Method for relieving pollution of carbon fiber paper-polyether sulfone compound conductive separation membrane

A technology of carbon fiber paper and composite conduction, which is applied in the field of water treatment, can solve the problems such as the decline of conductivity, and achieve the effects of excellent conductivity, alleviating membrane fouling, and alleviating membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

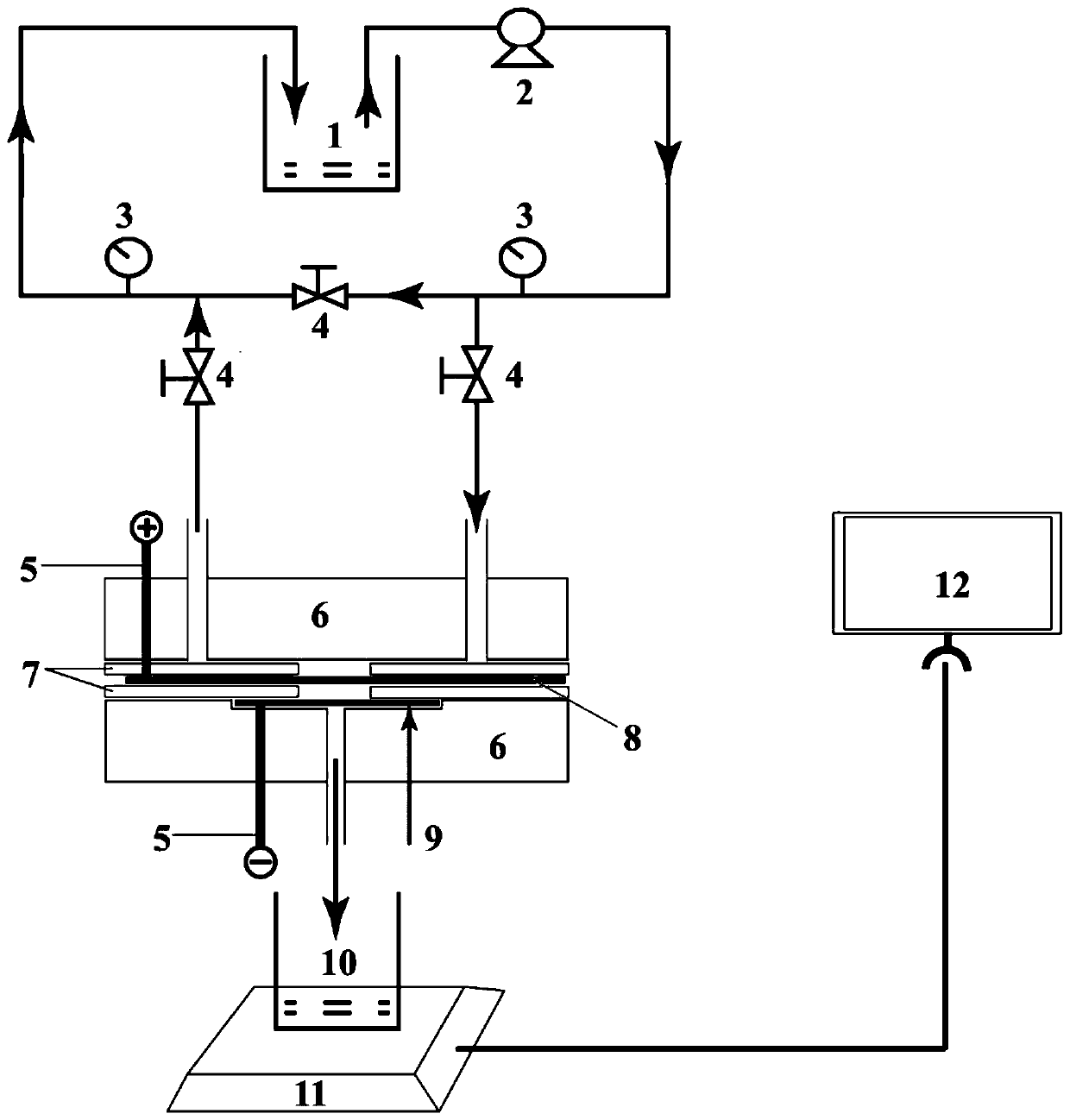

[0035] A method for alleviating carbon fiber paper-polyethersulfone composite conductive separation membrane pollution:

[0036] 1) After installing the carbon fiber paper-polyethersulfone composite conductive separation membrane in the cross-flow filtration device, under the pressure of 0.4Mpa, use deionized water to pre-press the membrane for 120 minutes to obtain a stable filtration membrane water flux; Adjust to the set operating pressure of 0.1Mpa, connect the balance to the computer, and use software to record the quality of the leachate. This measurement can be stopped when the mass change of leachate (referring to deionized water here) per minute is less than 2% (about 30 minutes).

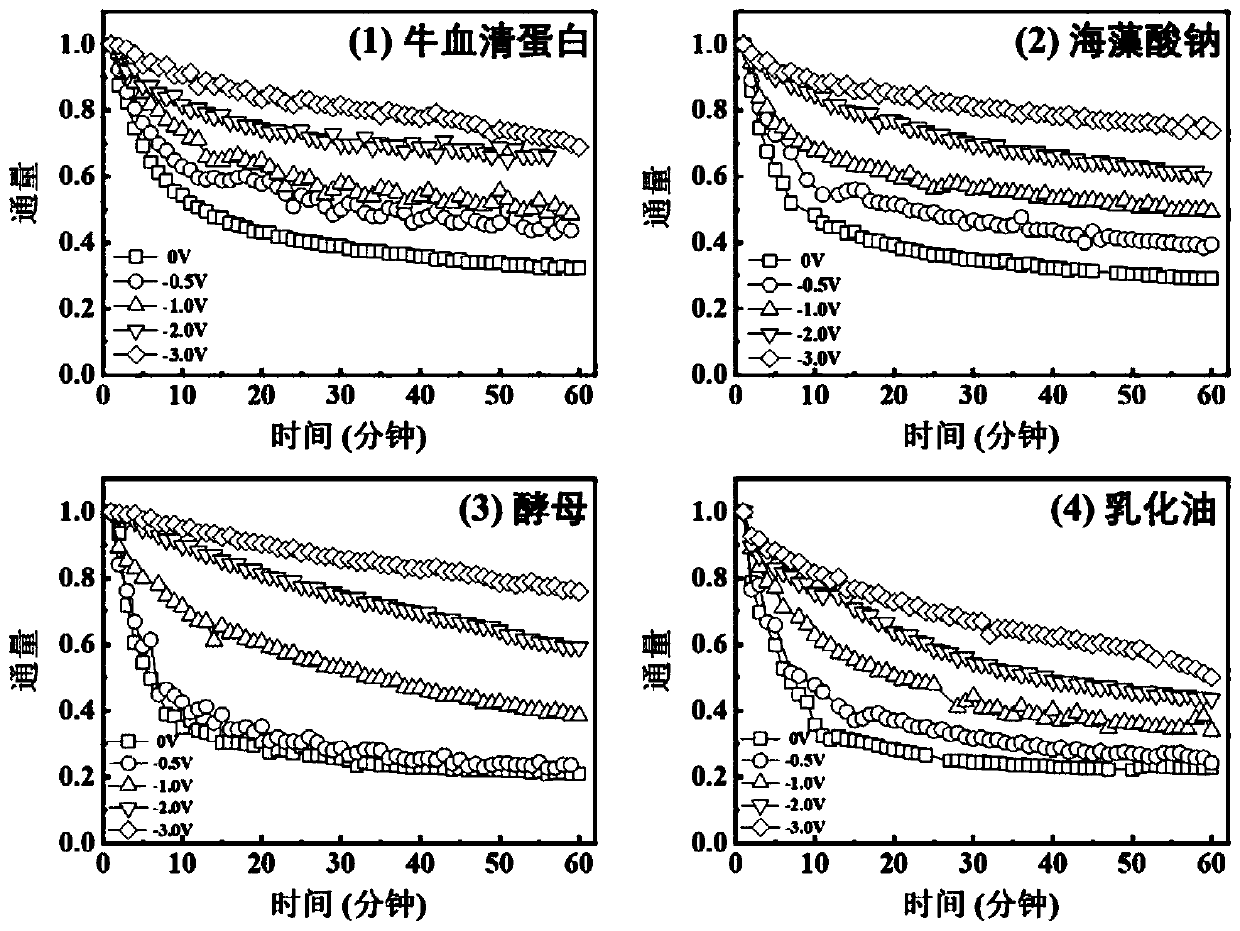

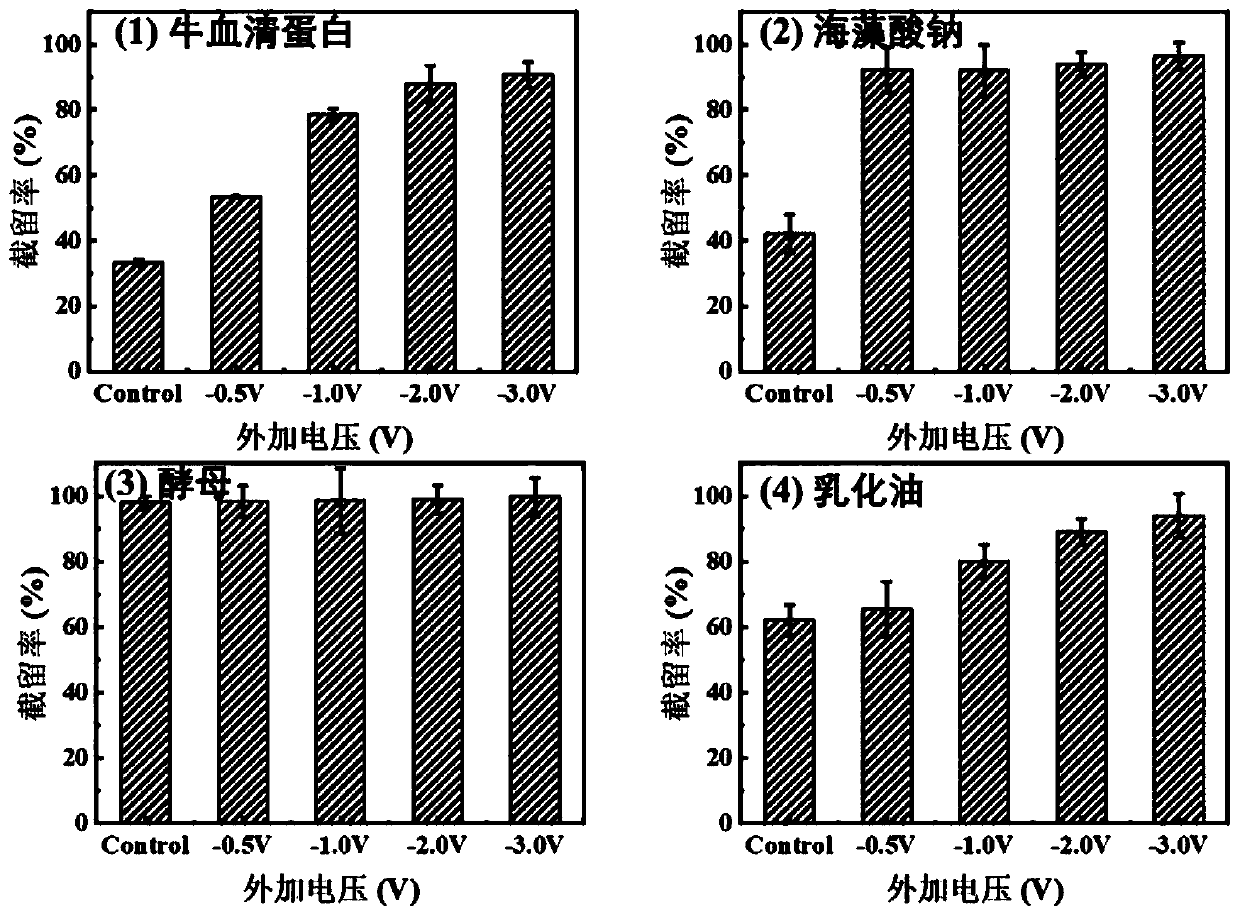

[0037]2) Dissolve 10 milligrams of bovine serum albumin in 10 millimolar sodium sulfate solution, then replace the deionized water with the bovine serum albumin solution, still connect the balance to the computer, and apply voltages of 0V, 0.5V, 1V, At 2V and 3V, use the software to recor...

Embodiment 2

[0040] A method for alleviating carbon fiber paper-polyethersulfone composite conductive separation membrane pollution:

[0041] 1) After installing the carbon fiber paper-polyethersulfone composite conductive separation membrane in the cross-flow filtration device, under the pressure of 0.4Mpa, use deionized water to pre-press the membrane for 120 minutes to obtain a stable filtration membrane water flux; Adjust to the set operating pressure of 0.1Mpa, connect the balance to the computer, and use software to record the quality of the leachate. This measurement can be stopped when the mass change of leachate (referring to deionized water here) per minute is less than 2% (about 30 minutes).

[0042] 2) Dissolve 10 mg of sodium alginate in 10 mmol of sodium sulfate solution, then replace deionized water with sodium alginate solution, still connect the balance to the computer, and apply voltages of 0V, 0.5V, 1V, At 2V and 3V, use the software to record the quality of the leachat...

Embodiment 3

[0045] A method for alleviating carbon fiber paper-polyethersulfone composite conductive separation membrane pollution:

[0046] 1) After installing the carbon fiber paper-polyethersulfone composite conductive separation membrane in the cross-flow filtration device, under the pressure of 0.4Mpa, use deionized water to pre-press the membrane for 120 minutes to obtain a stable filtration membrane water flux; Adjust to the set operating pressure of 0.1Mpa, connect the balance to the computer, and use software to record the quality of the leachate. This measurement can be stopped when the mass change of leachate (referring to deionized water here) per minute is less than 2% (about 30 minutes).

[0047] 2) Dissolve 10 mg of yeast in 10 millimolar sodium sulfate solution, then replace deionized water with yeast solution, still connect the balance to the computer, and apply voltages of 0V, 0.5V, 1V, 2V, and 3V respectively , use the software to record the quality of the leachate, en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com