Automatic charging system and automatic charging method of robot

A technology of automatic charging and robotics, applied in the field of robotics, can solve the problems of imperfection, exhaustion of robot power, failure of automatic charging, manual monitoring and other problems, so as to improve the degree of automation and ensure the effect of continuous work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

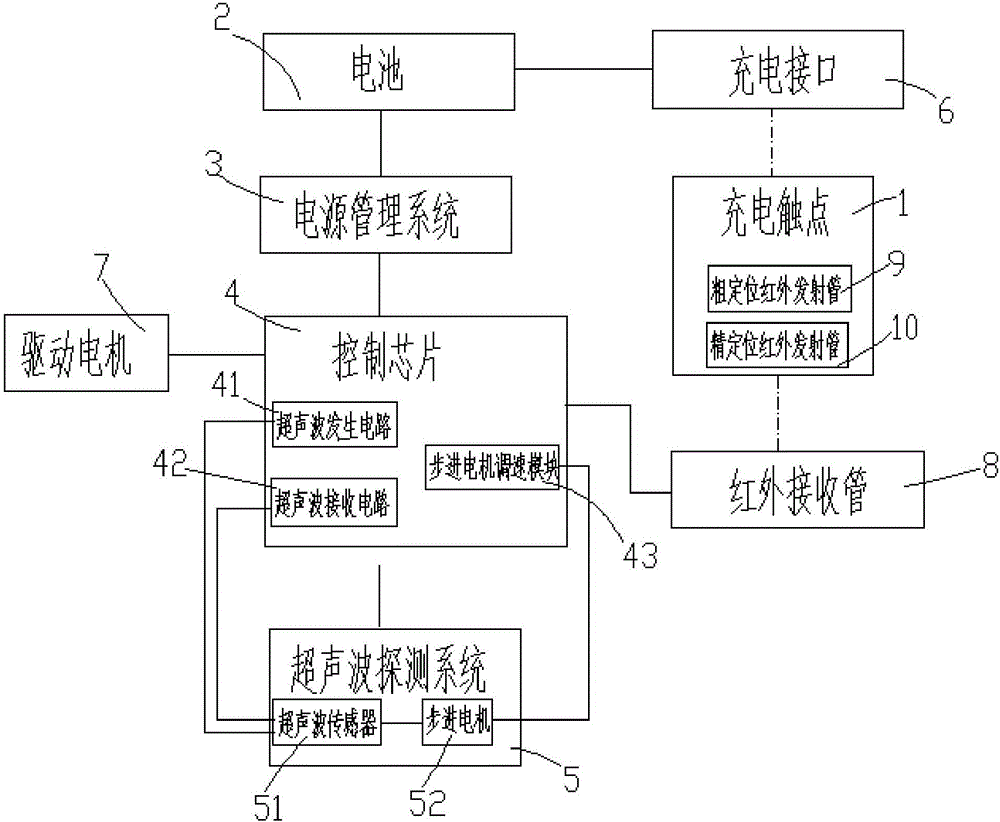

[0020] Such as figure 1 As shown, the automatic charging system of the robot provided in this embodiment includes a charging contact 1 and a battery 2 respectively arranged in the robot, a power management system 3, a control chip 4, an ultrasonic detection system 5, a charging interface 6 and a drive motor 7 , the power management system 3 is connected to the battery 2 and the control chip 4 respectively, the control chip 4 is also connected to the ultrasonic detection system 5 and the drive motor 7 respectively, the charging interface 6 matches the charging contact 1, and the charging interface 6 is connected to the battery 2. The power management system 3 can monitor the power usage of the battery 2 in real time, and feed back the power usage to the control chip 4 in real time. When the remaining power of the battery 2 is less than 20%, the control chip 4 starts the automatic charging operation. At this time, the ultrasonic The detection system 5 starts to operate, starts u...

Embodiment 2

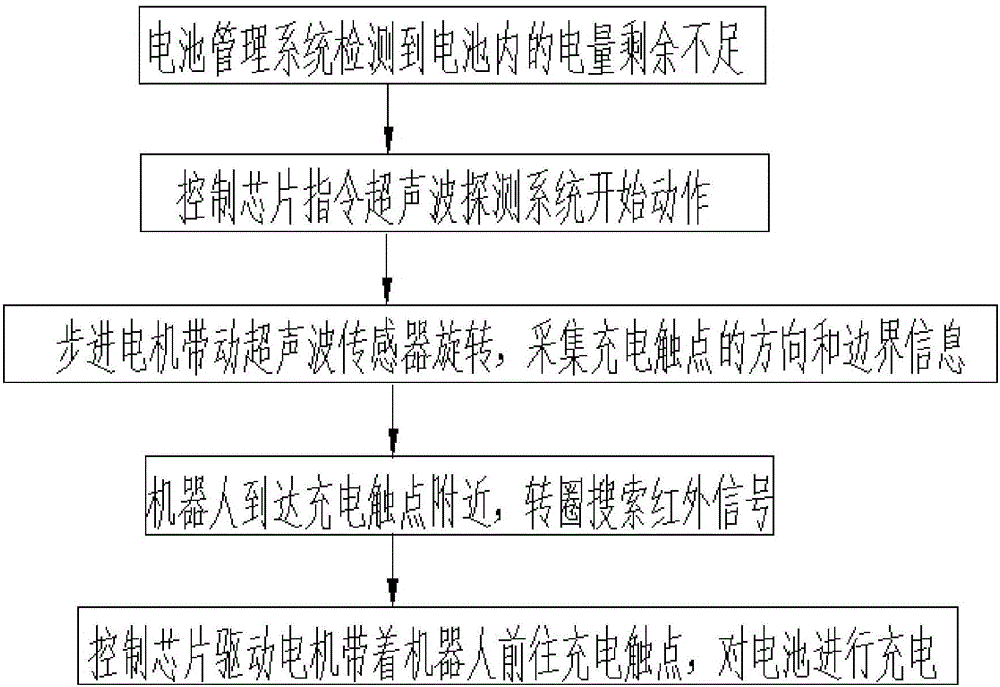

[0027] A method for automatic charging using the automatic charging system of the present invention provided in this embodiment at least includes the following steps:

[0028] When the power management system 3 detects that the power remaining in the battery 2 is less than 20%, the power management system 3 sends the signal to the control chip 4, and the control chip 4 instructs the ultrasonic detection system 5 to start operating to search and locate the charging contact 1 position, and then the ultrasonic detection system 5 sends the position information to the control chip 4, and the control chip 4 instructs the drive motor 7 to take the robot to the position of the charging contact 1, so that the charging interface 6 contacts the charging contact 1, and the battery 2 is charged. Charge.

[0029] When the ultrasonic detection system 5 is working, the stepping motor 52 drives the ultrasonic sensor 51 to rotate, and the stepping motor 52 rotates one step, the ultrasonic senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com