Transmission with gear wheel pump

A technology for transmissions and gear pumps, applied in gear lubrication/cooling, belts/chains/gears, pumps, etc., can solve problems such as increased cost and leaks, reduce slap noise, promote passive lubrication, and benefit The effect of conveying capacity and working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

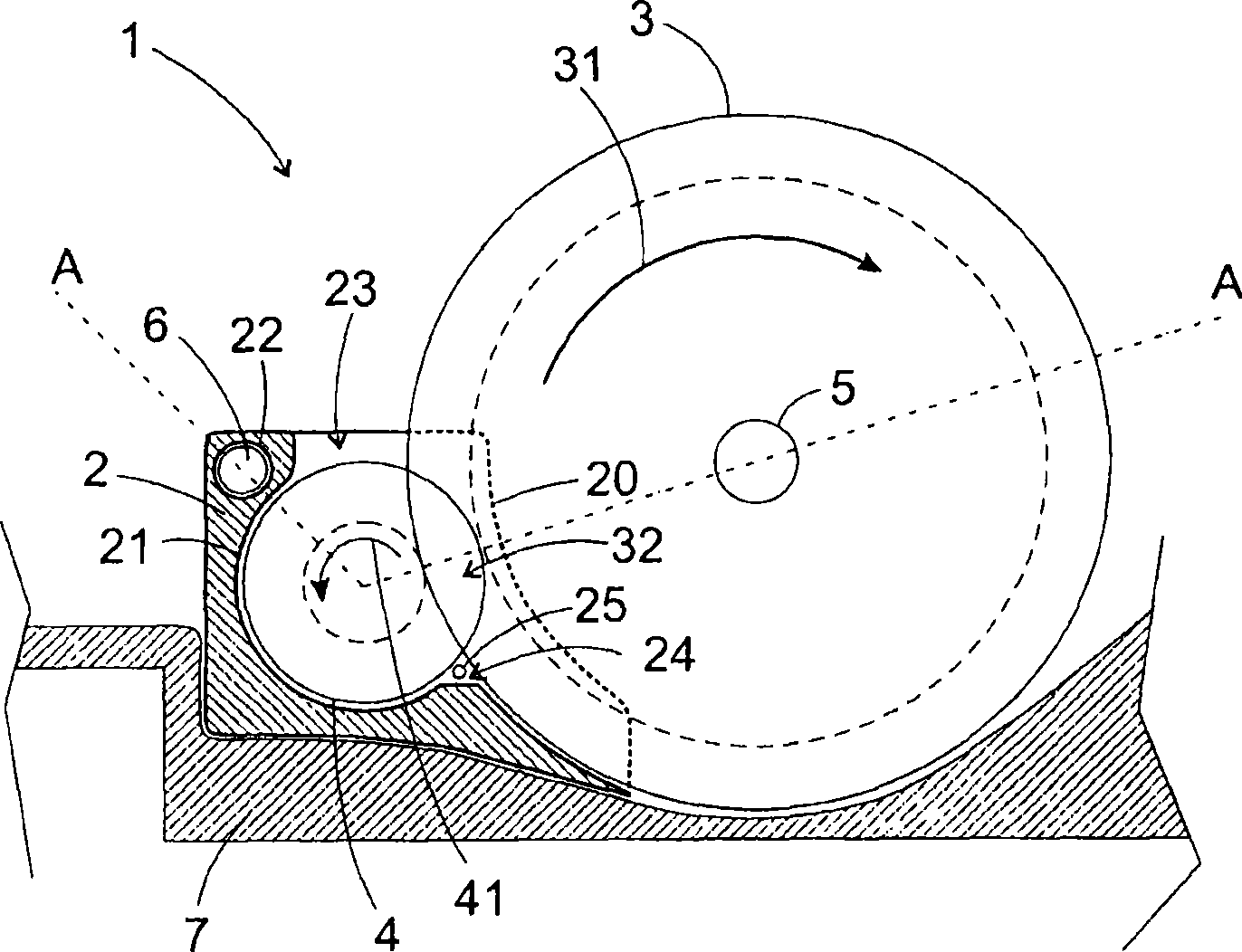

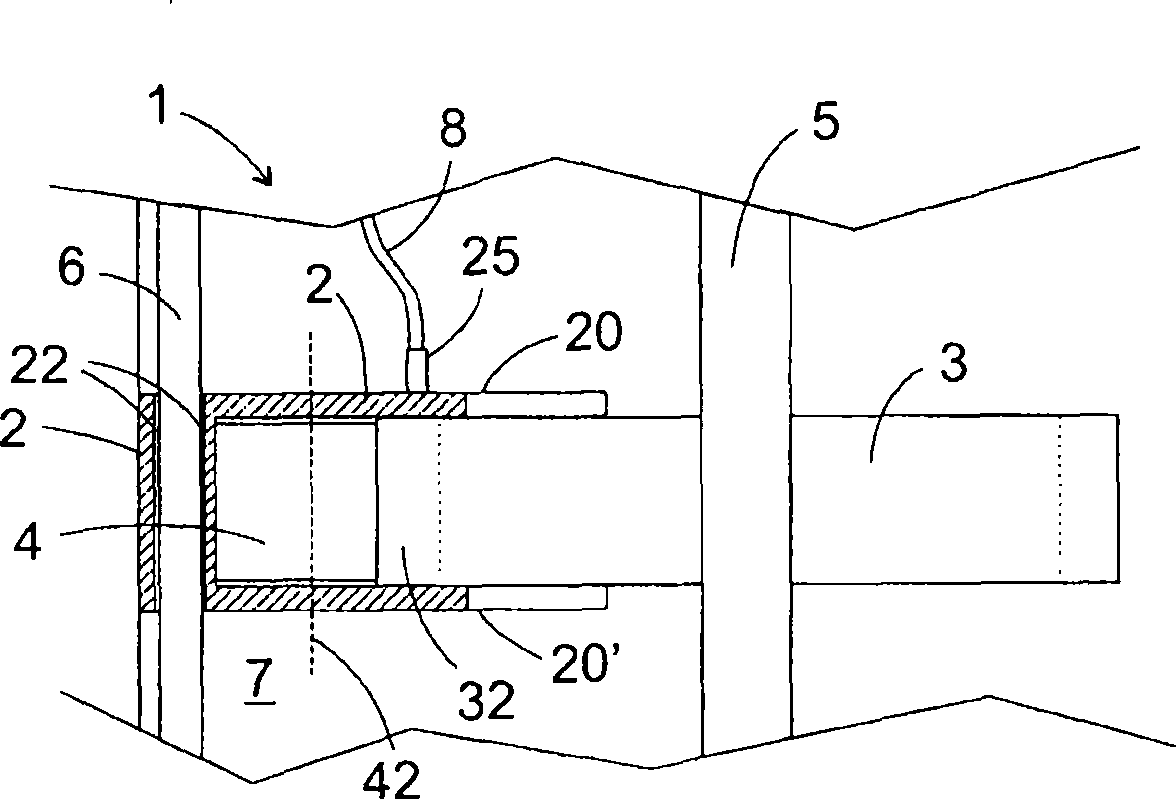

[0024] figure 1 A part of a vehicle transmission is shown, in particular a partial sectional view of a transmission with an external gear pump according to the invention is schematically shown.

[0025] The transmission includes a drive shaft, an output shaft and a plurality of gear sets, the gear sets engage the drive shaft and the output shaft with different transmission ratios and are arranged inside the transmission housing 7 . Furthermore, the transmission includes a gear pump 1 which is likewise surrounded by a transmission housing 7 .

[0026] The gear pump 1 is designed as an external gear pump and has a housing 2, a first gear 3 and a second gear 4, wherein the housing 2 and the second gear 4 are made of a plastic.

[0027] The first gear 3 is formed by a transmission gear in a gear set of the transmission, so the gear set and the gear pump 1 have a common gear 3 . The gear 3 is fixedly arranged on the transmission shaft 5 , is driven by it, and rotates about the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com