Dual-mode contour-following mop

a contour-following mop and dual-mode technology, applied in the field of mop, can solve the problems of insufficient weight to create a strong enough cleaning force, inability to adapt to contours, and inability to easily detach in fashion, etc., and achieve the effect of convenient use and cleaning, convenient detachable fashion, and low manufacturing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

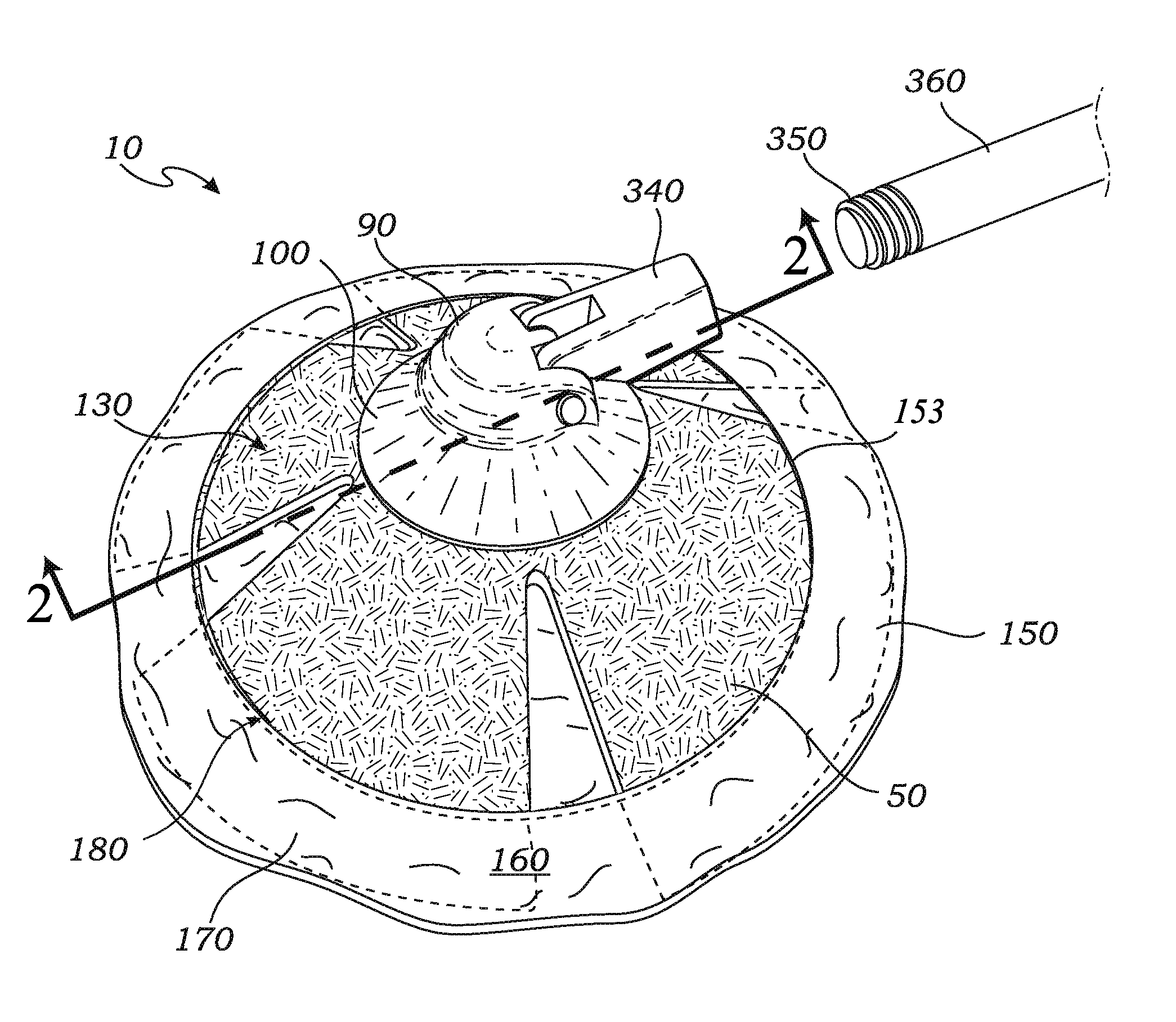

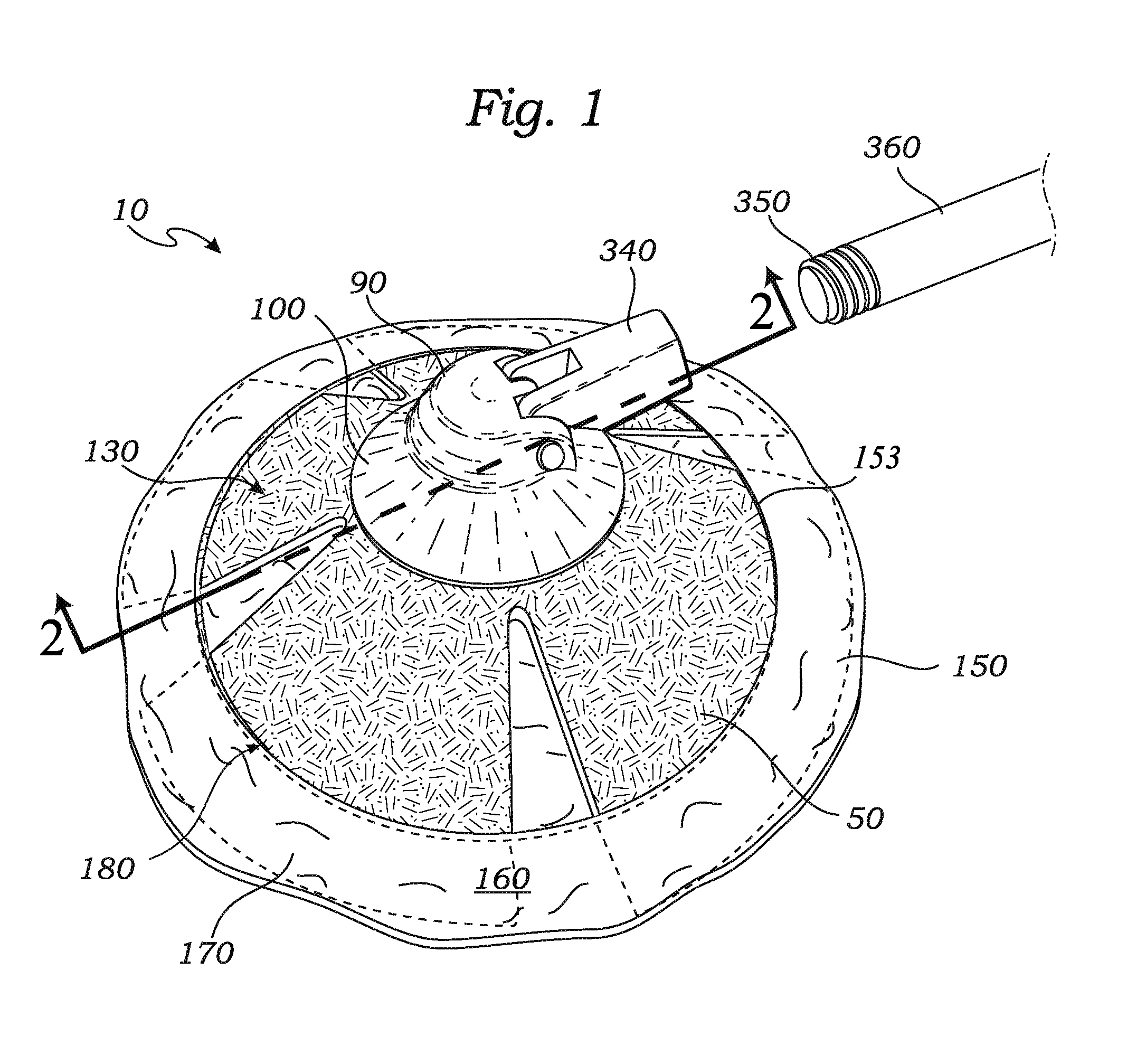

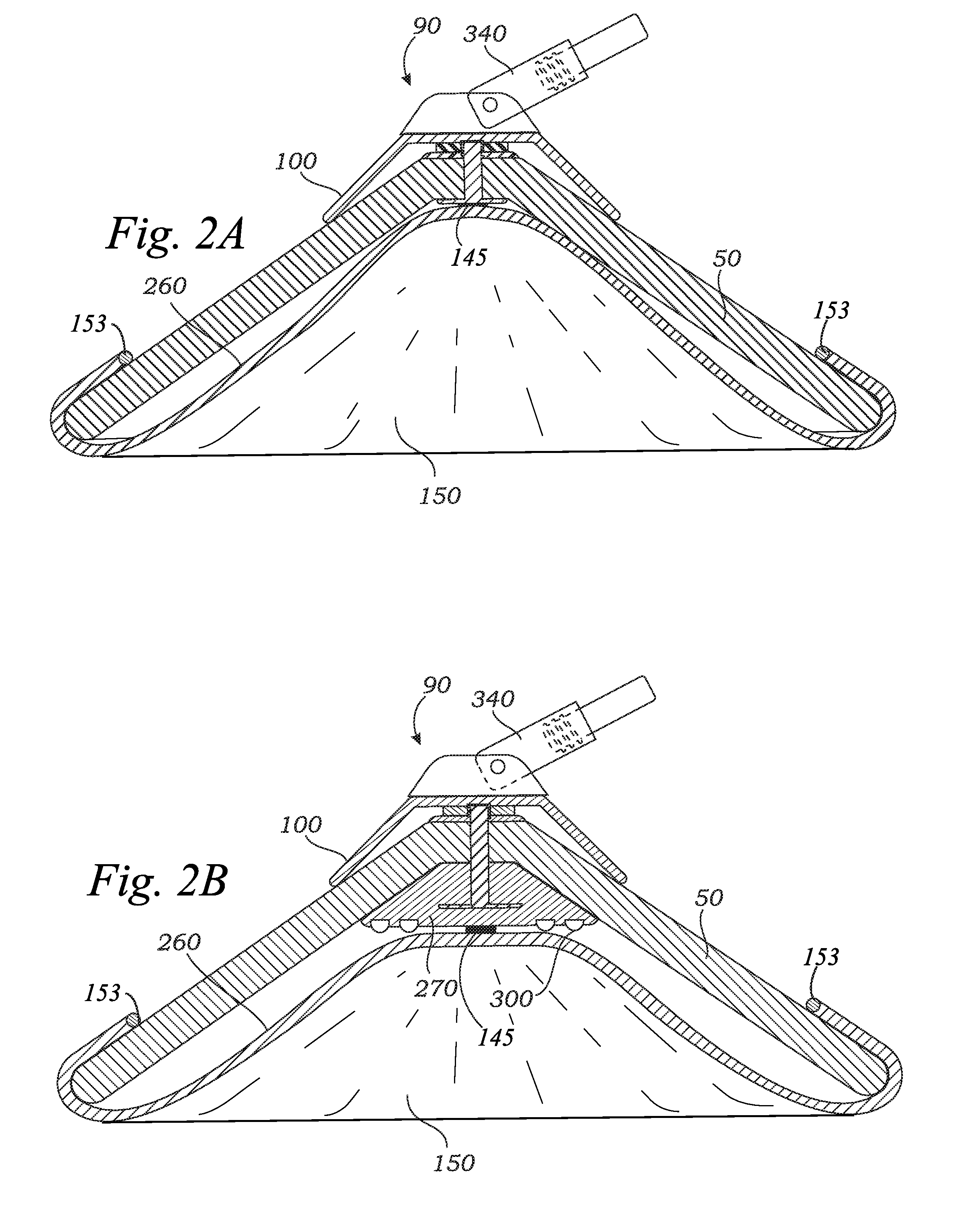

[0028]FIGS. 1 and 3 illustrate a scrubbing implement 10 for cleaning a surface 20. The scrubbing implement 10 includes a resilient base 30 that includes a plurality of resilient fingers 50, each of which are joined at a proximal end 60 to a hub 40 and extend radially away therefrom. Each finger 50 includes a distal end 70 opposite the proximal end 60. Preferably the hub 40 further includes a central aperture 80 therethrough. The resilient base 30 is preferably made from a resilient foam material such as EVA, or the like.

[0029]A rigid cap 90 comprises an inside upper end 120 and a wider open lower end 125. A frusta-conical side portion 100 is fixed at a top end 110 thereof to the upper end 120 of the cap 90. The upper end 120 preferably includes a central aperture 130 at least partially therethrough. The cap 90 preferably includes a handle receiving means 340 pivotally fixed to the cap 90 for receiving preferably a threaded end 350 of an elongated handle 360 (FIGS. 1 and 6), but may ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| downward angle | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com