Patents

Literature

142results about How to "Achieve axial movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

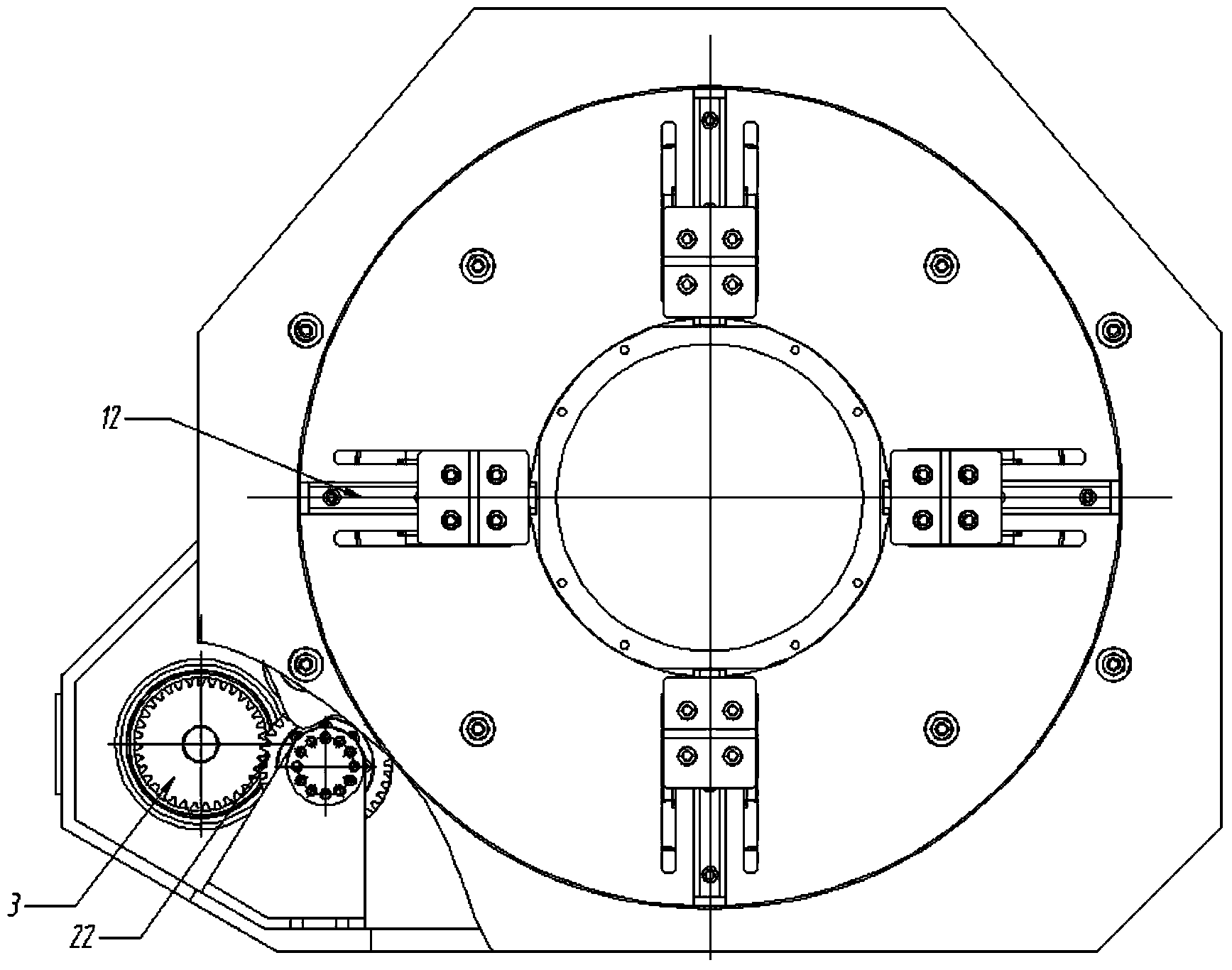

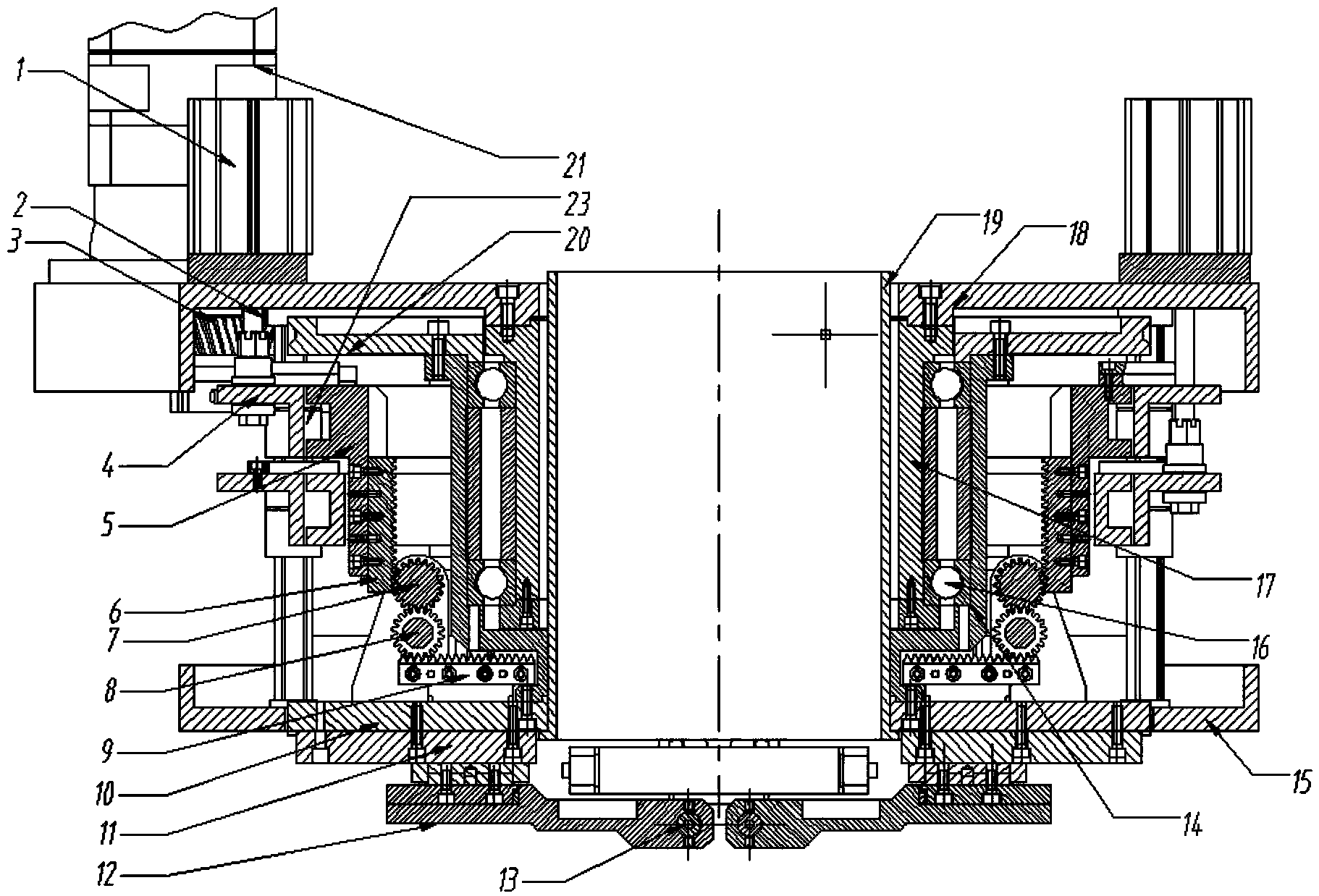

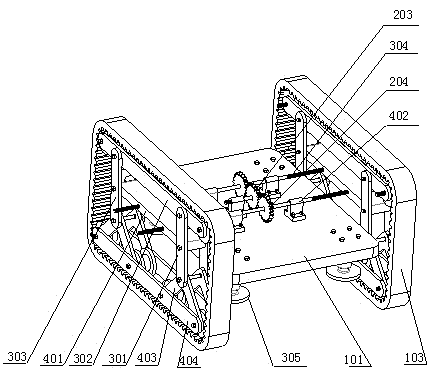

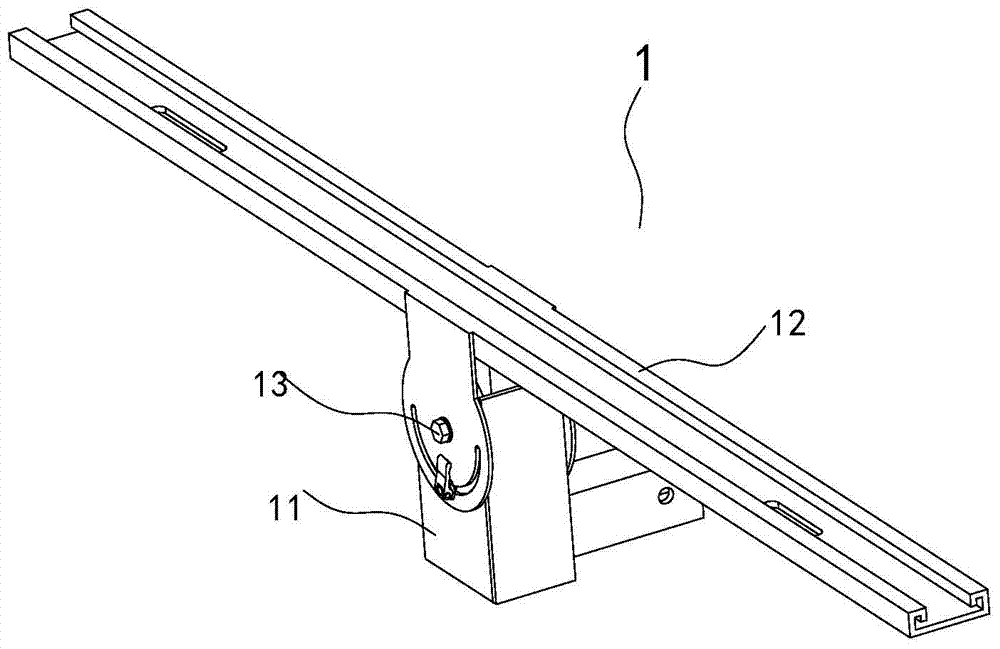

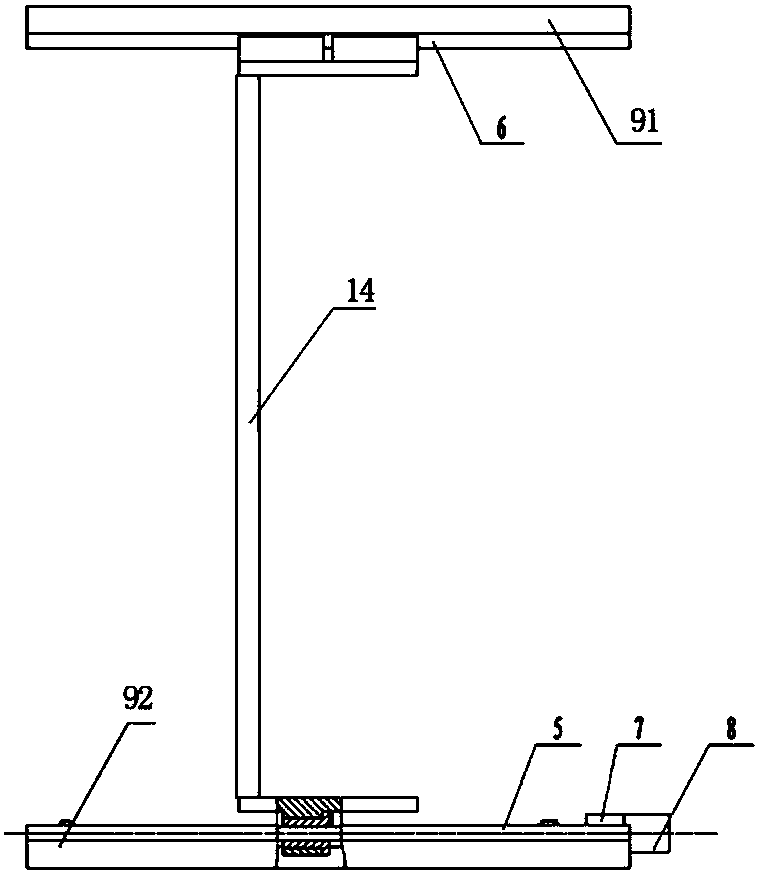

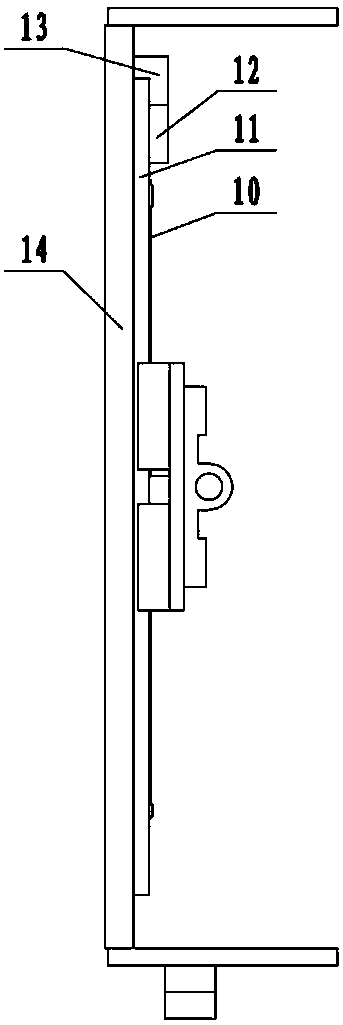

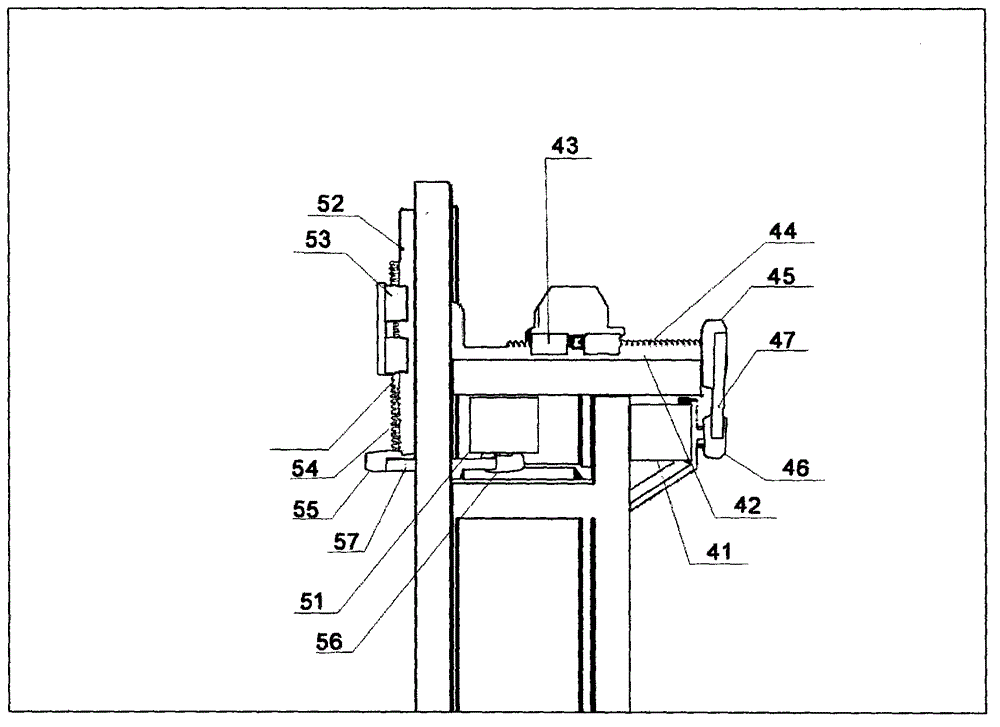

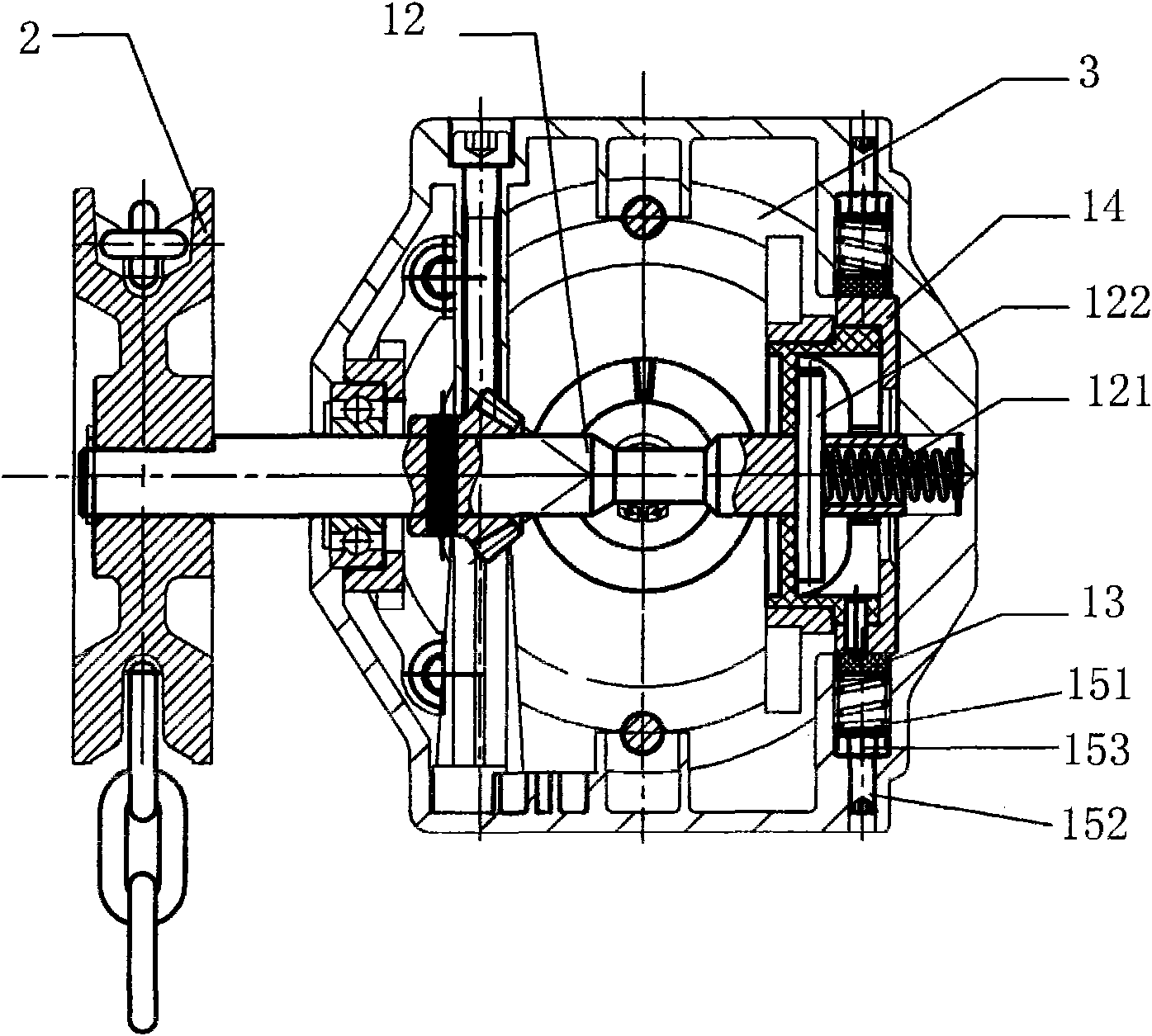

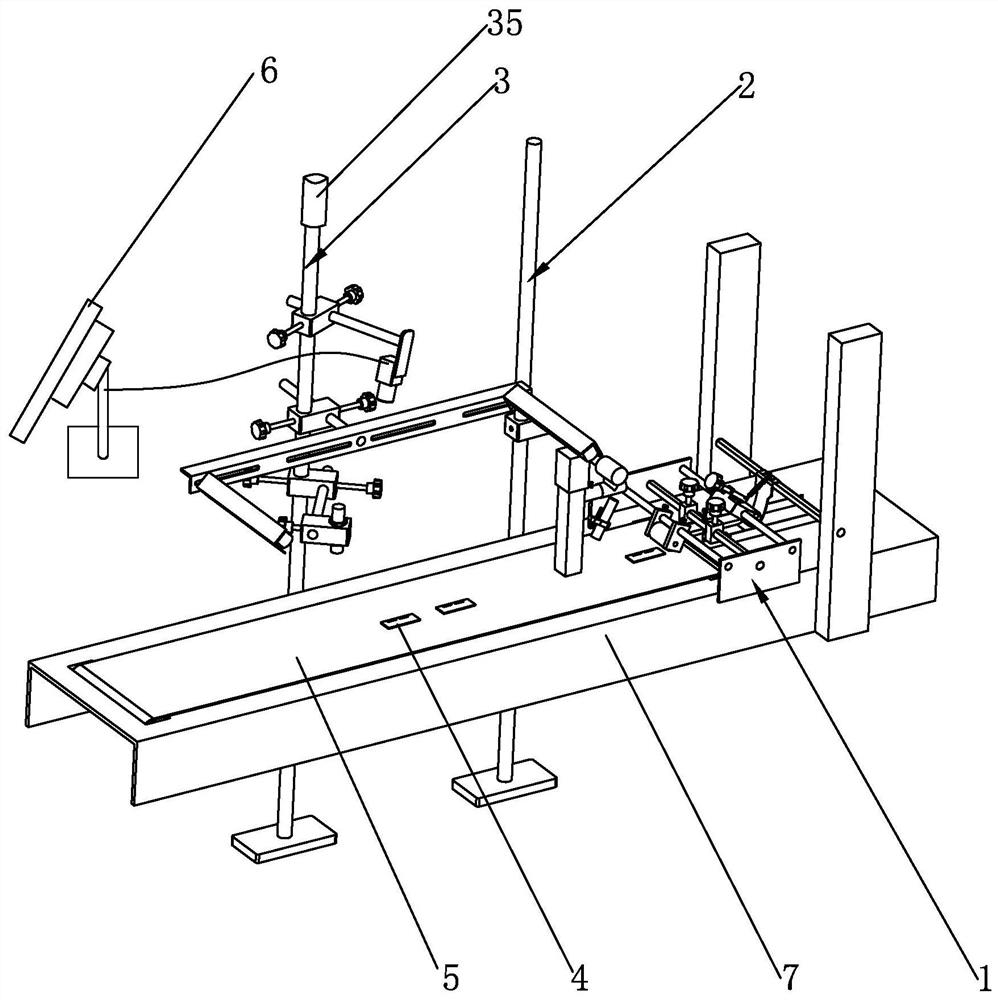

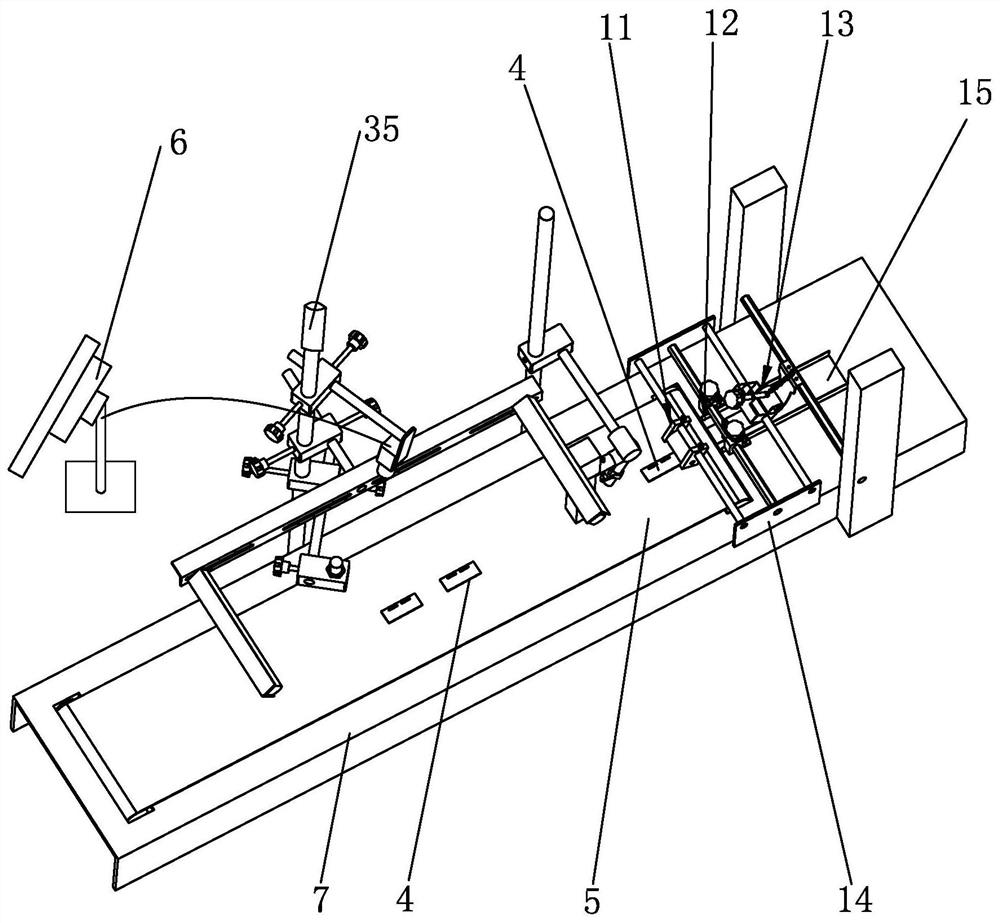

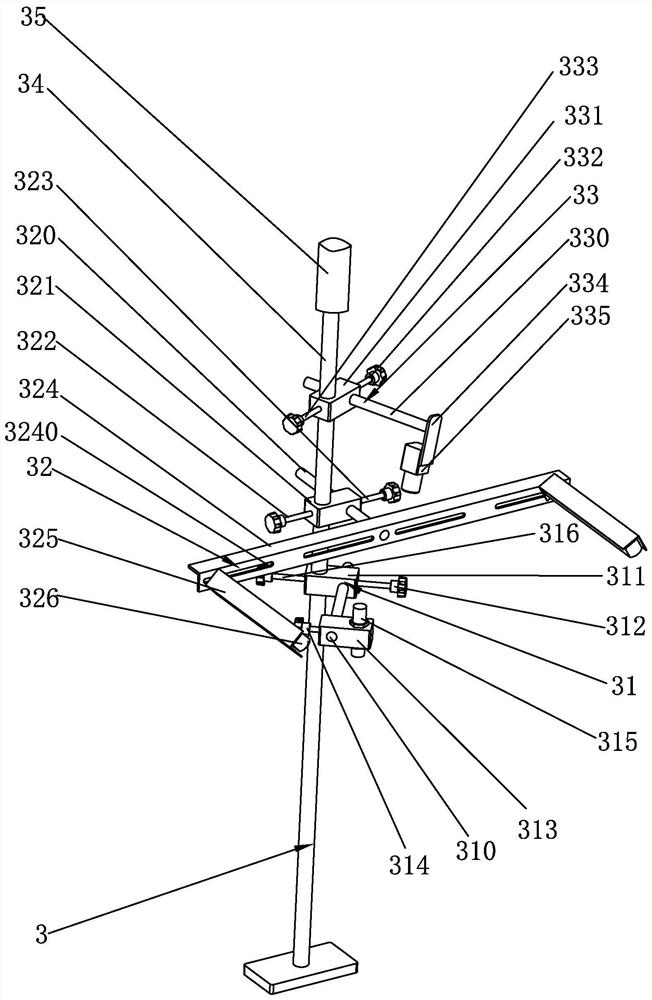

Center frame of square tube laser cutting machine

ActiveCN103659006AAchieve axial movementMetal working apparatusLaser beam welding apparatusLaser cuttingEngineering

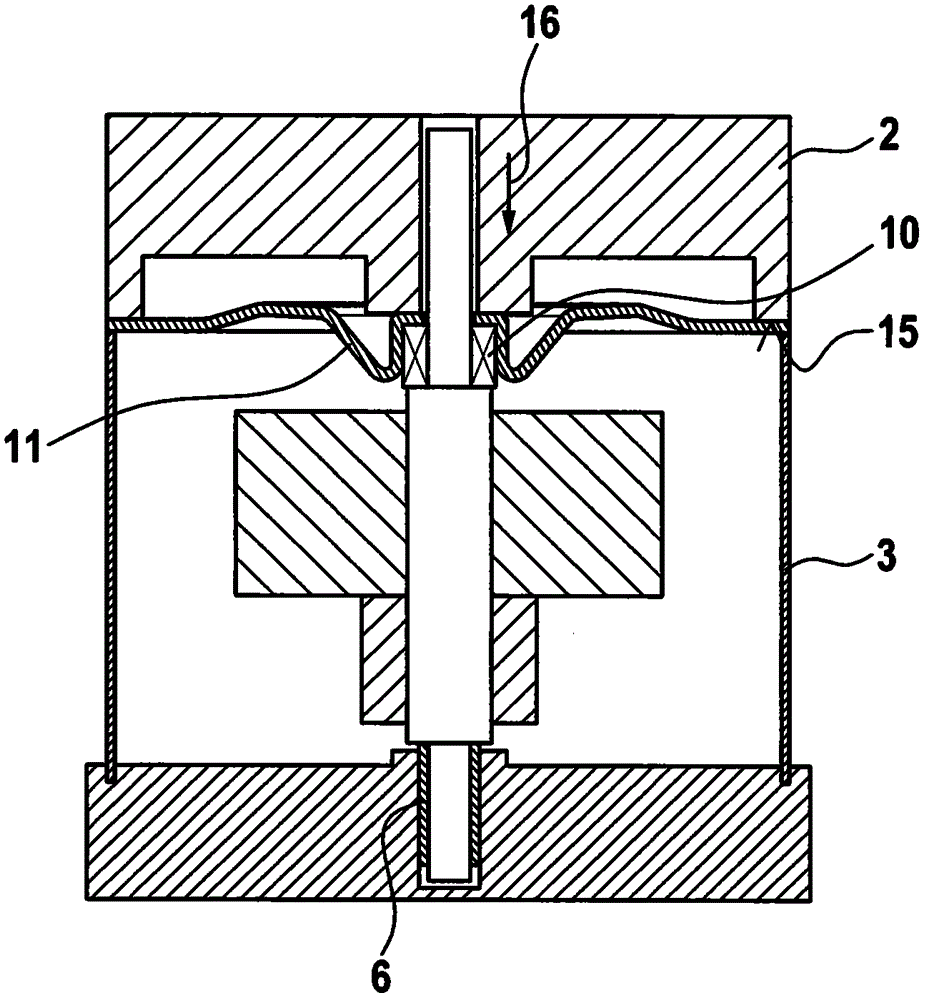

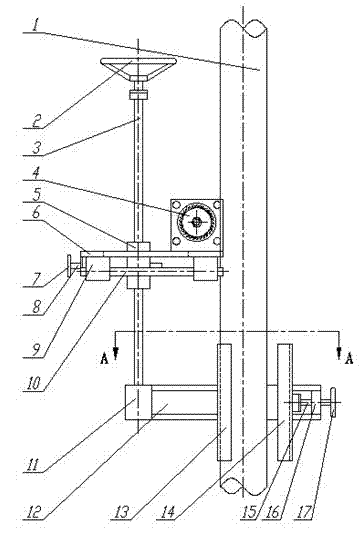

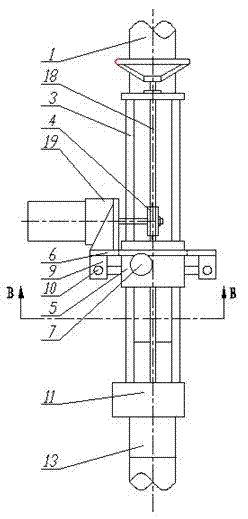

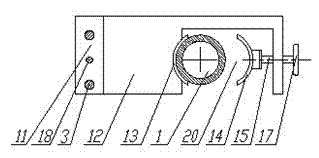

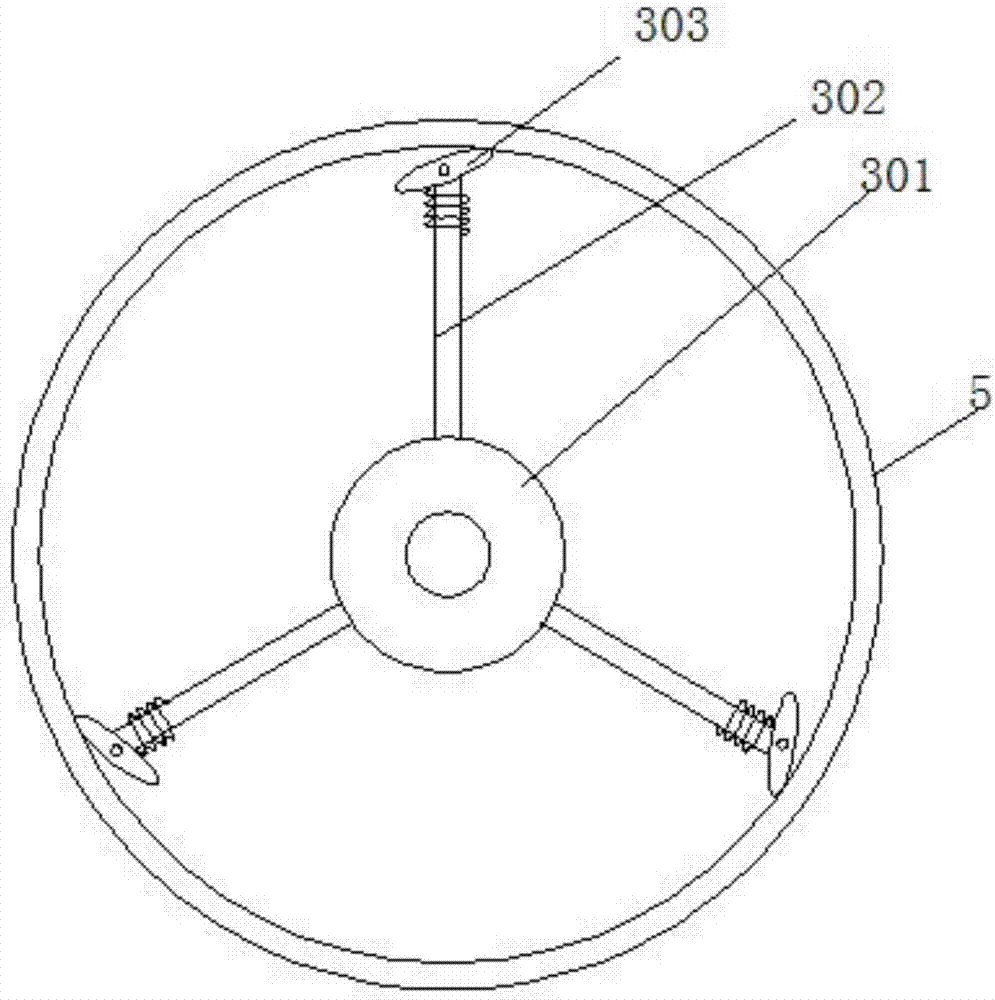

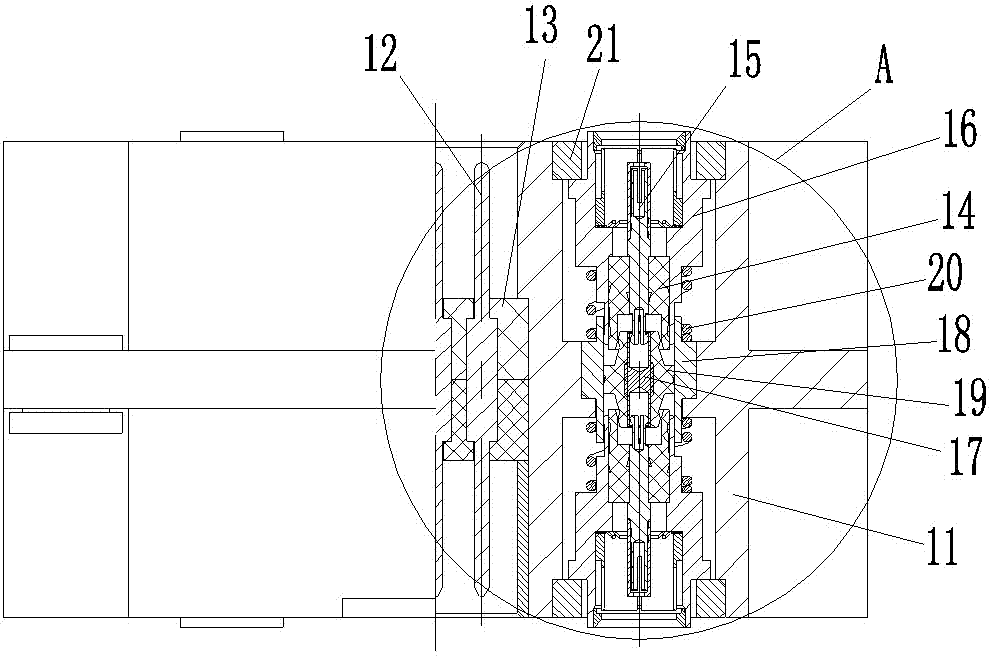

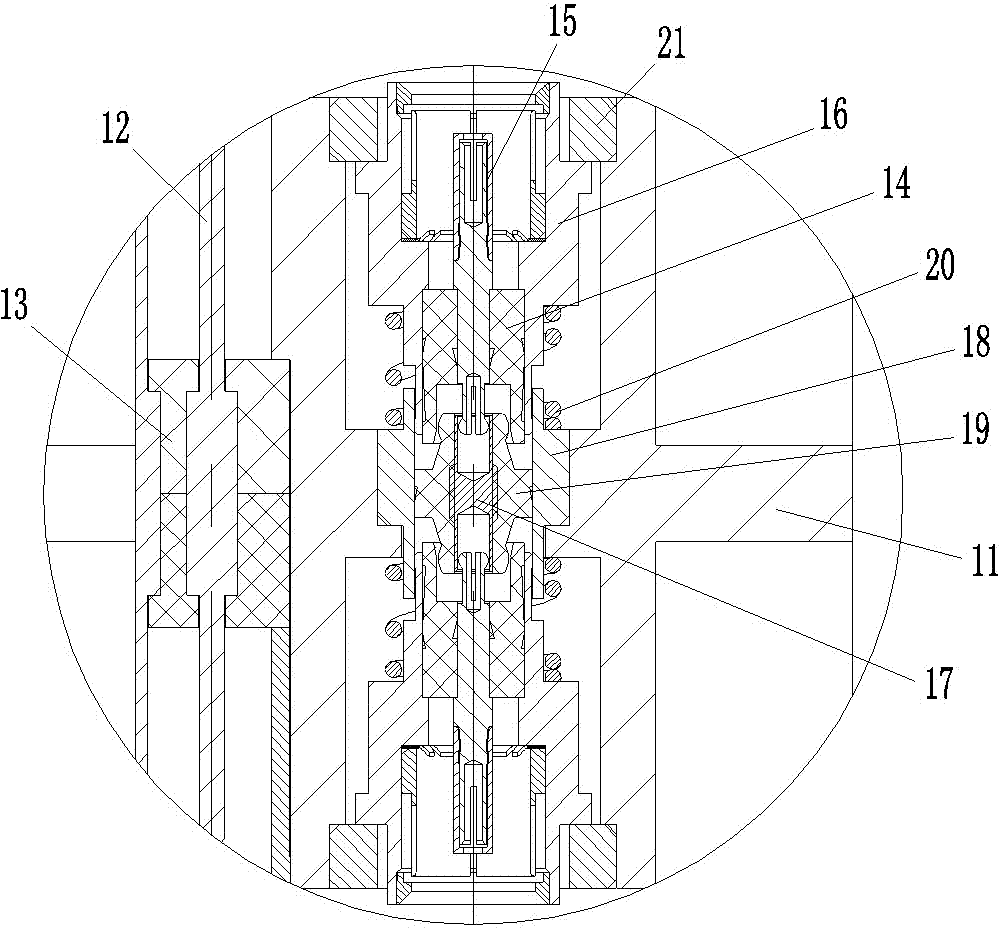

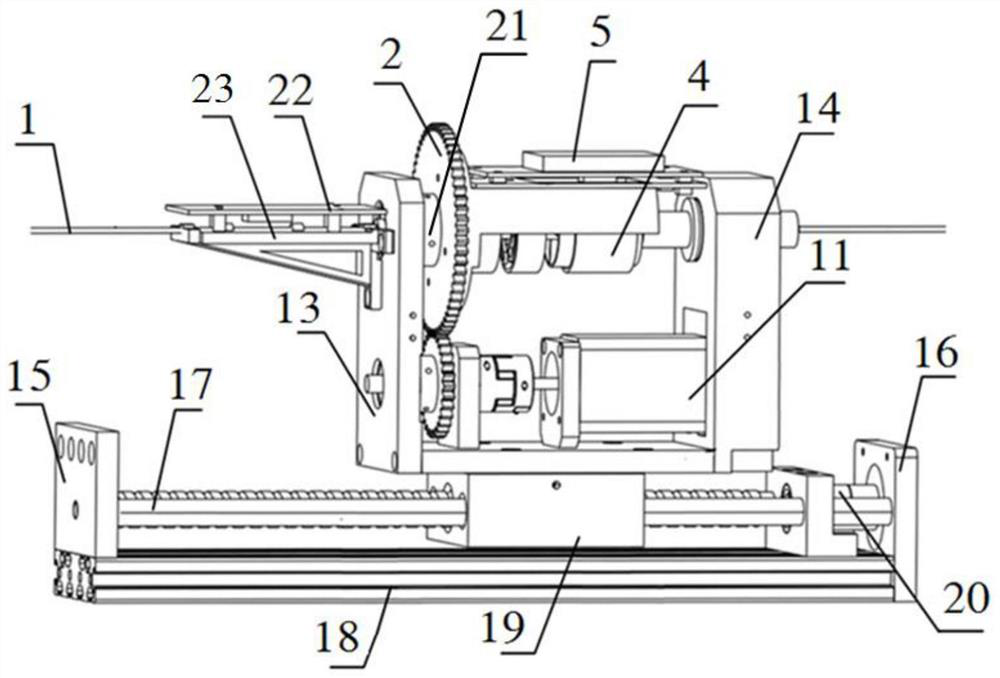

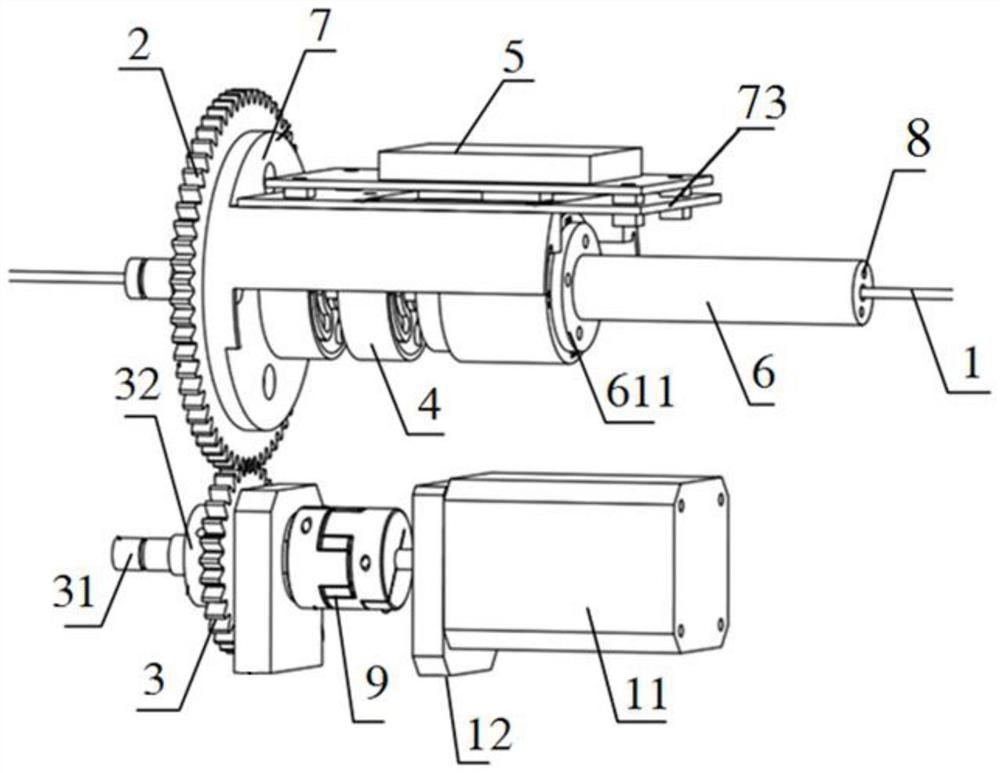

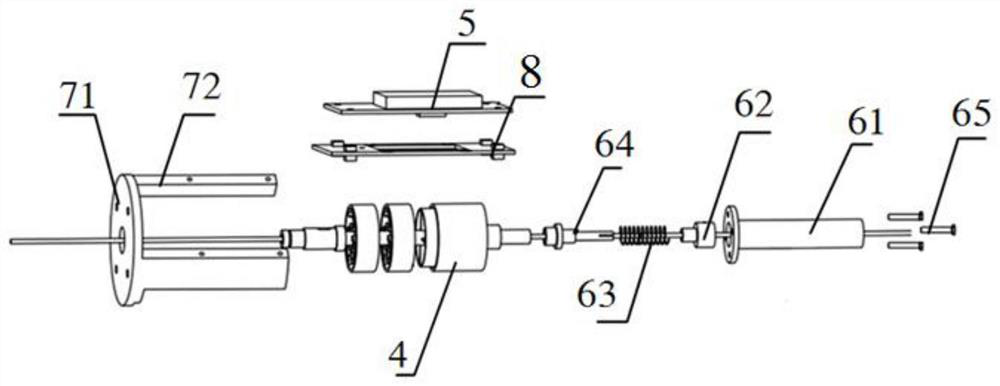

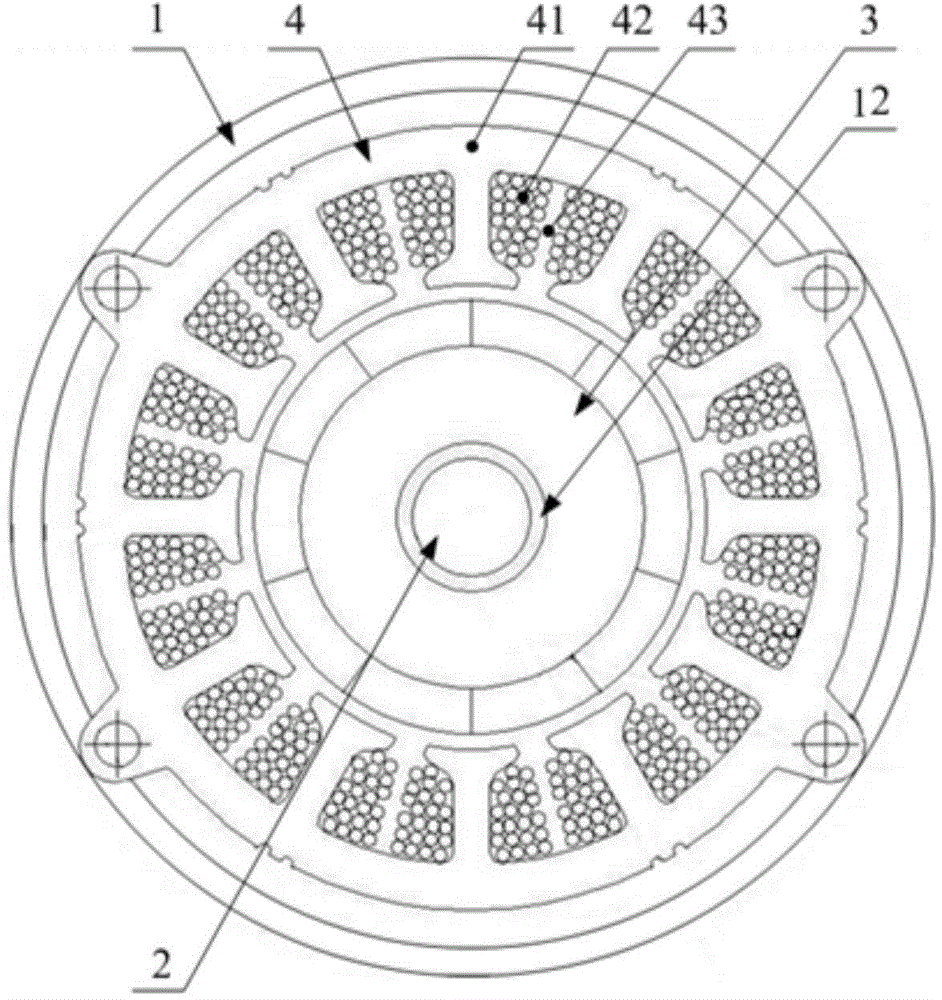

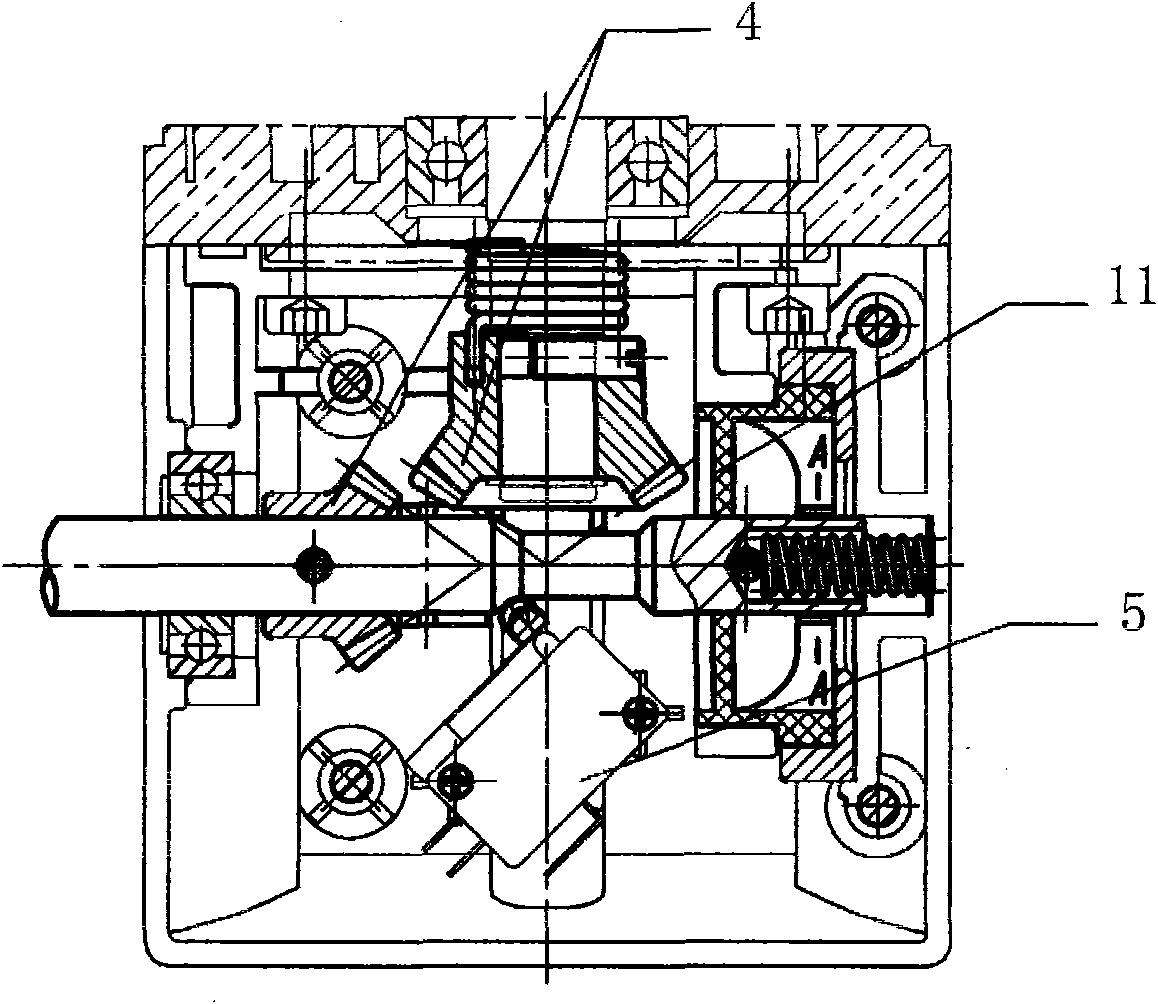

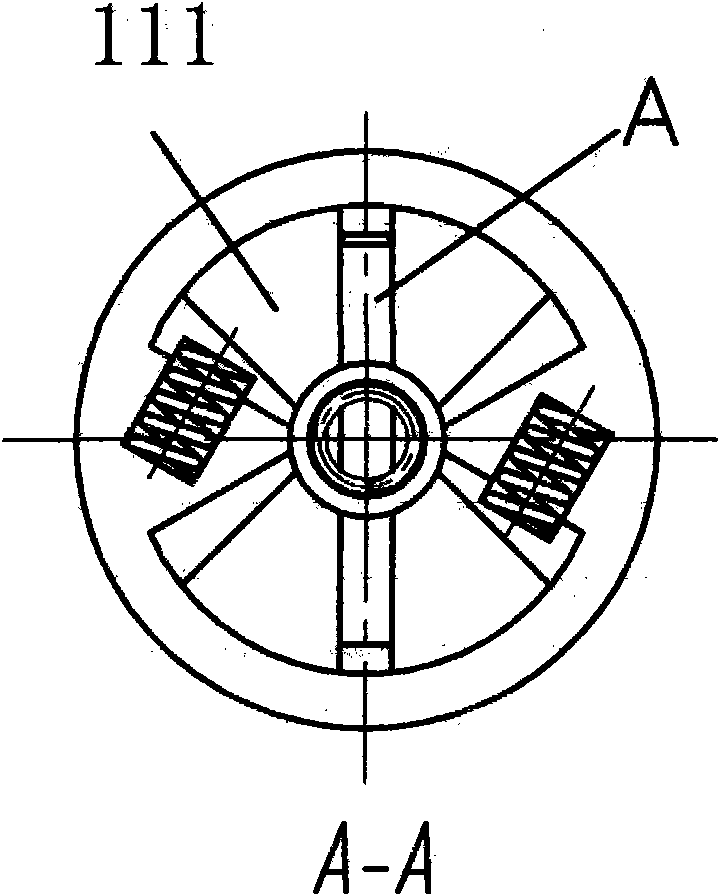

The invention discloses a center frame of a square tube laser cutting machine. The center frame used for supporting and clamping square tube workpieces and synchronously rotating with a spindle motor mainly comprises a synchronous clamping supporting mechanism, a synchronous rotating control mechanism, a hollow center frame structure, and a tube axial movement mechanism. The four mechanisms operate in coordination to clamp and support square tubes, under high precision, high accuracy and high stability, and axially feed the square tubes for laser machining. The workpieces can be clamped and supported accurately in sync through the synchronous clamping supporting mechanism; a rotating motor can drive a claw and a clamped workpiece to rotate in sync through the synchronous rotating control mechanism. The hollow center frame structure can coordinate with the tube axial movement mechanism to axially move the square tubes for machining. The center frame allows the square tube workpieces to be clamped and supported accurately, can rotate in sync with the spindle motor, and allows for axial movement for machining; accordingly, machining range is widened, and machining efficiency and machining precision are improved.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG +1

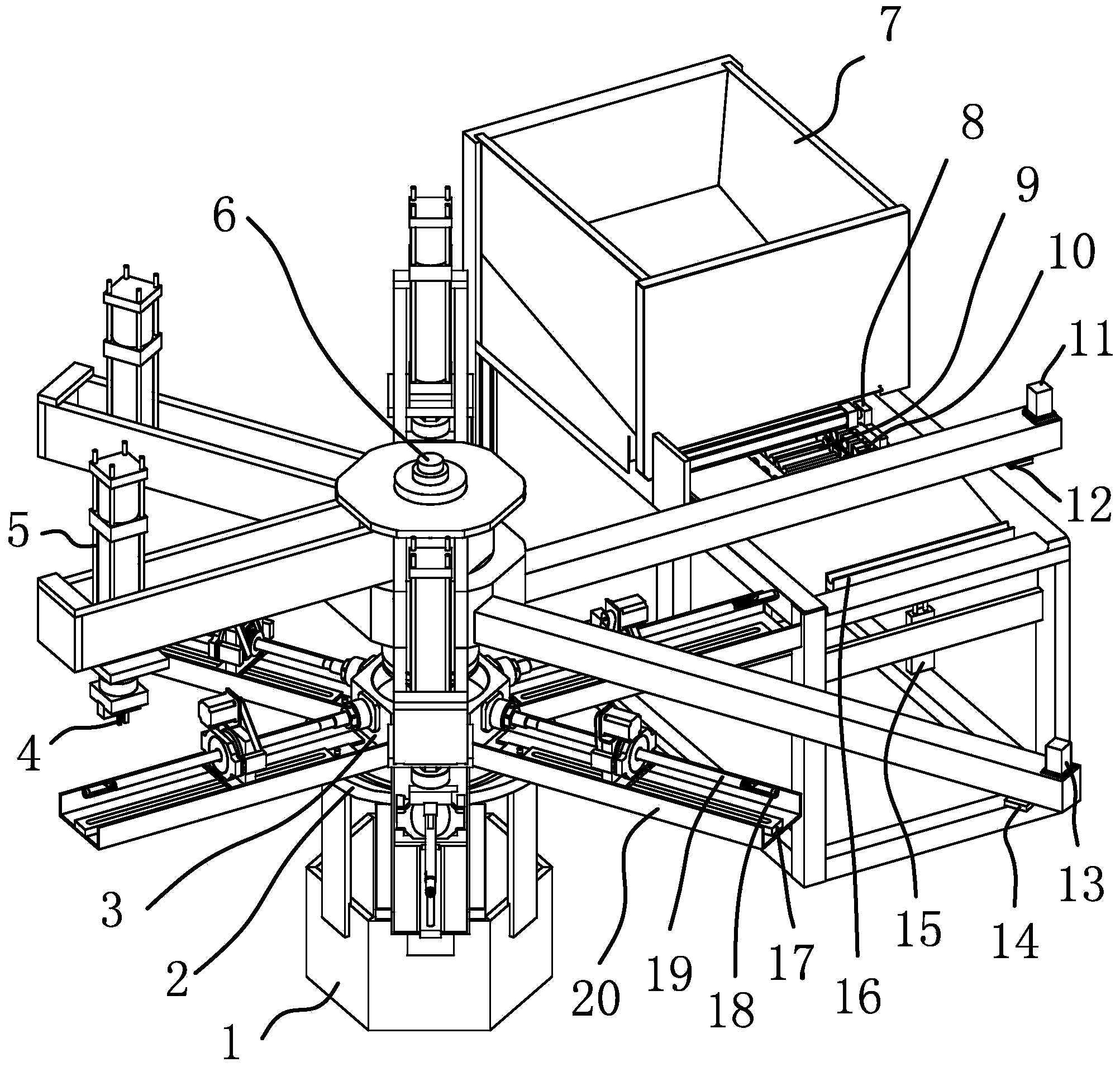

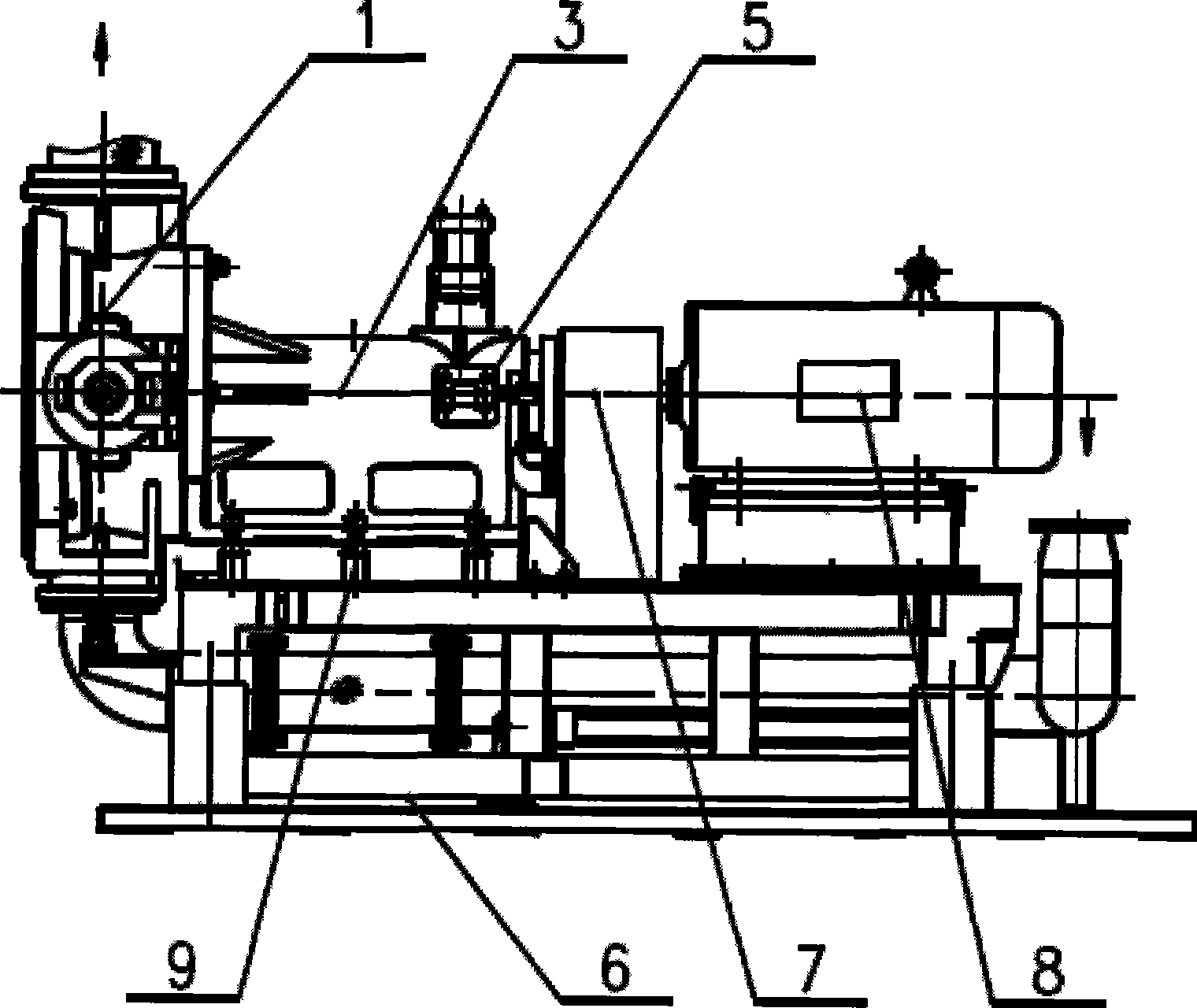

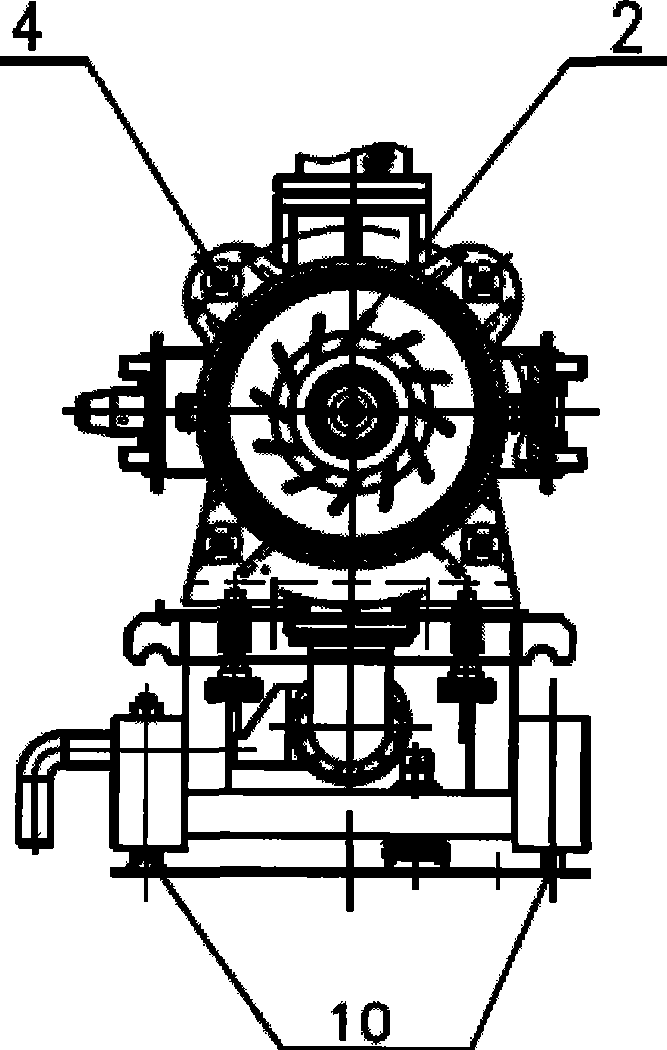

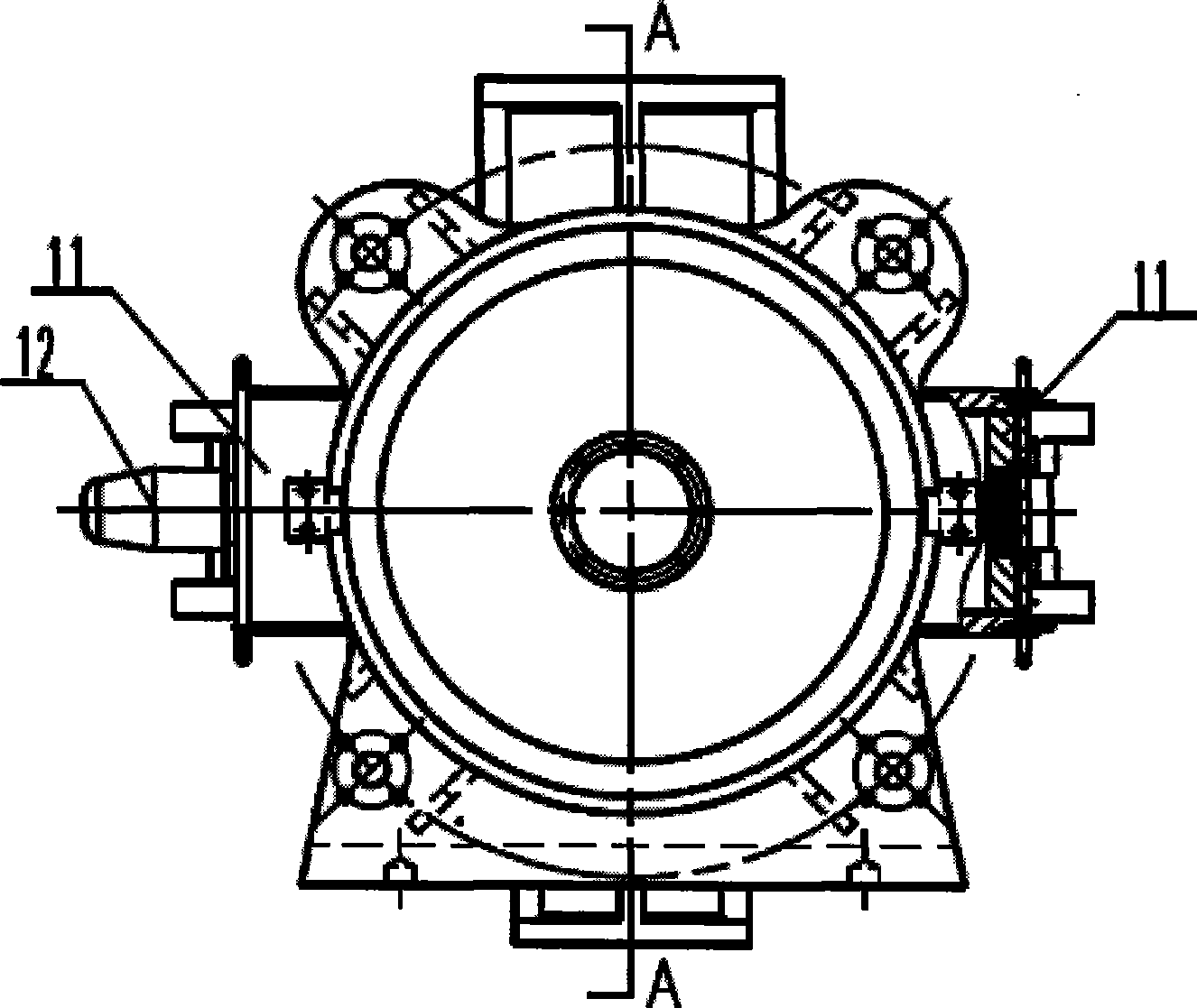

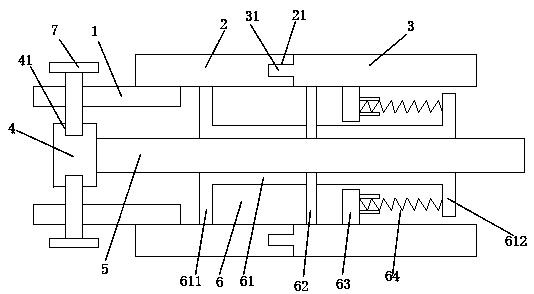

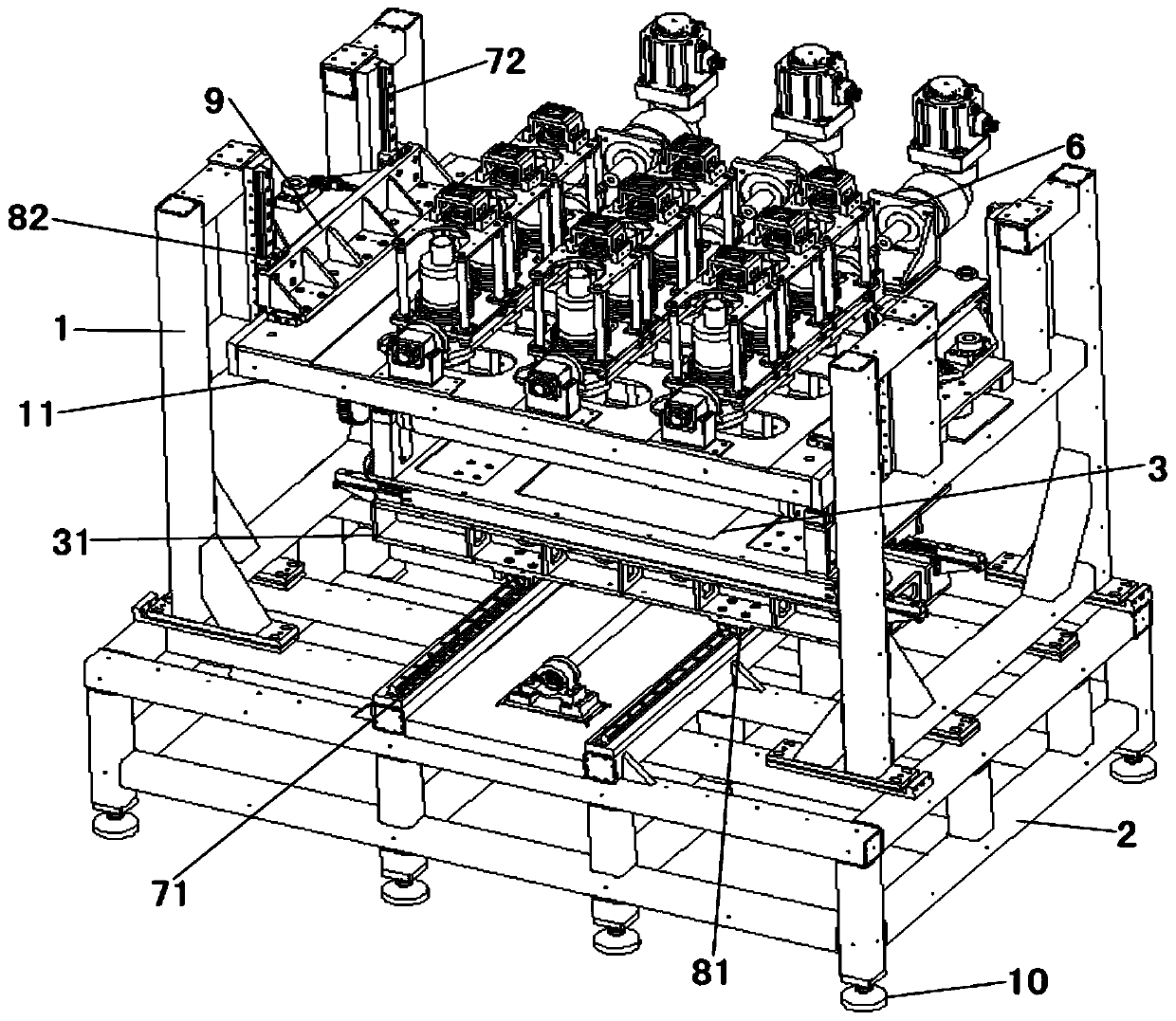

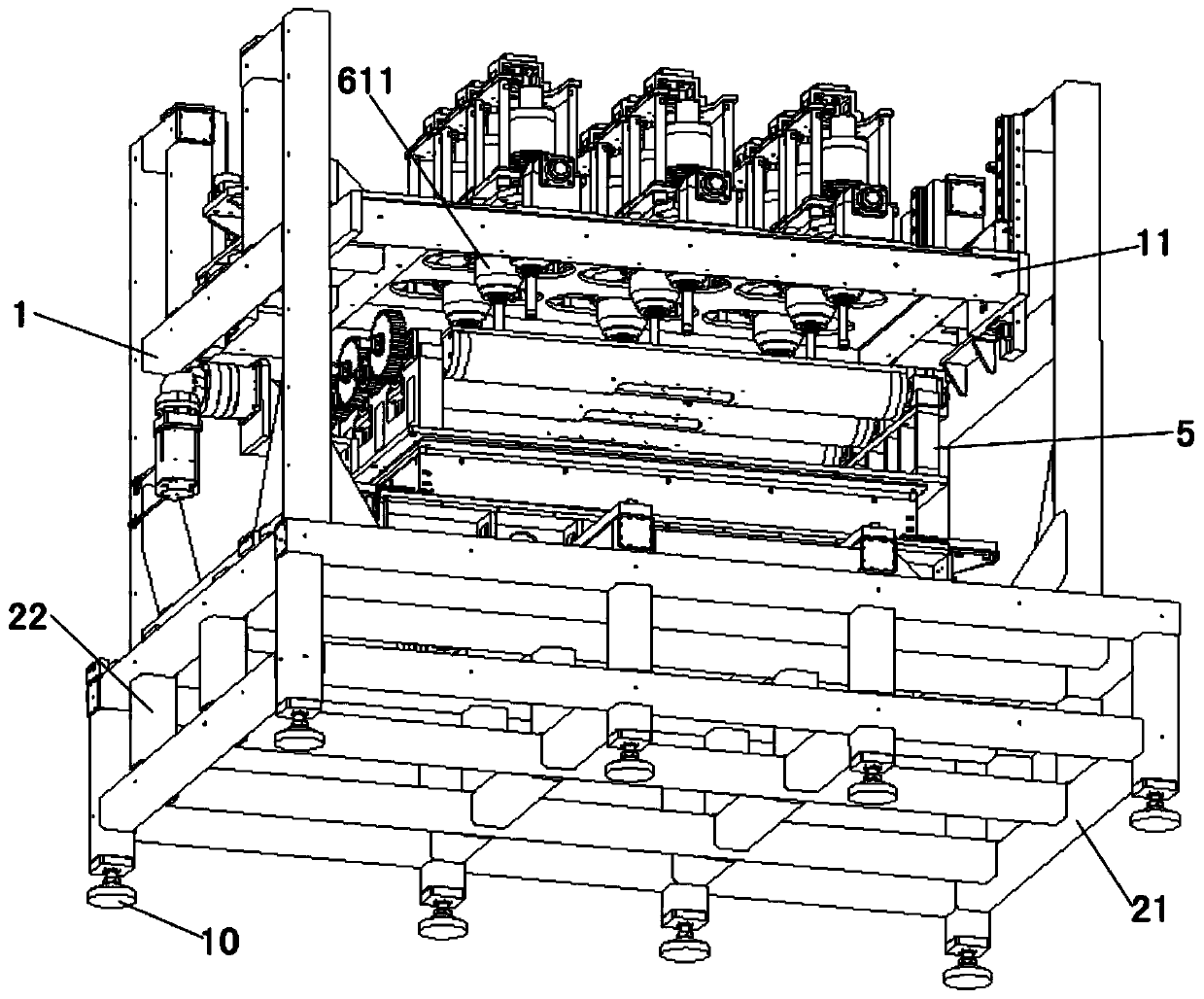

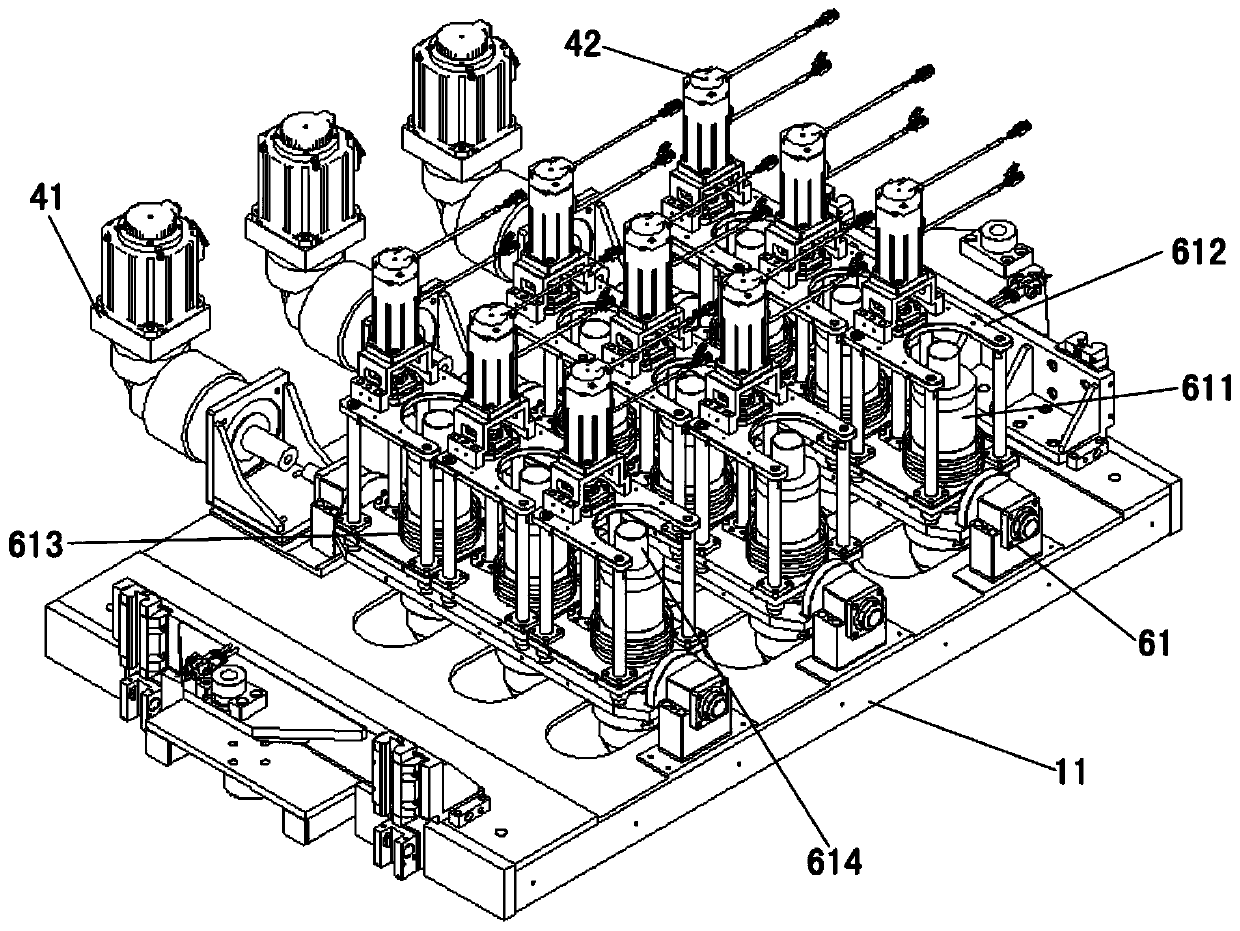

Full-automatic multi-station three-dimensional tube punching equipment

InactiveCN103963102AHigh positioning accuracyIncrease productivityMetal working apparatusPunchingEngineering

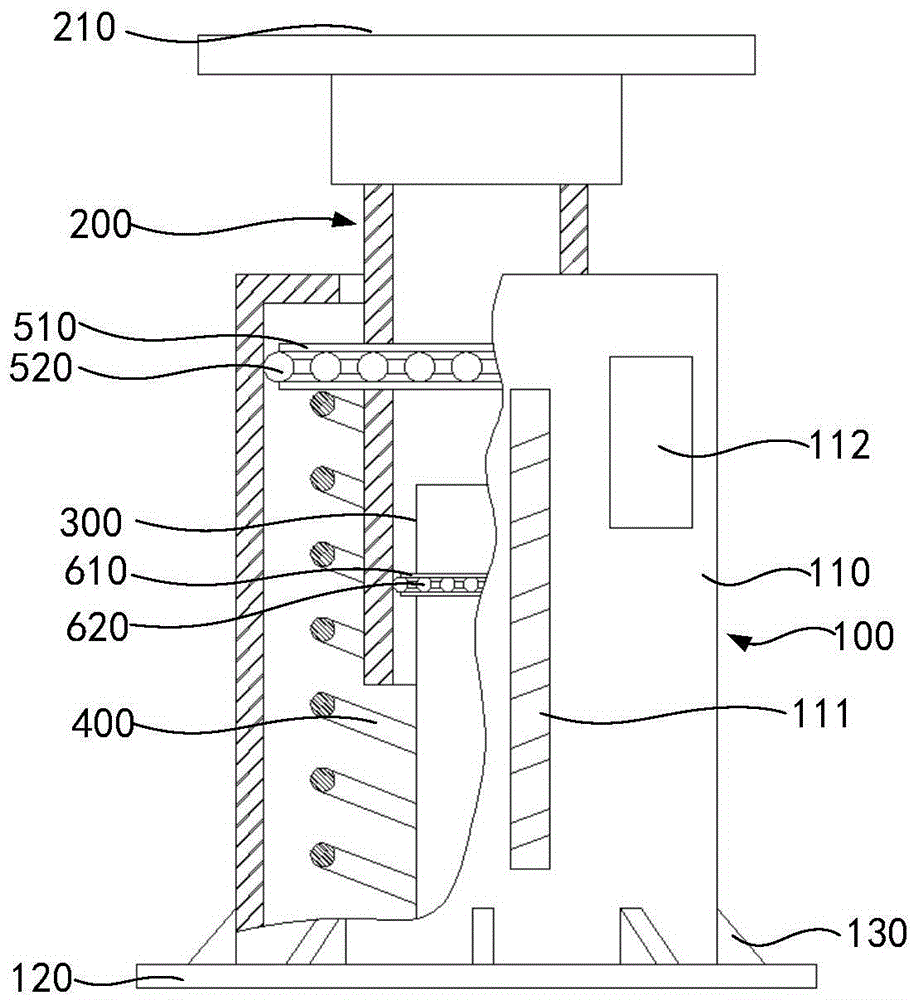

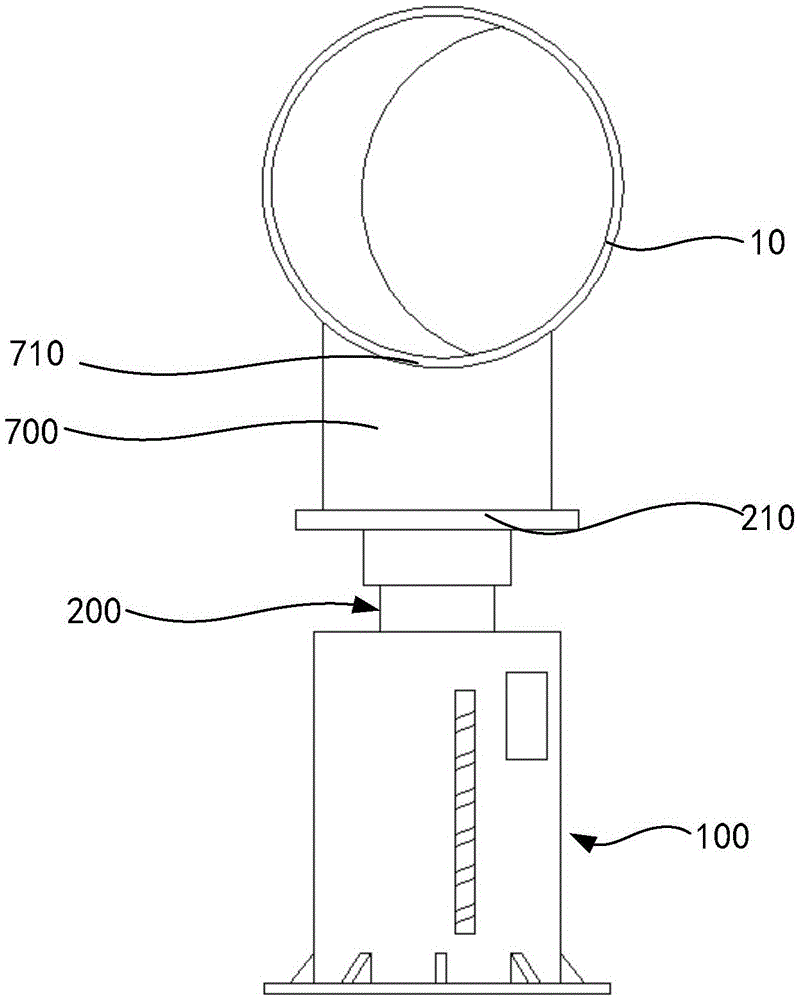

The invention provides full-automatic multi-station three-dimensional tube punching equipment and belongs to the technical field of machinery. The full-automatic multi-station three-dimensional tube punching equipment solves the technical problems that a punching machine in the prior art needs to assemble and disassemble tubes for many times when being used for punching holes on the tubes at different positions, and the punching accuracy cannot be guaranteed. The full-automatic multi-station three-dimensional tube punching equipment comprises a machine frame. A spindle is arranged on the machine frame, a rotating disk is fixed in the middle of the spindle, a plurality of core rods are evenly fixed on the rotating disk in the peripheral direction, a conveying device used for conveying the tubes to the core rods and sleeving the tubes on the core rods is arranged on the machine frame, locating devices which can axially locate the tubes sleeving the core rods are arranged on the core rods, and a punching device which can punch the tubes sleeving the core rods is arranged on the machine frame. The punching device comprises a punching head, wherein the punching head is arranged right above through holes of the core rods. A discharging structure which is used for enabling the punched tubes to be break away from the core rods is arranged on the machine frame. The full-automatic multi-station three-dimensional tube punching equipment has the advantages of being capable of automatically punching the tubes in a three-dimensional mode and high in punching efficiency.

Owner:浙江飞戎机器人科技有限公司

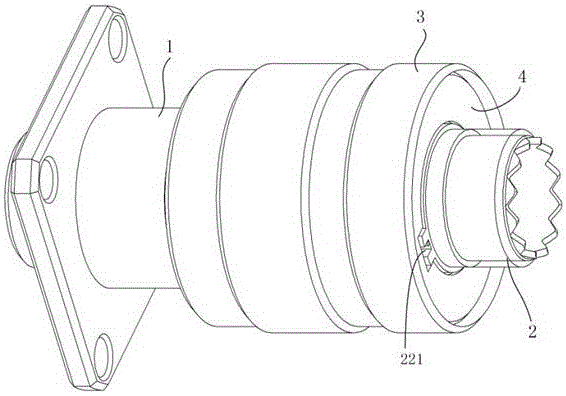

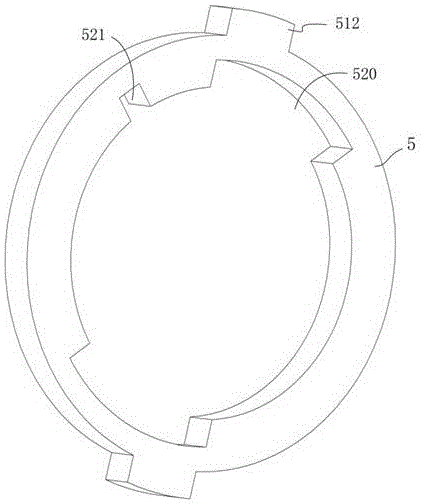

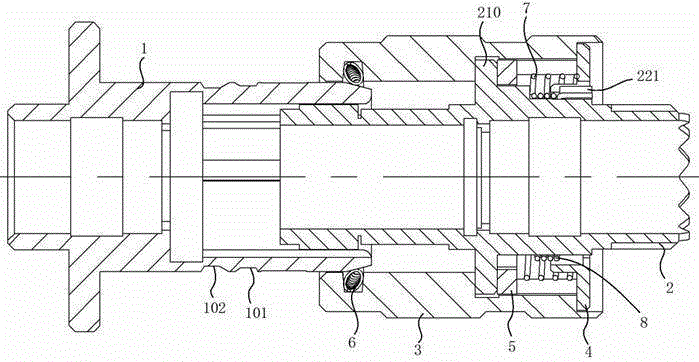

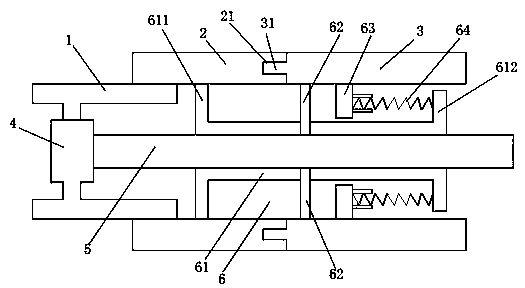

Housing assembly and connector

ActiveCN105140720AAvoid connection failureGuaranteed reliabilityCoupling device detailsCoil springEngineering

The invention provides a housing assembly and a connector. The connector comprises a locking cap and a connector housing, wherein the front end of the locking cap is provided with a canted coil spring. The locking cap is rotatingly disposed on the connector housing in a sleeve manner, and the rear end of the locking cap is provided with a peripheral chute and an axial chute, wherein the axial chute is communicated with the peripheral chute and extends backwards from the peripheral chute. The connector housing is provided with a sliding block which can rotate in the peripheral chute relative to the locking cap, and also can move axially in the axial chute relative to the locking cap. The housing assembly also comprises an elastic part which provides a clockwise torque for the locking cap. The housing assembly also comprises a peripheral limiting structure which is used for limiting the clockwise rotating limit of the locking cap when the sliding block is located in the peripheral chute. When the locking cap is located at a limit position of clockwise rotation, the sliding block is staggered with the axial chute in a peripheral direction. The connector is reliable in locking, and is convenient to use.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

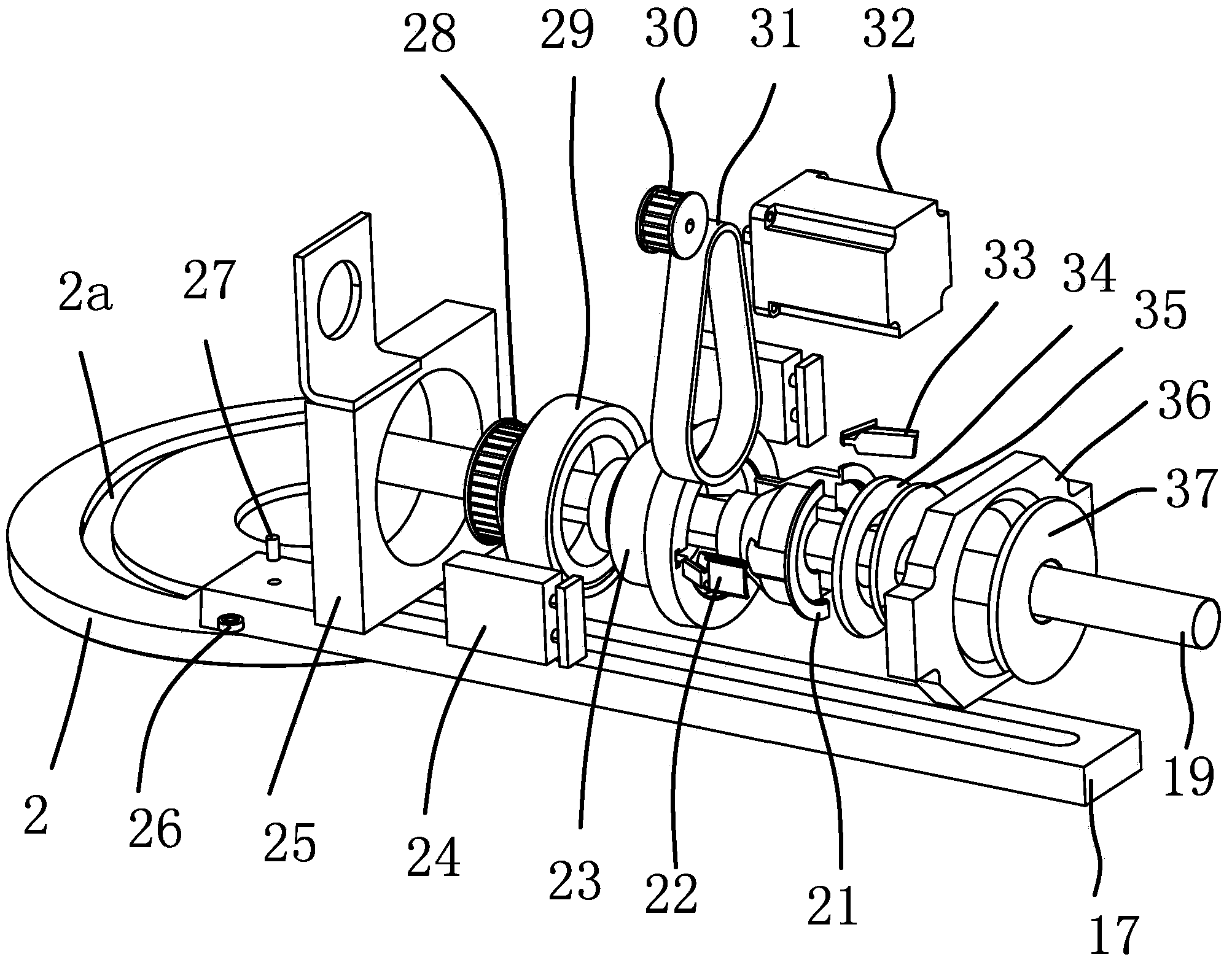

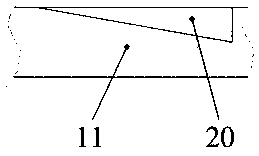

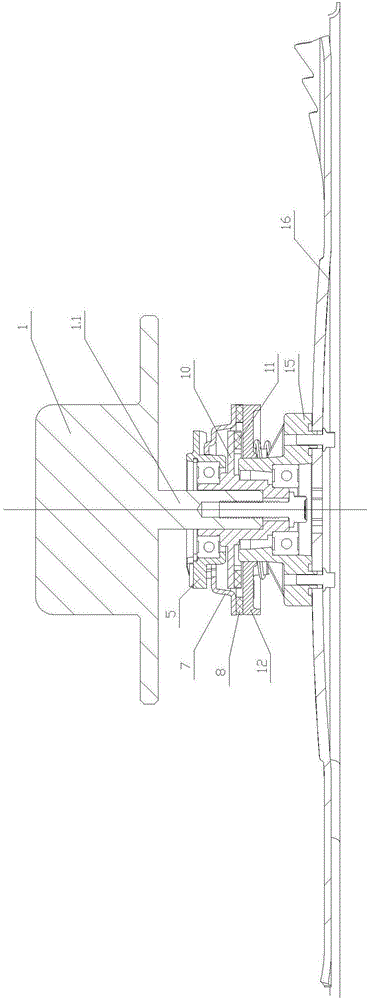

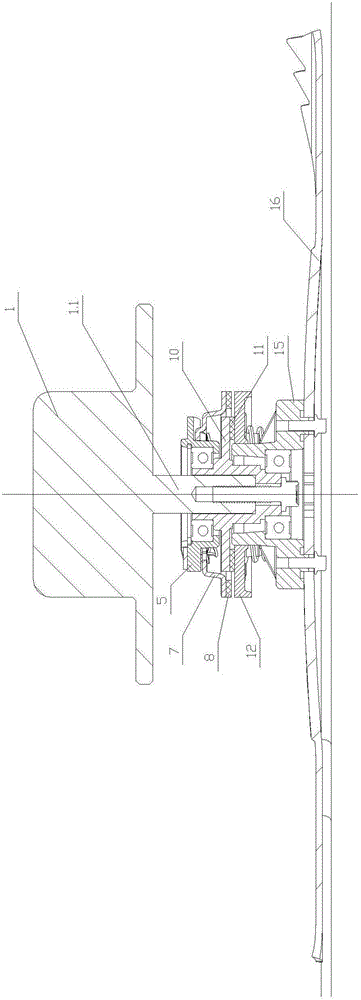

Grinding attachment suitable for freely curved face

ActiveCN101249628ARealize the grinding processReduce labor intensityBelt grinding machinesDrive wheelFree form

Owner:CHONGQING SAMHIDA GRINDING MACHINE

Transformable caterpillar

InactiveCN103693121AImprove mobilityEffective regulationEndless track vehiclesDrive wheelGravity center

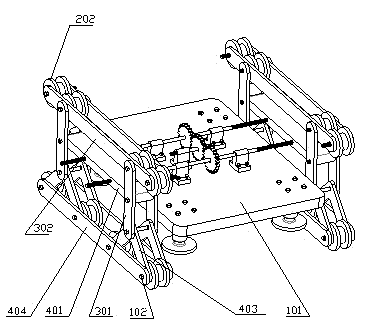

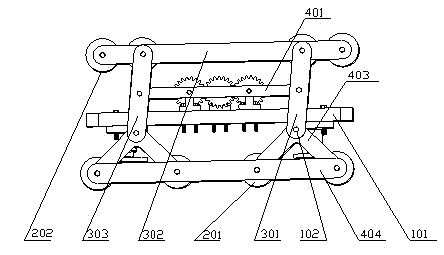

The invention discloses a transformable caterpillar, which comprises a chassis, wherein two sides of the chassis are symmetrically provided with crawler belt walking mechanism; each crawler belt walking mechanism comprises a first crank and a second crank which are parallel to each other; the upper ends of the first and second cranks are movably hinged to a first connecting rod by virtue of screws, the lower ends of the first and second cranks are movably hinged to the vertex angle parts of two V-shaped supports respectively through screws, and the middle sections of the first and second cranks are movably connected with a second connecting rod by virtue of screws; the first connecting rod is provided with bearing wheels; two bottom angle parts of each V-shaped support are provided with driving wheels; third connecting rods are connected with the driving wheels; crawler belts are wound on the driving wheels and the bearing wheels; the chassis is provided with a crawler belt spacing adjusting mechanism. The transformable caterpillar has the advantages that the transformation mechanisms can be used for adjusting the gravity center of the caterpillar and width between wheels when the caterpillar encounters a barrier, the body of the caterpillar is enabled to pass a steep road surface smoothly, and the caterpillar has good movement stability.

Owner:SOUTH CHINA UNIV OF TECH

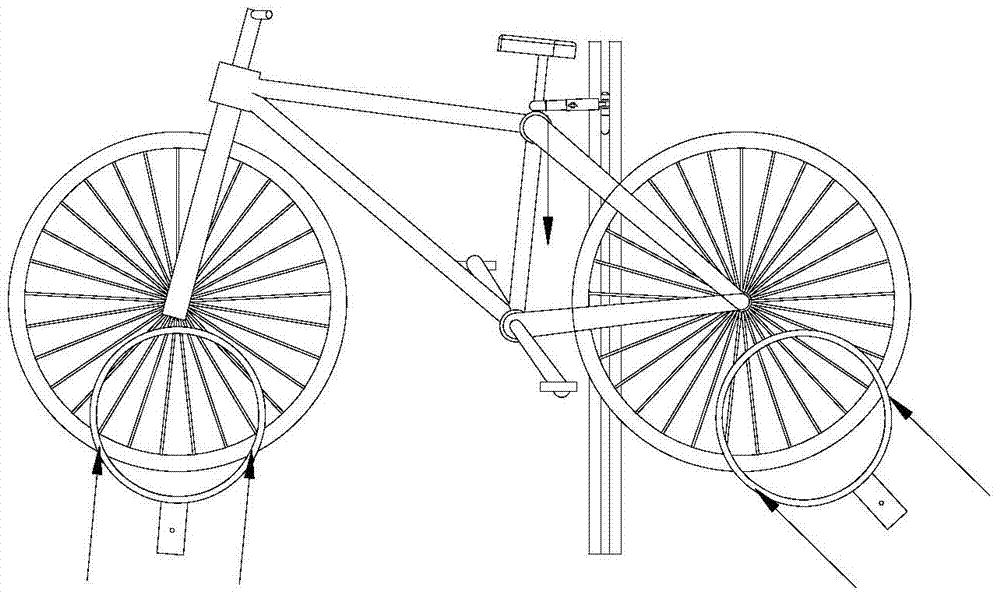

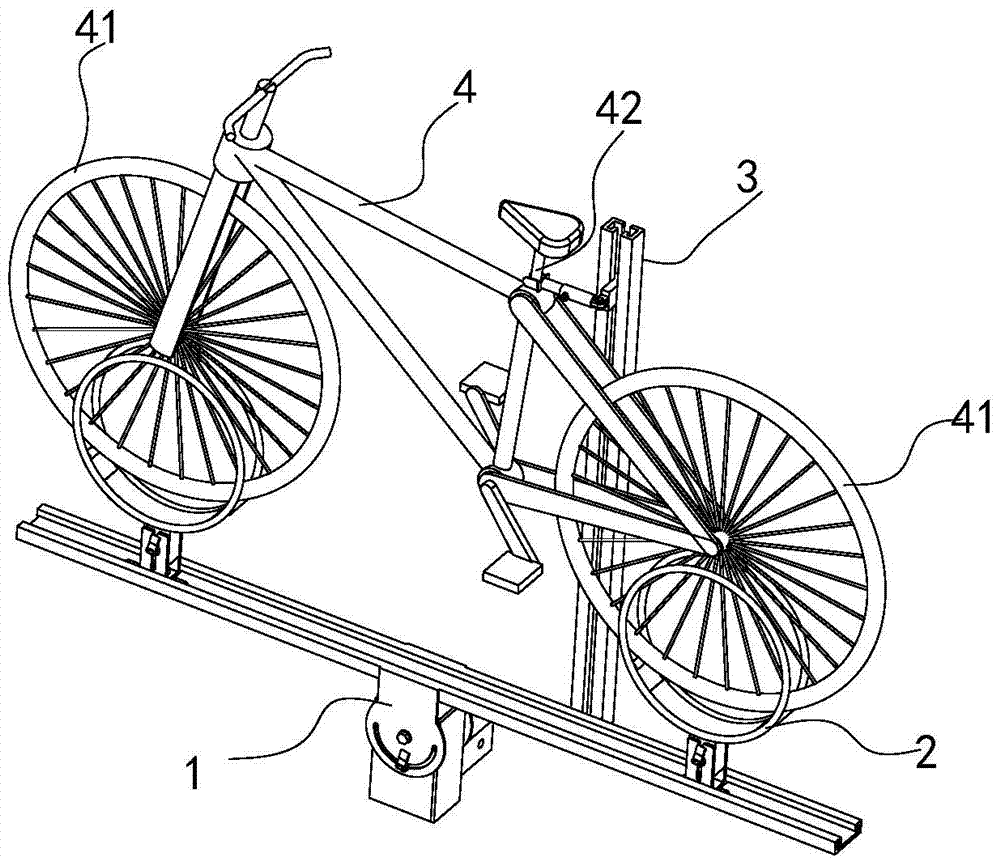

Vehicle-mounted bicycle rack

Owner:GREAT WALL MOTOR CO LTD

Underwater pelleting device of machine unit for compounding, squeezing and prilling

The invention relates to a mixing extrusion pelleting machine set. An underwater pelleting device of the mixing extrusion pelleting machine set is provided with a machine head template and a pelleting cutter head, wherein the machine head template is arranged on the wall surface of a hot water chamber and sealed, the cutter head is arranged in the hot water chamber through the end of a cutter shaft, a driving motor is in driving connection with the cutter shaft through a coupling, the cutter shaft is arranged in a bearing box and driven by a piston rod of a cylinder, the bearing box is arranged on a trolley bracket, trolley wheels are placed on a guide rail, and the cylinder drives a trolley to move along the guide rail so as to combine and separate the pelleting cutter head and the temperate. The mixing extrusion pelleting machine set rotates at high speed close to a discharge template in the water chamber filled with deionized water during operation, so as to finish pelleting. Cut particles are conveyed to a downstream device along with cooling water. The machine set is safe, is favorable for prolonging service life of the template and a pelleting cutter, and controls a system with simple and easy operation.

Owner:大连橡胶塑料机械有限公司

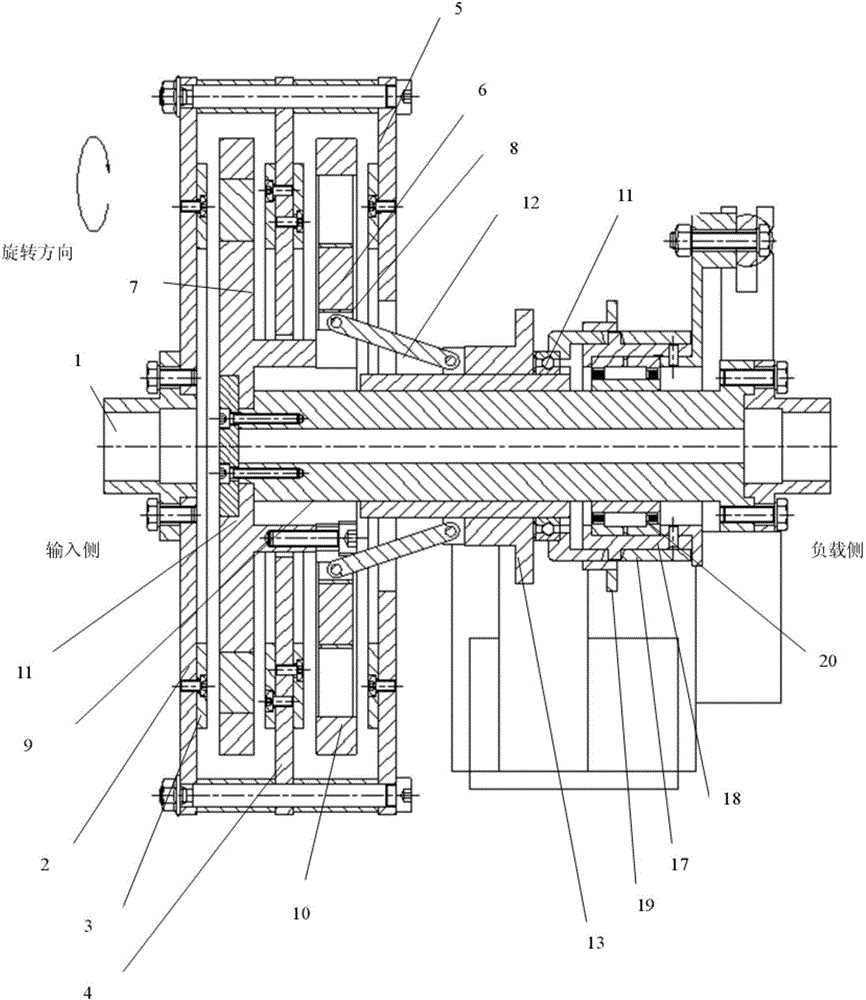

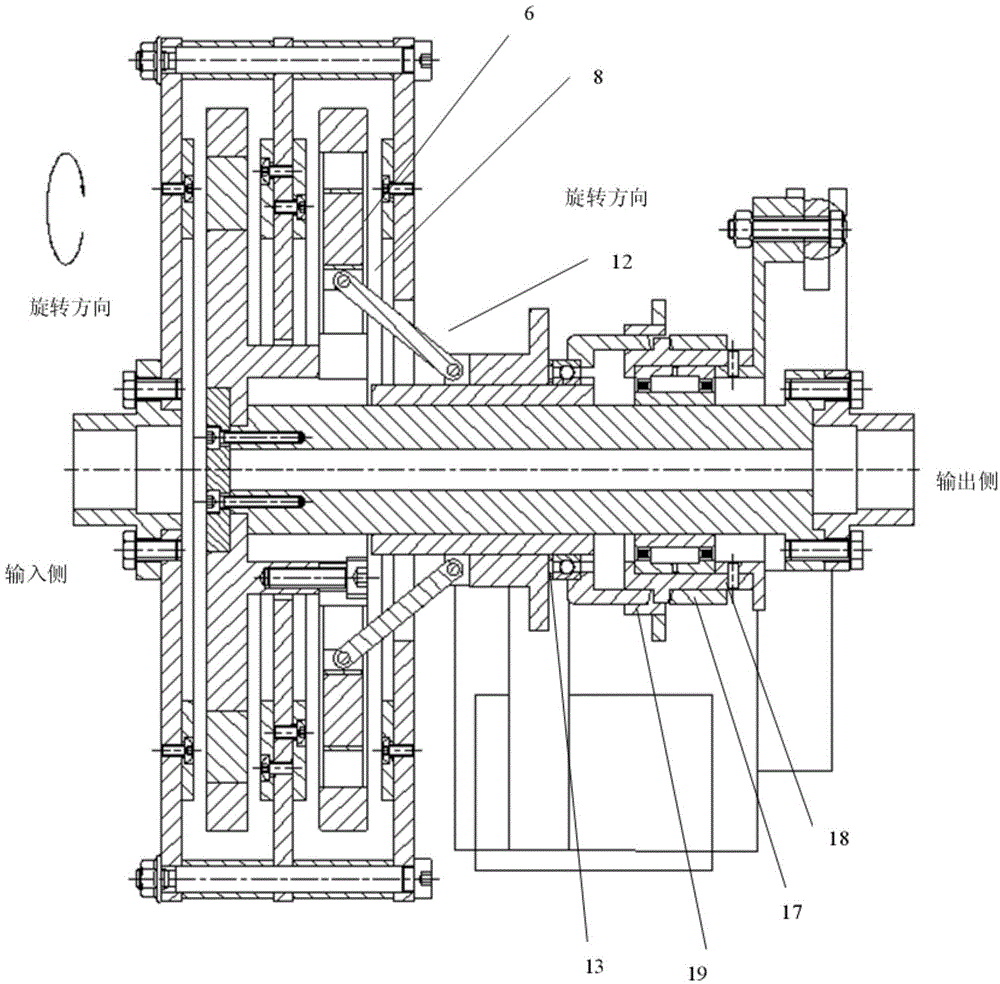

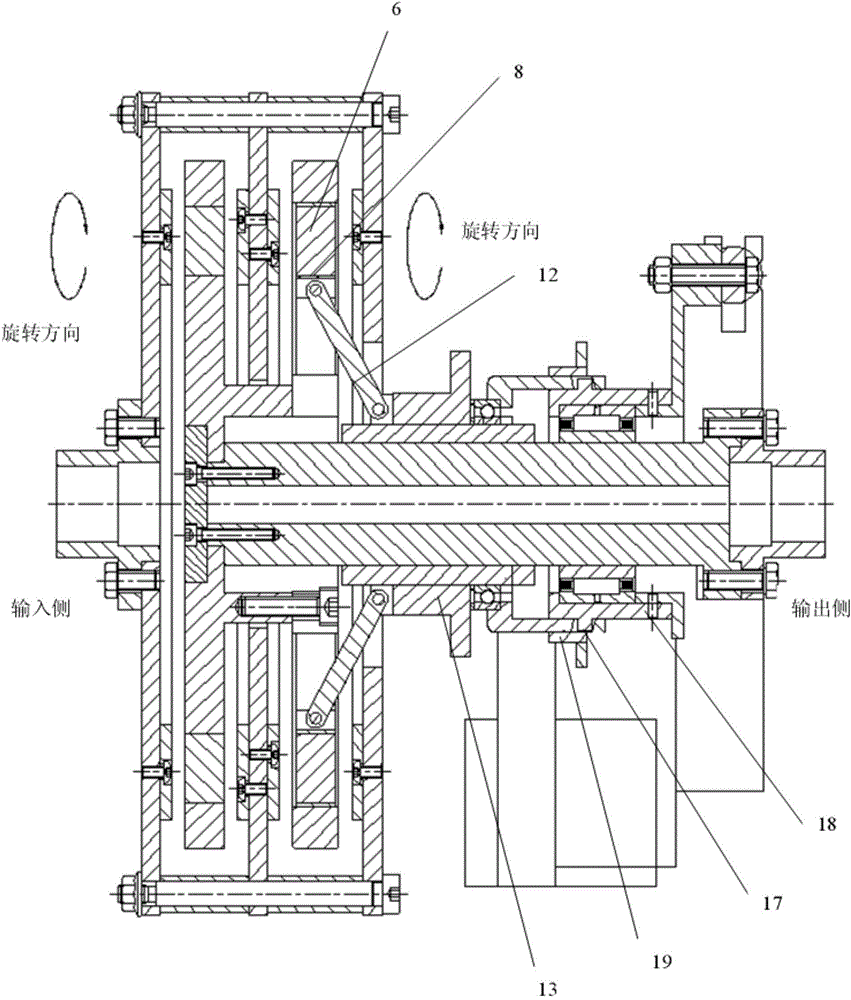

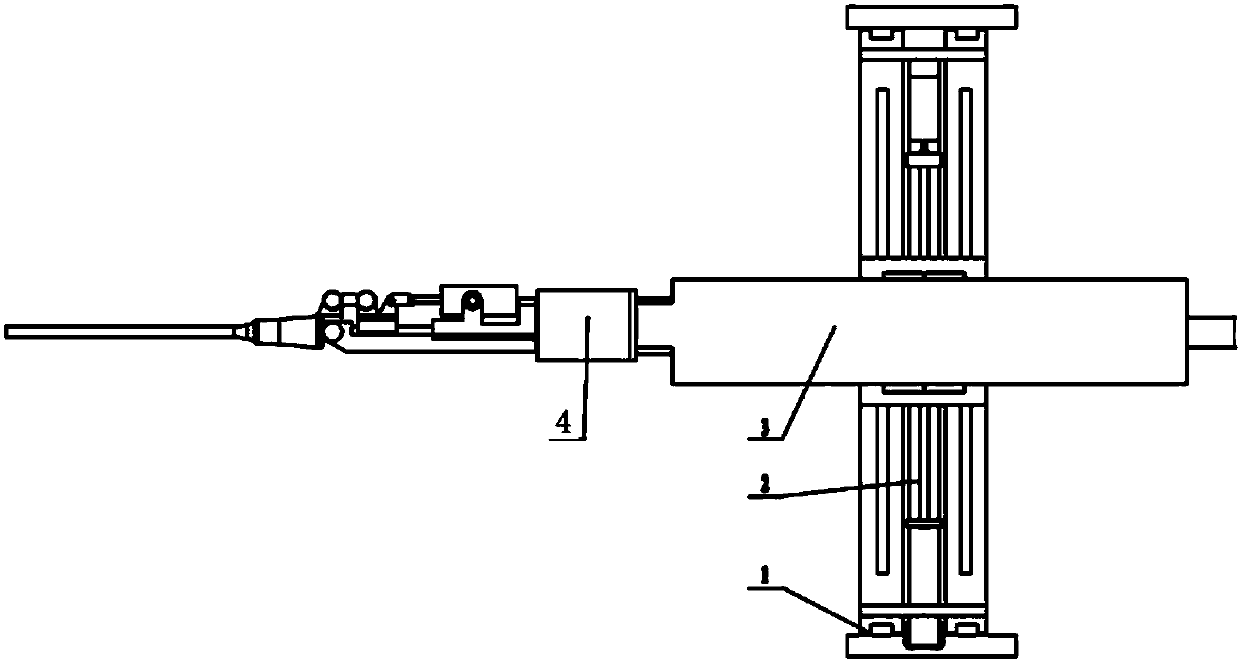

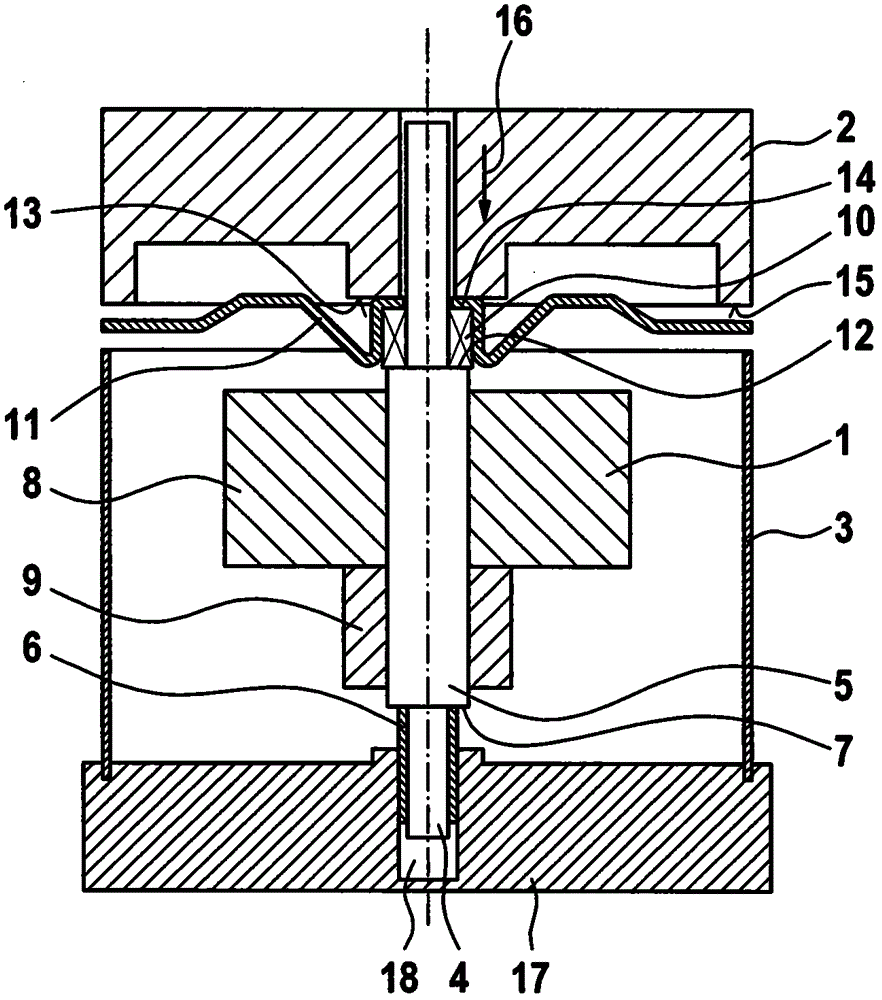

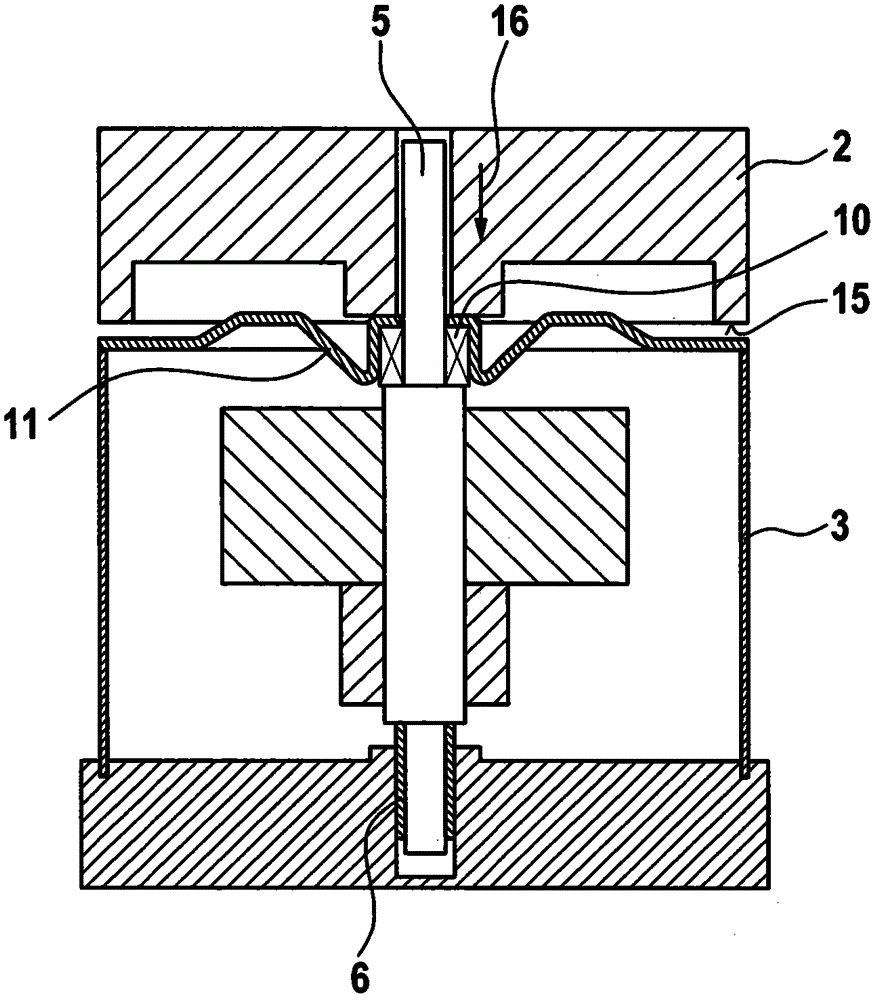

Delayed type magnetic coupler with actuating apparatus and radial ejector rod

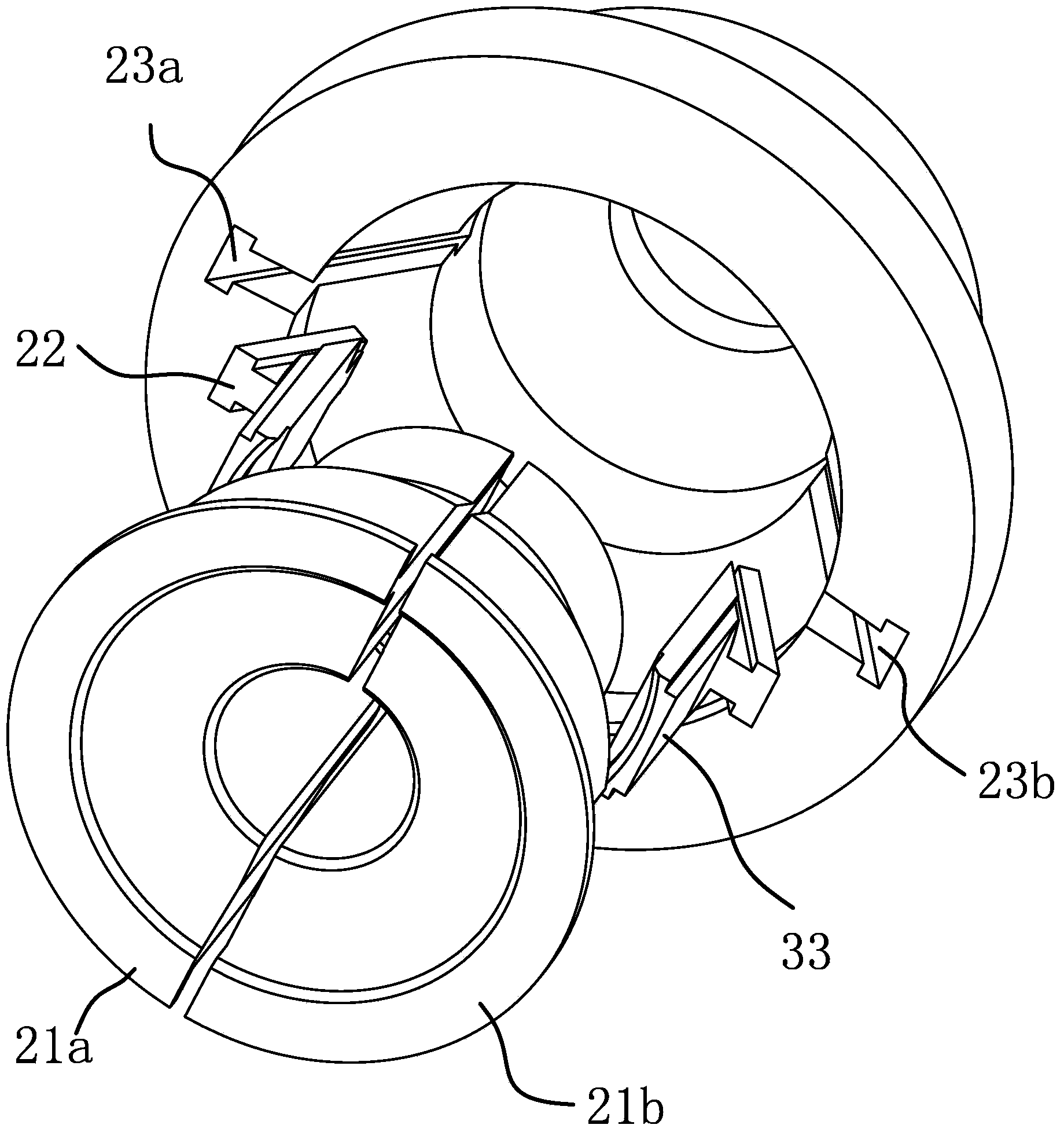

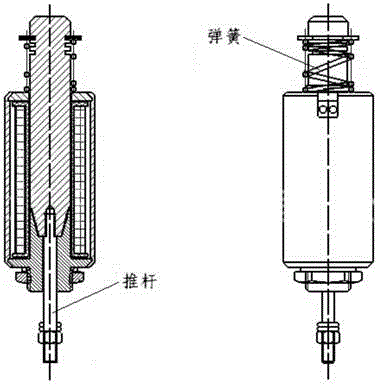

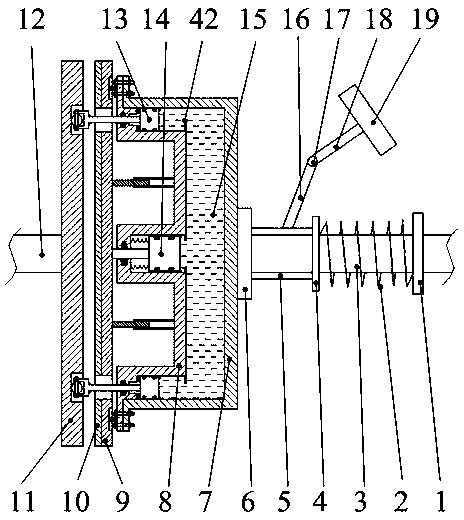

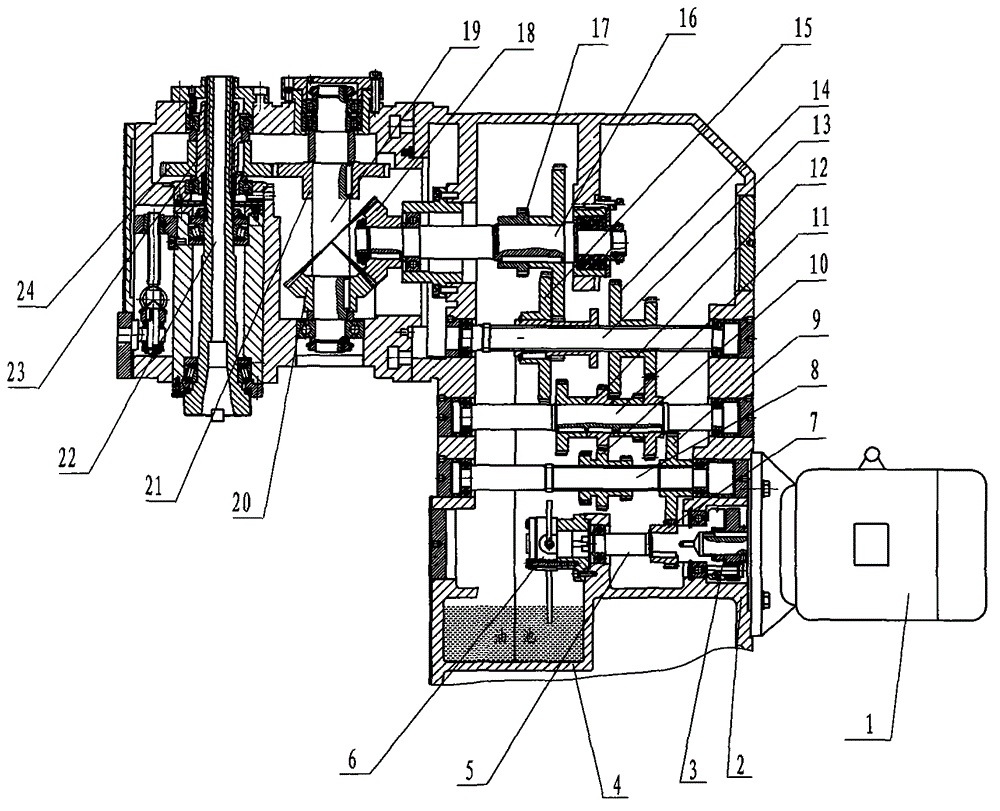

ActiveCN104953790AAchieve axial movementAchieve radial movementDynamo-electric gearsRadial motionCopper conductor

The invention relates to a delayed type magnetic coupler with an actuating apparatus and a radial ejector rod. The delayed type magnetic coupler is characterized by comprising an input side catcher (1) connected with a drive motor, input side steel discs (2) connected with the catcher, auxiliary steel discs (4) connected with the input side steel discs (2), wherein output side steel discs (5) are mounted on the right sides of the auxiliary steel discs (4) and connected with the auxiliary steel discs (4); copper discs (3) are fixed on the input side steel discs (5), the auxiliary steel discs (4) and the output side steel discs (5). According to the delayed type magnetic coupler with the actuating apparatus and the radial ejector rod, provided by the invention, when an actuating mechanism of the magnetic coupler works, through the combined action of an inner guide sleeve, an outer guide sleeve, a sliding sleeve and the ejector rod, the magnet in the auxiliary magnet disc can perform radial motion in the sliding groove of the auxiliary magnet disc in the external circumference direction, so that the magnetic coupling surfaces of rotating copper conductor discs and the auxiliary magnet disc are gradually enlarged, the torque needed in the starting state for overcoming the static frictional resistance torque is gradually increased, and the phenomenon that the torque is inadequate during the starting stage is changed.

Owner:南京迪瓦机械制造有限公司

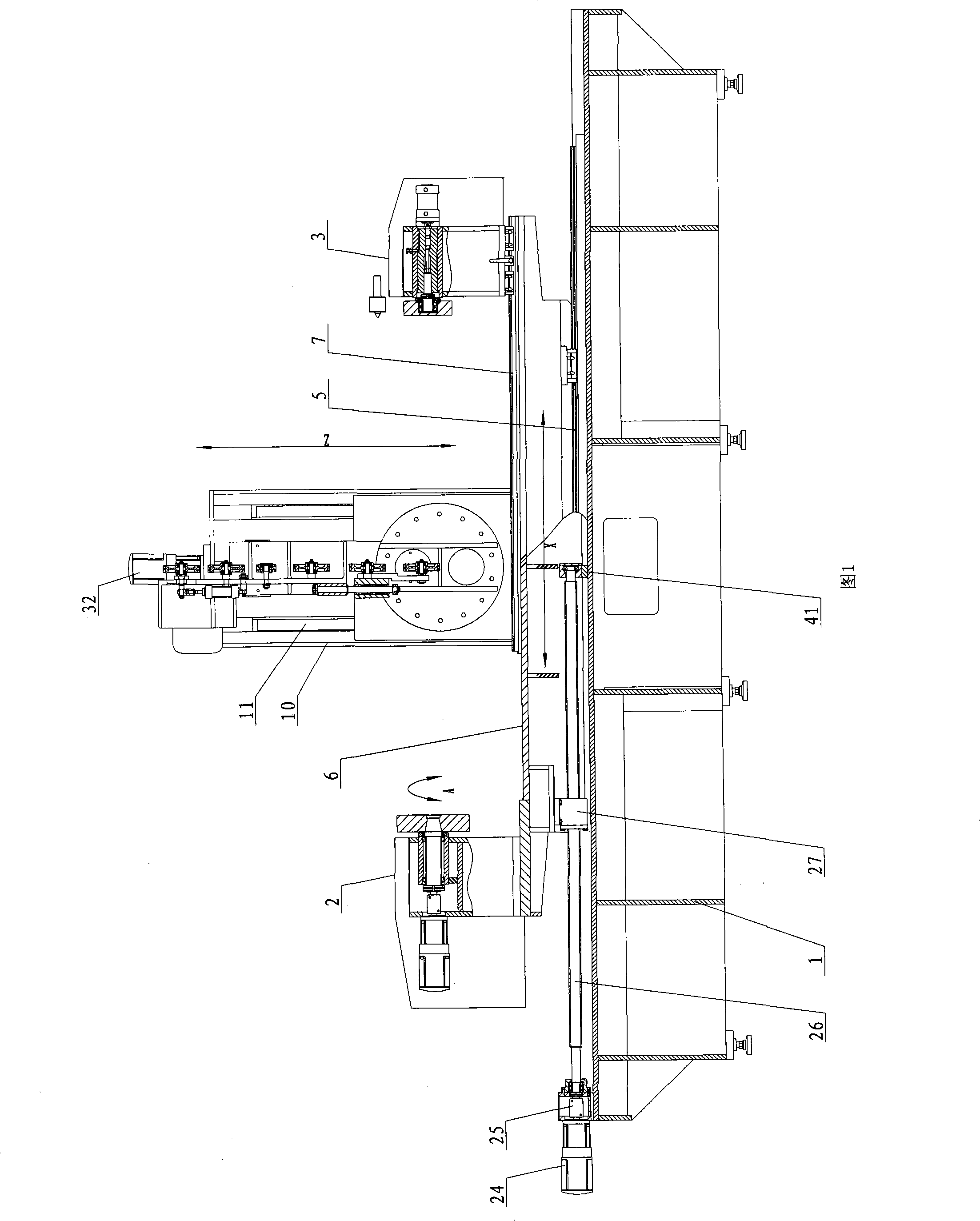

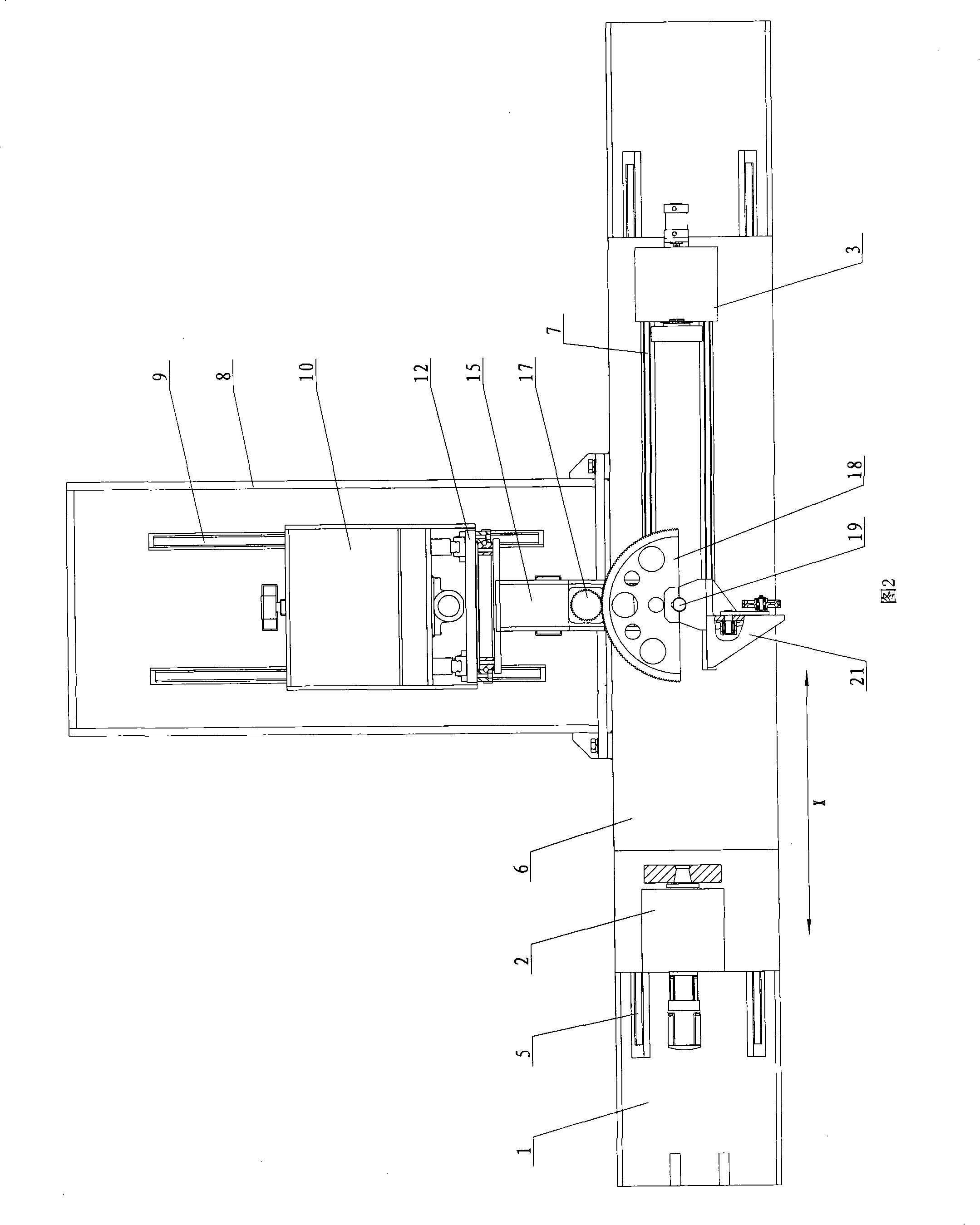

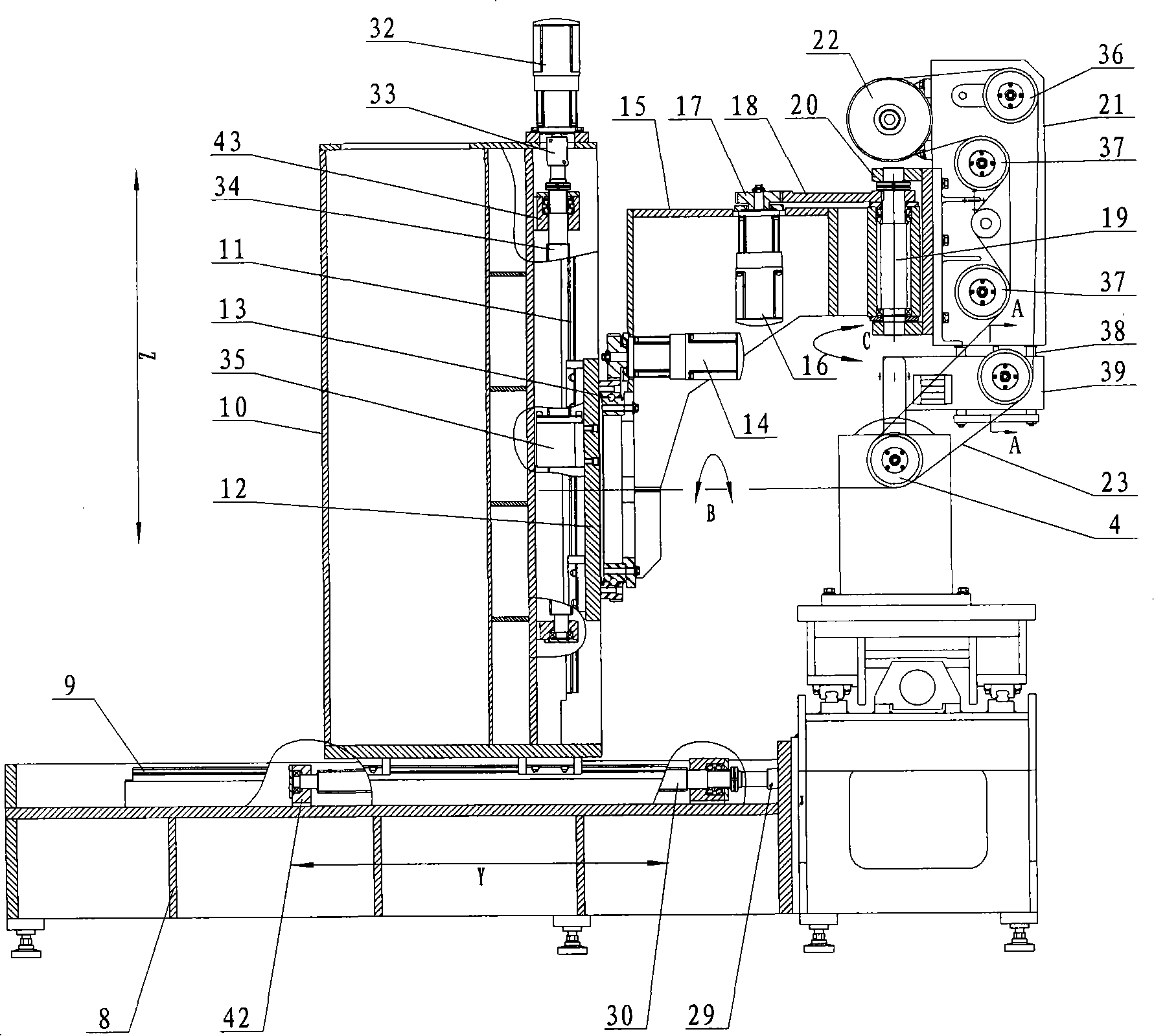

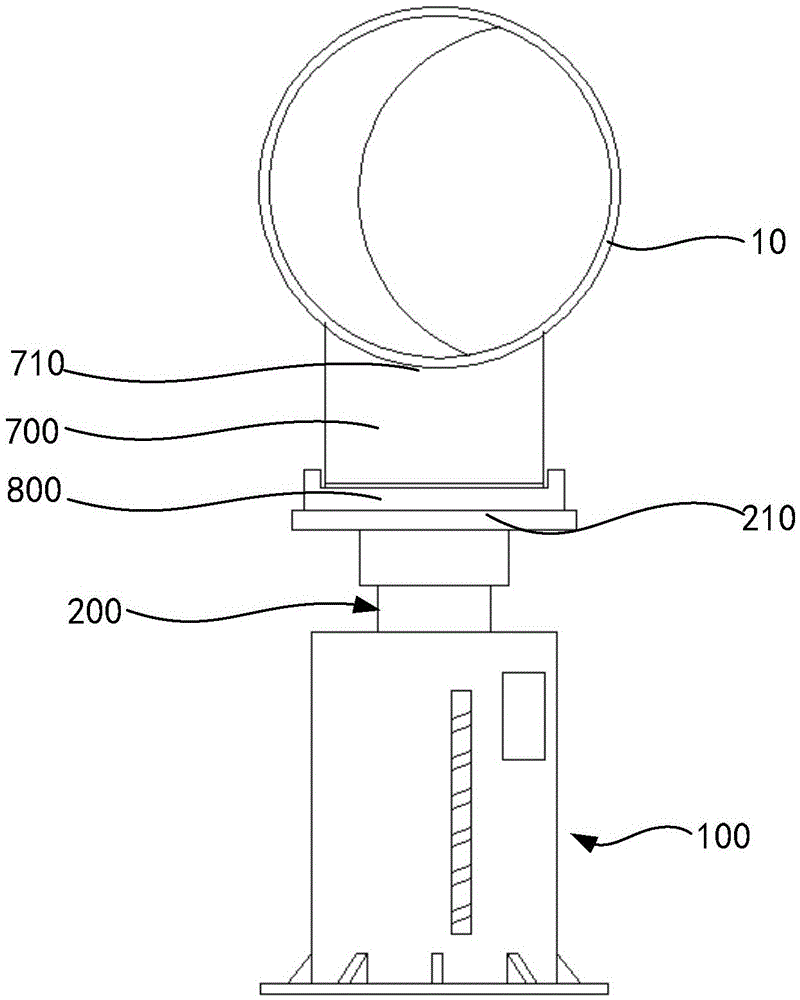

Six-degrees-of-freedom system of big load model track capturing test of large transonic speed wind tunnel

PendingCN107860545ASave installation spaceAchieve axial movementAerodynamic testingThree degrees of freedomLoad model

The invention provides a six-degrees-of-freedom system of big load model track capturing test of a large transonic speed wind tunnel, which comprises a cross movement mechanism, a normal movement mechanism, an axial movement mechanism and a three-degrees-of-freedom gesture movement mechanism. The system solves the problems of small route, low bearing ability and poor rigidity of the six-degrees-of-freedom system in the track capturing test. The cross movement mechanism is installed on leeside of upper and lower wall panels of the testing section, the normal movement mechanism is installed on the cross movement mechanism; the axial movement mechanism is installed on the normal movement mechanism, and three-degrees-of-freedom gesture movement mechanism is installed on the axial movement mechanism; the three-degrees-of-freedom gesture movement mechanism can achieve pitching, yawing and rolling movements at the tail end of the mechanism through the rolling, pitching and rotating movements.The first grade rotating mechanism is connected with the axial movement mechanism, and orderly equipped with the pitching mechanism and the second grade rotating mechanism in series. The six-degrees-of-freedom system has big movement route, high bearing ability and rigidity, high movement precision and small blockage.

Owner:AVIC SHENYANG AERODYNAMICS RES INST

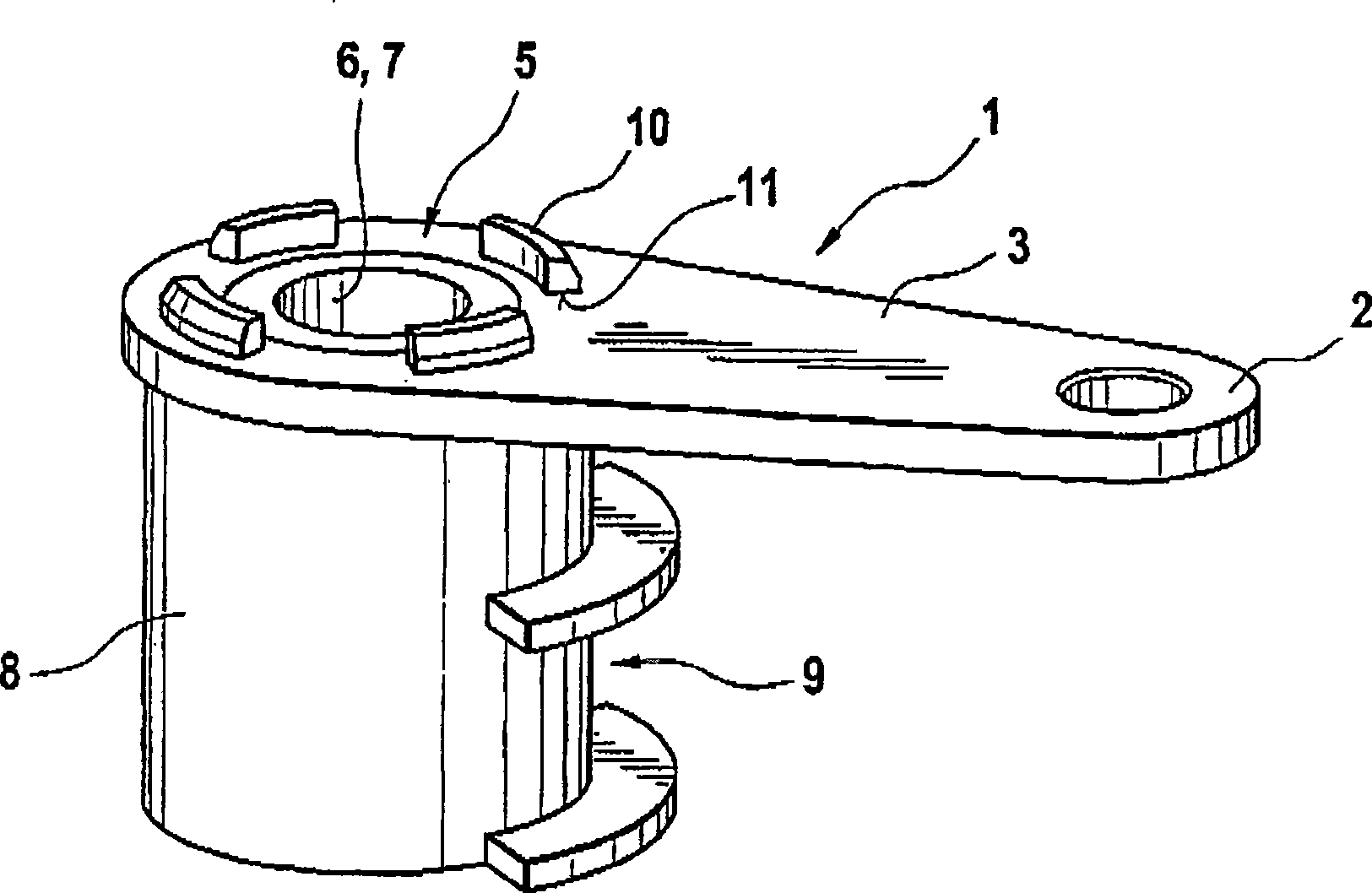

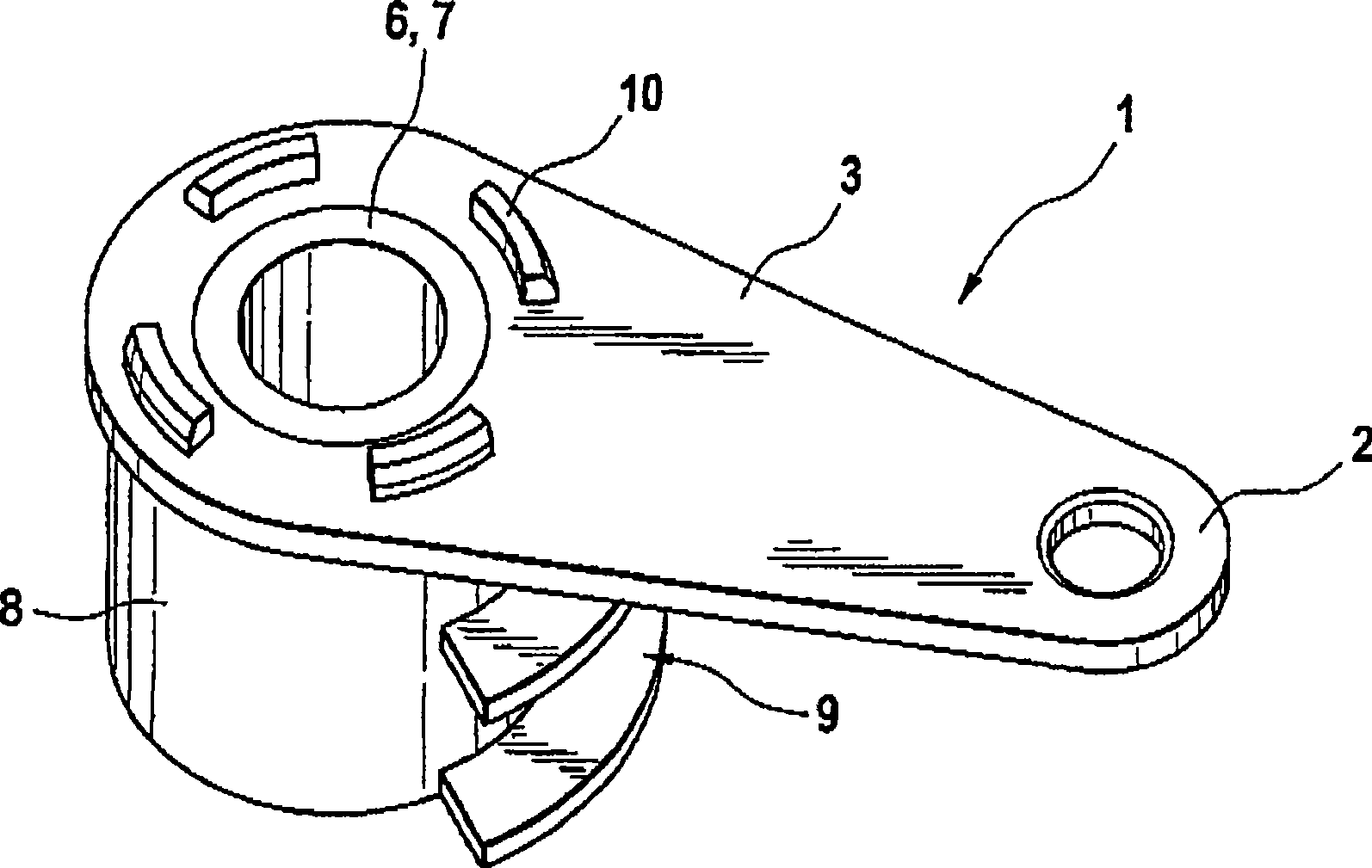

An electric machine and a method for adjusting the axial bearing clearance

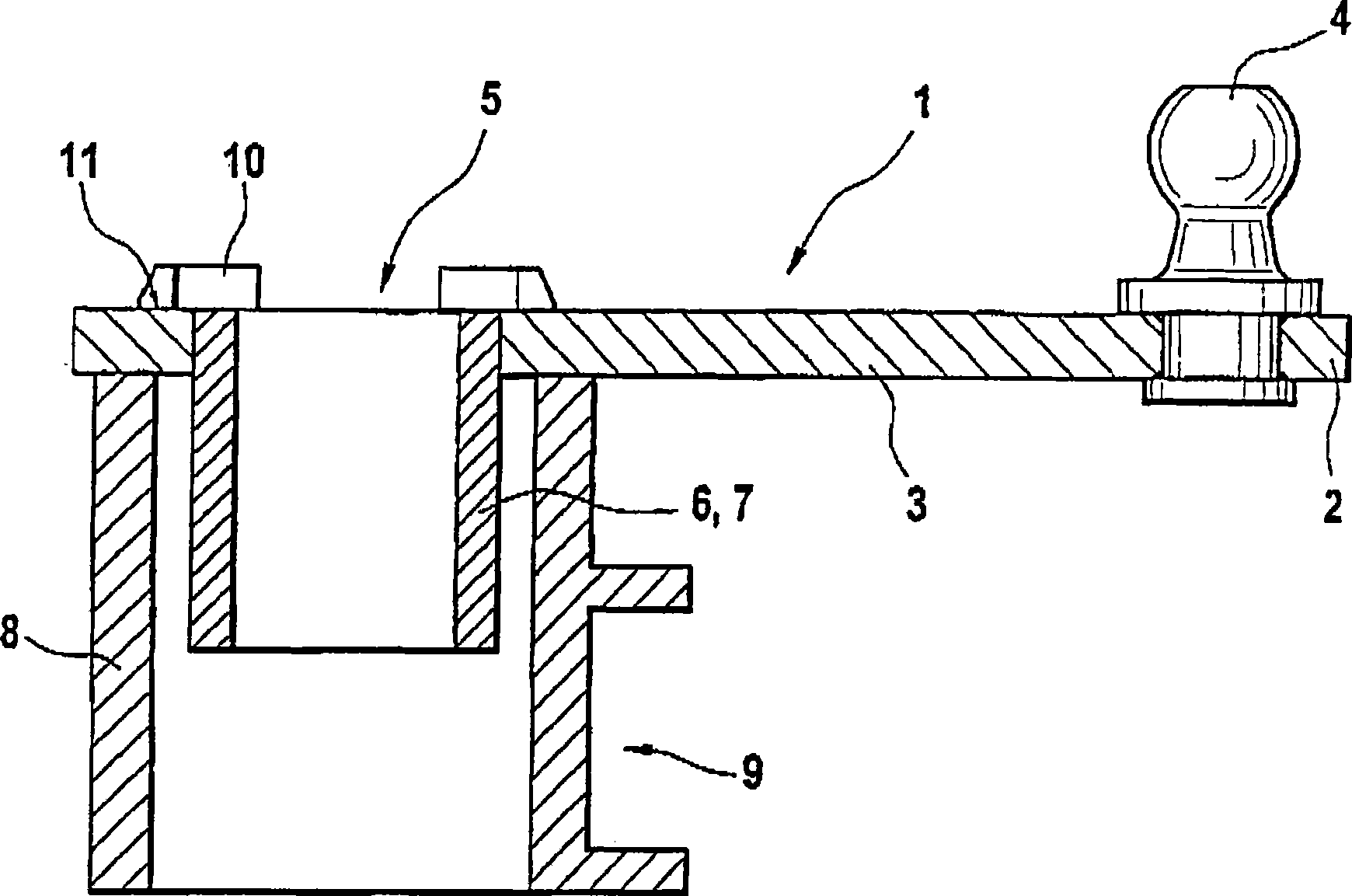

InactiveCN104578541AAvoid offsetEasy to implementManufacturing dynamo-electric machinesSupports/enclosures/casingsAxial displacementElectric machine

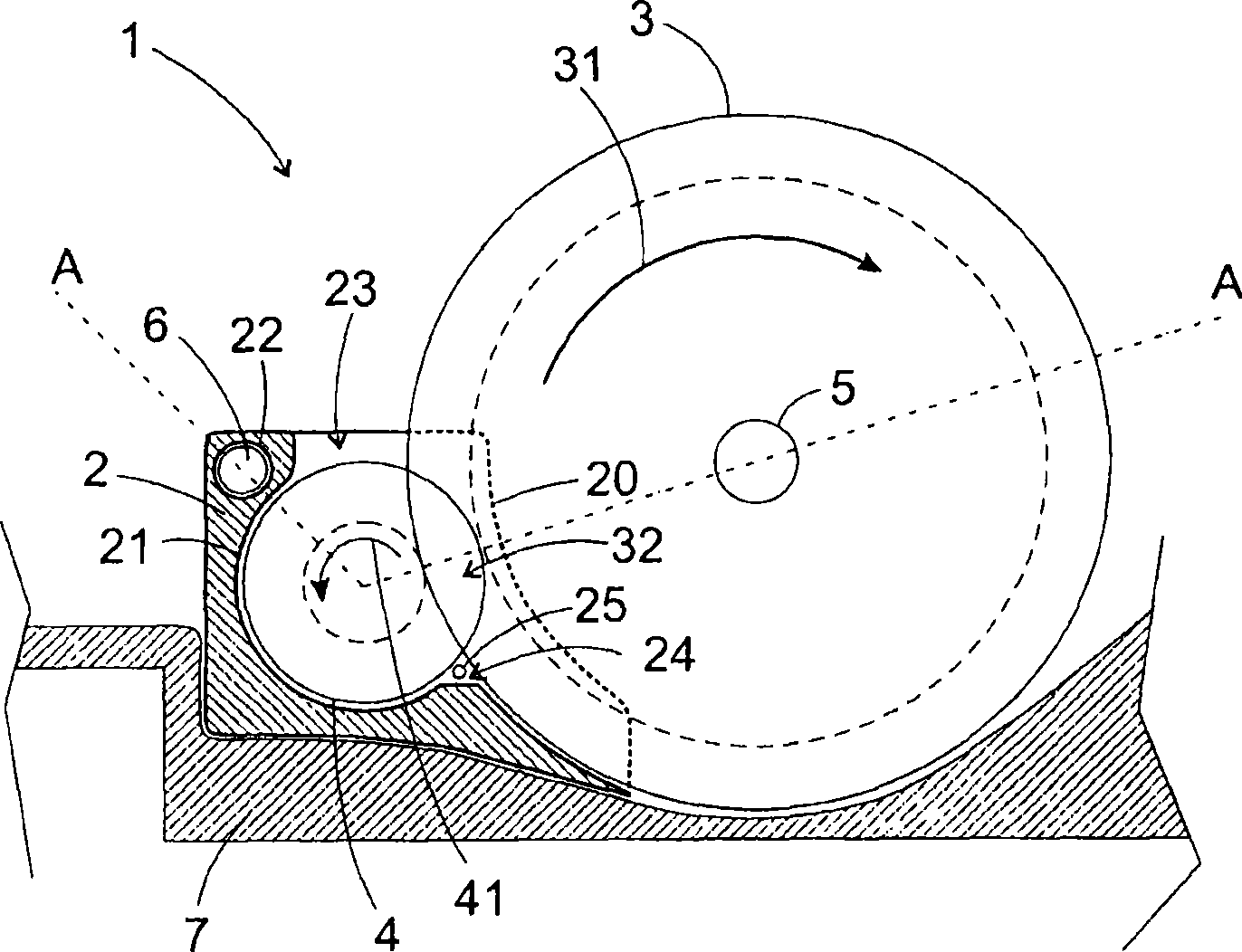

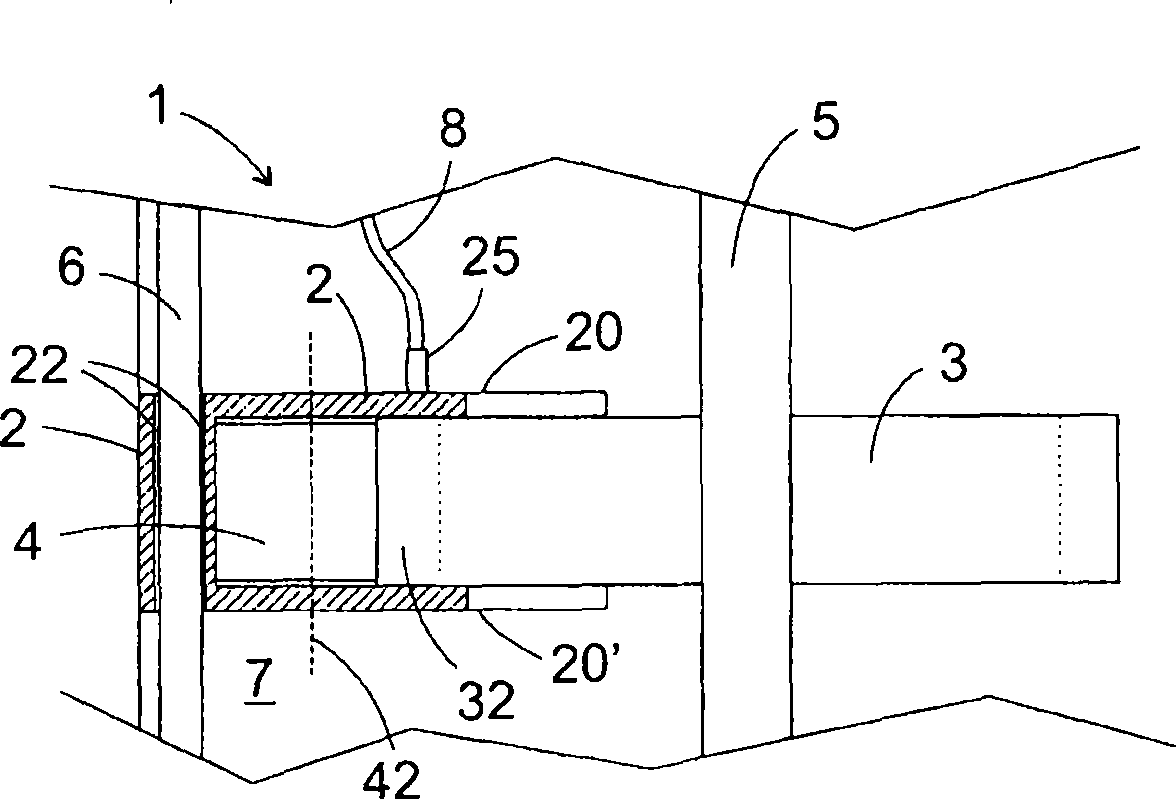

The invention relates to an electrical machine and a method for adjustment of the axial bearing clearance (LS) between two bearings (6, 10) for mounting a rotor shaft (5) and provided on both sides of a rotor (1) of an electrical machine, wherein the rotor shaft (5) is at least supported axially displaceably in a bearing (6). The axial bearing clearance is adjusted by an axial displacement of the rotor shaft (5) adjoining the bearing (6) with an annular shoulder (7) in its axial position of a slidable first bearing (6), by the deflection movement, compared to a basic position without axial bearing clearancethe, the movable first bearing (6) moves to a final position with a predetermined axial clearance (LS).

Owner:SEG AUTOMOTIVE GERMANY GMBH

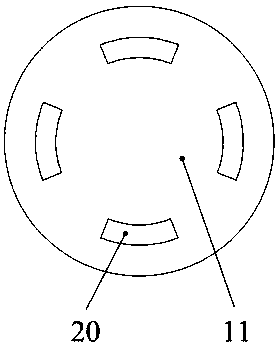

Electromagnetic self-locking plane connection device

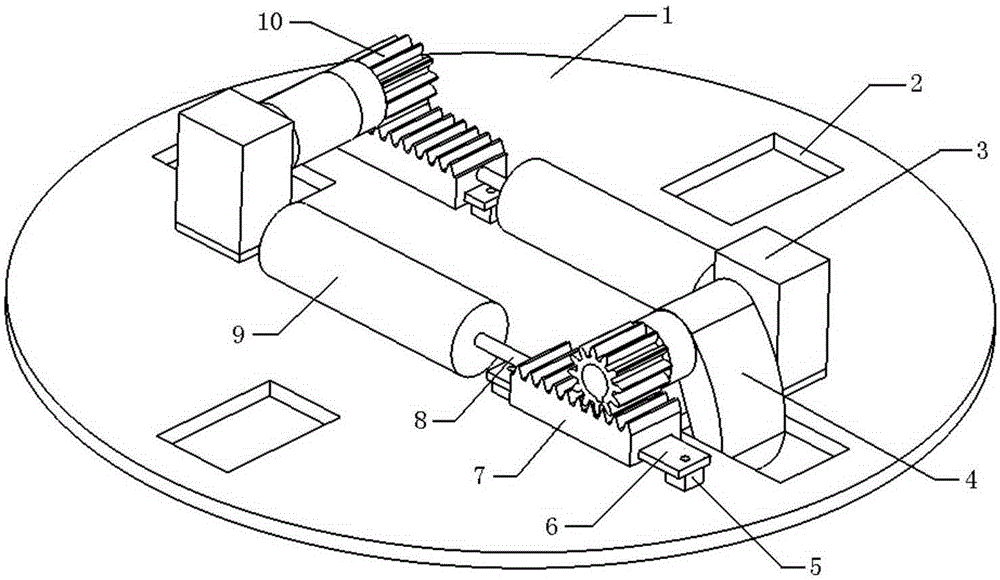

InactiveCN105173123AEasy to controlAchieve axial movementCosmonautic component separationMotor driveButt joint

The invention belongs to the technical field of space modularization mechanism butt joint, and specifically relates to an electromagnetic self-locking plane connection device. According to the electromagnetic self-locking plane connection device, the mode that electromagnetic force and transmission of a gear and a rack are combined is adopted, and butt joint is achieved through the rotation of clamping jaws; due to the fact that driving of electromagnetic force is simple, complex controllers and speed reduction devices on which motor driving relies are not needed, the production cost of the connection device is reduced, and the size and weight of the connection device are effectively reduced; due to the fact that the connection device has a self-locking function, and after a connection task is completed through the connection device, an actuator can be de-energized without the worry of the problem that connection is broken after the actuator is de-energized, so that the reliability of the connection is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Axial cutting machine for steel pipe

InactiveCN102814538ALow calorific valueImprove processing efficiencyFeeding apparatusMilling equipment detailsSteel tubeFlywheel

The invention relates to an axial cutting machine for a steel pipe. The technical scheme is that a milling cutter (4) is arranged on an output shaft of a speed regulating motor (19) mounted on an upper plane of a platform; radial sliding blocks (9) which are installed at four corners of a lower plane of the platform (6) are sleeved on corresponding sliding rods (10) at the same side in a sliding manner; sliding rods (10) are respectively fixed at two sides of an axial sliding block (5); the axial sliding block (5) is sleeved on a guide rail (3) in the sliding manner; the axial sliding block (5) is driven to slid along the guide rail (3) through an axial feeding flywheel (2) by utilizing threads, so as to drive the milling cutter (4) to axially move along the steel pipe (1); the platform (6) is driven to slide along the sliding rods (10) through a radial feeding flywheel (7) by utilizing the threads, and therefore, the milling cutter (4) can move along the steel pipe (1) in the radial direction; and a cutting machine is fixed on the steel pipe (1) by adjusting a movable clamping block (14) through a clamping hand wheel (17). According to the axial cutting machine for the steel pipe, a mechanical cutting mode is adopted; the axial cutting machine for the steel pipe has a simple structure, and is suitable for being applied to axially cutting a steel pipe, a natural gas pipeline, a petroleum pipeline and the like which are provided with cables in a paving way; and the axial cutting machine has a good market prospect.

Owner:WUHAN UNIV OF SCI & TECH

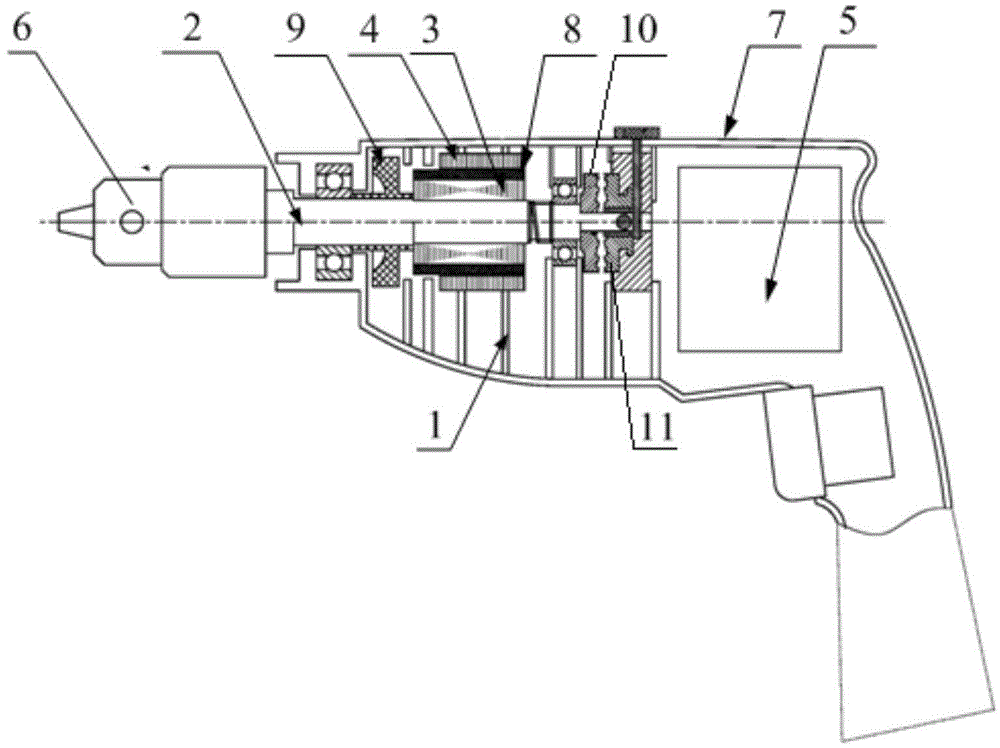

Flexible damping clutch based on hydraulic pressure

ActiveCN107763114APrevent disengagementPressure balanceFriction clutchesVibration absorptionControl theory

The invention provides a flexible damping clutch based on hydraulic pressure. The flexible damping clutch mainly comprises a hydraulic auxiliary device, a flexible pressing device, a guide device, a control device, and driving and driven devices; the flexible pressing device, the guide device and the control device are respectively mounted on the hydraulic auxiliary device; and the driving and driven devices are connected with the hydraulic auxiliary device through the flexible pressing device and the guide device. The flexible damping clutch has the characteristics of rolling flexible joint and hydraulic vibration absorption. The no-vibration automatic clutching of the clutch is realized through the hydraulic auxiliary device; the low-wear flexible joint and the quick separation of the clutch are realized through the flexible pressing device; the no-deviation oriented motion of a pressing disc and a driven disc is realized through the guide device; the free clutching of the clutch isrealized through the control device; and the power transfer is realized through the driving and driven devices.

Owner:UNIV OF JINAN

Film wrapping machine winding device for flat-shaped wires

InactiveCN103489530AAchieve axial movementThe distance is adjustable and appropriateInsulating conductors/cablesScrew threadEngineering

The invention discloses a film wrapping machine winding device for flat-shaped wires, and relates to the technical field of film wrapping machine equipment production. A winding guide wheel is arranged on a machine frame, a compaction wheel parallel to the winding guide wheel in the axial direction is arranged on one outer side of the winding guide wheel, the center of the compaction wheel is connected with one end of an adjusting screw rod through a connecting shaft, the axial direction of the adjusting screw rod is perpendicular to the axial direction of the winding guide wheel, a nut in threaded connection with the adjusting screw rod is fixedly connected to the machine frame, and an adjusting hand wheel is arranged at the other end of the adjusting screw rod. The compaction wheel is arranged on the outer side of the winding guide wheel in a matched mode, and the adjusting screw rod rotates on the nut through the adjusting hand wheel so that the adjusting screw rod can move in the axial direction, the distance between the compaction wheel and the winding guide wheel can be adjusted and appropriate to adapt to the flat-shaped wires with different thicknesses, the flat-shaped wires can be effectively prevented from turning over in the process of passing the winding guide wheel, an insulating layer can wrap the flat-shaped wires smoothly and tightly, and the wrinkling phenomenon cannot occur.

Owner:江苏朗顺电工电气有限公司

Oil conveying pipeline inner wall cleaner

InactiveCN107262468AImprove flexibilityAchieve axial movementHollow article cleaningFixed frameDrive motor

The invention provides an oil conveying pipeline inner wall cleaner which comprises a drive motor and a fixing frame. The drive motor is arranged in the middle of the fixing frame. The fixing frame is formed by multiple supporting legs. The multiple supporting legs are distributed around the circumference and connected into one through the fixing plate. A pulley is arranged at the outmost end of each supporting leg. A rotating cleaner is arranged at the front end of an output shaft of the drive motor. A sweeping brush is arranged at the rear end of the rotating cleaner and fixed to the output shaft of the drive motor. The oil conveying pipeline inner wall cleaner overcomes the defect of the prior art and is reasonable in design and compact in structure, the drive motor is supported through the traveling supporting frame, and the rotating cleaner is arranged at the front end of the output shaft of the drive motor and provided with an elastic mechanism which has good flexibility and good corner passing ability. Cleaning blades on the rotating cleaner are spirally distributed in pipeline space, tensioned on the pipeline wall through springs, and driven to rotate while moving axially.

Owner:安徽大地环保科技有限公司

Bidirectional floating adapter and adapting contact assembly thereof

InactiveCN104332735AAchieve axial movementIncrease contactCoupling device detailsElectricityElectrical conductor

The invention relates to the field of electrical connectors and particularly relates to a bidirectional floating adapter and an adapting contact assembly thereof. The bidirectional floating adapter includes a casing. Installation holes are arranged in the casing. The adapting contact assembly is assembled in the installation holes. The adapting contact assembly includes floating contacts and a fixed contact part. Resetting springs are installed between the floating contacts and the fixed contact in a butting manner. Swing gaps are arranged between the floating contacts and the walls of the installation holes. Each floating contact includes a floating conductor and the fixed contact includes a fixed conductor. The floating conductors and the fixed conductor are in plug-in connection through plug-in heads and plug-in holes arranged in the floating conductors and the fixed conductor respectively. The plug-in heads and the plug-in holes cooperate so that a universal swing structure is formed. The adapter is a bidirectional floating adapter, the contact parts of which are capable of floating and swinging in the axial and radial directions.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

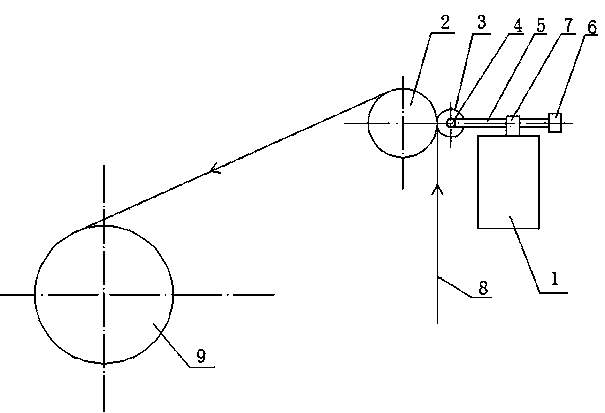

Device for detecting near-end force and torque of catheter of minimally invasive vascular interventional surgical robot

ActiveCN113769238ANo lubricationNo wearMedical devicesCatheterSurgical roboticsMechanical engineering

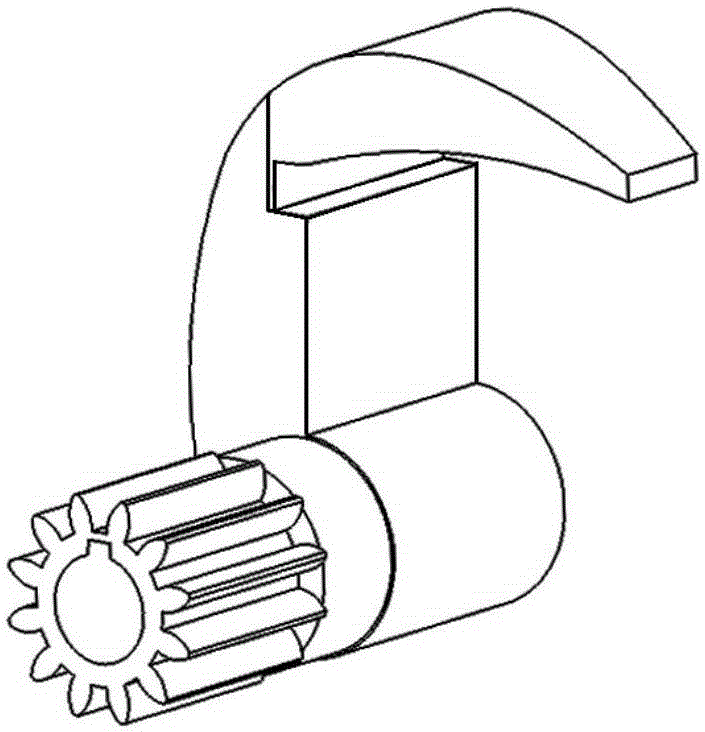

The invention relates to a device for detecting near-end force and torque of a catheter of a minimally invasive vascular interventional surgical robot. The device comprises a catheter pushing device, a torsion transmission mechanism and a wireless photoelectric sensing PCB, wherein the torsion transmission mechanism comprises a torsion motor, rotating shafts, a transmission pinion, a transmission bull gear, a flexible bending piece and a catheter clamping device, wherein the flexible bending piece is connected with the transmission bull gear, and the catheter clamping device is connected with the flexible bending piece; the torsion motor can drive the transmission pinion to drive the transmission bull gear to rotate so as to drive a catheter to rotate; the catheter pushing device can drive the torsion transmission mechanism to do linear motion; and when a slave end catheter is subjected to resistance, the resistance is transmitted to the flexible bending piece through the catheter clamping device to cause the flexible bending piece to generate circumferential displacement deformation, and the wireless photoelectric sensing PCB generates a digital signal according to the displacement deformation, so that torque on-line detection of the slave end catheter is realized, a doctor can conveniently and directly sense the operation resistance of the catheter, and the operation state of the slave end surgery is further perceived.

Owner:TIANJIN UNIV

Pipe limiting spring support and support set

InactiveCN105626972AReduce frictional resistanceReduce resistance to moving up and downPipe supportsVertical tubeArchitectural engineering

The invention discloses a pipe limiting spring support. The pipe limiting spring support comprises an outer sleeve, a middle sleeve and an elastic element located in the outer sleeve; one end of the middle sleeve is provided with a bearing face for supporting a pipe, and the other end of the middle sleeve extends into the outer sleeve; and a first rolling connecting piece is arranged between the inner wall of the outer sleeve and the outer wall of the middle sleeve, and the two ends of the elastic element abut against the bottom of the outer sleeve and the middle sleeve. The invention further discloses a support set which comprises at least two above pipe limiting spring supports and second fixing supports fixed to the bearing faces; and the two second fixing supports are symmetrically distributed on the two sides of a vertical tube and are connected with the vertical tube. According to the pipe limiting spring support and the support set, displacement of the pipe in the horizontal direction can be limited, the pipe can be elastically borne in the vertical direction, and dual functions of horizontal limitation and spring bearing are achieved. The pipe limiting spring support and the support set have the beneficial effects of being complete in function, simple in structure, easy to manufacture and the like; and the design of the pipe limiting spring support and the support set is reasonable and effective, and the manufacturing cost is low.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Standby start and stop type electronic connector

InactiveCN109586112AAchieve axial movementAchieve separationCoupling device detailsEngineeringElectrical connector

The invention discloses a standby start and stop type electronic connector comprising a first connecting ring, a conducting block, a second connecting ring, a telescopic conducting rod and a standby start and stop assembly. The conducting block and the telescopic conducting rod are connected and separated through the first connecting ring and the second connecting ring. In order to prevent screwsfrom rusting, the standby start and stop assembly is added, a pressing ring is pulled, the pressing ring drives a connecting rod to slide in a strip sliding groove of an insertion connection cylinder,at the same time, the connecting rod drives the telescopic conducting rod to telescopically move in the insertion connection cylinder, the axial movement of the telescopic conducting rod is achieved,therefore, the separation of the telescopic conducting rod and the conducting block is achieved, after the adjustment is completed, the pressing ring is loosened, an elastic body elastically pressesa moving ring such that the moving ring drives the pressing ring to abut on the second connecting ring, at the same time, the telescopic conducting rod and the conducting block abut against each otherto be connected, and the standby start and stop type electronic connector is convenient to operate and convenient to use.

Owner:东台市高科技术创业园有限公司

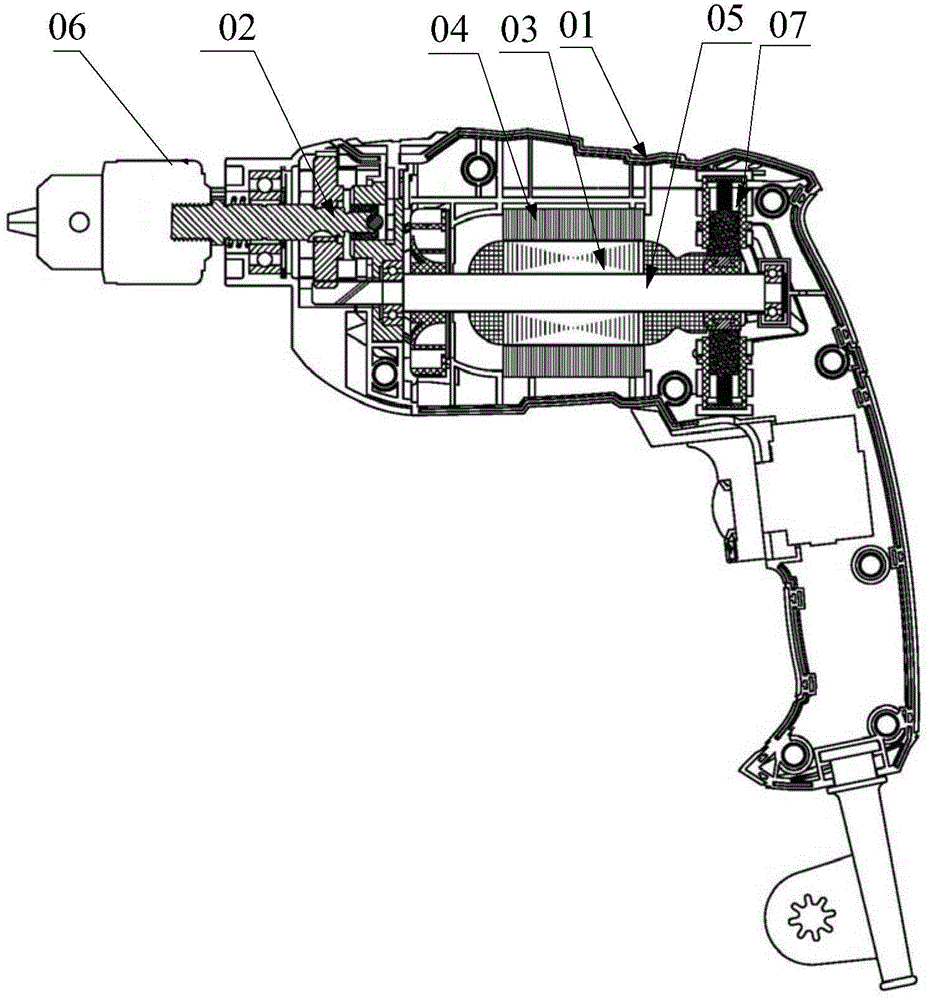

Percussion drill

InactiveCN105305721AEasy to useReduce volumeMechanical energy handlingPortable drilling machinesBrushless motorsEngineering

The invention discloses a percussion drill. The percussion drill comprises a case; a supporting part and a high power density brushless motor erected on the supporting part are arranged in the case; a controller of the high power density brushless motor is arranged in the case; the high power density brushless motor comprises a rotor shaft rotationally arranged in the supporting part; a chuck of the percussion drill is fixed at one end of the rotor shaft; an impact movable gear is arranged at the other end, far from the chuck, of the rotor shaft; and an impact static gear, arranged corresponding to the impact movable gear, is arranged in the case. According to the percussion drill provided by the invention, the service life of the percussion drill is prolonged; the generation of carbon powder is avoided, and environmental pollution is avoided; and a transmission apparatus arranged in the case is avoided, so that the service life of the percussion drill is prolonged, the energy consumption is reduced, the output efficiency is improved, the noise and the vibration are reduced, the trouble in engagement installation of the transmission gears is avoided, the volume and the weight of the percussion drill are effectively reduced, and convenience is brought for the assembling of the percussion drill.

Owner:ZHEJIANG LVDONG MOTOR TECH CO LTD

Transmission with gear wheel pump

InactiveCN101377235ALow costSmall location requirementsGear lubrication/coolingRotary piston pumpsGear pumpGear wheel

The invention relates to a gearbox for a motor vehicle that includes, but is not limited to an input shaft, an output shaft and a plurality of wheel sets for coupling input and output shaft with different transmission ratios and a gear pump, which is arranged to for delivering from a reservoir of the gearbox. The gear pump is an outer gear pump and one of two gears of the gear pump meshing with one another belongs to one of the wheel sets.

Owner:GM GLOBAL TECH OPERATIONS LLC

Simple mechanical arm stacking machine

InactiveCN104555472AAchieve axial movementRealize automatic palletizingStacking articlesDe-stacking articlesFailure rateEngineering

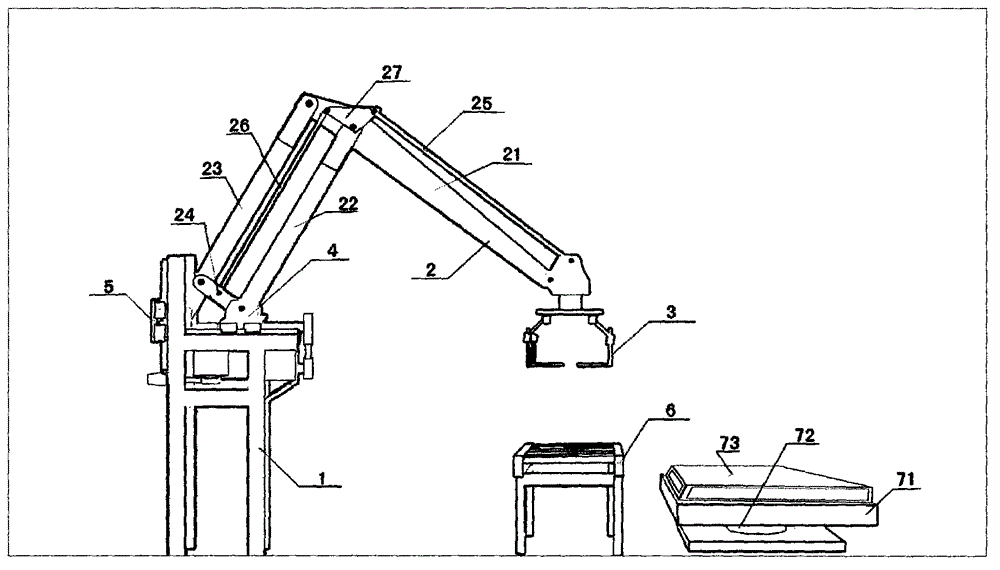

The invention relates to a simple mechanical arm stacking machine. The machine comprises a rack, a mechanical arm, a mechanical grip, a horizontal driving mechanism and a vertical driving structure, wherein the mechanical arm comprises a main arm, a front arm, a rear arm and a front and rear arm connecting rod; the front arm is parallel to the rear arm and forms a parallelogram with the front and rear arm connecting rod and the rear end part of the main arm; the mechanical grip is arranged at the front end of the main arm; the horizontal driving mechanism and the vertical driving structure are both arranged on the rack and are used for driving the movement and the action of the mechanical arm. By using two-axis control, the production precision requirement and cost are reduced, the failure rate of equipment is obviously reduced, the labor is saved and the stacking efficiency is improved while automatic stacking of the mechanical arm is realized, and the stacking machine is applicable to widespread application.

Owner:王超

Movable clamping type electronic connector

InactiveCN109411912AEasy to disassemble and overhaulAchieve axial movementElectric connection structural associationsClamped/spring connectionsSize changeEngineering

The invention discloses a movable clamping type electronic connector. The movable clamping type electronic connector comprises a first connection ring, a breakover block, a second connection ring, a flexible breakover rod, a standby start / stop assembly and a clamping screw. The breakover block is clamped and connected in the first connection ring through the clamping screw, so that the operation is more convenient and rapid when the breakover needs to be dismounted for size change or overhauling.

Owner:东台市高科技术创业园有限公司

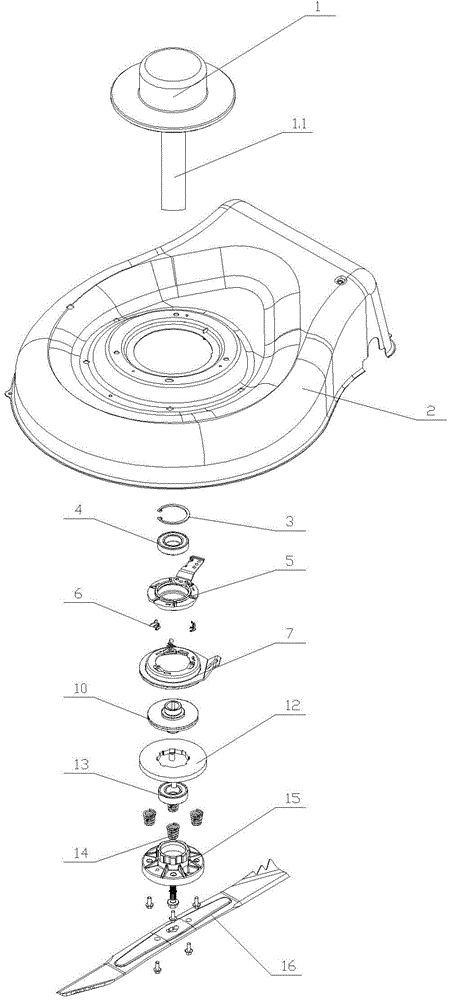

Rotary blade device with brake and clutch functions

The invention discloses a rotary blade device with brake and clutch functions. The rotary blade device comprises a bottom disc (2), a blade (16), a driving device (1), a clutch device, a brake device, a driving wheel disc (10) and a driven wheel disc (12), the driving device (1) is fixed to the bottom disc (2) and drives the blade (16) to rotate, the clutch device and the brake device are arranged in the bottom disc (2), the driving wheel disc (10) is arranged on an output shaft (1.1), and the driven wheel disc (12) capable of being meshed with the driving wheel disc (10) is arranged on the end face. The driven wheel disc (12) is connected with the blade (16), the clutch device comprises a pressure device and a resetting device, the pressure device presses the driven wheel disc (12) to enable the driven wheel disc (12) and the driving wheel disc (10) to be separate or reduce the pressure on the driven wheel disc (12), and the resetting device enables the driven wheel disc (12) to be reset to be meshed with the driving wheel disc (10) again. According to the rotary blade device with the brake and clutch functions, the blade can stop rotating immediately without shutting down an engine.

Owner:NINGBO YINZHOU LANGLIN MACHINERY

Five-axis multi-head polishing machine

PendingCN109759935AImplement the rotation functionAchieve axial movementGrinding carriagesPolishing machinesEngineering

The invention discloses a five-axis multi-head polishing machine, which comprises a main frame, a base frame and a worktable. The base frame is fixedly connected to the lower part of the main frame. The five-axis multi-head polishing machine is characterized in that A-axis rotating modules are arranged on the worktable at intervals, a first linear rail sliding block is arranged at the bottom of the main frame, a first saddle is arranged at the position, corresponding to the first linear rail sliding block, of the bottom face of a sliding seat, the first saddle is slidably arranged on the firstlinear rail sliding block, two second saddles are arranged at the two ends of a gap bridge plate correspondingly, second linear rail sliding blocks are arranged at the positions, corresponding to thesecond saddles, of the upper parts of the two sides of the main frame, and the second saddles are slidably arranged on the second linear rail sliding blocks. The multiple sets of A-axis rotating modules and a plurality of sets of B-axis rotating modules are adopted, the rotating function of the A-axis rotating modules and the B-axis rotating modules is achieved, the linear rail sliding blocks andthe saddles are combined to achieve axial motion of the X axis and the Y axis, B-axis rotation and Z-axis axial motion of main shafts are achieved through connection of the gap bridge plates and theZ axes, and different angle machining requirements are met.

Owner:嘉泰数控科技股份公司

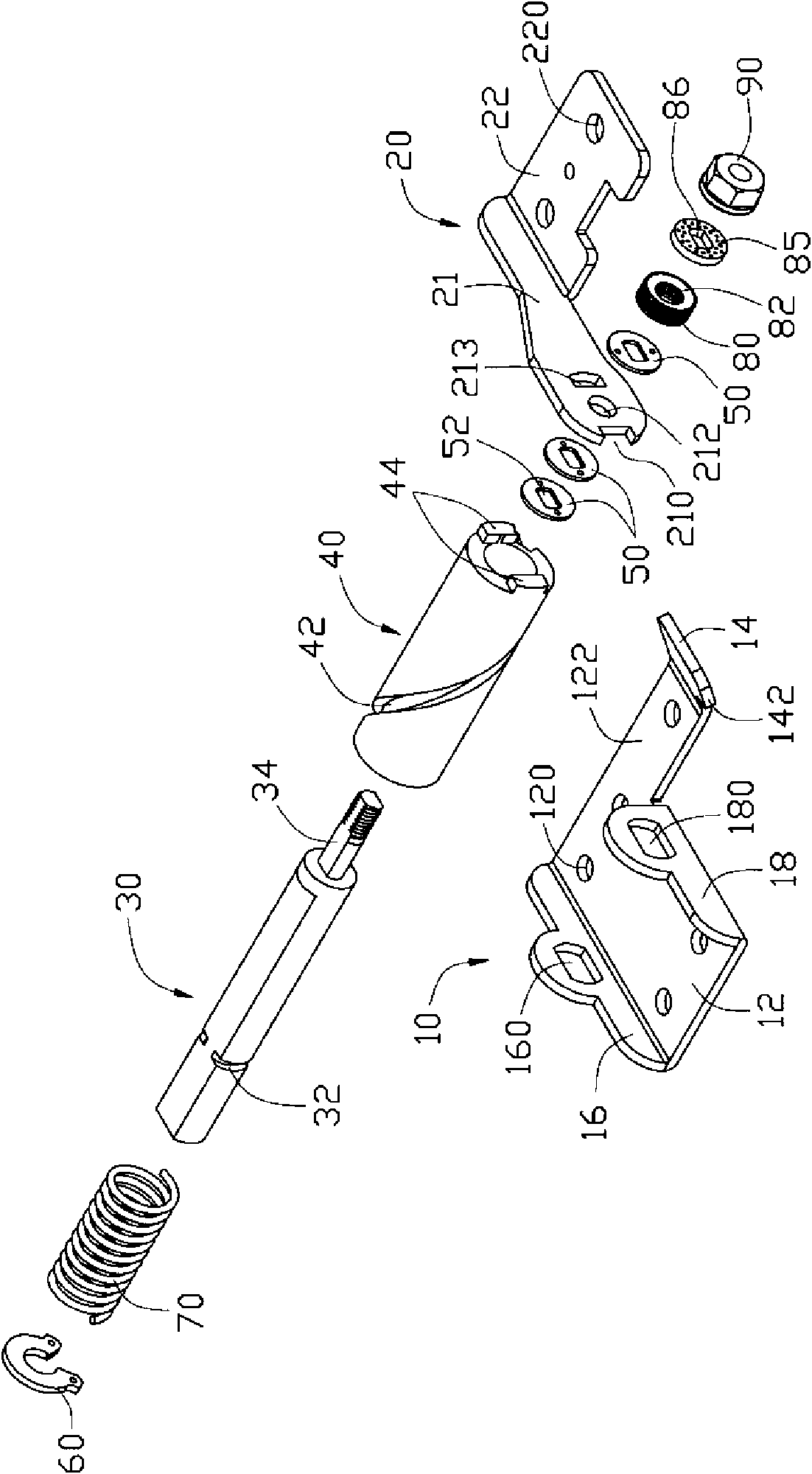

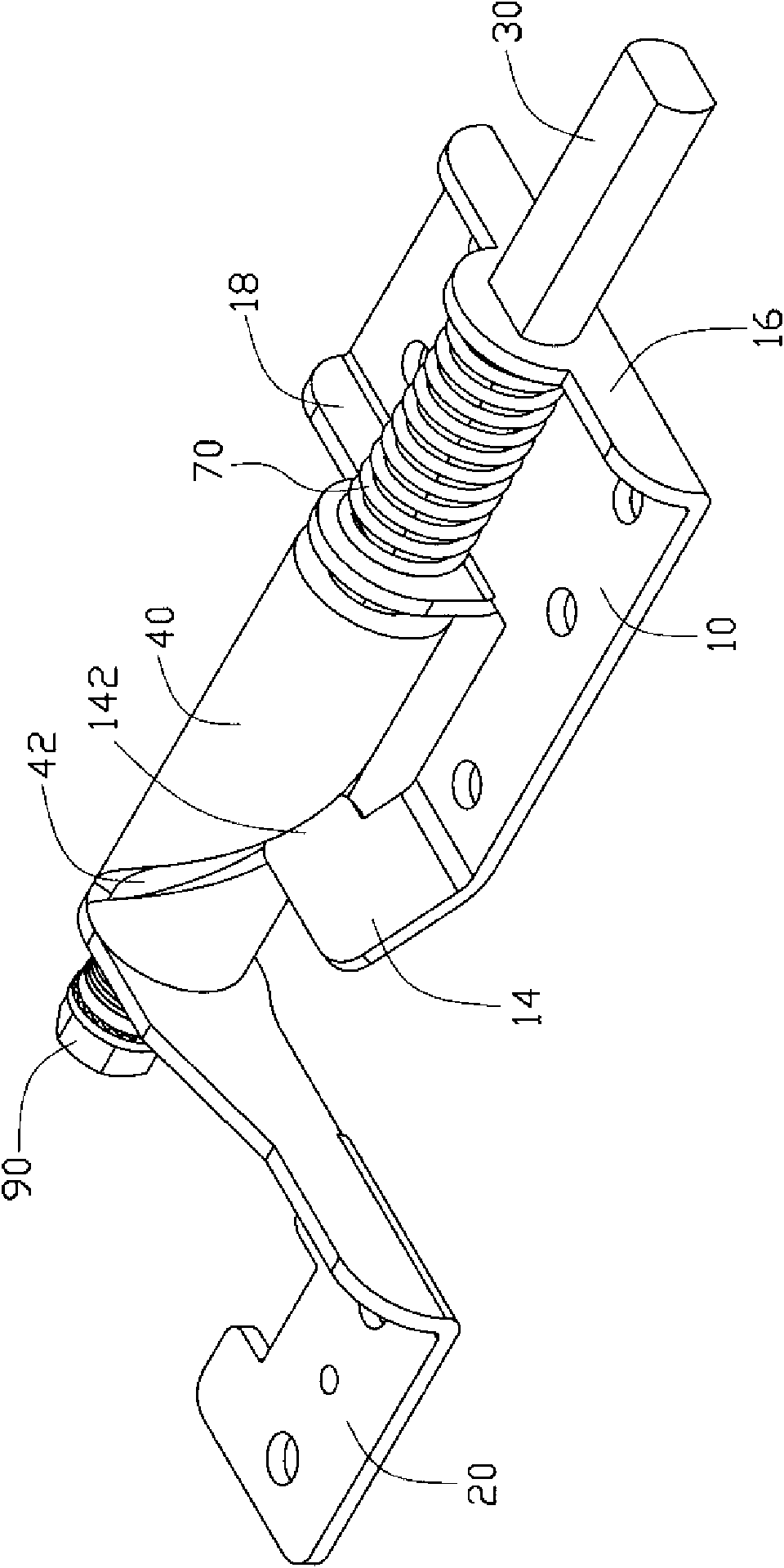

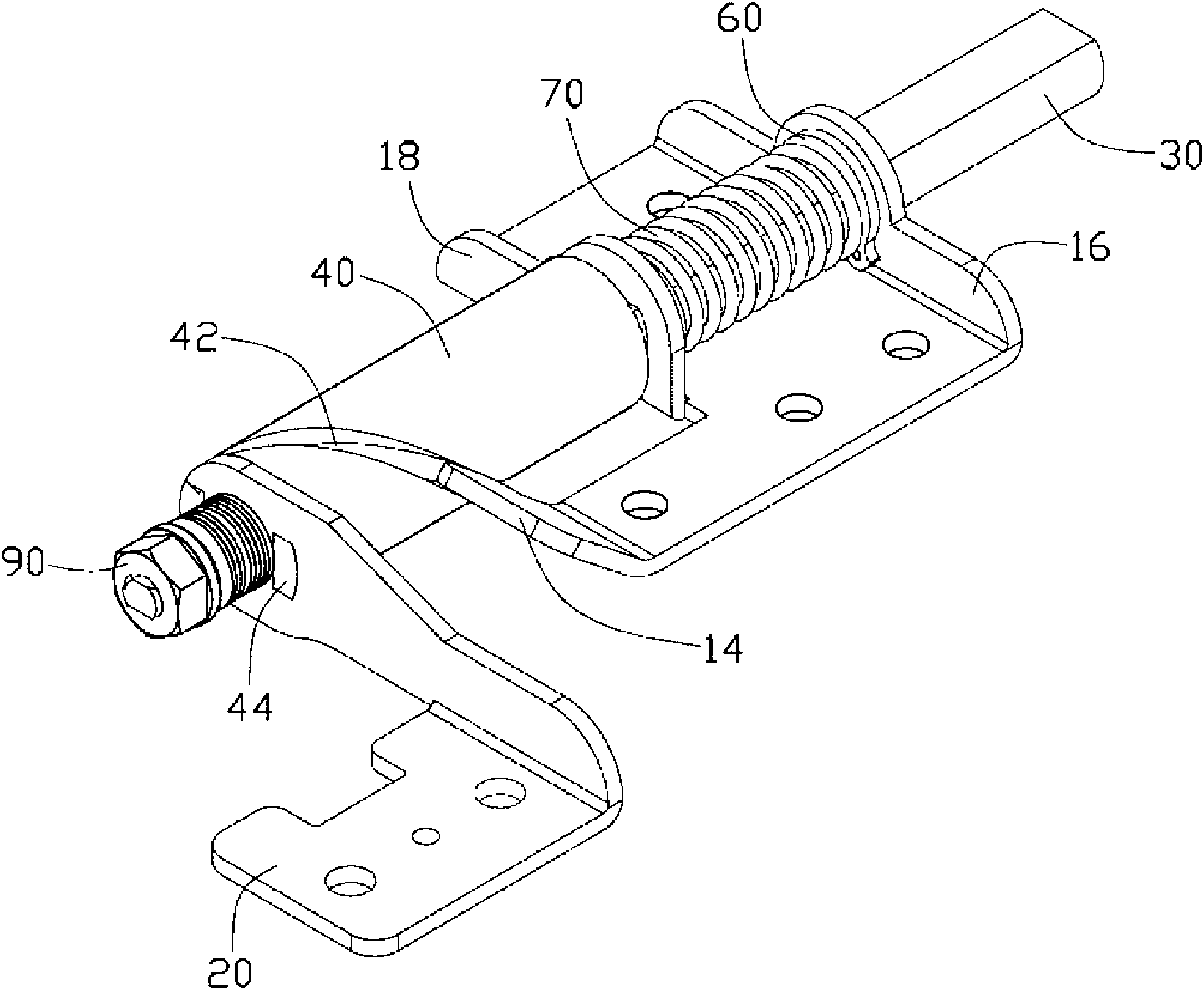

Pivotal device

InactiveCN101871484AAchieve axial movementDigital data processing detailsPivotal connectionsEngineeringMechanical engineering

The invention discloses a hinge device, comprising a first connecting piece, a second connecting piece, a shaft rod and a fixation component, wherein, one end of the shaft rod is provided with a fixation part which can be rotatablely assembled in the second connecting piece; the fixation component is fixed at the tail end of the fixation part; and the first connecting piece protruded with a clamp block; and the first connecting piece can be axially and movably connected with the shaft rod. The hinge device also comprises a sleeve fixed on the second connecting piece; a helical chute is arranged on the sleeve; the clamp block is slidably clamped on the chute; and when the second connecting piece is rotated, the clamp block pushes the sleeve, thereby driving the second connecting piece and the shaft rod to go away from the first connecting piece in an axial direction, so as to realize axial movement of the hinge device.

Owner:KANGZHUN ELECTRONICS TECH KUNSHAN +1

Transmission device of industrial door opener capable of automatic switching

ActiveCN101581179AProblems overcoming harsh constraintsNo training requiredDoor/window protective devicesPower-operated mechanismMotor drivePower switching

The invention provides a transmission device of an industrial door opener capable of automatic switching. The invention mainly aims to provide a two-way lead cam and a critical fixing device, wherein the two-way lead cam is fixed in axial direction and does not rotate in an initial state under the action of the critical fixing device; when a hand-pulled chain wheel fixed on the same mandrel along with the two-way lead cam is pulled in random directions, a part A can slide from a low point to the highest point of a spiral surface or a thread groove; thus, the mandrel moves in axial direction towards the same direction and cooperates with a bevel gear pair and a power supply switch to switch motor drive to manual drive flexibly; and when a hand-pulled chain is loosened, motor drive is switched back under the action of a mandrel restore device.

Owner:漳州市杰龙机电有限公司

Main driving device for vertical milling machine

ActiveCN102717291AAchieve axial movementWide speed rangeDriving apparatusMaintainance and safety accessoriesGear wheelAgricultural engineering

The invention discloses a main driving device for a vertical milling machine, which has wide speed regulation range and can achieve axial feeding and good lubrication effect, wherein the main driving device comprises a main motor, a drive housing, an elastic coupler, an oil basin, a first transmission shaft, a cycloid pump, a second transmission shaft, a second shaft gear, a triple gear, a third transmission shaft, a change gear, a fourth transmission shaft, a duplicate gear, a change gear, a fifth transmission shaft, a change gear, a bevel gear and a vertical shaft; a first shaft gear is arranged on the first transmission shaft; the bevel gear is arranged at one end of the vertical shaft; a skew gear is arranged at the other end of the vertical shaft; a main shaft is arranged on one side of the vertical shaft; and a spline housing and the skew gear are arranged on the outer side of the main shaft. The main driving device has the advantages as follows: the main shaft can obtain 12-level rotational speed within 35 to 1500 rpm (Revolutions Per Minute) through a 3*2*2 structural formula, and the speed regulation range is wide; the main shaft and the spline housing are connected through a spline, and the main shaft can move upwards and downwards in the spline housing in the axial direction; in addition, the cycloid pump is installed at one end of the first transmission shaft, lubricant in the oil basin in the drive housing can be conveyed to lubricating points on the gears and bearings through an oil line with the help of the power of the first transmission shaft, and the lubrication effect is good.

Owner:SHANDONG YOURONG MACHINE TOOL

Ger lever for operation device of automobile gear-box

InactiveCN101424333AAchieve axial movementAchieve radial rotationGearing controlControl devicesEngineeringAutomotive transmission

Owner:SCHAEFFLER TECH AG & CO KG

Intelligent visual inspection device for code spraying

PendingCN112903717AHigh degree of automationHigh precisionMaterial analysis by optical meansComputer hardwareVisual inspection

An intelligent visual inspection device for code spraying comprises an image processor and a supporting platform. A belt is arranged on the supporting platform, and a detection mechanism, a code spraying mechanism and a paging mechanism are sequentially arranged in the length direction of the supporting platform. The detection mechanism comprises a supporting rod, a photoelectric detection mechanism, a light supply mechanism, an image capturing mechanism and an alarm are sequentially arranged in the height direction of the supporting rod, the image capturing mechanism is electrically connected with the image processor, and the alarm is arranged at the top of the supporting rod. In comparison with the traditional detection device, on one hand, various unqualified sprayed codes on the packaging bag can be detected, and on the other hand, the device has a self-learning capability and can collect and calculate error information, so that the precision of detecting the subsequent sprayed codes of the packaging bag is improved.

Owner:ZHEJIANG SHOUXIANGU PHARMA CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com