Ger lever for operation device of automobile gear-box

A technology for automobile gearboxes and shift levers, which is applied in the field of shift levers, and can solve problems such as laborious work of the shift levers and shift shafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

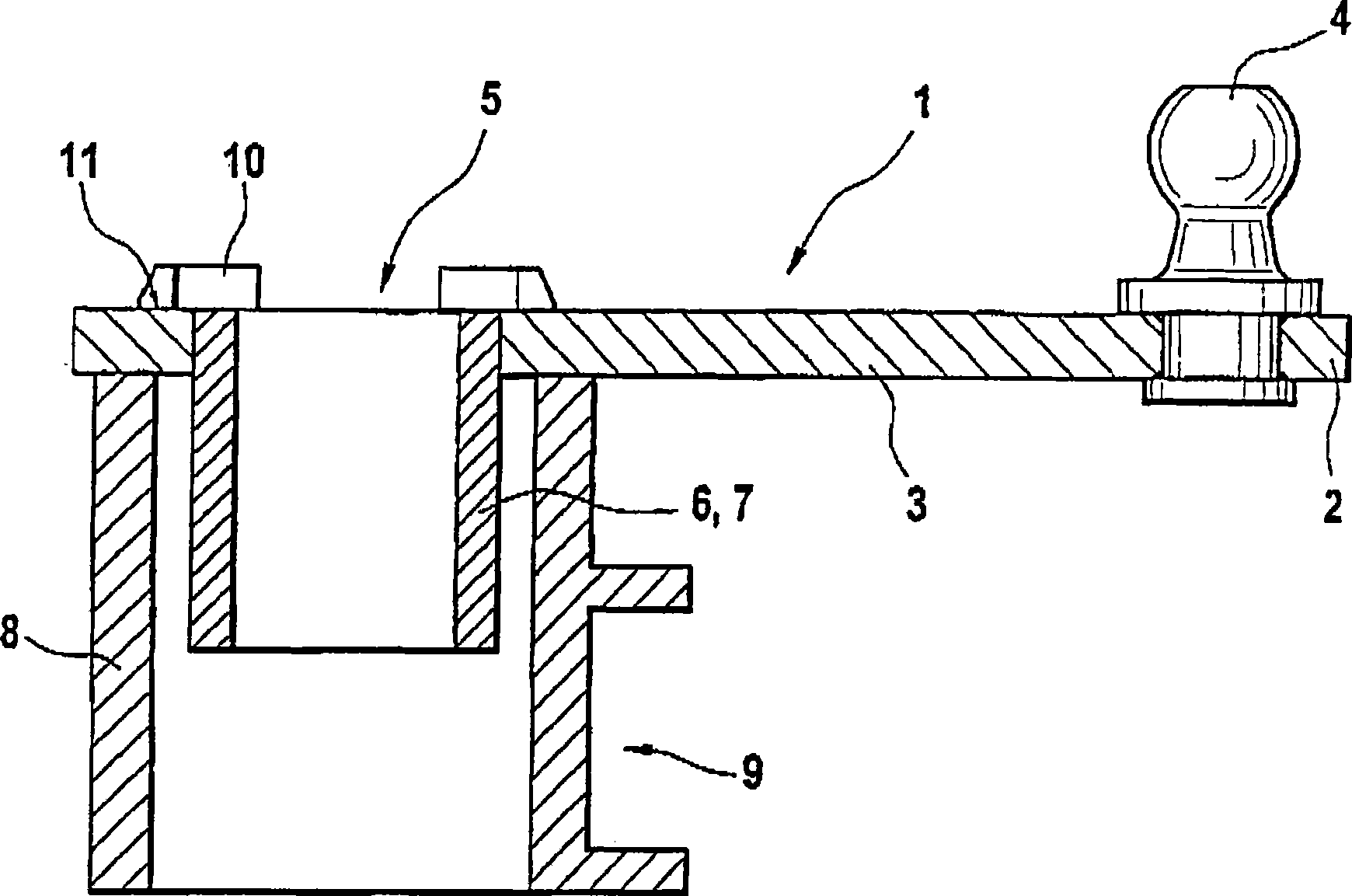

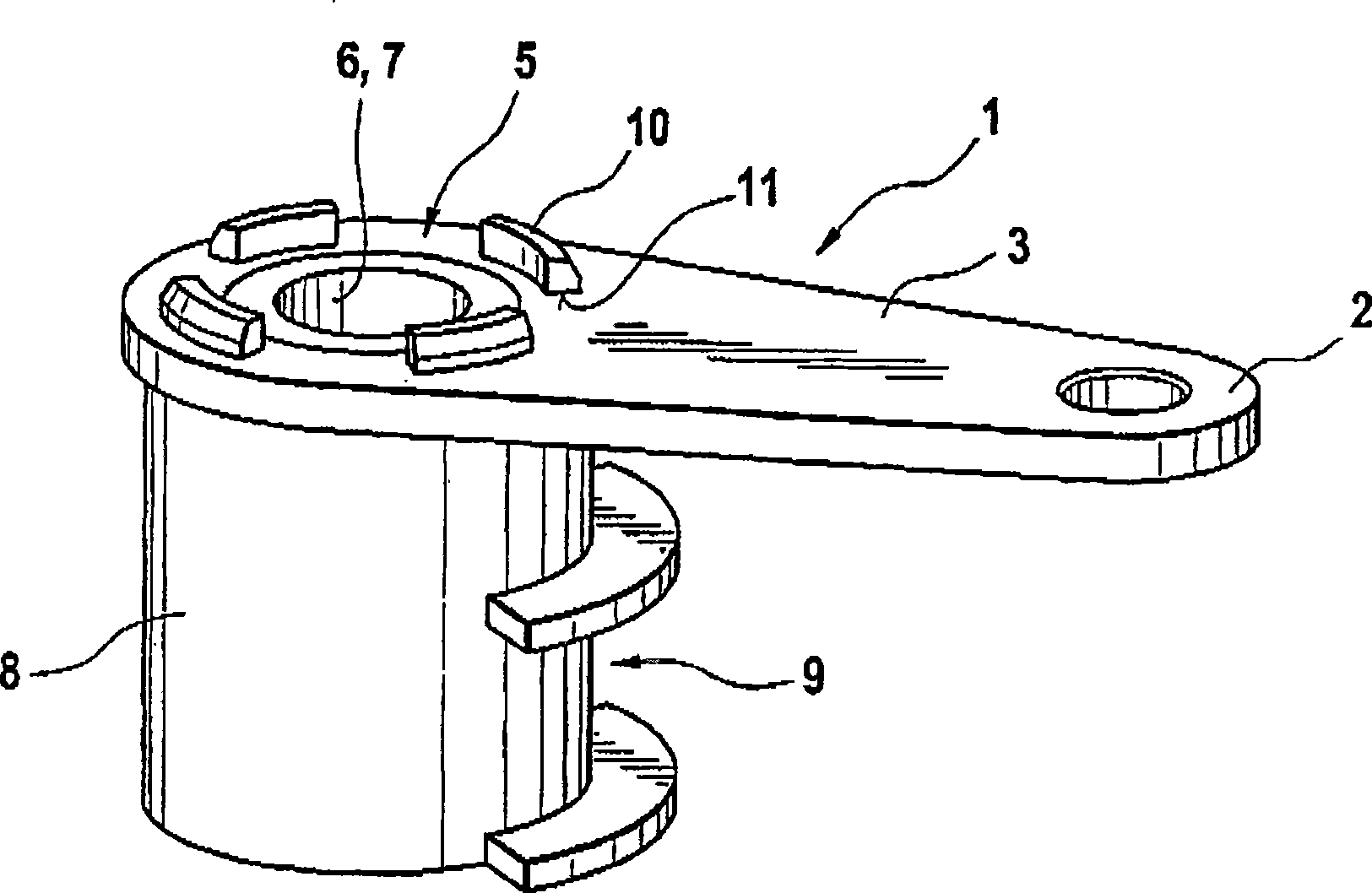

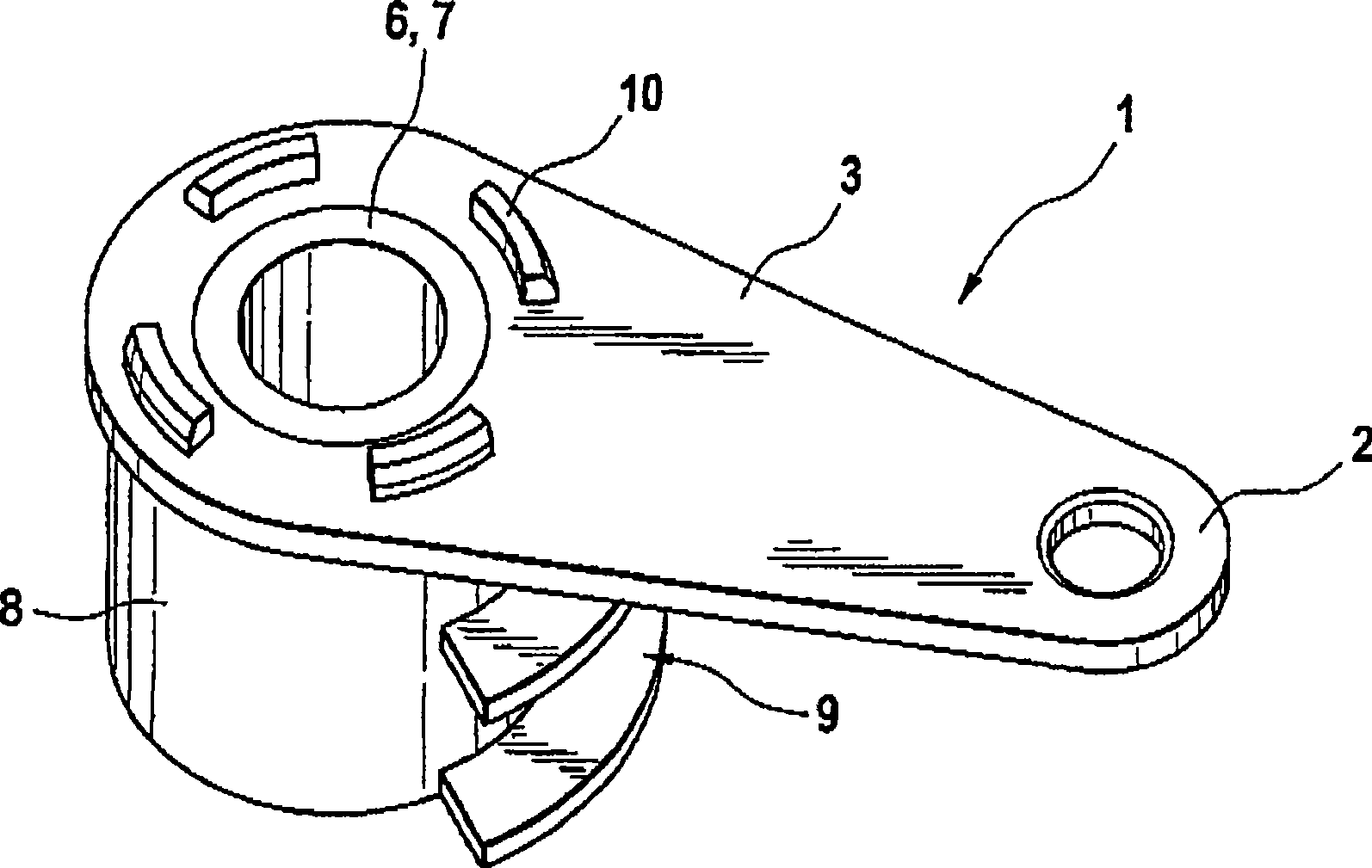

[0021] Figures 1 to 4 The schematic diagram of FIG. 1 illustrates the structure and operating principle of a first variant of the gear lever 1 , which is a component part of an operating device for a gearbox (not shown) of a motor vehicle. The selector lever 1 generally remains operatively connected to a gearshift shaft (not shown) of the gearbox and is used for axial displacement of this gearshift shaft. The shift shaft is mounted rotatably and axially displaceably in the gearbox housing. A selector lever (not shown) is usually fixed in a rotationally fixed manner on the end face of the selector shaft, so that the selector shaft can be rotated by a pivotal movement of the selector lever by a defined rotational angle amount, which is necessary for switching the shift stages is compulsory. The selector shaft can be displaced in the axial direction by means of the illustrated selector lever 1 . In the illustrated embodiment, the selector lever 1 is provided with a ball head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com