Axial cutting machine for steel pipe

A cutting machine, axial technology, applied in metal processing machinery parts, feeding devices, milling machine equipment, etc., can solve the problem of low heat generation, and achieve the effect of low heat generation, good processing effect and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiment, is not the limitation of its protection scope:

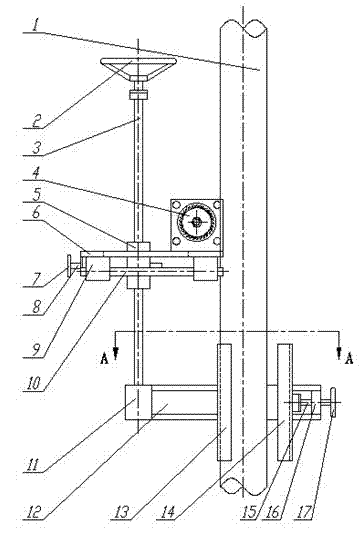

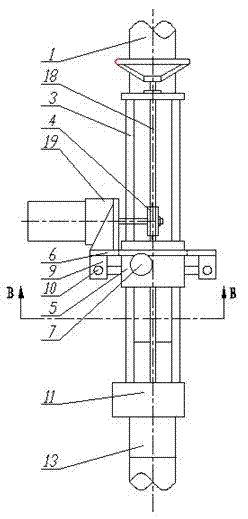

[0024] A steel pipe axial cutting machine, its structure schematic diagram is as follows figure 1 , figure 2 Shown: the milling cutter 4 is installed on the output shaft of the speed-regulating motor 19, the speed-regulating motor 19 is fixedly installed on the upper plane of the platform 6, and the four corners of the lower plane of the platform 6 are respectively fixed with radial sliders 9, and the two sides of the platform 6 The two radial sliders 9 are slidingly sleeved on the respective corresponding sliding rods 10 on the same side, and the sliding rods 10 are respectively fixed on both sides of the axial slider 5 .

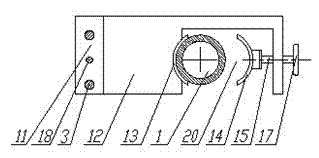

[0025] Such as Figure 4 As shown, the axial slider 5 is a rectangular block, and an axial threaded hole is processed at the middle position of the horizontal plane of the rectangular block. The two sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com