Wireless automatic charging method of automobile

A technology of automatic charging and wireless charging, which is applied in the direction of electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of inconvenient power receiving devices for charging devices, occupying land resources, and limited number of cars, so as to save precious time and save Land resources, the effect of solving charging difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

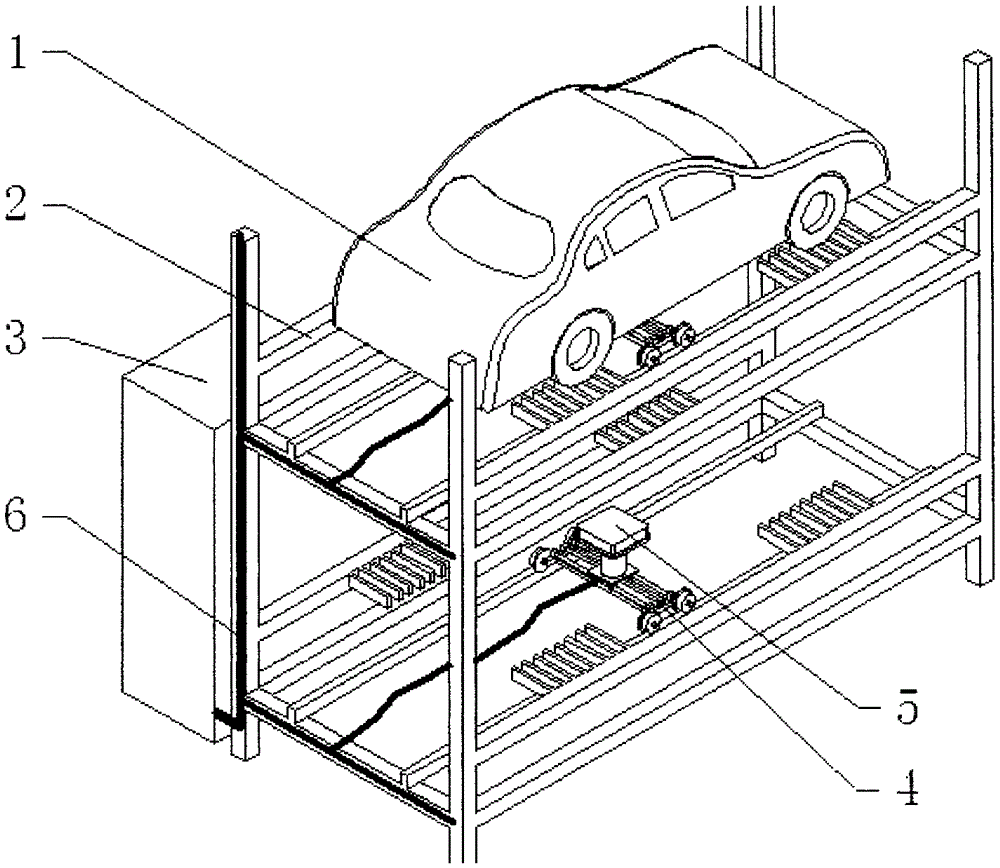

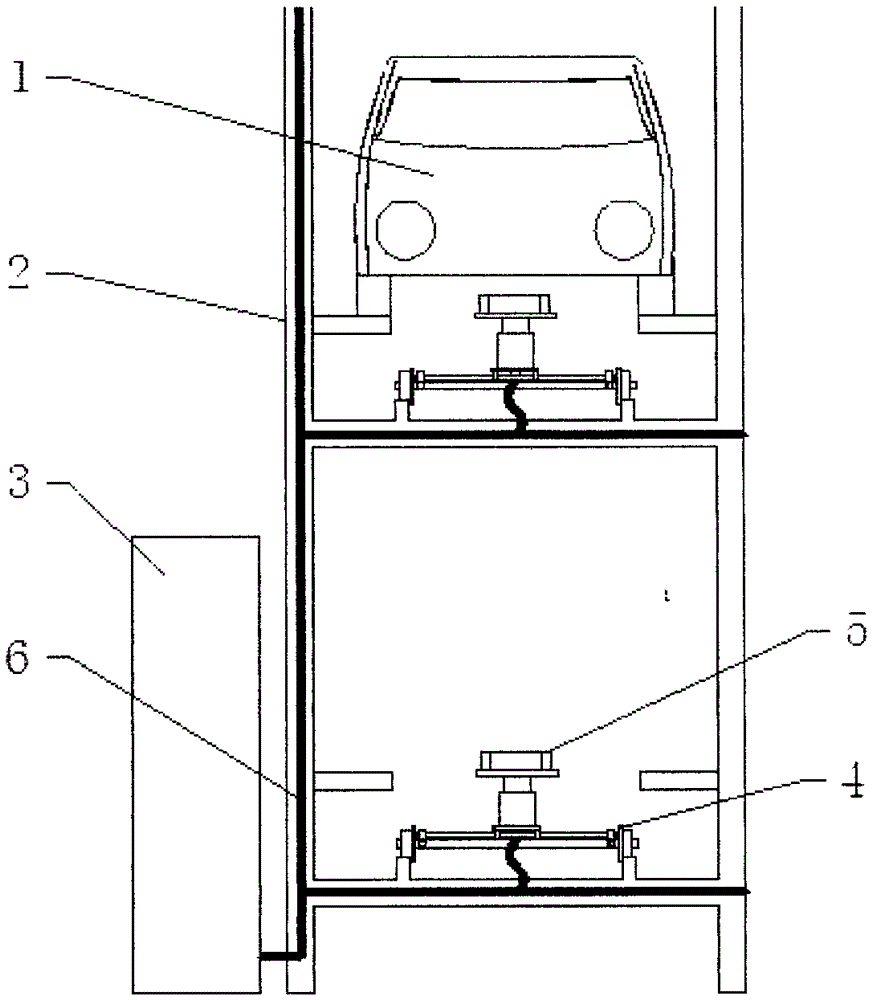

[0026] The structure of a kind of embodiment 1 of the present invention is as Figure 4 to Figure 7 As shown, the supporting platform assembly 4 is an XYZ three-axis structure, including an X-axis moving platform 402, a Y-axis moving platform 401, and a Z-axis lifting platform 403. Driven by the control system, the supporting platform assembly 4 can move along the X and Y directions, and can Lifting along the Z-axis direction drives the wireless charging device 5 on the supporting platform assembly 4 to move along the X, Y, and Z directions.

[0027] After the control system receives the charging command, the first step is to drive the supporting platform assembly 4 and the wireless charging device 5 to move on the XY plane at the bottom of the car 1 to be charged according to the trajectory set by the program, and to detect the position of the car 1 to be charged in the parking space unit 2. The position of the power receiving device; the second step, when the position of the...

Embodiment 2

[0030] The only difference between this embodiment and Embodiment 1 is that the supporting platform assembly 4, the structure of this embodiment is as follows Figure 8 to Figure 11 As shown, the support platform assembly 4 is a mechanical arm structure, including an arm 413 that rotates around a shaft 414, an arm 411 that rotates around a shaft 412, and a Z-axis lifting platform 403. The control system drives the arm 413 and the arm 411 around the shaft 414 and The axis 412 rotates, so that the Z-axis lifting platform 403 and the wireless charging device 5 can move on the XY plane at the bottom of the car 1 to be charged according to the trajectory set by the program, and detect the position of the power receiving device of the car 1 to be charged in the parking space unit 2 .

[0031] This embodiment is driven by a motor or a hydraulic cylinder, and is especially suitable for a three-dimensional garage.

Embodiment 3

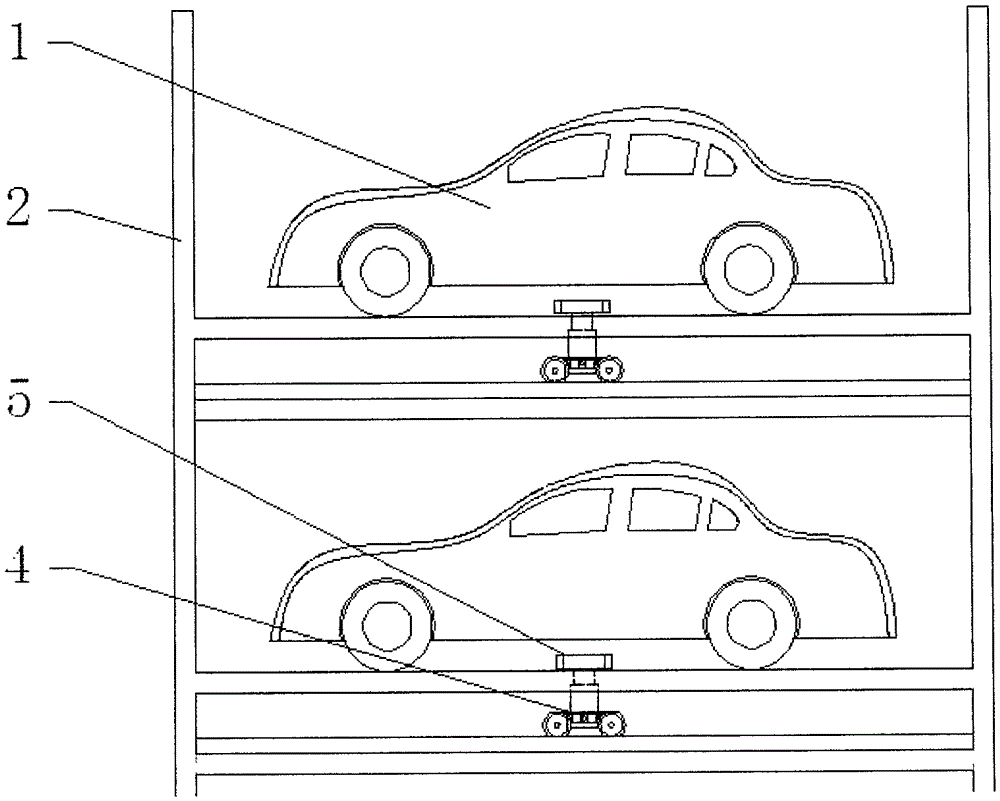

[0033] The only difference between this embodiment and Embodiment 1 is that the supporting platform assembly 4, the structure of this embodiment is as follows Figure 12 to Figure 14 As shown, the supporting platform assembly 4 is an intelligent mobile robot structure, including an intelligent robot 422 with universal wheels 423 and a platform 421 that can be lifted along the Z axis. Driven by the control system, the intelligent mobile robot 422 can follow the trajectory set by the program. The bottom of the car to be charged moves on the XY plane to detect the position of the power receiving device of the car to be charged 1 in the parking space unit 2 .

[0034] This embodiment is driven by a motor or a hydraulic cylinder, and is especially suitable for flat places such as charging stations and common garages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com