Patents

Literature

618 results about "Paint roller" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A paint roller is a paint application tool used for painting large flat surfaces rapidly and efficiently. The paint roller typically consists of two parts: a "roller frame," and a "roller cover." The roller cover absorbs the paint and transfers it to the painted surface, the roller frame attaches to the roller cover. A painter holds the roller by the handle section. The roller frame is reusable. It is possible to clean and reuse a roller cover, but it is also typically disposed of after use.

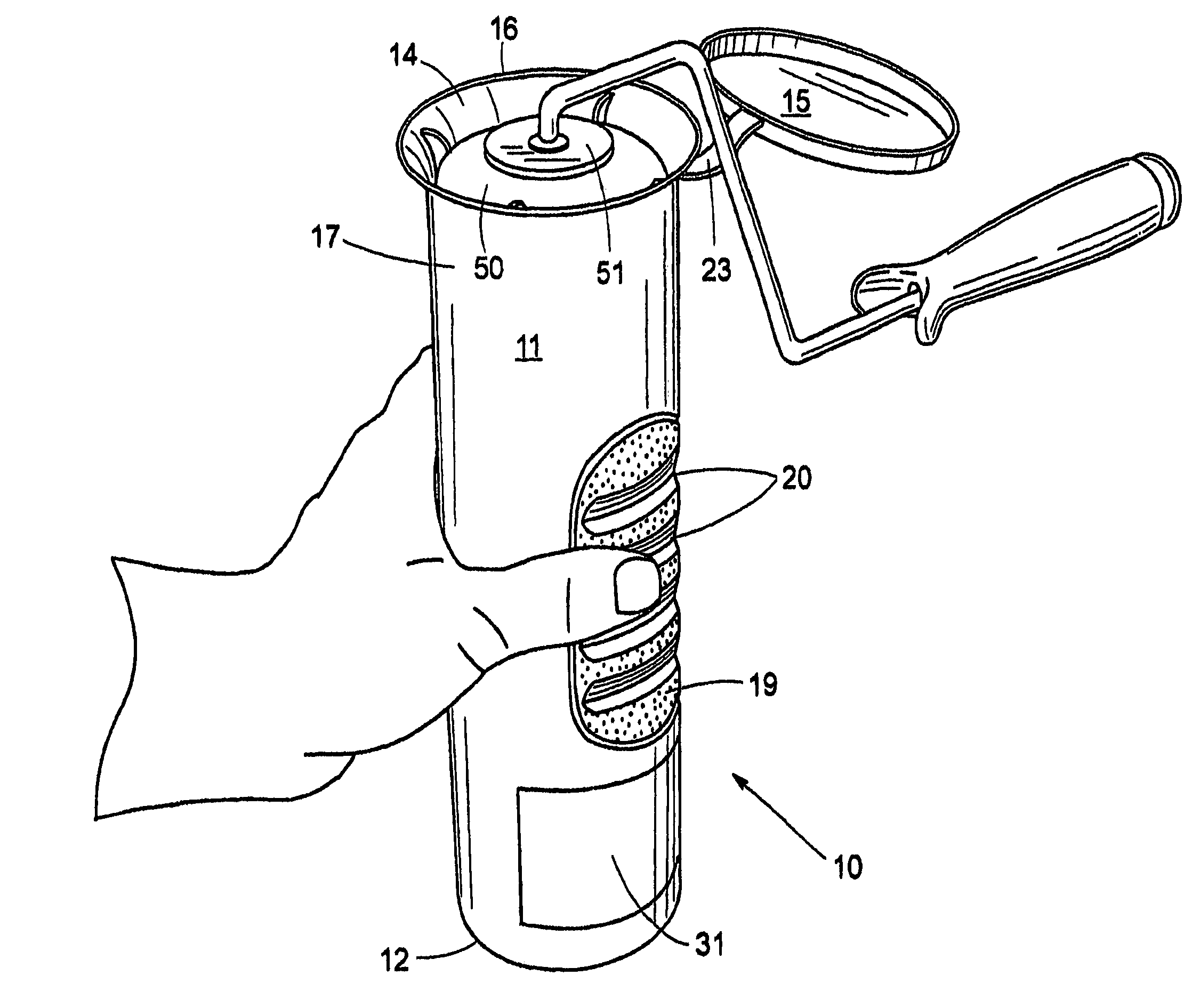

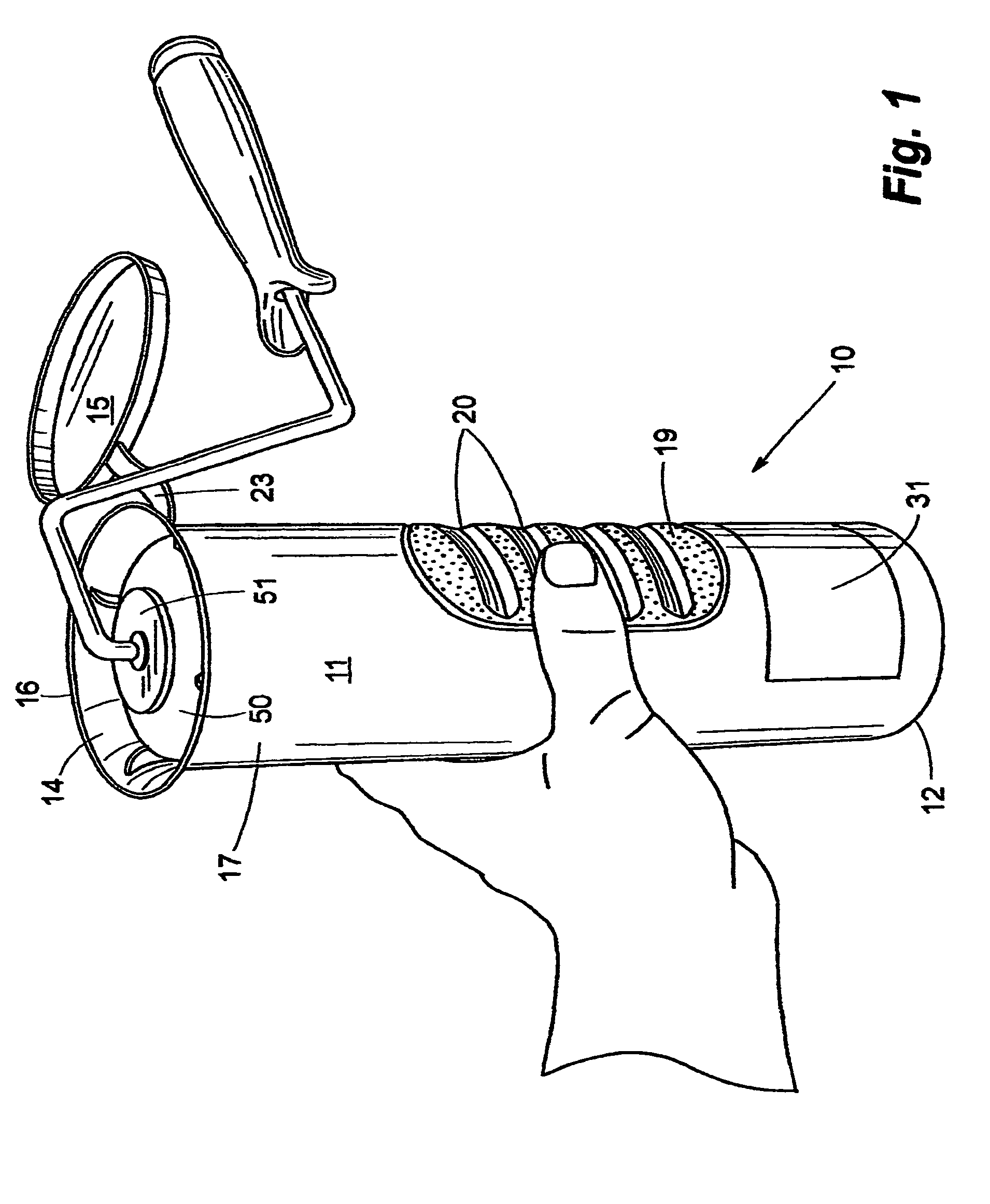

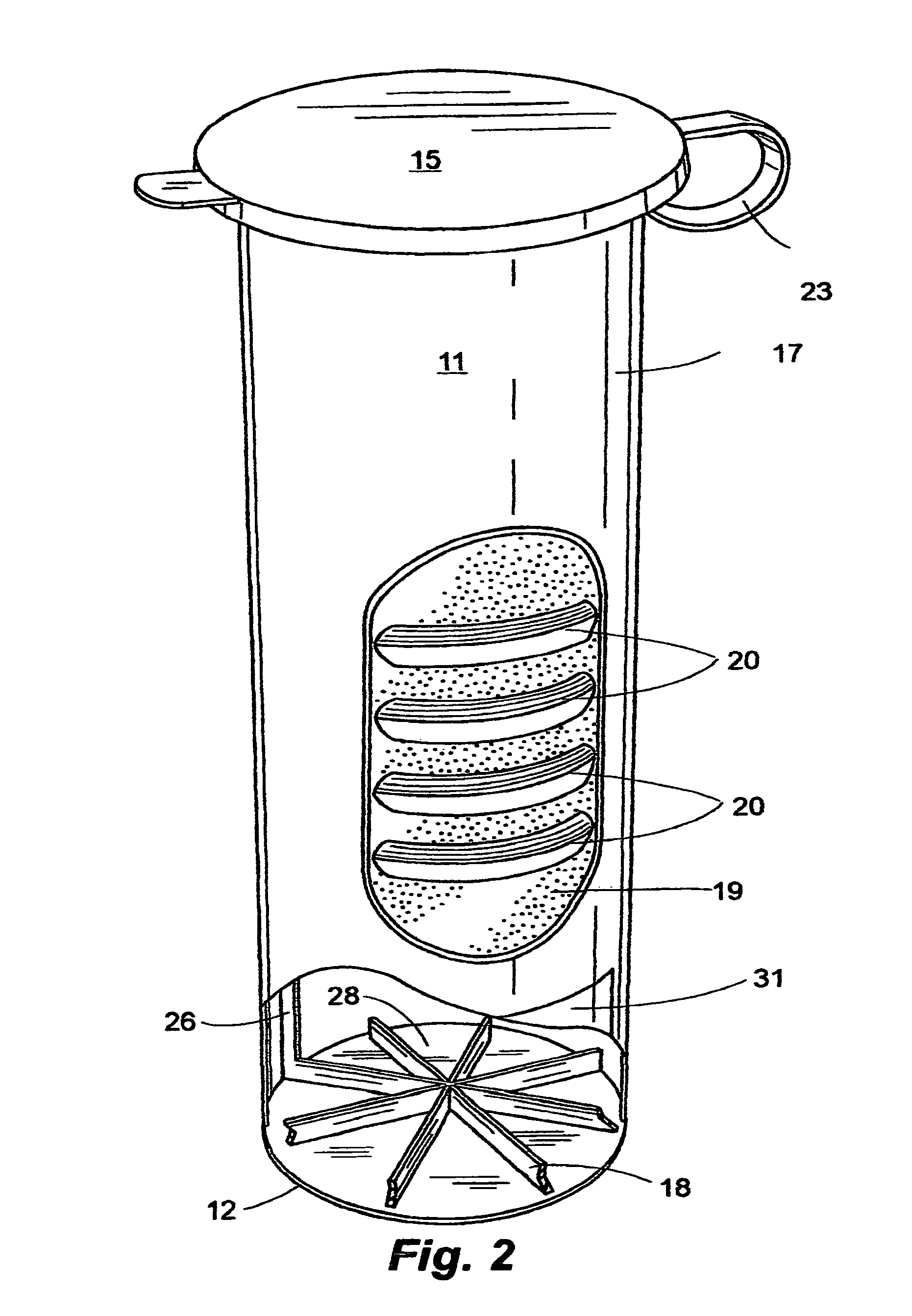

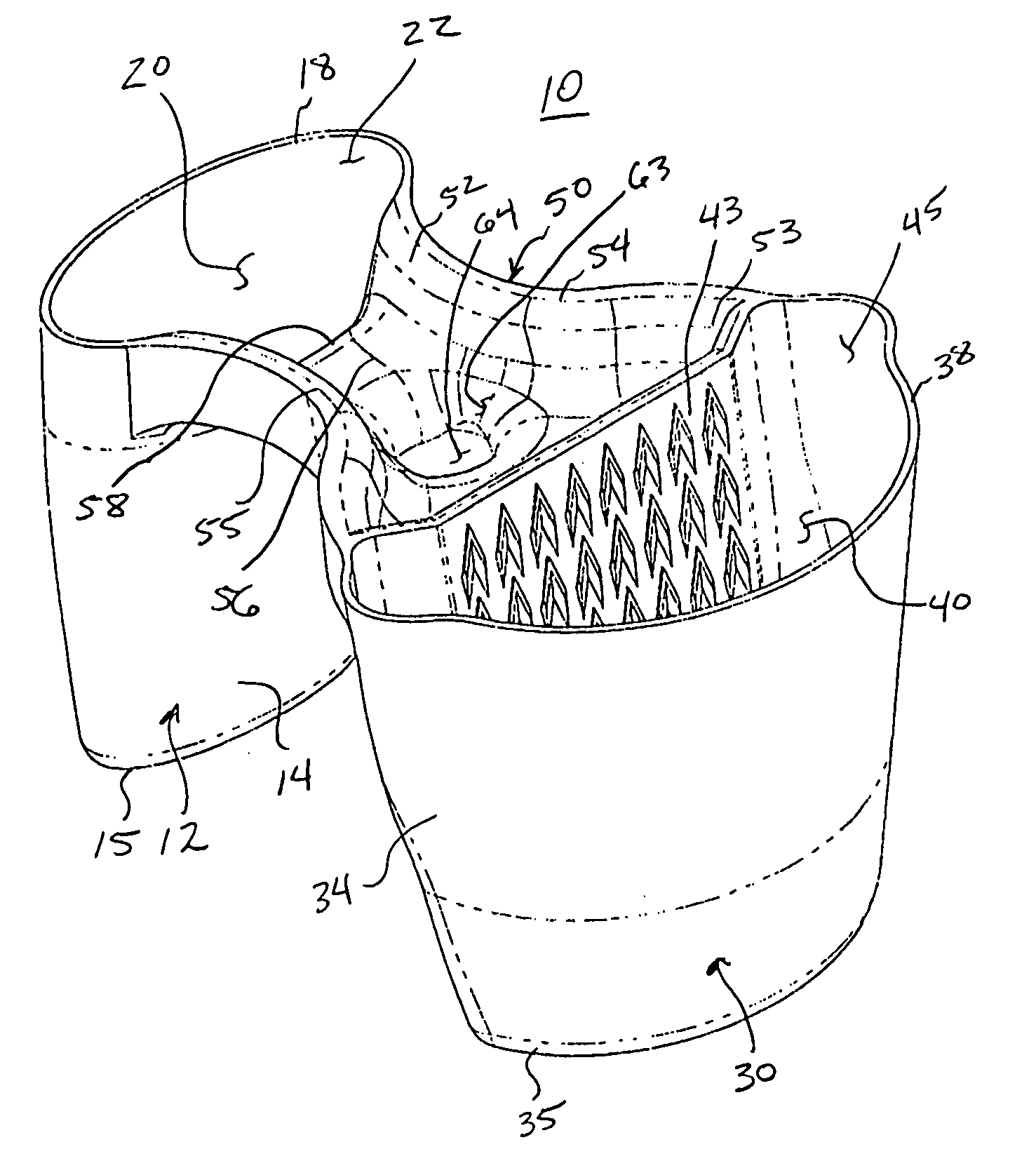

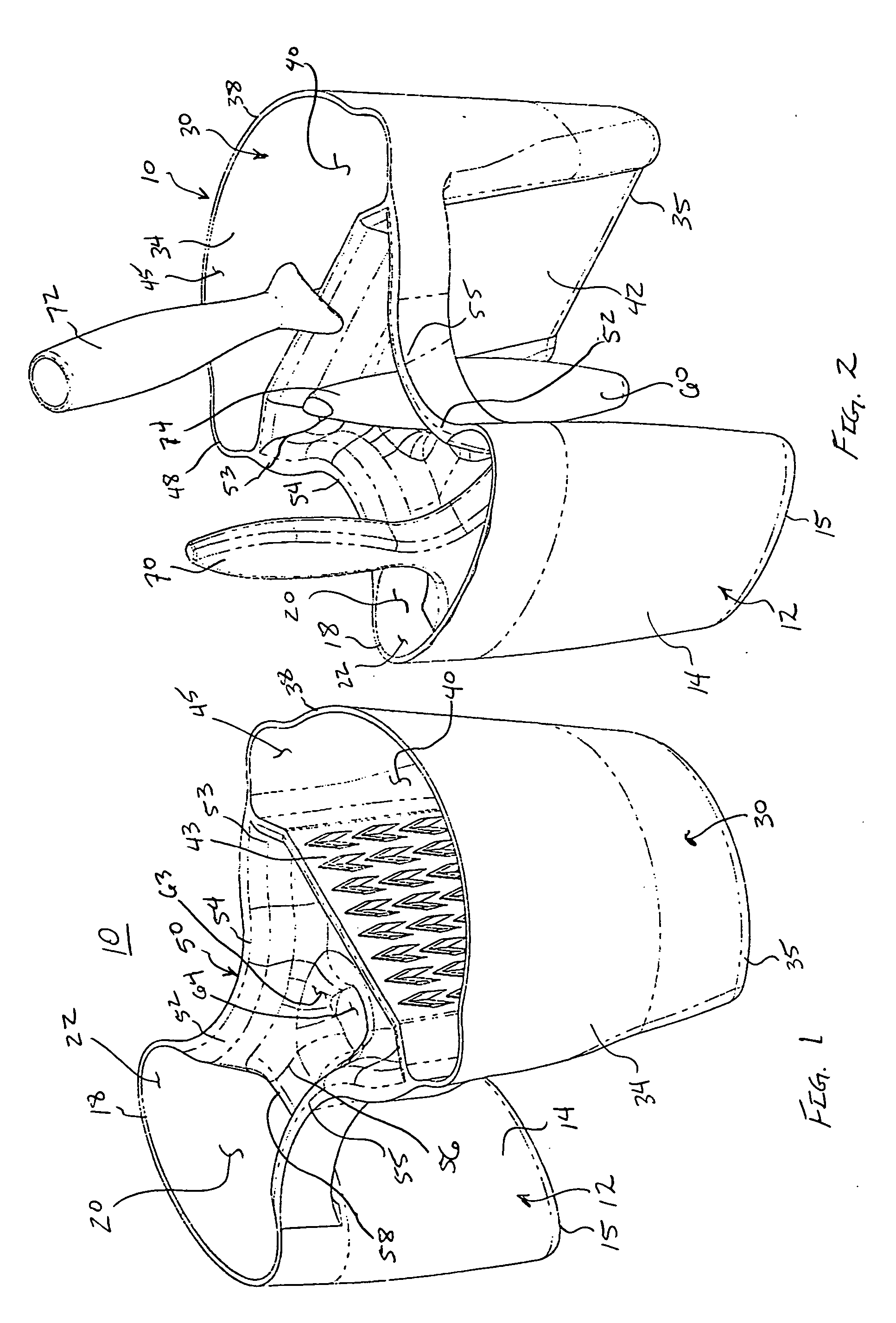

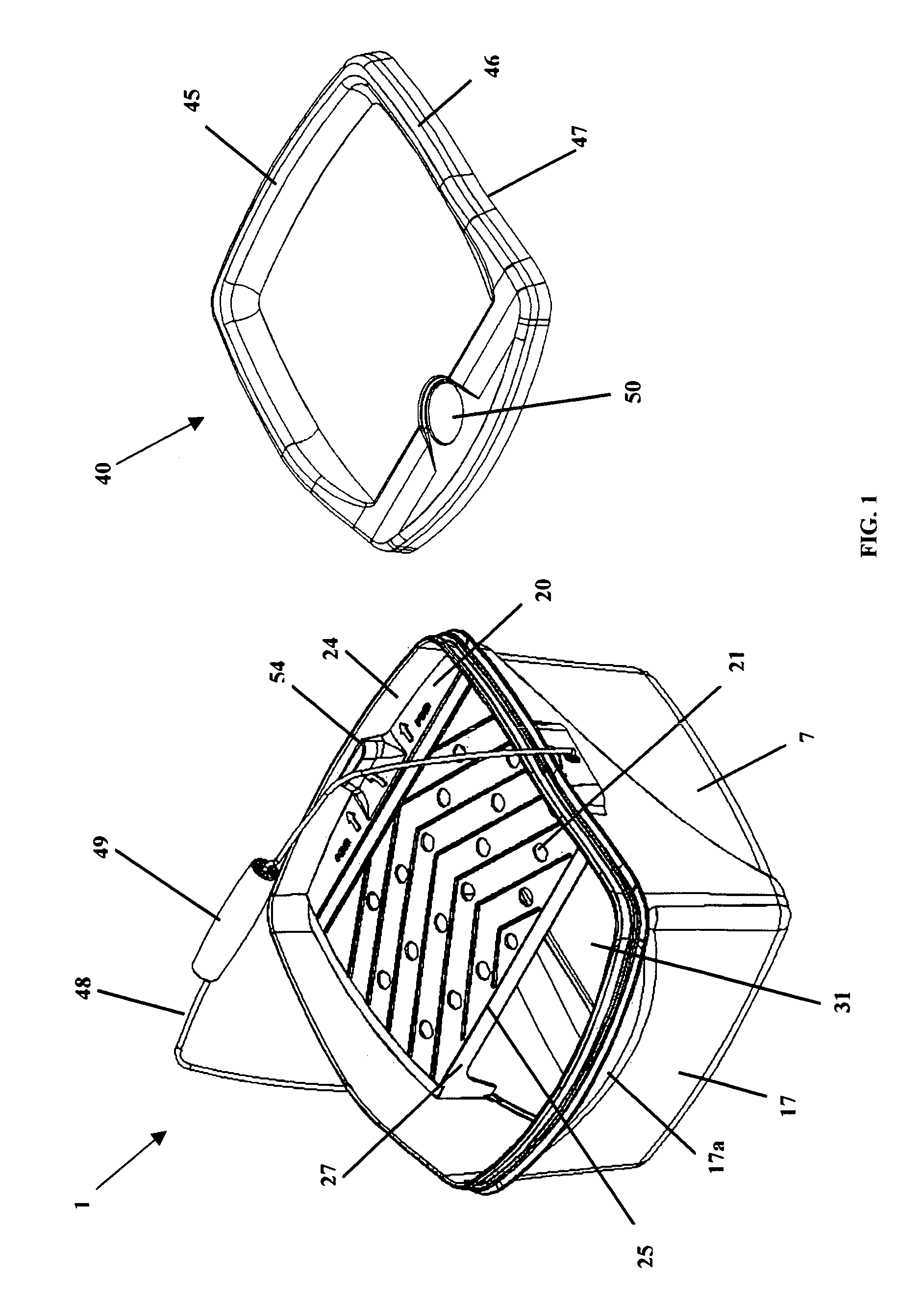

Paint roller sleeve storage container

A storage container for paint roller sleeve includes a set of flutes on at least two opposing sides of an interior surface of said cylinder for stabilizing a roller cover in place from rattling inside of the housing and for holding said roller cover in place when extracting a roller frame from said roller cover. Each set of flutes includes three interior flutes that located between said two exterior flutes. The interior flutes include a middle flute that is set back a distance from the other two interior flutes so that when the exterior surface of the container is pressed inward said middle interior flute cuts into a paint roller sleeve housed within the container and the other two interior flutes bend outward around a nap of said roller sleeve to better hold said roller sleeve in place when a roller frame is being extracted from said roller sleeve.

Owner:OBVIOUS SOLUTIONS

Paint roller

InactiveUS20070056132A1Easy to disassembleExchanged conveniently and efficientlyLiquid surface applicatorsBrush bodiesFemale structureEngineering

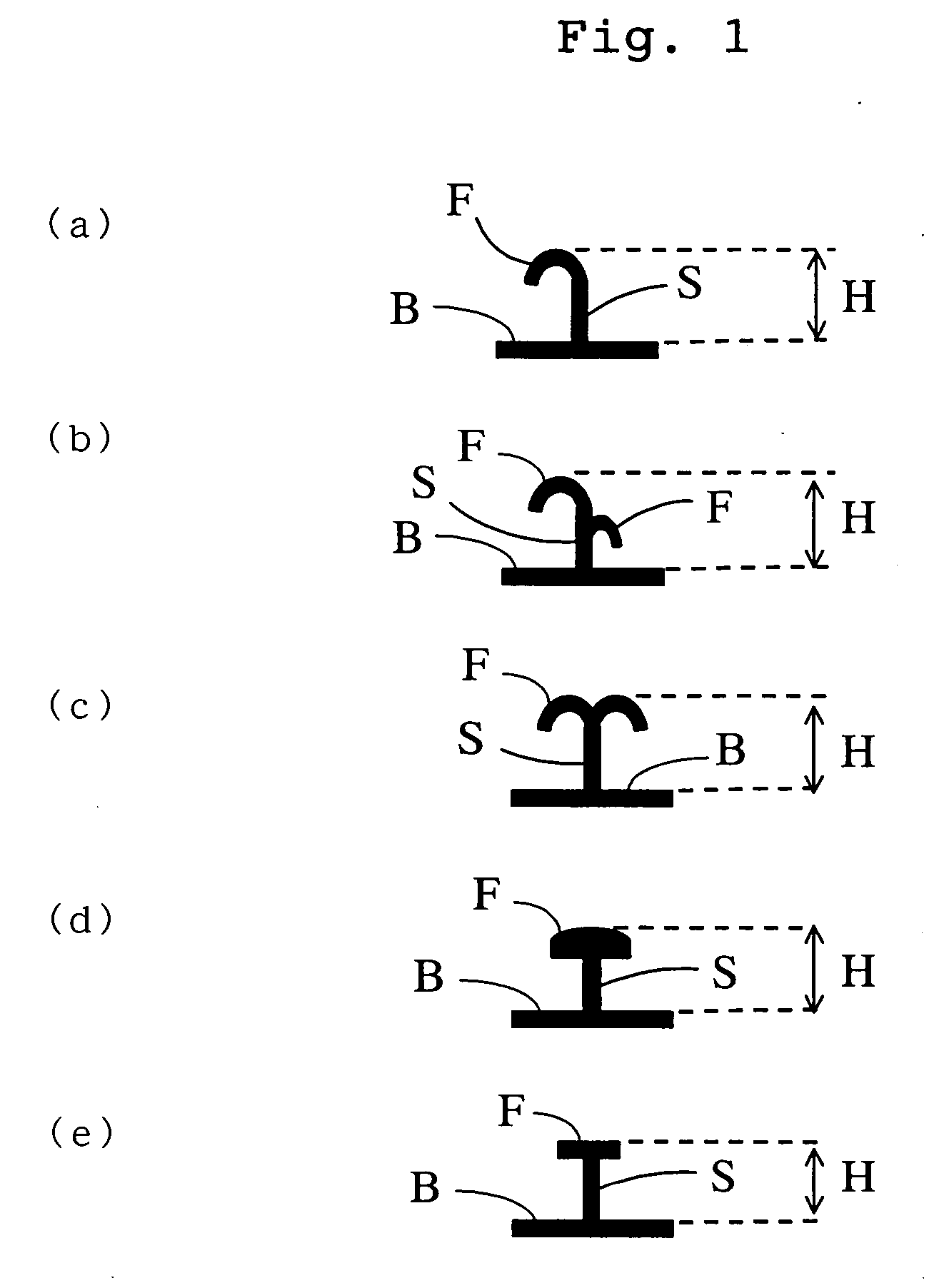

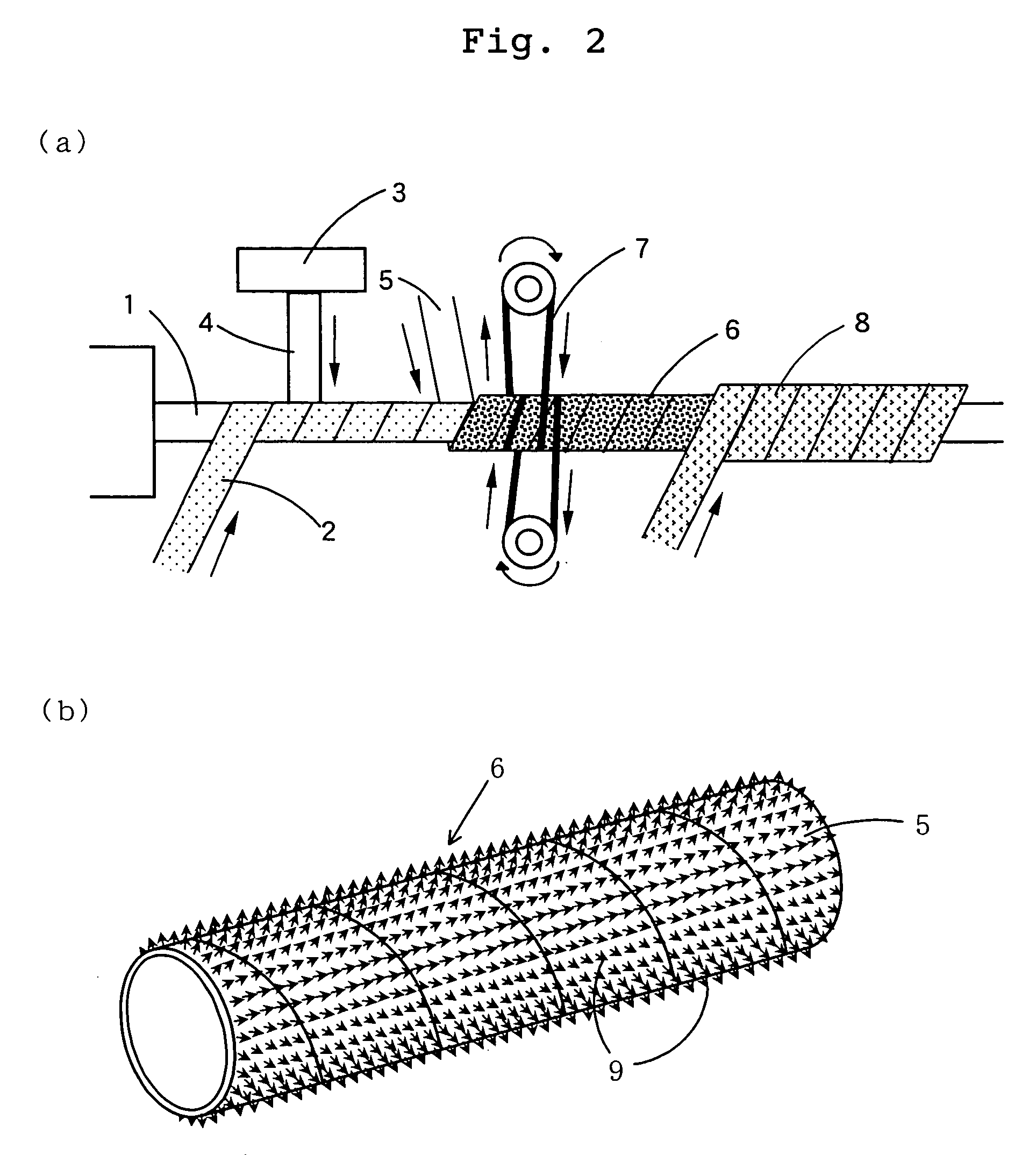

A paint roller comprises a liquid-impermeable tubular core member 6 with an engaging element 9 having a male structure of a separable fastener and a height of 0.3 to 4.0 mm on a surface thereof, and a cover member 8 with a female structure and a loop on the inner surface capable of male-female engaging with the engaging element on the surface of the core member. The density of the engaging element on the surface of the core member is 30 to 150 / cm2. Thus, in such paint roller, when the cover member becomes dirty, damaged, or worn, the cover member can be exchanged to a new cover member. Such that, a roller body is repeatedly usable, and the paint roller can provide a good painted surface. Moreover, there is also provided an effect roller in which a painting pattern can be changed optionally.

Owner:KURARAY CO LTD +1

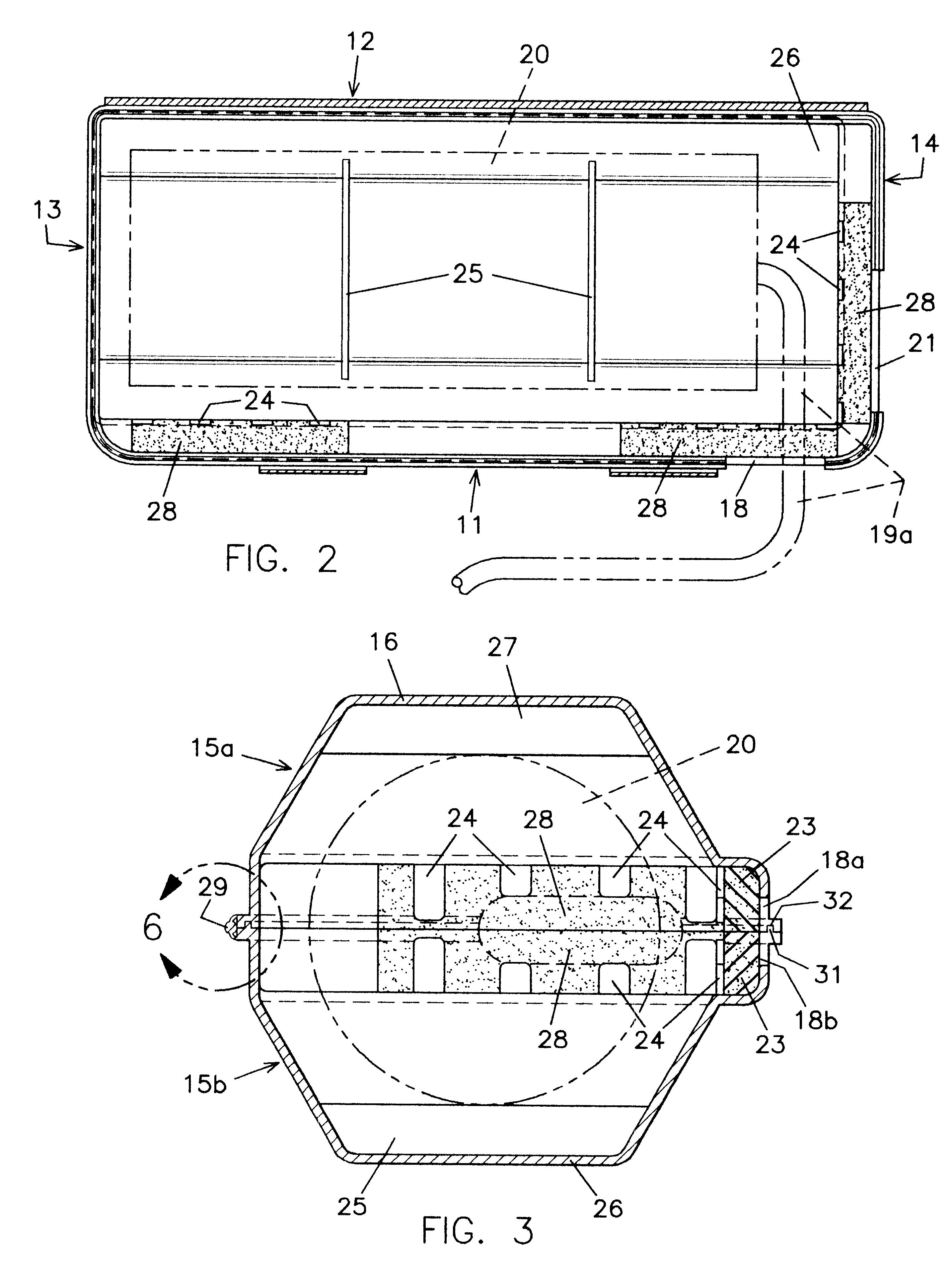

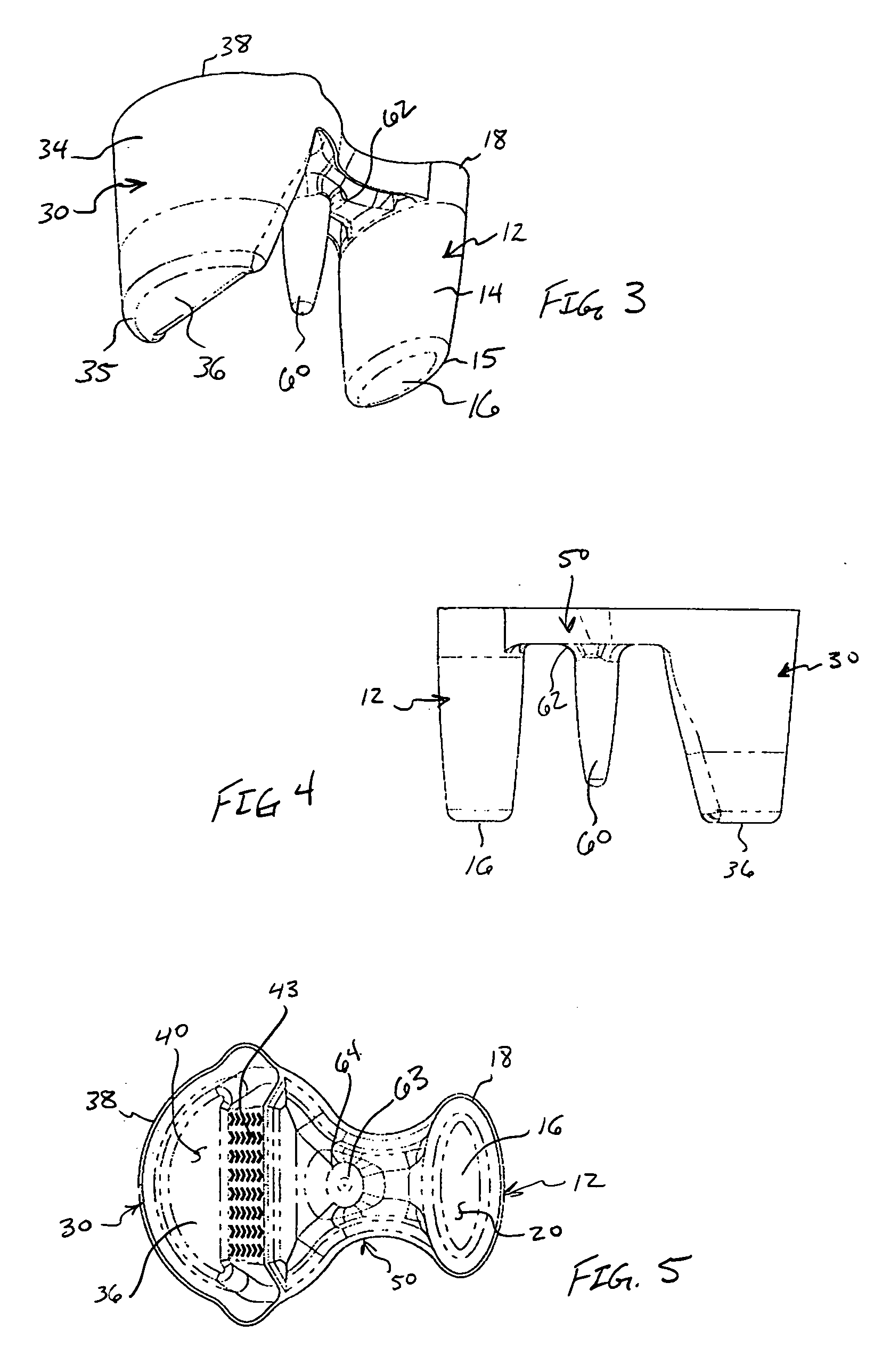

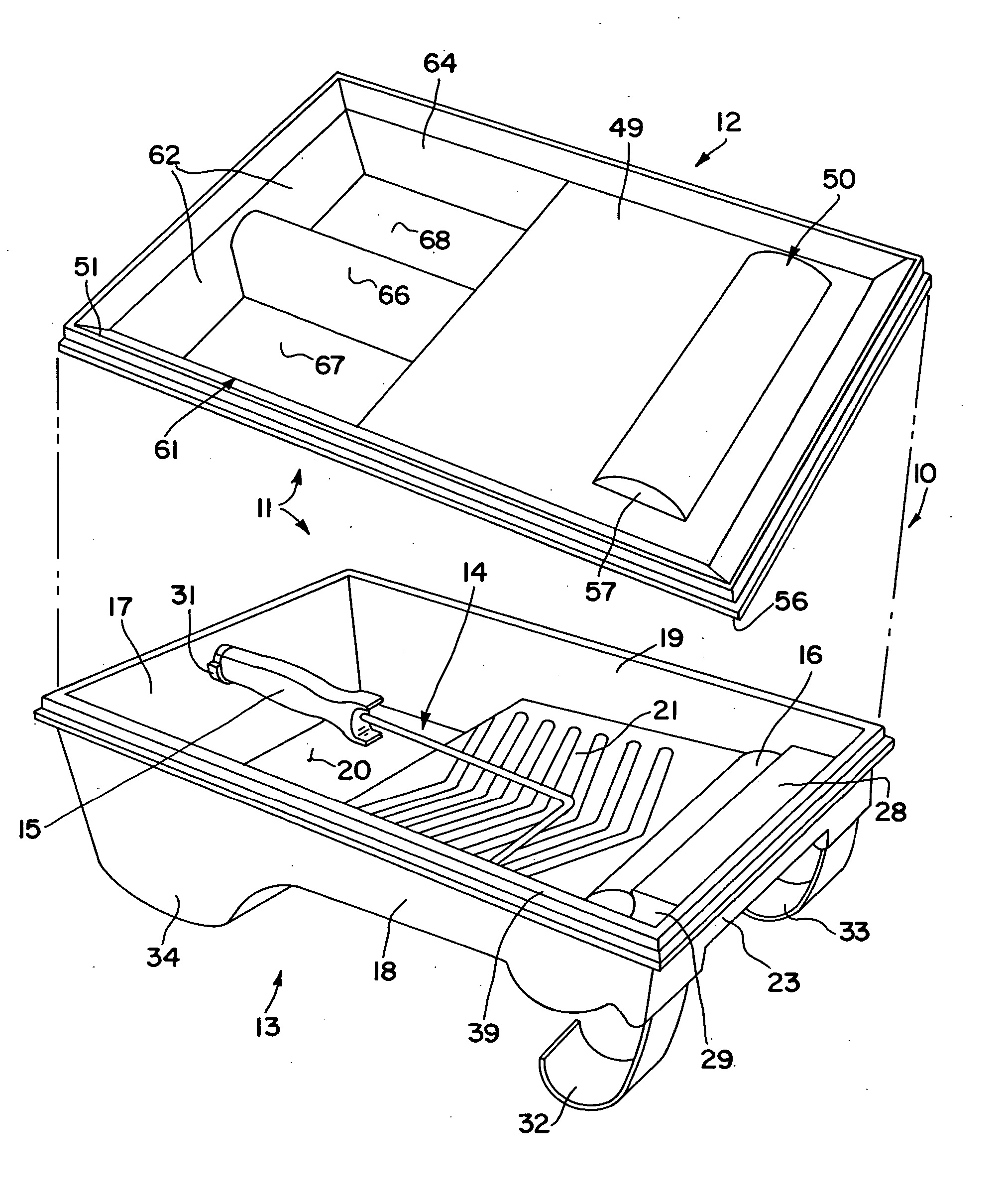

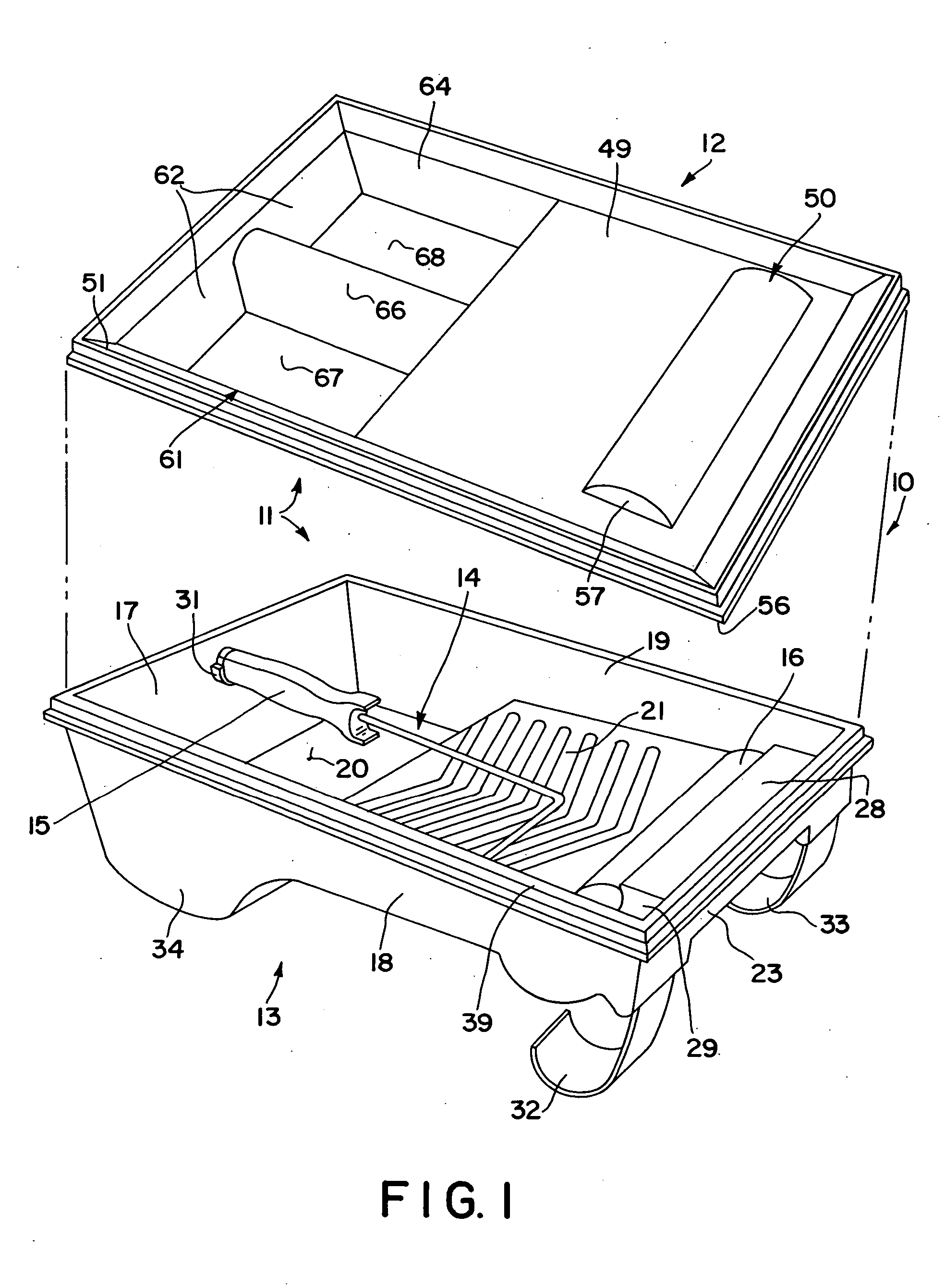

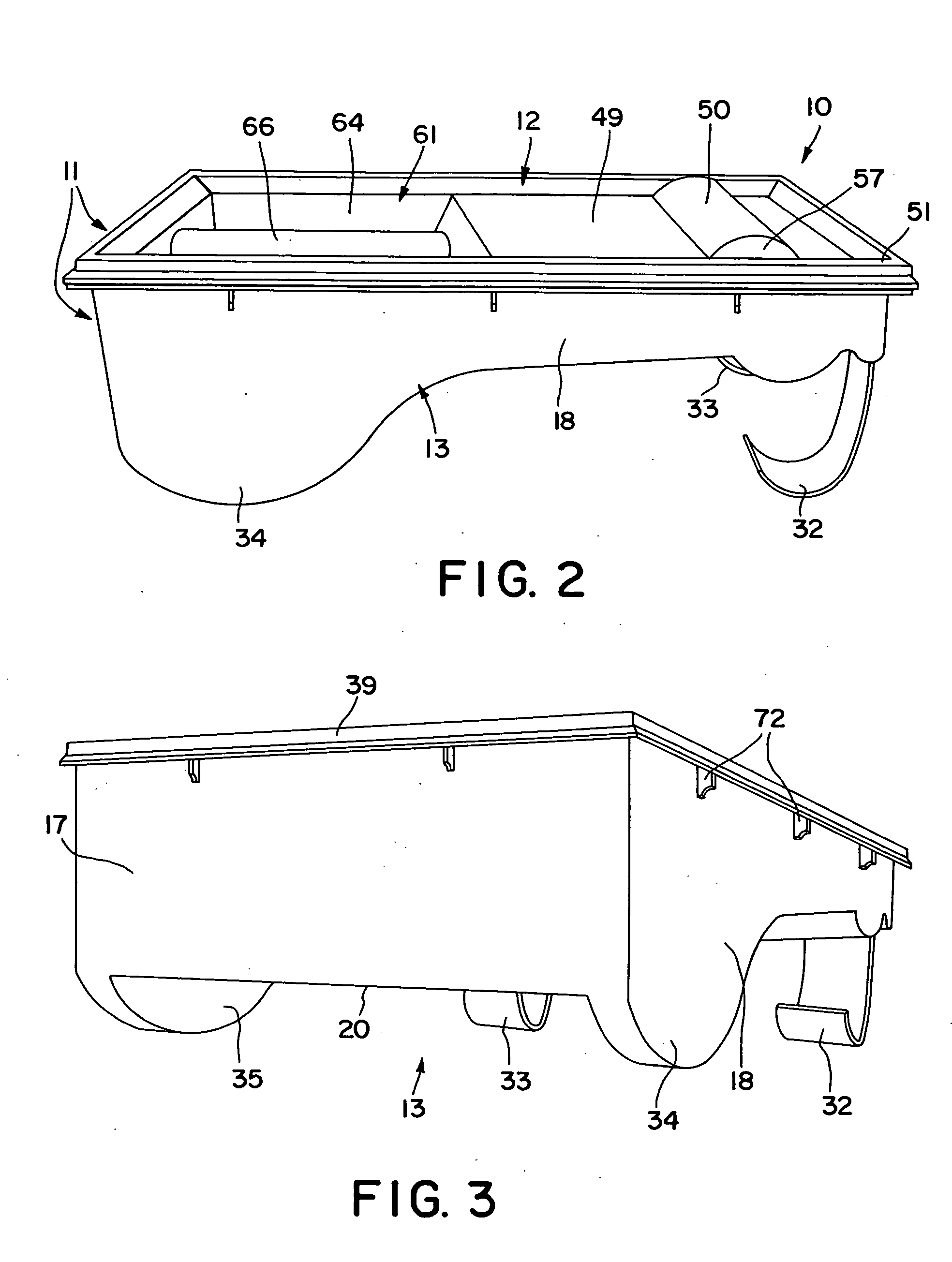

Paint roller tray

A paint roller tray is provided with a removable cover. The paint roller tray includes a paint brush support formed in a front side of the tray, front and back paint roller support notches, a pour spout, a hanging fixture, and support legs. The cover includes paint roller and paint brush accommodating bulges that allow the cover to be mounted to the tray while a paint roller and a paint brush are disposed wholly or partially between the tray and cover.

Owner:STANLEY WORKS THE

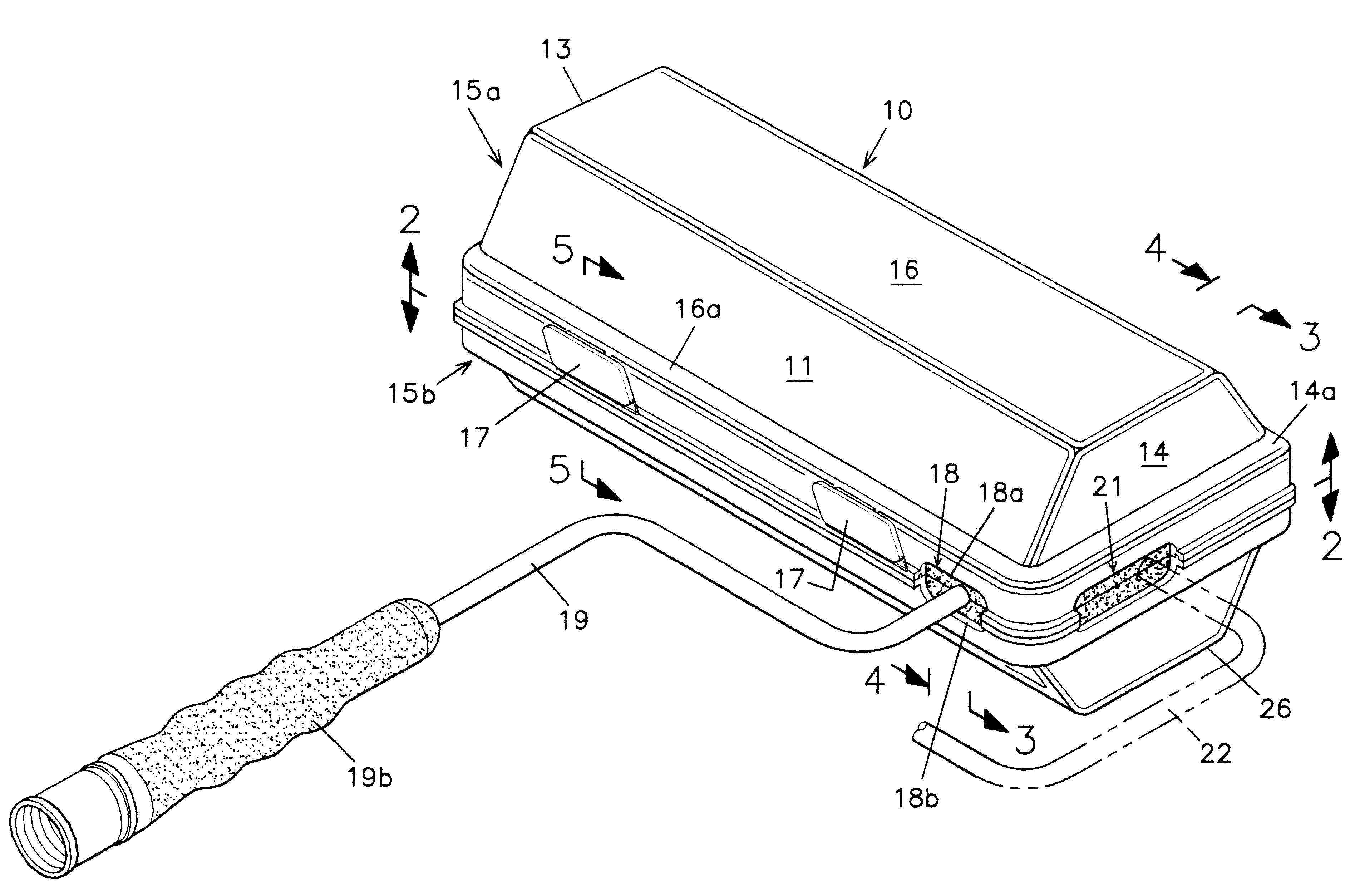

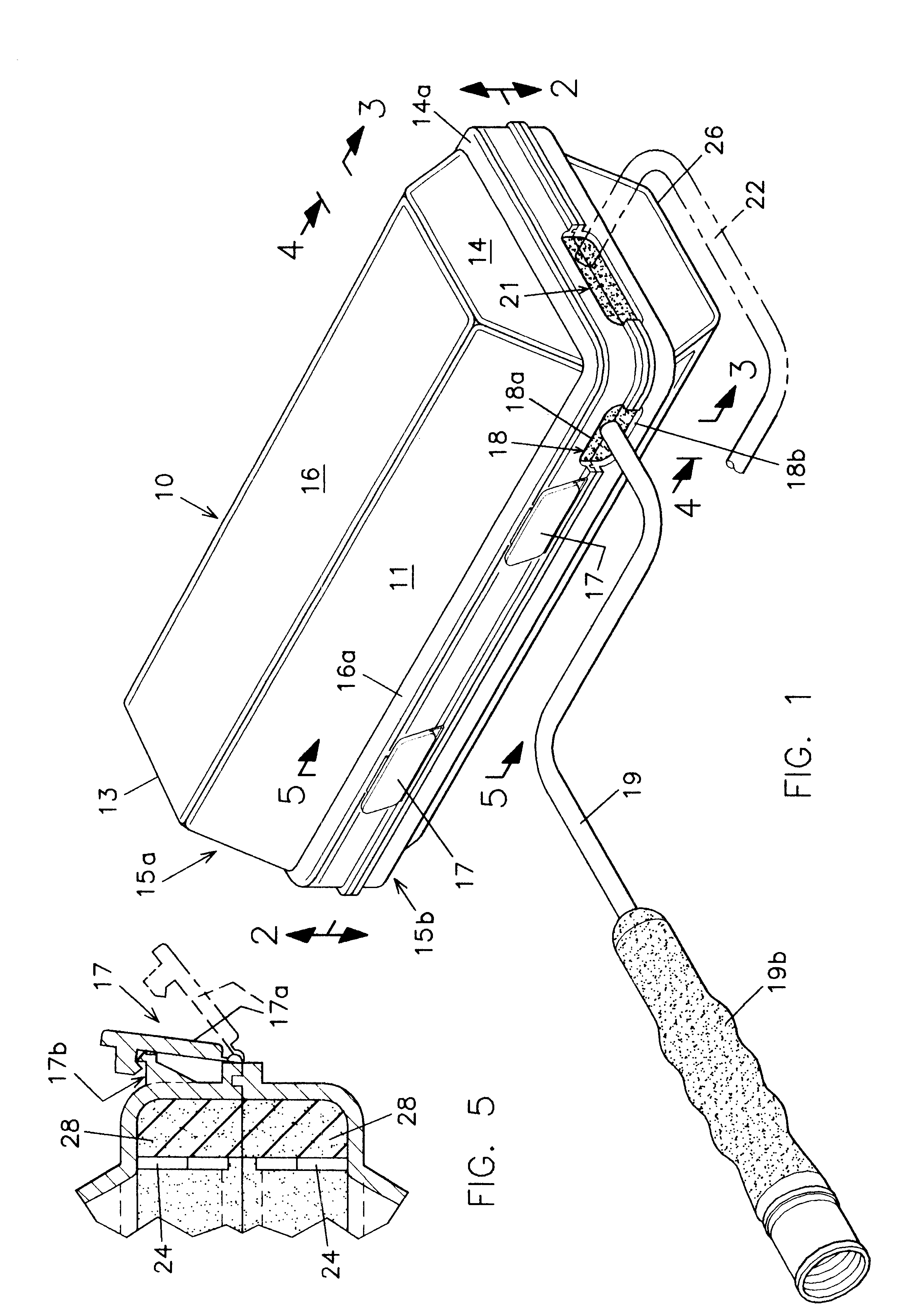

Holding box for paint-applying roller wet with paint

A paint roller filled with wet paint may be stored for a period of time, such a over lunch break or overnight, or for longer times, and still be useable for painting, by substantially sealing the roller while attached to the usual handle-attached, paint applicator to which the roller is mounted, in an elongate box which covers the roller and through an opening in which a portion of the paint applicator extends. The portion of the paint applicator extending through the opening is substantially sealed by deformable paint solvent absorbent material in the opening to which a small amount of paint solvent, such as water, is added to maintain a solvent rich atmosphere in the box to help maintain the paint on the roller in wet, usable condition.

Owner:BRUSH SAVER

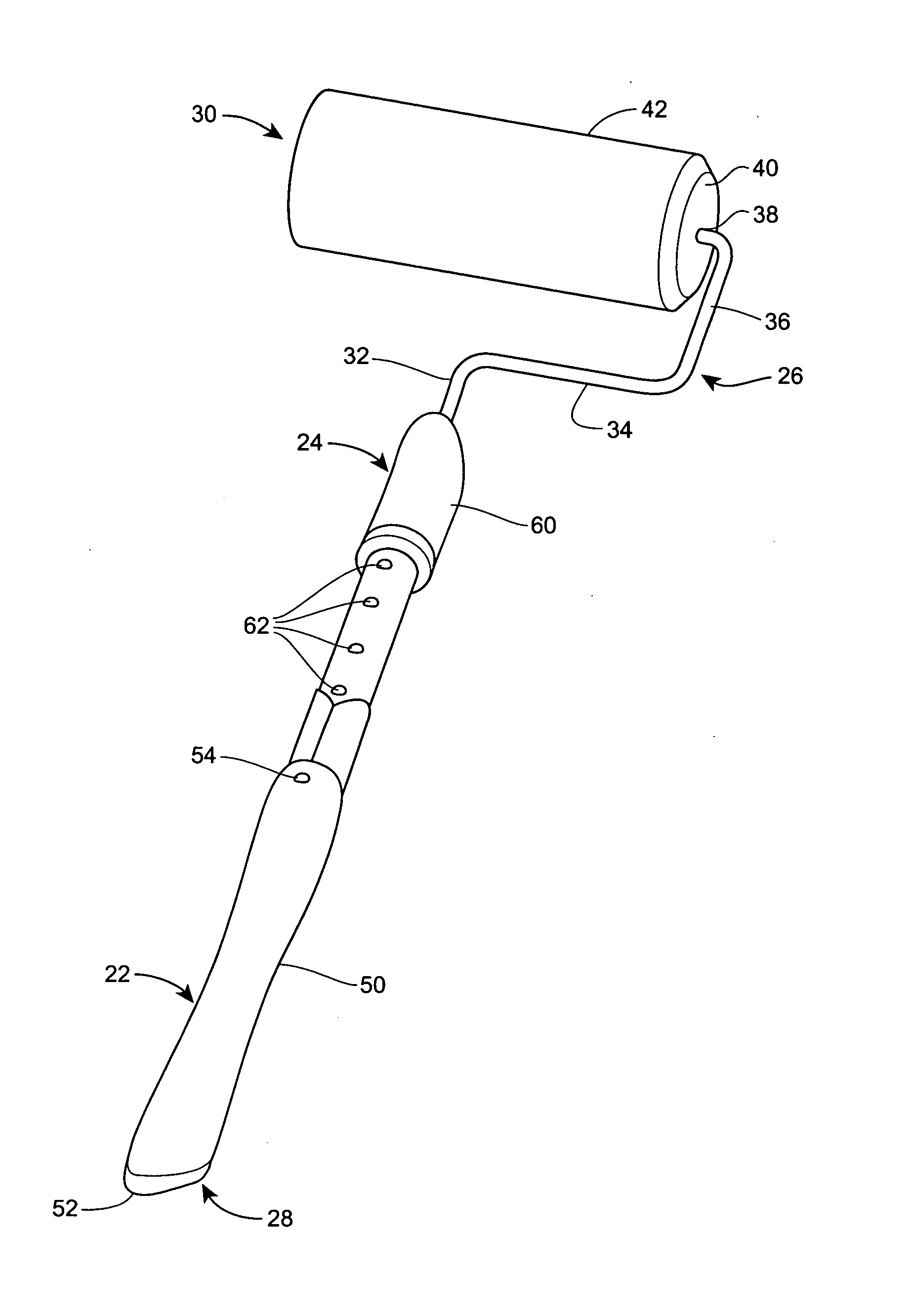

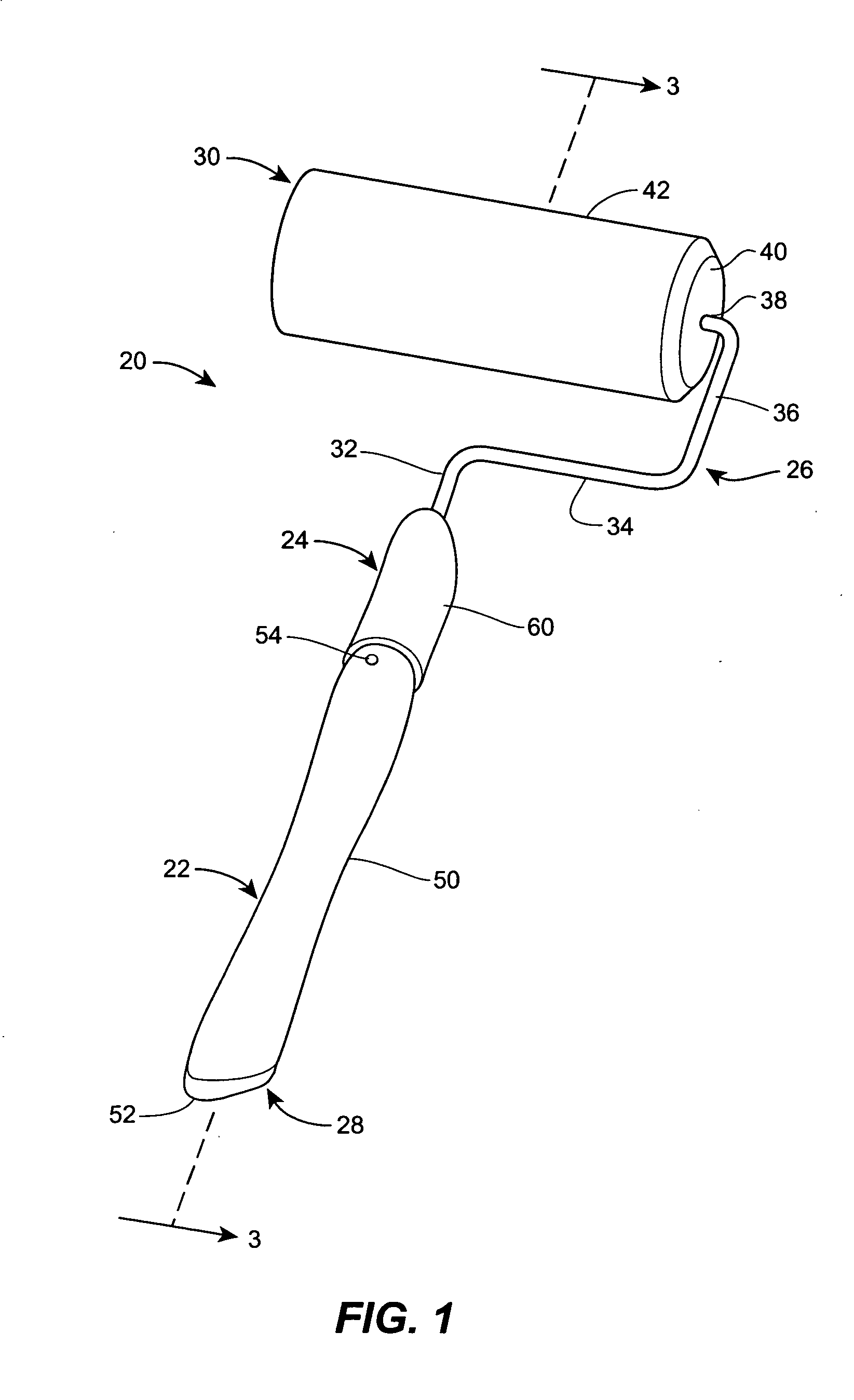

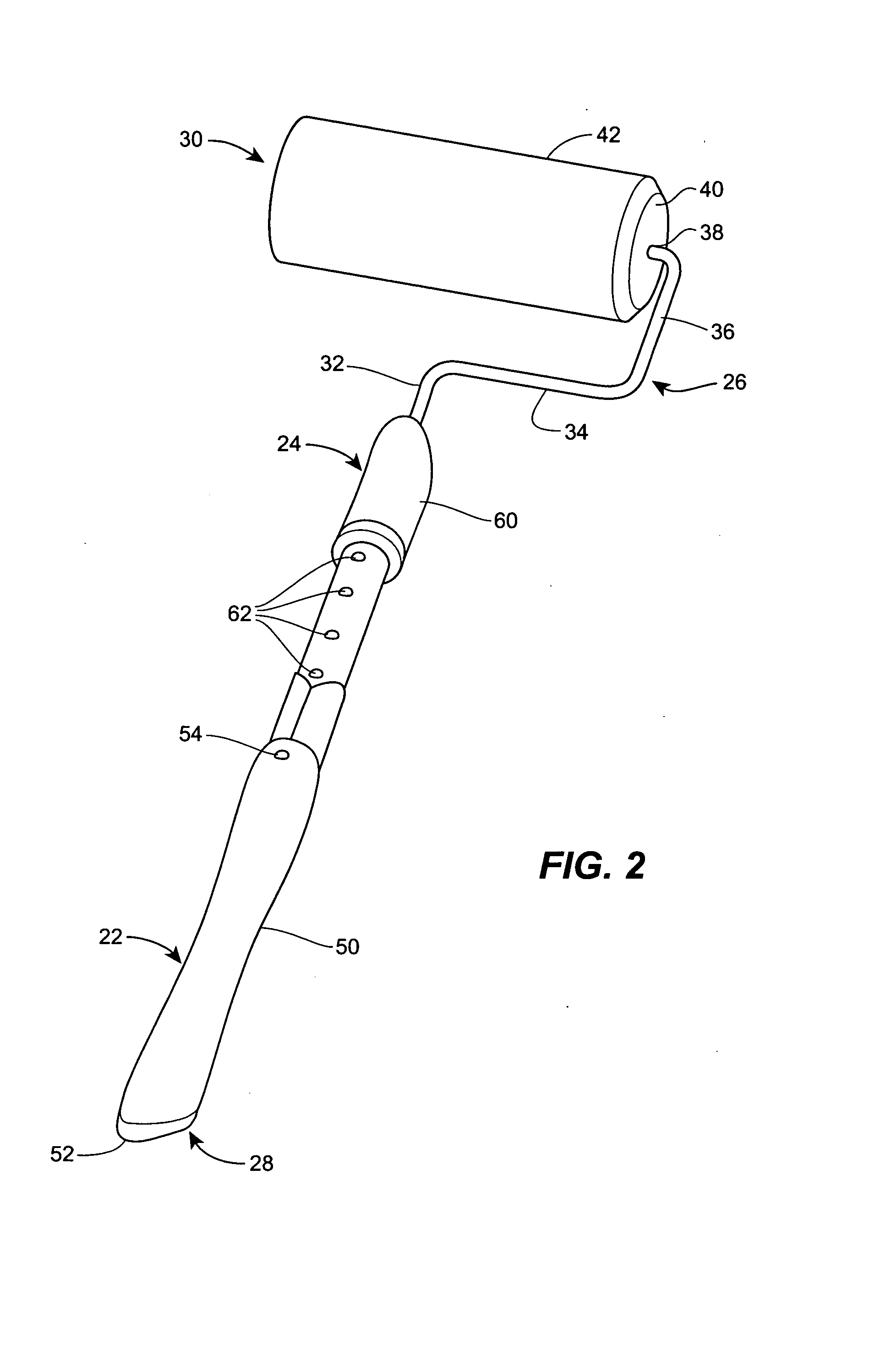

Paint roller with extendable handle

An extendable handle for a paint applicator includes an first shaft having a distal end and a proximal end and a second shaft with a distal end and a proximal end and which is telescopically disposed within the first shaft. A guide block is disposed on the second shaft and defines a curved channel. A third shaft has a distal end and a proximal end and is telescopically disposed within the second shaft. An advancement strip has a first end connected to the distal end of the first shaft and a second end connected to the proximal end of the third shaft and is disposed through the curved channel of the guide block. The advancement strip can both push and pull the third shaft relative to the second shaft.

Owner:NOVA WILDCAT SHUR LINE LLC

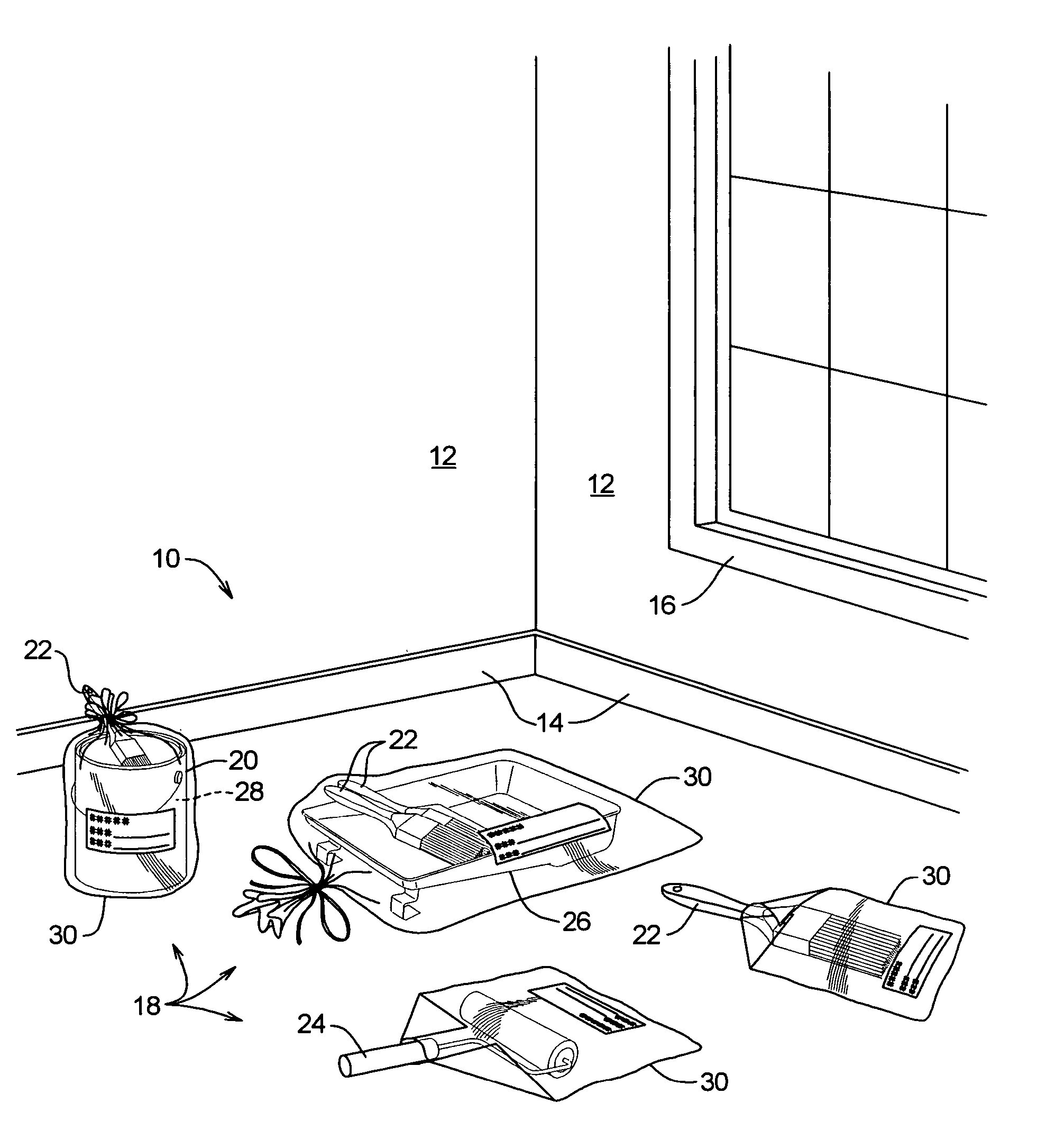

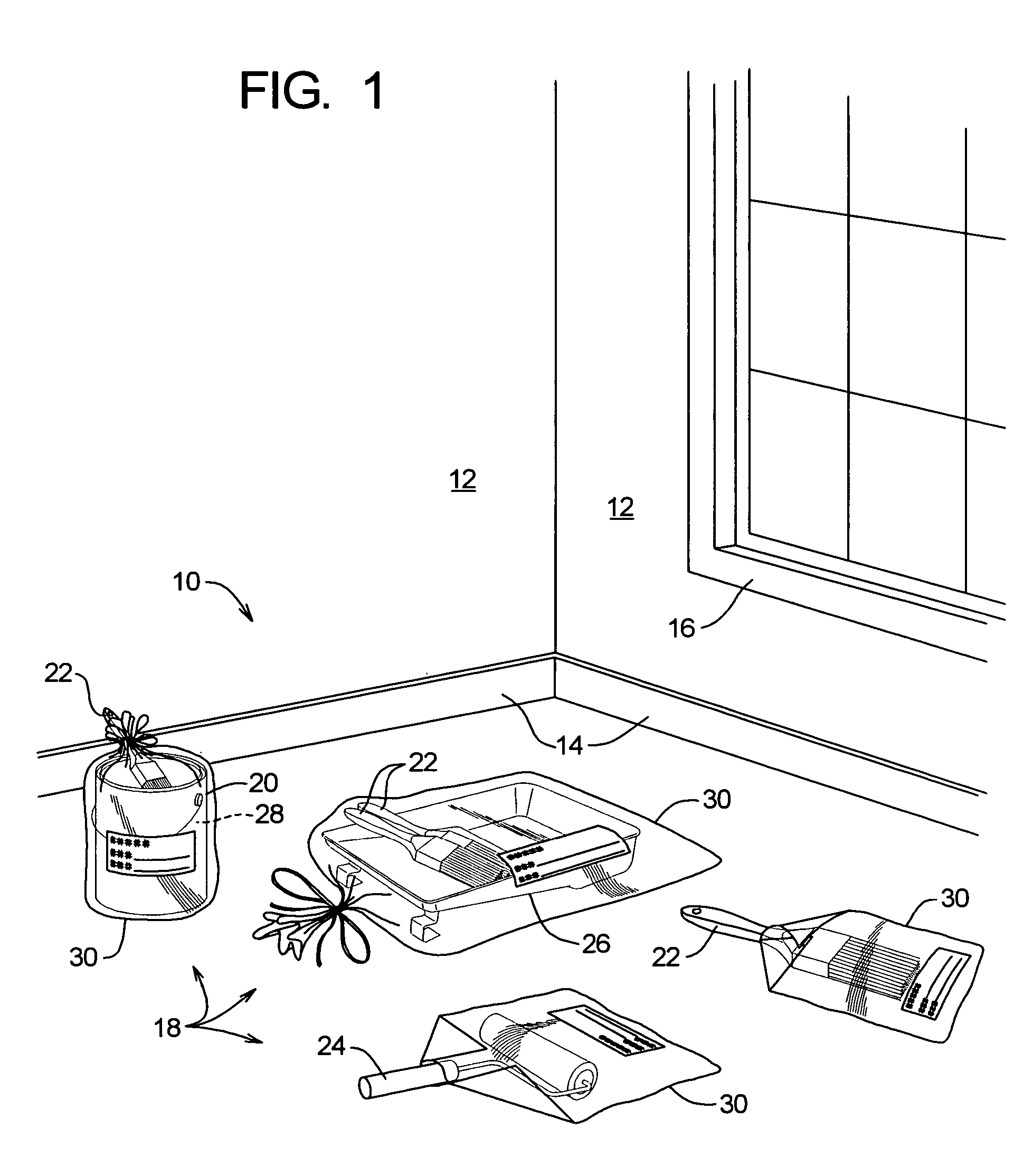

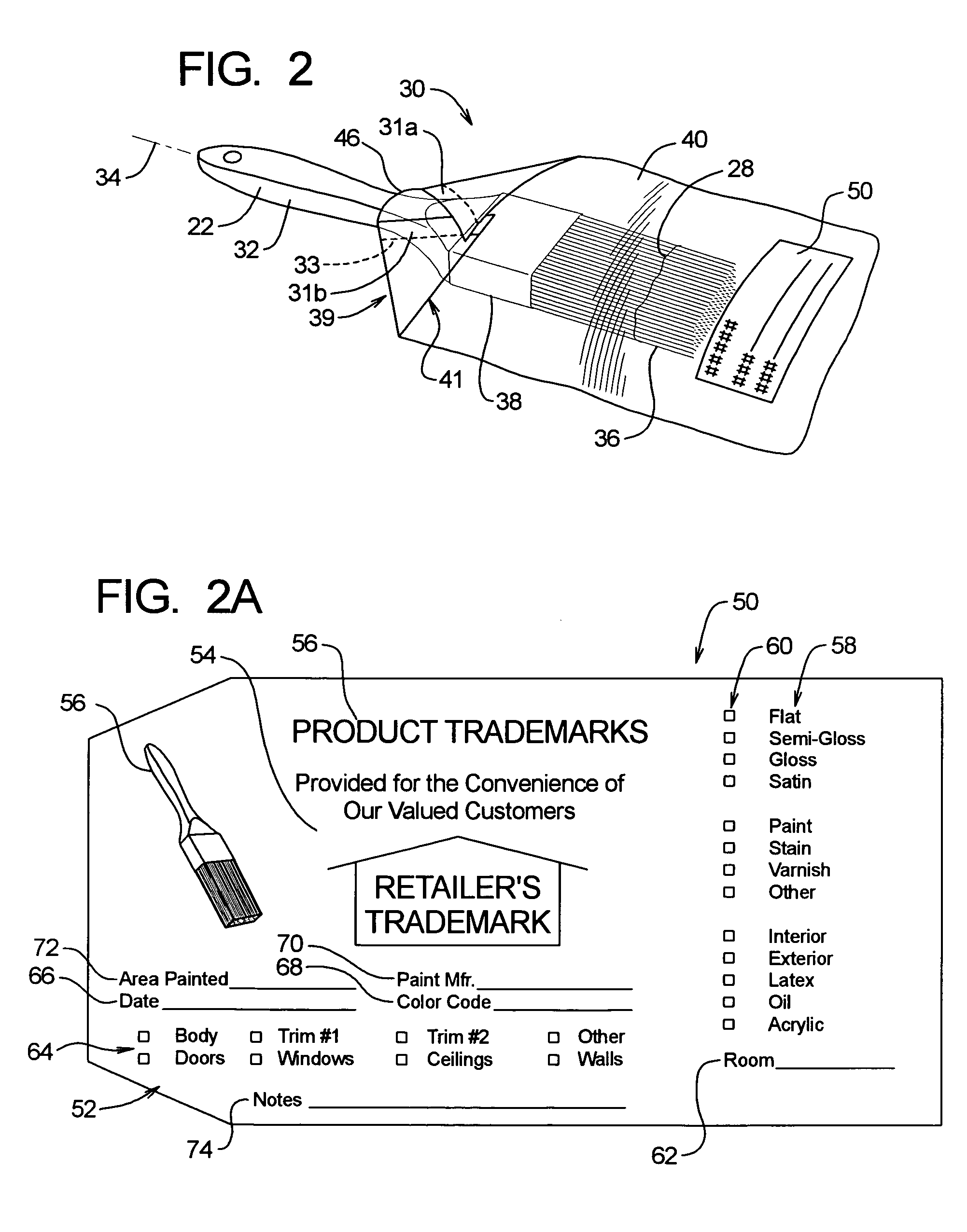

Paint paraphernalia method and apparatus

What is provided is a protective environment for paint paraphernalia and wet paint being used in a painting process. Examples of paint paraphernalia includes paint brushes, paint rollers, paint trays, and paint cans. The protective environment in one form is a flexible polyvinyl chloride of at least ½ mil in thickness. The flexible polyvinyl chloride is arranged two provided a three sided connecting edge with the fourth side left unconnected for an opening into the interior portion of the protective environment. The protective environment is placed over the paint paraphernalia and marked with various paint paraphernalia characteristics to aide in the temporary storage and reuse of the paint paraphernalia during a painting job.

Owner:ENGLEHART MICHIKO D +1

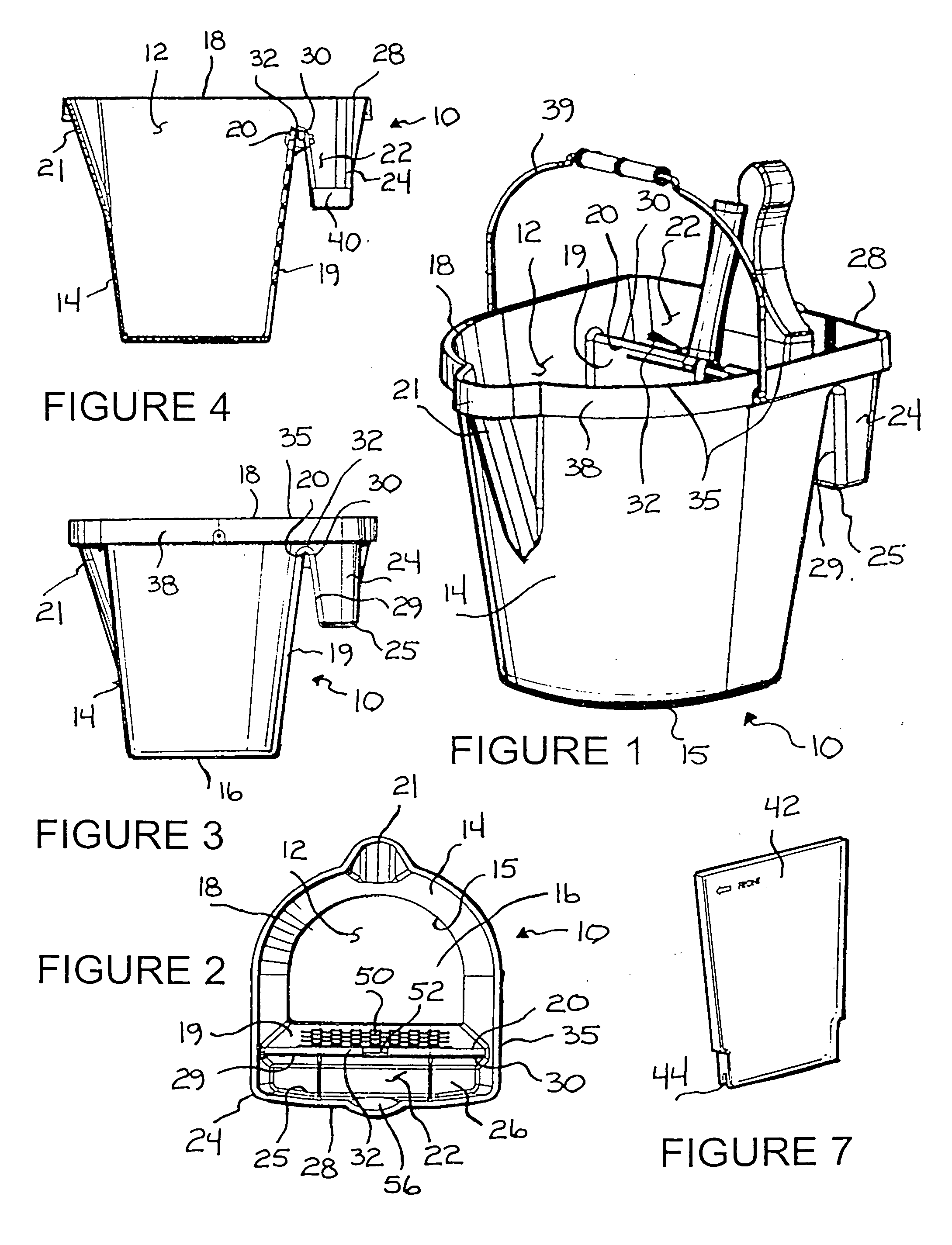

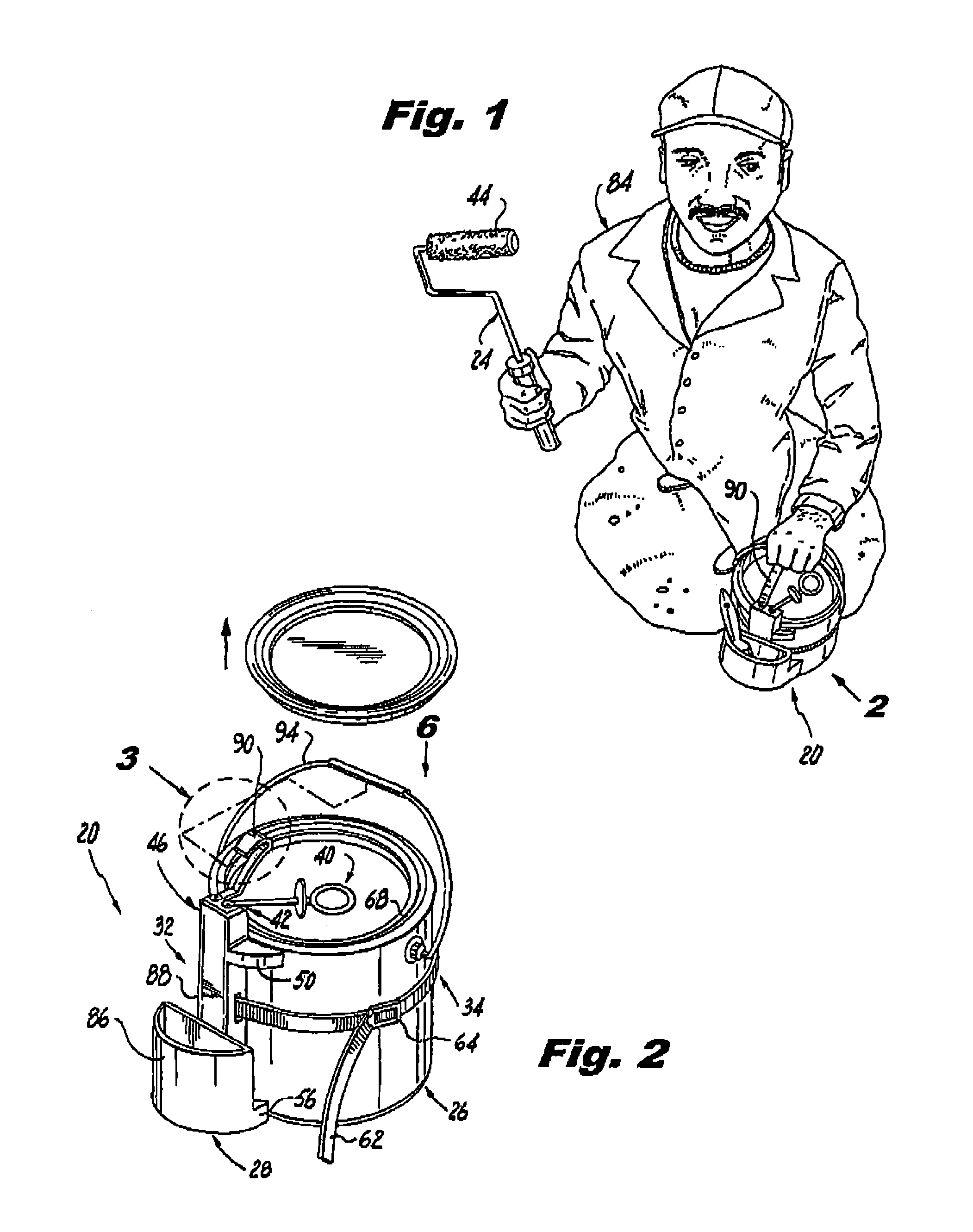

Handheld painter finishing bucket

A painter finishing bucket includes a first vessel, a second vessel and a bridge member. The first vessel has a continuous sidewall extending from a periphery of a bottom and terminating in a rim. The bottom and sidewall define a volume accessed through an open top. The second vessel has a continuous sidewall extending from a periphery of a bottom and terminating in a rim. The bottom and sidewall define a volume accessed through an open top. The sidewall includes a flattened portion extending from proximate the bottom to proximate the rim and having an inner surface textured to form a paint roller surface. A bridge member coupled the first vessel to the second vessel and includes a grip extending from a bottom of the bridge. The grip defines a volume opening in the bridge.

Owner:WONDER LINE SALES L L C

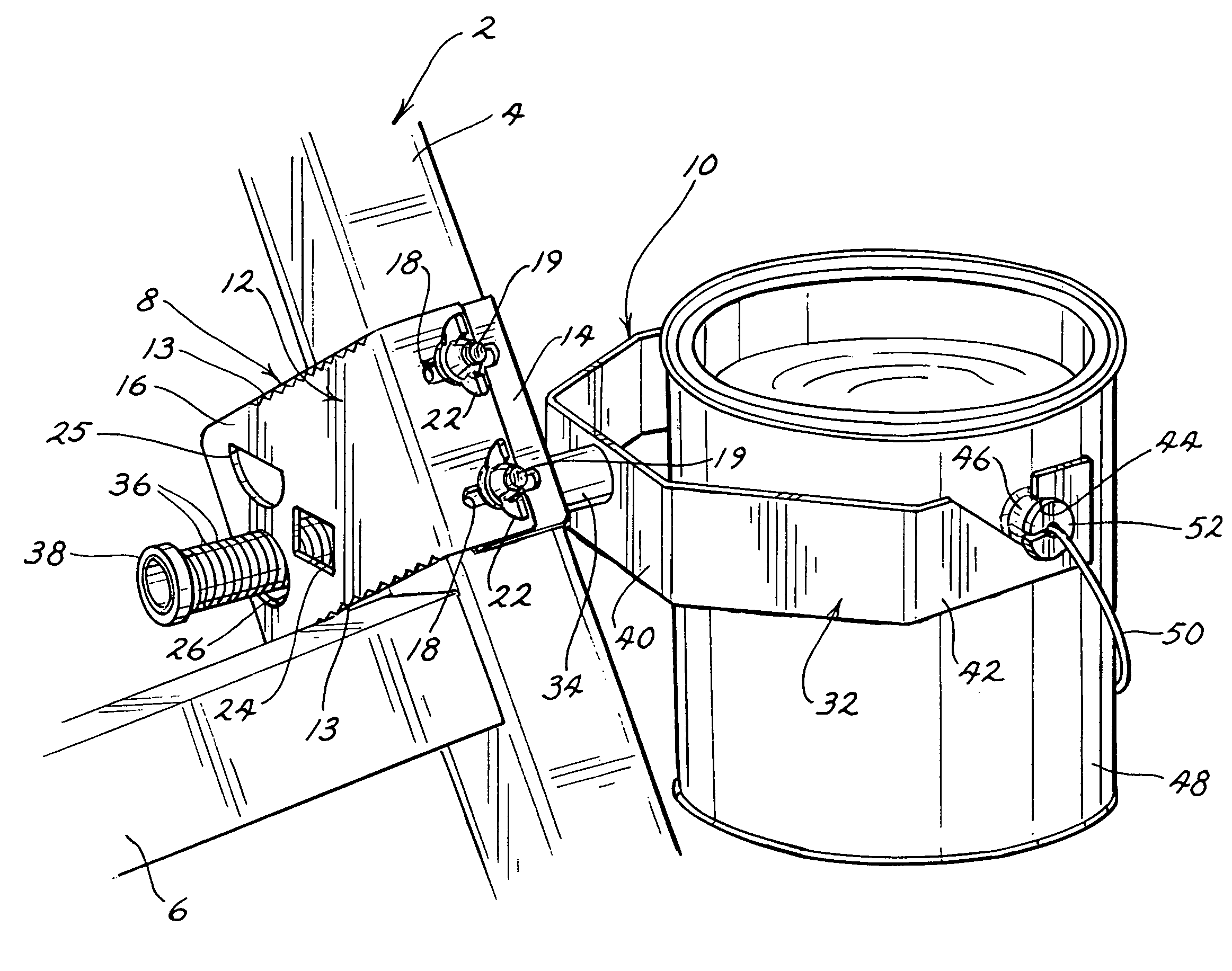

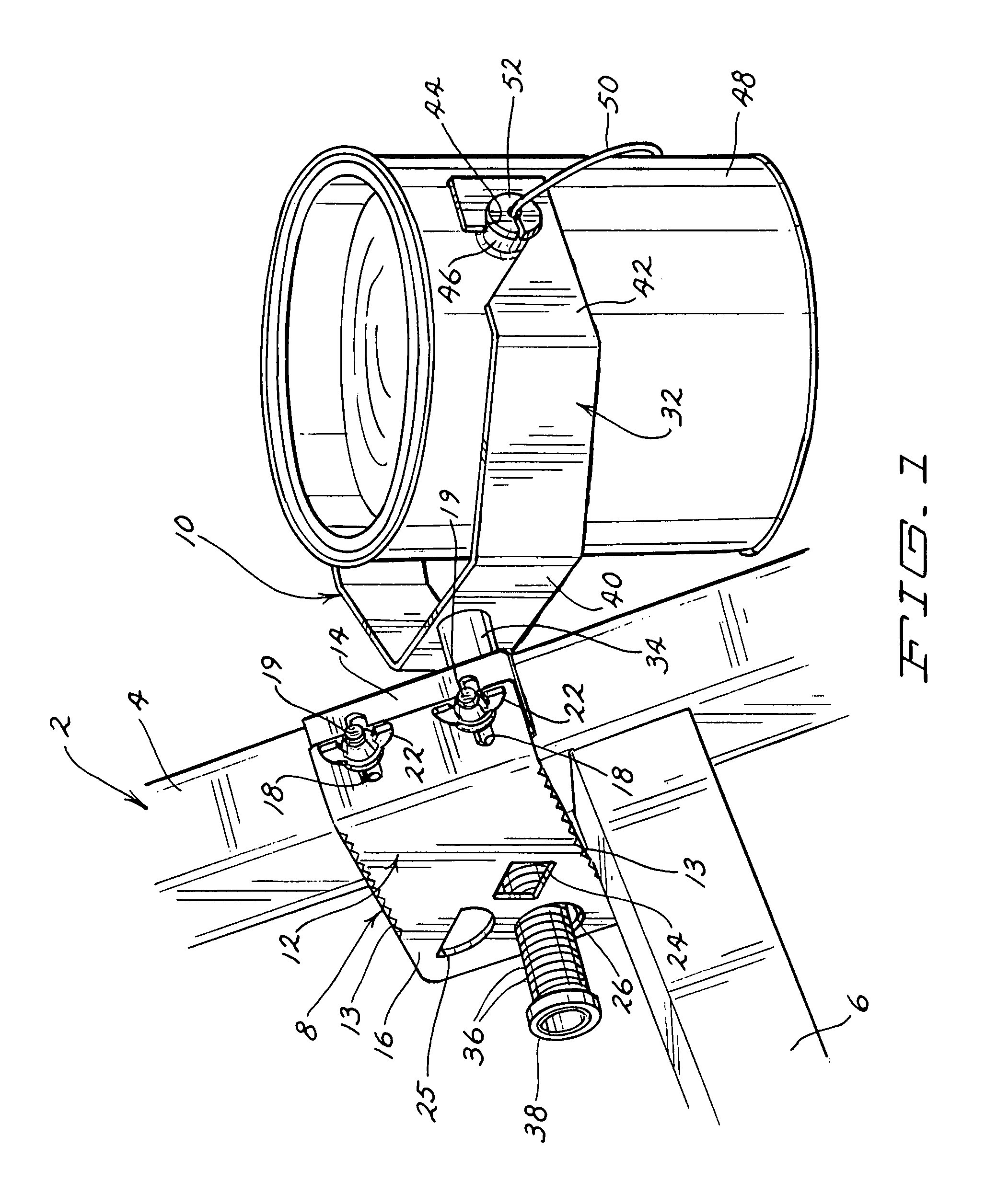

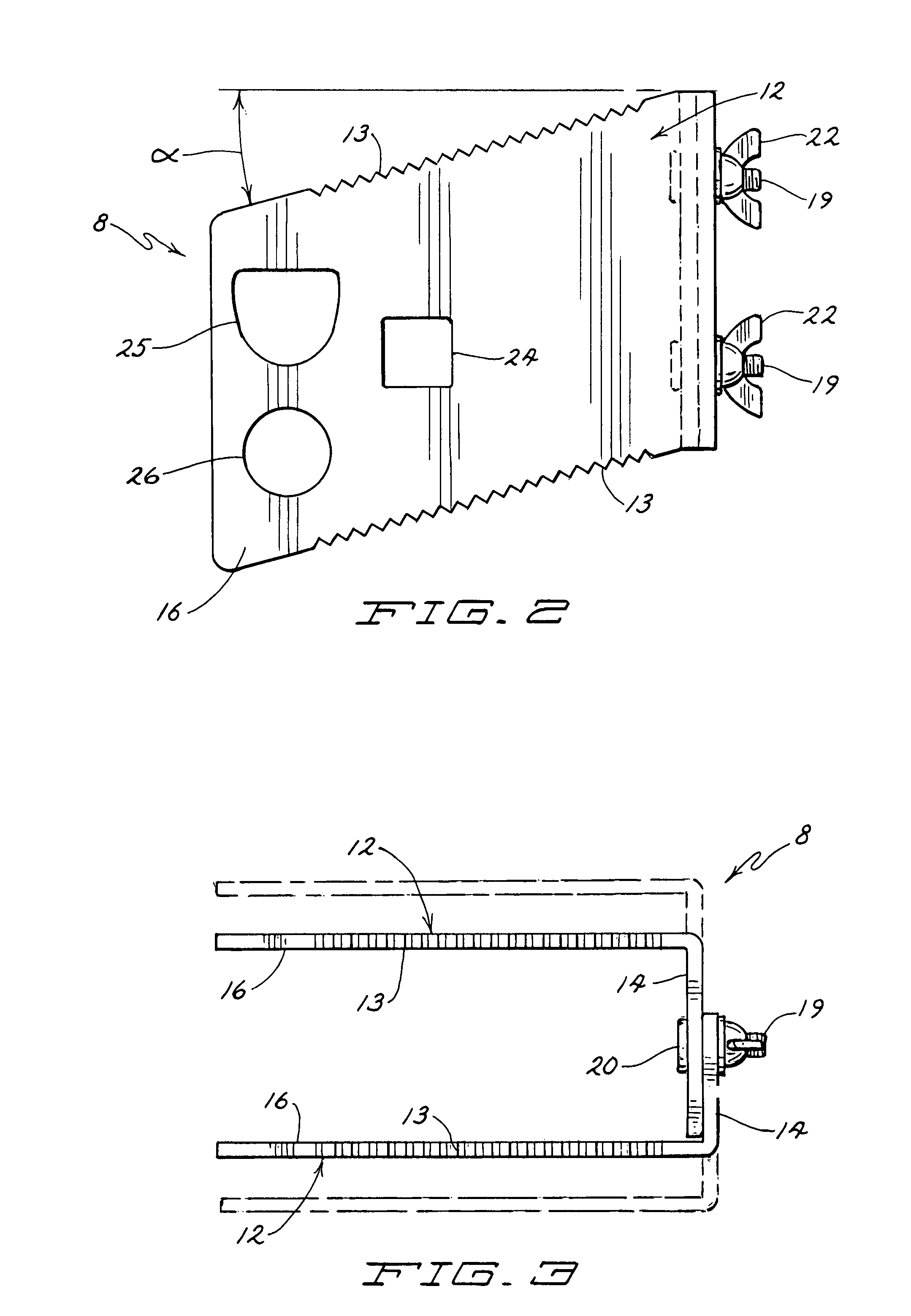

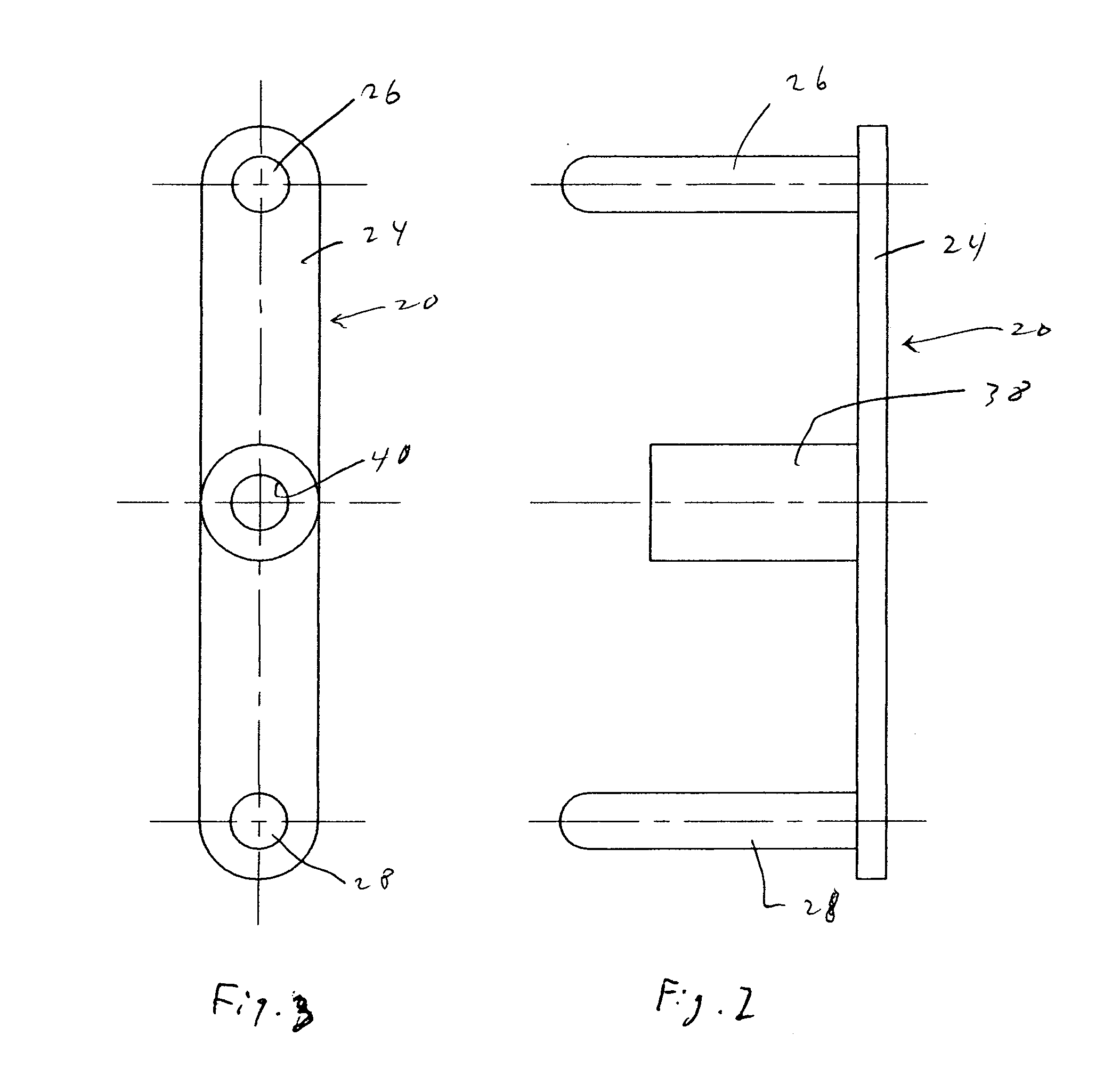

Ladder attached support bracket and paint can and roller pan holders for use therewith

A U-shaped bracket having an adjustable width is telescopically inserted around a side rail of the ladder by pushing the bracket onto the side rail with the open end of the bracket receiving the side rail as the bracket is pushed onto the side rail. Side walls of the bracket have extended wall portions that stick out past the rear of the side rail. A paint can holder can be telescopically inserted through a set of aligned holes in the extended wall portions to couple the paint can holder to the side rail of the ladder. A paint roller pan holder can also be telescopically inserted through a set of aligned holes in the extended wall portion to couple the paint roller pan holder to the side rail of the ladder. The paint roller pan holder includes a pivot connection to allow the portion of the holder that supports a paint roller pan to be leveled relative to the horizontal.

Owner:PETERSON LLOYD E

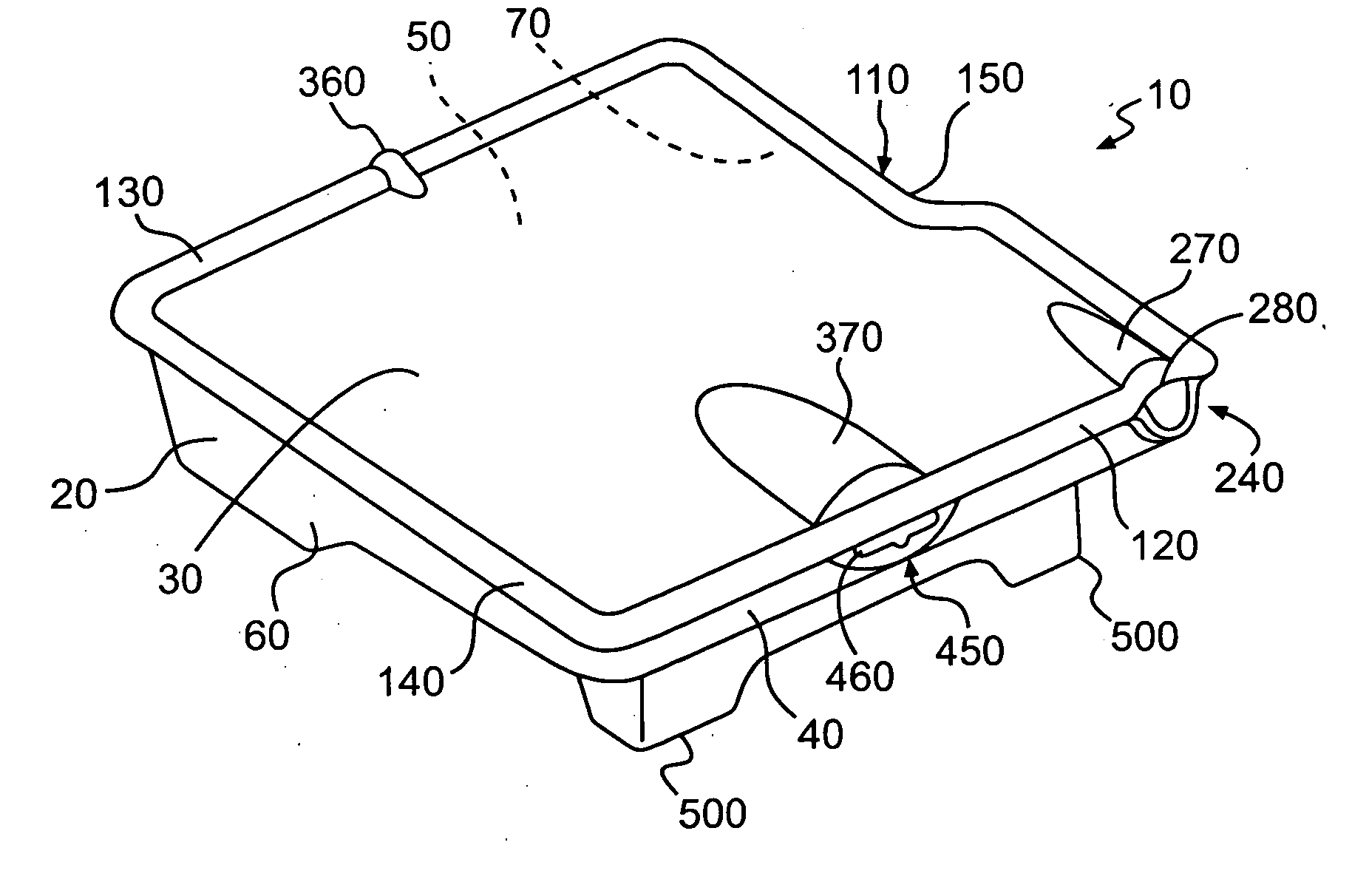

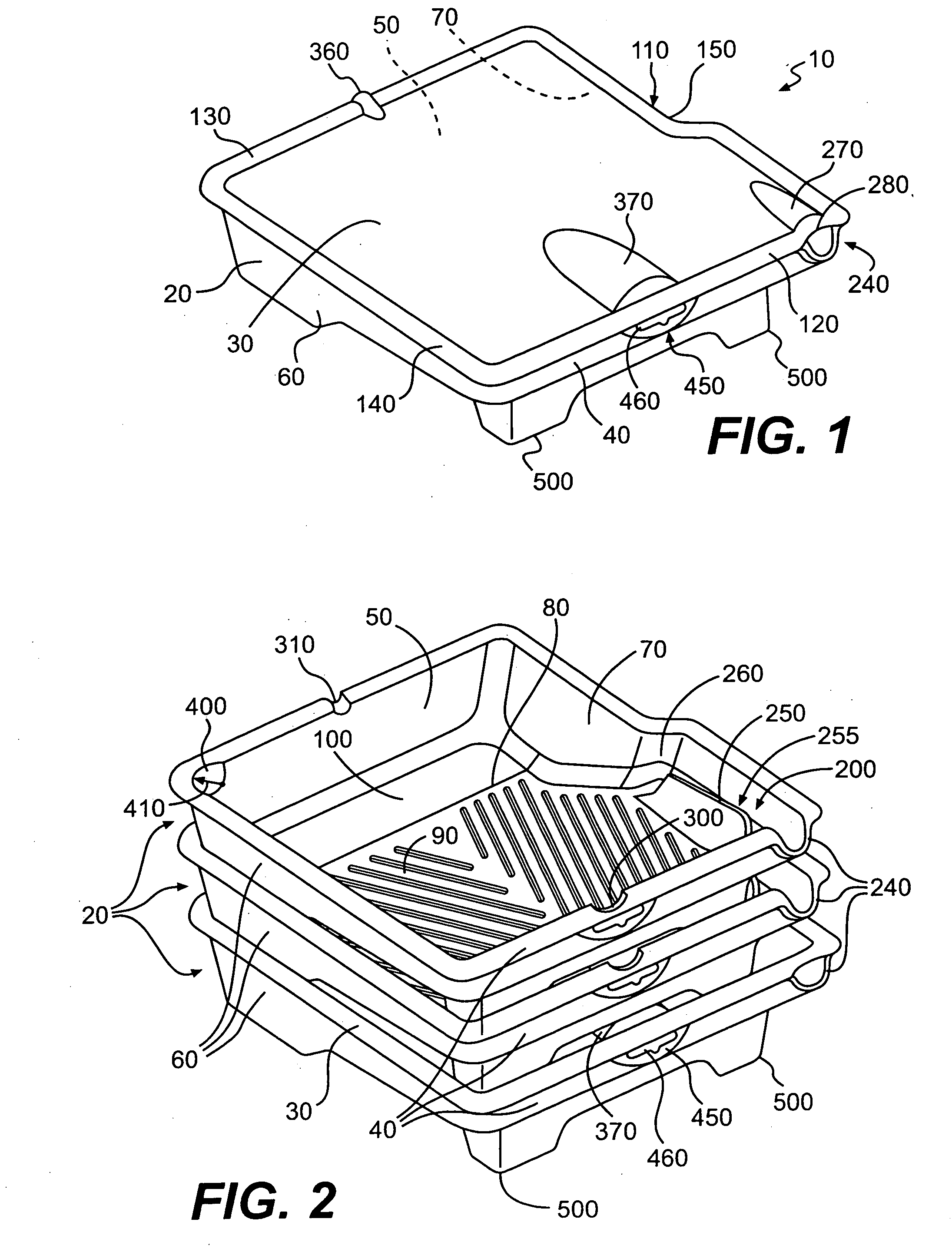

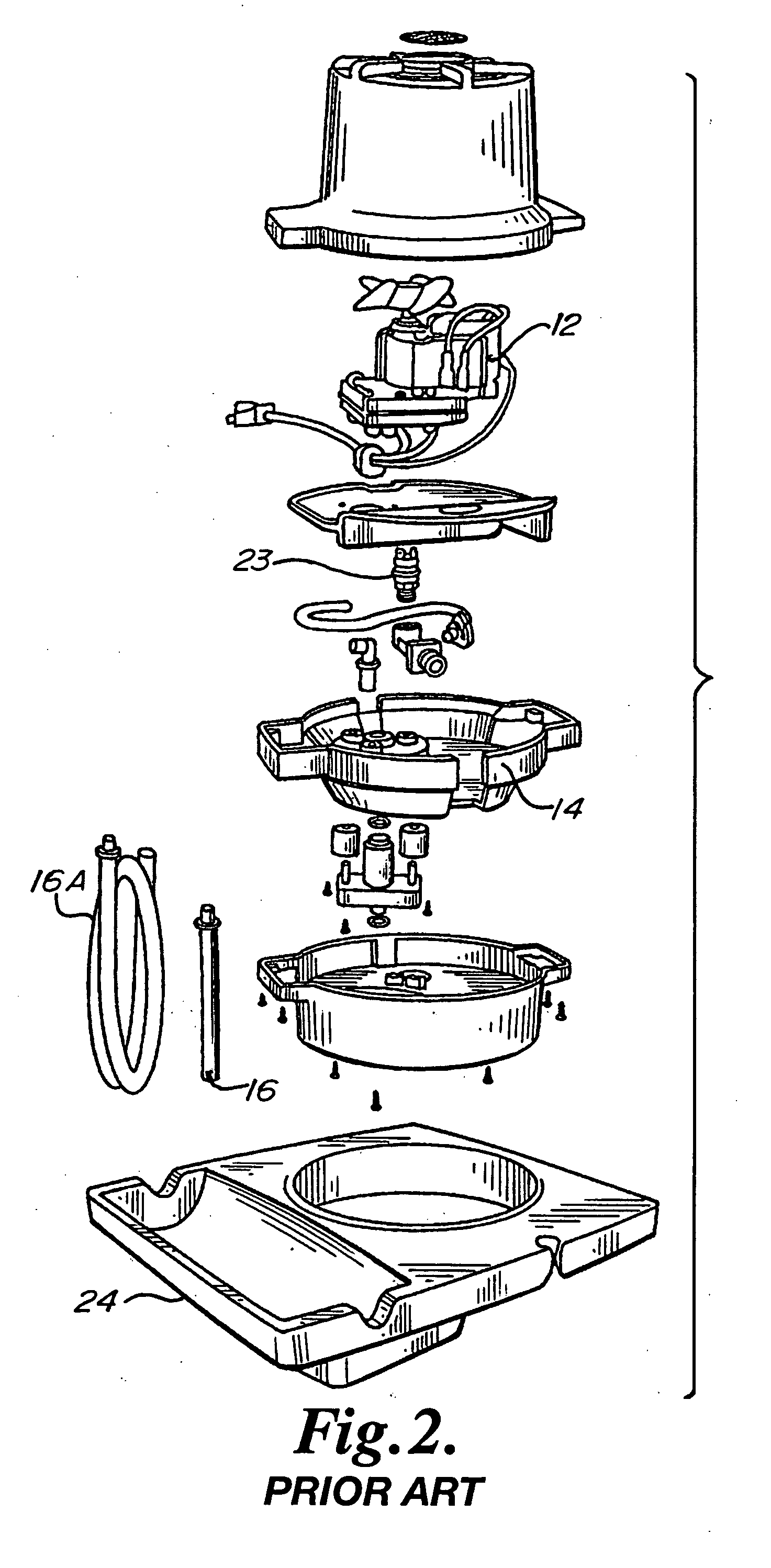

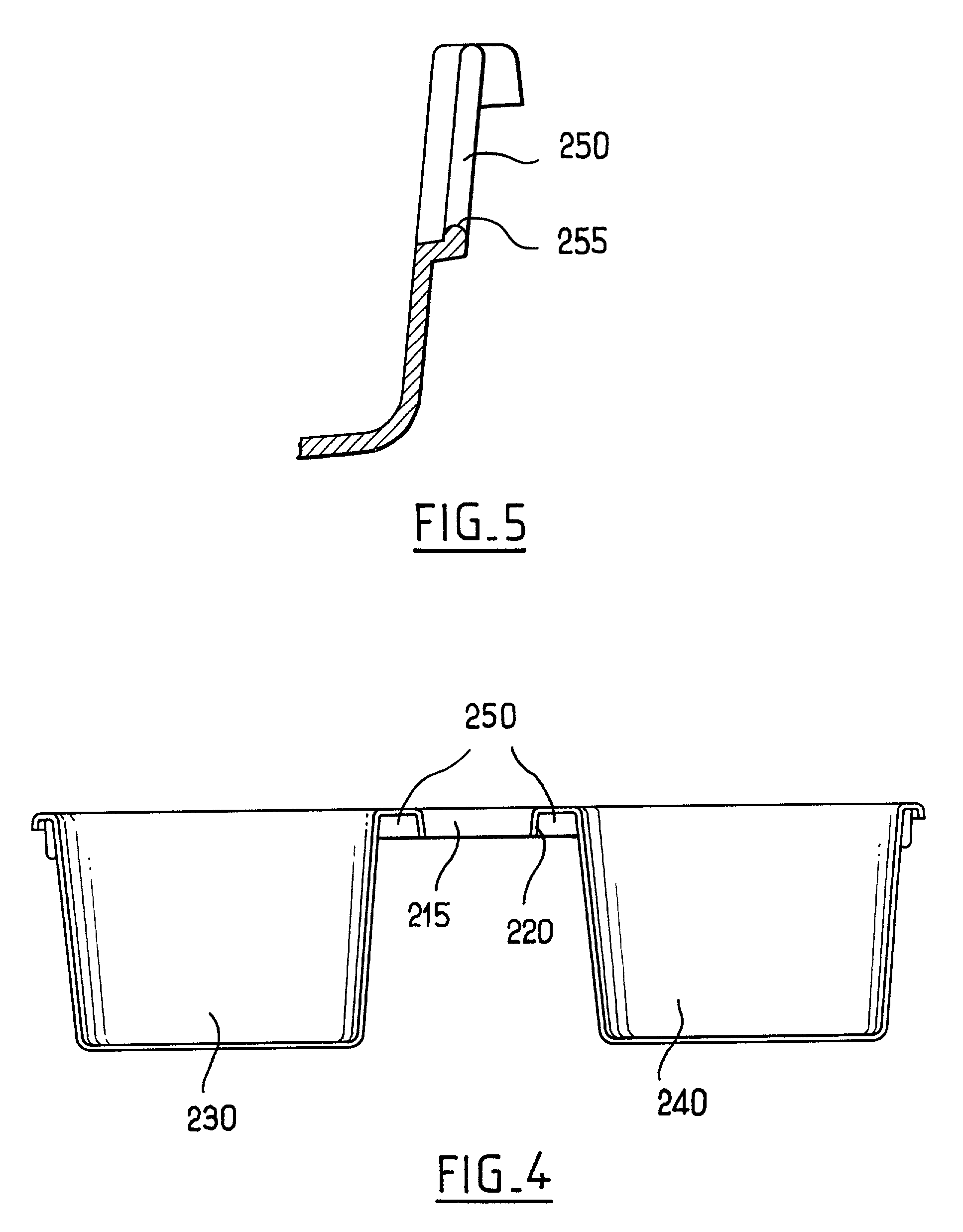

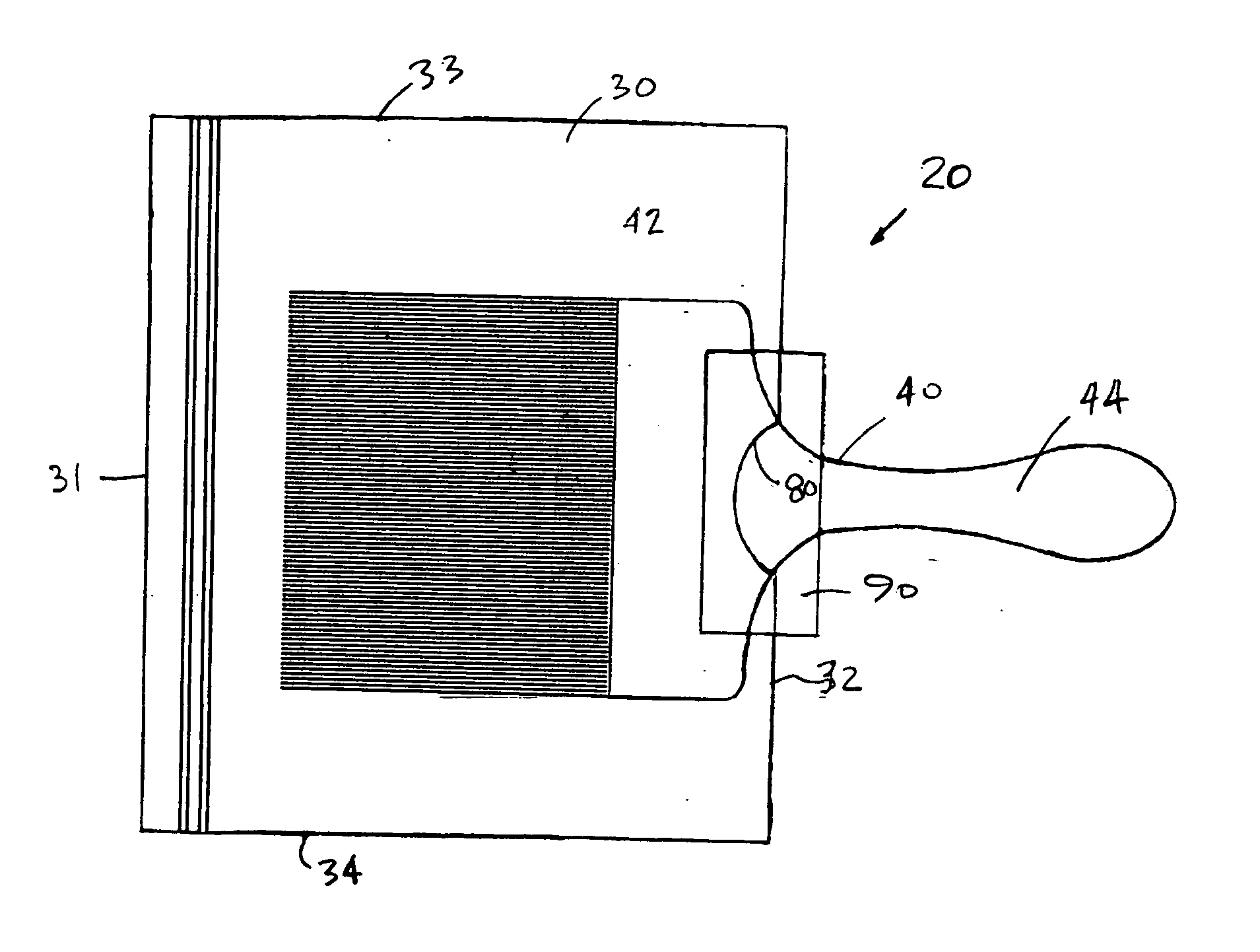

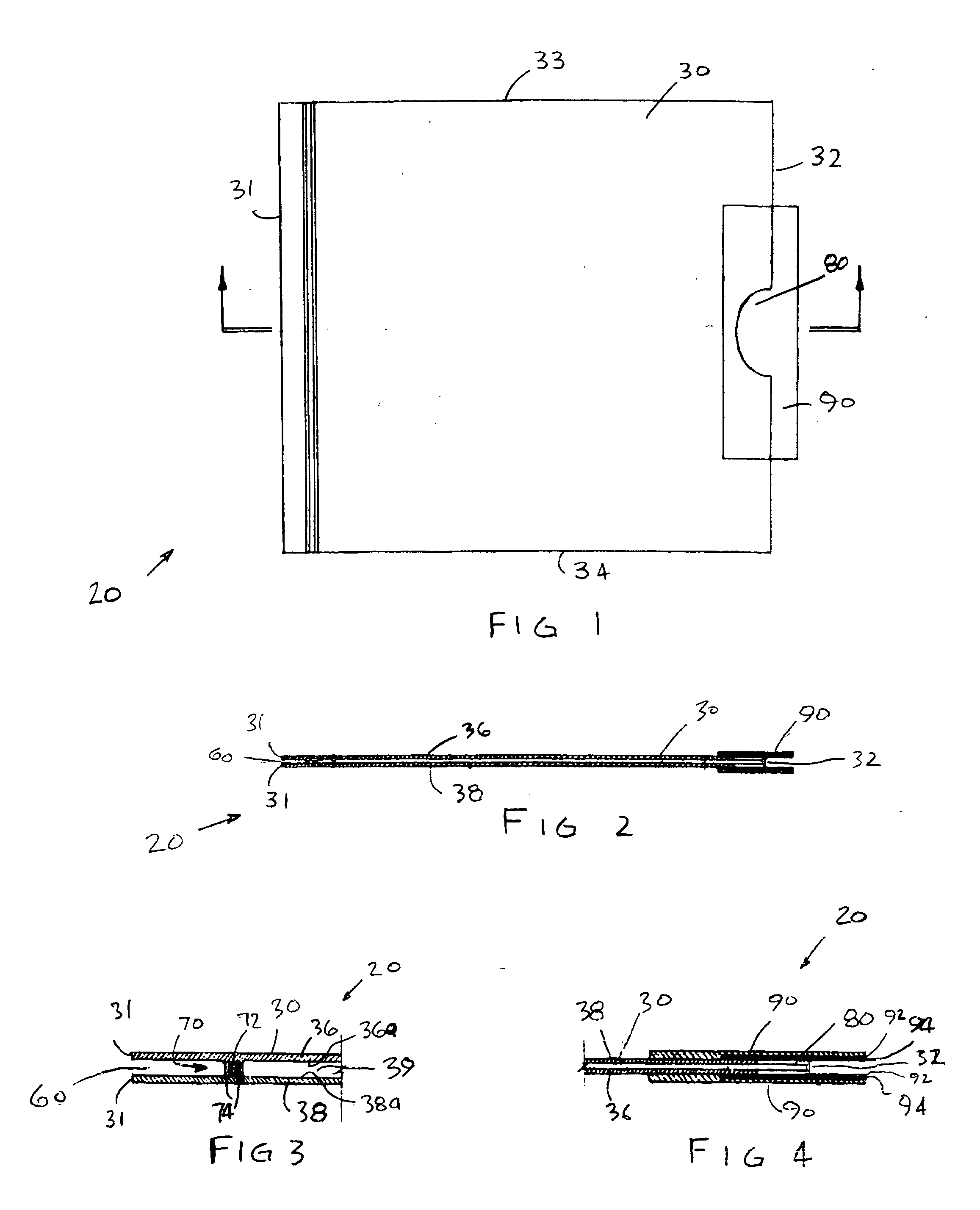

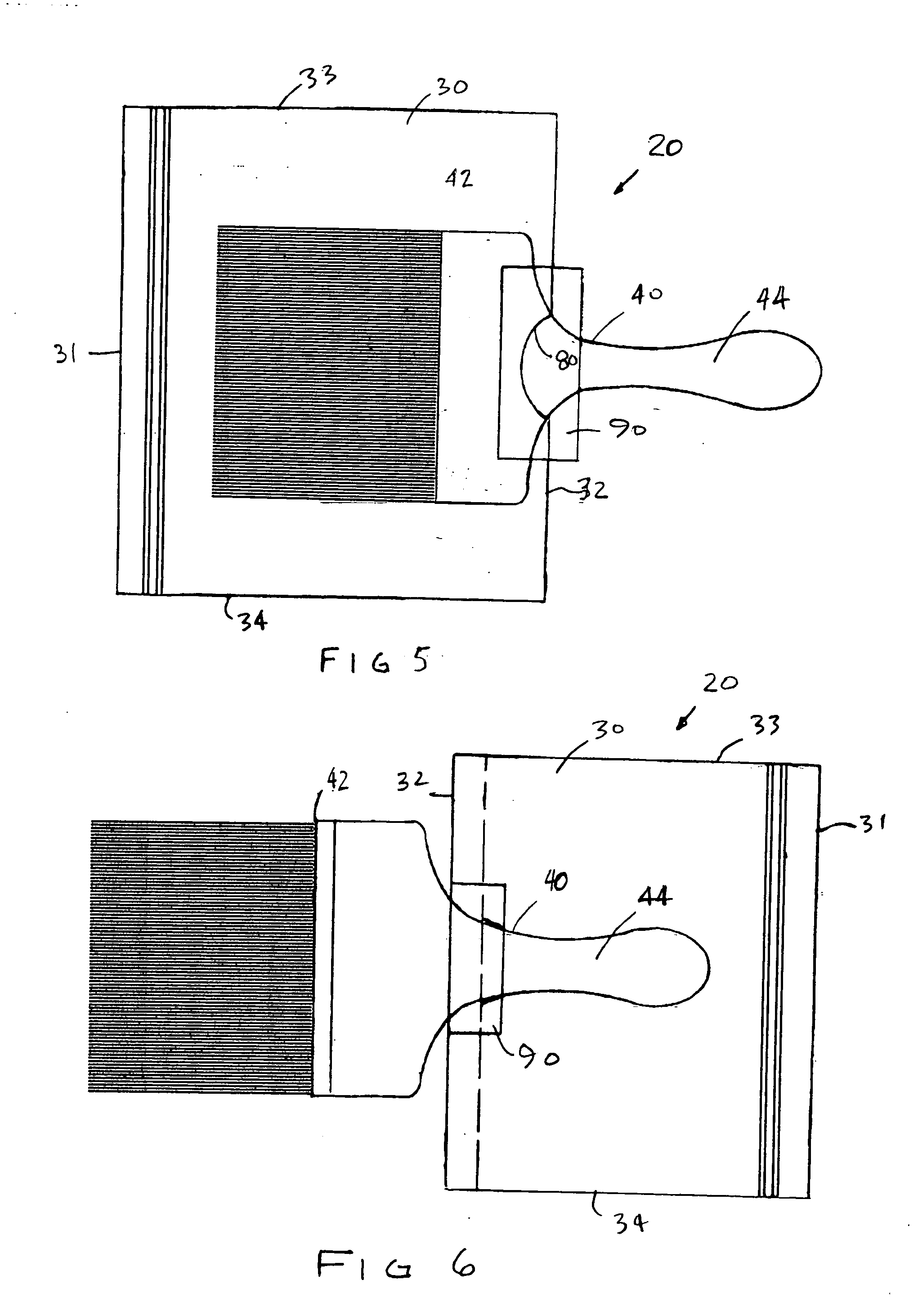

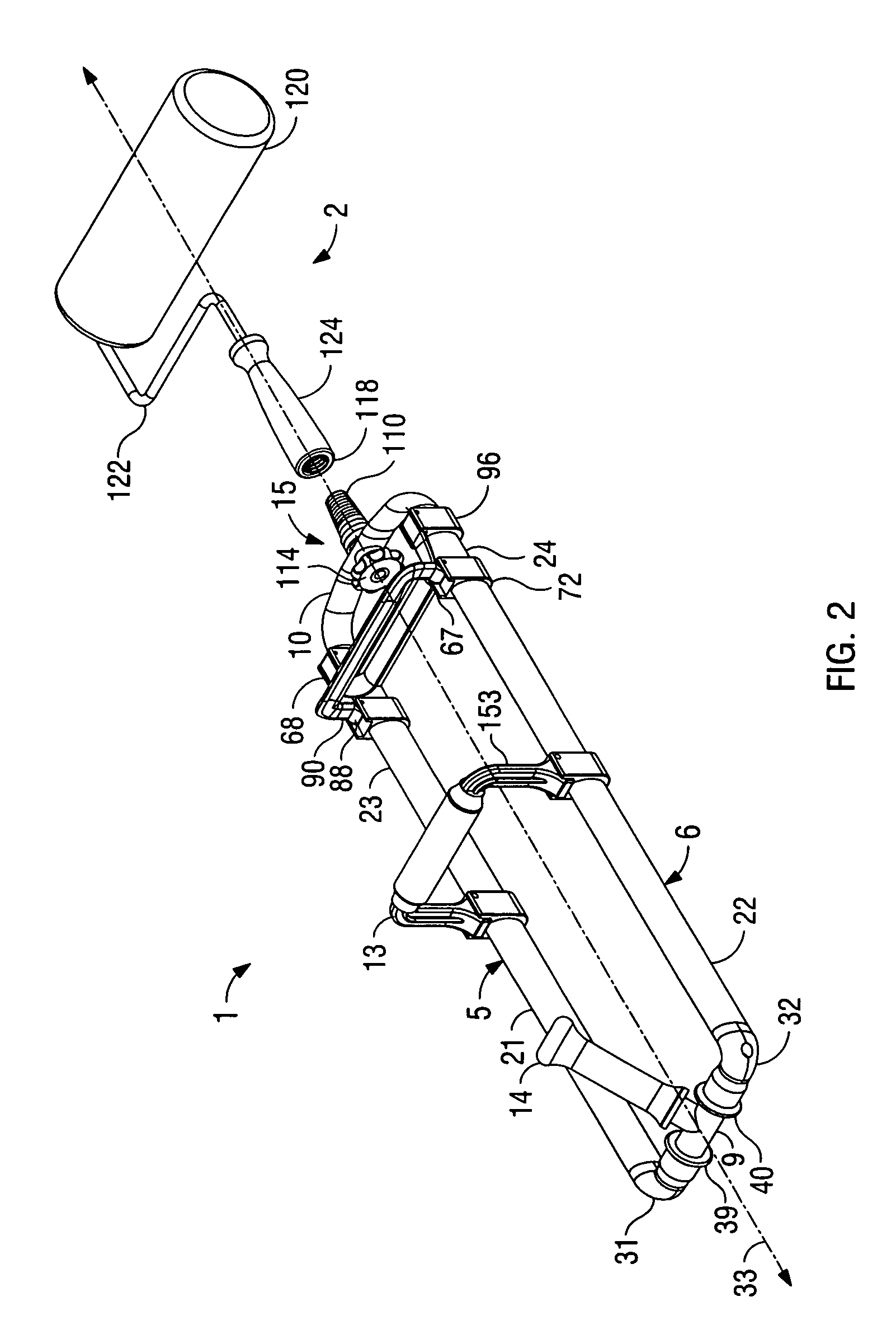

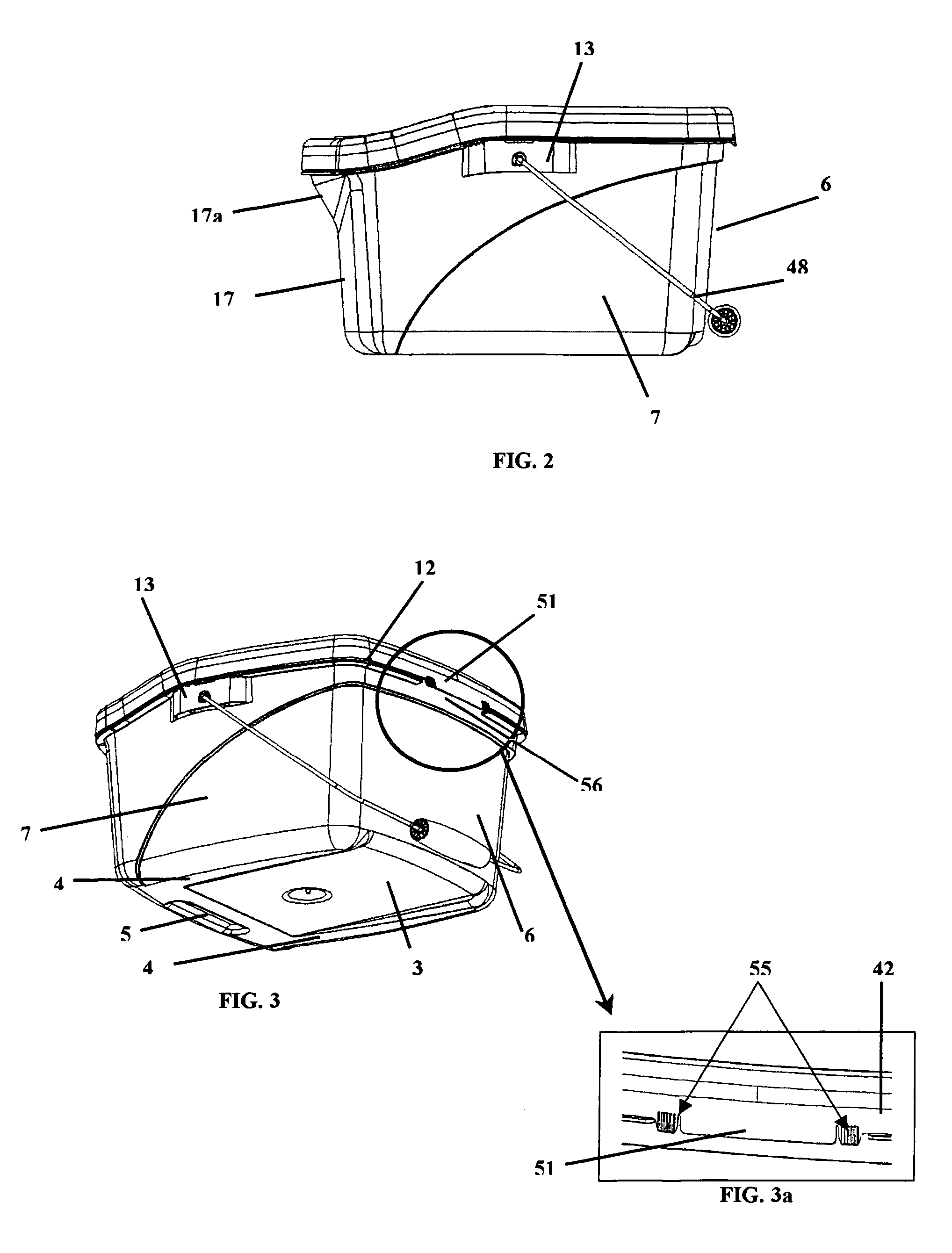

Sealable paint tray assembly

InactiveUS20040238399A1Reduce compoundingWithout a skin forming on the paint or allowing the paint applicator to hardenLiquid surface applicatorsCarpet cleanersEngineeringPaint roller

A paint tray system including a paint tray and a lid that may be sealed to the paint tray in a generally airtight manner. The shape of the lid corresponds to the interior of the paint tray so that the volume of air sealed in the paint try by the lid is minimized. The underside of the lid may also include a recess that may receive a paint applicator between the paint tray and the lid. The paint tray may also include an applicator rest for holding a paint roller in the paint tray while keeping the handle out of a paint reservoir.

Owner:BILLADO HARRY S JR

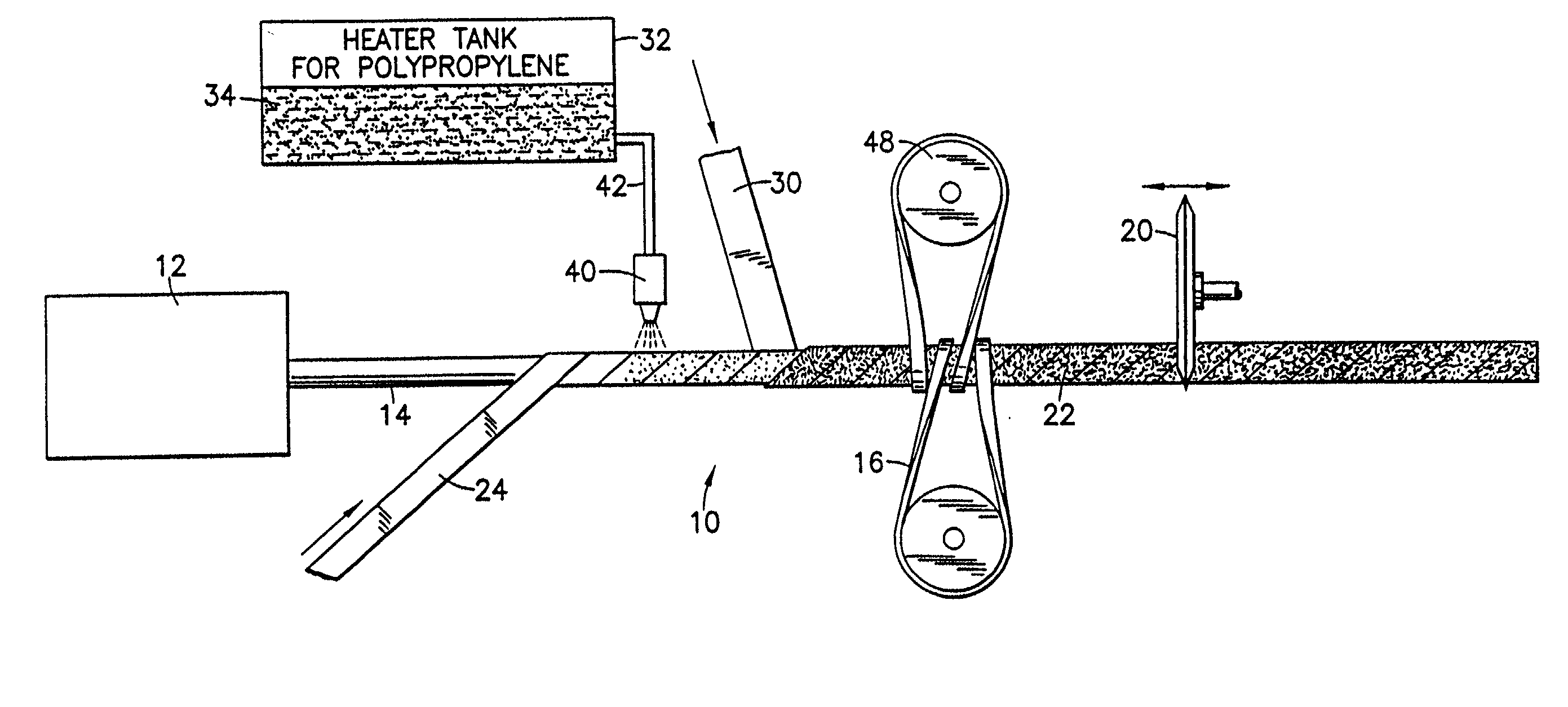

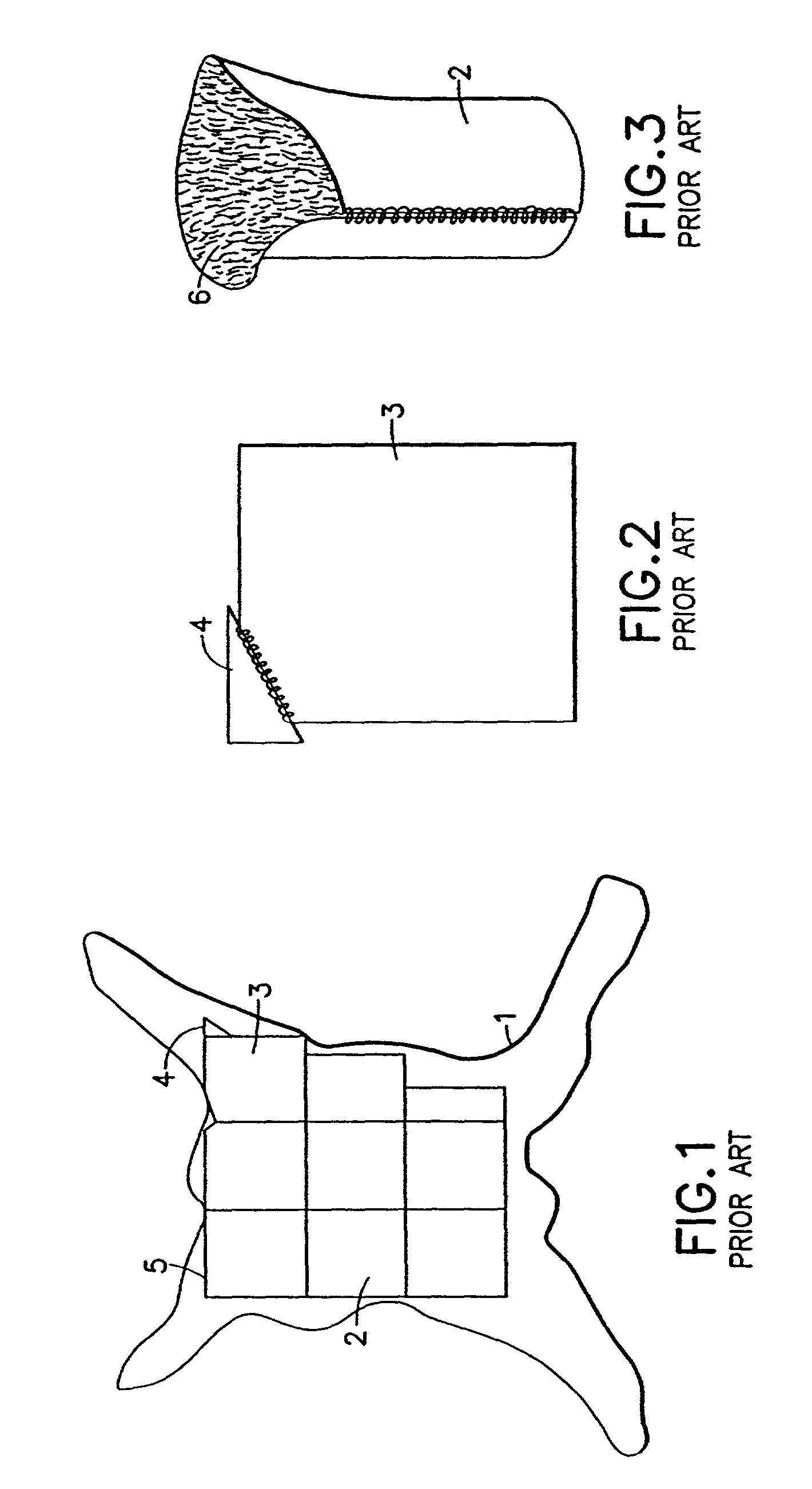

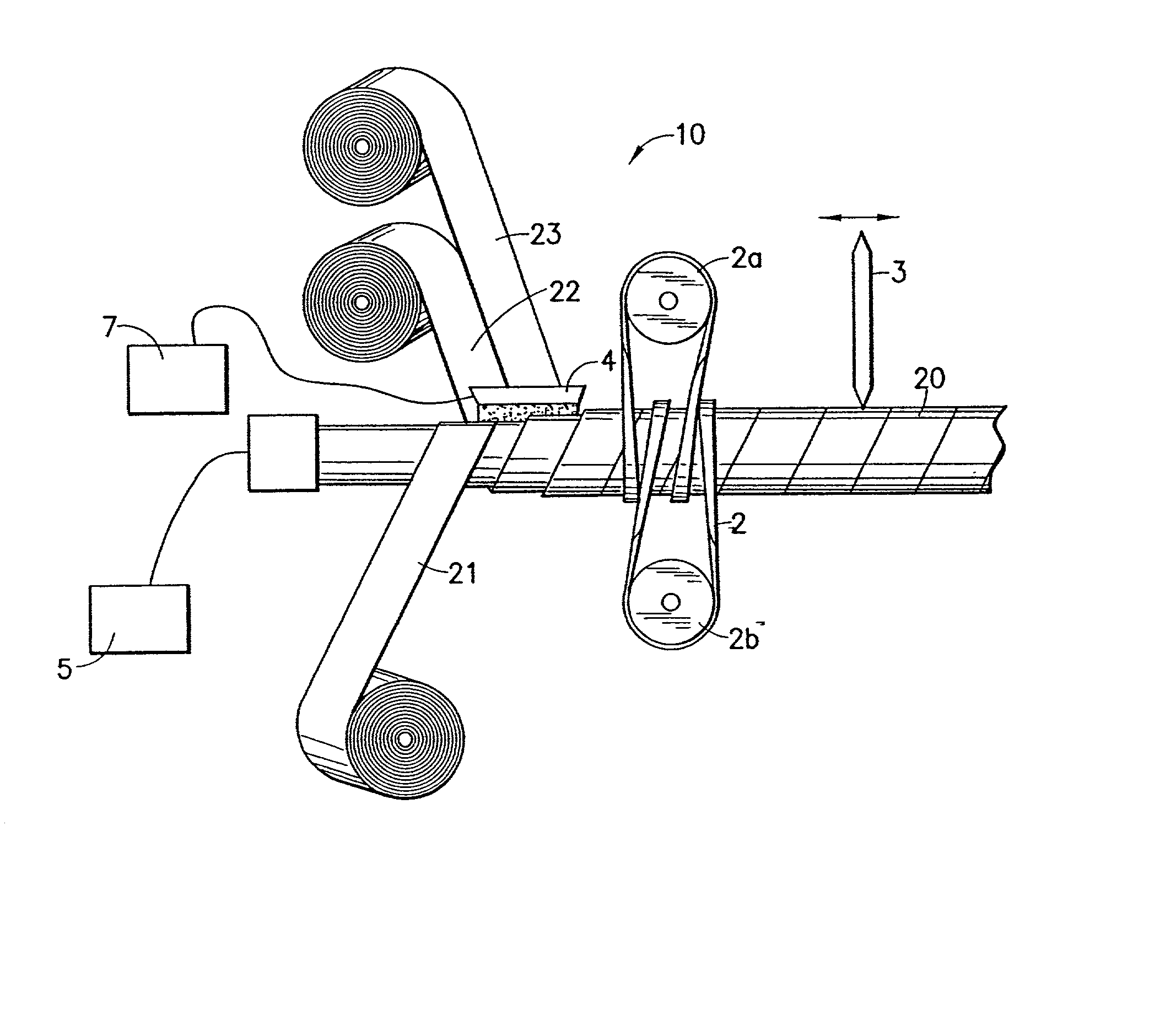

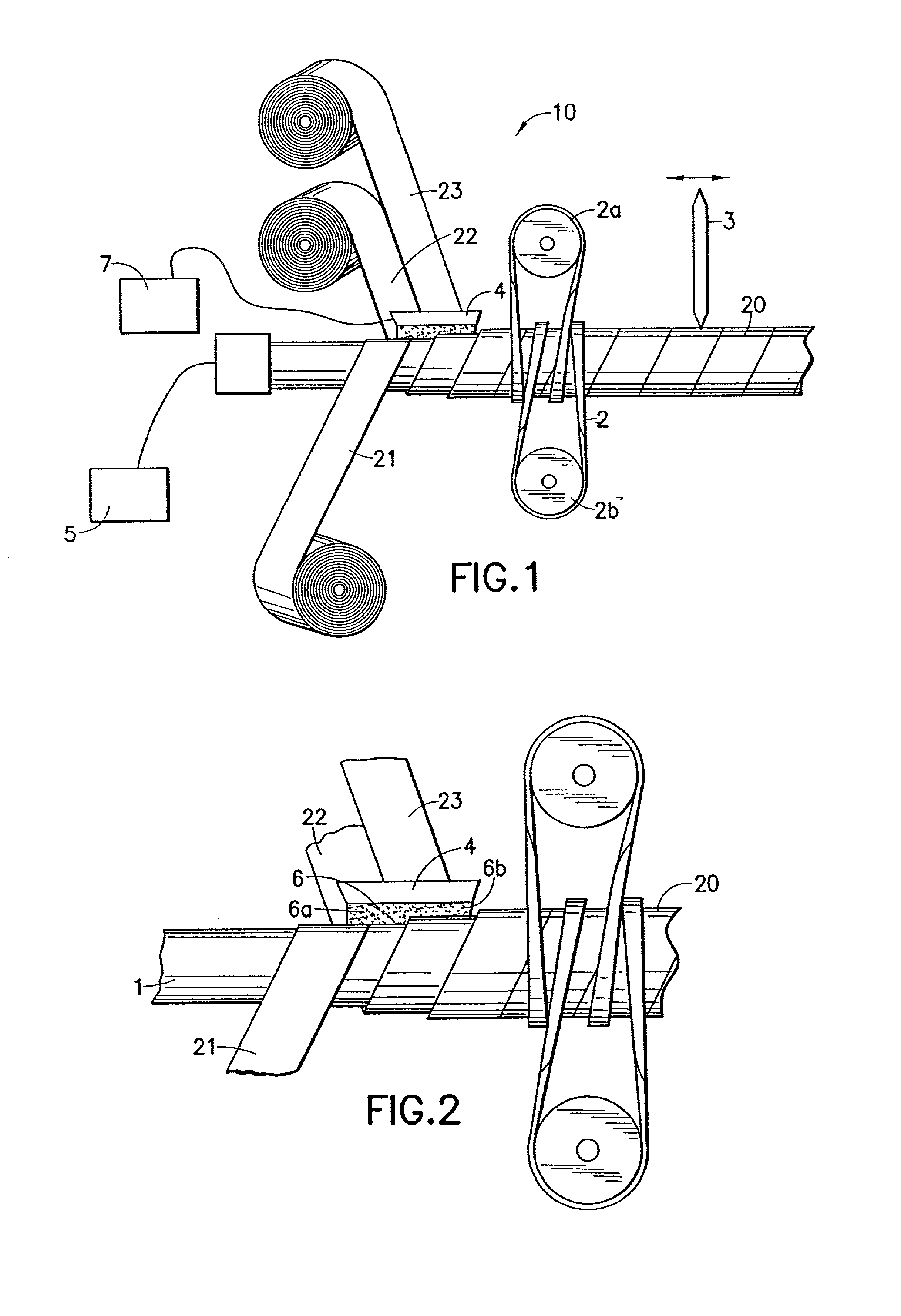

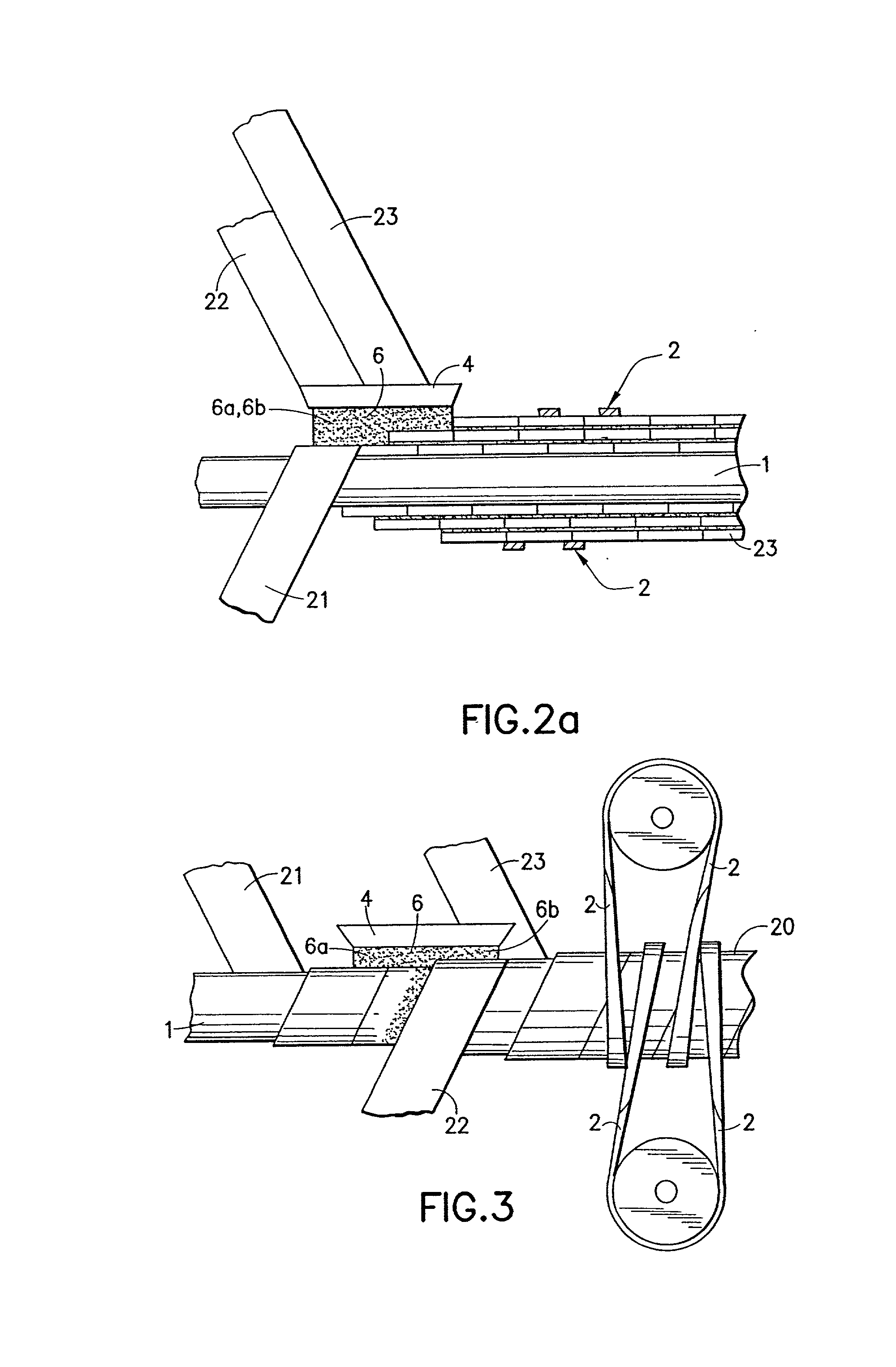

Paint roller with integrated core and natural cover and method and apparatus for production of same

A method and apparatus for making a paint roller having a natural skin cover are provided. The natural skin cover being bonded to the paint roller using a thermoplastic material, preferably polypropylene, and the natural skin cover being formed from a strip of natural skin, such as lambskin, provided in a width sufficient to accommodate shrinkage in the manufacturing process. The resulting product providing a superior natural skin covered paint roller that is substantially integral and that will remain integral when exposed to paint solvents.

Owner:SEKAR CHANDRA

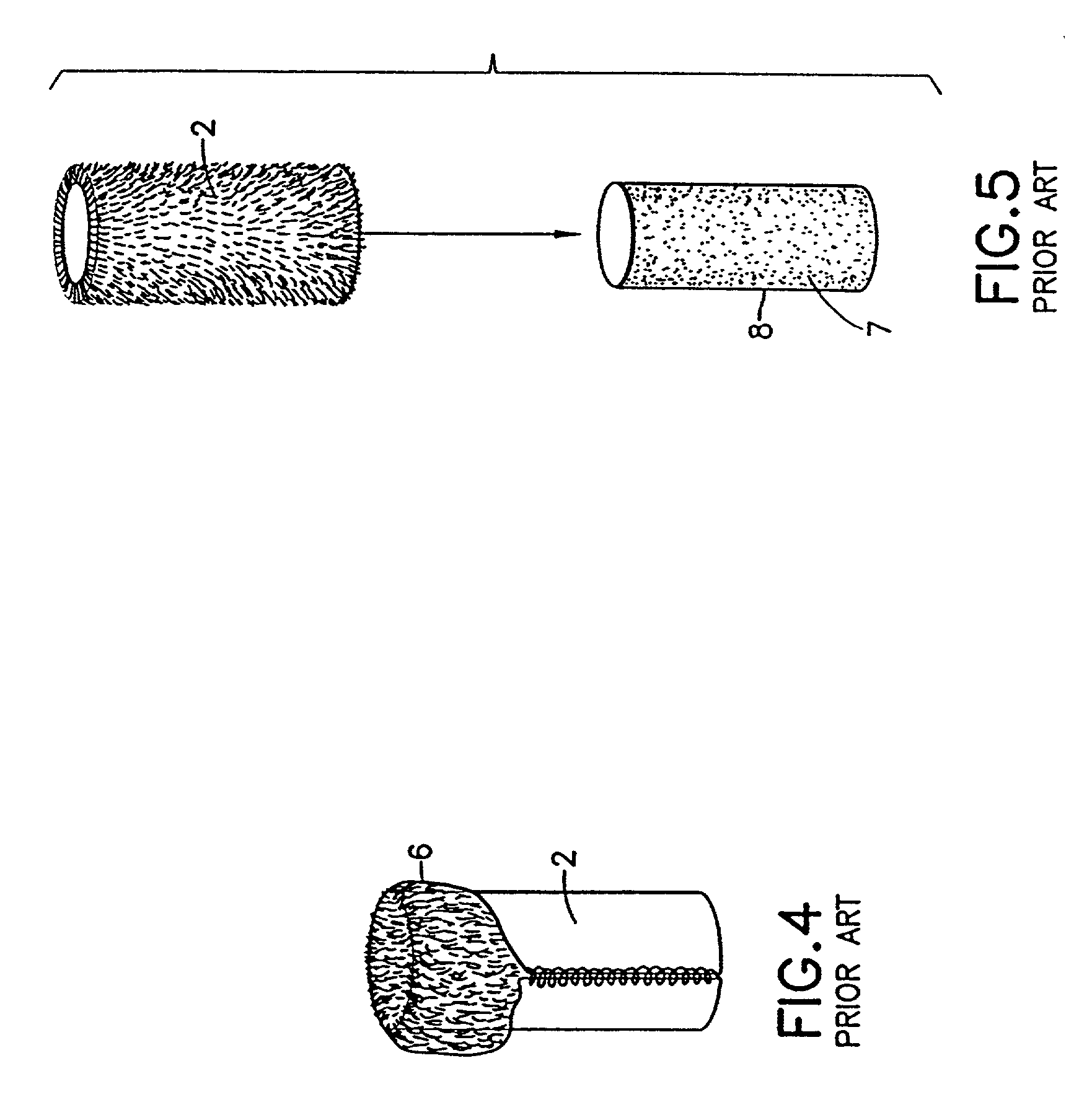

Reversible electric pump and paint roller assembly

InactiveUS20070134050A1Prevents wasting paintPrevents contaminating environmentLiquid surface applicatorsFlexible member pumpsEngineeringPaint roller

A paint roller dispenser apparatus has an electric motor; a pump driven by the motor; a tube connected to the pump for receiving paint; a hose connected to the pump; a handle; a paint roller connected to the hose and to the handle; and a mechanism for reversing the direction of flow of paint between the tube and the roller. In one embodiment, the mechanism is electronic. In other embodiment, the mechanism is mechanical.

Owner:DIVERSIFIED DYNAMICS

Paint roller with integrated core and cover and method and apparatus for production of same

InactiveUS20020077234A1Simple processLiquid surface applicatorsPaper/cardboard wound articlesThermoplastic materialsPaint roller

Owner:SEKAR CHANDRA

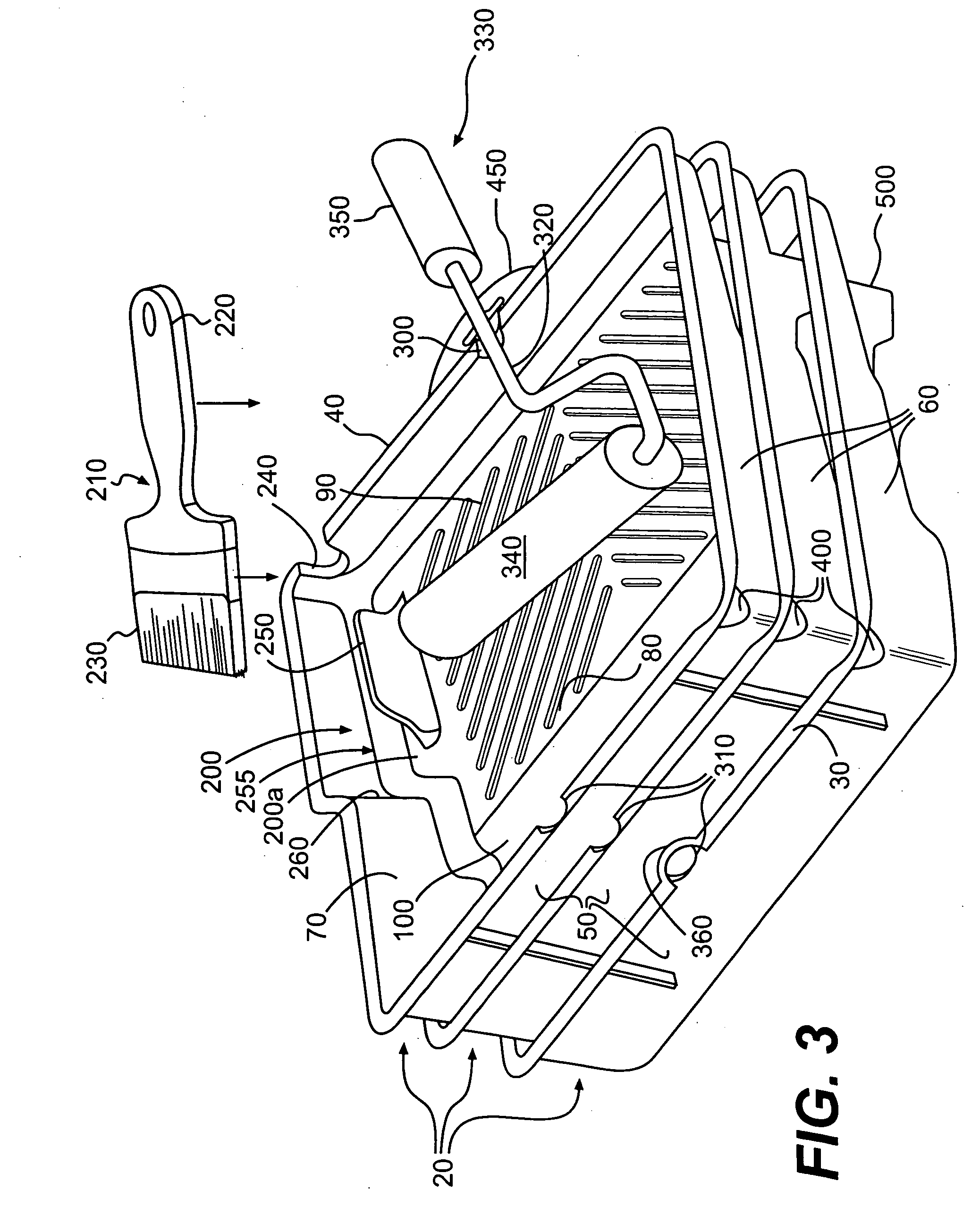

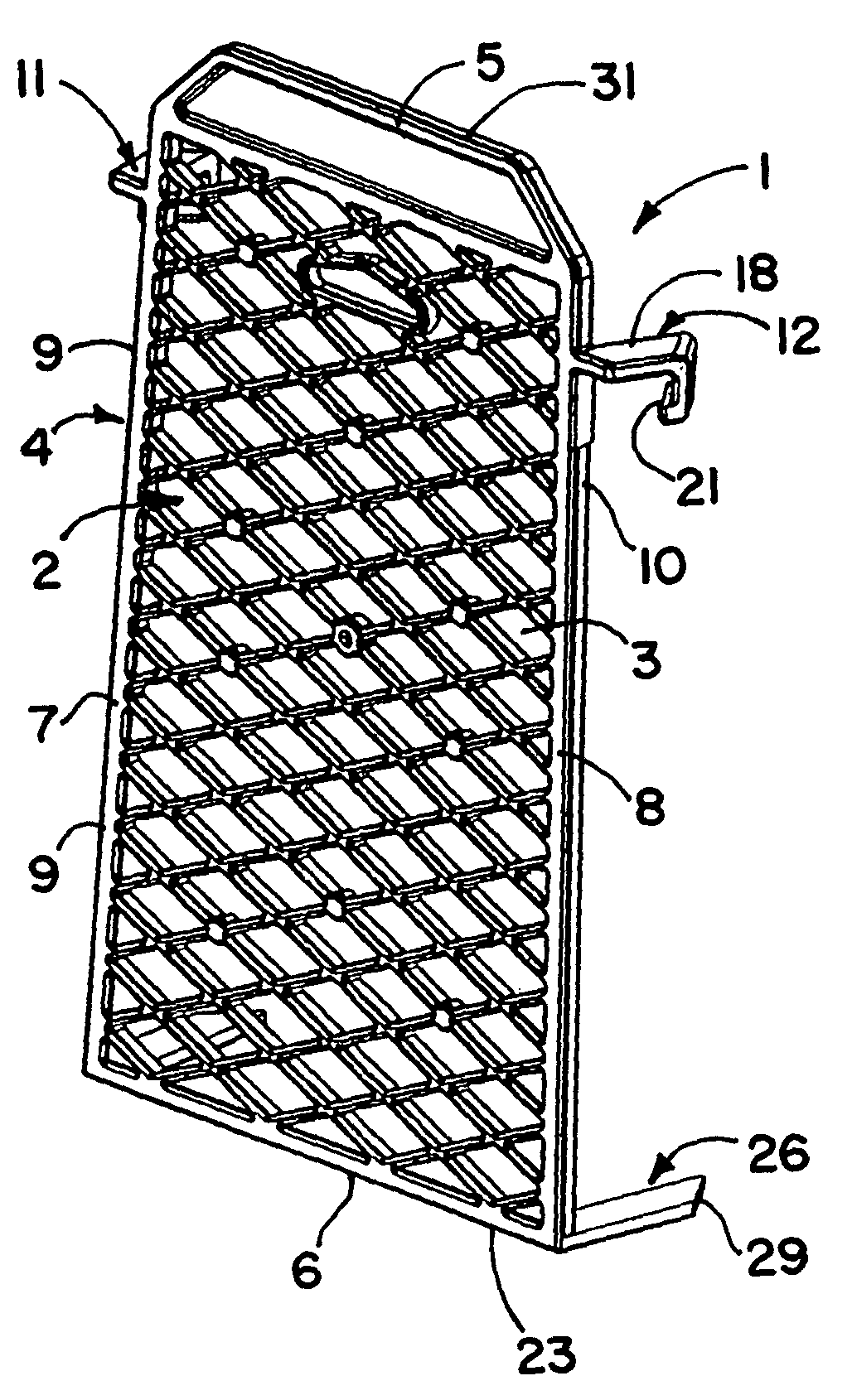

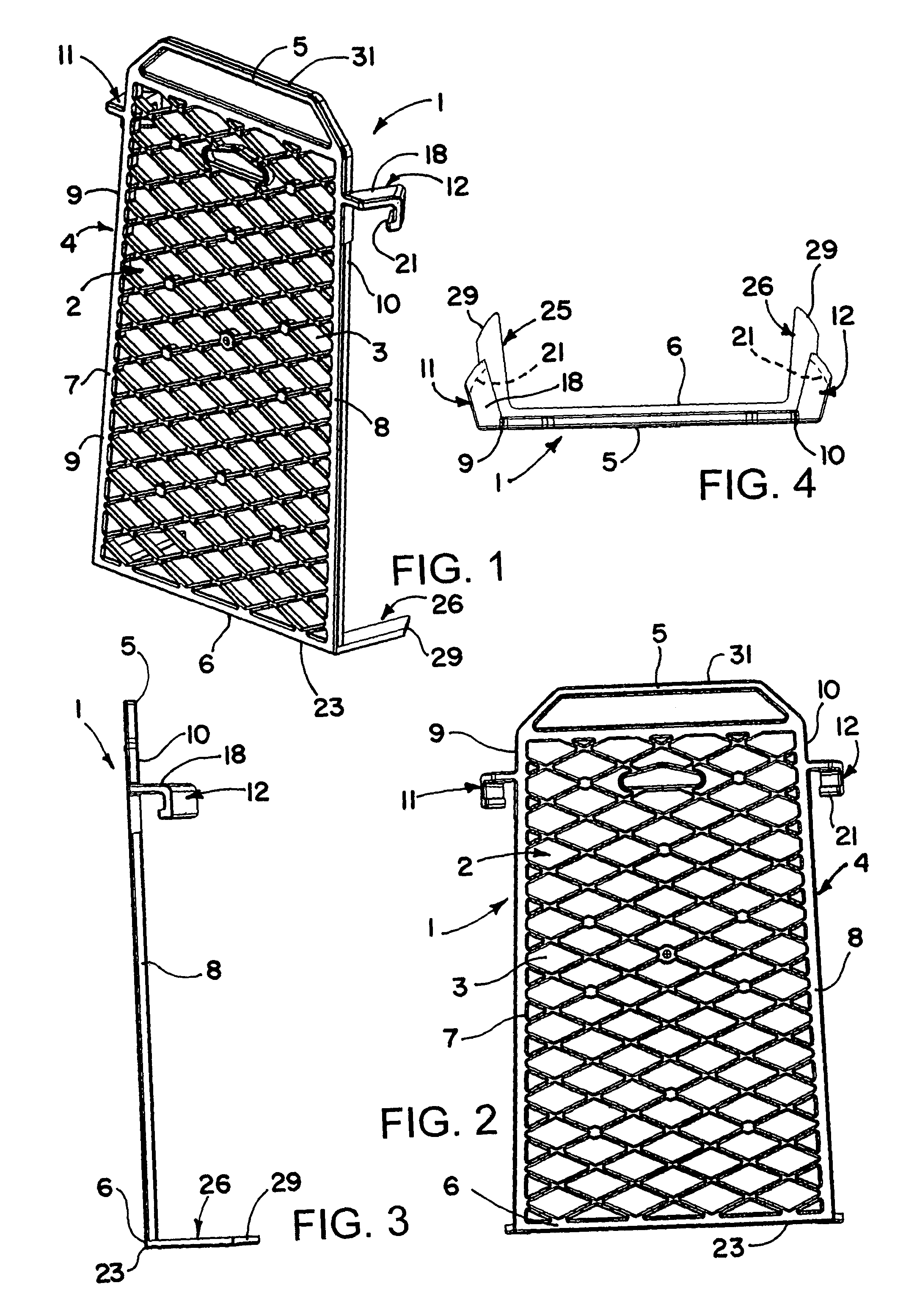

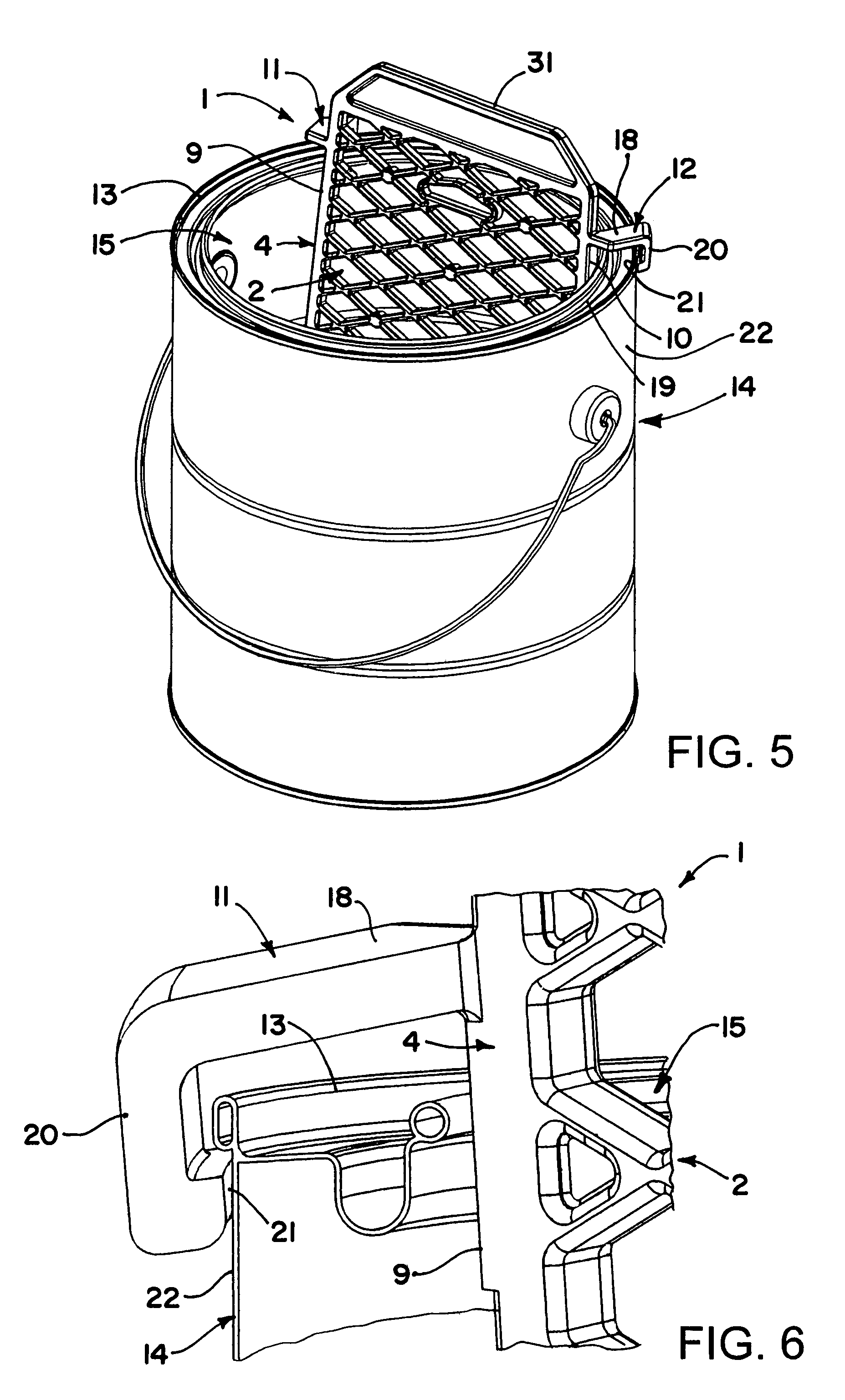

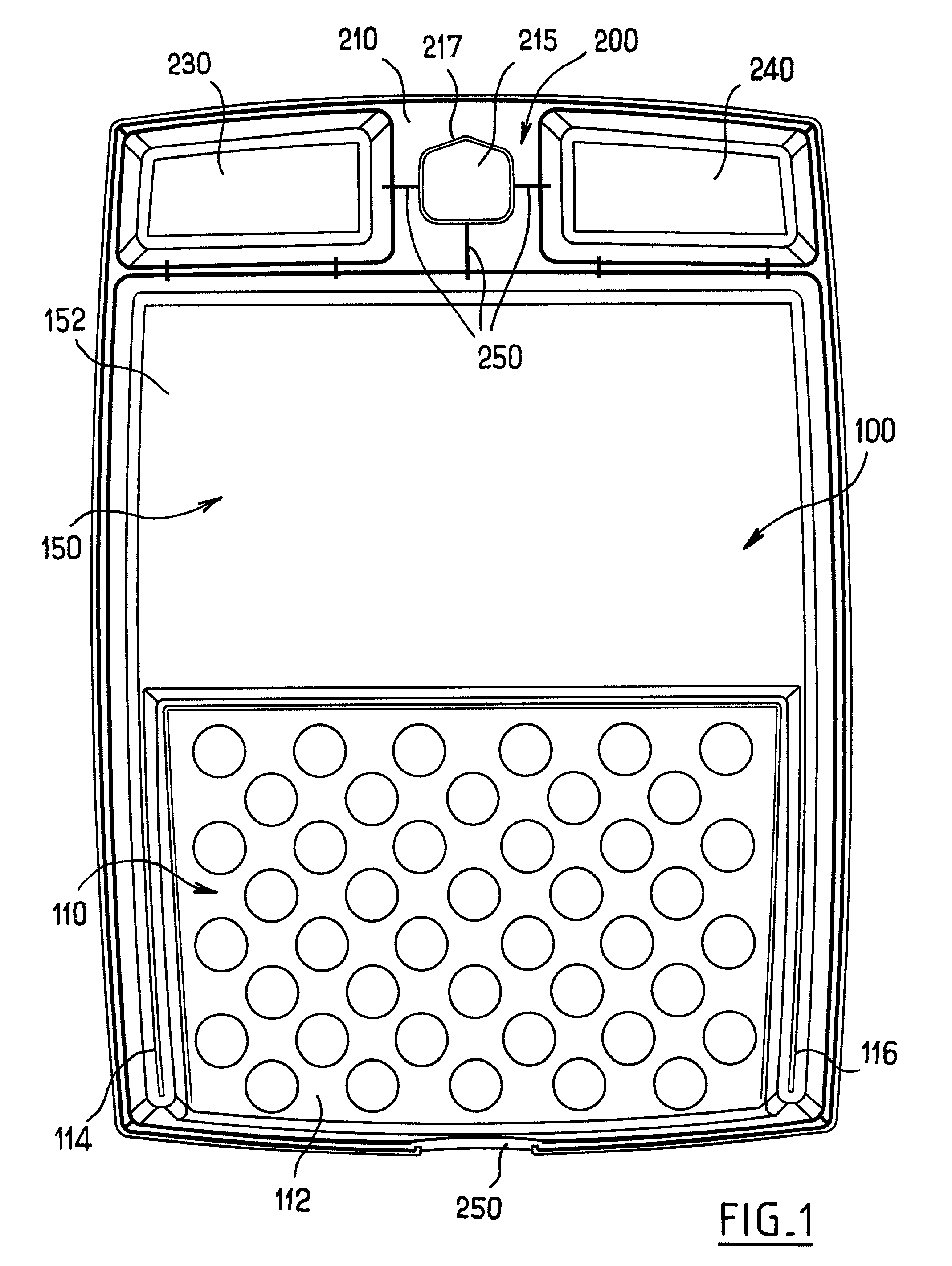

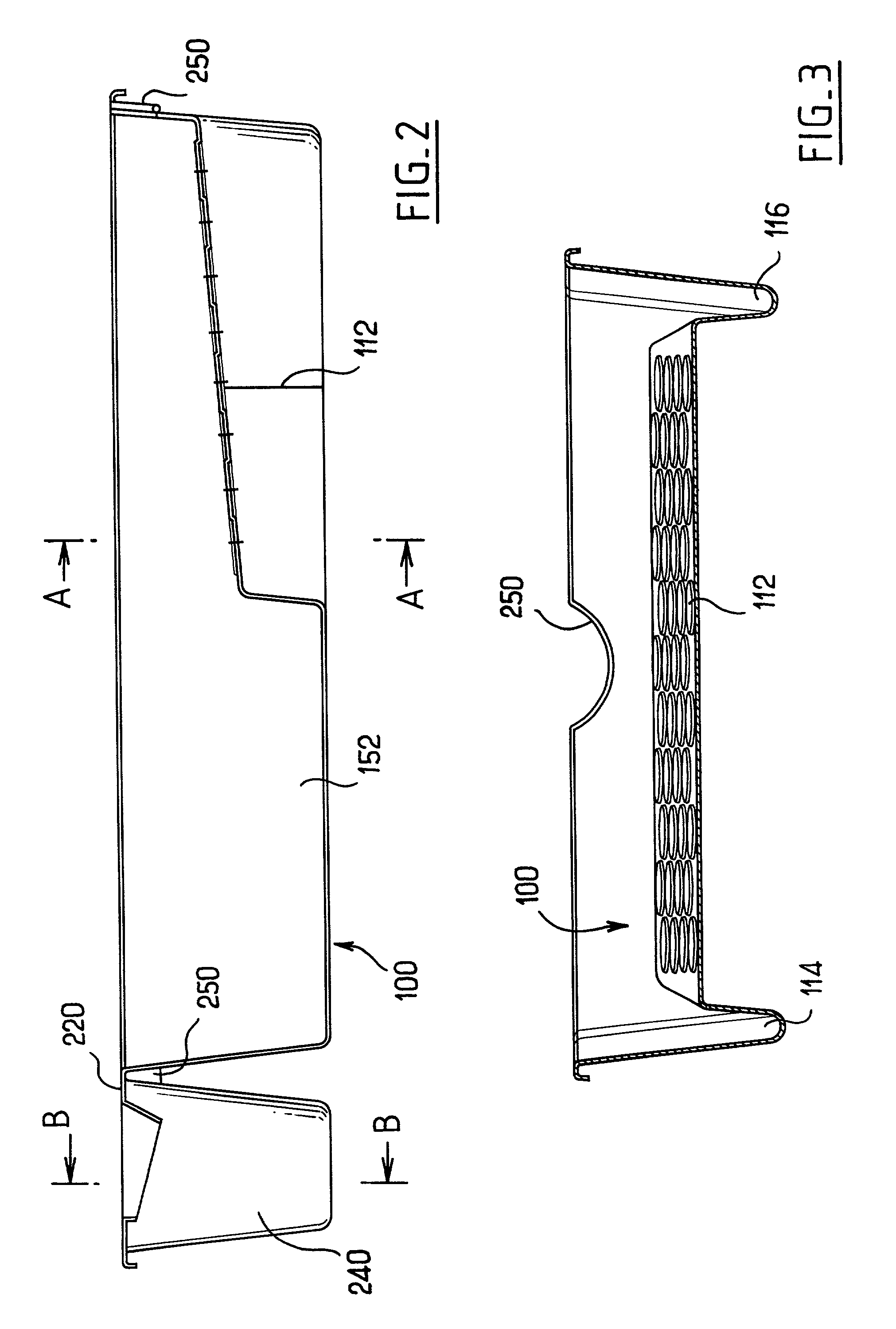

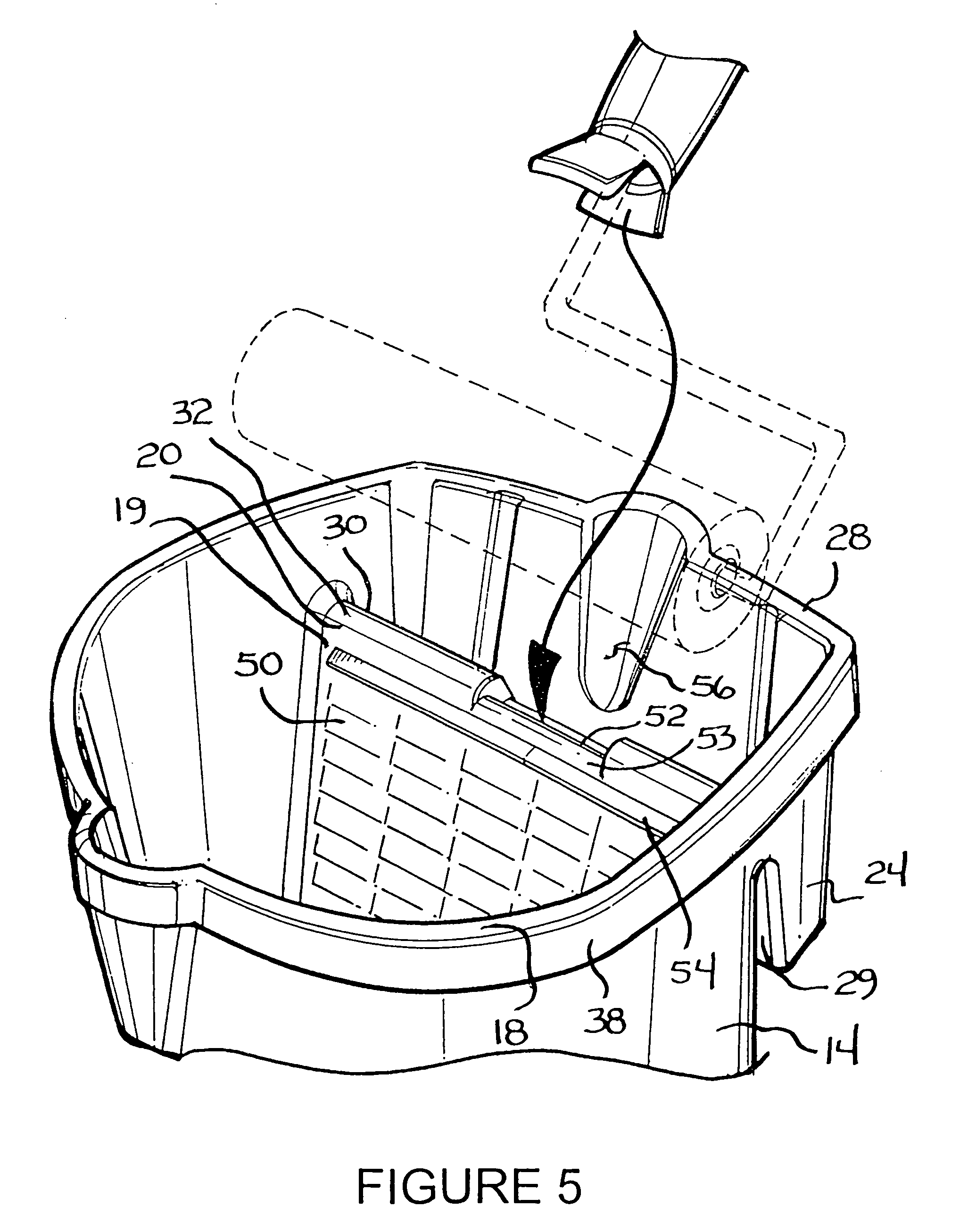

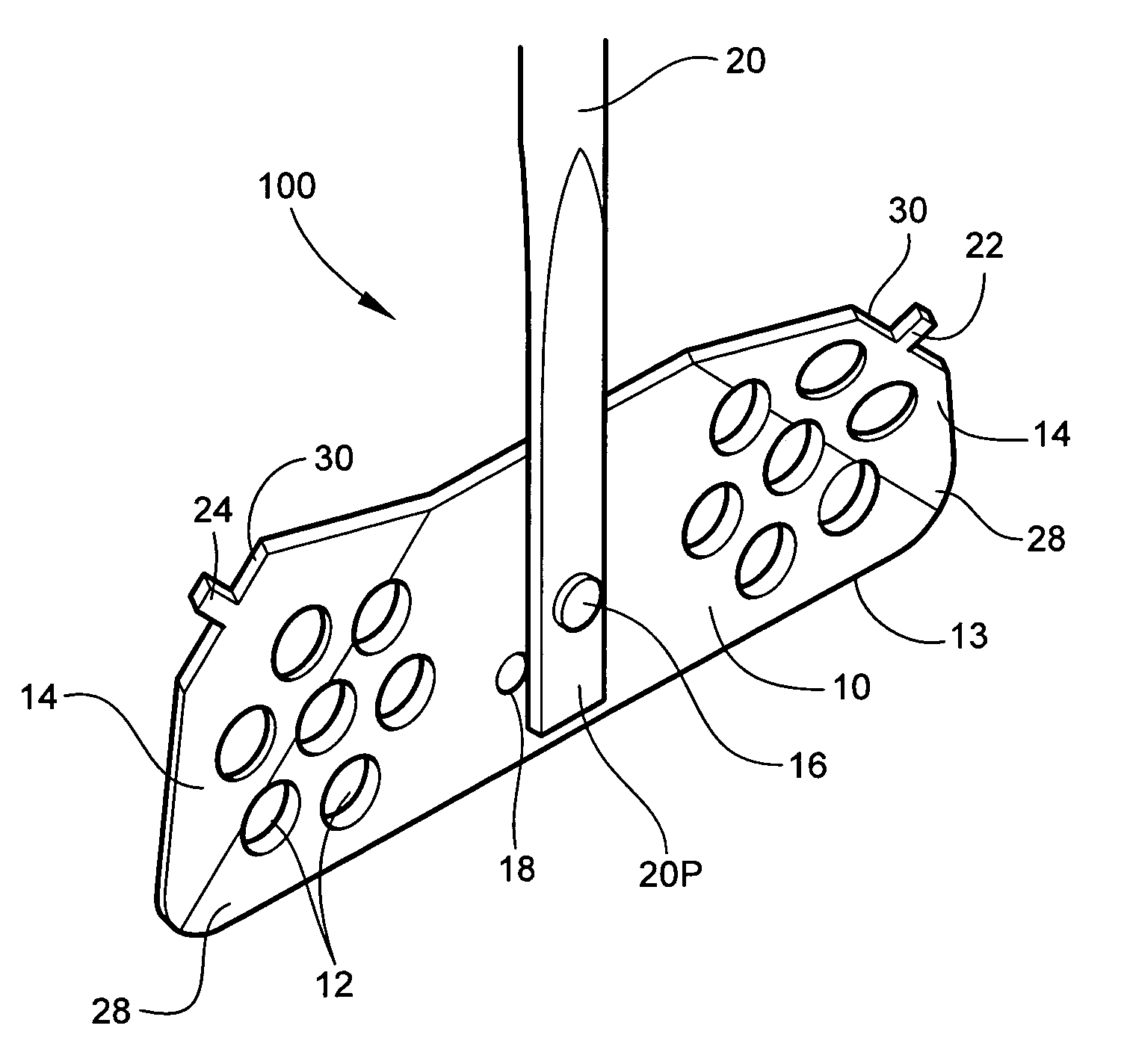

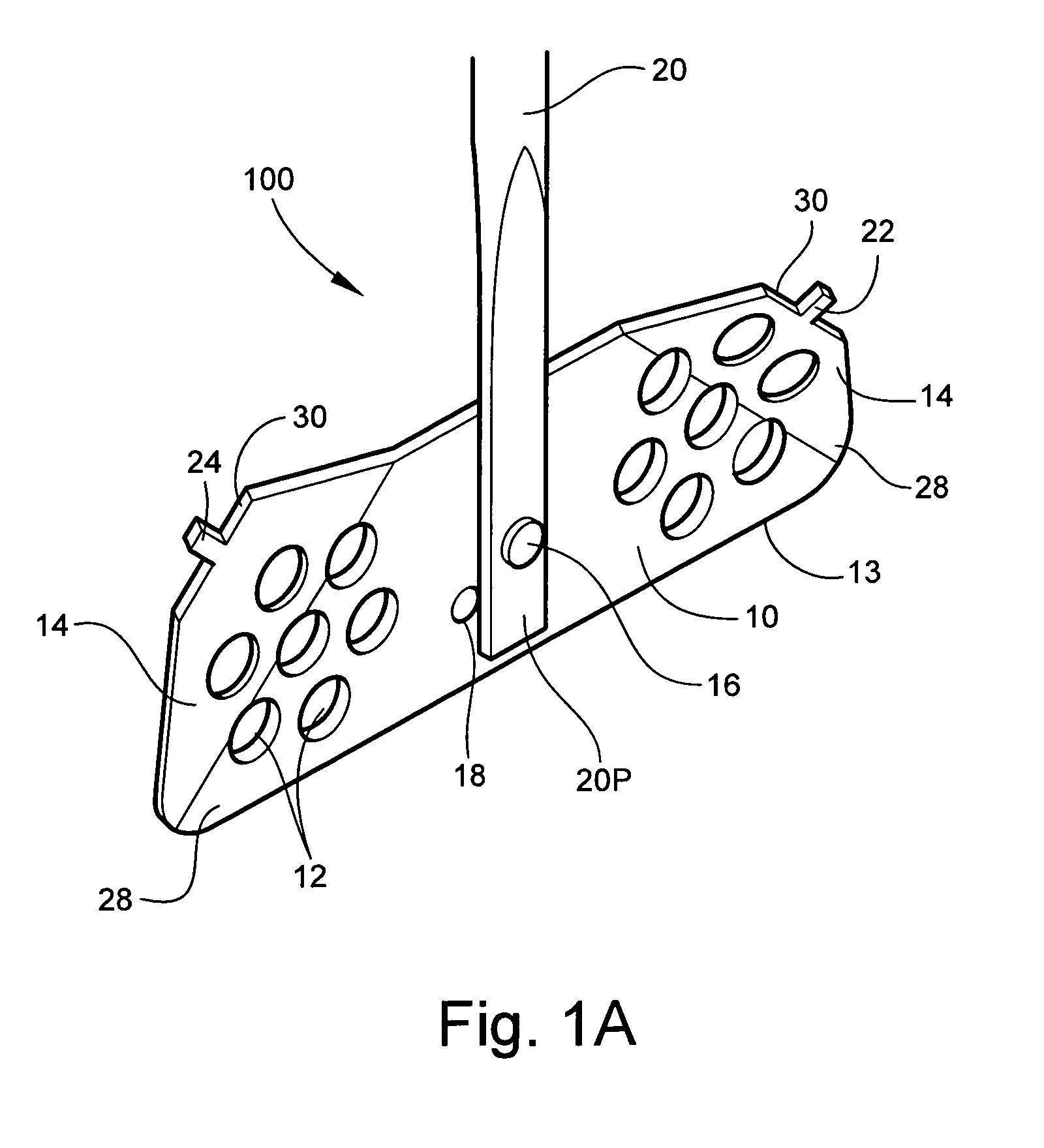

Paint roller grid

Paint roller grid includes a pair of hooks each including a rearwardly extending upper portion and a downwardly extending inturned lip having a forwardly facing inwardly angled surface for engaging an outer cylindrical surface of a container below the container rim when the hooks are hooked over the container rim and the grid is inserted into the top opening of the container. The hooks may be spaced from a bottom edge of the grid a distance slightly greater than the height of the container, whereby when the grid is inserted into the container opening and the hooks are hooked over the container rim, the bottom edge of the grid will engage the inside bottom surface of the container. A pair of feet may extend rearwardly from the grid for engagement with the inner cylindrical surface of the container to prevent the grid from moving within the container during rolling of a roller cover on the grid wiping surface.

Owner:WOOSTER BRUSH

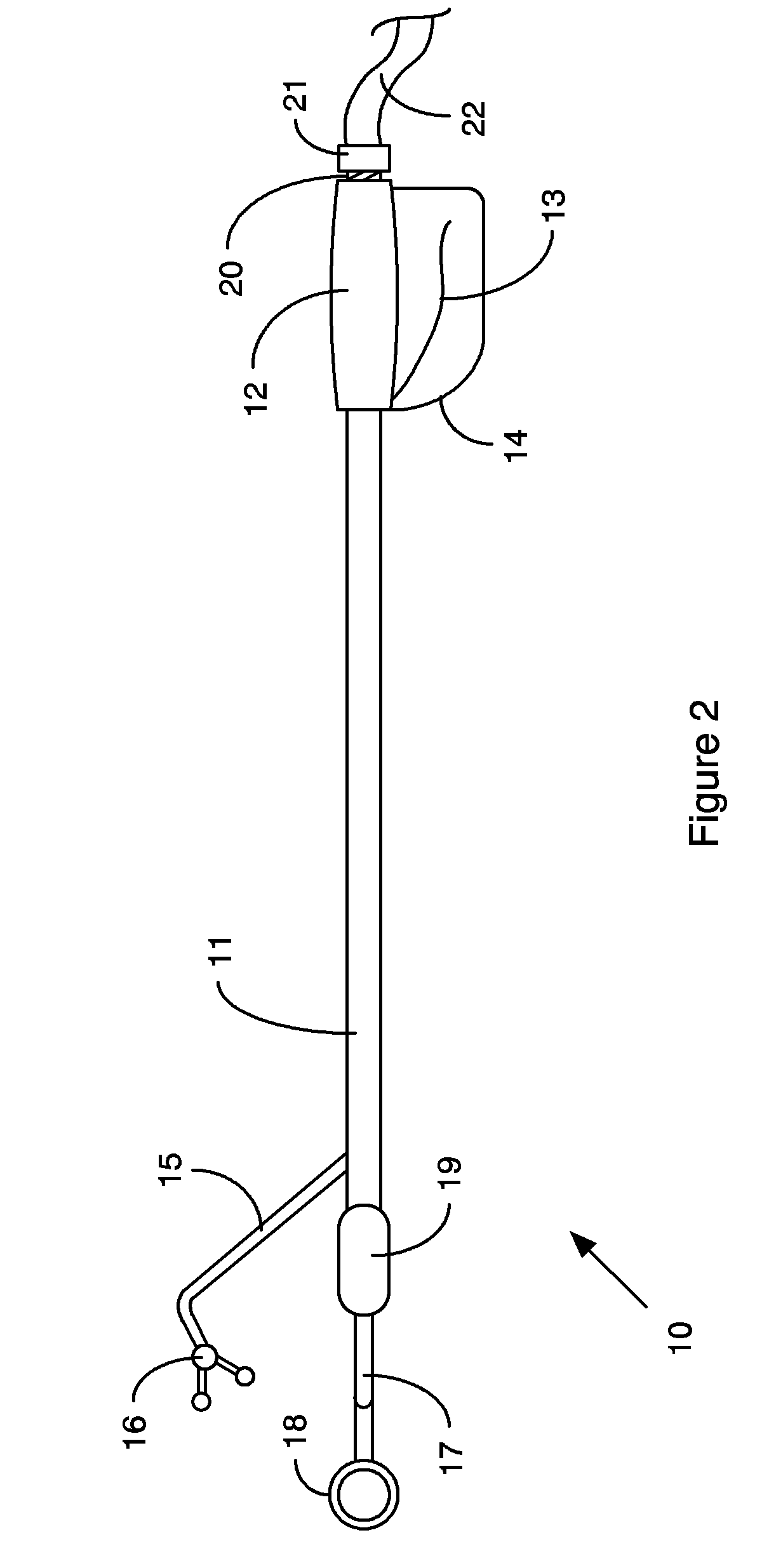

Paint roller with extendable handle

An extendable handle for a paint applicator includes an first shaft having a distal end and a proximal end and a second shaft with a distal end and a proximal end and which is telescopically disposed within the first shaft. A guide block is disposed on the second shaft and defines a curved channel. A third shaft has a distal end and a proximal end and is telescopically disposed within the second shaft. An advancement strip has a first end connected to the distal end of the first shaft and a second end connected to the proximal end of the third shaft and is disposed through the curved channel of the guide block. The advancement strip can both push and pull the third shaft relative to the second shaft.

Owner:NOVA WILDCAT SHUR LINE LLC

Paint tray with roller-holding means

InactiveUS20010013518A1Robust and stableLiquid surface applicatorsOther artistic work equipmentsPaint roller

The invention provides a paint tray for a paint roller, the tray comprising a paint pan and holding arrangements for a roller comprising a handle and a rotary roller proper, the holding arrangements being provided to hold the roller in a selected position in which at least the lowest portion of the roller proper is in a position to drip into the paint pan, wherein the holding arrangements are designed to co-operate essentially with the handle of the roller.

Owner:FRANPIN

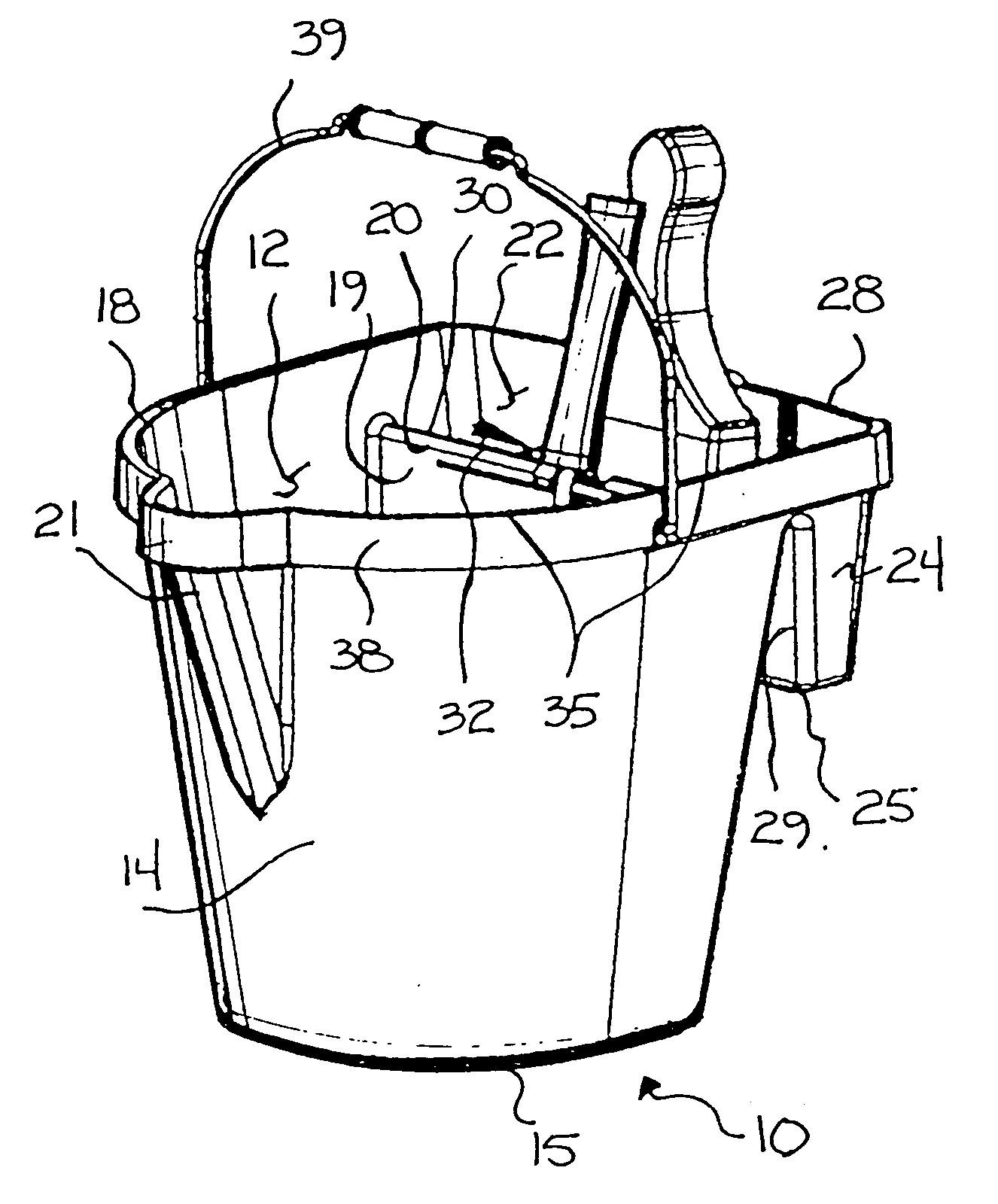

Bucket

A bucket includes a first volume defined by a continuous primary sidewall extending from a periphery of a first bottom to a primary rim and has a flattened portion extending from the periphery of the first bottom to a subjacent portion of the primary rim. An inner surface of the flattened portion of the primary sidewall is textured to form a paint roller grid. A second volume is defined by a continuous secondary sidewall extending from a periphery of a second bottom to a secondary rim and has a flattened portion extending from the periphery of the second bottom to a subjacent portion of the secondary rim adjacent the subjacent portion of the primary rim. An edge couples the subjacent portion of the secondary rim and the subjacent portion of the primary rim.

Owner:WONDER LINE SALES L L C

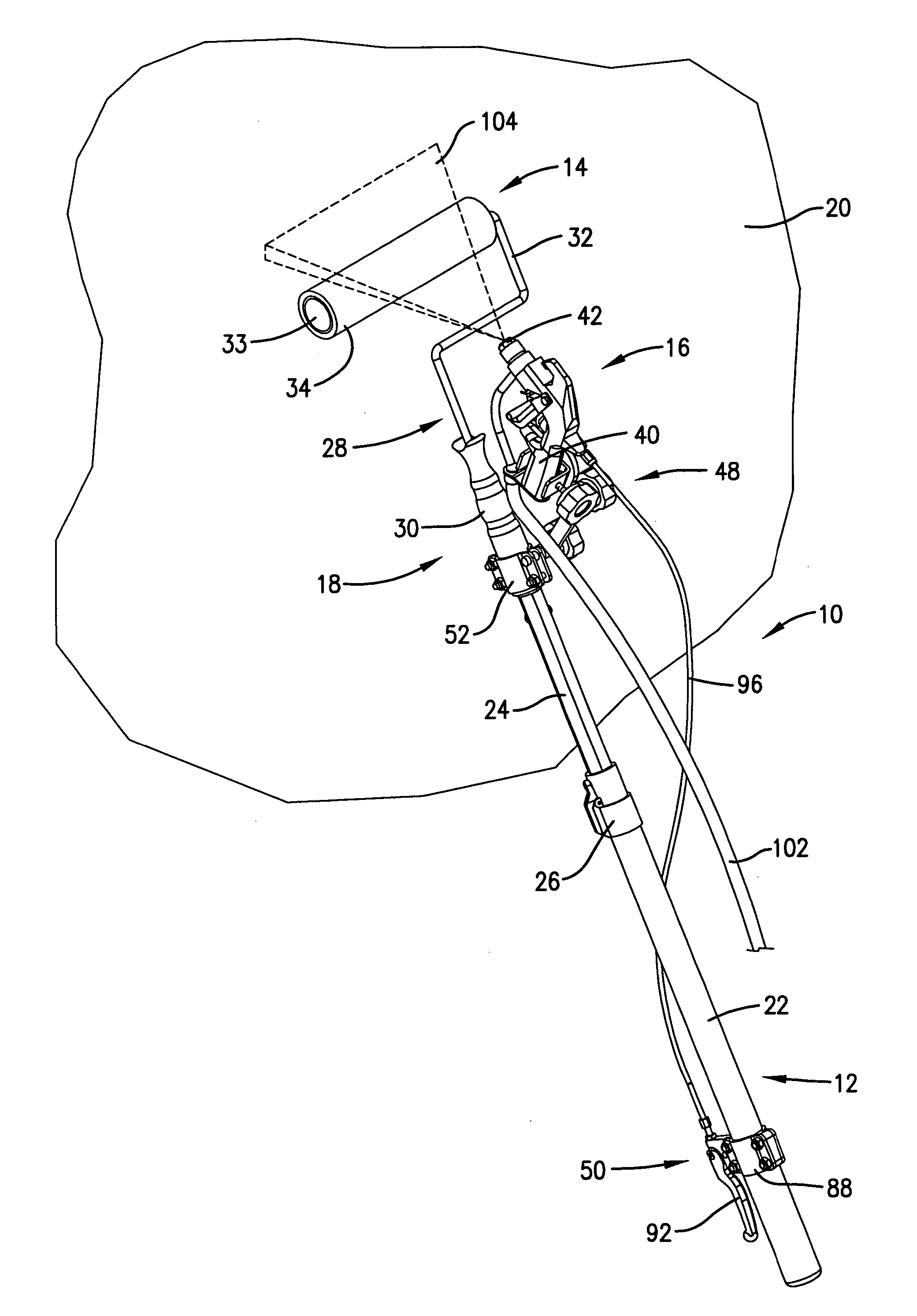

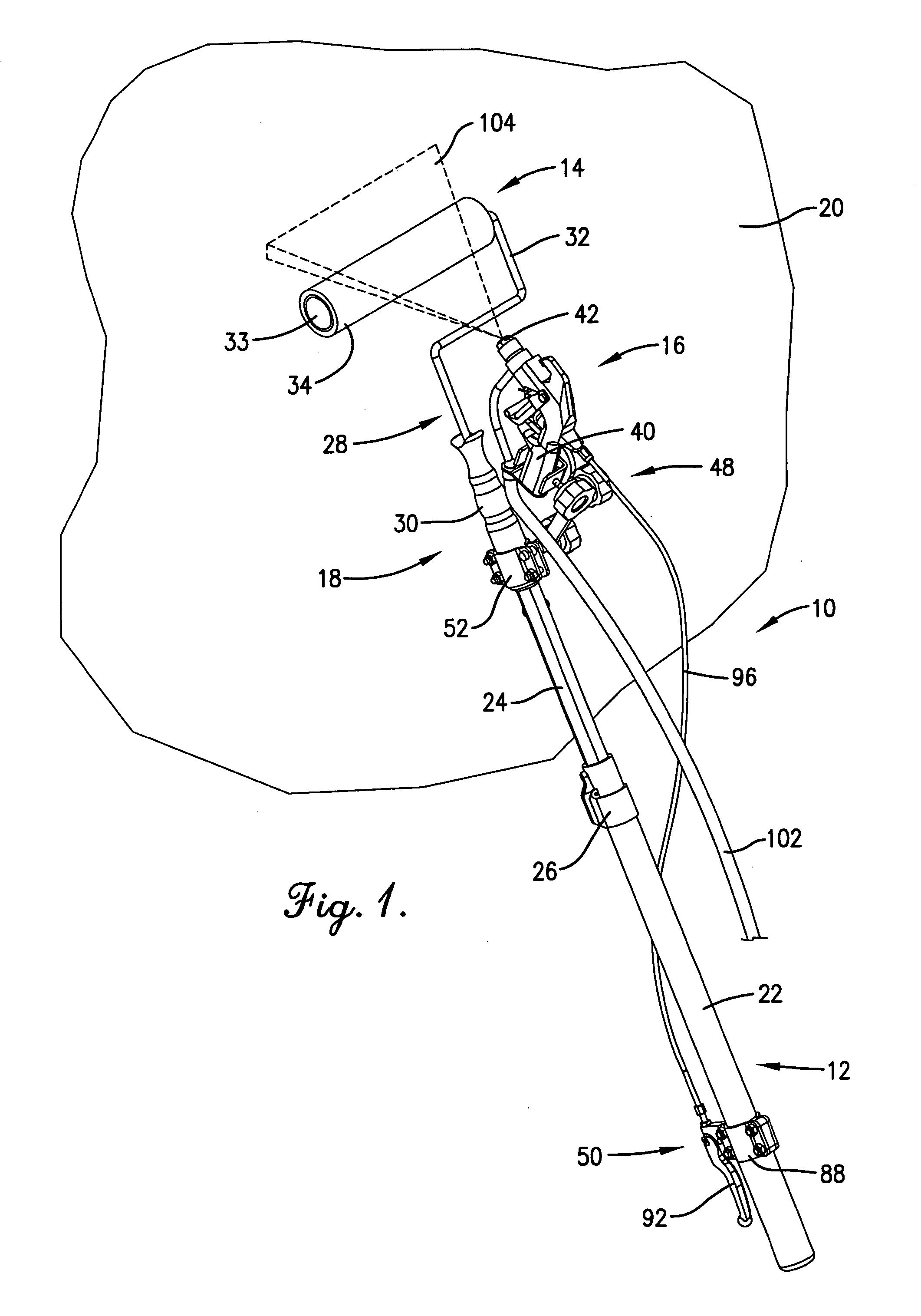

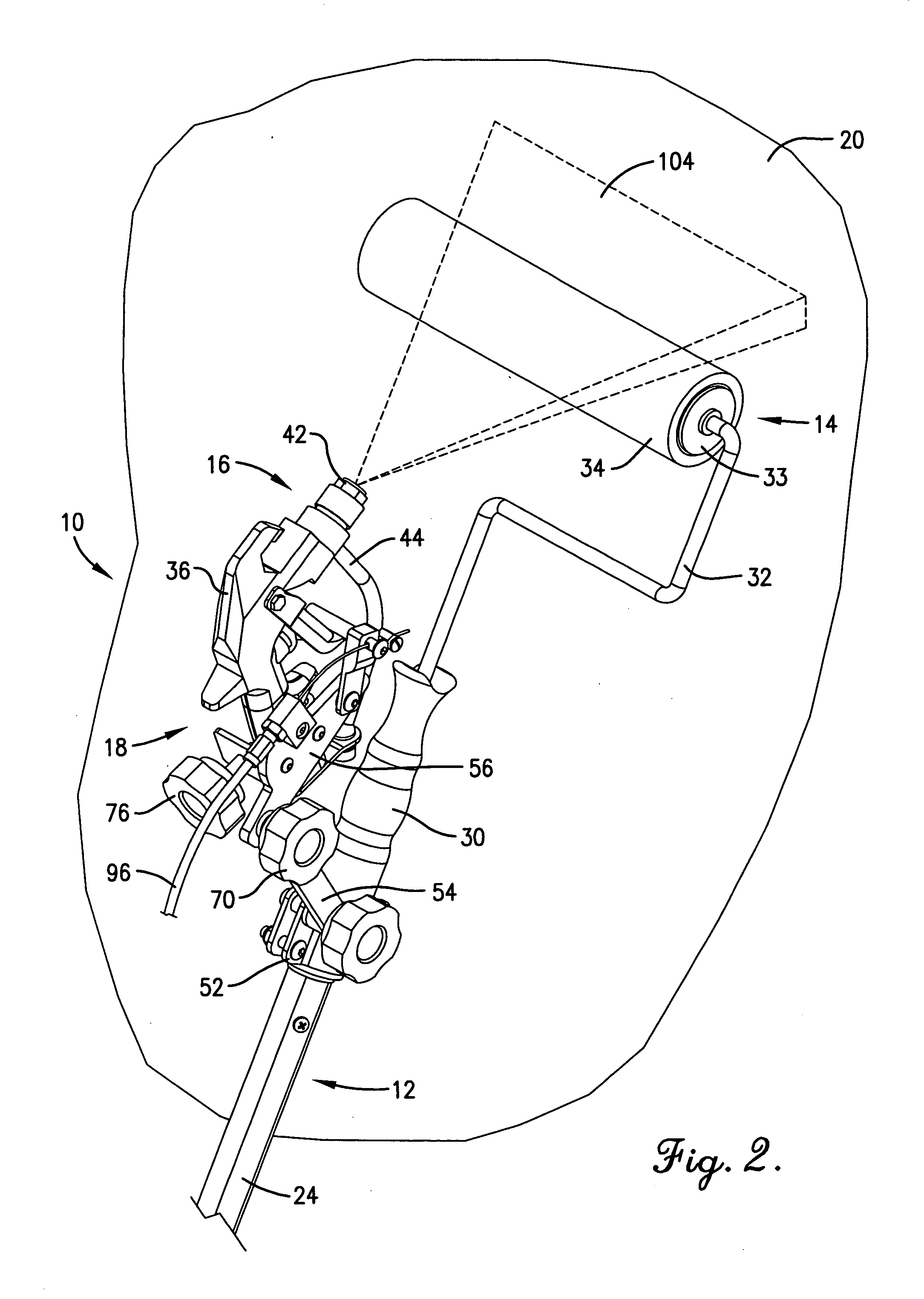

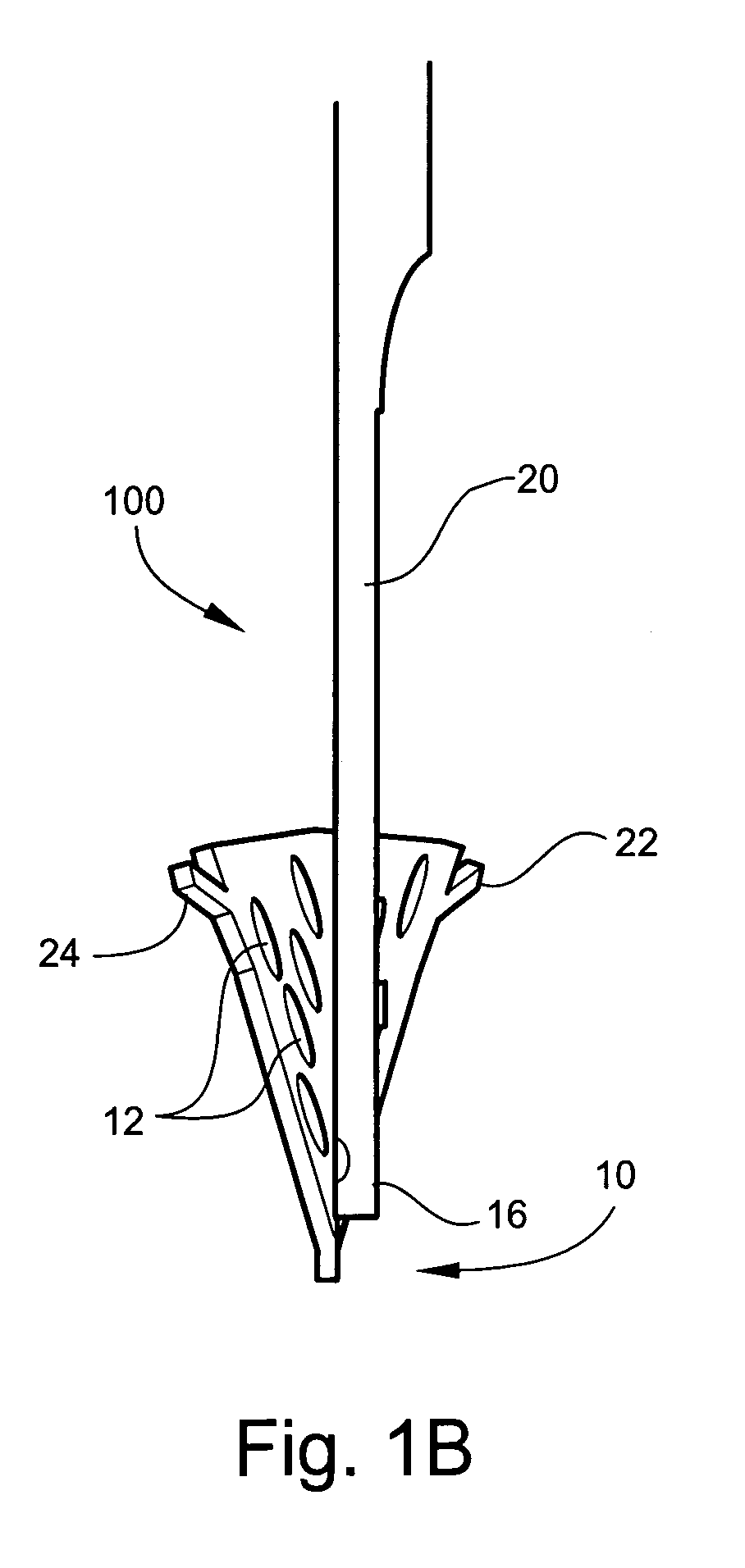

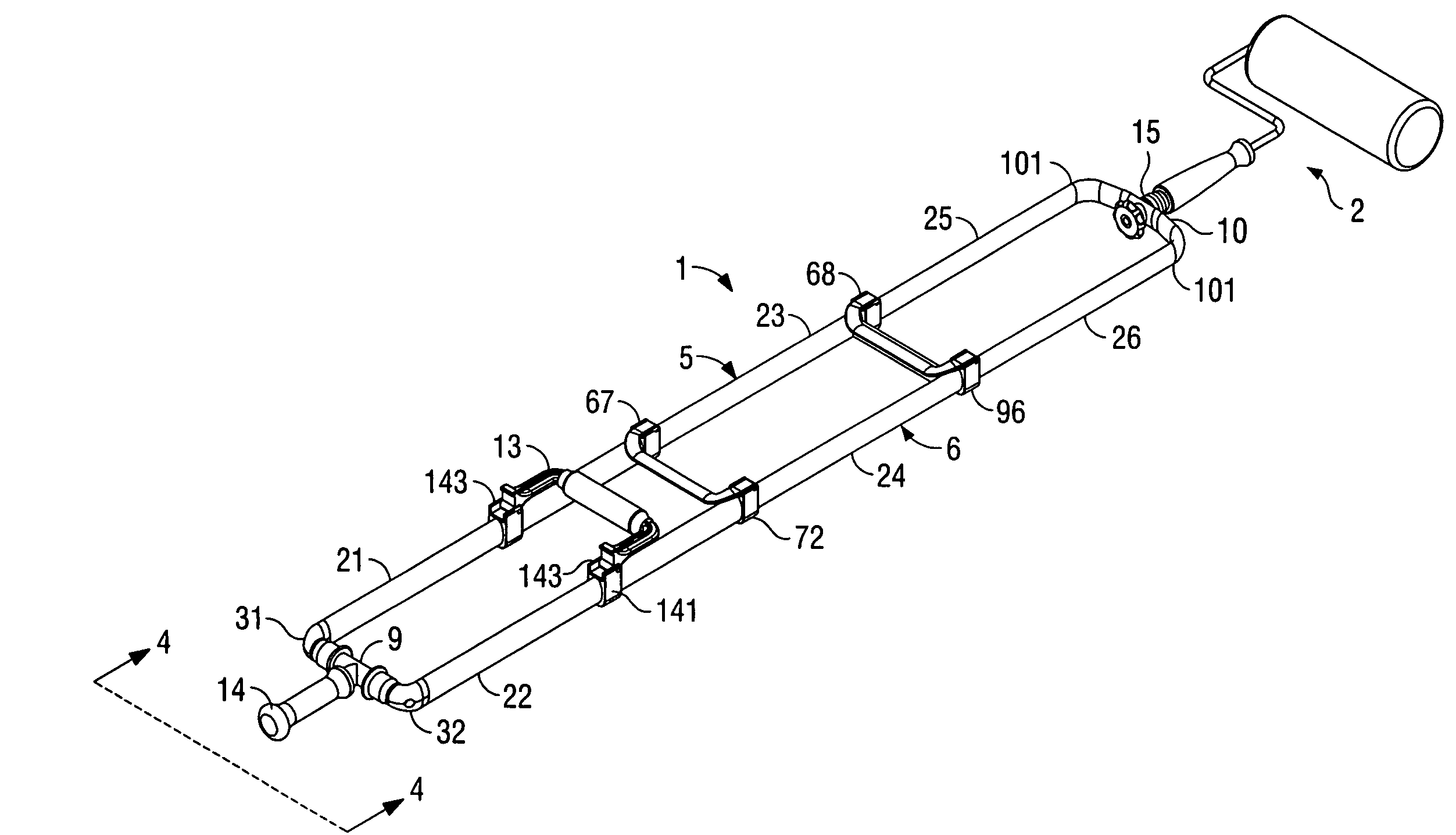

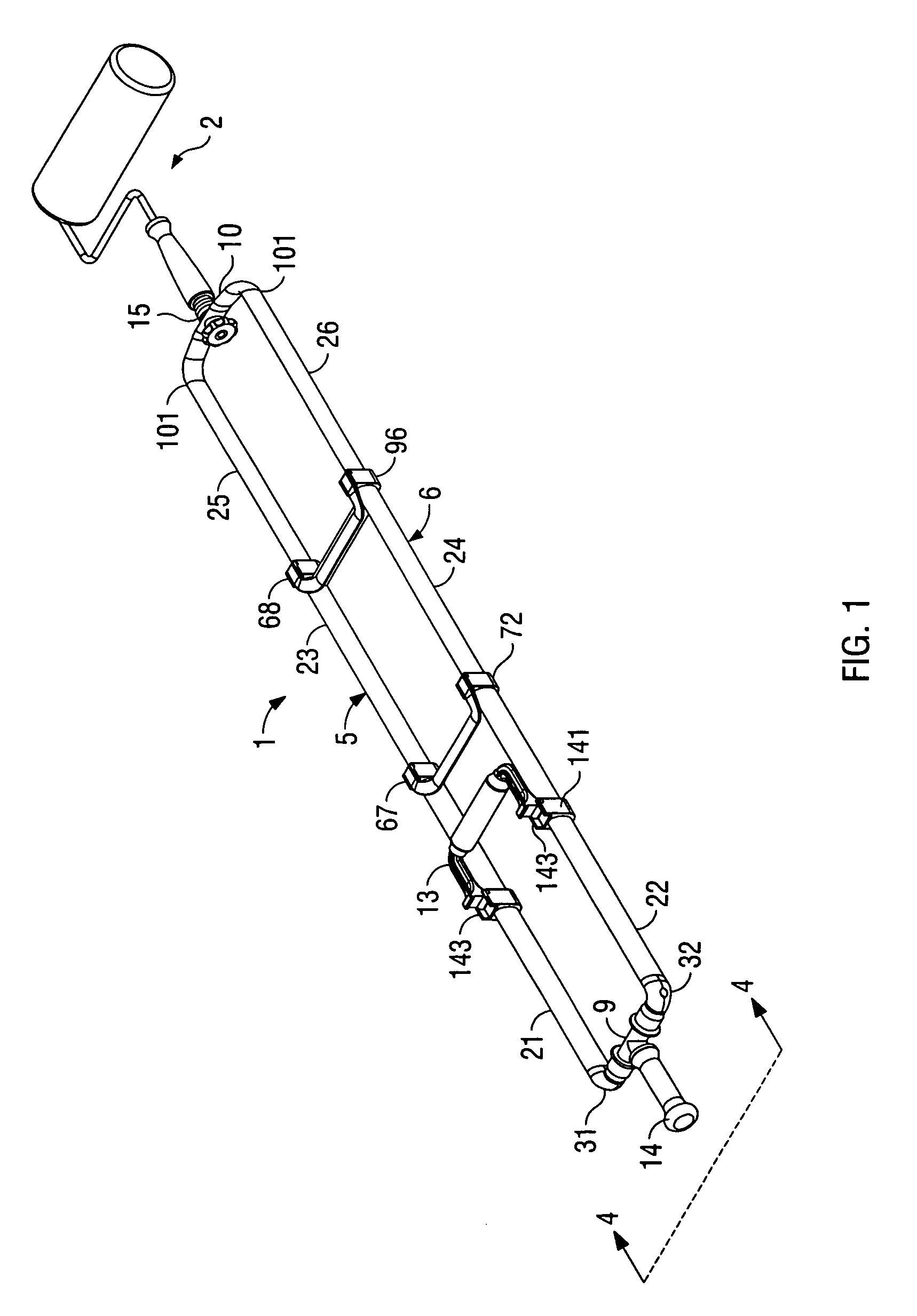

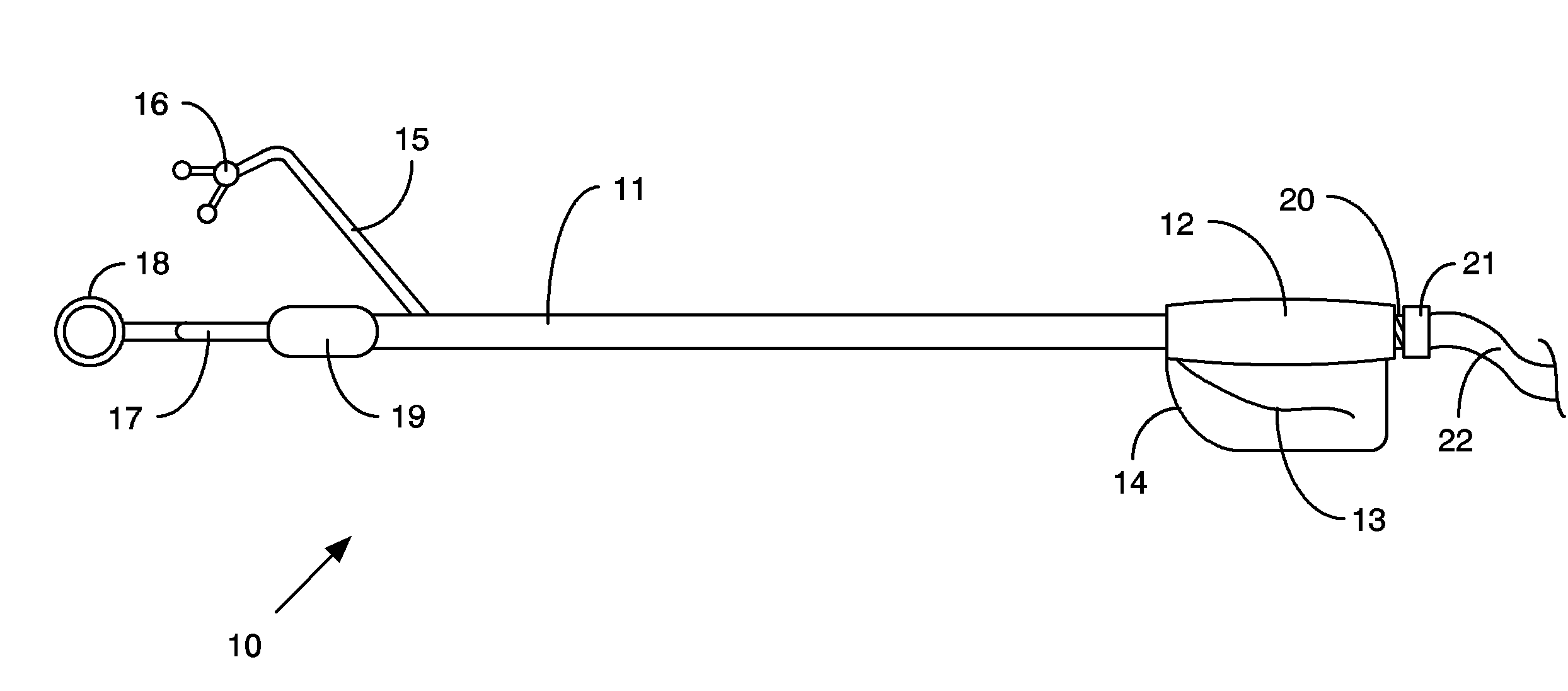

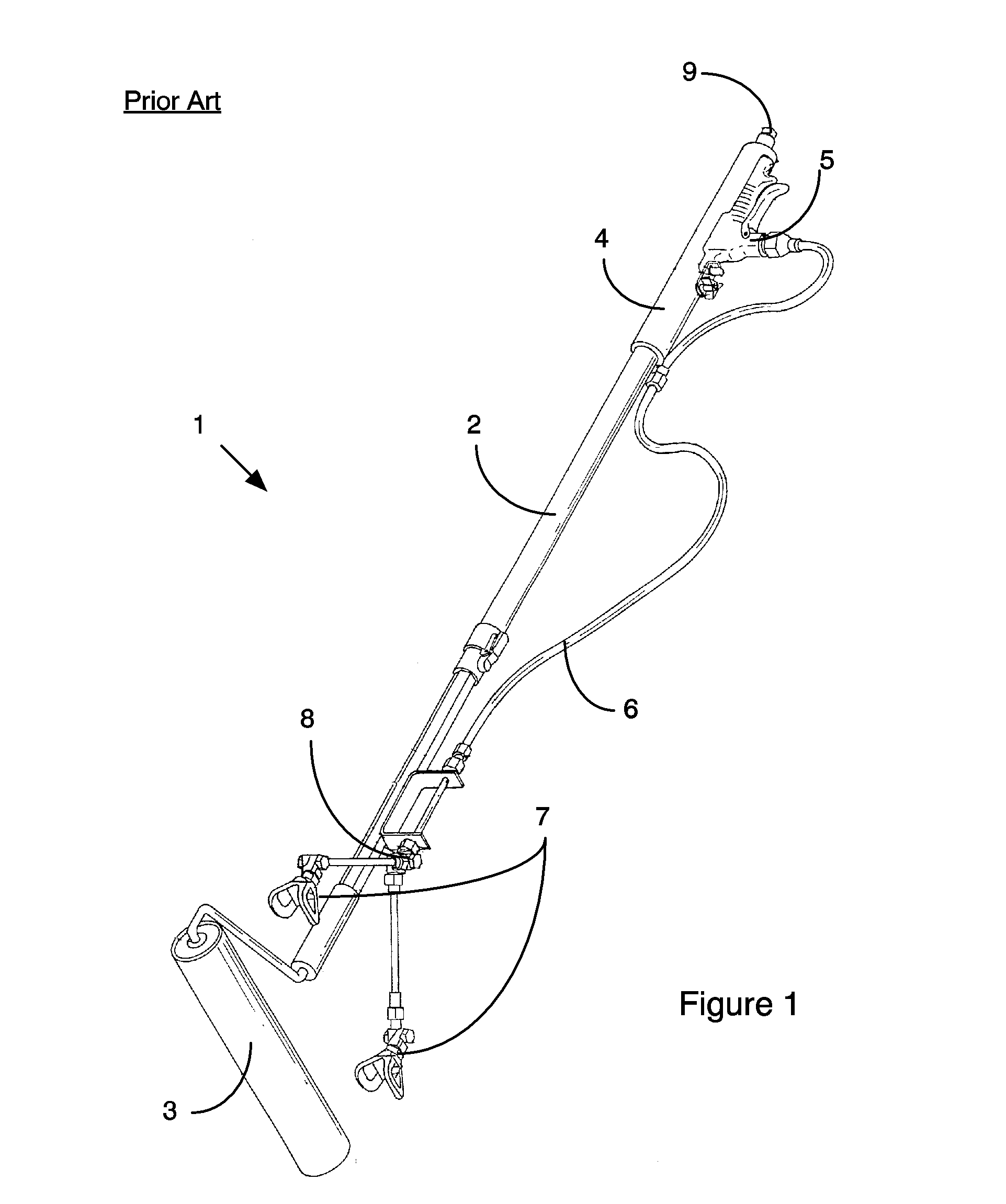

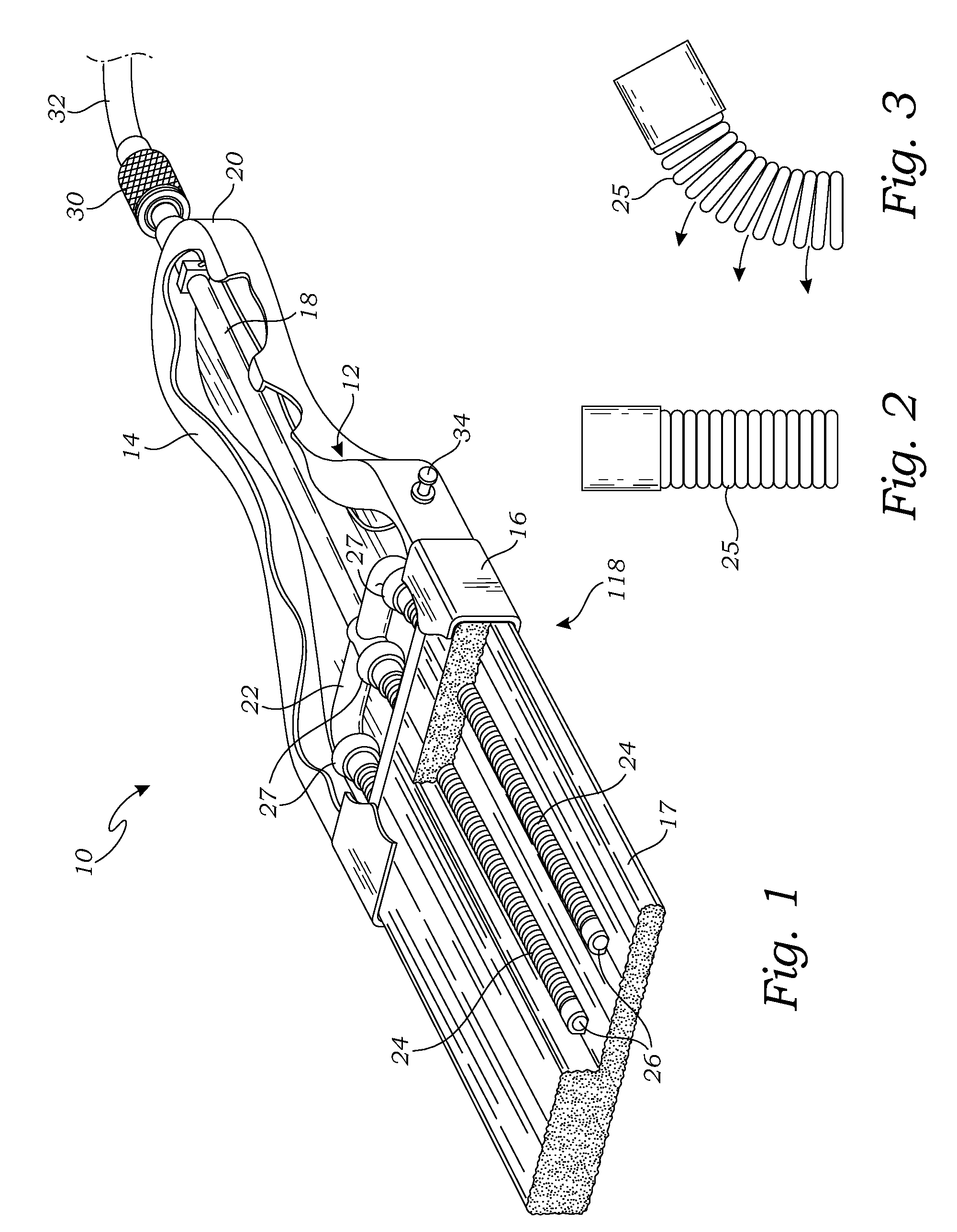

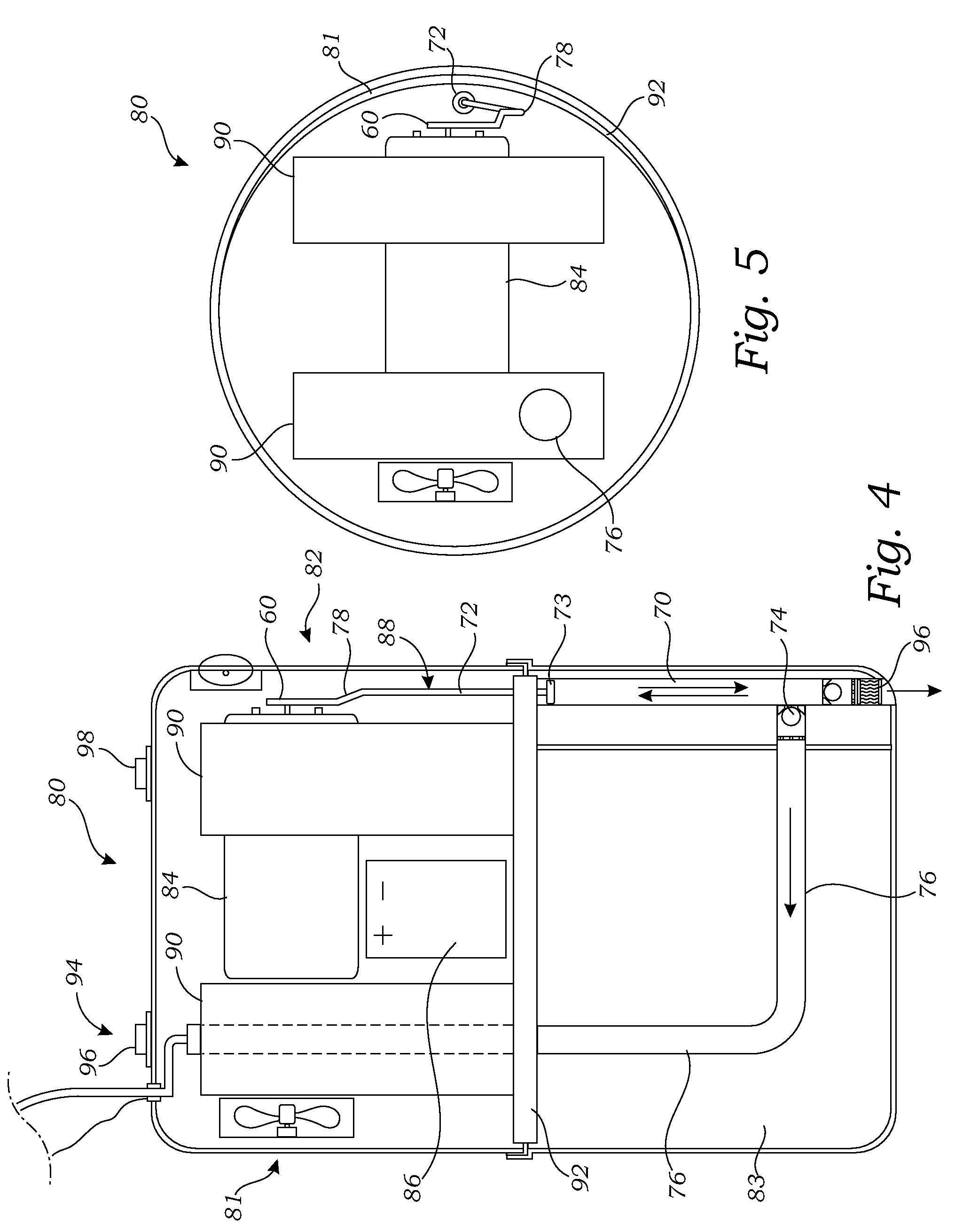

Assembly for mounting paint spray gun to extension pole with paint applicator

A paint applicator (10) for application of paint to a surface (20) is provided which includes a telescopic pole (12) supporting a paint applicator (14) (e.g., a paint roller (28)) and a paint sprayer (16). The sprayer (16) is detachably secured to pole (12) by means of adjustable mounting assembly (48) and is operatively connected with an operating lever (92) also supported on pole (12) through assembly (50). The assemblies (48, 50) and sprayer (16) may be retrofitted onto otherwise conventional pole-type paint applicators. The applicator (10) may be operated by a single user to selectively spray paint onto the surface (20) as needed while appropriately spreading the paint using applicator (14).

Owner:COATINGS MANAGEMENT SYST

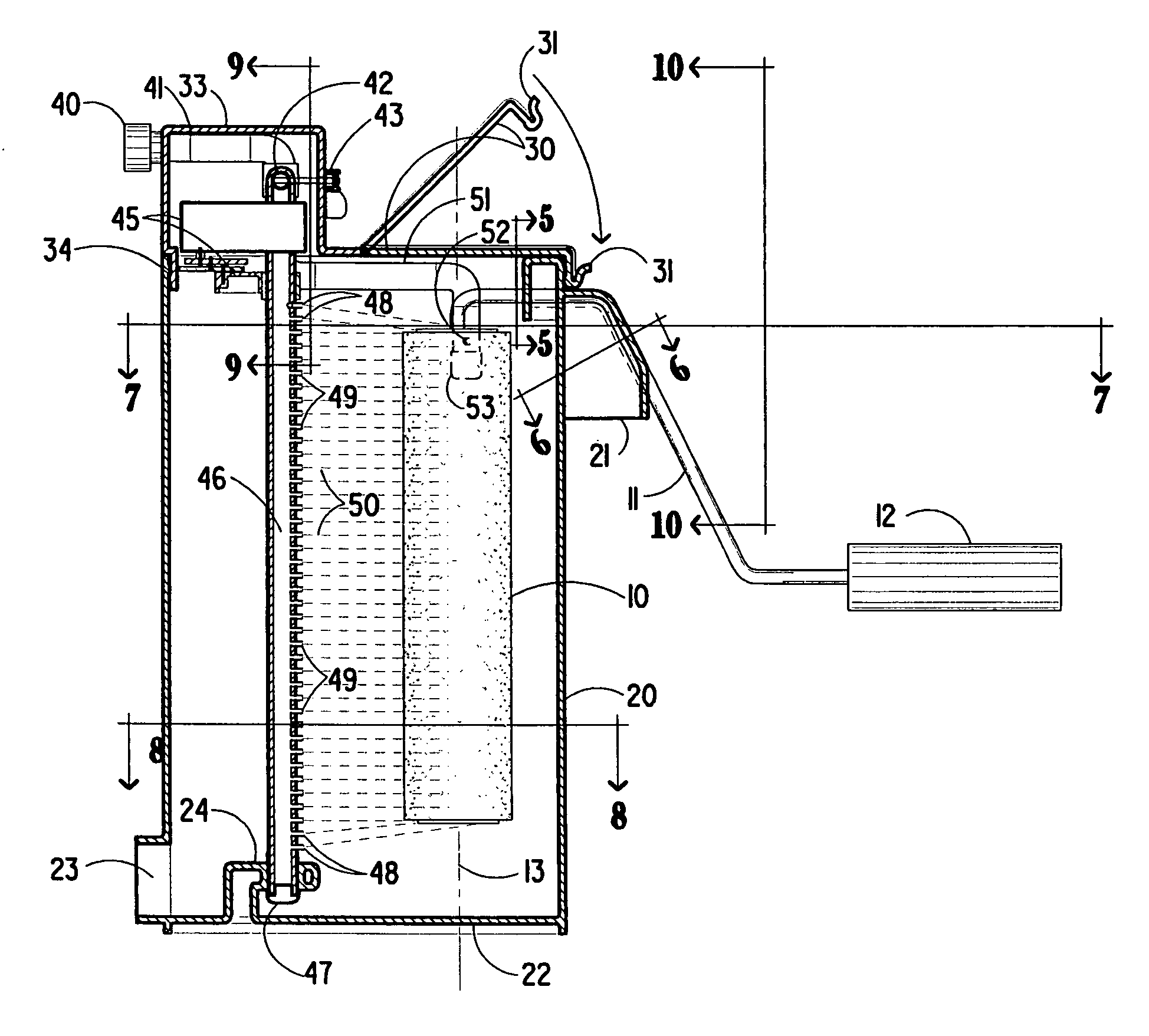

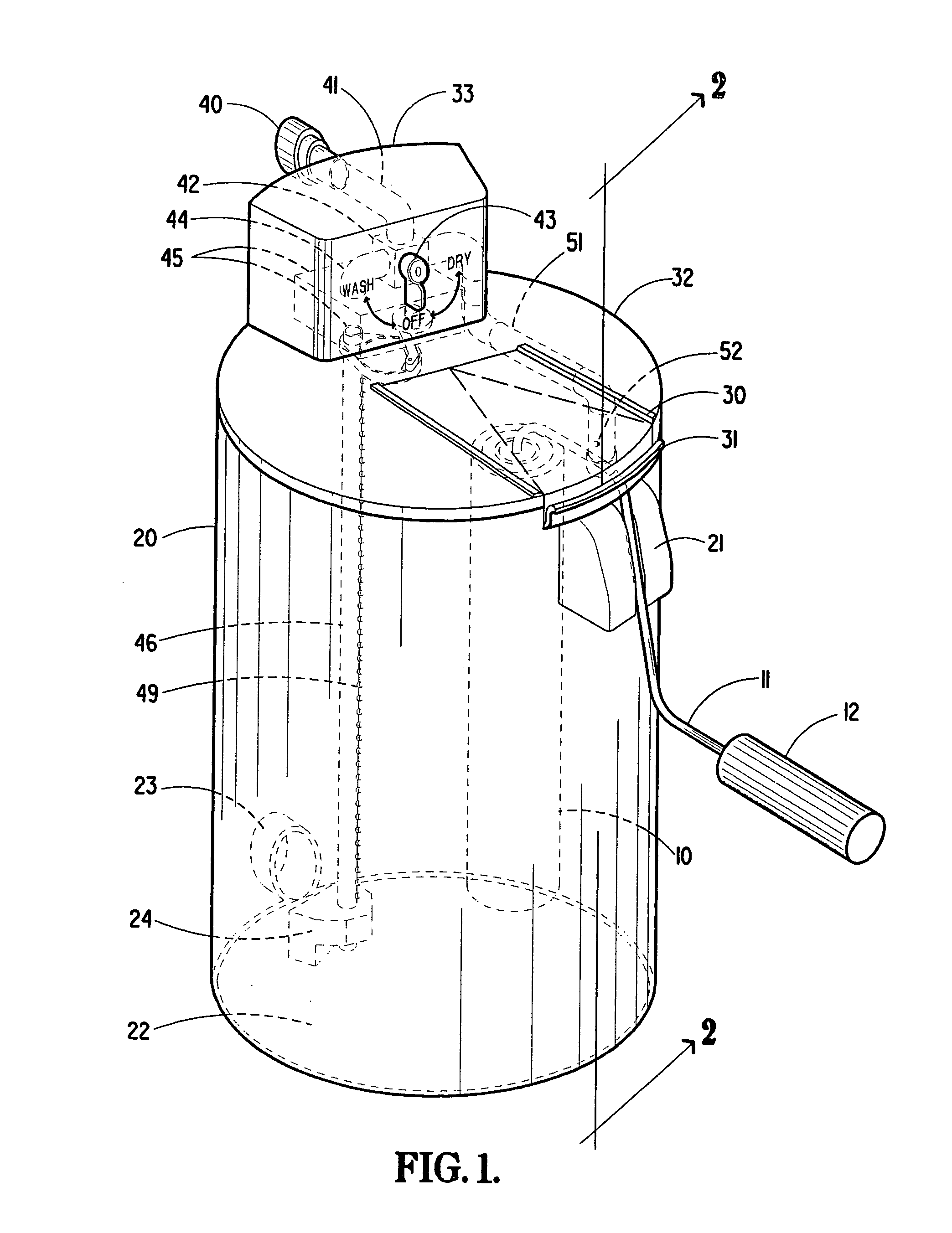

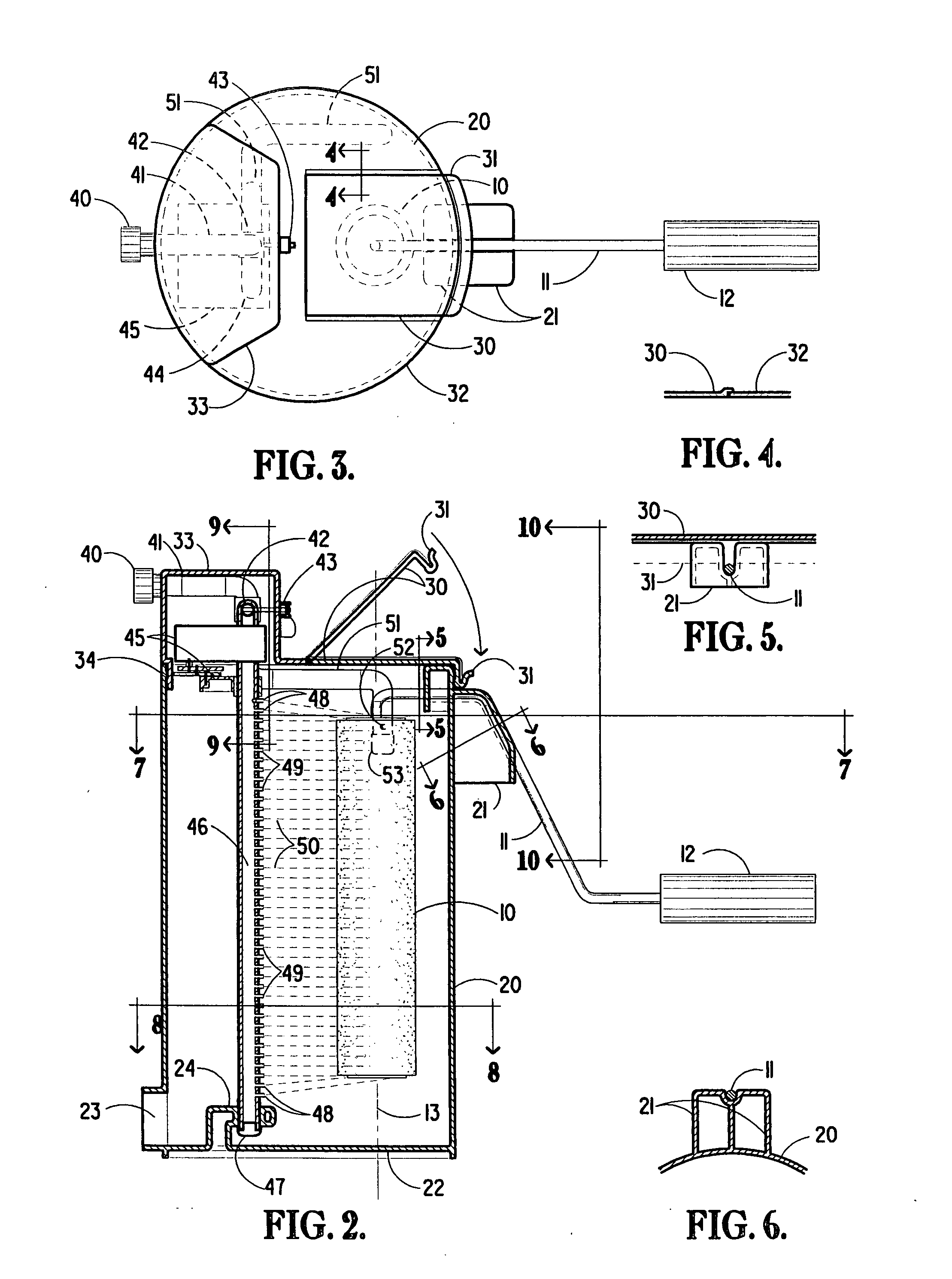

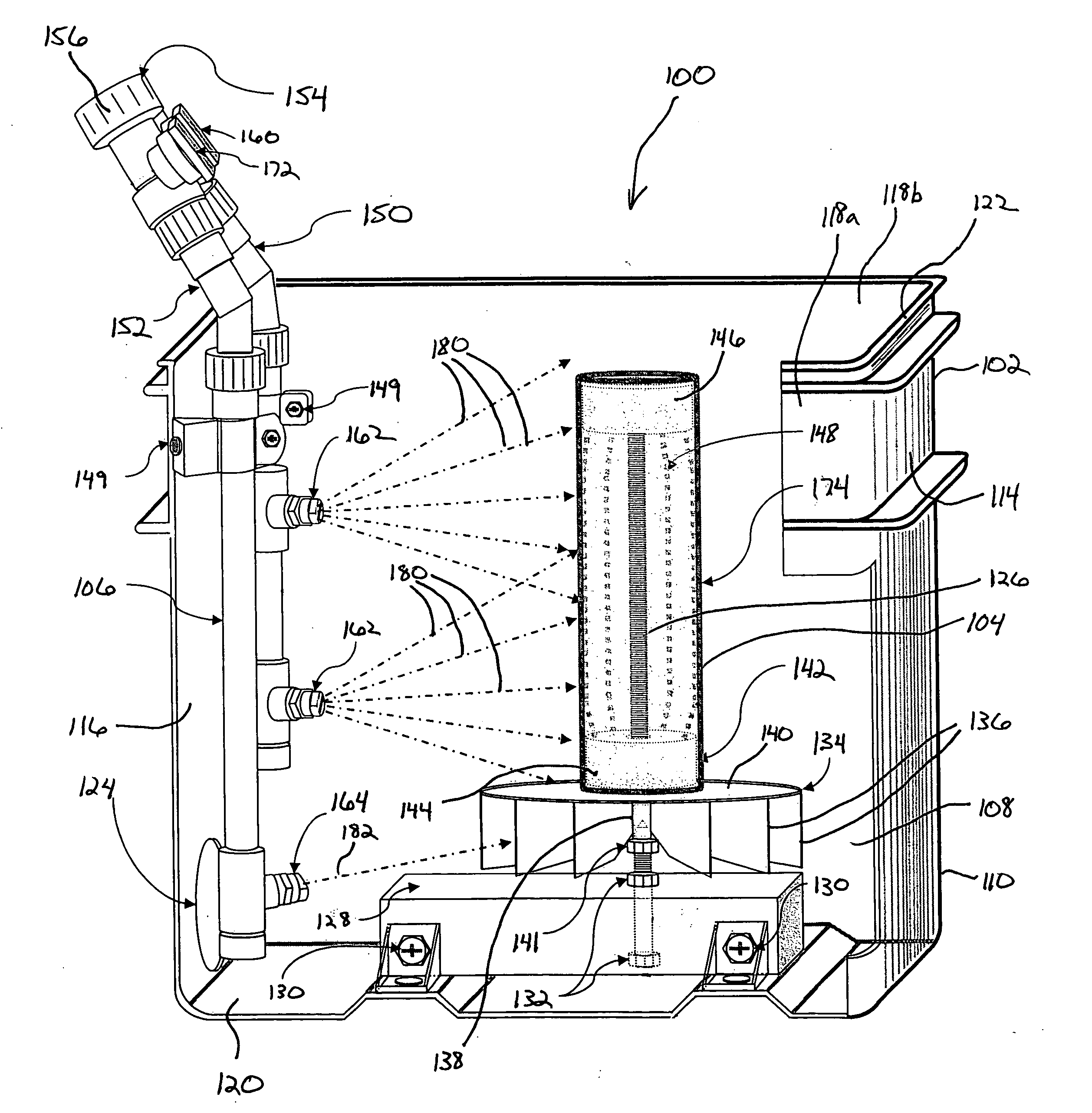

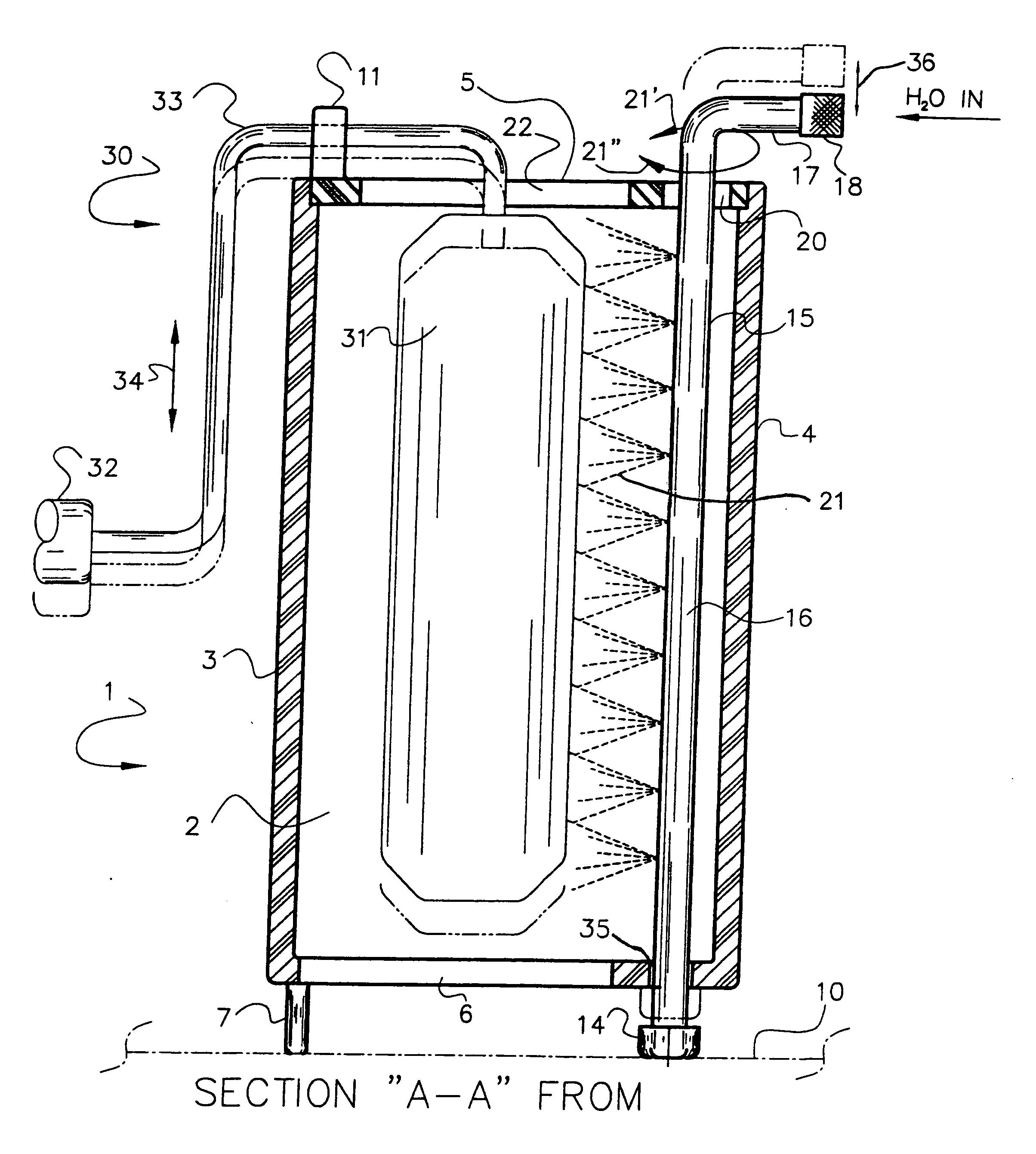

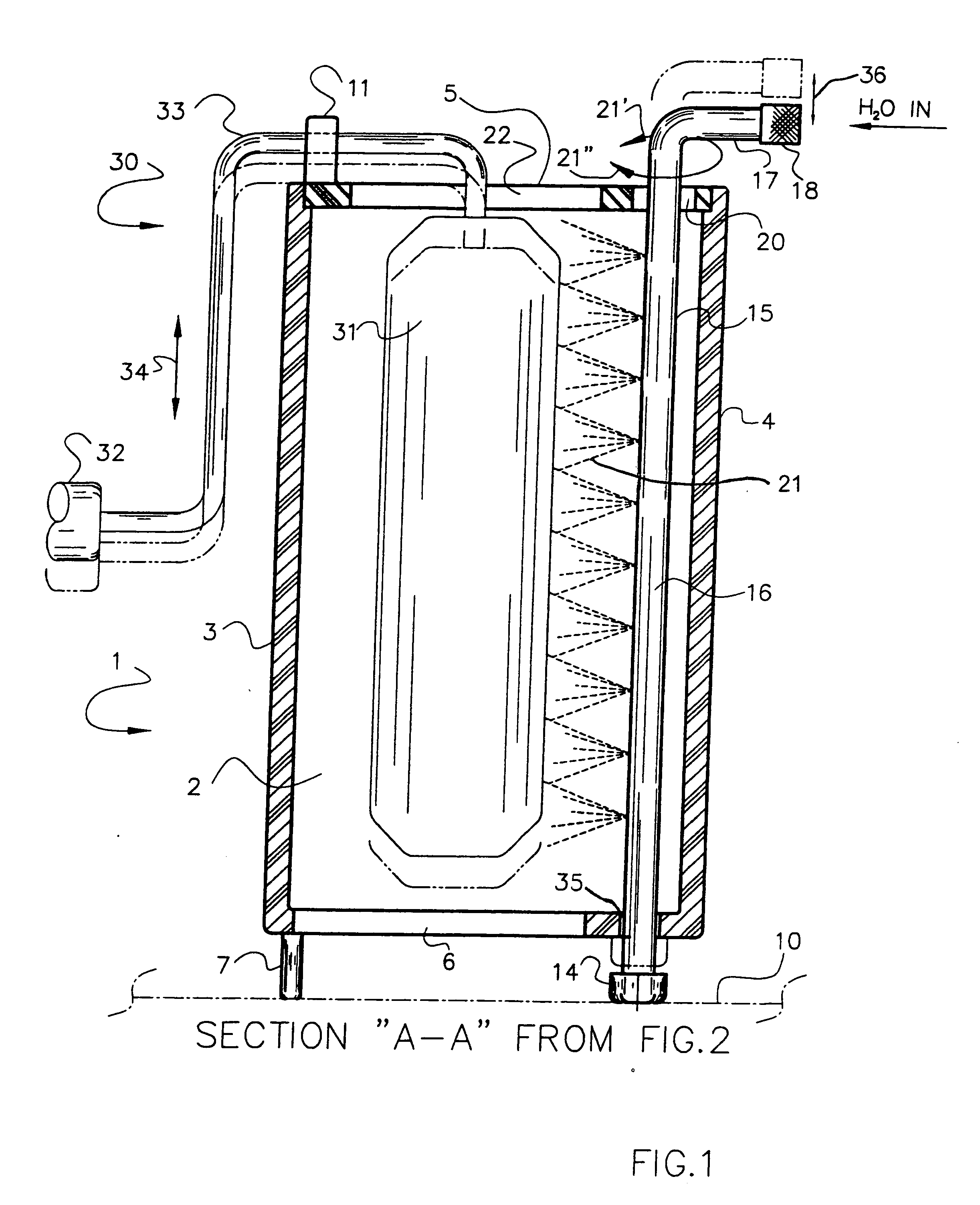

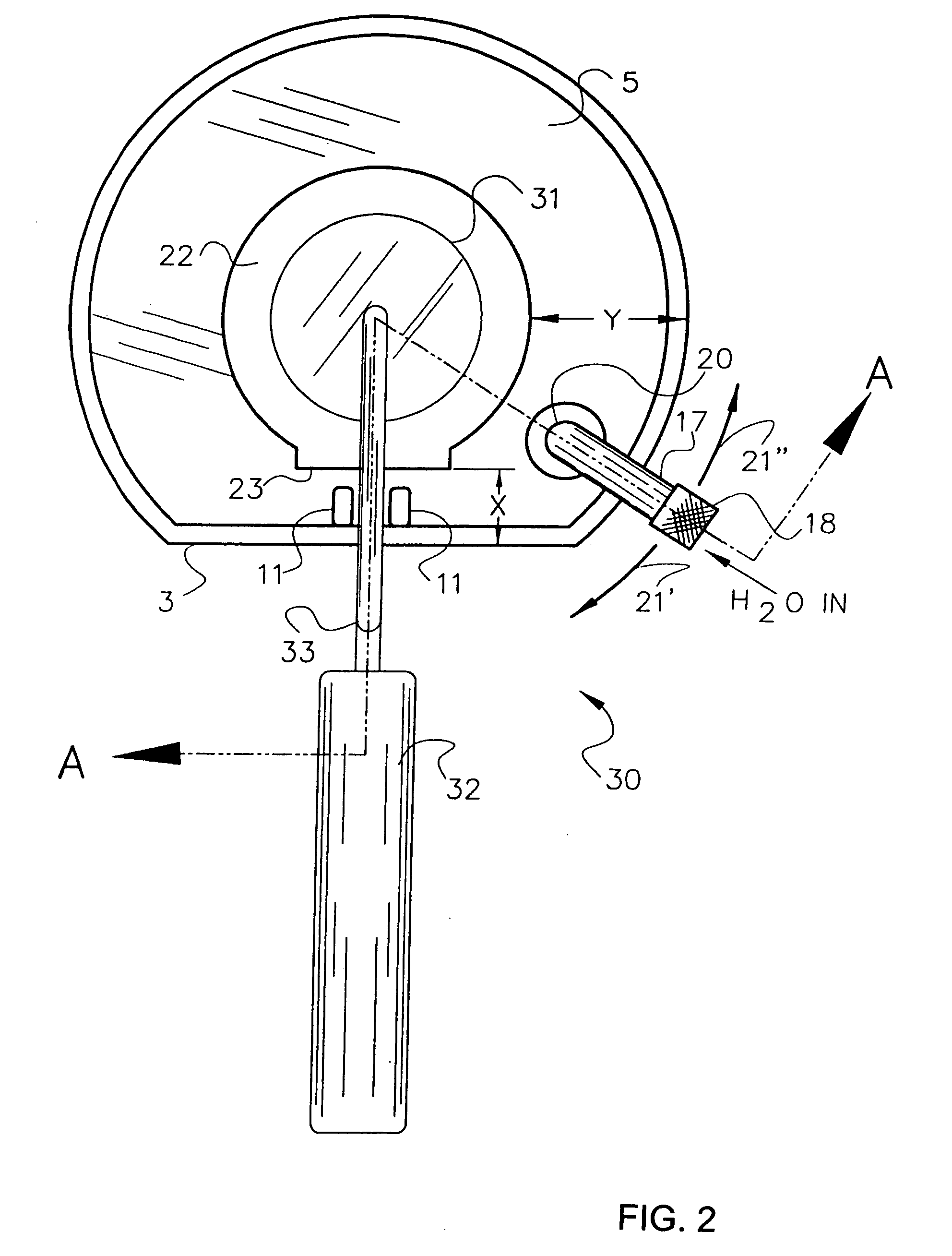

Cleaning device for paint rollers

InactiveUS20080078429A1Rule out the possibilityDeep cleaningElectrostatic cleaningOther artistic work equipmentsWash waterWater flow

Paint rollers may be cleaned of water soluble paints within this apparatus which is comprised of an enclosed housing with a drain at the bottom which also contains an oscillating water manifold the length of the roller which produces a series of water jets aligned with the elongated axis of the housing which impact the paint roller starting at a tangent to the roller so as to impart a spin. The water manifold oscillates aligned with the elongated axis of the roller from the tangent to a center of roller that slows the spin of the roller which oscillates to the opposite tangent of the roller and which spins the roller in the opposite direction. The enclosed housing also contains a single jet of water aligned near the top of the roller and at a tangent to the roller which impacts the paint roller starting at a tangent to the roller so as to impart a spin. The single water jet and the oscillating water jets are connected to a three-way valve which sends water to either the oscillating water manifold, the single water jet or shuts off the flow of water entirely. An opening with a hinged lid at the top of the enclosed housing allows the insertion of the paint roller. A clamping means is located on the outside of the housing on the side opposite the location of the oscillating water manifold and single fixed water jet which adapts to a variety of paint roller holder rods in order that the paint roller itself may be properly align the roller parallel to the oscillating water manifold within the housing. The water jets on the oscillating water manifold impact off-center on the pile of the paint roller, washing out the water soluble paint, and imparting a spin on the roller which throws out the diluted paint and the wash water. As the water manifold oscillates to the center of the paint roller, the rotation of the paint roller decreases and forces water deep into the pile of the paint roller that will dilute the paint. As the oscillating water manifold passes the center of the roller, the roller starts to spin in the opposite direction imparting a spin on the roller that throws out the diluted paint and wash water from deep within the pile of the paint roller.

Owner:HOFFMANN TERRY A

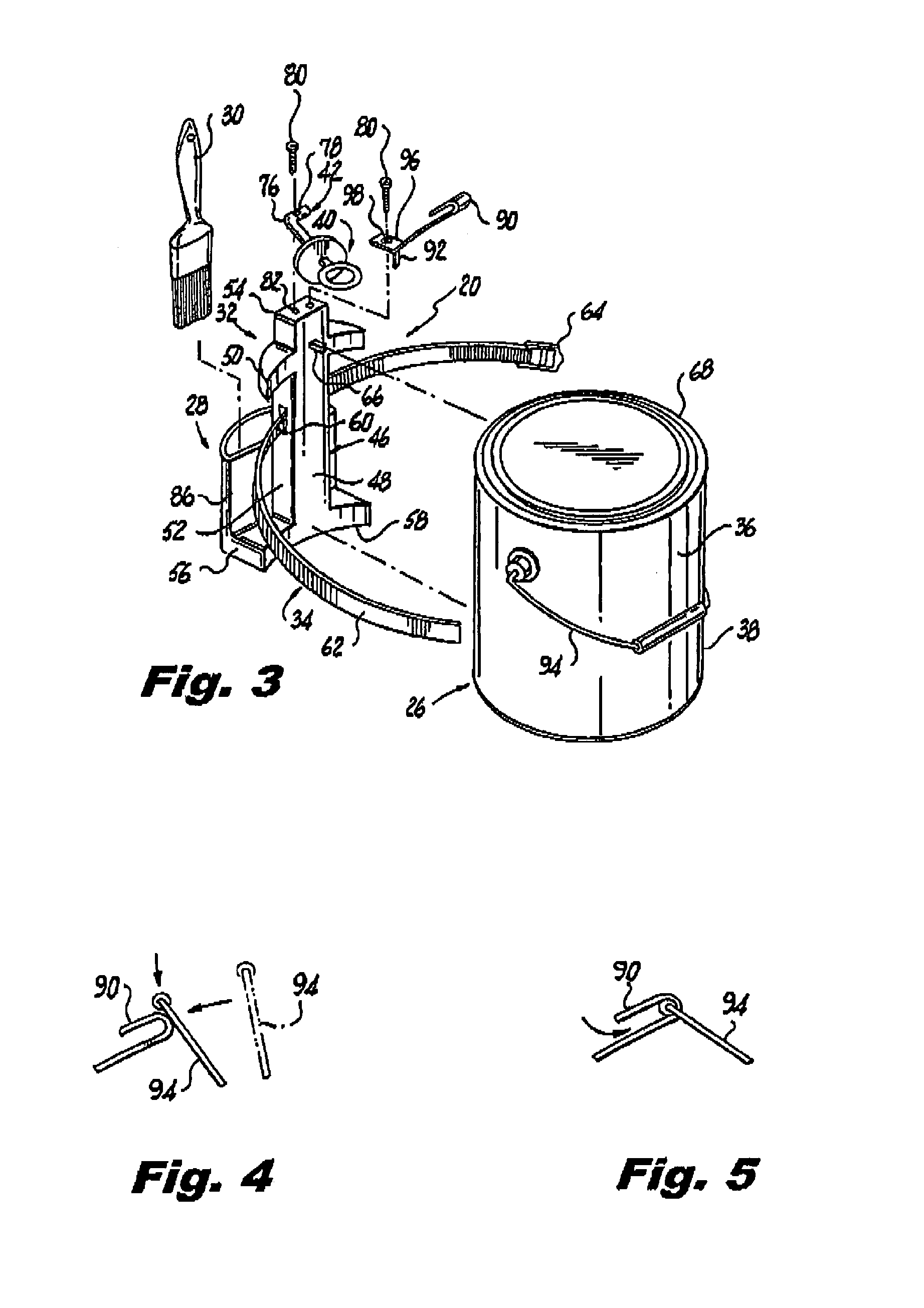

Geometric and perforated paint mixer and paint roller cleaner

InactiveUS7229206B2Well mixedSimple designOther chemical processesTransportation and packagingEngineeringDrill

The present invention sets forth an implement which enables the user to mix paint, clean the can and can lip, and to clean conventional paint rollers utilizing a hand drill. The implement is selectively adjustable to be configured to mix paint in large and small containers and to support a paint roller for cleaning, thereby being capable of providing several functions. The implement is provided with a paddle member that is perforated and of a geometric form to enhance mixing. A paint can remover and a paint can rim cleaning device are also incorporated into the implement. A single implement serves the six functions of opening paint cans, stirring paint in large or small containers, cleaning the groove around the lip of a paint can, cleaning a paint roller, and as a spatula to aid in removing paint from a can.

Owner:WHITNEY INNOVATIONS

Protector for protecting paint brushes and paint rollers having paint thereon

A protector for protecting paint brushes and paint rollers having paint thereon comprises a main body made from a flexible material and having a hollow interior for receiving the head portion of a paint brush or the roller portion of a paint roller therein. A first opening permits a paint brush or paint roller to pass therethrough. A self-sealing plastic strip seals the first opening to preclude paint from escaping from the substantially hollow interior of the main body through the first opening. A second opening is disposed in opposed relation to the first opening, for permitting the handle of a paint brush or paint roller to be received therein. Tape is used to selectively seal the second opening when the handle of a paint brush or paint roller is received therein, to preclude paint from escaping from the substantially hollow interior of the main body through the second opening.

Owner:HONG THOMAS K

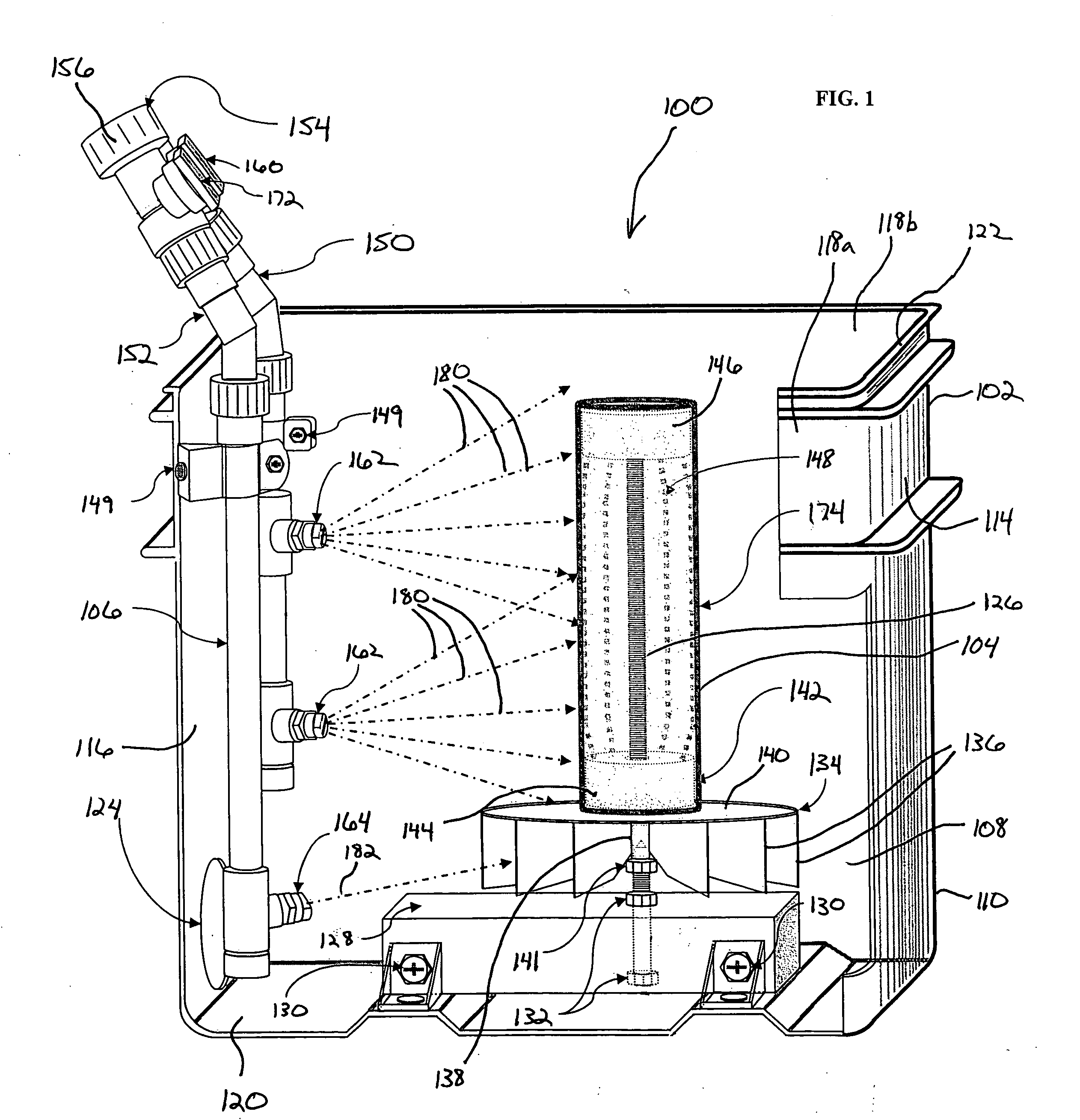

Cylindrical element cleaning assemblies and related methods

InactiveUS20060243309A1Improve convenienceEfficient use ofElectrostatic cleaningOther artistic work equipmentsTurbineWaste management

A portable cleaning assembly for cleaning cylindrical elements such as paint roller covers and pool and spa cartridge filters. The portable cleaning includes a housing structure for fully enclosing the cylindrical element during cleaning so as to prevent overspray and subsequent clean-up of the surrounding area. The housing structure further includes a top accessible door for positioning the cylindrical element for cleaning as well as allowing visible access during a cleaning, rinsing and / or drying step without interfering with operation of the cleaning assembly. The portable cleaning assembly includes a manifold assembly including a plurality of water jet assemblies for spraying the cylindrical elements. In addition, the portable cleaning assembly includes a turbine assembly upon which the cylindrical element is mounted and spun, under the direction of the water jet assemblies, during the cleaning operation.

Owner:PRESCOTT JAMES M +1

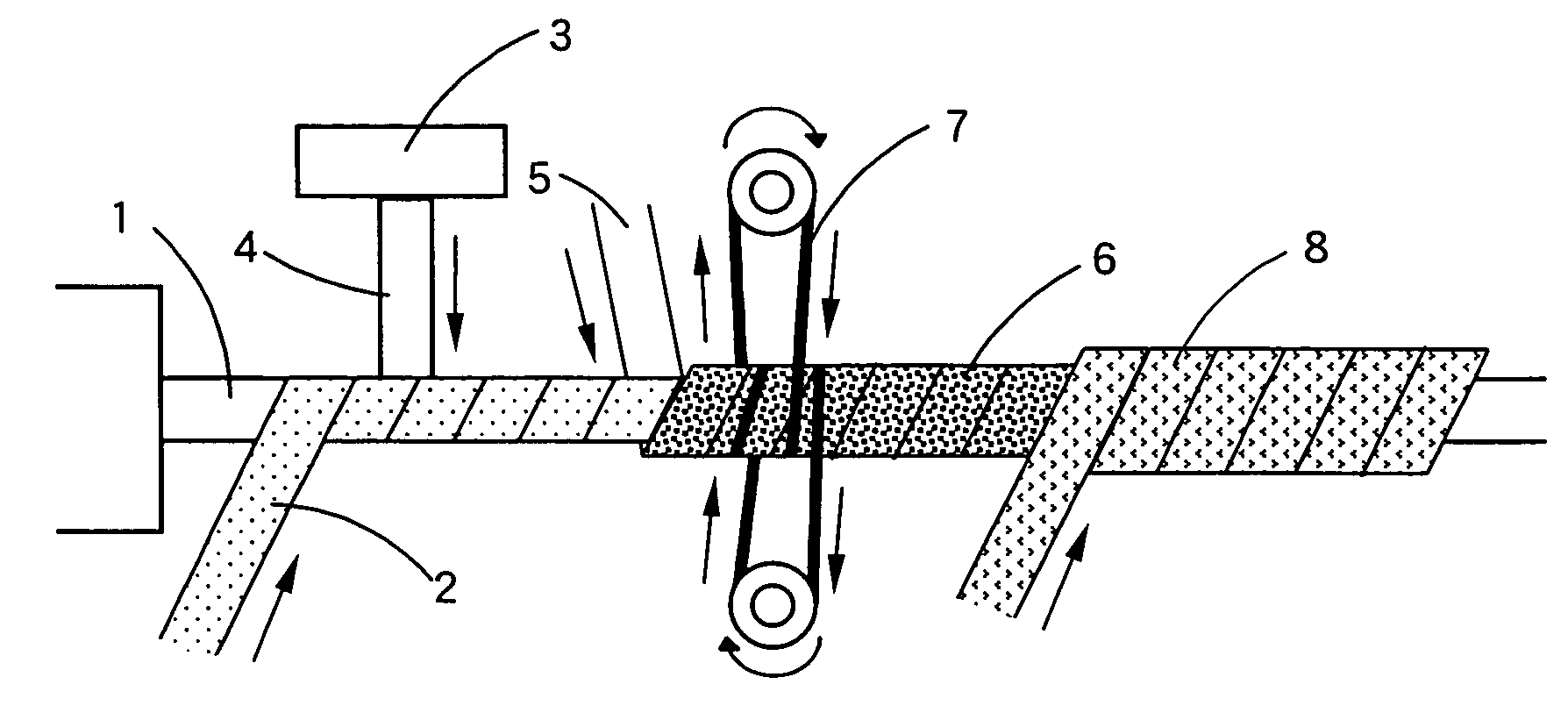

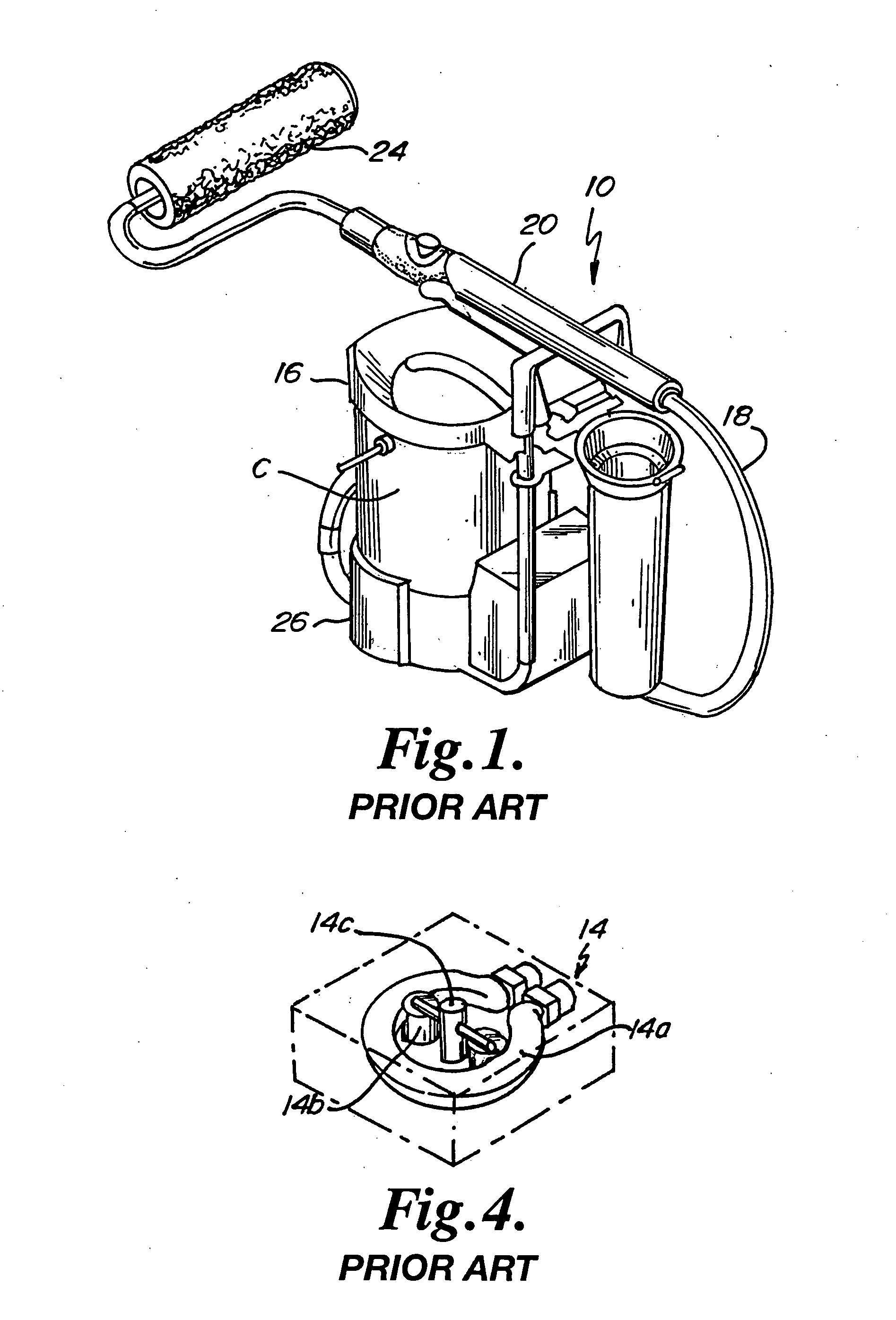

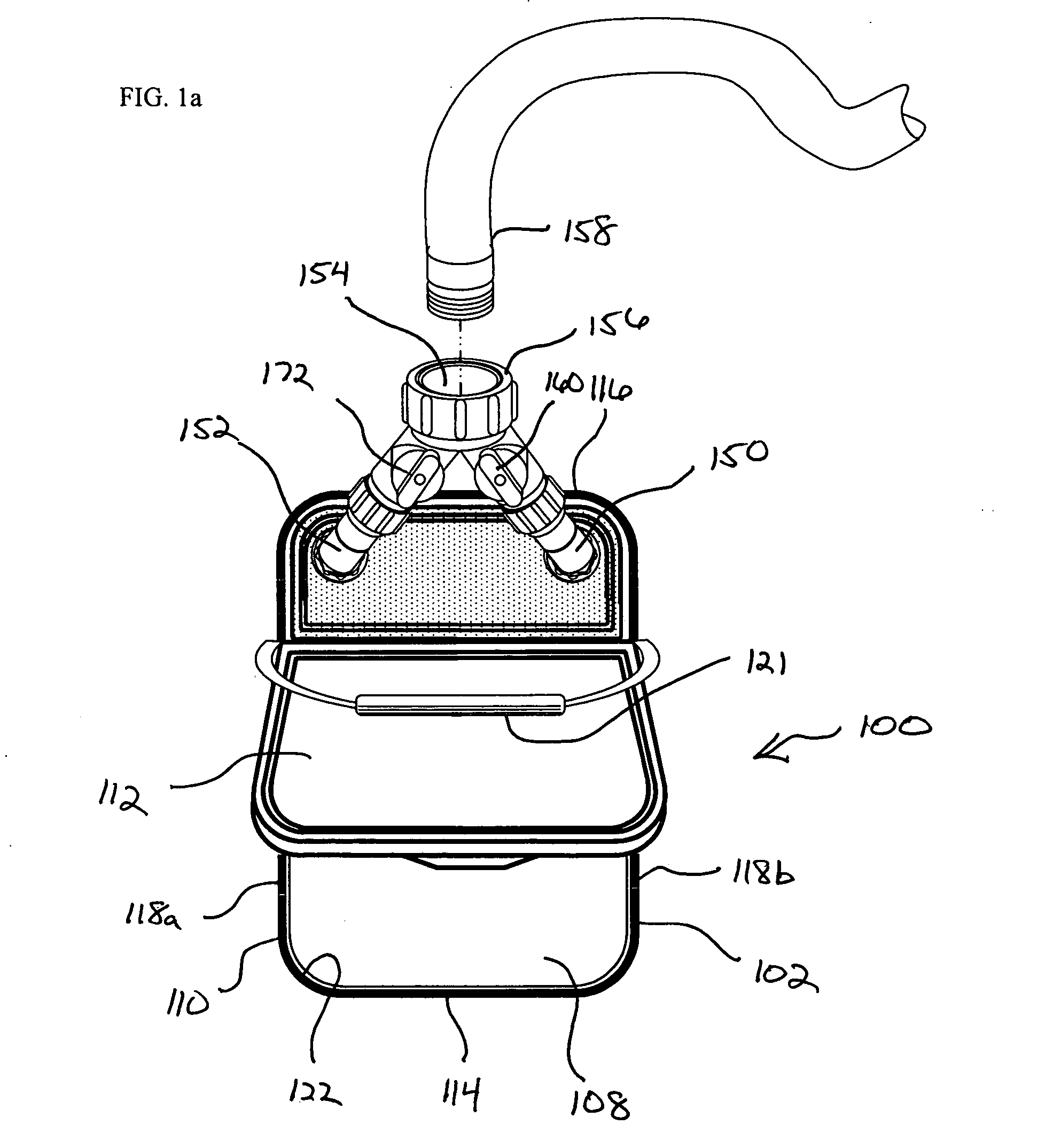

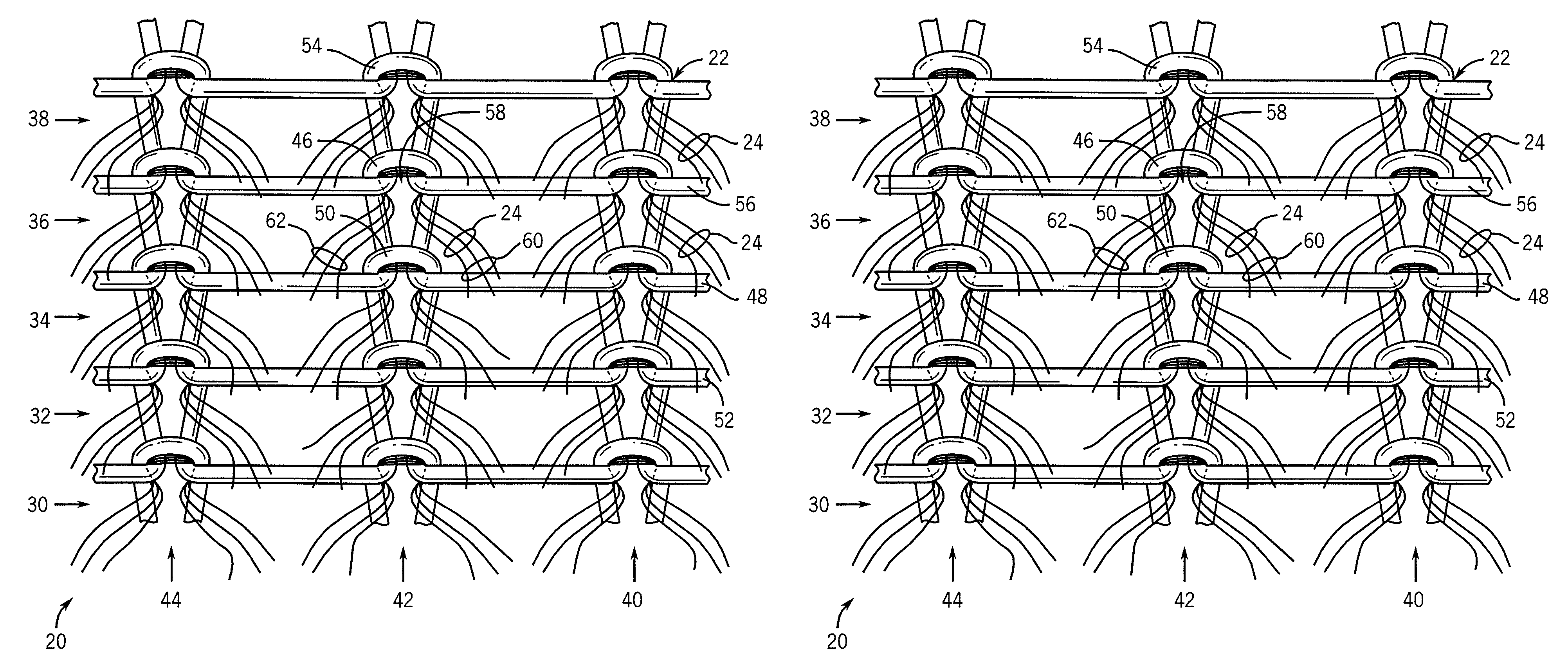

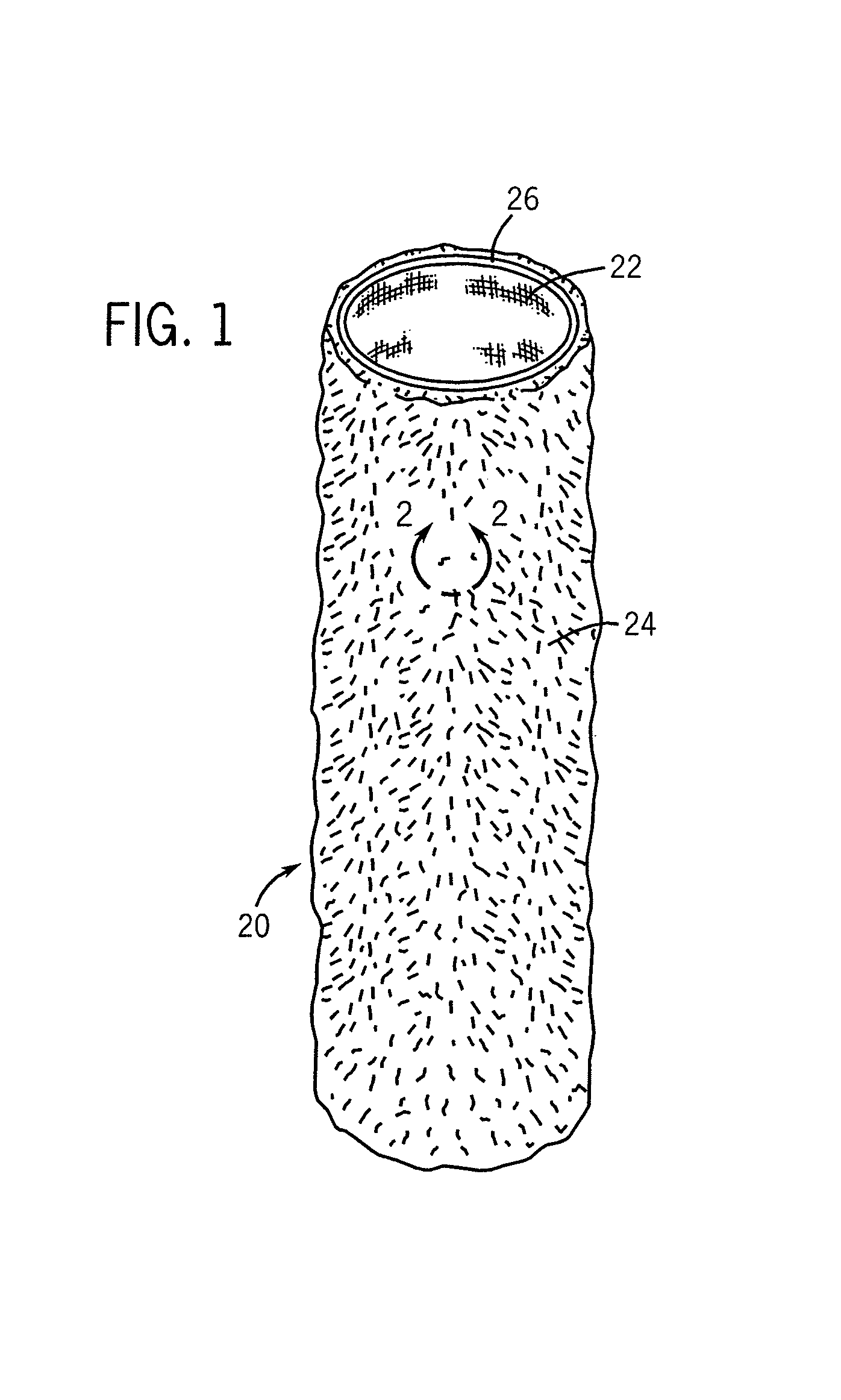

Forming a tubular knit fabric for a paint roller cover

ActiveUS7503190B1Increased durabilityImprove robustnessCircular knitting machinesStraight-bar knitting machinesFiberYarn

A method and apparatus are provided for forming a tubular-shaped knitted covering for a paint roller, or the like, having a pile extending from an outer surface of the covering, through use of a dial needle knitting arrangement. A cylinder needle knitting arrangement may be utilized in conjunction with the dial needle knitting arrangement for forming a tubular-shaped knitted covering for a paint roller having a pile formed from a combination of sliver and yarn fibers in successive courses of the tubular-shaped knitted covering.

Owner:SEAMLESS TECH

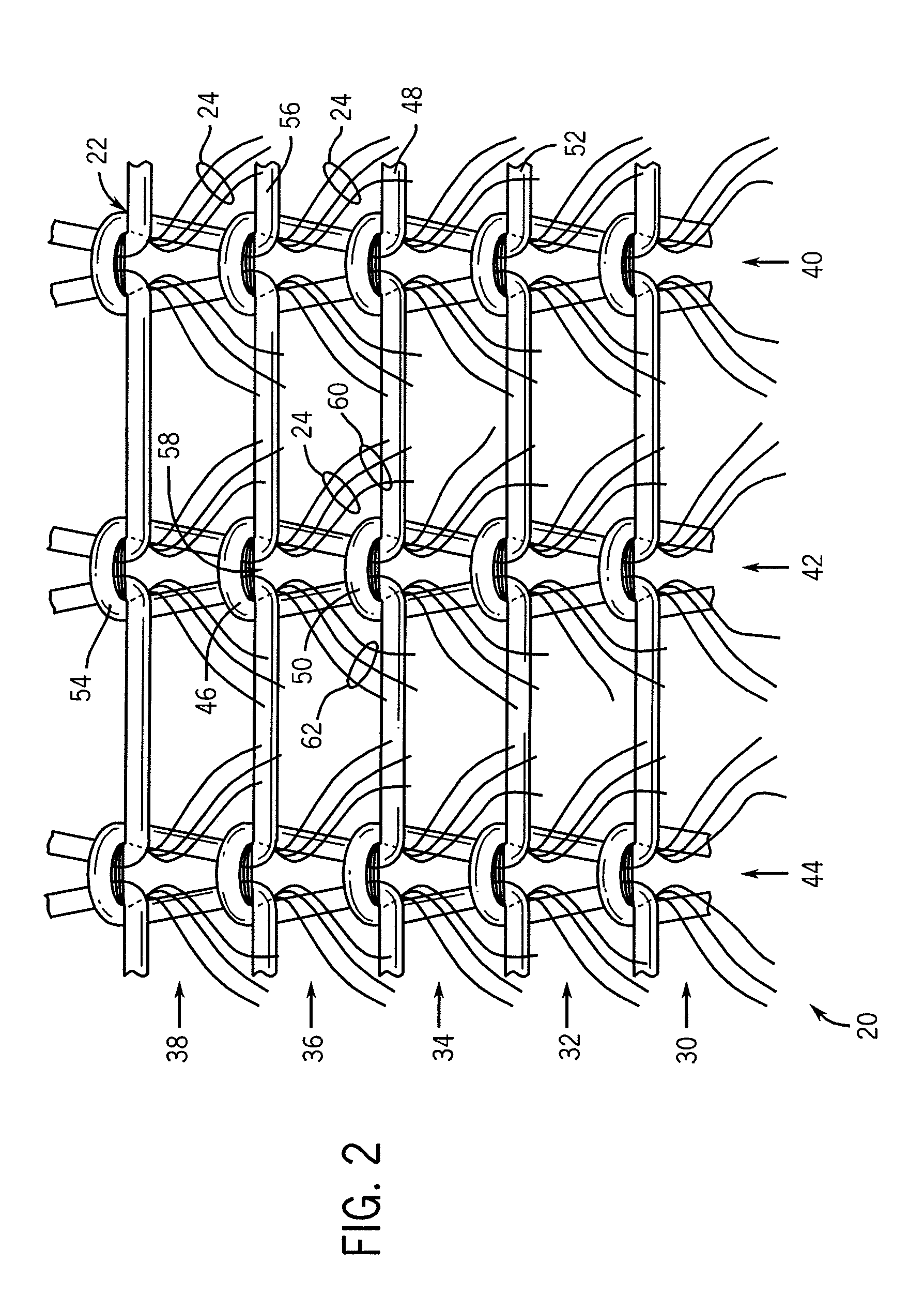

Multi paint roller connector

InactiveUS20070143946A1Time wastingLess dipping timeLiquid surface applicatorsArtistic surface treatmentPorosityHigh density

A bracket for mounting one or more paint rollers to the shaft of a paint roller frame. A mounting plate carries a pair of roller engaging members extending normal to the mounting plate on opposite ends thereof, each roller engaging member being formed to rollingly engage an end of a paint roller. A shaft engaging member is located between the pair of roller engaging members and has a shaft opening formed there through of a dimension, and arranged, to pivotally receive the shaft of a paint roller frame. In one embodiment, one or more mini-rollers, with internal roller bearings, are carried on shafts integral with and extending from opposing mounting brackets. In other embodiments, two or three standard paint rollers are carried on members that extend from opposing mounting brackets and are rotatable thereon. In further embodiments, a first roller is formed with a surface material that has sufficient nap or a sufficiently low density or porosity to carry an amount of paint sufficient to cover a desired area of surface to be painted, and a second roller is formed with a surface material of a sufficiently high density to provide a smooth finish to said surface area.

Owner:KIM SONG

Apparatus for cleaning paint rollers

InactiveUS20080035185A1Simple wayPrevent sprayingElectrostatic cleaningOther artistic work equipmentsEngineeringPaint roller

An apparatus for cleaning a paint roller includes a container having a top with an insertion opening for introducing a paint-carrying surface of the paint roller into the container and a bottom with a discharge opening for discharging paint out of the container. A spray pipe has holes formed therein for directing water toward the paint-carrying surface within the container. The spray pipe rotates and the paint roller is movable vertically, for washing paint off substantially all of the paint-carrying surface and out of the discharge opening.

Owner:BARATTA JOSEPH P

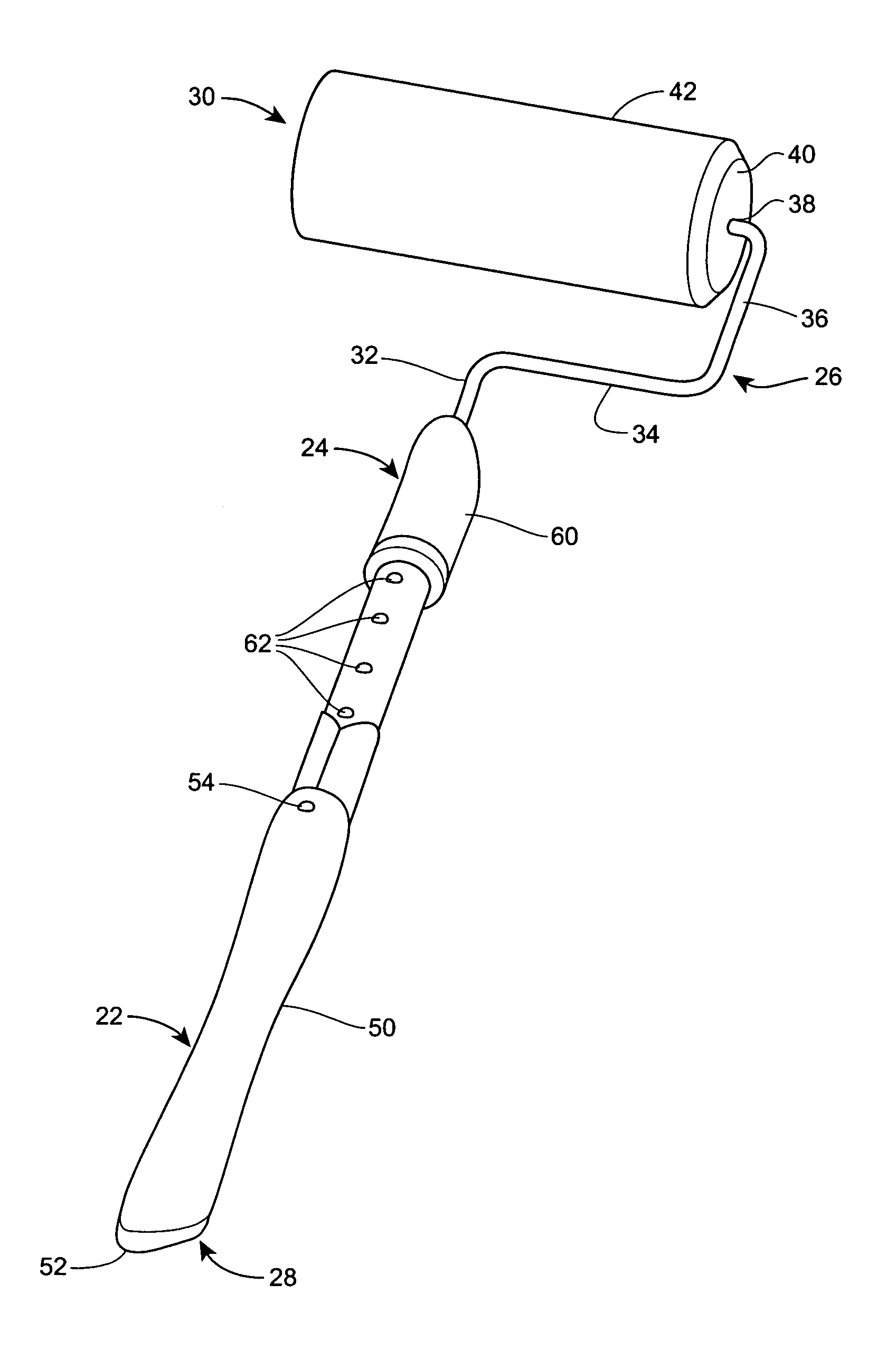

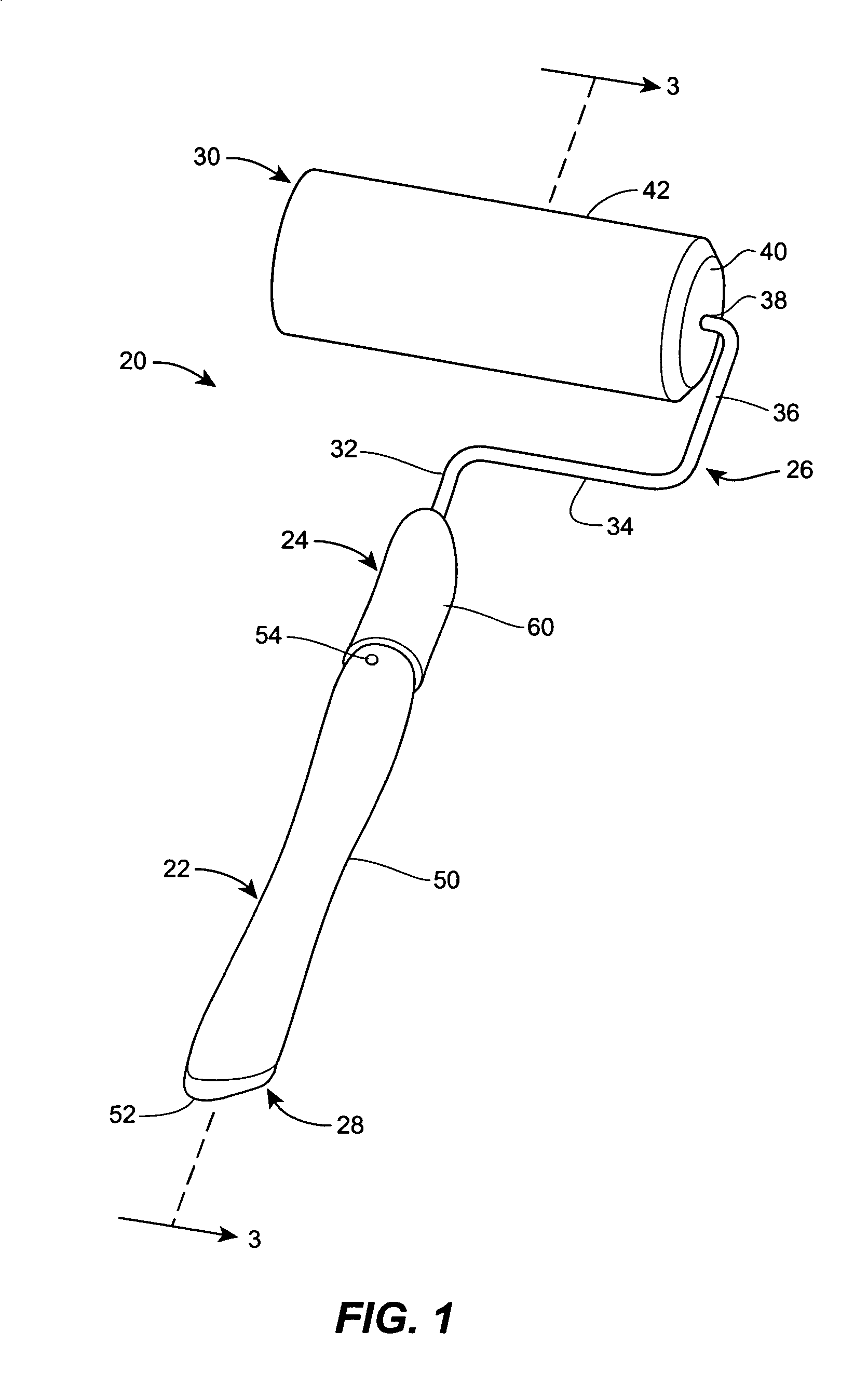

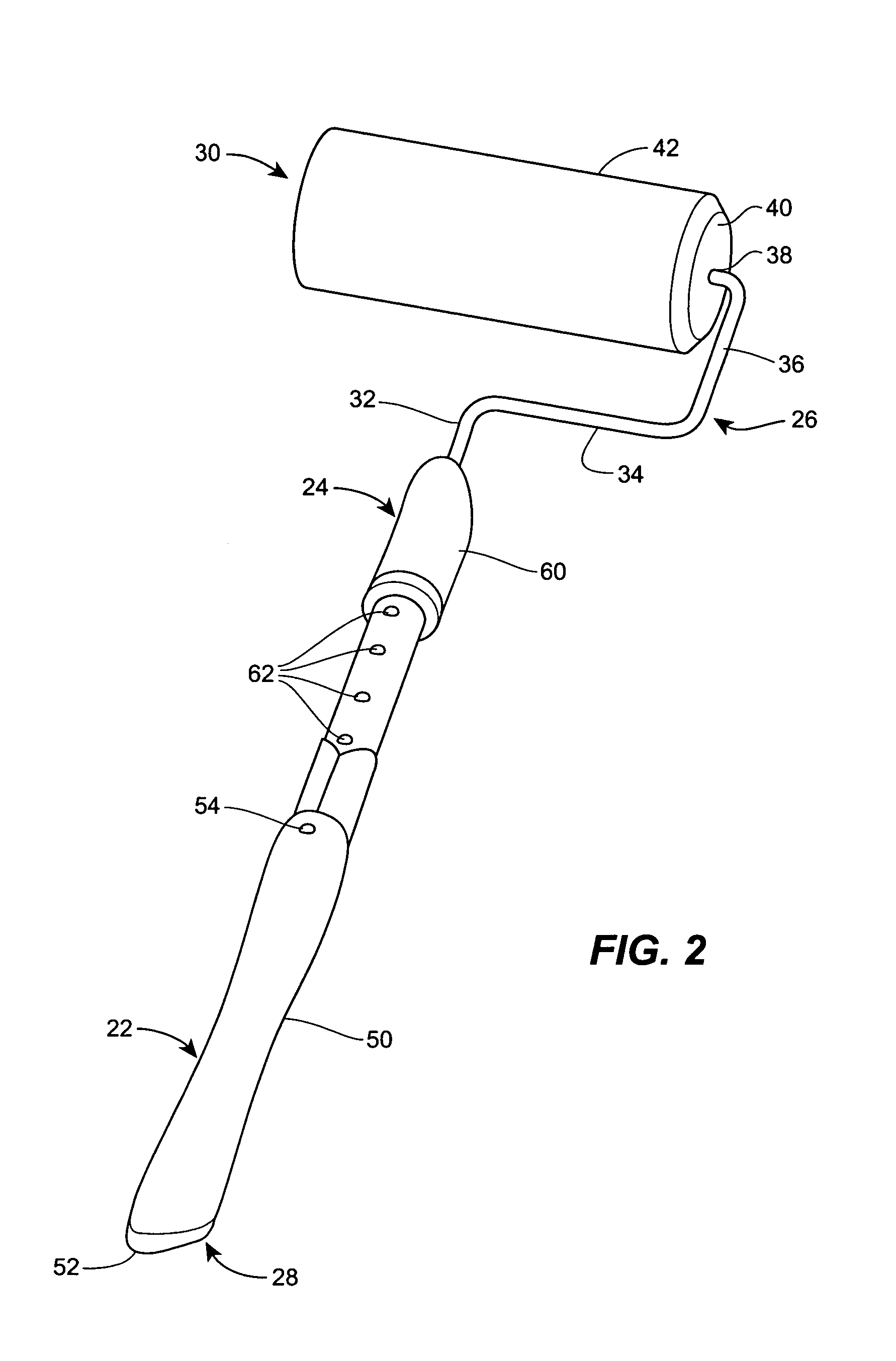

Adjustable tool handle for paint rollers and the like

A tool handle assembly adapted to be connected to a tool head comprises a leg with an inner grip handle connected to the leg between first and second ends thereof, an outer grip handle connected to the first end of the leg and a tool head connector connected to the second end of the leg. The inner grip handle includes a grip extending perpendicular to the leg. The outer grip handle preferably pivots about an axis extending perpendicular to an axis extending through the leg. The inner grip handle is preferably pivotal between a storage and use position and is slidably connected to the leg. The leg of the tool handle preferably telescopes and comprises a pair of parallel extending legs connected together by cross-members.

Owner:NICOLAY FAMILY ENTERPRISES

Container

Owner:THE SHERWIN-WILLIAMS CO

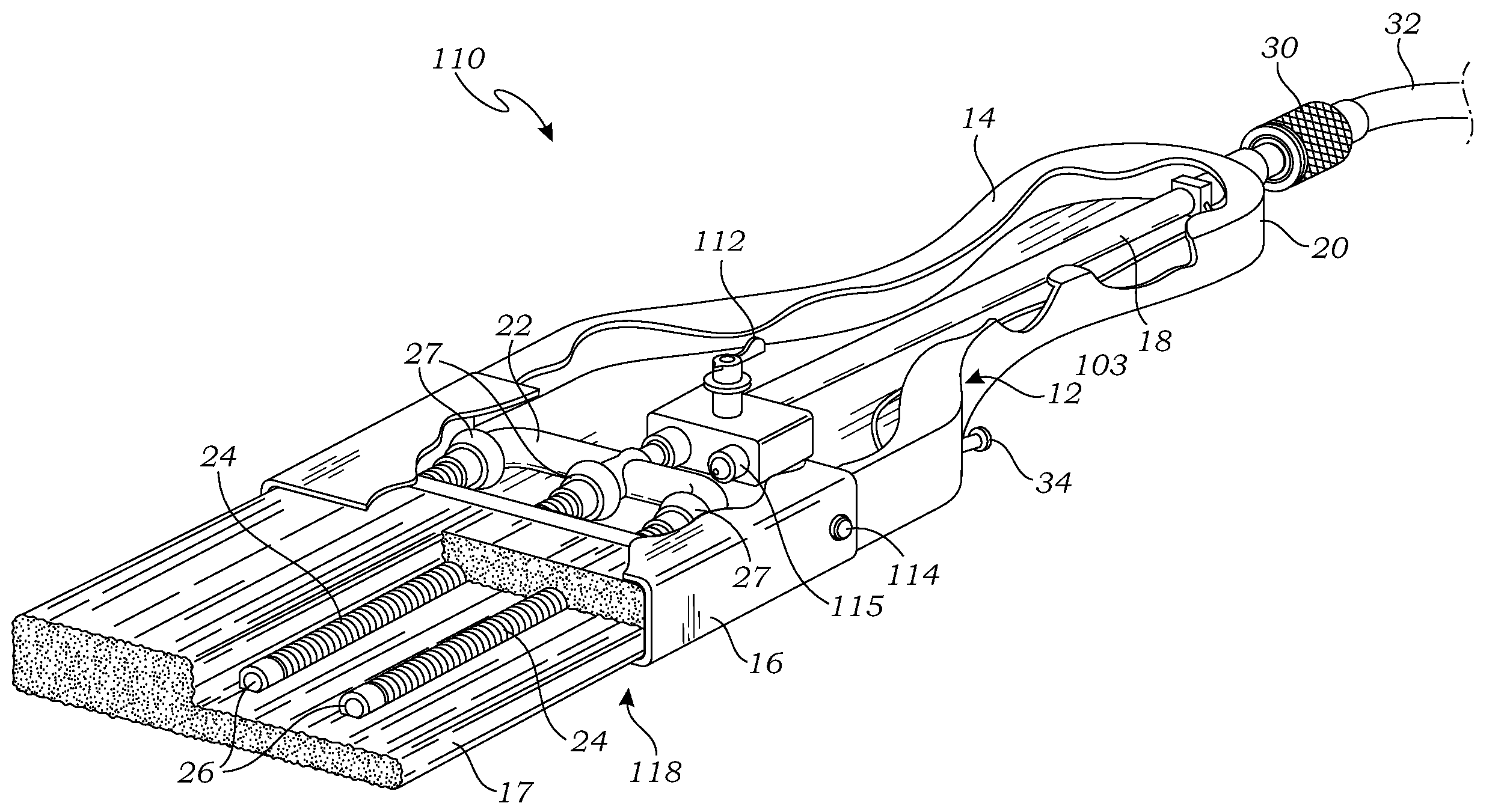

Paint Roller with Integral Paint Delivery Mechanism

A combination roller / spray gun device with a spray gun nozzle that is held in alignment with a paint roller, and sprays paint at a predetermined point on a surface in front of the roller. A pressurized supply of paint is provided to a trigger controlled paint supply valve at the proximal end of the paint roller device. A removable nozzle / conduit assembly extends from the paint supply valve to the distal end of paint roller device. The nozzle / conduit assembly is secured inside of the shaft of the paint roller device by a removable roller assembly.

Owner:COSTIGAN MICHAEL D

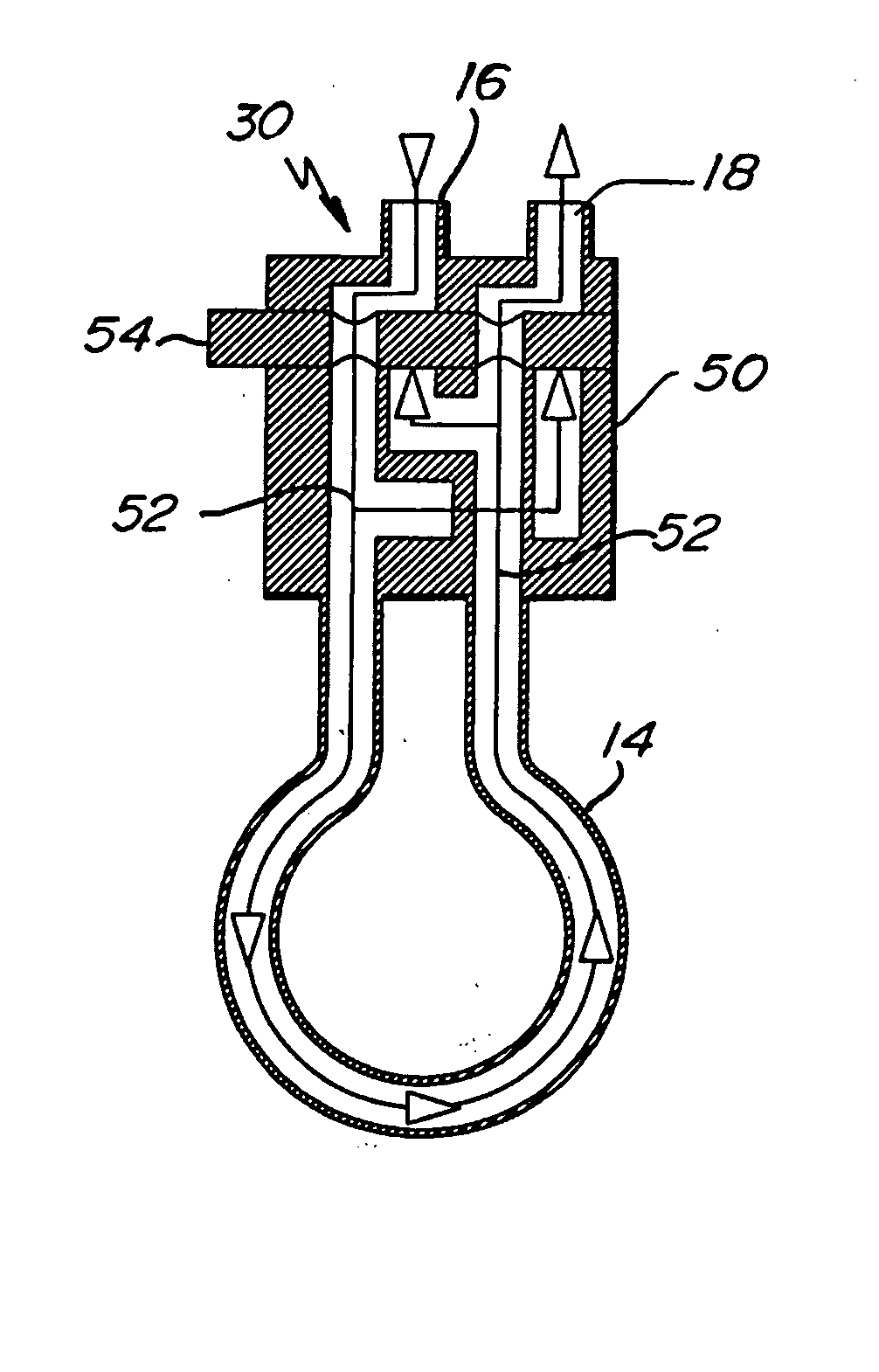

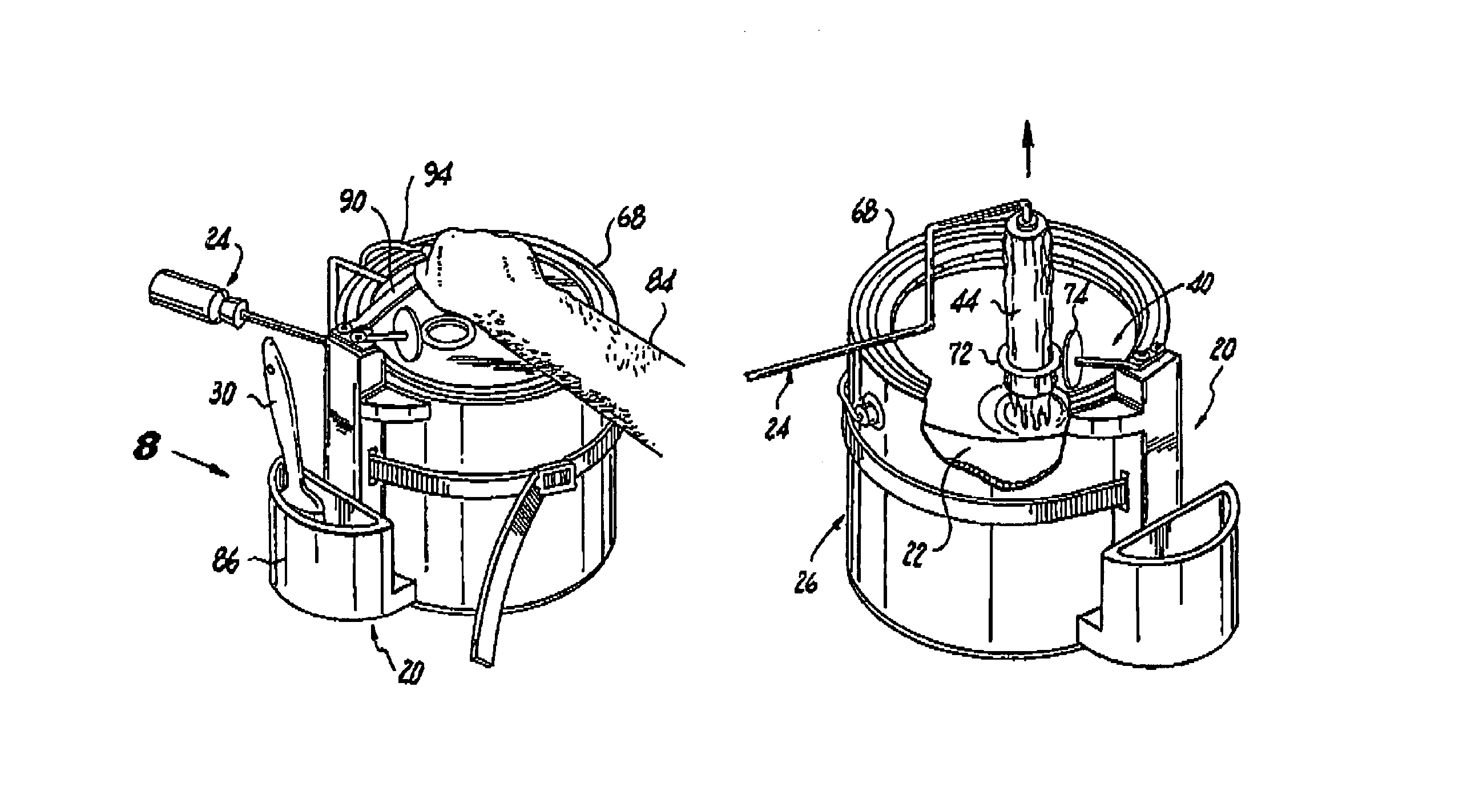

Apparatus for delivering paint to a paint roller directly from a paint can with a compartment for holding a paint brush

InactiveUS8079768B1Avoid disadvantagesSimple and inexpensive to manufactureBrushesOther artistic work equipmentsEngineeringPaint roller

An apparatus for delivering paint to a paint roller directly from a paint can with a compartment for holding a paint brush which comprises a housing. A mechanism is for securing the housing to an exterior surface of a cylindrical side wall of the paint can. A roller wiper component is also provided. Another mechanism is for mounting the roller wiper component on the housing to extend over the paint can. After a roller cover of the paint roller is charged with paint contained in the paint can, excessive paint on the roller cover of the paint roller will be removed therefrom by the roller wiper component to safely drip back into the paint can.

Owner:MCLAUGHLIN THOMAS

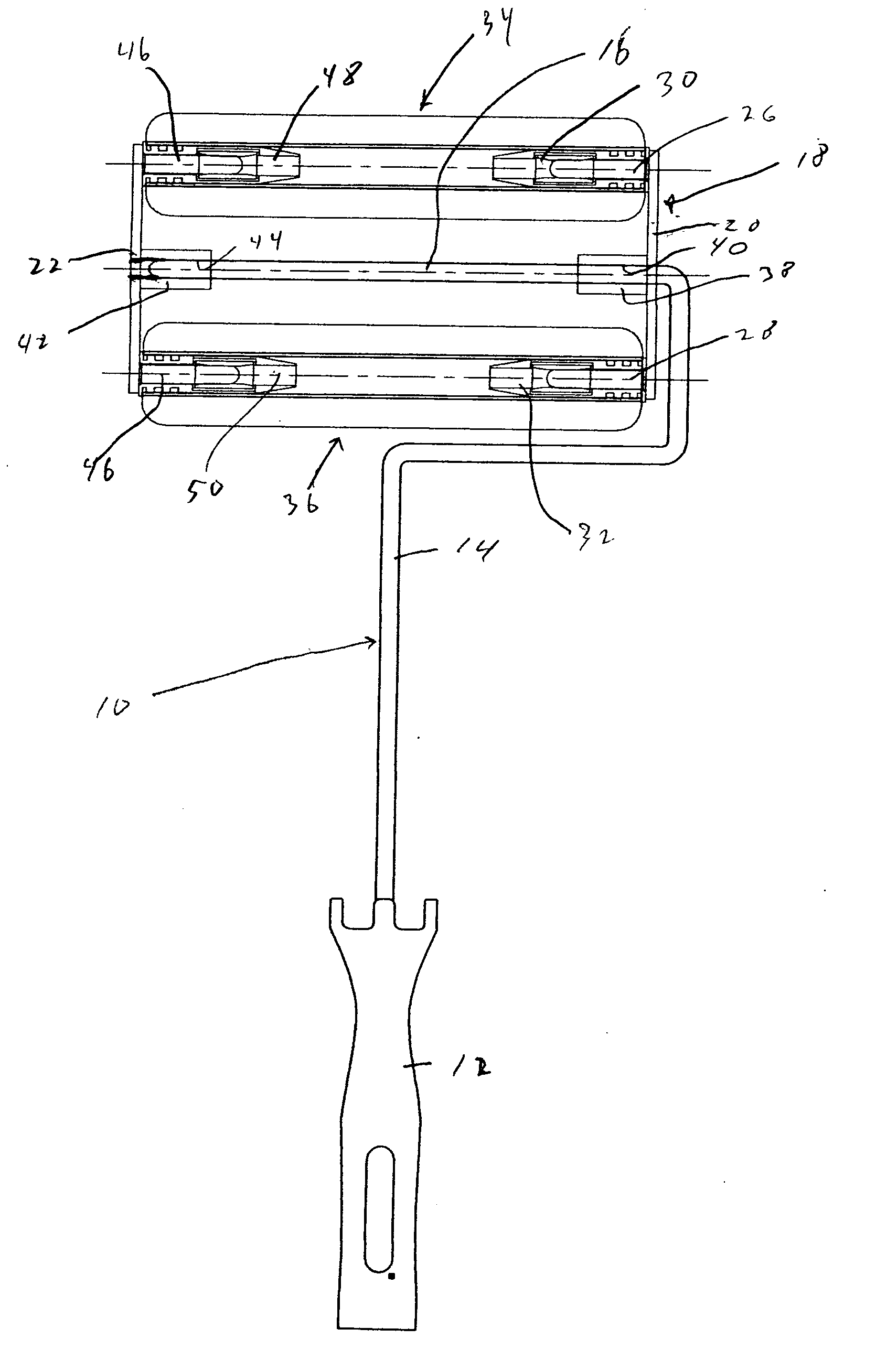

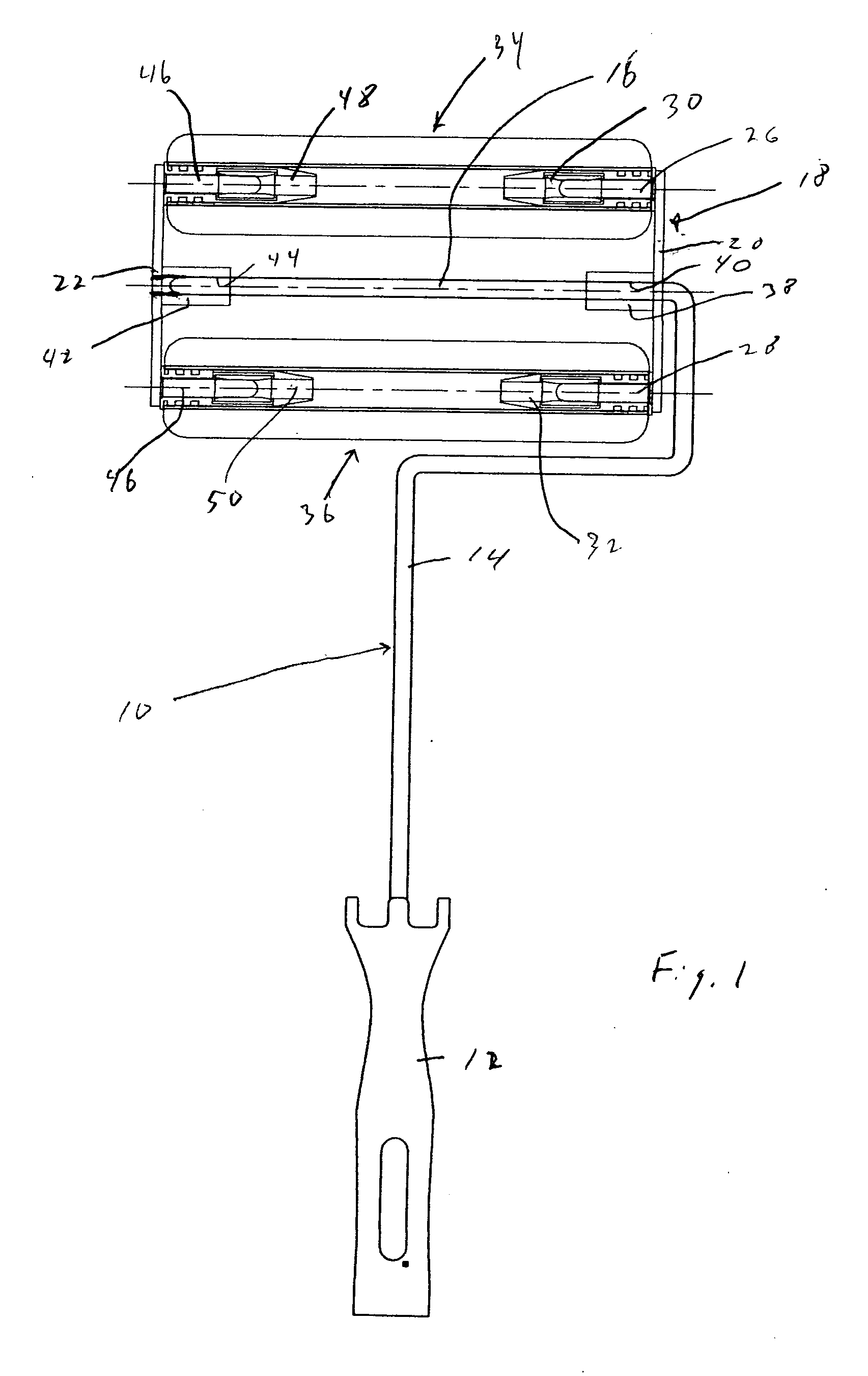

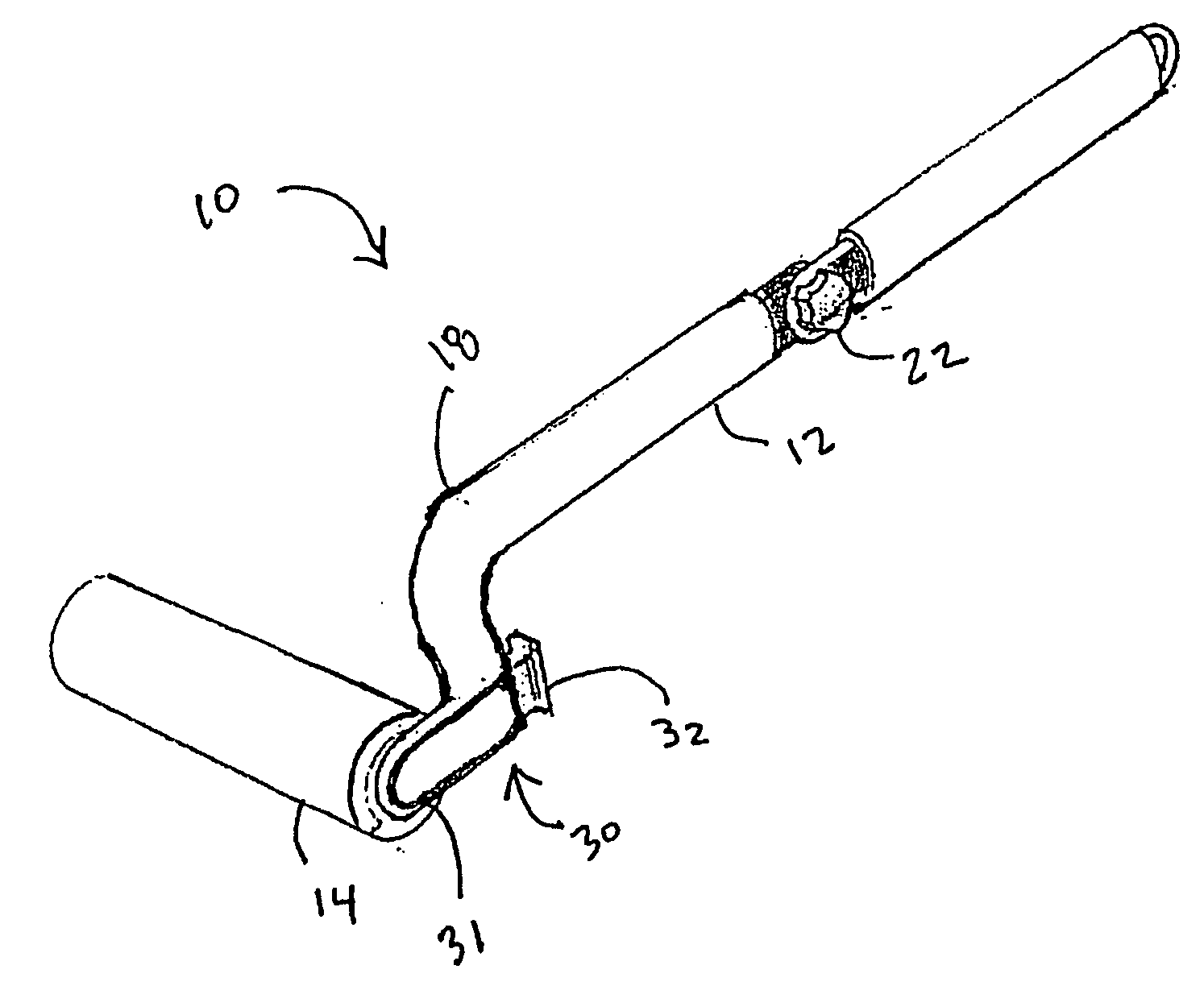

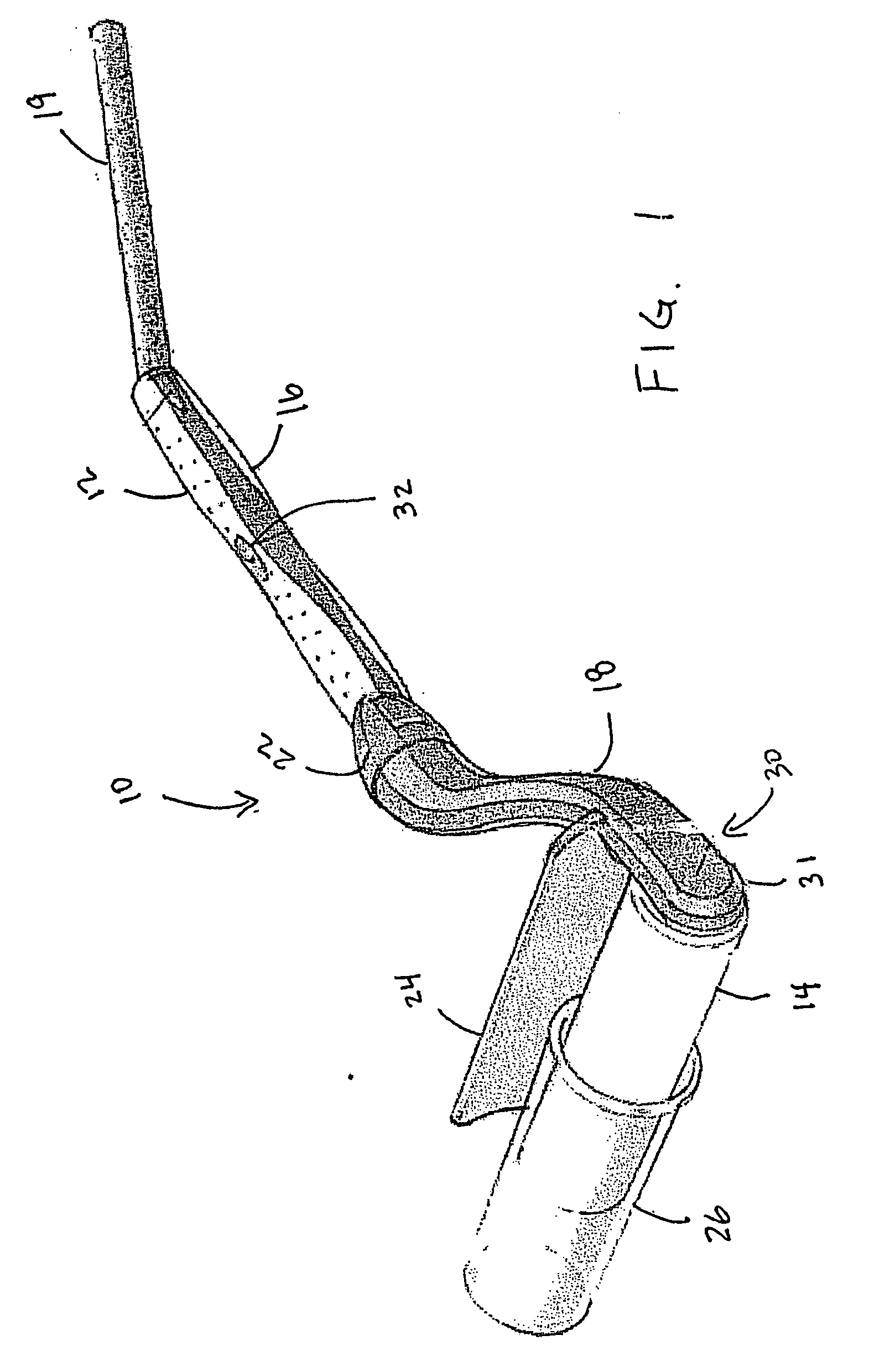

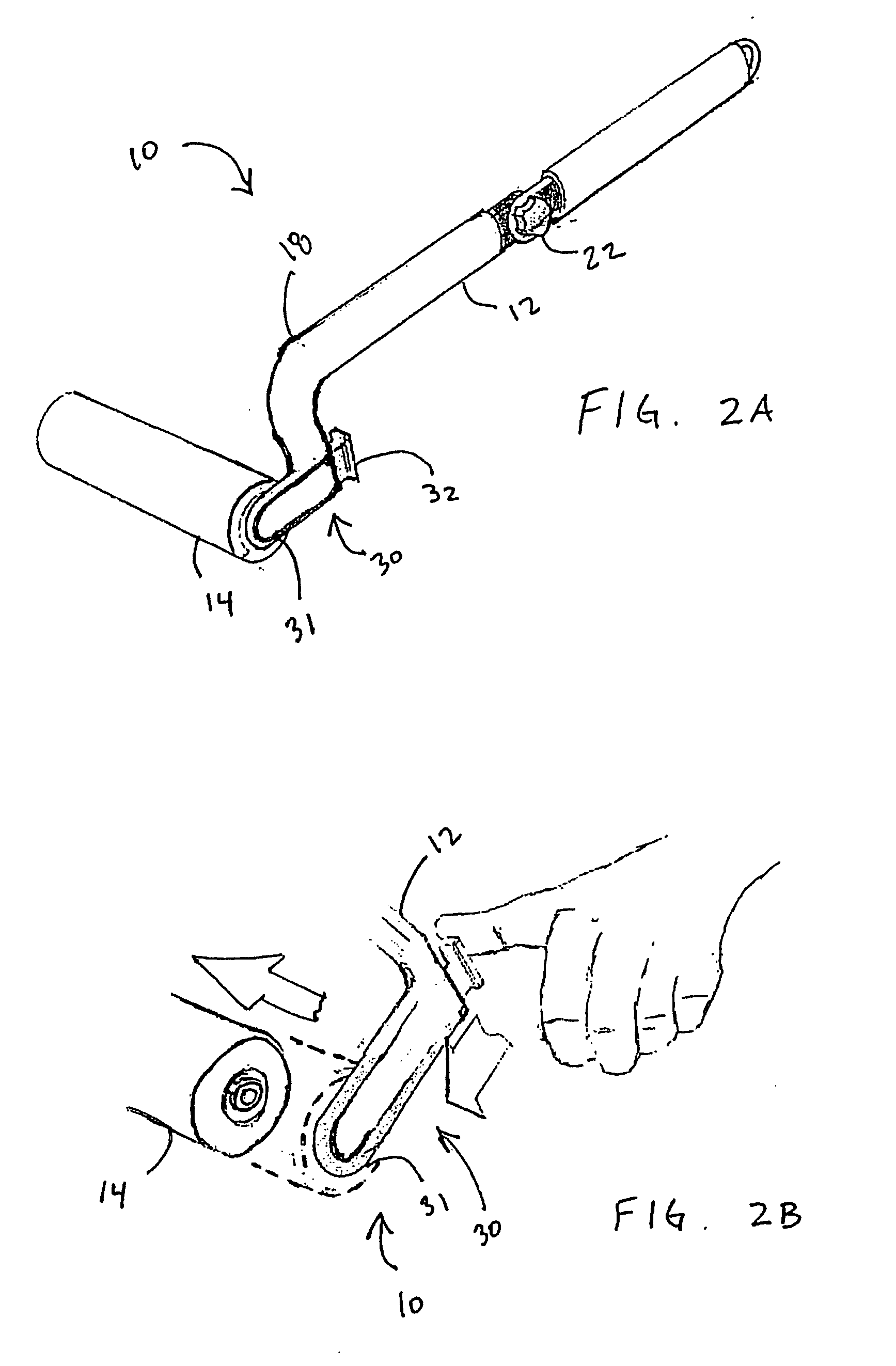

Quick release paint roller assembly

InactiveUS20060130261A1Prevent movementLiquid surface applicatorsArtistic surface treatmentFast releaseActuator

A quick-release paint roller having a roller cover that can be removed from a handle assembly without requiring the user to apply a force directly to the roller cover. The paint roller includes a pair of end caps. The end caps have axial bores therein and are disposed at opposing ends of the roller tube. The inner end cap has a hub with a nipple extending there from, the nipple having a head portion and an annular groove between the head portion and the hub. The paint roller also includes a handle assembly. The handle assembly includes a housing having an opening configured to receive the nipple of the roller cover. The handle assembly also includes a roller support having an elongate shaft, the elongate shaft being received by the bores of the inner and outer end caps to rotatably support the roller cover about an axis of rotation along the elongate shaft. The handle assembly further includes a latching mechanism movable between a latched position and a release position, the latching mechanism including an actuator and a latch. When the actuator is in the latched position, movement of the roller cover in a direction along the axis of rotation away from the housing is prevented. The handle assembly also includes a latch spring for biasing the actuator toward the latched position, and an ejector spring acting upon the nipple, wherein the ejector spring urges the nipple out of the opening, wherein when the latch is free of the nipple, the ejector spring ejects the roller cover from the handle assembly.

Owner:ZIBRA

Powered painting system

InactiveUS20090080964A1Easy and quick to cleanLiquid surface applicatorsCarpet cleanersPaint rollerGas pressure

A gas pressurized painting system comprises a pressurized paint canister and a powered paint brush or powered paint roller connectable to the pressurized paint canister. The canister includes a paint reservoir, an air pressure fitting in fluid communication with the paint reservoir and configured to be connected to a gas pressure source, a paint outlet in fluid communication with the paint reservoir, and a removable cap for filling the paint reservoir with paint. A flexible tube is used to interconnect the paint outlet to the paint inlet of the powered paint brush or powered paint roller. The painting system also includes a cleaning system for quickly and easily cleaning the system using a standard source of cleaning fluid, such as a garden spigot.

Owner:CASTELLANA JERRY D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com