Folding automatic charging mechanical arm and electric vehicle carried with same

A technology for automatic charging and electric vehicles, applied in the direction of electric vehicles, electric vehicle charging technology, charging stations, etc., can solve the problem of failure to fully realize the intelligentization of electric vehicle charging, low flexibility and practicability of charging devices, and insufficient space utilization Sufficient and other issues to achieve the effect of mentioning docking speed and accuracy, avoiding potential safety hazards and wrong operations, and ensuring charging needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

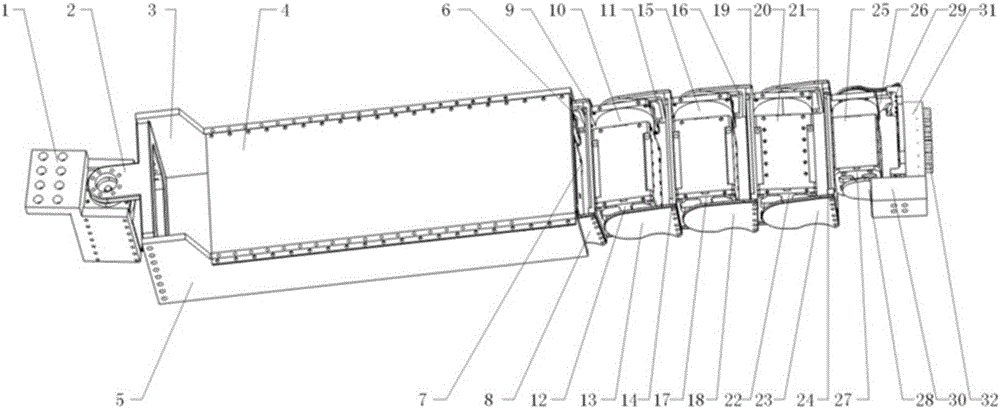

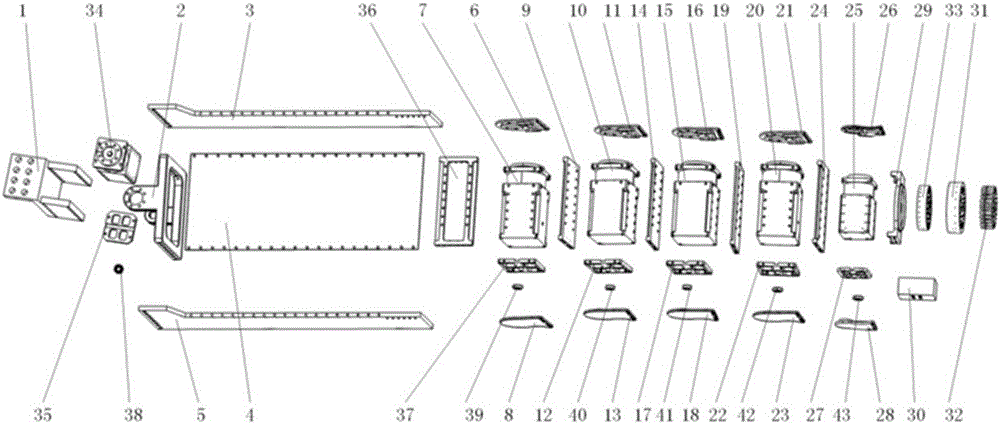

[0047] A foldable self-charging robotic arm with a structure such as figure 1 and figure 2 shown. The mechanical arm is made of aluminum alloy material.

[0048] The mechanical arm body consists of a swing arm fixing plate 1, a first joint, a connecting plate left guard plate 3, a connecting plate right guard plate 5, a cover plate 4, five parallel joints, an end plug and a camera 30.

[0049] One end of the swing arm fixing plate 1 is embedded on the chassis of the electric vehicle, so that the mechanical arm is connected with the electric vehicle.

[0050] The first joint includes the mechanical arm connecting plate 2, the first steering gear 34, the first joint bearing frame 35 and the rolling bearing 38 to form the first joint, and the first steering gear 34 controls the rotation of the first joint moving parts; the first steering gear 34 and the swing arm The other end of the fixed plate 1 is connected, and the upper end of the first steering gear 34 is directly threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com