Paint roller with integrated core and cover and method and apparatus for production of same

a paint roller and core technology, applied in the field of paint rollers with integrated cores and covers, can solve the problems of paint rollers made out of cores, paint rollers that are easily damaged, and require a long assembly line,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

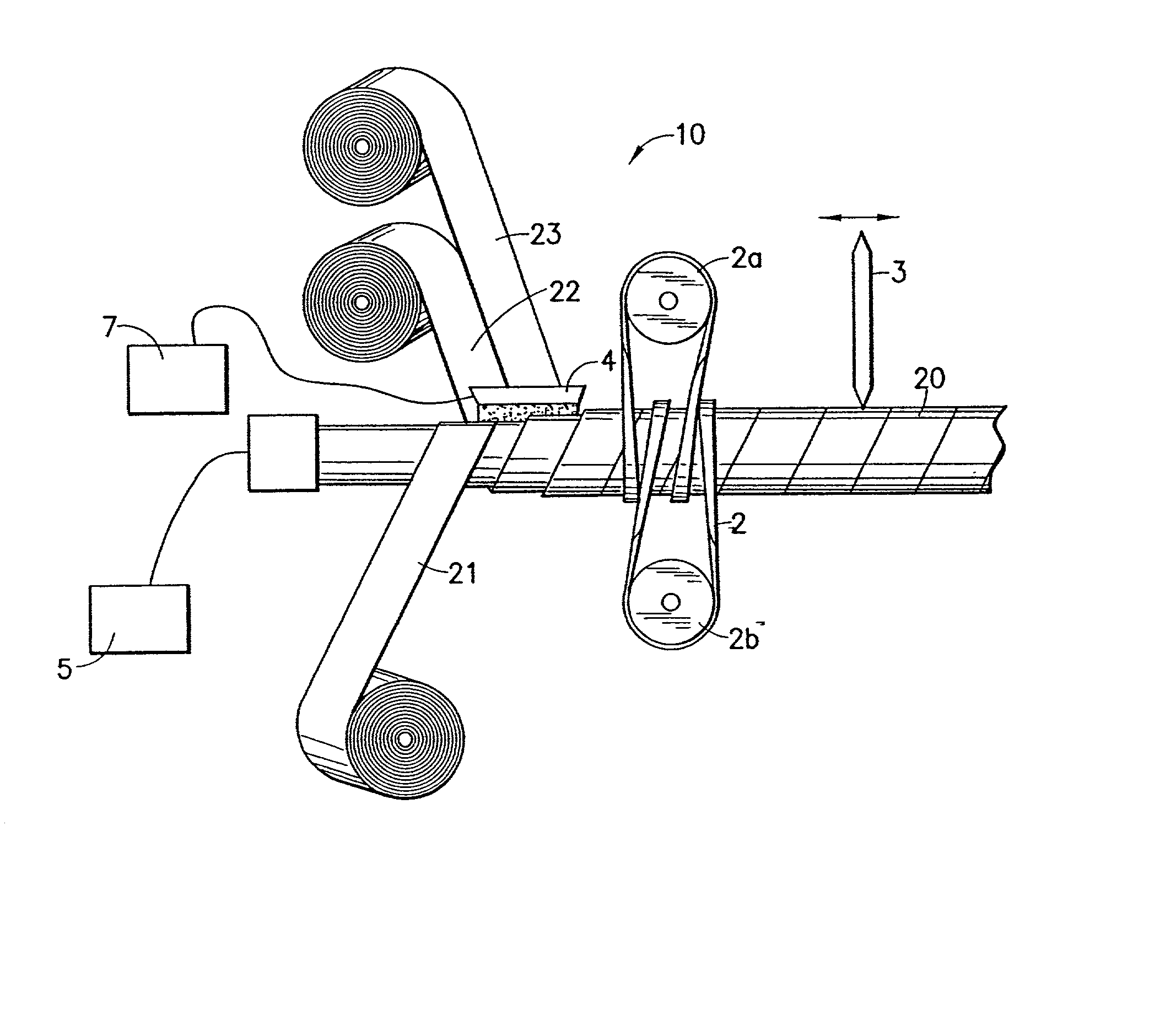

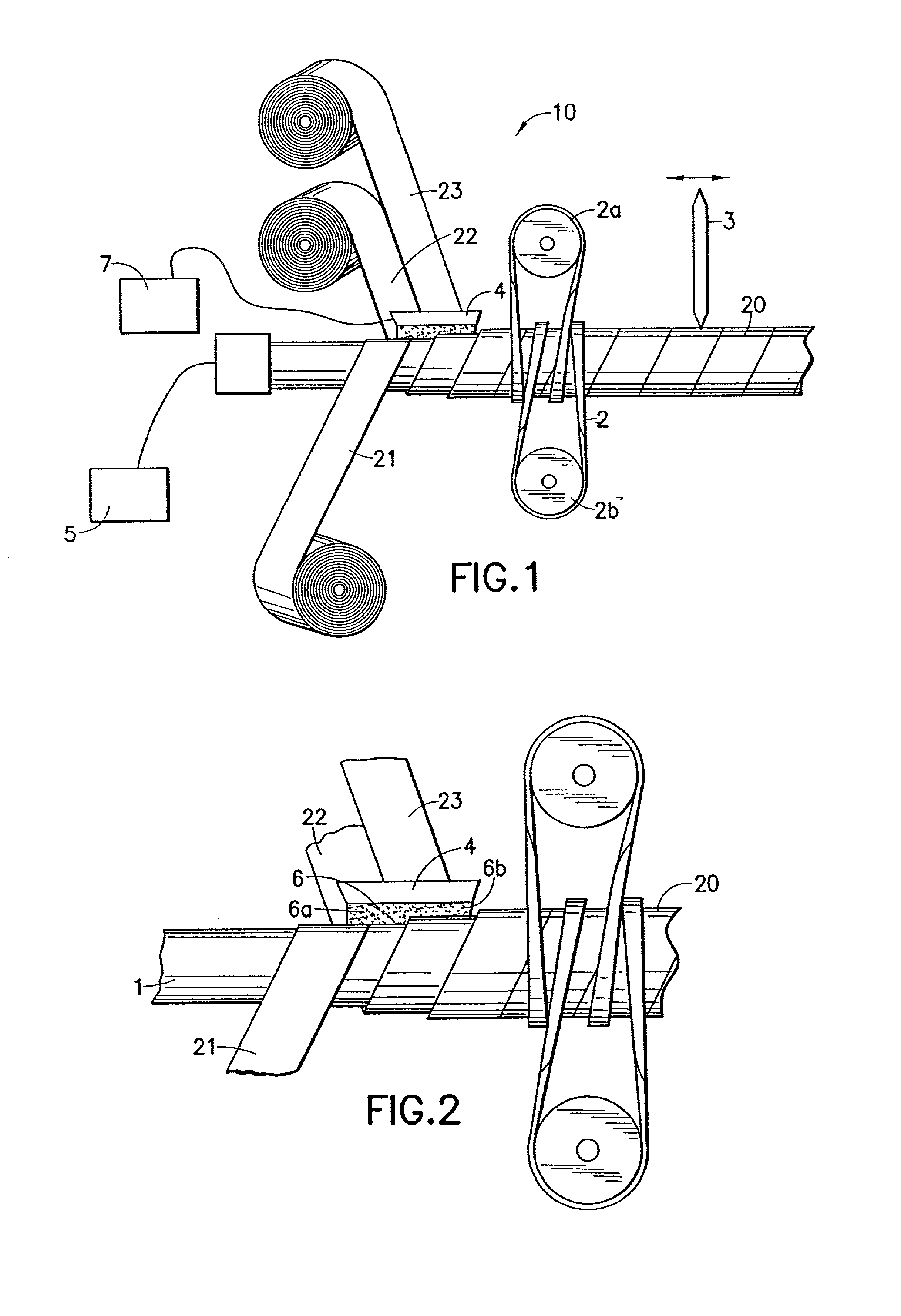

[0040] In a first embodiment, shown in FIG. 1, a detail shown in FIG. 2, and a cutaway detail shown in FIG. 2a, a continuous paint roller is manufactured from an inner strip of thermoplastic material 21, an outer strip of thermoplastic material 22, a cover 23, and an adhesive 6 applied from one or more heads 4. The thermoplastic material is preferably polypropylene. The cover 23 may be a well-known fabric cover for a paint roller, which can be made of polyester.

[0041] The inner strip 21 is helically advanced about the mandrel 1. The term helically as used herein means oriented about a mandrel so as to permit the downstream edge of a given wind of a strip to be in closely-spaced or abutting relation with the upstream edge of the preceding wind of the strip. As is well known in the art, a lubricant such as 5% mineral oil may be applied to the inner surface of the inner strip 21 prior to winding on the mandrel 1.

[0042] The outer strip 22 is helically advanced about the inner strip 21. ...

second embodiment

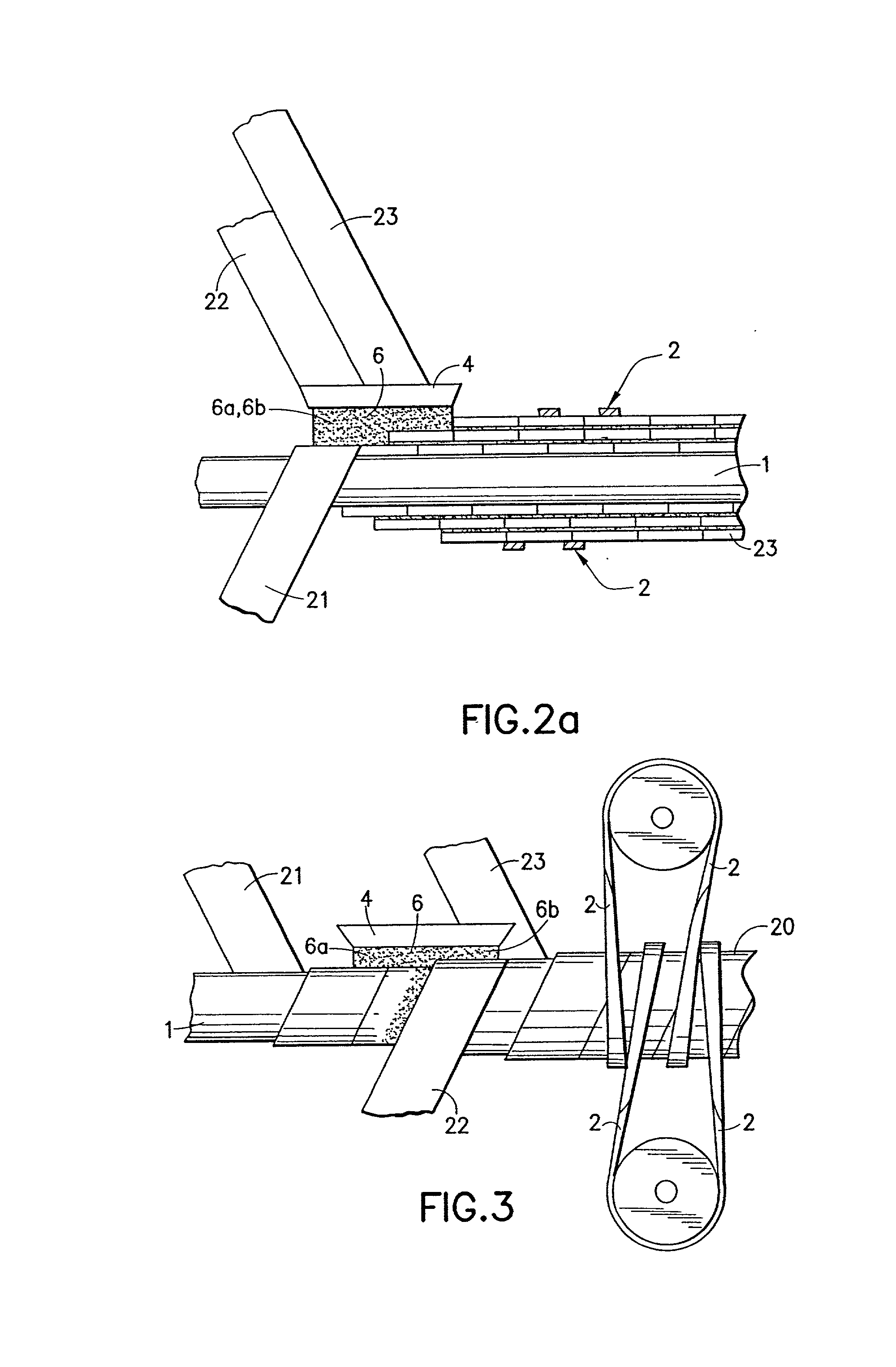

[0057] It is believed that providing an offset between the outer strip 22 and the cover 23 could yield an even sturdier product, a method permitting such offset is disclosed. Turning now to a second embodiment, having a detail shown in FIG. 3, a continuous paint roller is manufactured from an inner strip of thermoplastic material 21, an outer strip of thermoplastic material 22, a cover 23, and an adhesive 6 applied from one or more heads 4. The thermoplastic material is preferably polypropylene. The cover 23 may be a well-known fabric cover for a paint roller, which can be made of polyester.

[0058] The second embodiment differs from the first in the orientation of feed for the strips 21, 22 and cover 23. In the second embodiment, the cover 23 is offset from the outer strip 22.

[0059] The inner strip 21 is helically advanced about the mandrel 1. As is well known, a lubricant may be applied to the inner surface of the inner strip 21 prior to winding on the mandrel 1. The outer strip 22 ...

third embodiment

[0064] Turning now to a third embodiment, having a detail shown in FIG. 4, a continuous paint roller is manufactured from an inner strip of thermoplastic material 21, an outer strip of thermoplastic material 22, a cover 23, and an adhesive (not shown) applied from two heads 4a and 4b. The thermoplastic material is preferably polypropylene. The cover 23 may be a well-known fabric cover for a paint roller, which can be made of polyester.

[0065] The third embodiment differs from the first two in the orientation of feed for the strips 21, 22 and cover 23. The third embodiment consists of the shortest assembly line. The inner strip 21 is helically advanced about the mandrel 1. As is well known, a lubricant may be applied to the inner surface of the inner strip 21 prior to winding on the mandrel 1. The outer strip 22 is helically advanced about the inner strip 21 in offset relation. The cover 23 is helically advanced about the outer strip 22, the cover may but need not be in offset relatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lengths | aaaaa | aaaaa |

| lengths | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com