Patents

Literature

188results about How to "Guaranteed to work continuously" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

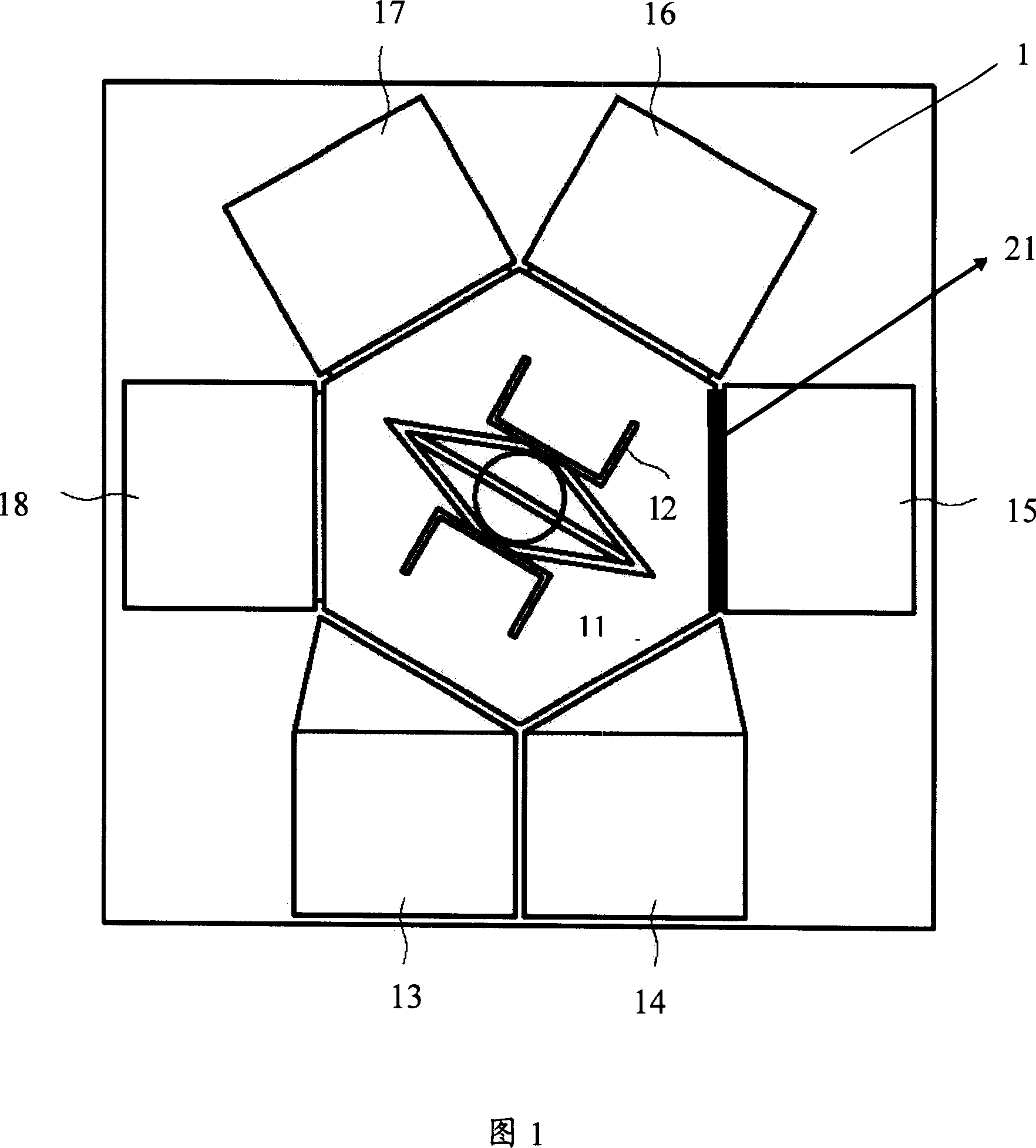

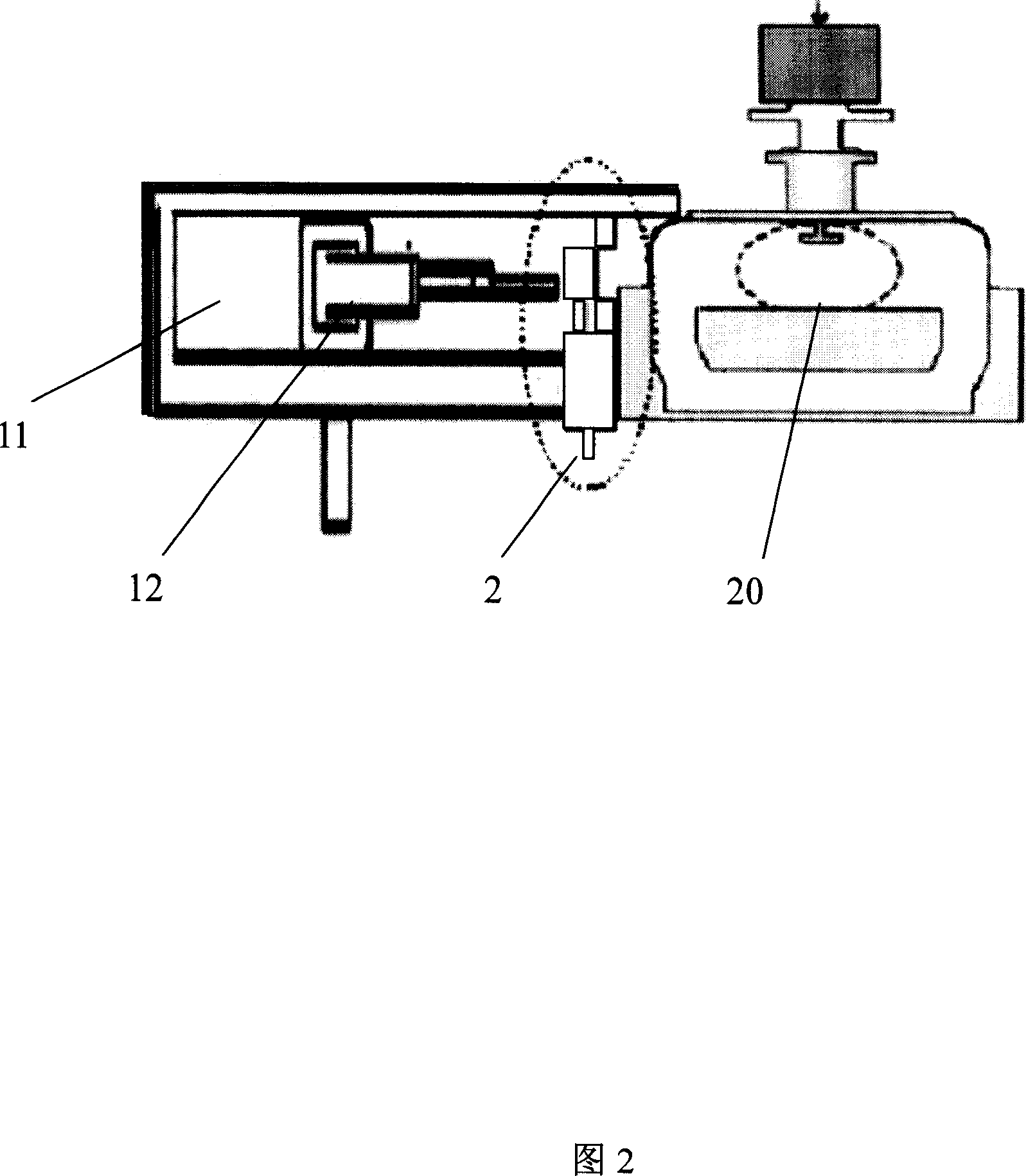

Real-time satellite signal simulator based device for synchronously increasing and decreasing visible satellites and construction method thereof

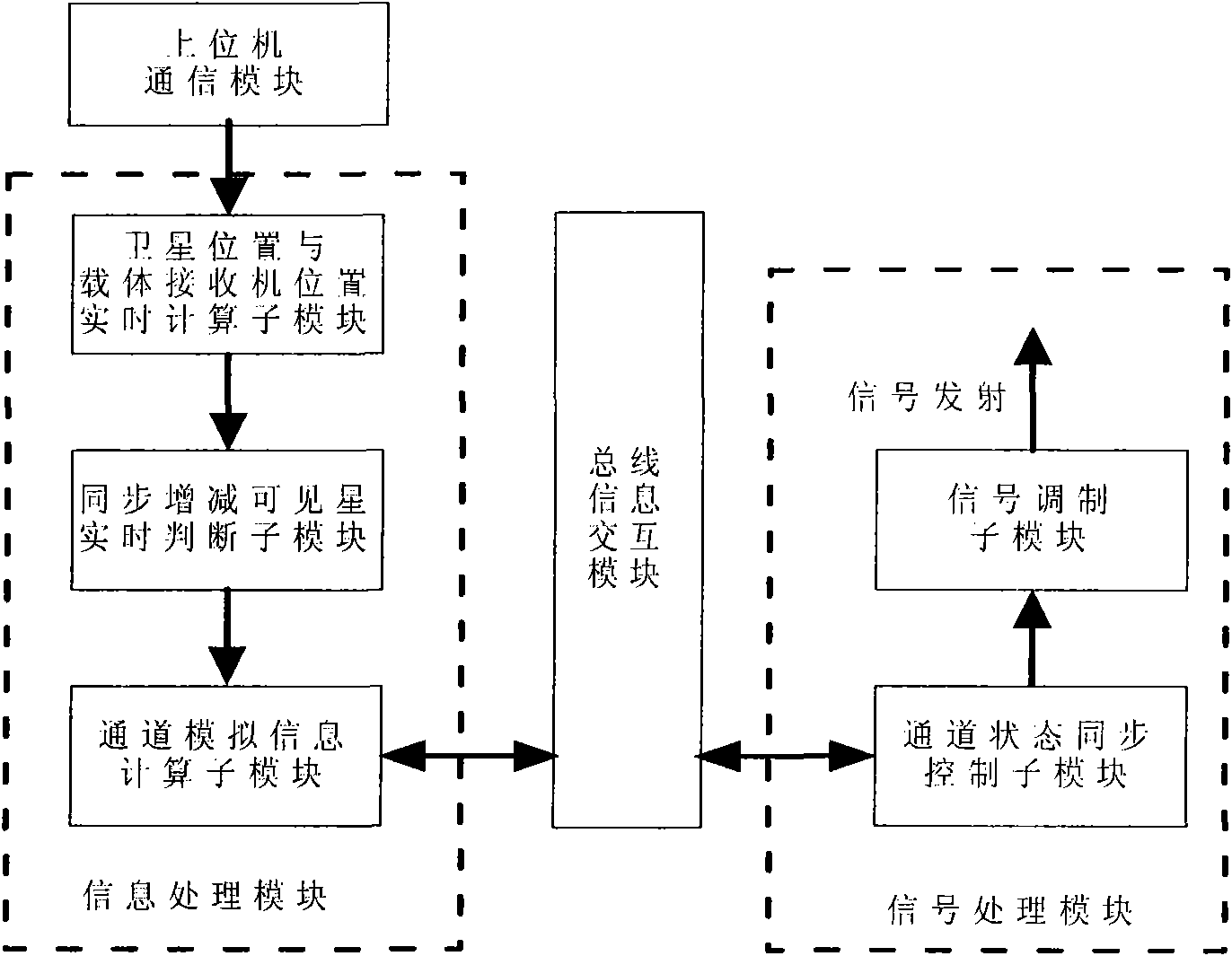

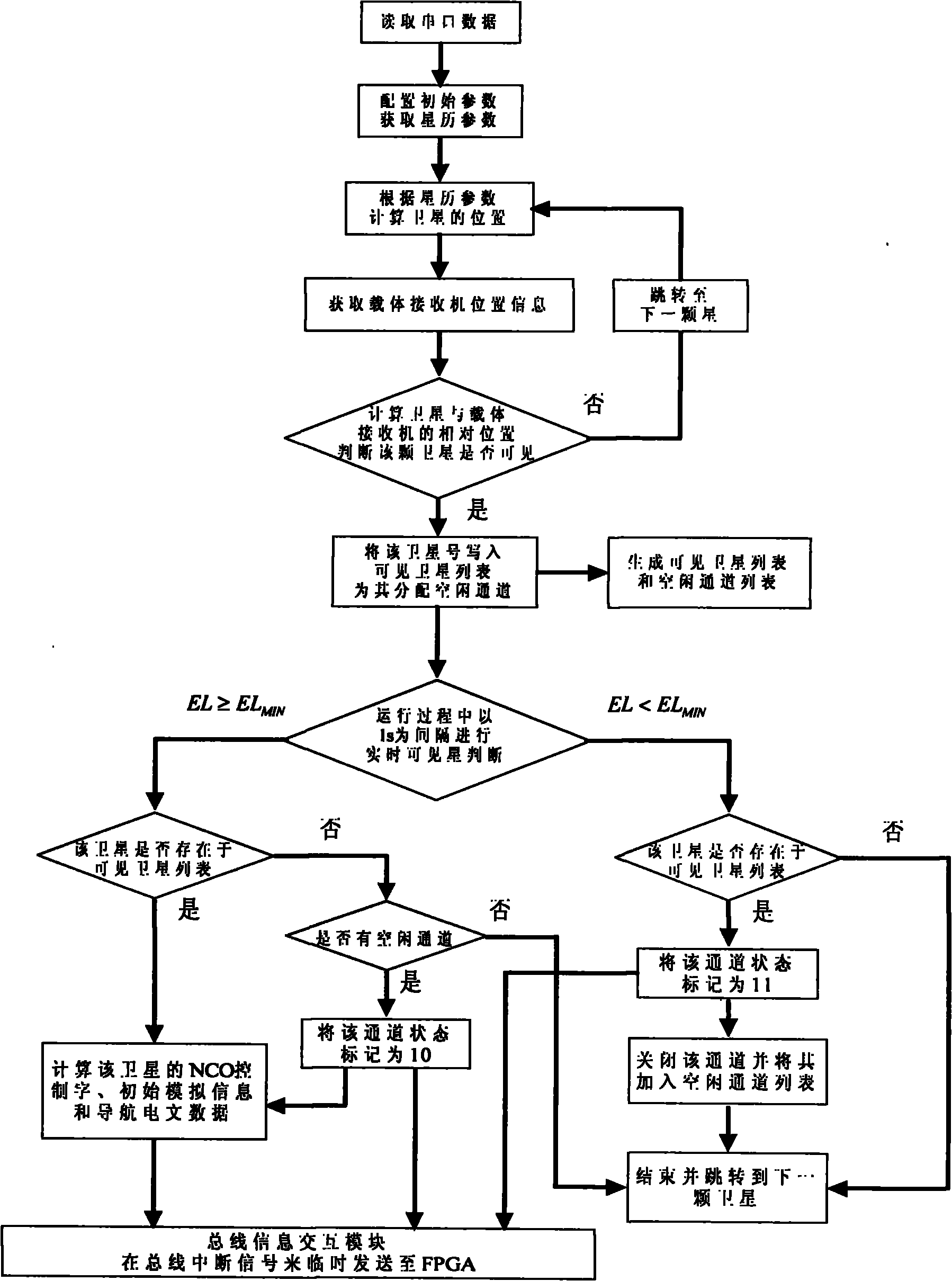

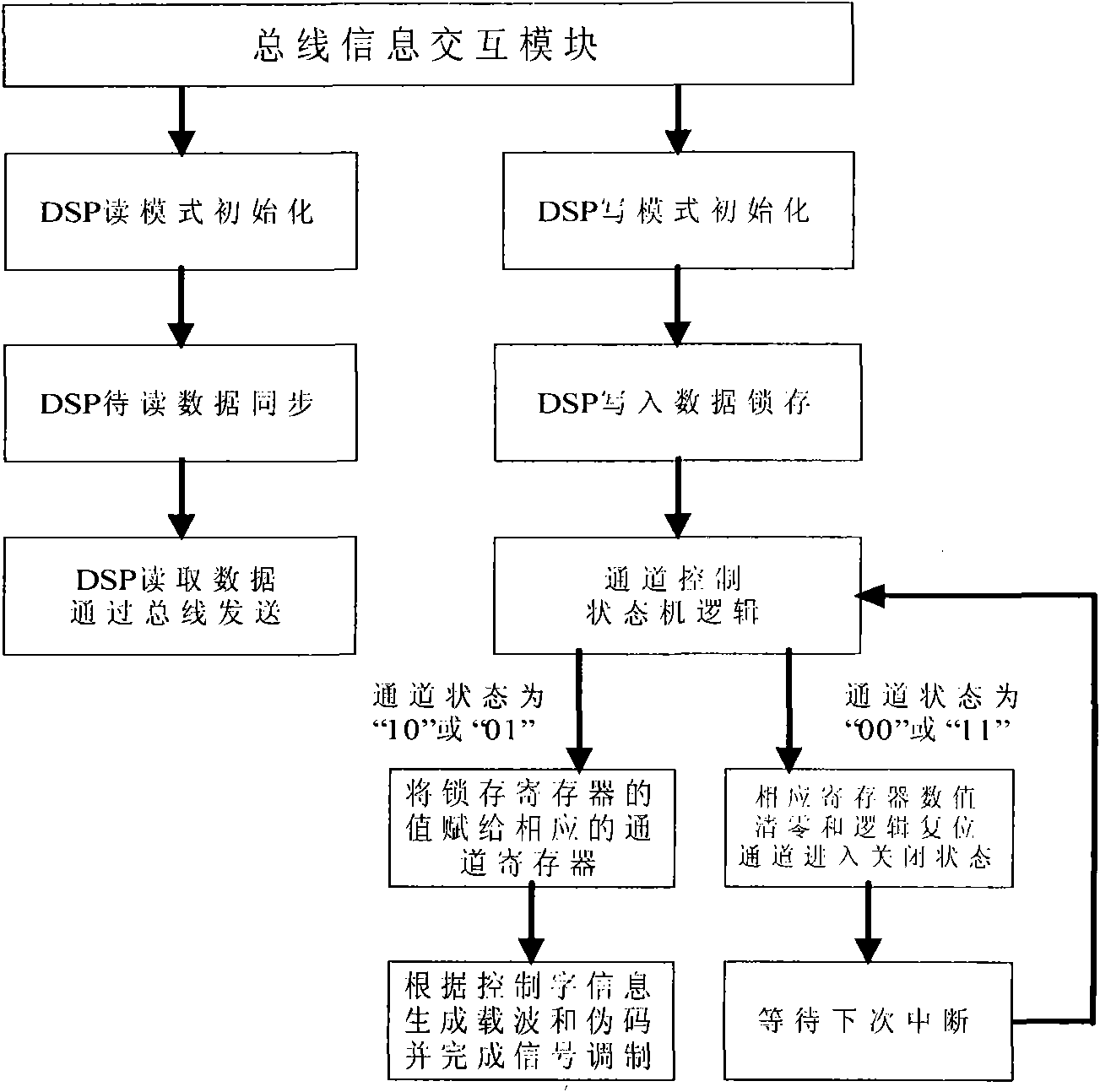

InactiveCN101876710AGuaranteed to work continuouslyRealize high-precision simulationSatellite radio beaconingChannel state informationInformation processing

The invention discloses a teal-time satellite signal simulator based device for synchronously increasing and decreasing visible satellites and a construction method thereof. The device comprises an upper computer communication module, an information processing module and a bus information interaction module. The construction method comprises the following steps of: firstly, inputting initial simulation information into a system; secondly, judging whether the satellite is visible or not and establishing a visible satellite list; thirdly, transmitting channel state information and finishing theinitialization of each simulation channel; fourthly, judging visible stars in real time; fifthly, calculating visible satellite data information; sixthly, transmitting the information calculated in the fourth step and the fifth step to the signal processing module; seventhly, carrying out resetting and read latching on the simulation channels; eighthly, reading state information of the communication channels in real time and synchronously updating the state of each channel and inputting the initial simulation information; ninthly, latching and transmitting real-time simulation data of the channels back to the information processing modules; tenthly, synchronously changing the channel states by using a switch to control a state machine and realizing the real-time work of the simulator by repeating the steps from the fifth step to the tenth steps when each synchronously pulse approaches.

Owner:BEIHANG UNIV

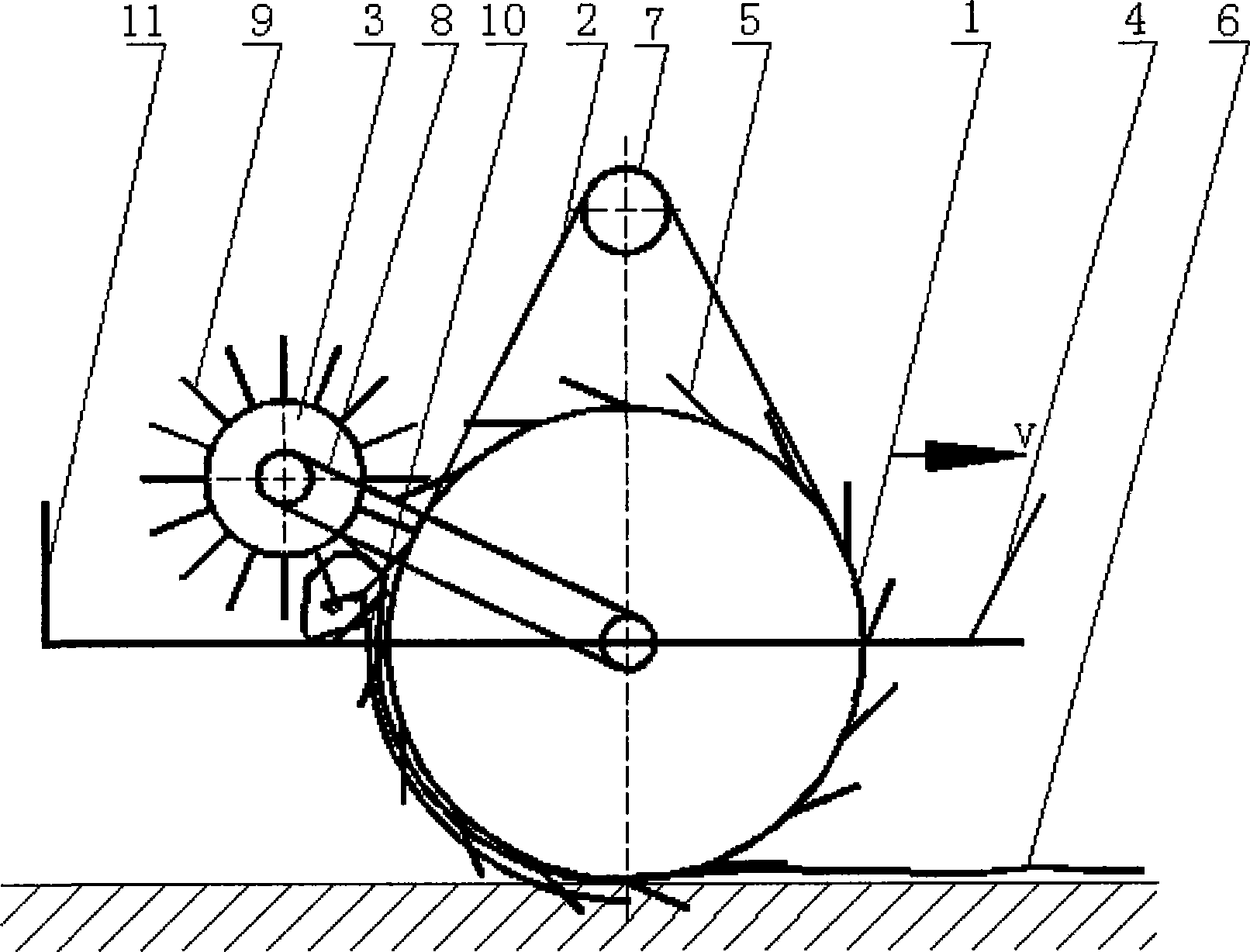

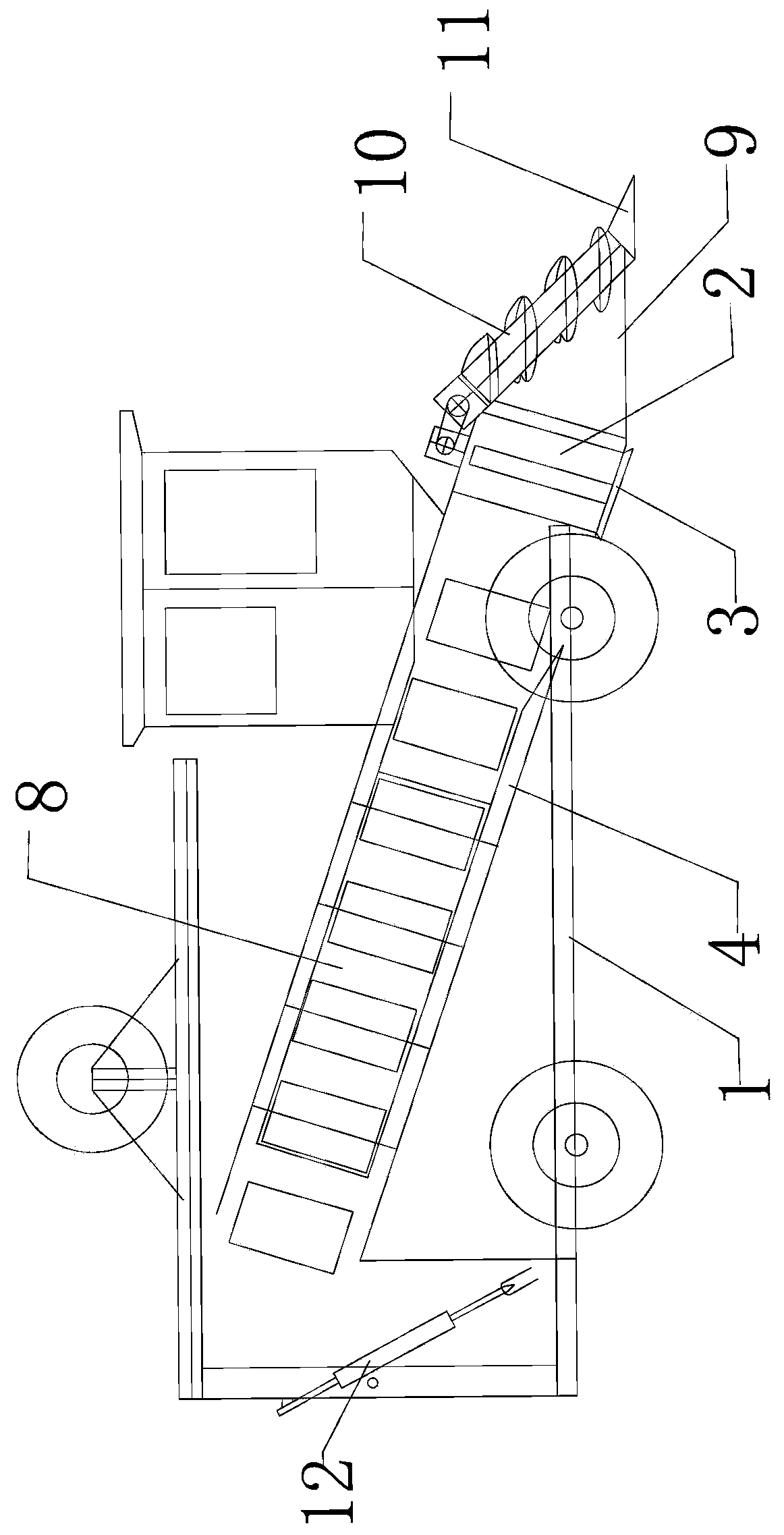

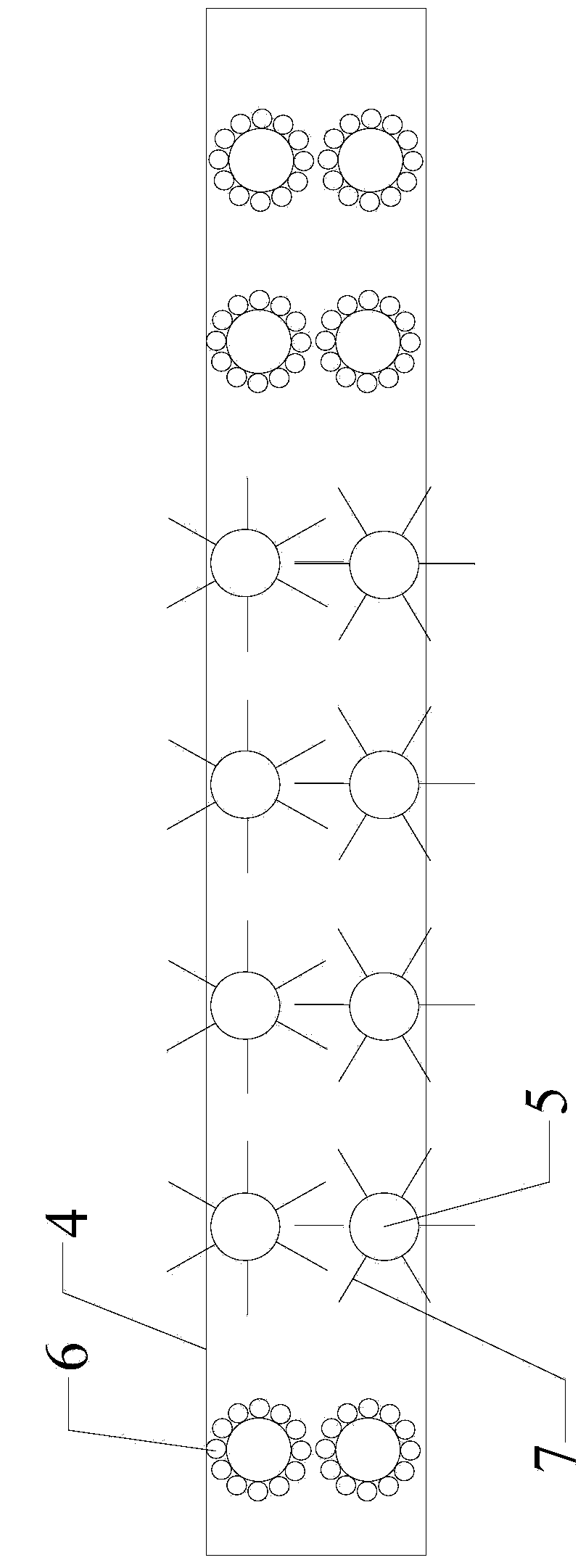

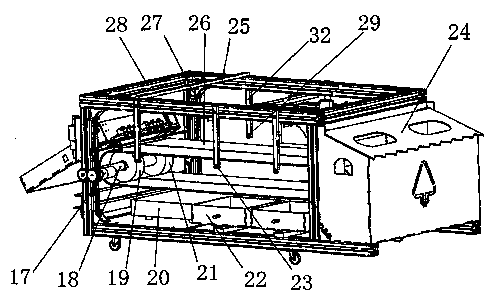

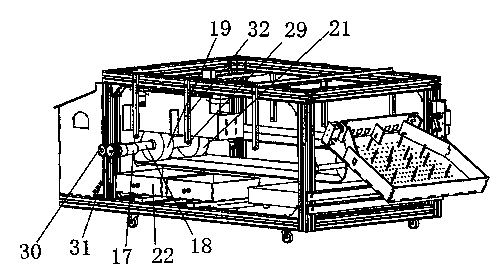

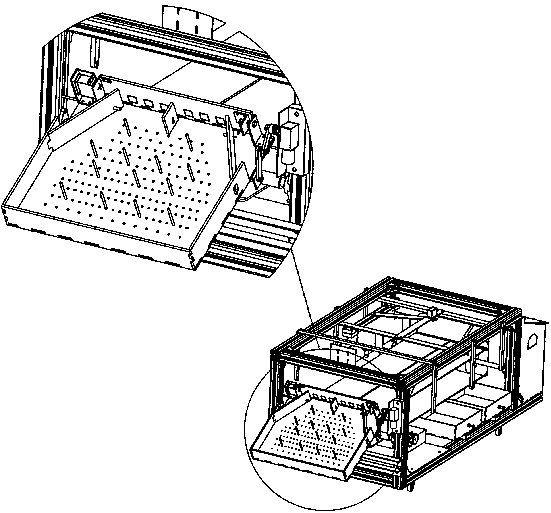

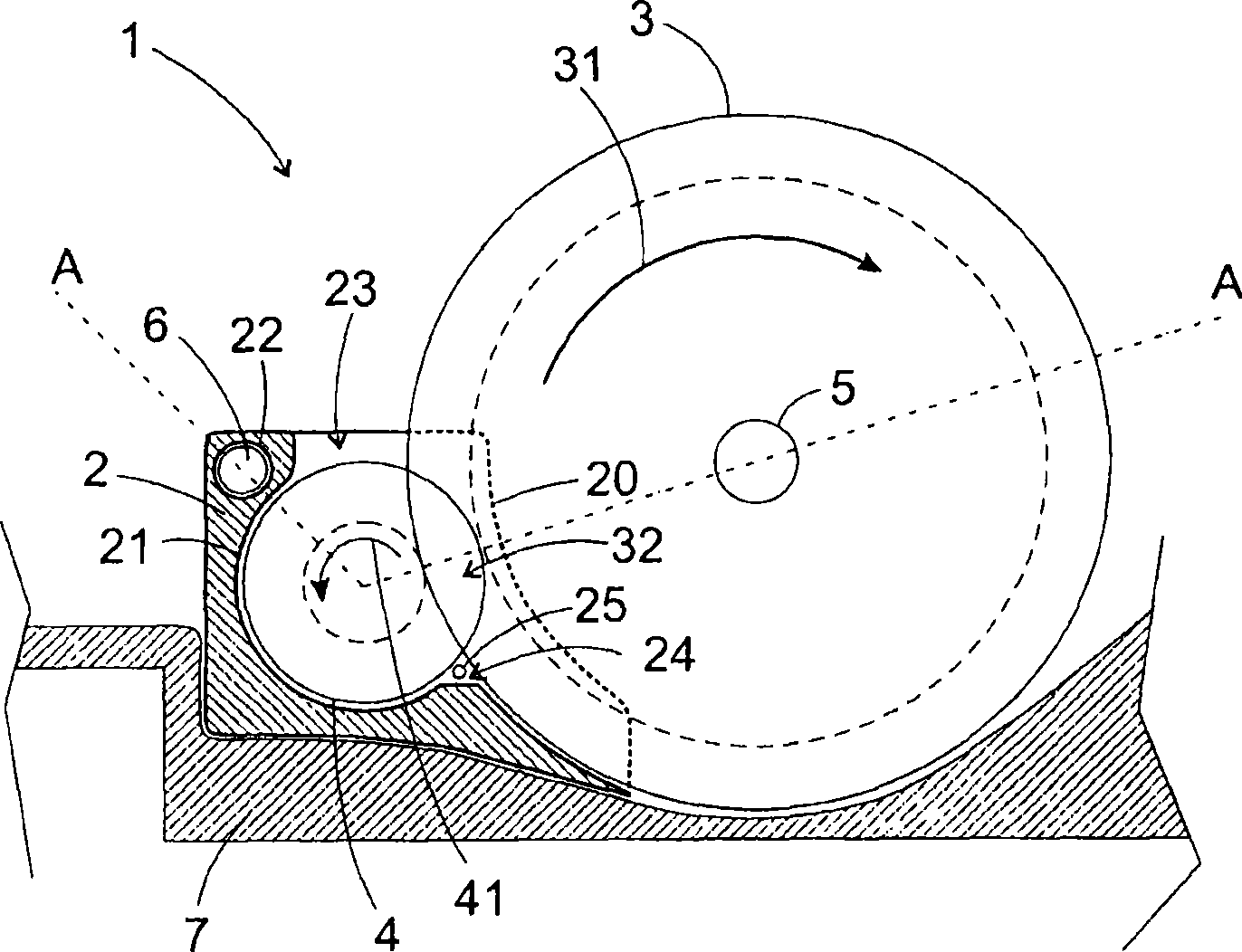

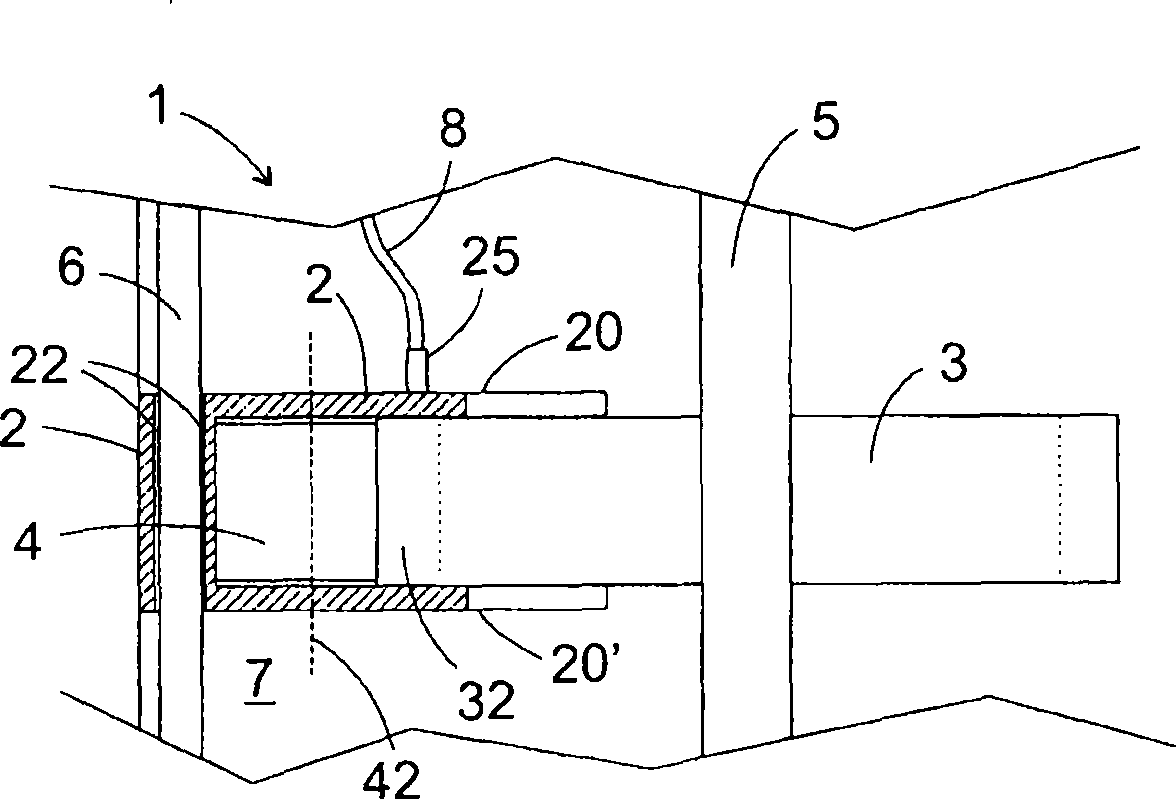

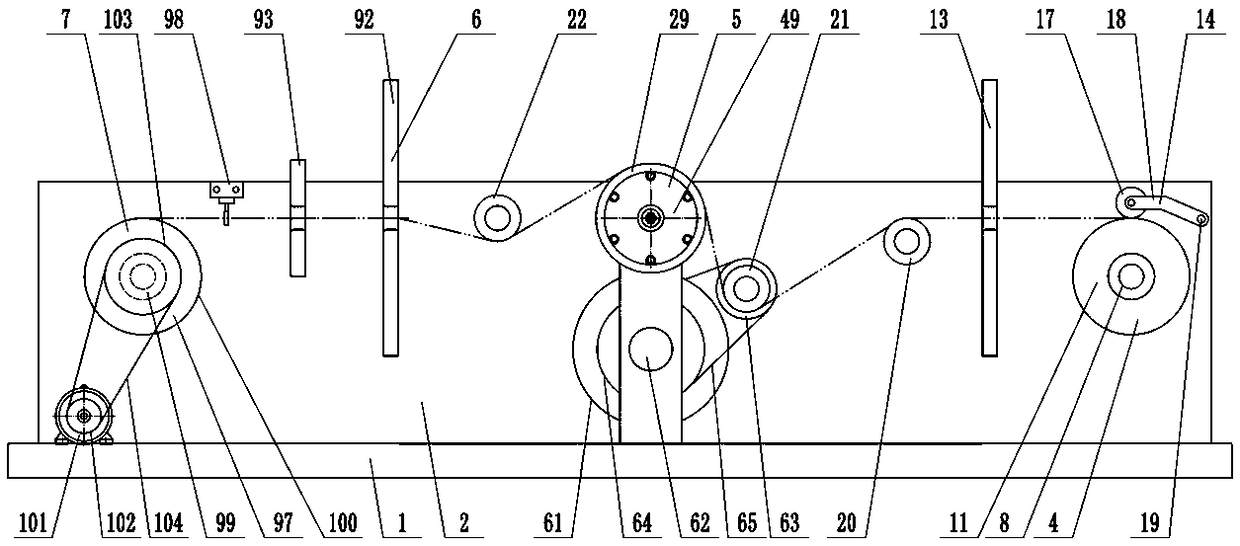

Machine for recycling mulch film during seedling stage

InactiveCN101496464AGuaranteed to work continuouslyHigh yieldGatherer machinesAgricultural engineeringSeedling

The invention relates to a seedling period mulching film recovering machine. The seedling period mulching film recovering machine is characterized in that: the seedling period mulching film recovering machine comprises a film raising wheel, a film obstructing and unloading flat belt and a film unloading wheel; the film raising wheel is designed into a wheel type and is fixedly arranged on a machine frame on both sides of crop seedlings; a plurality of film raising teeth are circumferentially arranged on the outer ring of the film raising wheel, and each film raising tooth has the same dip angle design; a pulley is fixedly arranged on the machine frame above the central line of the film raising wheel, the film raising wheel is taken as the other pulley, and the film obstructing and unloading flat belt is arranged between the film raising wheel and the pulley; the film unloading wheel is fixedly arranged on the machine frame on the rear upside of the film raising wheel and is connected with the film raising wheel through a driving chain; and a plurality of film scraping plates are circumferentially arranged on the outer ring of the film unloading wheel at the same angular intervals and are in contact with the film raising teeth and the film unloading flat belt. The seedling period mulching film recovering machine is characterized by simple structure, low power consumption, high film raising rate, low seedling hurting rate, low price, excellent performance, and the like. The seedling period mulching film recovering machine is suitable for being applied to and generalized in the recovery of seedling period mulching films of various crops.

Owner:CHINA AGRI UNIV

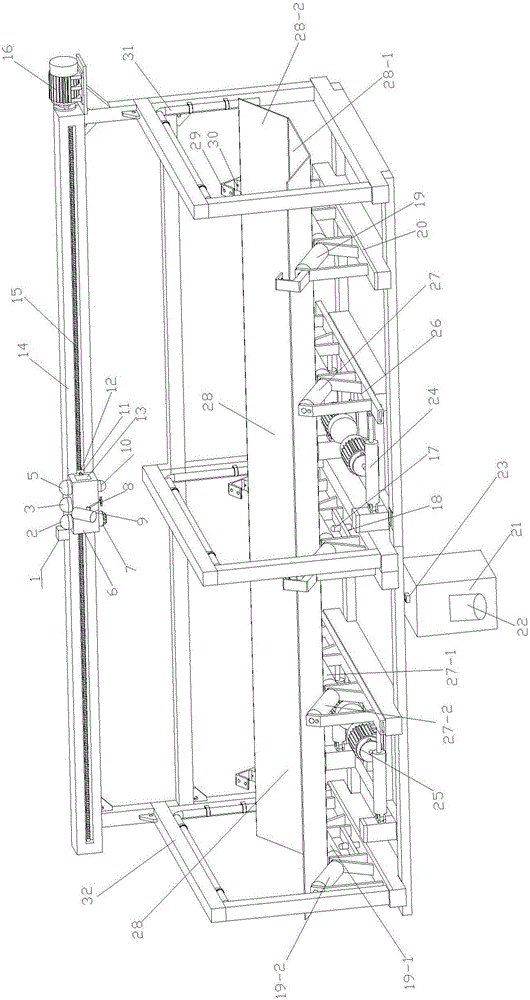

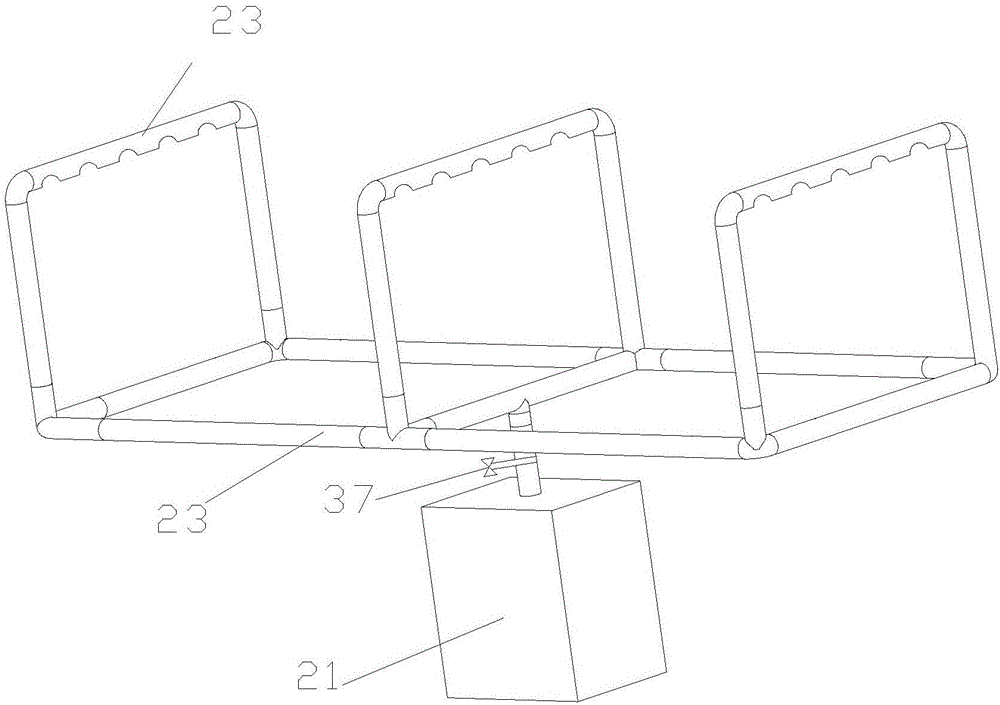

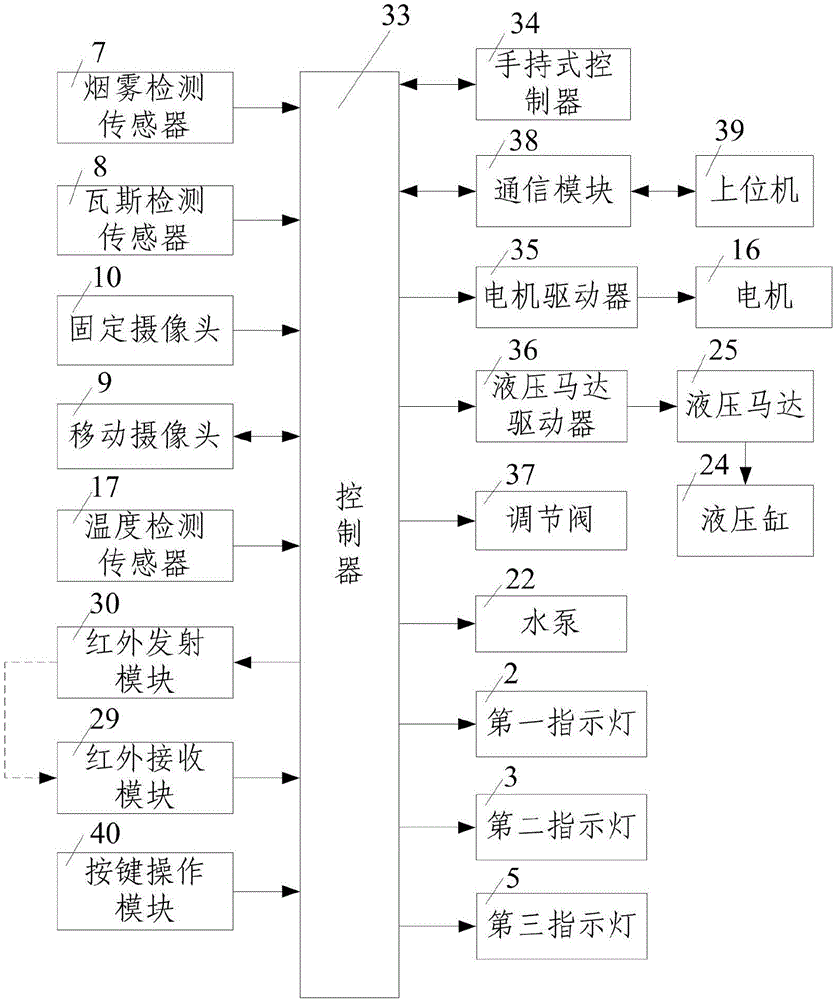

Belt transportation system

InactiveCN106219193ASimple structureReasonable designConveyorsControl devices for conveyorsEngineeringLeather belt

The invention discloses a belt transportation system which comprises a belt transportation mechanism, a belt detection device, a monitor device, belt deviation adjusting mechanisms and a belt cooling mechanism. The belt transportation mechanism comprises a belt and belt supporting components. The belt detection device comprises a routing inspection mechanism, temperature detection sensors and belt deviation detection modules. A routing inspection sliding mechanism and a sliding drive mechanism are arranged on a rack. The routing inspection mechanism comprises a routing inspection box, a smoke detection sensor, a gas detection sensor and a fixed camera. The monitor device comprises a control device, a wireless power supply module, a cooling control mechanism and a deviation adjusting drive mechanism. The belt transportation system is simple in structure and convenient to implement; the belt transportation work condition is detected in real time; the belt is adjusted and cooled; belt deviation or high-temperature work is prevented from bringing potential safety hazards to workers and coal mine transportation; continuous transportation of the belt is achieved; and the coal production efficiency is improved, and labor intensity is relieved.

Owner:XIAN UNIV OF SCI & TECH

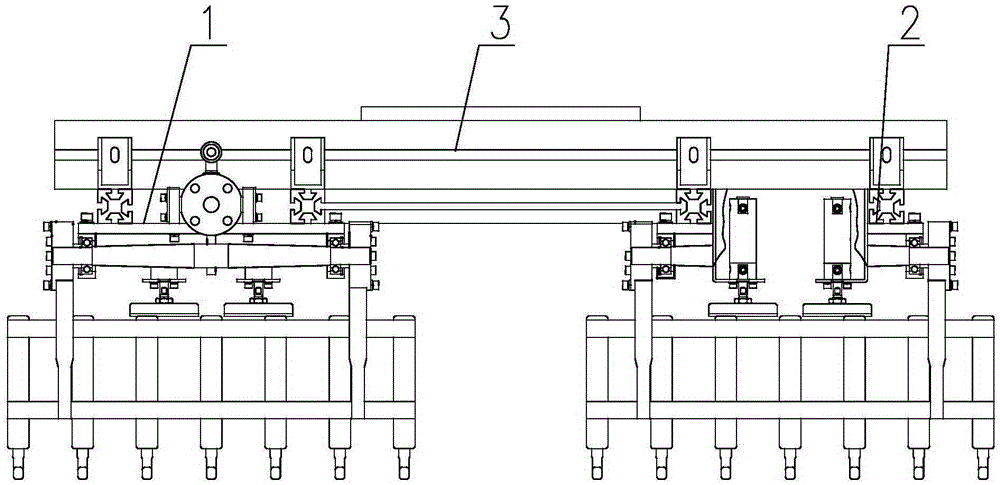

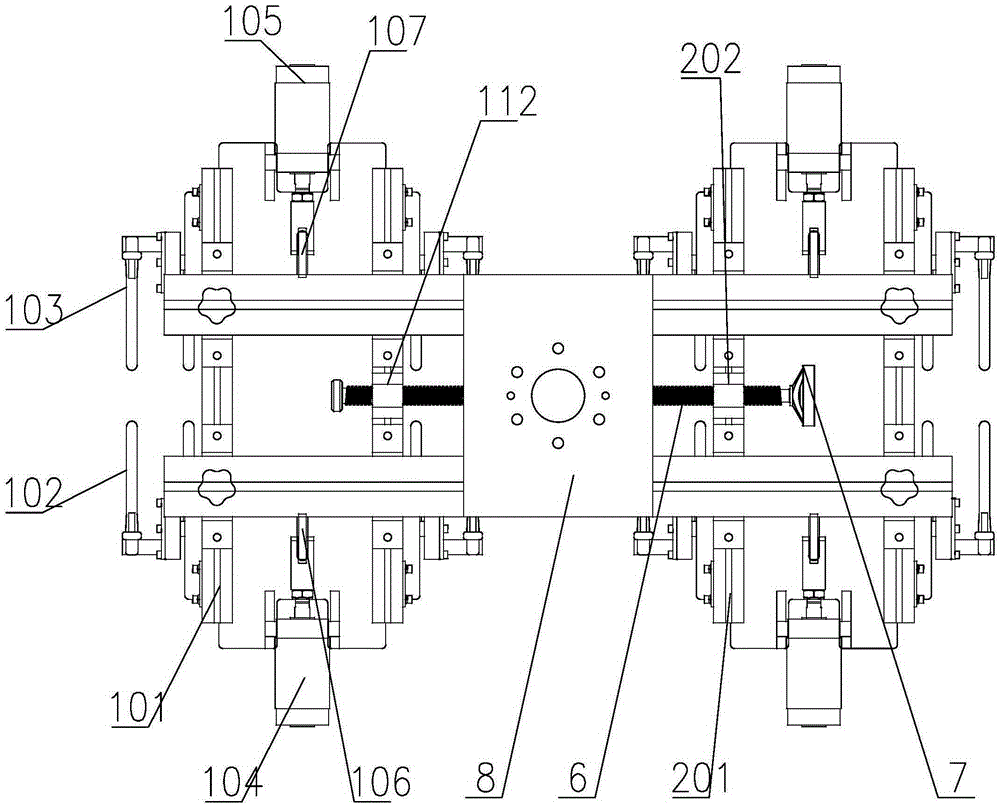

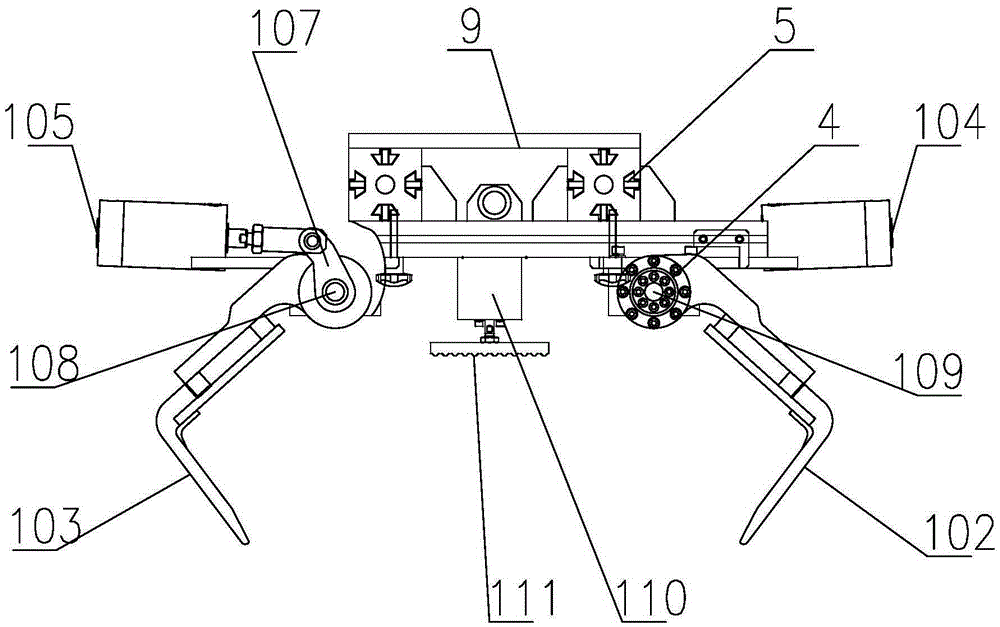

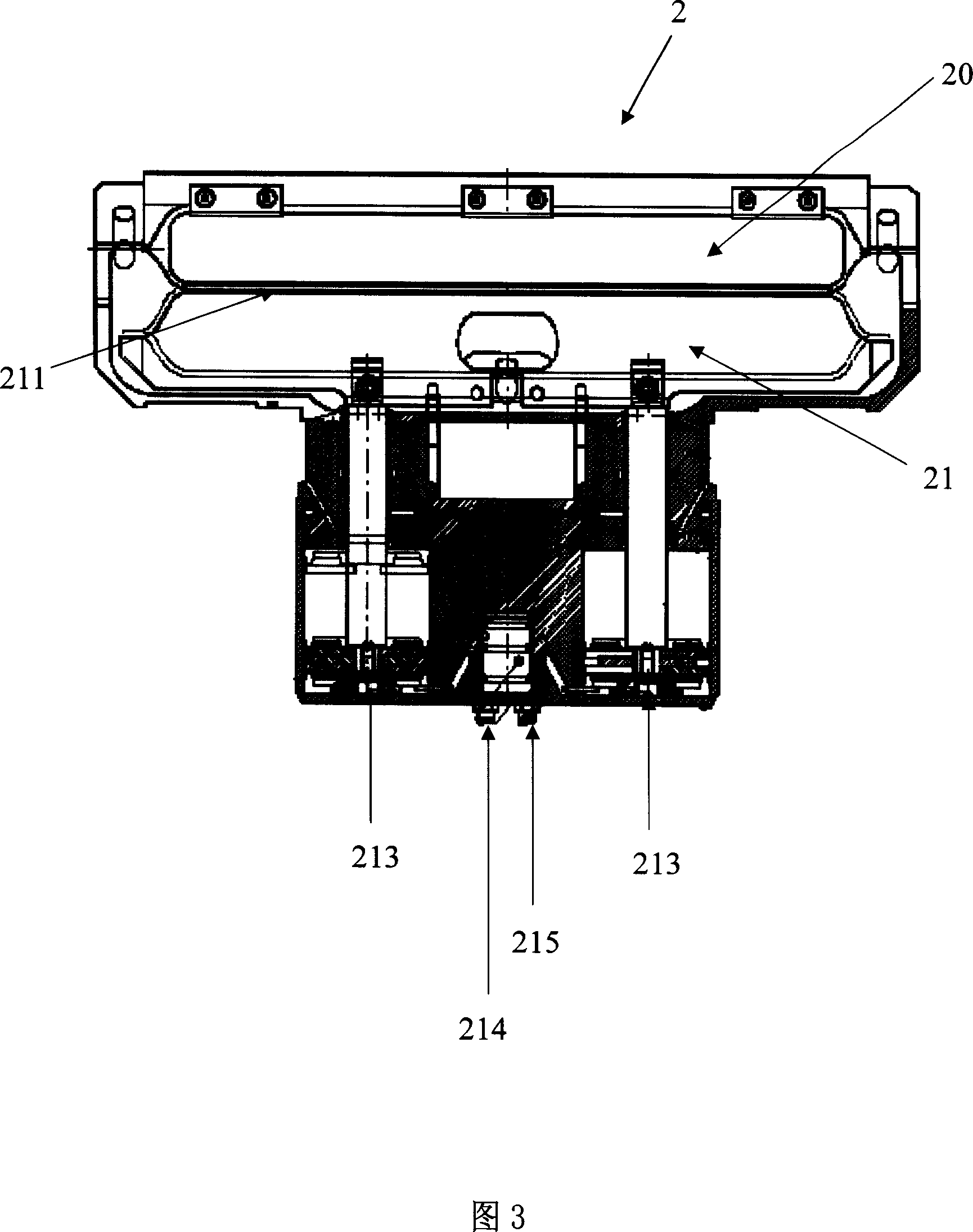

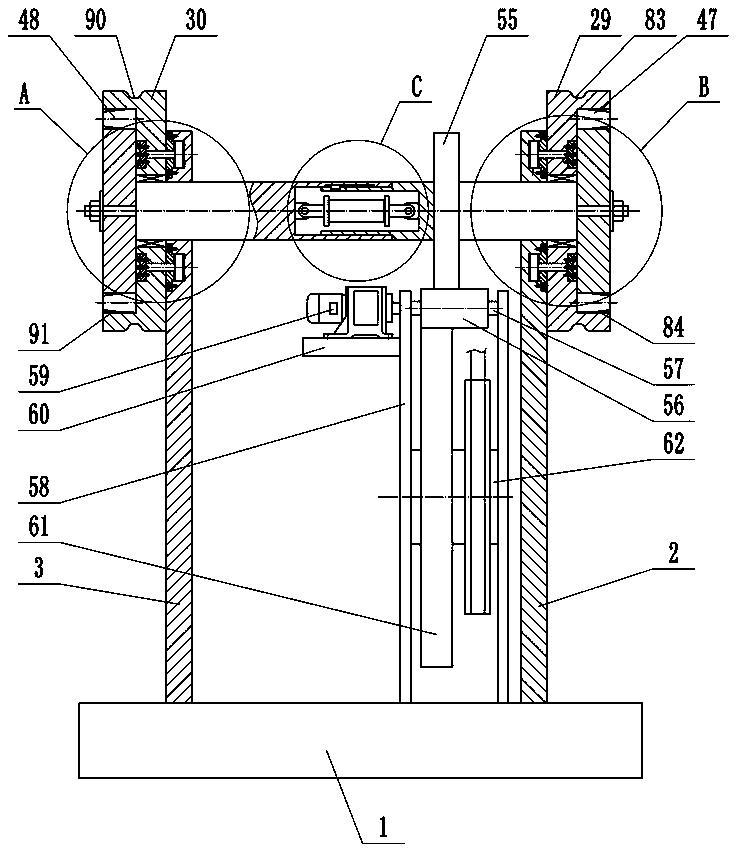

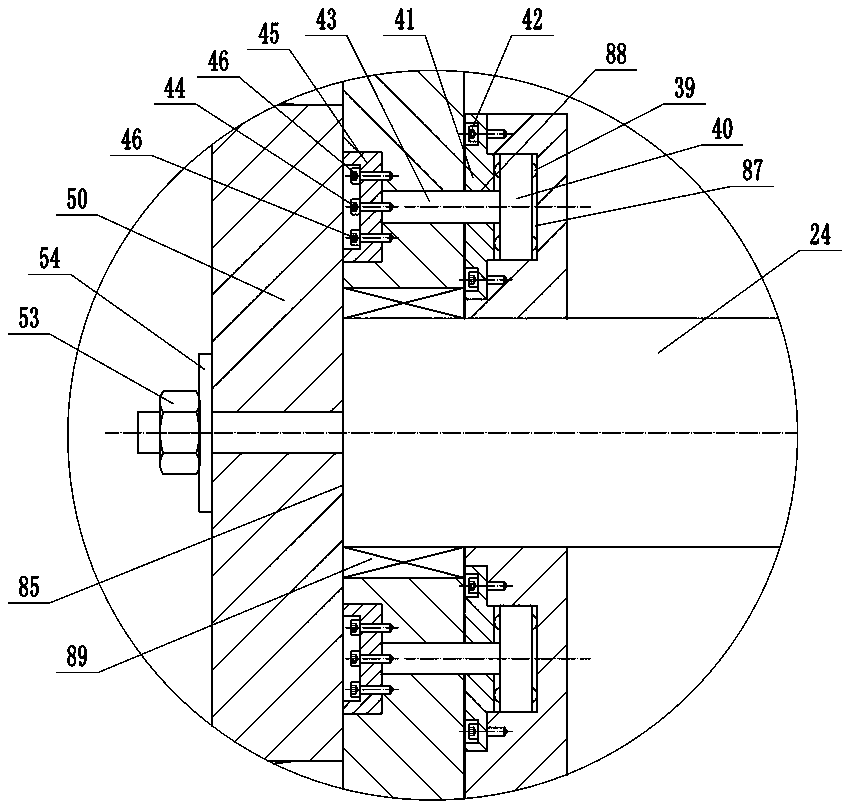

Double-position adjustable robot palletizer clamp

InactiveCN105252542AGuaranteed to work continuouslyIncrease profitProgramme-controlled manipulatorGripping headsPalletizerEngineering

The invention belongs to the field of logistics equipment, and relates to a device used for stacking boxes and bags, in particular to a double-position adjustable robot palletizer clamp. The double-position adjustable robot palletizer clamp comprises a sliding block and guide groove parallel frame. A first clamp body is arranged at one end of the sliding block and guide groove parallel frame in a sliding manner. A second clamp body is arranged at the other end of the sliding block and guide groove parallel frame in a sliding manner. The first clamp body and the second clamp body are in threaded connection through a lead screw and are the same in structure. The first clamp body comprises a first grabbing tooth cross frame. A first grabbing tooth assembly and a second grabbing tooth assembly are arranged at the bottom of the first grabbing tooth cross frame. A first grabbing air cylinder and a second grabbing air cylinder are fixed to the middle of the first grabbing tooth cross frame. The end of a piston rod of the first grabbing air cylinder is connected with a first rocker rod. The first rocker rod is connected with a first rocker rod shaft in a welding manner. The clamp can adapt to materials of multiple sizes and specifications, and the application range is wide. When the clamp works, two bags of materials are grabbed at a time, the rotation frequency of a robot palletizer is reduced, and the stacking efficiency is greatly improved.

Owner:WUXI DADONG MACHINERY MFG

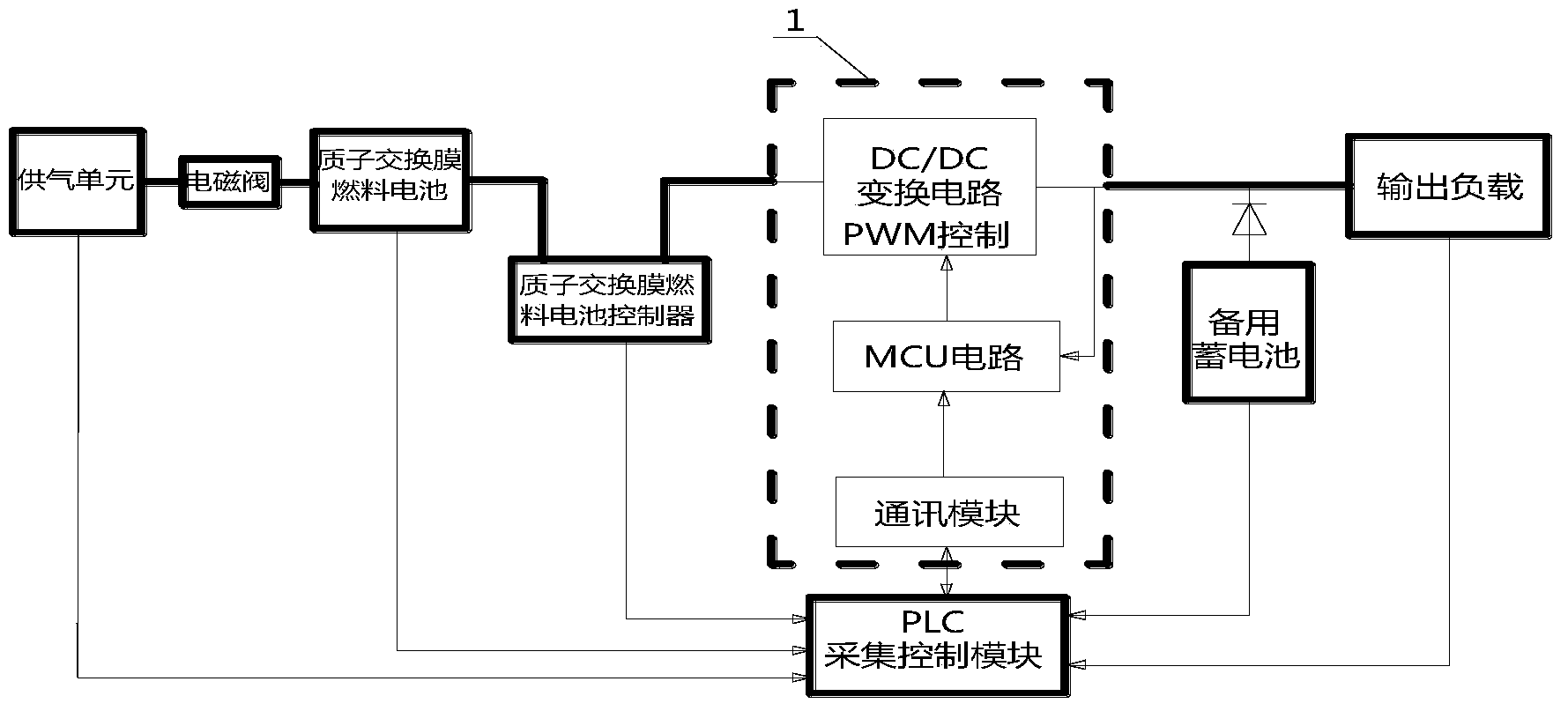

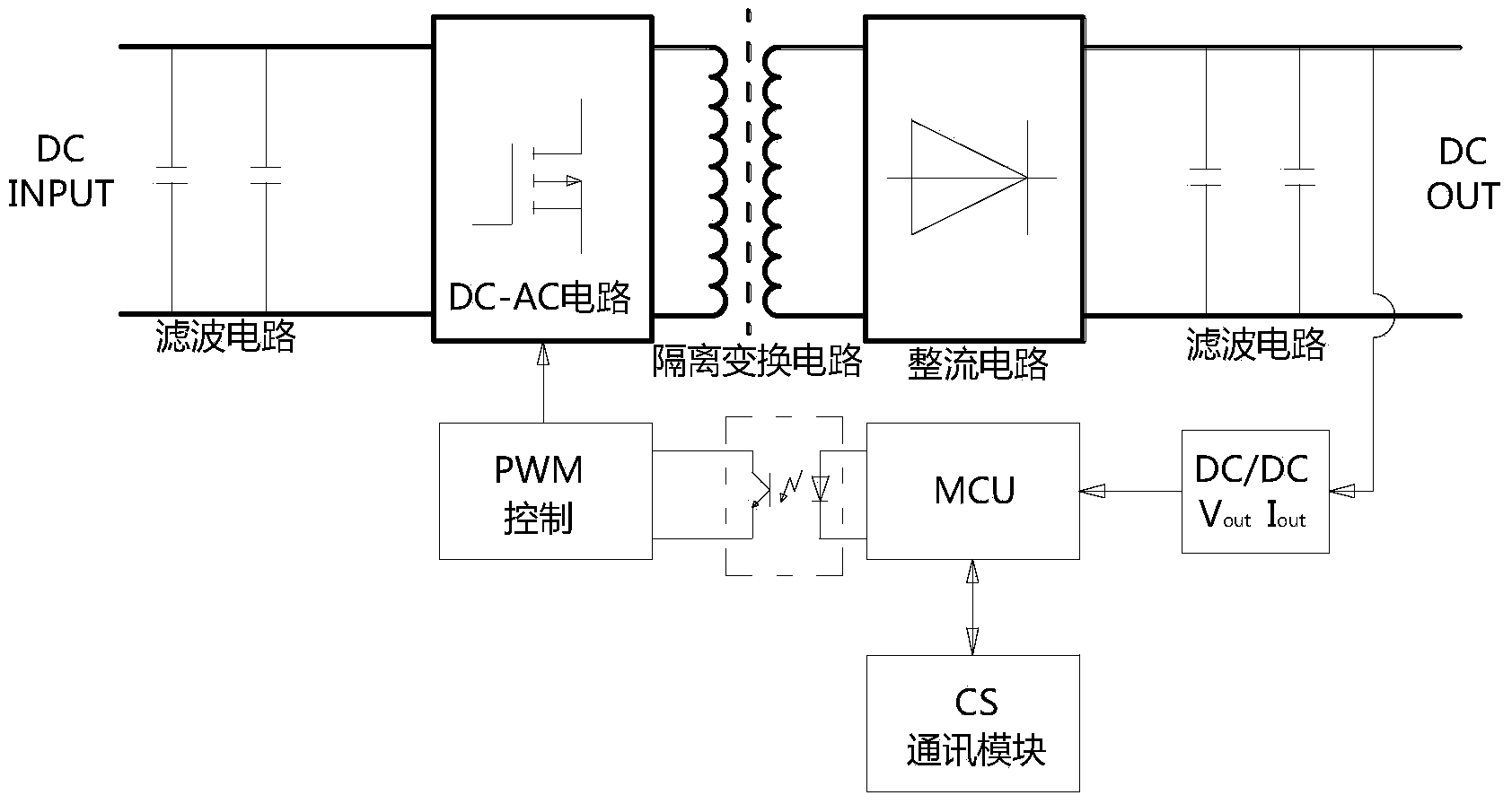

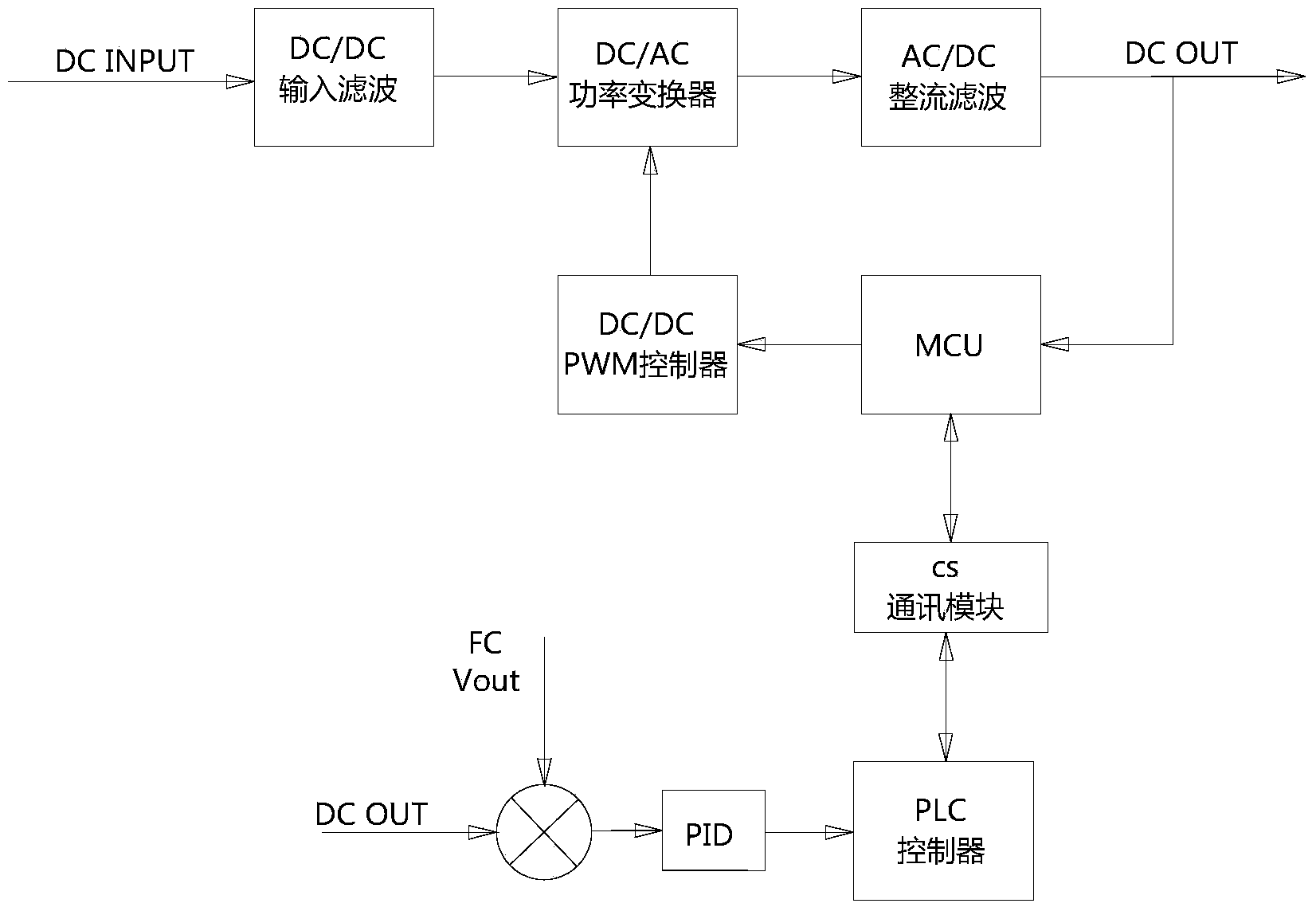

DC/DC conversion and control system used for standby power system of proton exchange membrane fuel cell

ActiveCN103595096AProtection against overloadingReduce usageBatteries circuit arrangementsFuel cell controlLoad circuitLoop control

The invention relates to a DC / DC conversion and control system used for a standby power system of a proton exchange membrane fuel cell. The DC / DC conversion and control system comprises a main circuit loop and a control loop. The main circuit loop comprises a gas supply unit, a gas loop control electromagnet valve, the proton exchange membrane fuel cell, a DC / DC conversion circuit of a DC / DC converter and a standby storage battery. The control loop comprises a collection PLC, a communication module of the DC / DC converter and a MCU circuit. The communication module is used for realizing communication between the collection PLC and the MCU circuit, and the MCU circuit is connected with a load circuit and the DC / DC converter and is used for collecting output voltages and output currents of the DC / DC converter, sending the output voltages and the output currents of the DC / DC converter to the collection PLC, receiving processing information of the collection PLC and adjusting a PWM chip of the DC / DC converter according to the processing information.

Owner:中氢新能源(江苏)有限公司

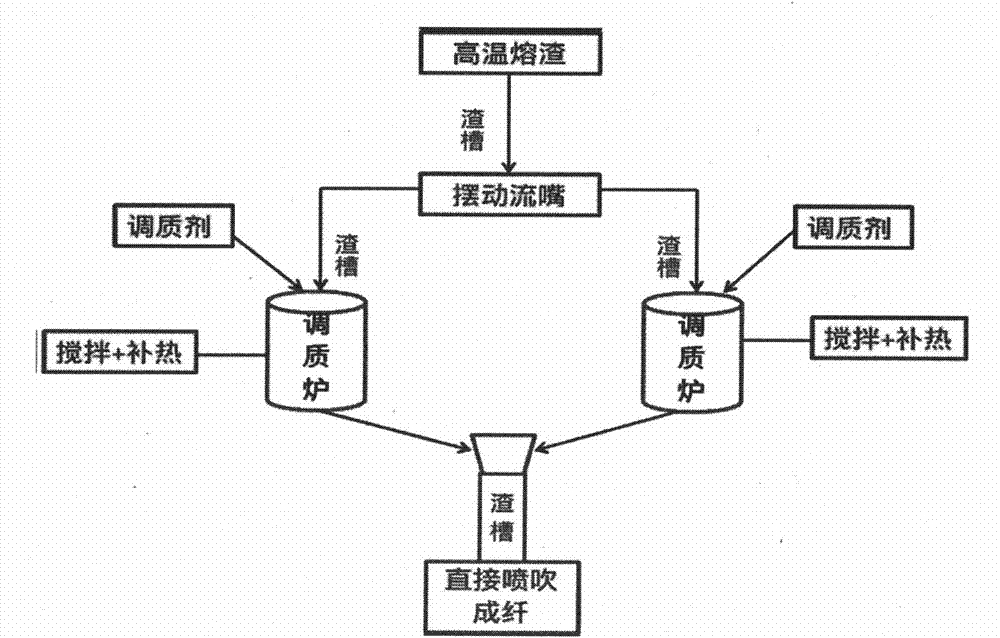

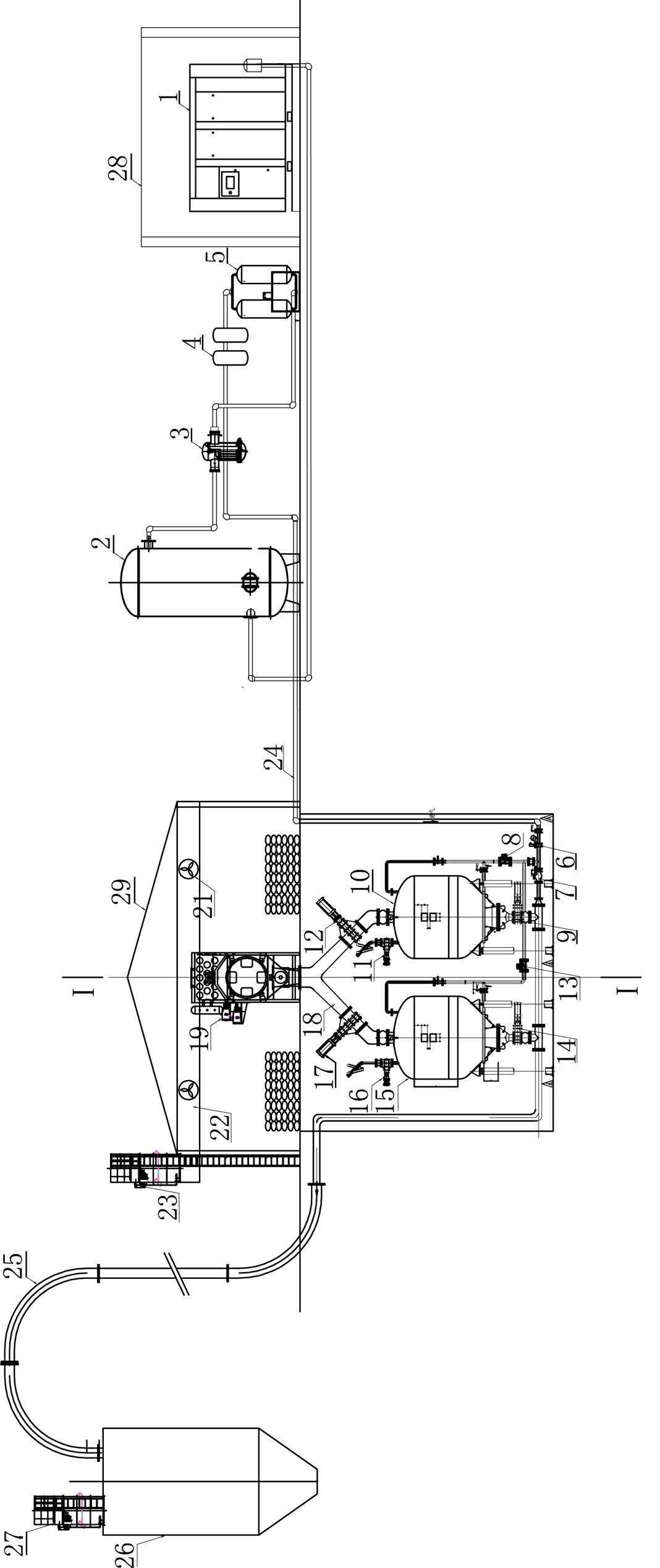

Method for preparing inorganic fibers by using direct blowing of blast furnace molten slag

InactiveCN103803793AEasy to adjustRealize comprehensive utilizationGlass making apparatusFiberMaterials preparation

The invention discloses a method for preparing inorganic fibers by using direct blowing of blast furnace molten slag, and belongs to the field of inorganic nonmetallic material preparation. The method comprises the following steps: conveying high temperature molten slag generated in a blast furnace to a high temperature quenching and tempering furnace through a slag groove, adding a quenching and tempering agent so as to carry out high temperature quenching and tempering on liquid molten slag, and carrying out direct blowing on the quenched and tempered blast furnace slag by adopting a direct blowing device so as to produce the inorganic fibers. The method comprises two critical processes of online dynamic quenching, tempering and homogenizing, and direct blowing for fiber formation; and in the production process, two sets of quenching and tempering systems alternatively work, the other set of system is used for molten slag pouring for fiber formation while one of the two sets of system is used for quenching and tempering, so that the continuity of the direct blowing fiber formation process is ensured. The method has the advantages that the direct blowing device is used for blowing the inorganic fibers, and the shortcomings of complexity, high requirements on operating personnel, water cooling, high energy consumption and the like existing in a conventional centrifugal fiber formation system device are overcome; meanwhile, the sensible heat of the blast furnace molten slag is directly utilized, so that the reasonable utilization of industrial raw materials and waste energy sources can be realized and has important significance.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

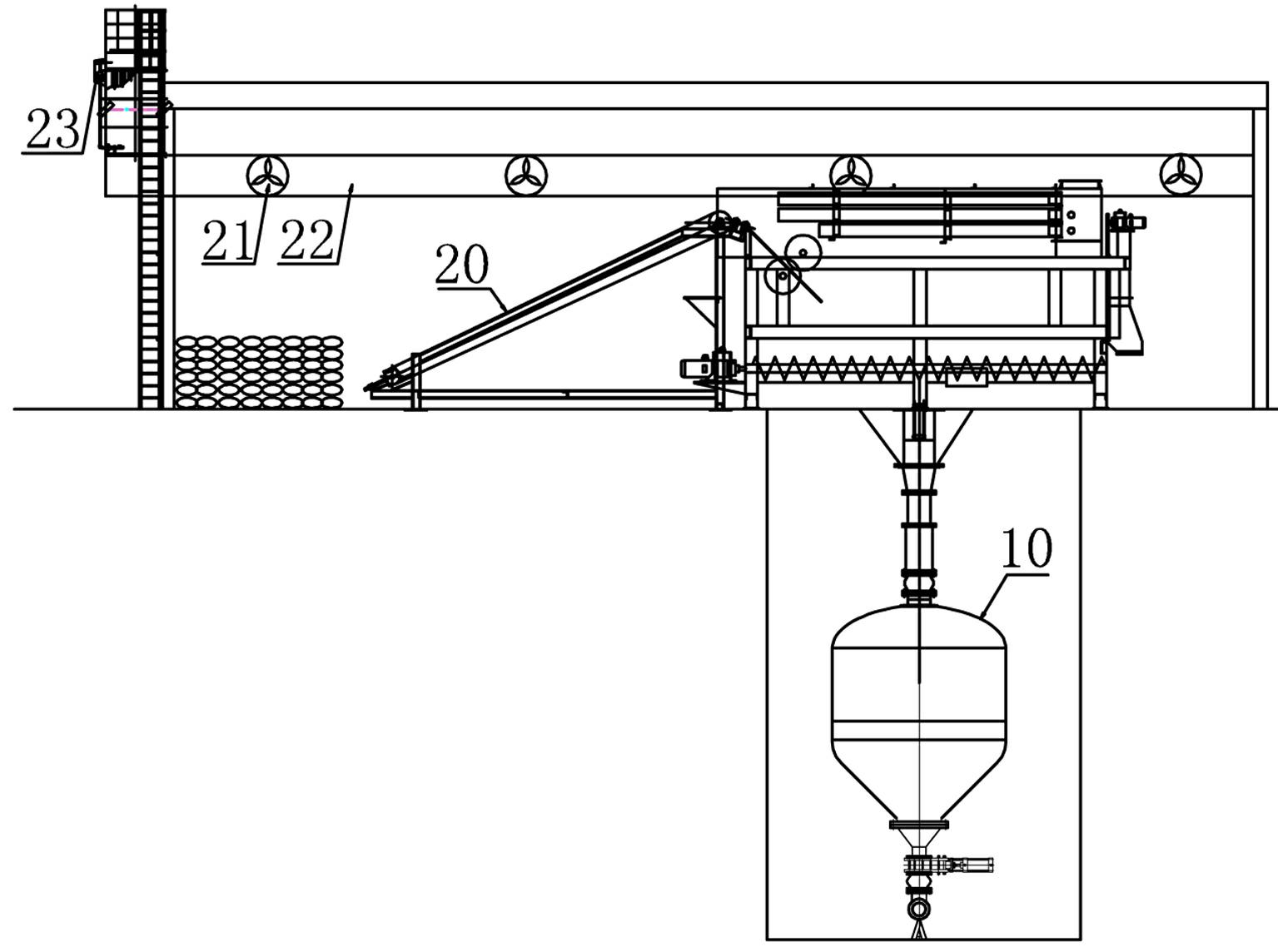

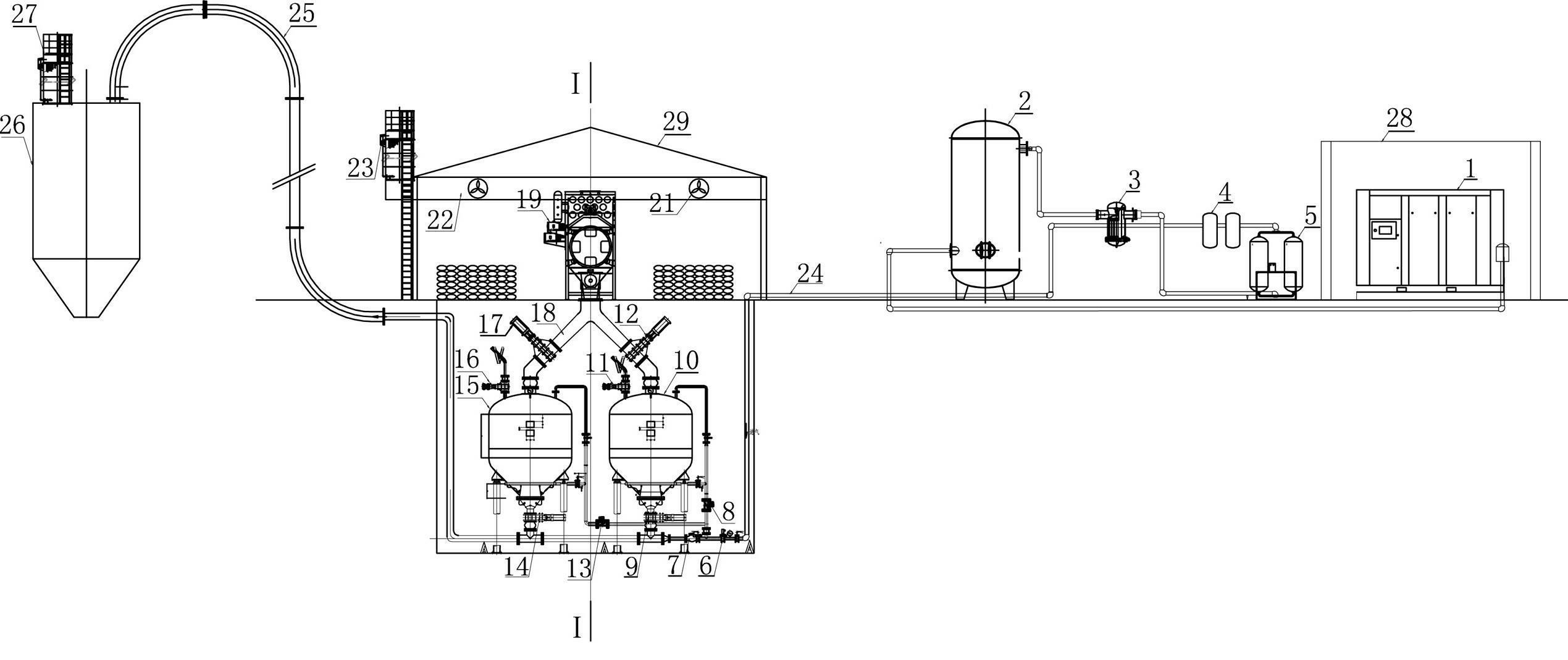

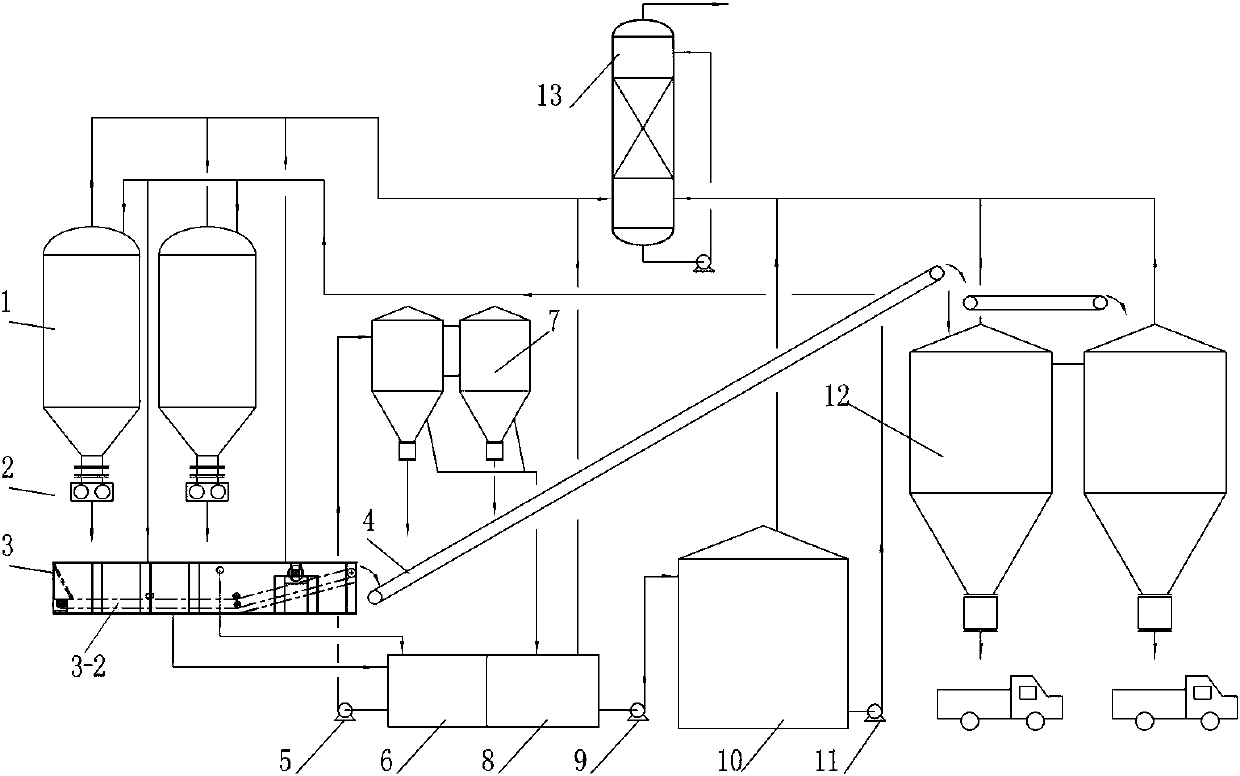

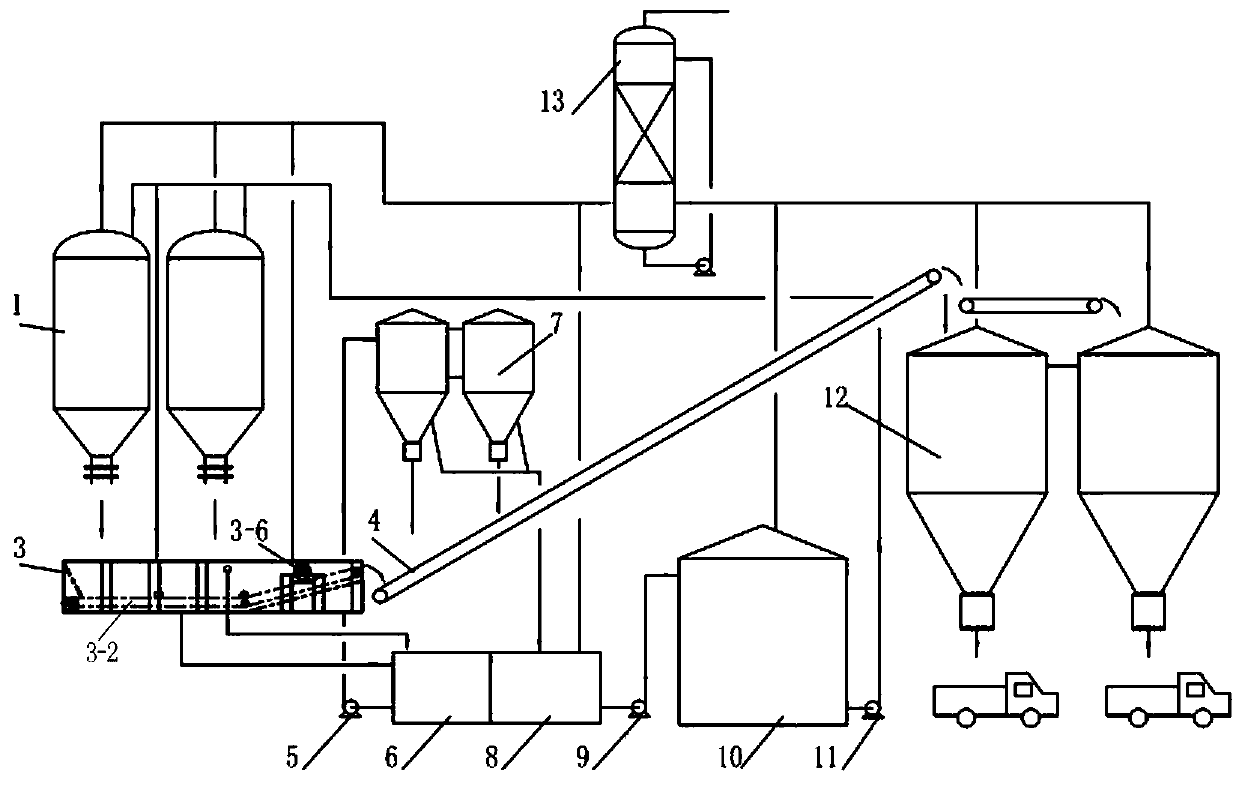

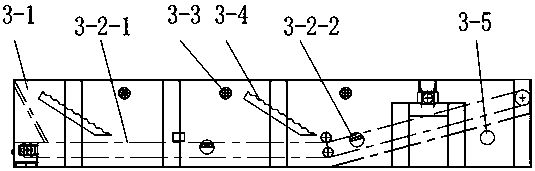

Bagged cement or fly ash unpacking and conveying system and operation method thereof

InactiveCN102633026AEfficient separationAvoid cakingArticle unpackingBulk conveyorsAutomatic controlSlide plate

The invention relates to an operation method of a bagged cement or fly ash unpacking and conveying system. The bagged cement or fly ash unpacking and conveying system controls an air supply system, a material storage system, an axial flow fan, a dust collector, a double-bin pump, an unpacking machine and a belt conveyor to sequentially run by utilizing an automatic control program. The operation method comprises the following steps of: transmitting bagged cement or fly ash through the belt conveyor to a sliding plate with an angle of 45 degrees, sliding down along the sliding plate depending on the gravity, cutting off a package bag by a blade in a sliding process, enabling a cut broken bag and cement or fly ash to slide into a rotary drum screen to be screened, outputting the cement or the fly ash falling down through the rotary drum screen by a spiral conveyor, catching dust generated in a bag breaking process by a cloth bag type dust catcher, shaking off the dust into the spiral conveyor, enabling the dust to flow into the double-bin pump through a forked funnel, and conveying the dust into a material storage pot to be stored through a pneumatic conveying pipe. The bagged cement or fly ash unpacking and conveying system disclosed by the invention is of an integral structure, circularly works by utilizing the vertical double-bin pump, realizes the continuous operation of an unpacking and conveying system, and has the characteristics of high work efficiency, reliability in operation, high automatic degree and good environmental friendliness.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

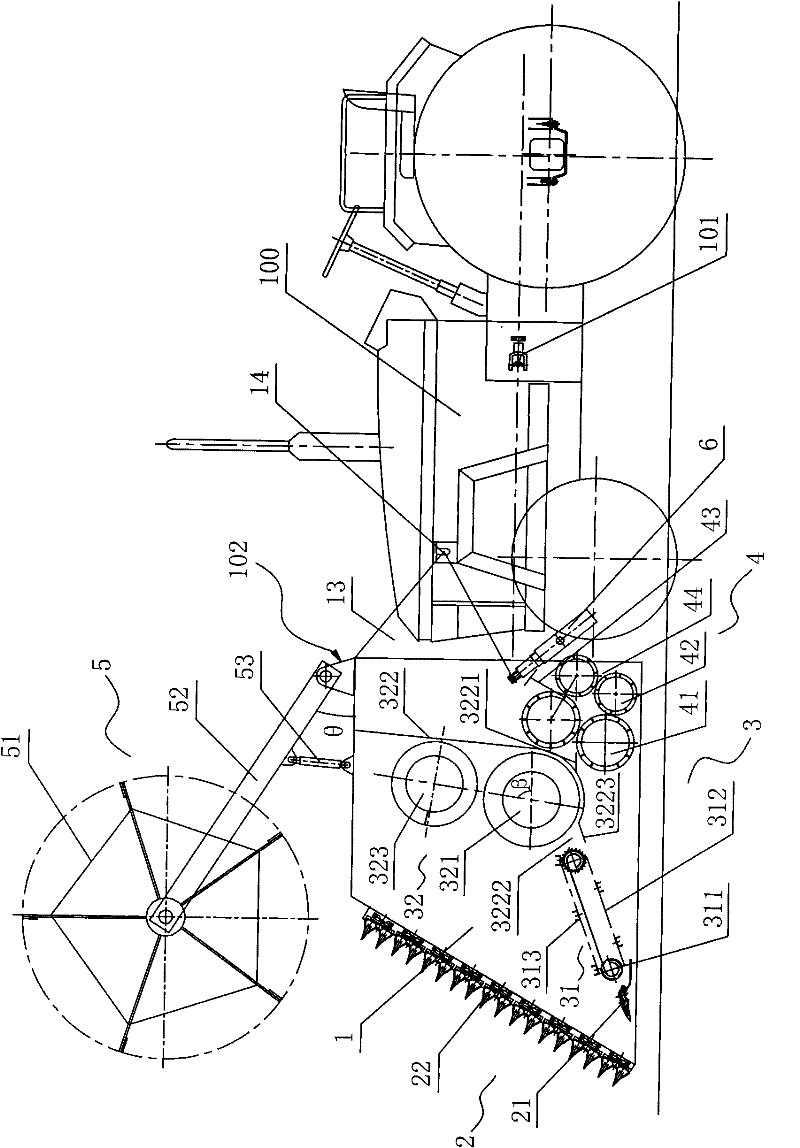

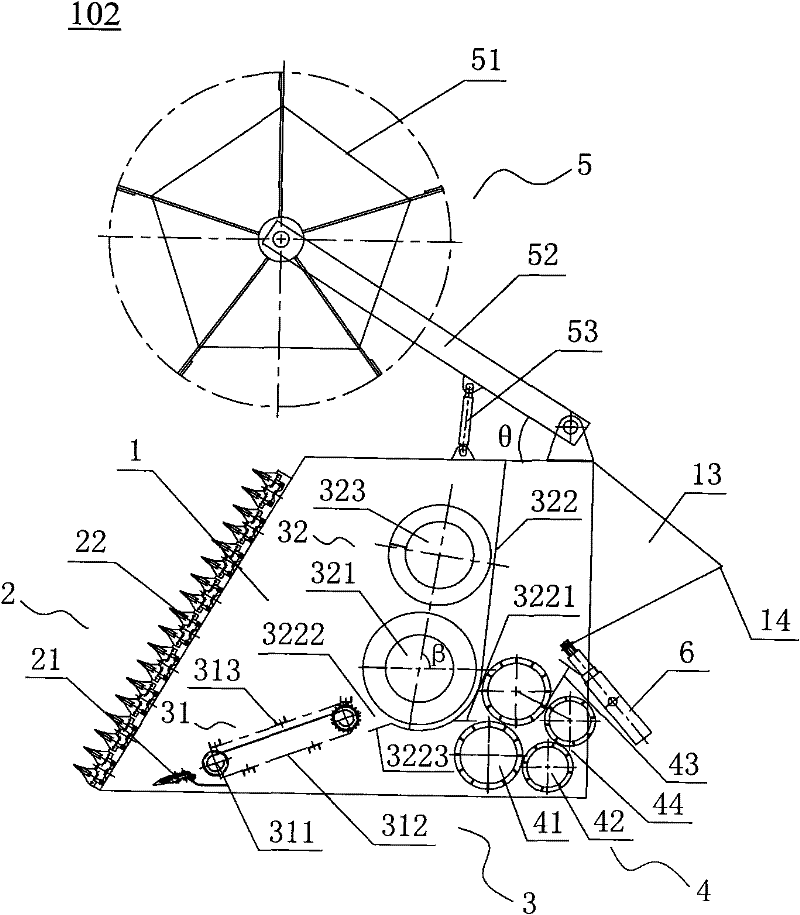

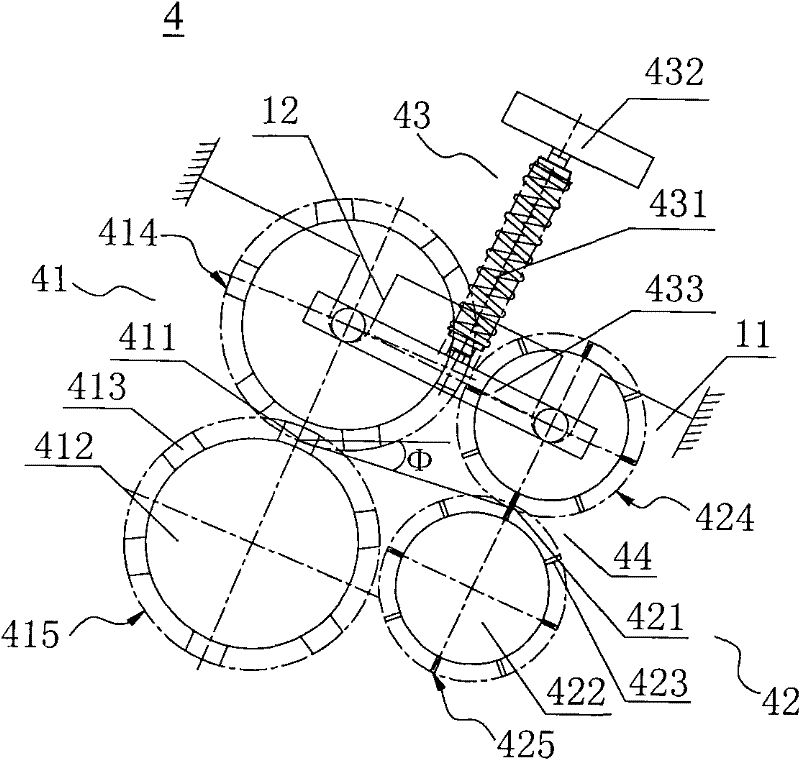

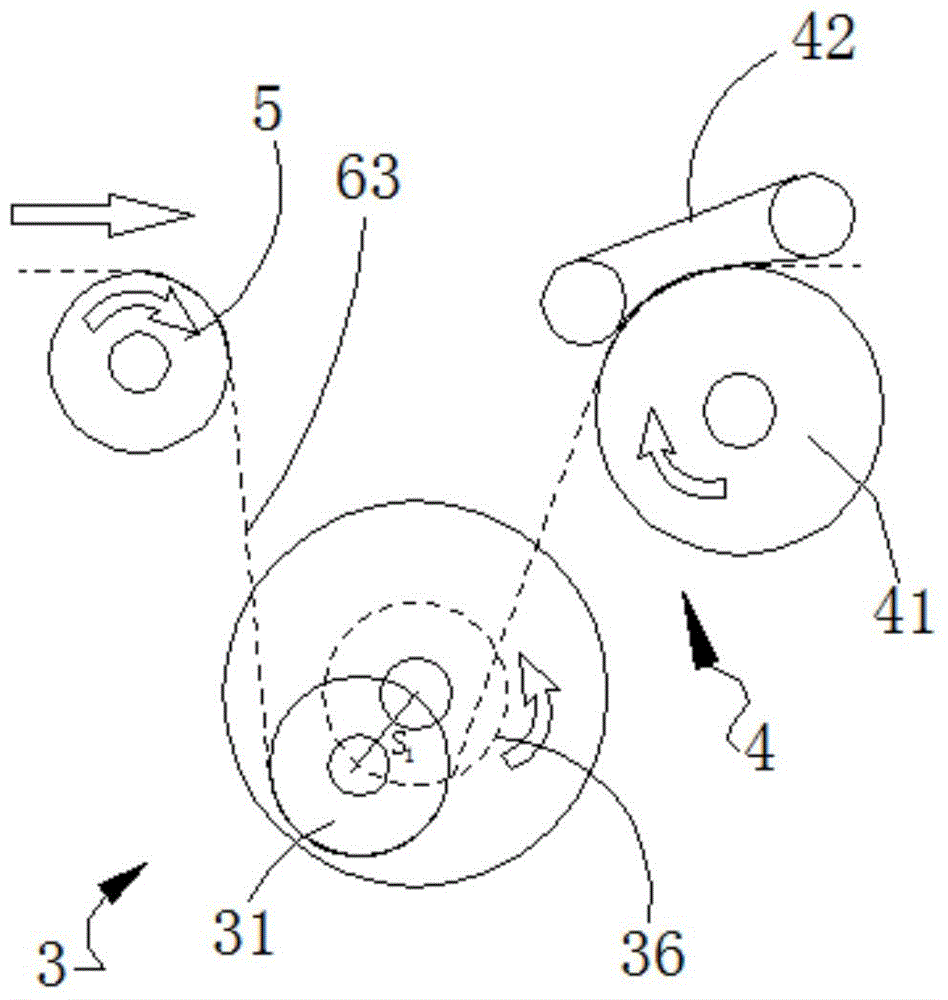

Suspended cornstalk harvesting device

InactiveCN102342211AMeet the operation needs of direct picking and bundlingMeet power generationMowersEngineeringExercise state

The invention discloses a suspended cornstalk harvesting device, which comprises a frame and a cutting mechanism, a conveying mechanism, a transmission system and a stalk extrusion mechanism arranged on the frame, wherein the cutting mechanism, the conveying mechanism and the stalk extrusion mechanism are sequentially arranged in the stalk conveying direction; the transmission system is respectively connected with the cutting mechanism, the conveying mechanism and the stalk extrusion mechanism; the stalk extrusion mechanism is arranged at the rear lower part of the frame; the rear part of thestalk extrusion mechanism is provided with a discharge hole for spreading stalks in a strip mode; and the stalk extrusion mechanism has extrusion, kneading and flaking functions and can be used for directly implementing extrusion, kneading and flaking on the stalks, and the treated stalks are spread in a field in a strip mode through the discharge hole to meet the subsequent operation requirements for picking and bundling. Through the device, the upright movement state of the cornstalks can be kept in the conveying process, sequential conveying and feeding of the stalks are realized, and the comprehensive utilization requirement of the stalks can be met.

Owner:MODERN AGRI EQUIP

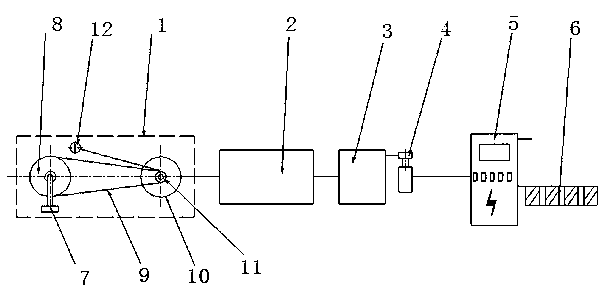

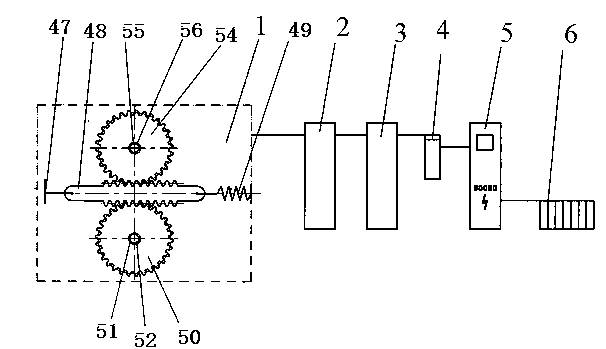

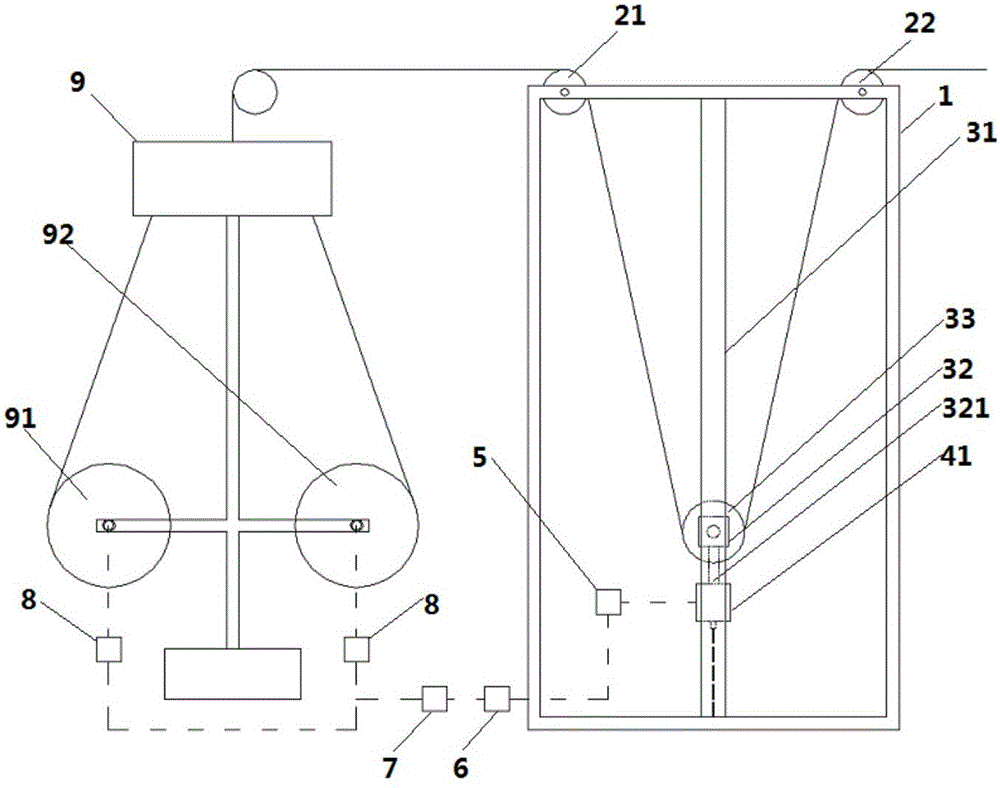

Method and system for body-building energy storage power generation

ActiveCN103174608AGuaranteed to work continuouslyGuaranteed power requirementsBatteries circuit arrangementsFrom muscle energyBuilding energyControl theory

The invention discloses a method and a system for body-building energy storage power generation. The method and the system for the body-building energy storage power generation comprise a body-building power transmission mechanism, an energy storage mechanism, a speed change mechanism, a generator, a control module and a storage battery, wherein the body-building power transmission mechanism, the energy storage mechanism, the speed change mechanism, the generator, the control module and the storage battery are sequentially connected, the body-building power transmission mechanism transmits kinetic energy to the energy storage mechanism, the kinetic energy is converted into potential energy of high elastic material groups in the energy storage mechanism, and thus acting energy is generated and is accumulated in the high elastic material groups in the energy storage mechanism, the potential energy of the high elastic material groups in the energy storage mechanism gently outputs kinetic energy torque after being released stably and adjusted, and the speed of the output kinetic energy torque is changed by the speed change mechanism and then the output kinetic energy torque drives the generator to generate power. According to the method and the system for the body-building energy storage power generation, manual or pedal energy generated in exercise can be converted into the potential energy of the high elastic material groups at any time, and compared with power generation by using solar energy, the method and the system for the body-building energy storage power generation are more efficient, more convenient, more economical and higher in general applicability.

Owner:湖南省小尹无忌环境能源科技开发有限公司

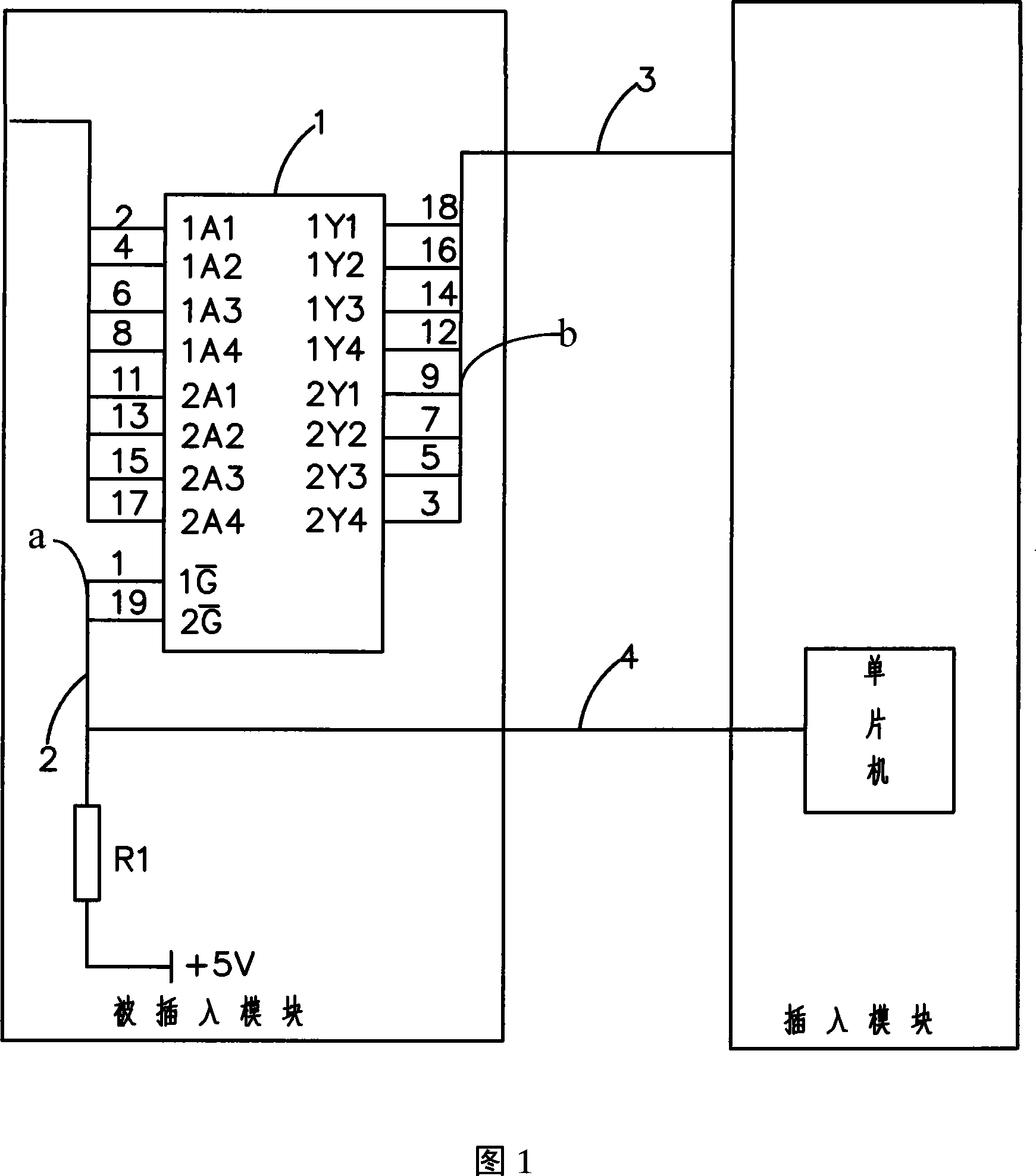

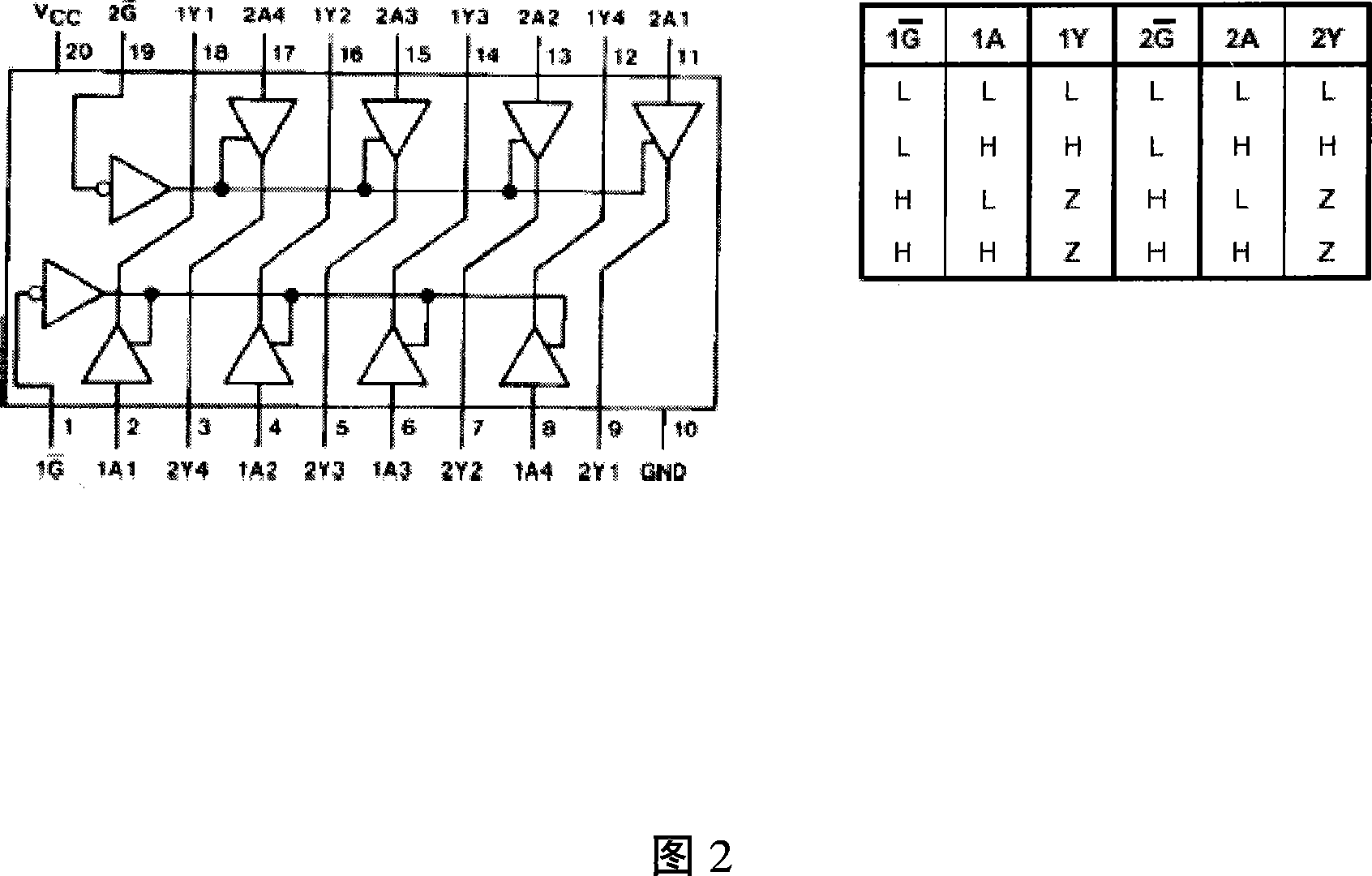

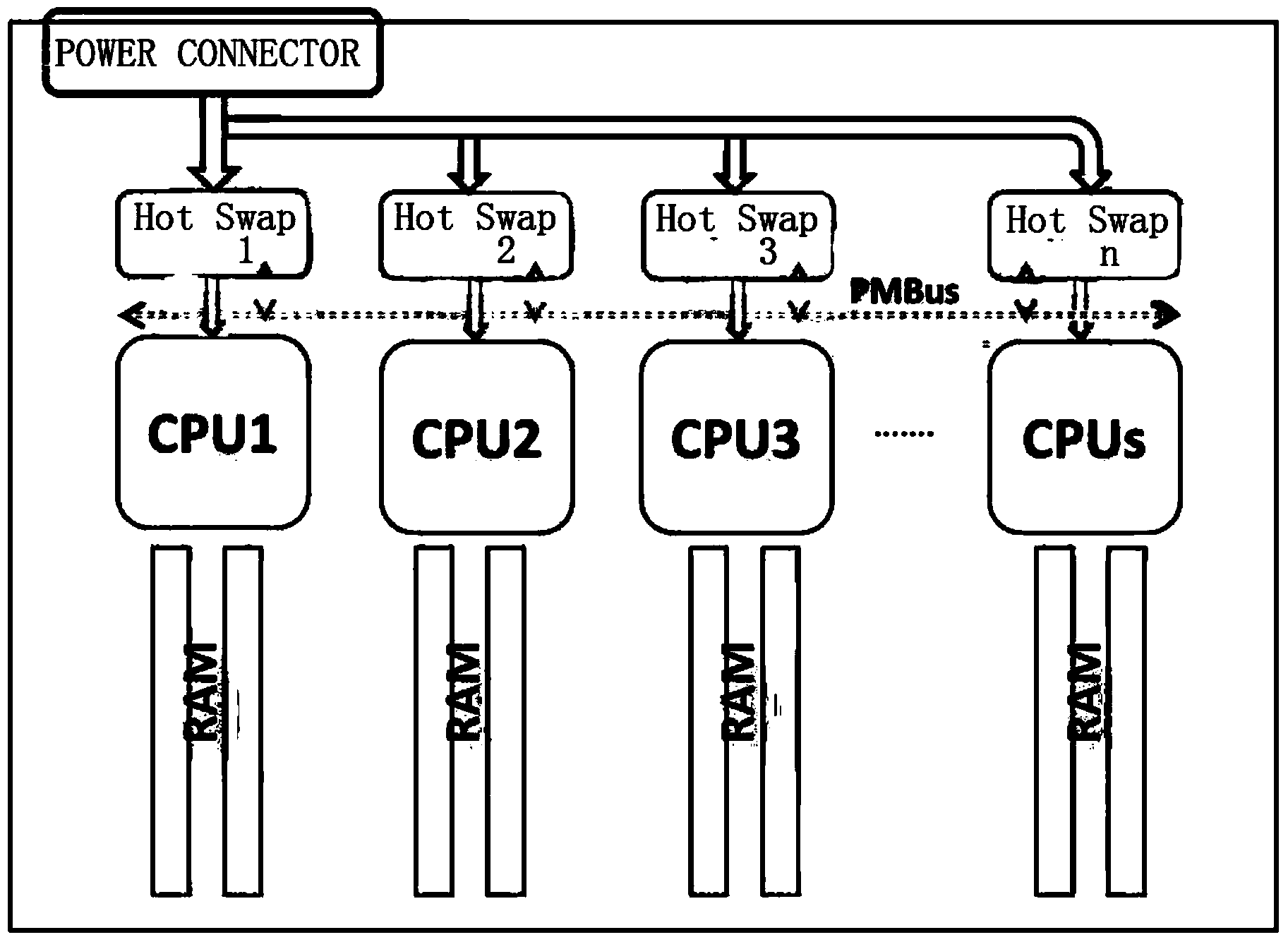

Protection circuit for interface signal hot-plug

InactiveCN101154809AEasy to replaceGuaranteed to work continuouslyTwo-part coupling devicesTransmissionHigh resistanceControl line

The invention relates to the communication field, in particular to an interface signal hot plug protective circuit, comprising a tristate control chip, a hot plug connecting piece, a hot plug control line and a pull-up resistor R1, wherein, a signal output pin of the tristate control chip is connected with a long needle in the hot plug connecting piece; a control pin of the tristate control chip is connected with one end of the hot plug control line; the other end of the hot plug control line is connected with the pull-up resistor R1 and a short needle in the hot plug connecting piece; the other end of the pull-up resistor R1 is connected with a 5V power source on an inserted module; the tristate control chip comprises high resistance state. The invention is capable of realizing hot plug of fault board on the premise that the power is not cut off, guarantees of normal operation of the device, improves working efficiency, and reduces the maintenance cost at the same time.

Owner:北京英华达电力电子工程科技有限公司

Long-time continuous working creep and rupture tester

ActiveCN105510117AMeet the requirements of temperature fluctuationsExtend working lifeMaterial strength using tensile/compressive forcesWorking lifeEngineering

The invention discloses a long-time continuous working creep and rupture tester. The tester comprises a long-life-design mechanical creep and rupture loading host, heating furnace fault replacement equipment and a double-wire heating furnace, wherein the double-function redundancy design is adopted in electric components of the long-life-design mechanical creep and rupture loading host, and long-time continuous working of a loading mechanism is ensured. The double-wire heating furnace comprises a test heating furnace body and a standby heating furnace body, the test heating furnace body is arranged on the long-life-design mechanical creep and rupture loading host, and the standby heating furnace body is arranged on the heating furnace fault replacement equipment. The long-time continuous working creep and rupture tester is characterized in that when tests on the creep and rupture tester are interrupted by faults of the electric components or the heating furnace bodies, on the premise of ensuring original temperature and loads, the fault components and the fault heating furnace bodies can be replaced fast, continuous working of the tester is ensured within the load and temperature fluctuation range required by standards, and therefore the working life of the creep and rupture tester is prolonged infinitely.

Owner:UNIV OF SCI & TECH BEIJING

Sugarcane harvester

InactiveCN103416155AImprove efficiencyGuaranteed to work continuouslyHarvestersStructural engineeringStrip steel

The invention provides a sugarcane harvester, which comprises a four-wheel drive traveling device, a straightening device, a harvesting device and a vertical leaf stripping device, wherein the vertical leaf stripping device is obliquely arranged on a motor vehicle, and comprises a vertical leaf stripping box; openings are formed in the two ends of the vertical leaf stripping box; vertical leaf discharge ports are formed in the two sidewalls of the vertical leaf stripping box; one end of the vertical leaf stripping box is connected with a bracket; vertical conveying parts and vertical leaf stripping parts are arranged in the vertical leaf stripping box; the vertical conveying parts are arranged at the two openings respectively; the vertical leaf stripping parts are arranged between the vertical conveying parts; the vertical conveying parts and the vertical leaf stripping parts all comprise roll shafts perpendicular to the top and the bottom of the vertical leaf stripping box; rubber pipes for vertically conveying sugarcanes are arranged on the roll shafts of the vertical conveying parts; vertical leaf stripping steel wires for stripping leaves are arranged on the roll shafts of the vertical leaf stripping parts; the vertical leaf discharge ports are opposite to the vertical leaf stripping parts. The sugarcane harvester is higher in sugarcane harvesting speed and efficiency.

Owner:张汉生

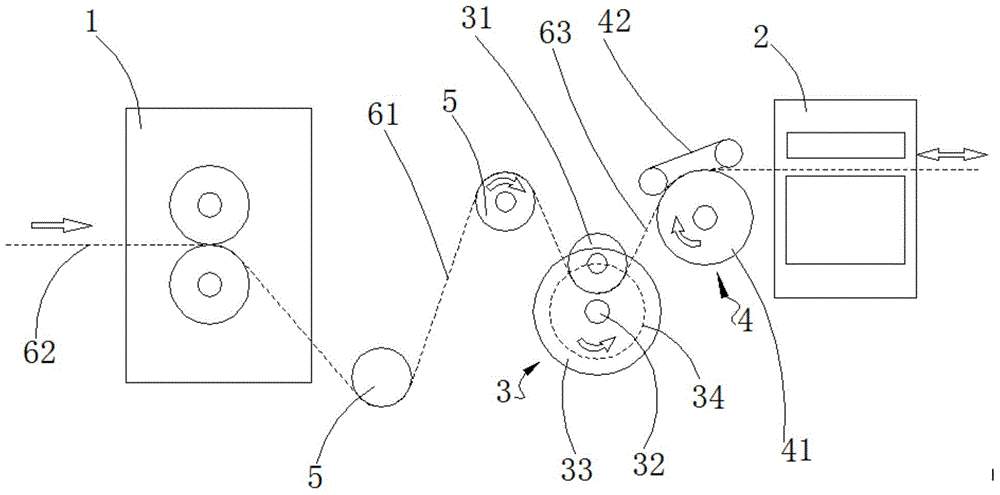

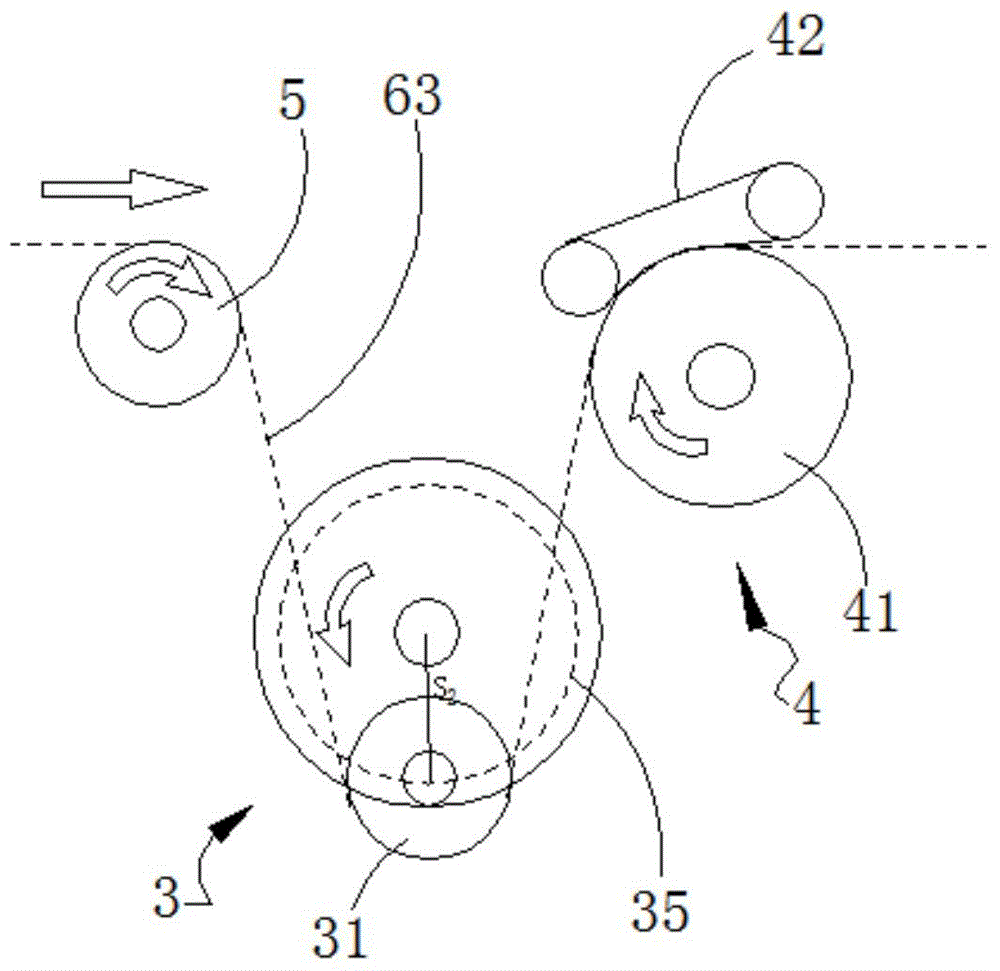

Paper conveying device

The invention discloses a paper conveying device, comprising a continuous working unit and an intermittent work unit; an eccentric control device is arranged between the continuous work unit and the intermittent work unit; when the intermittent work unit works, the eccentric control device gradually lengthens a first paper path between the continuous work unit and the intermittent work unit; the eccentric control device for changing the length of the first paper path is arranged between the continuous work unit and the intermittent work unit, and is used for gradually lengthening the first paper path, so the speed of a third paper path entering the intermittent work unit is slowed, and the intermittent work unit has enough time to perform operations such as die cutting or gold stamping on the third paper path entering the intermittent work unit. While being operated at a high speed, the paper conveying device can perform intermittent operations such as die cutting and gold stamping on the paper path, the paper conveying device meets the printing demands of a long order form, the obtained printed paper product has high quality and the work efficiency is high.

Owner:广州互通气动机器工程有限公司

Connection table for cooling hold-up tank with PCB

InactiveCN103964177AReasonably adjust the running speedFull cooldownConveyor partsCold airButt joint

The invention discloses a connection table for a cooling hold-up tank with a PCB, and belongs to the technical field of transmission equipment. The connection table for the cooling hold-up tank with the PCB comprises a first connection table body and a second connection body, the first connection table body and the second connection body are respectively provided with a driving motor for driving the corresponding connection table body to rotate respectively, the first connection table body and the second connection body are connected through the hold-up tank, an input port allowing the PCB to fall into is formed in the top of the hold-up tank, an output port allowing a single PCB to penetrate through is formed in the bottom of the hold-up tank, the tail end of the first connection table body is in butt joint with the input port, the head end of the second connection table body is in butt joint with the output port, and a pushing device for pushing the PCB out of the output port is further mounted on the bottom of the hold-up tank. The hold-up tank comprises an outer tank body and a cooling tank arranged in the outer tank body, cold air channels are reserved between the cooling tank and the outer tank body, a plurality of through holes enabling the inter portion of the cooling tank and the cold air channels to be communicated are formed in the cooling tank, an air cooler is connected with the outer tank body, the air outlet of the air cooler is communicated with the cold air channels.

Owner:SUZHOU BECHENLAI ELECTRONICS

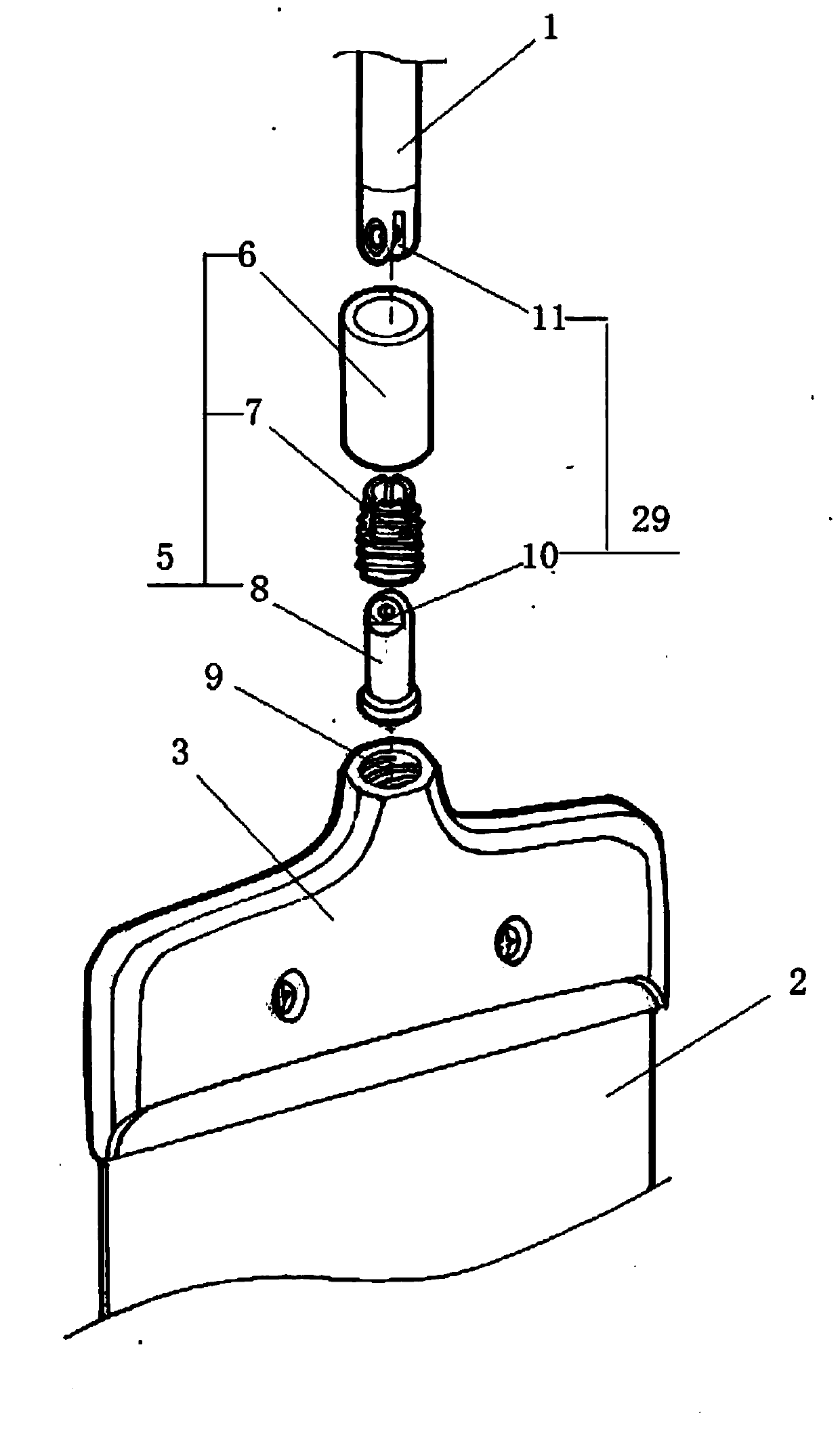

Light mop and mop bucket used with same

The invention relates to a light mop and a mop bucket used with the same. The light mop comprises a mop rod, and is characterized in that the mop rod is provided with a turning mechanism, the turning mechanism comprises a sleeve nut, a locking swivel nut and a hinge stepped rotary shaft, and a hinge plane is arranged at an upper tip of the hinge stepped rotary shaft and is inserted into a hinge connecting lug of a lower tip of the mop rod via a hinge pin, so that a hinge mechanism of the mop rod can be formed; squeezing rotary rollers of the mop bucket used with the light mop are connected with a brush by a combined support to form an integral squeezing and brushing device, a combined support mechanism comprises left and right barriers, and the brush and the squeezing rotary rollers are fixedly integrally connected with one another by connecting screws. The light mop and the mop bucket have the advantages that concealed corner turning and wiping functions can be realized; special mop heads for different narrow and wide working surfaces can be quickly changed, and the squeezing rotary rollers and the brush are reset, so that a working space of the mop bucket can be enlarged, and cleaning can be facilitated; functions of wiping and simultaneous water replenishing and a function shoveling hard dirt further can be realized.

Owner:李军

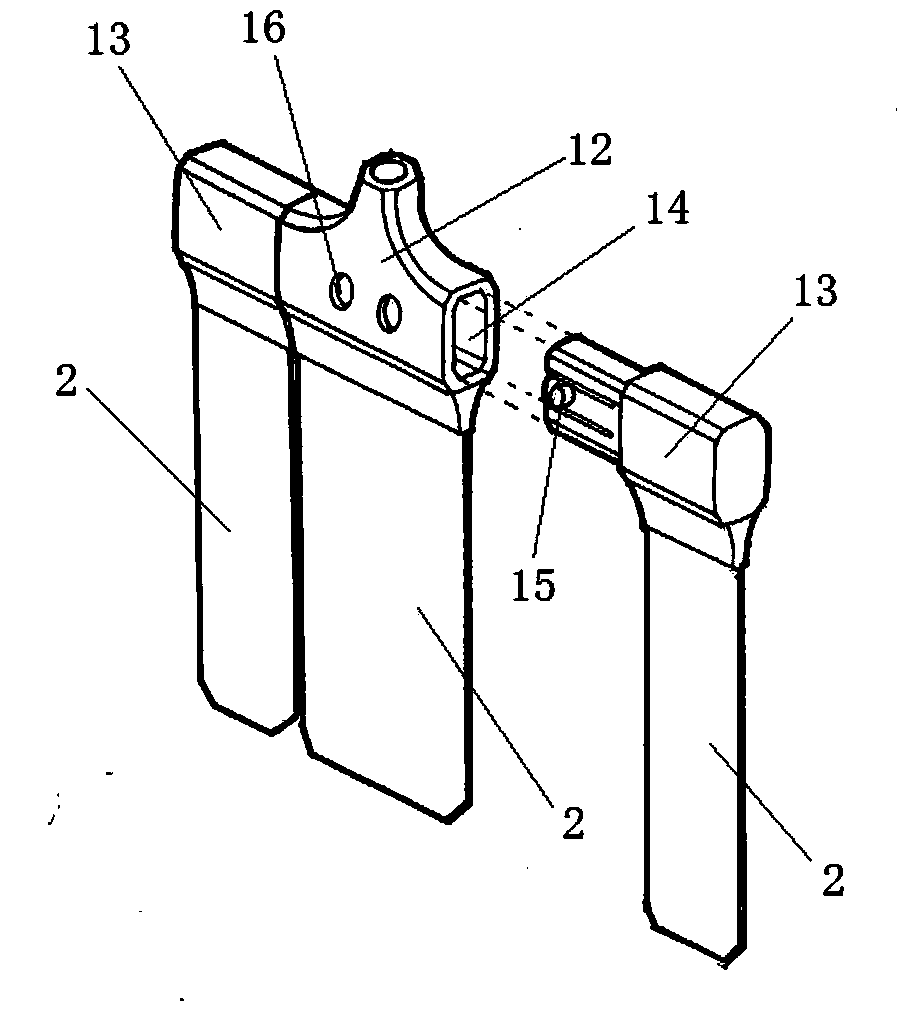

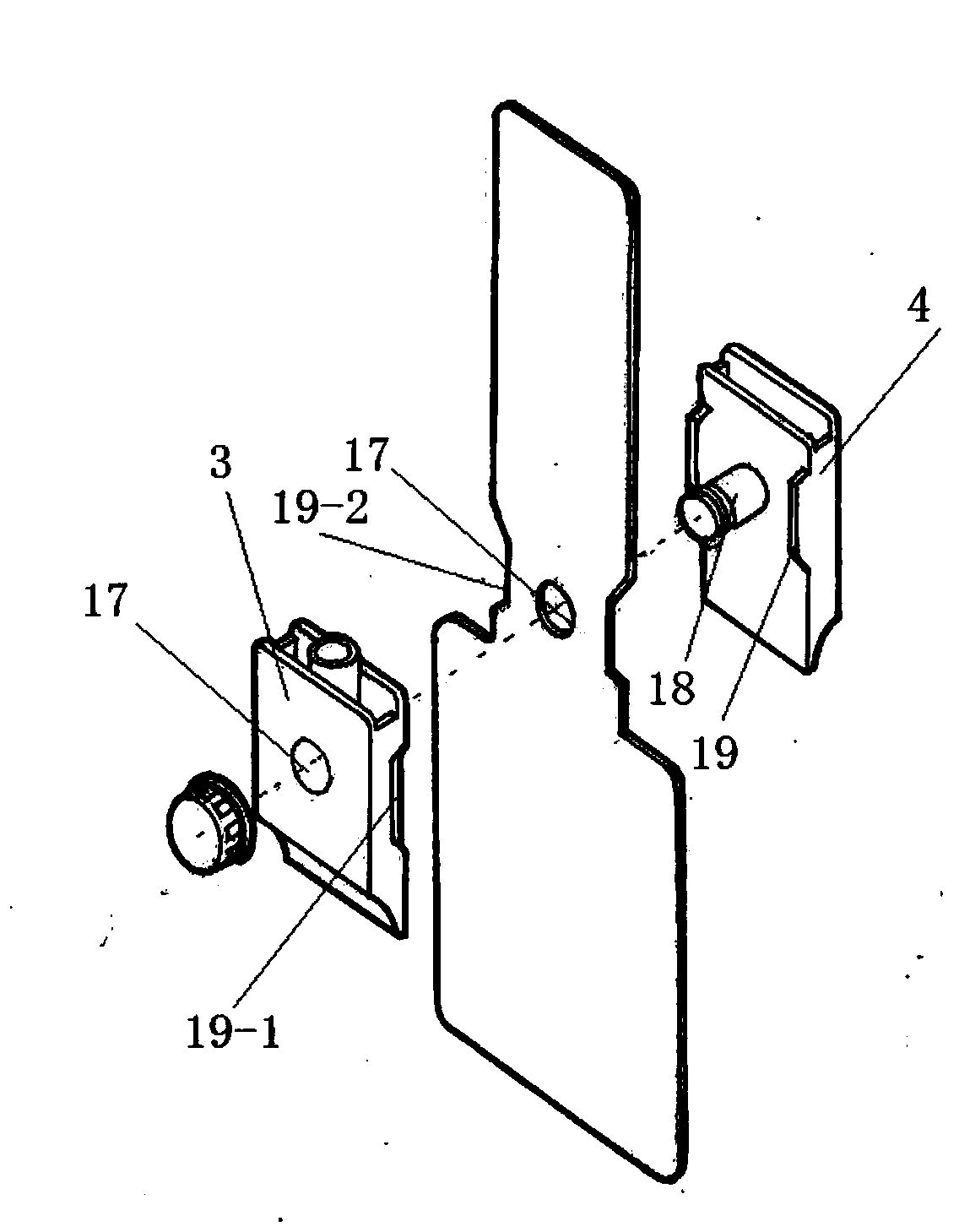

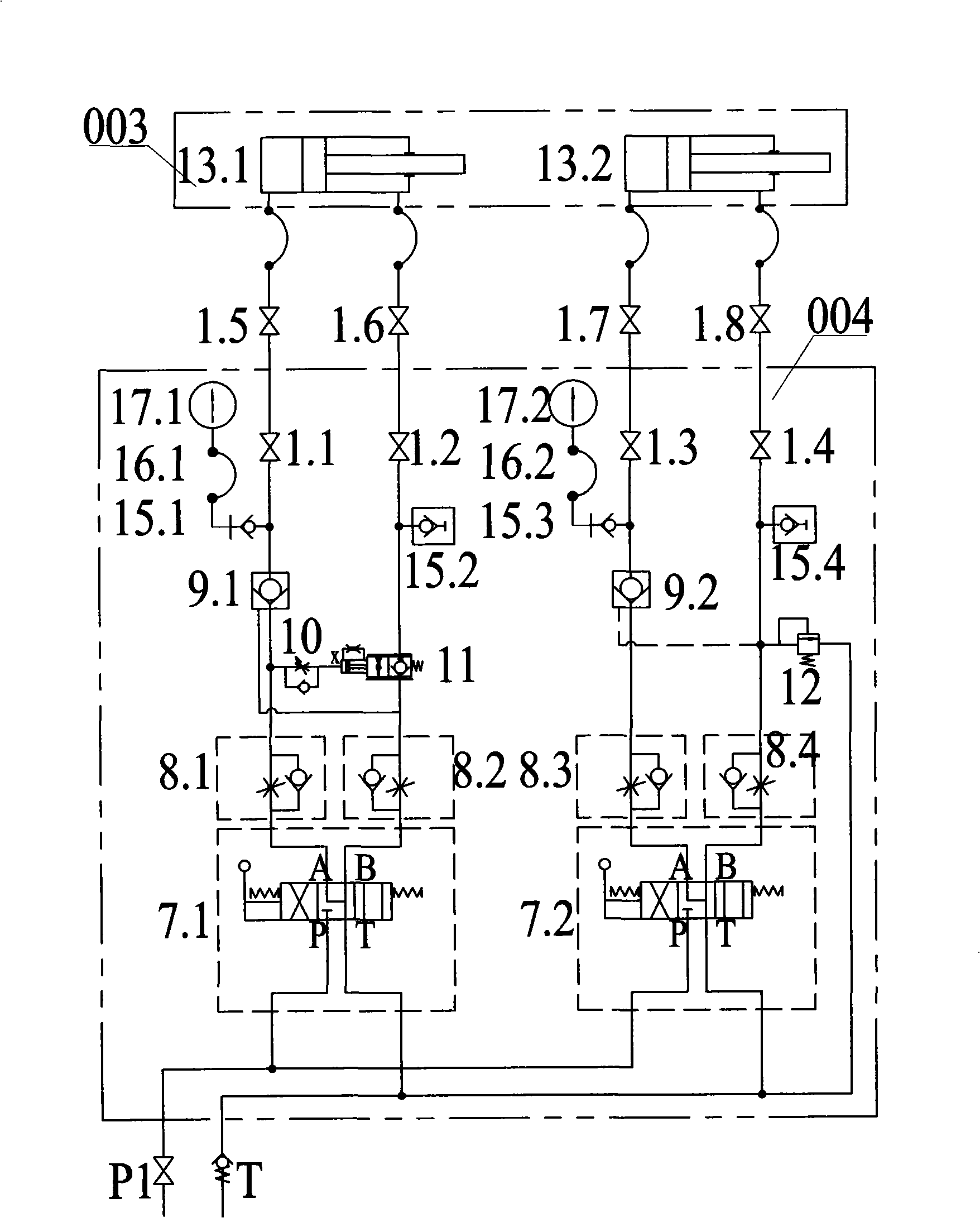

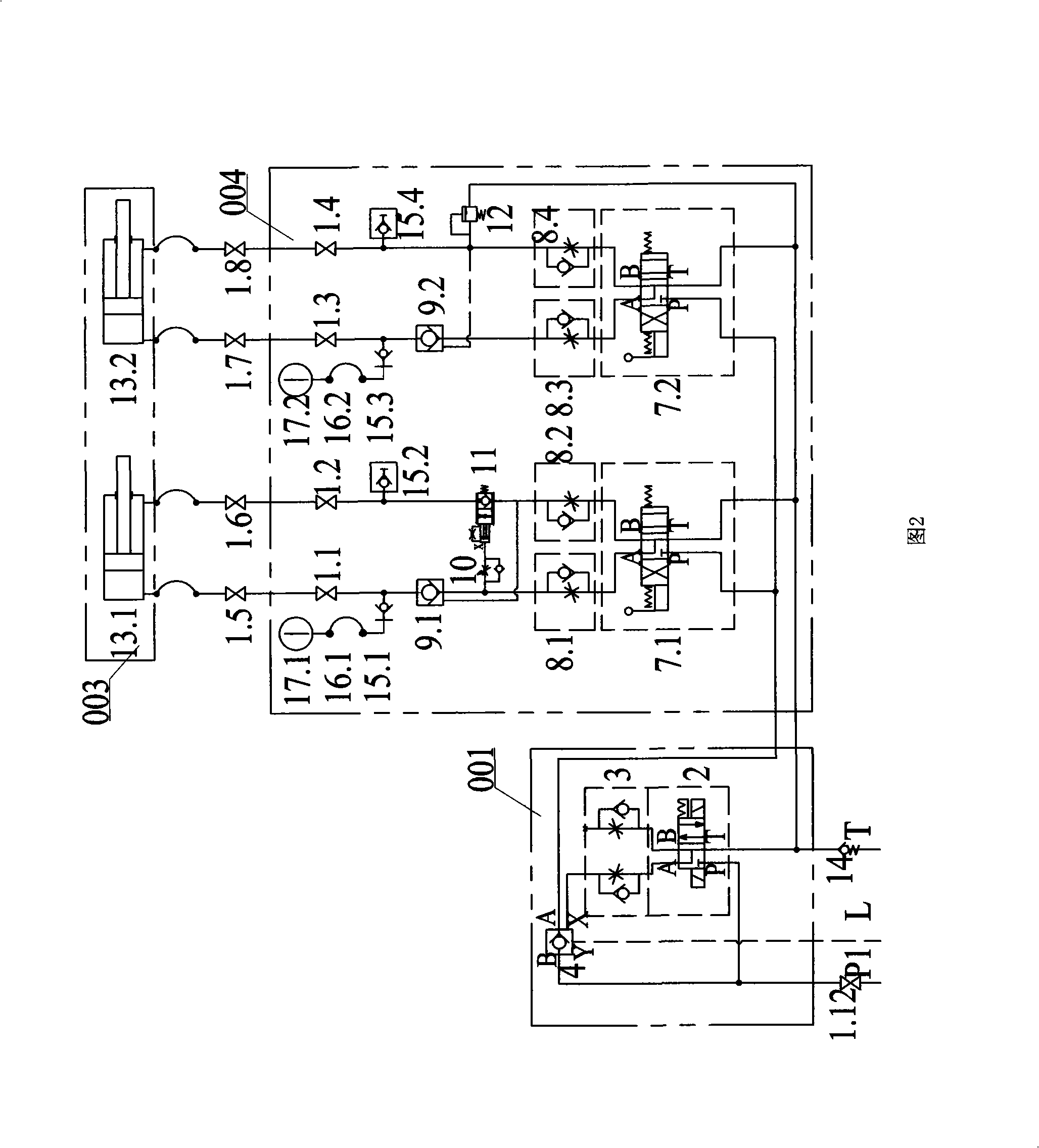

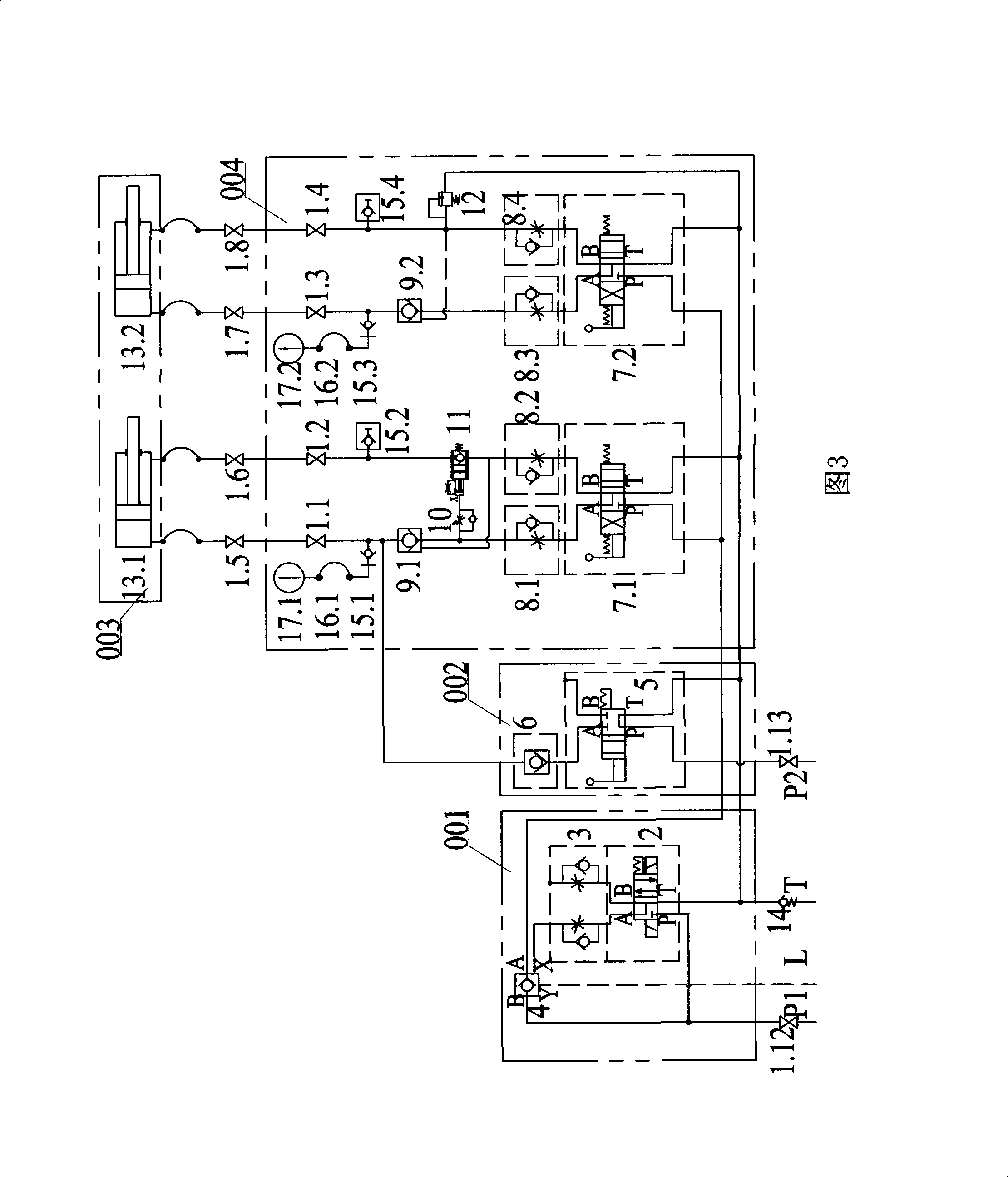

Hydraulic system of blast furnace gun

InactiveCN101315087ATake advantage ofReduce replacement frequencyServomotor componentsBlast furnace componentsHydraulic cylinderSafety control

The invention discloses a blast furnace gun hydraulic system, which comprises a safety control circuit (001), a hydraulic cylinder component (003), and a hydraulic cylinder control circuit (004). The safety control circuit (001) is connected with the hydraulic cylinder control circuit (004) via a hydraulic pipeline, and the hydraulic cylinder control circuit (004) is connected with the hydraulic cylinder component (003) via the hydraulic pipeline. The blast furnace gun hydraulic system also comprises a pressure maintaining circuit (002), which communicates with a rotary oil cylinder (13.1) via the hydraulic pipeline, a first ball valve (1.1) and a fifth ball valve (1.5), an oil supply pipe of the pressure maintaining circuit (002) communicates with a constant displacement pump oil source, and an oil return pipe of the pressure maintaining circuit (002) communicates with a system oil return pipe. The inventive blast furnace gun hydraulic system has the advantages of simple control, good safety and reliability, prolongs service life of components, and saves production cost.

Owner:HUATIAN ENG & TECH CORP MCC

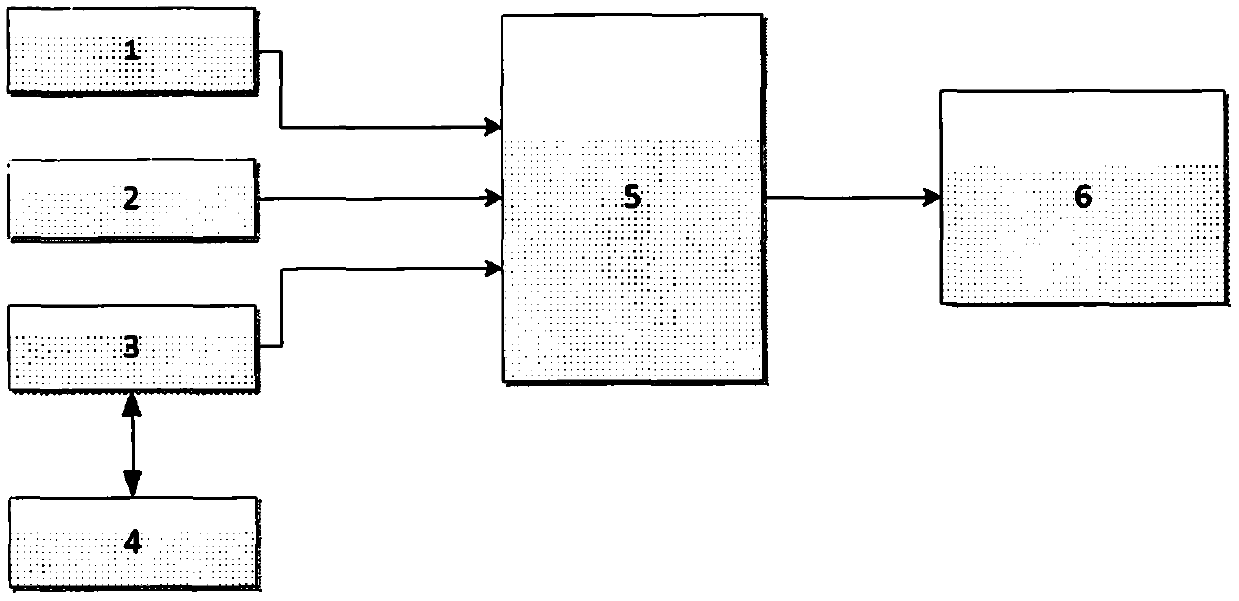

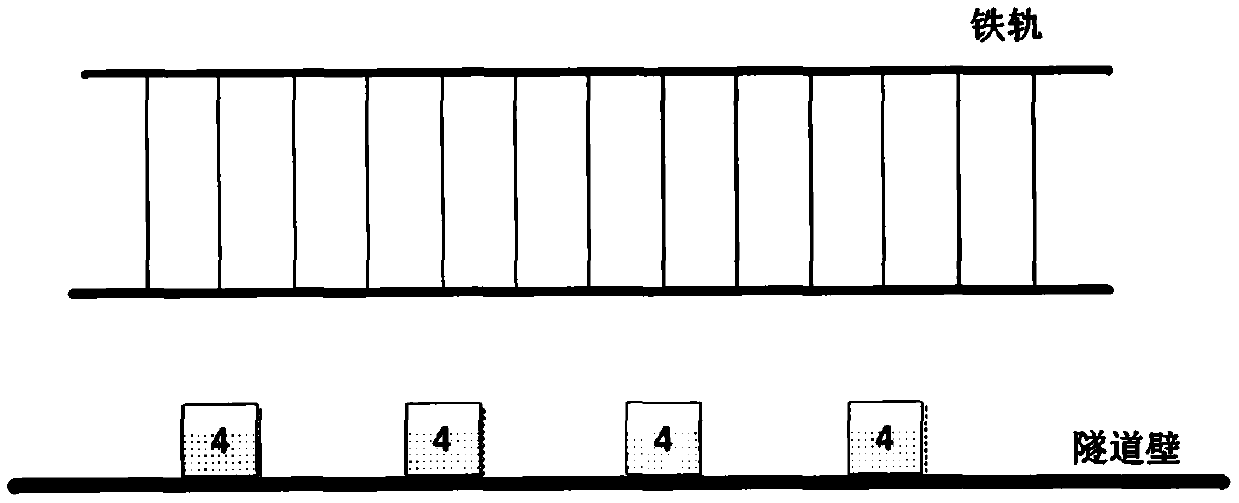

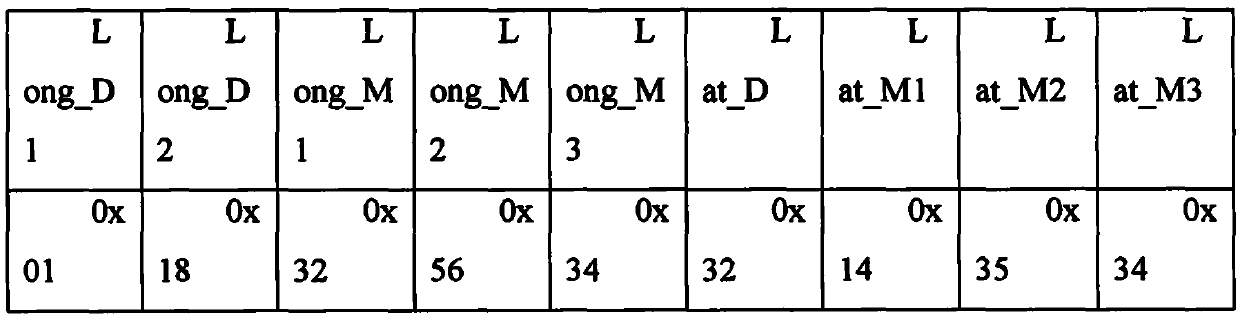

RFID-based high-precision positioning system in train tunnel

PendingCN110687564AGuaranteed to work continuouslyUninterrupted outputSatellite radio beaconingCard readerComputer science

An RFID-based high-precision positioning system in a train tunnel comprises a multi-mode GNSS receiver, an inertial measurement unit, a data processing unit, RFID tags, an RFID card reader, and a train position information monitoring system. The RFID-based high-precision positioning system in the train tunnel provided by the invention has the advantages that precise train position information canbe output uninterruptedly, and the applicability to a high-speed train with a speed of 350 km per hour is achieved.

Owner:中科凯普(北京)导航通信技术有限公司

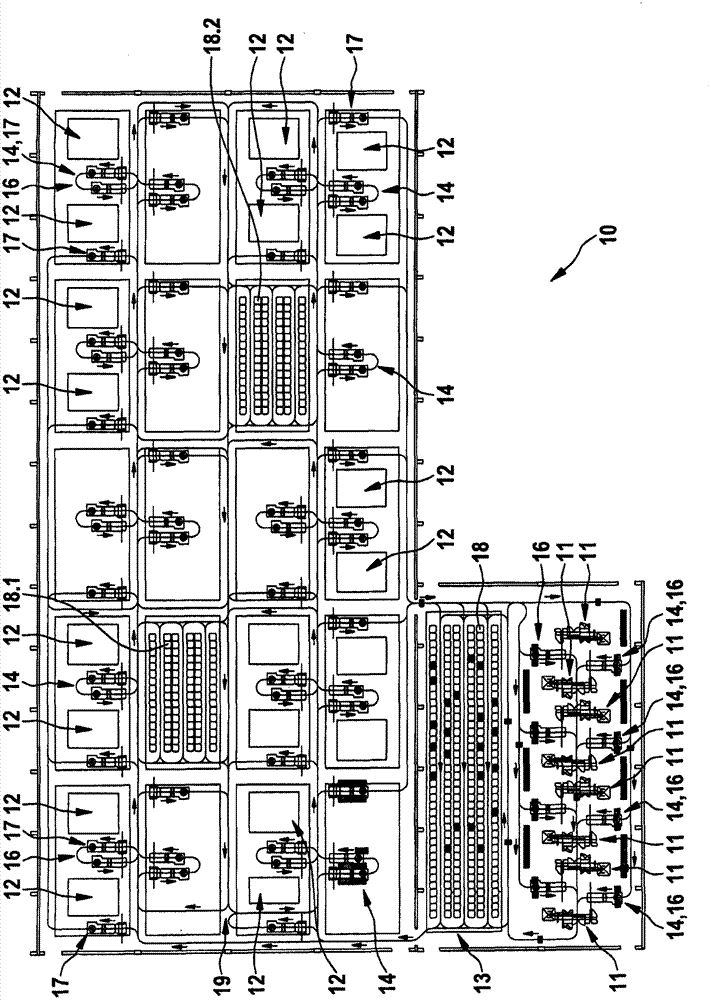

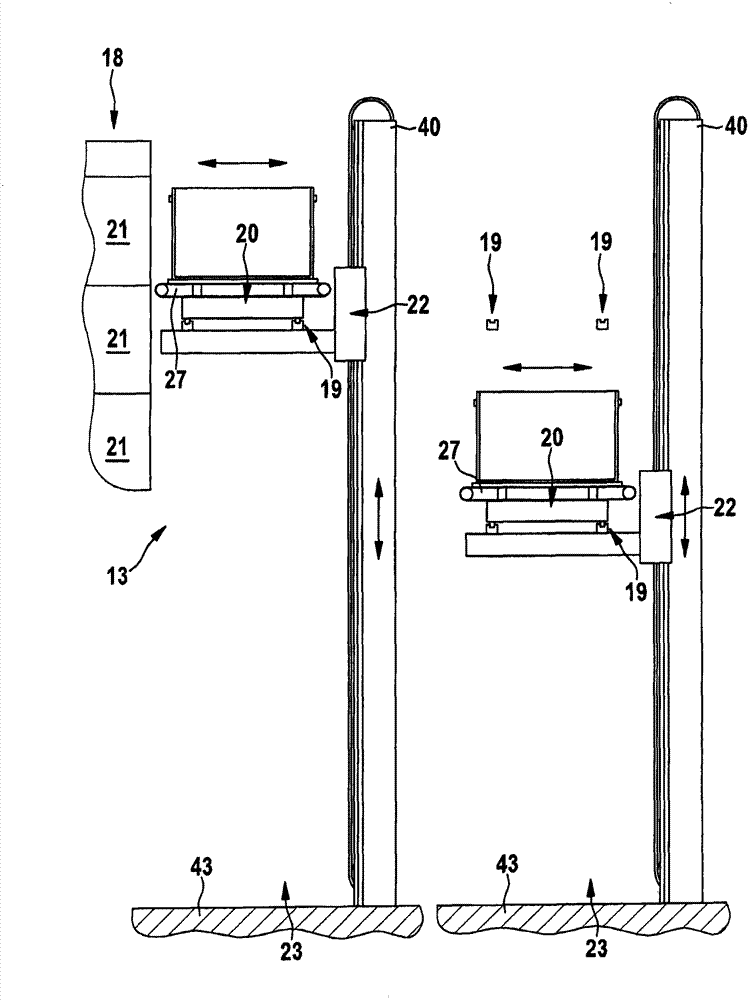

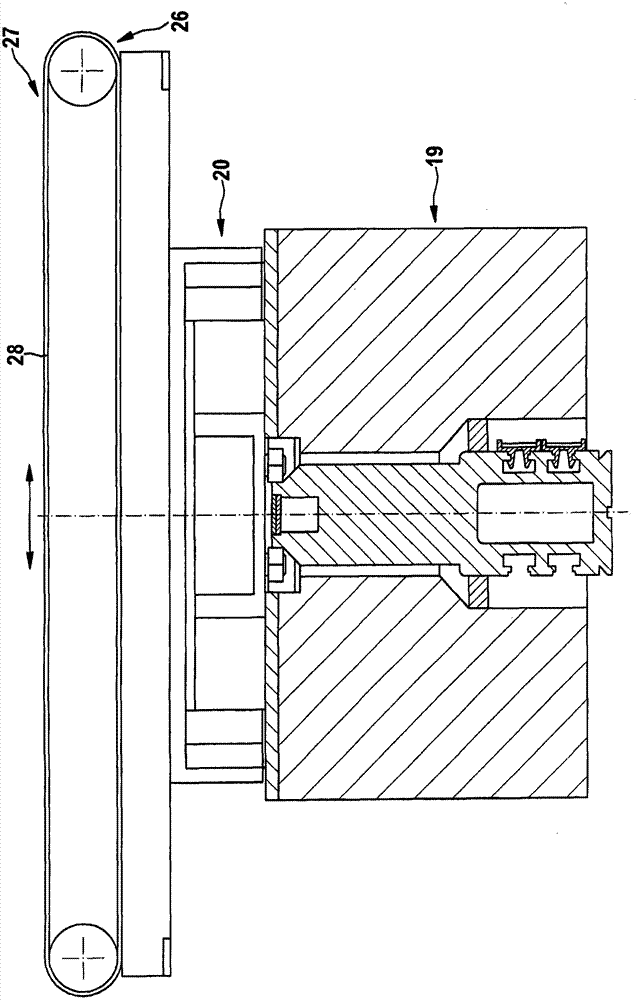

Device for producing, storing and transporting products from the tobacco processing industry

InactiveCN103027372ASave spaceIncrease storage capacityCigarette manufactureStorage devicesTransport systemEngineering

The invention relates to a device for producing, storing and transporting products from the tobacco processing industry. The device comprises a production device for manufacturing intermediate products of tobacco industry, a production device for manufacturing finished products of tobacco industry, a storage and transport system that is provided for storing and transporting material needed for manufacturing, manufactured intermediate and / or finished products of tobacco industry in or on load carriers in the device, and a station provided for changing the level of load carrier. The storage and transport system is connected with the production devices for manufacturing intermediate and finished products of tobacco industry, and the station for changing the level of the load carrier. The storage and transport system is designed into a storage rack which, except for storing and carrying products storage, is provided with a rail network and a movable transport vehicle for receiving and discharging the load carrier above the rail plane.

Owner:HAUNI MASCHINENBAU AG

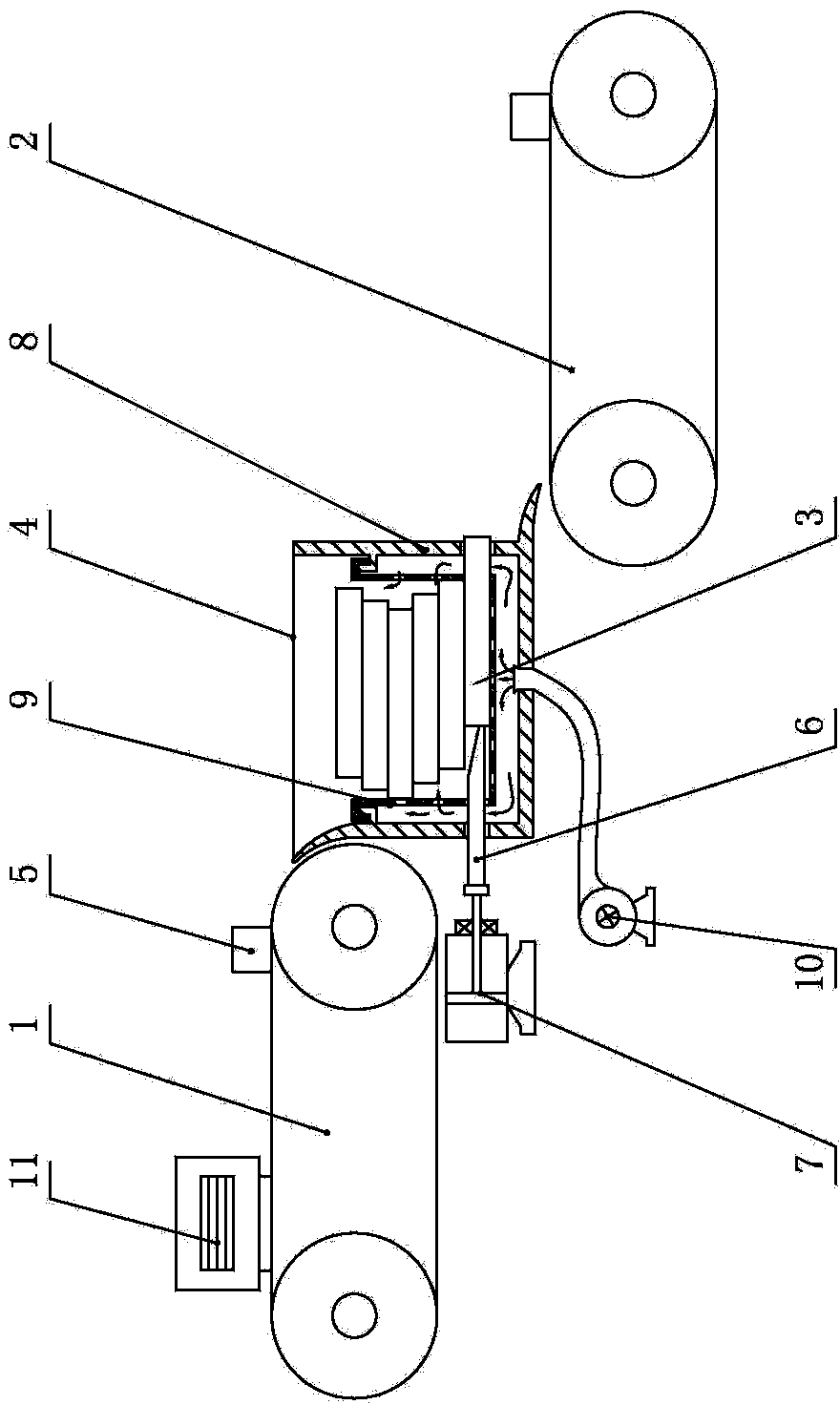

Tension adjusting device of automatic paper splicing machine

The invention discloses a tension adjusting device of an automatic paper splicing machine. The tension adjusting device comprises a rack, guide rollers, a floating roller, a position detector, a terminal controller, a proportional flow valve, a solenoid directional valve and band-type brake control air valves. The floating roller is formed by two oppositely-placed guide rails fixed to the position, between the first guide roller and the second guide roller, on the rack in the vertical direction, sliding blocks which are mounted on the guide rails and can move back and forth along the guide rails and a third guide roller with the two ends mounted on the sliding blocks of the two guide rails correspondingly. A laser distance measuring sensor serves as the position detector. Universal components in the automatic paper splicing machine are fully utilized, and the mechanical structure is optimized; the tension adjusting device is simple in structure and low in manufacturing cost; the problems that a tension adjusting device in the prior art is complex in structure and high in cost are solved; the use effect is good, and extremely short response time and extremely high work sensitivity are achieved; and the tension of paper keeps constant all the time, and tension control is accurate.

Owner:安徽浙源再生纸业科技有限公司

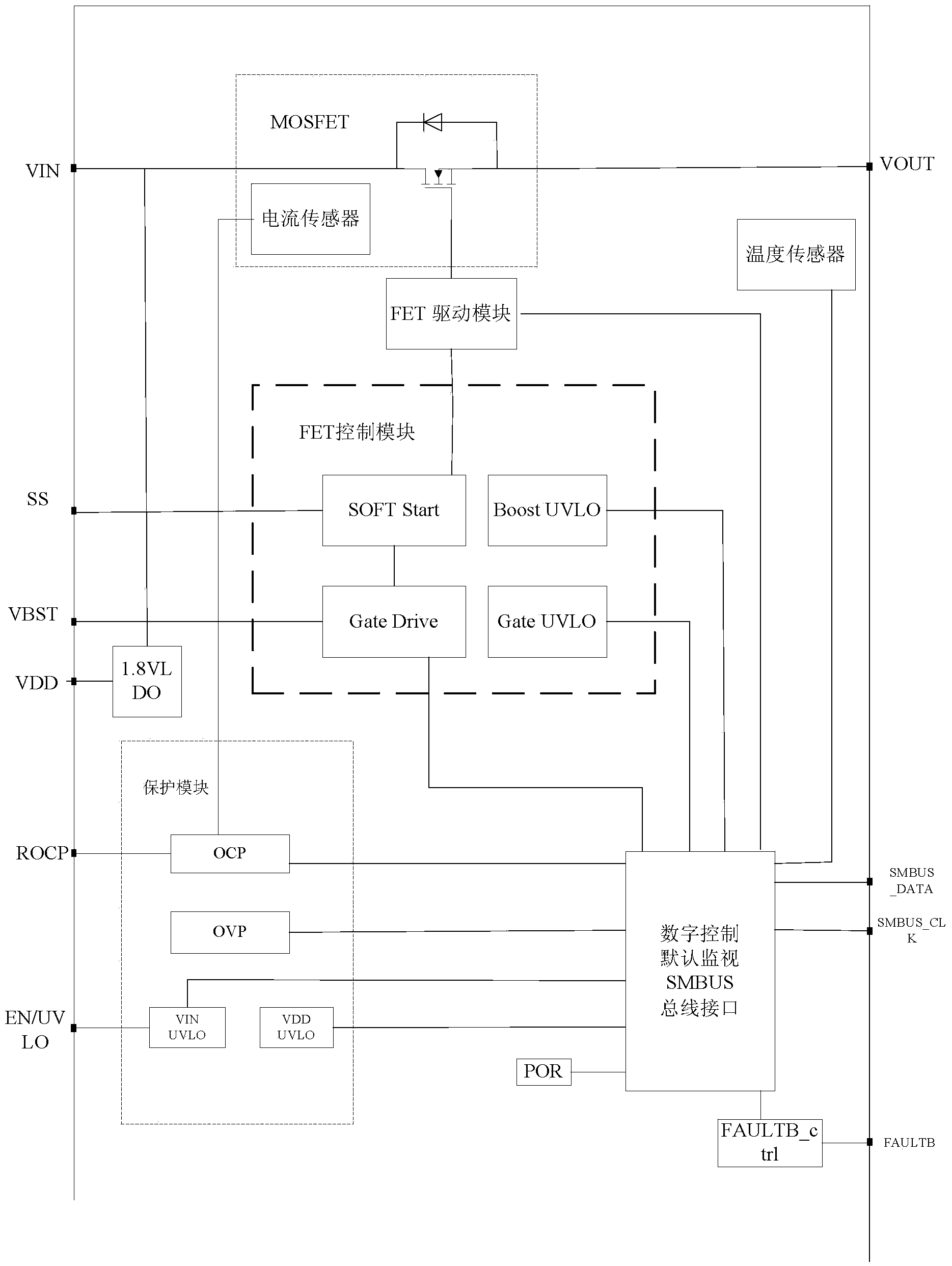

Hot swap protection circuit system

ActiveCN103777554AHigh consistency of electrical characteristicsSo as not to damageProgramme controlComputer controlComputer moduleEngineering

A hot swap protection circuit system comprises multiple integrated circuits and a mainframe module. Each integrated circuit comprises a protection module, an on-off module, an on-off control module and a control interface module, wherein the control interface module and the mainframe module are mutually connected through a bus. The input end of each on-off module is connected with a load power source outside the corresponding integrated circuit, and the output end of each on-off module is connected with a load outside the corresponding integrated circuit. The protection modules are used for performing real-time detection on the on-off modules. If the detection result exceeds a standard value, an action command requesting protection is transmitted to the control interface modules. The control interface modules are used for transmitting a protection action command to the on-off control modules and transmitting fault information to the mainframe modules. The on-off control modules are used for receiving the protection action command to the control interface modules to control on-off of the on-off modules. The mainframe modules are used for storing addresses of the integrated circuits where faults happen.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

Method and device for preventing grain defect of wafer in use for vacuum system

InactiveCN1959928AGuaranteed to work continuouslyPass rate impactValve arrangementsSemiconductor/solid-state device manufacturingContinuous operationElectrical and Electronics engineering

The method includes steps: collecting granules; analysis of counted granules; sending information of analyzed result of counted granules to controller of air pressure valve; the controller selects to drive first or second switch valve, and makes switching between two switch valves. The devices in use for the method is composed of switch valve module including first switch valve, and second switch valve, grading analysis instrument, and controller of air pressure valve. Granules generated from switch valve are monitored in real time. One switch valve is working, and the other is standby. Transferring and controlling information of granules makes automatic or manual switching between two valves so as to guarantee continuous operation of machine unit, and yield of wafer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

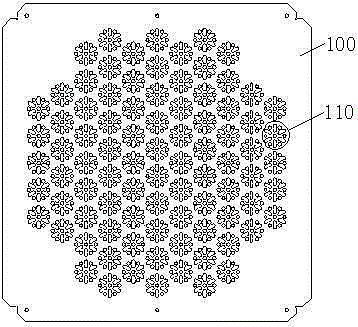

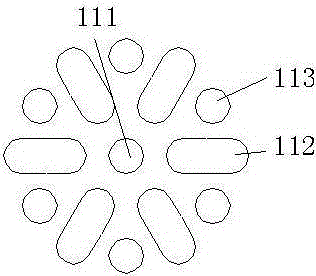

Wind-uniformizing plate

ActiveCN105344474AEven air intake is goodImprove dust removal efficiencyElectrostatic separationElectrostatic precipitatorEngineering

The invention provides a wind-uniformizing plate. The wind-uniformizing plate comprises a plate body and a plurality of through hole arrays having the consistent hole shape and arranged on the plate body, wherein each through hole array is corresponding to an anode tube in an electrostatic dust removal unit. Through the structure improvement, the wind-uniformizing plate provided by the invention is capable of realizing a better uniform wind-intake effect, and then increasing the dust removal efficiency; in addition, the wind-uniformizing plate is capable of guaranteeing continuous normal working of a dust remover, and avoiding the problem of failed dust removal of the traditional wind-uniformizing plate due to that dust enters an insulation position of an electrostatic dust removal unit, thus the fault rate of dust removal equipment is reduced, the working efficiency is correspondingly increased, and the cost is reduced.

Owner:KELAN TECHNICS ENVIRONMENTAL PROD CO LTD

Intelligent garbage classification robot

InactiveCN103464380AImprove classification efficiencyReduce sorting costsSortingControl systemCoupling

An intelligent garbage classification robot comprises a garbage separation device and a garbage classification device, the garbage separation device is formed by a garbage bucket and a crank rocking bar mechanism, the garbage bucket comprises a garbage baffle board, a baseboard, side boards, a laser transmitting tube I, metal proximity switches, a laser receiver I, a partition board, a metal proximity switch support, a rotation shaft, a steering engine I, a garbage separating column jack and a garbage separating column, the crank rocking bar mechanism comprises a shaft coupling, a crank I, a direct current deceleration motor I and a connecting rod, and the garbage classification device comprises a direct current deceleration motor II, transmission shafts, driving sprocket wheels, a control system, driven sprocket wheels, garbage boxes, a laser transmitting tube II, a solar board, a camera support, chain boards, a camera, a support body, a laser receiver II, a driven gear, a driving gear, a vertical support, a steering engine II, a crank II, slide rails and a slide block. The robot has the advantages of intelligence, high classification efficiency, environmental protection, low price and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

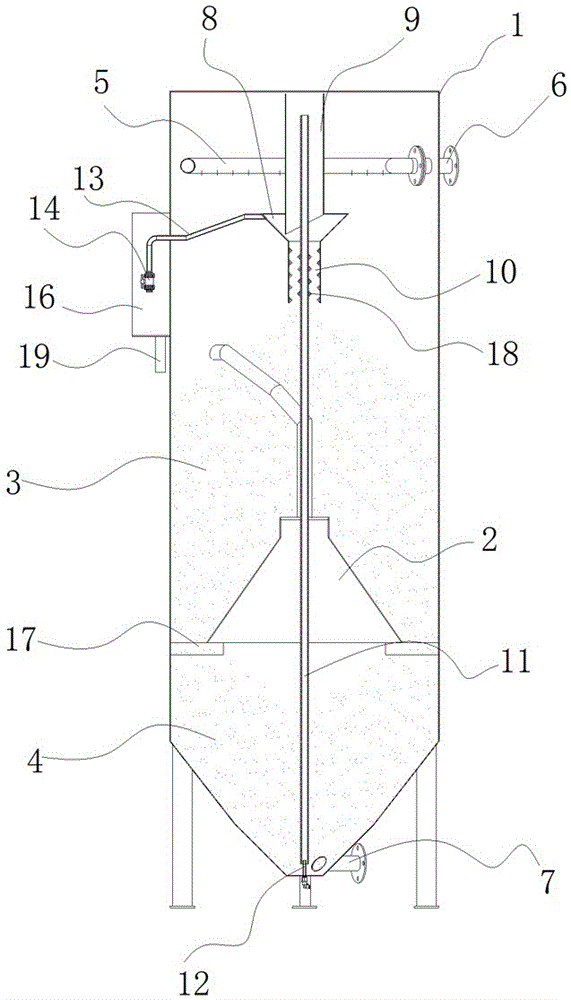

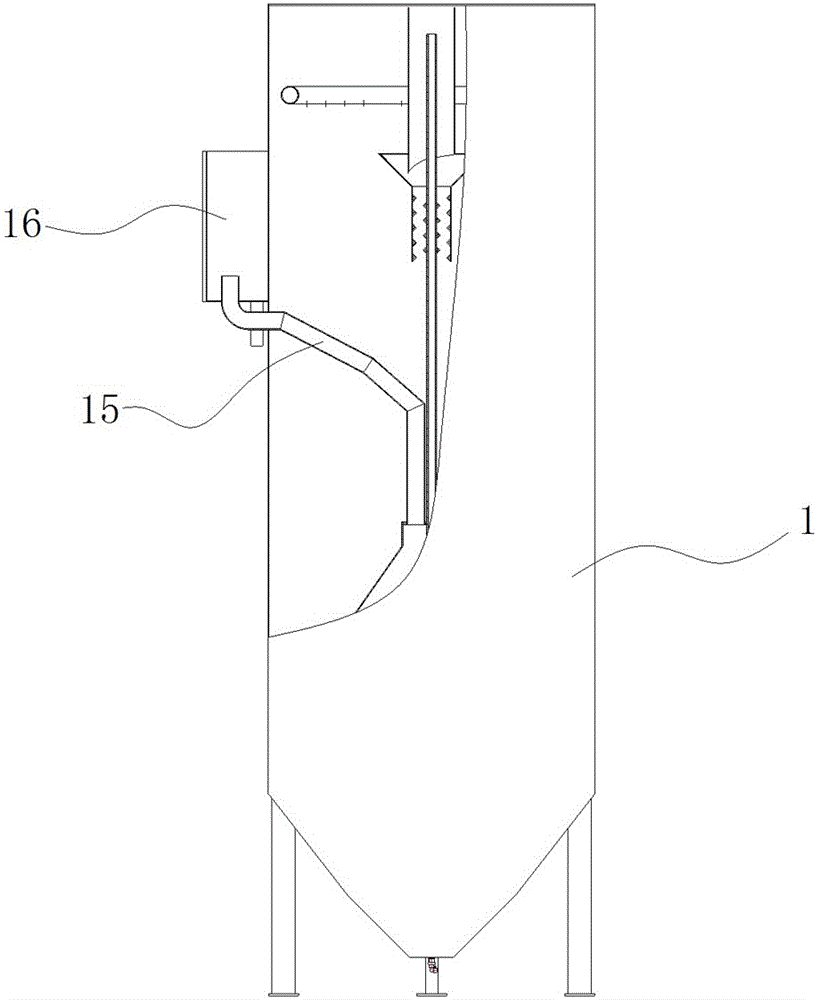

Downward-flow type continuous sand filter and operating method thereof

InactiveCN106422448ASimple structureGuaranteed continuity of operationLoose filtering material filtersGravity filtersSewageSewage treatment

The invention relates to a sand filter, in particular to a downward-flow type continuous sand filter, and belongs to supporting machinery of sewage treatment equipment. The downward-flow type continuous sand filter comprises a filter barrel, wherein a sand distribution device is arranged in the filter barrel; a sand filtering chamber is formed in the upper end of the sand distribution device; a to-be-cleaned sand chamber is formed in the lower end of the sand distribution device; a sand-filtering backwash assembly and a clear water output assembly are arranged in the sand filtering chamber. The downward-flow type continuous sand filter has the beneficial effects of being simple in structure, and capable of guaranteeing the operating continuity and improving the sewage filtering efficiency.

Owner:ZHEJIANG SUNLAND ENVIRONMENTAL TECH CO LTD

Transmission with gear wheel pump

InactiveCN101377235ALow costSmall location requirementsGear lubrication/coolingRotary piston pumpsGear pumpGear wheel

The invention relates to a gearbox for a motor vehicle that includes, but is not limited to an input shaft, an output shaft and a plurality of wheel sets for coupling input and output shaft with different transmission ratios and a gear pump, which is arranged to for delivering from a reservoir of the gearbox. The gear pump is an outer gear pump and one of two gears of the gear pump meshing with one another belongs to one of the wheel sets.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method of preparing inorganic mineral fibre by smelting gangue and laterite-nickel ore by utilization of ore-smelting electric furnace

ActiveCN103992031AImprove utilization efficiencyEffective temperature controlGlass making apparatusGlass productionFiberHigh energy

The invention relates to a method of preparing inorganic mineral fibre by smelting gangue and laterite-nickel ore by utilization of an ore-smelting electric furnace. The method is characterized in that: the laterite-nickel ore and lime are added into the gangue so that components of slag meet requirements of the inorganic mineral fibre; the gangue is smelted by the ore-smelting electric furnace after component adjustment and drying; by adjusting the secondary voltage and the electric current, the temperature and the viscosity of the slag are effectively controlled, and nickel and iron in the slag are reduced into a nickel iron alloy side product by utilizing fixed carbon in the smelting process as a reductant; an electric mantle heater is disposed between the ore-smelting electric furnace and a centrifugal fiber manufacturing machine; the slag and the nickel iron are discharged at fixed period during smelting of the ore-smelting electric furnace; and the slag flows into the electric mantle heater, and then is fed into the centrifugal fiber manufacturing machine continuously and at a constant flux from the electric mantle heater so as to prepare the inorganic mineral fibre. The nickel and the iron in the laterite-nickel ore are reduced by utilizing the fixed carbon in the gangue to produce the side product nickel iron alloy. The method has characteristics of high energy utilization rate in processes, low pollution, low operation cost, and good economic and social benefit.

Owner:山西聚义宝鑫新材料有限公司 +1

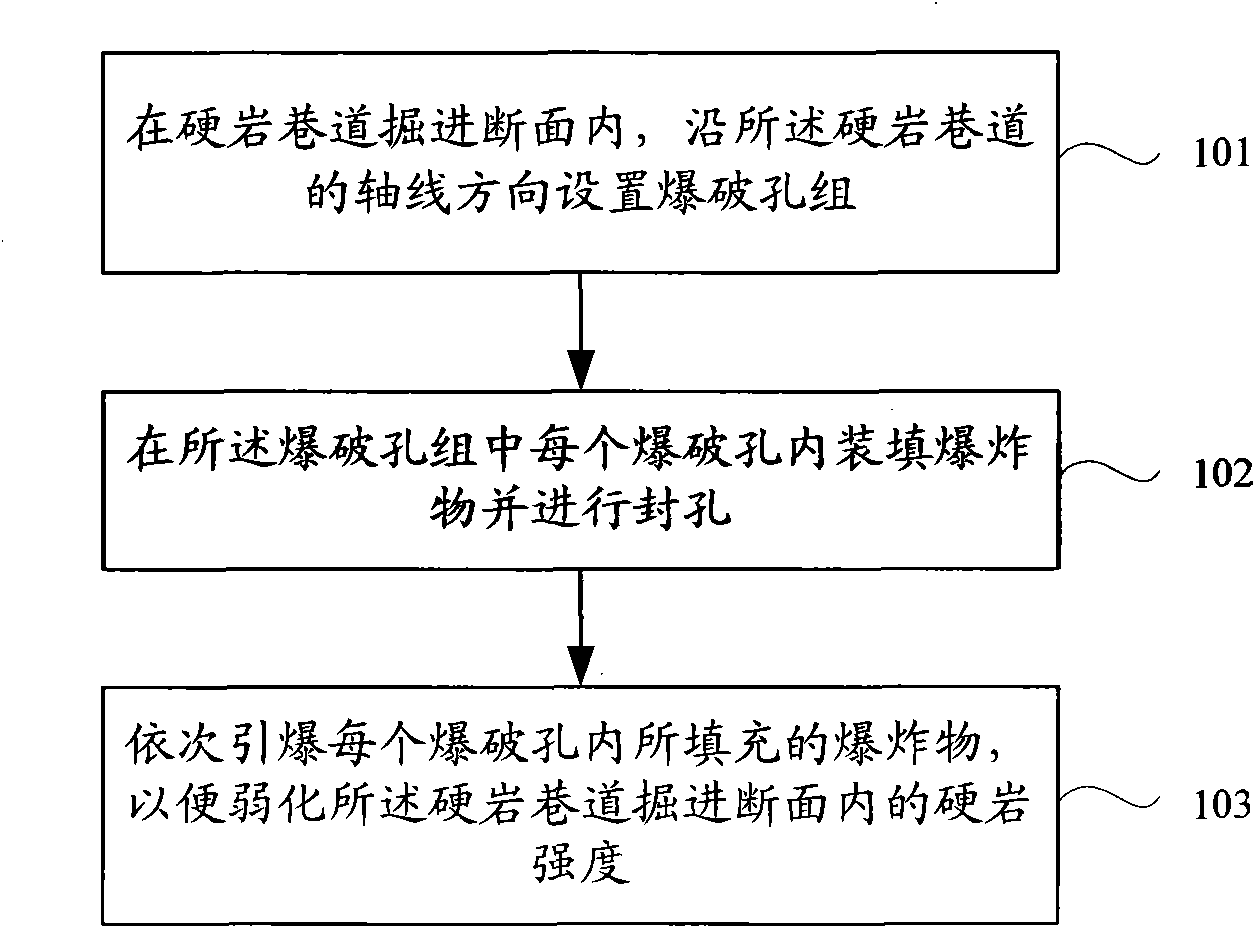

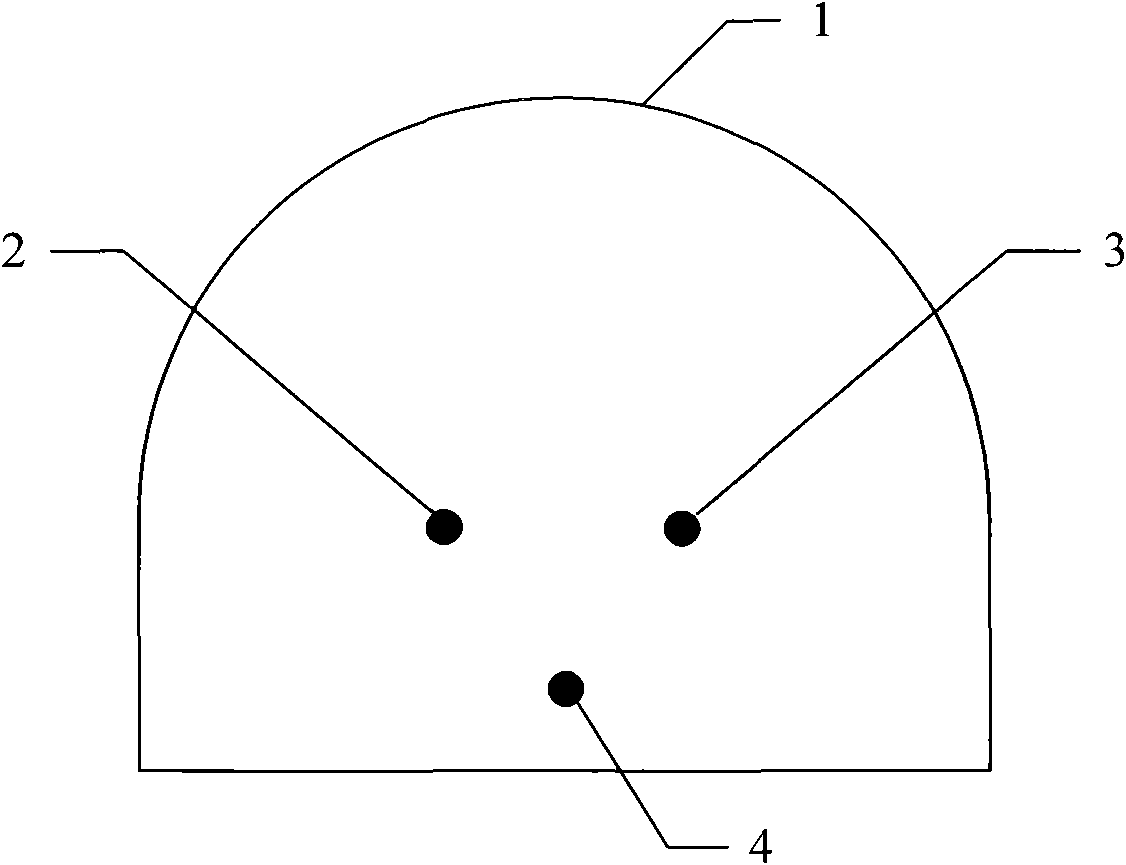

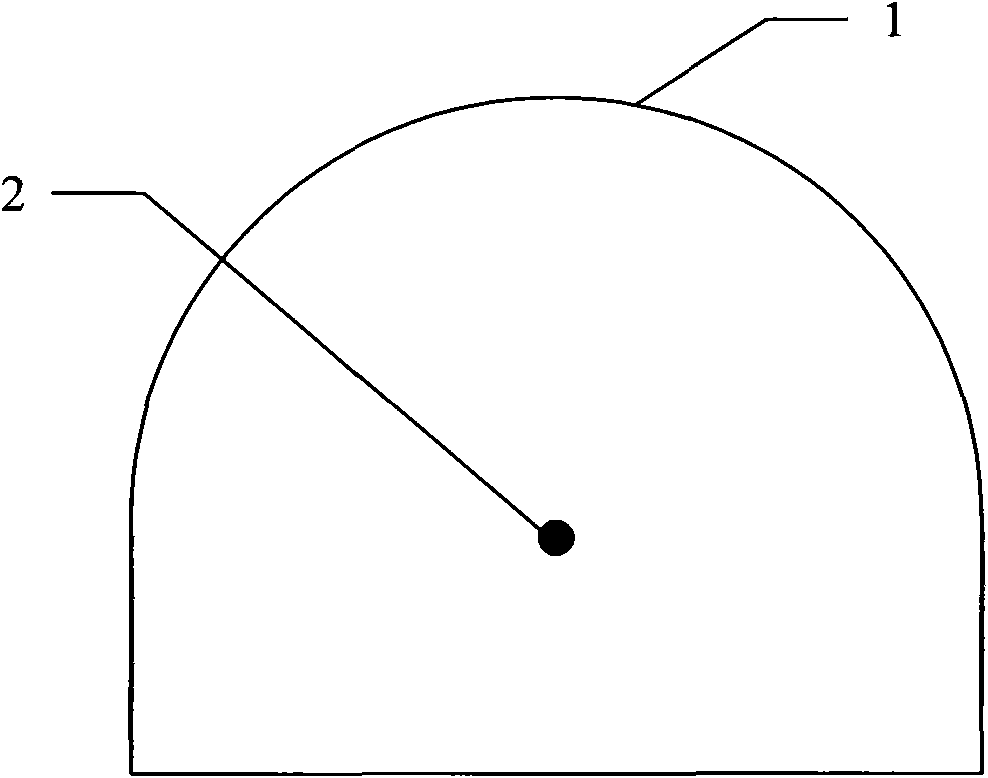

Method for weakening strength of hard rock

ActiveCN101922902AGuaranteed to work continuouslyReduce wearBlastingRock tunnelUltimate tensile strength

The invention discloses a method for weakening strength of hard rock, comprising the following steps: setting blasthole groups along the axial direction of a hard rock tunnel in the tunneling fracture surface; filling explosives in each blasthole of the blasthole groups and sealing the blastholes; setting off explosives in each blasthole in sequence so as to weaken the hard rock strength of tunneling fracture surface of the hard rock tunnel. The method of the invention is designed for addressing the technical defect that in the prior art, when a complex driving device tunnels hard rock with protodyaknove's number reaching or surpassing 8, the cutting part of the complex driving device is likely to be seriously worn, which affects stone drifting speed and weakens strength of hard rock, reduces abrasion of the cutting part of the complex driving device, ensures continuous working of the complex driving device and accelerates stone drifting speed.

Owner:HUAINAN MINING IND GRP +1

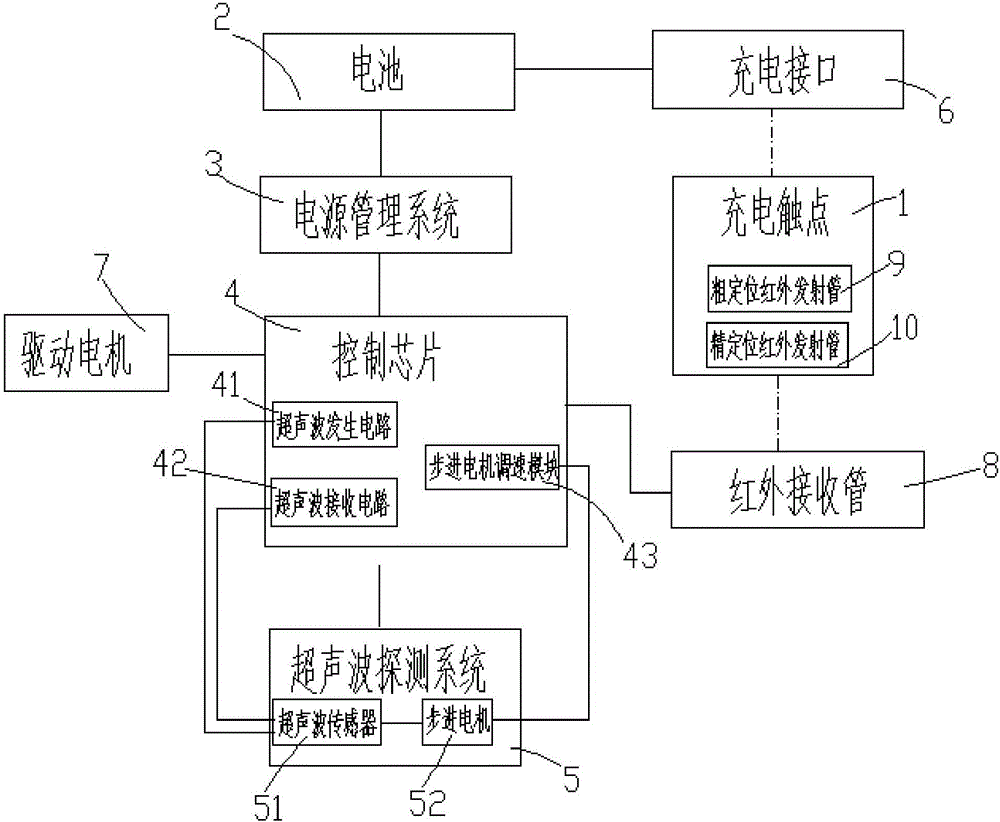

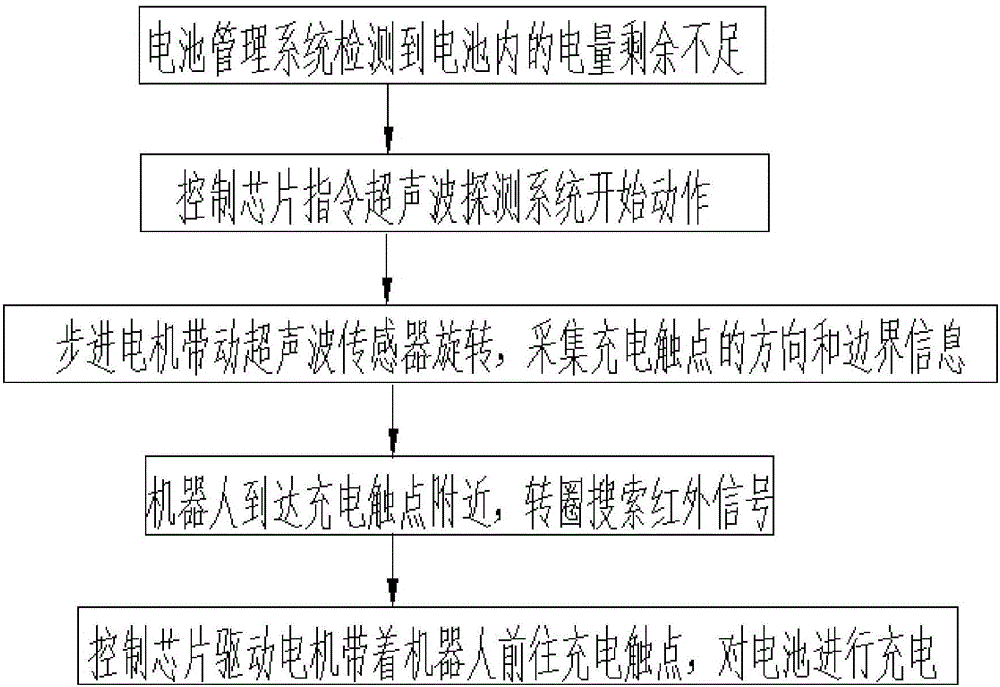

Automatic charging system and automatic charging method of robot

ActiveCN106160087ARealize automatic chargingGuaranteed to work continuouslyBatteries circuit arrangementsSecondary cells charging/dischargingDrive motorPower management system

The invention belongs to the technical field of robots, and particularly relates to an automatic charging system of the robot. The automatic charging system comprises a charging contact, a battery, a power supply management system, a control chip, an ultrasonic detection system, a charging interface and a driving motor, wherein the battery, the power supply management system, the control chip, the ultrasonic detection system, the charging interface and the driving motor are independently arranged in the robot; the control chip is also independently connected with the ultrasonic detection system and the driving motor; and the charging interface is matched with the charging contact. Compared with the prior art, the system is characterized in that the automatic charging of the robot can be realized to guarantee the continuous work of the robot and improve the degree of automation of the robot.

Owner:东莞市胡瓜儿童健康科技有限公司

Petroleum coke transportation, dehydration and storage equipment for delayed coking

PendingCN107937004AAvoid accumulationAchieve dehydrationCoking carbonaceous materialsDischarging devicesWater dischargeOptimal control

The invention relates to petroleum coke transportation, dehydration and storage equipment for delayed coking. The equipment consists of a coke water separator, dehydration tanks, a purified water temporary storage tank, a coke conveyor, coke storage tanks and the like. The coke water separator is internally equipped with a horizontal conveying mechanism suspended above the internal bottom surface,the horizontal conveying mechanism is equipped with sieve holes for water to pass through, the end of the horizontal conveying mechanism is connected to the coke storage tanks through the coke conveyor, a coke water mixture output from a lower water outlet of the coke water separator is conveyed to the dehydration tanks, and the dehydration tanks are respectively connected to the coke storage tanks and purified water temporary storage tank. The equipment changes the coke concentrated dehydration way to a distributed treatment way of dehydrating granular coke of different sizes separately, thetreatment speed is faster, the efficiency is higher, and the amount of coke needing treatment by dehydration tanks and other single component can be substantially reduced, thus being more conducive to optimal process control. When the amount of coke or water discharged by coke towers in a moment is too large, the volumetric overlay buffering effect of the components can effectively prevent spillover, thus ensuring continuous operation of the petroleum coke airtight conveying system.

Owner:LUOYANG JIANGUANG SPECIAL EQUIP

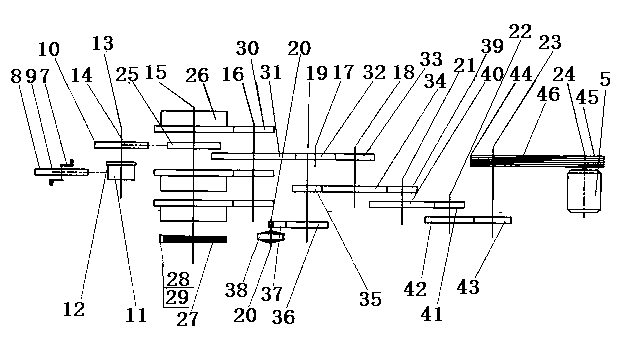

Yarn drafting and mixing device

ActiveCN108914273AGuaranteed stabilityPrevent axial movementDrafting machinesContinuous wound-up machinesYarnEngineering

The invention provides a yarn drafting and mixing device, and belongs to the technical field of textile machinery. The device comprises a yarn reversal mechanism, a drafting mechanism, a mixing mechanism and a yarn collecting mechanism. A front drafting spindle connecting ring of a front drafting spindle and a rear drafting spindle connecting ring of a rear drafting spindle of the drafting mechanism are in sliding connection through a rotation preventing guide sliding block and a rotation preventing guide sliding slot. Six front synchronous notches are evenly distributed in the outside of a front synchronous sheave, and front synchronous columns are uniformly disposed in front notches of a front drafting wheel in equal circumference. Six rear synchronous notches are evenly distributed in the outside of a rear synchronous sheave, and rear synchronous columns are uniformly disposed in rear notches of a rear drafting wheel in equal circumference. A mixing guide frame of the mixing mechanism is provided with a first mixing guide hole and a second mixing guide hole. The mixing frame is provided with a mixing hole, and the yarn collecting mechanism is disposed on the left side of the mixing mechanism. The yarn drafting and mixing device can achieve synchronous drawing and mixing of two yarns of different colors of the same material for yarn collecting.

Owner:浙江常山康辉纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com