Patents

Literature

34results about How to "There is no problem of shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

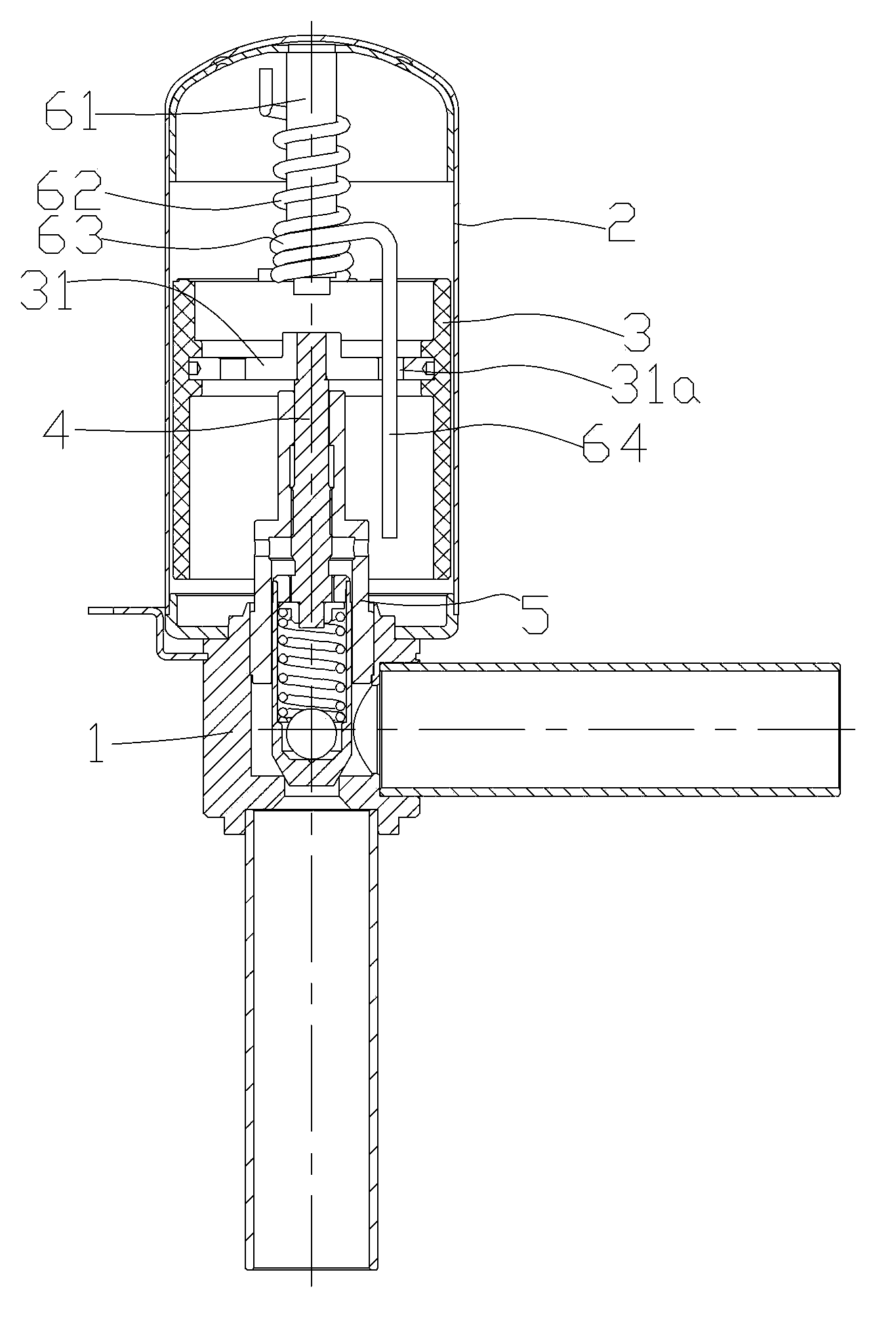

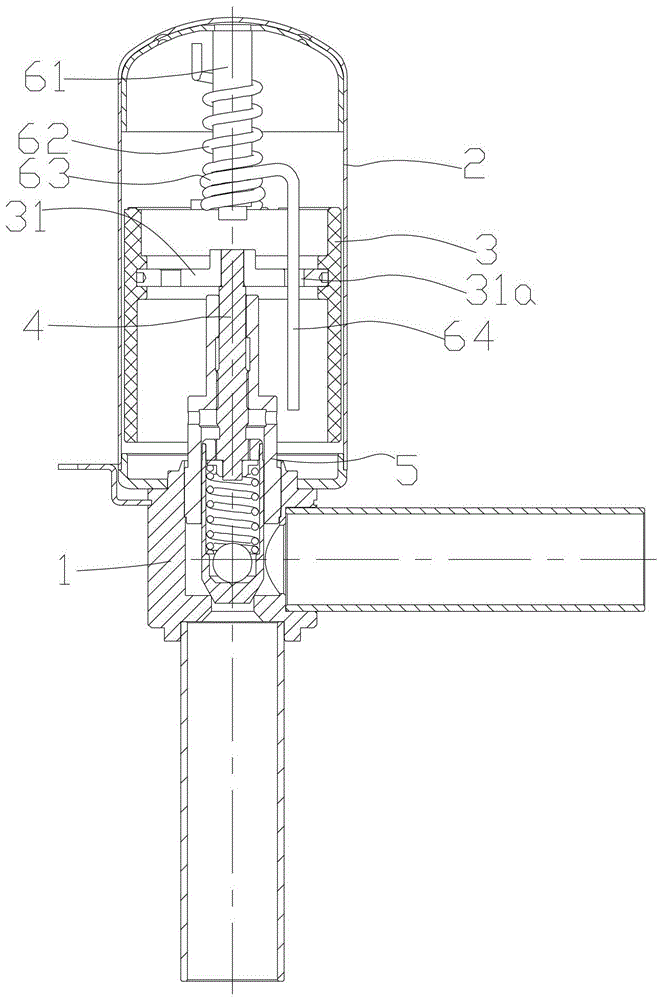

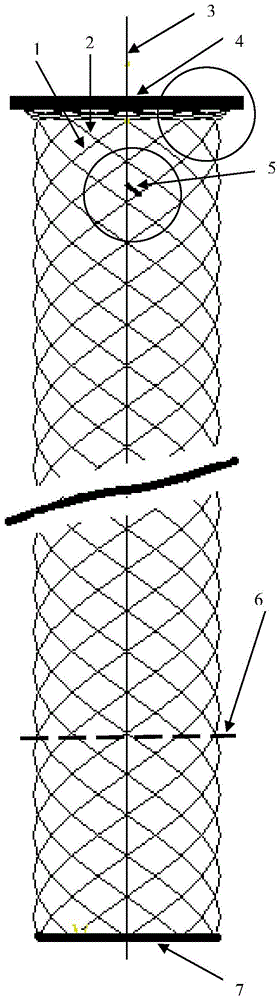

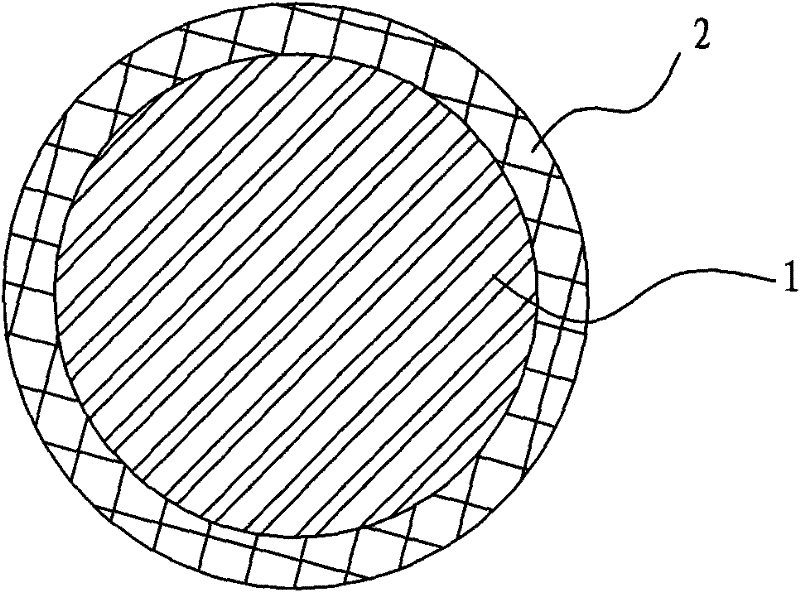

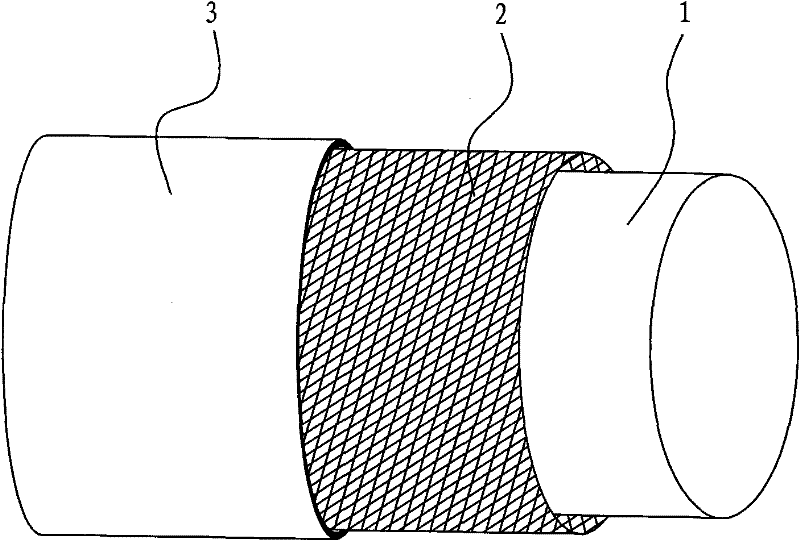

Composite material core used for enhanced cable, preparation process thereof and enhanced cable

InactiveCN102024517AImprove lateral strengthImprove fatigue resistance and fatigue resistanceInsulated cablesCable/conductor manufactureElectrical conductorFiber bundle

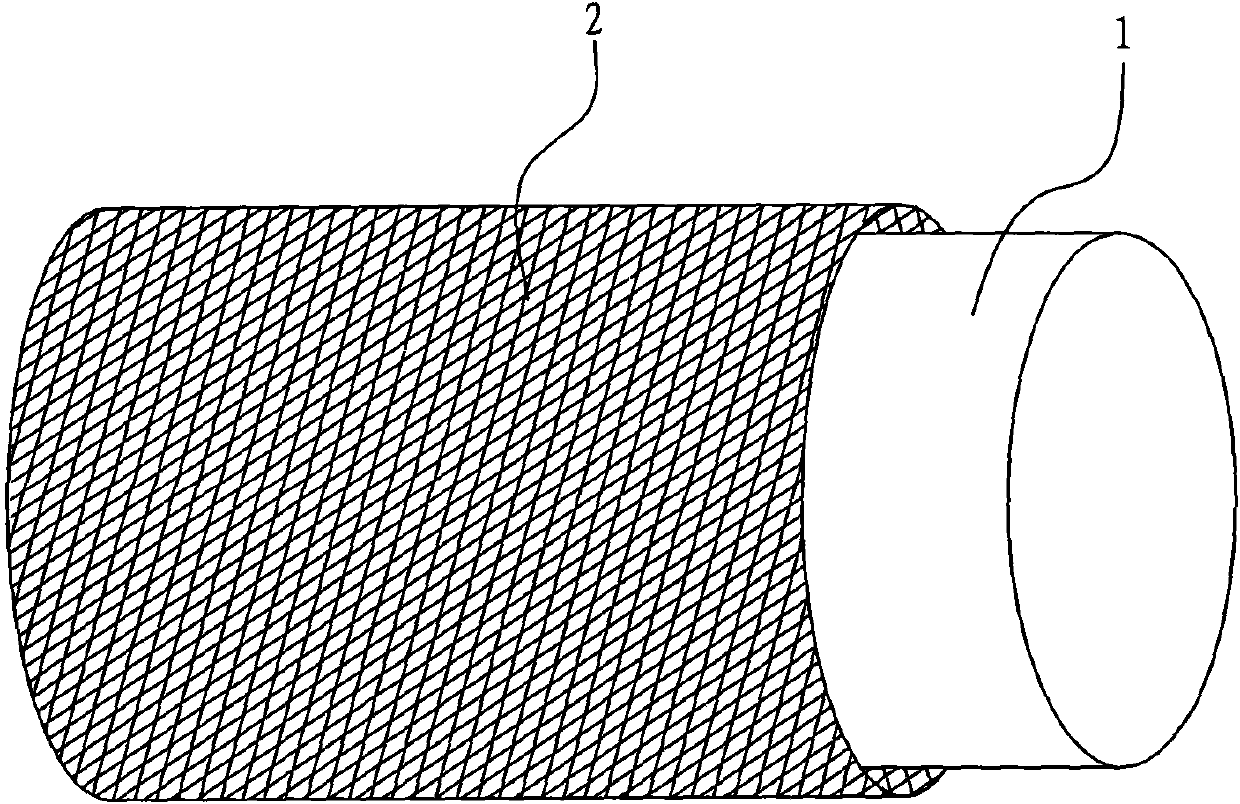

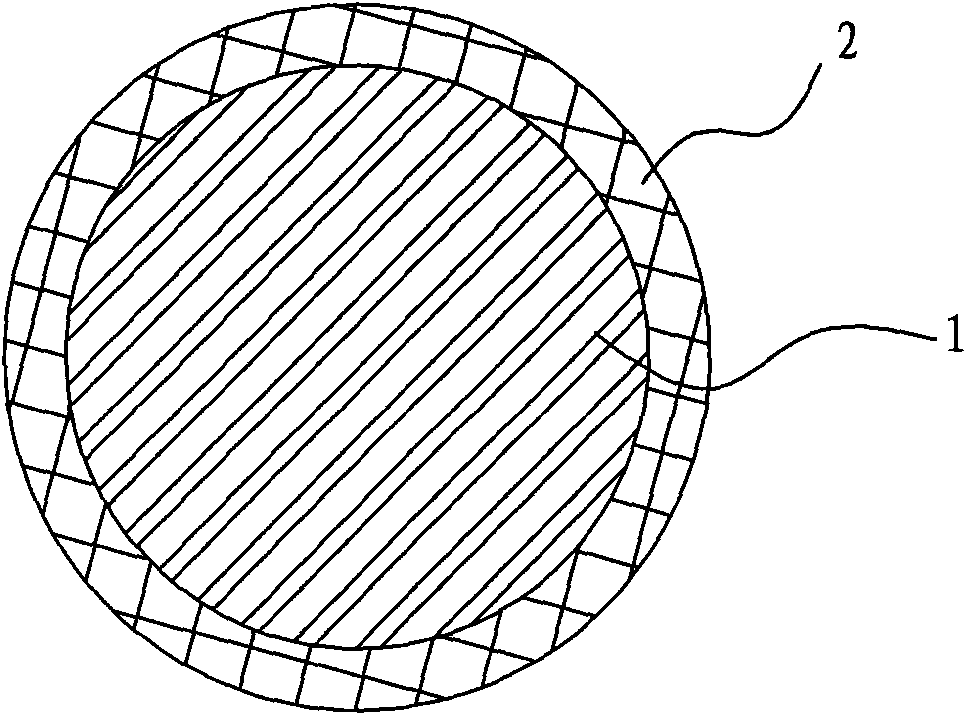

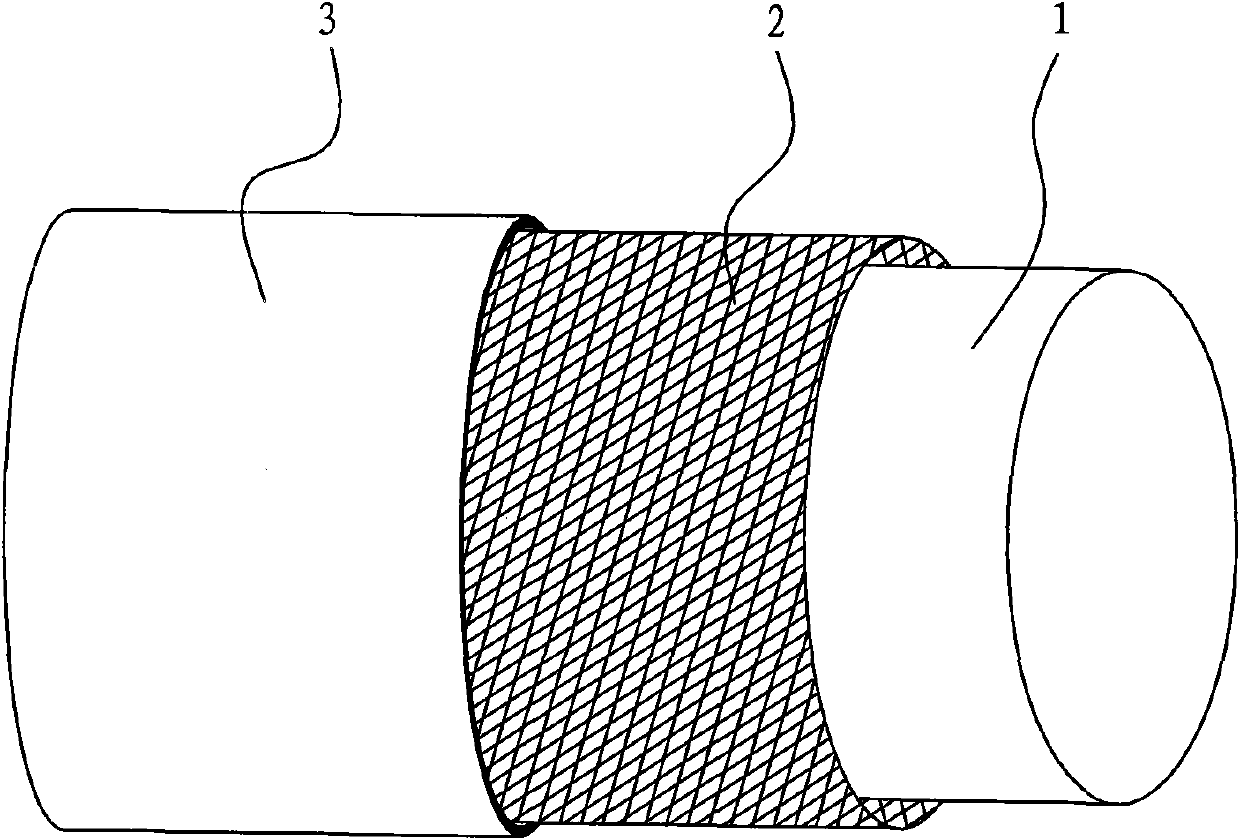

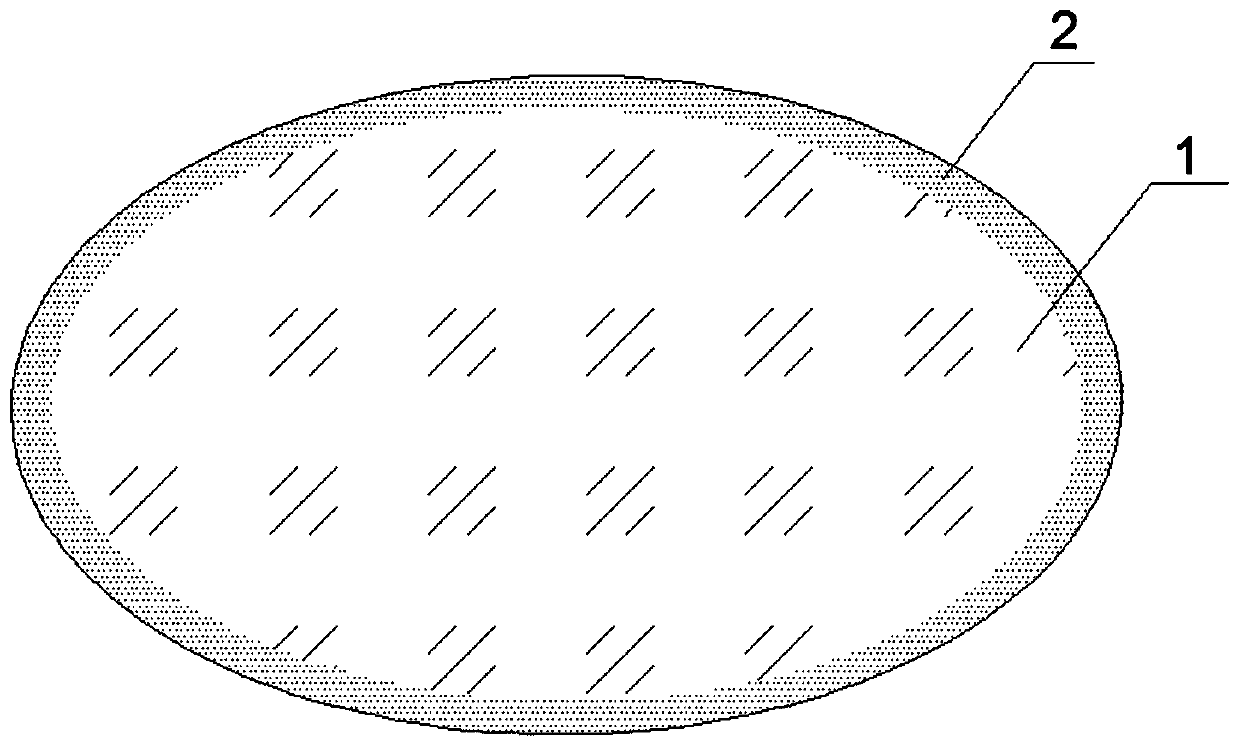

The invention relates to a composite material core used for an enhanced cable, a preparation process and the enhanced cable. The composite material core comprises an inner core and an outer layer, wherein the inner core is composed of fiber and thermosetting resin; the outer layer comprises a fiber woven pipe and thermosetting resin which are composited to form the outer layer; and the fiber woven pipe of the outer layer is a network structure which is woven by interlacing a plurality of fiber bundles. The transversal strength of the composite material core is greatly improved by the interlaced network structure, the fatigue resistance of the composite material core is greatly improved, and the service life of the composite material core and a power transmission cable is prolonged; and the problem that the composite material core is broken when the composite material core is stranded, wound and extruded by a conductor in the manufacturing process of the cable is completely avoided. As the fiber woven pipe is adopted by the outer layer, the flexibility of the outer layer is greatly increased by the interlaced and woven structure, thereby meeting the requirement of manufacturing composite material core with major diameter.

Owner:JIANGSU JIATAI TECH MATERIAL

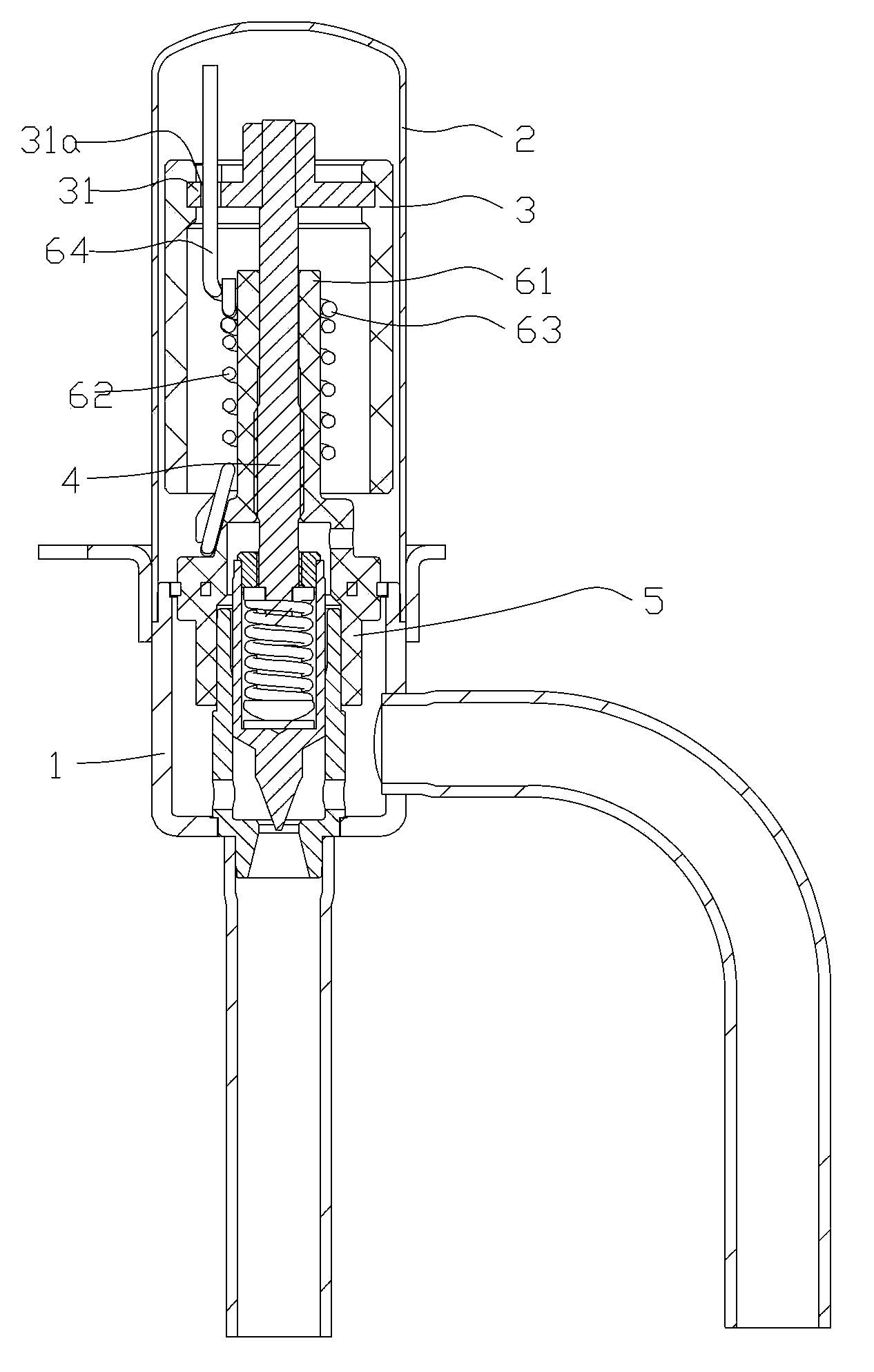

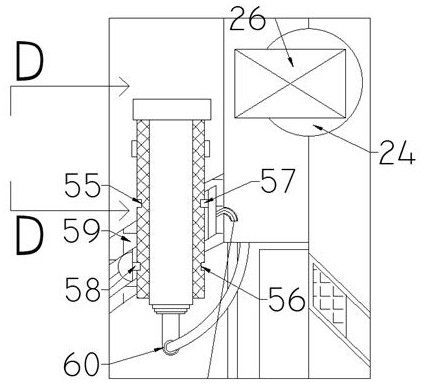

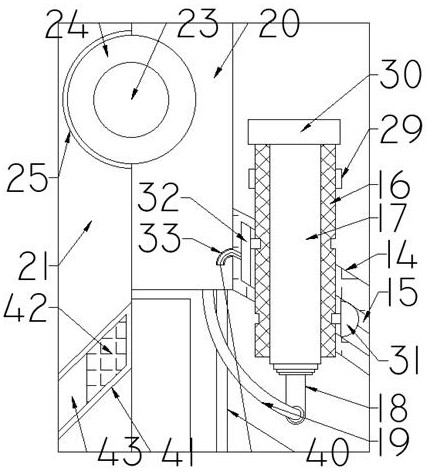

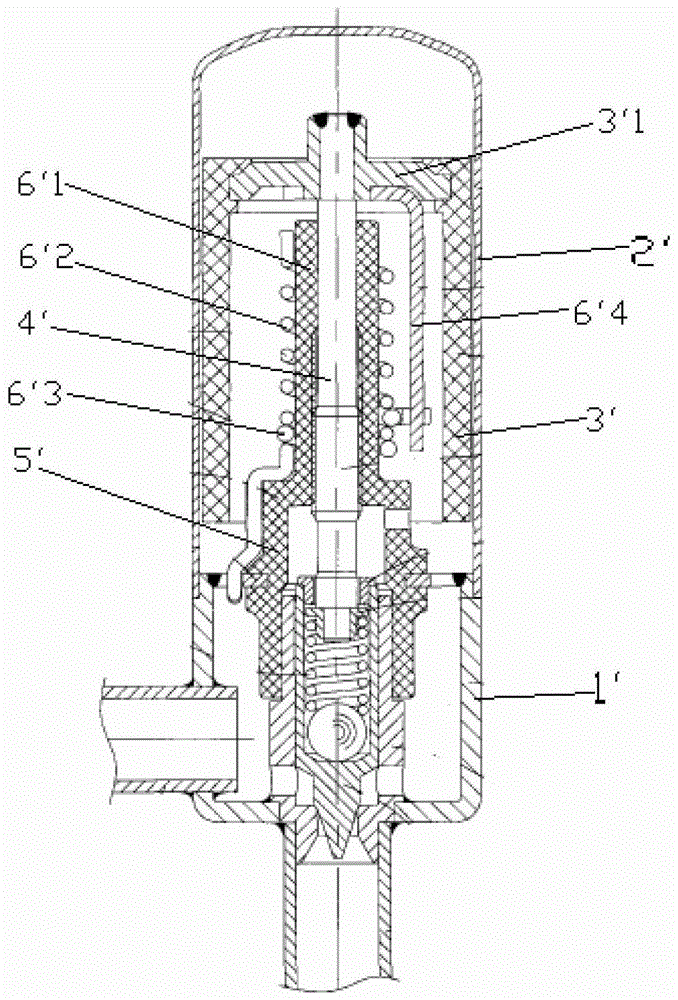

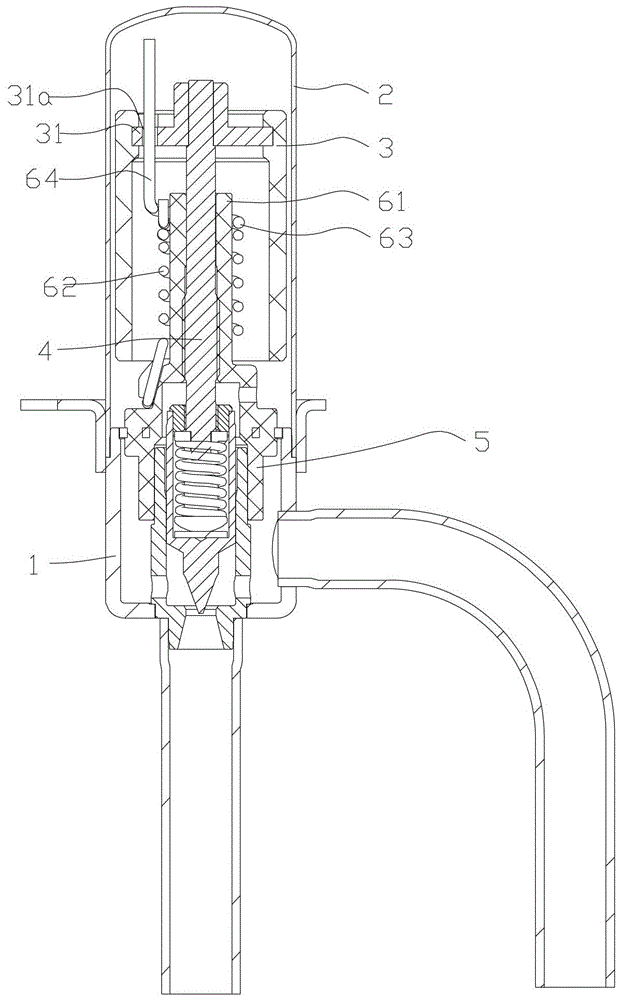

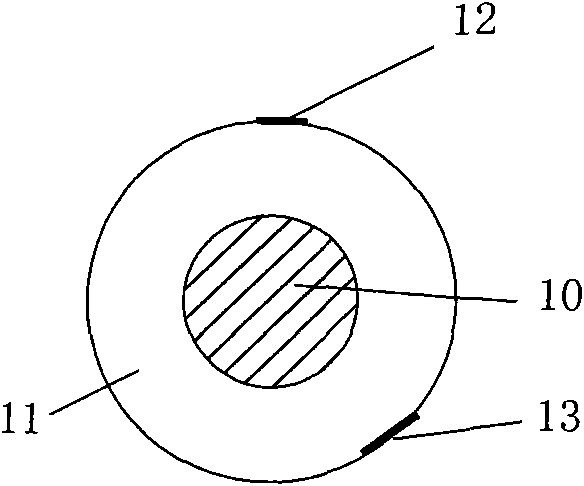

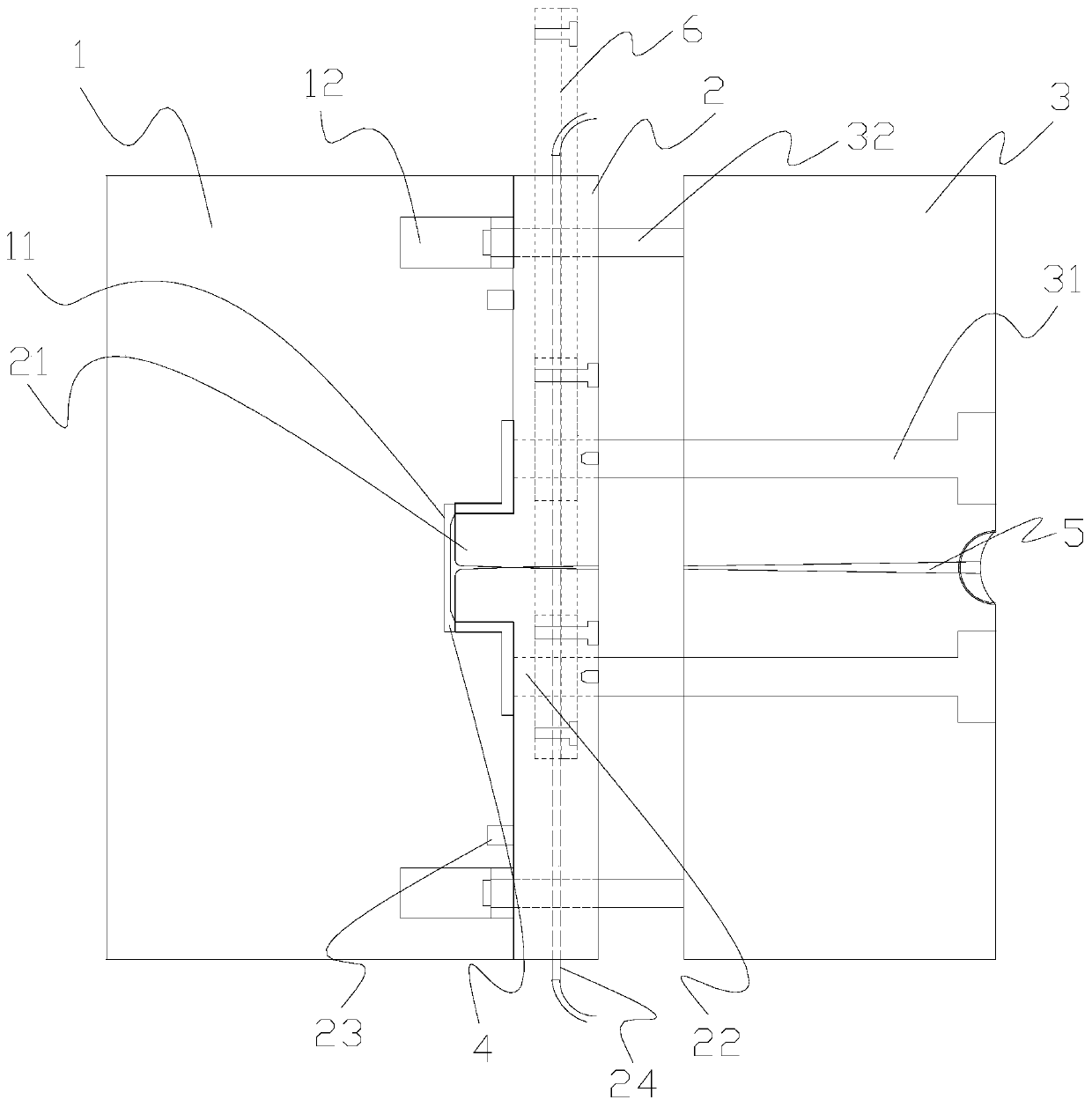

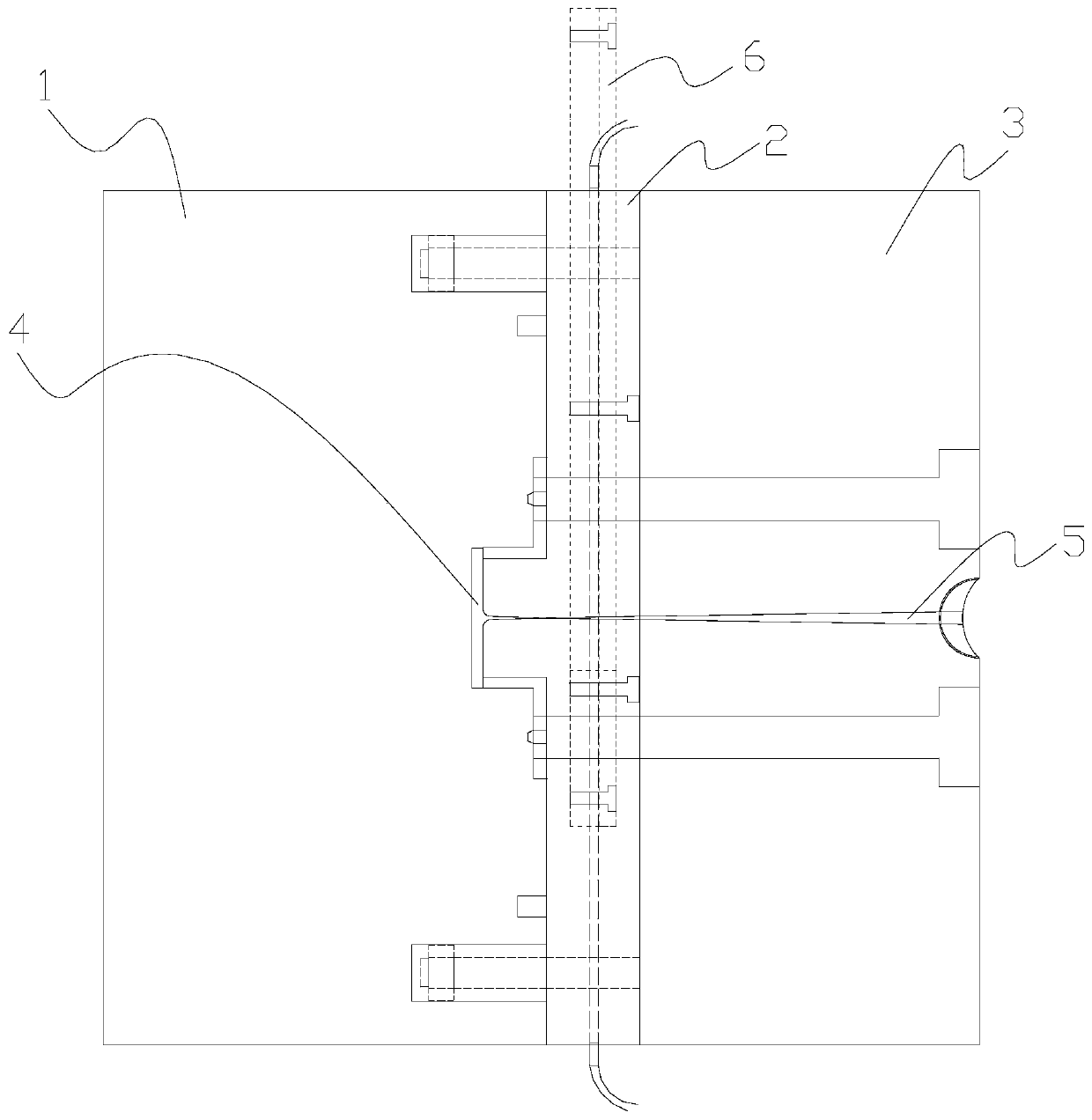

Electronic expansion valve

ActiveCN103575000ASimplify the assembly processReduce in quantityOperating means/releasing devices for valvesEfficient regulation technologiesMiniaturizationEngineering

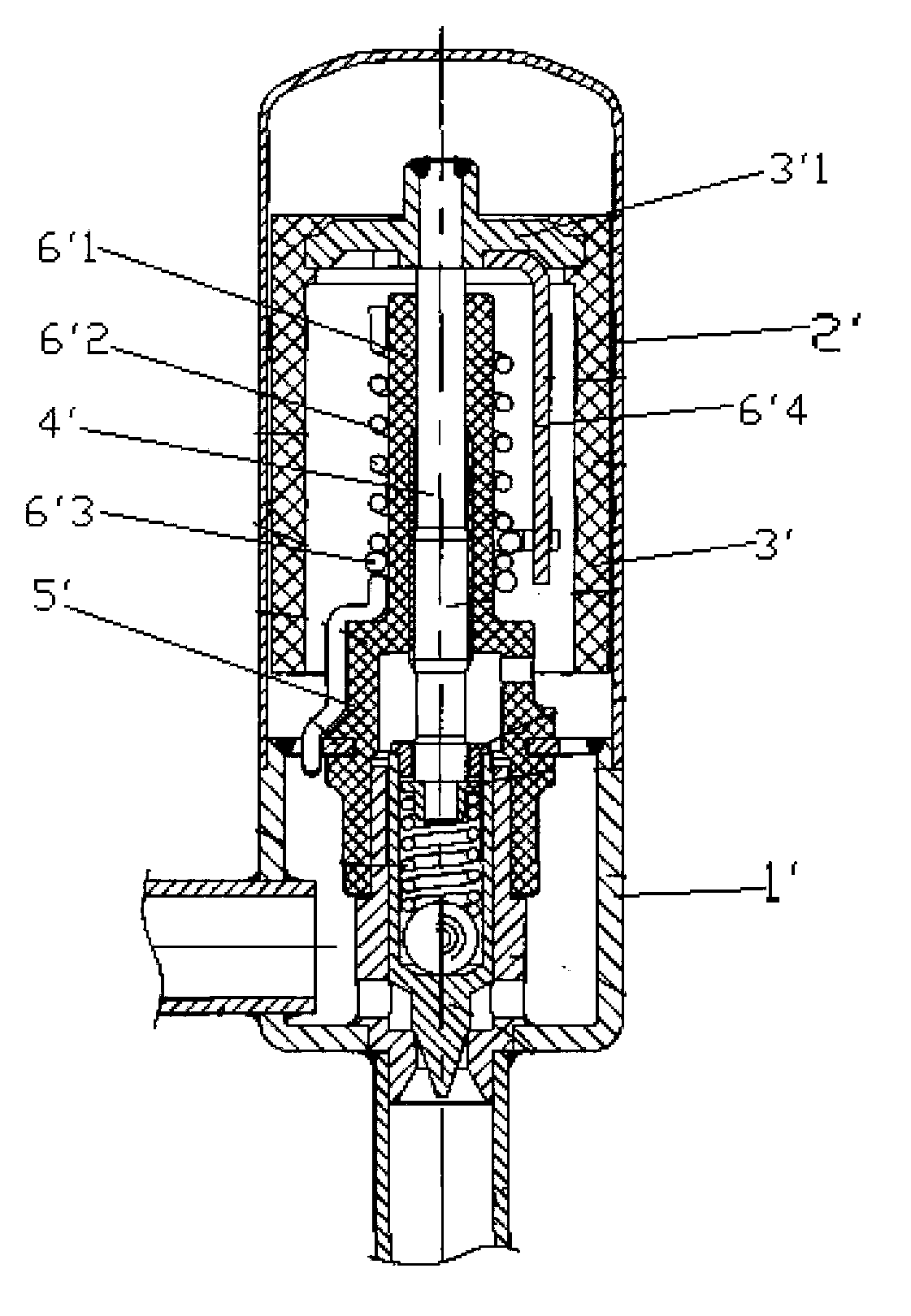

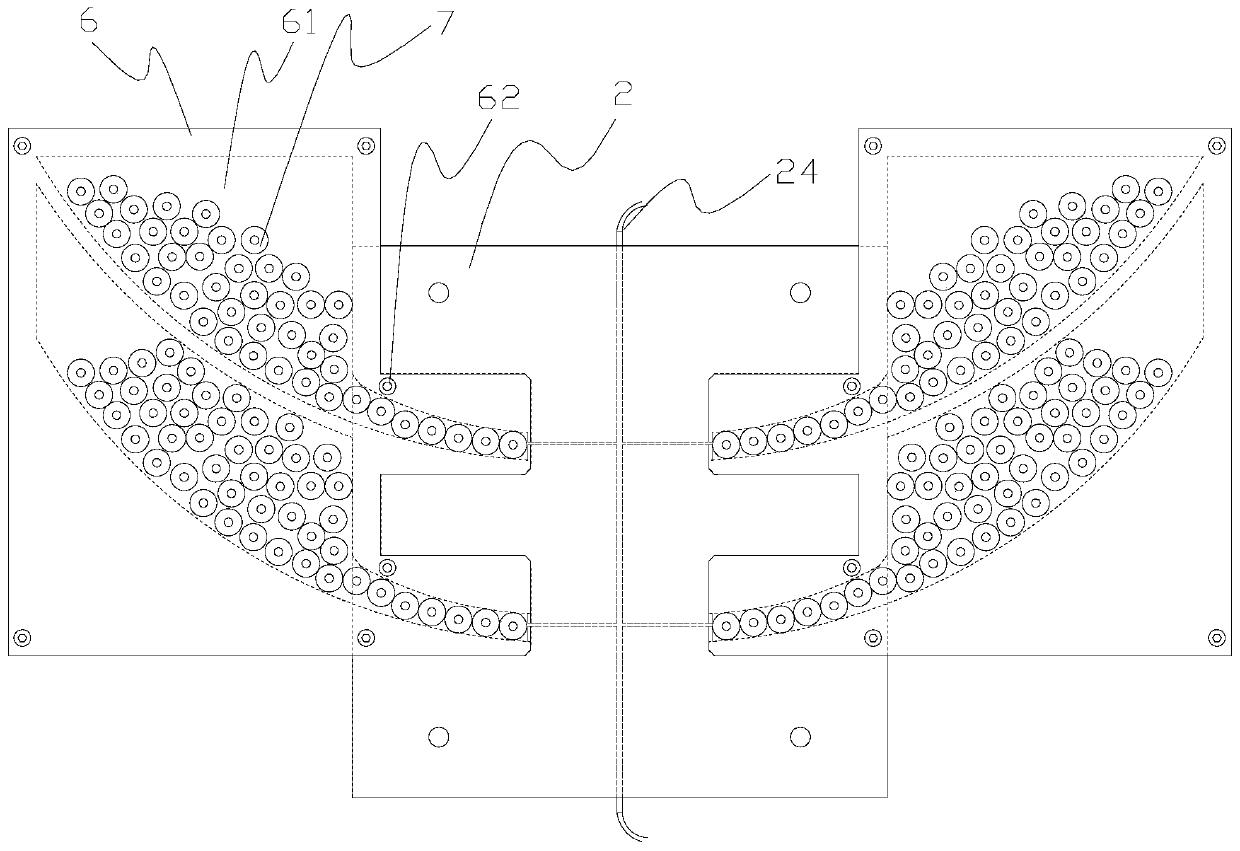

The invention discloses an electronic expansion valve. The electronic expansion valve is characterized in that a stopping part comprises a core shaft (61), a spring guide rail (62) and a sliding ring (63), wherein the core shaft (61) is fixed relative to a valve seat (1); the spring guide rail (62) is sheathed at the outer part of the core shaft (61); the sliding ring (63) is matched with the spring guide rail (62); one end of the sliding ring (63) extends out to form a stopping rod (64); the top part of a magnet (3) is provided with a stopping hole (31a); the stopping rod (64) penetrates through the stopping hole (31a), and when the sliding ring (63) is positioned at an upper stopping position and a lower stopping position, the stopping rod (64) is respectively retained in the stopping hole (31a). The electronic expansion valve disclosed by the invention has the advantages that due to the structural design, on one hand, the quantity of parts can be reduced, the assembling process of the stopping rod can be simplified, and the working reliability can be improved; on the other hand, the radial size of the magnet can be reduced, so that the cost of materials can be saved and the miniaturization of a product can be realized.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

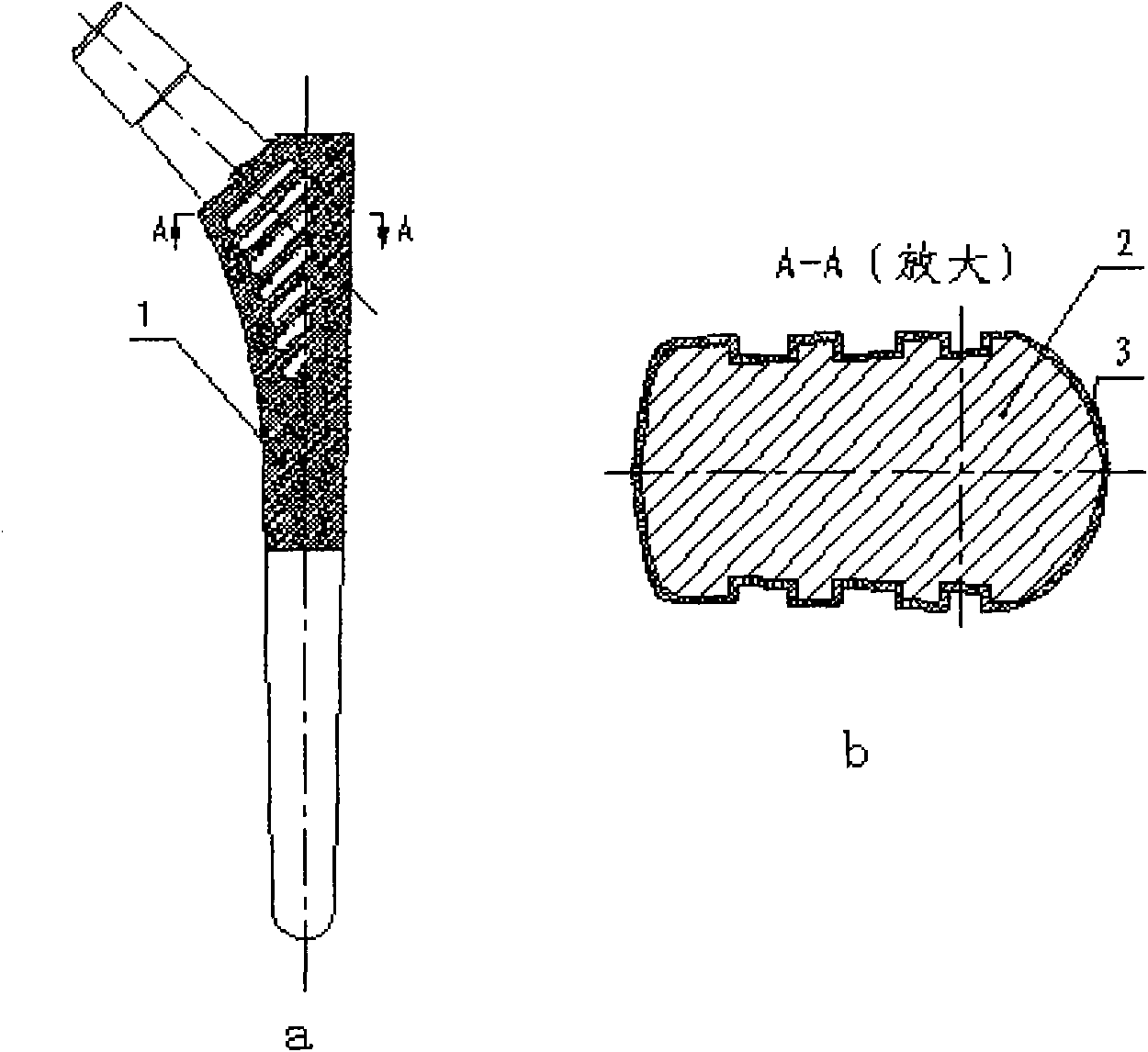

Artificial joint prosthesis with biologically activated surface

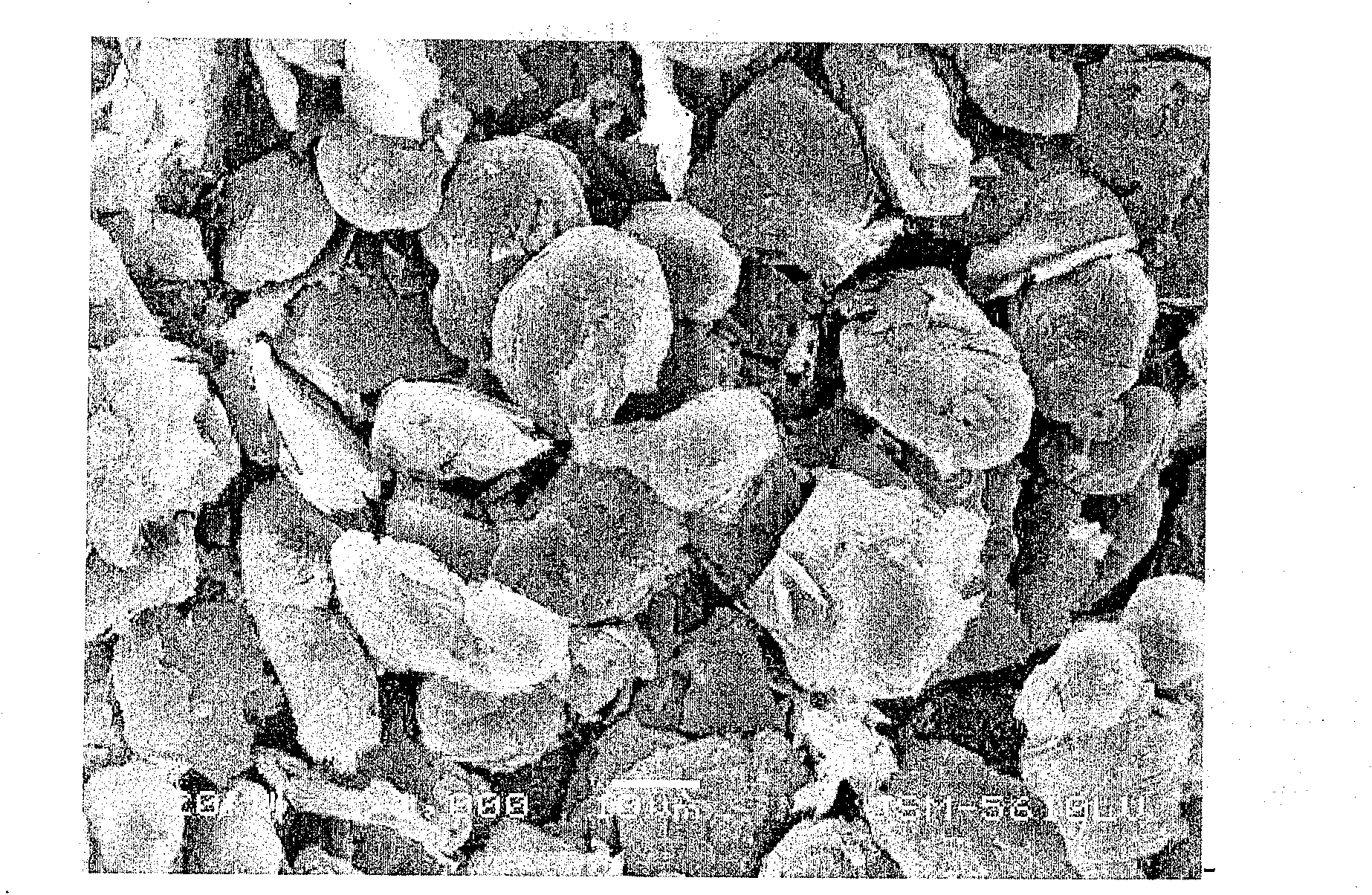

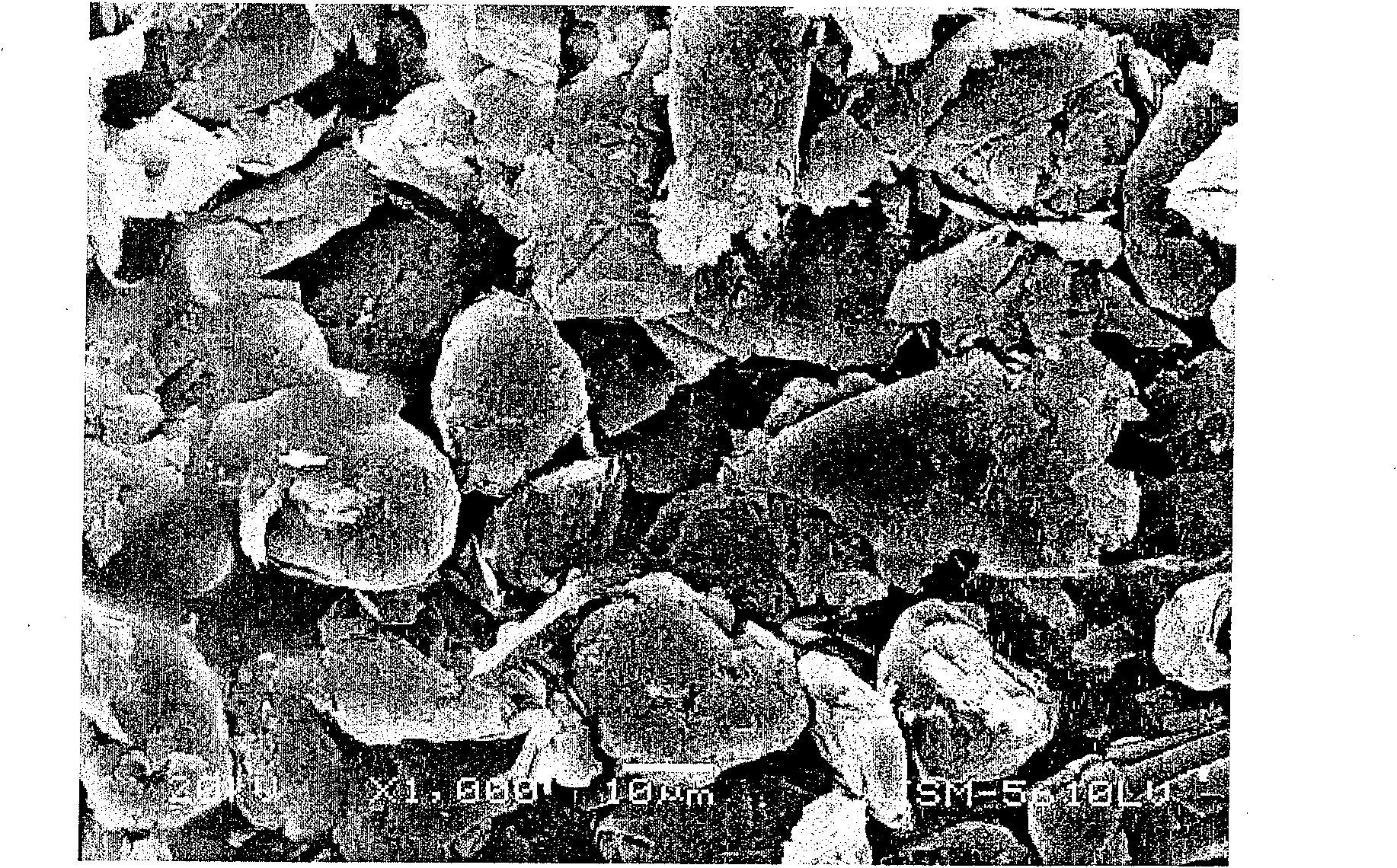

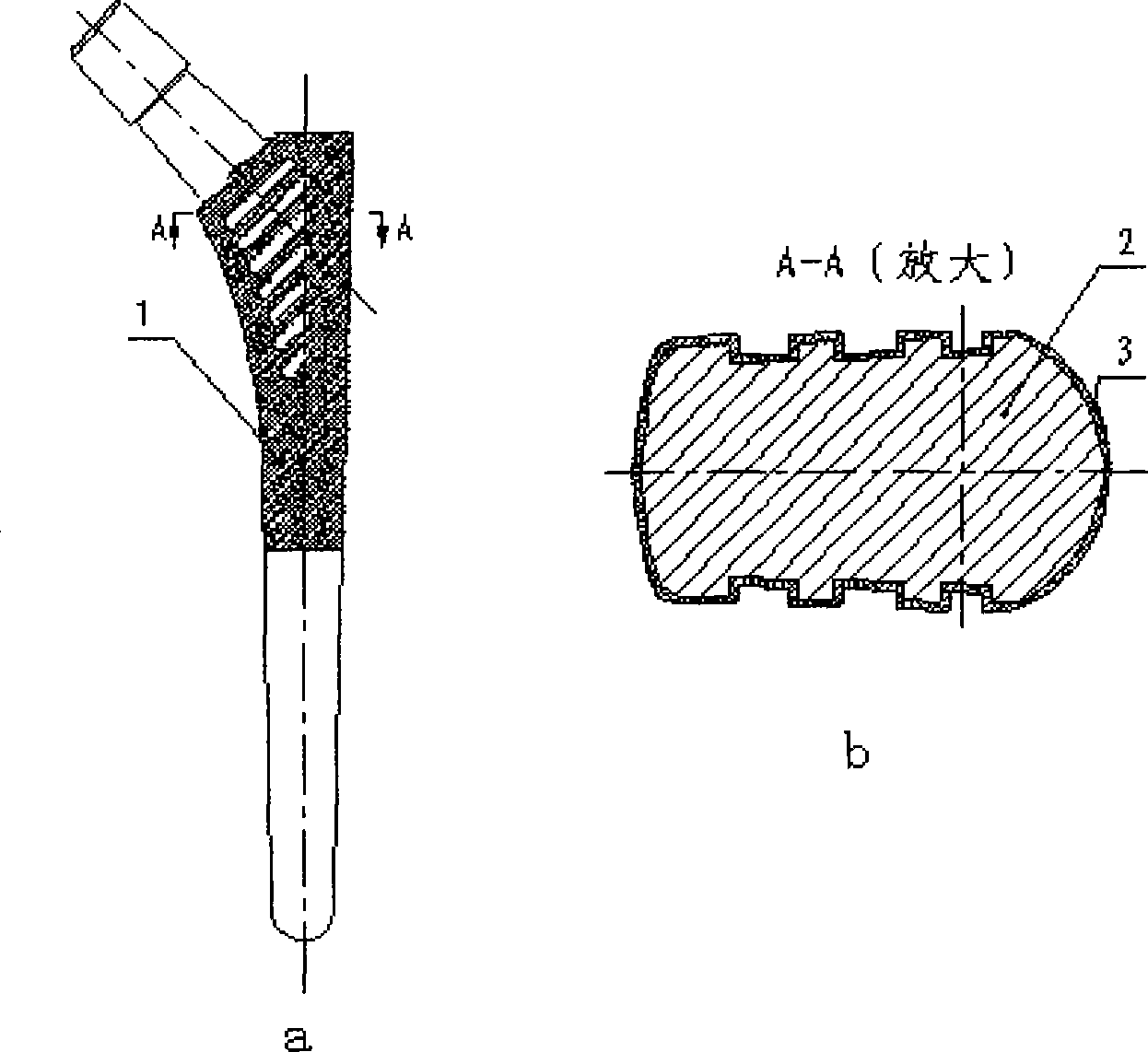

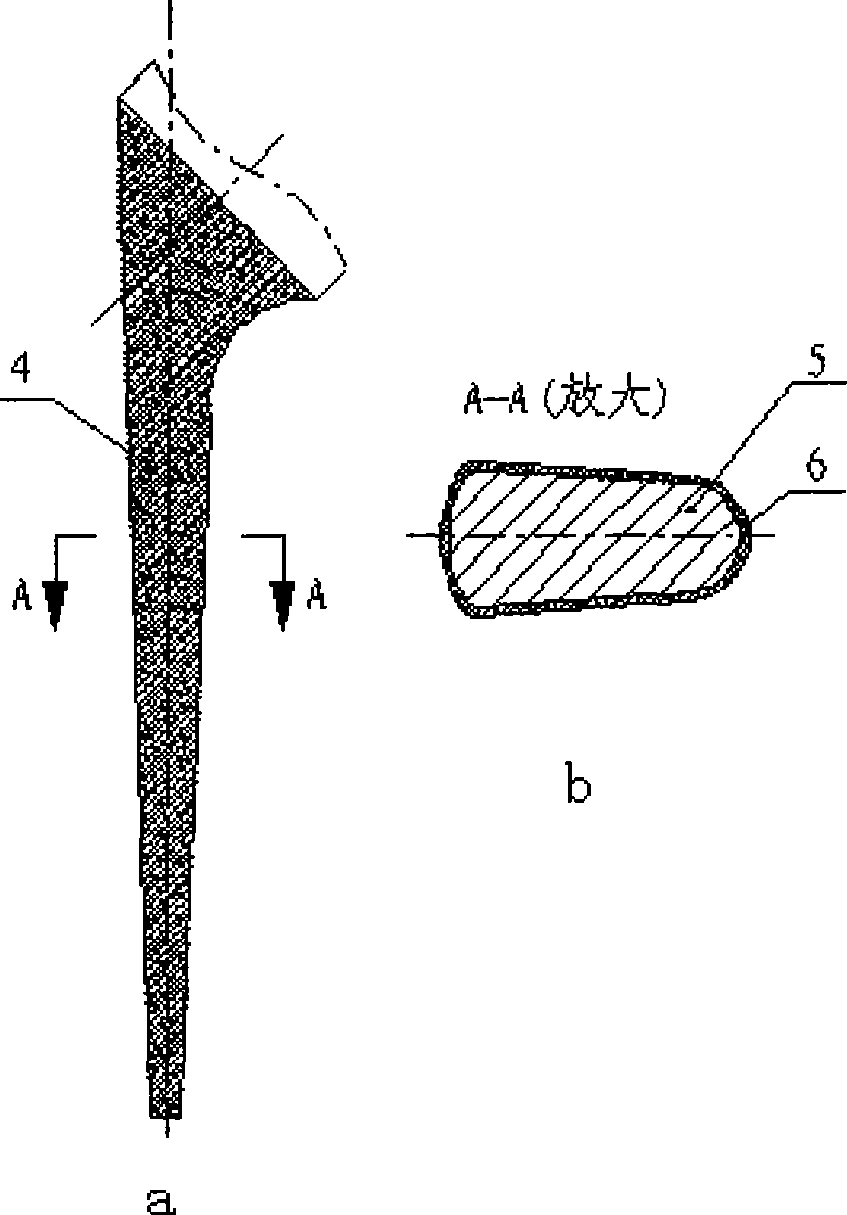

ActiveCN101982203APostoperative long-term effect guaranteeGood biocompatibilityCoatingsProsthesisChemical reactionBiocompatibility Testing

The invention belongs to the technical field of surgical implants and relates to an artificial joint prosthesis with biologically activated surface. The biological activation layer formed on the surface of the artificial joint prosthesis has good biocompatibility and bioactivity and forms natural chemical bonding with the bone tissues, thus improving the bond strength between the prosthesis and the bone tissues, ensuring the stress transfer to be more reasonable and reducing the negative effect of stress shielding. The biological activation layer on the surface of the artificial joint prosthesis is formed by chemical reaction and forms chemical bonding with the matrix, therefore, the problem that the biological activation layer on the surface sheds is avoided, thus ensuring the postoperative long-term effect of the prosthesis. The artificial joint prosthesis is biologically fixed; therefore, wear particles produced when bone cement is adopted for fixation are avoided, thus reducing the possibility of occurrence of aseptic loosening. Besides, the artificial joint prosthesis adopts simple raw materials and process, has low cost and is easy to realize.

Owner:BEIJING JINGHANG BIOTECH CO LTD

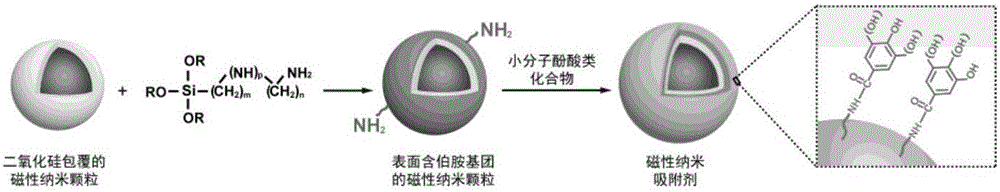

Hexavalent chromium-wastewater treatment method integrating 'reduction, adsorption and magnetic removal'

InactiveCN105836925ARealize "detoxification"There is no problem of sheddingOther chemical processesWater contaminantsHexavalent chromiumPhenols

The invention discloses a hexavalent chromium-wastewater treatment method integrating 'reduction, adsorption and magnetic removal'. The method comprises the following steps: anchoring a small-molecular phenolic acid compound to the surface, with a primary amine group, of a magnetic nano particle, to prepare a magnetic nano adsorbent; then controlling the ionization degree of a phenolic hydroxyl group on the surface of the adsorbent to realize automatic reduction, adsorption and magnetic removal of hexavalent chromium in the wastewater. The magnetic nano adsorbent realizes 'detoxification' of hexavalent chromium when separating the hexavalent chromium from the wastewater, and secondary pollution in the hexavalent chromium treatment process is avoided.

Owner:SICHUAN UNIV

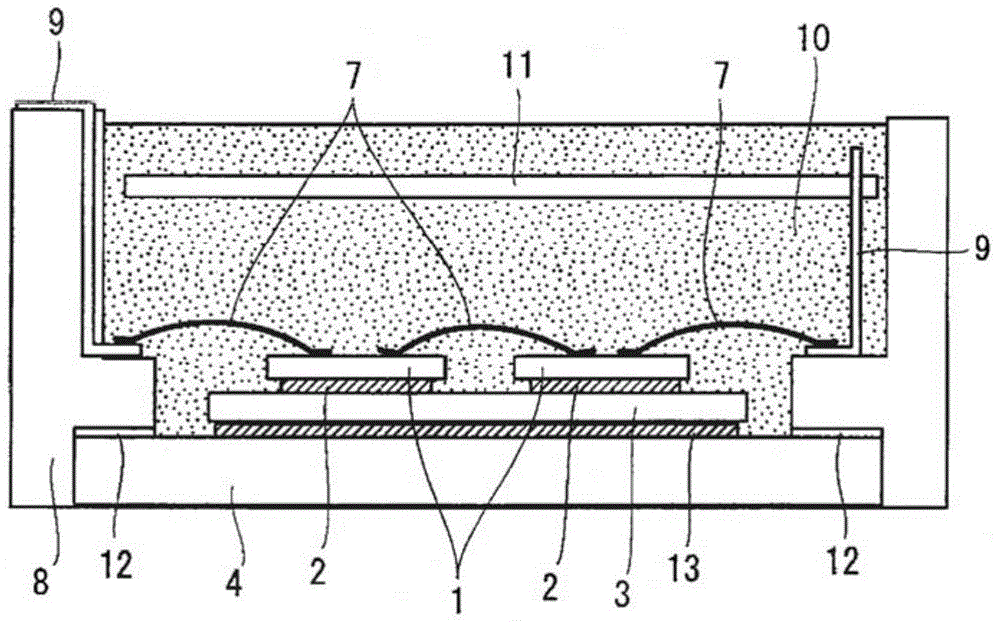

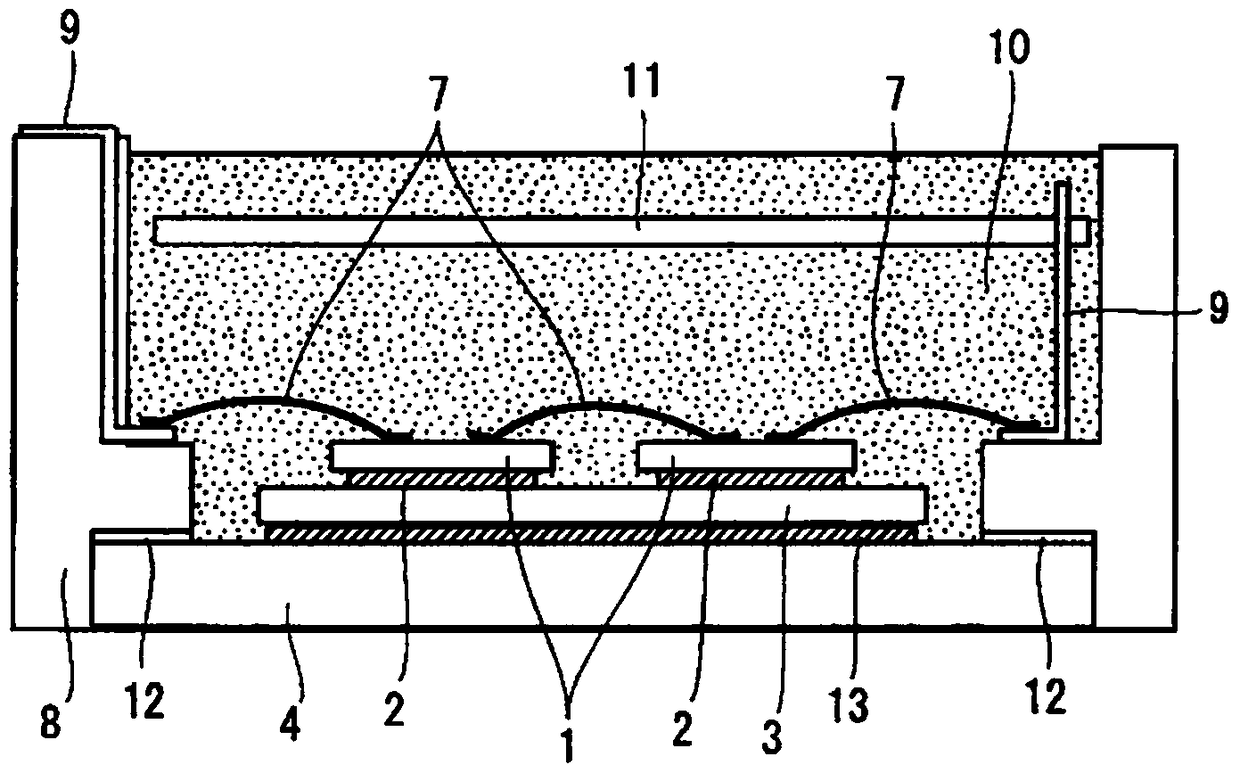

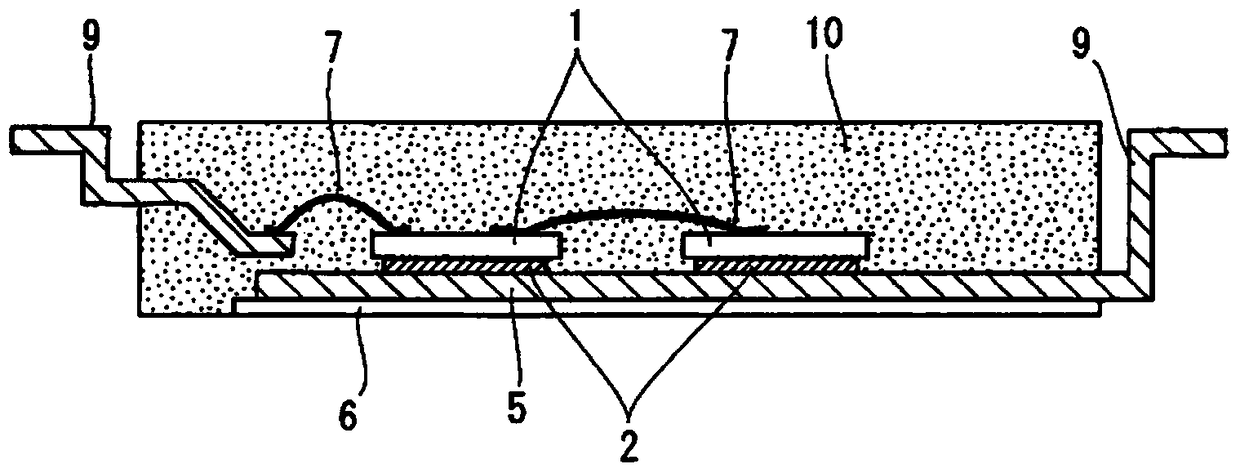

Semiconductor device and manufacturing method thereof

ActiveCN104637832AImprove qualityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialStructural engineering

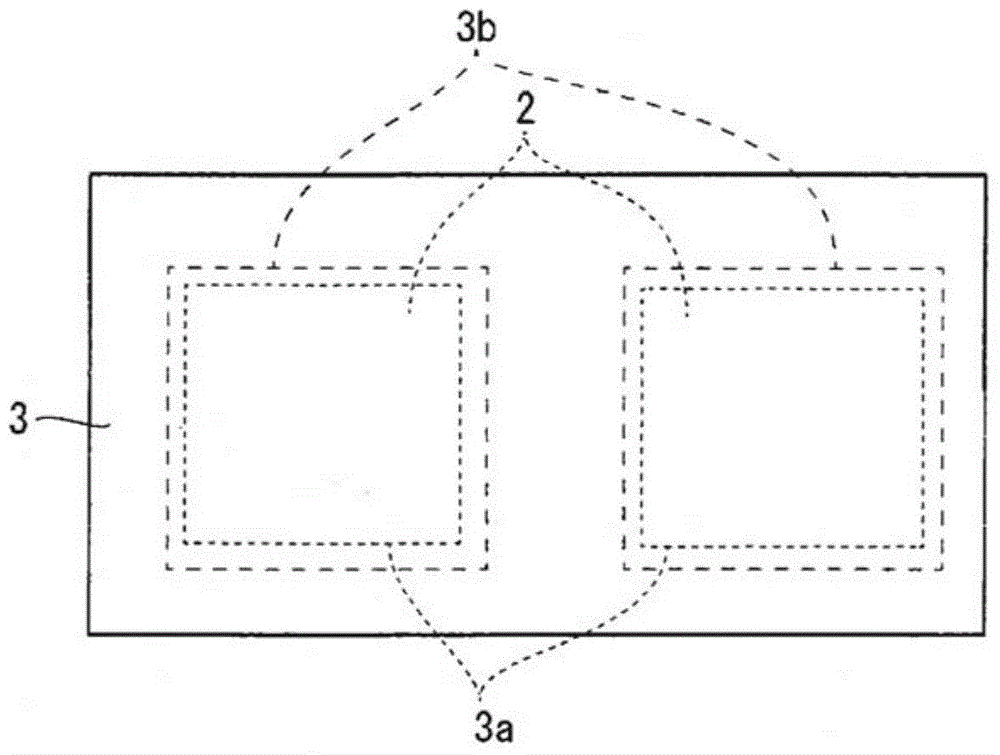

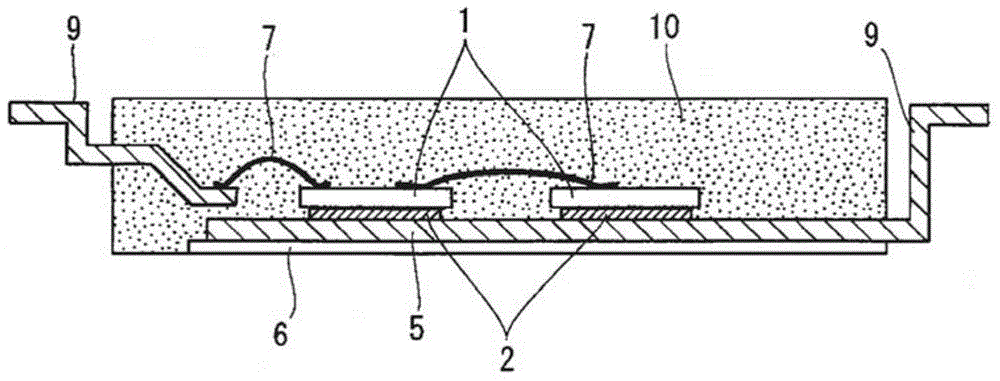

A manufacturing method of a semiconductor device according to the present invention includes the steps of (a) preparing an insulating or conductive substrate; (b) arranging a bonding material having sinterability in at least one bonding region of a principal surface of the substrate (i.e., insulating substrate); and (c) sintering the bonding material while a bonding surface to be subjected to bonding of at least one semiconductor element is brought into pressurized contact with the bonding material, and bonding the substrate (i.e., insulating substrate) and the semiconductor element together through the bonding material. The bonding region in the step (b) is inwardly positioned from the bonding surface (i.e., region) of the semiconductor element in plan view, and the bonding material is not protruded outwardly from the bonding surface of the semiconductor element in plan view even after the step (c).

Owner:MITSUBISHI ELECTRIC CORP

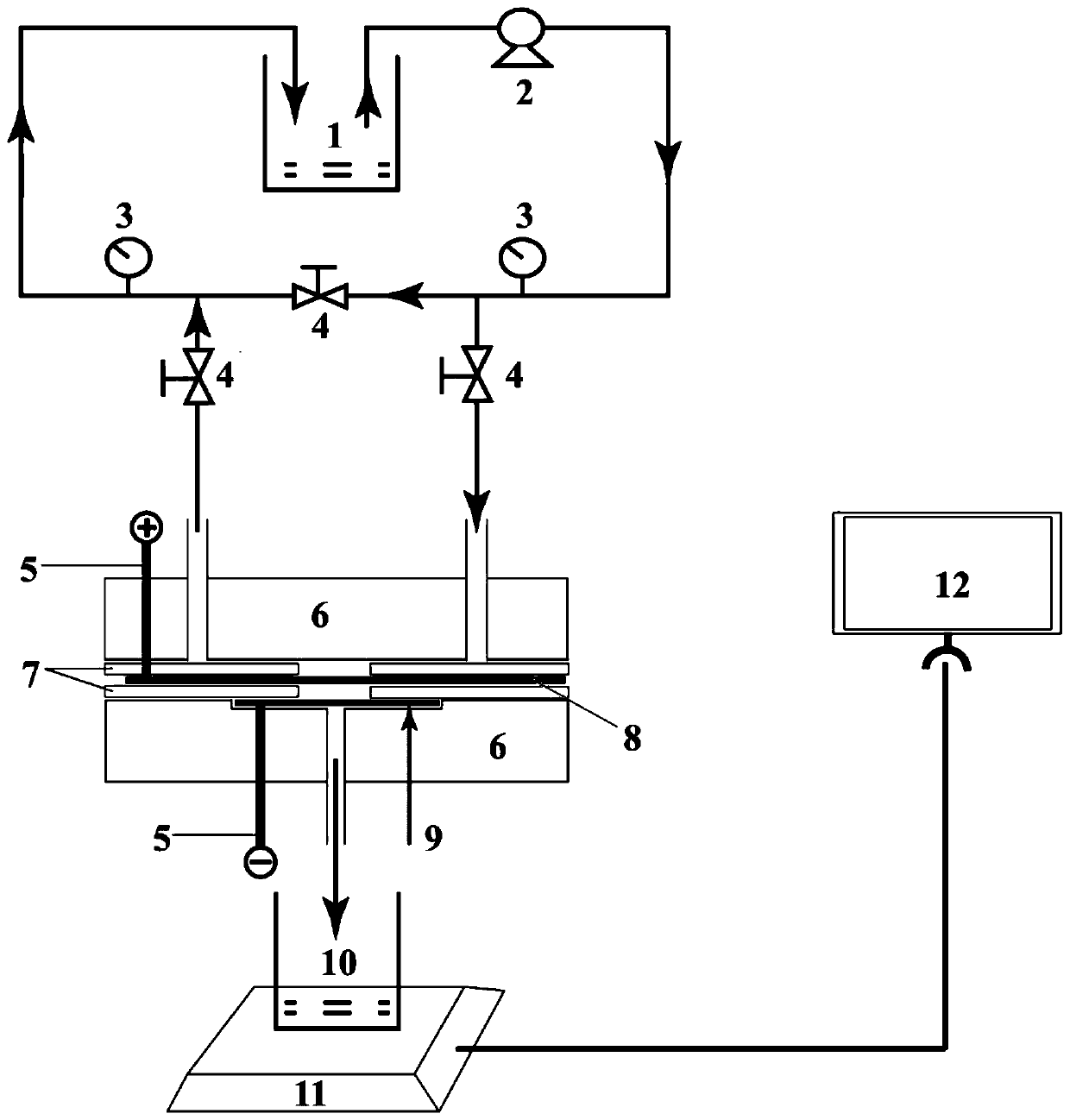

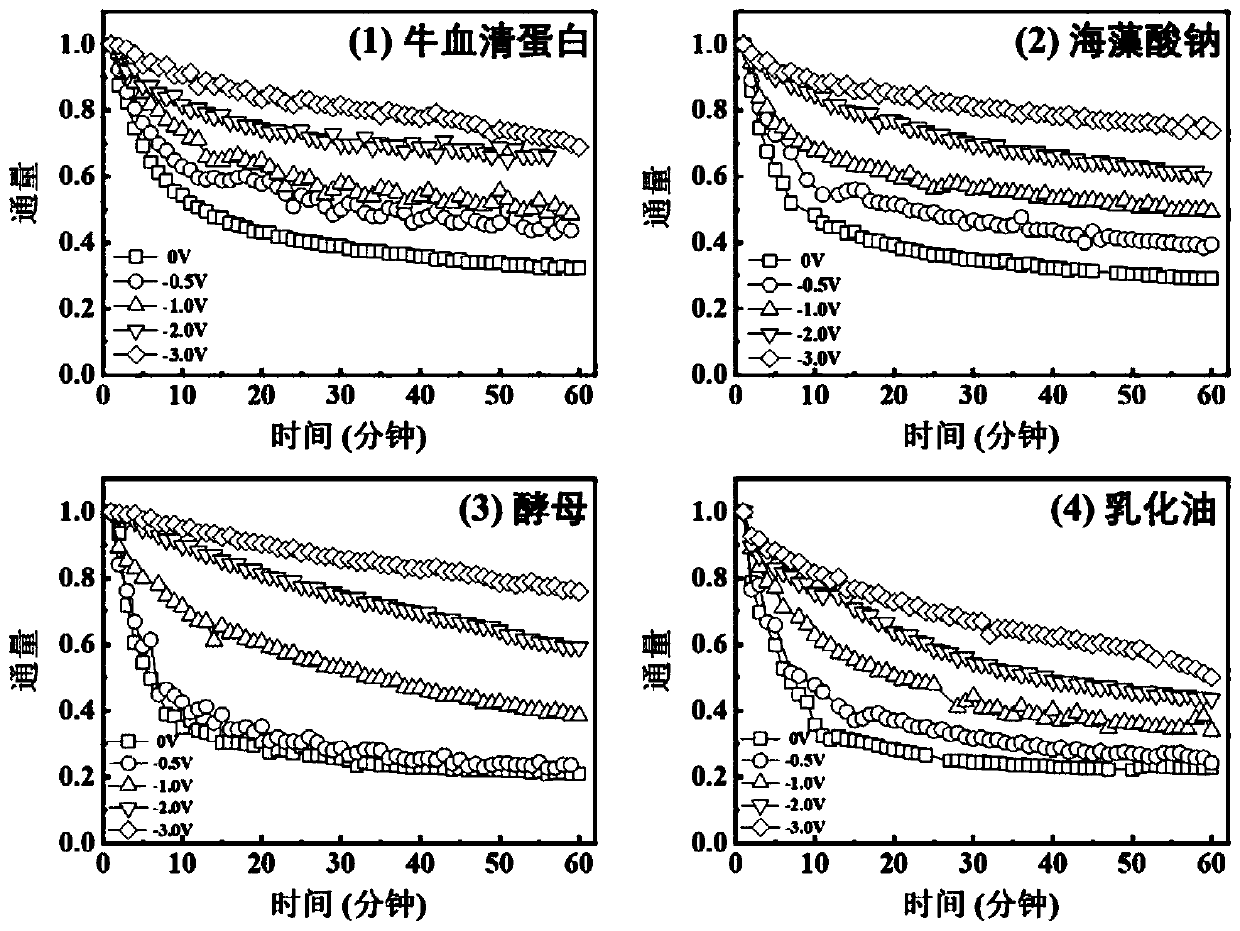

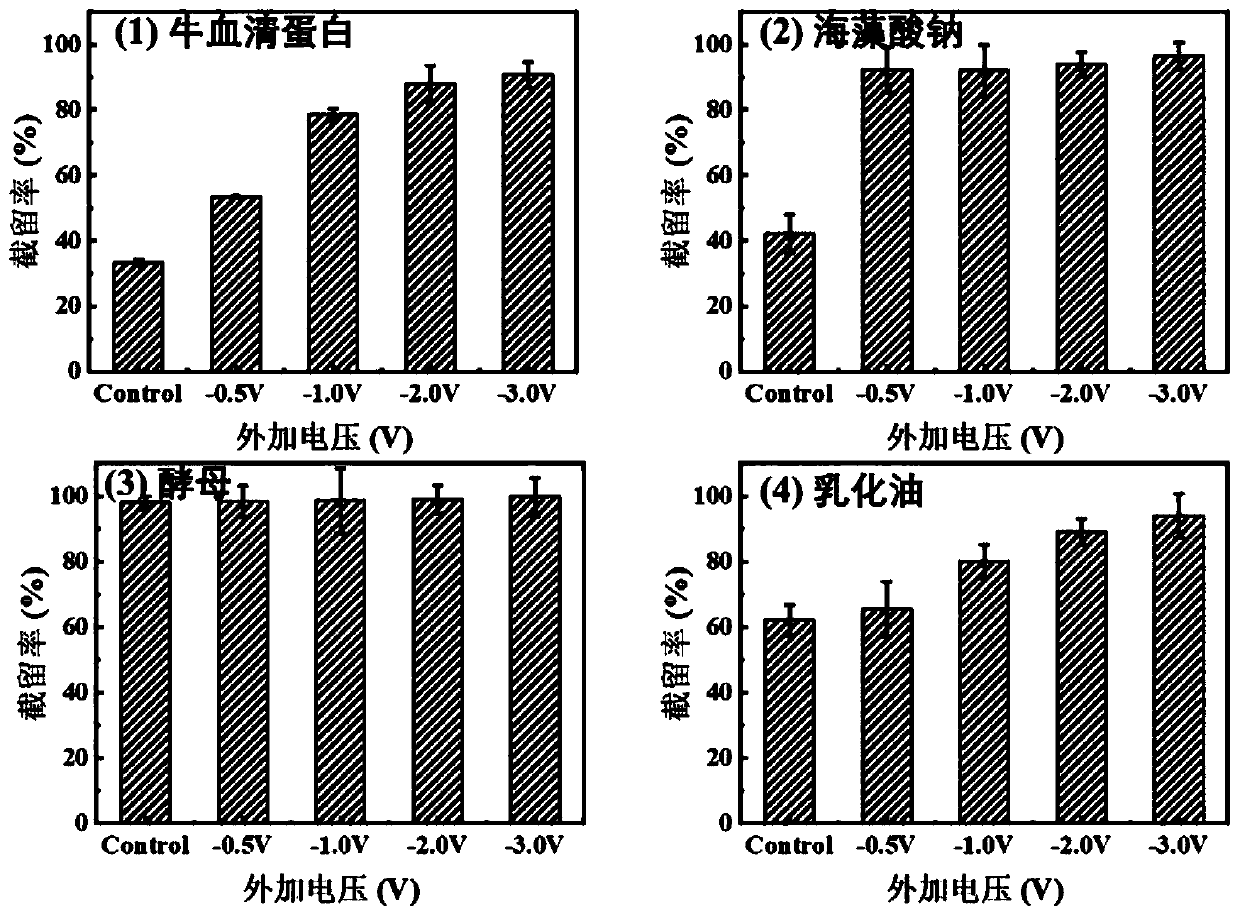

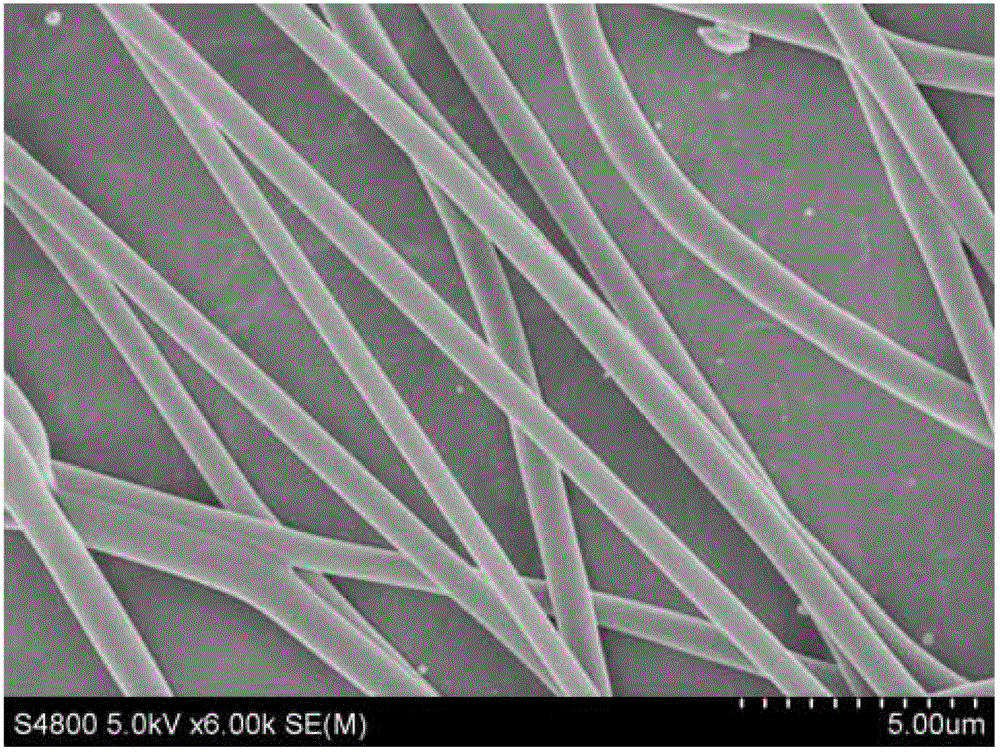

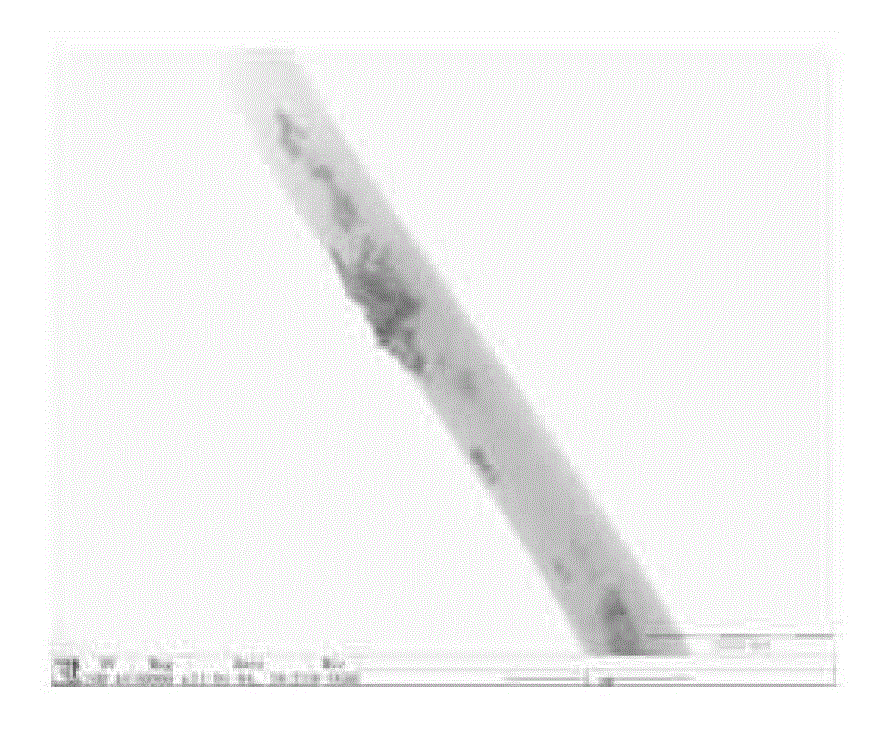

Method for relieving pollution of carbon fiber paper-polyether sulfone compound conductive separation membrane

PendingCN110038443AReduce pollutionThere is no problem of sheddingSemi-permeable membranesFiberCross-flow filtration

The invention discloses a method for restraining membrane pollution of a carbon fiber paper-polyether sulfone compound conductive separation membrane in a cross-flow system by utilizing an auxiliary electric field. The method comprises the following steps: guiding a feeding liquor to flow in from one side above a cross-flow filtering mold; guiding one part to flow out from the other side above themold along a horizontal direction and using as effluent; guiding the other part to pass by the carbon fiber paper-polyether sulfone compound conductive separation membrane along a vertical direction,and then guiding leachate to flow out from the lower side of the mold. A separation membrane is placed in the middle of the mold; silica gel gaskets on the two sides are used for separating the mold;a polyether sulfone surface of the membrane is upward; one side of carbon fiber paper of the membrane is used as a cathode; a titanium sheet embedded under the mold is used as an anode; the two electrodes are separated by a silica gel gasket and are connected with a direct current power supply by wires; the range of applied direct current voltage is 0-3V; the membrane pollution caused by variouscharge pollutants can be effectively relieved under a combined action of electrostatic repulsion of electric field and shear force of water flow.

Owner:DONGHUA UNIV

In-situ preparation method for cadmium telluride/polyvinyl alcohol fluorescent fiber

InactiveCN102877149AEvenly dispersedThere is no problem of sheddingFilament/thread formingMonocomponent synthetic polymer artificial filamentFiberIce water

The invention discloses an in-situ preparation method for cadmium telluride / polyvinyl alcohol fluorescent fiber and relates to a preparation method for fluorescent fiber. The invention aims to solve the problems that in the prior method, the quantum dots of cadmium telluride reunite easily in a polymer solution, the fluorescence of the fiber is led to be non-uniform, so that the fluorescent effect is poor. The in-situ preparation method comprises the following steps: firstly, sodium borohydride, tellurium powder and deionized water are mixed and reacted to obtain sodium hydrogen telluride solution under the condition of ice-water bath; secondly, polyvinyl alcohol solution is added to a three-necked flask, nitrogen is introduced to the three-necked flask while the solution in the flask is stirred, then CdCl.2.5 H2O and mercaptoacetic acid are added to the flask, sodium hydroxide solution is dropwise added to the flask while the solution in the flask is stirred, then sodium hydrogen telluride solution is added to the flask, and the solution in the flask is subjected to heating and reflux, so that telluride / polyvinyl alcohol spinning solution is obtained; and thirdly, the spinning solution is subjected to static spinning, so that the fluorescent fiber is obtained. With the in-situ preparation method, the quantum dots of cadmium telluride can be uniformly scattered in polymer, and the prepared fluorescent fiber has good fluorescent effect. The in-situ preparation method is used for preparing the fluorescent fiber.

Owner:EAST UNIV OF HEILONGJIANG

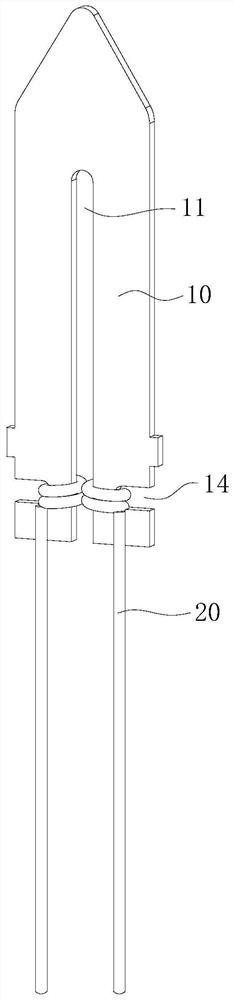

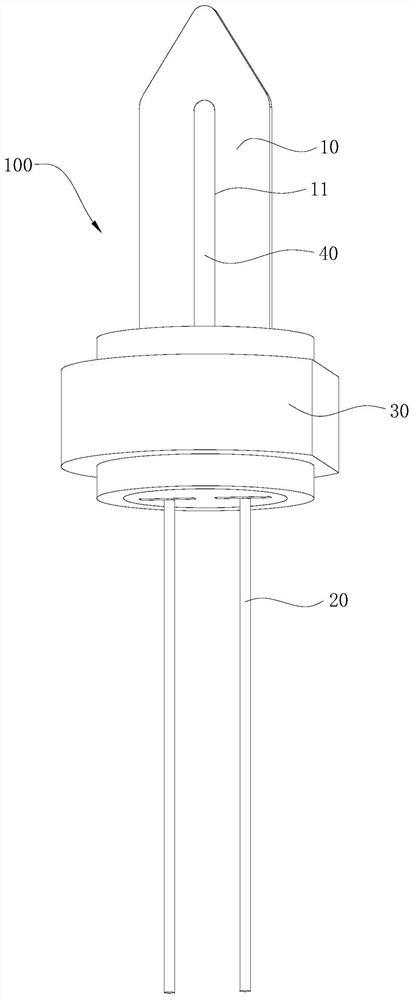

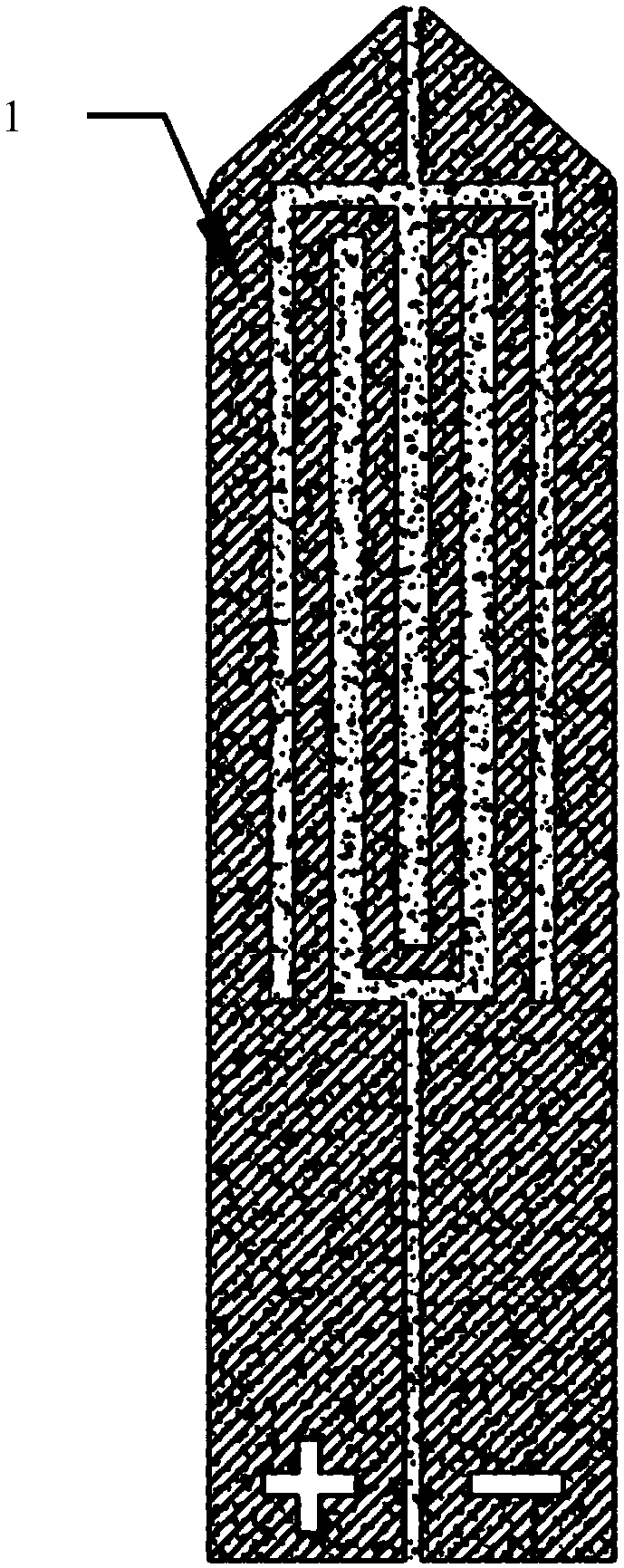

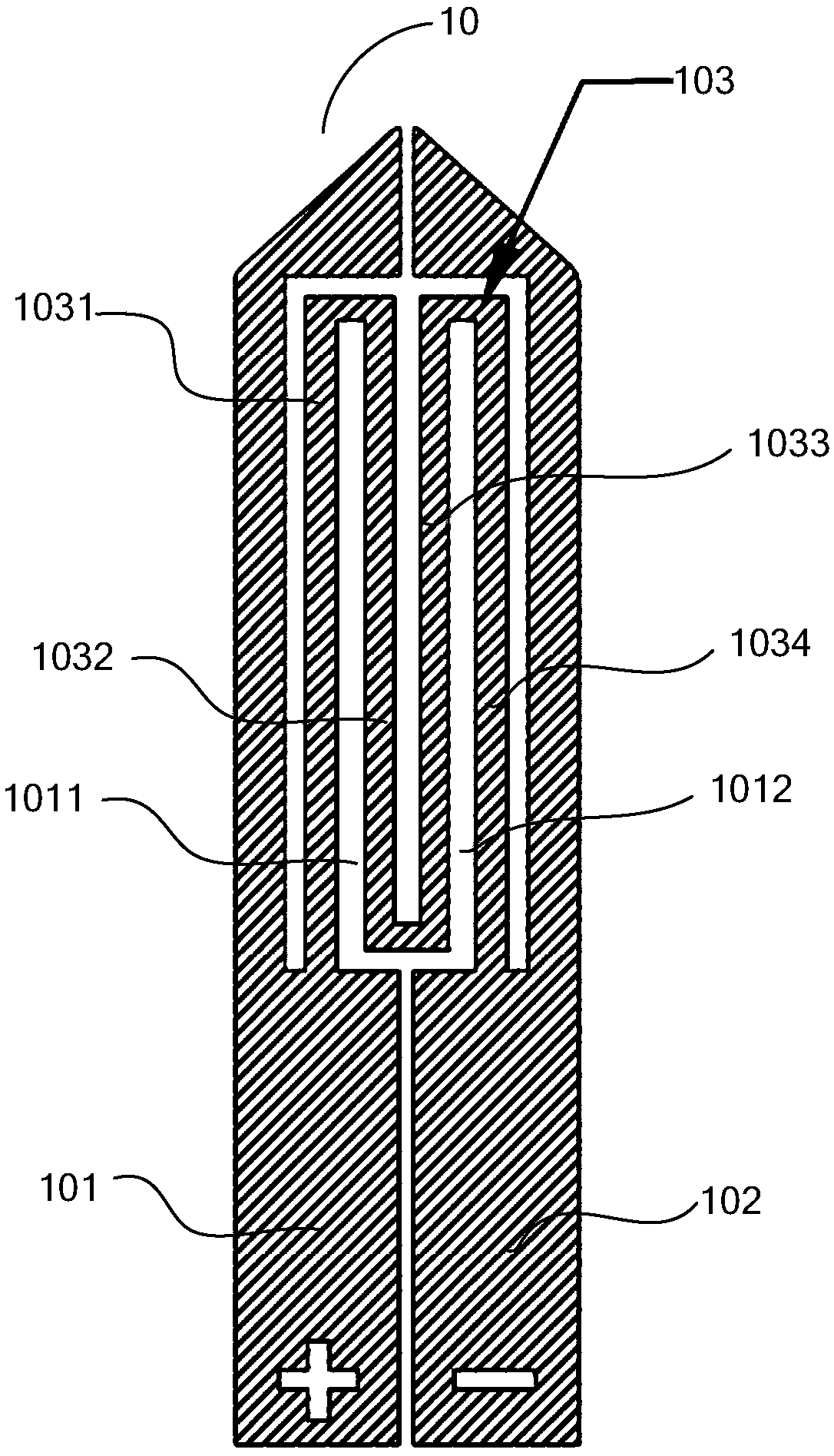

Heating body, preparation method thereof, heating assembly and aerosol generating device

PendingCN113179559AUniform heating temperature distributionImprove efficiencyOhmic-resistance heating detailsAerogel preparationPhysicsThermal conductivity

The invention relates to a heating element and a preparation method thereof, the heating element is formed by stacking a plurality of conductive layers and a plurality of insulating layers at intervals and integrally sintering, and the conductive layer is arranged on the outermost layer. The heating body provided by the embodiment of the invention is formed by compounding the plurality of conductive layers and the plurality of insulating layers, so that the heating temperature of the heating body is ensured to be uniformly distributed during heating, and the heating body has the characteristics of quick temperature rise, high heat efficiency, high heat conductivity and the like; the bending strength, fracture toughness and other properties of the whole heating body can be adjusted by adjusting the thickness of the ceramic insulating layer during preparation according to actual conditions, so that the heating body is not easy to break in actual application, and the service life is ensured; due to the fact that the conducting layers and the insulating layers are stacked at intervals and form a whole after high-temperature co-firing, the problem that the conducting tracks fall off in the using process does not exist, and the problem that the conducting tracks printed on an existing base body fall off after being used for a long time is solved.

Owner:ALD GRP

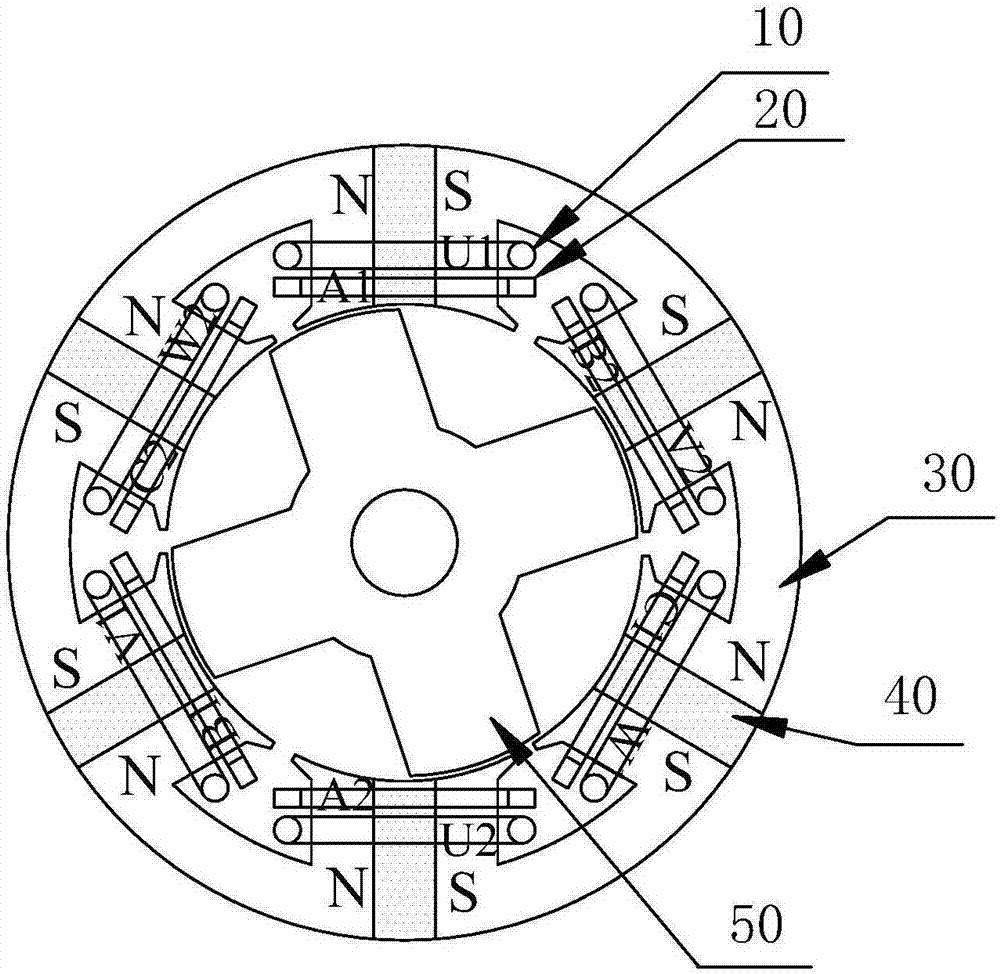

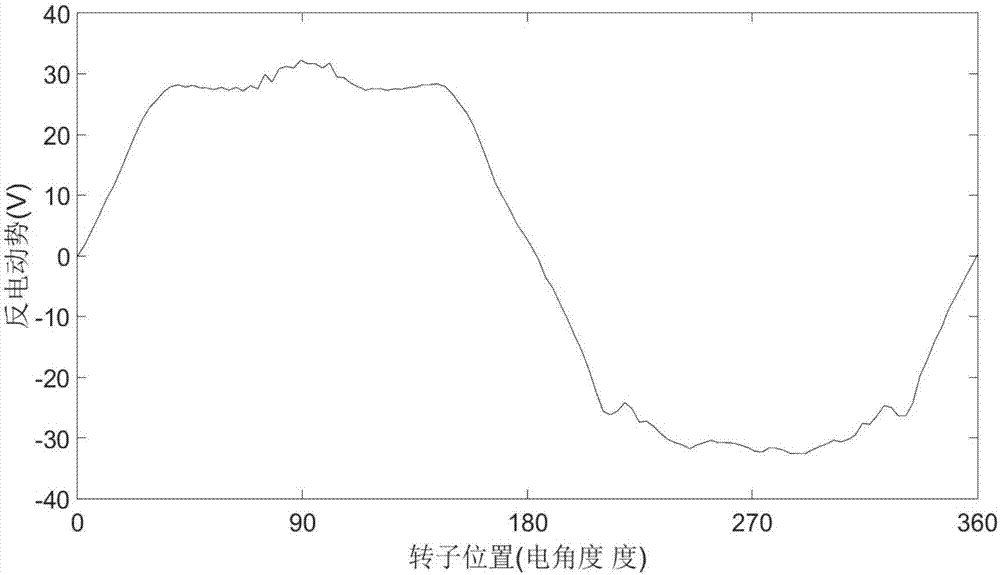

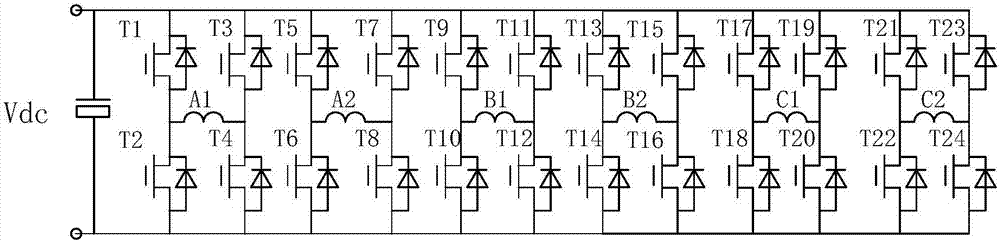

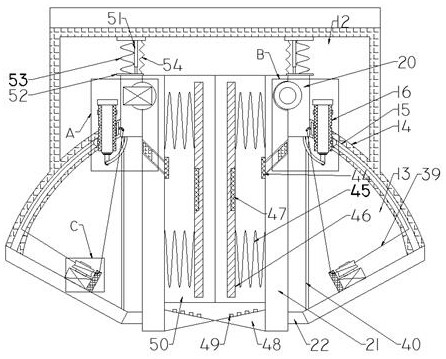

Double-winding bearingless magnetic flux switching permanent magnet motor

InactiveCN107134866AImprove stabilityImprove reliabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectrical polarityThree-phase

The invention discloses a double-winding bearingless magnetic flux switching permanent magnet motor comprising a stator, a rotor and windings. The stator and the rotor have a doubly salient structure and have the axial symmetry. The stator and rotor iron cores are formed by silicon steel plates through lamination. The stator iron core is formed by six U-shaped lamination plates. A tangentially and alternately magnetized permanent magnet is embedded between every two U-shaped lamination plates so as to form a stator tooth together. The windings are centralized windings and are installed on the stator teeth, and the end parts of the windings are small. There are two sets of windings. As for one set of windings, the coils on the two spatially opposite stator teeth are successively connected in series in an end-to-end way to form a phase so as to form the three-phase torque control windings; as for the other set of windings, the coils on the two spatially opposite stator teeth are reversely connected in series to form a phase so as to form the suspension force control windings, and the polarity of the adjacent sides of the adjacent permanent magnets is identical. The double-winding bearingless magnetic flux switching permanent magnet motor has the characteristics of high speed, high power, high efficiency, high power density, high operation stability and high reliability.

Owner:TIANJIN UNIV

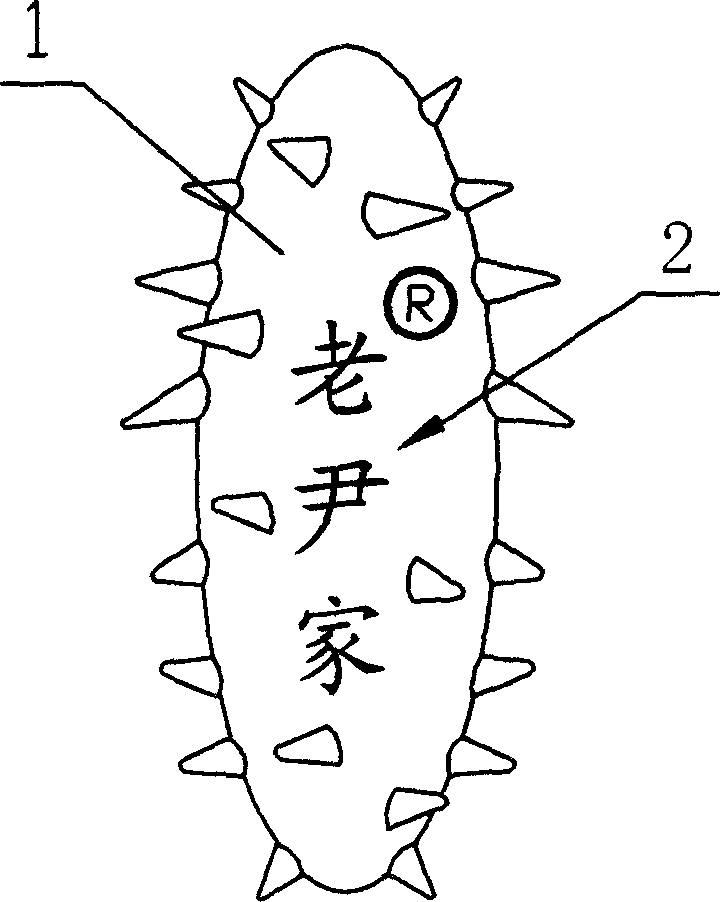

Method for carving mark on sea cucumber

InactiveCN1561845AThere is no problem of sheddingDoes not affect normal consumptionFood preparationLaser beam welding apparatusCarvingSea cucumber

A method for carving trademarker on sea cucumber includes such steps as choosing dried sea cucumber and laser carving.

Owner:尹宝昌

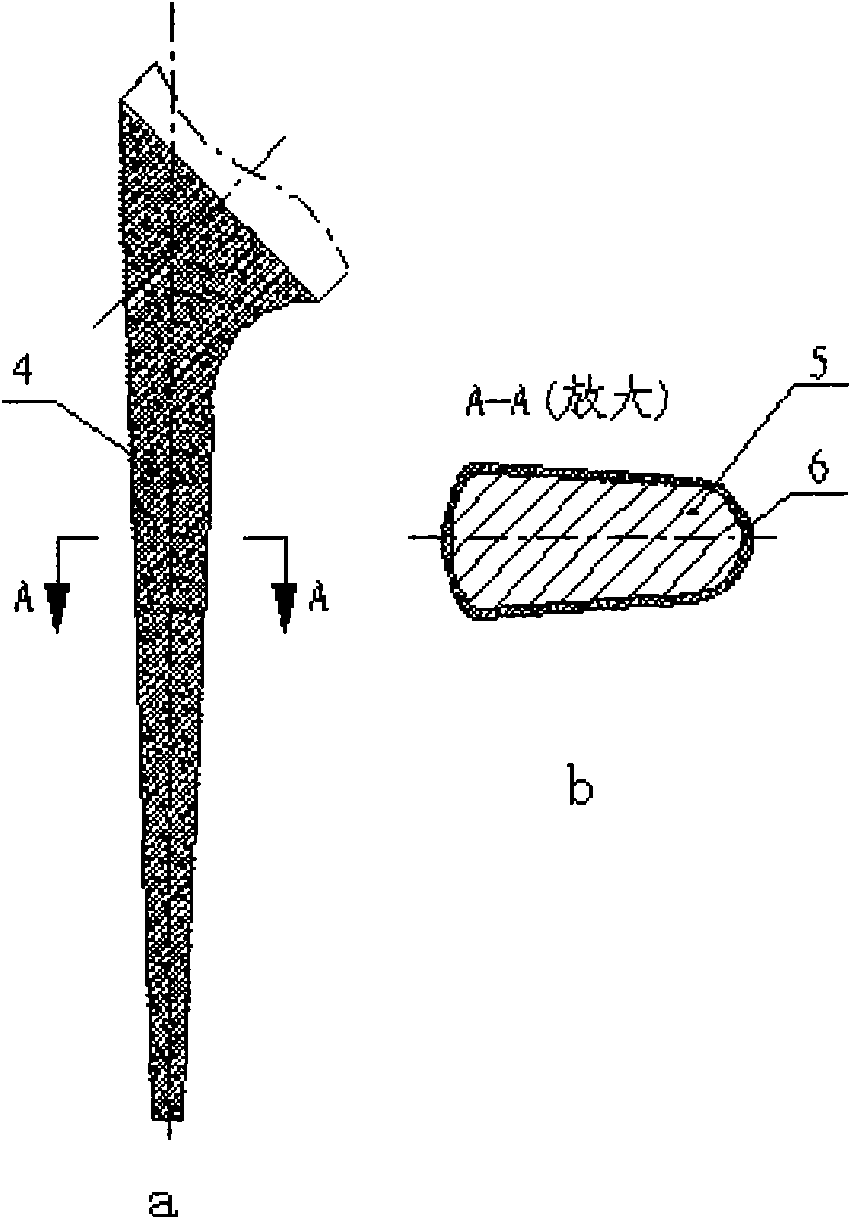

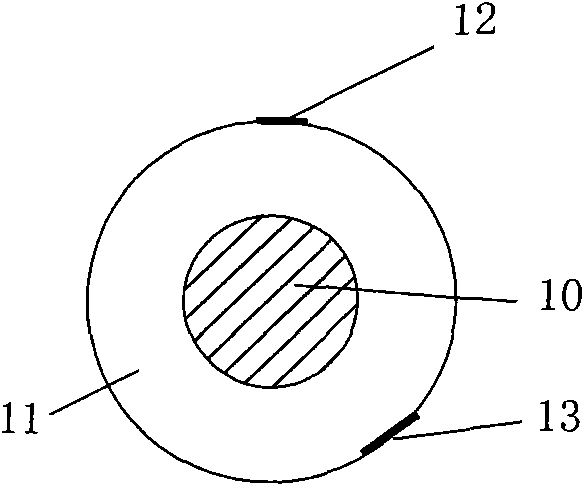

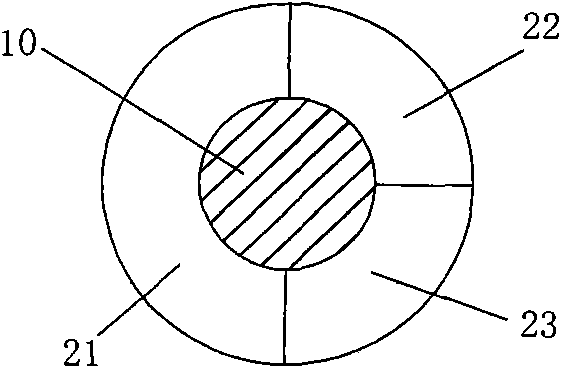

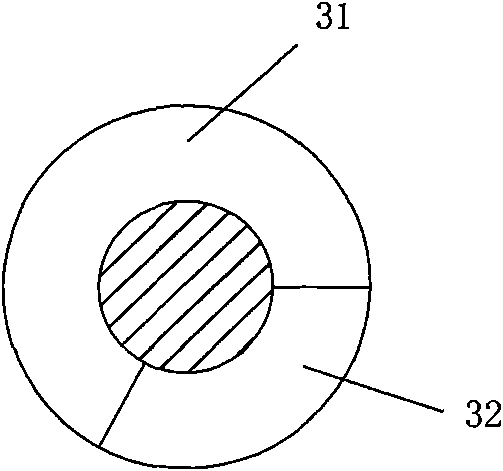

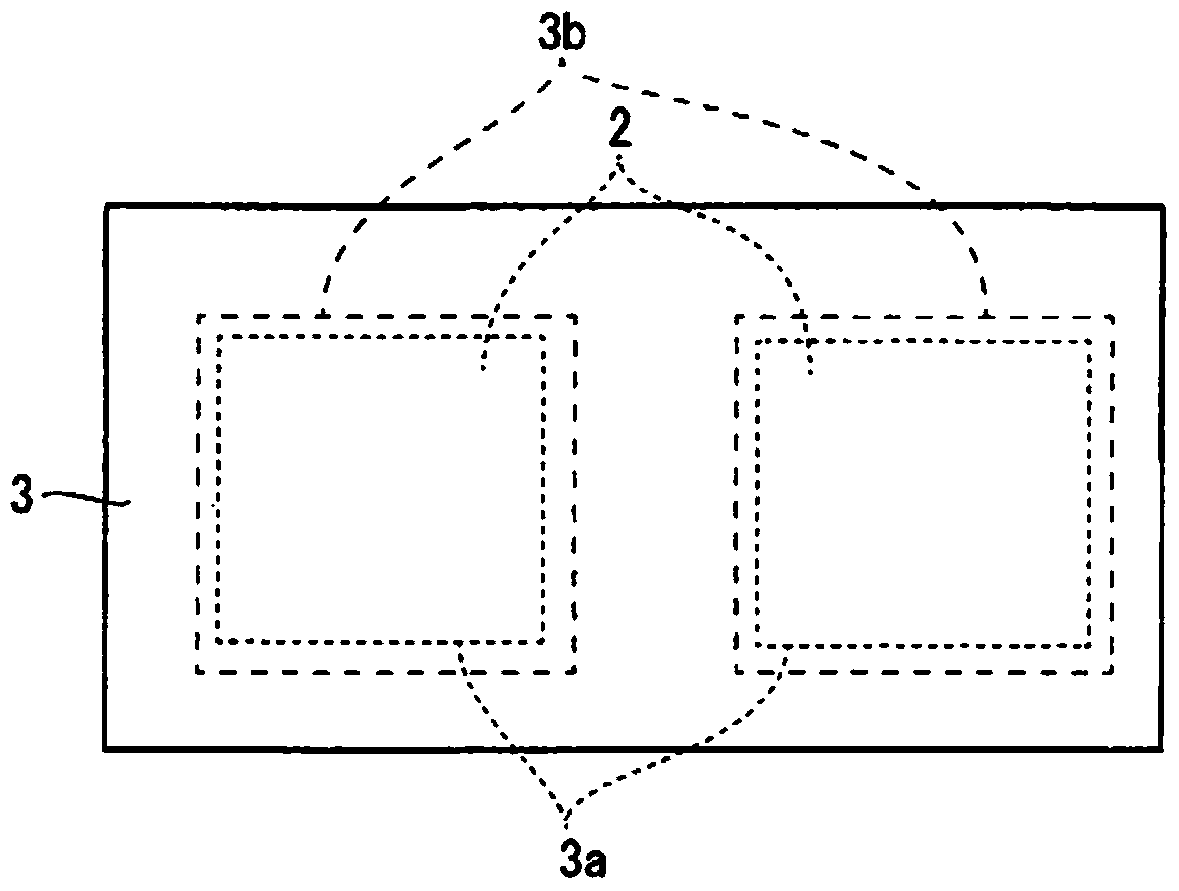

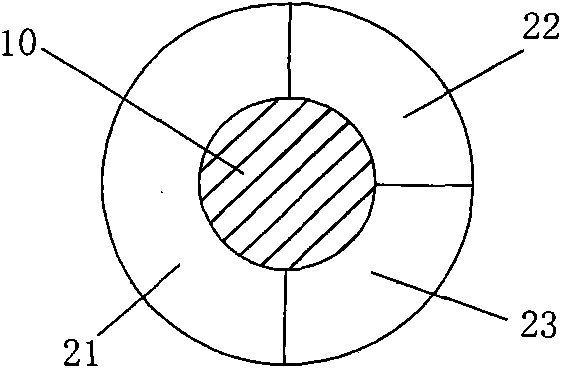

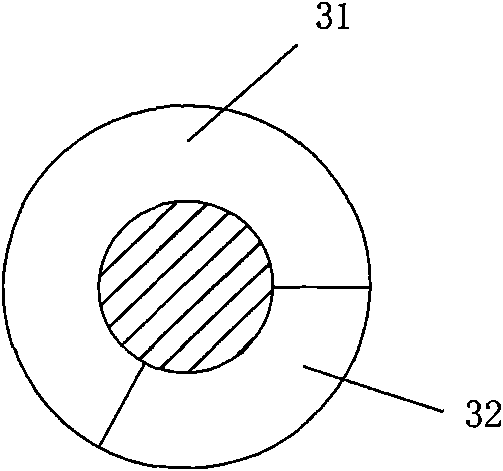

Insulated wire coded by entity color bars and preparation method thereof

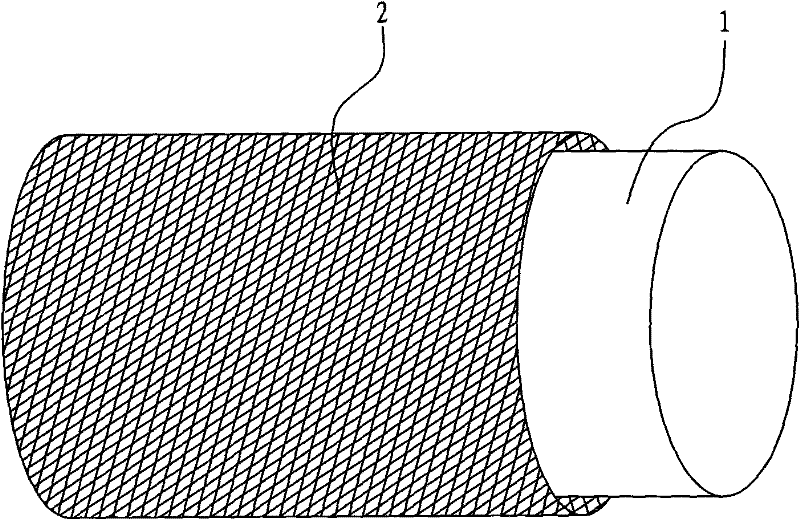

InactiveCN101950607AThere is no problem of sheddingAvoid influenceInsulated cablesConductor/cable markingComputer scienceElectric wire

The invention discloses an insulated wire coded by entity color bars and a preparation method thereof. The preparation method is characterized in that an outermost layer rubber jacket is set as fan-shaped entity zones with different colors in a zoning mode on the cross section of a wire; and the fan-shaped entity zones with the different colors are helical in the axial direction of the wire so as to form helical color bars at the periphery of the wire. The color bars of the invention can not drop and has exact color code and large coding capacity; and the preparation method of the invention is simple and reliable and has high production efficiency.

Owner:HUAINAN XINGUANGSHEN OPTICAL FIBER CABLE

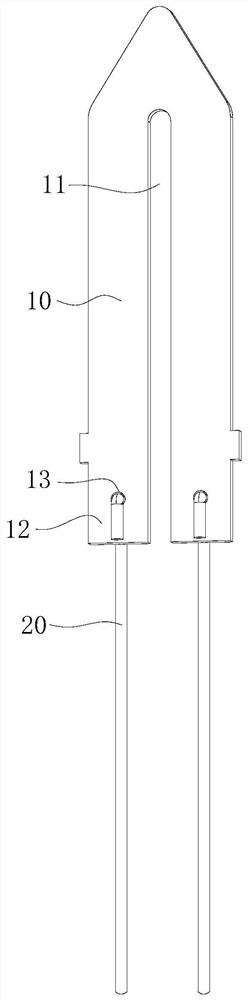

Heating device and electronic cigarette

InactiveCN108552597AImprove heating uniformityStable resistance valueTobacco devicesEngineeringElectronic cigarette

The invention relates to a heating device and an electronic cigarette. The heating device comprises a heating element body and an insulating layer which is arranged on the heating element body and covers the surface of a heating element, and at least one end of the heating element body is shaped like a tip. The heating element of the heating device is of an integrated structure and is good in stability and consistency, the fall off problem does not exist, the heating uniformity is good, a resistance value and the temperature varying coefficient are more stable, and the temperature of the heating element can be easily and precisely controlled conveniently.

Owner:达文金属制品有限公司

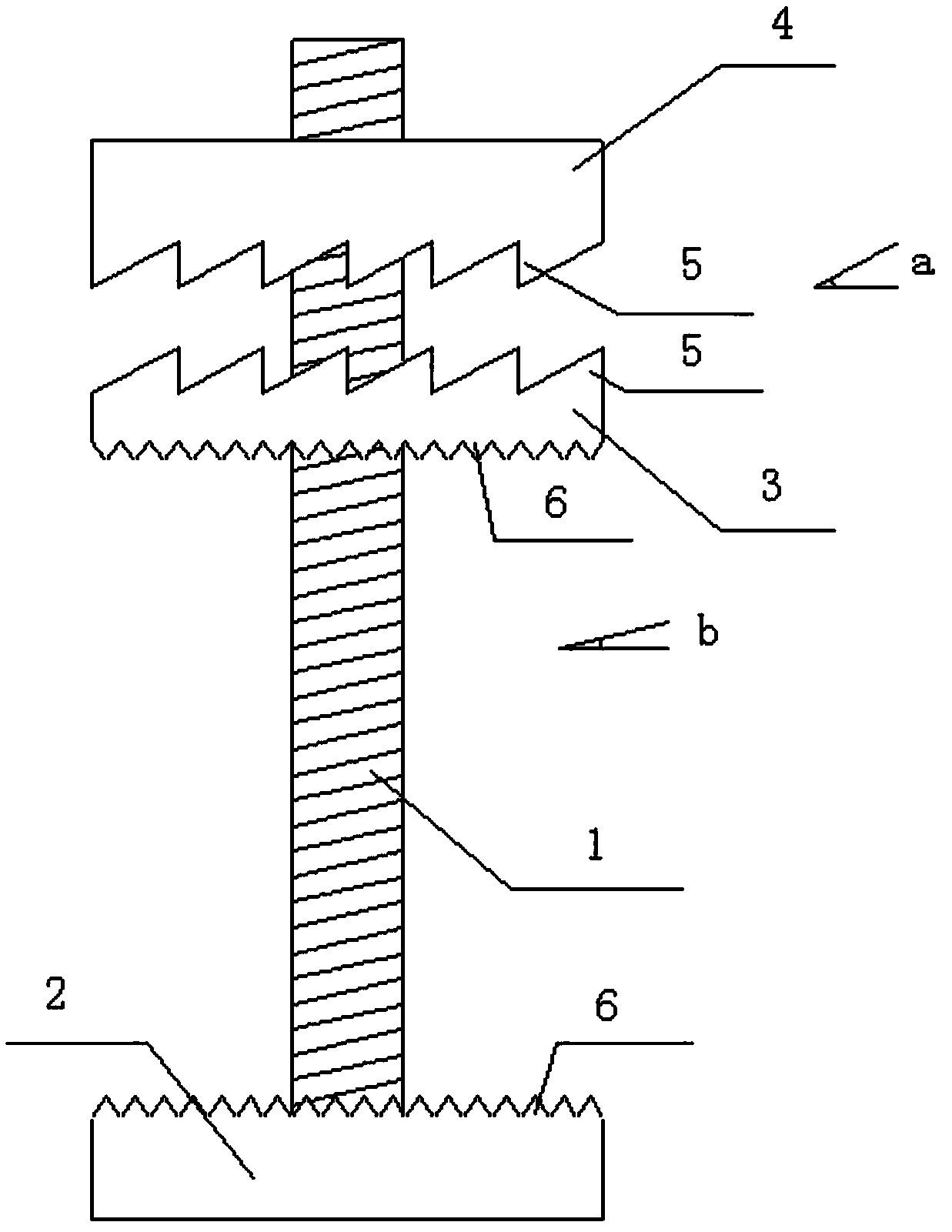

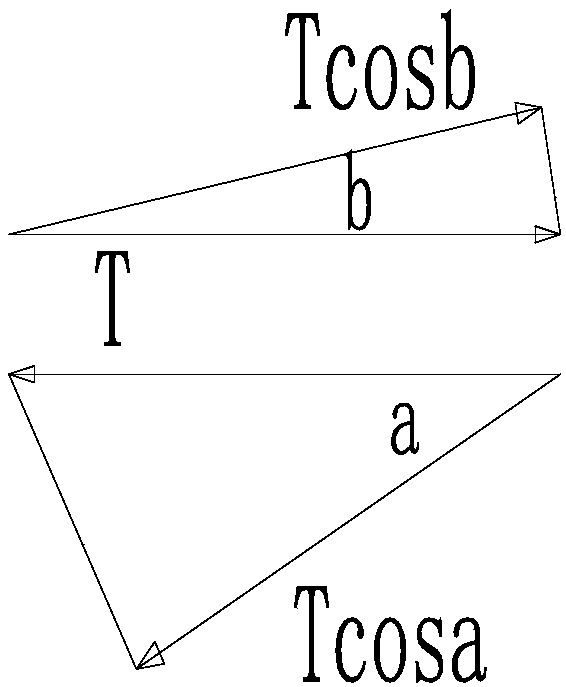

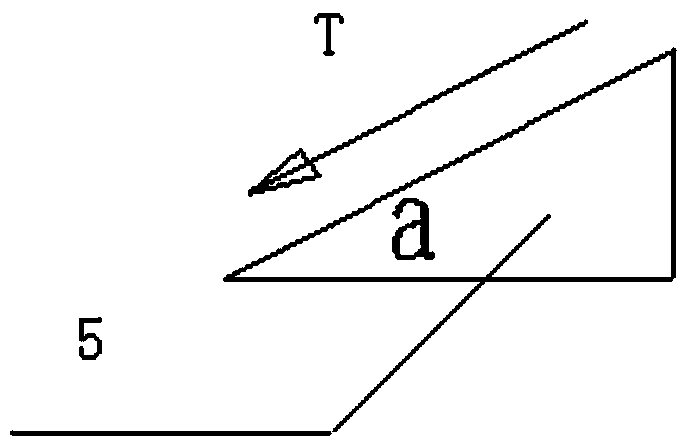

Self-fastening type bolt

The invention belongs to the technical field of high-voltage electric power facility pole tower fasteners and particularly relates to a self-fastening type bolt. The self-fastening type bolt comprisesa bolt rod, a nut A, a nut B and a nut C, wherein the nut A, the nut B and the nut C are sequentially connected to the bolt rod. The nut A is fixedly connected to the top end of the bolt rod. The nutB and the nut C are in thread connection with the bolt rod. Matched large teeth are arranged on the contact faces of the nut B and the nut C correspondingly. Each large tooth on the nut B has a vertical edge and a bevel edge, wherein the inclination direction of the bevel edge is the same as that of a thread on the bolt rod, and the degree a of the included angle formed between the bevel edge ofeach large tooth of the nut B and the horizontal plane is larger than the degree b of the included angle formed between the thread on the bolt rod and the horizontal plane. The self-fastening type bolt is simple in construction and convenient to use, the self-fastening and falling-preventing effects are obvious, and the bolt can serve as a conventional connecting bolt for an electric transmissionline pole tower.

Owner:SHENYANG ELECTRIC POWER SURVEY DESIGN INST

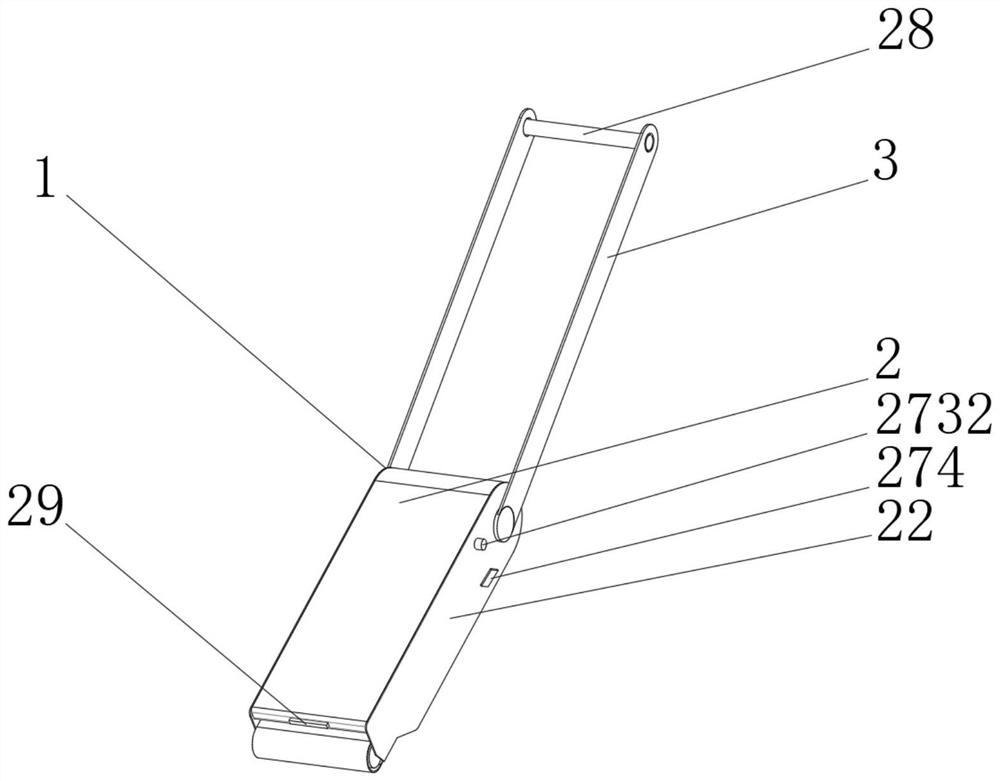

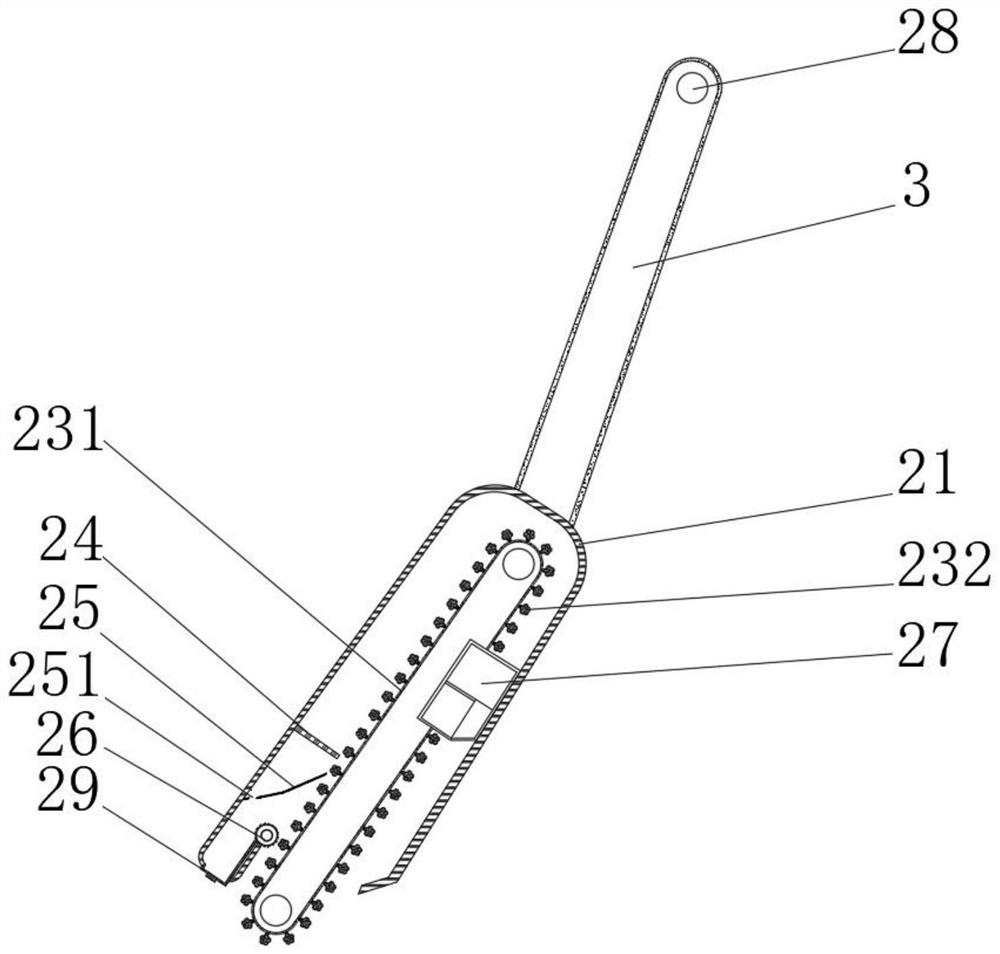

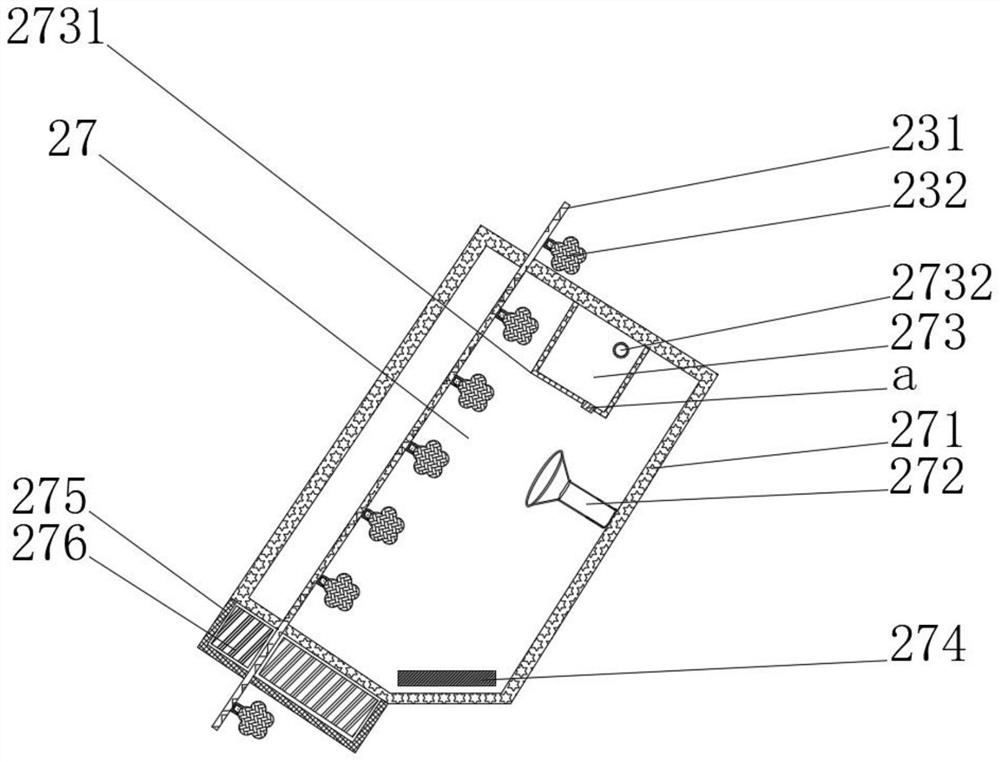

Portable single-person tea-leaf picker

ActiveCN112425368AThere is no problem of sheddingAvoid wastingPicking devicesAgricultural engineeringStructural engineering

The invention discloses a portable single-person tea-leaf picker which comprises a tea-leaf picker body, a collecting box is arranged in the tea-leaf picker body, a conveying pipe cavity is fixedly connected to the upper side of the left end of the collecting box, a picking box is fixedly connected to the left end of the collecting box, and two moving blocks are arranged in the picking box in a bilateral symmetry manner; and rotating clamping plates are hinged to the left ends of the moving blocks, and two baffles are fixedly arranged on the left end face of each rotating clamping plate in a front-back symmetrical manner. According to the portable single-person tea-leaf picker, a pinch-off head of an existing single-person type tea-leaf picker is improved, no baffle is arranged on the front portion and the rear portion of an existing tea-leaf picking clamp, tender shoots of tea leaves fall off in the clamping process, and therefore resource waste is caused; and according to the portable single-person tea-leaf picker, in the picking process, the baffles are arranged on the front portion and the rear portion, springs are arranged between clamping plates, tea tender shoots can be restrained in the shearing process, the problem that the tea tender shoots fall off does not exist, resource waste is avoided while the tea quality is guaranteed, and economical influences on tea growersare avoided.

Owner:湖北宣恩维民实业有限公司

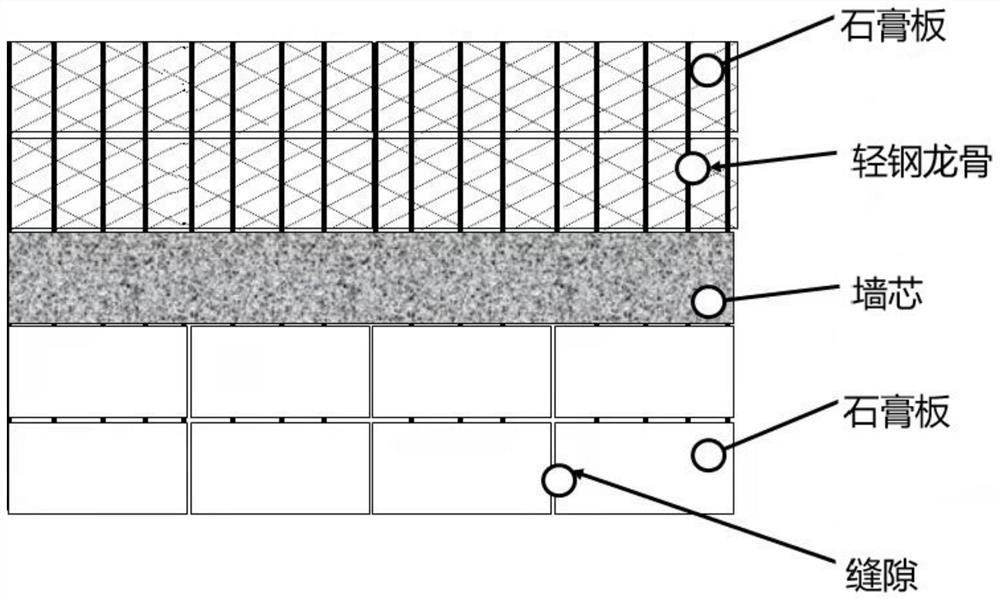

Construction method of gypsum cast-in-place wall

PendingCN114278091ANo wrinklingThere is no problem of sheddingWallsCeramic shaping apparatusKeelArchitectural engineering

The invention relates to the technical field of engineering construction, in particular to a construction method of a gypsum cast-in-place wall. The construction method mainly comprises the following steps that according to the thickness of a wall to be built, light steel keels are selected and installed into a keel frame; gypsum boards are selected as wall panels, and the gypsum boards are laid on the two sides of the keel frame; preparing gypsum paste, and filling the gap between the two adjacent gypsum boards with the gypsum paste; and gypsum slurry is prepared and poured into the cavity mold box located between the gypsum boards on the two sides of the keel frame, and after the gypsum slurry is solidified, construction of the cast-in-place wall is completed. The construction technology is simple in step, convenient to operate and control and low in comprehensive wall building cost, industrial byproduct gypsum waste such as ardealite can be fully utilized, and waste recycling is achieved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Mechanical cleaning equipment

The invention discloses mechanical cleaning equipment, which comprises a cleaning equipment body composed of a cleaning device and a rod body, the cleaning device comprises a shell, side plates are fixedly connected to the two sides of the shell respectively, a conveying mechanism is arranged in the cleaning device, and a cleaning brush is arranged on the left side of the conveying mechanism. Thetop of the cleaning brush is fixedly connected with the interior of the shell, a dust sliding plate and a rolling mechanism are sequentially arranged at the bottom of the left side of the cleaning brush, the top of the dust sliding plate is fixedly connected with the interior of the shell, a dust sliding hole is formed in the middle of the dust sliding plate, a cleaning device is fixedly connectedwith the bottom of the inner wall of the shell, and the conveying mechanism comprises a conveying belt. The invention relates to the technical field of cleaning. According to the mechanical cleaningequipment, the problems that self-cleaning cannot be achieved, hair is prone to falling off, recycling cannot be achieved, garbage cannot be collected, and the ground cannot be sterilized and disinfected while the ground is cleaned are solved.

Owner:刘江山

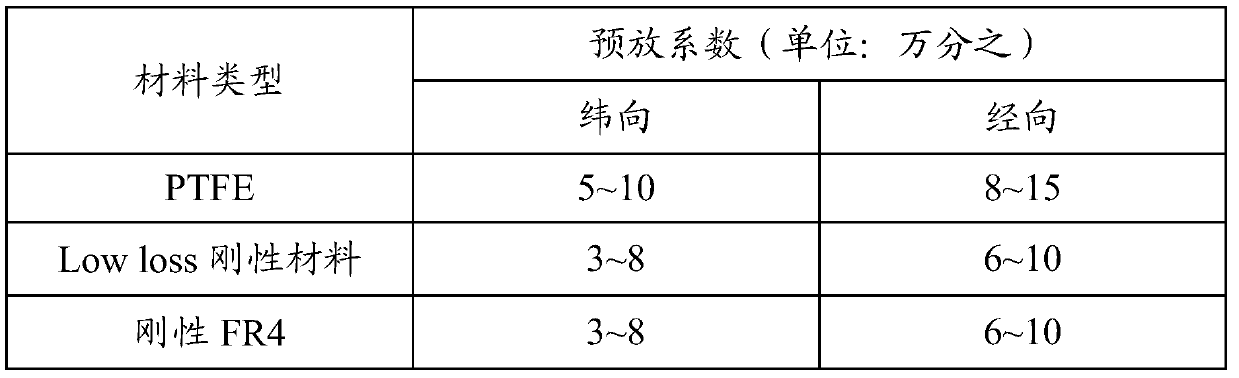

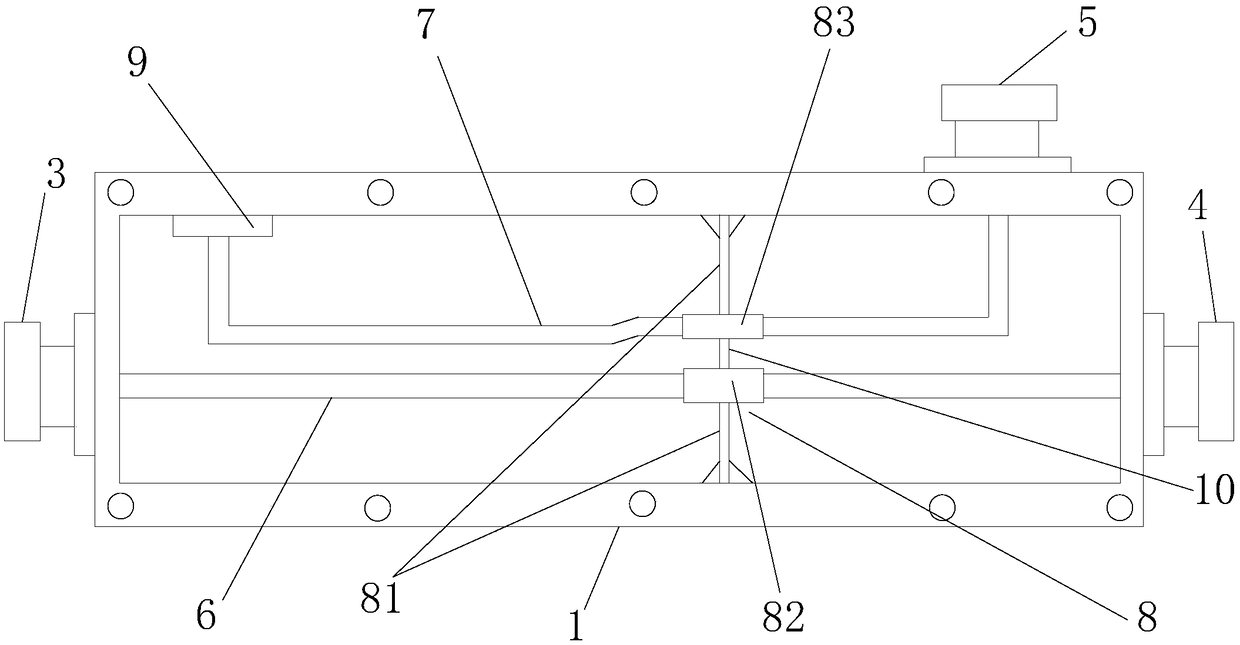

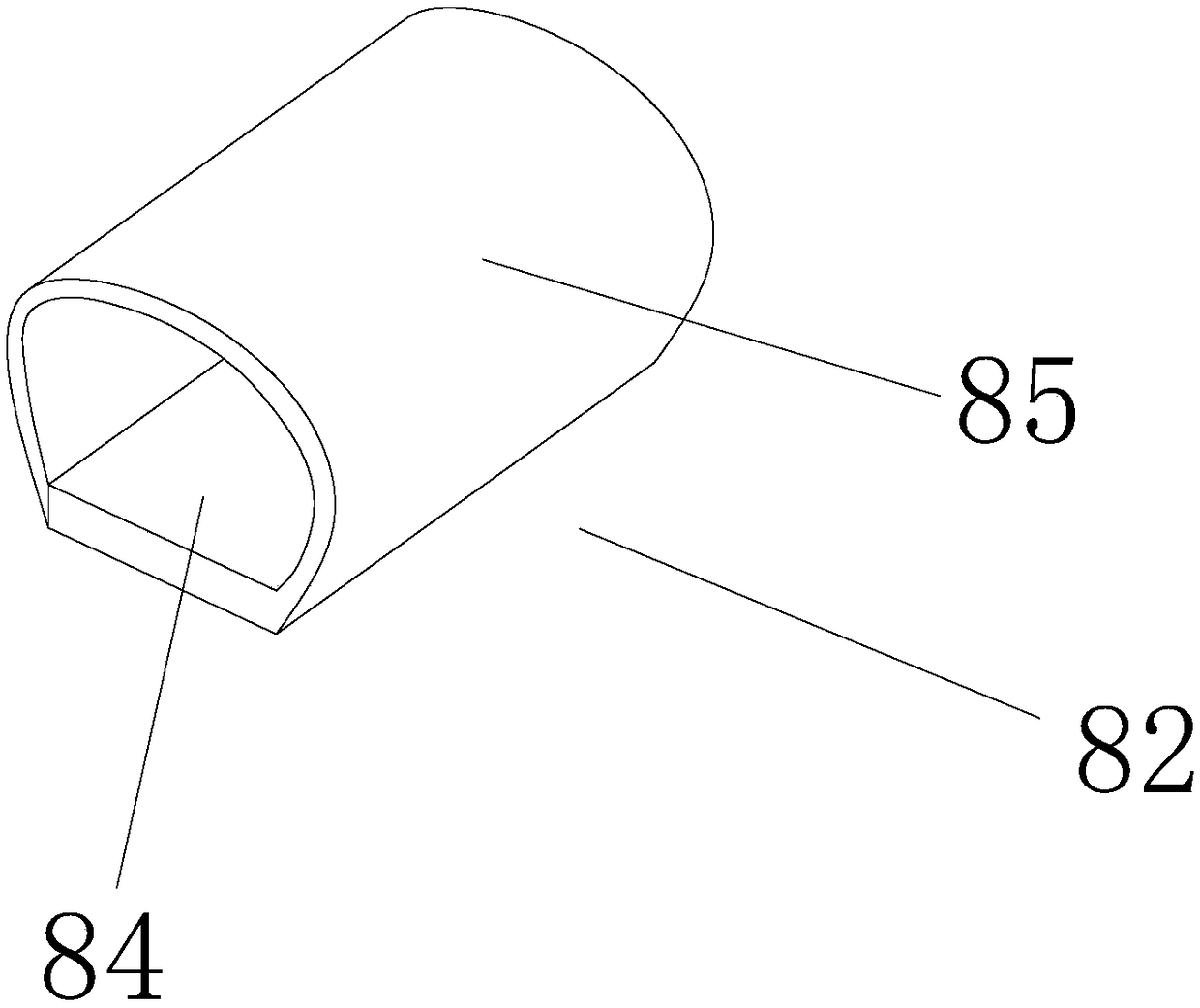

A high-frequency high-speed PCB and its manufacturing method

ActiveCN106132081BMeet high-speed/high-frequency signal requirementsReduce material costsCircuit susbtrate materialsCopper platingSolder mask

The invention discloses a high-frequency and high-speed printed circuit board (PCB) and a fabrication method thereof. The high-frequency and high-speed PCB comprises at least two layers of rigid substrate core plates, at least one layer of PTFE substrate core plate and at least one layer of FR4 substrate core plate, wherein a PCB main body is formed by sequentially laminating the rigid substrate core plate, the PTFE substrate core plate, the FR4 substrate core plate, the PTFE substrate core plate and the rigid substrate core plate from bottom to top, PTFE prepregs are laminated among the core plates, and a through hole is drilled in the PCB main body. The fabrication method of the high-frequency and high-speed PCB comprises the steps of board cutting, surface roughness processing, inner-layer pattern fabrication, baking plate processing, board lamination, drilling, copper plating, soldering and surface processing. The PCB disclosed by the invention has the characteristics of excellent high-speed / high-frequency transmission and low transmission loss, the production processes such as drilling, shaping and board grinding are easier to control, and the problem that a soldering layer is easy to drop off is solved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

Improved cavity coupler

The invention discloses an improved cavity coupler. The improved cavity coupler comprises a housing and a cover plate, wherein the outer side walls of three side edges of the housing are respectivelyprovided with a first connector, a second connector and a third connector; a cavity is formed between the housing and the cover plate; a main conductor, a coupling conductor and an insulating supportassembly are arranged in the cavity; one end of the main conductor is connected with the first connector, and the other end of the main conductor is connected with the second connector; one end of thecoupling conductor is connected to the third connector, and the other end of the coupling conductor is connected to a resistor on the inner side wall of one side edge of the housing; the insulating support assembly comprises a support rod, a first insulating sleeve and a second insulating sleeve; the first insulating sleeve is connected to the inner side wall of one side edge of the housing through a support rod; the first insulating sleeve sleeves the outer circumference of the main conductor; the second insulating sleeve is connected to the inner side wall of the other side edge of the housing through the other support rod; and the second insulating sleeve sleeves the outer circumference of the coupling conductor. The improved cavity coupler has the advantages of endurance of the insulating support device.

Owner:安徽创客邦网络运营有限公司

An electronic expansion valve

ActiveCN103575000BSimplify the assembly processReduce in quantityOperating means/releasing devices for valvesEfficient regulation technologiesMiniaturizationEngineering

The invention discloses an electronic expansion valve, the stopping part of which includes a mandrel (61) fixed relative to a valve seat (1), a spring guide rail (62) sleeved on the outside of the mandrel (61), and the spring guide rail ( 62) A matching slip ring (63); one end of the slip ring (63) protrudes to form a stop rod (64), and a stop hole (31a) is opened on the top of the magnet (3), and the stop rod ( 64) pass through the stop hole (31a), and when the slip ring (63) is in the upper stop position and the lower stop position, the stop rod (64) is held in the stop hole (31a) . On the one hand, the structural design of the electronic expansion valve can reduce the number of parts, simplify the assembly process of the stop rod, and improve its working reliability; on the other hand, it can reduce the radial dimension of the magnet, thereby saving material costs and realizing Product miniaturization.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

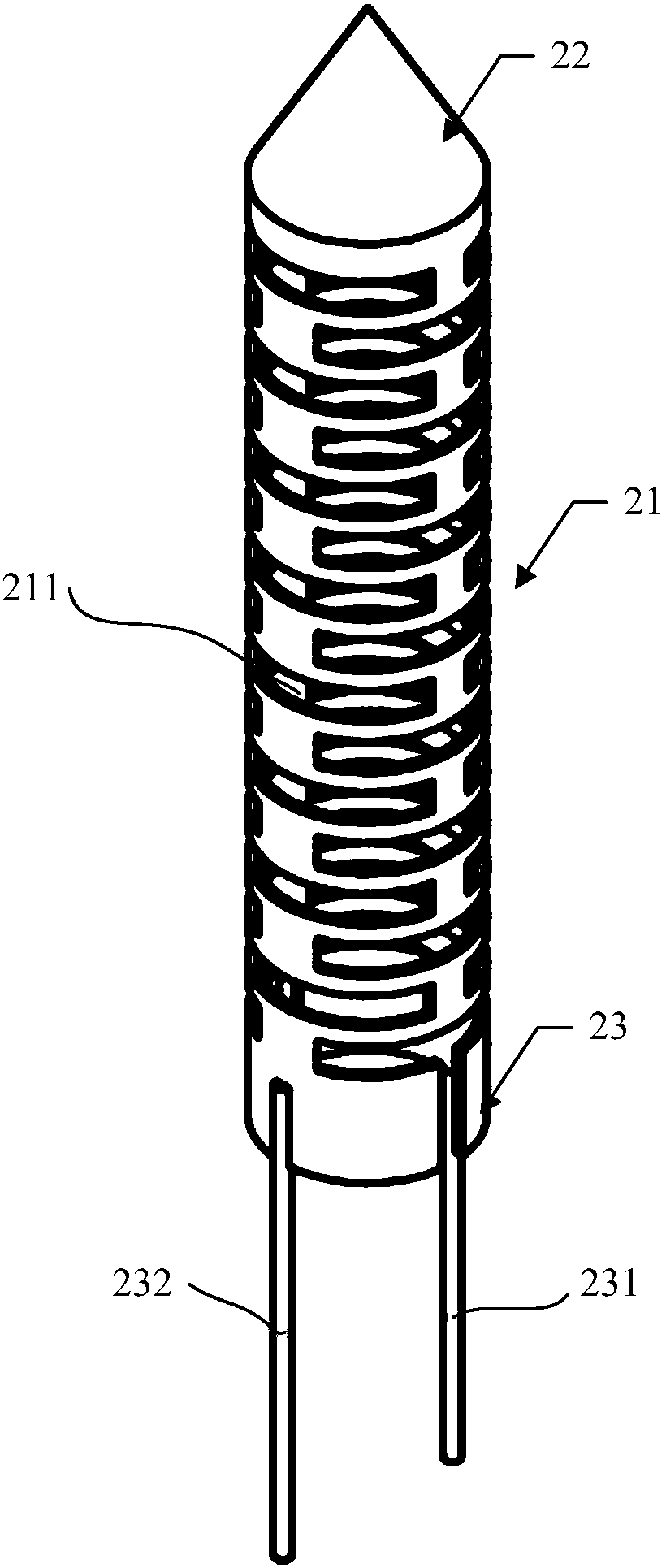

A resin-based composite material dust removal bag cage

ActiveCN104785031BLower assembly costsThere is no problem of sheddingDispersed particle filtrationResin matrixResin-Based Composite

The invention provides a resin matrix composite dust bag cage. The dust bag cage adopts a resin matrix composite, and solves the problem that the dust bag cage made of the traditional material is easily corroded during surface treatment. The dust bag cage takes a continuous fiber and matrix resin as raw materials and adopts a winding forming technology; the cage in a lattice structure is formed on a mold; and the strength, the temperature resistance and the corrosion resistance of the bag cage can be adjusted according to a use requirement.

Owner:重庆亿煊新材料科技有限公司

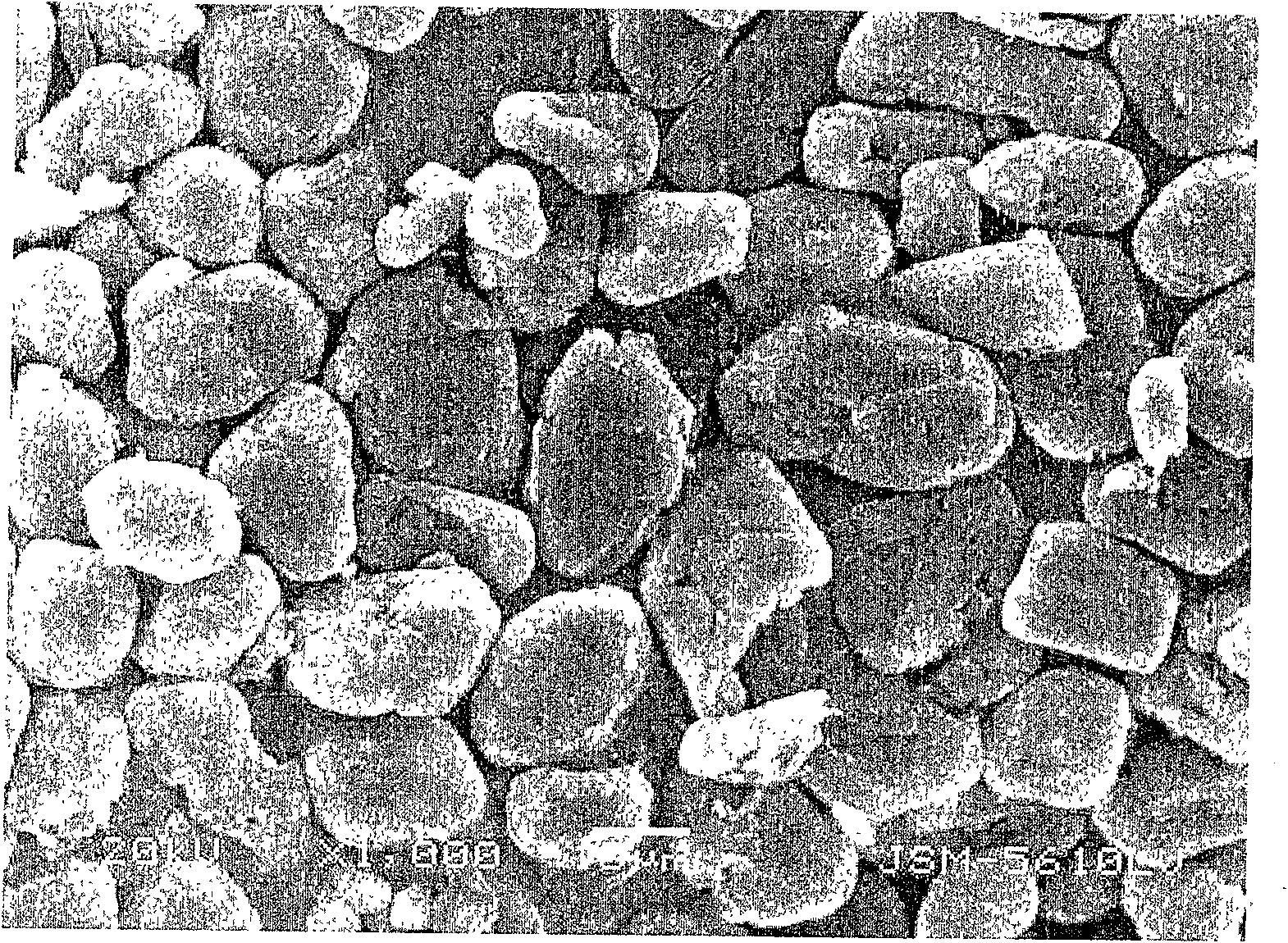

Method for encapsulating active material for negative pole of Li-ion secondary battery

InactiveCN100557862CImprove the first charge and discharge efficiencyImprove cycle performanceElectrode manufacturing processesLithiumElectrical battery

The invention relates to a method for coating cathode active substance in a lithium iron secondary battery. The method comprises the following steps: a mixture containing the cathode active substance and coating agent is heated under the atmosphere of inert gases. The mixture also comprises an initiator and the initiator is the organic peroxide only containing the C, H and O. Due to the invention does not adopts the method of forming a coating layer on the cathode active substance by the coating agent using the physical mixing of the coating agent and the cathode active substance as well as the heat polymerization, but adopts the way of adding the initiator in the process of mixing the coating agent and the cathode active substance to form a coating layer on the cathode active substance by the coating agent under the moderate condition and completing the fixing and the grafting reaction at the same time; thus the caking phenomenon can not occur, furthermore, the even and complete cathode active substance of the coating layer is obtained through the direct carbonization and graphitization without breakage. The battery manufactured according to the cathode active substance has a high efficiency of charge and discharge at the first time and a better circulation performance.

Owner:BYD CO LTD

Optical glass element with light absorption layer and preparation method of optical glass element

InactiveCN111423136AReduce temperature and pressureLow equipment requirementsGlass tempering apparatusOptical elementsLight absorbanceReflectivity

The invention relates to an optical glass element with a light absorption layer and a preparation method of the optical glass element, wherein the preparation method comprises the steps: pretreating optical glass to form a nano-scale or micron-scale gas diffusion channel on the surface of the optical glass; carrying out reduction treatment on the pretreated optical glass in a reducing atmosphere;and carrying out post-treatment on the optical glass subjected to reduction treatment to obtain the optical glass element with the light absorption layer. The optical glass element comprises an optical glass substrate and the light absorption layer, the light absorption layer is located on the periphery of the optical glass substrate, and the interface reflectivity between the light absorption layer and the optical glass substrate is smaller than 1%. The light absorption layer is a self-substrate light absorption layer, and the light absorption rate of the light absorption layer is greater than 99%. According to the preparation method, the problem that the light absorption layer is difficult to prepare in the optical glass with a compact structure is solved, and the problem that the lightabsorption layer falls off after being heated or subjected to external acting force does not exist.

Owner:CHINA BUILDING MATERIALS ACAD

Artificial joint prosthesis with biologically activated surface

ActiveCN101982203BPostoperative long-term effect guaranteeGood biocompatibilityCoatingsProsthesisChemical reactionBiocompatibility Testing

The invention belongs to the technical field of surgical implants and relates to an artificial joint prosthesis with biologically activated surface. The biological activation layer formed on the surface of the artificial joint prosthesis has good biocompatibility and bioactivity and forms natural chemical bonding with the bone tissues, thus improving the bond strength between the prosthesis and the bone tissues, ensuring the stress transfer to be more reasonable and reducing the negative effect of stress shielding. The biological activation layer on the surface of the artificial joint prosthesis is formed by chemical reaction and forms chemical bonding with the matrix, therefore, the problem that the biological activation layer on the surface sheds is avoided, thus ensuring the postoperative long-term effect of the prosthesis. The artificial joint prosthesis is biologically fixed; therefore, wear particles produced when bone cement is adopted for fixation are avoided, thus reducing the possibility of occurrence of aseptic loosening. Besides, the artificial joint prosthesis adopts simple raw materials and process, has low cost and is easy to realize.

Owner:BEIJING JINGHANG BIOTECH CO LTD

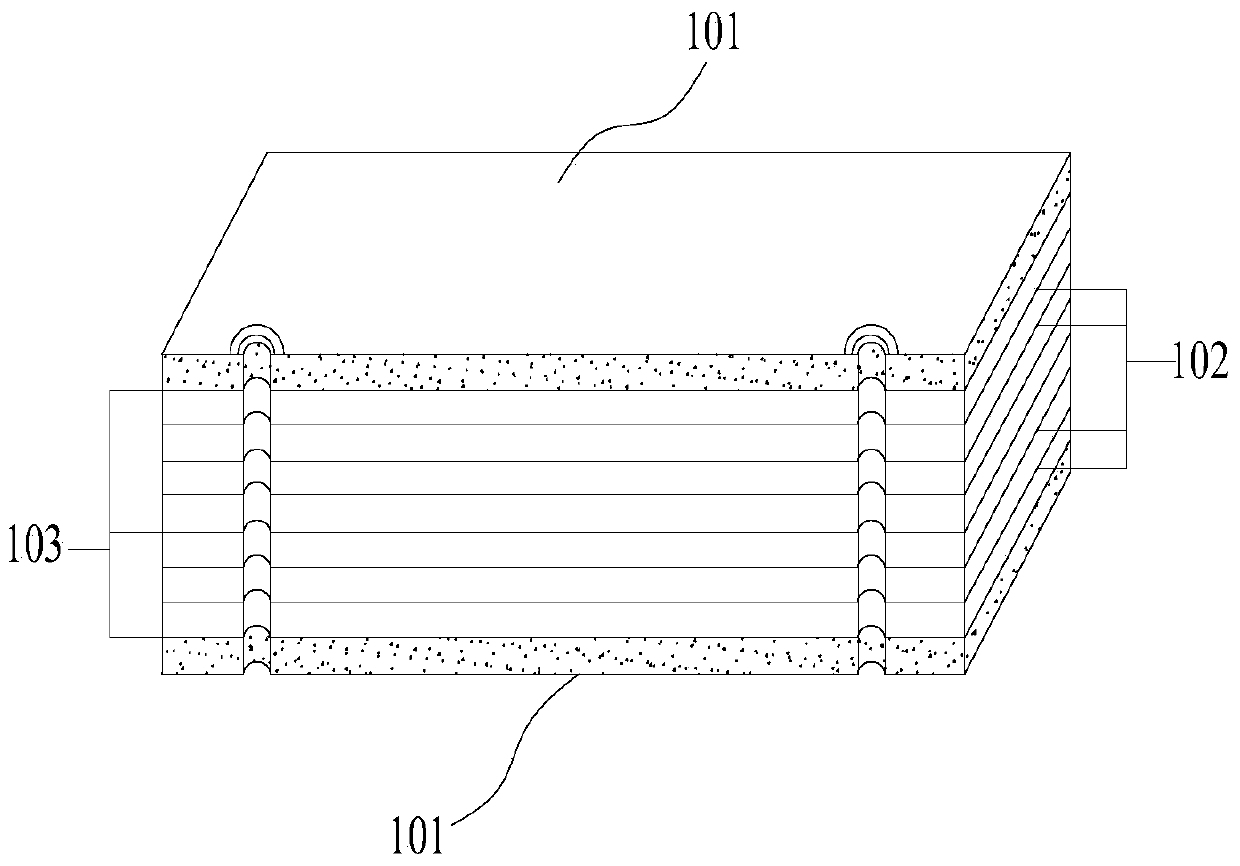

Composite material core used for enhanced cable, preparation process thereof and enhanced cable

InactiveCN102024517BSolve the problem of no transverse fiber reinforcementImprove lateral strengthInsulated cablesCable/conductor manufactureFiber bundleElectrical conductor

The invention relates to a composite material core used for an enhanced cable, a preparation process and the enhanced cable. The composite material core comprises an inner core and an outer layer, wherein the inner core is composed of fiber and thermosetting resin; the outer layer comprises a fiber woven pipe and thermosetting resin which are composited to form the outer layer; and the fiber woven pipe of the outer layer is a network structure which is woven by interlacing a plurality of fiber bundles. The transversal strength of the composite material core is greatly improved by the interlaced network structure, the fatigue resistance of the composite material core is greatly improved, and the service life of the composite material core and a power transmission cable is prolonged; and the problem that the composite material core is broken when the composite material core is stranded, wound and extruded by a conductor in the manufacturing process of the cable is completely avoided. Asthe fiber woven pipe is adopted by the outer layer, the flexibility of the outer layer is greatly increased by the interlaced and woven structure, thereby meeting the requirement of manufacturing composite material core with major diameter.

Owner:JIANGSU JIATAI TECH MATERIAL

Semiconductor device and manufacturing method thereof

ActiveCN104637832BImprove qualityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor device

Owner:MITSUBISHI ELECTRIC CORP

Insulated wire coded by entity color bars and preparation method thereof

InactiveCN101950607BThere is no problem of sheddingIncrease the total amount of color codesInsulated cablesConductor/cable markingStructural engineeringElectric wire

The invention discloses an insulated wire coded by entity color bars and a preparation method thereof. The preparation method is characterized in that an outermost layer rubber jacket is set as fan-shaped entity zones with different colors in a zoning mode on the cross section of a wire; and the fan-shaped entity zones with the different colors are helical in the axial direction of the wire so asto form helical color bars at the periphery of the wire. The color bars of the invention can not drop and has exact color code and large coding capacity; and the preparation method of the invention is simple and reliable and has high production efficiency.

Owner:HUAINAN XINGUANGSHEN OPTICAL FIBER CABLE

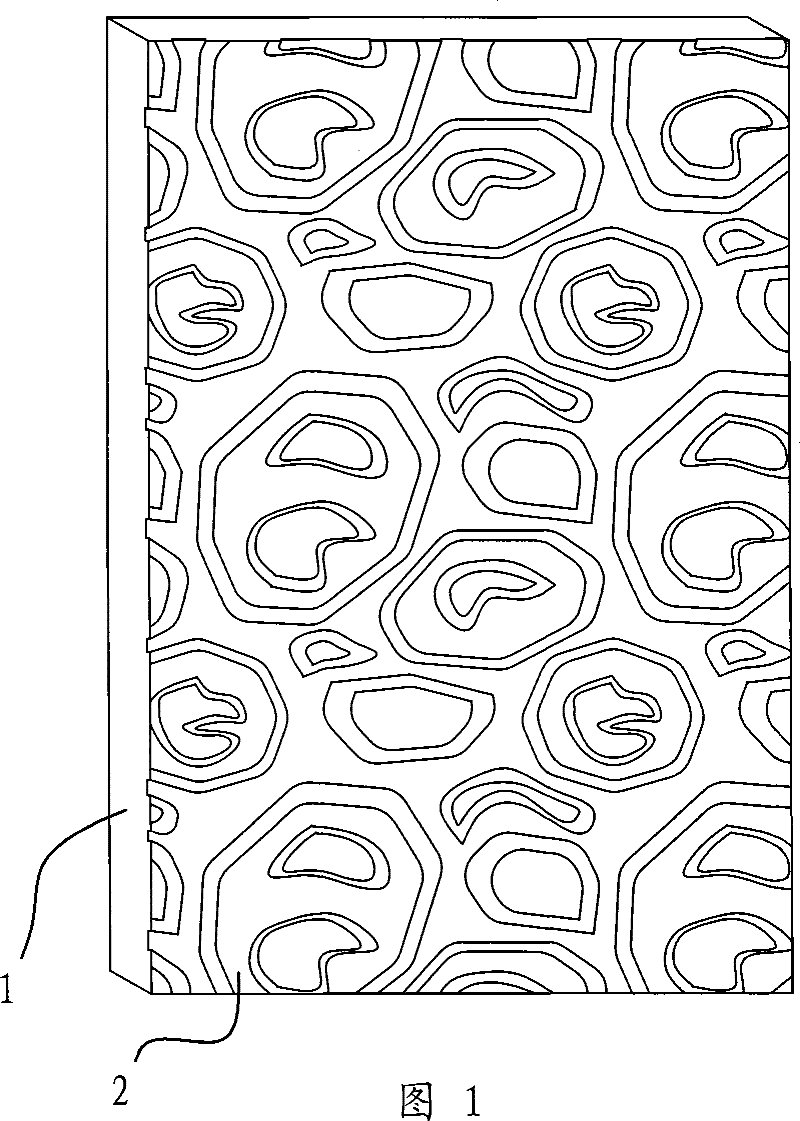

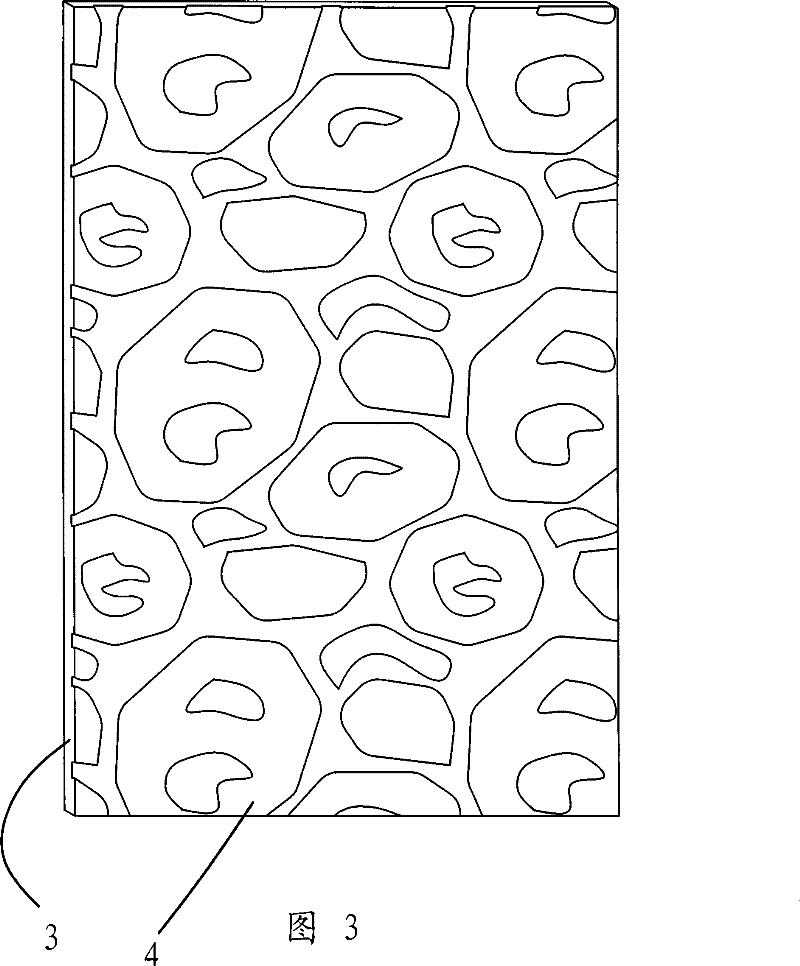

A manufacturing method of surface concave-convex type wood board

InactiveCN101157317BAppropriate moisture contentHigh water expansion rateDecorative surface effectsArtistic surface treatmentOn boardEngineering

Owner:张纪元

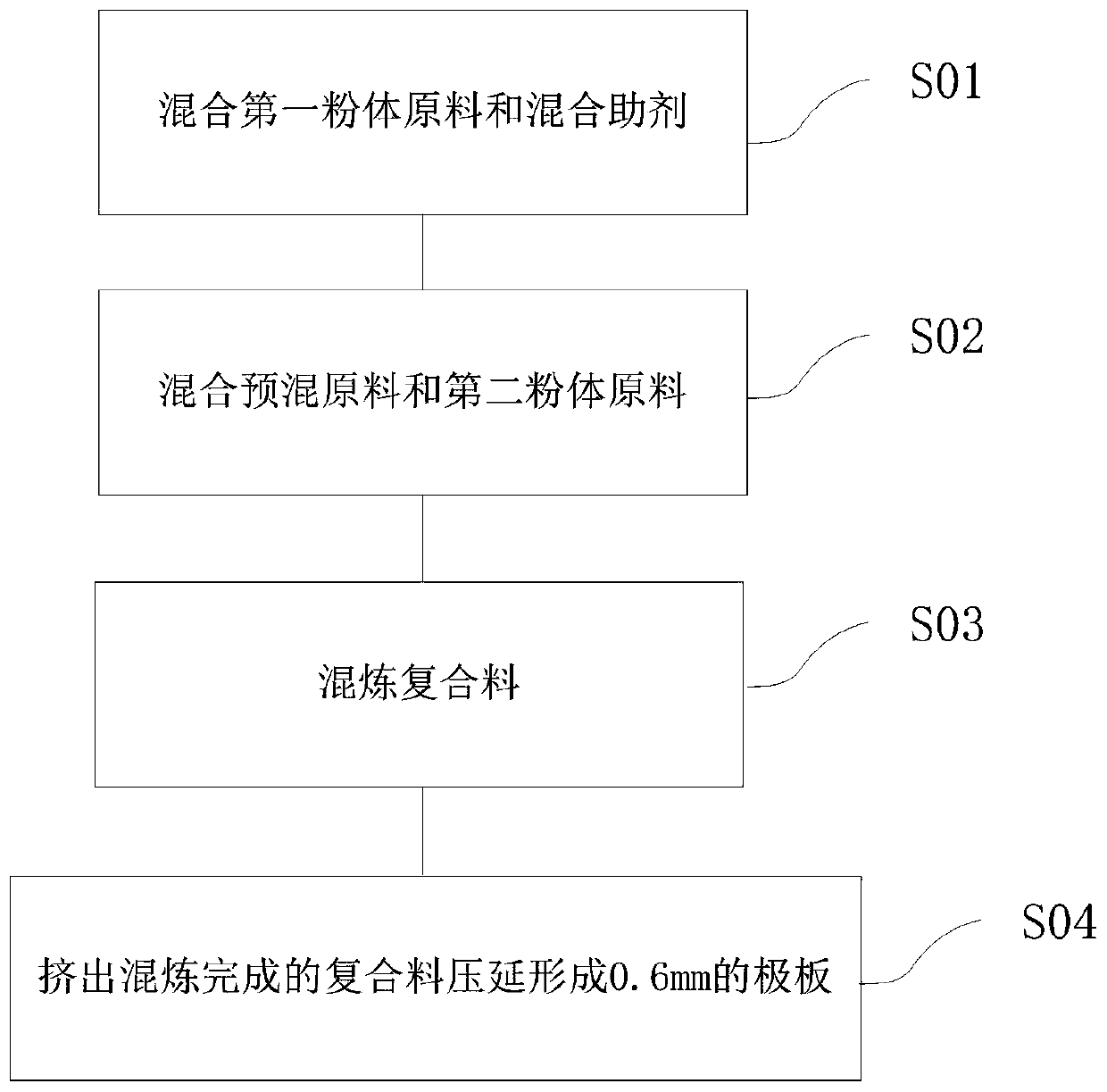

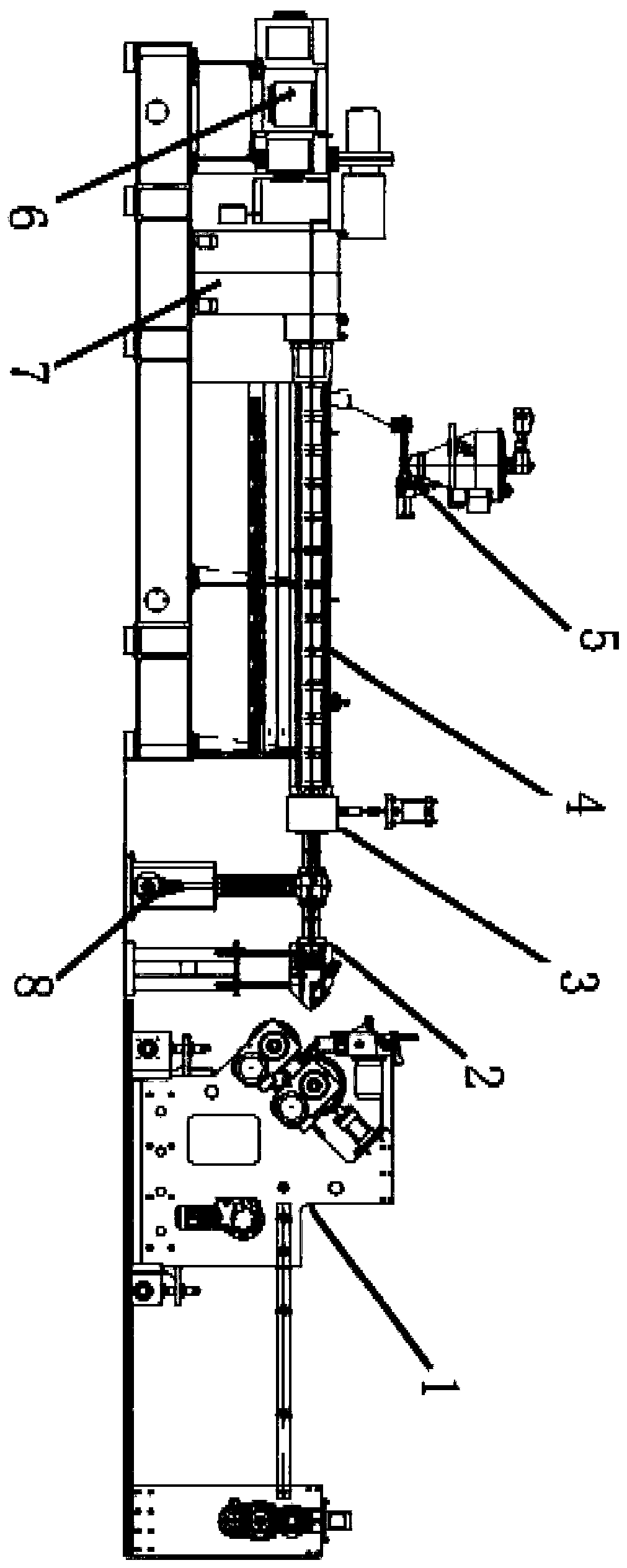

Electrode plate preparation method applied to all-vanadium redox flow battery, electrode plate and preparation device

PendingCN110808385AStrong toughnessStrong air tightnessElectrode rolling/calenderingRegenerative fuel cellsElectrical batterySilane coupling

The invention discloses an electrode plate preparation method applied to an all-vanadium redox flow battery, which comprises the following steps: S01, a first powder raw material and a mixing auxiliary agent are mixed to obtain a premixed raw material, wherein the first powder raw material comprises carbon black powder, graphite powder and carbon nanotube powder, and the mixing auxiliary agent isa powder silane coupling agent; S02, the premixed raw material and the second power raw material are mixed to obtain a composite material, wherein the second powder raw material comprises HDPE powder,PP powder and SEBS powder; S03, the composite material is imported into a blanking device, the composite material is mixed in the screw mixing section of an extruder at a mixing temperature of 200 DEG C to 225 DEG C; and S04, the extruded and mixed composite material is calendered to form a 0.6 mm electrode plate. The invention also discloses an electrode plate and a preparation device for the electrode plate.

Owner:江苏恒安储能科技有限公司

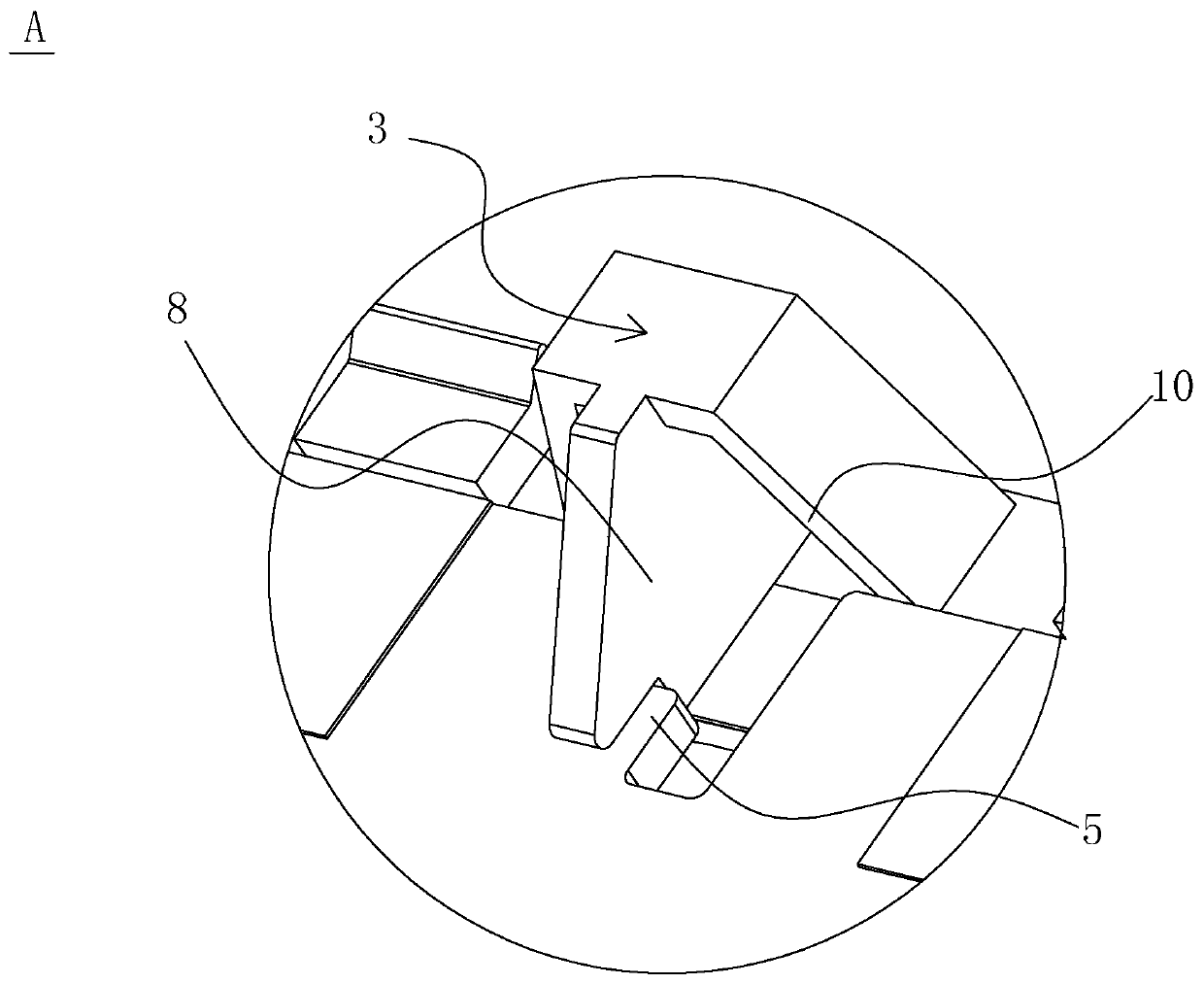

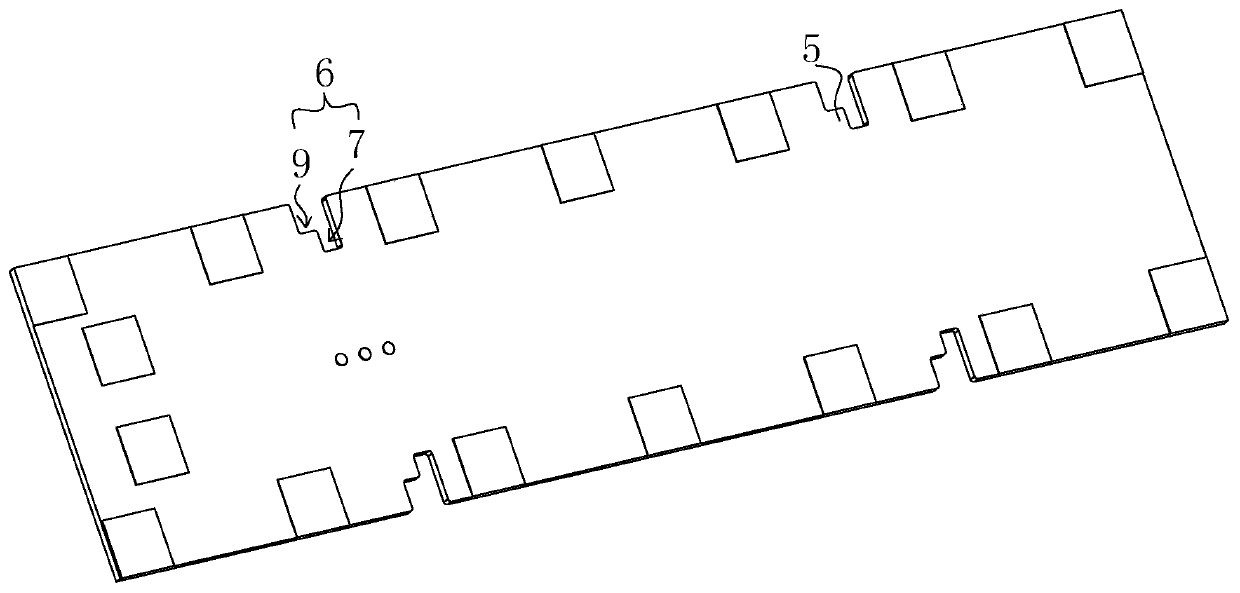

A molding die for an injection molded part with an insert

ActiveCN108582665BThere is no problem of sheddingShort cycle times for injection moldingCoatingsEngineeringInjection molding process

The invention discloses a forming mold of an injection molding part with an insert. The forming mold comprises a first template, a second template and a third template; the first template and the second template are detachably connected; the second template and the third template are slidingly matched and connected; a first forming part is arranged on the first template; the second template is provided with a second forming part and an insert hole; the second forming part and the first forming part correspondingly form an injection forming cavity; the insert hole corresponds to the injection forming cavity; and an ejection rod is arranged on the third template, and corresponds to the insert hole. Through cooperation of the first template, the second template and the third template, the formation of plastic parts with inserts can be realized without using external auxiliary loading equipment, so that the injection molding period is short, and the insert falling problem dose not occur inthe injection molding process.

Owner:GOERTEK INC

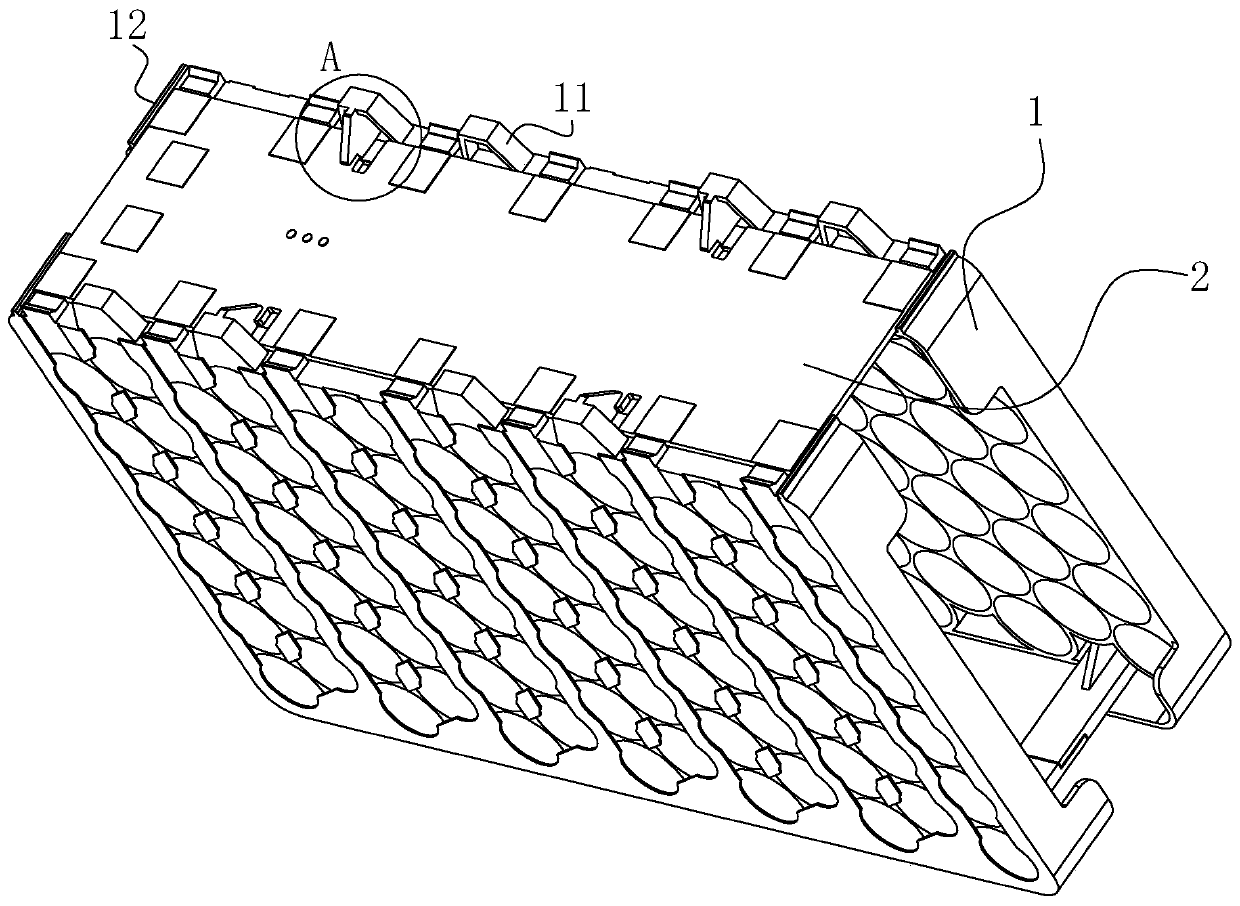

Installation fixing method of lithium battery pack protection plate and device thereof

PendingCN110600647ASimple installation methodLow costCell component detailsLithium electrodeEngineering

The present invention provides an installation fixing method of a lithium battery pack protection plate and a device thereof, and belongs to the field of lithium ion batteries. The invention solves the existing problems such as high cost in fixing a protection plate and a battery pack bracket with screws and glue. The installation fixing method of the lithium battery pack protection plate comprises the following steps: S01, the protection plate is put on the battery pack bracket; S02, the protection plate is pressed and pushed and a fixture block of the protection plate slides into a slot of the battery pack bracket so that the fixture block and the slot are engaged. The invention has the advantages such low cost and firm fixation.

Owner:TIANNENG SAFT ENERGY JOINT CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com