Six-degrees-of-freedom system of big load model track capturing test of large transonic speed wind tunnel

A transonic technology with degrees of freedom, applied in the field of aero aerodynamic wind tunnels, can solve the problems of poor bearing capacity, small stroke, poor stiffness, etc., to achieve the effect of improving bearing capacity and stiffness, and reducing installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

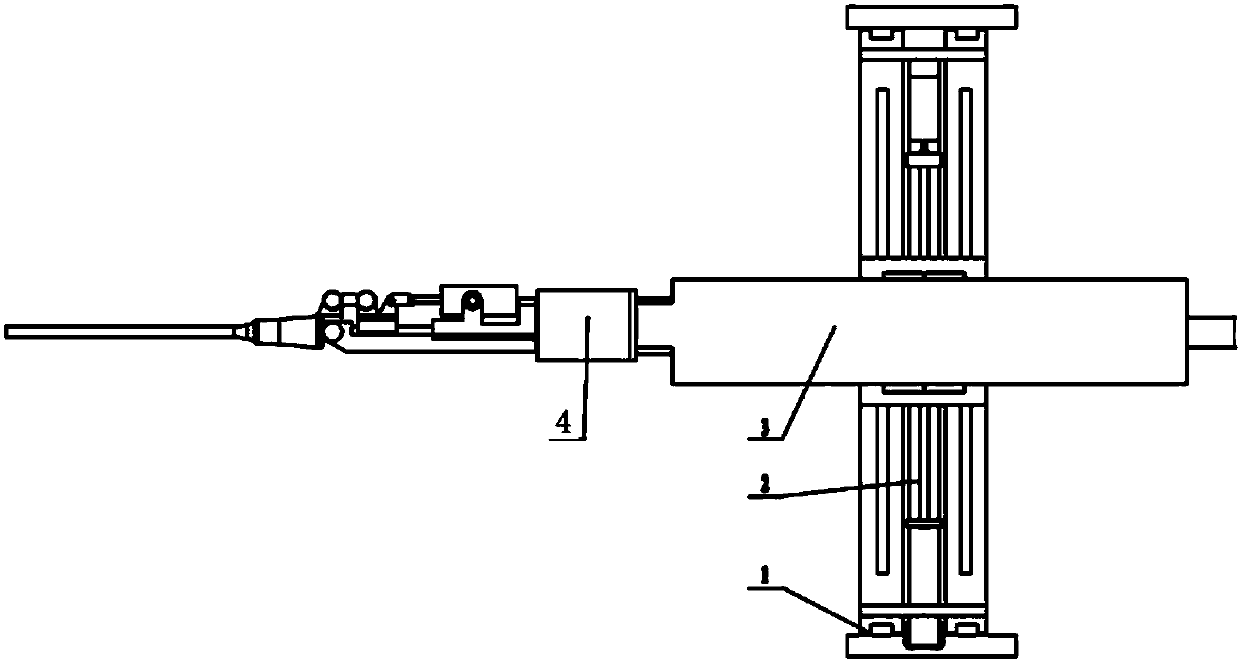

[0028] Such as figure 1 As shown, a six-degree-of-freedom system for a large-scale transonic wind tunnel large-load model capture trajectory test includes a lateral movement mechanism 1, a normal movement mechanism 2, an axial movement mechanism 3, and a three-degree-of-freedom attitude movement mechanism 4. The lateral movement mechanism 1 is installed on the leeward surface of the upper and lower wall panels of the test section, the normal movement mechanism 2 is installed on the transverse movement mechanism 1, the axial movement mechanism 3 is installed on the normal movement mechanism 2, and the three-degree-of-freedom attitude movement The mechanism 4 is installed on the axial movement mechanism 3;

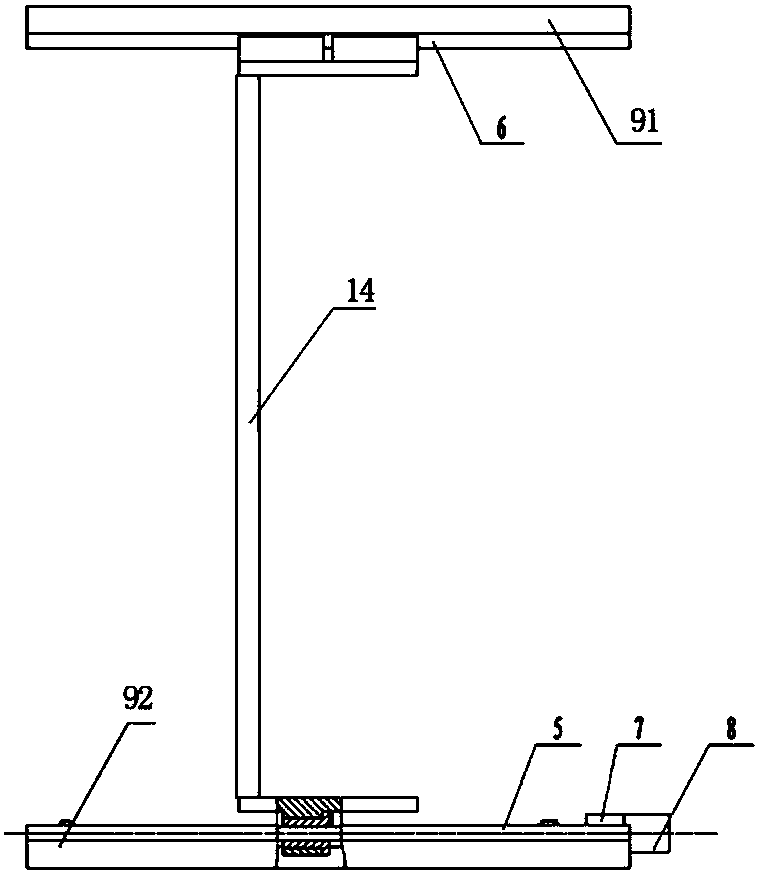

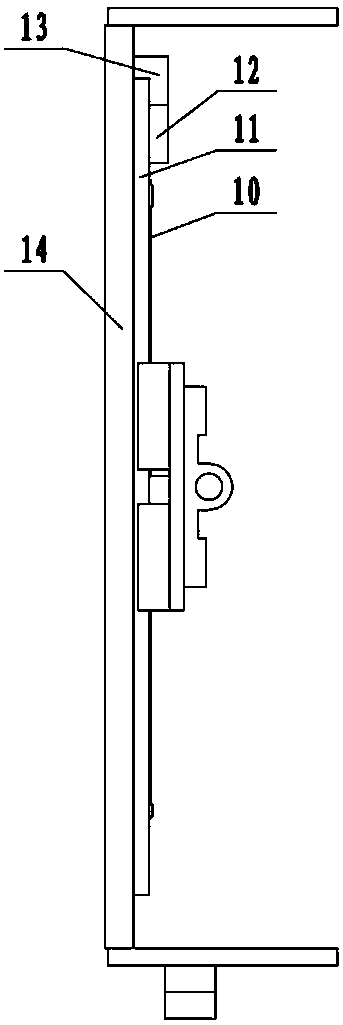

[0029] Such as Figure 2-3 As shown, the lateral motion mechanism 1 includes a first lead screw 5, a lateral linear guide rail 6, a first reducer 7, and a first servo motor 8, and the lateral linear guide rail 6 is installed on the leeward side base of the upper and lower w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com