Petroleum coke transportation, dehydration and storage equipment for delayed coking

A delayed coking and storage equipment technology, applied in the petroleum industry, conveyor objects, coking carbon-containing materials, etc., can solve the problems of large coke-water mixture, slow processing speed, and high equipment cost, and achieve low equipment cost and fast processing speed , to avoid the effect of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

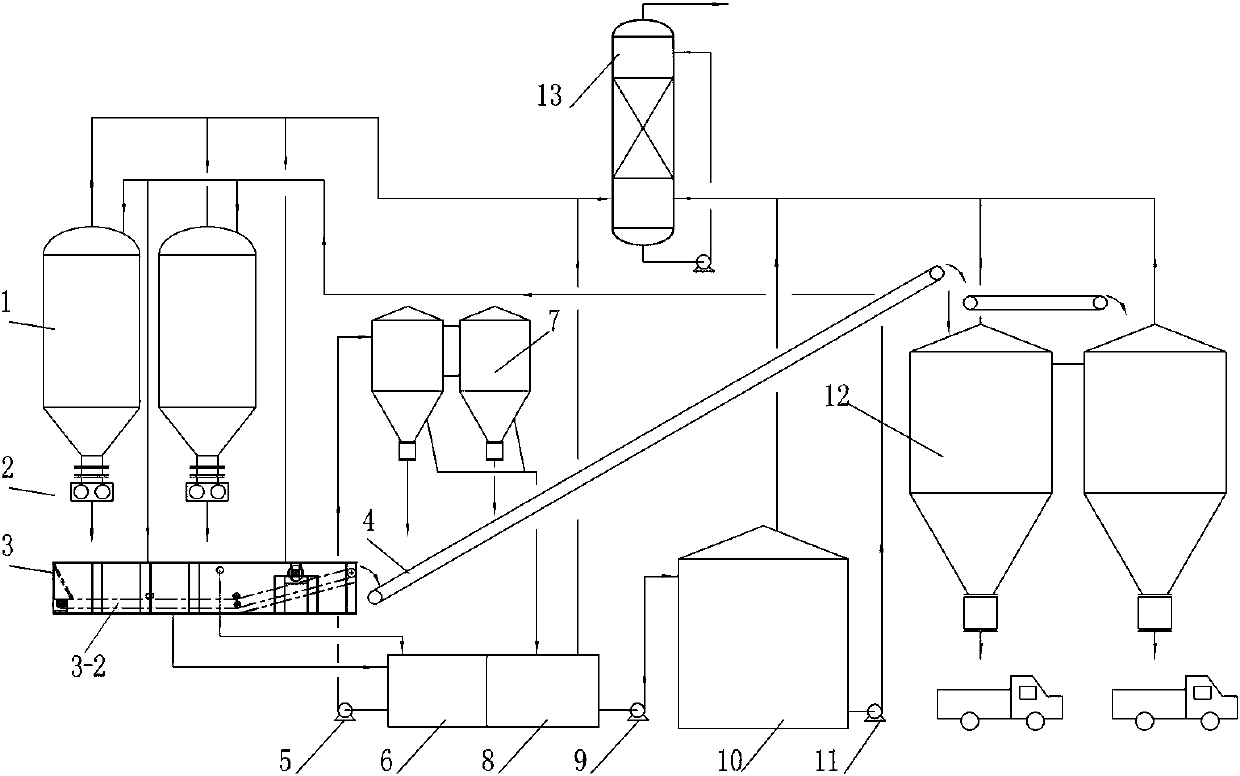

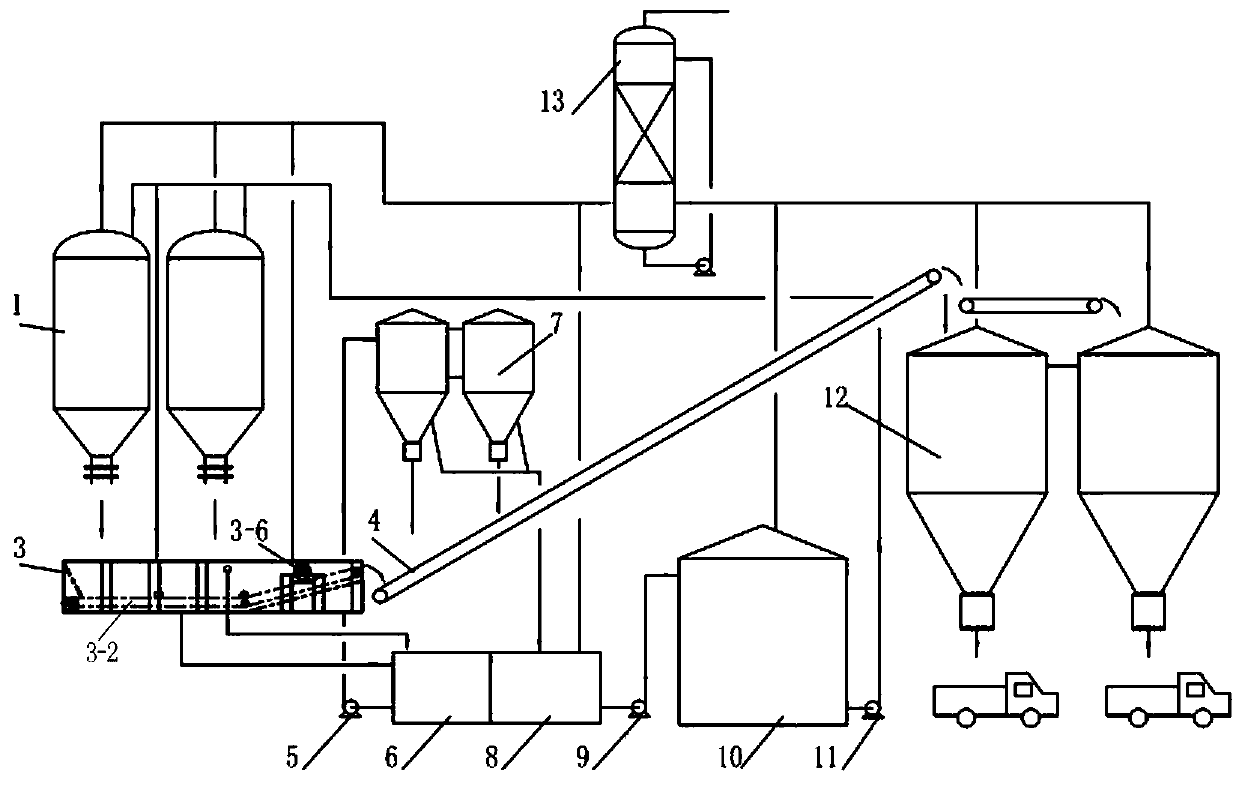

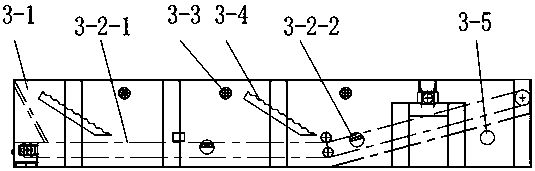

[0022] Such as figure 1 with 2 As shown, the petroleum coke transportation, dehydration and storage equipment for delayed coking of the present invention mainly includes coke water separator 3, dehydration tank 7, coke storage tank 12, water purification temporary storage tank 8 and other components. Among them, the coke water separator 3 is used to receive the coke water mixture discharged from the coke tower 1, and the coke water mixture mixed with small particles of coke discharged from the coke water separator 3 is sent to the dehydration tank 7, and the coke is dehydrated by the dehydration tank 7 . The coke outlet and the recovered water outlet of the dehydration tank 7 are respectively connected (including direct connection and indirect connection) to the coke storage tank 12 and the clean water temporary storage tank 8, the coke storage tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com