Method and device for preventing grain defect of wafer in use for vacuum system

A vacuum system and particle defect technology, applied in the direction of valve devices, electrical components, engine components, etc., can solve irreparable losses, affect the working time of the machine and other problems, and achieve the effect of ensuring continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

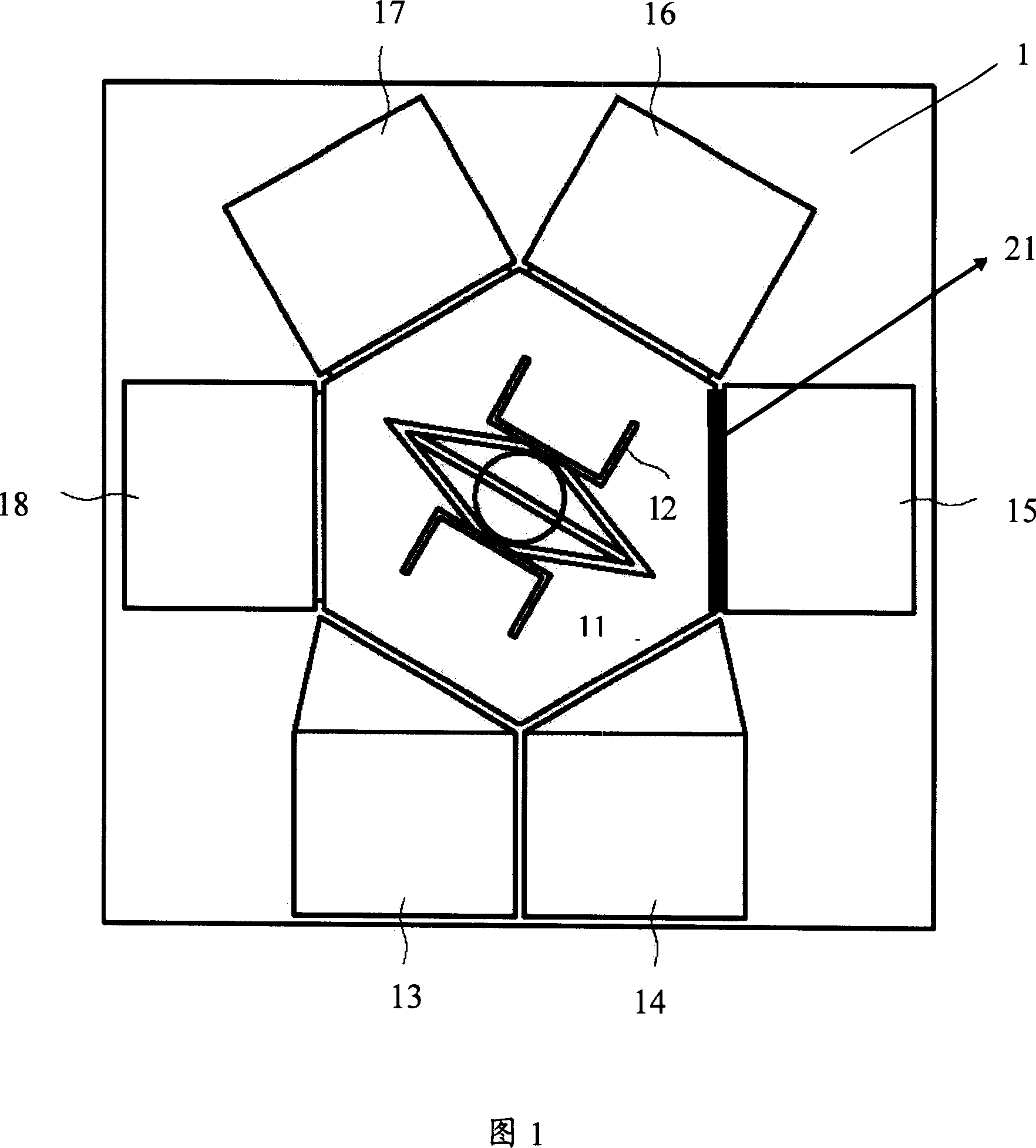

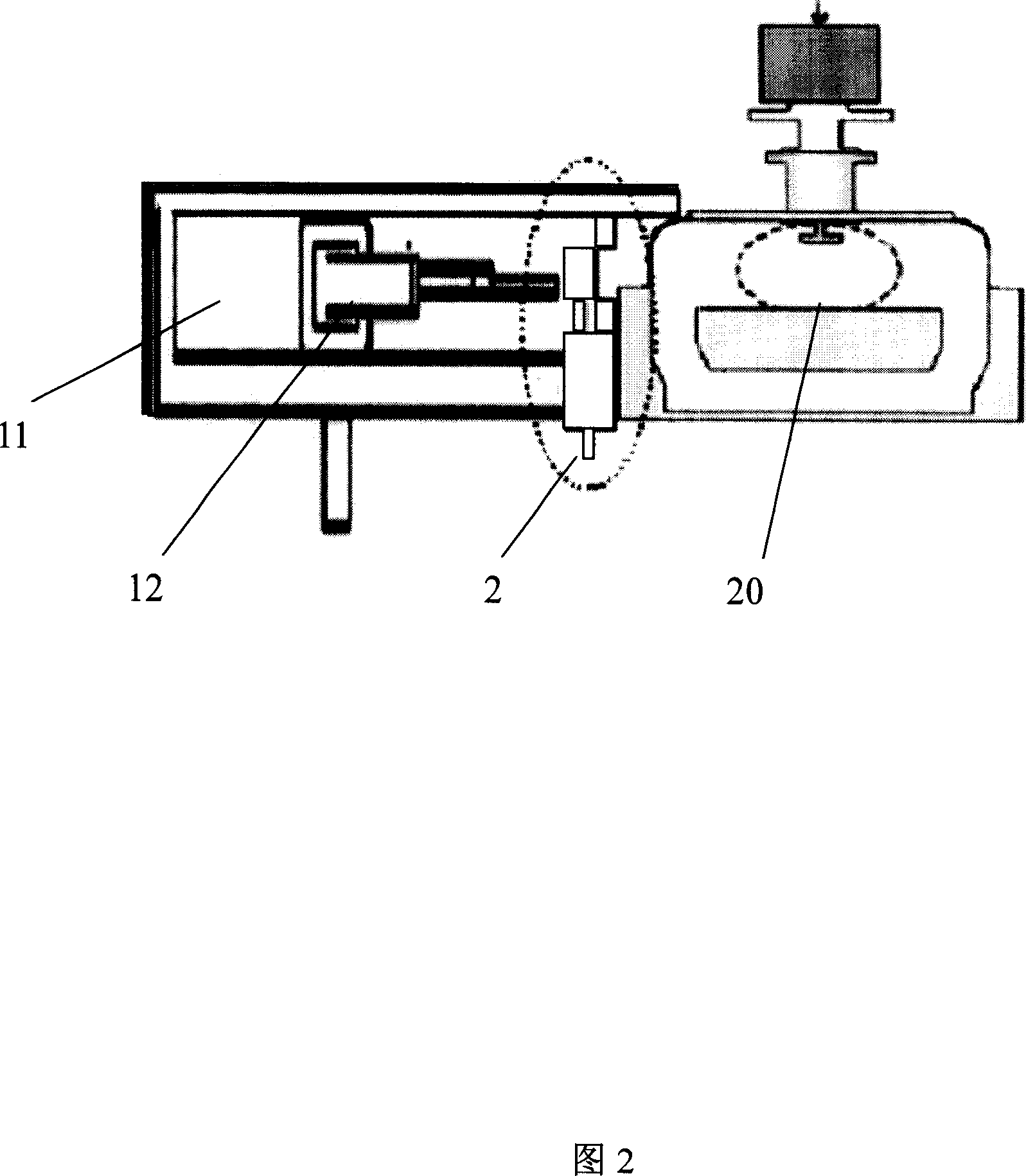

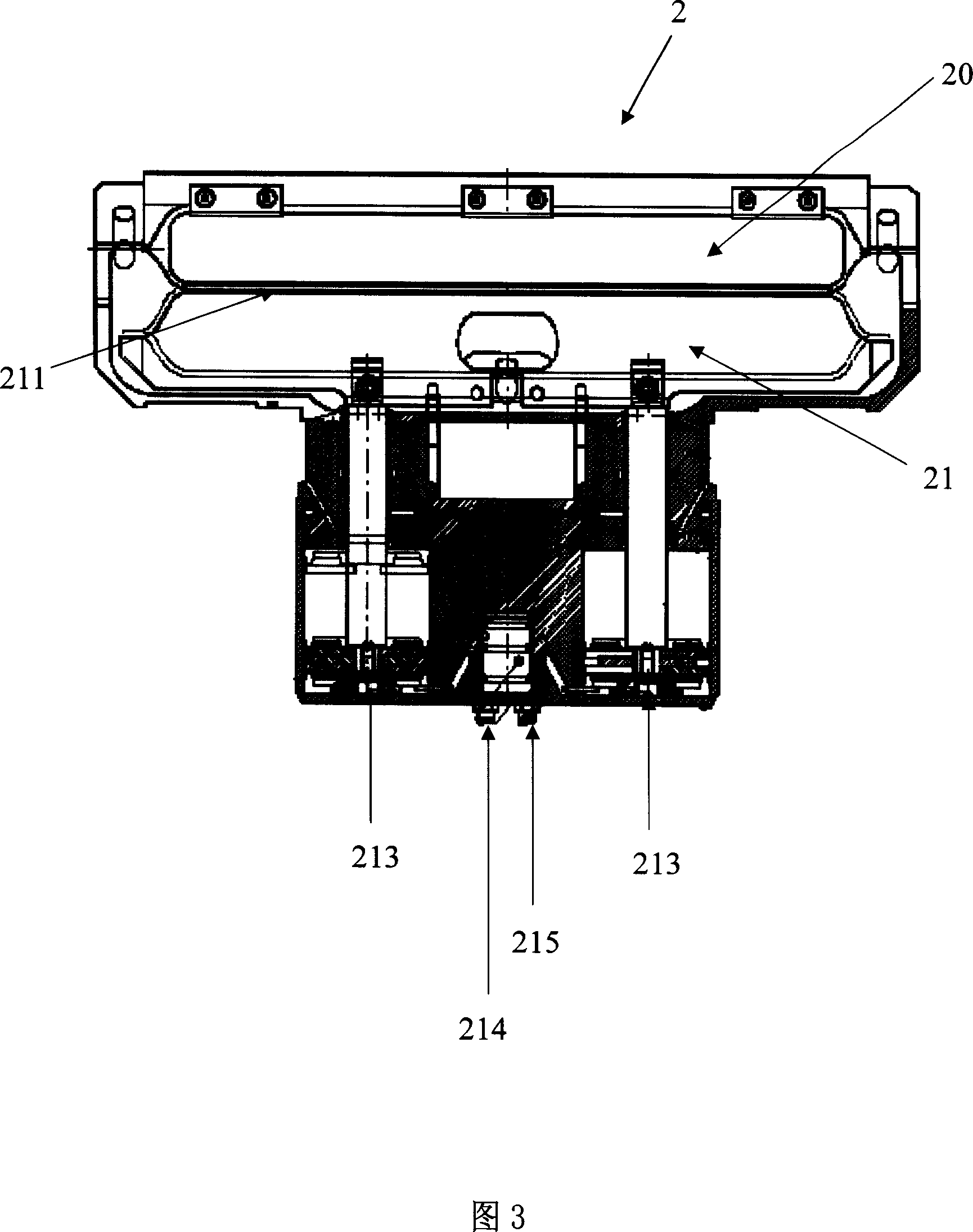

[0059] The method and device for preventing wafer particle defects in a vacuum system according to the present invention will be described in detail below with reference to the accompanying drawings.

[0060] The device for preventing wafer particle defects of the present invention comprises:

[0061] The on-off valve assembly is based on an on-off valve in the prior art, and an on-off valve is added. Therefore, it has a first on-off valve and a second on-off valve. The two valves are set upside down and serve as backup for each other. between bodies. The function of the switch valve is to isolate two different adjacent cavities when the switch valve is in the closed state, so that they can carry out different processes at the same time under different pressures. When the switch valve is in the open state, it provides wafers in and out. The channel of the cavity; the function of the double switch valve is to provide an additional switch immediately when the first switch valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com