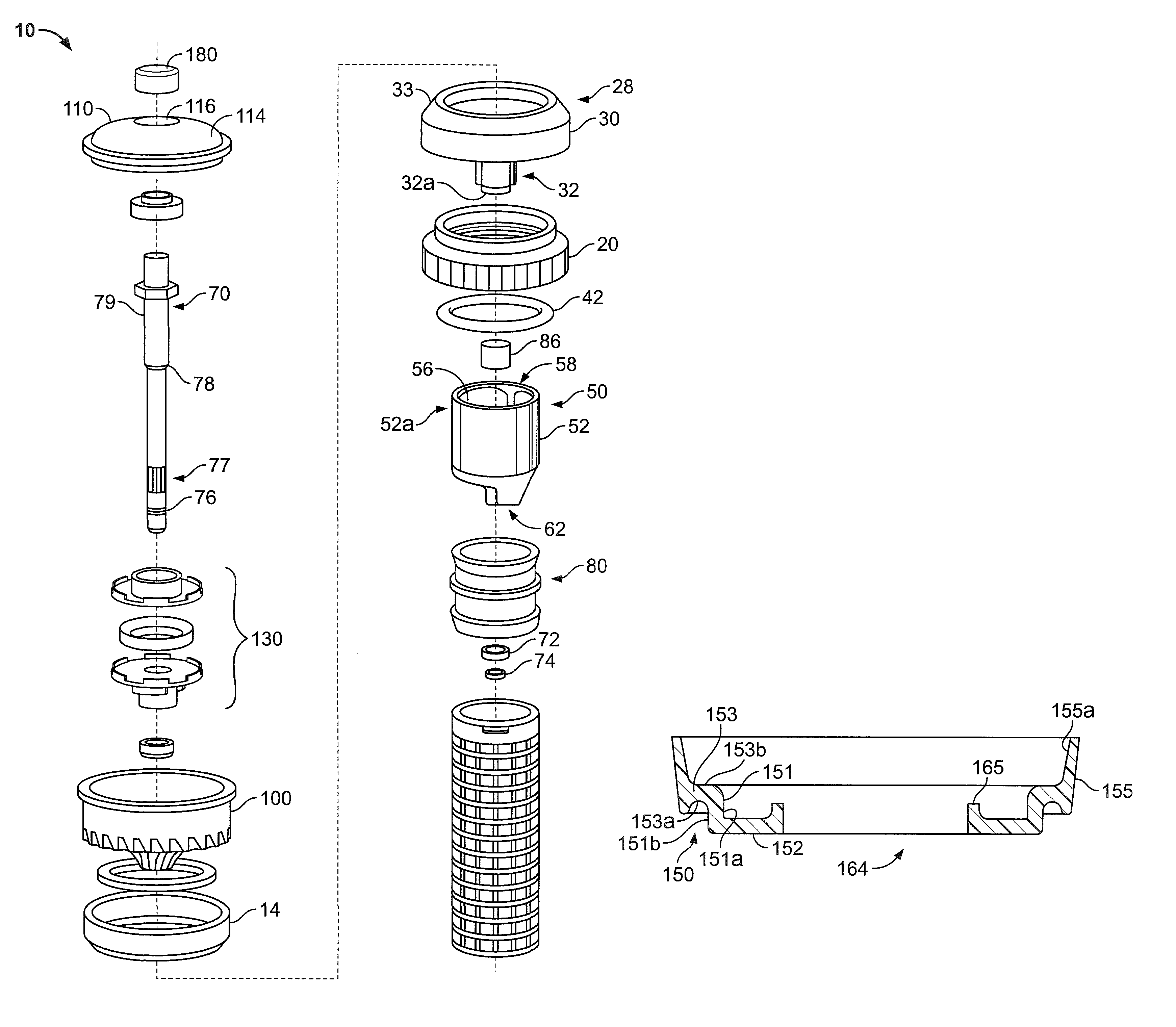

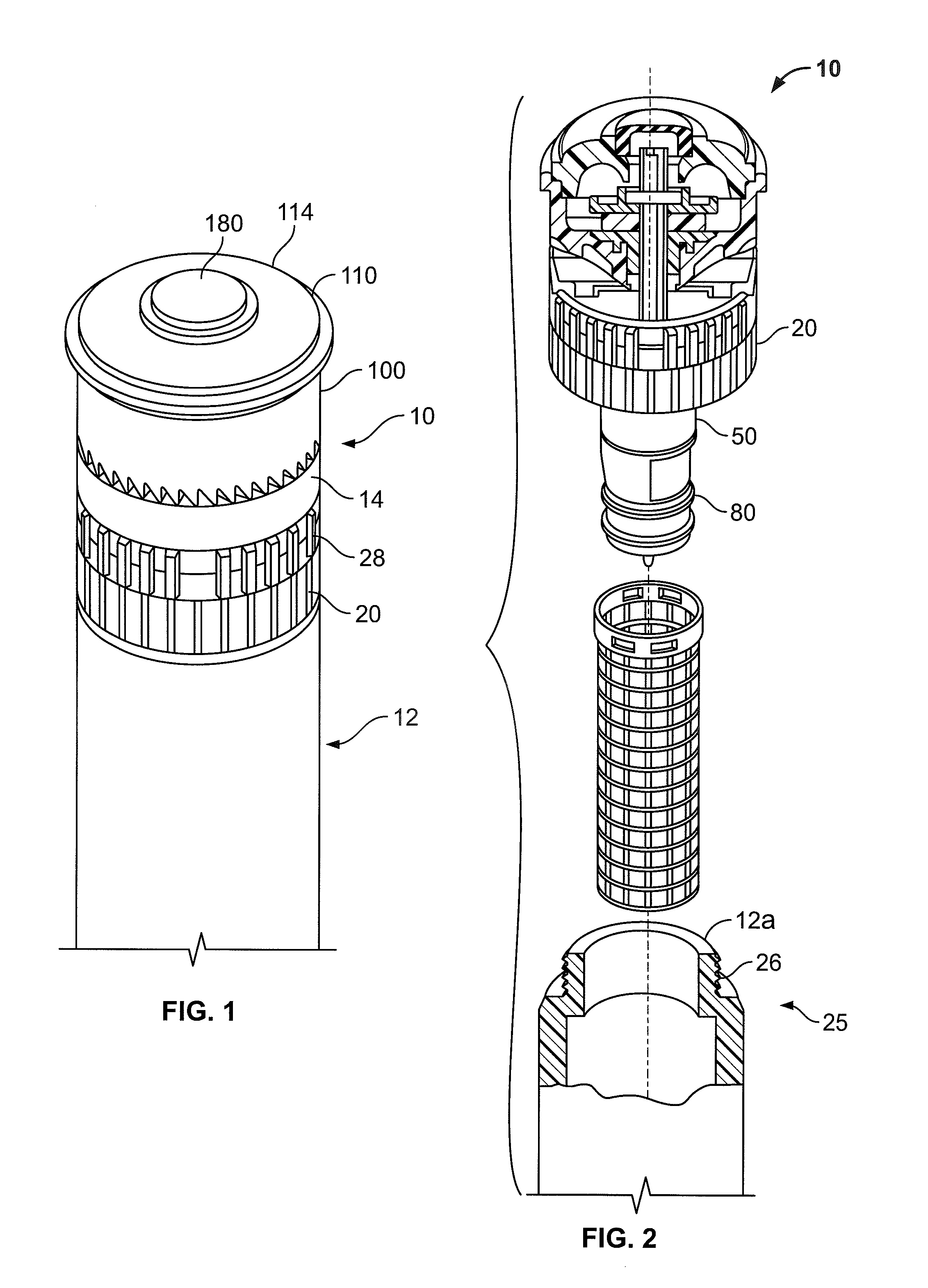

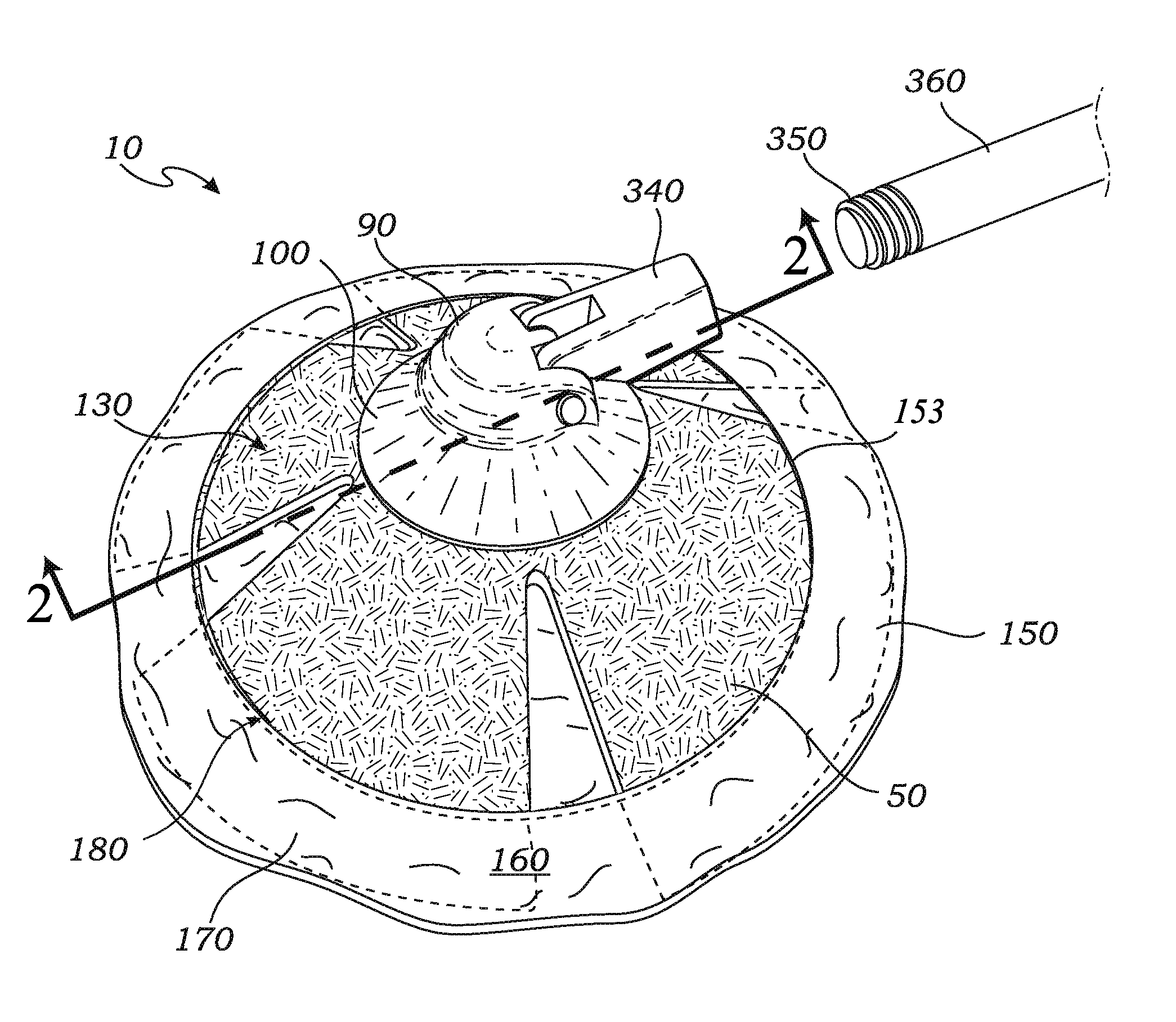

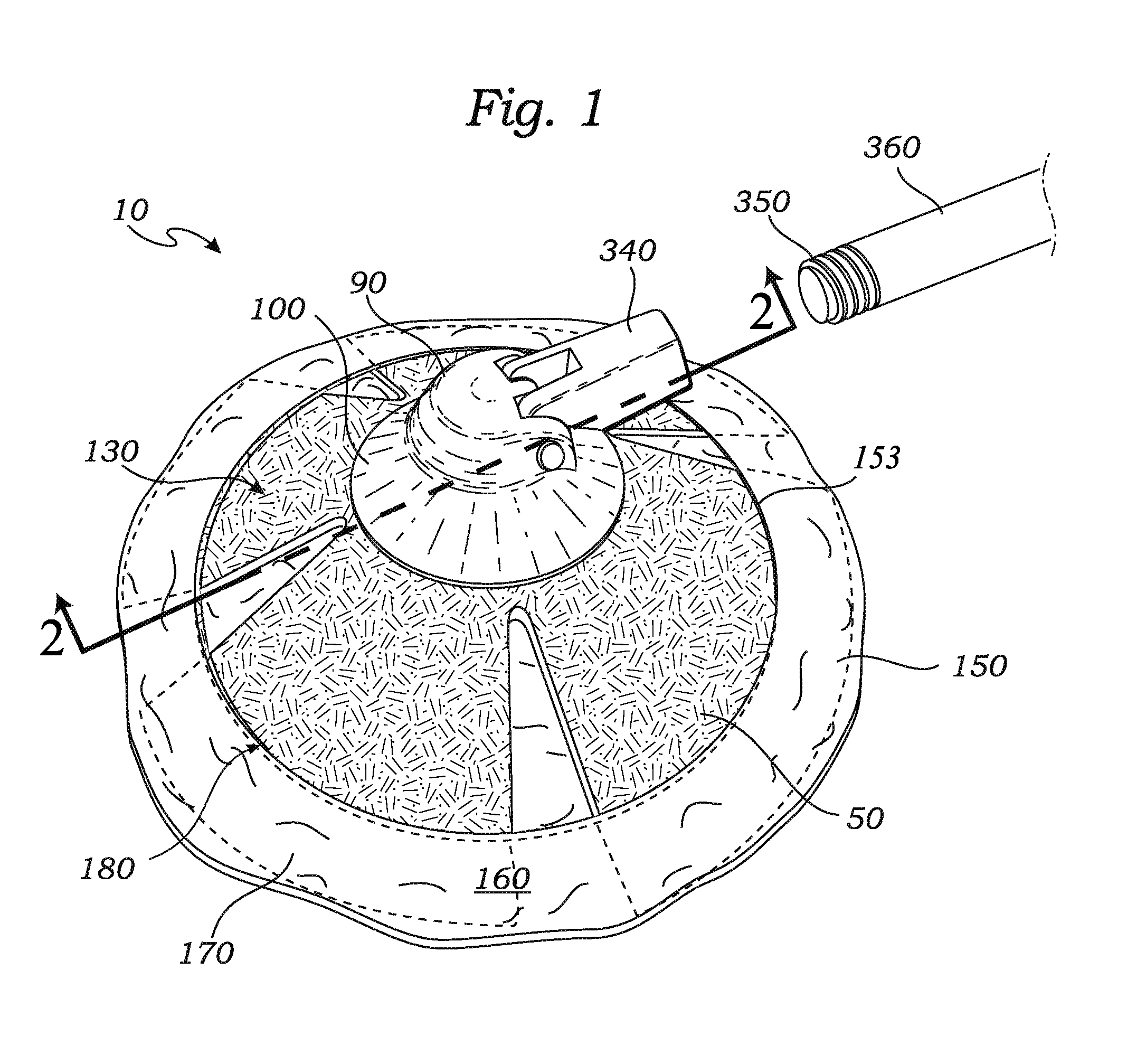

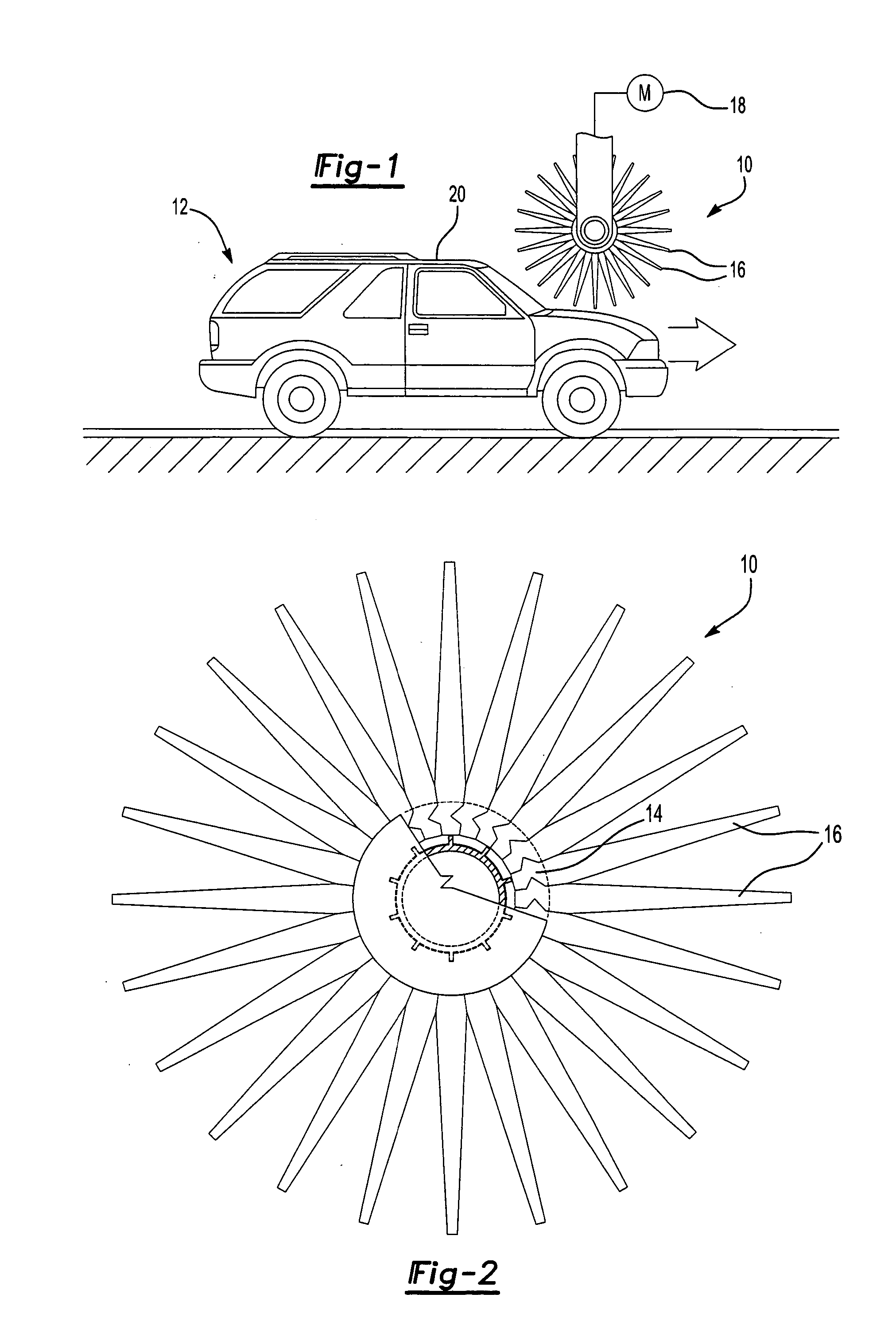

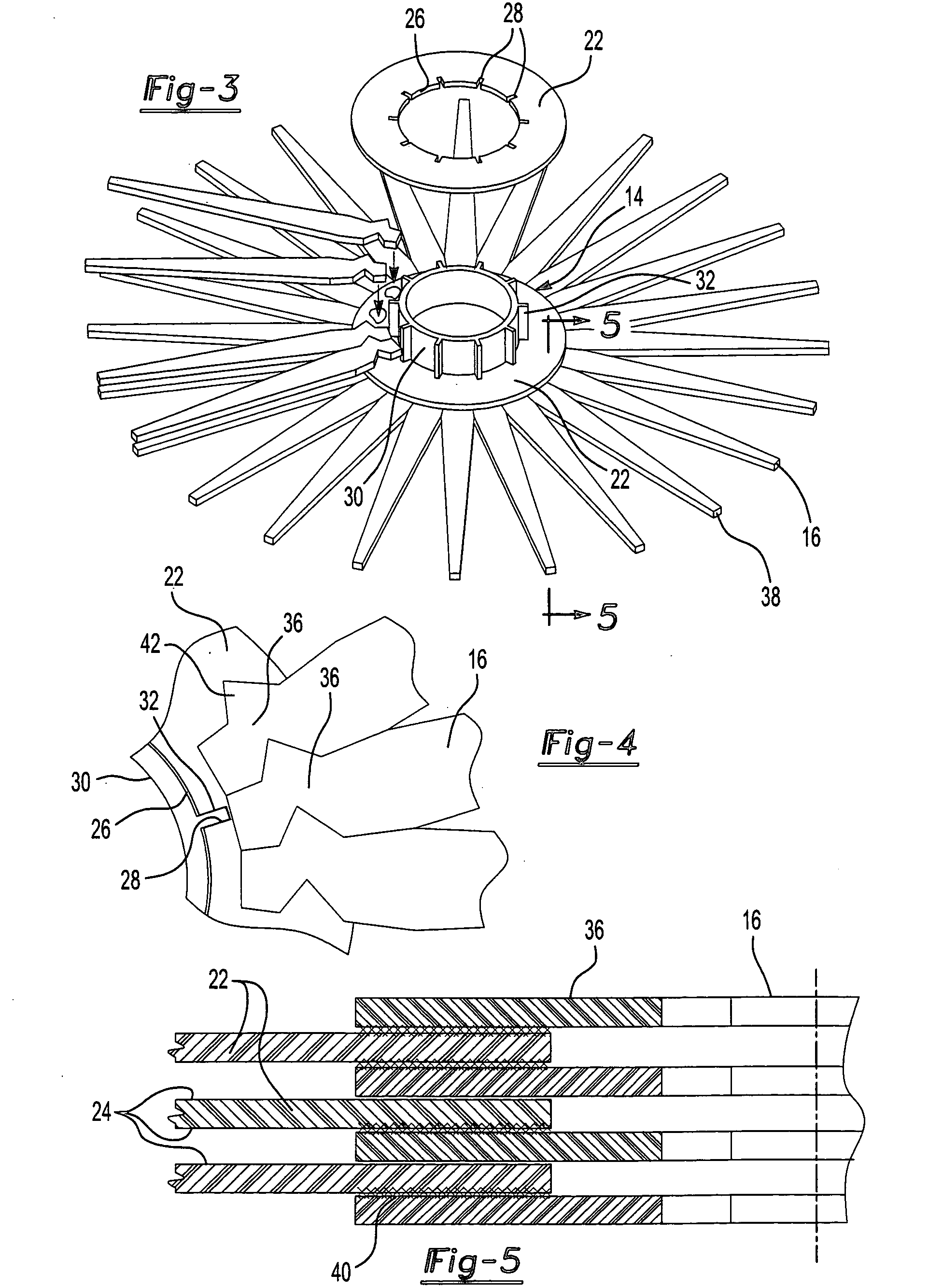

Debris resistant collar for rotating stream sprinklers

A sprinkler head having a deformable member forming a collar is disclosed. The deformable member allows the sprinkler head to resist entry of foreign grit or matter within the sprinkler head, and allows the sprinkler head to eject or force out foreign matter from within the sprinkler head. The sprinkler head may be a spinning sprinkler head including a vane deflector, and the spinning sprinkler head may include a portion that shifts in response to being struck by water such that a braking mechanism is engaged in response to the force of the water. When water flow ceases, the spinning head may shift towards the deformable member so that a portion of the spinning head is received within the deformable member to restrict foreign matter from entering the sprinkler head.

Owner:RAIN BIRD CORP

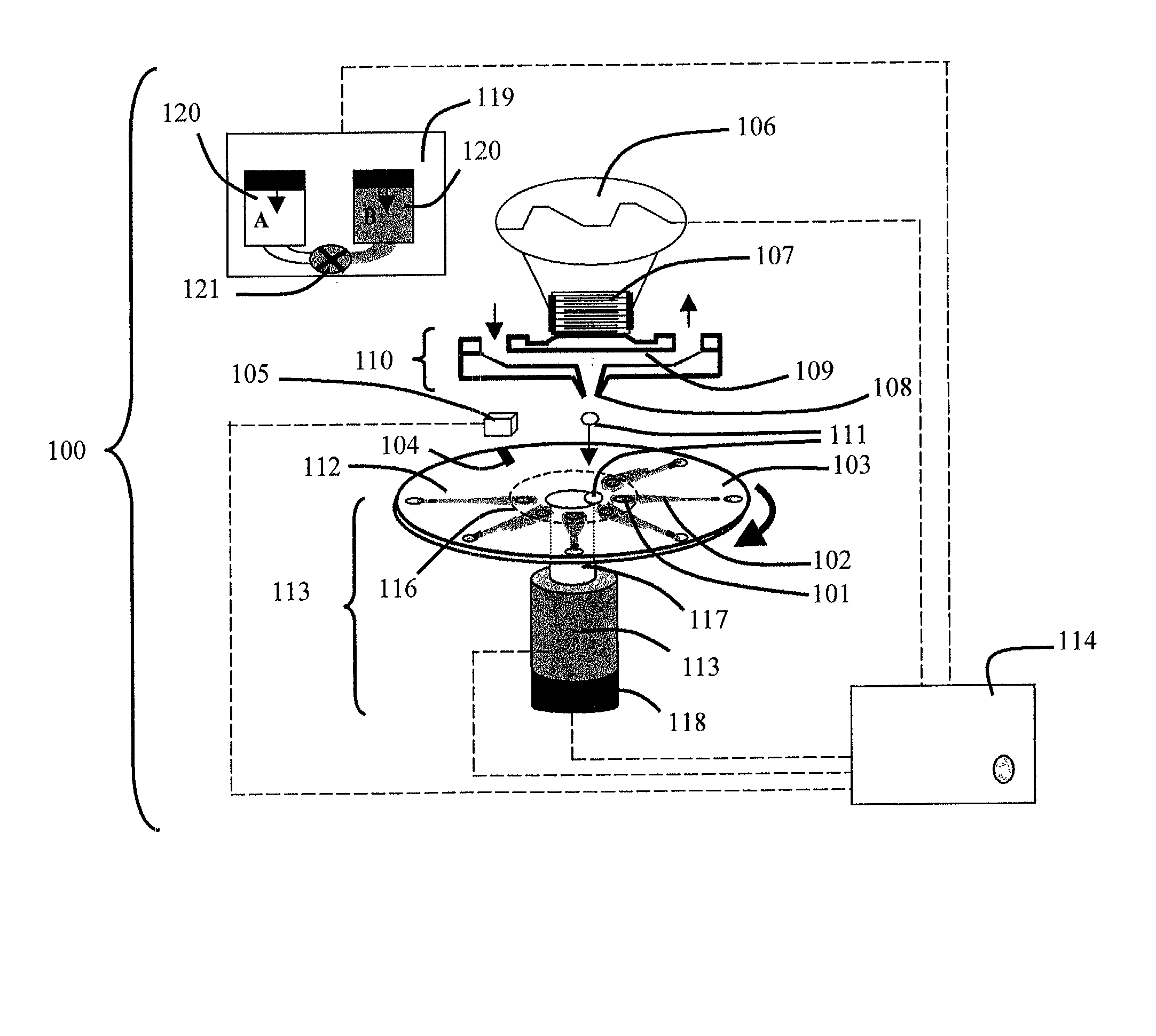

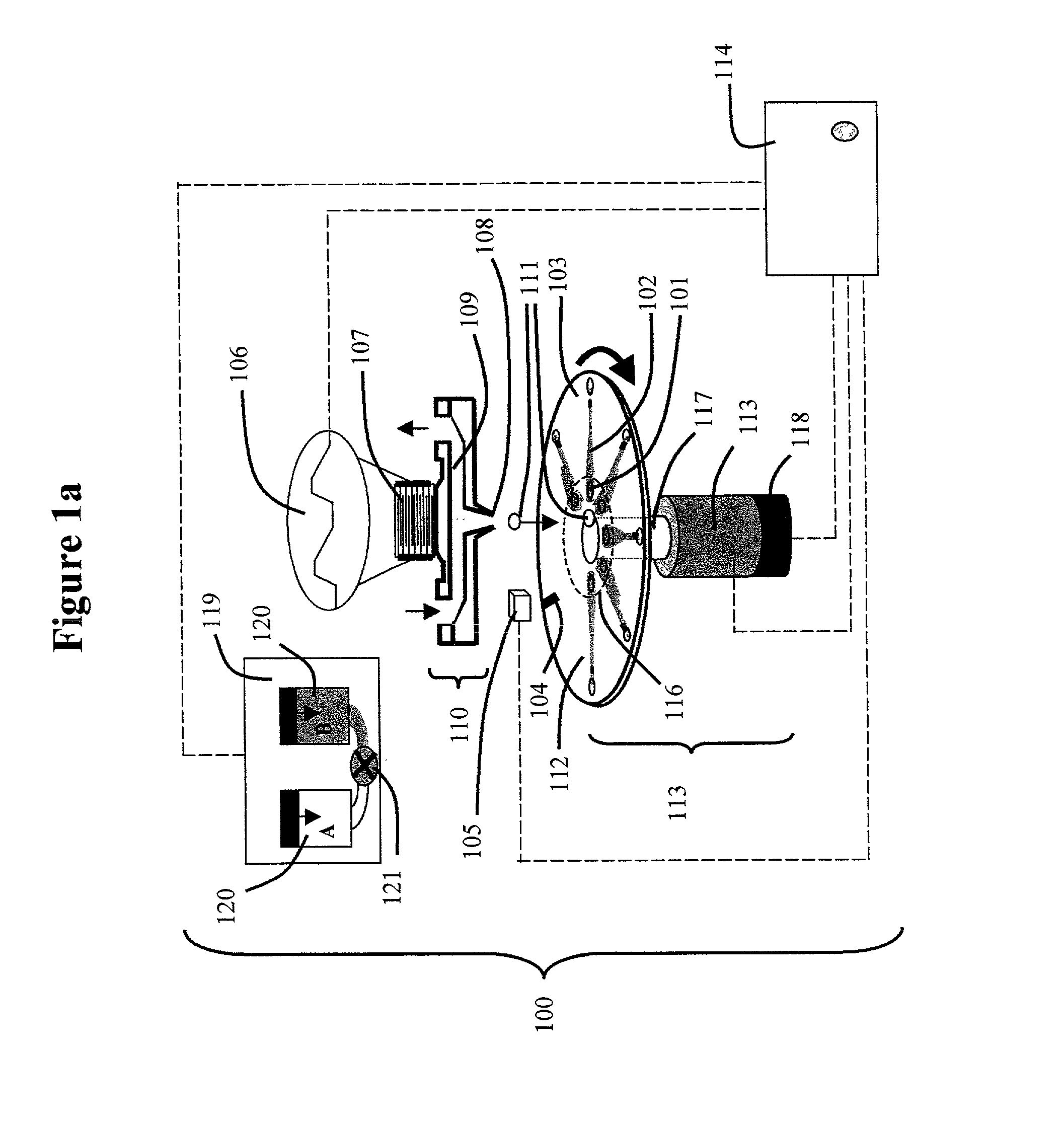

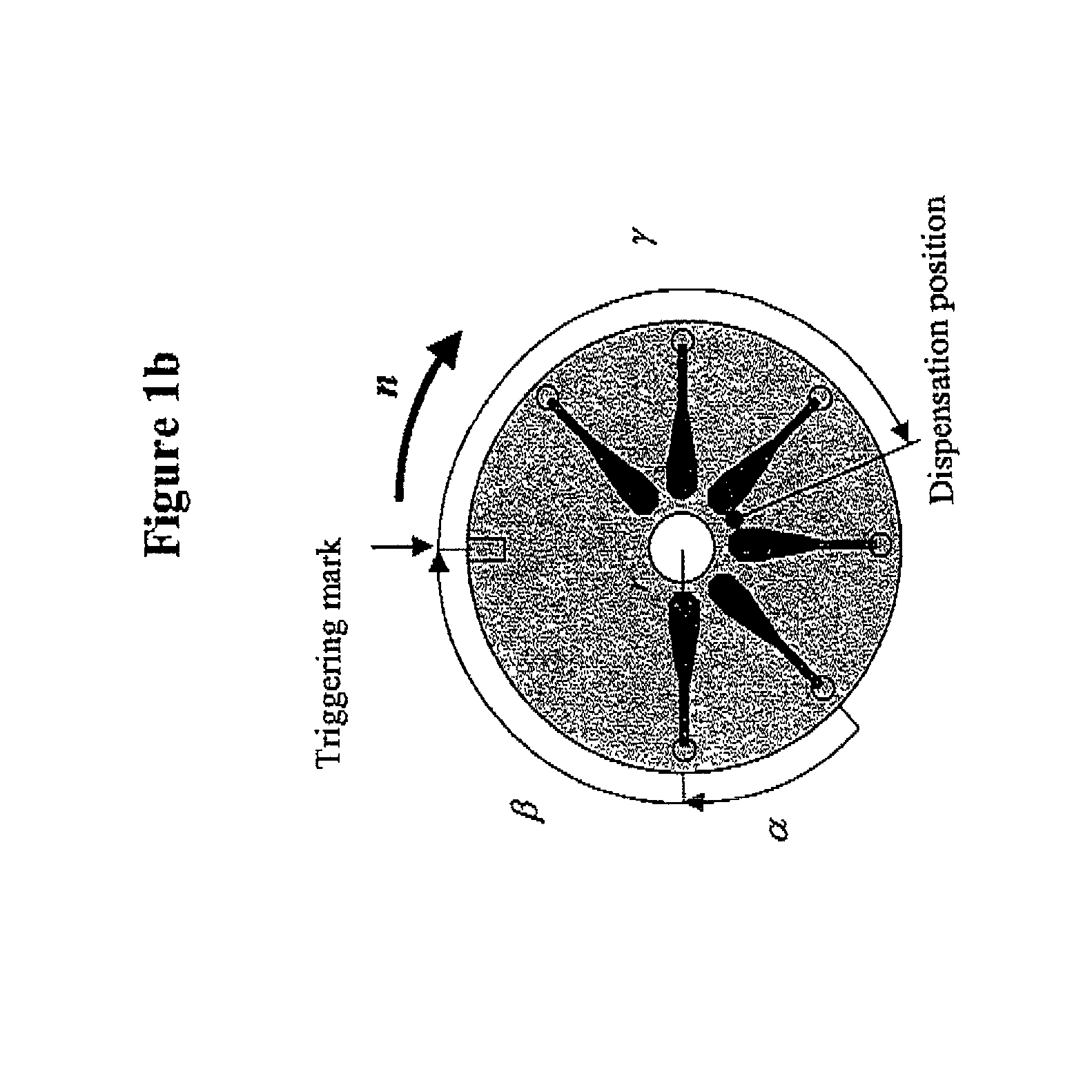

Method and instrumentation for micro dispensation of droplets

InactiveUS20030094502A1Easy to mass producePrevent leakageBurnersLiquid handlingMechanical engineeringInstrumentation

A method for dispensing droplets of a liquid to a microsystem in the form of a disc comprising a target area (TA0I) in its surface, said disc preferably being a microfluidic disc comprising a microchannel structure with an inlet port that is a target area (TA0I). The method is characterized by comprising the steps of: i) providing (1) said disc which has a triggering mark, and (2) a dispenser arrangement comprising: a) a spinner for rotating the disc around its axis, b) a drop dispenser permitting dispensation of droplets to inlet port I, c) a fixed trigger position outside the disc, and d) a controller which is capable of triggering the dispensation of a droplet into (TA0I) as a function of the triggering mark passing the trigger position; ii) placing the disc in the spinner and programming the controller with values for dispensing parameters that will give dispensation of the droplets to TA0I; iii) dispensing the droplets. The invention also comprises the dispenser arrangement as such.

Owner:GYROS

Cleaning tool sheet and cleaning tool

ActiveUS7870635B2Increase in sizeEfficient use ofBoard cleaning devicesLiquid surface applicatorsFiber bundleEngineering

The present invention relates to a cleaning tool sheet and a cleaning tool capable of use for wiping cleaning by contacting the surface of objects to be cleaned in various locations. In a cleaning tool sheet (1), fiber bundles (3) are laminated on one side face of a base sheet (2); the central parts in the direction of flow of the fibers constituting the fiber bundles (3) are joined by a central joining part (4) continuously formed in the central part of the base sheet (2) and joined at a spot-form joining part (7) formed intermittently on a parallel line between the central joining part (4) and two end edges (2a, 2b) parallel therewith. The two ends (31a, 31b) in the direction of flow of the fibers of the fiber bundles (3) are not joined to the base sheet (2). An attaching part (8) for attaching onto a holding member is provided at both ends of the base sheet (2).

Owner:SELF SETTLED TRUST OF YAMADA KIKUO YAMADA KIKUO SETTLOR & TRUSTEE

Multipurpose cleaning apparatus

InactiveUS7496985B1Easy to pasteSufficiently durableBoard cleaning devicesLiquid surface applicatorsMechanical engineeringEngineering

The present invention is a multipurpose cleaning apparatus for cleaning a variety of surfaces which includes an apparatus for removably retaining a reusable cleaning swifter, an apparatus for removably retaining a disposable cleaning cloth, an apparatus for removably retaining a brush and an apparatus for removably retaining a scouring pad. The apparatus comprises a base having two hingeably attached sections which can be rotated to form a angle so that the swifter can be attached, rotated to form a rigid elongated structure to retain the disposable cleaning cloth through locking clasp assemblies, and configured to receive members which retain gripping members to removably retain a cleaning brush and a scouring pad.

Owner:WORLDWIDE INTEGRATED RESOURCES

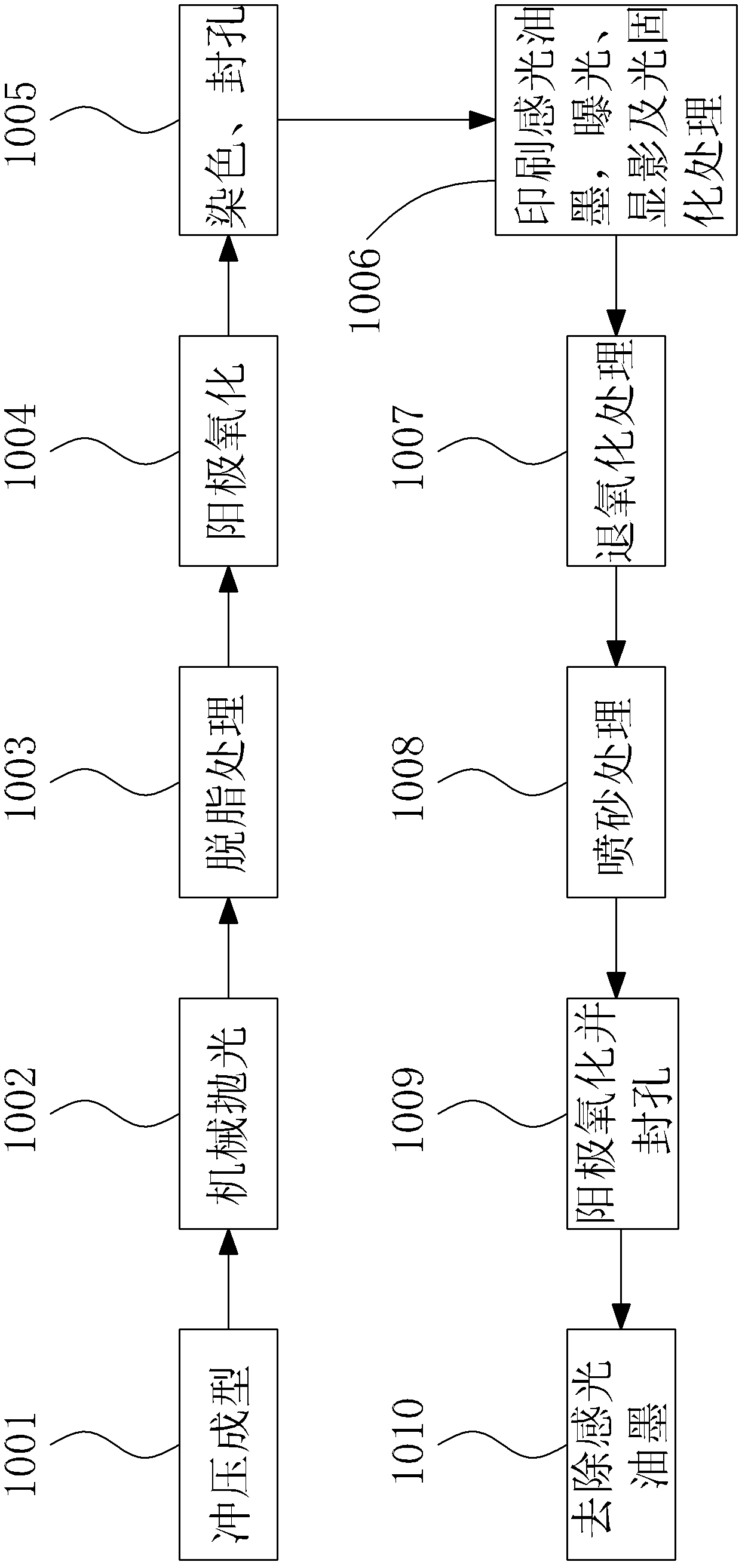

Method for surface treatment of aluminium alloy and product of aluminium alloy

ActiveCN103253072AImprove reflectivityImprove sandblasting resistanceAnodisationDuplicating/marking methodsScreen printingMetallurgy

The invention discloses a method for surface treatment of an aluminium alloy and a product of the aluminium alloy. The method comprises the steps of punching the aluminium alloy into a required shape; conducting mechanical polishing on the aluminium alloy which is subjected to punch forming; conducting degreasing treatment on the aluminium alloy which is subjected to mechanical polishing in a degreasing agent; placing the aluminium alloy which is subjected to degreasing treatment into an acid liquor tank for first-time anodic oxidation; placing the aluminium alloy which is subjected to first-time anodic oxidation into dye for dying, and conducting hole sealing treatment after dying; conducting screen printing on the surface of the aluminium alloy which is subjected to dying and hole sealing treatment with photosensitive ink, and conducting exposure, developing and photocuring treatment; conducting oxidation film removing treatment on the printed aluminium alloy in an alkaline solution; conducting sand blasting treatment on the treated product of the aluminium alloy; conducting second-time anodic oxidation on the product of the aluminium alloy, which is subjected to sand blasting treatment, and conducting hole sealing treatment on the product which is subjected to second-time anodic oxidation; and removing the photosensitive ink from the surface of the product of the aluminium alloy. The product of the aluminium alloy is processed by the method.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

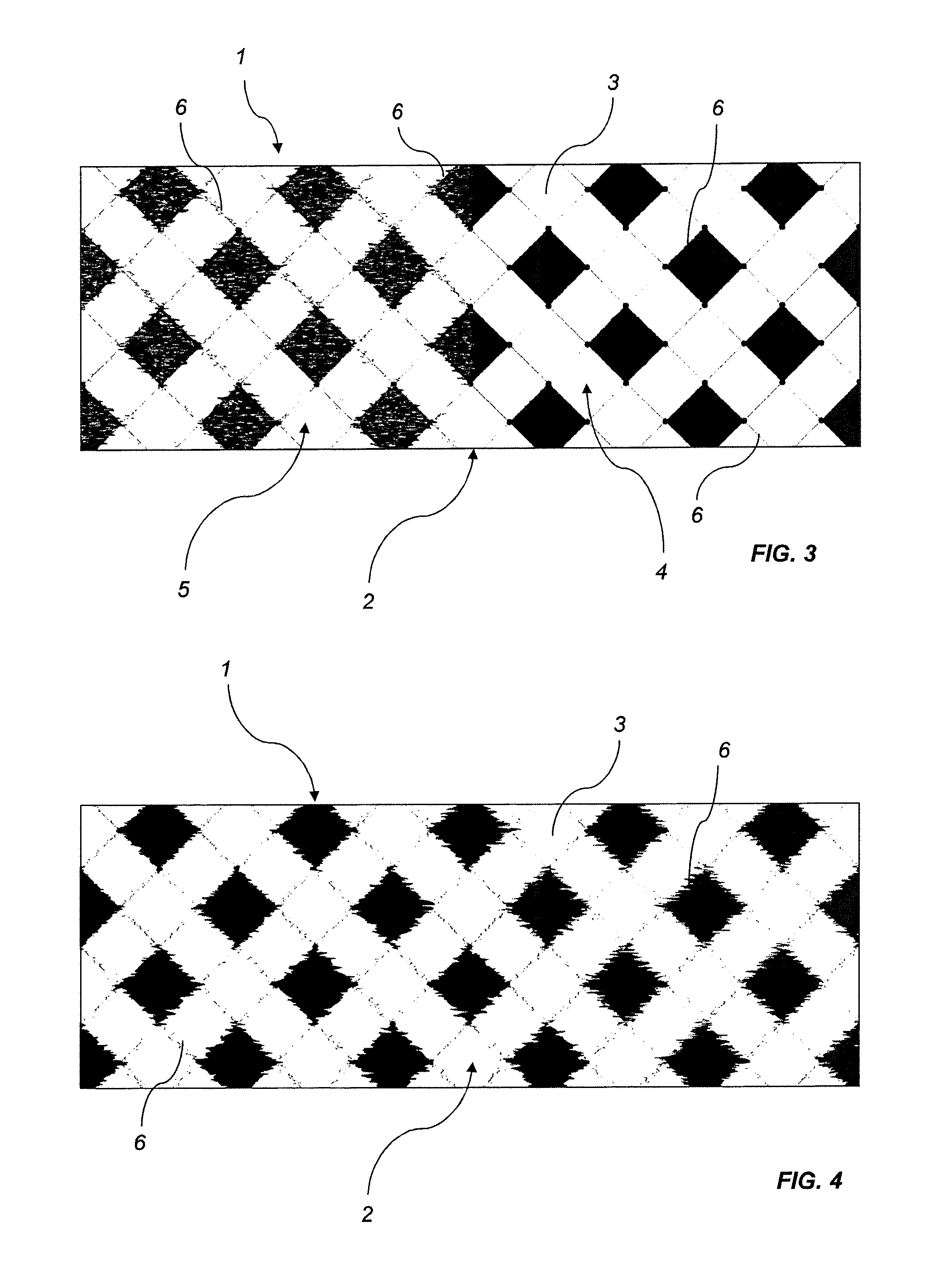

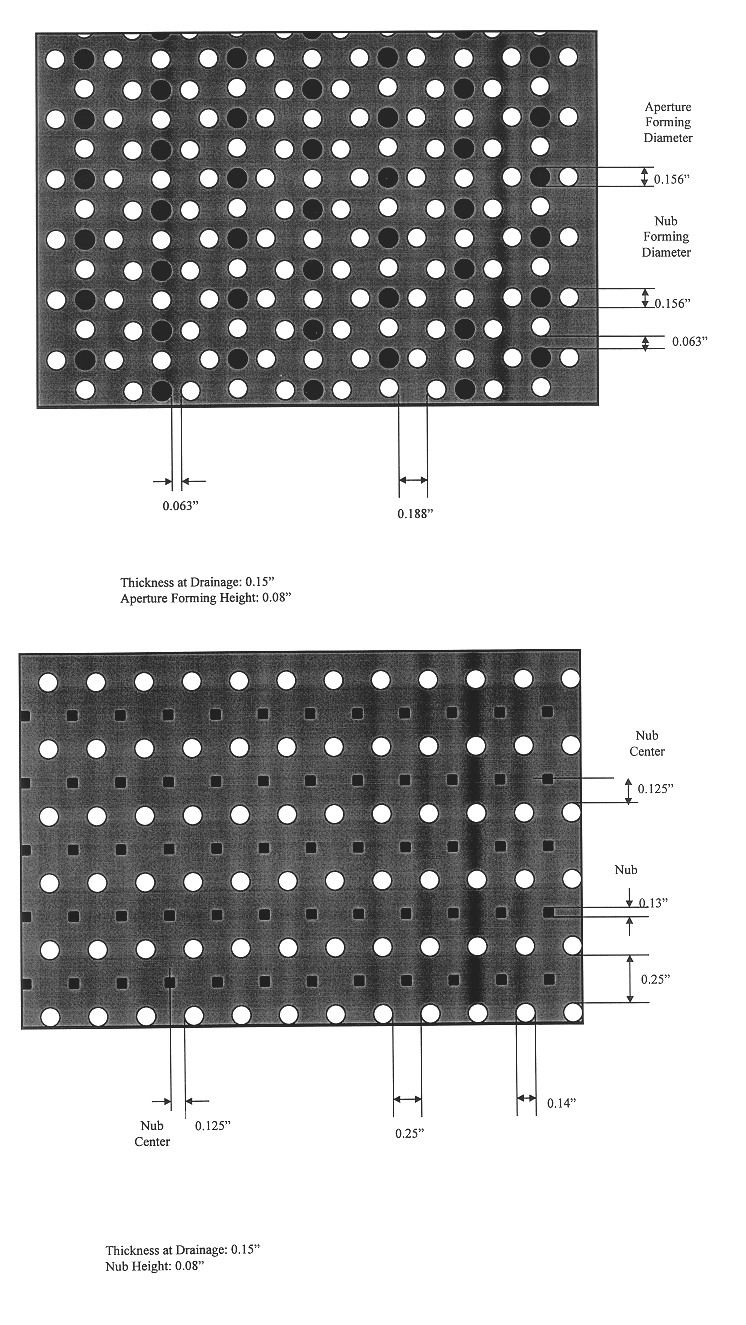

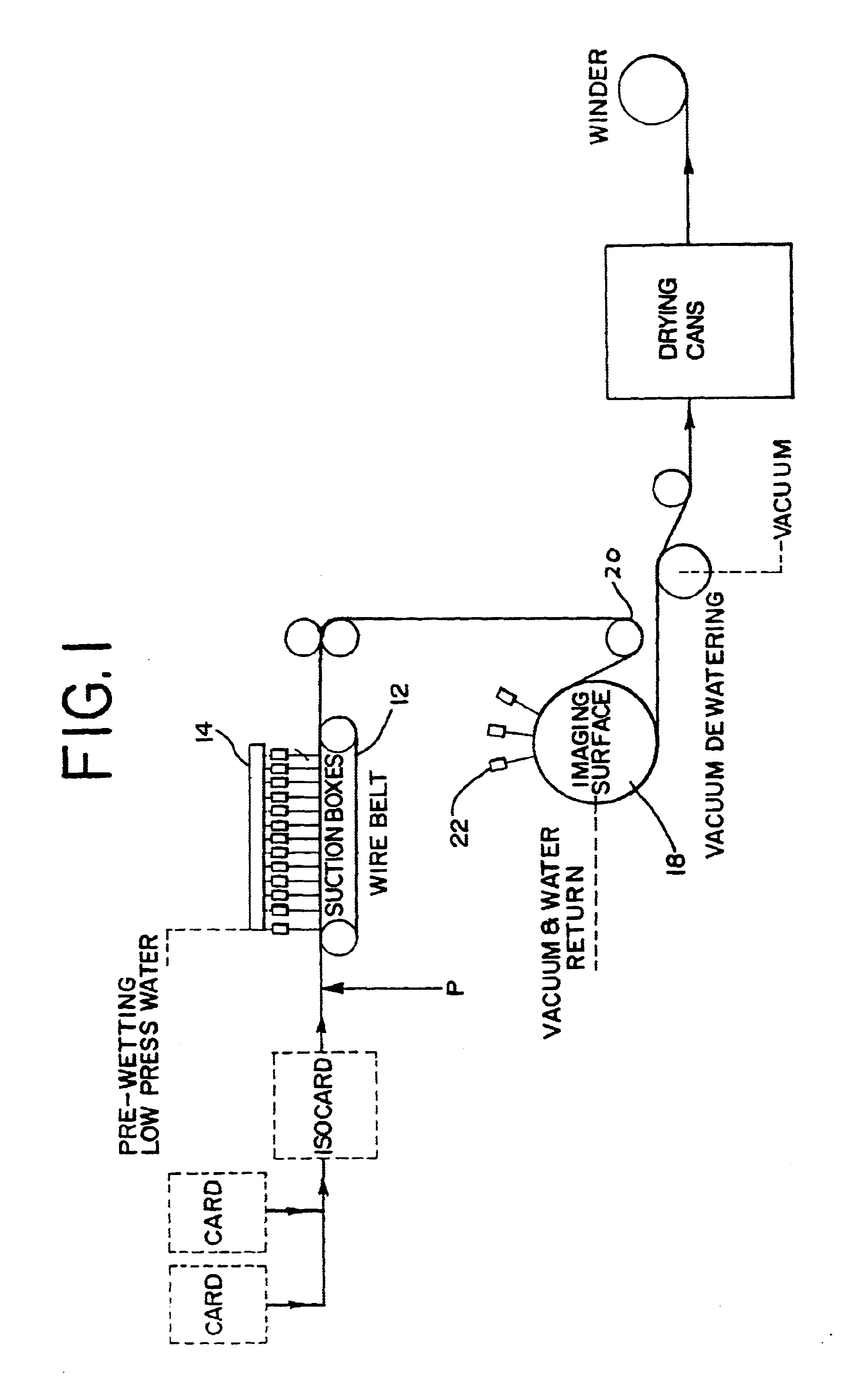

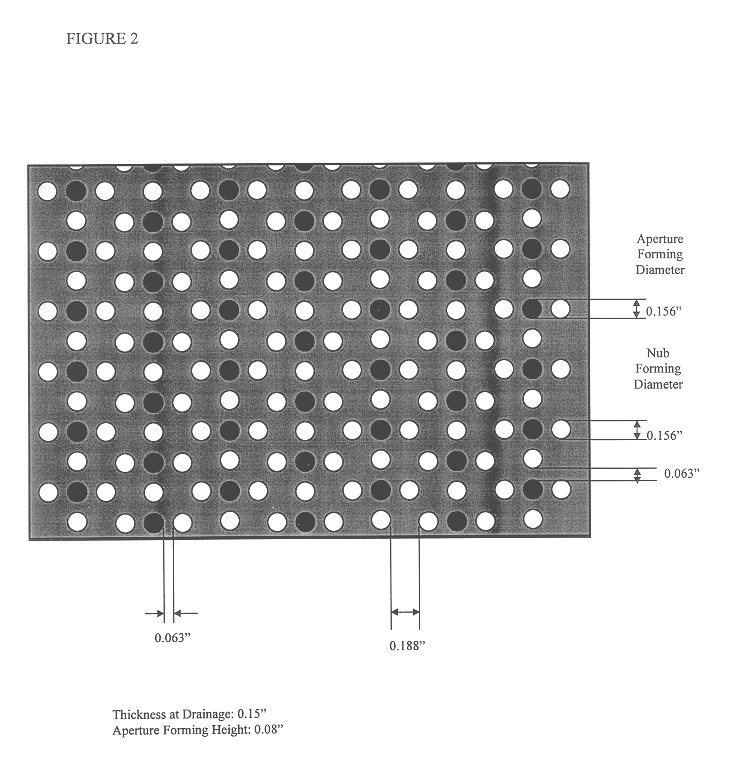

Imaged nonwoven fabric for imparting an improved aesthetic texture to surfaces

The present invention is directed to enhancing the aesthetic appearance of surfaces by the contact application of a nonwoven fabric having a three-dimensional image imparted therein. The three-dimensional image of the nonwoven fabric induces a topical modification in either the actual or perceived texture of a surface when the imaged nonwoven fabric is applied to, then removed from, the surface. The imaged nonwoven fabric disclosed herein exhibits low linting qualities thereby reducing the potential of fiber contamination of the treated surface and is sufficiently durable that the sample can be used and rinsed clean a plurality of times, markedly increasing the working life-span.

Owner:POLYMER GROUP INC

Paint spraying device

InactiveUS6010084AQuick changeEasy to changeLiquid spraying plantsMovable spraying apparatusCoated surfaceSolvent

PCT No. PCT / JP97 / 02446 Sec. 371 Date Mar. 18, 1998 Sec. 102(e) Date Mar. 18, 1998 PCT Filed Jul. 15, 1997 PCT Pub. No. WO98 / 03268 PCT Pub. Date Jan. 29, 1998A paint spraying apparatus on which a number of paint applicator units of different types can be selectively and replaceably mounted depending upon conditions of a paint coating operation required. A color changing valve assembly is provided in a valve casing which serves as a common base assembly for a number of paint applicator units to be chosen from, including rotary atomizing head type electrostatic paint applicator units and spray gun type electrostatic paint applicator units. Accordingly, depending upon conditions of coating operation, such as shape of a coating surface, nature of paint, properties of solvent etc., a suitable paint applicator unit, selected from the paint applicator units, can be easily and replaceably mounted in position on the valve casing. The color changing valve assembly which is provided within the valve casing can be shared as a common mount base by a plural number of paint applicator units of different types.

Owner:ABB IND

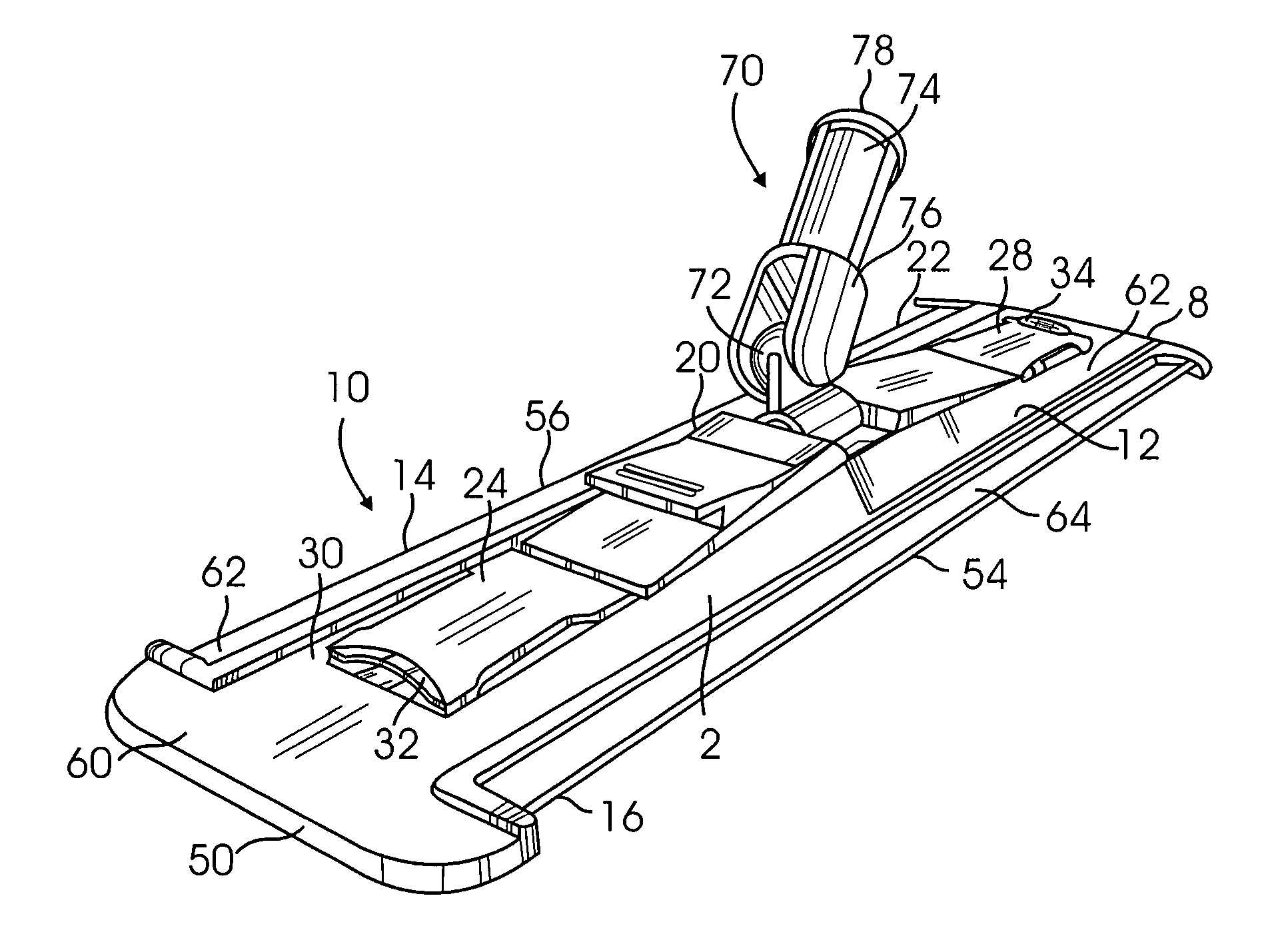

Dual-mode contour-following mop

InactiveUS20080040876A1Easy to disassembleReduce manufacturing costLiquid surface applicatorsLiquid processingDual modeContour following

Owner:AIYAR SANJAY

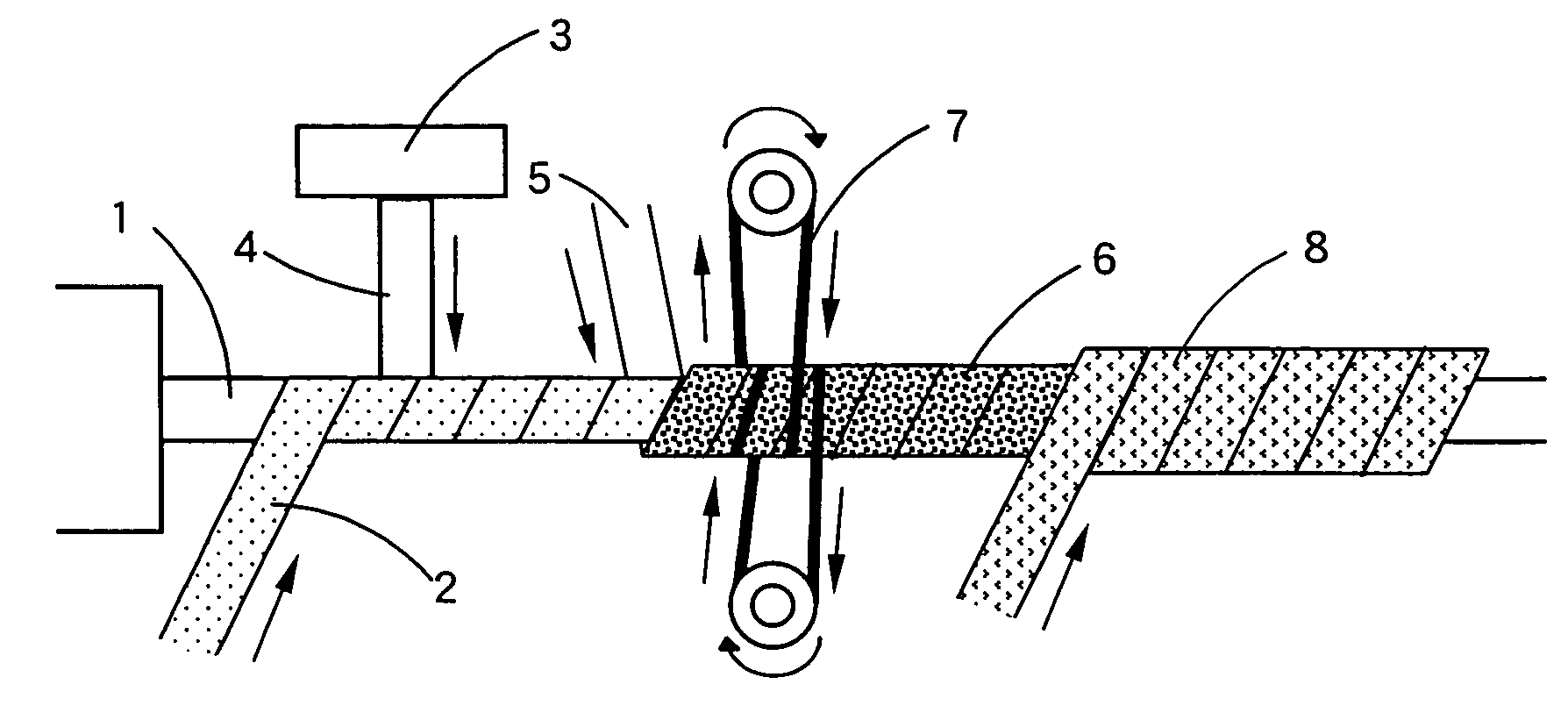

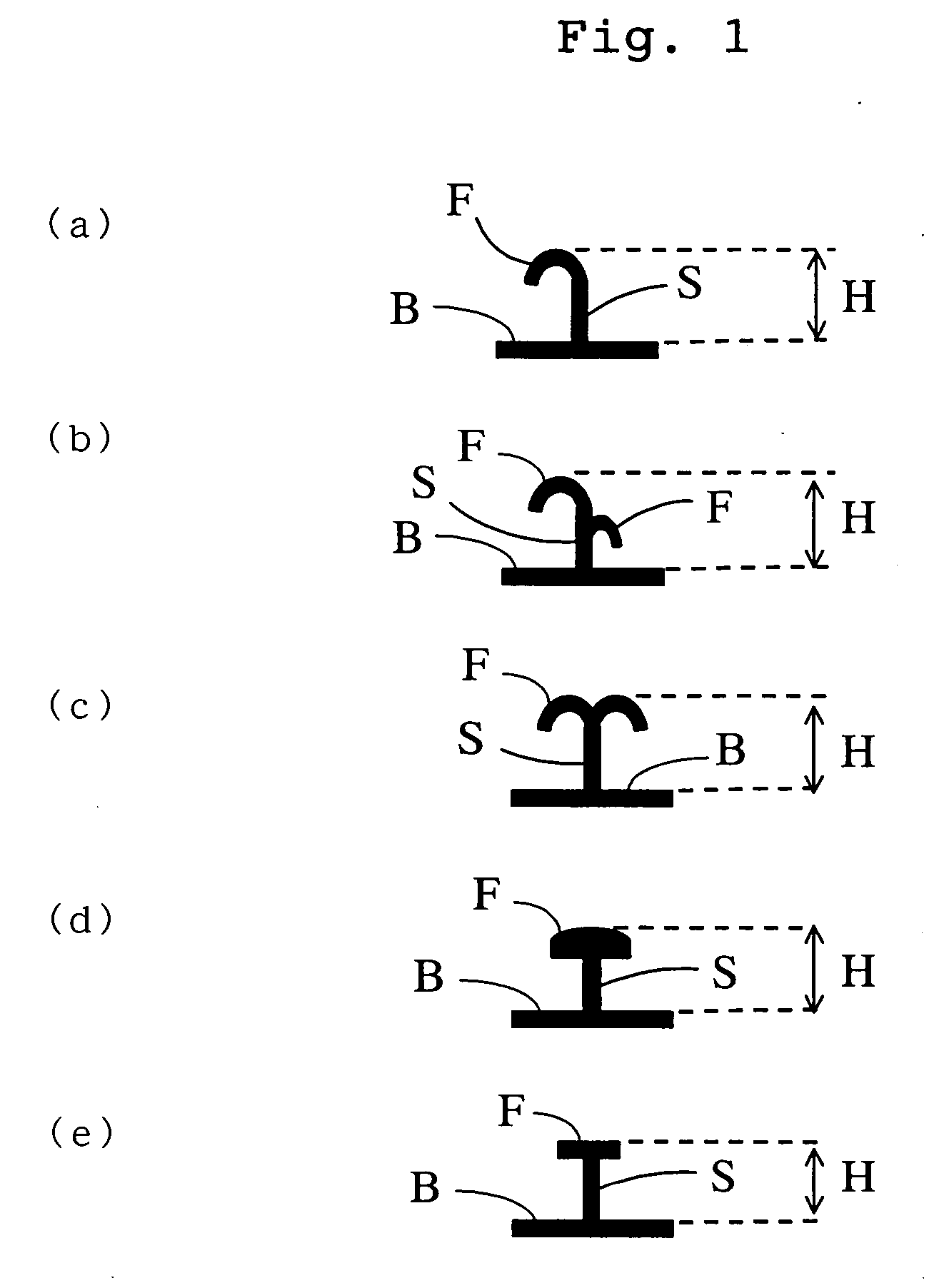

Paint roller

InactiveUS20070056132A1Easy to disassembleExchanged conveniently and efficientlyLiquid surface applicatorsBrush bodiesFemale structureEngineering

A paint roller comprises a liquid-impermeable tubular core member 6 with an engaging element 9 having a male structure of a separable fastener and a height of 0.3 to 4.0 mm on a surface thereof, and a cover member 8 with a female structure and a loop on the inner surface capable of male-female engaging with the engaging element on the surface of the core member. The density of the engaging element on the surface of the core member is 30 to 150 / cm2. Thus, in such paint roller, when the cover member becomes dirty, damaged, or worn, the cover member can be exchanged to a new cover member. Such that, a roller body is repeatedly usable, and the paint roller can provide a good painted surface. Moreover, there is also provided an effect roller in which a painting pattern can be changed optionally.

Owner:KURARAY CO LTD +1

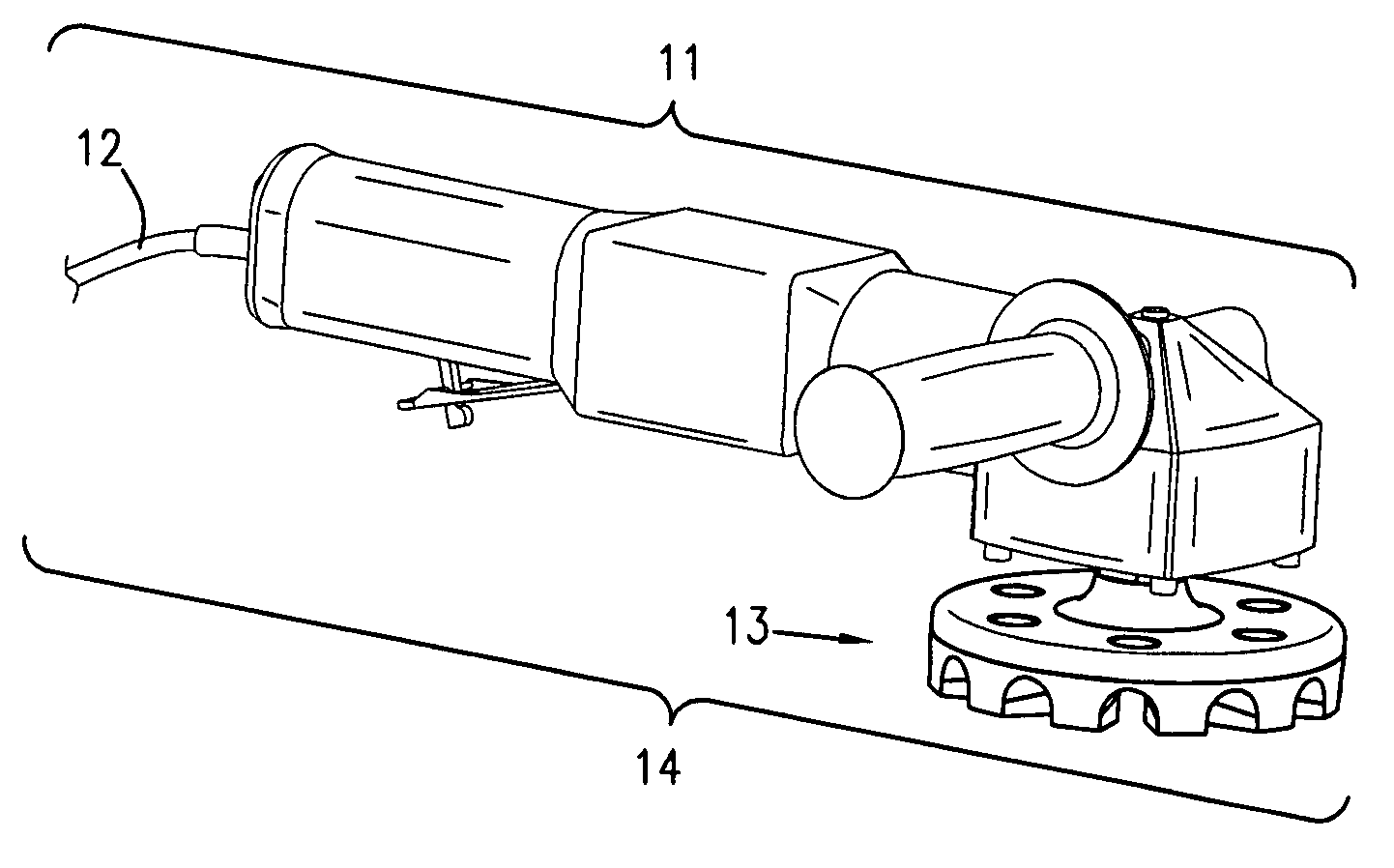

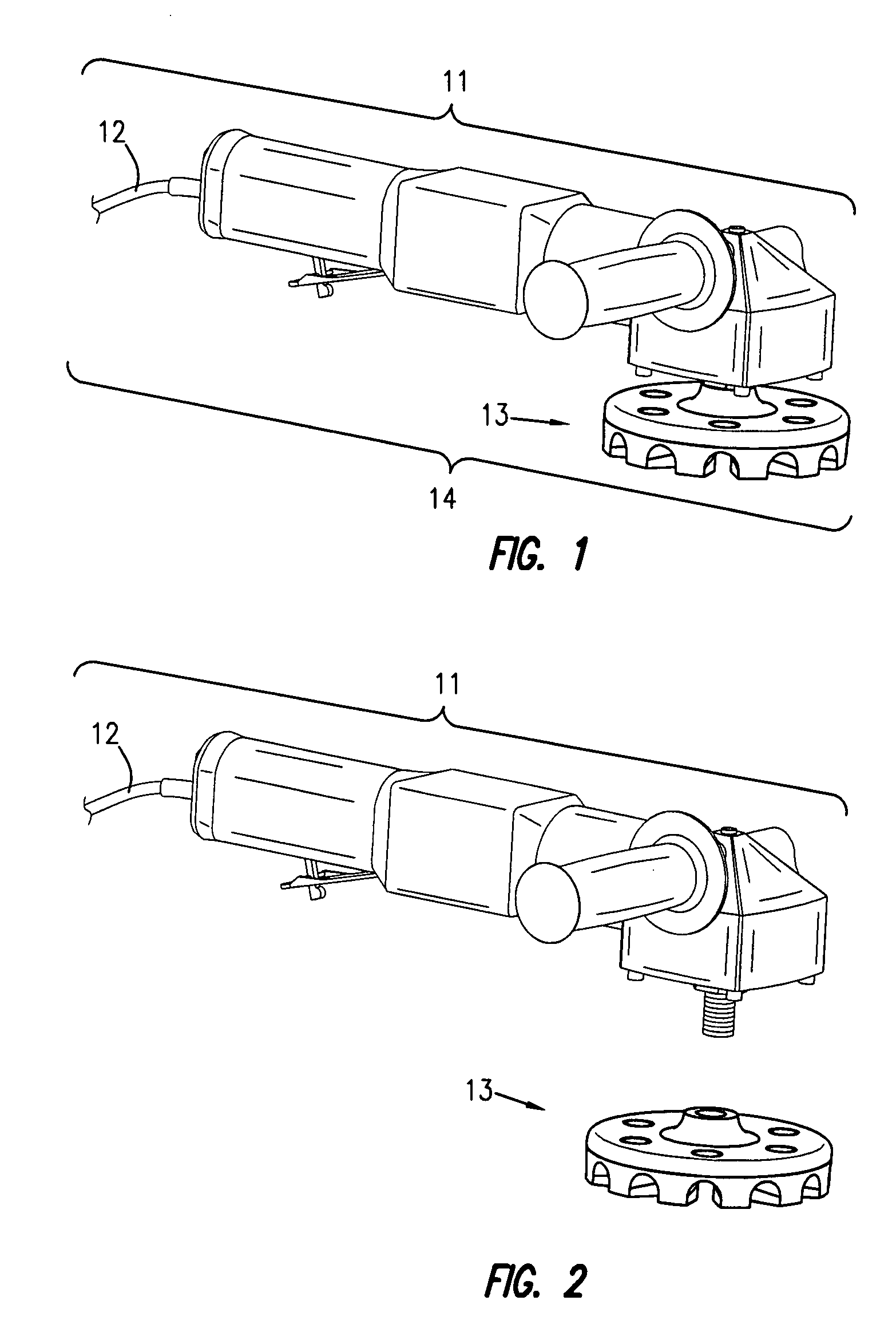

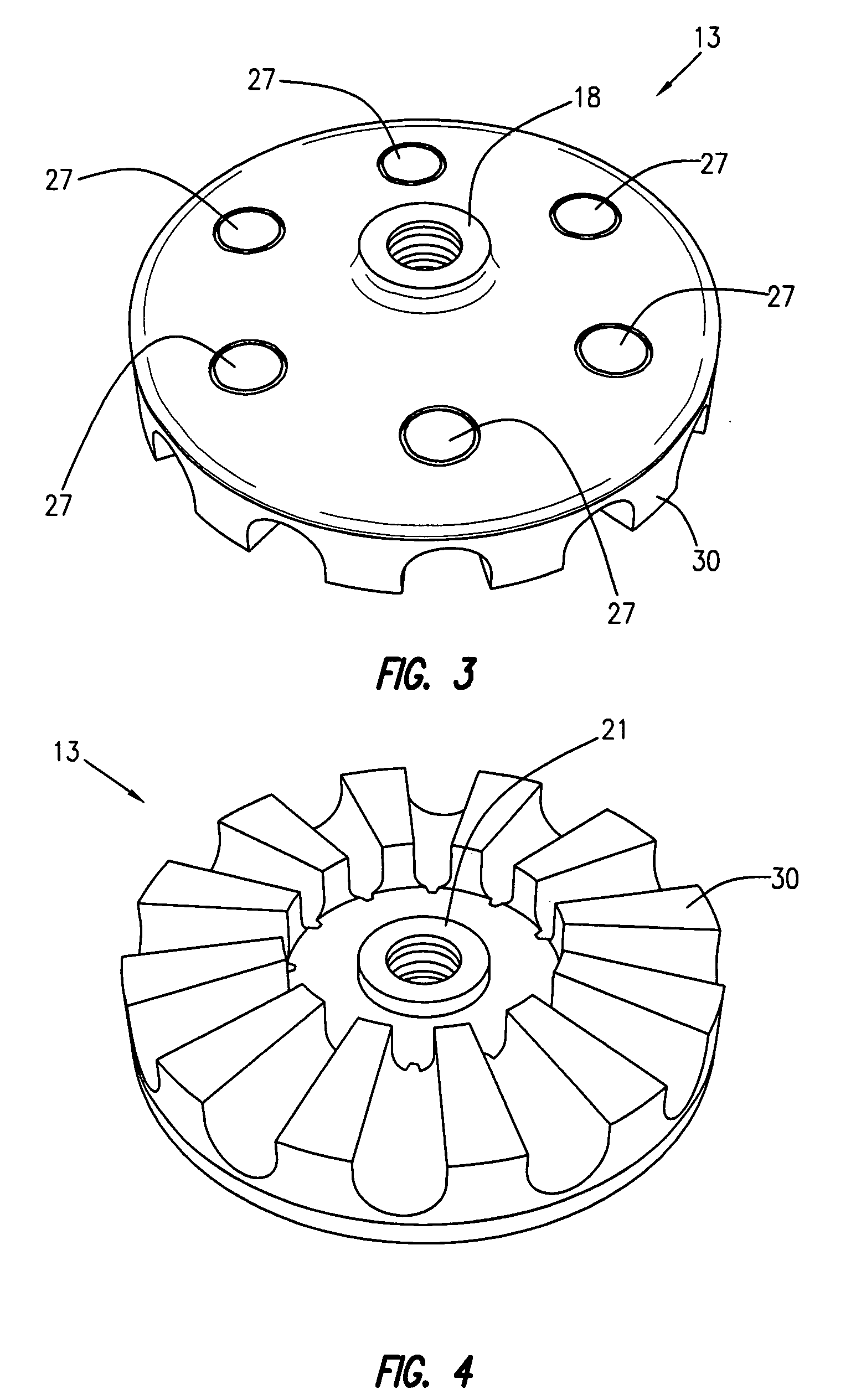

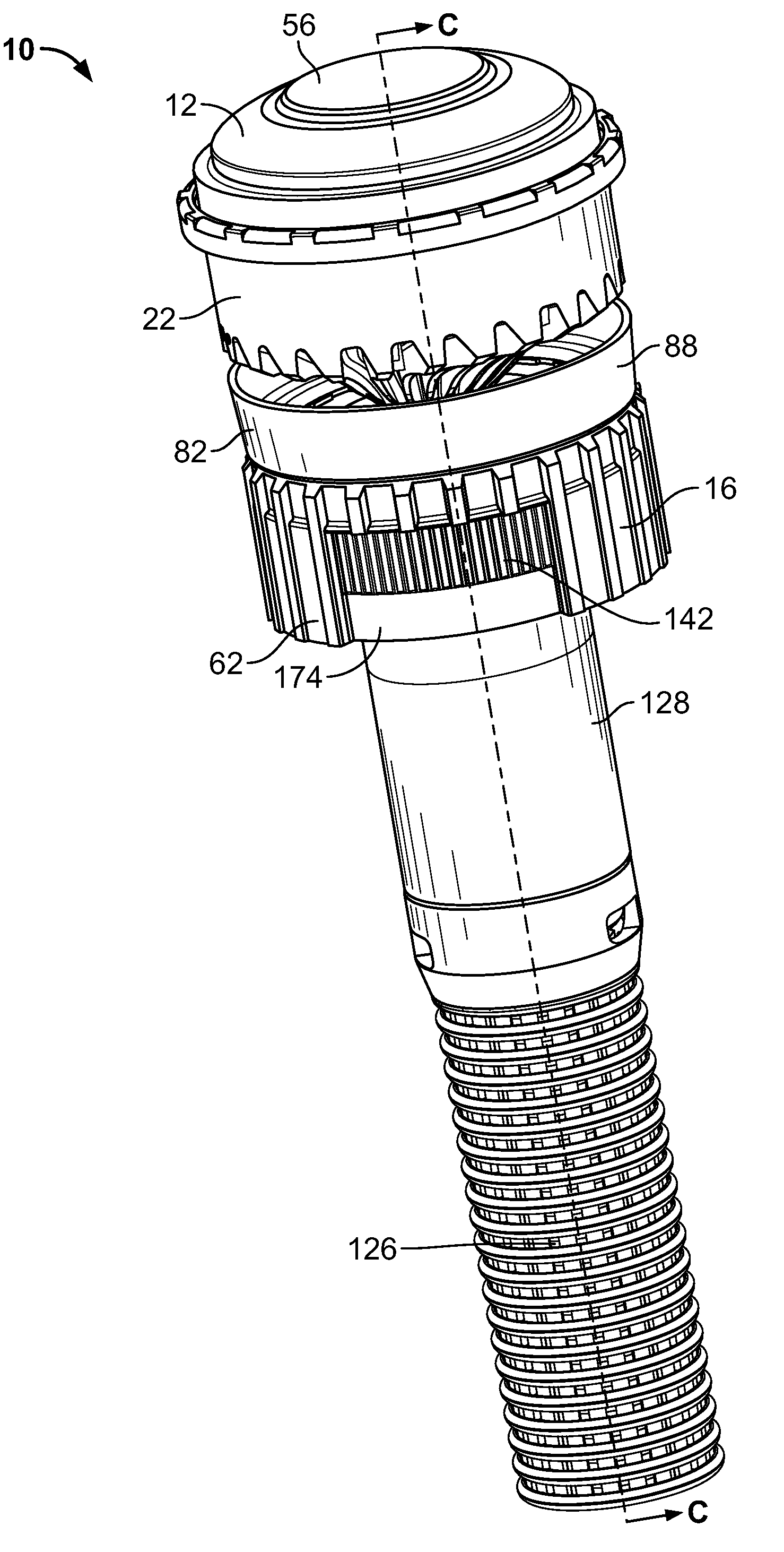

Eraser assembly for a rotary tool

InactiveUS20090083916A1Quick and convenient reinstallationEasy to disassembleErasing devicesLiquid surface applicatorsHand heldInk eraser

A two piece eraser assembly for use as a rotary tool attachment for abrading surfaces enables quick and easy replacement of worn eraser disks without requiring the assistance of any hand held tools in either the removal or in the reinstallation process. The assembly, including aftermarket replacement parts therefor, comprise an eraser disk and an eraser hub for mounting and holding the eraser disk. The eraser hub includes upper and lower surfaces, wherein the eraser hub upper surface features a centrally positioned throughbore, a flange at the peripheral edge of the hub and a stub shaft on the lower surface positioned axially with the throughbore. The eraser hub includes a plurality of spaced apertures for engaging with and detachably locking eraser disk extensions on the backside, so the eraser disk is mounted flush with the eraser hub. The upper surface of the eraser disk includes a central recess and an aperture in the recess keyed for axially alignment with the throughbore of the eraser hub. The eraser disk is also equipped with a plurality of abrading teeth running radially from the central recess to the peripheral edge thereof. The lower surface opposite the upper surface of the eraser disk further comprises a plurality of mounting elevations keyed for engaging with the spaced apertures or slots in the eraser hub for securely locking the eraser disk to the eraser hub, avoiding slippage of the eraser disk during operation, while allowing quick replacement when worn with manual dexterity only.

Owner:DYNABRADE

Sprinkler with variable arc and flow rate

A variable arc sprinkler may be set to numerous positions along a continuum to adjust the arcuate span of the sprinkler. The sprinkler includes a nozzle body and a valve sleeve that helically engage each other to define an arcuate slot that may be adjusted at the top of the sprinkler to a desired arcuate span. The sprinkler may include a flow rate adjustment device that may be adjusted by actuation or rotation of an outer wall portion of the sprinkler. Rotation of the outer wall portion may cause a throttle control member to move axially to or away from an inlet, or may cause one or more restrictor elements to open or close, to control the flow rate of the sprinkler.

Owner:RAIN BIRD CORP

Wooden wares surface archaizing treatment technology

InactiveCN1730255AEasy to produceVariety of colorsWood treatment detailsPretreated surfacesLacquerDiluent

The invention relates technology of surface treatment of wooden wares, comprising the following steps: drying the wood and blanking according to the requirement, processing and charring; brushing or spraying the archaized color priming paint which is compounded by diluent and mixture of yellow paint, red paint, black paint, and white paint in proper proportion, after drying, repairing the surface of the wood, then spraying the priming paint repeatedly twice or thrice, making it dry naturally; sanding the said wooden wares by fineness abrasive cloth, taking out the paint around 20%; spraying the press polish archaized paint to the surface of the wooden wares. The invention processes simple technology, good effect of imitation antique, convenience production, economy and utility.

Owner:DAKANG HLDG GROUP

Preparation method for multicolor oxide film

InactiveCN101619477APerformance impactAccelerated corrosionAnodisationArtistic surface treatmentWear resistanceCarving

The invention relates to a preparation method for multicolor oxide film, comprising that an anode oxide film forming step is repeatedly carried out. The anode oxide film forming step comprises: oxidizing color anode, and forming a protective layer and laser carving on a color anode oxide film. The color anode oxidation comprises anode oxidation, dyeing and hole sealing are carried out in turn on the surface of a base material so as to obtain a color anode oxide film. The protective layer is used for separating electrolyte oxidized by a color anode and a color anode oxide film formed previously. The laser carving is used for removing at least one part of color anode oxide film formed previously so as to cause the surface of parts of base material to be exposed. The integral corrosion resistance and abrasion resistance of the oxide film on the surface of the base material, which is prepared according to the method of the invention, are high, and no other macromolecule materials need to be coated, so that the texture of the oxide film is kept.

Owner:BYD CO LTD

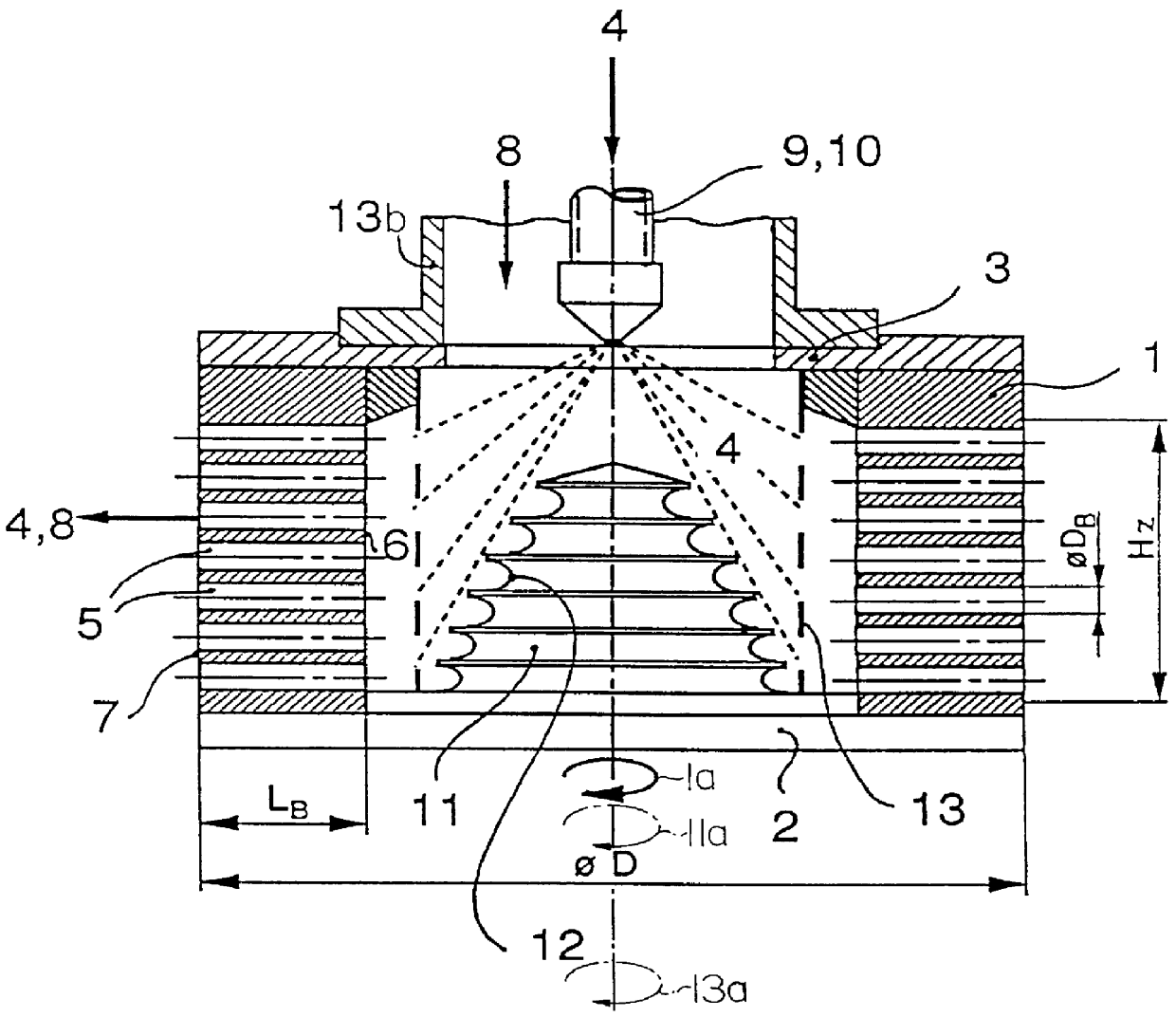

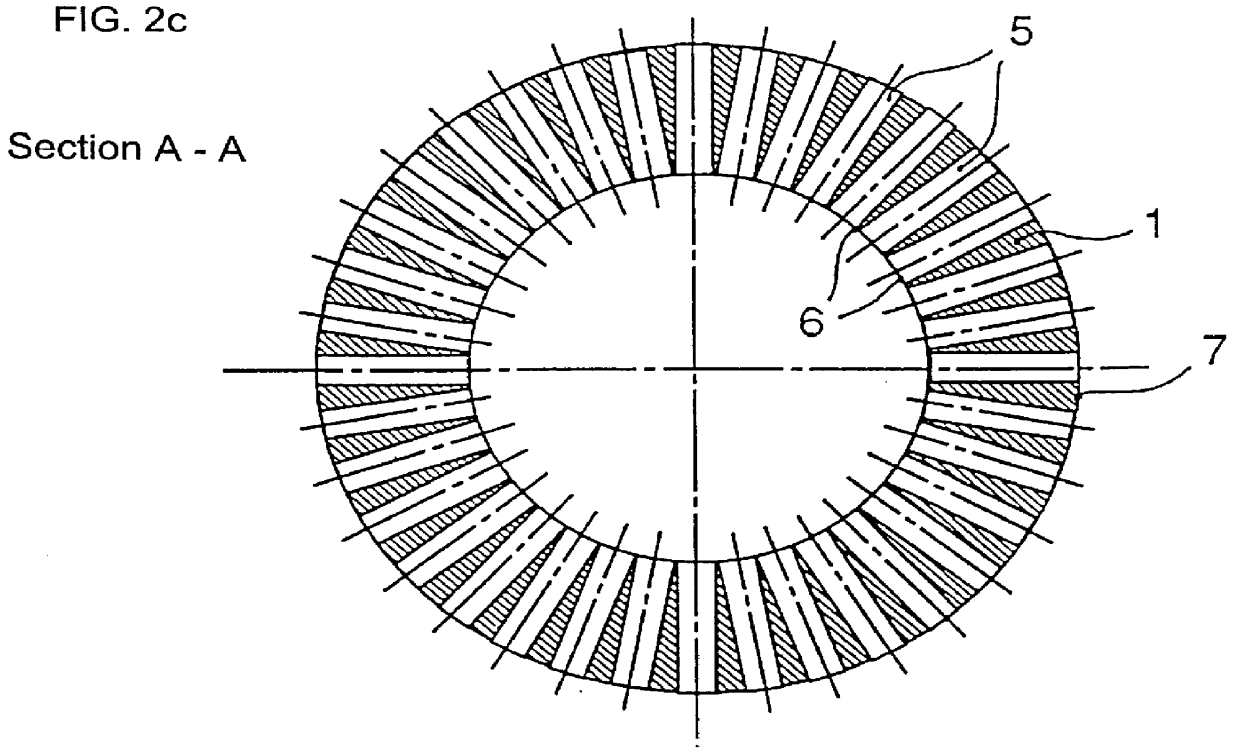

Process and a device for atomizing liquids

InactiveUS6098895ALarge caliberAvoid easy cloggingBurnersMovable spraying apparatusDecompositionEngineering

The liquid to be atomized is uniformly sprayed on the inner surface of a hollow rotating cylinder, for example by means of one- or two-fluid-nozzles and is thus distributed on bores provided in the cylinder wall. The rotation of the cylinder causes the liquid to flow outwards through the bores. Droplets are generated when the liquid flows out of the bores by laminary decomposition of the jet. The flow rate in each bore lies in the range 1.0<+E,dot V+EE B (a3 rho 5 / sigma 5)0.25<16 to prevent the droplets from becoming too large and to satisfy the condition of an adequate flow laminarity, i.e. for the value of the Reynolds number for the continuous liquid flow in the boress not to exceed Re delta 400. +E,dot V+EE B represents the flow rate of the liquid in each bore, a represents the centrifugal acceleration at the outer surface of the cylinder, rho represents the density of the liquid and delta indicates the surface tension of the liquid. The large number N>200 of bores having the diameter DB in the cylinder wall causes the flow rate of liquid through each bore to be relatively low, so that a continuous laminary flow in each bore is ensured even at low viscosities and technically useful total flow rates. Preferably cylindrical bores with a minimum length at least three times larger than the bore diameter are provided in the cylinder wall, with a narrow spacing in the range defined by 1.1<t / DB<5, so that a number of bores as large as possible may be arranged in the wall of the cylinder.

Owner:NIRO

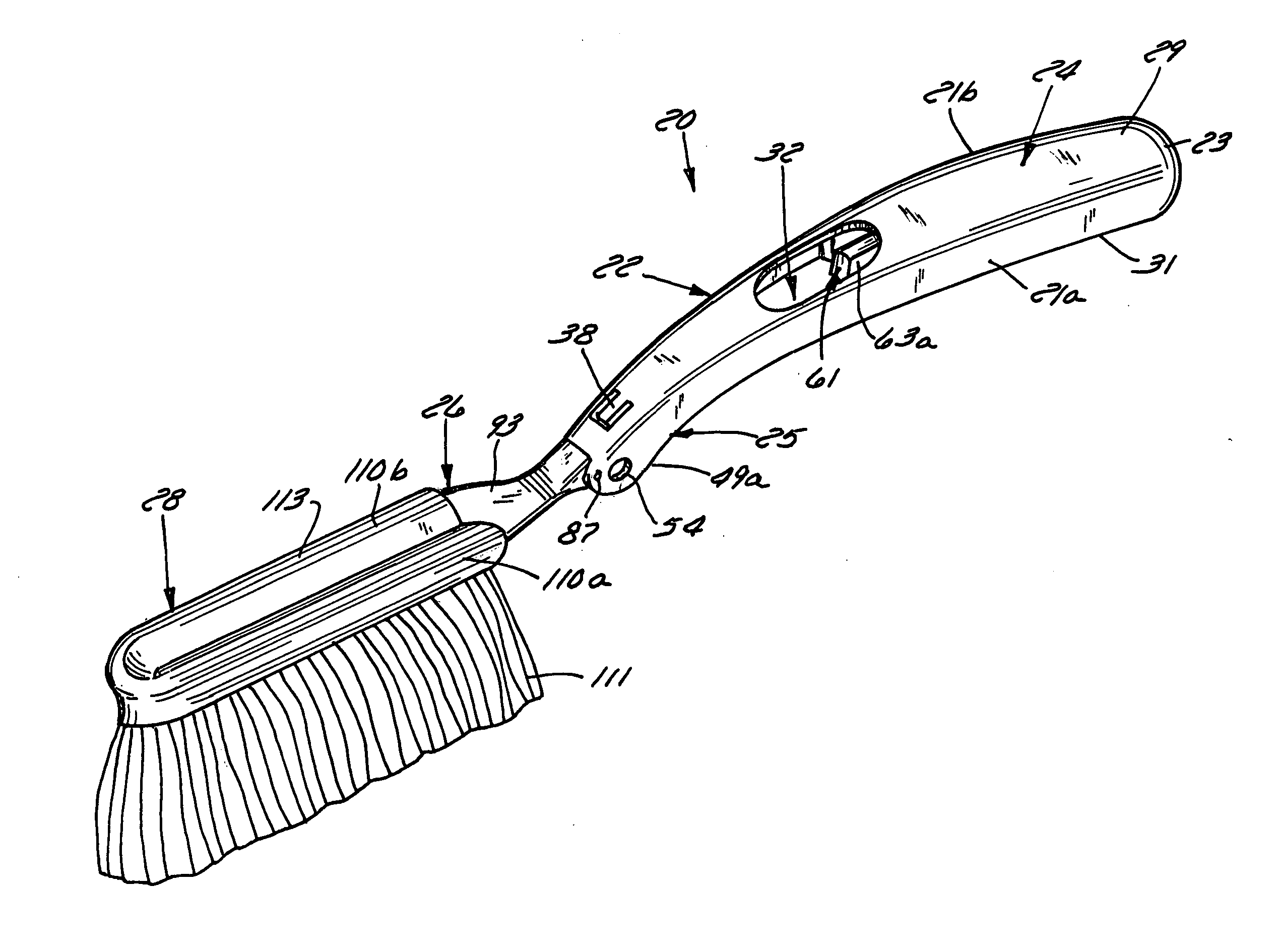

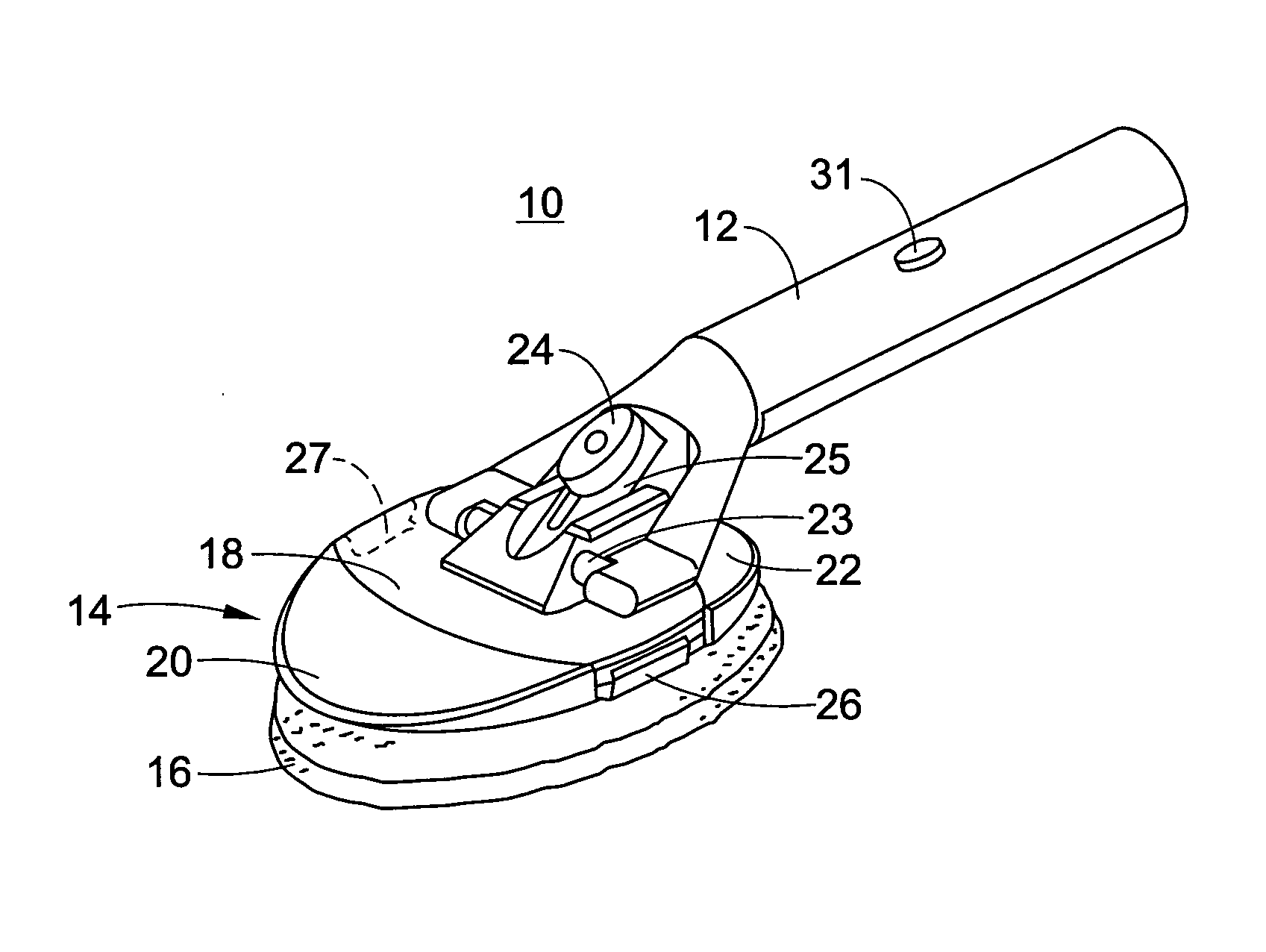

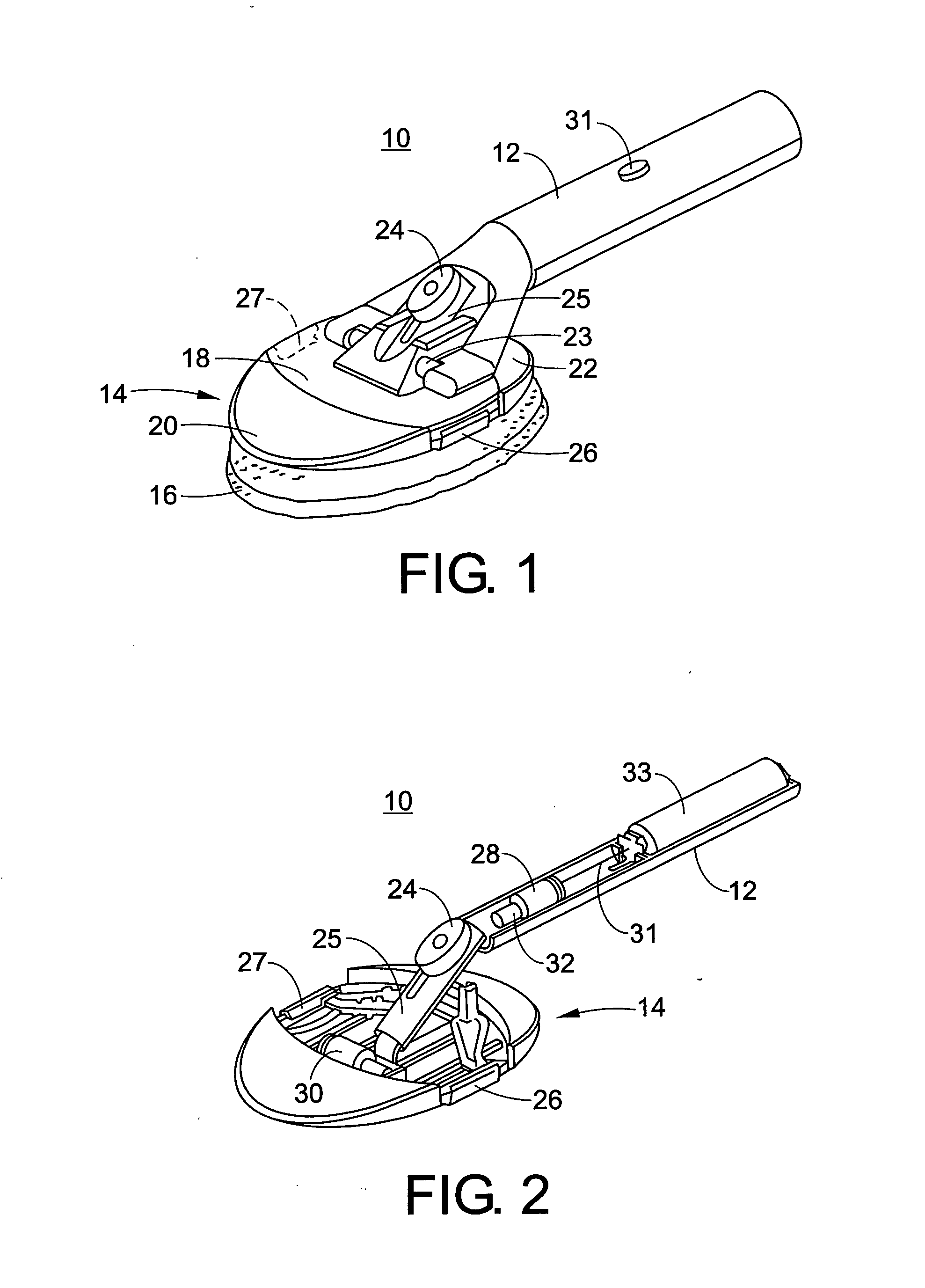

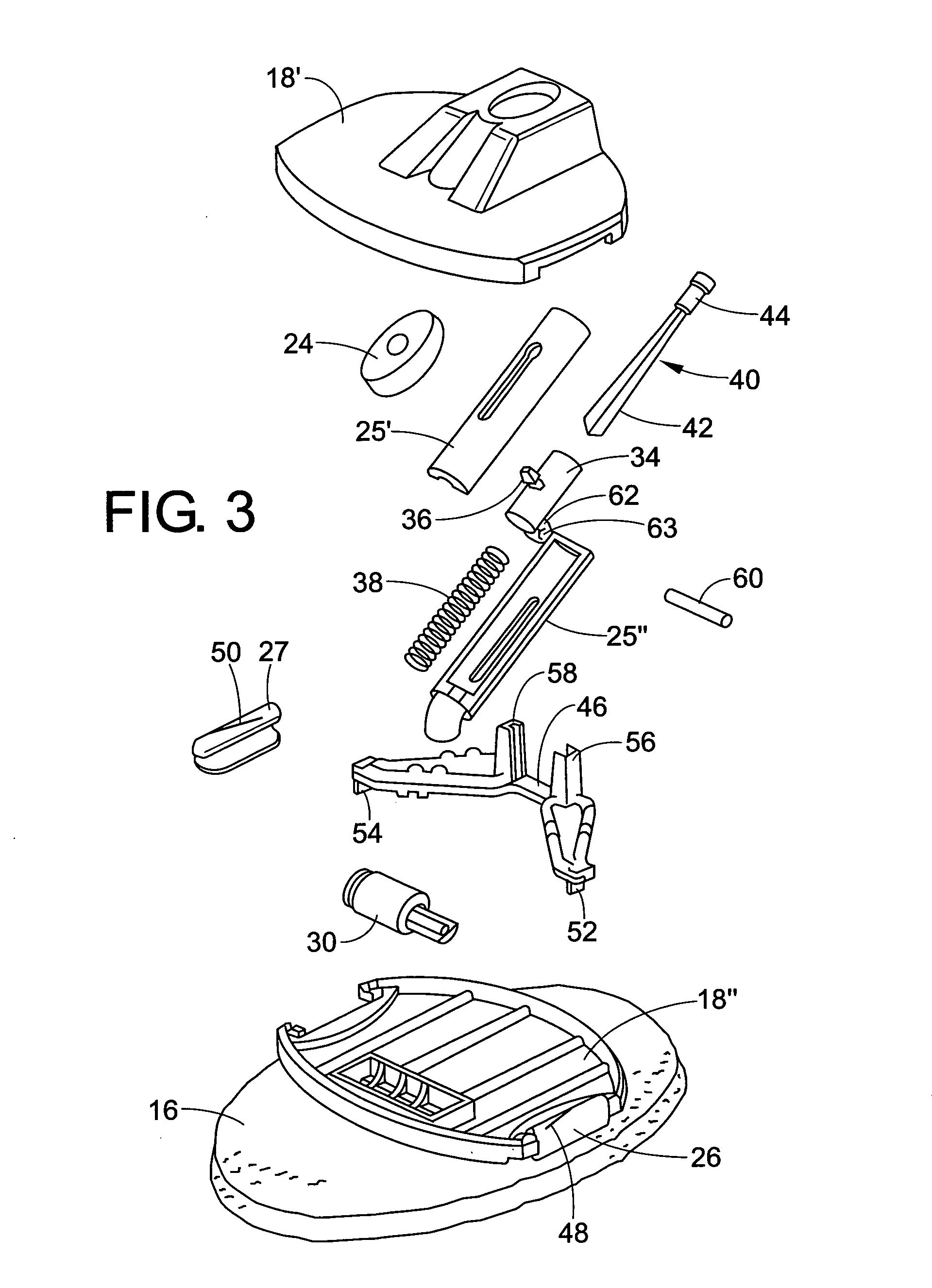

Cleansing system with disposable pads

A support tool for holding disposable pads and method of exfoliating or cleansing facial skin. The support tool includes a handle for supporting the pads during use, and a pad gripper system. A user of the cleansing system utilizes the pad gripper to either attach a disposable pad to the pad housing or to release a previously attached disposable pad. A method of exfoliating or cleansing facial skin includes attaching a disposable pad to a pad housing attached to a handle of a cleansing system by utilizing a grabbing / releasing means, moving the attached disposable pad over the facial skin with moderate pressure, and releasing the attached disposable pad from the pad housing by utilizing a grabbing / releasing means. A cleansing system package includes a cleansing device and a plurality of disposable pads.

Owner:ZUKO

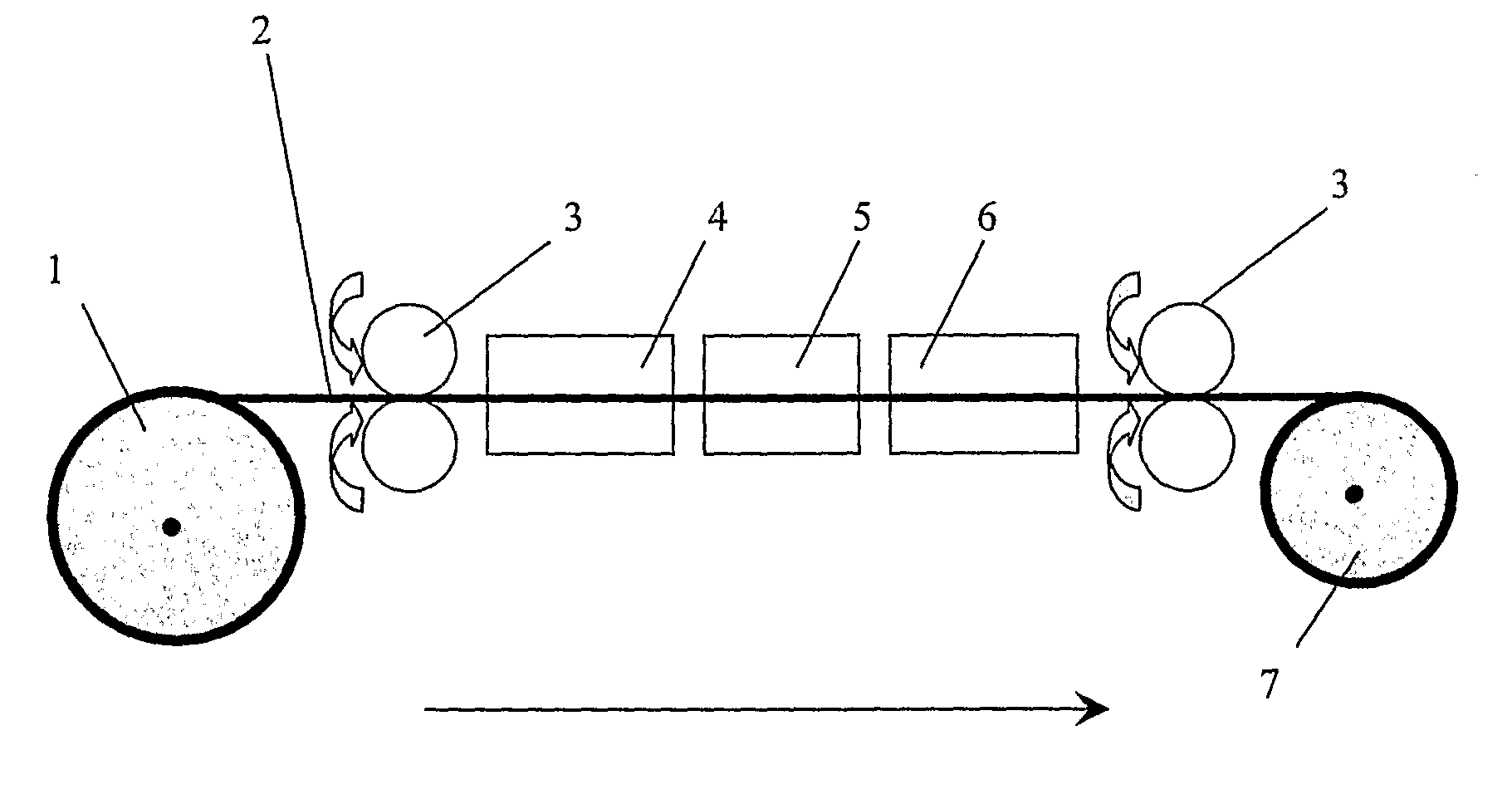

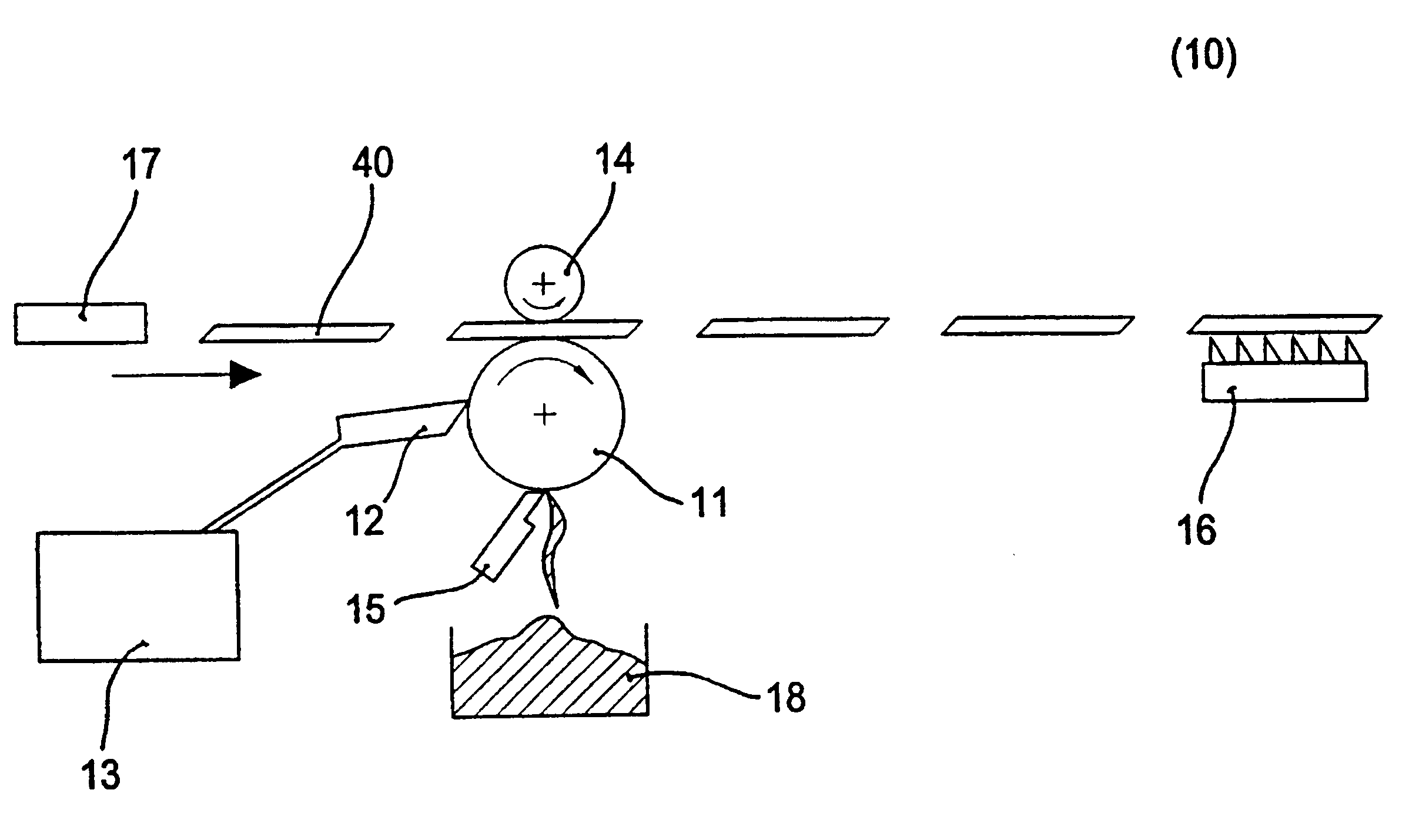

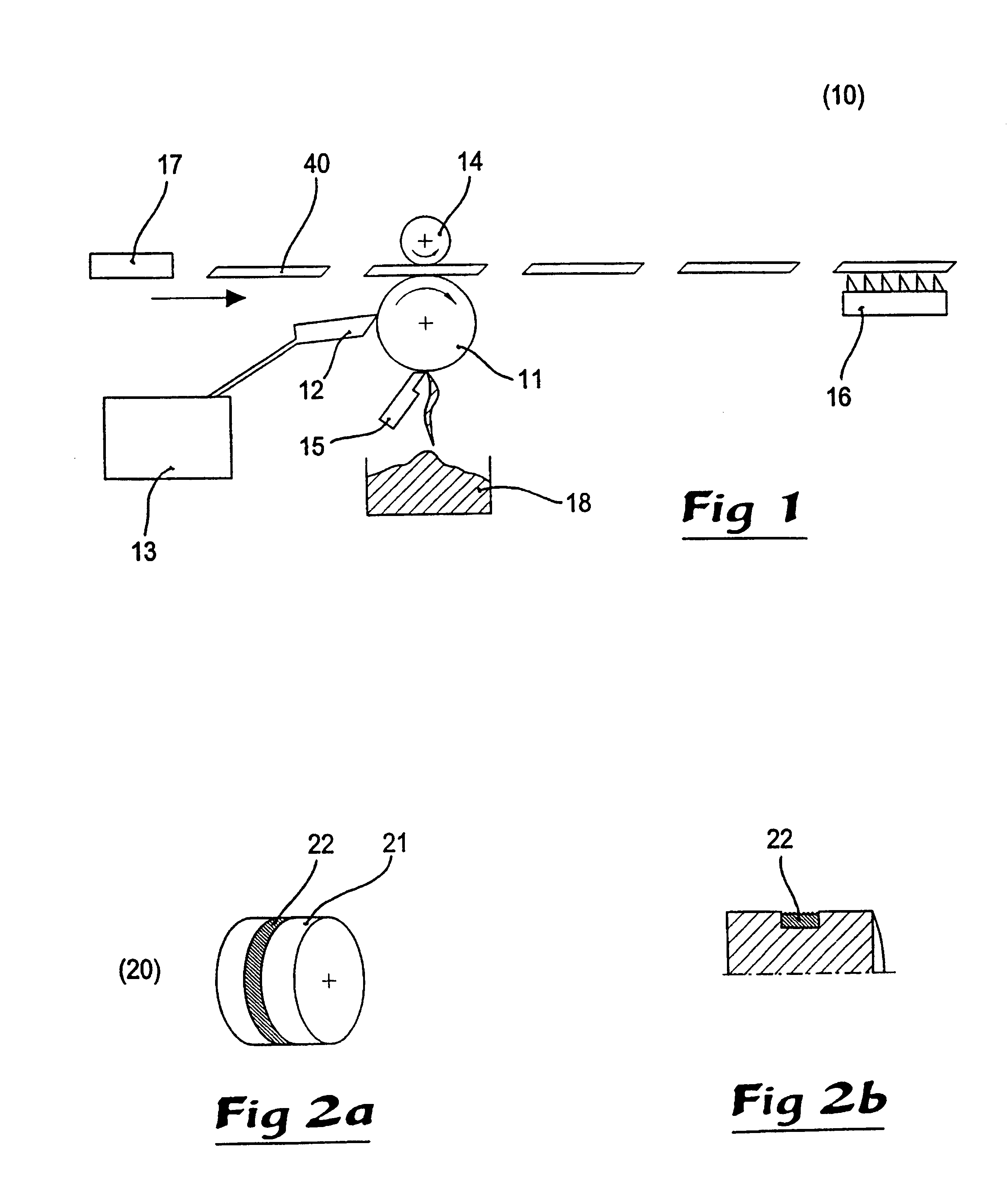

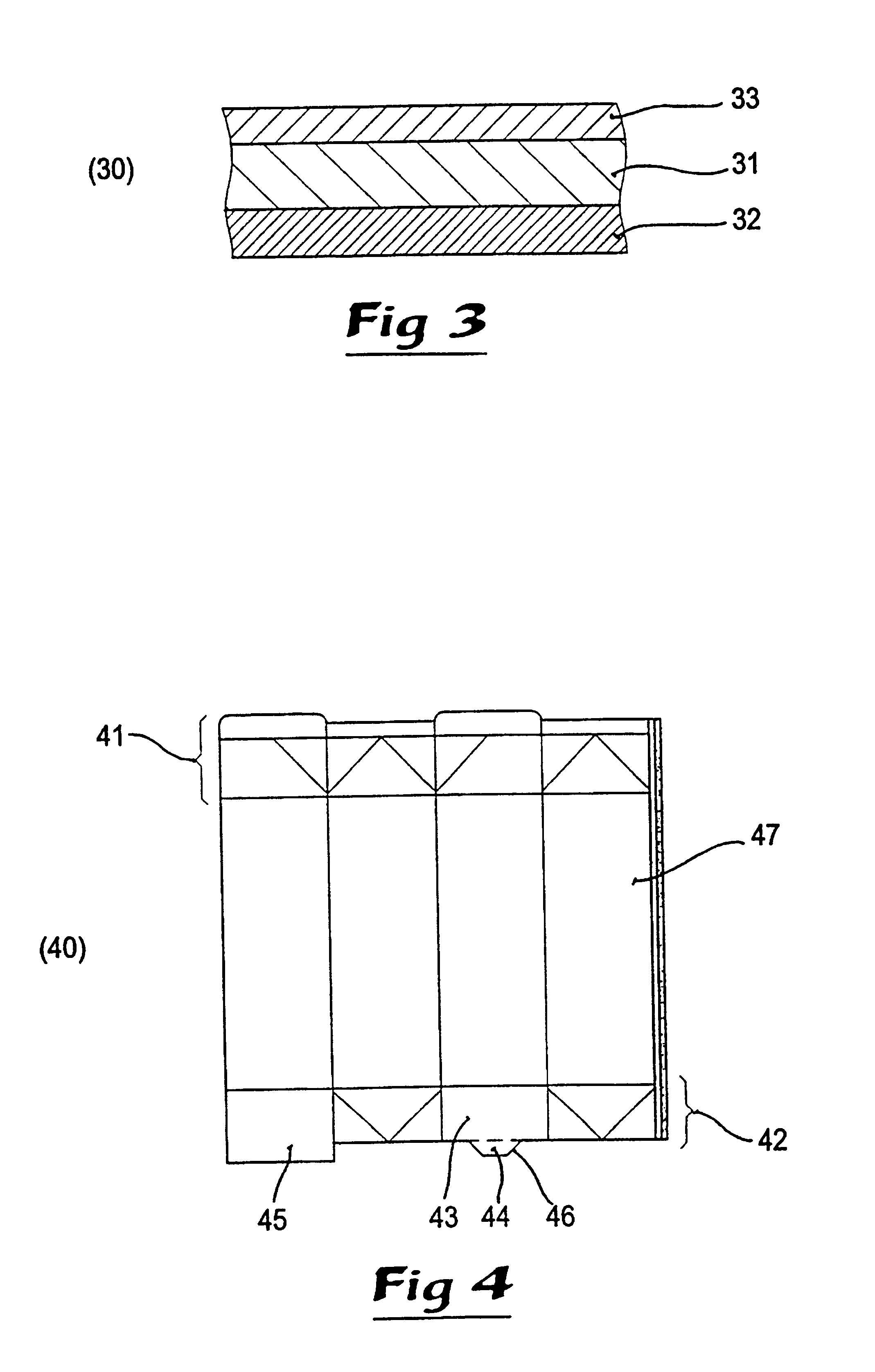

Method and an apparatus for producing packaging containers for liquid foods, as well as packaging containers

The disclosure relates to a method and an apparatus (10) for producing a packaging container for liquid foods from a packaging container blank (40) by permanently uniting and sealing at least two of its edges (61, 65) with the aid of a hot melt glue, the hot melt glue being applied along one of the two edges with the aid of a heated applicator roller (11). The circumferential surface (21) of the hot roller is preferably made of hardened steel with a coating (22) countersunk in a groove int he surface along the circumference of the circumferential surface, the coating possessing good slippage properties in relation to the hot melt glue and the coating being of a width which corresponds to the region intended for application. A counter roller (14) acts on the opposite side of the packaging laminate blank against the applicator roller for controlling the outflow of the applied hot melt glue strand. How melt glue is applied to the applicator roller by means of a heated nozzle (12) and the surplus which is not transferred to the packaging laminate blank is scrapped off from the applicator roller by means of a doctor blade (15). The hot melt glue is preferably an ethylene vinyl acetate based composition with a high melting point and high viscosity which is applied at least approx. 180° C.

Owner:TETRA LAVAL HLDG & FINANCE SA

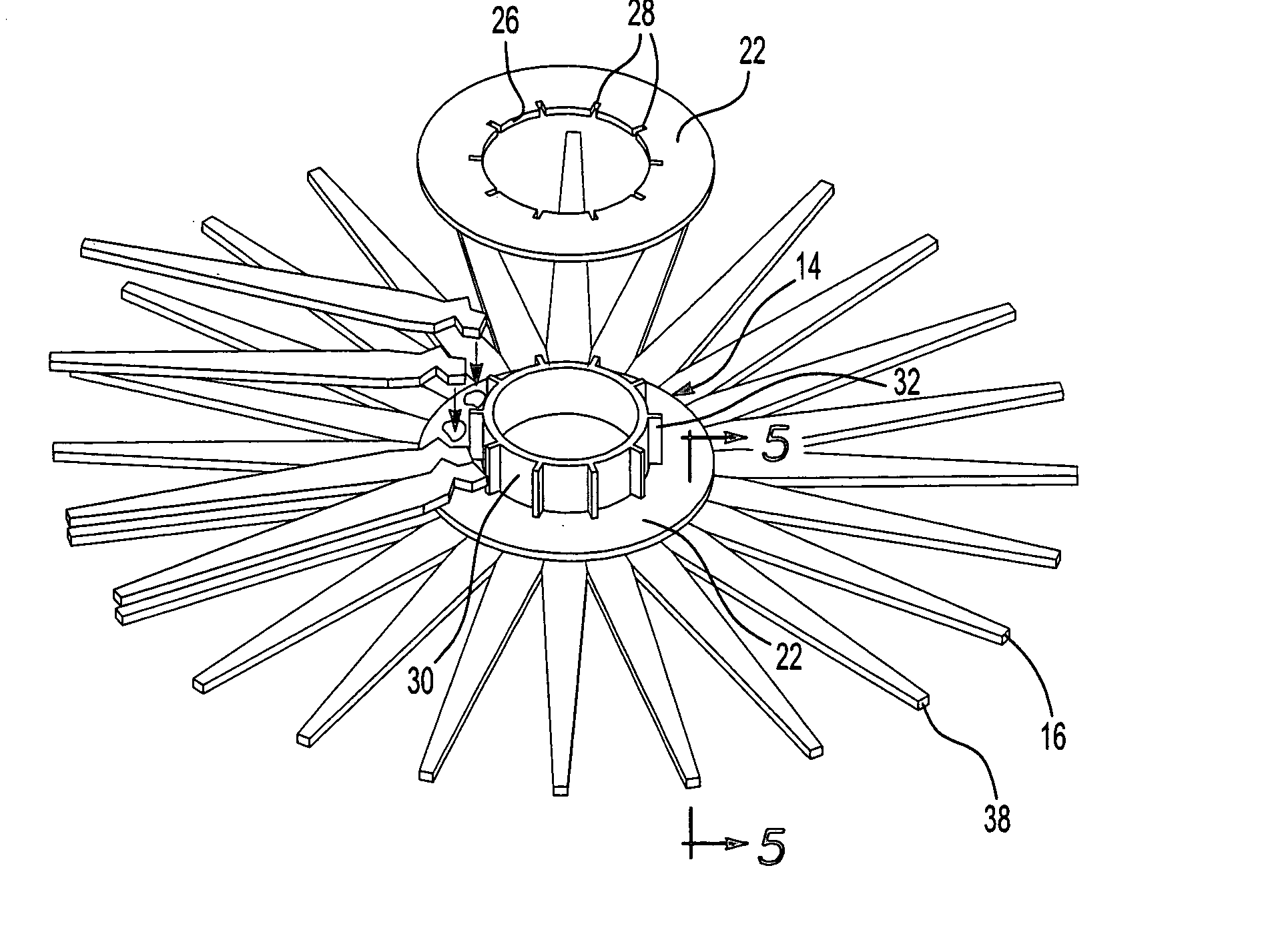

Carwash brush

InactiveUS20040200024A1Prevent water absorptionLiquid surface applicatorsBrush bodiesEngineeringElongated fingers

A carwash brush having a pair of annular hubs, each hub having a planar annular surface. A plurality of elongated fingers each have a first end sandwiched in between the hubs so that the fingers extend radially outwardly from the hubs and so that the second or outer ends of each finger are circumferentially spaced from each other. The first ends of the fingers are continuously bonded to the hubs. Preferably, both the hubs and the fingers are constructed of a closed-cell foam.

Owner:YAMIN THEODORE

Edging roller

The present disclosure provides a paint applicator which may be used to apply paint to corners, to junctions between adjacent walls, along window trim, along floor moldings, or other surface adjacent to the surface being painted, without smearing paint on the adjacent surface. Moreover, the present disclosure provides a paint applicator having a trim system that prevents the painter's hands from becoming covered with paint upon actuation of trim system.

Owner:NEWELL OPERATING COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com