Double-winding bearingless magnetic flux switching permanent magnet motor

A technology of flux switching and permanent magnet motors, applied in the shape/style/structure of winding conductors, magnetic circuits, electric components, etc., can solve the problems of increasing motor loss, reducing winding utilization, motor power density, and reducing efficiency. Achieve the effects of improving load capacity, avoiding high temperature demagnetization, and improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

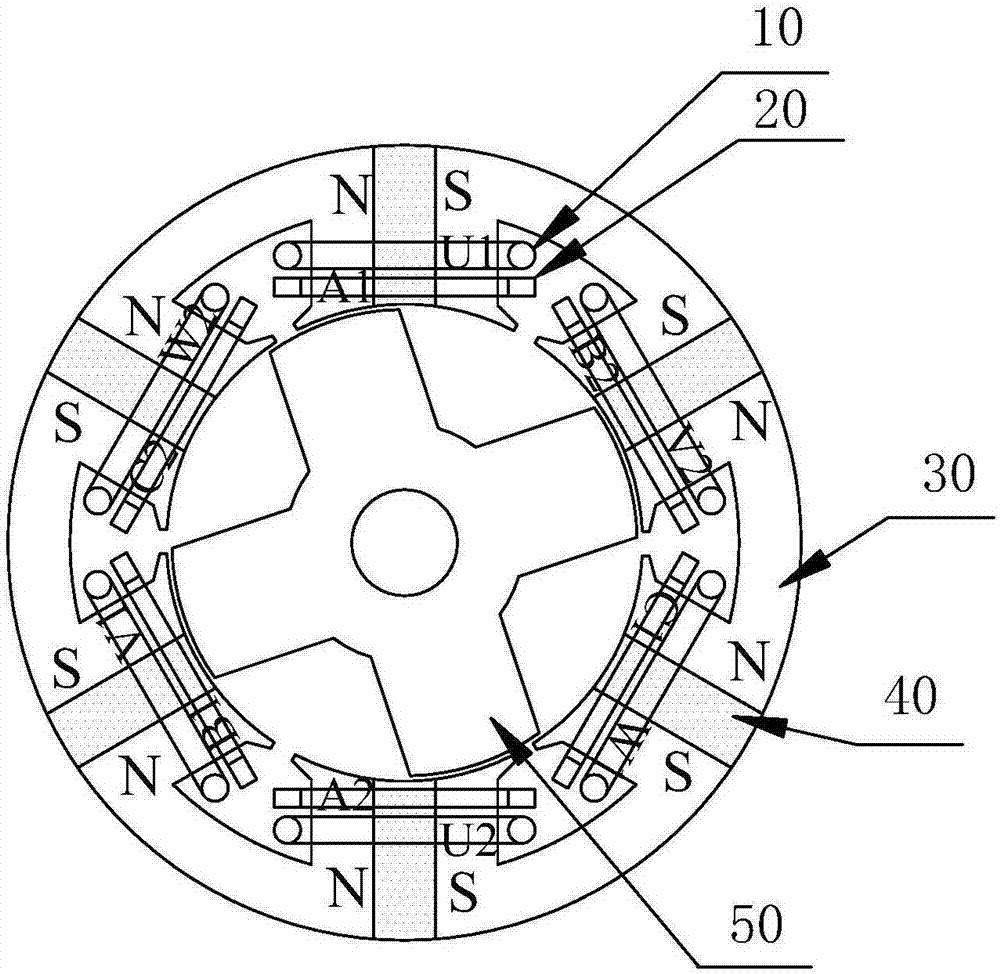

[0031] The design idea of the present invention is: by integrating the excellent characteristics of the magnetic flux switching permanent magnet motor and the magnetic bearing motor, the basic magnetic field of the air gap can be established by using the permanent magnet, which can generate a higher air gap flux density, and the air gap flux can be used To generate torque and provide suspension force, avoid the need for the main winding current to establish the air gap bias magnetic field, reduce the main winding current, reduce the loss of the motor, improve the overall efficiency and power density of the motor, and reduce the temperature rise , Improve the stability and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com