Film wrapping machine winding device for flat-shaped wires

A technology of wire take-up device and film wrapping machine, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, electrical components, etc., and can solve the problem that insulation material wrapping wires are difficult to meet the requirements of flatness, flipping, and affecting the insulation effect of wrapping, etc. problems, to achieve the effect of reliable performance, anti-turnover, flat and tight coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

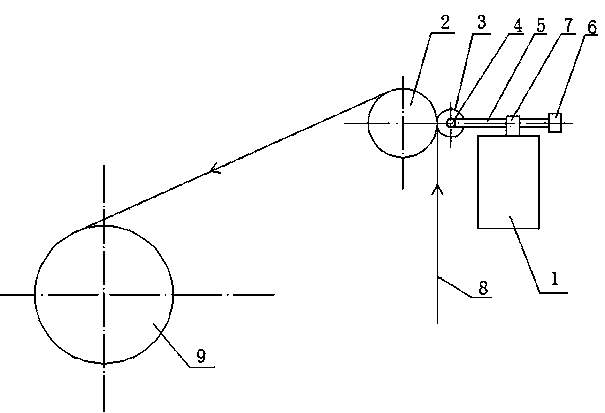

[0007] Such as figure 1 As shown, a take-up guide wheel 2 is arranged on the frame 1, and a compacting wheel 3 axially parallel to the take-up guide wheel 2 is arranged on one outer side of the take-up guide wheel 2 .

[0008] The center of the compacting wheel 3 is connected to one end of the adjusting screw rod 5 through the connecting shaft 4, and the other end of the adjusting screw rod 5 is provided with an adjusting handwheel 6. The axial direction of the adjusting screw rod 5 is perpendicular to the axial direction of the take-up guide wheel 2 , and the nut 7 which is threadedly connected with the adjusting screw rod 5 is fixedly connected on the frame 1 .

[0009] Such as figure 1 As shown, the wrapped wire 8 runs from bottom to top under the appropriate pressure of the compacting wheel 3 and the take-up guide wheel 2 until it enters the take-up reel 9 for take-up to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com