Simple mechanical arm stacking machine

A technology of manipulator and palletizer, applied in the field of simple manipulator palletizer, can solve the problems of large floor space, complex equipment structure and high cost, achieve tidy palletizing specifications, improve palletizing efficiency, and reduce failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

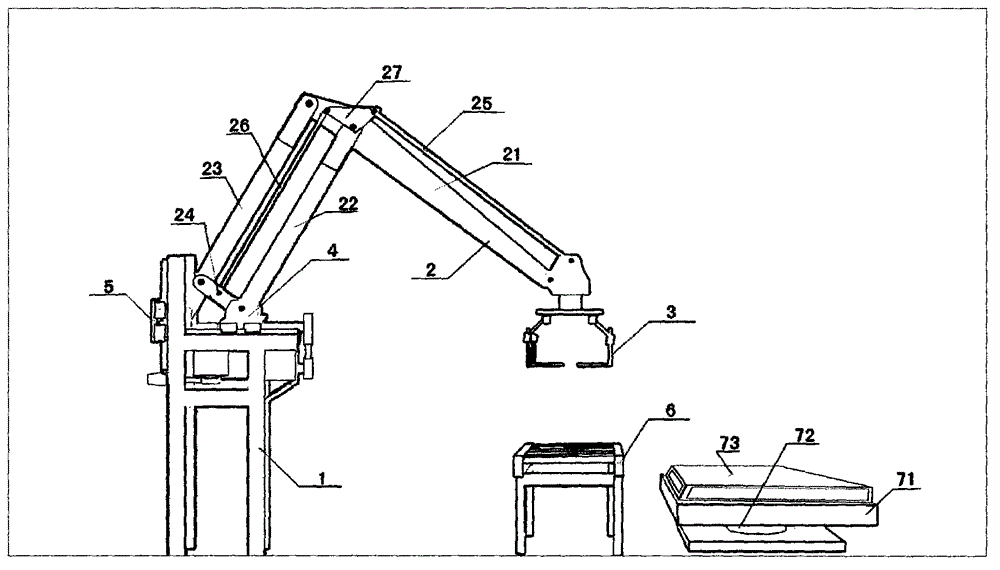

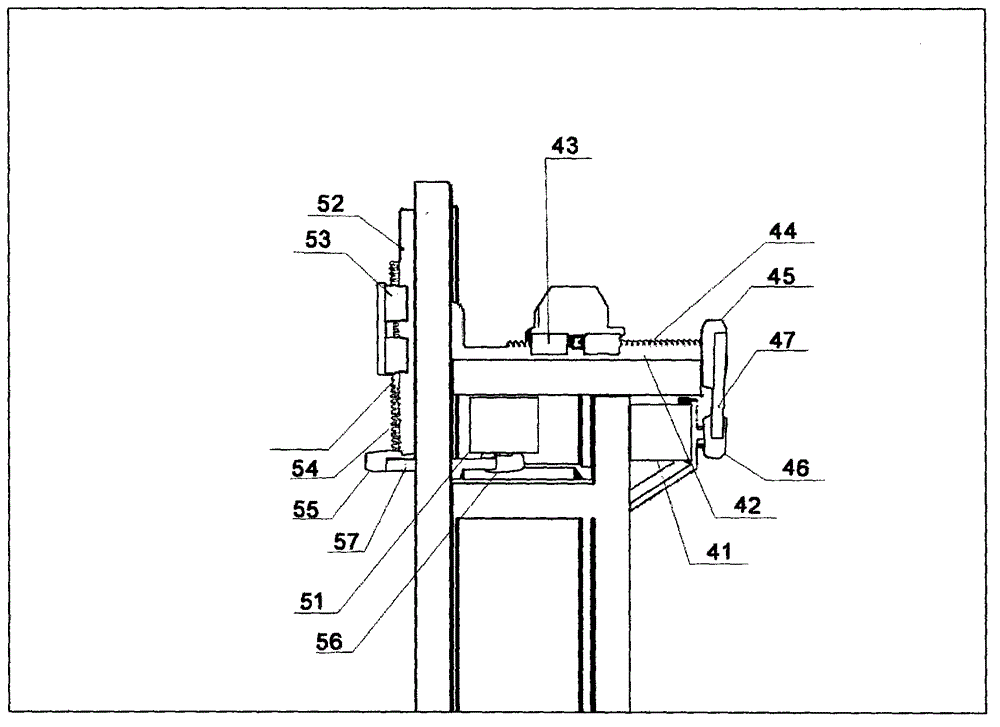

[0023] see figure 1 As shown, a simple mechanical arm palletizer of the present invention mainly includes a frame 1, a mechanical arm 2, a mechanical gripper 3, a horizontal driving mechanism 4 and a vertical driving structure 5.

[0024] Wherein, mechanical arm comprises main arm 21, forearm 22, rear arm 23 and front and rear arm connecting rod 24, and forearm 22 is parallel to rear arm 23, and forms parallelogram with the rear end of front and rear arm connecting rod 24 and main arm 21. The mechanical gripper 3 is installed at the front end of the main arm 21, and the horizontal driving mechanism 4 and the vertical driving mechanism 5 are installed on the frame 1, and drive the movement and action of the mechanical arm. Through the action of the front and rear arm links 24, the movement of either the forearm 22 or the rear arm 23 will drive the corresponding movement of the other. According to the principle of parallel hanging, the mechanical gripper 3 at the front end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com