In-situ preparation method for cadmium telluride/polyvinyl alcohol fluorescent fiber

A fluorescent fiber and in-situ preparation technology, which is applied in chemical instruments and methods, fiber treatment, luminescent materials, etc., can solve the problems of uneven fluorescence, easy aggregation, and poor fluorescent effect of fibers, and achieve good fluorescent effect and long-lasting fluorescent color , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

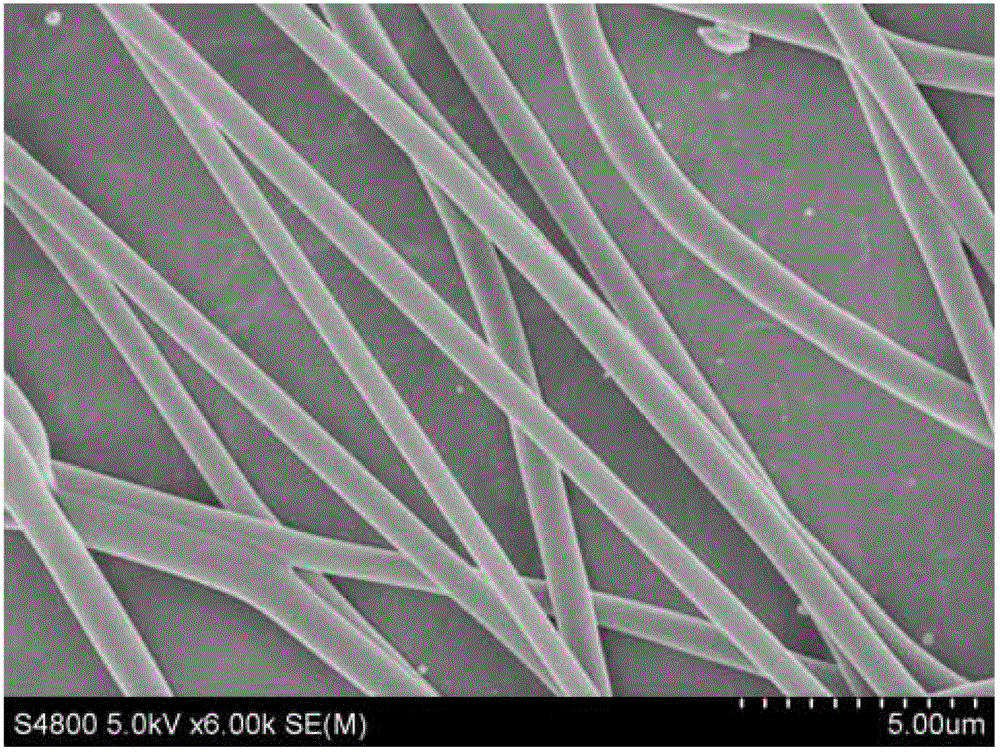

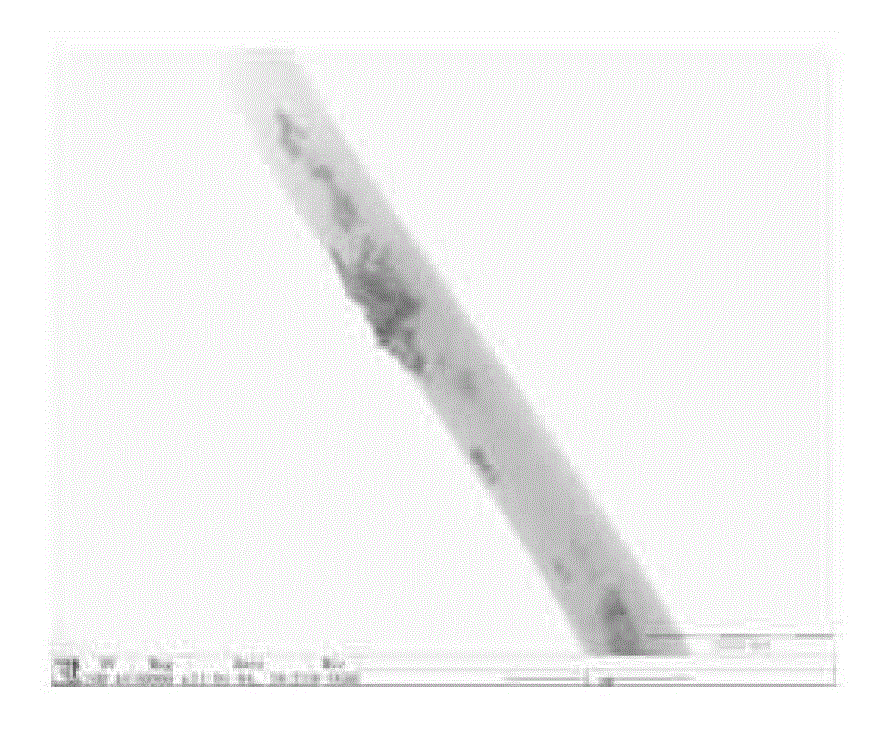

[0011] Specific embodiment 1: The method for preparing cadmium telluride / polyvinyl alcohol fluorescent fiber in situ in this embodiment is carried out according to the following steps:

[0012] 1. Mix 1-2g of sodium borohydride, 2-3g of tellurium powder and 20-40mL of deionized water, stir until dissolved, and react in an ice-water bath at 0-4°C for 10-12 hours to obtain a sodium tellurium hydride solution;

[0013] 2. Add 90-110mL polyvinyl alcohol solution with a mass concentration of 5-7% into the three-necked bottle, and feed nitrogen gas for 30 minutes while stirring, then add 91-92mg CdCl 2 2.5H 2 O and 61-62 μL mercaptoacetic acid, while stirring, add dropwise 0.5mol / L sodium hydroxide solution until the pH value of the mixed solution in the there-necked flask is 10-11, then add 0.1mL of the sodium telluride hydride solution prepared in step 1, and Under the atmosphere, heat up to 100°C and reflux for 0.5 to 5 hours to obtain a cadmium telluride / polyvinyl alcohol spinn...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, 1.6 g of sodium borohydride, 2.5 g of tellurium powder and 30 mL of deionized water are mixed. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: In step 2, 100 mL of polyvinyl alcohol solution with a mass concentration of 6% is added to the three-necked bottle. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com