Patents

Literature

136results about How to "No wrinkling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

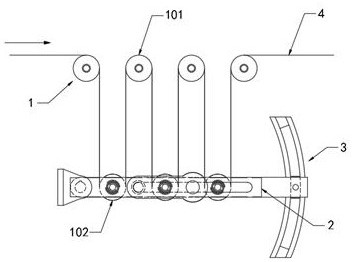

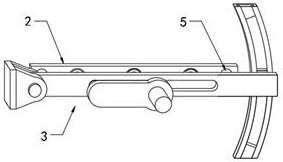

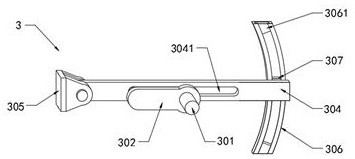

Film sticking machine capable of automatically tearing off release paper

InactiveCN102241180ANo wrinklingLamination ancillary operationsLaminationMechanical engineeringEngineering

The invention discloses a film sticking machine capable of automatically tearing off release paper. According to the film sticking machine, an absorbing device is used for adsorbing an adhesive film and feeding the adhesive film to a platform; the adhesive film is adsorbed and positioned on the platform through the suction hole on the platform; a pusher is used for upwards pushing and supporting a push piece and pushing and supporting an end corner of the release paper stuck above the adhesive film to tilt; and a clamping jaw of a clamping device is used for clamping the tilt part of the end corner to move along a track at a certain horizontal height and tearing off the release paper in a diagonal direction, thereby subsequent film sticking operation can be carried out. Therefore, one end corner of the release paper is lifted by a corner lifting device and a mode of tearing off the release paper by using the clamping jaw at a certain horizontal equal height is used, thereby the surface of the adhesive film is prevented from being touched and the condition that the adhesive film is crinkled is avoided.

Owner:SUNFUIN TECH

Low-alloy high-strength steel welding process

InactiveCN101337298ASolving the Elimination of Welding Residual StressHigh tensile strengthArc welding apparatusWelding/cutting media/materialsWelding residual stressAlloy

The invention discloses a technological method for welding low-alloy high-strength steel, which comprises the following steps: a divided edge is formed, a welding area is polished and cleaned, and the strength of welding material is equivalent to that of steel to be welded; Ar+CO2 mixed gas protective welding is adopted, preheating is performed before welding, and the welding speed is 250-300mm / min; a 800MPa solid welding wire is adopted to perform multilayer multirun welding; the interlayer temperature is kept at 150 DEG C plus or minus 20 DEG C during the welding process, a preheating spray gun is used from time to time for temperature compensation, the welding line energy is 16-18KJ / cm, low temperature aging is performed to the whole after welding, and the temperature is 300-400 DEG C. The welding technological method prevents welding cracks from being generated, eliminates residual stress generated during welding large-sized structural members, and serves the purpose that the tensile strength of weld joins equals the tensile strength of parent metal.

Owner:四川航天神坤装备有限公司

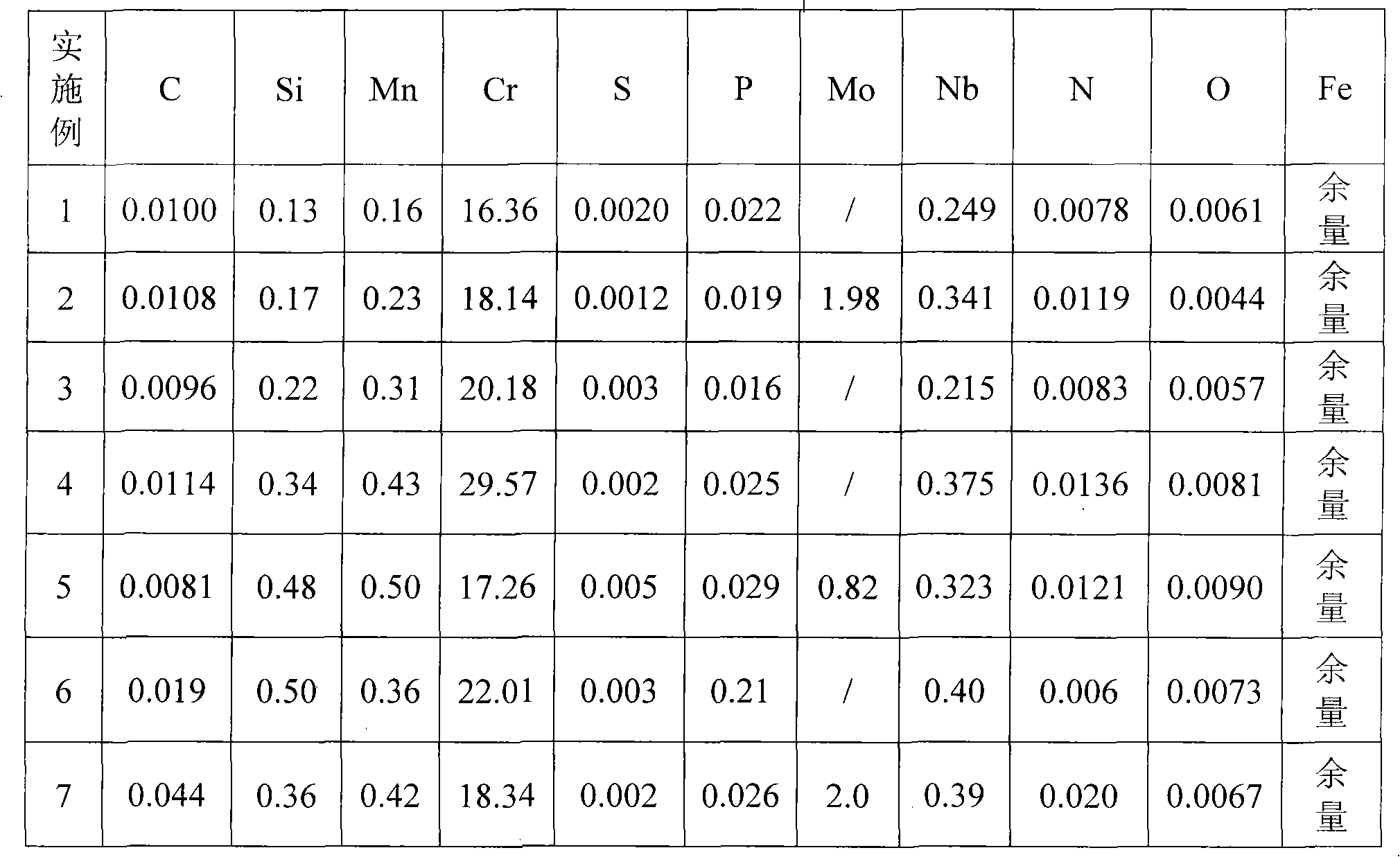

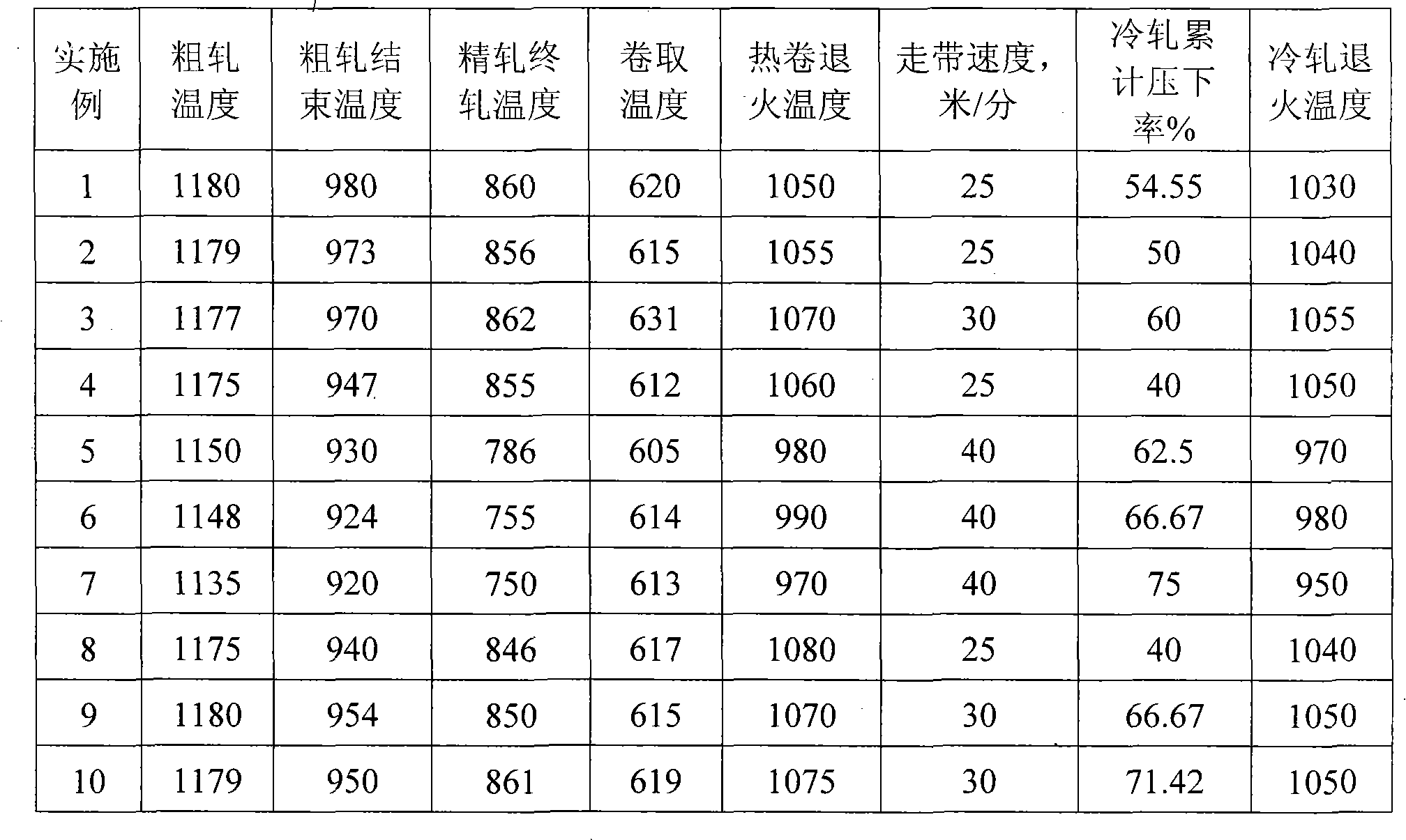

Ferritic stainless steel with good wrinkle resistance and production method thereof

InactiveCN101845595AGood wrinkle effectProduction process is feasibleWrinkle skinTransition temperature

The invention relates to ferritic stainless steel with good wrinkle resistance and a production method thereof. The ferritic stainless steel comprises the following components by weight percentage: less than or equal to 0.02 percent of C, less than or equal to 0.02 percent of N, 0.10-0.50 percent of Si, 0.10-0.50 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.01 percent of S, 16-30 percent of Cr, less than or equal to 1.00 percent of Ni, 0.15-0.40 percent of Nb, less than or equal to 16 percent of Nb / (C+N), less than or equal to 0.010 percent of O, less than or equal to 1.00 percent of Cu and the rest being Fe and inevitable impurity elements. Since the stabilization element Ti which can damage the surface quality of continuous casting and increase the brittle transition temperature is not added, and only the stabilization element Nb is added, the invention can reduce the quantity of casting blank repair and the strip breakage risk, improve the surface quality and overall performance, eliminate the wrinkle of the surface of the ferriticstainless steel cold-rolled plate with a medium and high Cr content, reduce the wear and repair loss during the production process, and decrease the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

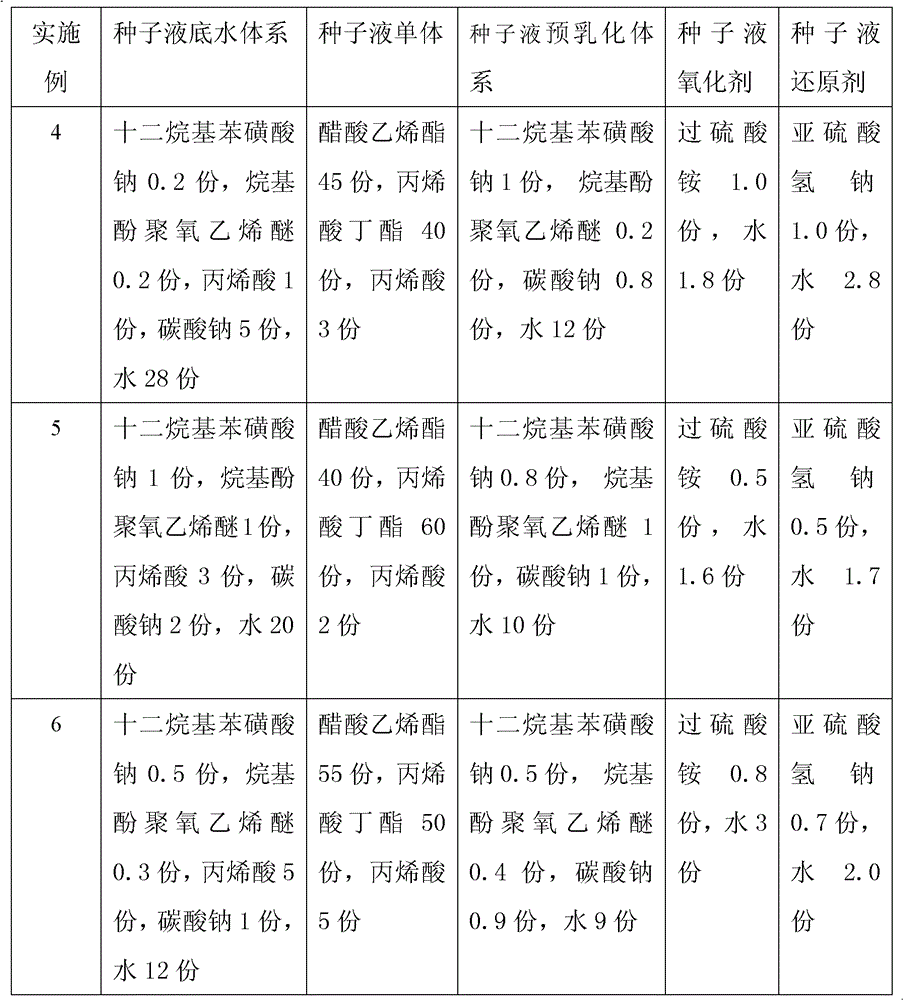

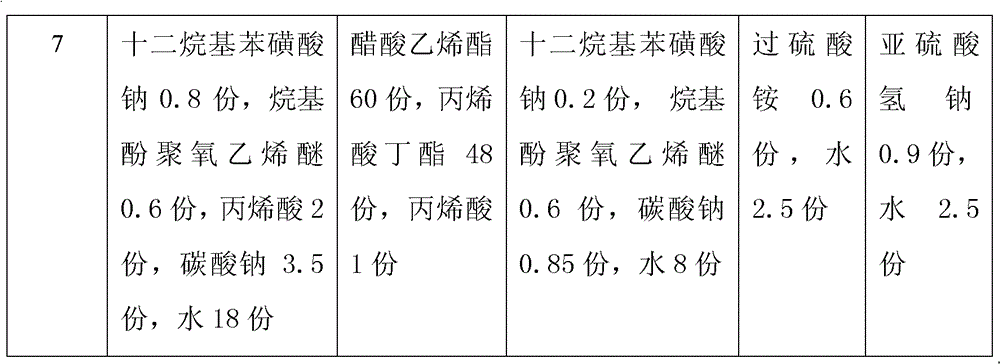

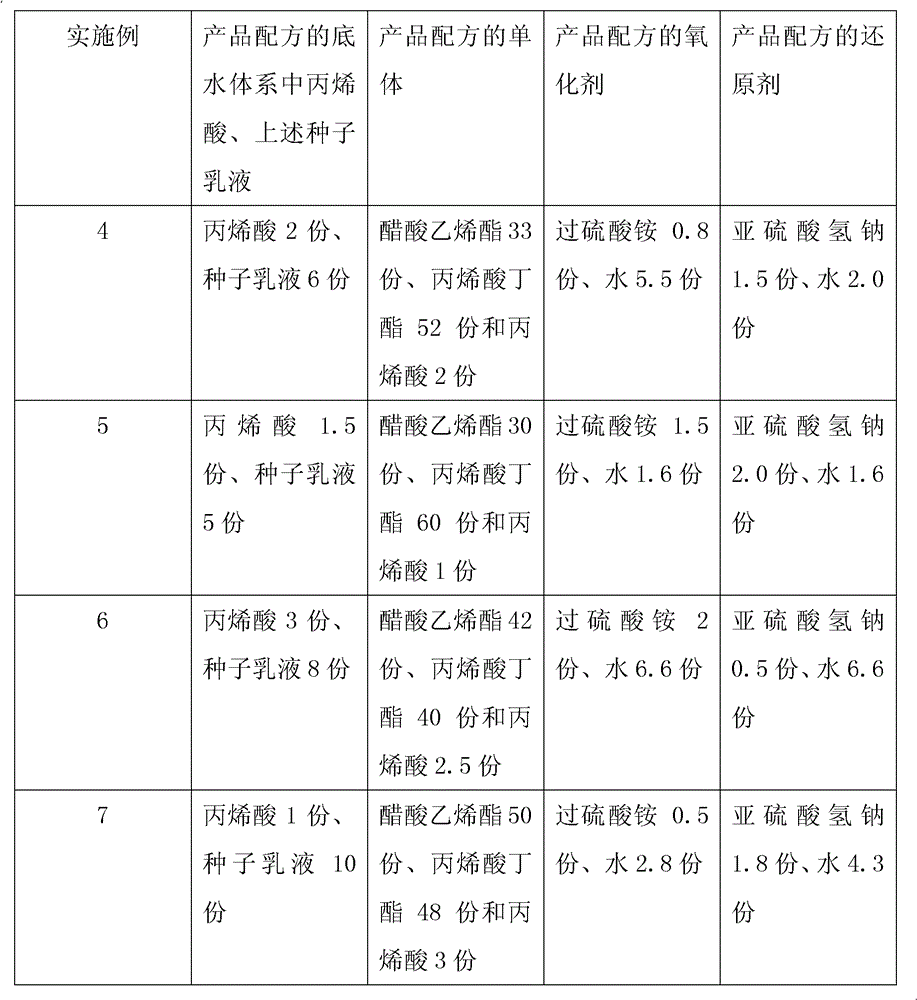

Vinyl acetate-acrylate copolymer emulsion, its synthesis method and application

ActiveCN103059211ALow coating viscosityHigh bonding strengthMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesAdhesiveSynthesis methods

The invention relates to a vinyl acetate-acrylate copolymer emulsion, which is prepared by adopting OP-10, SDBS, SVS, water, acrylic acid and a seed emulsion as the bottom water system, taking VAc, BA and AA as the monomer, employing ammonium persulfate as the oxidant, and using sodium bisulfite as the reducing agent. Specifically, the seed emulsion in the bottom water system is prepared by using SDBS, OP-10, AA, sodium carbonate and water as the base solution, adopting VAc, BA and AA as the monomer, employing SDBS, OP-10, sodium carbonate and water as the pre-emulsification system, taking ammonium persulfate as the oxidant, and adopting sodium bisulfite as the reducing agent. The emulsion provided in the invention has a solid content of 40%-45%, viscosity (in terms of a 4-cup application amount) of 20S-26S, bonding peel strength (N / 2.5cm) of 1.4-2.5, a surface tension force of 32-37 dyne, and a film contact angle of 25-29 degrees, thus being particularly suitable for application in dry paper-plastic or plastic-plastic composite adhesives. The preparation method of the vinyl acetate-acrylate copolymer emulsion has the characteristics of mild reaction conditions and safety reaction system, thus being conducive to factory mass production.

Owner:CHINA PETROCHEMICAL CORP +2

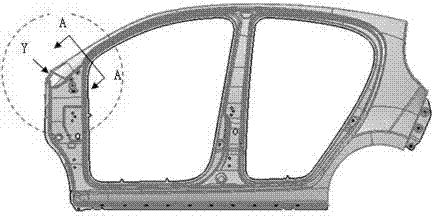

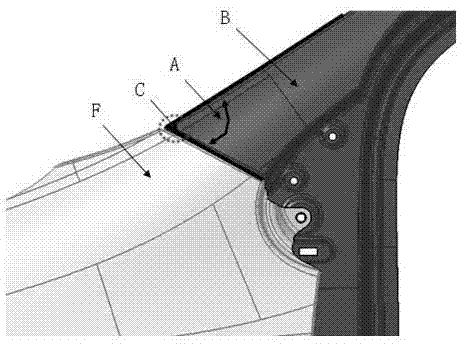

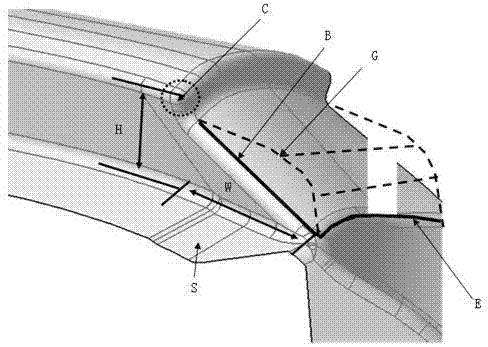

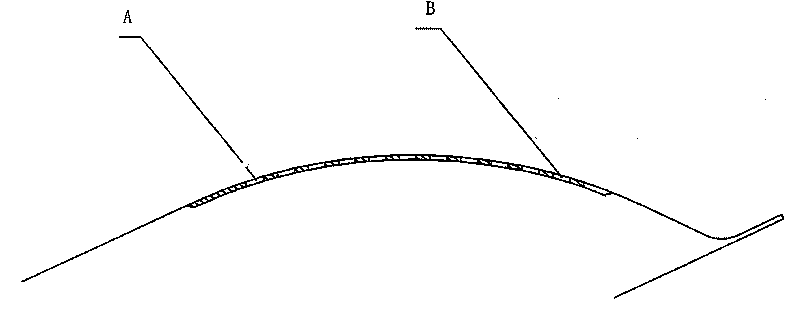

Structure for body-side outer panel and fender piece area of automobile

The invention relates to a structure for a body-side outer panel and a fender piece area of an automobile. The structure comprises the body-side outer panel and the fender piece area; a tail end of a body-side A pillar is closed; the structure is characterized in that a distance (H) between a body-side peak of a fender piece and a welding edge is in contrast with the distance (W) between a line of the fender piece and the tail end of the body-side A pillar; the distance (H) between the body-side peak of the fender piece and the welding edge is less than the distance (W) between the line of the fender piece and the tail end of the body-side A pillar; and transition (G), namely a profile of which is within an area between the line of the fender piece and the tail end of the body-side A pillar, is smooth. In the structure, the distance between the body-side peak of the fender piece and the welding edge and the distance between the line of the fender piece and the tail end of the body-side A pillar are controlled, so that the transition, namely the profile of which is within the area between the line of the fender piece and the tail end of the body-side A pillar, is smooth, thereby being capable avoiding the phenomena of folded materials and corrugation on the body-side welding edge.

Owner:CHERY AUTOMOBILE CO LTD

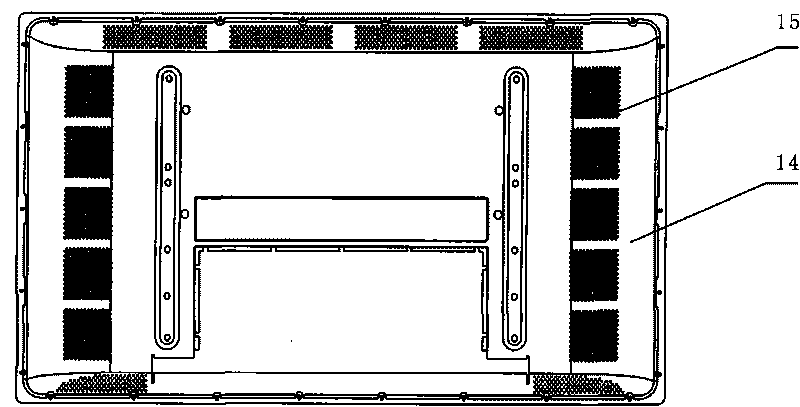

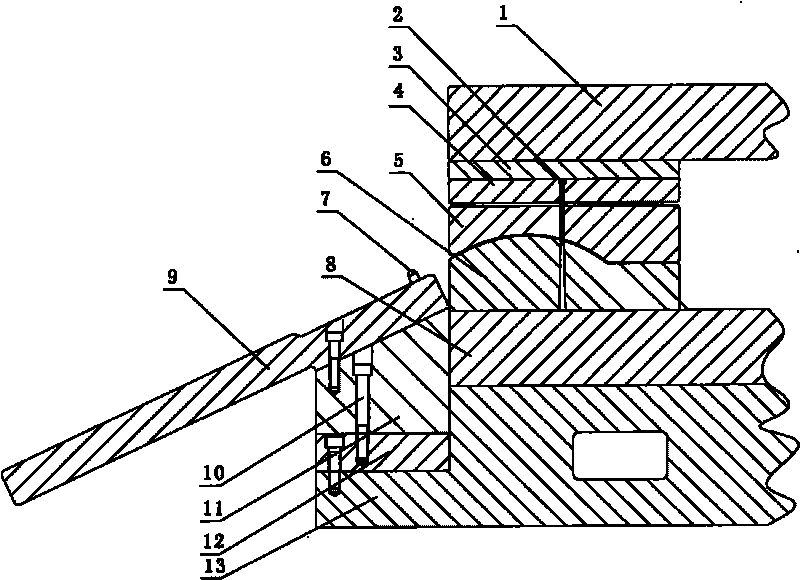

Method for punching arc-shaped surface or inclined surface of television rear shell and punching die

InactiveCN101716624AImprove clarityNo wrinklingPerforating toolsDomestic articlesPunchingEngineering

The invention discloses a method for punching an arc-shaped surface or an inclined surface of a television rear shell, comprising the processes of punching, stretching, and the like and comprising the steps of first performing stretch forming on blank of the television rear shell; and then, punching the arc-shaped surface or the inclined surface of the television rear shell. The invention also discloses a punching die of the arc-shaped surface or the inclined surface of the television rear shell, comprising an upper die and a lower die. Punching heads which correspond to holes in the quantity and the positions of holes, which are required for punching on the arc-shaped surface or the inclined surface of the television rear shell, are installed on the upper die; and the lower die fixes the television rear shell and contains the punching heads which pass through the television rear shell. With the punching method for first stretching and then punching and the punching die, the wrinkling of the punched television rear shell can be eliminated, and the disadvantages of oval irregular shape stretched from round heat radiating holes, poor appearance and heat radiating effect, high defective rate, and the like can be overcome.

Owner:QINGDAO HAILIDA STAMPING PARTS +1

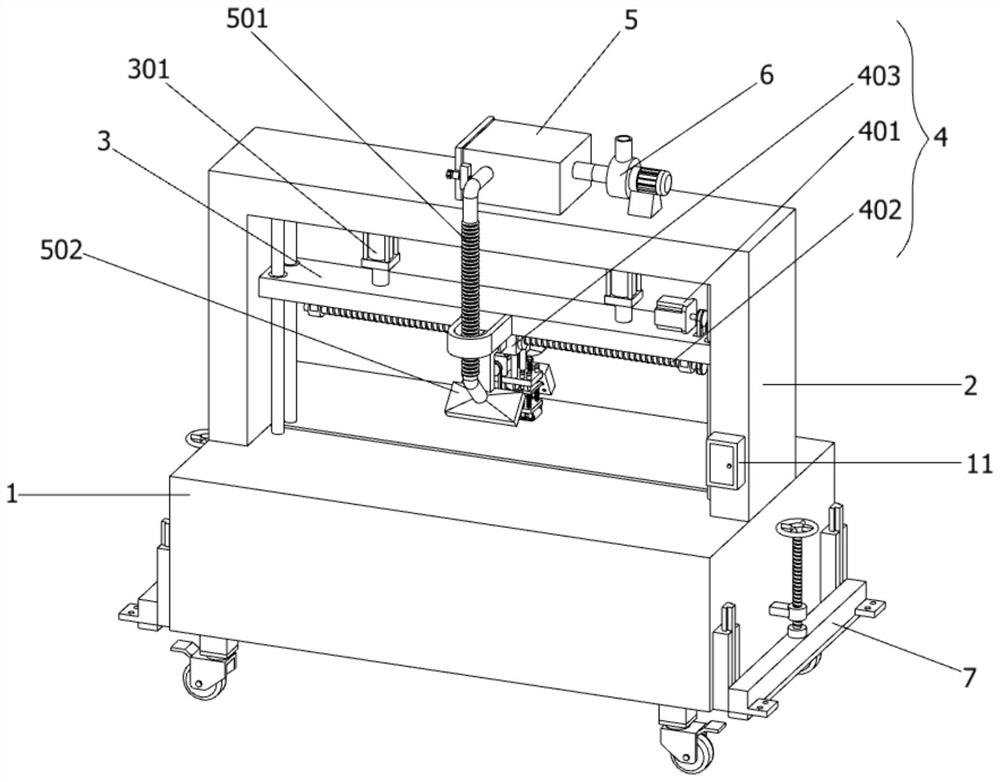

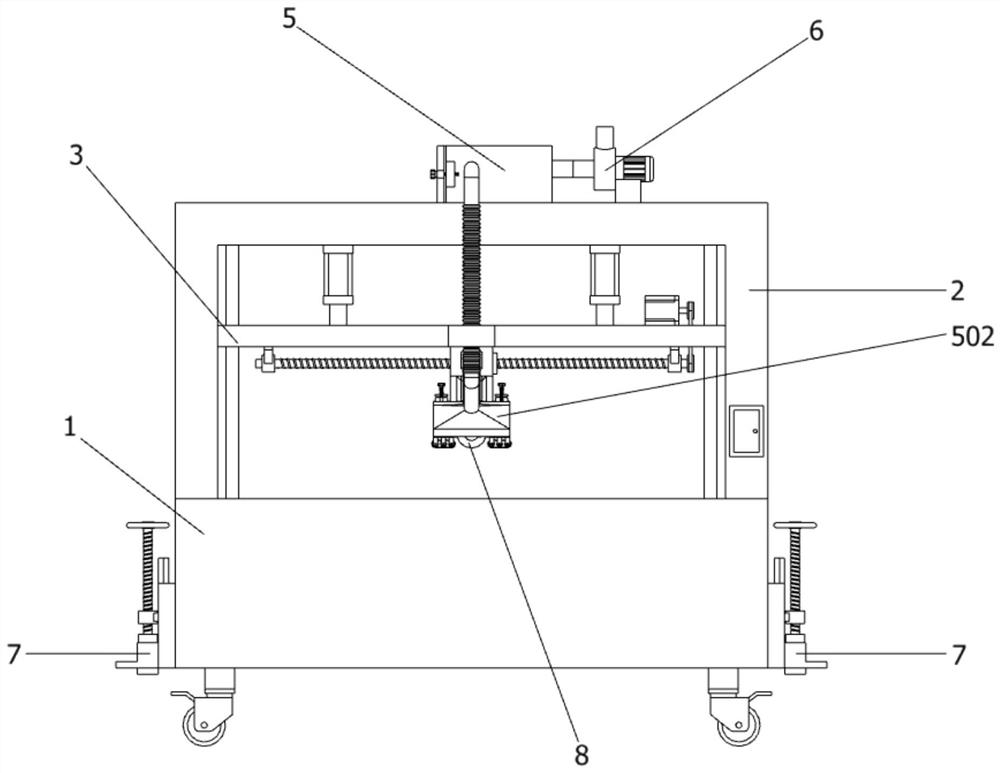

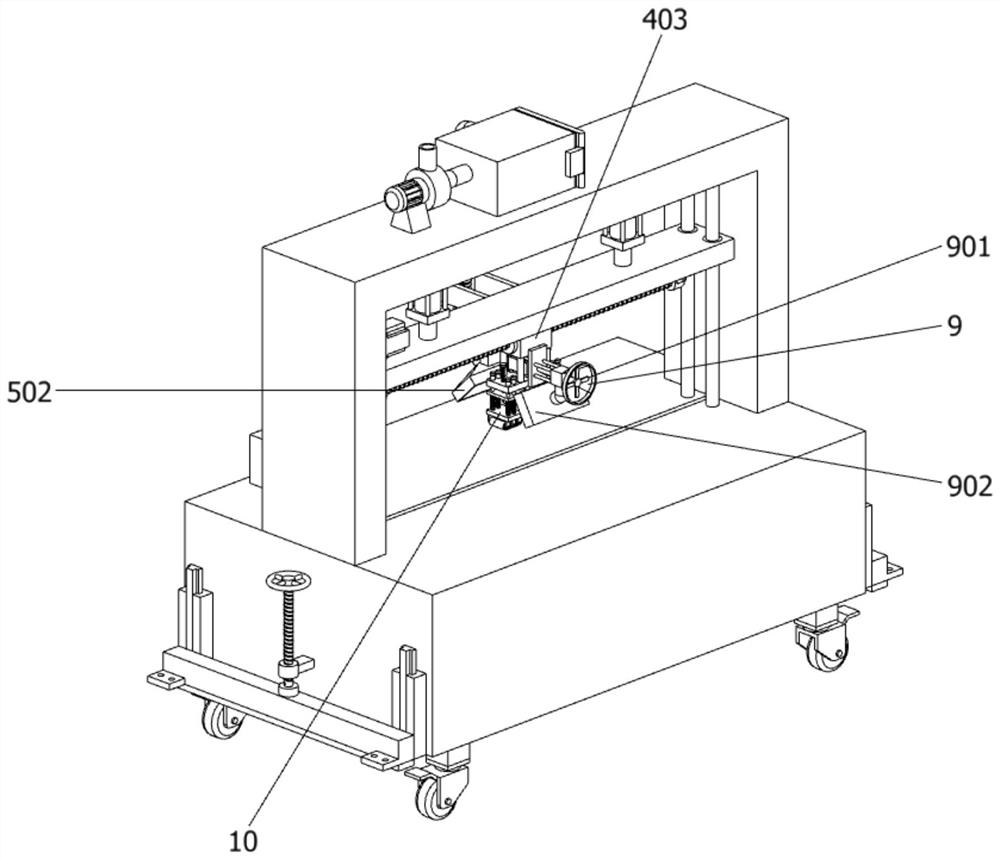

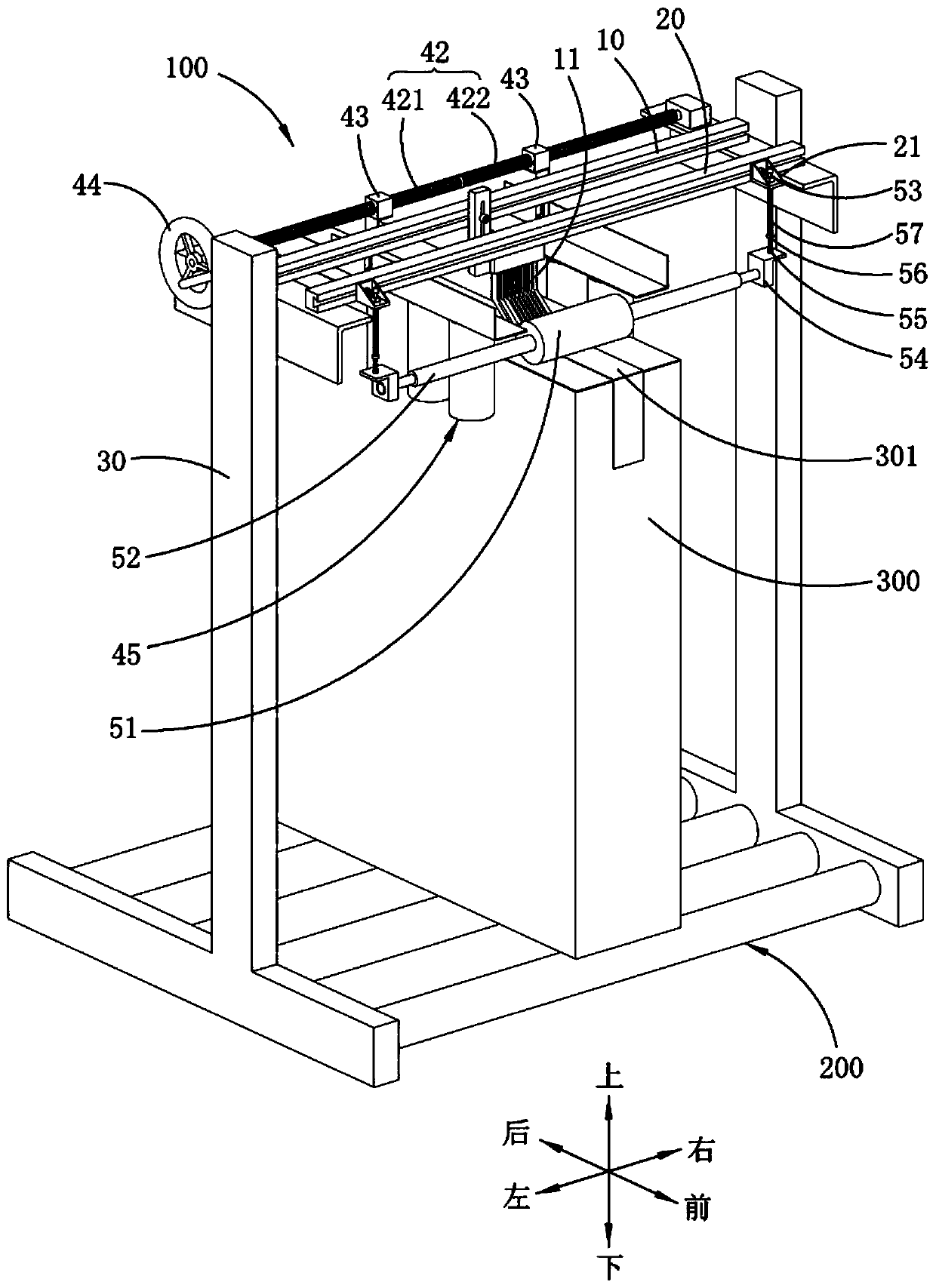

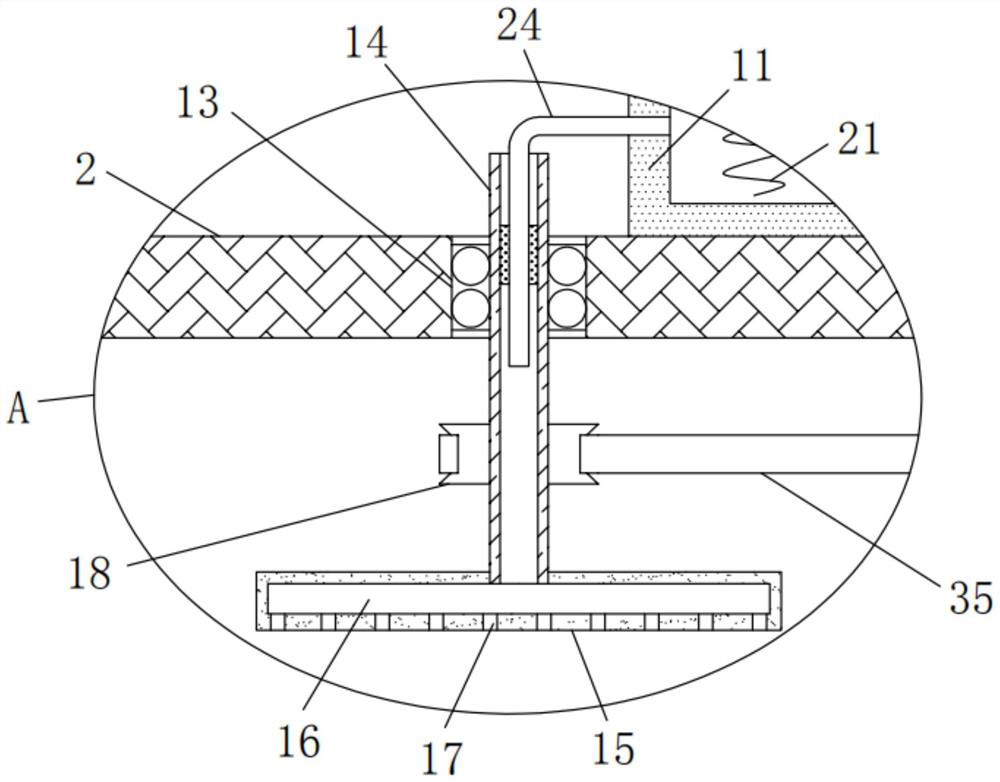

Intelligent new textile material cutting device for spinning

The invention provides an intelligent new textile material cutting device for spinning, belongs to the technical field of textile cutting devices, and aims to solve the problem that when a new textilematerial is cut by the cutting device, the middle of the new textile material is still wrinkled during cutting, so that the cutting quality of the cutting device during cutting is reduced. The cutting device comprises a base; a C-shaped support is fixedly connected to the middle of the upper end face of the base; and a lifting mechanism is arranged at the top of the inner side of the C-shaped support. Through the arrangement of pressing mechanisms, in the cutting process, when a circular cutting blade makes contact with the new textile material, and pressing belts on the two pressing mechanisms make close contact with the upper surface of the new textile material, so that a cutting area of the new textile material is effectively pressed; and when the circular cutting blade moves leftwardsand rightwards, the pressing belts can be driven on the peripheral surfaces of pressing rollers, so that the new textile material cannot be wrinkled during cutting, and the cutting quality of the cutting device during cutting is improved.

Owner:宿州市悦然纺织有限公司

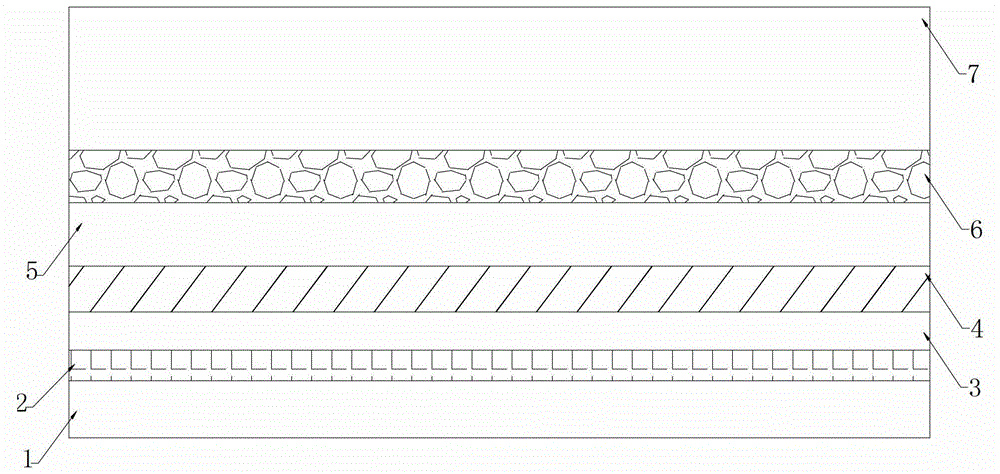

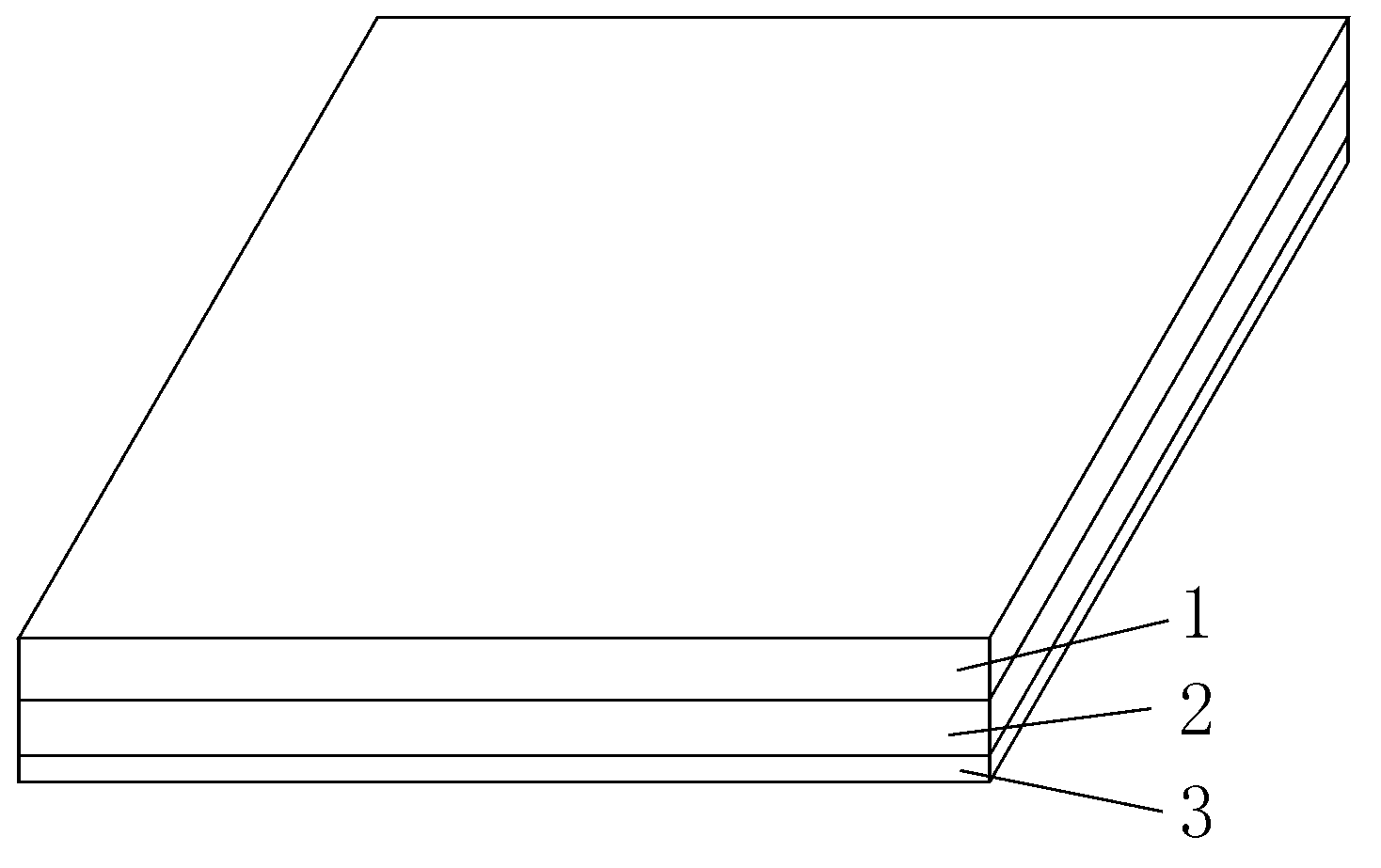

Soft laser self-adhesive label film and preparation method thereof

ActiveCN102941707AGood flexibilityGood followabilityStampsLamination ancillary operationsPolyolefinPolymer science

The invention discloses a soft laser self-adhesive label film and a preparation method thereof, successively comprising a polyolefin film layer, a polyurethane glue layer, an aluminium coated layer, an imaging layer, a peeling layer, a pressure-sensitive adhesive layer, and a PET silicone paper layer from top to bottom, wherein the longitudinal softness of the polyolefin film layer is 80-110mN, and the horizontal softness of the polyolefin film layer is 60-90 mN. The invention further provides a preparation method of the soft laser self-adhesive label film. Compared with the prior art, the soft laser self-adhesive label film disclosed herein has good softness and high following performance, and is suitable for flexible tubes or bottle bodies that can be extruded to deform.

Owner:GUANGZHOU JINWANZHENG PRINTING MATERIAL CO LTD

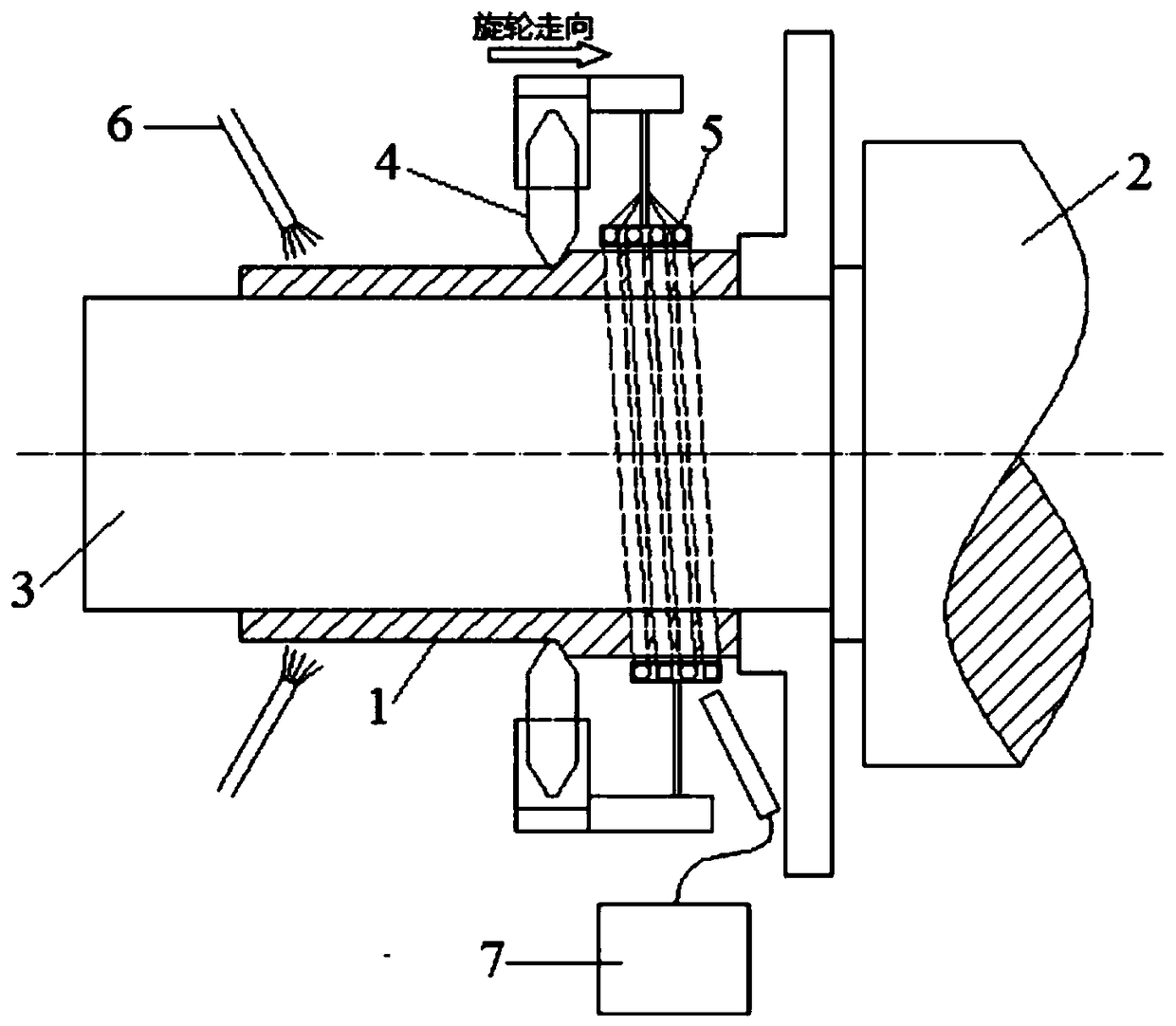

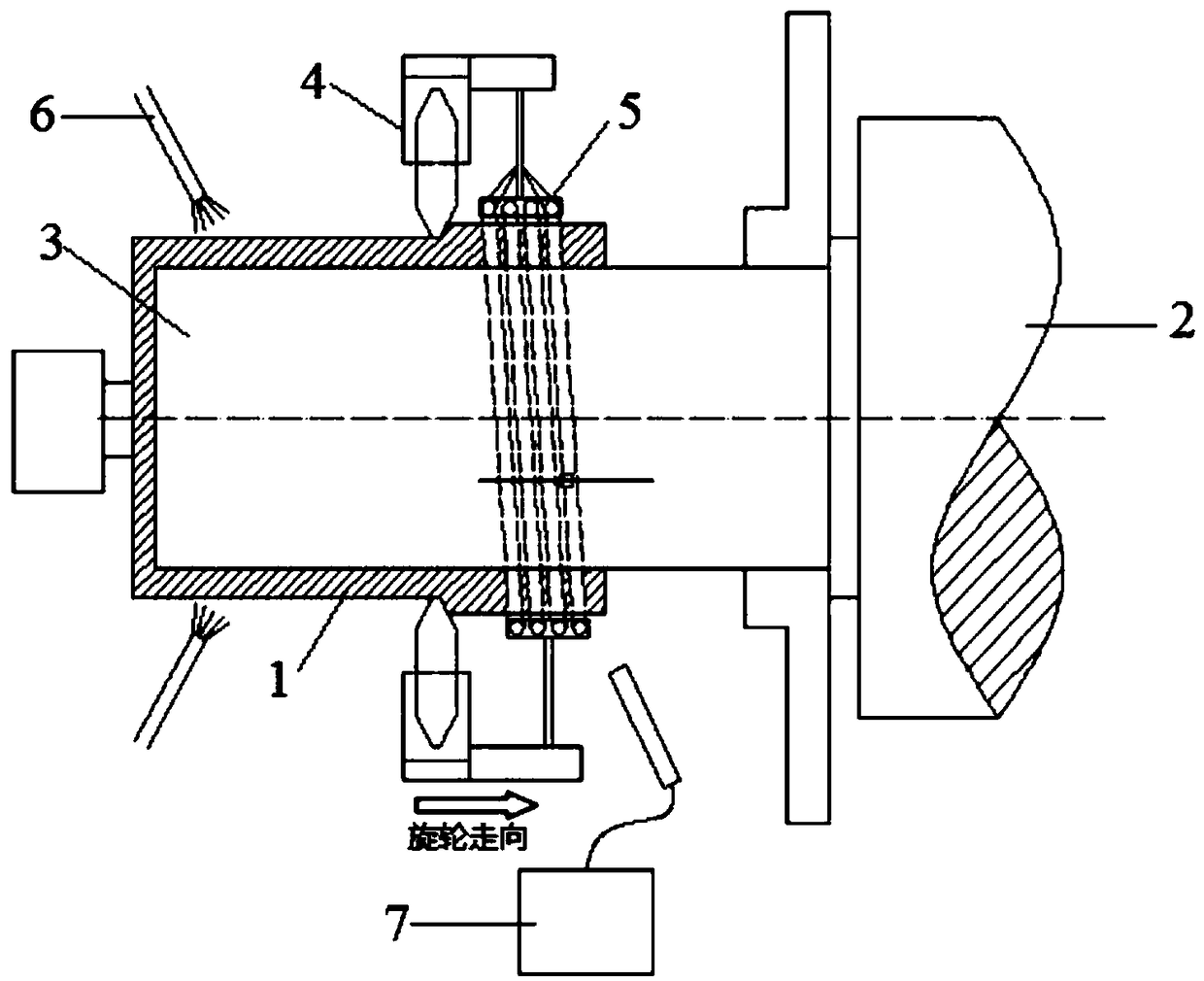

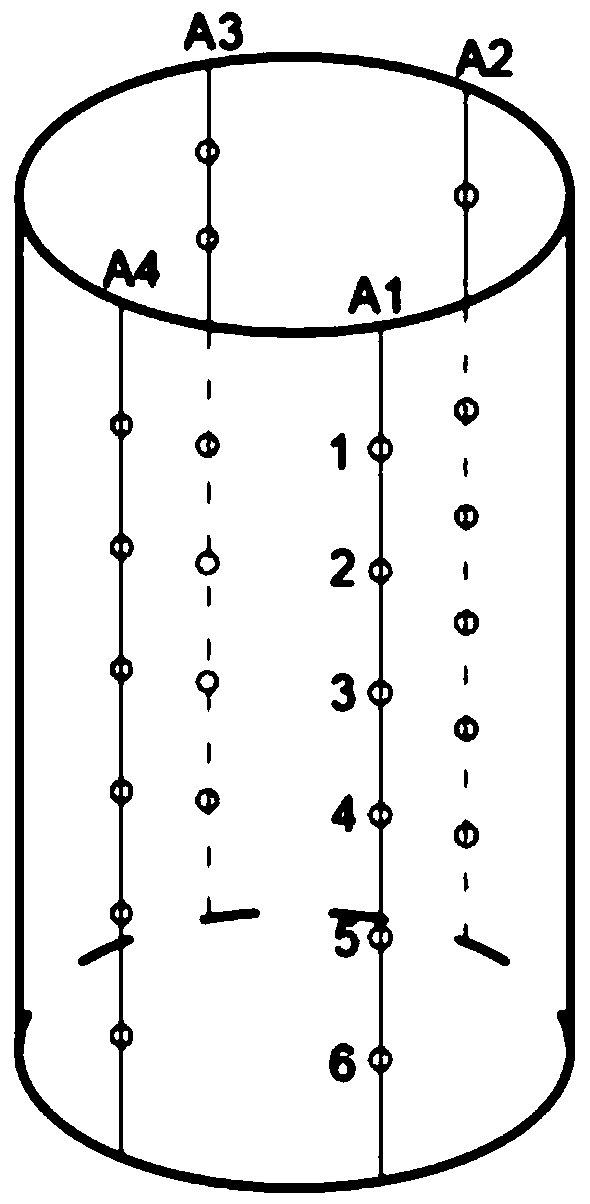

Titanium-based alloy material spinning forming method based on composite heating

ActiveCN109108139AEvenly heatedImproved deformation coordinationShaping toolsTemperature controlInstability

The invention provides a titanium-based alloy material spinning forming method based on composite heating. The titanium-based alloy material spinning forming method comprises the steps that firstly, ablank, a central spindle and a spinning roller are preheated with a flame gun; and secondly, the blank is heated to the spinning temperature with a follow-up induction heating coil, the temperature is monitored with an infrared thermal imager in the spinning process, and heating and heat preserving are conducted on the blank in a spun area behind the spinning roller with the flame gun. Accordingto the titanium-based alloy material spinning forming method based on composite heating, two heating modes including front-end electromagnetic induction heat source heating and back-end flame source heat compensating are combined, the temperature is monitored with the infrared thermal imager, and then online heating and precise temperature controlling in the spinning forming process are achieved.Embodiment results show that when spinning forming is conducted on a titanium-based alloy through the method, an obtained spun part is uniform in wall thickness, has no cracking phenomenon, is high inquality and can not generate defects such as instability wrinkling in the spinning process.

Owner:HARBIN INST OF TECH

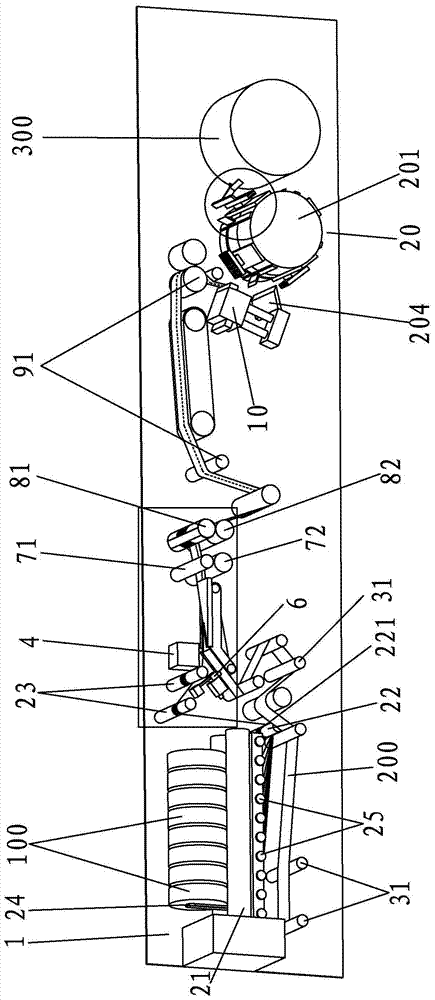

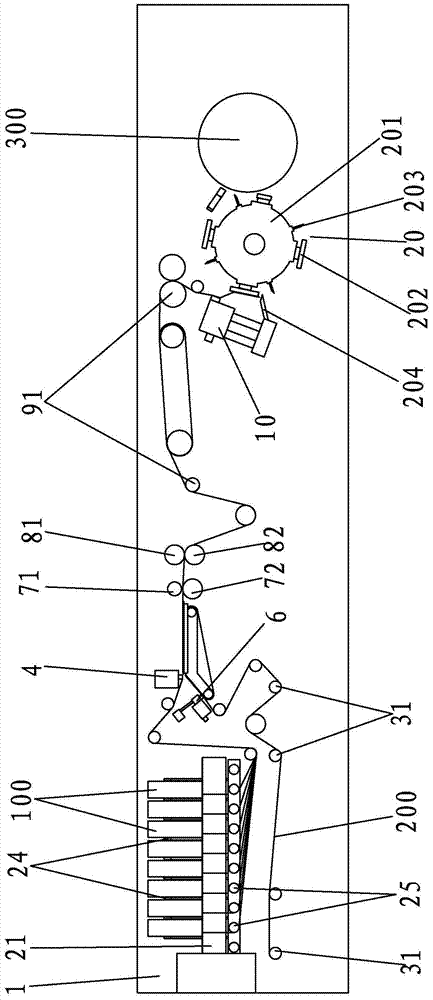

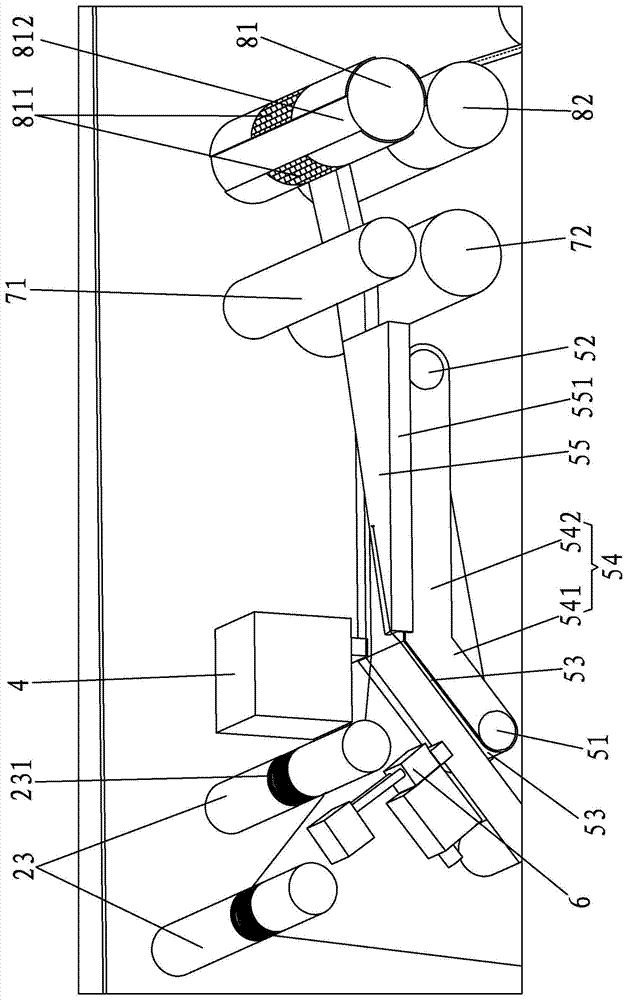

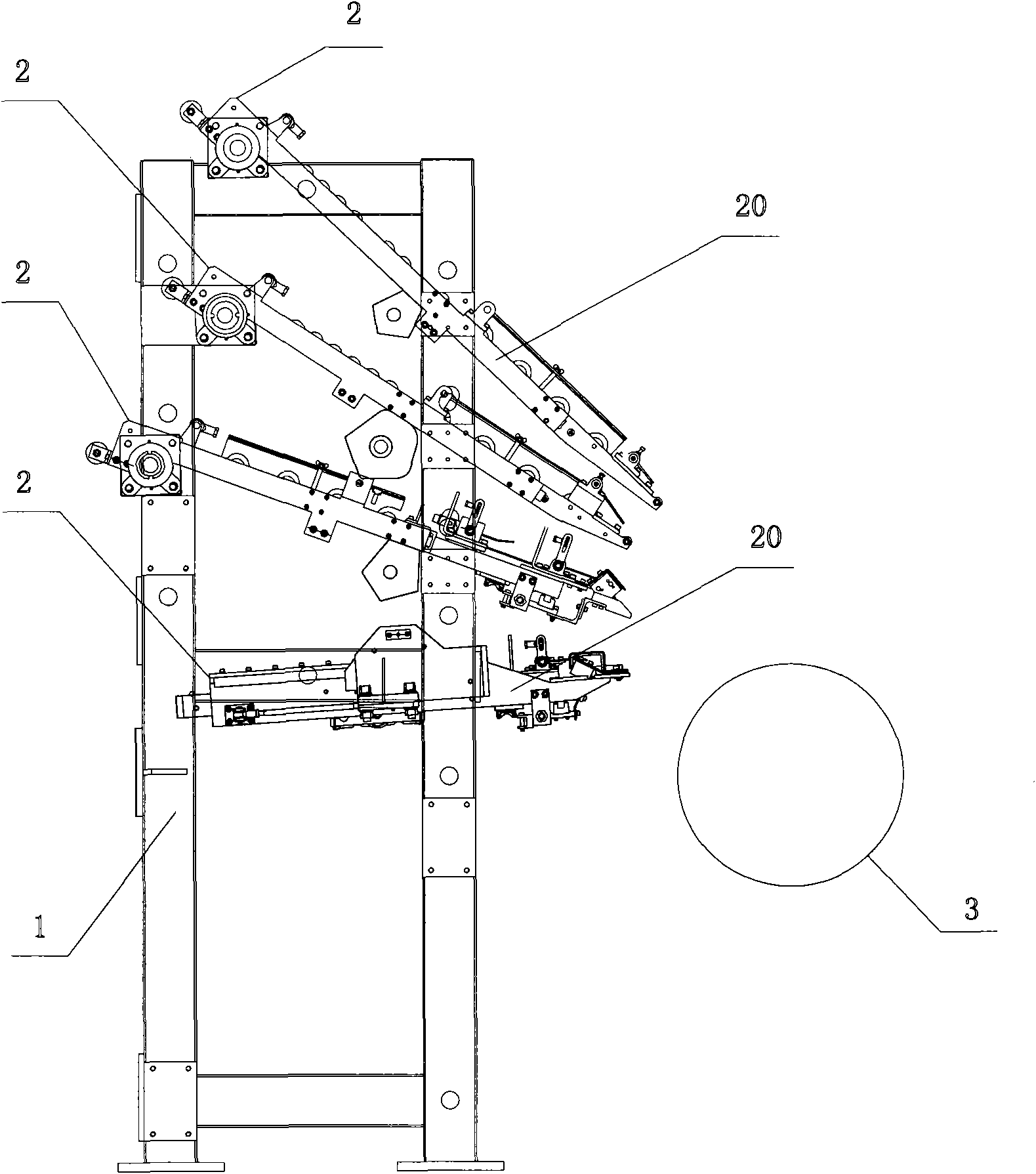

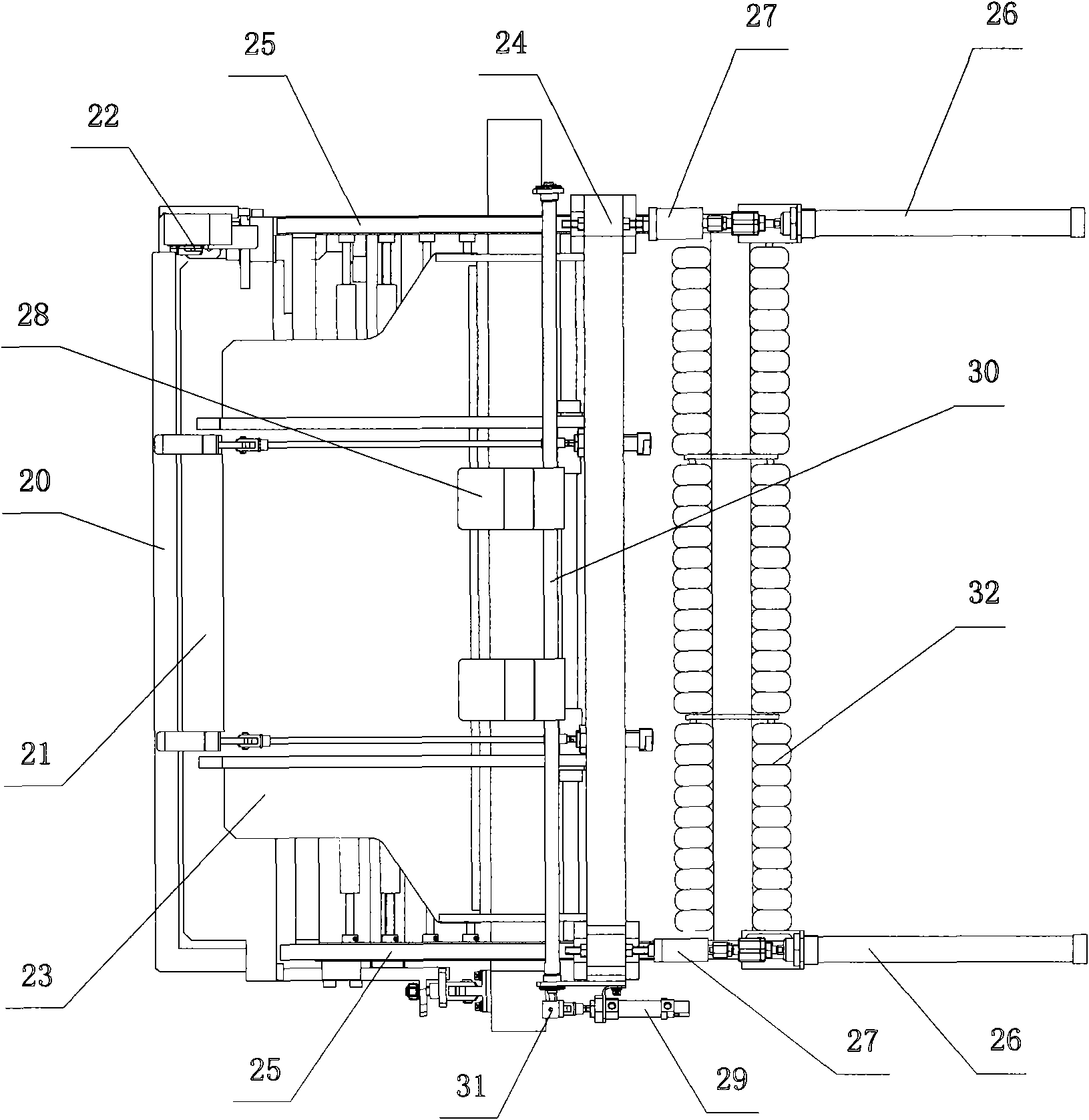

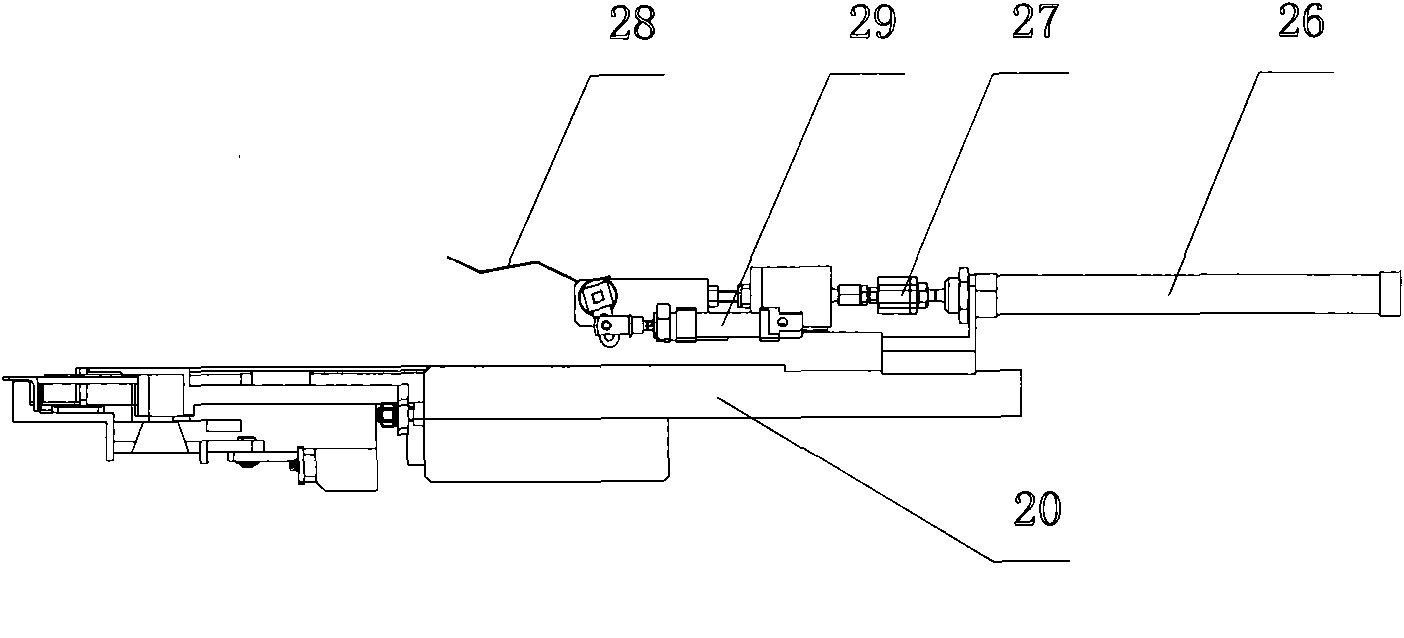

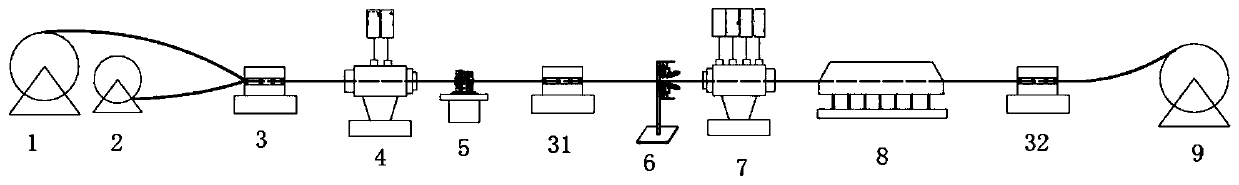

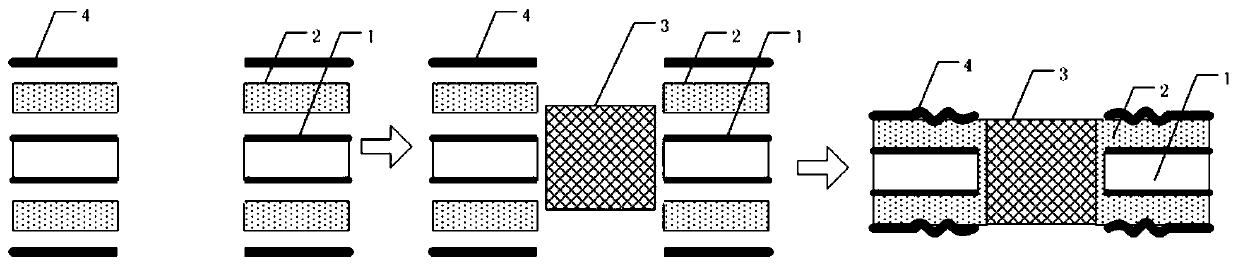

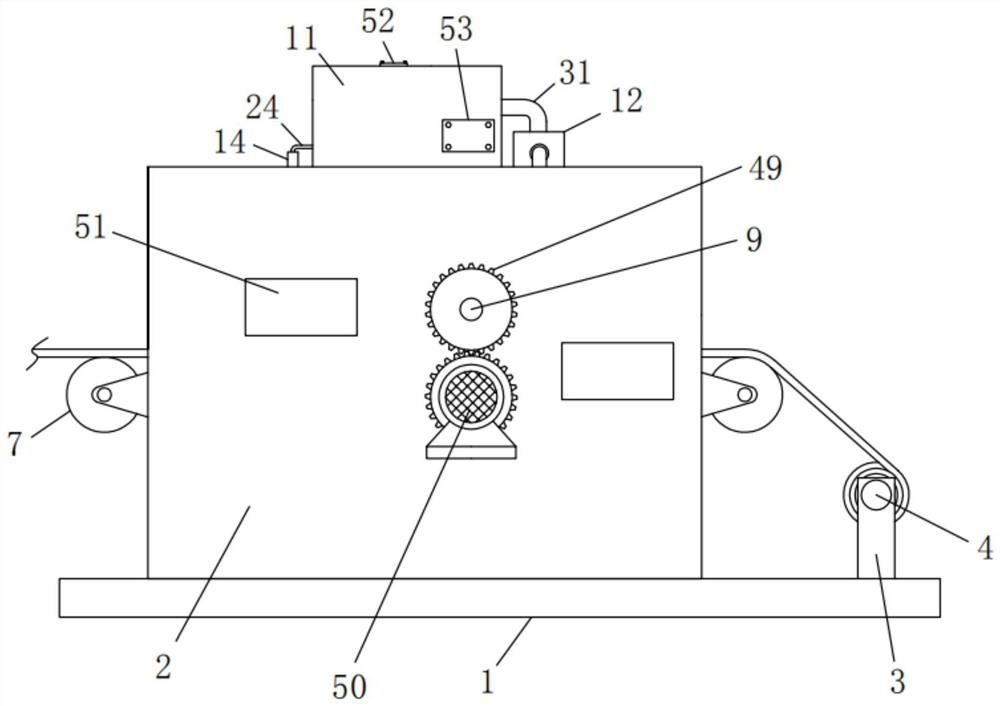

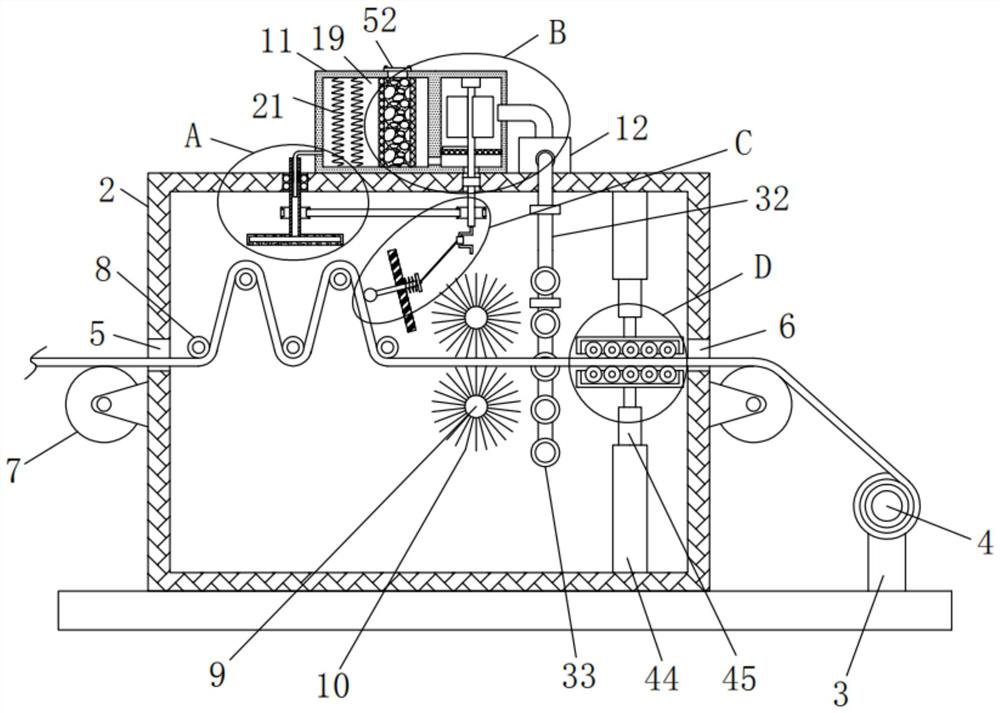

Elastic waistline shaping machine for waist-surrounding paper diaper

ActiveCN104323886AThe effect will not be reducedNo wrinklingAbsorbent padsBandagesAgricultural engineeringOutput device

The invention discloses an elastic waistline shaping machine for a waist-surrounding paper diaper. The elastic waistline shaping machine comprises a machine frame, a rubber band output device, a non-woven cloth output device, a rubber band gluing mechanism, a non-woven cloth gluing mechanism, a half folding mechanism, a cutting-off knife rest, a steering knife rest and a non-woven glue spraying mechanism, wherein the rubber band output device is arranged on the front side face of the machine frame; the rubber band gluing mechanism implements gluing on the surface of each rubber band; the non-woven gluing mechanism implements gluing on the surface of the output non-woven cloth; the half folding mechanism folds the output non-woven cloth in half; the cutting-off knife rest is installed on the front side face of the machine frame, and implements breakpoint cutting-off on a part of the rubber bands; the steering knife rest is located on the right side of the cutting knife rest; the non-woven glue spraying mechanism is located between the cutting-off knife rest and the steering knife rest, and sprays glue onto the surface of the folded non-woven cloth. Compared with the prior art, the elastic waistline shaping machine for the waist-surrounding paper diaper provided by the invention has the advantages that, the shaped elastic waistline is of a cut point structure corresponding to the rubber band of a part which coincides with an absorption core body, so that the part, corresponding to the absorption core body, of the elastic waistline has no elastic effect; therefore after the elastic waistline is combined with a paper diaper body, the wrinkling of the absorption core body is not caused.

Owner:JINJIANG SHUNCHANG MACHINE MFG

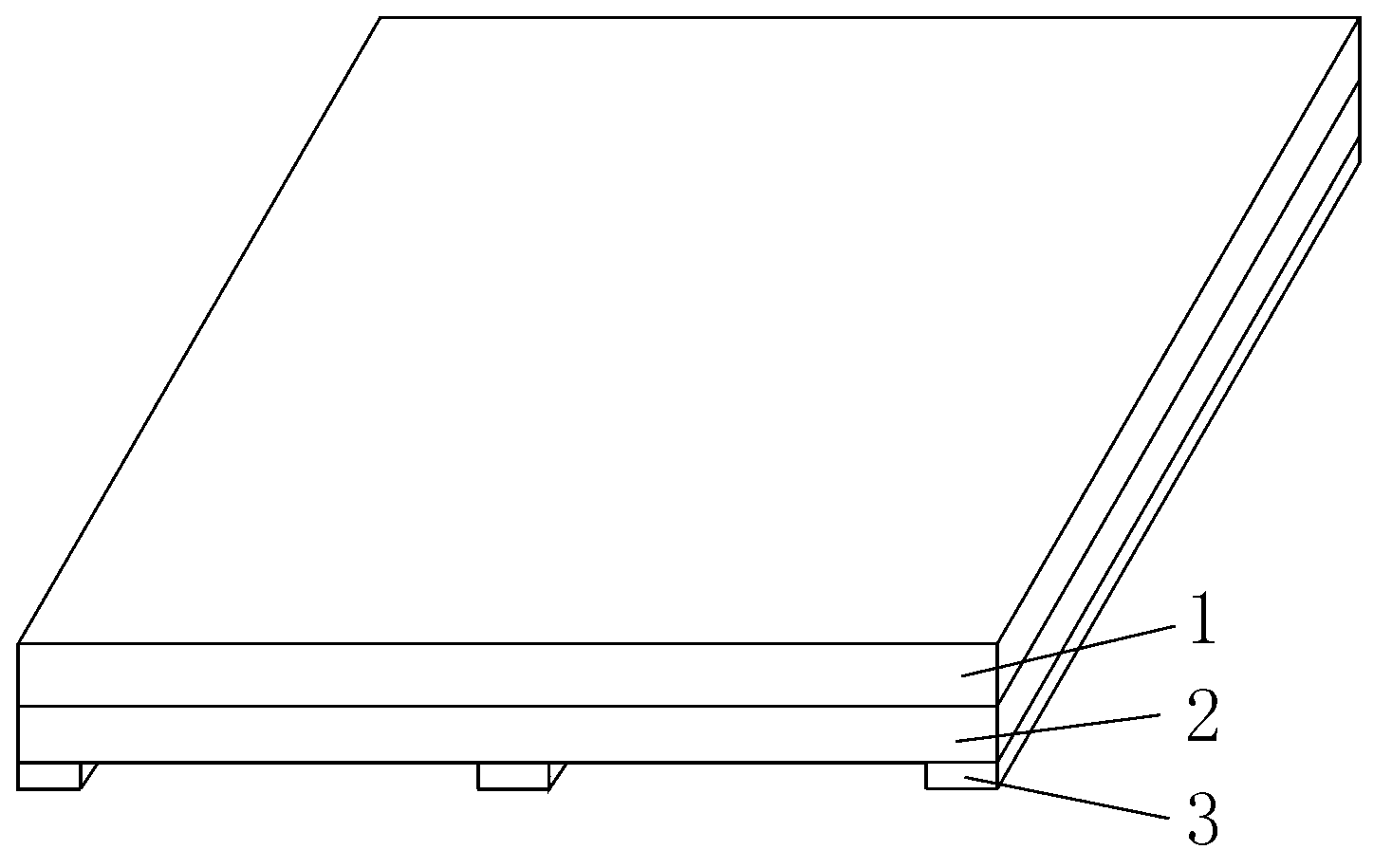

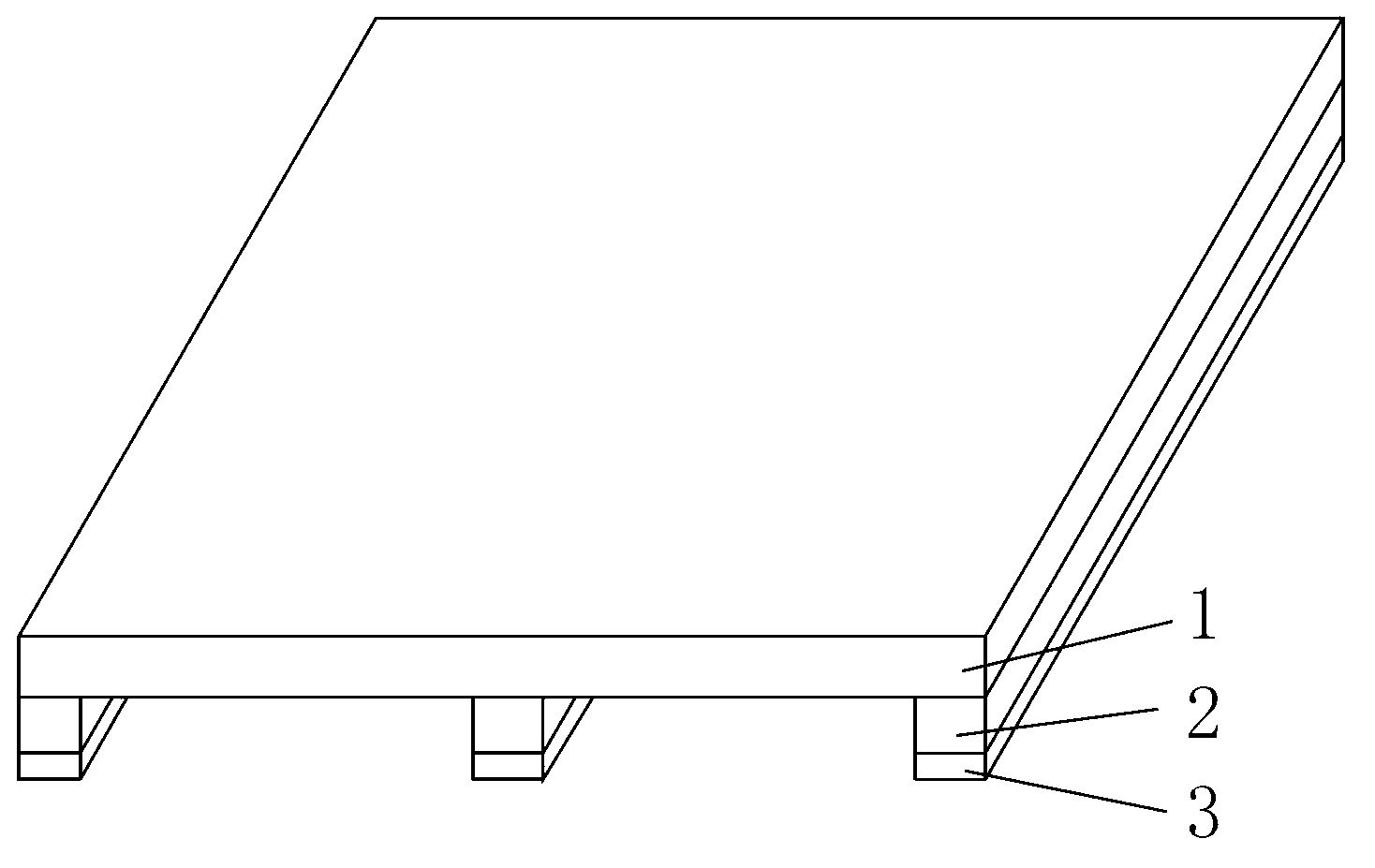

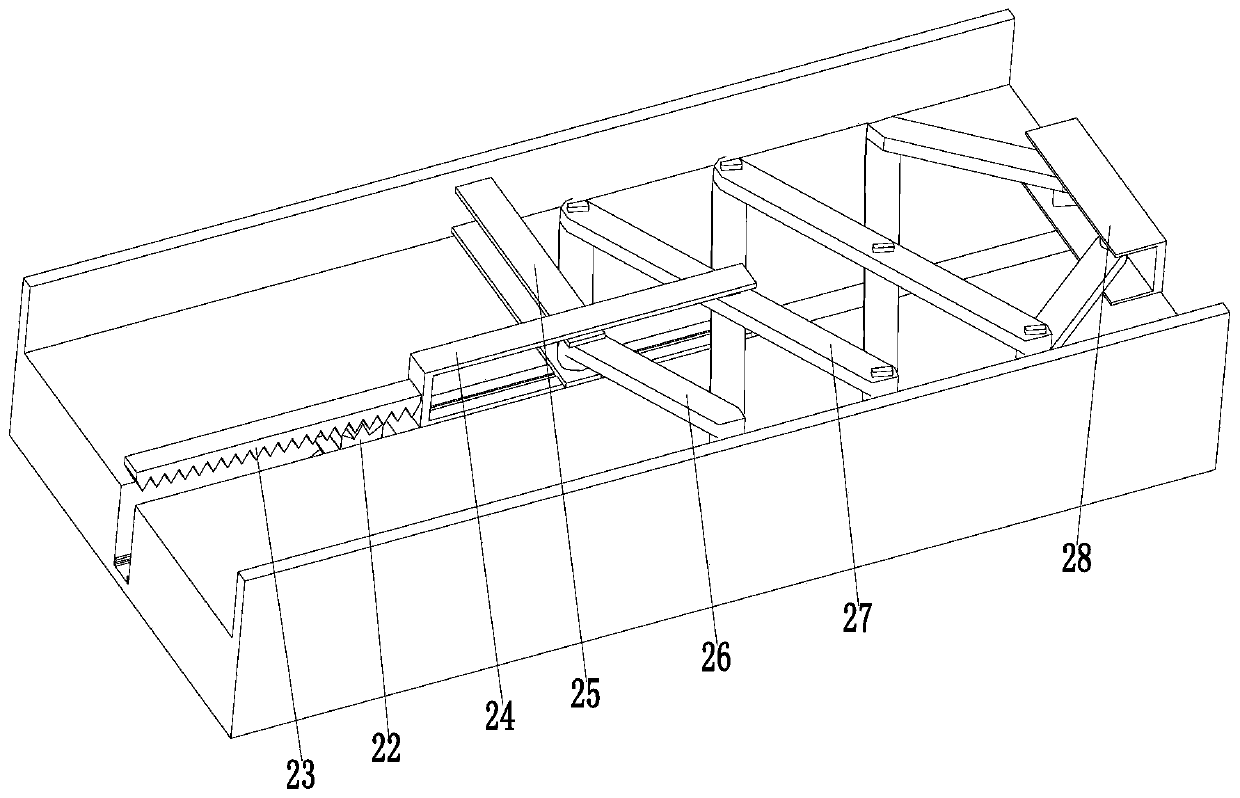

Feeding template used for automatic cutting of material and control method thereof

The invention relates to a feeding template used for the automatic cutting of material and a control method thereof, wherein, a material transmission device that can reciprocate in the longitudinal direction is adopted to control the material to be forwards conveyed accurately to reach a feeding station, and the material can move backwards for a certain distance so as to be detached from being in contact with a cutting knife when being processed through fixed-length cutting, so that the phenomenon that the material wrinkles or deflects caused by the backward reposition of the cutting knife is hindered, and the material can be protected from being abraded. The feeding template mianly comprises a frame, wherein, a front end plate and the cutting knife used for cutting the material transversely are arranged at the front end of the frame. A longitudinal material transmission device is arranged on the rear side of the front end plate; the longitudinal material transmission device is provided with a material transmission plate, at least a group of cylinder components, a pressure plate and a driving cylinder; the material transmission plate can bear upwards and can convey the material in the longitudinal direction; the cylinder components are connected with the rear end of the material transmission plate and can drive the material transmission plate to reciprocate in the longitudinal direction; the pressure plate is arranged above the material transmission plate; and the driving cylinder can drive the pressure plate to swing in the vertical direction. The material can move backwards for a certain distance so as to be detached from being in tight contact with the inner side surface of the cutting knife after being processed through fixed-length cutting.

Owner:MESNAC

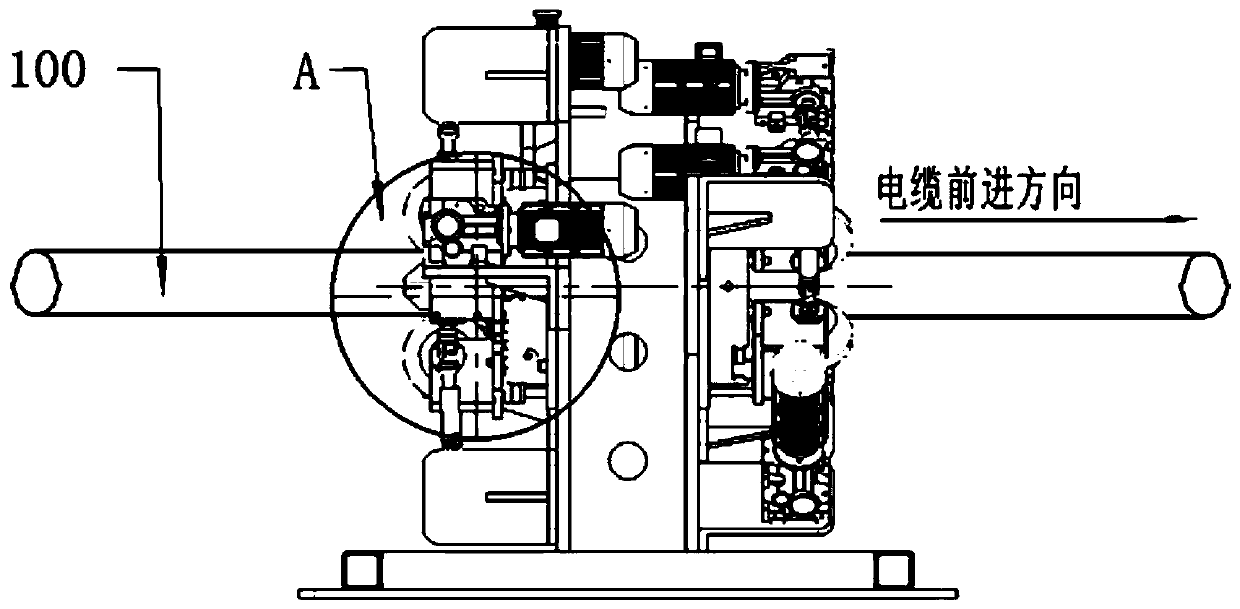

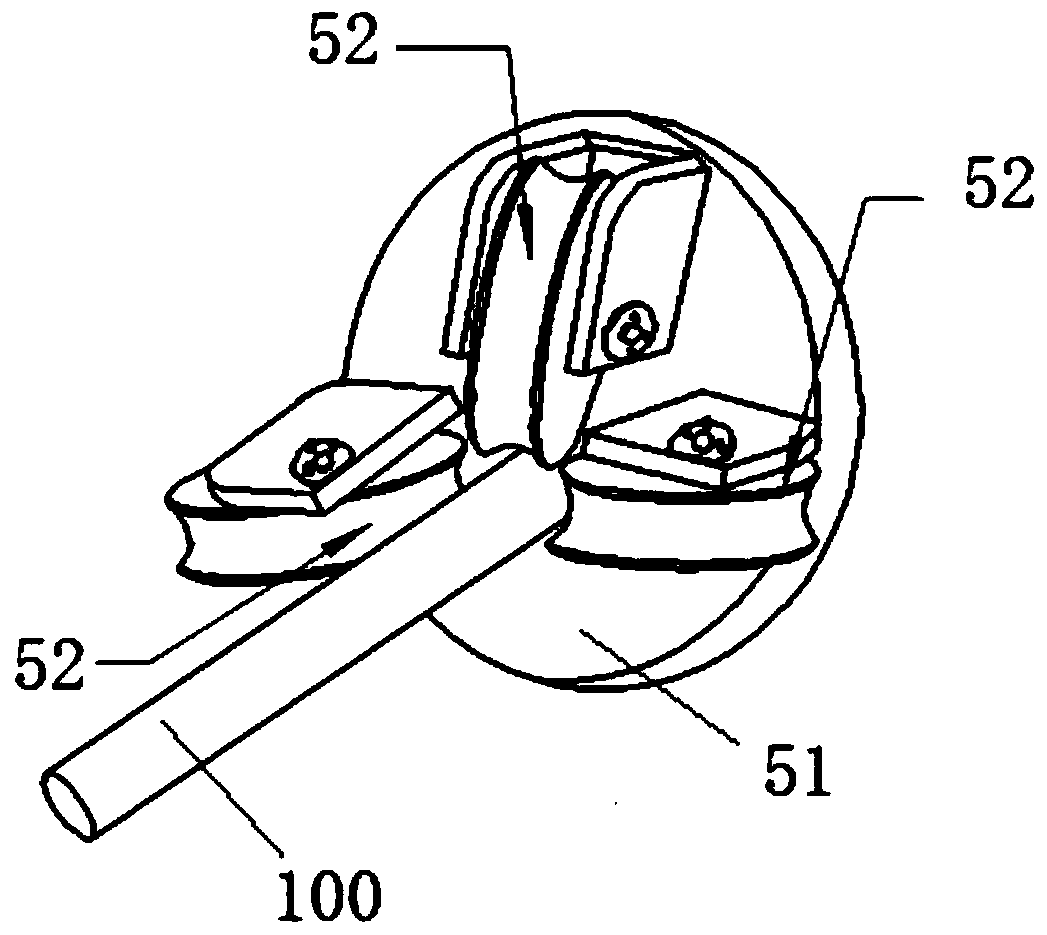

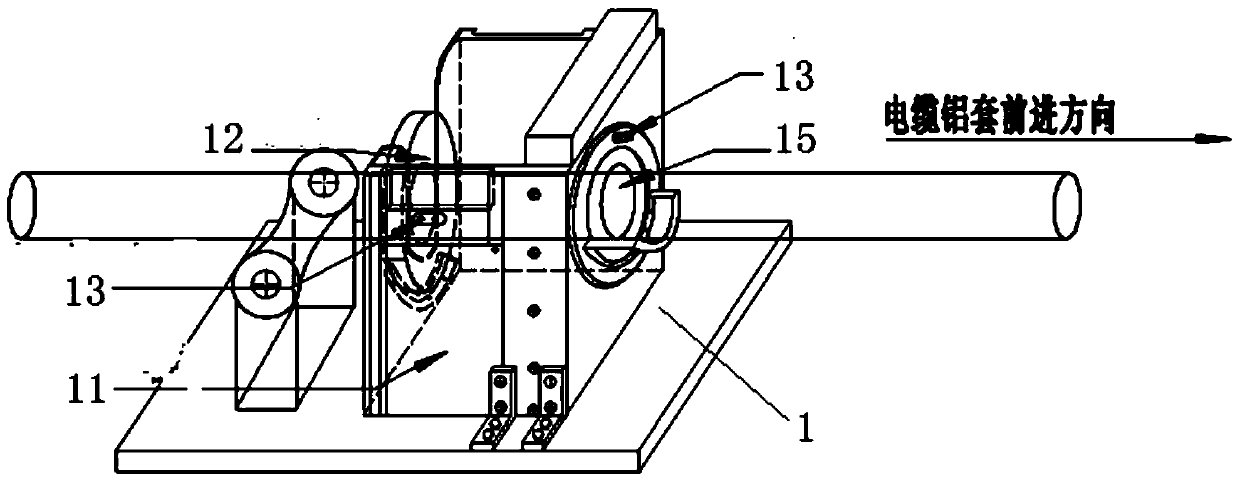

Extruded composite smooth aluminum sleeve cable production equipment and a production method

PendingCN111524657AReduce manufacturing costCompact structureInsulated cablesCable/conductor manufactureEngineeringHot melt

The invention discloses extruded composite smooth aluminum sleeve cable production equipment and a production method. The production equipment comprises an extruded aluminum sleeve device, a wheel type reducing device, a preheating device, a multi-layer co-extrusion device and a cooling water tank, and the extruded aluminum sleeve device continuously extrudes an aluminum sleeve; the cable coated with the aluminum sleeve passes through a shaft hole, and the aluminum sleeve is tightened to the outer diameter designed by the process by the wheel type reducing device, so that the whole aluminum sleeve is coated on the surface of the cable core; the preheating device is used for heating the aluminum sleeve; the multi-layer co-extrusion device is used for compounding the aluminum sleeve with thehot melt adhesive, a PE sheath, a PVC sheath and a conductive layer together and carrying out cooling molding through the cooling water tank. According to the hot melt adhesive extrusion technology designed by the invention, the hot melt adhesive not only achieves an anti-corrosion effect, but also achieves a bonding effect, so that the PE sheath, the PVC sheath, the conductive layer and the smooth aluminum sheath of the cable are firmly bonded together, and the phenomena of arching or wrinkling cannot be generated during bending, take-up and construction of the cable.

Owner:ZHEJIANG CHENGUANG CABLE CO LTD

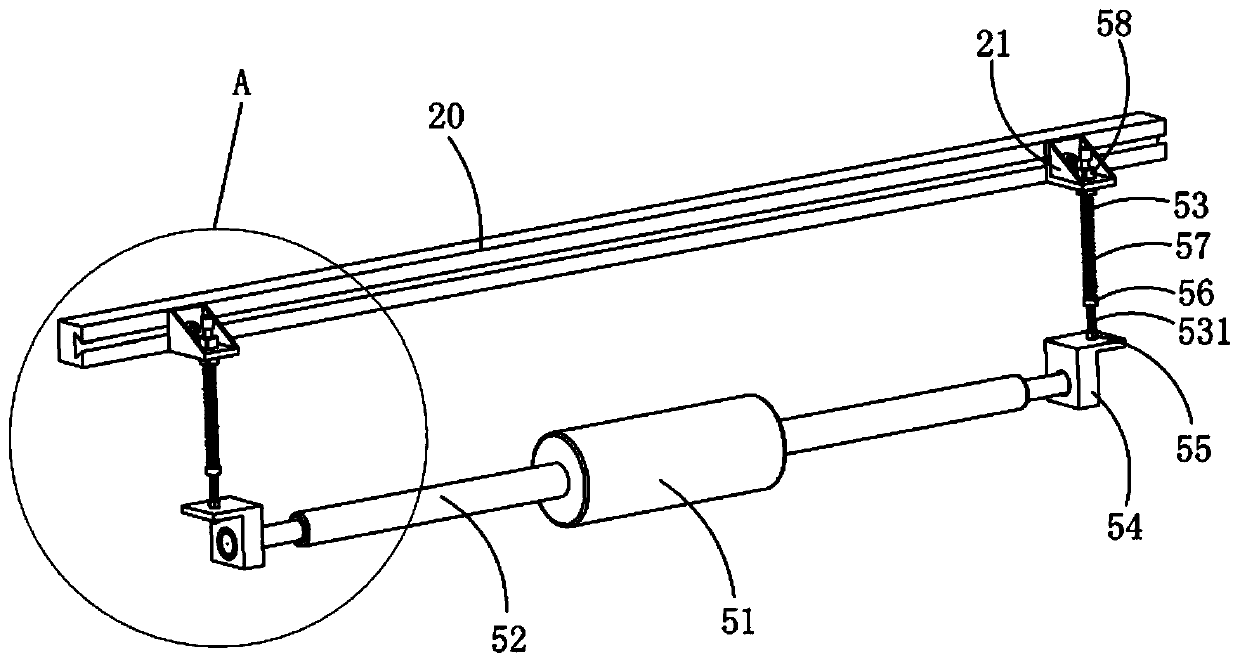

Film wrapping machine winding device for flat-shaped wires

InactiveCN103489530AAchieve axial movementThe distance is adjustable and appropriateInsulating conductors/cablesScrew threadEngineering

The invention discloses a film wrapping machine winding device for flat-shaped wires, and relates to the technical field of film wrapping machine equipment production. A winding guide wheel is arranged on a machine frame, a compaction wheel parallel to the winding guide wheel in the axial direction is arranged on one outer side of the winding guide wheel, the center of the compaction wheel is connected with one end of an adjusting screw rod through a connecting shaft, the axial direction of the adjusting screw rod is perpendicular to the axial direction of the winding guide wheel, a nut in threaded connection with the adjusting screw rod is fixedly connected to the machine frame, and an adjusting hand wheel is arranged at the other end of the adjusting screw rod. The compaction wheel is arranged on the outer side of the winding guide wheel in a matched mode, and the adjusting screw rod rotates on the nut through the adjusting hand wheel so that the adjusting screw rod can move in the axial direction, the distance between the compaction wheel and the winding guide wheel can be adjusted and appropriate to adapt to the flat-shaped wires with different thicknesses, the flat-shaped wires can be effectively prevented from turning over in the process of passing the winding guide wheel, an insulating layer can wrap the flat-shaped wires smoothly and tightly, and the wrinkling phenomenon cannot occur.

Owner:江苏朗顺电工电气有限公司

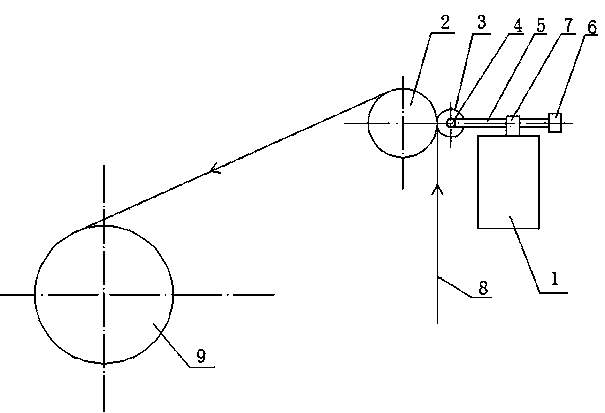

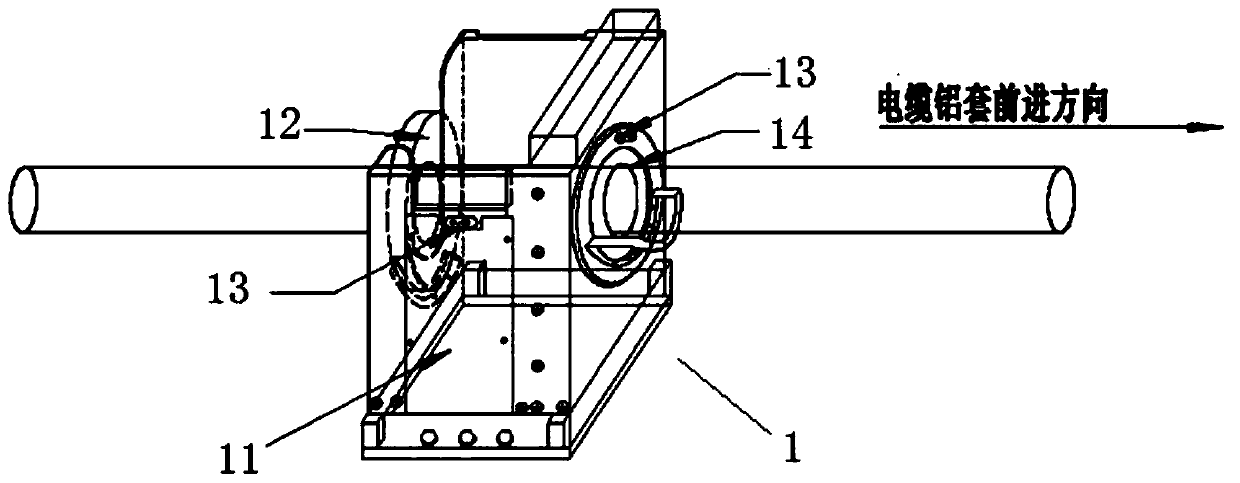

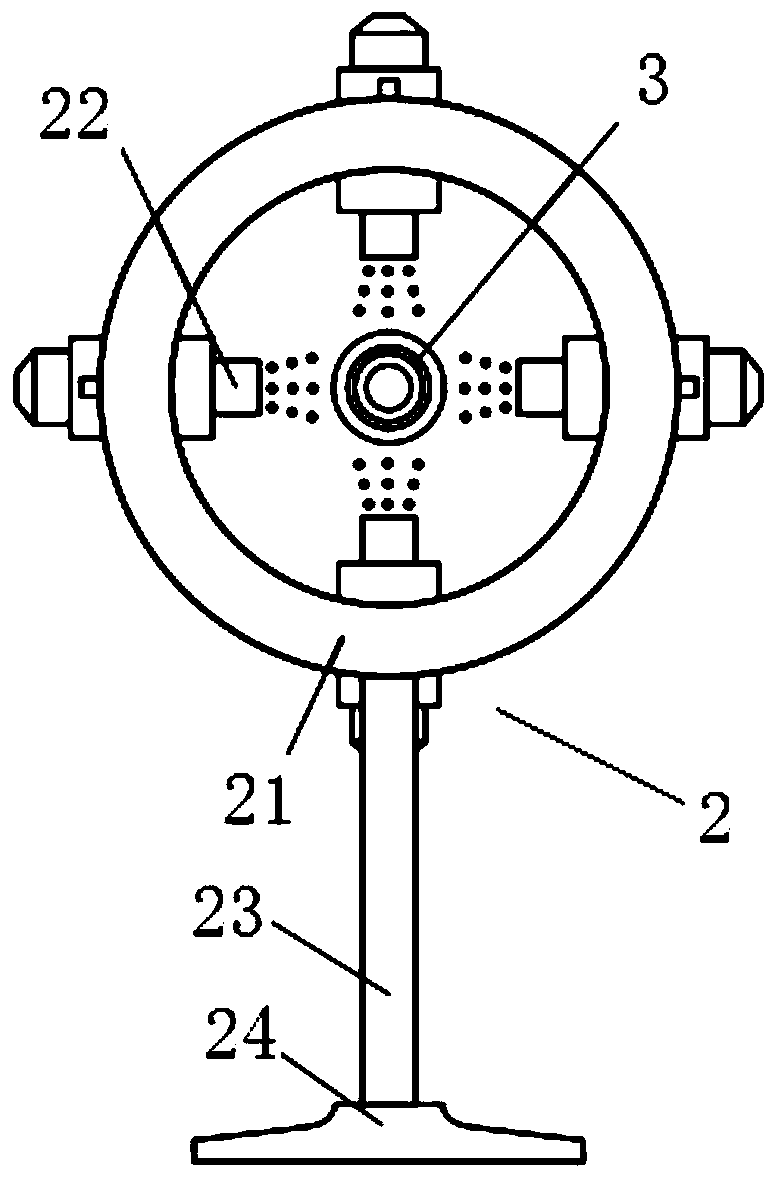

Hot melt adhesive coating device and coating method for composite smooth aluminum sheathed high-voltage cables

PendingCN110739106ANo bowingNo wrinklingCable/conductor manufactureTemperature controlProduction line

The invention discloses a hot melt adhesive coating device and coating method for composite smooth aluminum sheathed high-voltage cables. The coating device comprises an argon arc welding production line and a plastic extruding machine, wherein the argon arc welding production line comprises a welding gun part and a traction part; the coating device further comprises a first hot melt adhesive coating device and a second hot melt adhesive coating device; the first hot melt adhesive coating device is arranged between the welding gun part and the traction part; the first hot melt adhesive coatingdevice comprises a hot melt adhesive groove, an adhesive blocking die, a drawing die and an electric heating temperature control assembly; the hot melt adhesive groove is filled with hot melt adhesive particles; the hot melt adhesive particles are heated by the electric heating temperature control assembly to become liquid and completely immerse an aluminum sheath; the aluminum sheath enters thefirst hot melt adhesive coating device and is subjected to primary hot melt adhesive coating while being subjected to a drawing process; and the second hot melt adhesive coating device is arranged atthe front side of the inlet of the plastic extruding machine and is structurally similar to the first hot melt adhesive coating device. According to the hot melt adhesive coating device and coating method for the composite smooth aluminum sheathed high-voltage cables of the invention, secondary hot melt adhesive coating is performed in front of the plastic extruding machine, and therefore, the smooth aluminum sheath and an outer sheath are tightly integrated into a whole, and the phenomena of arching or wrinkling can be avoided during cable bending, take-up and construction.

Owner:ZHEJIANG CHENGUANG CABLE CO LTD

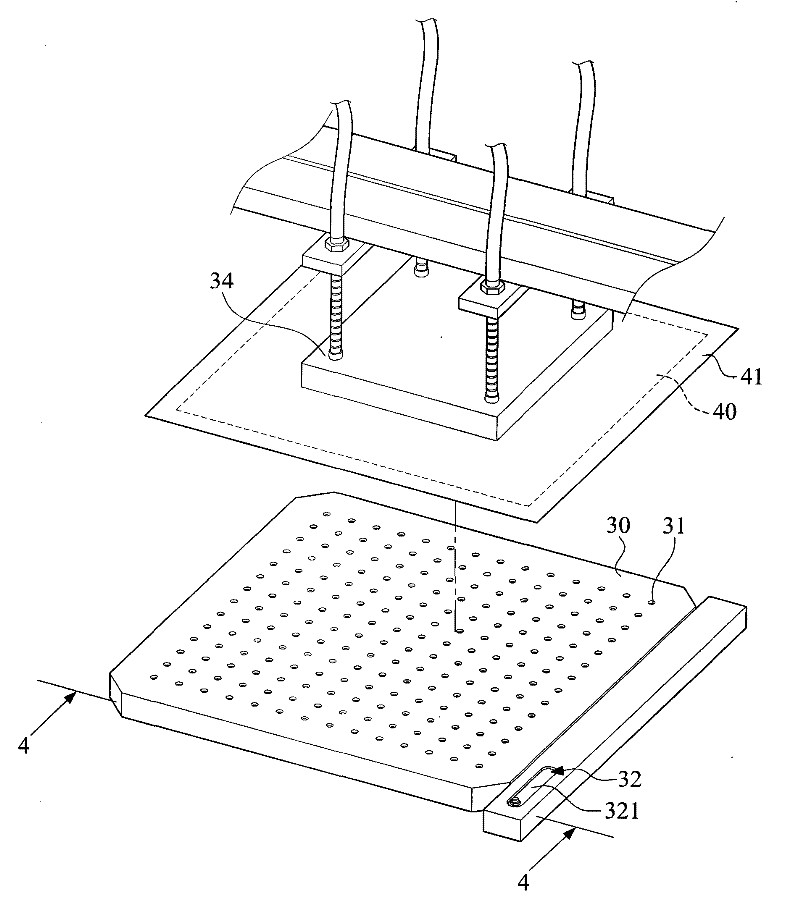

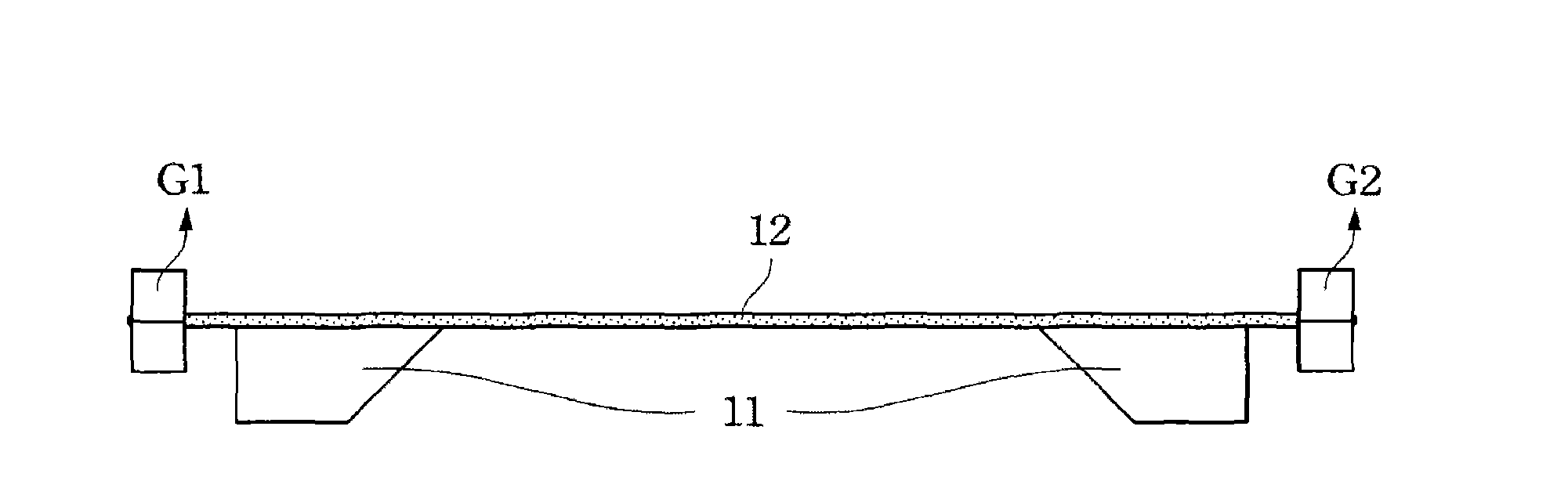

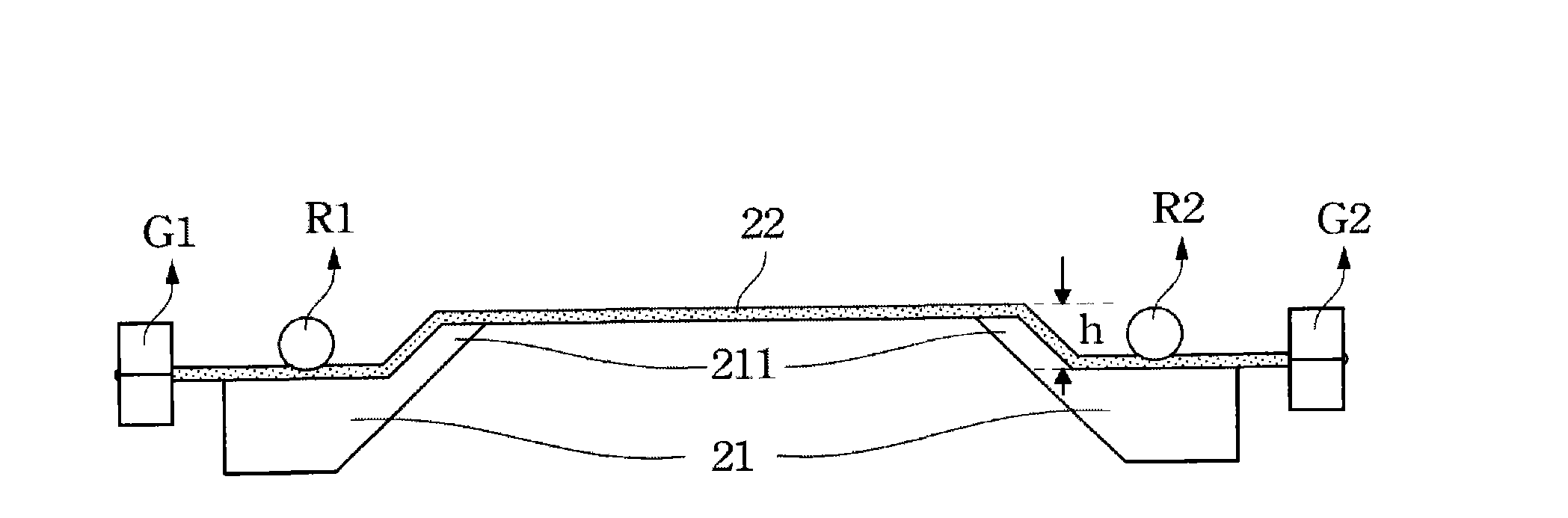

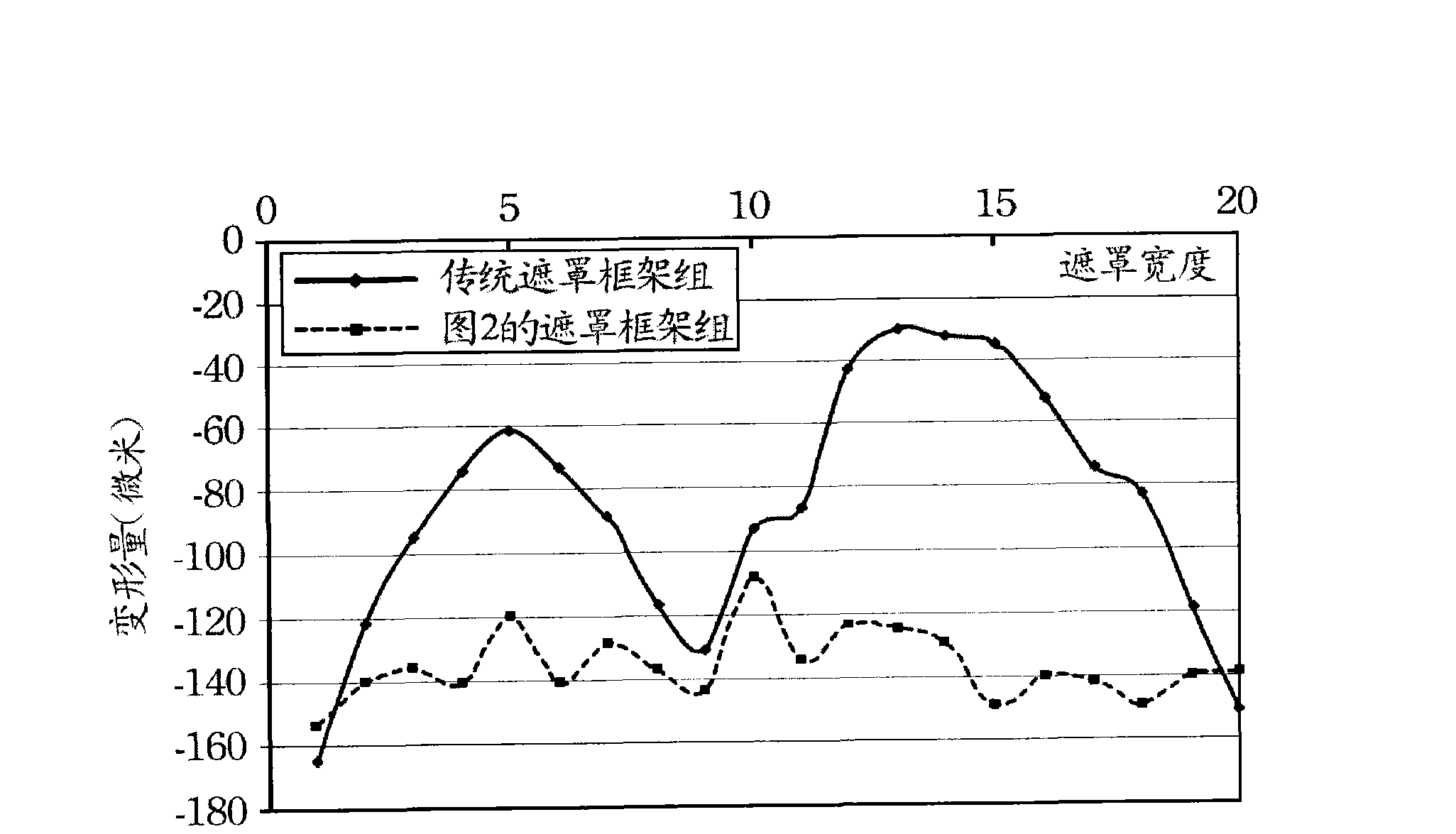

Mask and frame assembly of mask tensioning machine for deposition process

InactiveCN102618821AEasy levelingNo wrinklingVacuum evaporation coatingSputtering coatingEngineeringShadow effect

The invention provides a mask and frame assembly of a mask tensioning machine for a deposition process. The mask and frame assembly comprises a frame and a mask, bumps are arranged on the peripheral edge of the frame, and the mask is assembled on the frame and is jacked by the bumps of the frame. The mask and frame assembly has the advantages that the mask is jacked by the bumps of the frame, the surface of the mask is flatly pressed by a roller so as to be easily flattened, accordingly, crinkling of the mask is prevented, and a shadow effect caused by crinkling of the mask is avoided.

Owner:AU OPTRONICS CORP

Process of regenerating waste medicine packing aluminium plastic sheet

InactiveCN101020183ARestore does not appearImprove qualitySolid waste disposalNon-surface-active detergent solventsOrganic solventChemical reaction

The process of regenerating waste medicine packing aluminum-plastic sheet includes setting waste medicine packing aluminum-plastic sheet in some liquid at temperature over 60 deg.c to separate plastic layer from the aluminum layer, winding the separated plastic layer from the aluminum layer separately onto two drums, stoving the aluminum foil and washing in non-protonic organic solvent to eliminate residual adhesive, and adhering the cleaned aluminum foil to plastic film with new polyurethane adhesive to form the regenerated aluminum-plastic sheet. The present invention has complete stripping of aluminum foil and complete cleaning, and the regenerated aluminum-plastic sheet has high quality the same as new one.

Owner:刘继福

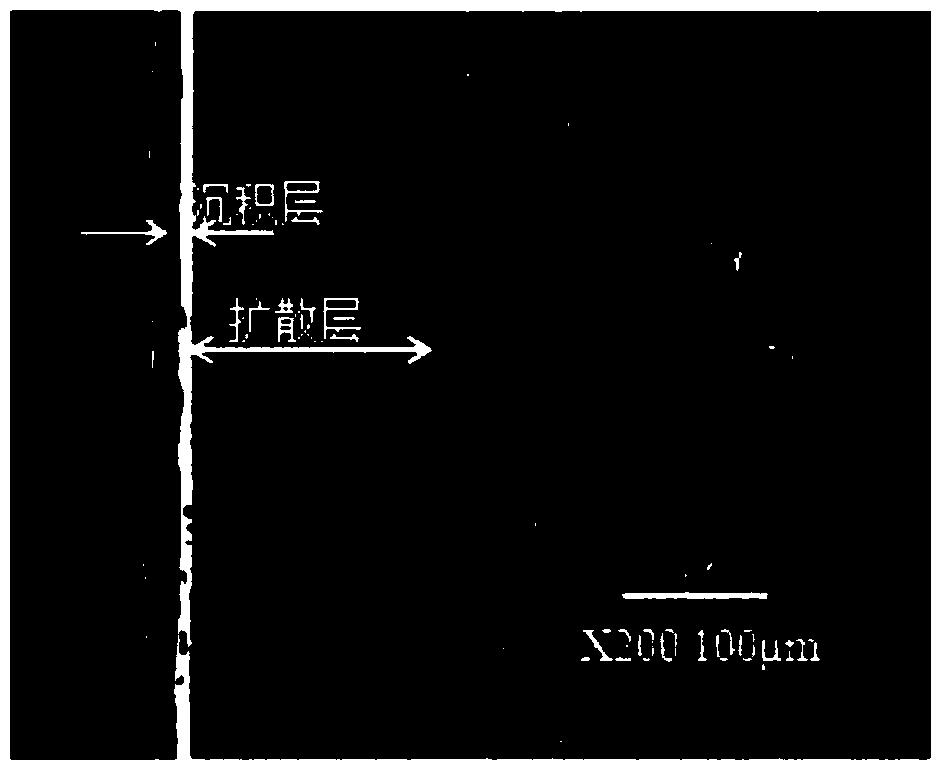

Fe-Al-Nb alloy coating and preparation method thereof

ActiveCN104070725ASolve the problem of cracking and even peelingTake full advantage of performanceHot-dipping/immersion processesSolid state diffusion coatingFragilityAlloy coating

The invention discloses a Fe-Al-Nb alloy coating which comprises three parts such as a base body layer, a sedimentary layer and a diffusion layer, wherein the base body layer is made of ordinary carbon steel; the sedimentary layer comprises 99.5 weight percent of Nb, and 5 weight percent of AlNb2, Fe7Nb6, Fe2Al5 and Fe3Al; the diffusion layer comprises 25 to 34 weight percent of Al, 65 to 73 weight percent of Fe and 1.0 to 2.0 weight percent of Nb; the thickness of the Fe-Al-Nb alloy coating is 150 to 200 <Mu>m; the ordinary carbon steel is 45 steel or Q235 steel. According to the invention, not only can the strength and high-temperature corrosion resistance of an Fe-Al based coating improved, but also the tenacity of the Fe-Al based coating is improved, so as to effectively reduce the ambient temperature fragility of the Fe-Al based coating.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

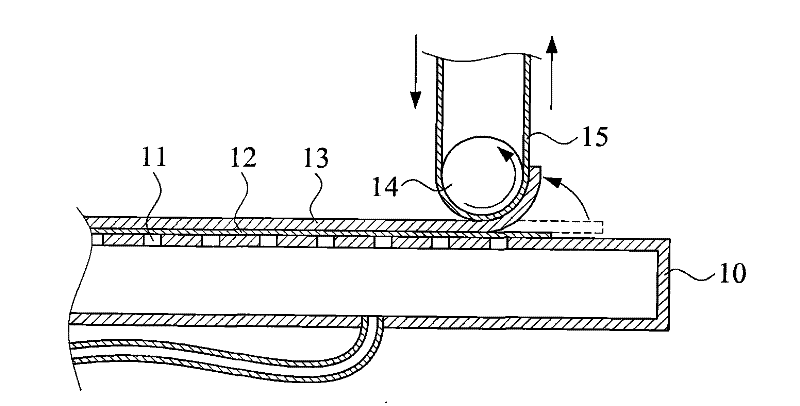

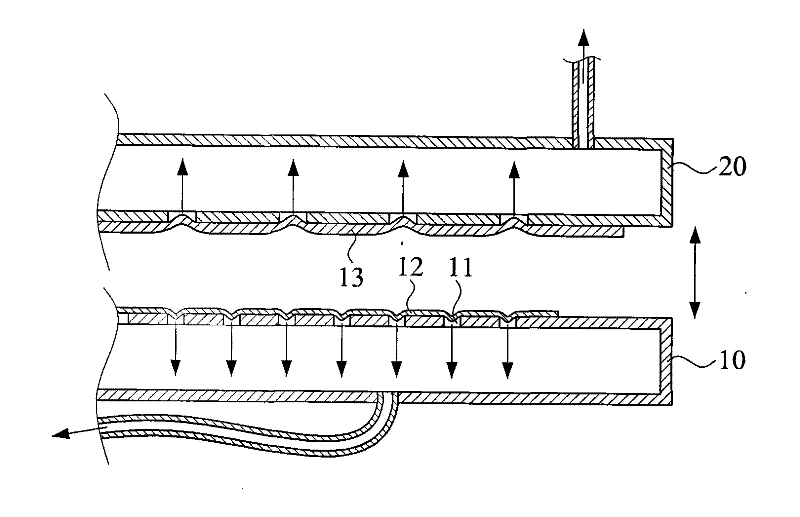

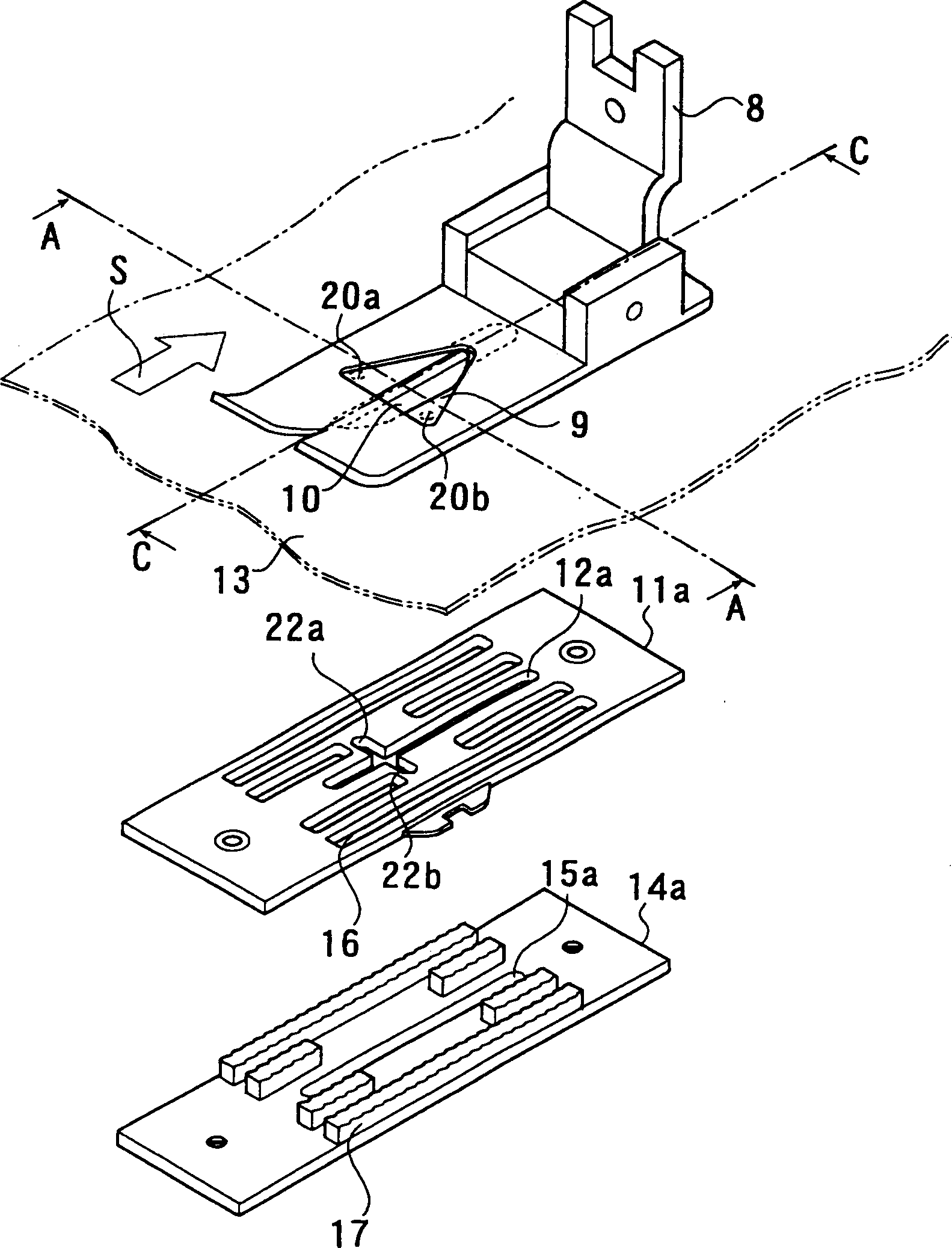

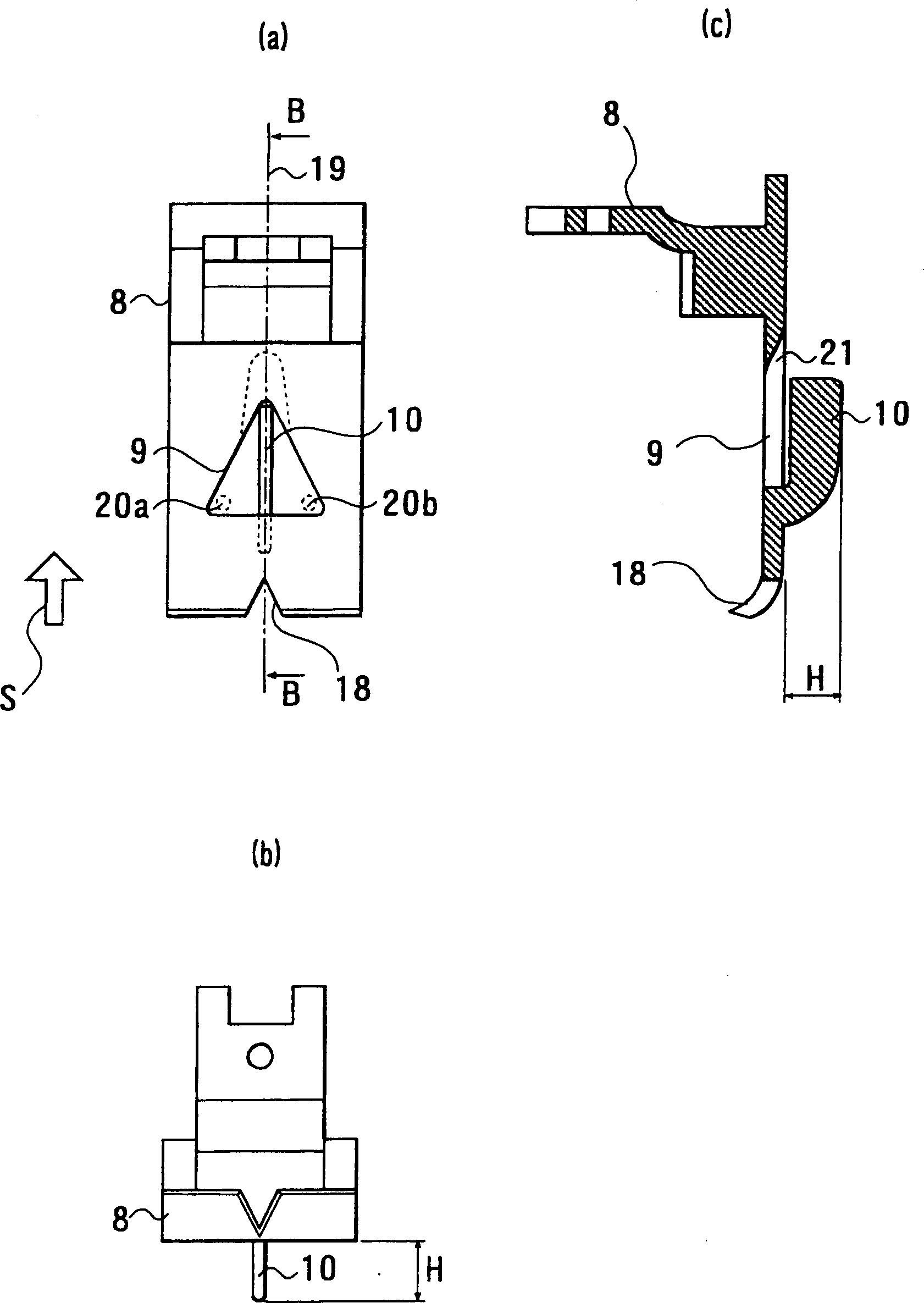

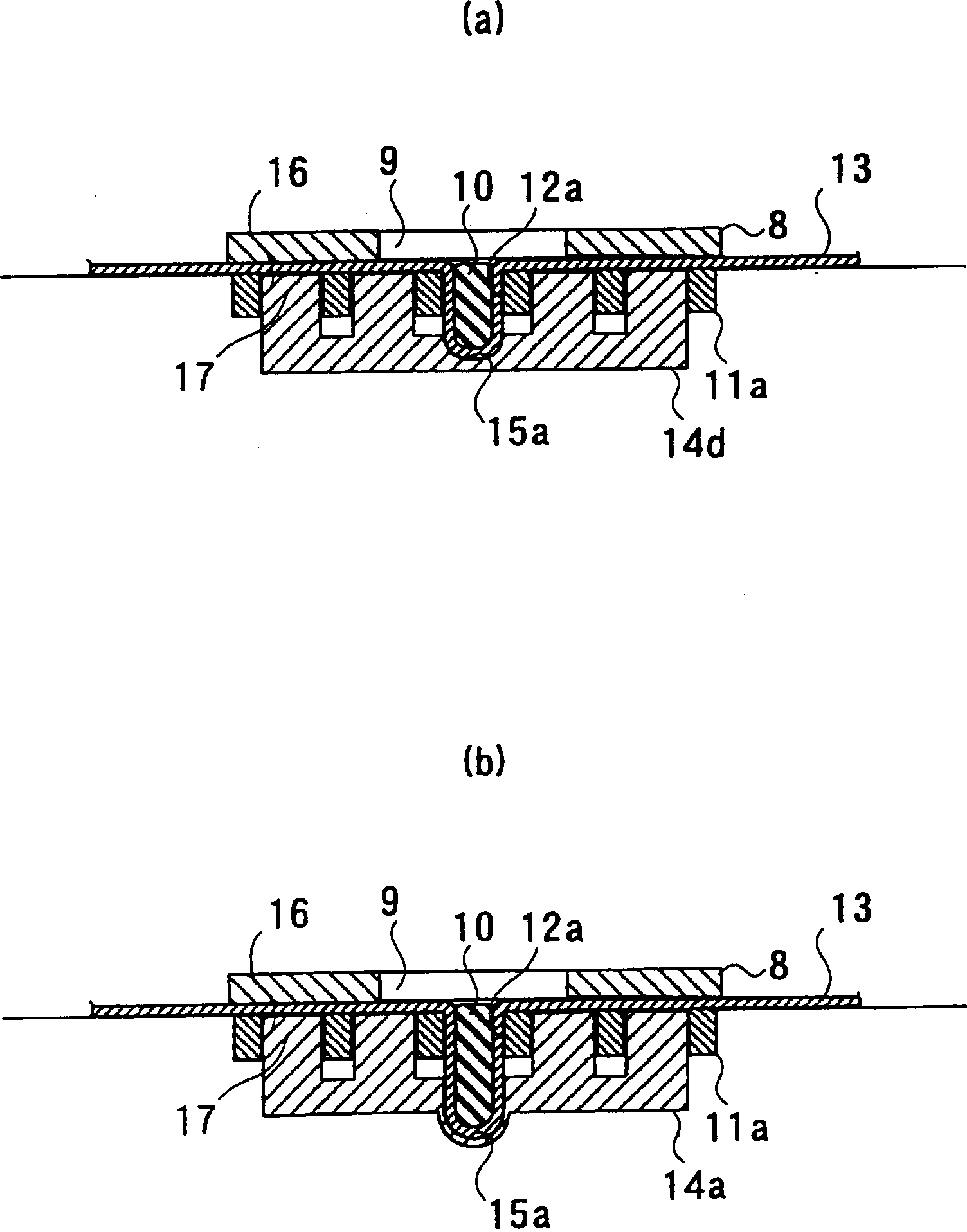

Cloth decoration edge forming device constituted from sawtooth stitch sewing machine

InactiveCN1378003AShape stableAvoid disorderSewing-machine casingsWork-feeding meansFeeding forceEngineering

PURPOSE: To allow a worker to easily, efficiently and stably sew uniform and beautiful pin-tucks regardless of its skill by improving the stability stitch balancing thread tension, the feeding stability of a sewing matter (cloth), and the visual confirmability of seams in sewing in the formation of pin-tucks by use of a zigzag lock stitch sewing machine. CONSTITUTION: A throat plate 11a comprises a hole 12a located between the lateral needle locating positions 20a and 20b of one needle and extended long in the feeding direction S of a sewing matter 13. A guide plate 10 for freely inserted to the hole 12a from the upper surface side of the throat plate 11a is formed on the lower surface of a presser 8. A feed dog 14a has a U-shaped sectional U-groove 15a in a position opposed to the hole 12a to work a feeding force to a pin-tuck part.

Owner:JUKI CORP

Preparation method for anti-wrinkle and anti-crack bamboo floor

InactiveCN105710943AReduce dosageMade with reduced dosageCane mechanical workingReed/straw treatmentEngineeringMoisture absorption

The invention discloses a preparation method of an anti-wrinkle and anti-cracking bamboo floor. Take bamboo slices with a width of 18-25 mm, layer the surface bamboo green and bamboo yellow through a green cutting machine, and plan the bamboo yellow to obtain a thickness of 3. ~6mm bamboo slices, the obtained bamboo slices are dissected again, cut into bamboo strips with a width of 4~6mm, the bamboo strips are degreased and desugared by high temperature and high pressure, and finally the bamboo strips are dried to a moisture content of less than 10% for soaking Glue, soaked bamboo strips are dried again, after curing, the dried bamboo strips are pressed and formed by cold presses and molds, and then cured at high temperature and sliced to obtain slabs that can be used to produce finished flooring. The invention controls the thickness of the bamboo strips by cutting the bamboo slices into strips, can ensure uniform glue application during the glue application process, and at the same time greatly reduces the amount of glue used, shortens the drying time after glue, and reduces the energy consumption. Consumption, the finished board has higher strength, lower moisture absorption expansion rate, no wrinkling, cracking, wire jumping, etc., and the bamboo strips in the entire bamboo floor will not break the silk road.

Owner:WUXI BODA BAMBOO & WOOD INDAL

Plant asphalt emulsion, preparation method, water emulsion modified plant asphalt waterproof coating using plant asphalt emulsion and preparation method

InactiveCN105602263AEasy constructionGood film formingBuilding insulationsBituminous coatingsFiberEngineering

The invention discloses plant asphalt emulsion and a water emulsion modified plant asphalt waterproof coating using the plant asphalt emulsion. The plant asphalt emulsion is prepared from plant asphalt, deionized water, styrene cis-butadiene diacid, a stabilizer, an initiator, an emulsifier A, a defoamer A and a thickener. The water emulsion modified plant asphalt waterproof coating using the plant asphalt emulsion comprises the following various raw materials: the plant asphalt emulsion, elastic emulsion, talcum powder, deionized water, light calcium carbonate, hydroxy propyl cellulose, short fibers, a dispersing agent, a defoamer B, a water repellent, a preservative, a surfactant and an emulsifier B. An environment of a technological process is clean, water serves as a carrier diluent, and therefore, the plant asphalt emulsion and the water emulsion modified plant asphalt waterproof coating are nontoxic, harmless, environmentally friendly, pollution-free, corrosion-free and combustion-free, and belong to aqueous system non-dangerous products. The products are convenient to construct, excellent in film-forming property and suitable for waterproofing of a roof and underground impermeability.

Owner:河南建筑材料研究设计院有限责任公司

Packing tape compaction device

ActiveCN110451032AGuaranteed smoothNice appearanceWrapper twisting/gatheringBox-sealing tapeEngineering

The invention discloses a packing tape compaction device which comprises a rack, a first cross beam, a guiding mechanism and a compaction mechanism, wherein the rack is mounted on a conveyor line which is used for conveying a packaging box; the first cross beam is mounted on the rack, a hairbrush is arranged on the first cross beam, and a brush head end of the hairbrush leans against the packing tape on the packaging box to brush the packing tape flat; the guiding mechanism forms a guiding channel where the packaging box passes through, and the brush head end of the hairbrush stretches into the guiding channel; and the compaction mechanism comprises a compaction roller and a lifting driving assembly, the hairbrush and the compaction roller are arranged in a spaced manner along a first direction, the first direction is consistent to the conveying direction of the packaging box, and the lifting driving assembly is used for driving the compaction roller to descend to lean against the packing tape so as to compact the packing tape to the packaging box or is used for driving the compaction roller to ascend to be separated from the packing tape. According to the packing tape compaction device, the packing tape on the packaging box is brushed flat and compacted successively without being wrinkled, and seals the packaging box tightly, and the packaging box which is stacked is unlikelyto fall off, so that the safety is high.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

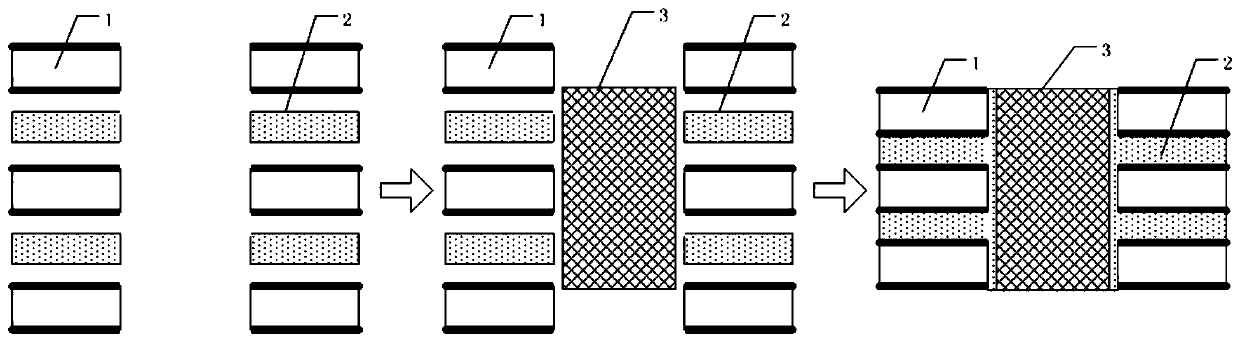

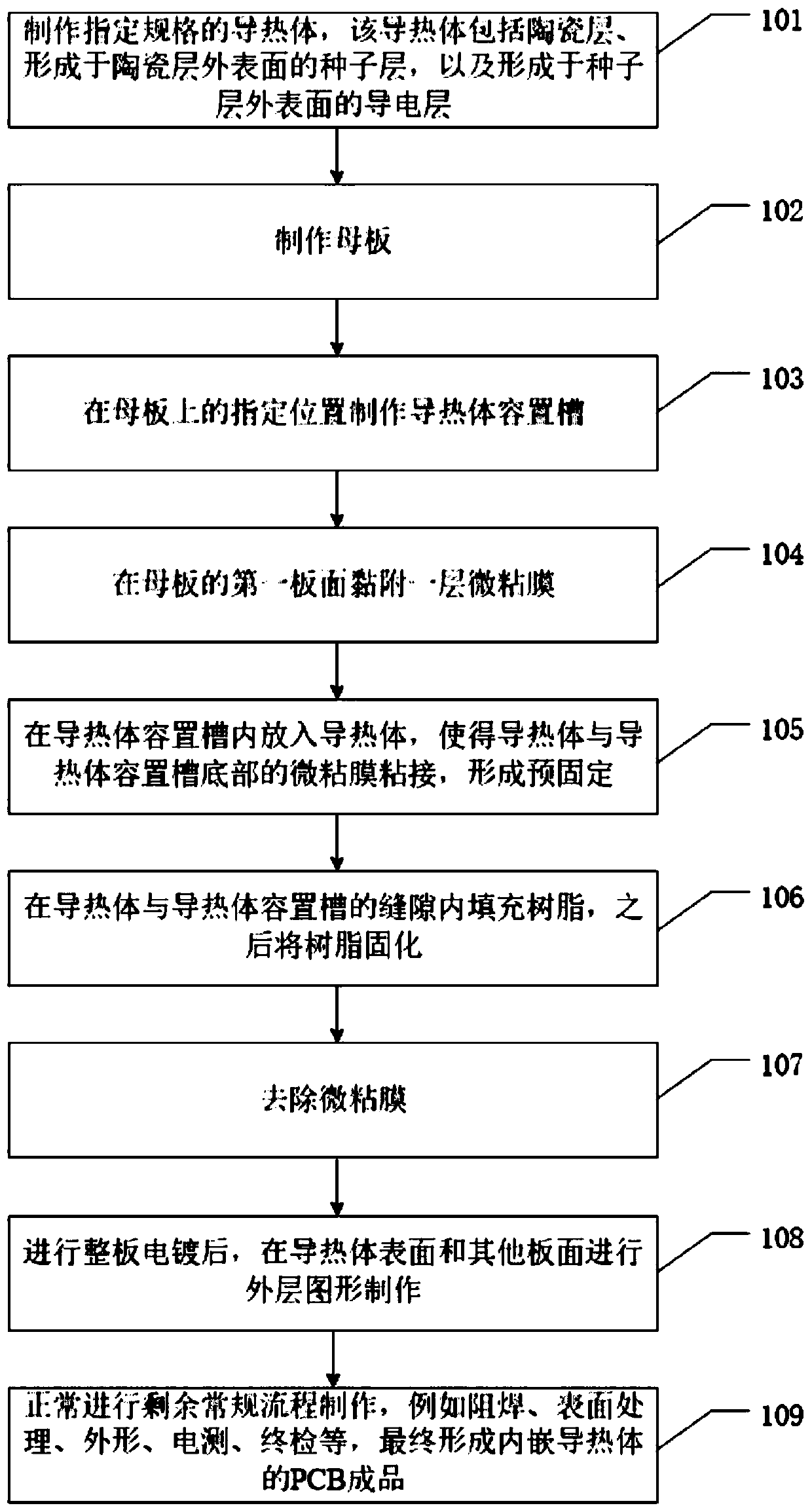

Manufacturing method of heat conduction PCB and PCB

InactiveCN110621123AAvoid displacementAvoid residueMultilayer circuit manufactureCircuit thermal arrangementsOn boardCopper foil

The invention belongs to the technical field of PCBs and discloses a manufacturing method of a heat conduction PCB and a PCB. The manufacturing method comprises the following steps that: a mother board is manufactured, and then a heat conductor accommodating groove is formed in the mother board; a micro-viscous film is adhered to the mother board; a heat conductor is placed in the heat conductor accommodating groove and bonded to the micro-viscous film, and the heat conductor is fixedly connected with the mother board through resin, wherein the heat conductor comprises a ceramic layer and a conductive layer; the micro-viscous film is removed, and then the whole board is electroplated; and an outer-layer pattern is manufactured on the surface of the heat conductor and / or other board surfaces. According to the manufacturing method, the heat conductor accommodating groove is manufactured after a pressing process, so that windowing treatment on outer-layer copper foil is not needed beforepressing, and therefore, the good flatness of the outer-layer copper foil can be kept in the pressing process, and the wrinkling phenomenon of the outer-layer copper foil is avoided; the micro-viscousfilm can be used for pre-fixing the heat conductor and also can be used for preventing a large amount of redundant resin from being left on board surfaces; a copper-clad ceramic sheet is used as theheat conductor; a pattern can be also made on the conductive layer on the surface of the heat conductor; and therefore, the overall wiring density of the PCB is improved.

Owner:DONGGUAN SHENGYI ELECTRONICS

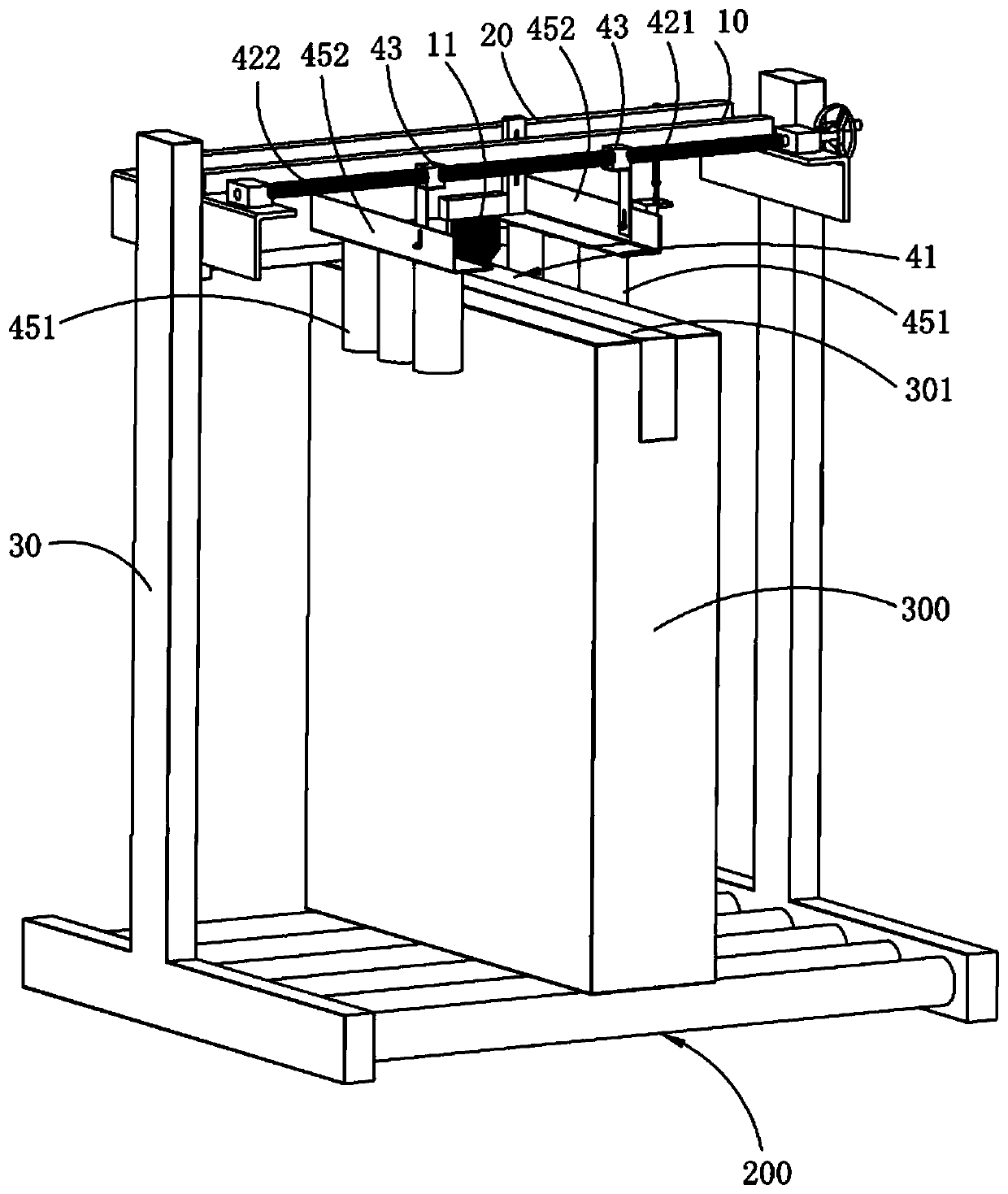

Thin film tension floating adjusting device for storage bag preparation

PendingCN113428706ANo wrinklingNo tensile deformationBag making operationsPaper-makingRotational axisThin membrane

The invention belongs to the technical field of storage bag preparation, and particularly relates to a thin film tension floating adjusting device for storage bag preparation. The device comprises a set of rollers, a floating bracket and a swing guide rod mechanism, wherein, the set of rollers comprises a plurality of fixed rollers and floating rollers which are arranged up and down at equal intervals; the floating bracket is used for mounting and fixing the floating rollers; the swing guide rod mechanism comprises a rotating shaft connected with an output shaft of the driving motor, a rotating rod, a transmission rod, a swing rod, a movable mounting seat, an arc guide rail and an arc sliding block, and one end of the rotating rod is fixedly connected with the rotating shaft. According to the device, by means of the quick-return characteristic of the swing guide rod mechanism, the floating rollers are driven to do downward slow release motion when a thin film machining section is static, the time interval requirements for constant-speed unwinding, thin film tapping, valve welding and the like of an unwinding device are met, and when a thin film is in a stepping state, the floating rollers are driven to do upward quick-return motion meeting the thin film stepping speed, the constant-speed stepping traction requirement that the initial speed of the thin film is zero and is higher than the unwinding speed is met, and it is guaranteed that damage, wrinkling and tensile deformation cannot be generated during stepping traction of the thin film.

Owner:黄山永皓新材料科技有限公司

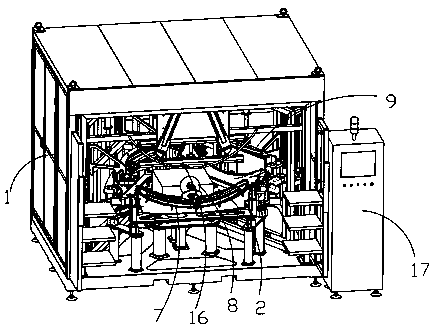

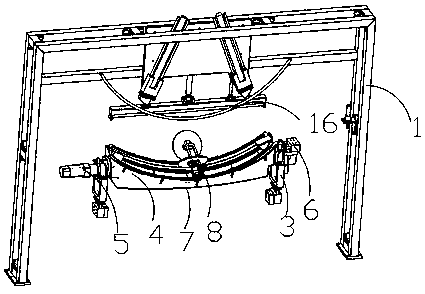

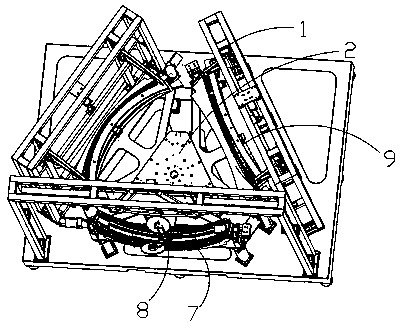

Automatic pasting and covering machine for pasting and covering adhesive tapes on curved panel

InactiveCN108638633AImprove efficiencyNo wrinklingLaminationLamination apparatusAdhesive beltLocking mechanism

The present invention provides an automatic pasting and covering machine for pasting and covering adhesive tapes on a curved panel. The automatic pasting and covering machine comprises a machine framein a frame structure, a rotary plate rotatably arranged relative to the machine frame by a vertical rotation shaft, and a driving motor driving the rotary plate to rotate; a positioning mechanism forpositioning the rotary plate in a plurality of work stations is arranged between the rotary plate and machine frame; the rotary plate is provided with a plurality of workpiece stations; each workpiece station comprises support frames on both sides fixedly connected with the rotary plate, and a rotary frame rotatably arranged between the support frames on the both sides; a rotary motor for drivingthe rotary frame to rotate is arranged on the support frame on one side, and a locking mechanism for locking the rotary frame is arranged between the support frame on the other side and the rotary frame; a workpiece fixing structure used for fixing workpieces is arranged on the rotary frame; and the machine frame is successively provided with a tape pasting work station and a plurality of tape pressing work stations, wherein the outer side of one of the tape pressing stations is provided with an automatic material unloading mechanism. The automatic pasting and covering machine uses a conceptof curve modules to realize the tape pasting and covering of the curved surfaces of the workpieces, and is simple in structure and high in degree of automation.

Owner:泉州台商投资区溪林机械有限公司

Medical isolation adhesive pad

InactiveCN103263327ANot easy to fall offNot easy to misplaceNursing accommodationAdhesiveIsolation layer

The invention discloses a medical isolation adhesive pad which comprises a sanitary isolation layer, a membrane layer and an adhesive layer. The membrane layer is laid on one surface of the sanitary isolation layer, and the adhesive layer is coated on the other surface of the membrane layer. Compared with the prior art, the medical isolation adhesive pad has the advantages that the medical isolation adhesive pad can be used after being directly adhered on the surface of a public facility, is peeled off after being used and is replaced by a new product; the medical isolation adhesive pad is not easy to drop or displace owing to the adhesive layer arranged on the surface, which is adhered on the public facility, of the medical isolation adhesive pad, and accordingly the probability of cross infection is greatly reduced; and a pattern layer and / or a character layer are printed on the sanitary isolation layer 1, so that a visual effect is improved, and propaganda requirements of medical and health institutions and the like can be met.

Owner:天津市金盾胶粘制品厂

Environment-friendly garment fabric finishing and drying device

PendingCN114576937AEvenly heatedImprove quality and efficiencyMechanical cleaningPressure cleaningMechanical engineeringIndustrial engineering

The environment-friendly garment fabric finishing and drying device comprises a base, a drying box and a winding frame are fixedly mounted at the top of the base, a winding shaft is rotatably mounted on the winding frame, and a feeding port and a discharging port are formed in the inner walls of the two sides of the drying box correspondingly; first guide rollers are fixedly installed on the two sides of the drying box, and five second guide rollers are fixedly installed in the drying box. The device is reasonable in design and good in practicability, the drying quality and the drying efficiency of the garment fabric are improved, the surface of the garment fabric can be cleaned and dedusted, the cleaning and dedusting effect on the garment fabric is better, the surface of the garment fabric can be flattened, the rolled garment fabric cannot be wrinkled, and the garment fabric can be better dried. Therefore, the integrated work of drying, cleaning and dedusting, flattening treatment and rolling of the garment fabric is achieved.

Owner:吴跃华

Crease-resistant shirt collar and processing method of crease-resistant shirt collar

The invention relates to the field of a garment, in particular to a crease-resistant shirt collar and a processing method of the crease-resistant shirt collar. The crease-resistant shirt collar comprises a collar body, wherein the collar body is fixedly connected with a shirt and comprises a front piece and a back piece; the front piece and the back piece are sewed and connected and form a cavity structure; openings are formed in the two ends of the collar; a crease-resistant device is arranged in an opening position in the cavity; and a support device is arranged in the cavity in a direction facing the shirt connecting part. The crease-resistant shirt collar and the processing method of the crease-resistant shirt collar provided by the invention have the advantages that by using the structure and the processing method, when the shirt is worn, the collar cannot curl or crease; and the wearing feeling is comfortable.

Owner:ZHEJIANG QIAO XIANG PROFESSIONAL GARMENT CO LTD

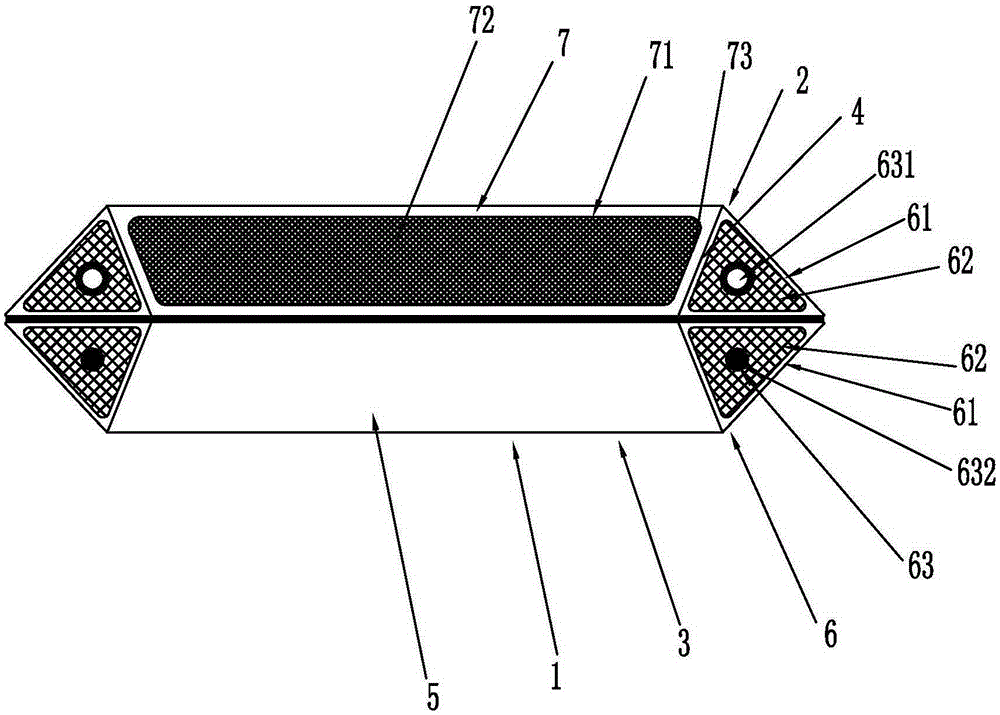

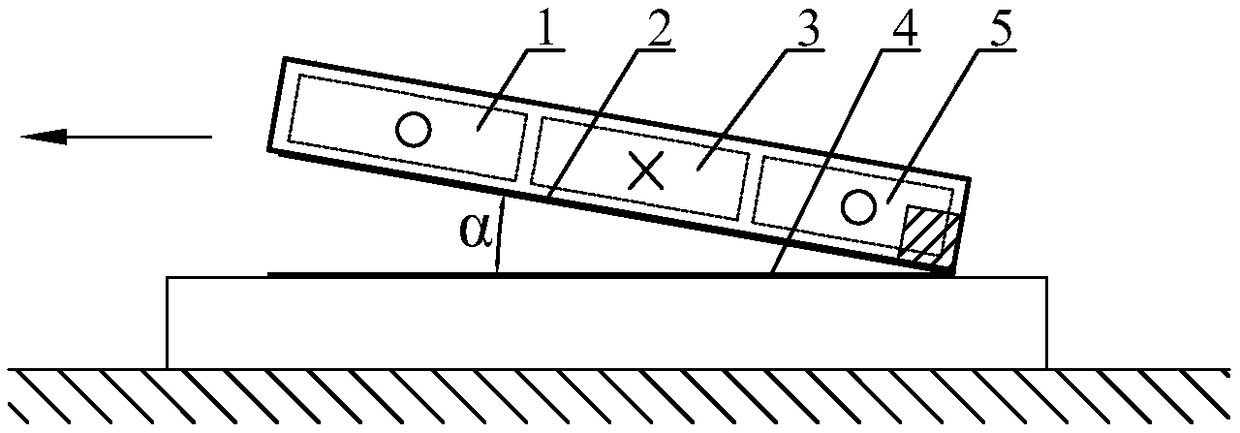

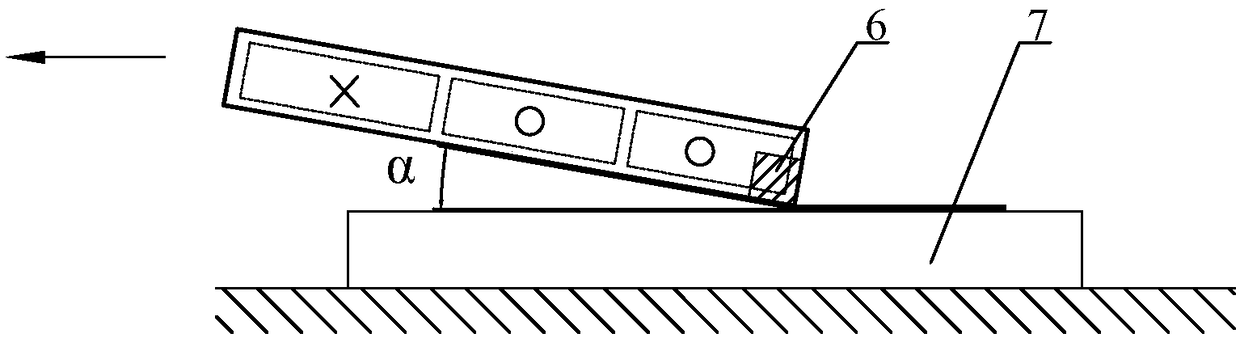

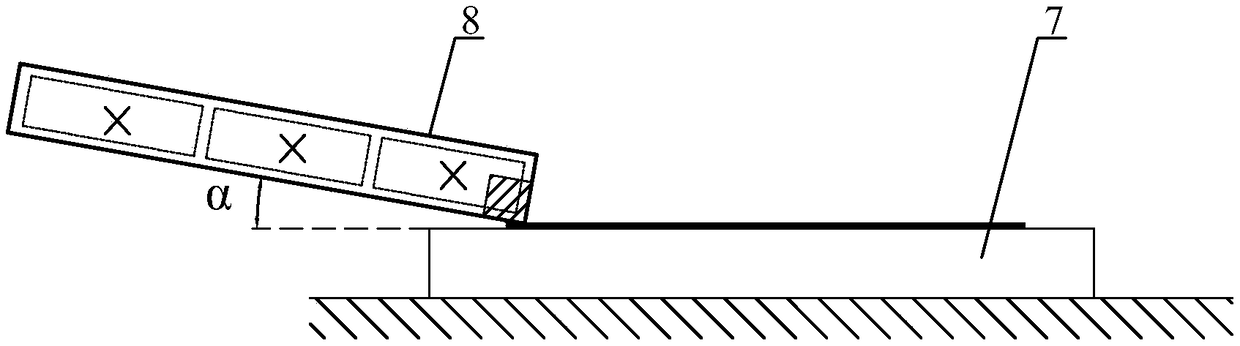

Thin film attaching method

Provided is a thin film attaching method. When an absorbing face of an attaching head and an attaching plane of an attaching platform are in an included angle state, a linear cutting edge of the attaching head or a rolling wheel are attached to the attaching plane, till a thin film at the position of an attaching acting portion and a base material are in press fit; then the attaching head horizontally moves relatively along the attaching plane relative to the attaching platform in the opening direction of the included angle; and in the horizontal moving process, the thin film slides to the position of the attaching acting portion relative to the absorbing face of the attaching head, the thin film and the base material are in press fit through the attaching acting portion, the attaching acting portion abuts against and scraps the back side of the thin film, till attaching of the thin film and the base material is completed. In the attaching process, the attaching head and the attachingplatform horizontally move relatively by forming an included angle, the attaching acting portion of the attaching head abuts against the thin film and scraps the thin film so that the thin film can beattached onto the base material; and bubbles between the thin film and the base material are removed while attaching is performed, the attaching quality is high, and products are free of a wrinklingphenomenon. The method is especially suitable for manufacturing sensor films detecting hydrogen leaking in hydrogen fuel batteries.

Owner:苏州凯蒂亚半导体制造设备有限公司

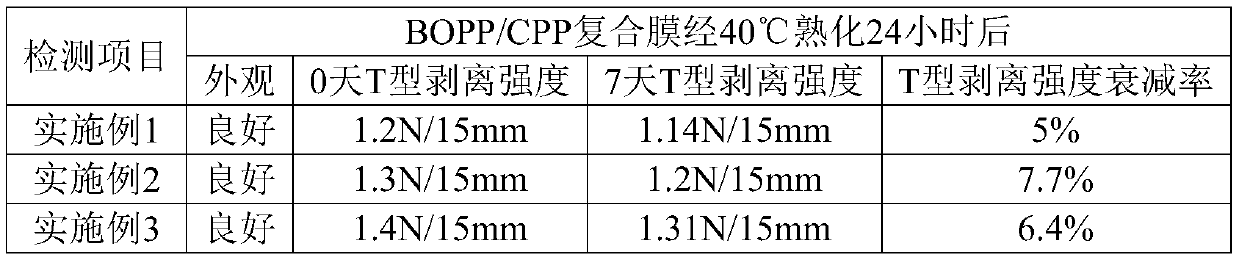

Solvent-free two-component polyurethane laminating adhesive and preparation method thereof

InactiveCN110734732AGood lookingLow peel strengthPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention relates to a solvent-free two-component polyurethane laminating adhesive and a preparation method thereof. The solvent-free two-component polyurethane laminating adhesive comprises a component A and a component B, wherein the component A is prepared by carrying out polymerization reaction on a homogeneous mixture containing polyisocyanate, polyether glycol with the average molecularweight of 1000 and polyether glycol with the average molecular weight of 2000; the component B is a homogeneous mixture comprising a polyether triol having an average molecular weight of 1000, a polyester diol having an average molecular weight of 500, and a polyether triol having an average molecular weight of 3000. According to the method, BOPP and CPP are compounded; after the BOPP / CPP composite film is completely cured, the T-shaped peel strength is 1.2-1.4 N / 15mm, the T-shaped peel strength is attenuated by 5%-8% after seven days, the BOPP / CPP composite film is good in heat resistance, hot sealing edge wrinkling does not occur during bag making, and a made packaging bag is not prone to air leakage.

Owner:BEIJING JINGDU DACHENG CHEM

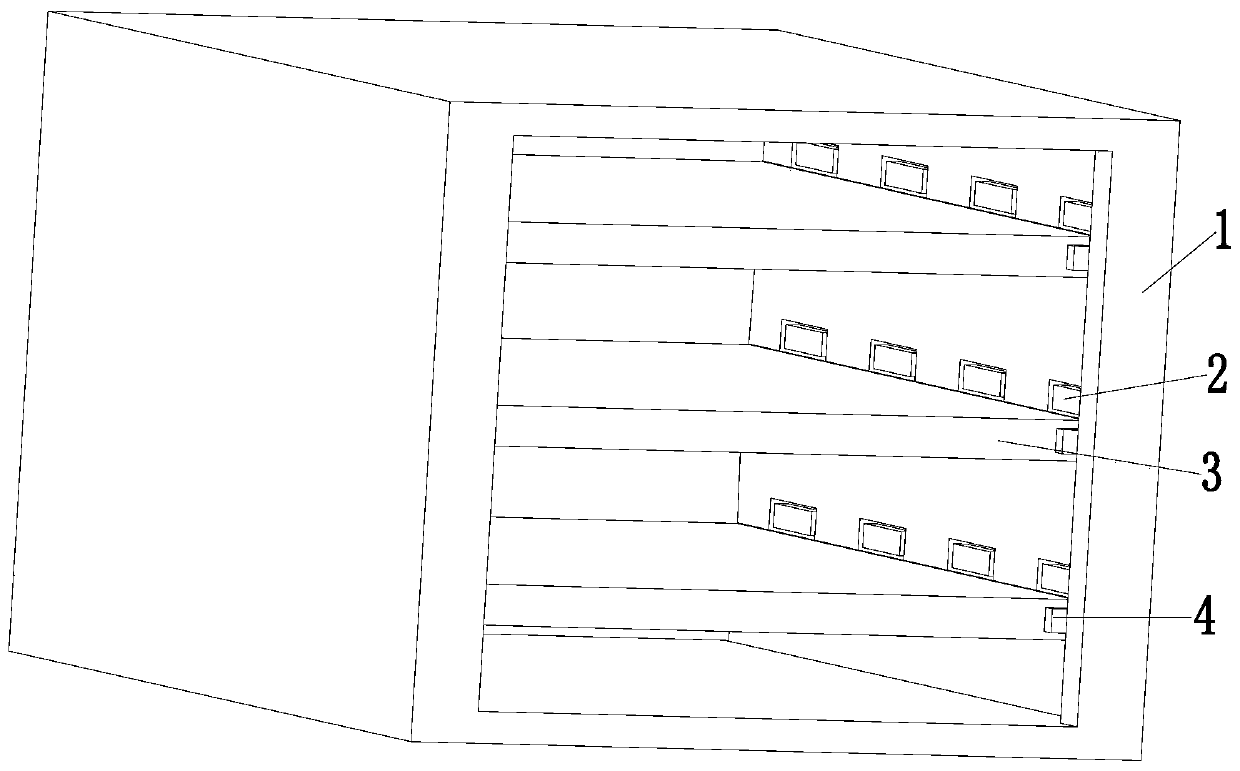

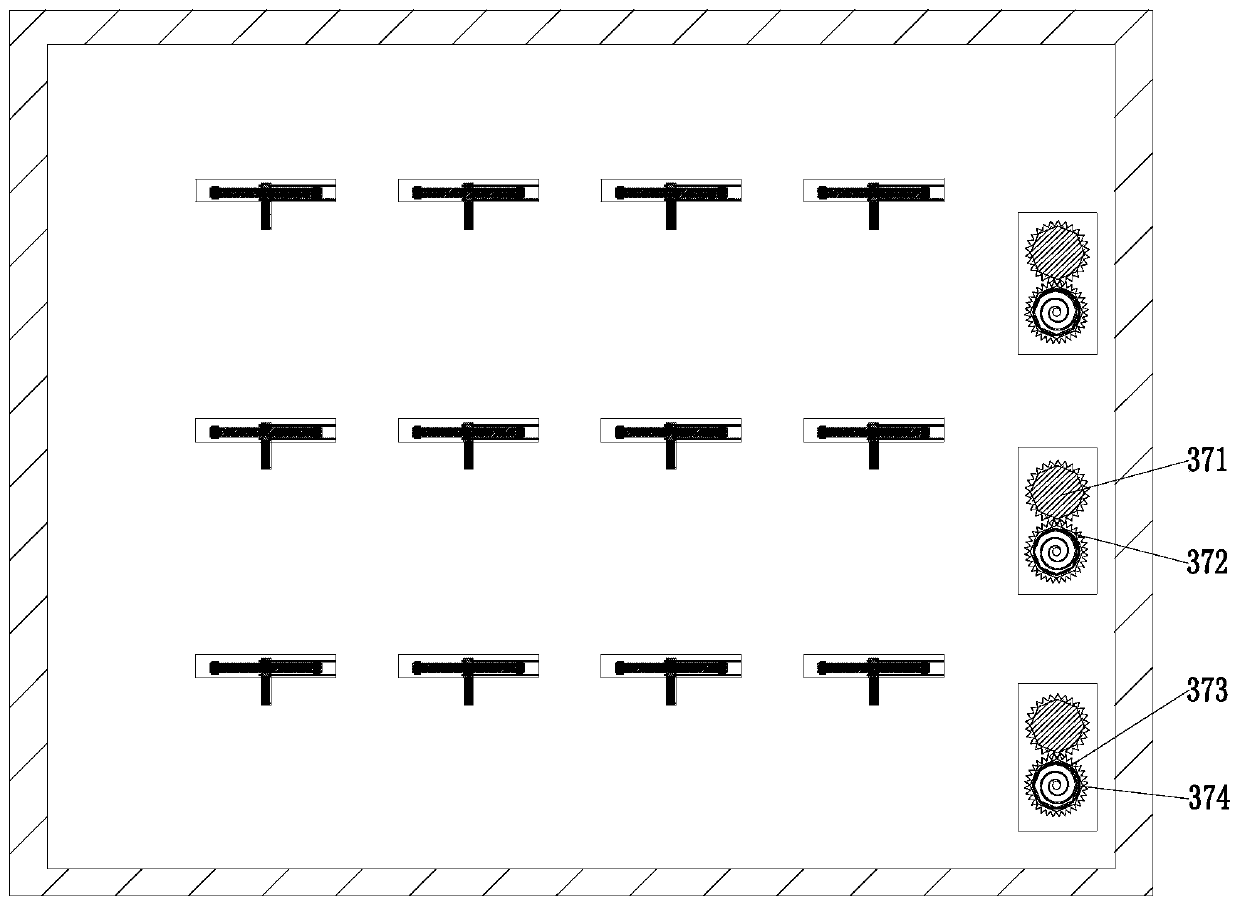

Adjustable article isolation refrigerated transport carriage

ActiveCN110817166AIncrease labor intensityIncrease shipping costsLarge containersTank wagonsMarine engineeringCarriage

The invention relates to an adjustable article isolation refrigerated transport carriage. The adjustable article isolation refrigerated transport carriage comprises a carriage body, temporary placingdevices, winding devices and clamping devices, wherein the winding devices are uniformly mounted between the inner walls of the left end and the right end of the carriage body from top to bottom; thetemporary placing devices are uniformly mounted on the inner walls of the left end and the right end of the carriage body; and the clamping devices are symmetrically mounted on the inner walls of theleft end and the right end of the front end of the carriage body. According to the adjustable article isolation refrigerated transport carriage, the following problems existing during existing refrigerated article transportation and isolation can be solved, firstly, partition plates are usually adopted for the refrigerated article transportation, after the partition plates are used for isolating refrigerated articles, the same refrigerated articles need to be manually stacked together, after the partition plates are placed on the refrigerated articles, different refrigerated articles are stacked on the partition plates, so that the labor intensity of workers is increased; and secondly, the refrigerated articles are various in transported goods, so that different types of refrigerated articles need to be assembled and transported by adopting different transport carriages, and if all the refrigerated articles are transported by using a single vehicle, the transportation cost is greatly increased.

Owner:QINGDAO YAKAI SPECIAL AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com