Patents

Literature

578results about "Discharging devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

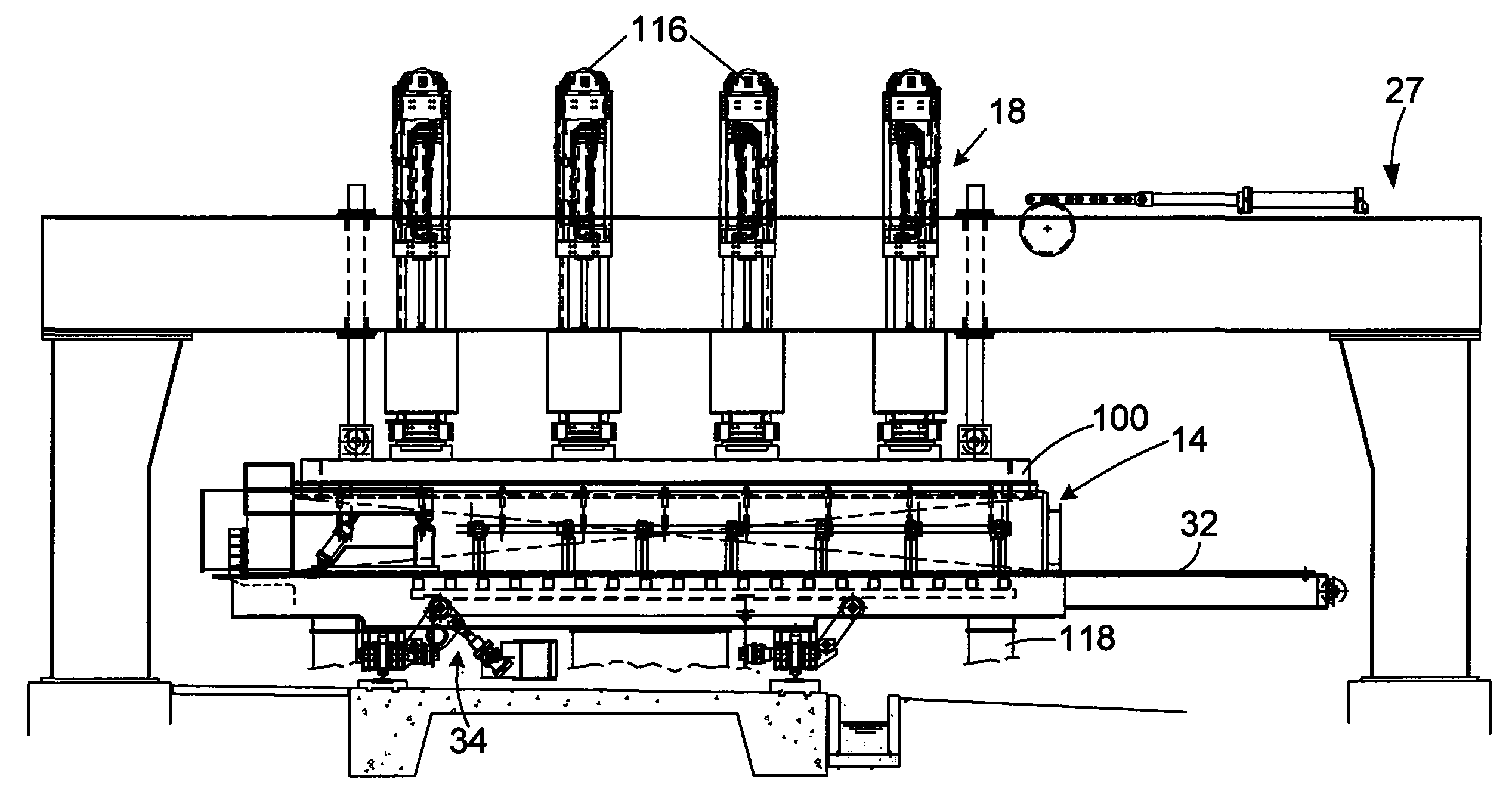

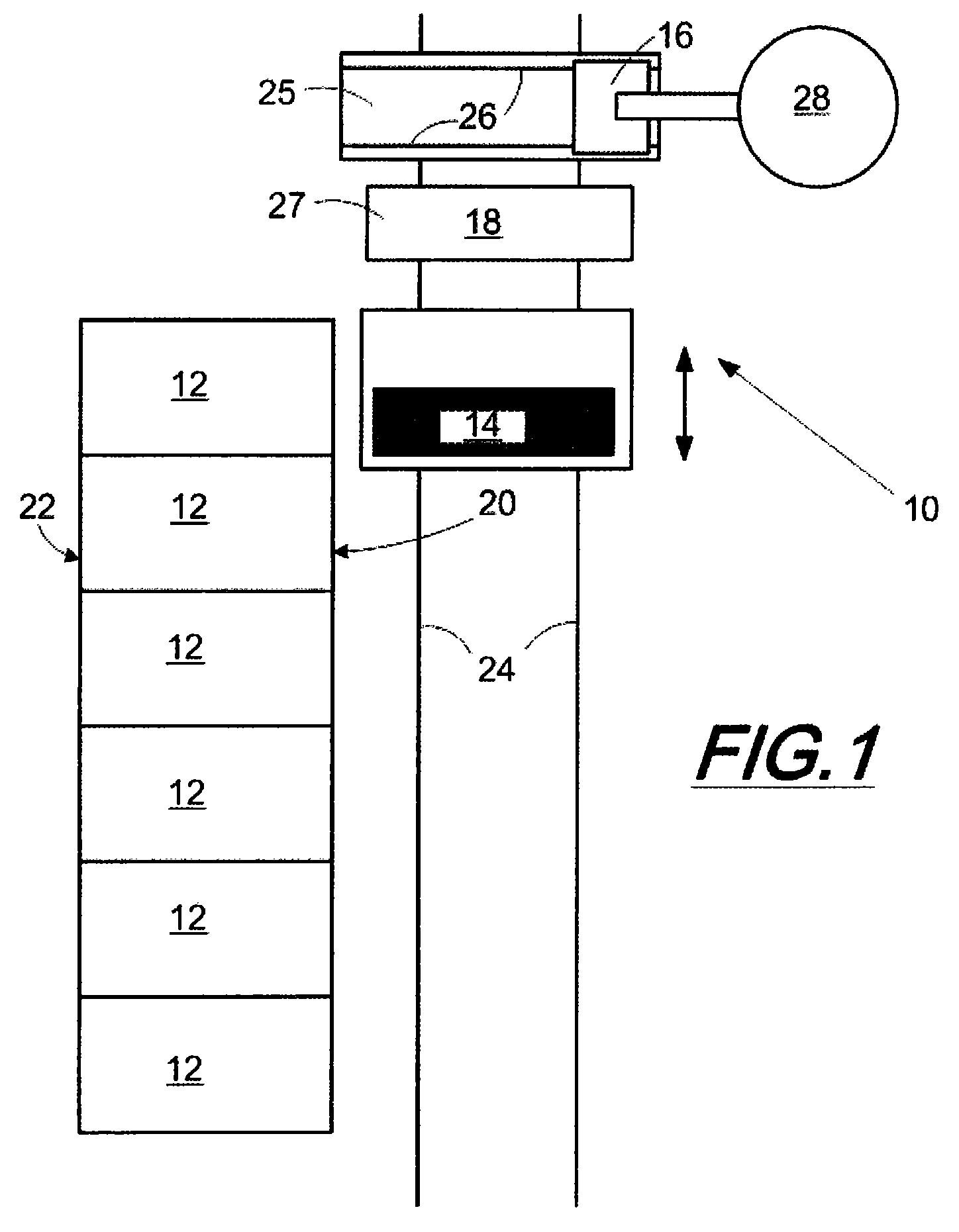

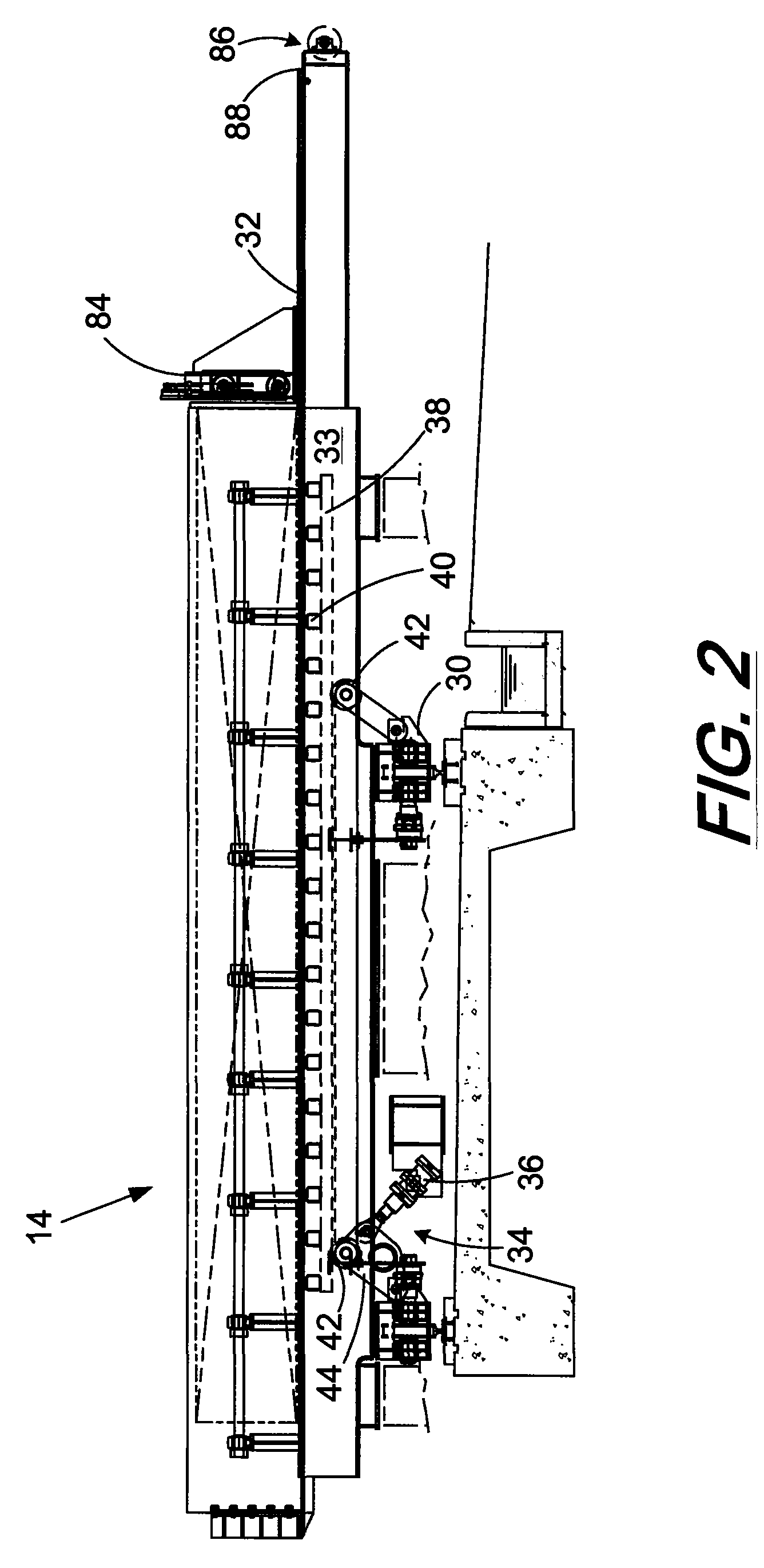

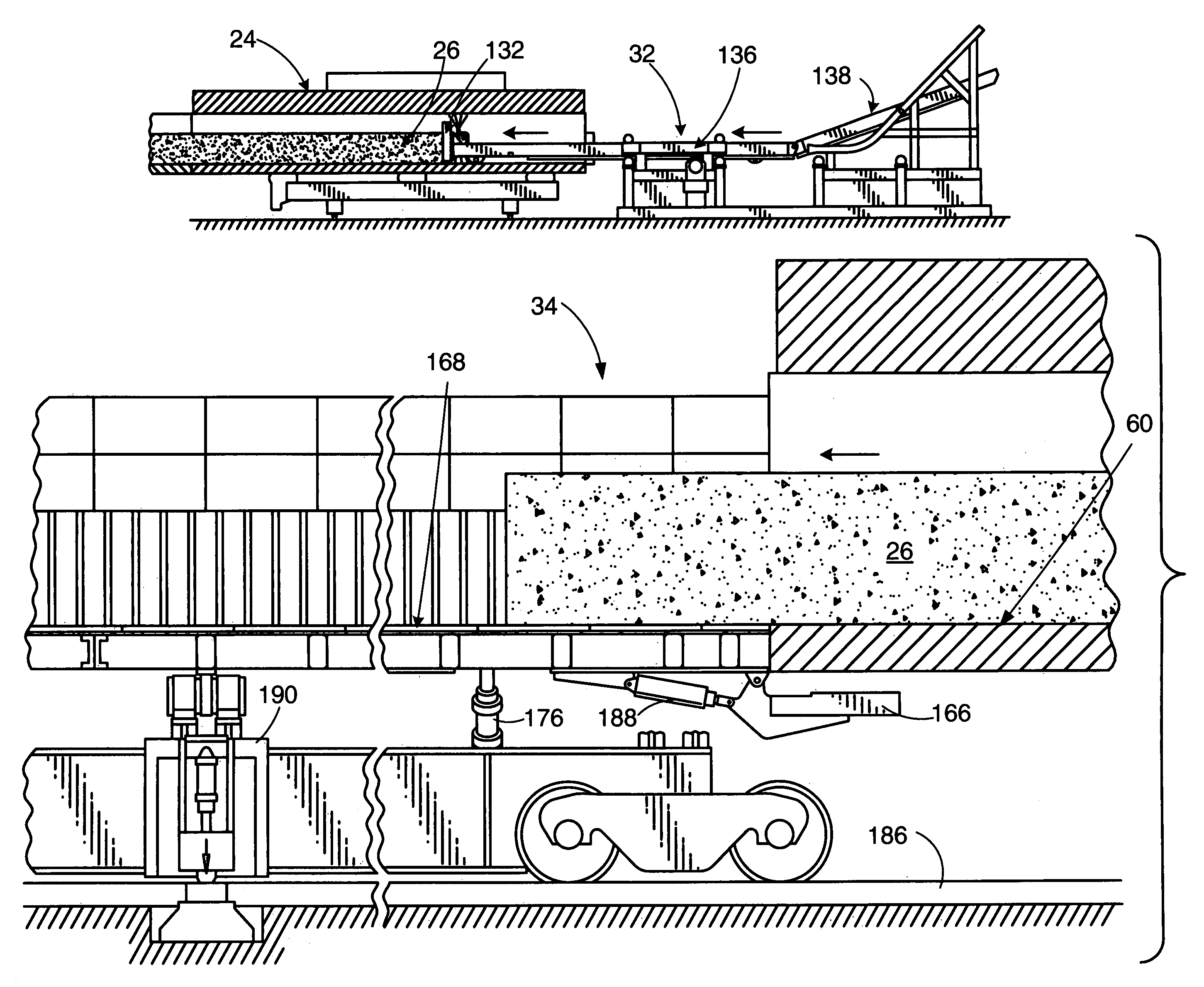

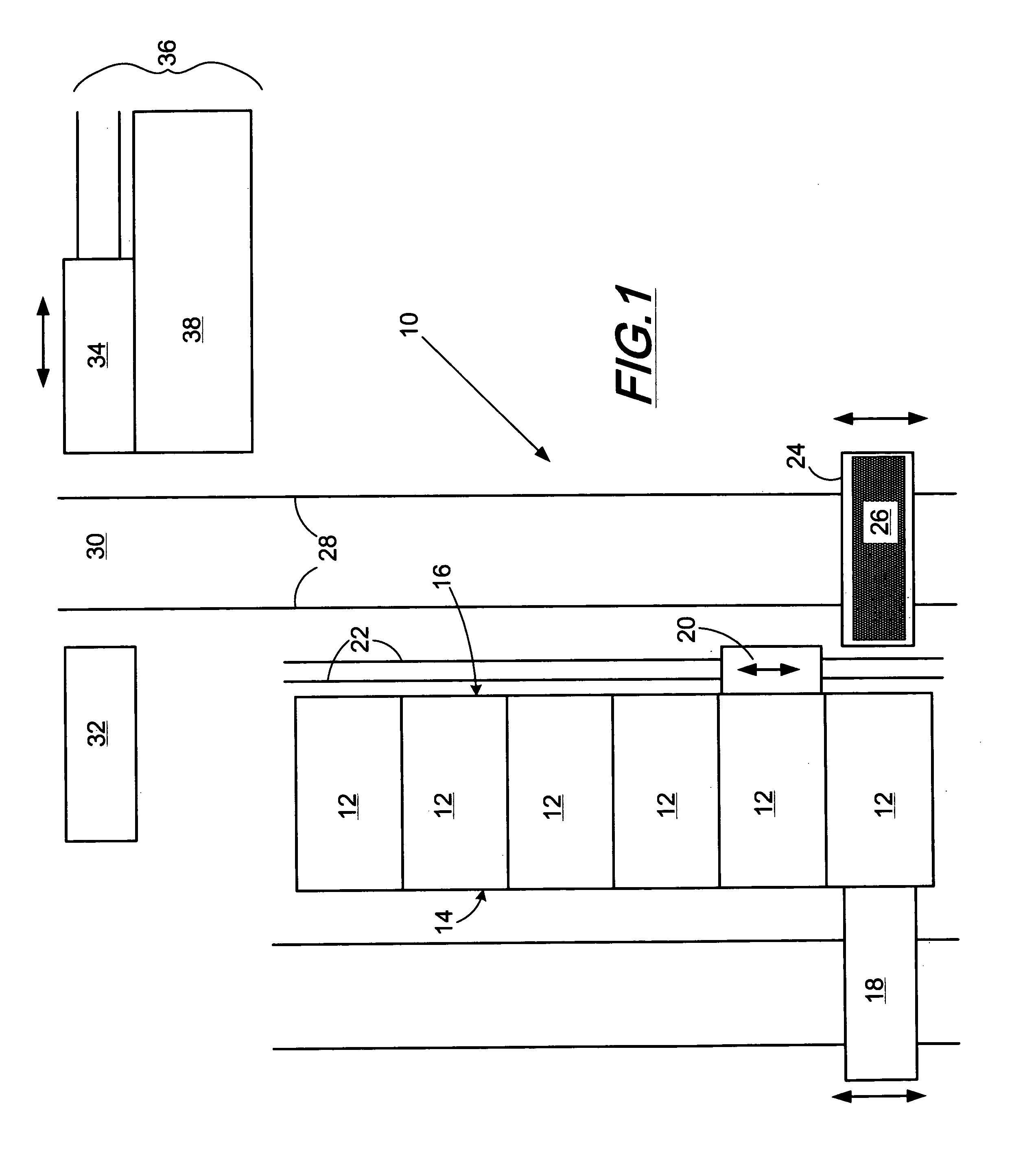

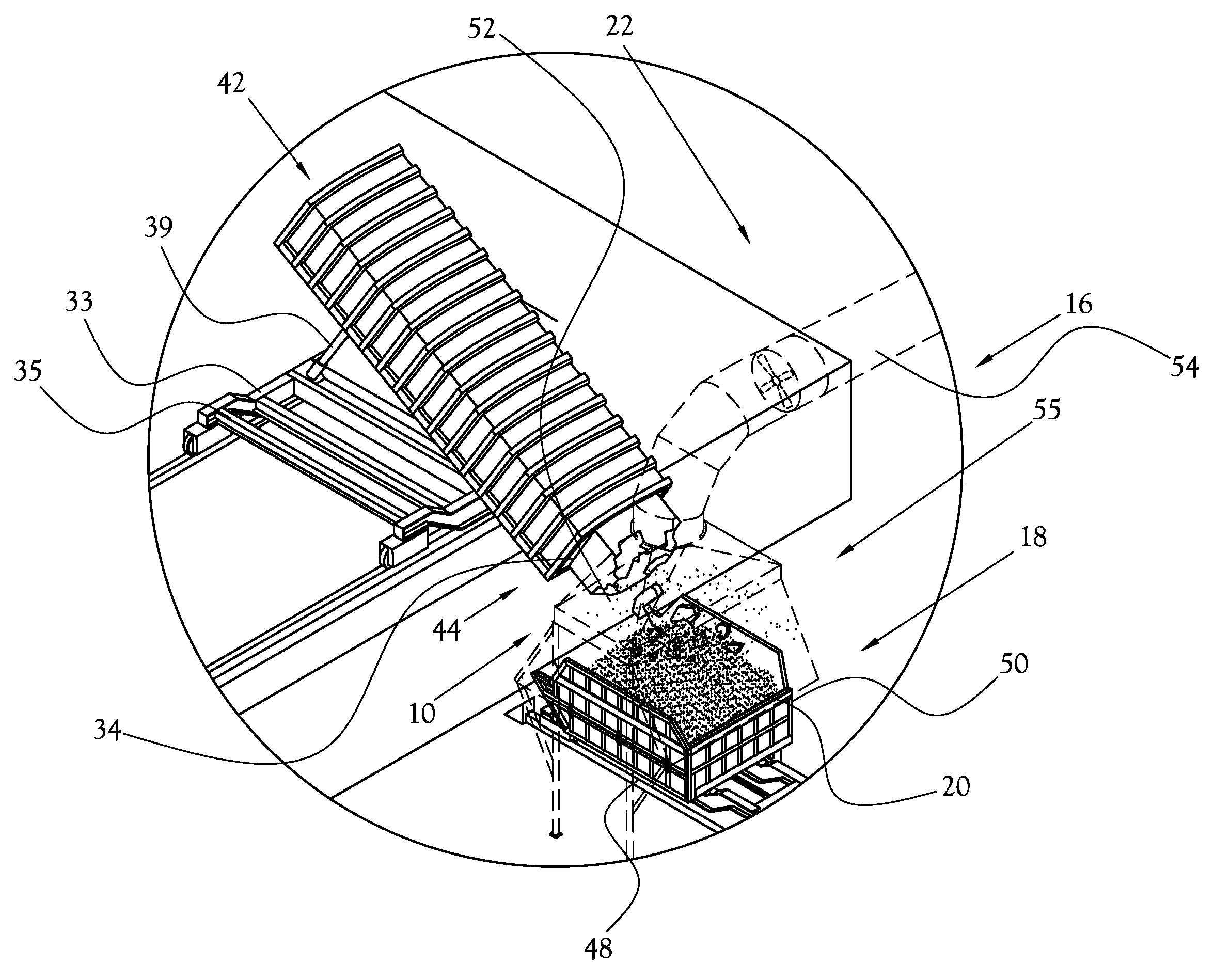

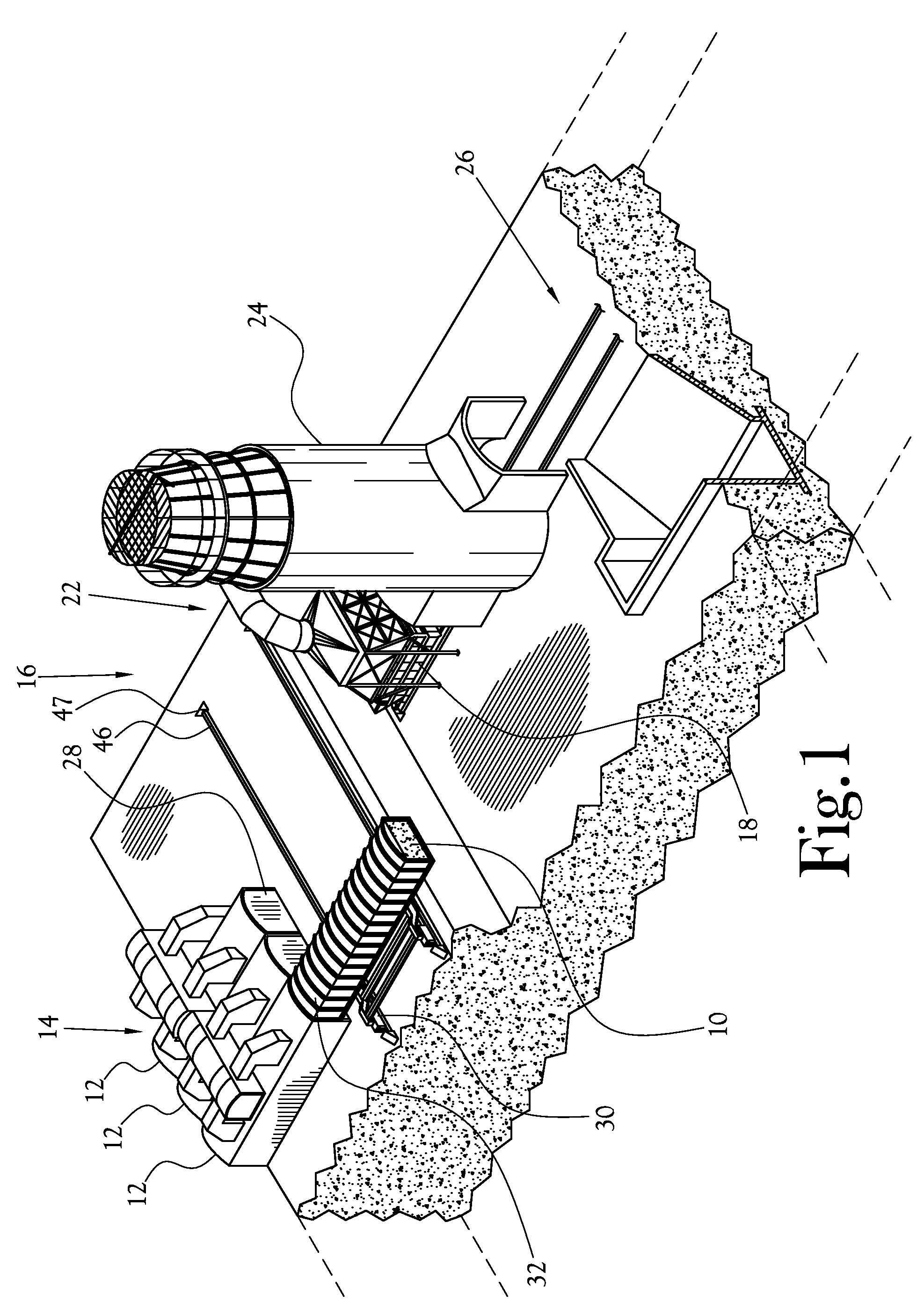

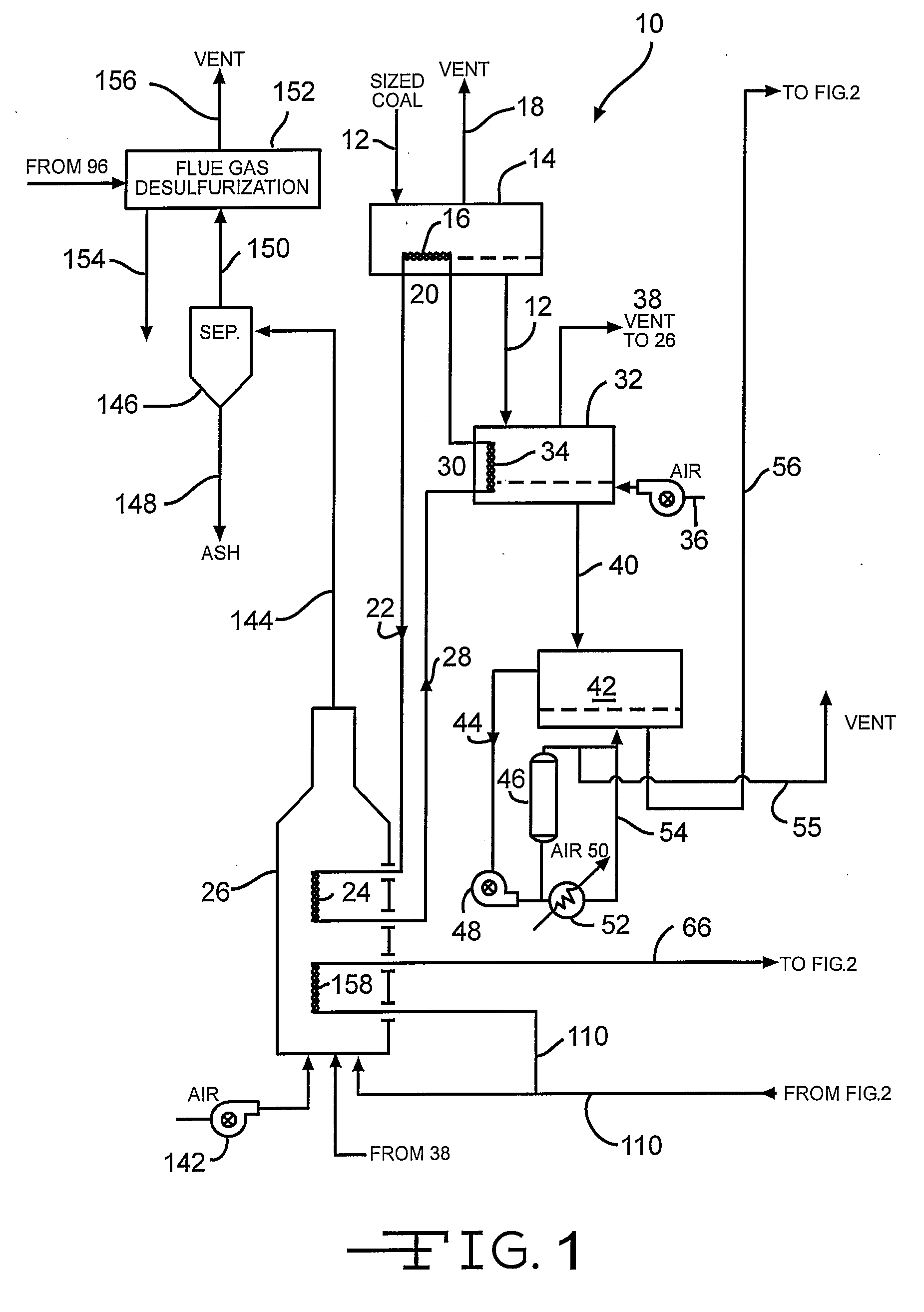

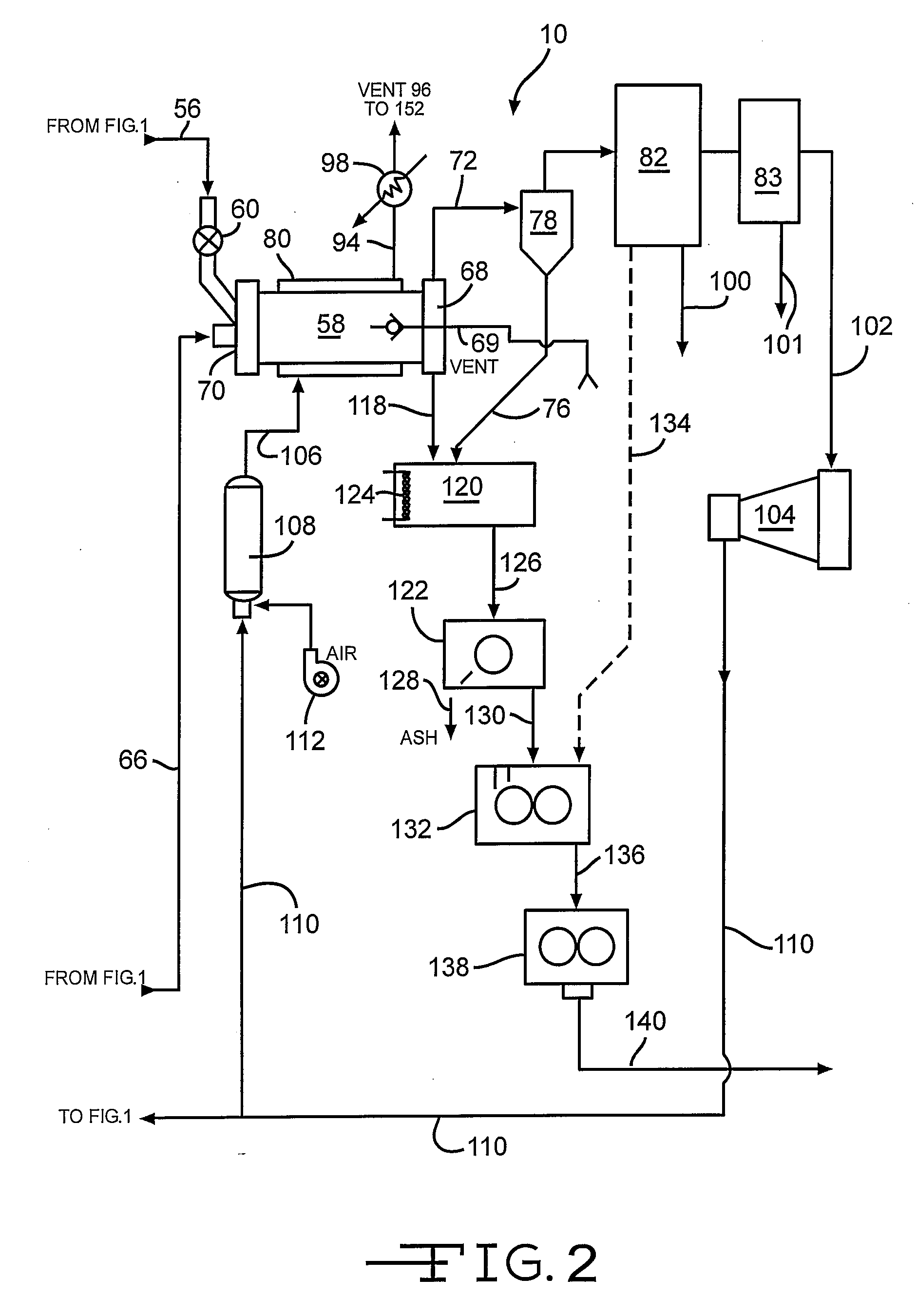

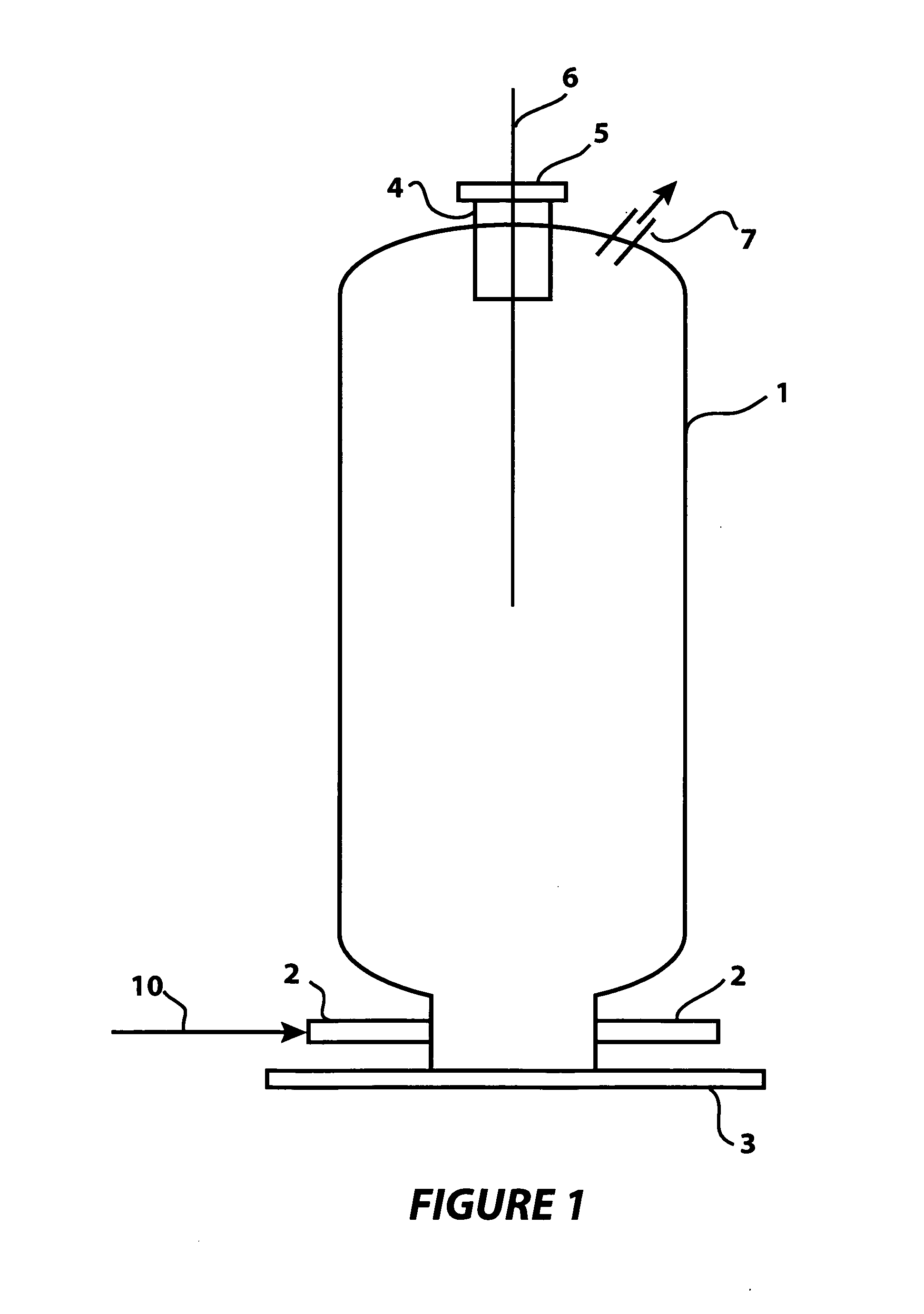

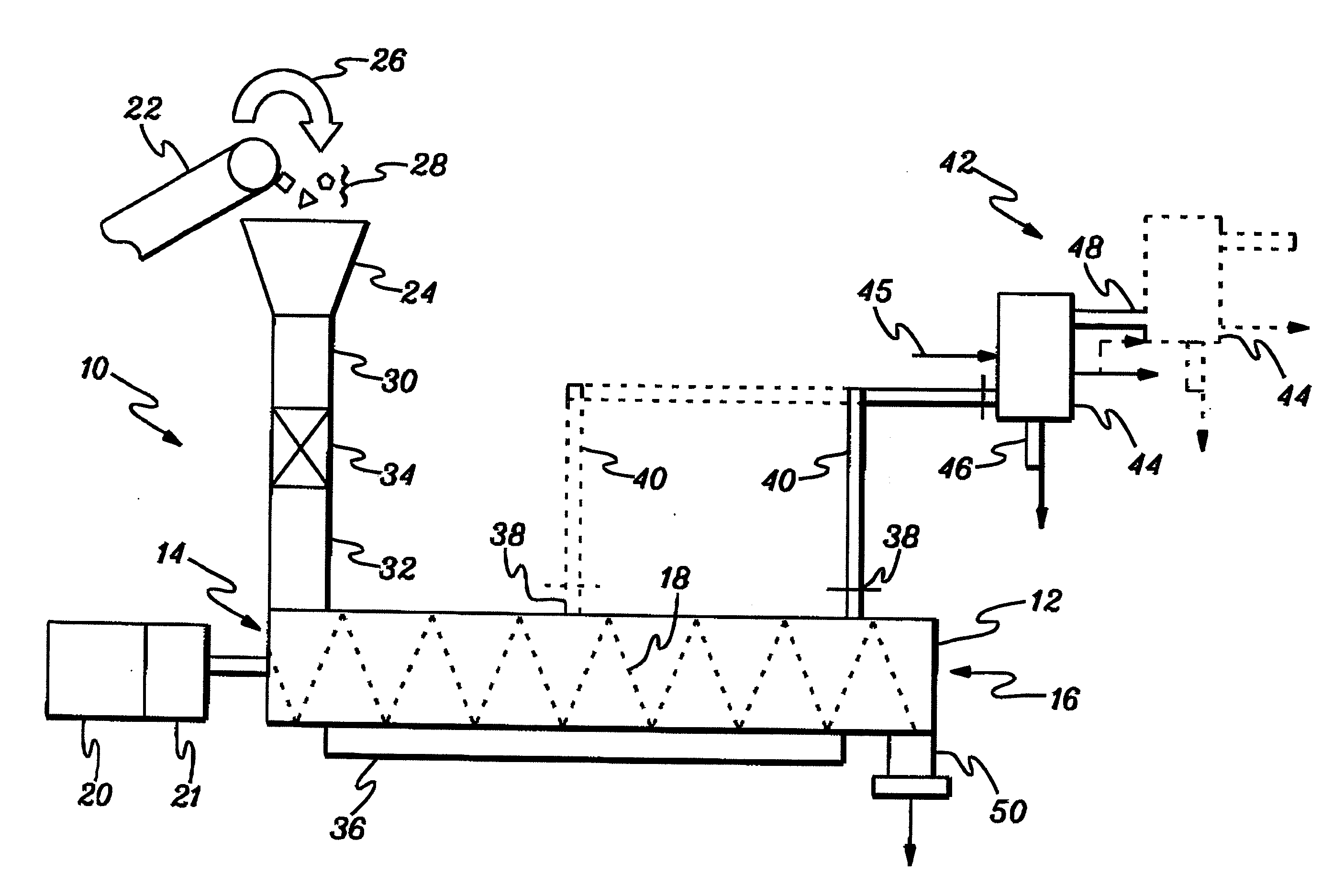

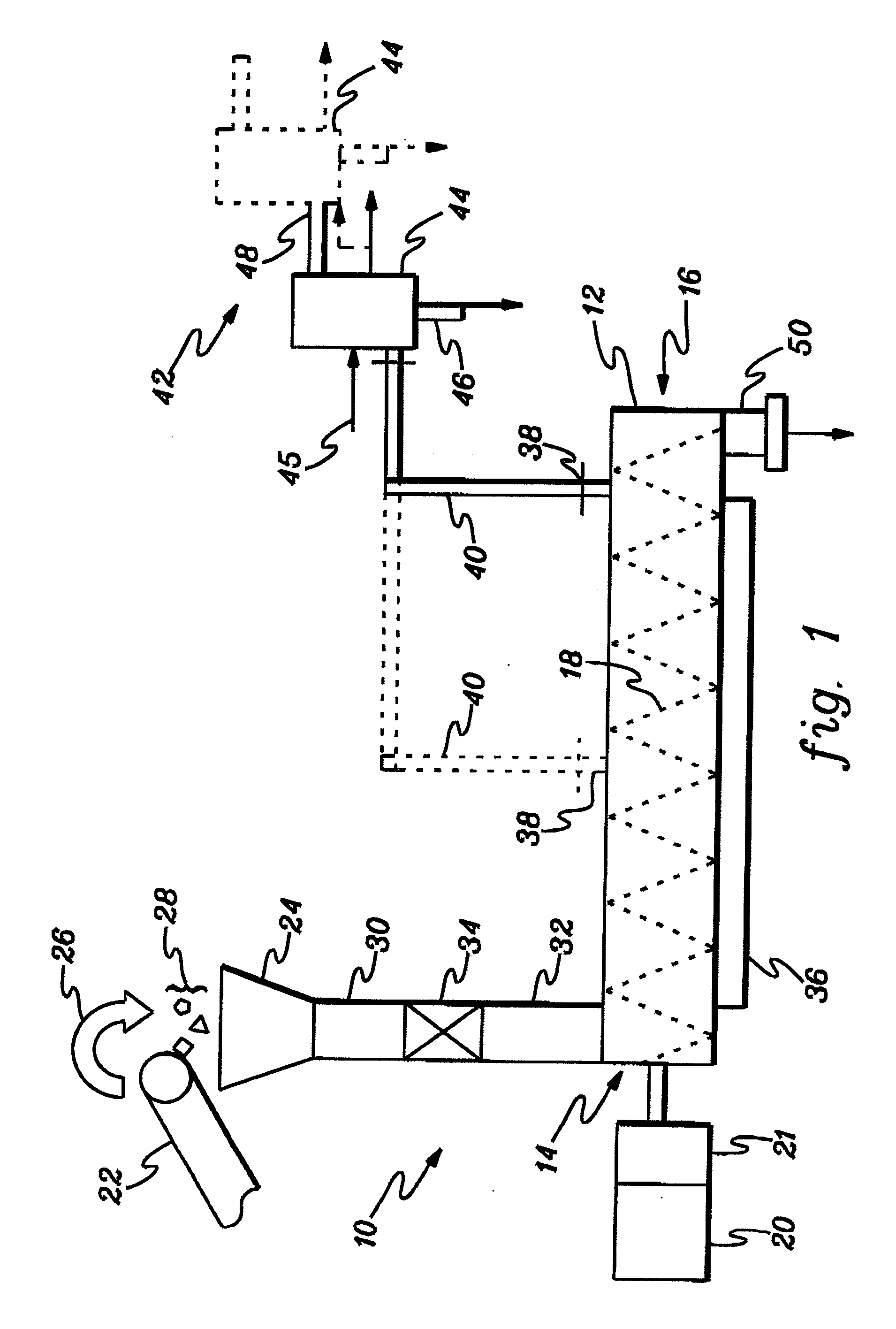

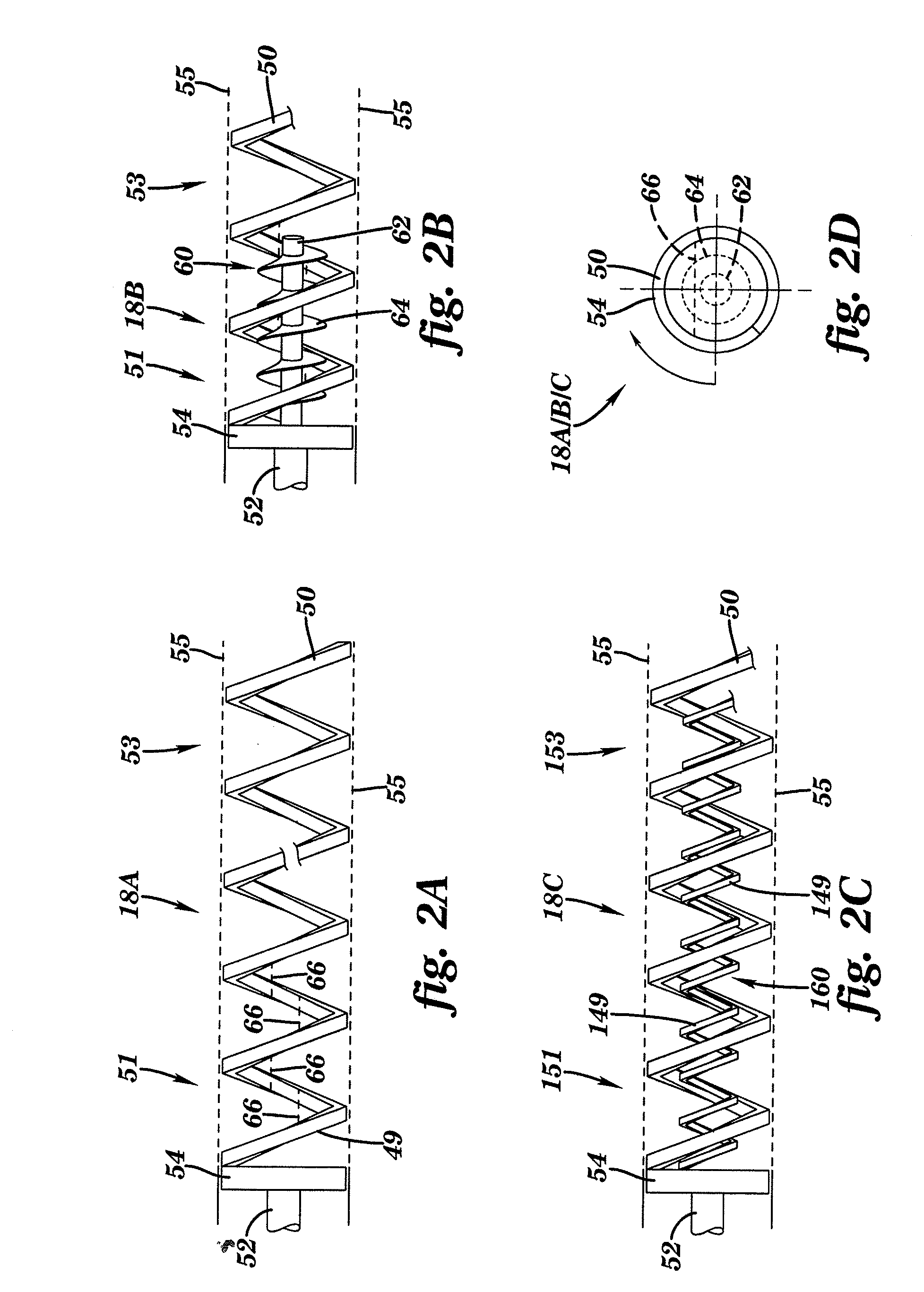

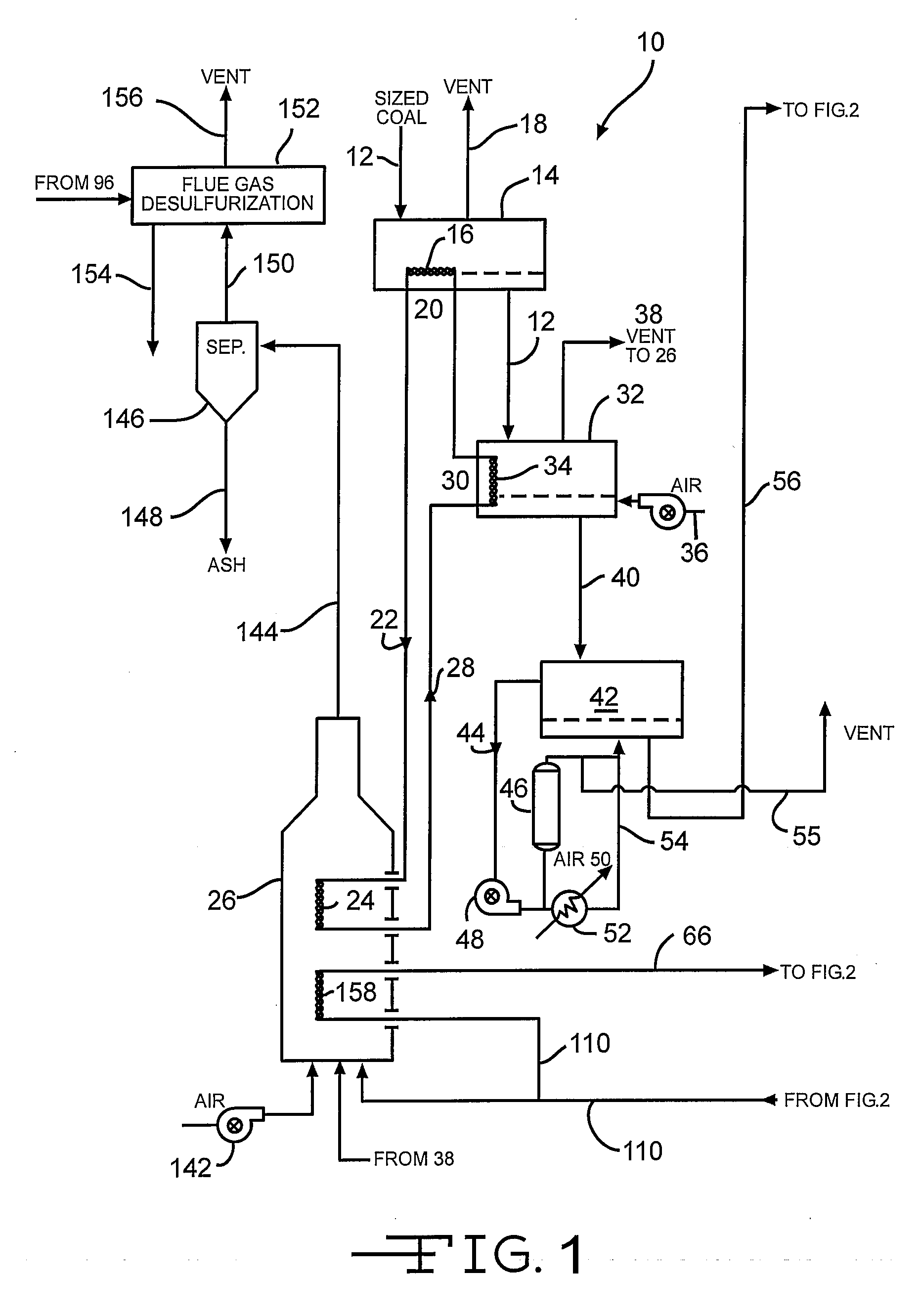

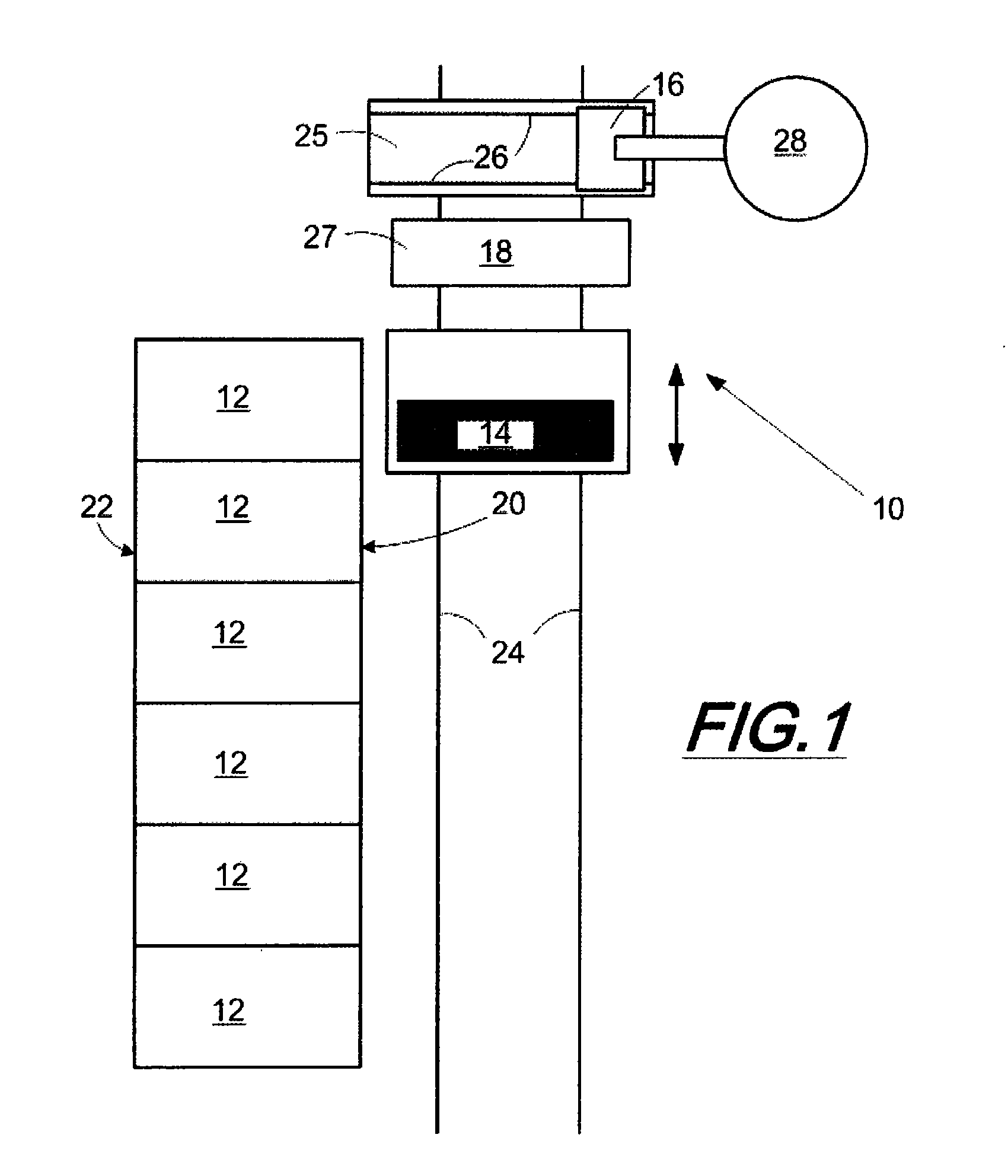

Method and apparatus for compacting coal for a coal coking process

InactiveUS7497930B2Minimize amount of timeUniform bulk densityCoke quenchingCharging-discharging device combinationsEngineeringCoke oven

Relatively high speed methods for increasing the bulk density of coal particles, apparatus for increasing the bulk density of coal particles and methods for making metallurgical coke. Once such method includes depositing coal particles onto a charging plate external to a coking oven to provide an elongate bed of dry, uncompacted coal having an upper surface of the charging plate. The charging plate has side walls, and at least one movable end wall An impact pressure is applied to the upper surface of the bed of dry, uncompacted coal while degassing the coal to provide a dry, compacted coal bed having a bulk density ranging from about 960 to about 1200 kilograms per cubic meter.

Owner:SUNCOKE TECH & DEV LLC

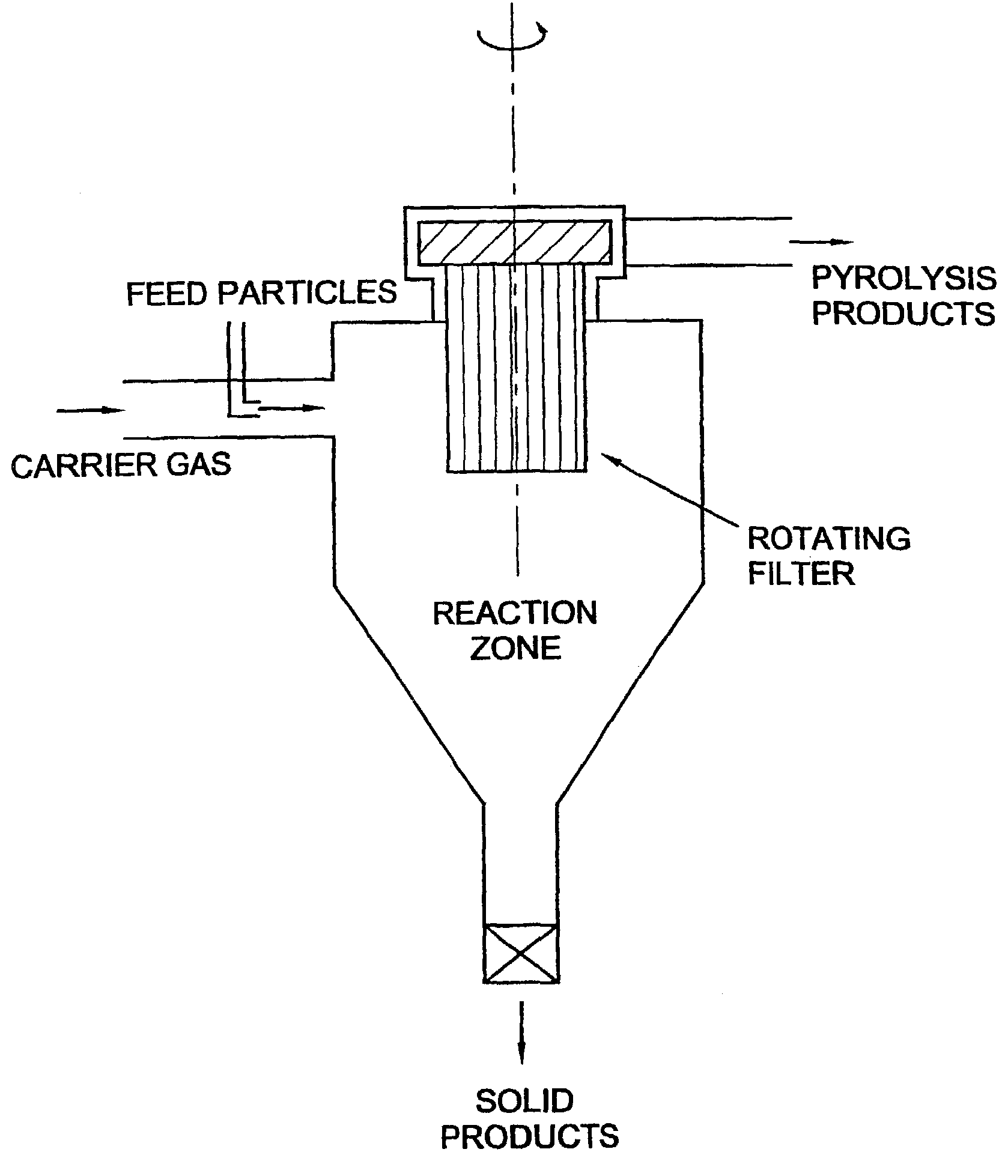

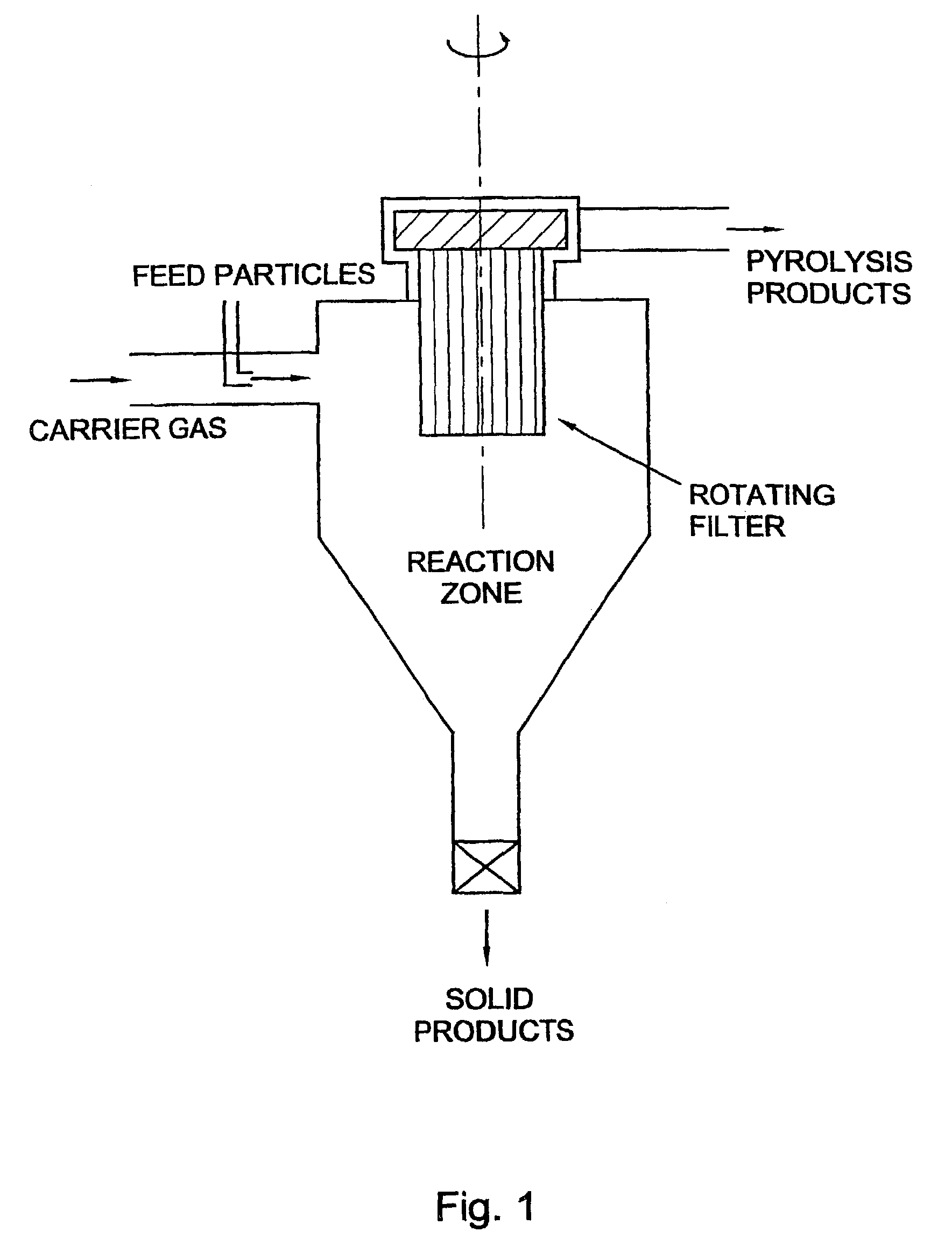

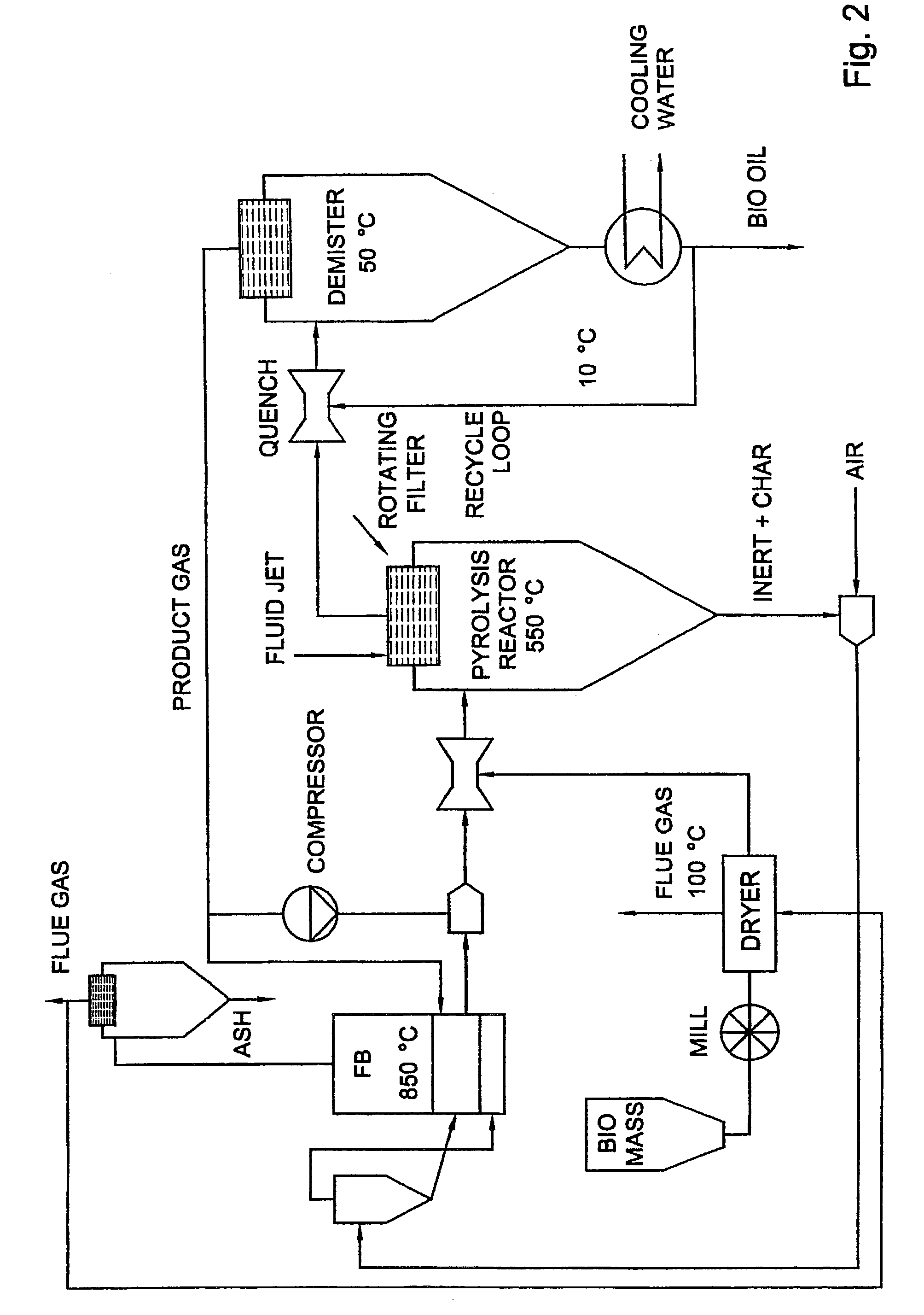

Flash-pyrolysis in a cyclone

InactiveUS7202389B1Excessive crackingCombination devicesDispersed particle filtrationParticulatesCyclone

A process for the pyrolysis of carbonaceous material is carried out in a cyclone reactor which is fitted with enhanced filtering equipment. In addition the invention relates to the use of a cyclone fitted with a rotating filter as a pyrolysis reactor. By using a cyclone of the rotating separator type as a pyrolysis reactor, carbonaceous material, such as biomass, can effectively be converted in a product having excellent chemical properties and which product is free from particulate matter.

Owner:UNIVERSITY OF TWENTE

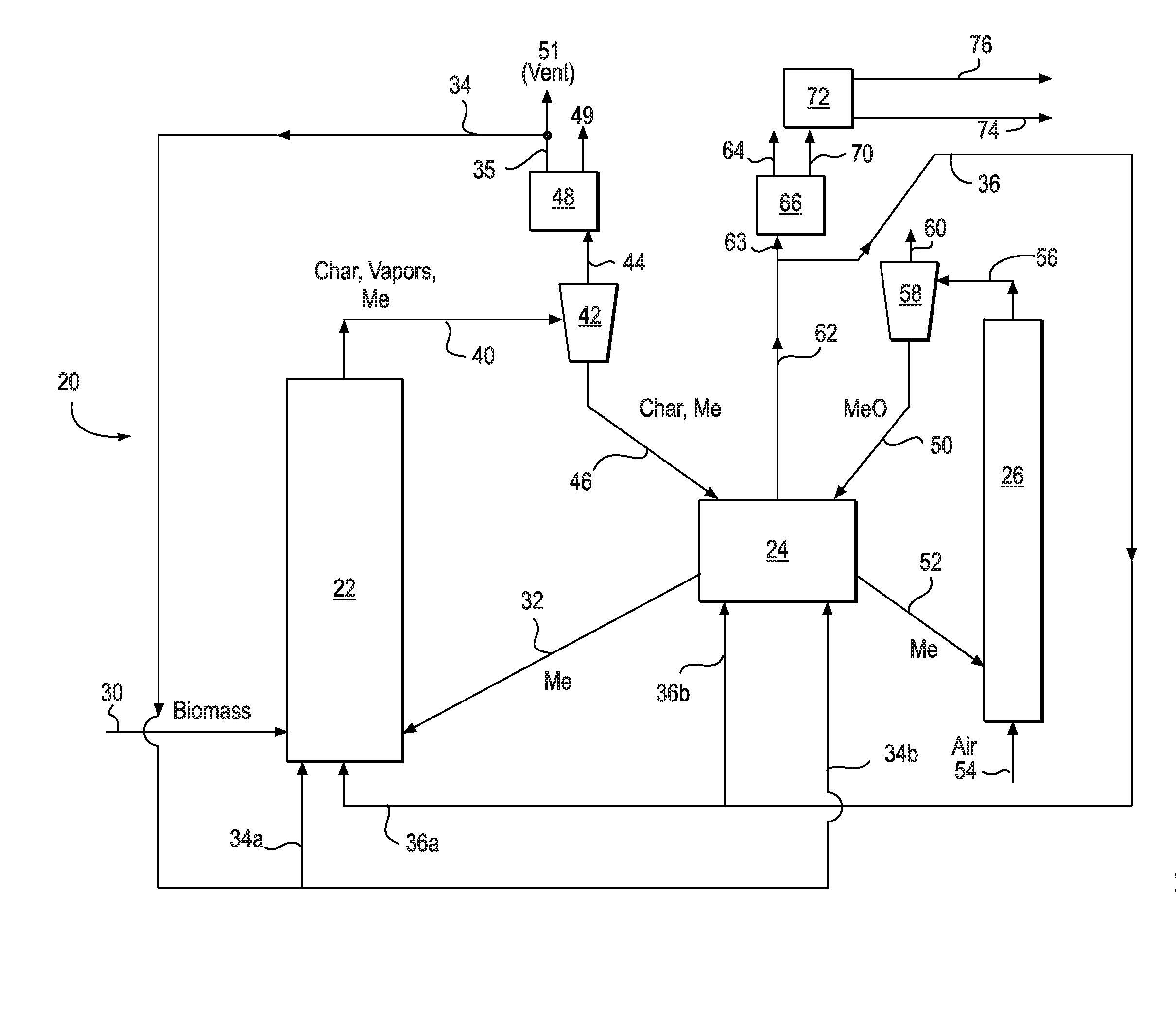

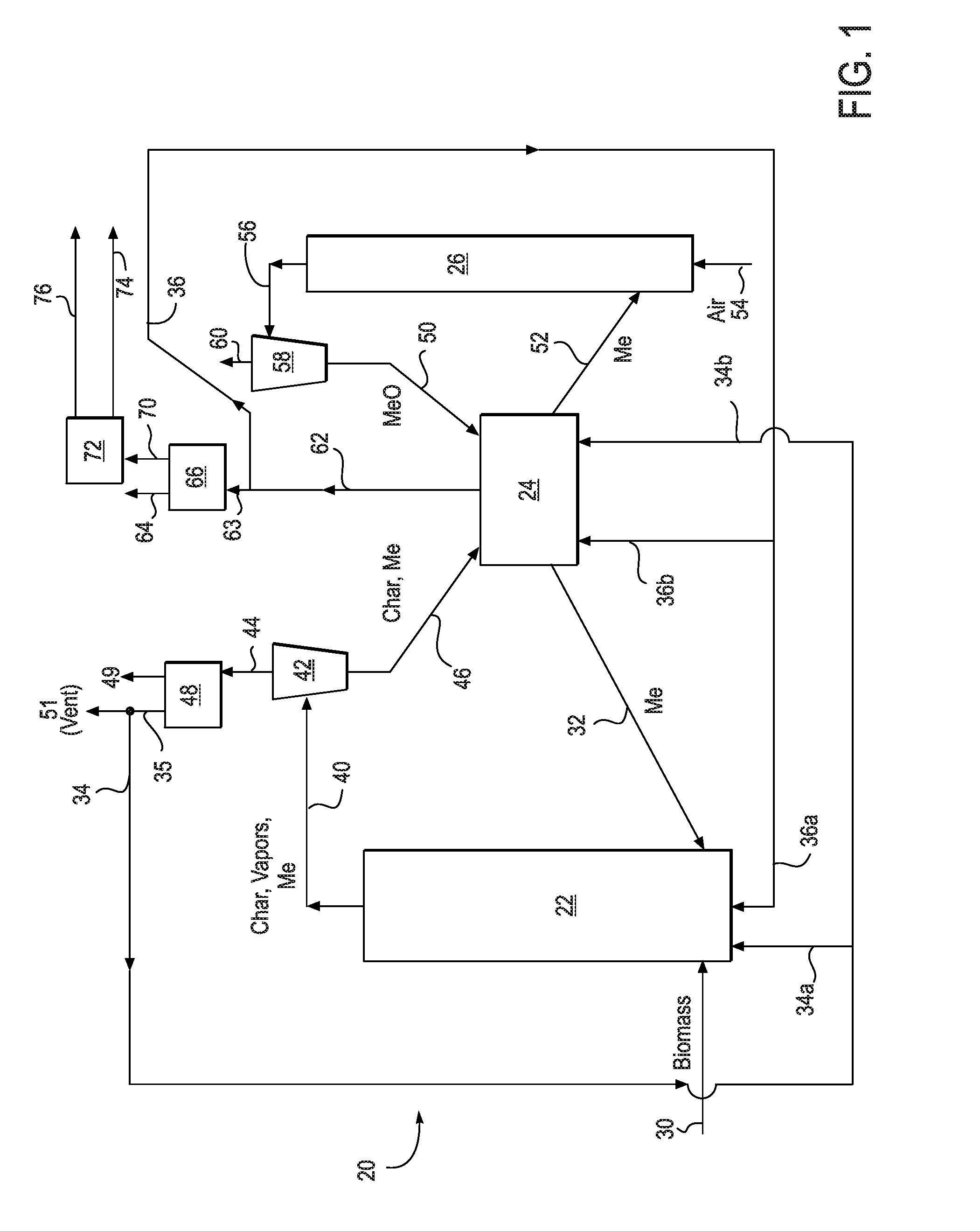

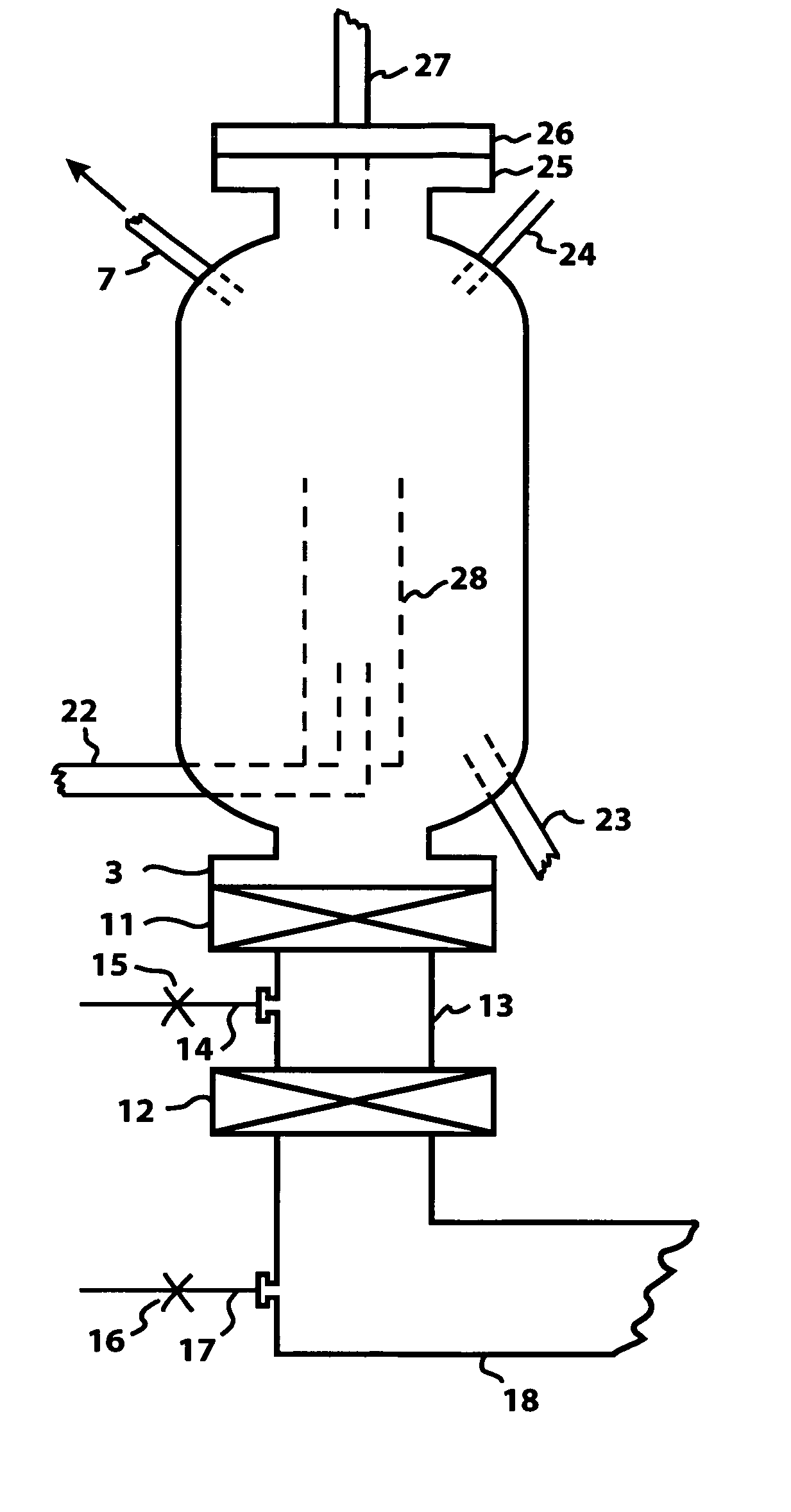

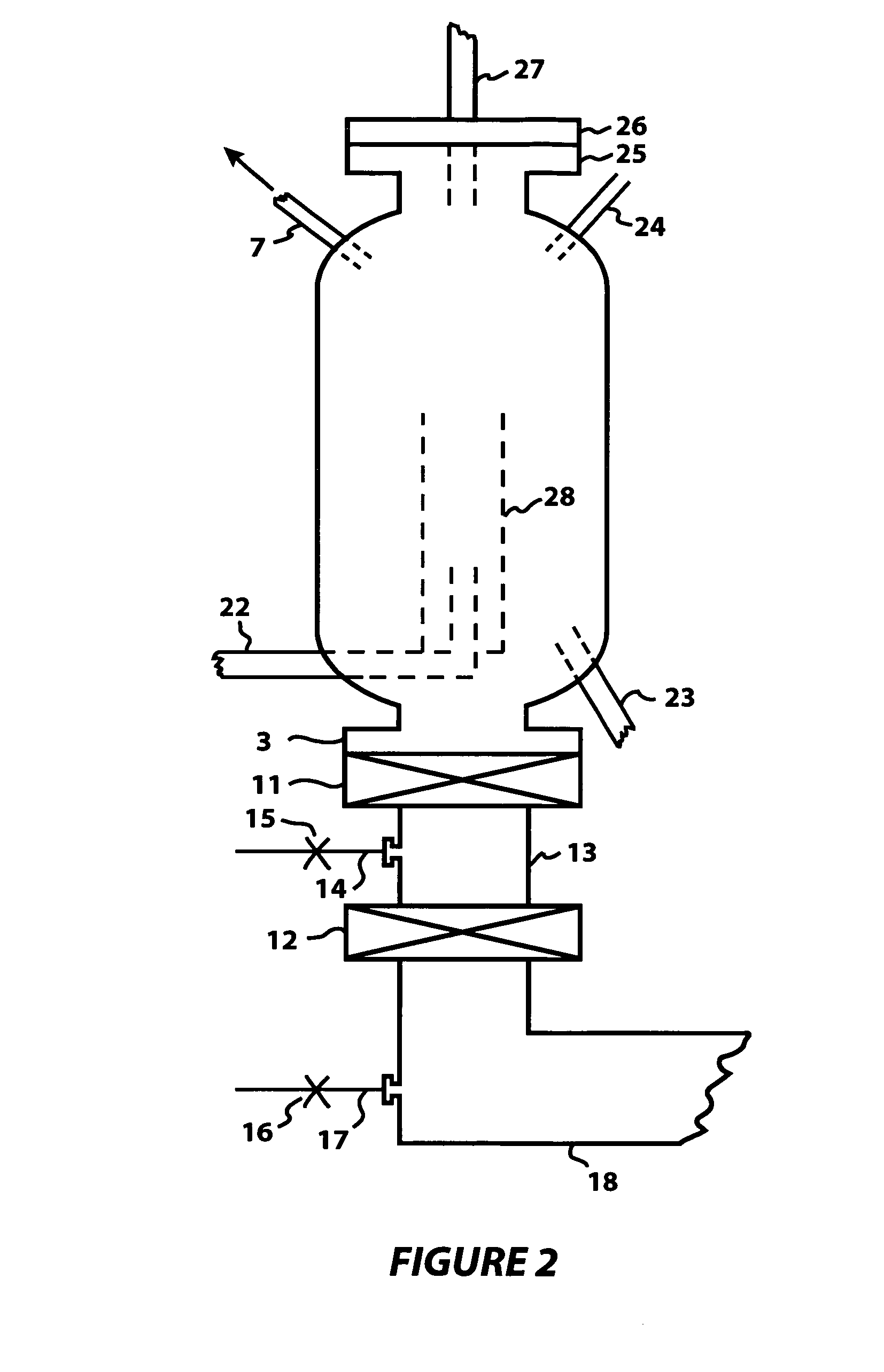

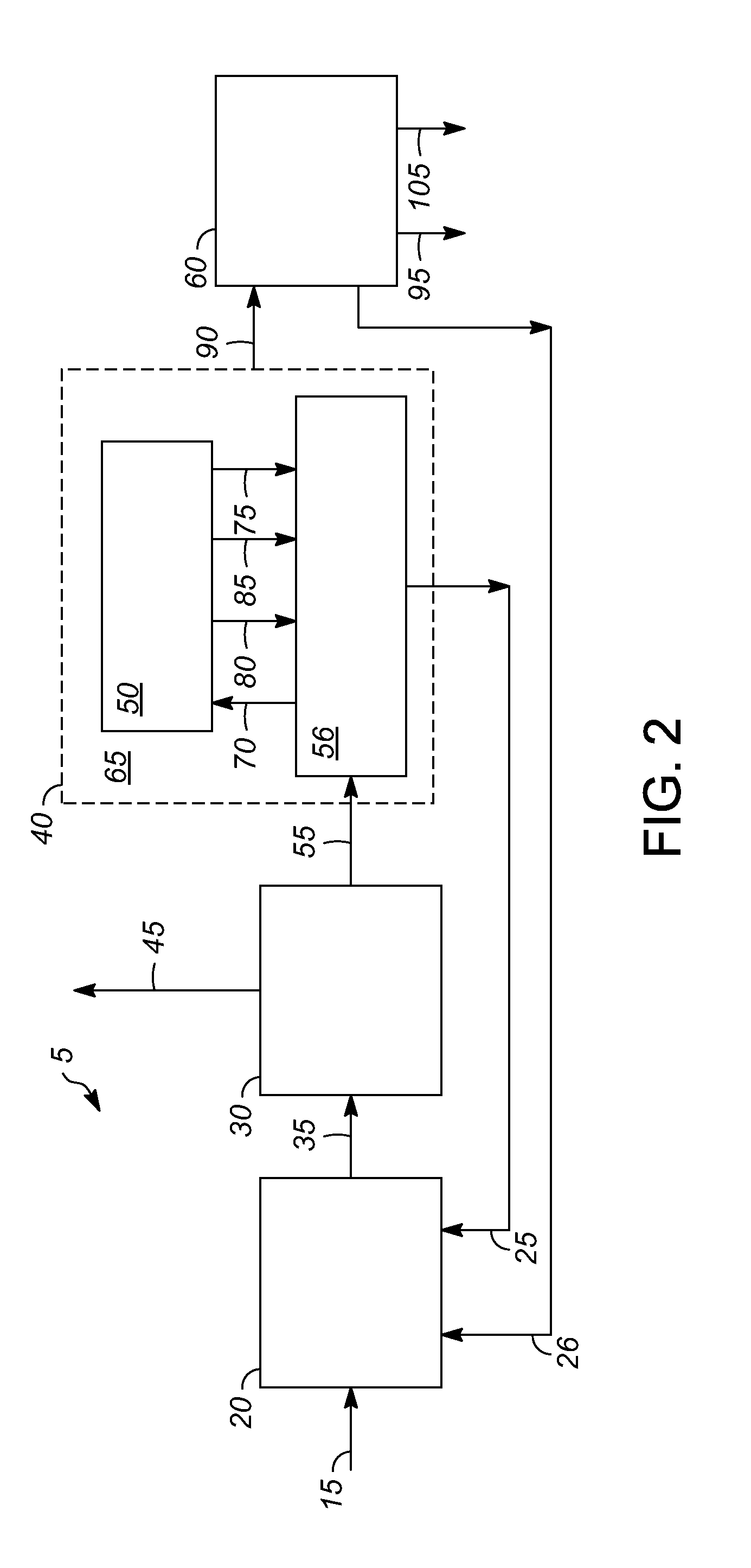

Method and system for capturing carbon dioxide from biomass pyrolysis process

A system and method for biomass pyrolysis utilizing chemical looping combustion of a produced char to capture carbon dioxide is disclosed. The system includes a biomass pyrolysis reactor, a char combustor, and oxidation reactor and a separator for separating carbon dioxide from flue gas produced by the char combustion. The pyrolysis reactor pyrolyzes biomass in the presence of reduced metal oxide sorbents producing char and pyrolysis oil vapor. The char is separated and combusted in the char combustor, in the presence of oxidized metal oxide sorbents, into a gaseous stream of carbon dioxide and water vapor. The carbon dioxide and water are separated so that a stream of carbon dioxide may be captured. The oxidation reactor oxidizes, in the presence of air, a portion of reduced metal oxide sorbents into oxidized metal oxide sorbents that are looped back to the char combustor to provide oxygen for combustion. A second portion of the reduced metal oxide sorbents is recycled from the char combustor to the pyrolysis reactor to provide heat to drive the pyrolysis. Pyrolysis oil upgrading catalyst particles may be used in addition to the metal oxide sorbents as heat energy carrier particles to improve the quality of the pyrolysis oil vapors produced in the pyrolysis reactor. Also, the metal oxide sorbents may have metals incorporated therein which serve to upgrade the pyrolysis vapors produced during pyrolysis. Non-limiting examples of such metals include Ni, Mo, Co, Cr, W, Rh, Ir, Re, and Ru.

Owner:CHEVROU USA INC

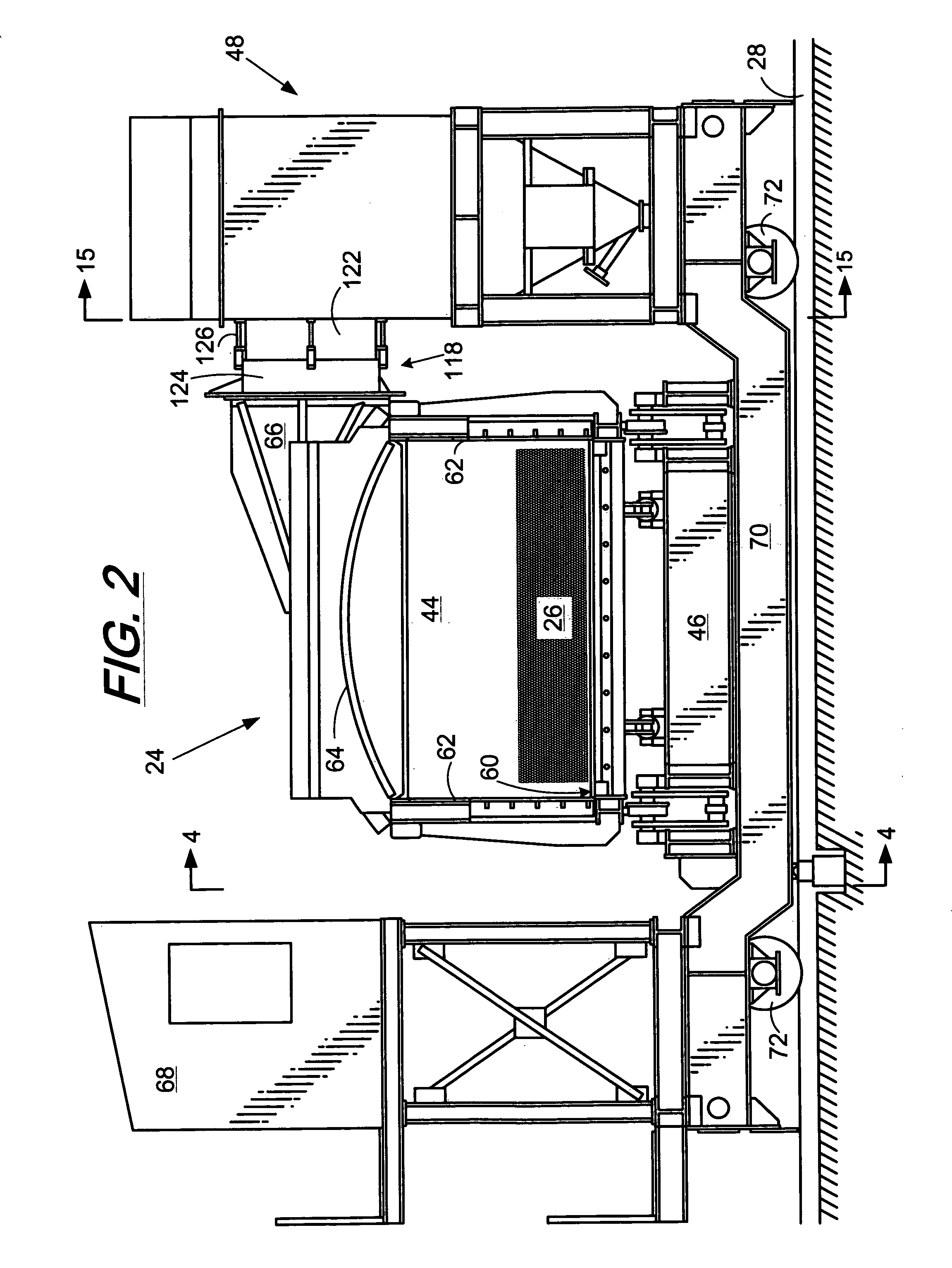

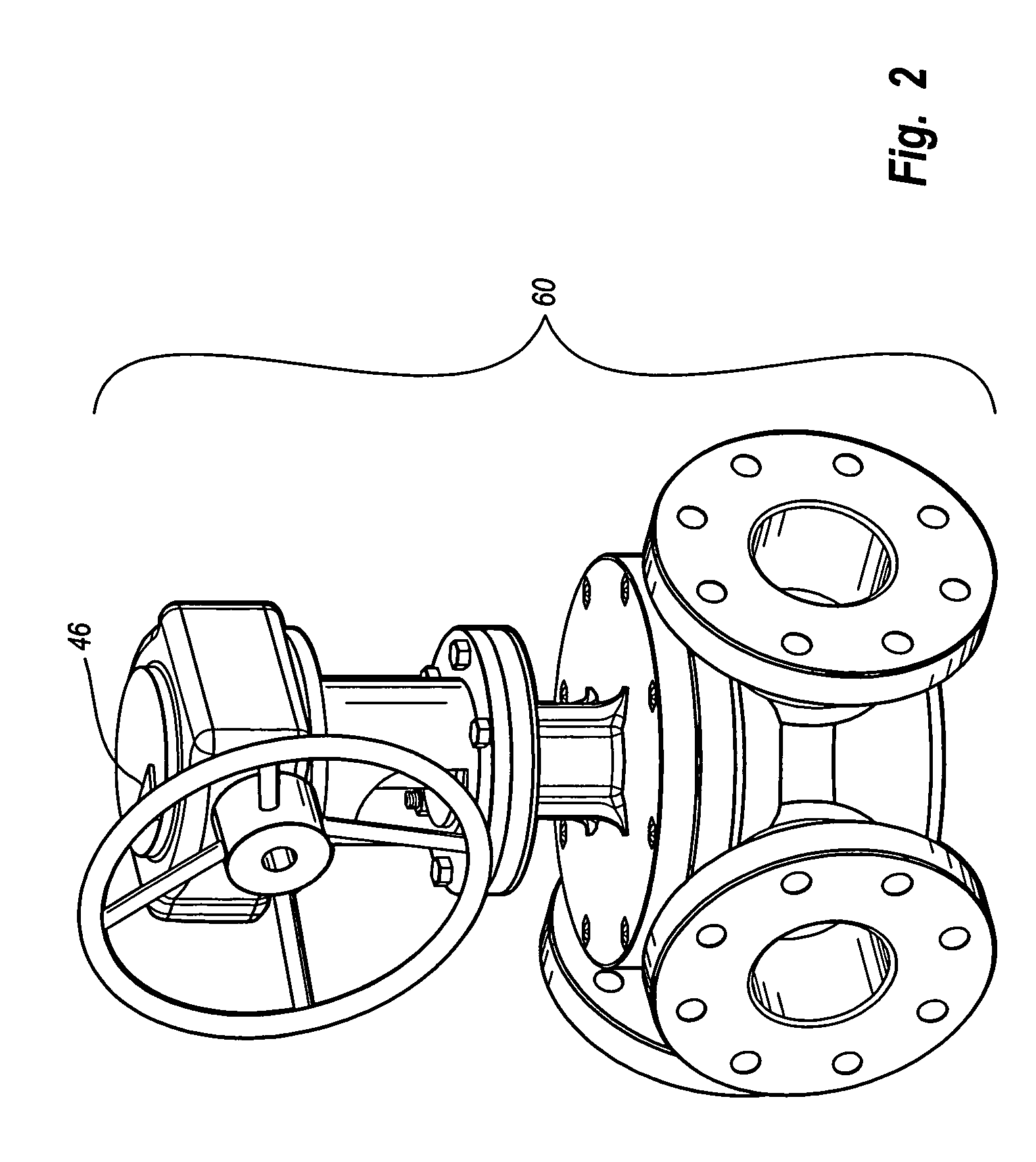

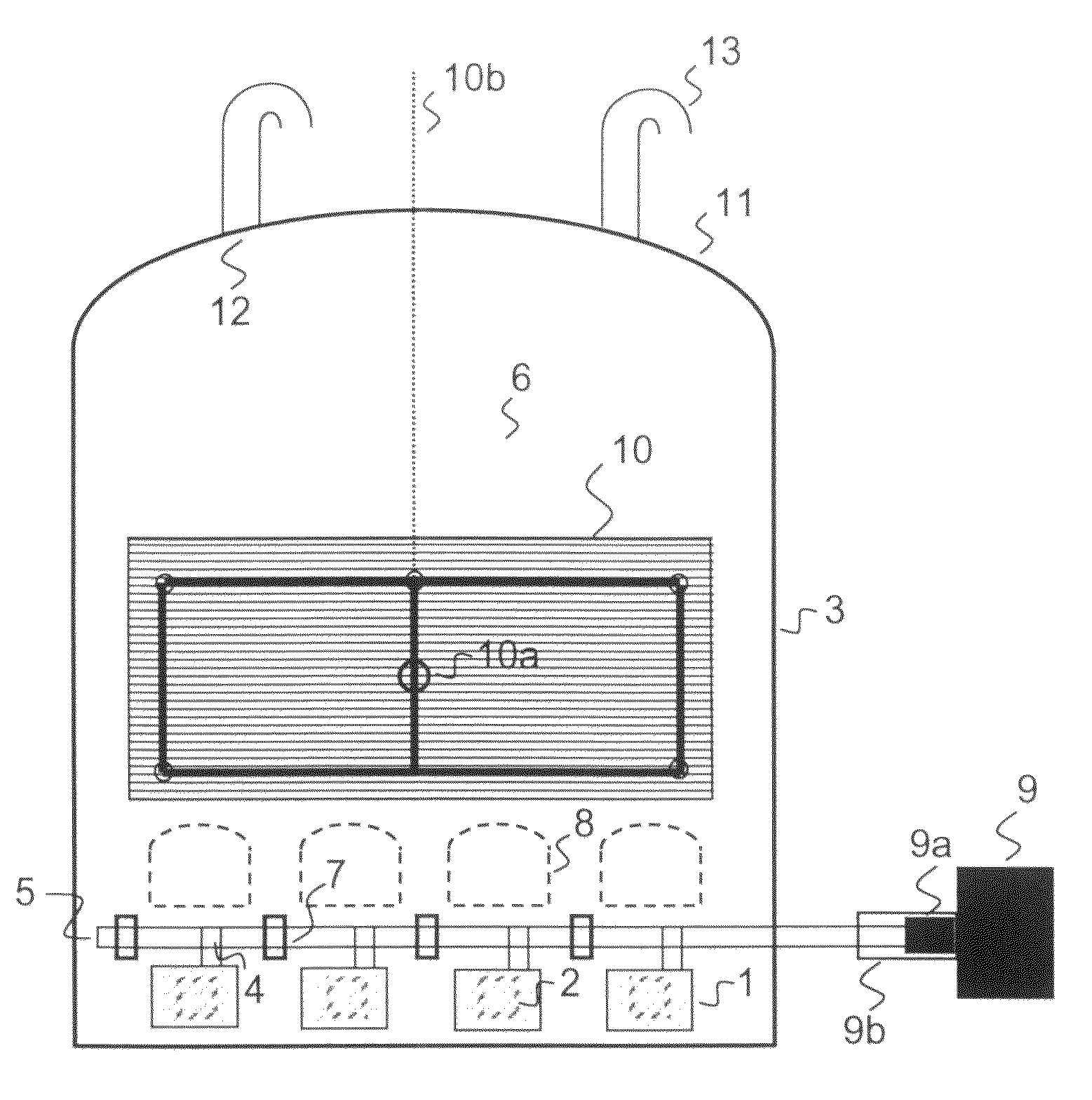

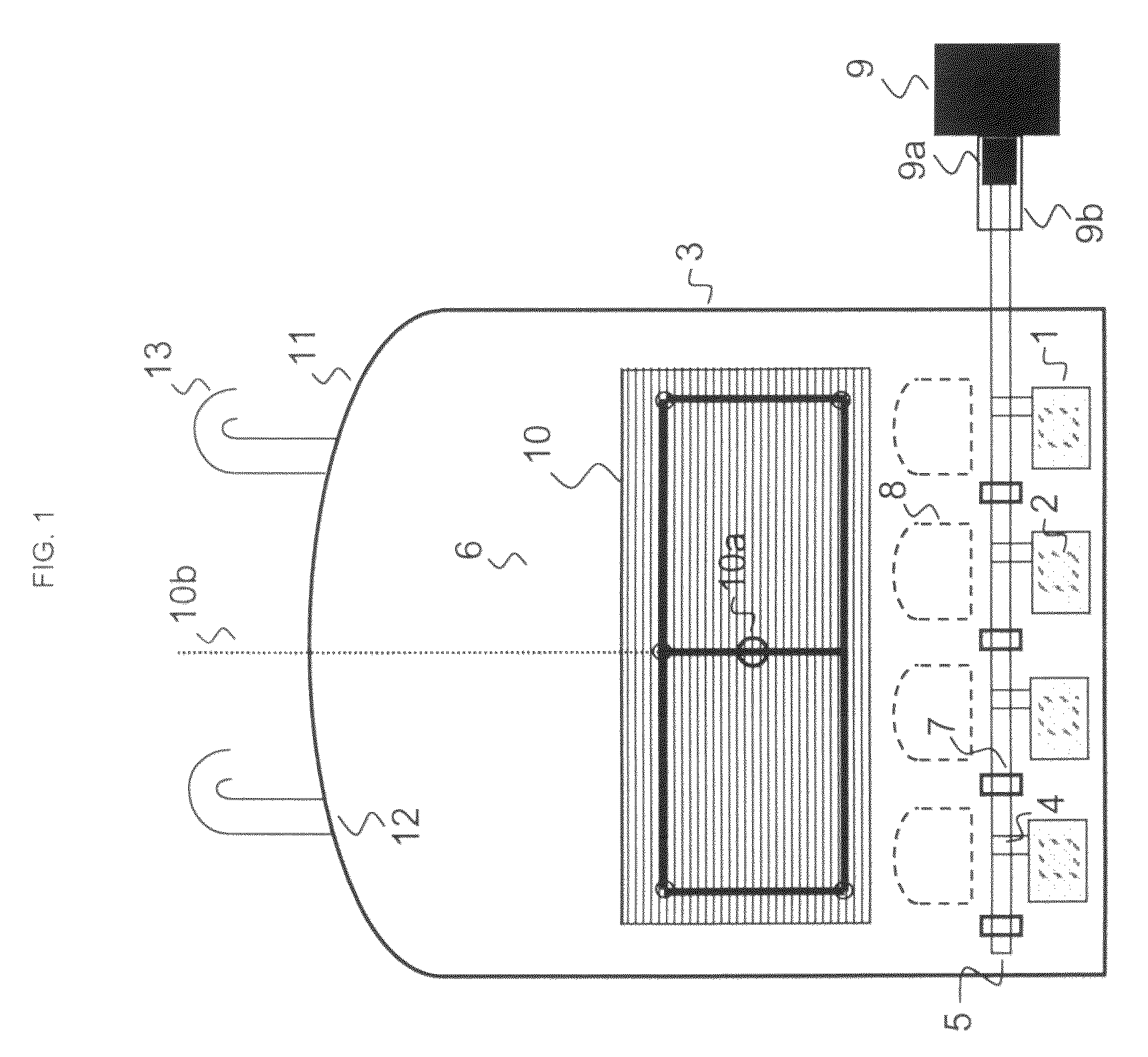

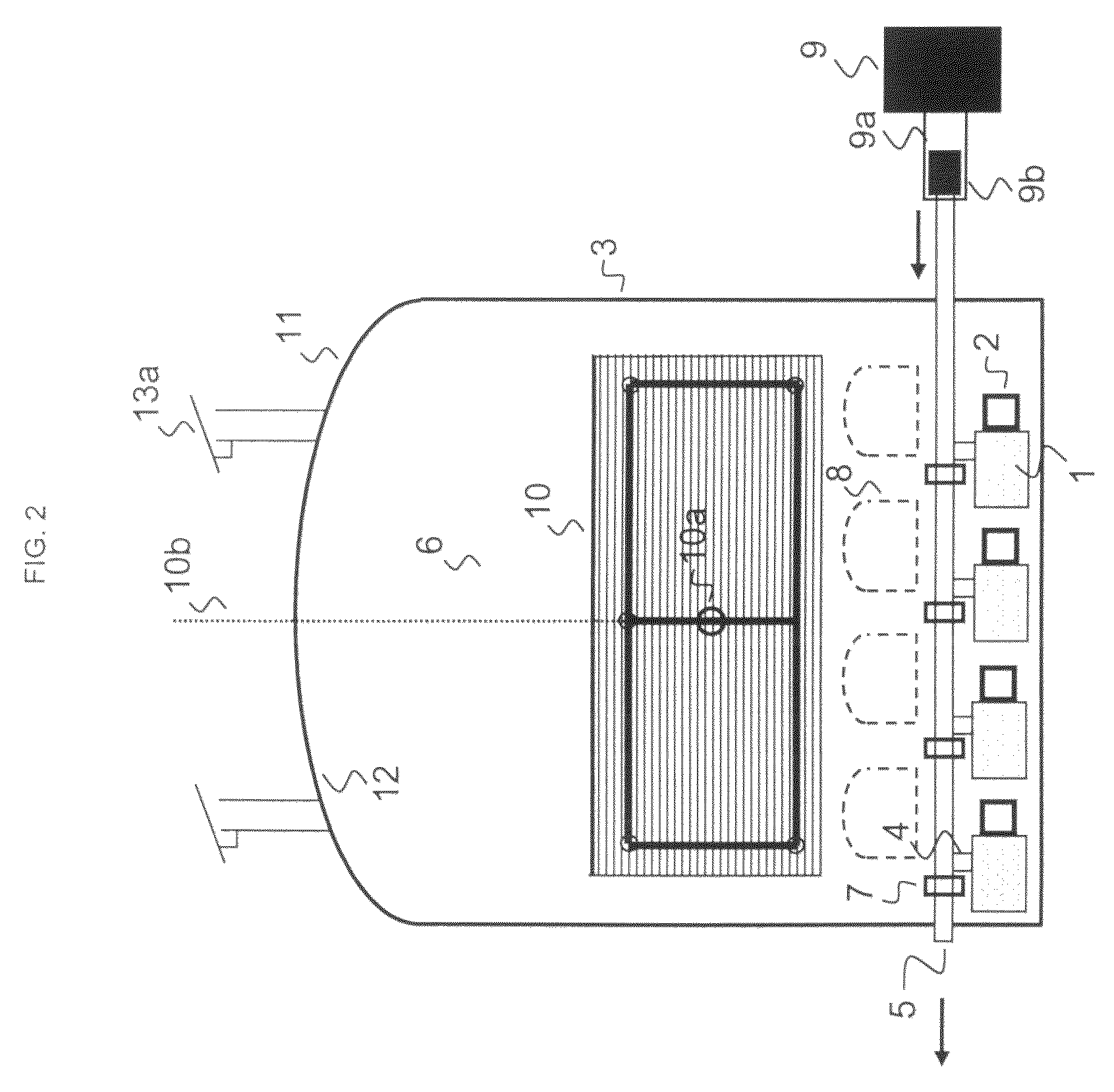

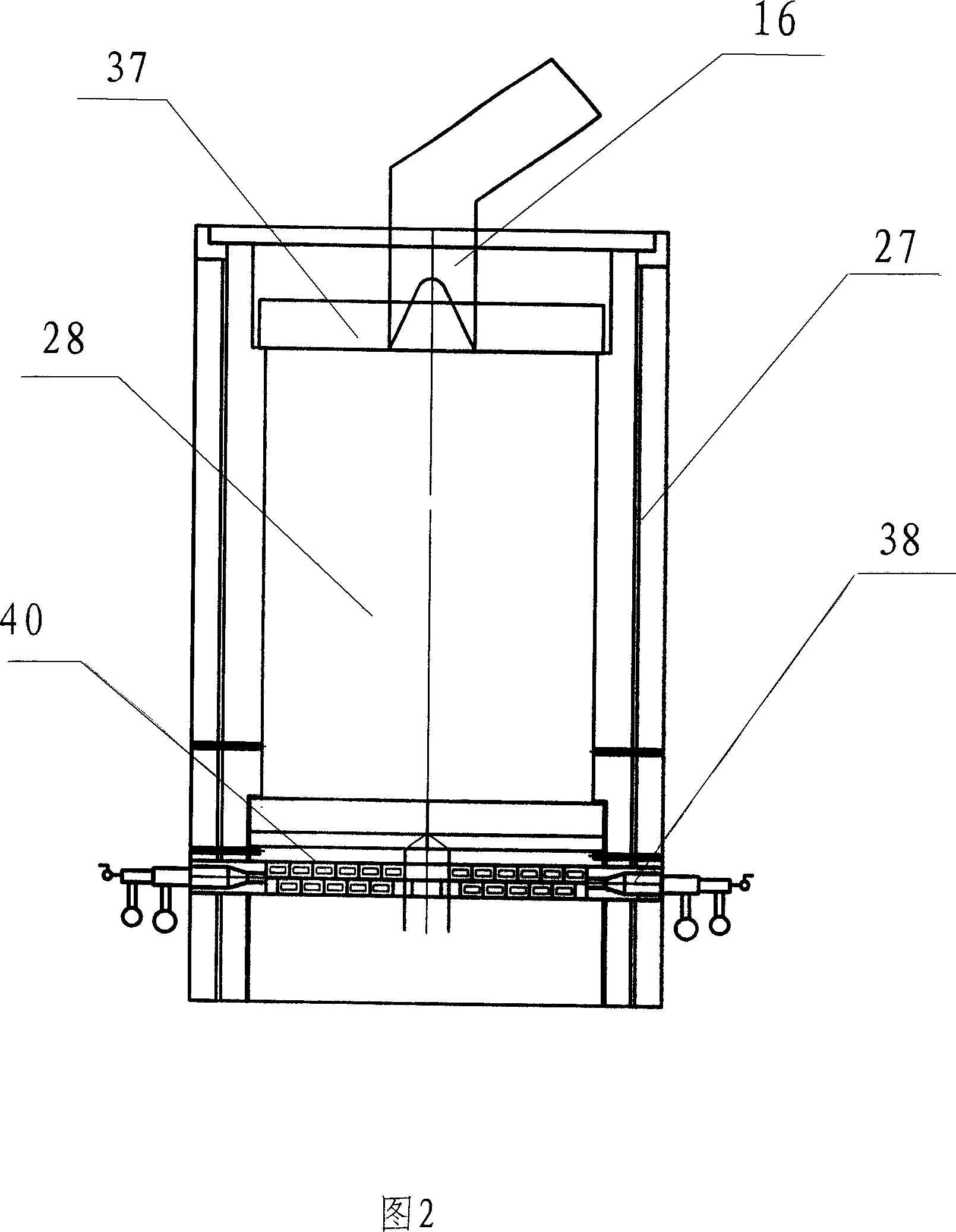

Method and apparatus for producing coke

ActiveUS8152970B2Reduce the amount requiredReduce moisture contentSpeed controllerCoke quenchingMetallurgyMetallurgical coke

A method and apparatus for quenching metallurgical coke made in a coking oven. The method includes pushing a unitary slab of hot coke onto a substantially planar receiving surface of a hot car. The hot car containing the coke is then transported to a quench car station. The unitary slab of hot coke is pushed onto a substantially planar receiving surface of a quench car at the quench car station. Quenching of the slab of hot coke is conducted in the quench car with a predetermine amount of water. After quenching, the quenched coke is dumped onto a receiving pad for collection thereof.

Owner:SUNCOKE TECH & DEV LLC

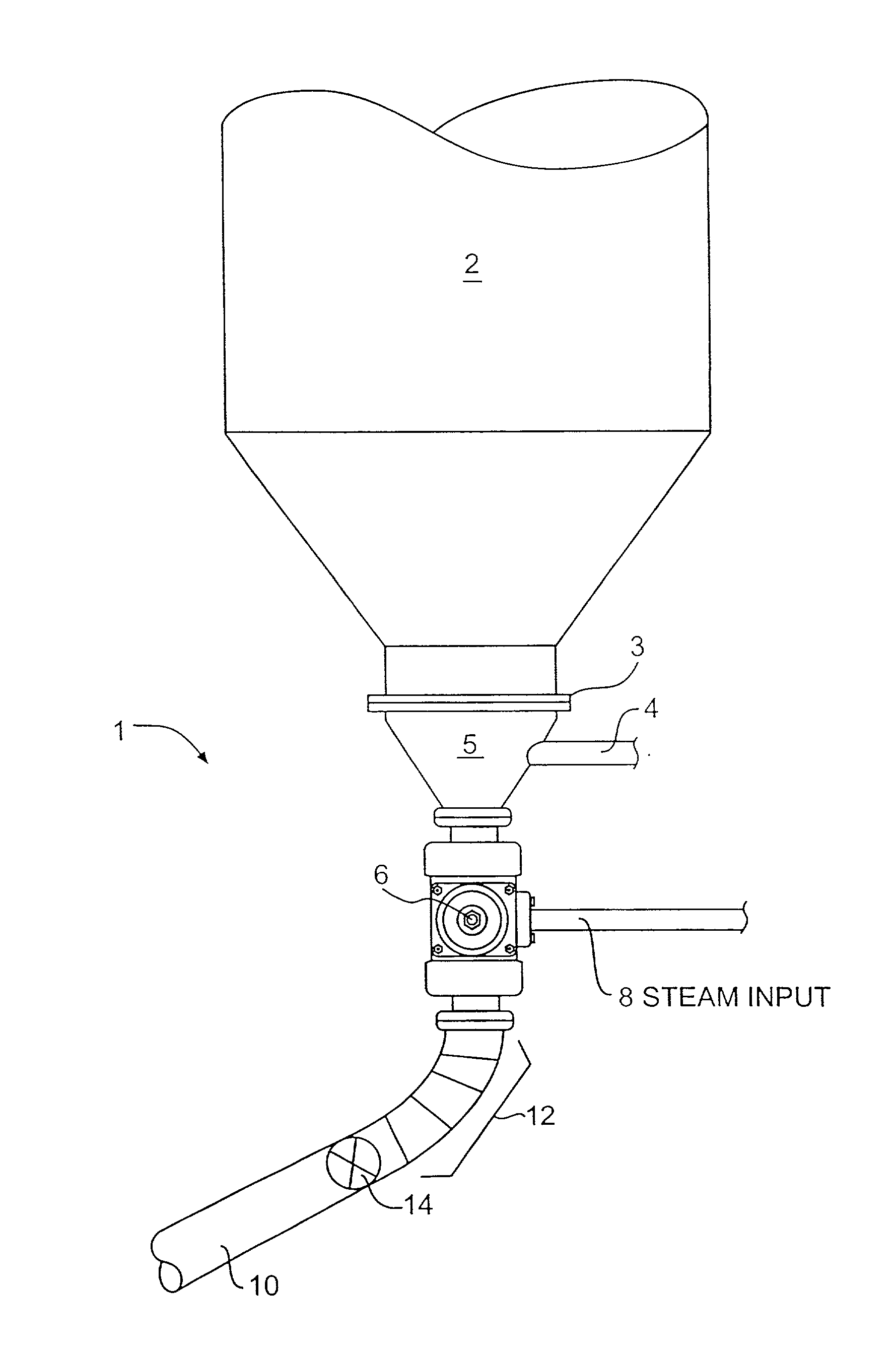

Process and device for the pyrolysis of feedstock

InactiveUS7947155B1Thermal non-catalytic crackingCombustible gas coke oven heatingVolatilesEngineering

This invention involves pyrolysis of feedstock by introducing carbonaceous feedstock, into a hopper and moving it into a reactor tube enclosed in an oven, generating heat within the oven that is in part transferred to the feedstock, heating it to sufficient temperature to pyrolyze the feedstock into useful volatiles and char. A Venturi system produces a negative pressure directing volatiles into a pyro-gas oven producing heat necessary for pyrolysis and generating useful excess heat. The extruded pyrolysis char has uses including charcoal fuel, soil amendments, and activated charcoal while liquids can be produced for processing into fuels. Excess heat may be used to heat water, steam, and air, may be used in air heating and cooling systems, perform mechanical work with a Stirling engine or generate electricity on the order of 100 kW and higher. The system may be operated in a carbon neutral or even carbon negative manner, allowing sequestration of atmospheric carbon dioxide.

Owner:GREEN LIQUID & GAS TECH

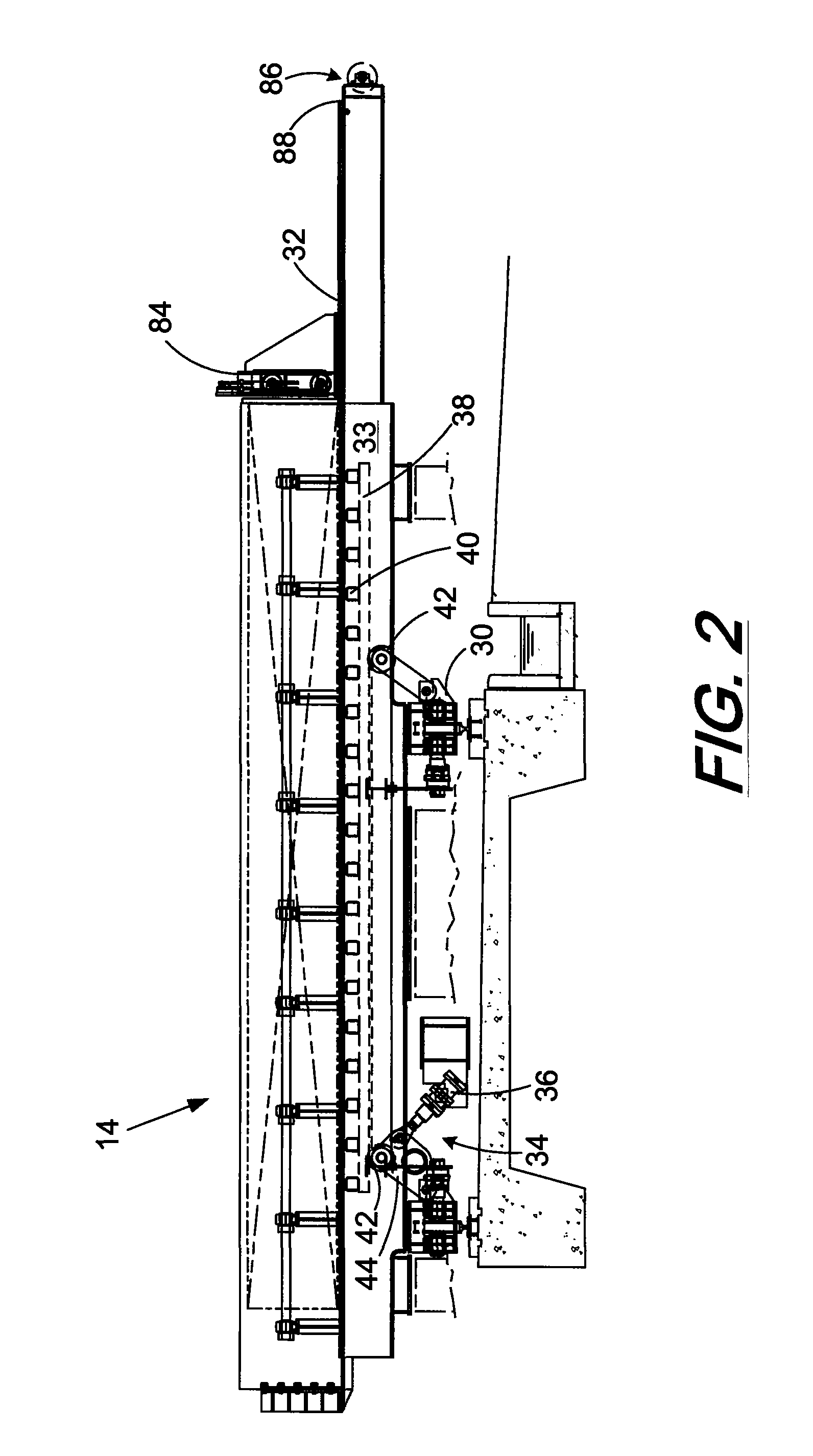

Process for transporting and quenching coke

ActiveUS8236142B2Emission minimizationMinimize timeCoke quenchingDirect heating destructive distillationDust controlProcess engineering

A method and apparatus for transporting and quenching coke, useful in quenching a batch of coke produced in one of a plurality of coke ovens forming a coke oven battery, is disclosed. A hot car defining a substantially planar receiving surface is positioned adjacent a coke oven of the coke oven battery, and a unitary cake of unquenched coke is placed onto the hot car receiving surface. The hot car and unquenched coke are transported to a transfer station having a dust collection system. A quenching car is positioned at the transfer station adjacent the hot car, under the dust collection system. The unitary cake of unquenched coke is dumped into the quenching car receptacle, thereby separating the unitary cake. At least a portion of the dust generated by separation is collected. The quench car is then transported to a quenching station, where the separated coke is quenched.

Owner:WESTBROOK THERMAL TECH

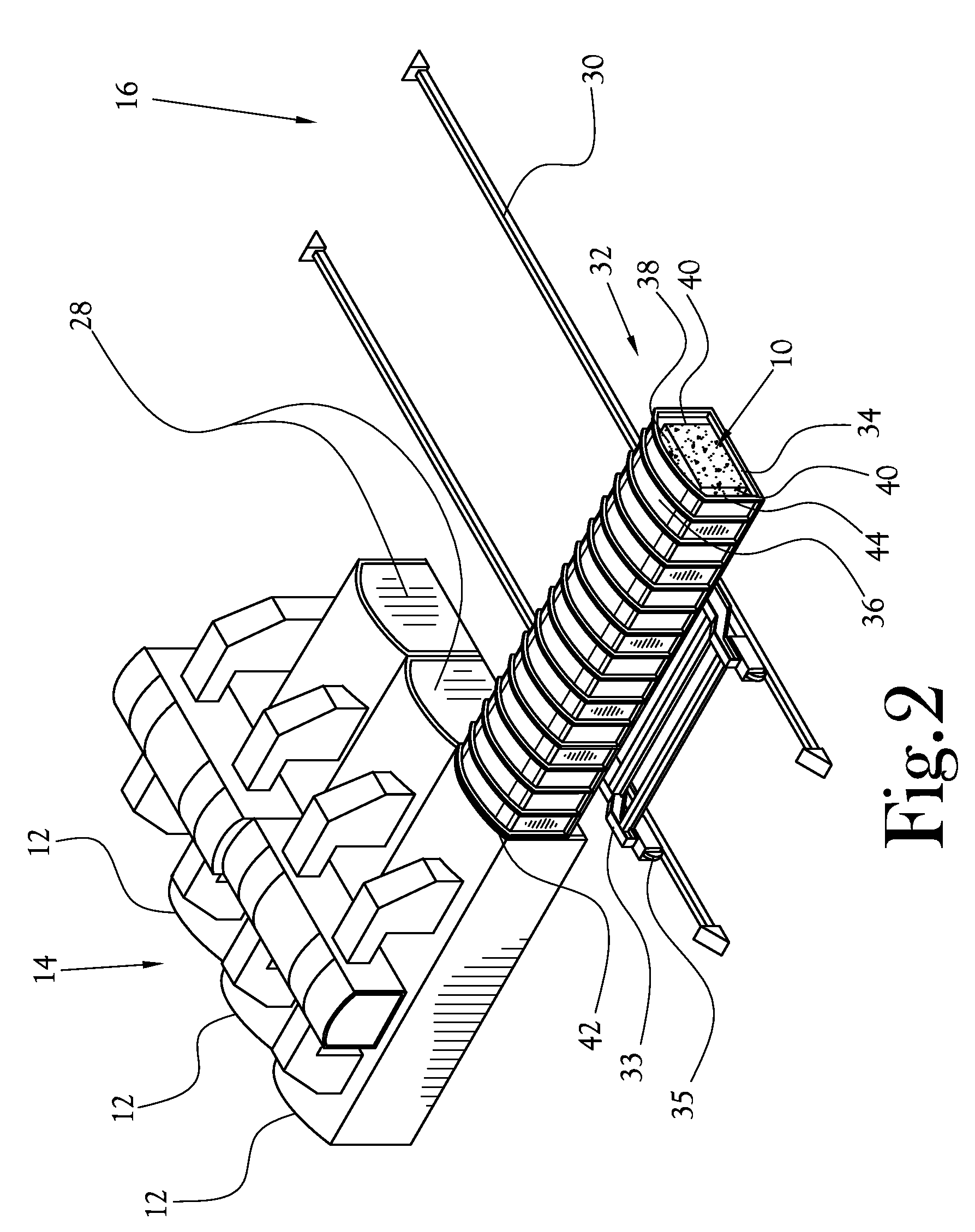

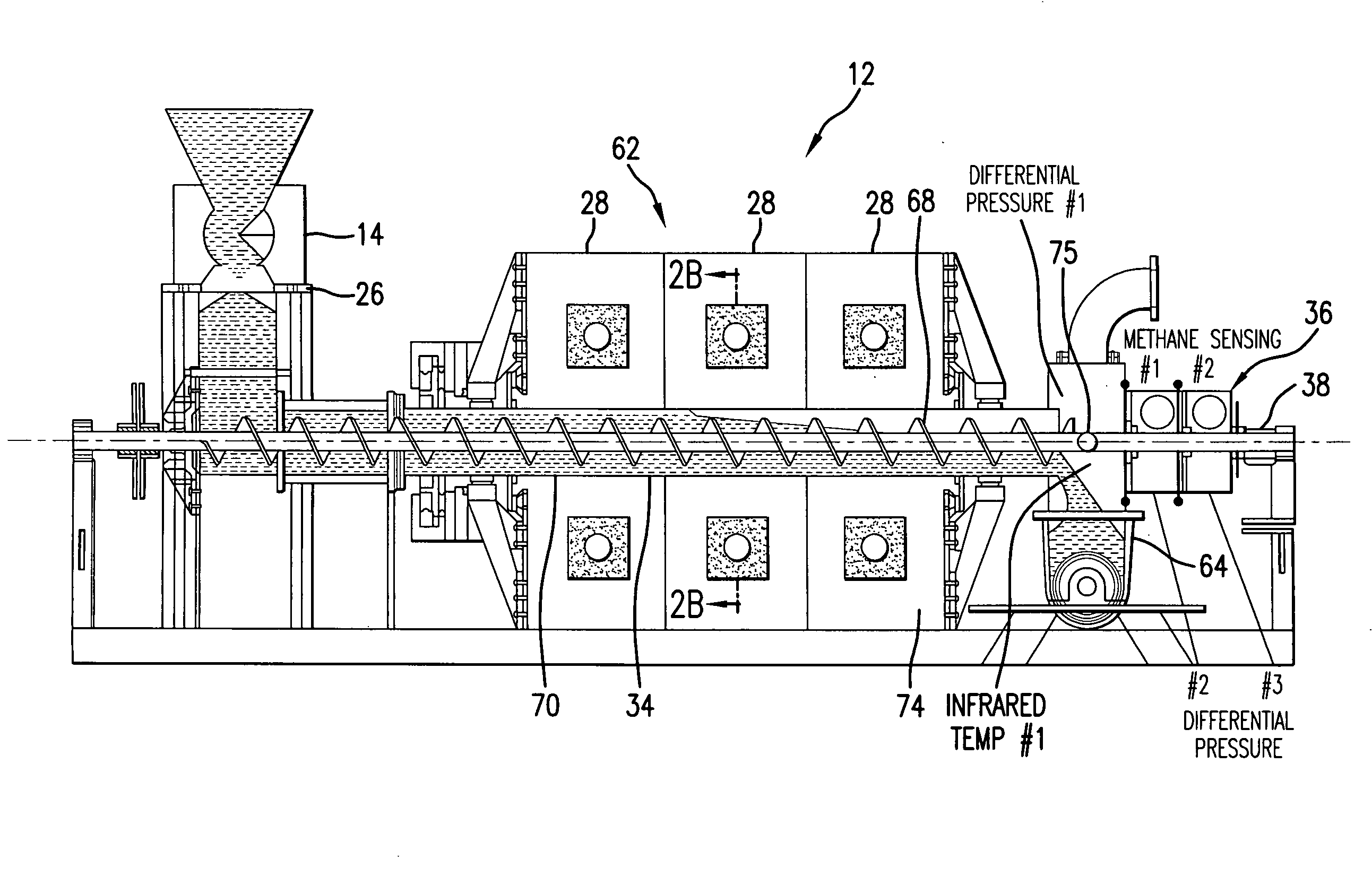

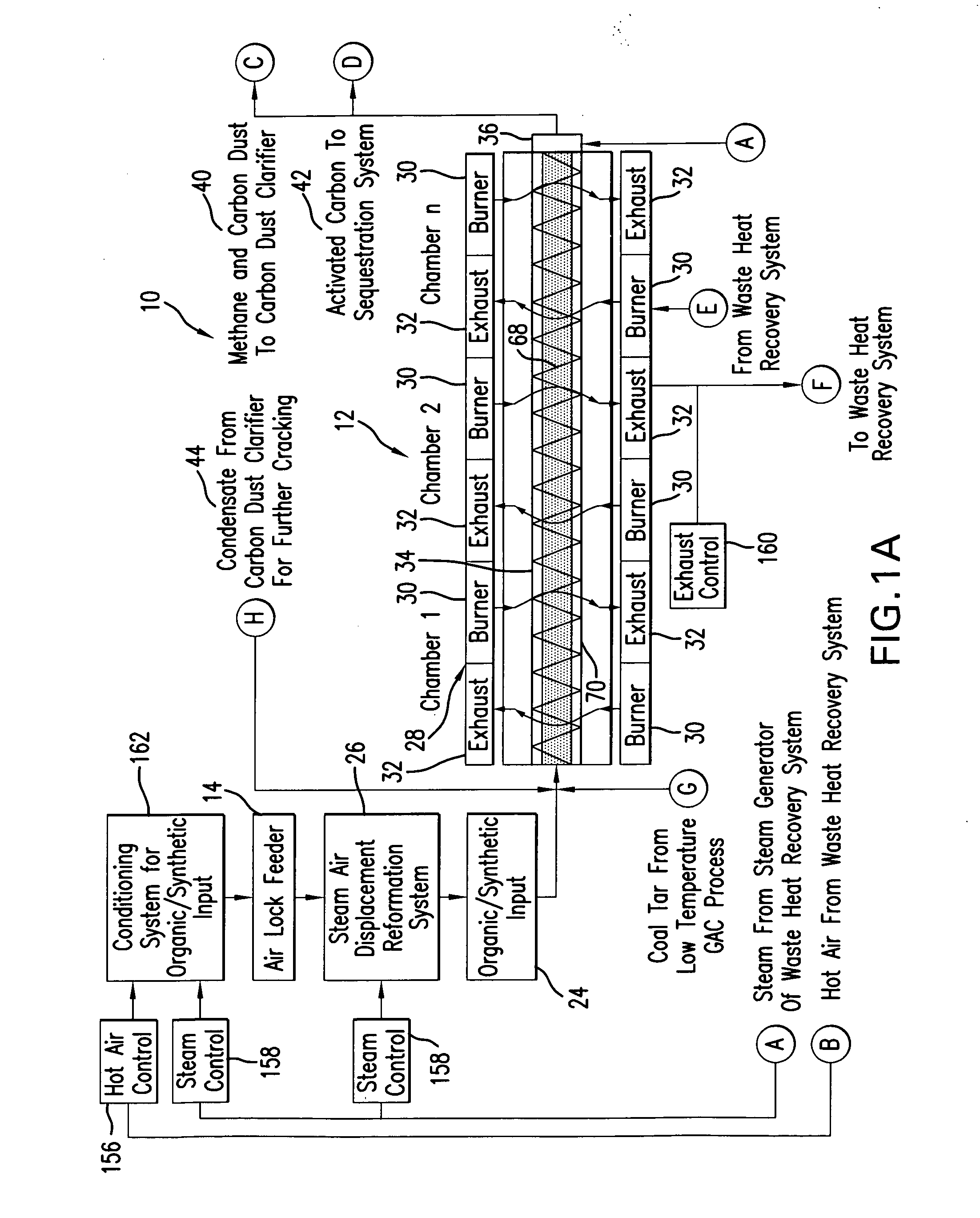

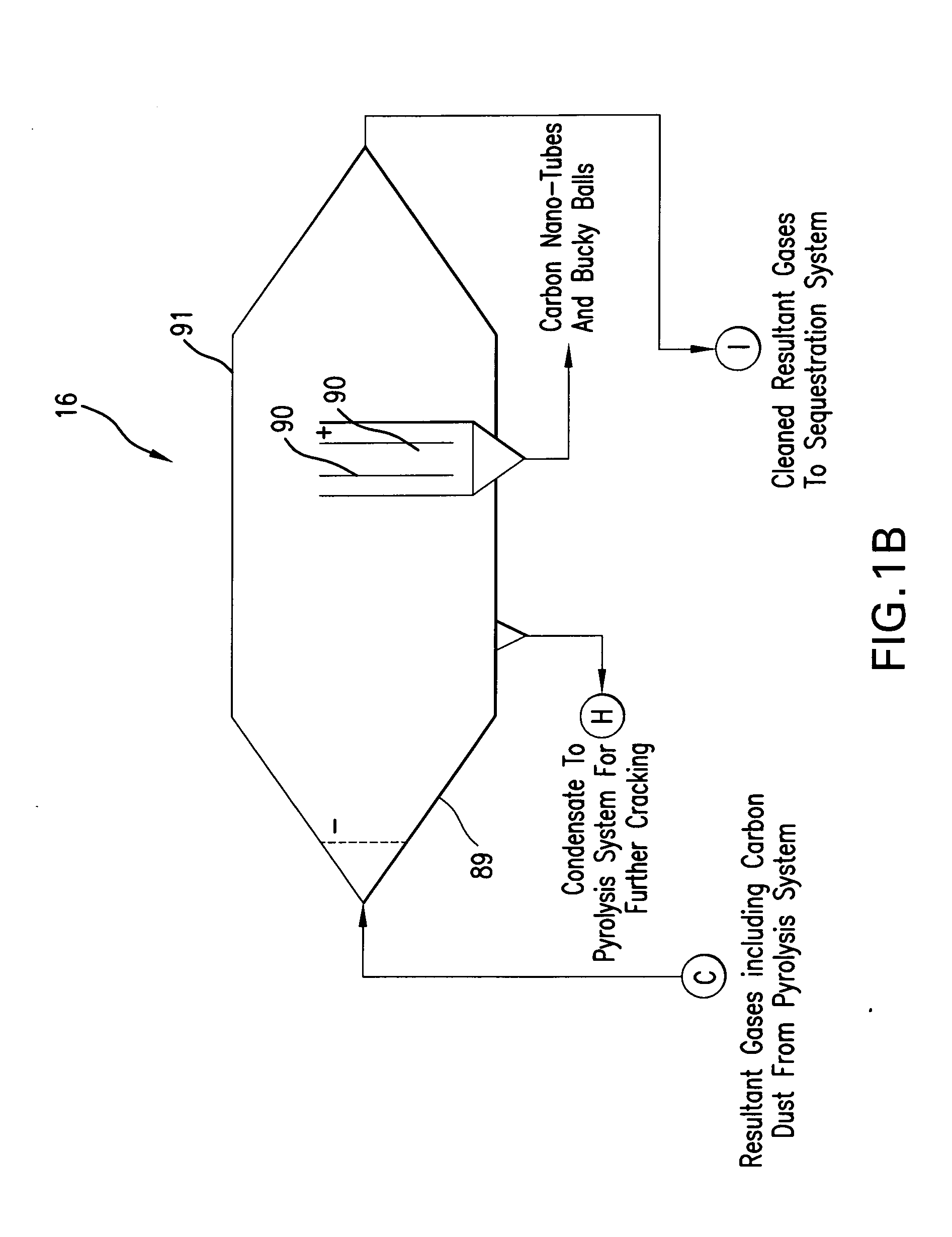

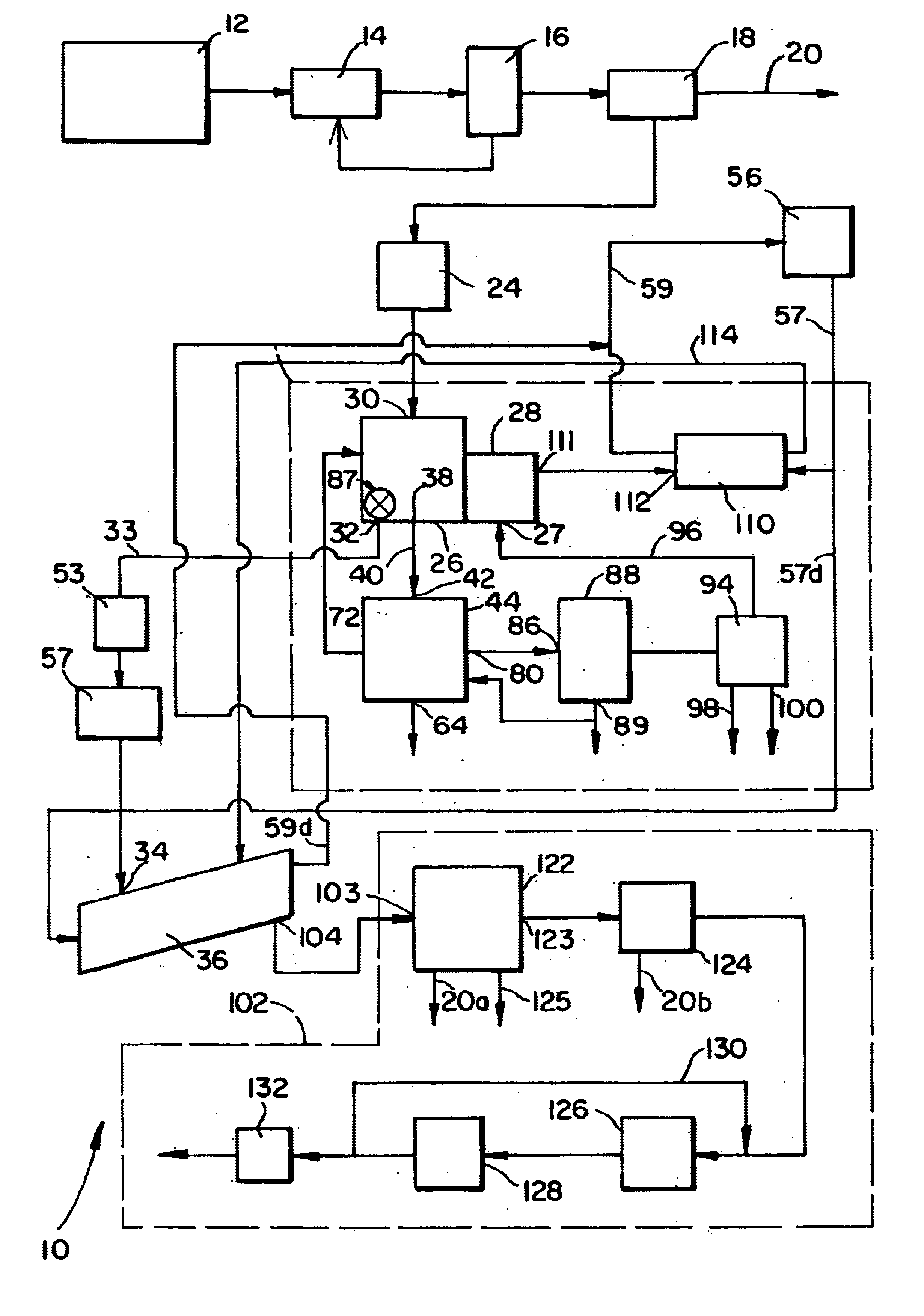

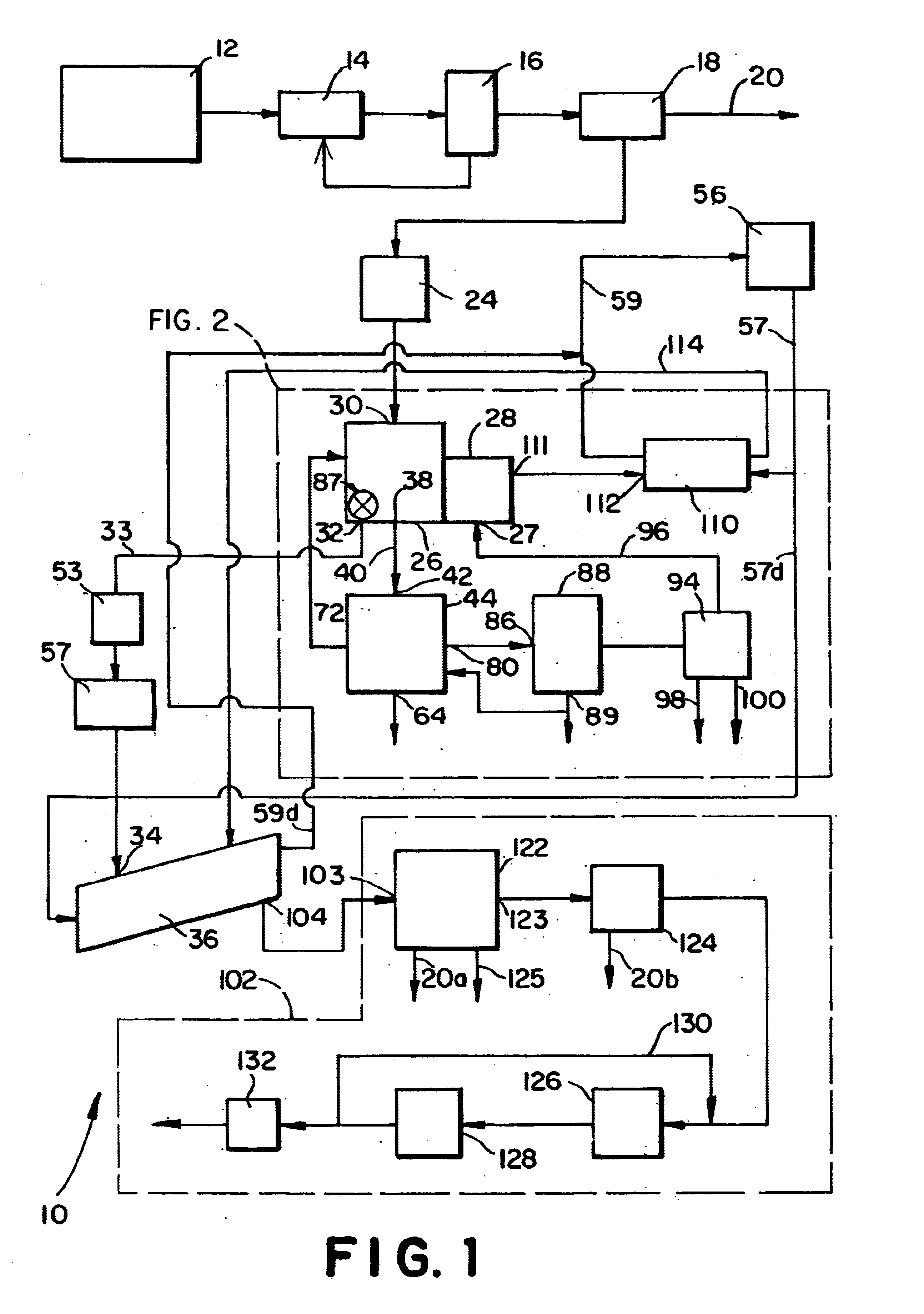

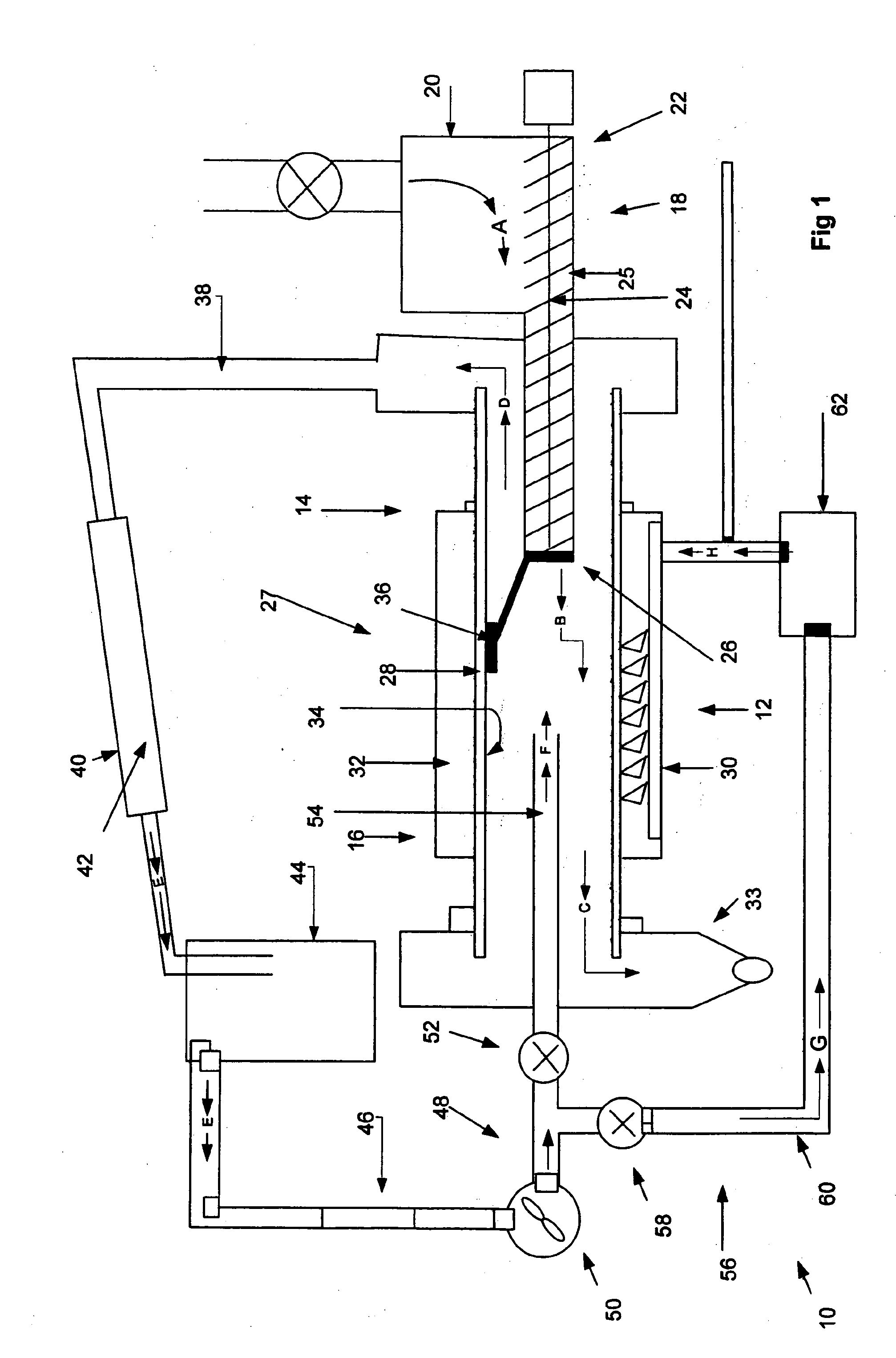

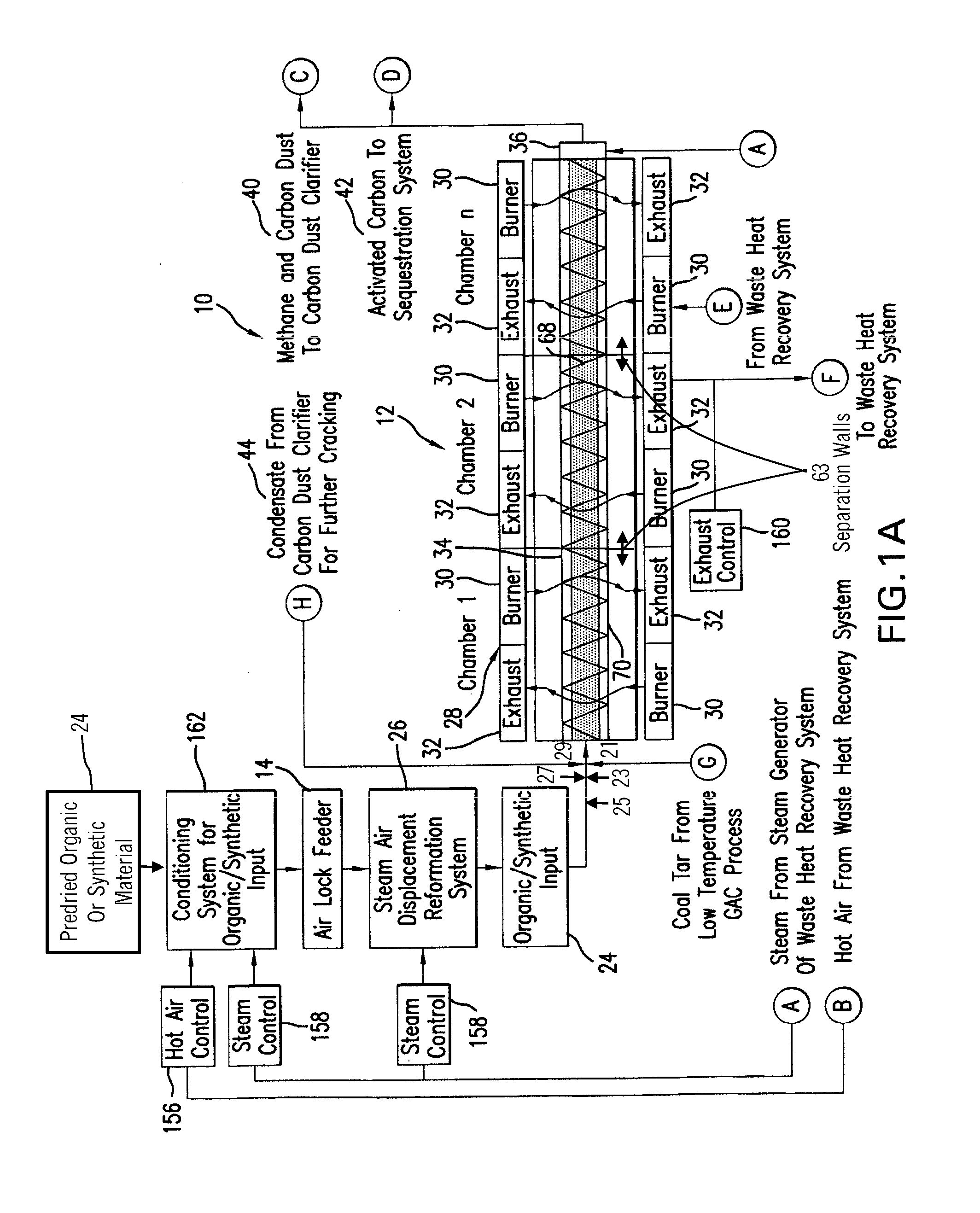

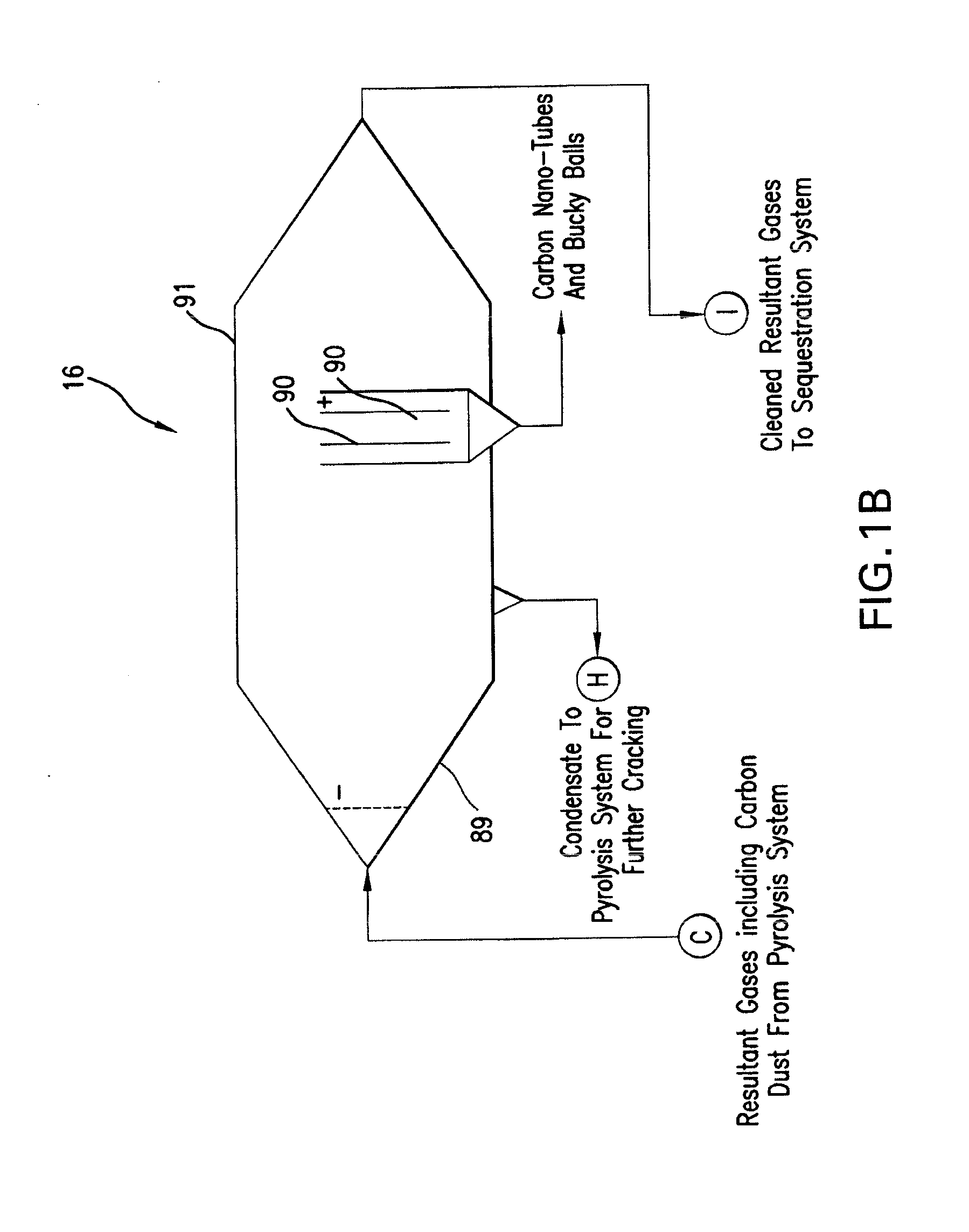

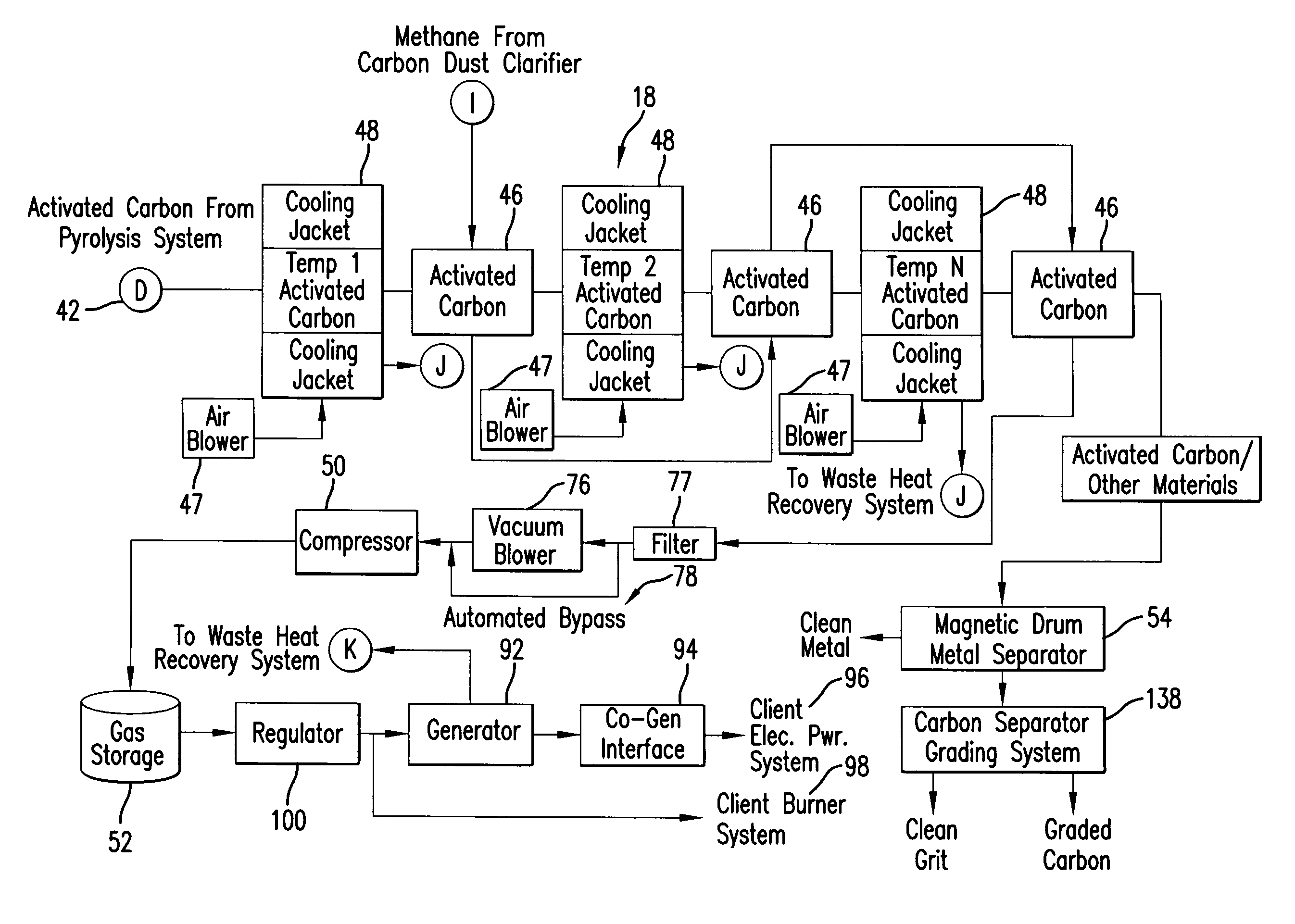

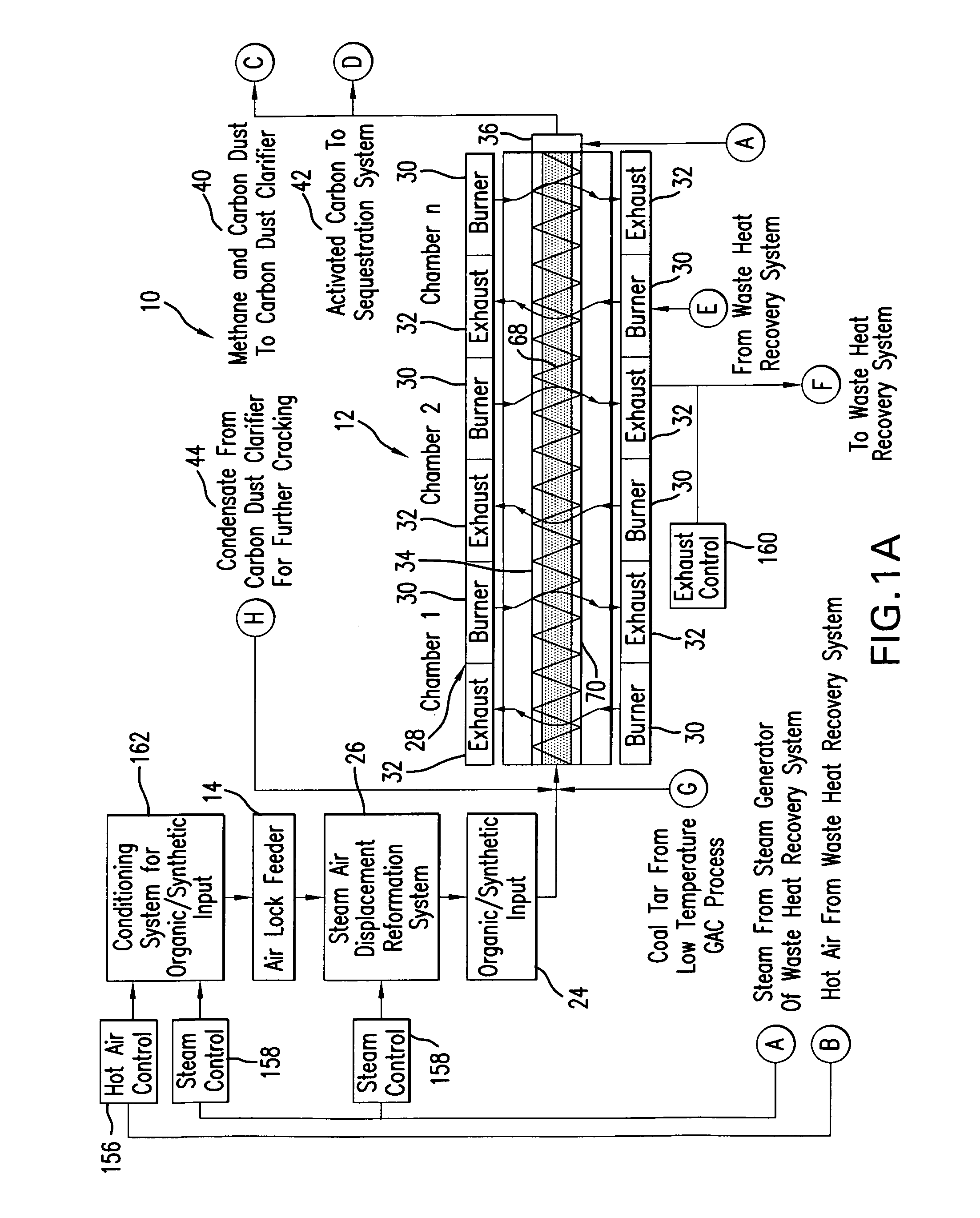

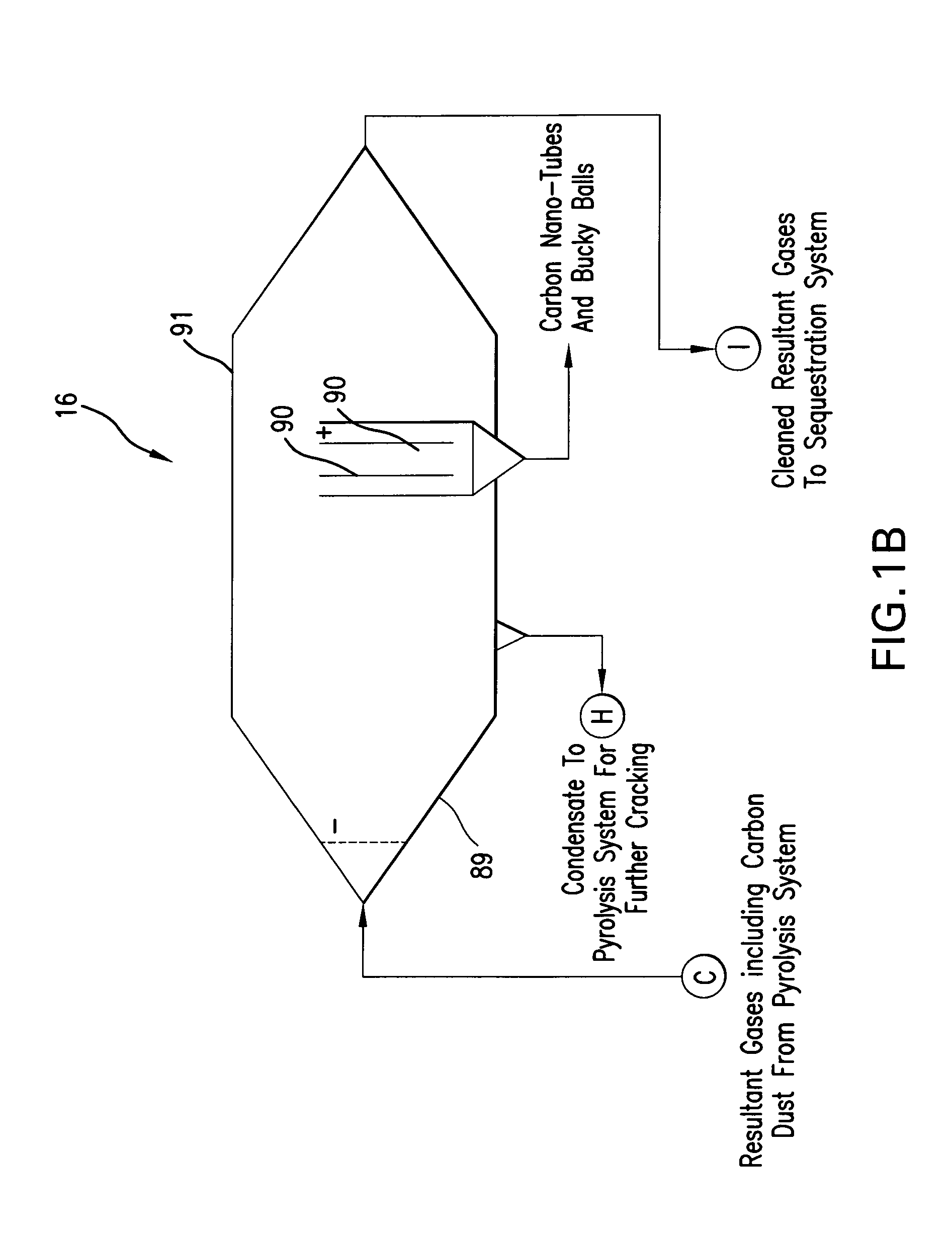

Pyrolysis Systems, Methods, and Resultants Derived Therefrom

ActiveUS20080286557A1Fit closelyWithout undesired degradation of communication system performanceLayered productsUsing liquid separation agentActivated carbon filtrationSilicon dioxide

A system and process for gasification of a carbonaceous feedstock uses pyrolysis to produce a gas product, which may include methane, ethane, and other desirable hydrocarbon gases, and a solids product, which includes activated carbon or carbon. The gas product may then be filtered using at least a portion of the activated carbon from the solids product as a filtering medium. In an embodiment, at least some of the noxious chemicals are sequestered or removed from the gas product in one or more filtering steps using the activated carbon as a filtering medium. In a further embodiment, the filtering steps are performed in stages using activated carbon at different temperatures. A high-temperature pyrolysis system that produces activated carbon may be combined with another high-temperature pyrolysis system that does not produce activated carbon to provide filtering of noxious compounds using activated carbon from the first high-temperature pyrolysis system. A high-temperature pyrolysis system may be combined with one or more low-temperature feedstock conversion processes such that waste heat from the high-temperature pyrolysis system is used to operate the low-temperature process. A novel non-wetting carbon having pores fused with silica can be produced from using the system and process.

Owner:TUCKER RICHARD D

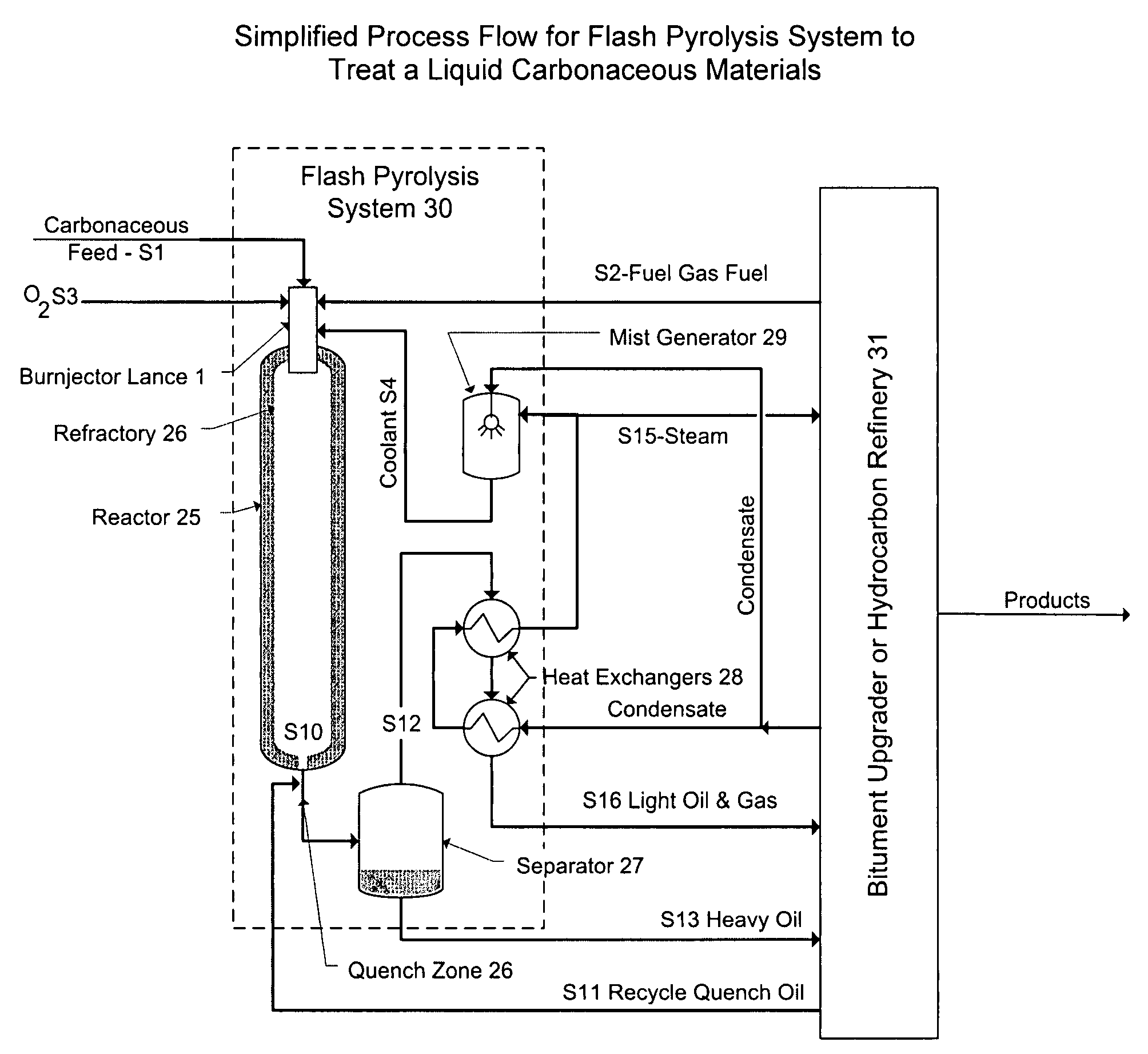

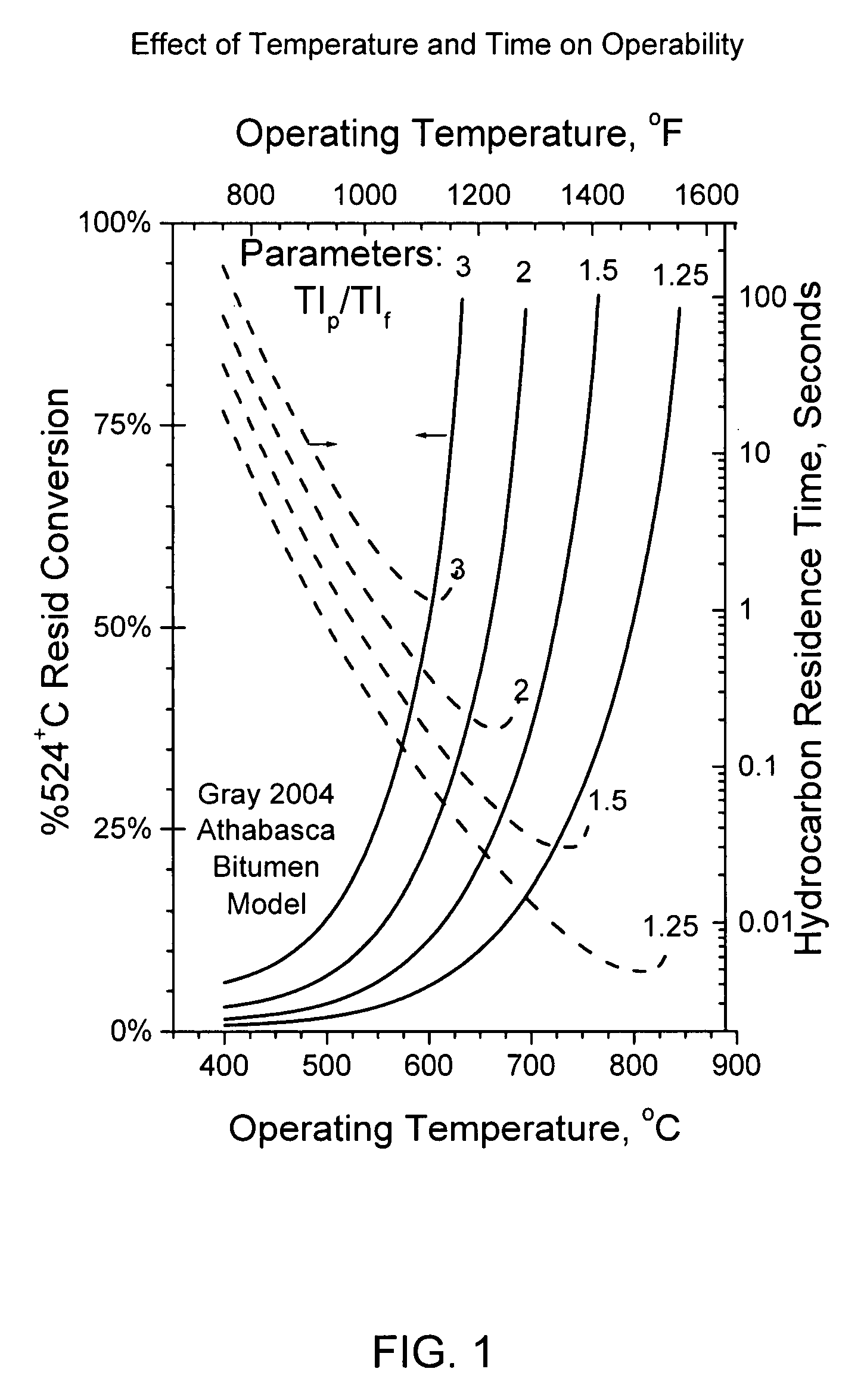

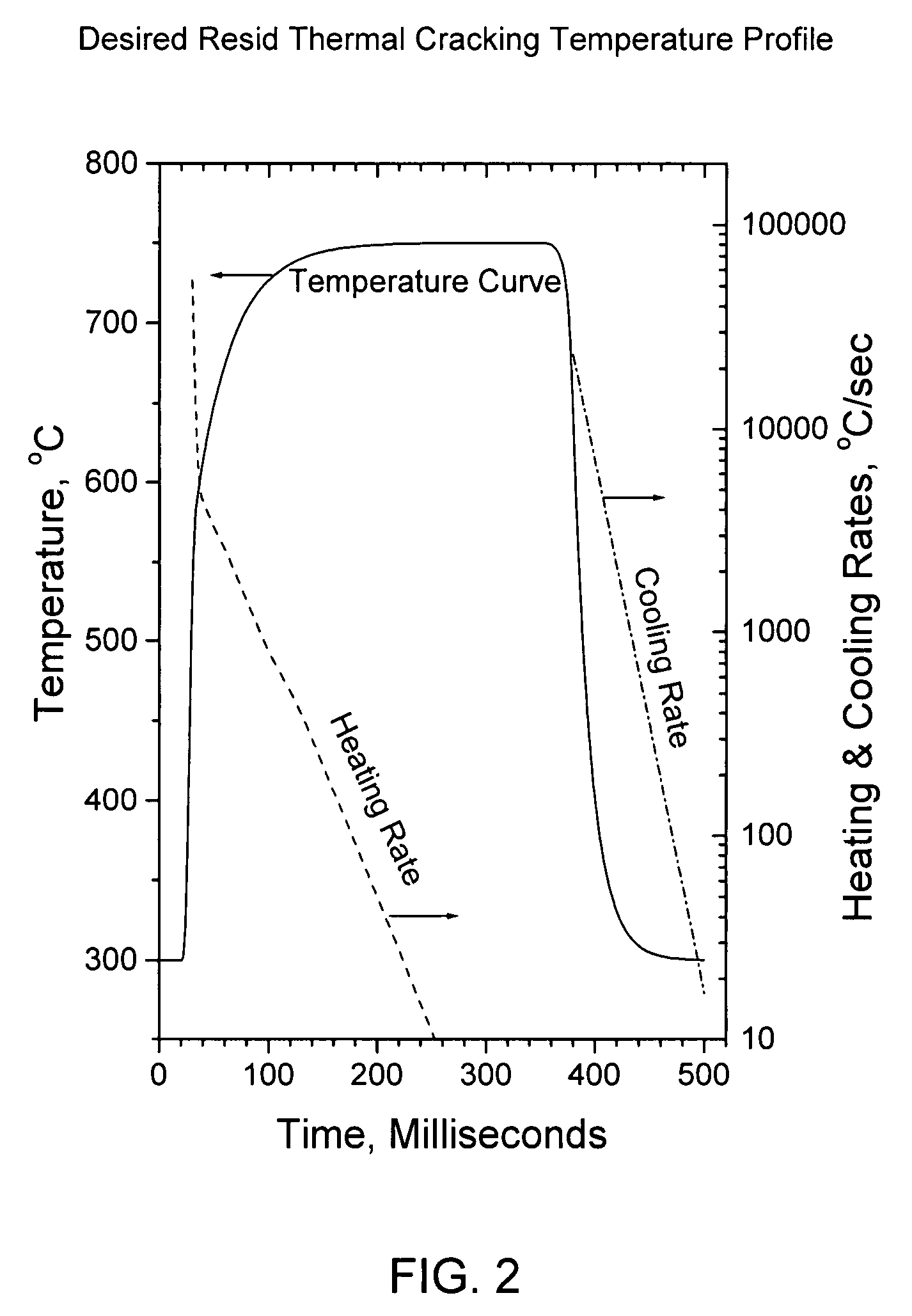

Flash pyrolosis method for carbonaceous materials

InactiveUS20070272538A1Efficient transferFast heatingThermal non-catalytic crackingDirect heating destructive distillationSufficient timeBoiling point

Methods are disclosed for pyrolizing carbonaceous materials to carbonaceous materials having lower boiling points by heating the carbonaceous material to a desired reaction temperature and holding the carbonaceous material in contact with the heat for a sufficient time to achieve the desired reaction to a lower boiling point carbonaceous materials, then rapidly cooling the desired reaction products. The heating source is a jet which will provide hot and high velocity gas streams to the carbonaceous material to be heated.

Owner:BOC GRP INC

Method of converting pyrolyzable organic materials to biocarbon

InactiveUS20100300866A1Simple methodWidespread benefit to the efficiency of the method and the biocarbon qualityCombustible gas coke oven heatingCarbon compoundsVolatilesCarbonization

A method of forming a pyrolysed biocarbon from a pyrolyzable organic material is delineated. The method involves the conversion of pyrolyzable organic materials to biocarbon for subsequent use. A carbonization circuit is employed with individual feedstock segments being advanced through the circuit. The method facilitates user manipulation of rate of advancement of the feedstock through the circuit, selective collation of volatiles from pyrolyzing feedstock, selective exposure of predetermined feedstock segments to collated volatiles as well as thermal recovery and redistribution as desired by the user. This results in the capacity for a customizable biocarbon product, the latter being an auxiliary feature of the methodology.

Owner:ALTERNA ENERGY

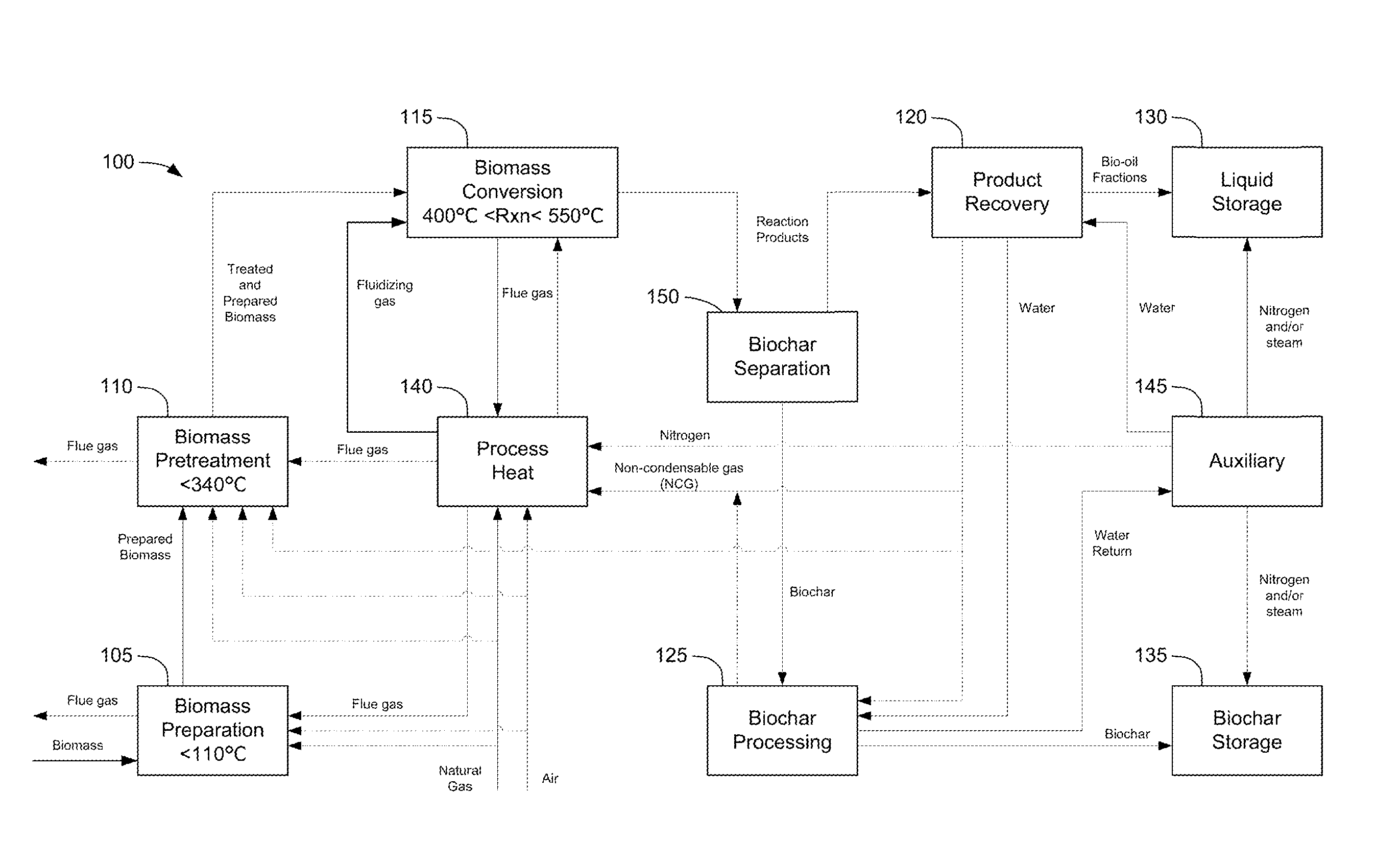

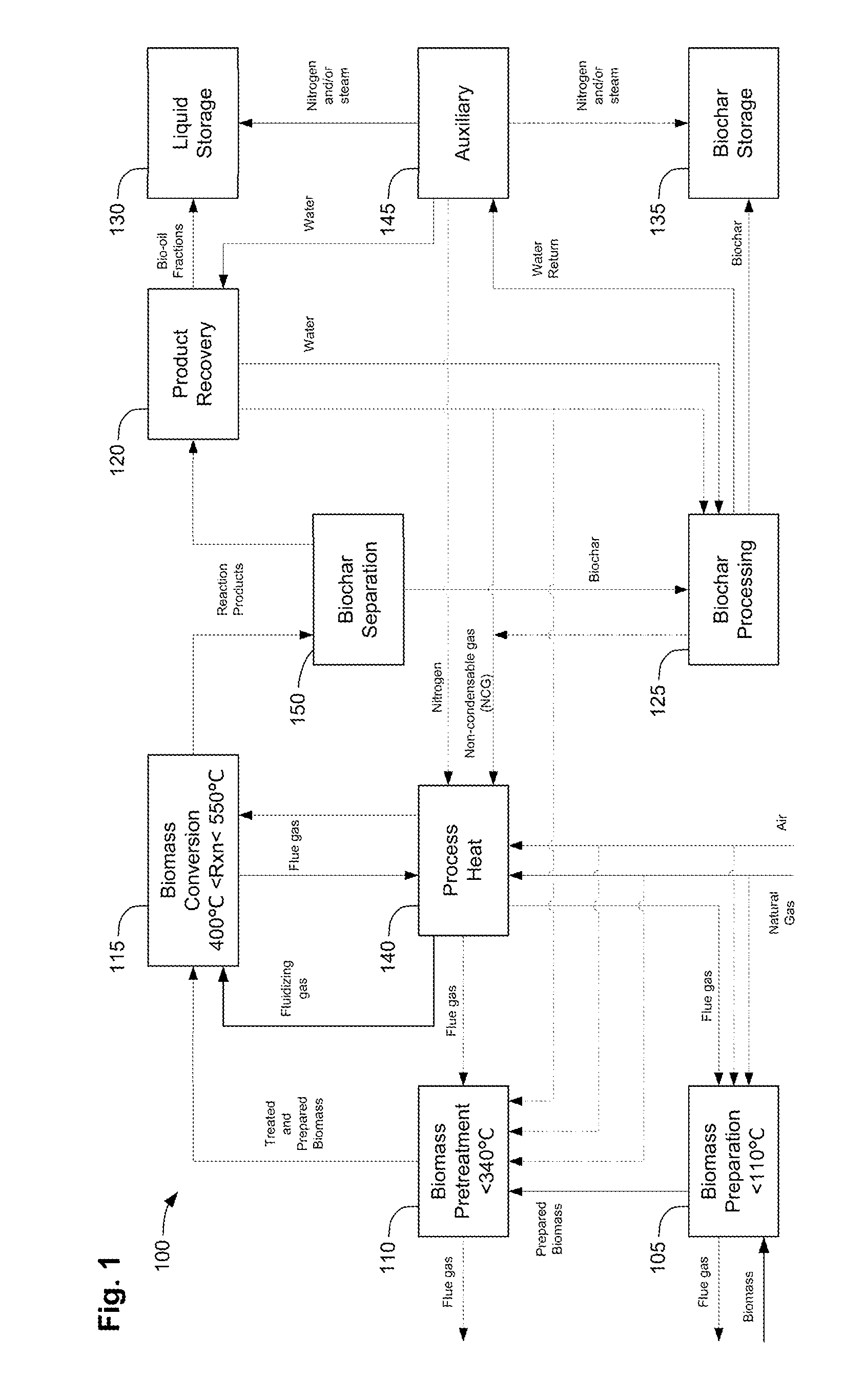

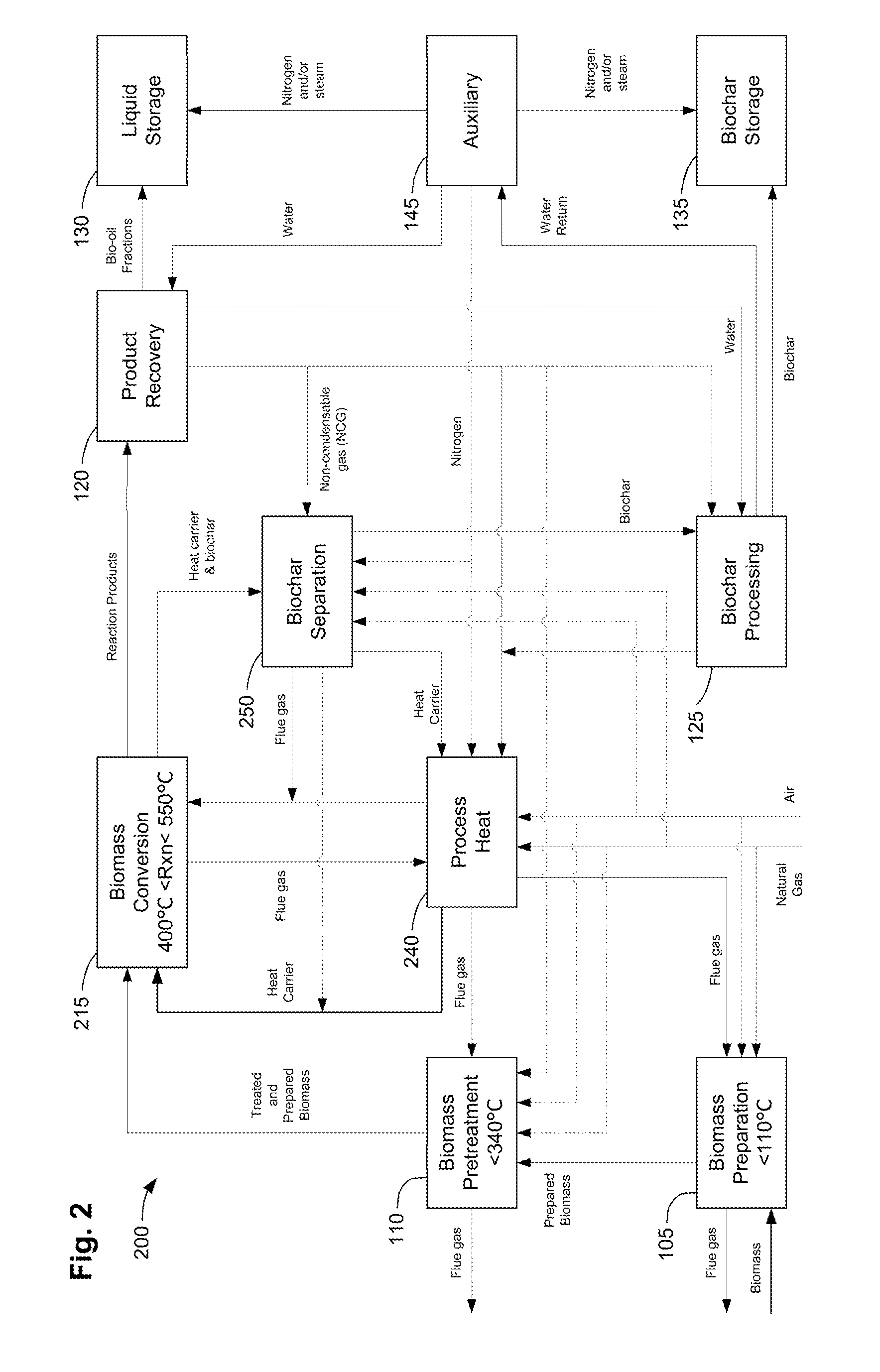

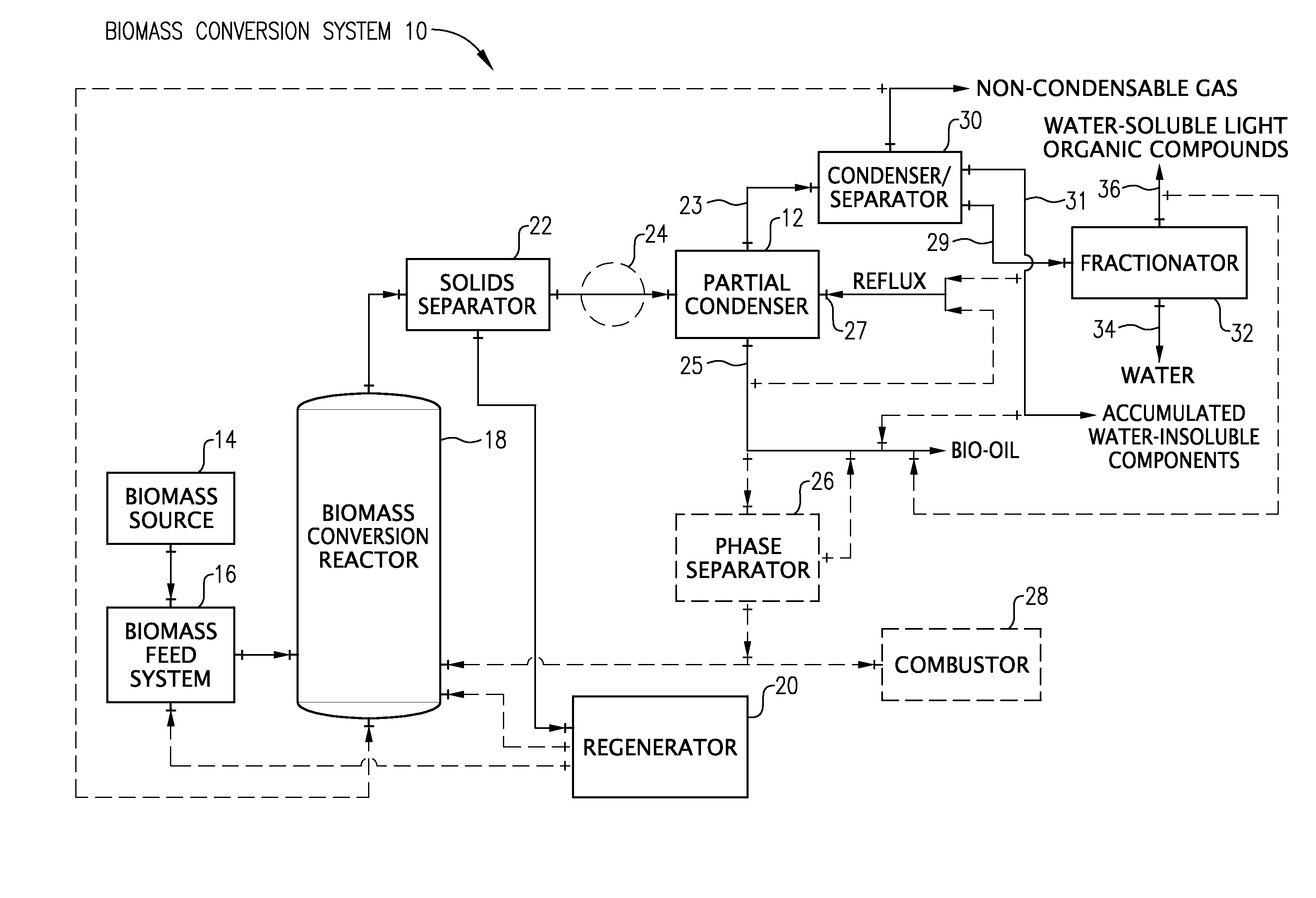

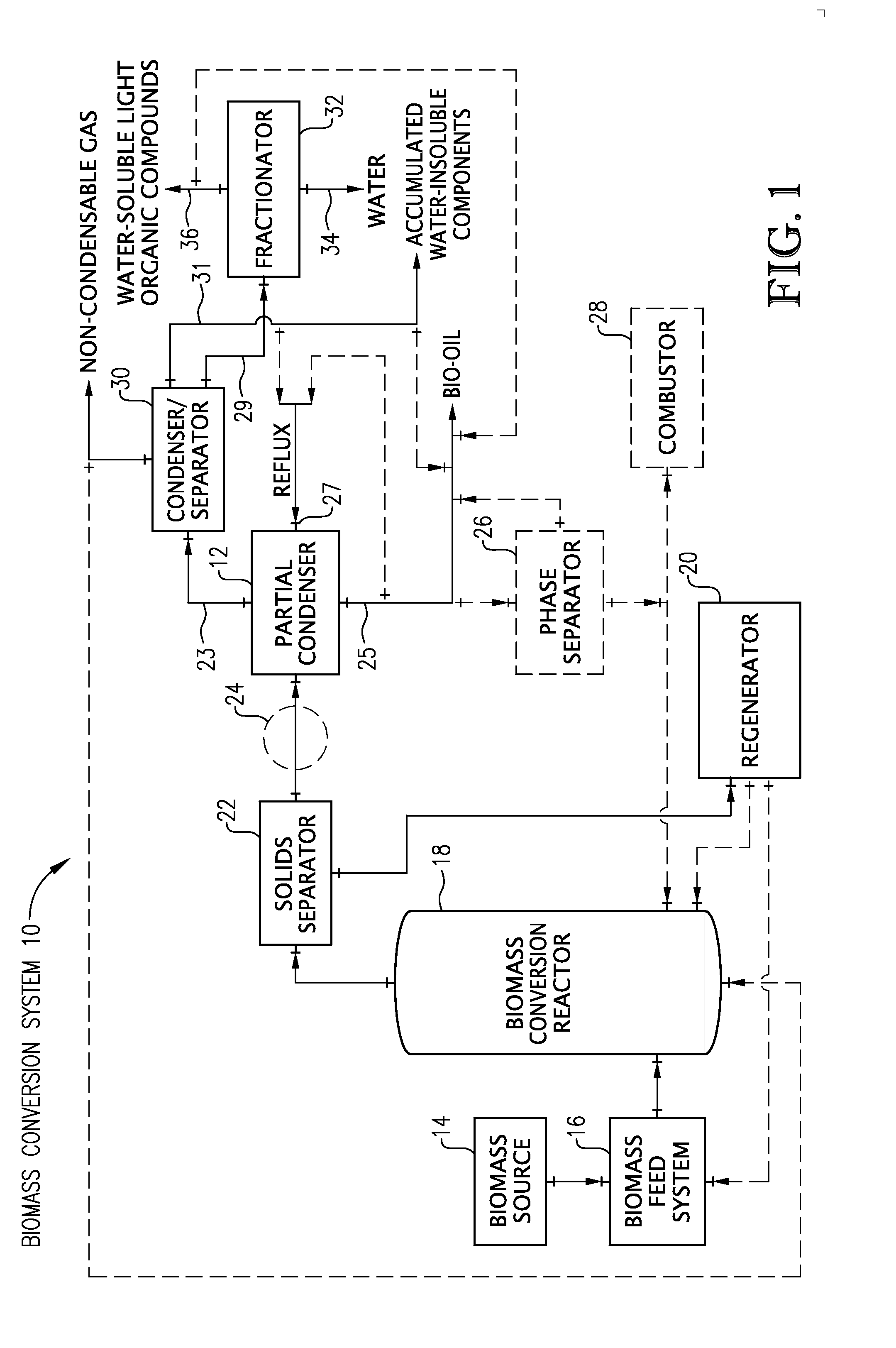

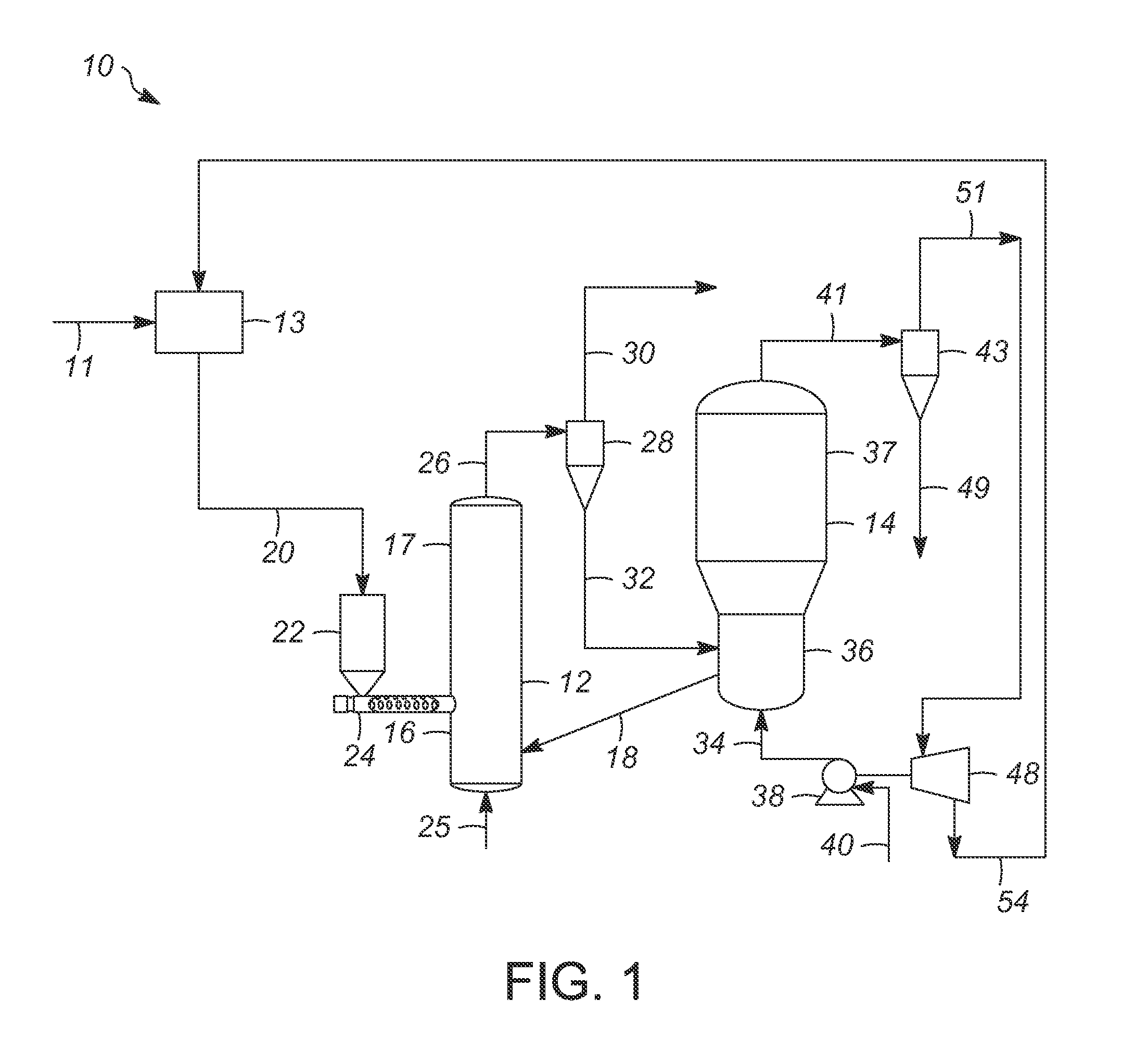

Methods for integrated fast pyrolysis processing of biomass

ActiveUS8100990B2Minimizes water contentImprove collection efficiencyDirect heating destructive distillationBiofuelsPre treatmentSafe handling

Methods, process, apparatus, equipment, and systems are disclosed for converting biomass into bio-oil fractions for chemicals, materials, feedstocks and fuels using a low-cost, integrated fast pyrolysis system. The system improves upon prior art by creating stable, bio-oil fractions which have unique properties that make them individually superior to conventional bio-oil. The invention enables water and low-molecular weight compounds to be separated into a final value-added fraction suitable for upgrading or extracting into value-added chemicals, fuels and water. Initial bio-oil fractions from the process are chemically distinct, have low-water content and acidity which reduces processing costs normally associated with conventional bio-oil post-production upgrading since fewer separation steps, milder processing conditions and lower auxiliary inputs are required. Biochar is stabilized so that it can be handled safely. The integrated fast pyrolysis process includes biomass storage, preparation, pretreatment, and conversion, product recovery and processing to create and store stable biochar and bio-oil fractions.

Owner:AVELLO BIOENERGY

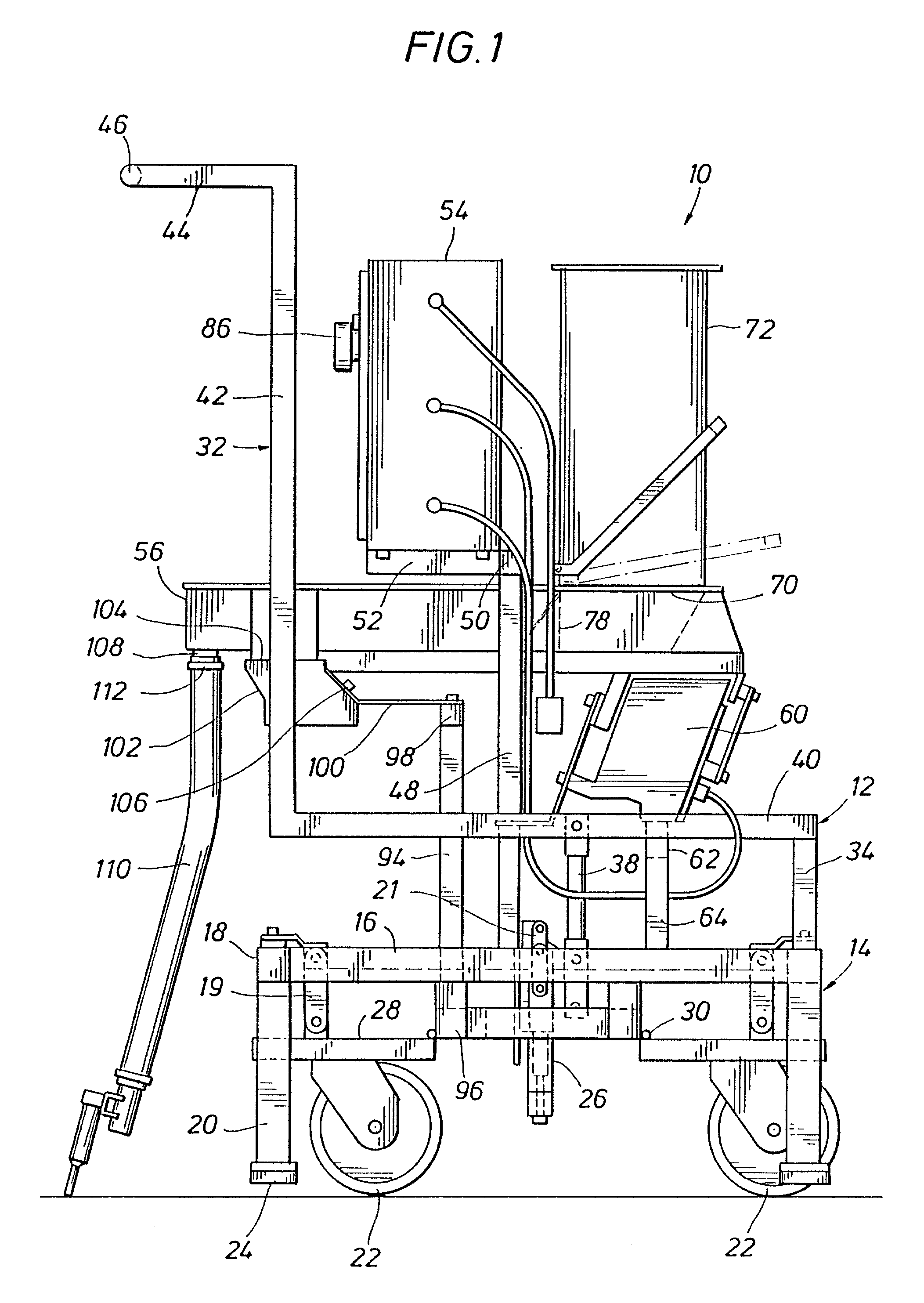

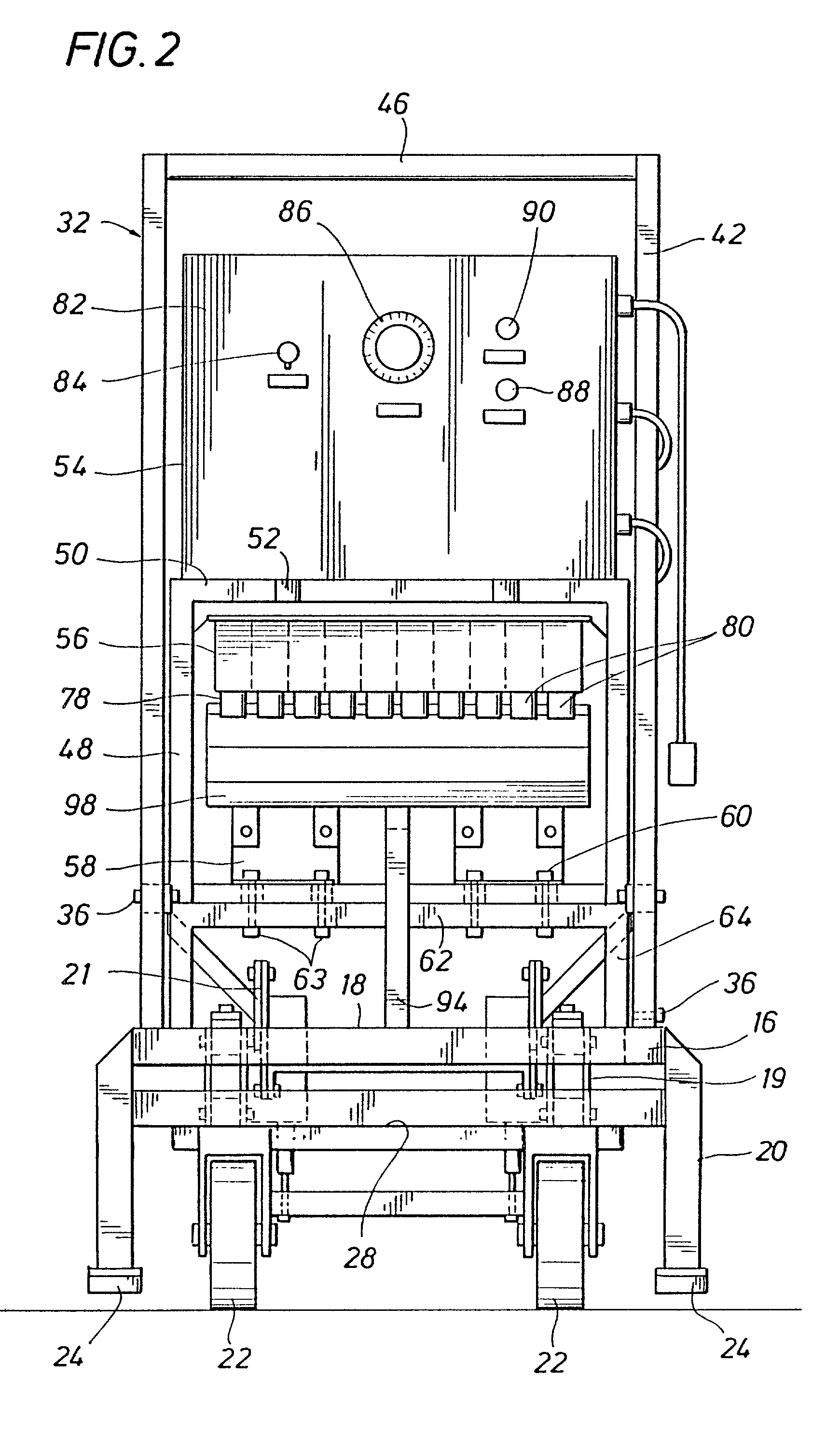

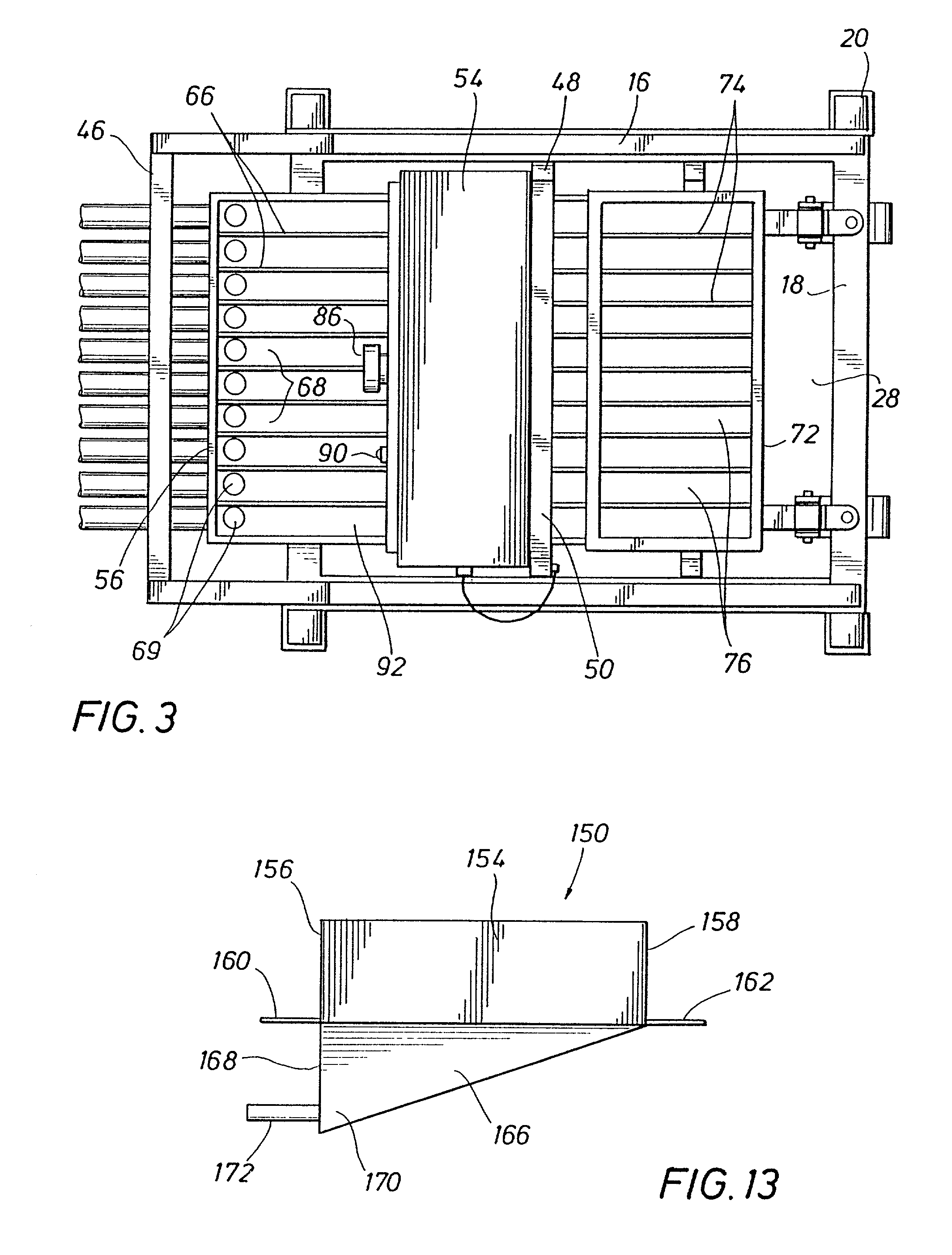

Catalytic reactor charging system and method for operation thereof

InactiveUS20010041117A1Permit accuracyPermit efficiencyTank vehiclesBell-and-hopper arrangementPtru catalystControl system

A catalyst loading system for utilizing catalyst from a bulk supply located adjacent but not on the upper tube sheet of a catalytic reactor and for mechanized measuring of multiple identical quantities of catalyst and for mechanized loading of catalyst pellets into the reaction tubes of the reactor to achieve even drop rate, compaction and outage of the reaction tubes. From the bulk supply, multi-compartment catalyst charging hoppers are individually filled in rapid and accurately measured fashion by mechanized filling equipment having a predetermined sequence of operation that ensures accuracy of volumetric catalyst measurement. The charging hoppers are used for delivery of measured volumes of catalyst of a reactor tube loading mechanism which may take the form of a mobile cart framework being selectively positionable relative to the upper tube sheet and reaction tubes of a catalytic reactor to be charged with catalyst pellets. A pair of electronic vibrators are mounted to the cart framework and provide for support and vibratory movement of a vibratory tray having a catalyst feed hopper adapted to feed catalyst pellets to a plurality of generally parallel catalyst transfer troughs along which catalyst pellets are moved by vibration of the vibratory tray to a plurality of drop tubes. A compartmented hopper is fixed to the vibratory tray and controllably feeds catalyst pellets into respective catalyst transfer troughs. A plurality of charging tubes are connected to respective drop tubes by a plurality of elongate flexible tubes and are maintained in fixed, spaced relation by a structural element so as to define a charging manifold for simultaneous, timed delivery of catalyst pellets into a plurality of reactor tubes. The charging manifold has locator pins which are inserted into selected reactor tubes for orienting the charging tubes of the charging manifold with respect to a selected group of reaction tubes. A system is also provided for raising and lowering the charging manifold for efficiency of reactor tube charging operations. An electronic control system is effective for controlling the vibrators to achieve even drop rate from each of the catalyst transfer troughs and to control the vibrators responsive to catalyst weight to achieve even catalyst drop rate during an entire catalyst charging cycle.

Owner:COMARDO MATHIS P

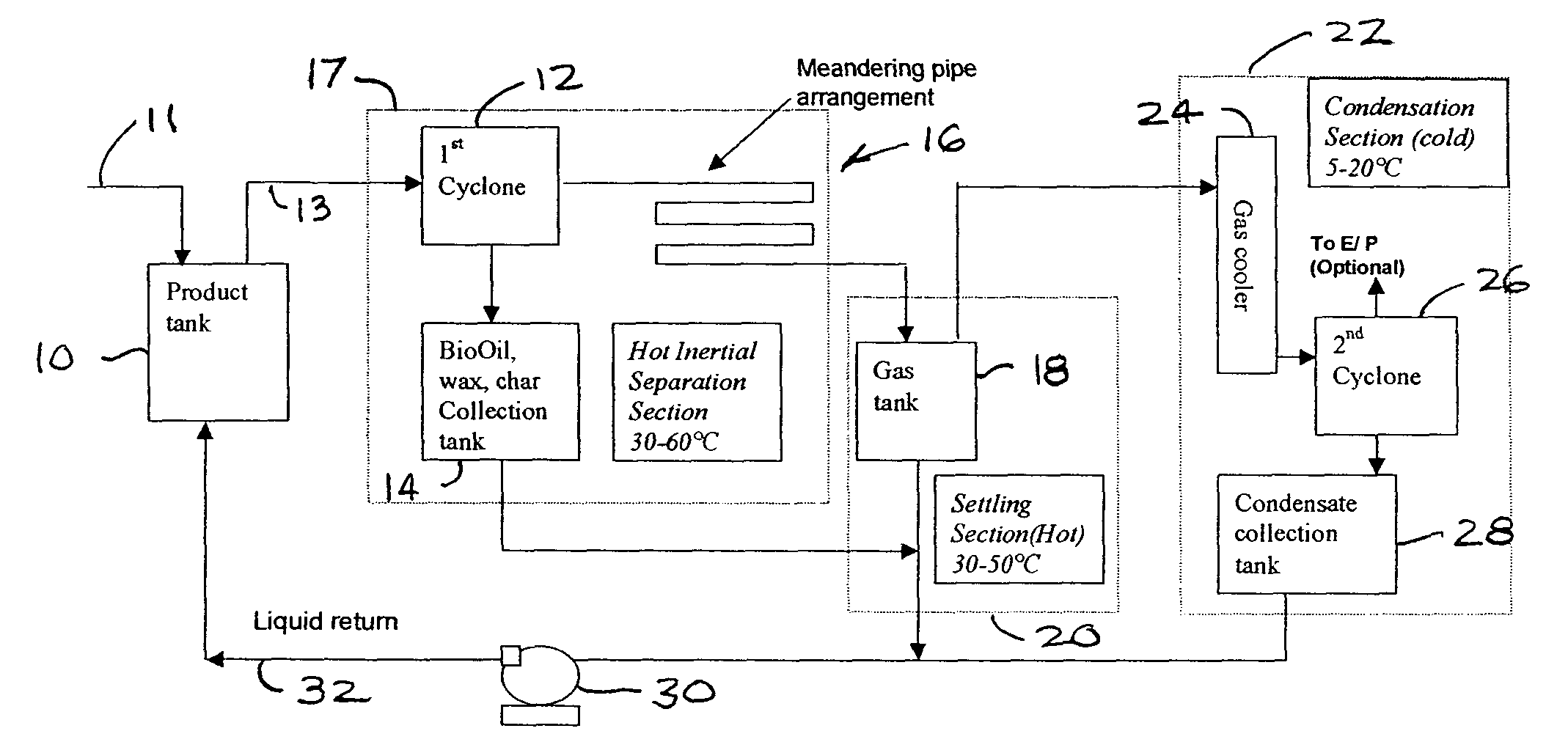

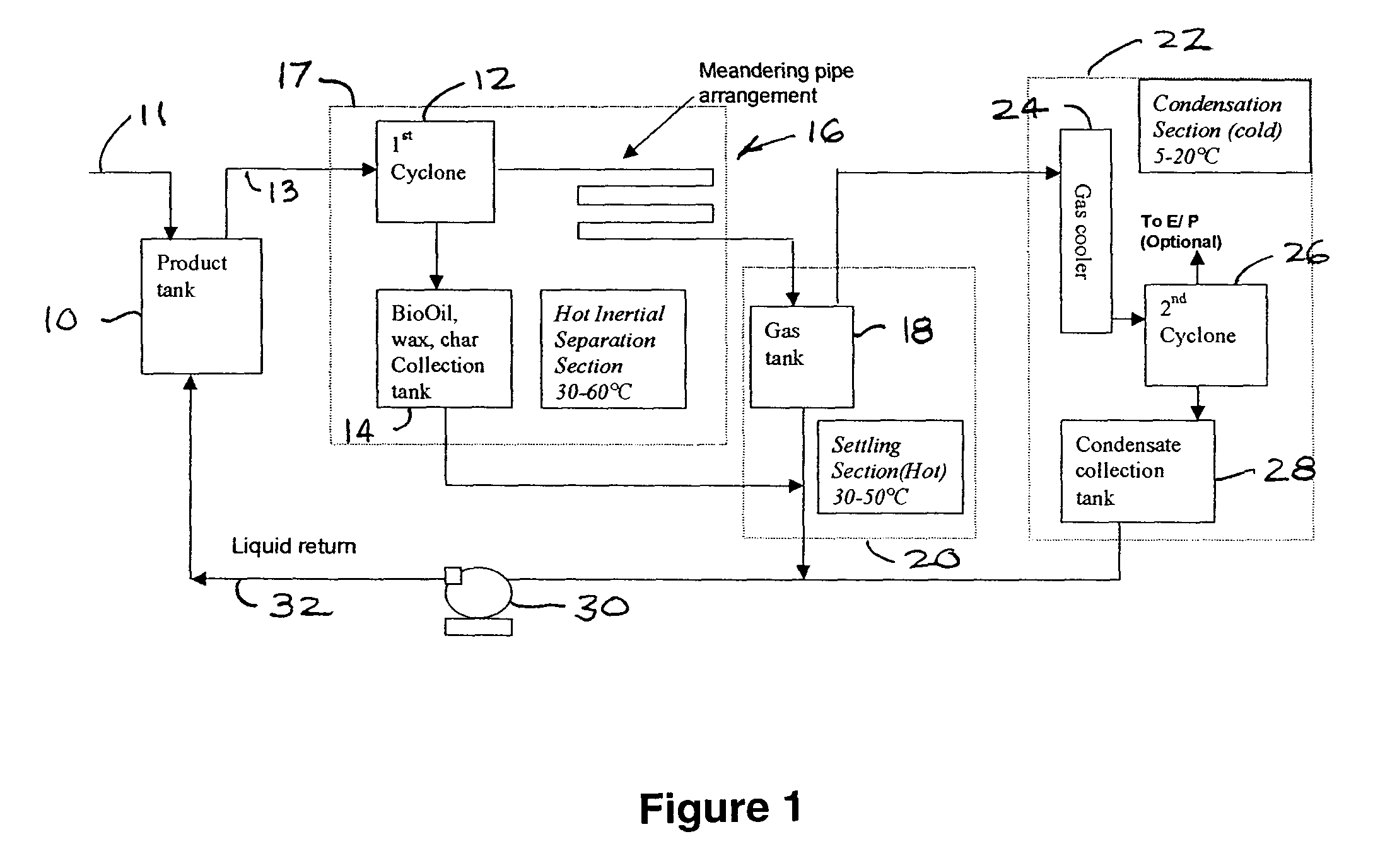

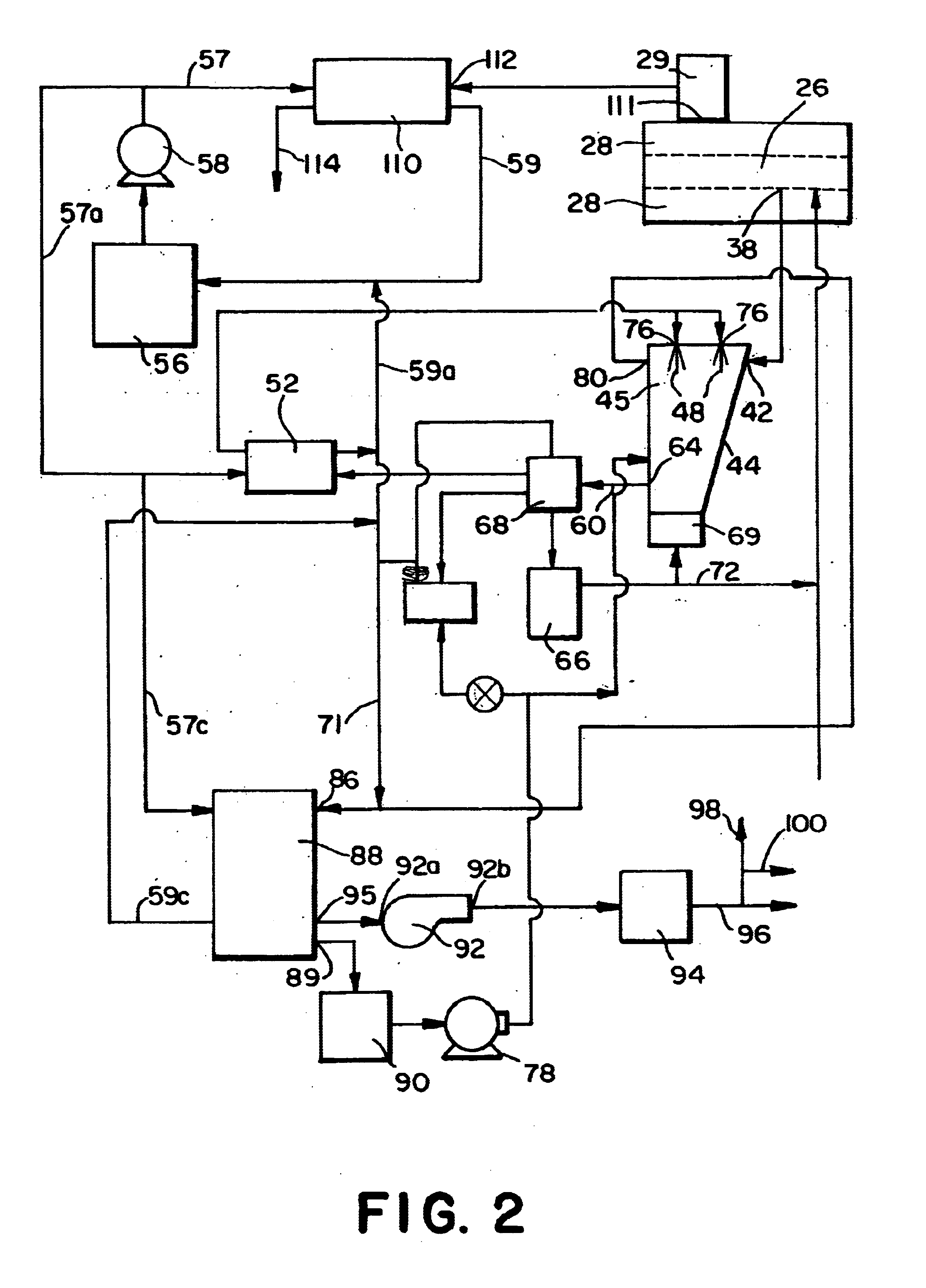

Apparatus for separating fouling contaminants from non-condensable gases at the end of a pyrolysis/thermolysis of biomass process

InactiveUS7004999B2Extended retention timeSlow downCombination devicesLiquid degasificationProduct gasComponents of crude oil

A method of continuously capturing BioOil and its constituents from a gas stream produced in a fast pyrolysis / thermolysis process, in a usable liquid form so as to produce a non-condensable gas free of fouling contaminates. The method includes separating BioOil and its constituents from a gas stream using hot inertial separation to maintain the temperature of said BioOil and its constituents above a temperature at which the thick and / or sticky constituents cause inefficient operation of the equipment but low enough so that they do not undergo rapid degradation. Next the gas velocity is reduced to a temperature sufficiently low to allow droplets in the gas stream to settle out but high enough so that a viscosity of said droplets remains low enough to avoid inefficient operation of the separation equipment. Finally, liquid is condensed out of the gas stream.

Owner:DYNAMOTIVE ENERGY SYST CORP

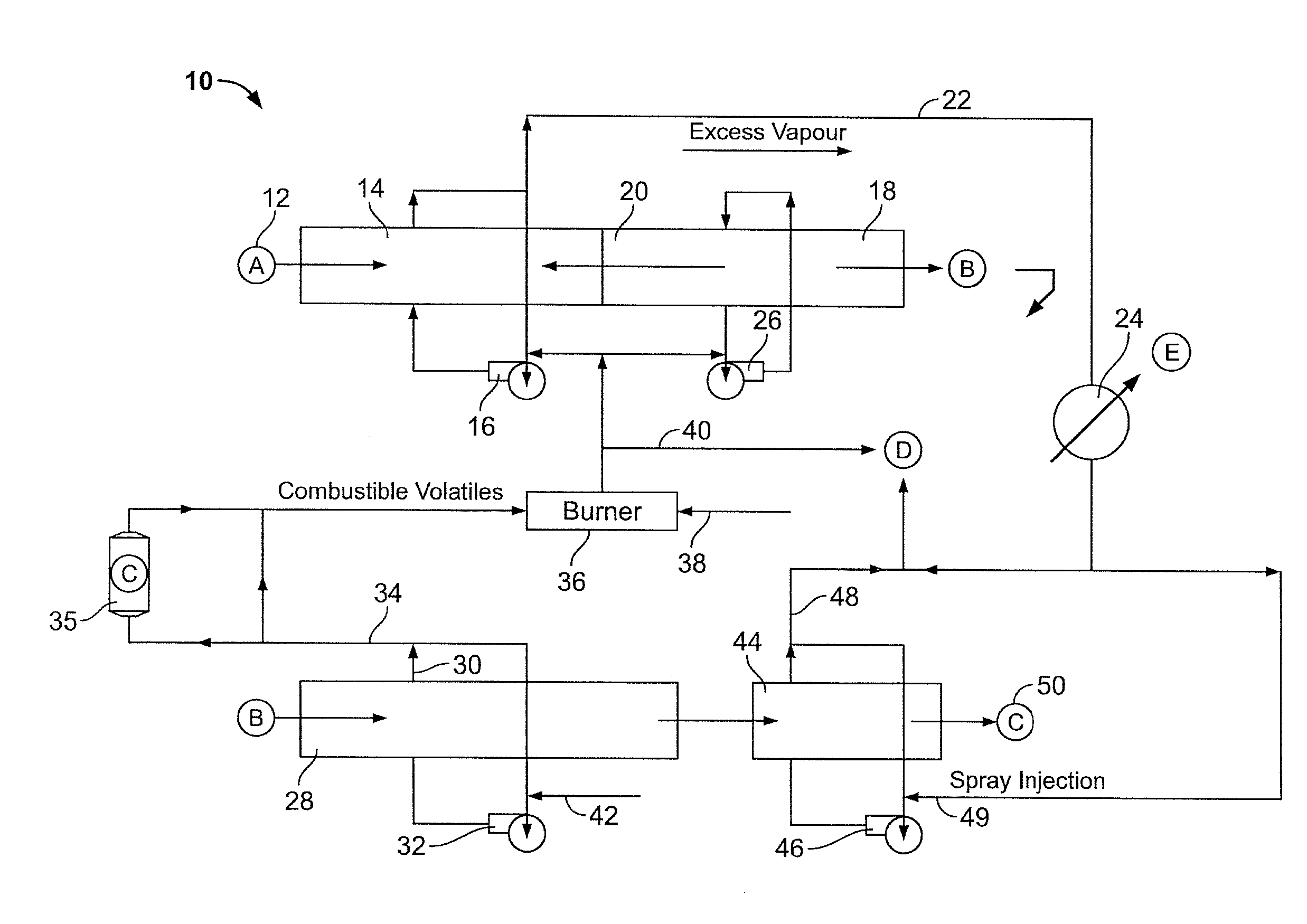

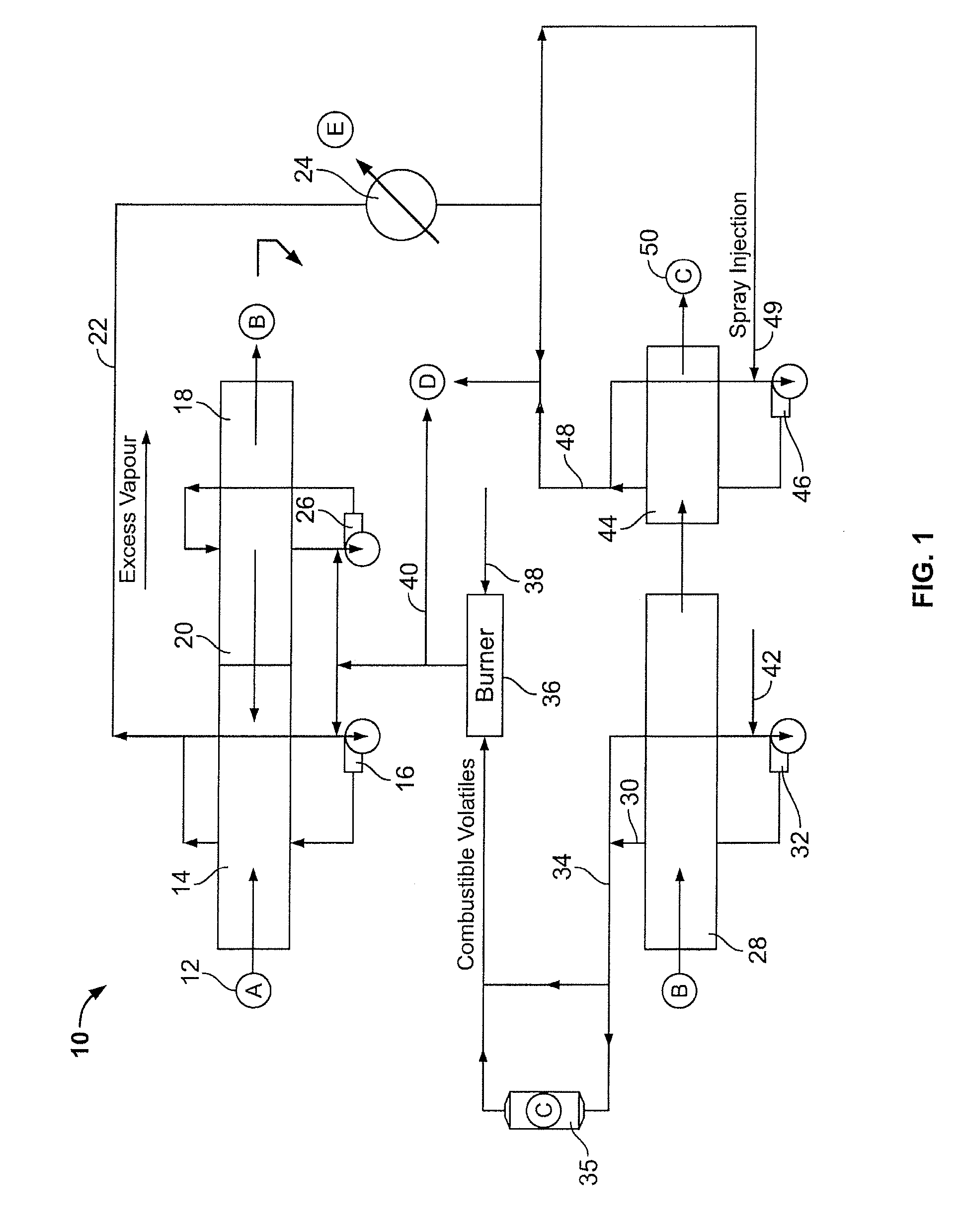

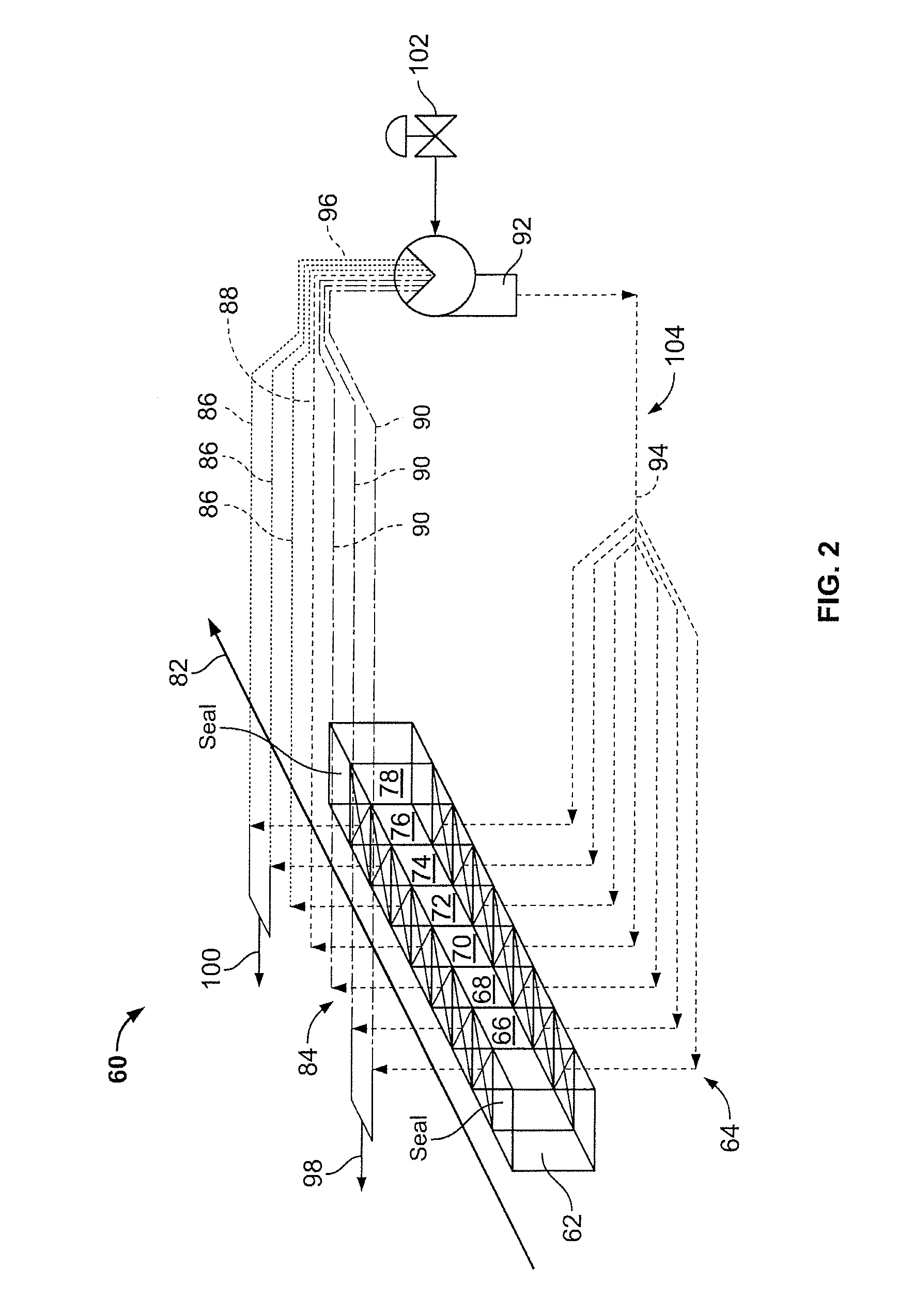

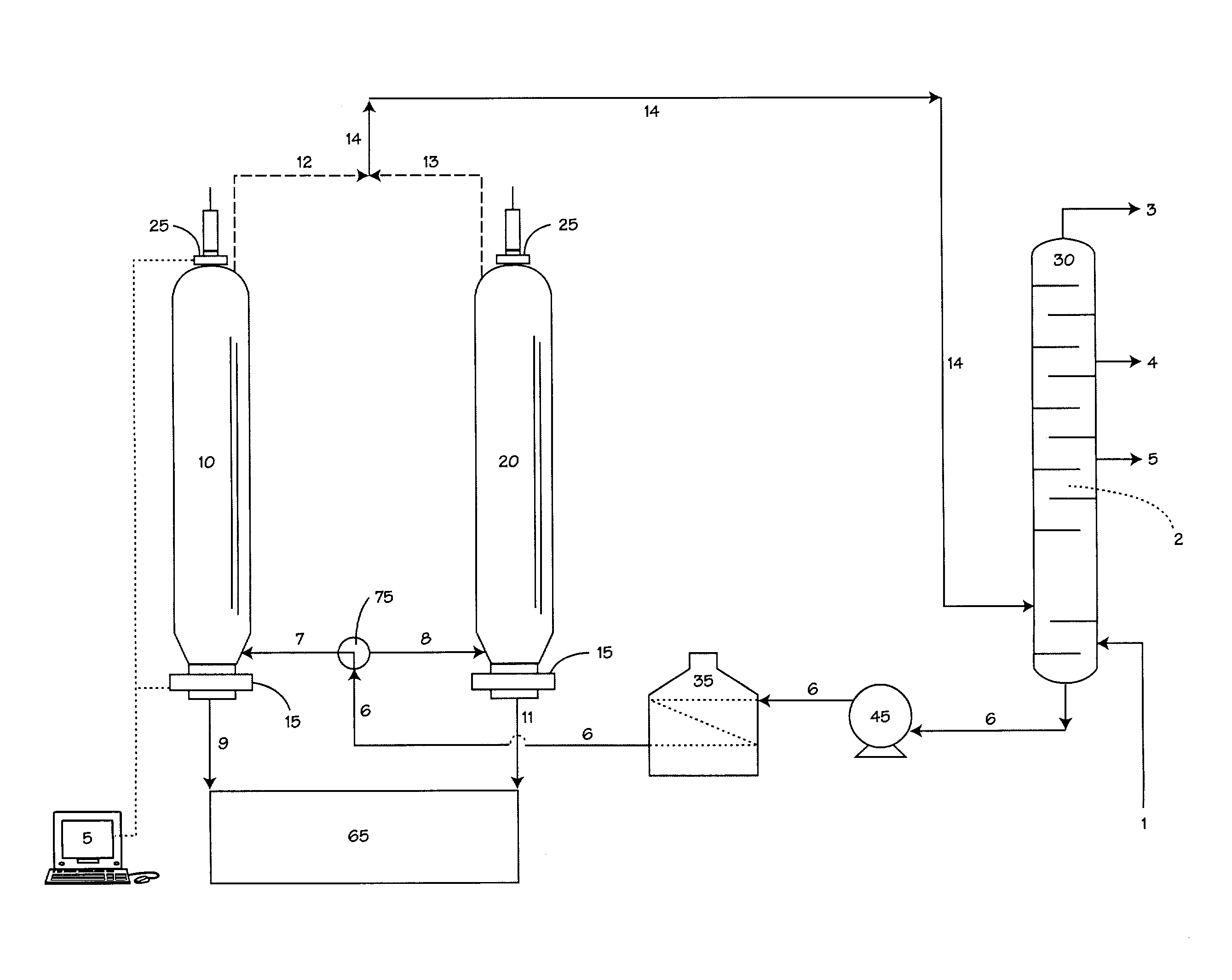

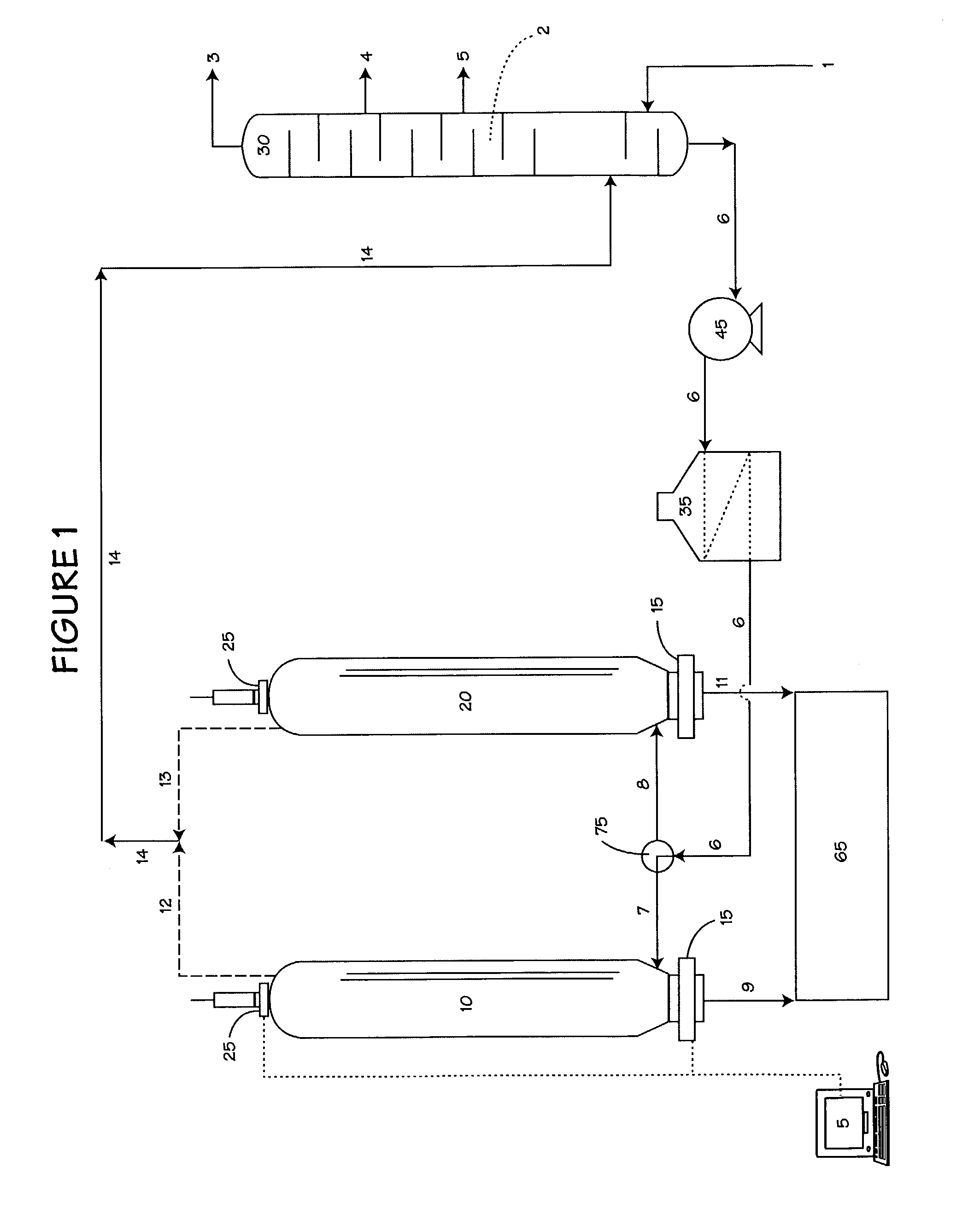

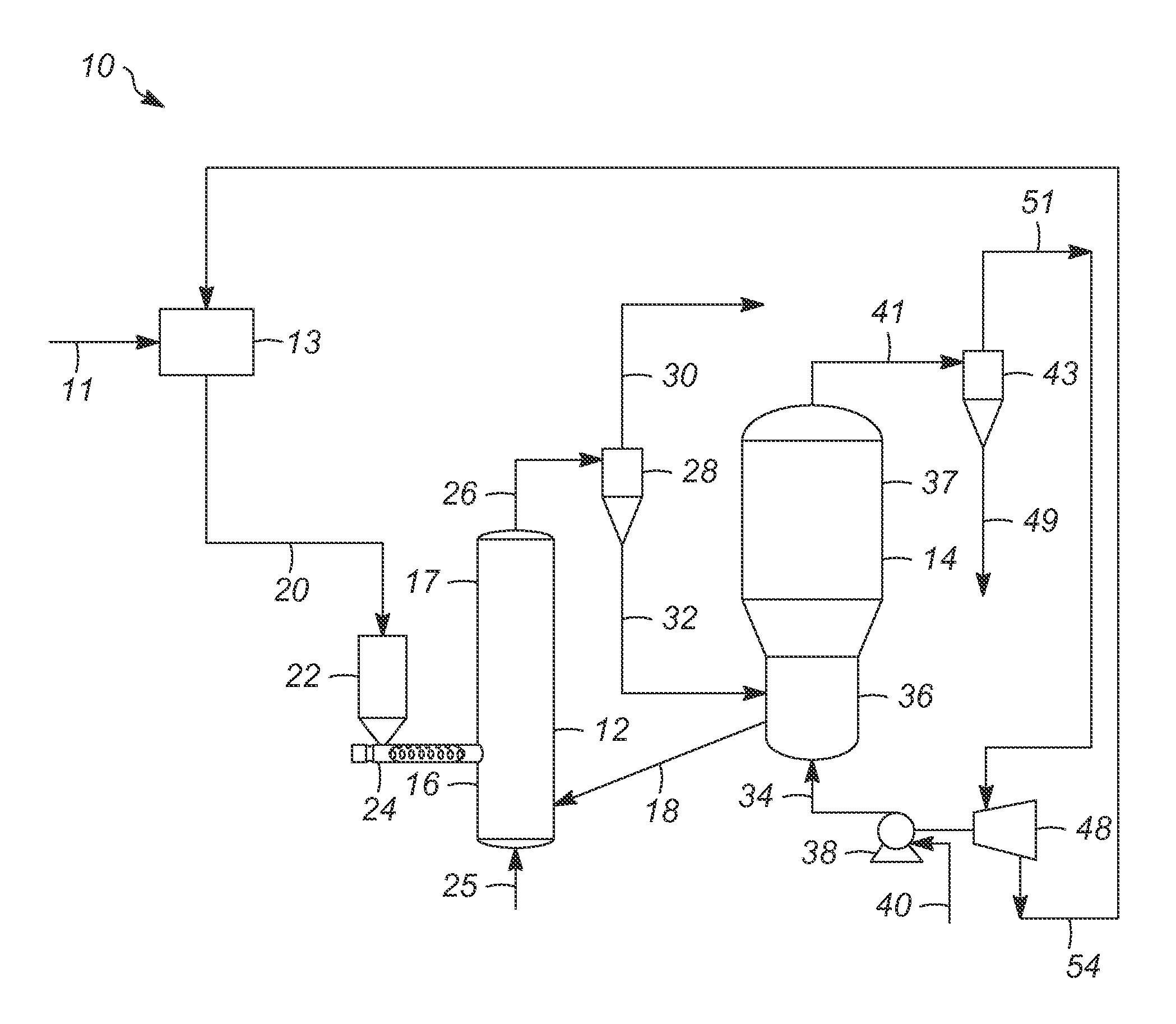

Process for pyrolyzing tire shreds and tire pyrolysis systems

Tire pyrolysis systems and processes are provided which include feeding tire shreds to a pyrolysis reactor, pyrolyzing the shreds in a pyrolysis reactor to produce a hydrocarbon-containing gas stream and carbon-containing solid, removing the carbon-containing solid from the reactor, directing the hydrocarbon-containing gas stream into a separator, contacting the hydrocarbon-containing gas stream with an oil spray in the separator thereby washing particulate from the hydrocarbon-containing gas stream and condensing a portion of the gas stream to oil, removing and cooling the oil from the separator, directing non-condensed gas from the gas stream away from the separator, and directing a portion of the cooled oil removed from the separator to an inlet of the separator for use as the separator oil spray. A process is also provided in which solids from the pyrolysis reactor are directed to an auger having a pressure which is greater than the pressure in the pyrolysis reactor, and in which non-condensed gas from the gas stream after condensing a portion of the gas is directed to at least one burner in heat exchange relation with the pyrolysis reactor, and burned to heat the reactor and generate an effluent flue gas, a portion of which effluent flue gas is cooled and injected into the auger which is a trough auger in one embodiment.

Owner:RENAISSANCE ENERGY GROUP

Removal of water from bio-oil

A process and system for separating water from bio-oil by using a partial condenser. The process comprises partially condensing vapor conversion products from a biomass conversion reaction to produce a water-rich overhead stream and a water-depleted stream comprising condensed bio-oil. The partial condenser removes a substantial portion of the water from the bio-oil, while providing an effective and flexible process for producing bio-oil.

Owner:MARD INC

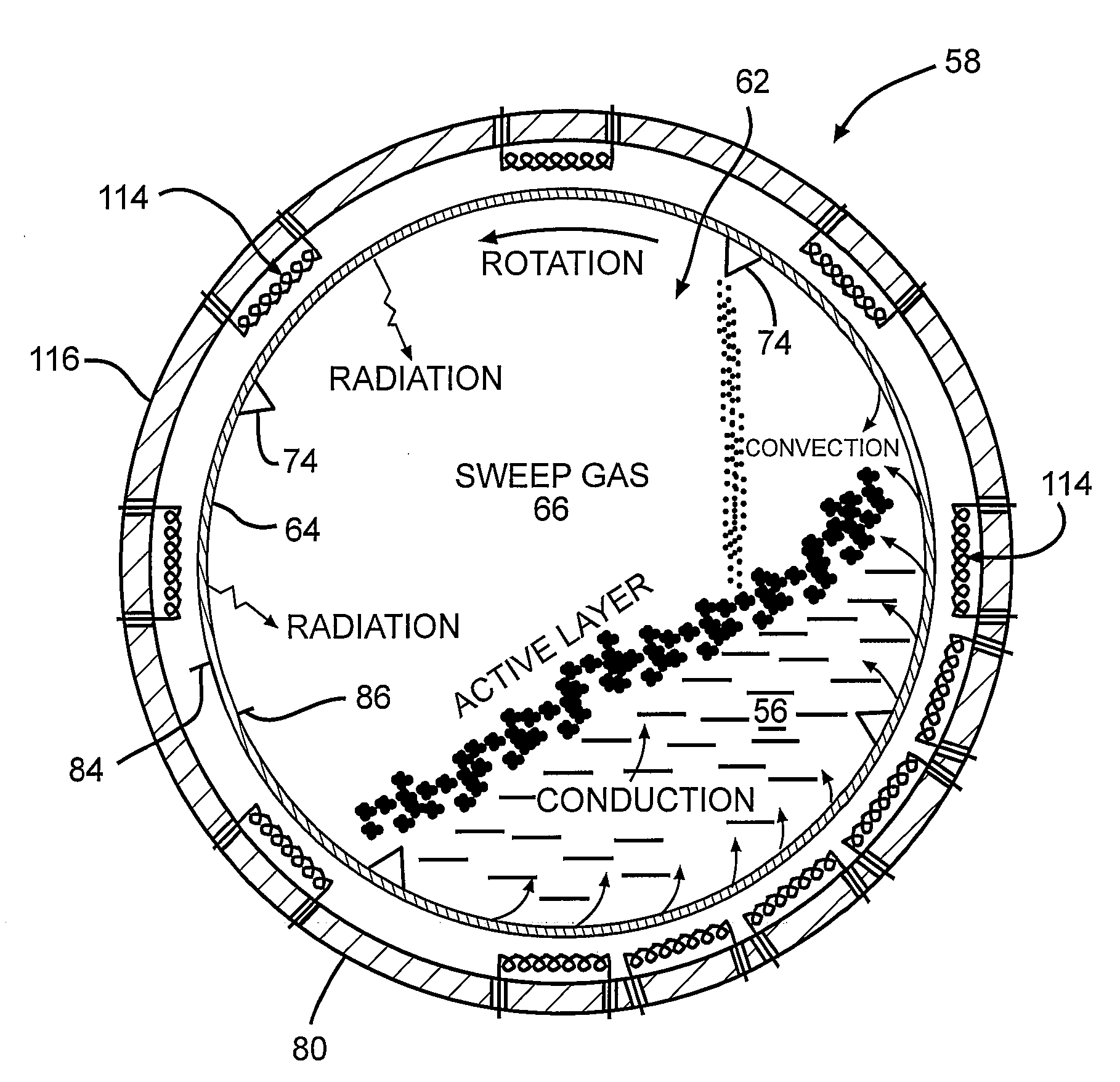

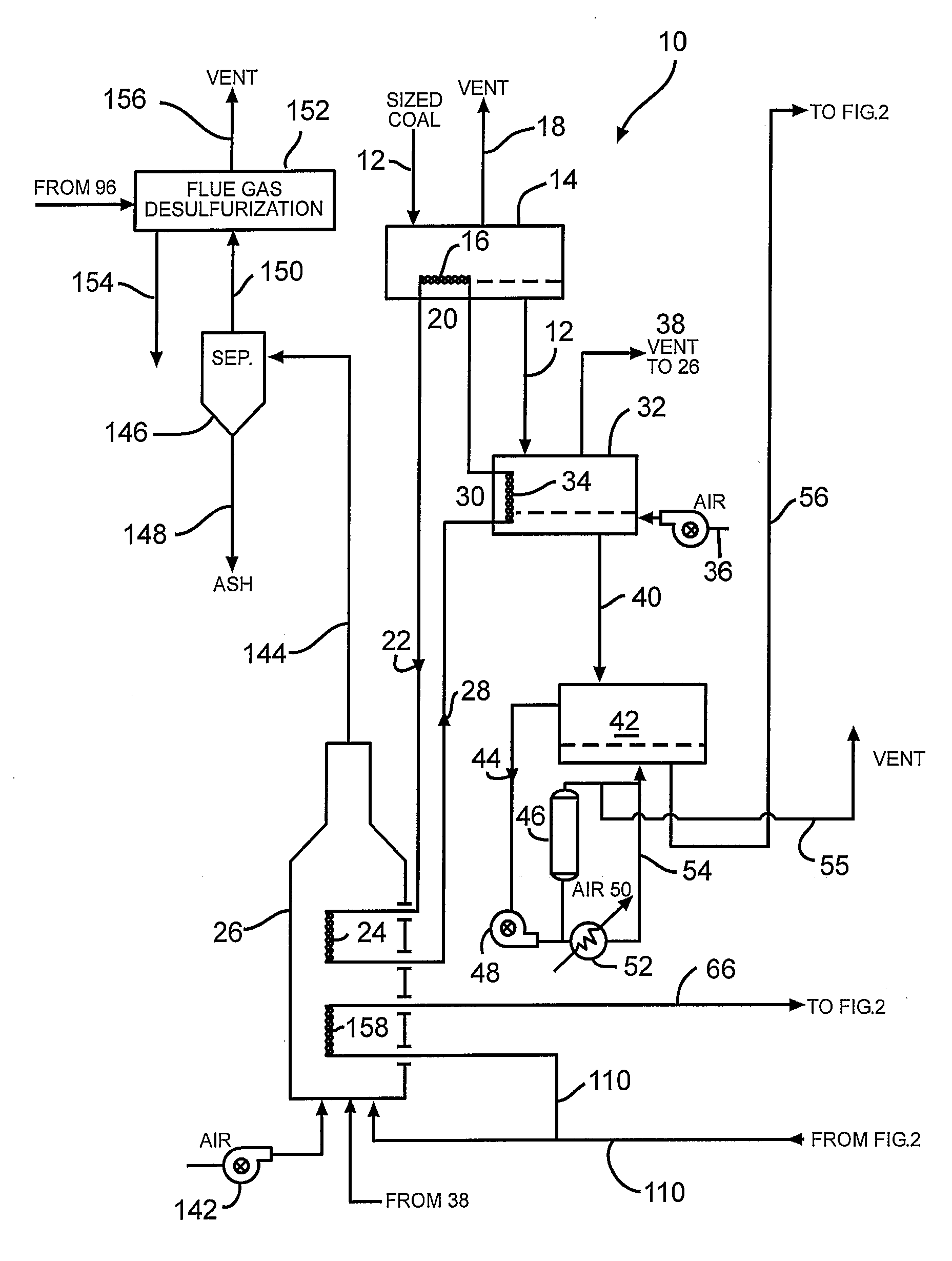

Process for treating agglomerating coal by removing volatile components

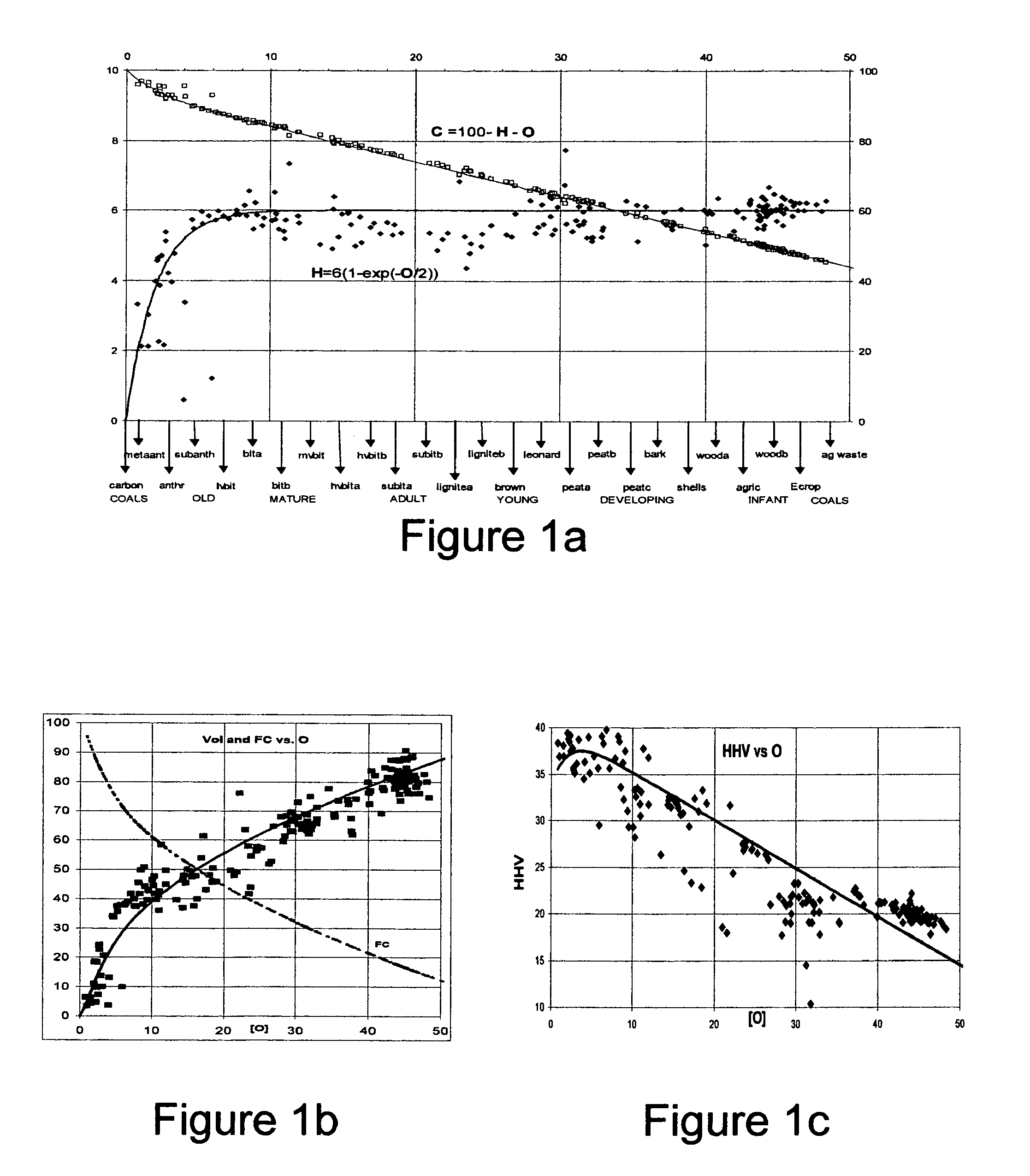

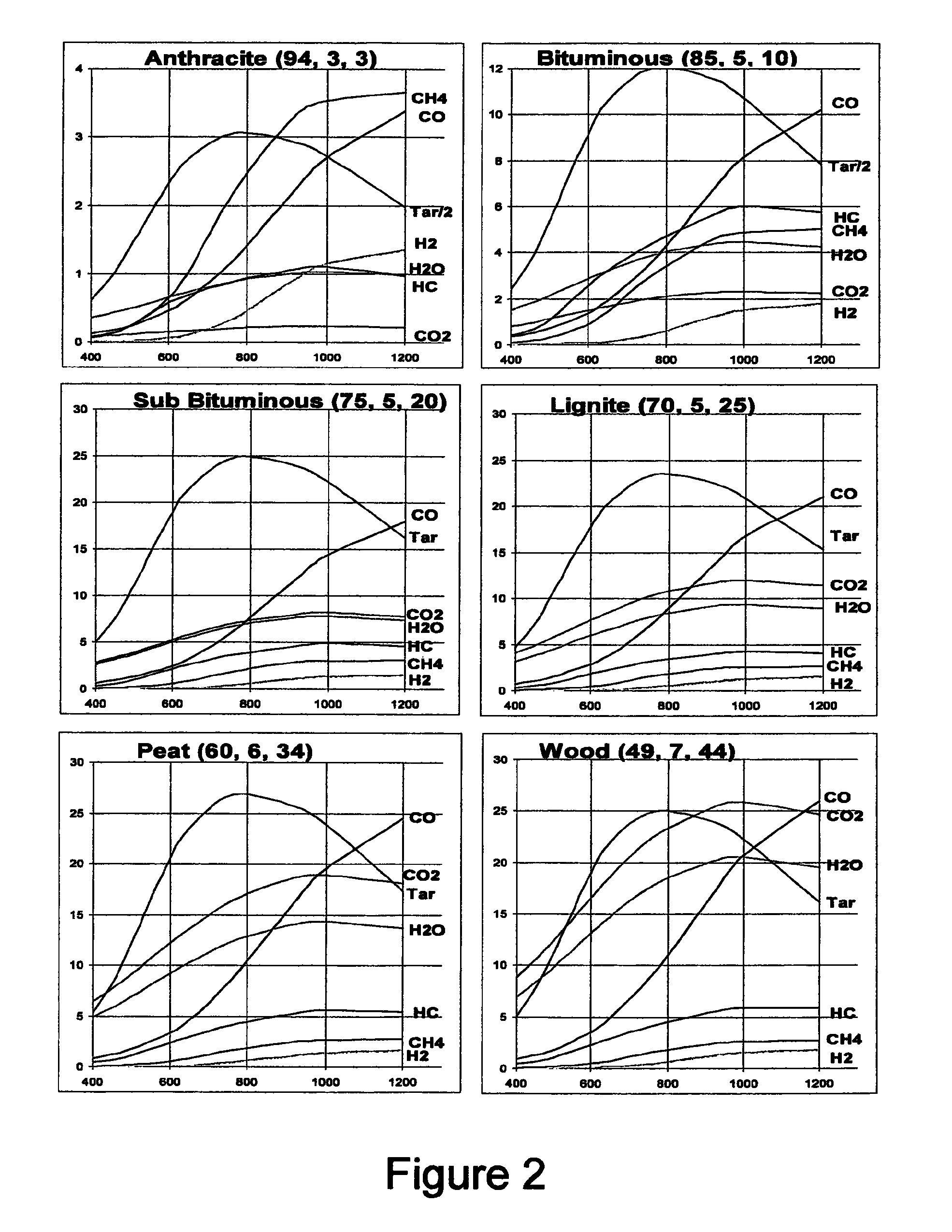

InactiveUS20110011720A1Gain weightSolid waste disposalDirect heating destructive distillationOxygen contentCoal particle

A process for treating agglomerating coal includes providing dried, pulverized, agglomerating coal, and treating the coal in a vessel with a gas stream having an oxygen content sufficient to form at least some oxides on surface of coal particles, wherein the oxides are sufficient to convert coal into substantially non-agglomerating coal. The treated coal is transferred into a pyrolyzing chamber and passed into contact with an oxygen deficient sweep gas, the sweep gas being at a higher temperature than the temperature of the coal so that heat is supplied to the coal. The process further includes providing additional heat to coal indirectly by heating the chamber, wherein the heating of coal by the sweep gas and by the indirect heating from the chamber causes condensable volatile components to be released into the sweep gas. The sweep gas is removed from the chamber and treated to remove condensable components of coal.

Owner:C2O TECH

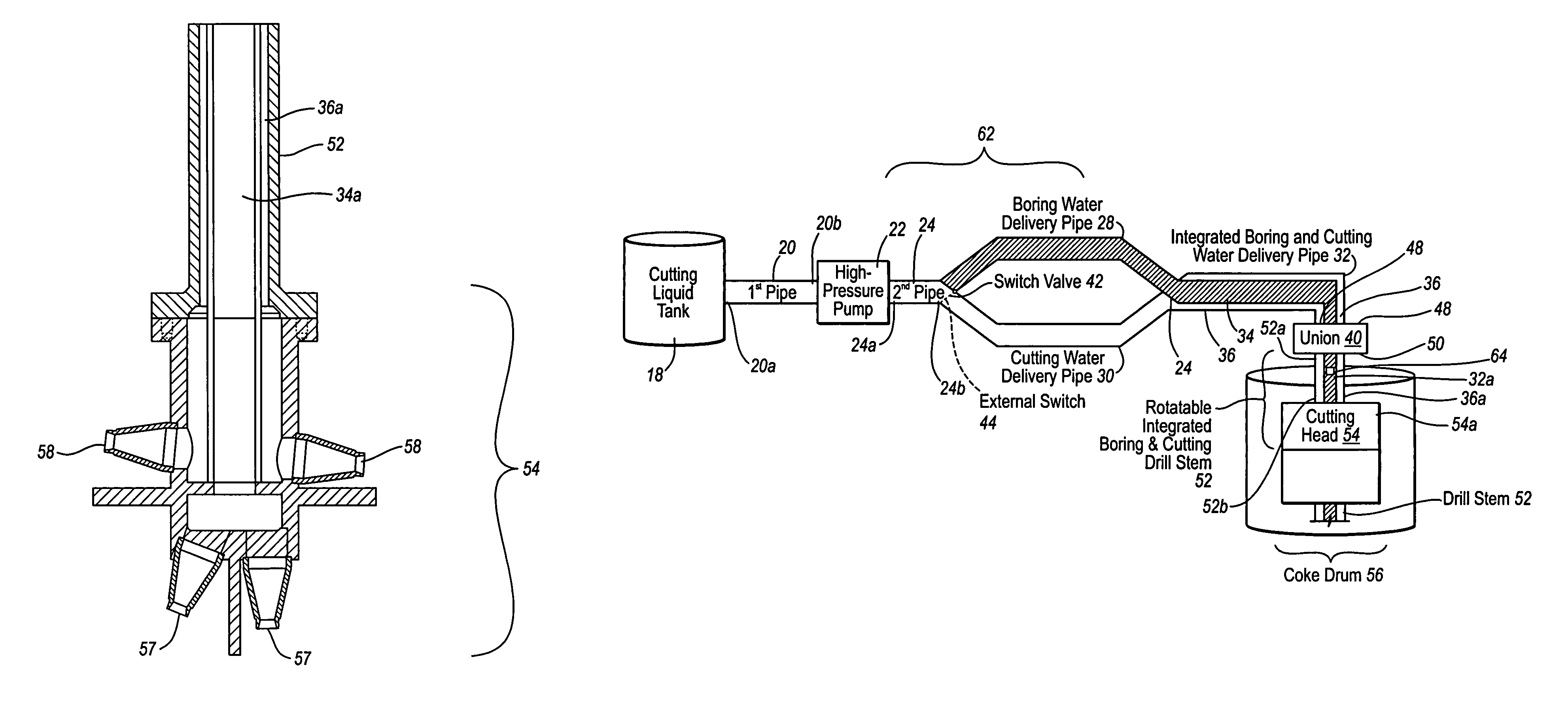

Safe and automatic method for preparation of coke for removal from a coke vessel

InactiveUS7037408B2Prevent leakageReduces and eliminates dangerousThermal non-catalytic crackingDirect heating destructive distillationSteam pressureDrill

A safe, efficient and repetitively operable coke vessel decoking system is disclosed. In a preferred embodiment the closed system comprises a coker vessel pressure-tightly sealed to a top head system, which includes a closure housing with a laterally moveable horizontal closure member therein and a cutting head enclosure, which further comprises a drill stem guide, an access door, and a cutting assembly mounted therein. A novel feature of the invention is a steam purge / blocking system whereby steam pressure is maintained in the closure housing during the coking cycle to maintain seal integrity. Personnel safety during decoking operations is greatly enhanced by eliminating dangerous manual tasks associated with the prior art such as unbolting and removing top head devices. The system can be remotely and repetitively operated through numerous coking / decoking cycles without removal of any system element.

Owner:CHEVROU USA INC

Continuous coking process

InactiveUS20070108036A1Thermal non-catalytic crackingCombustible gas coke oven heatingThermodynamicsCoke

The invention relates to a thermal conversion process for continuously producing hydrocarbon vapor and continuously removing a free-flowing coke. The coke, such as a shot coke, can be withdrawn continuously via, e.g., a staged lock hopper system.

Owner:EXXON RES & ENG CO

Methods and apparatus for pyrolyzing material

InactiveUS20080128259A1Direct heating destructive distillationIndirect and direct heating destructive distillationHydrogenProcess engineering

Methods and systems for substantially continuously treating comminuted material containing carbon and hydrogen, for example, used tires, are provided. The methods include the steps of introducing the tire material to an elongated chamber, transferring the tire material through the elongated chamber, heating the tire material to a temperature sufficient to pyrolyze the material to produce a gaseous stream; discharging the gaseous stream from the chamber, and cooling at least some of the gaseous stream to liquefy components of the stream. The transfer may be effected by a flexible, center-less screw conveyor to minimize material buildup in the vessel. The cooling of the gaseous stream may be practiced by reverse condensation. One or more re-usable fuel streams are provided by aspects of the invention.

Owner:KOSTEK STANISLAW

Process for treating bituminous coal by removing volatile components

InactiveUS20110011719A1Reduce ashReduce total sulfurCombustible gas coke oven heatingDirect heating destructive distillationSulfurProcess engineering

A process for treating bituminous coal includes providing dried, pulverized coal, and treating the pulverized coal in a vessel with a gas stream having an oxygen content sufficient to form oxides on surface of coal particles. The treated coal is transferred into a pyrolyzing chamber and passed into contact with an oxygen deficient sweep gas, the sweep gas being at a higher temperature than the temperature of the coal so that heat is supplied to the coal. The process further includes providing additional heat to the coal indirectly by heating the chamber, wherein the heating of coal by the sweep gas and by the indirect heating from the chamber causes condensable volatile components to be released into the sweep gas. Some of the oxides are converted into paramagnetic mineral components, which are removed from coal to form a coal char having reduced ash and sulfur.

Owner:C2O TECH

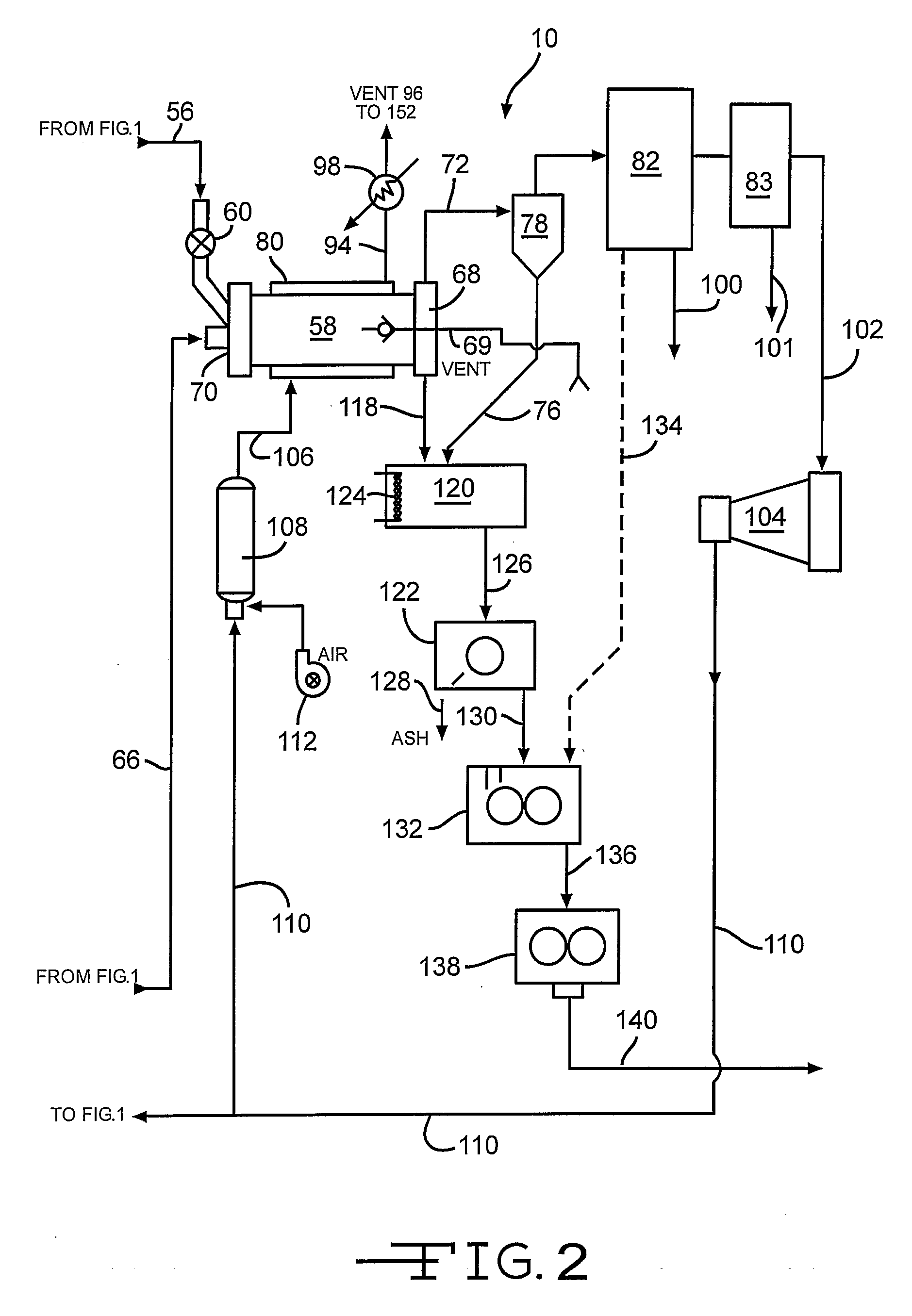

Systems and methods for remotely determining and changing cutting modes during decoking

InactiveUS7117959B2Improve convenienceImprove efficiencyCoke oven safety devicesLiquid/gas jet drillingEngineeringDrill

A decoking system that not only enables an operator to remotely switch the coke-cutting process from boring to cutting mode without removing the drill stem from the coke drum, but also to remotely determine the drill stem's mode so that efficiency, safety and convenience are not compromised, is provided.

Owner:CURTISS WRIGHT FLOW CONTROL CORP

Coke drum discharge system

An apparatus including a coke drum for coking hydrocarbon substances, a valve disposed near the bottom of the coke drum, and a discharge conduit for removing coke from the coke drum, wherein the discharge conduit is connected to the valve such that when the valve is open, the coke may be removed via the discharge conduit.

Owner:FOSTER WHEELER USA

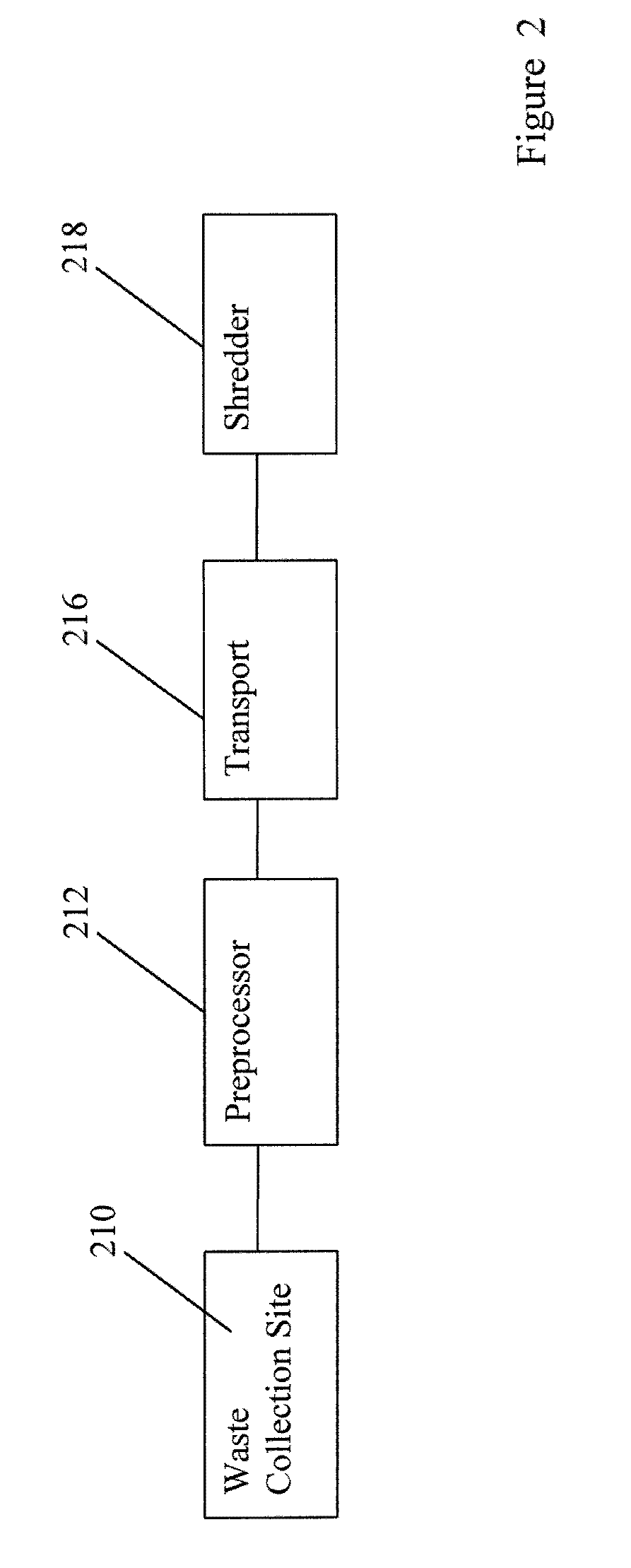

System And Method For Recycling Of Carbon-Containing Materials

ActiveUS20100133085A1Increase ratingsMaintain internal temperatureCombustible gas coke oven heatingSolid waste disposalPlastic materialsProduct gas

There is described a system and method for recycling carbon-containing material, in particular tyres and plastics materials. The system includes a heating arrangement for anaerobically heating carbon containing material to produce carbon-containing gases. A condensing arrangement is also used to condense a proportion of the carbon-containing gases to provide condensed gases and non-condensed gases. In addition, a recirculating arrangement is provided for recirculating the non-condensed gases into the heating arrangement. Further systems and methods for pre- and post-processing of the carbon-containing material are also disclosed and products of the systems and methods are also described.

Owner:USED TIRE DISTILLATION RES

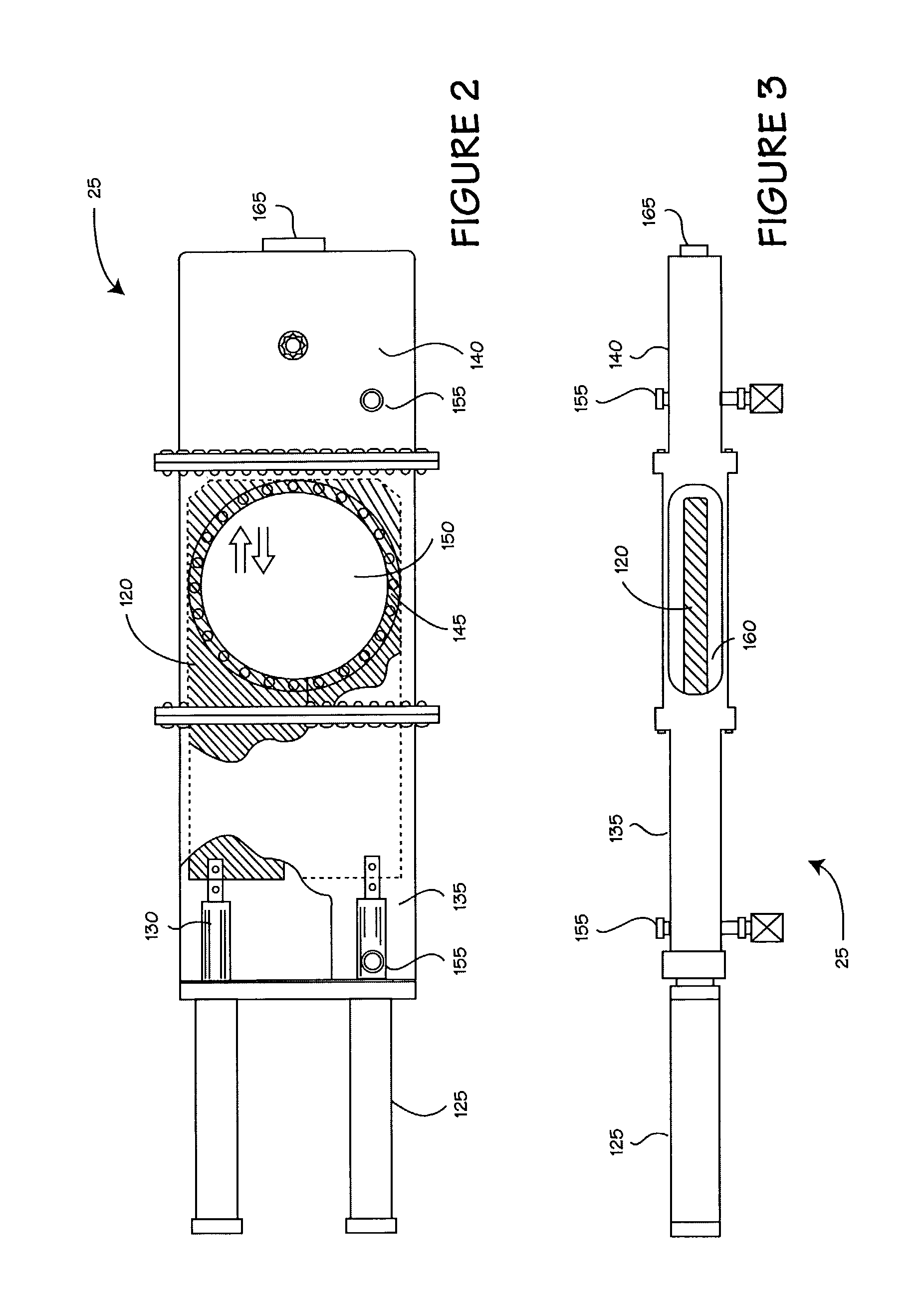

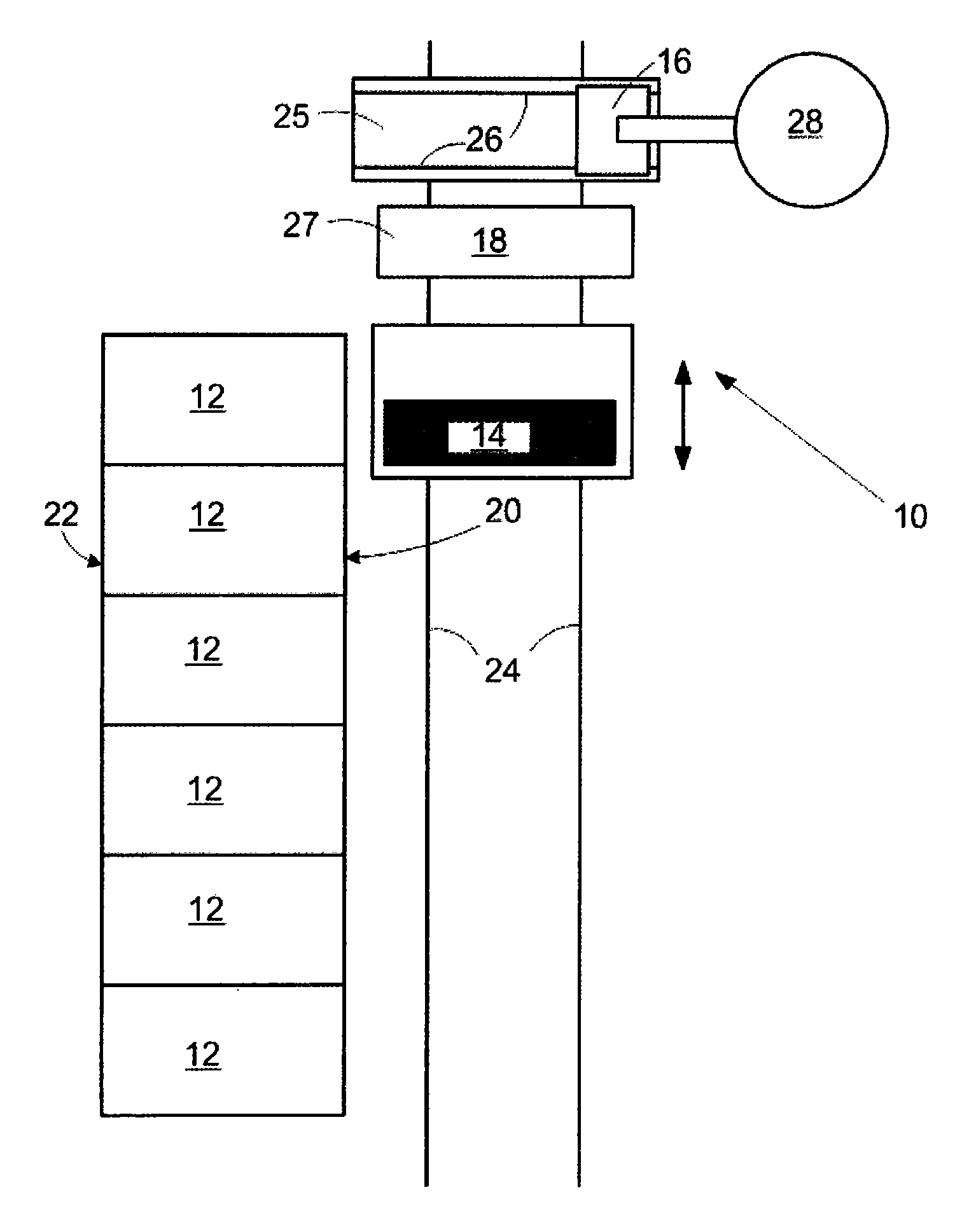

Method and apparatus for compacting coal for a coal coking process

InactiveUS20070289861A1Minimize amount of timeUniform bulk densityCoke quenchingCharging-discharging device combinationsCoke ovenEngineering

Relatively high speed methods for increasing the bulk density of coal particles, apparatus for increasing the bulk density of coal particles and methods for making metallurgical coke. Once such method includes depositing coal particles onto a charging plate external to a coking oven to provide an elongate bed of dry, uncompacted coal having an upper surface of the charging plate. The charging plate has side walls, and at least one movable end wall An impact pressure is applied to the upper surface of the bed of dry, uncompacted coal while degassing the coal to provide a dry, compacted coal bed having a bulk density ranging from about 960 to about 1200 kilograms per cubic meter.

Owner:SUNCOKE TECH & DEV LLC

Air proportioning system for secondary air in coke ovens depending on the vault vs. sole temperature ratio

ActiveUS8980063B2Easy to useCombustible gas coke oven heatingCoke oven safety devicesCombustionCoke oven

A device for proportioning of secondary combustion air into the secondary air soles of coke oven chamber ovens is shown. The device is formed by a slide gate or a parallelepiped device or by plates moved by means of a thrust bar, the thrust bar being moved longitudinally in parallel to the coke oven chamber wall so that the plates move away from the secondary air apertures and open or close these. The thrust bar is moved by means of a positioning motor, with the power transmission being effected hydraulically or pneumatically. Via suitable measuring parameters, it is thus possible to optimize secondary heating so that heating is provided evenly from all sides, thus achieving an improvement in coke quality.

Owner:THYSSENKRUPP IND SOLUTIONS AG

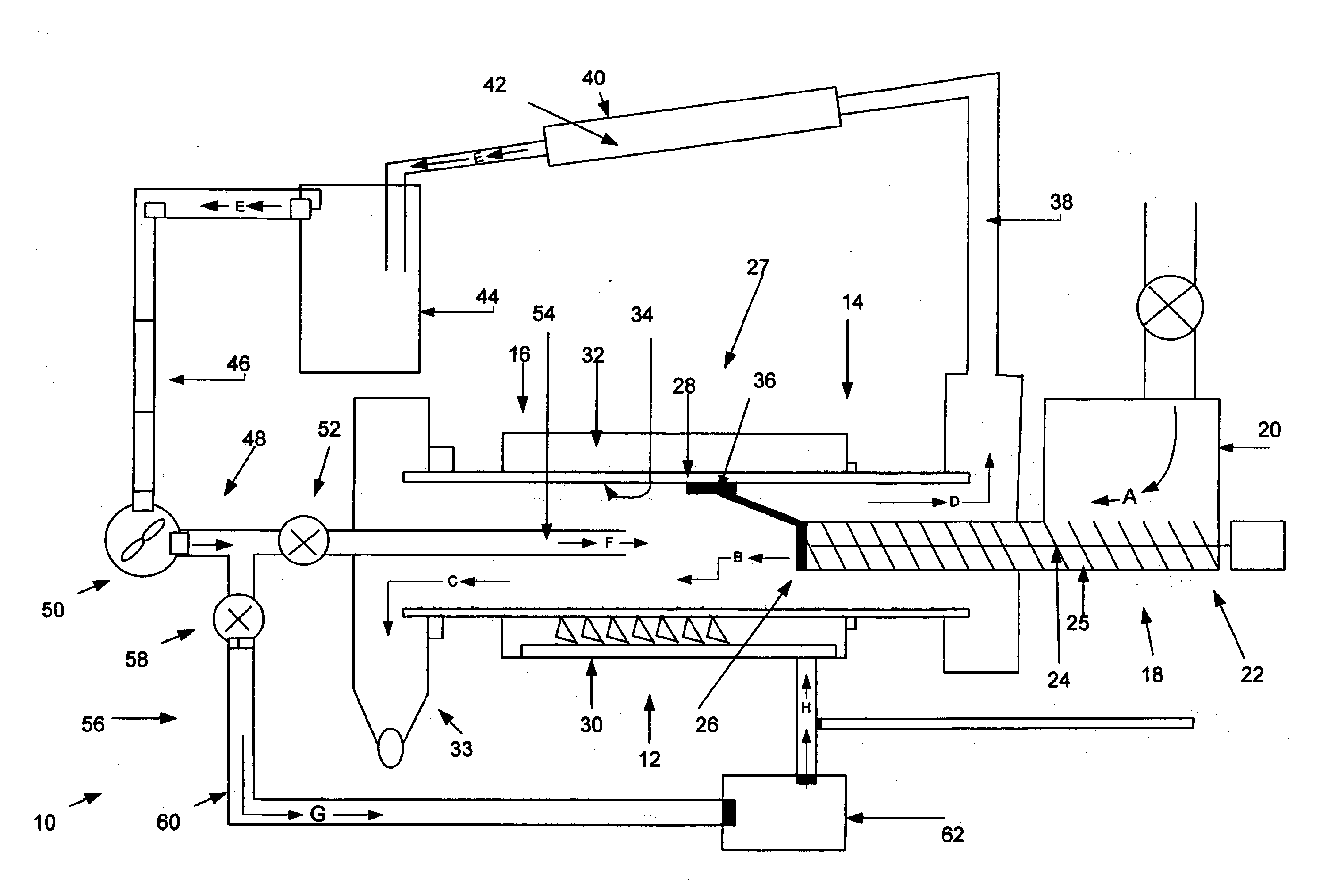

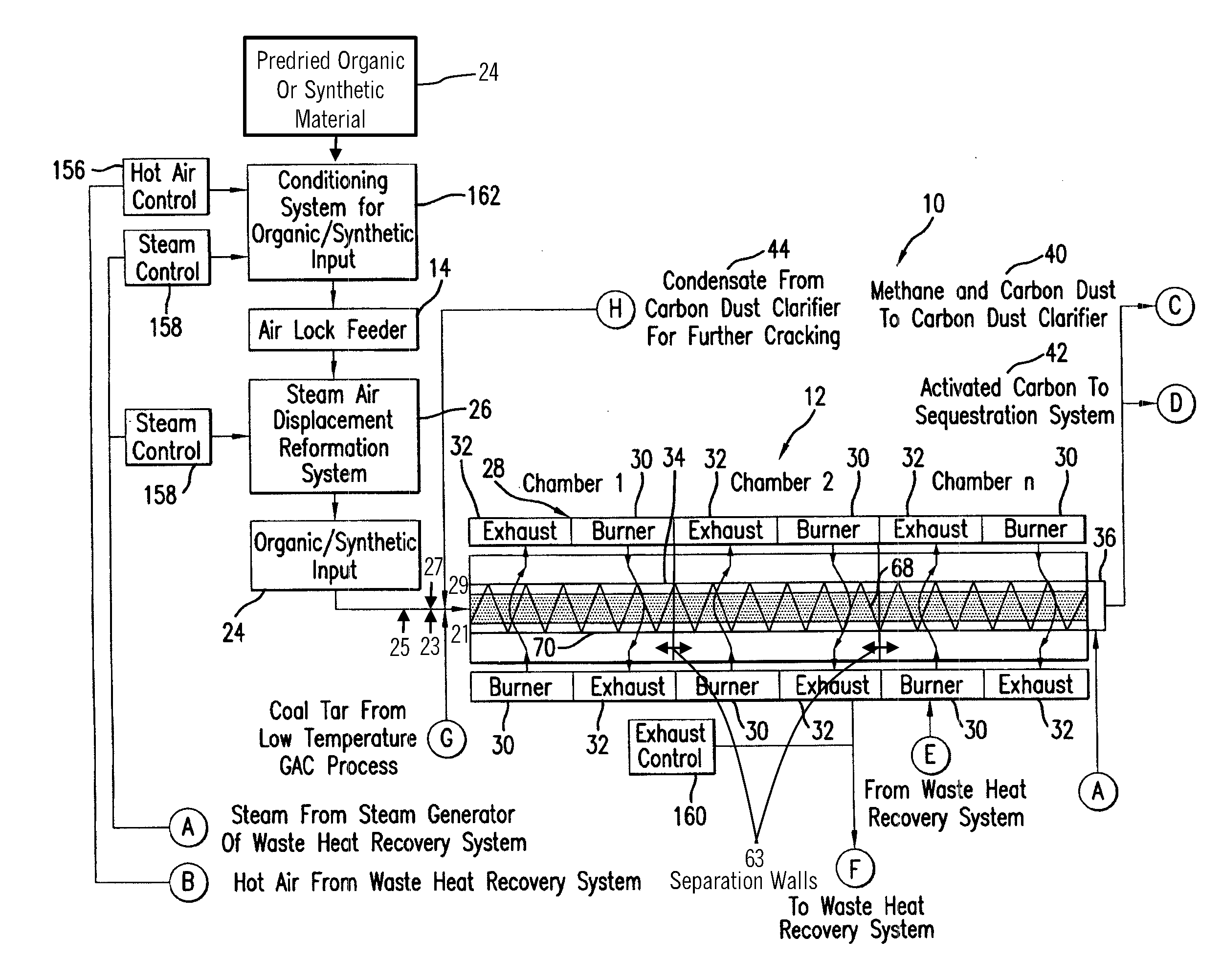

Pyrolysis systems, methods, and resultants derived therefrom

ActiveUS20110136971A1Fit closelyMaterial nanotechnologyDirect heating destructive distillationHazardous substanceProcess engineering

The present invention provides a process for the controlled gasification of a carbonaceous feedstock, including: pyrolizing the feedstock to produce a gas product and a solid product, wherein the gas product includes methane and noxious chemicals and the solid product includes carbon; and controlling the pyrolizing step using feedback related to constituents of the gas product. The present invention also provides a system for the controlled gasification of a carbonaceous feedstock, including: a pyrolysis unit including a heater and a conveyor for transporting the feedstock through the heater; a resultant chamber disposed downstream of the pyrolysis unit for separating gas products and solid products; means for adjusting the temperature of the solid products; and a filter for sequestering noxious materials from the gas products, wherein the filter uses at least some of the solid products to filter at least a portion of the gas products.

Owner:TUCKER RICHARD D

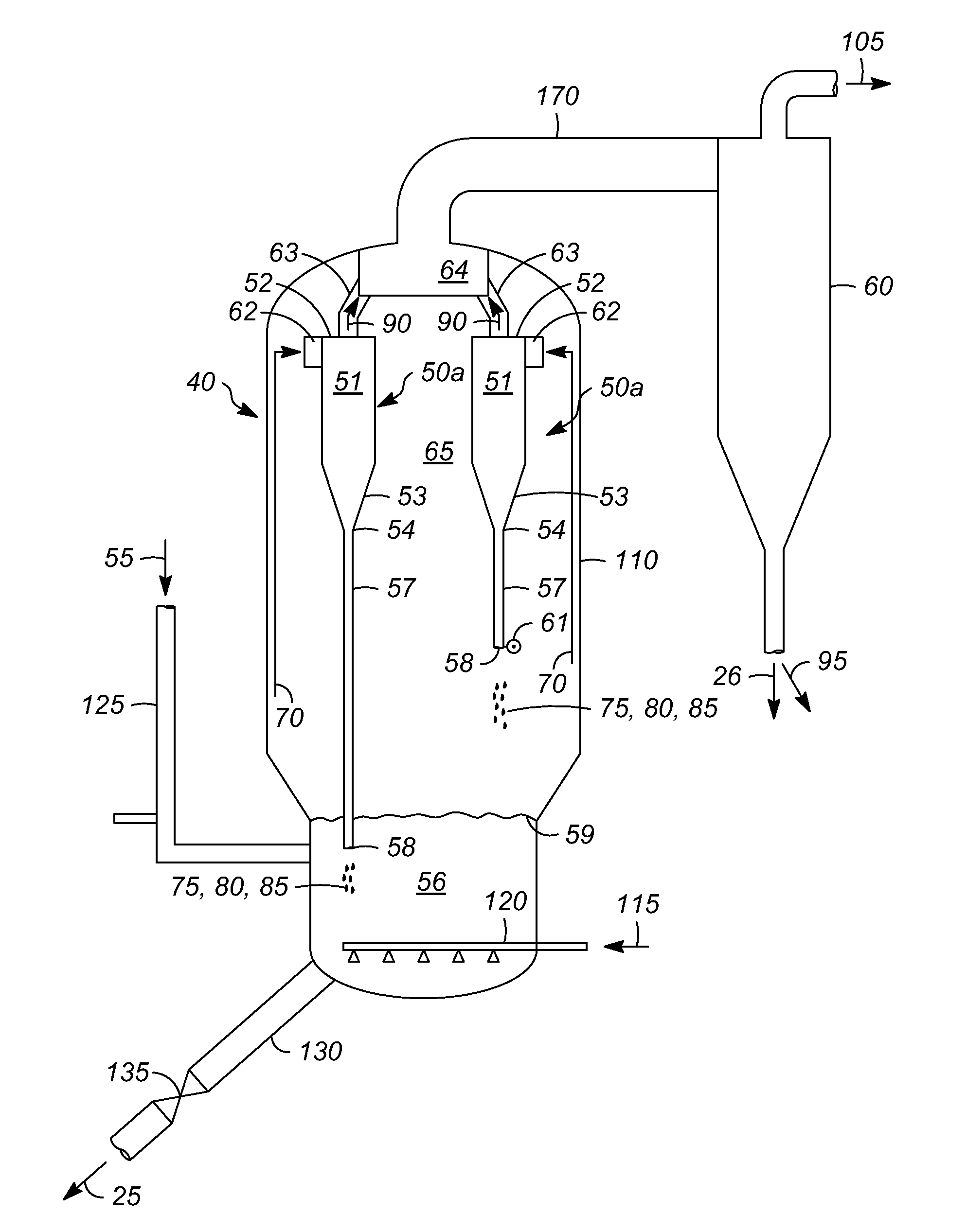

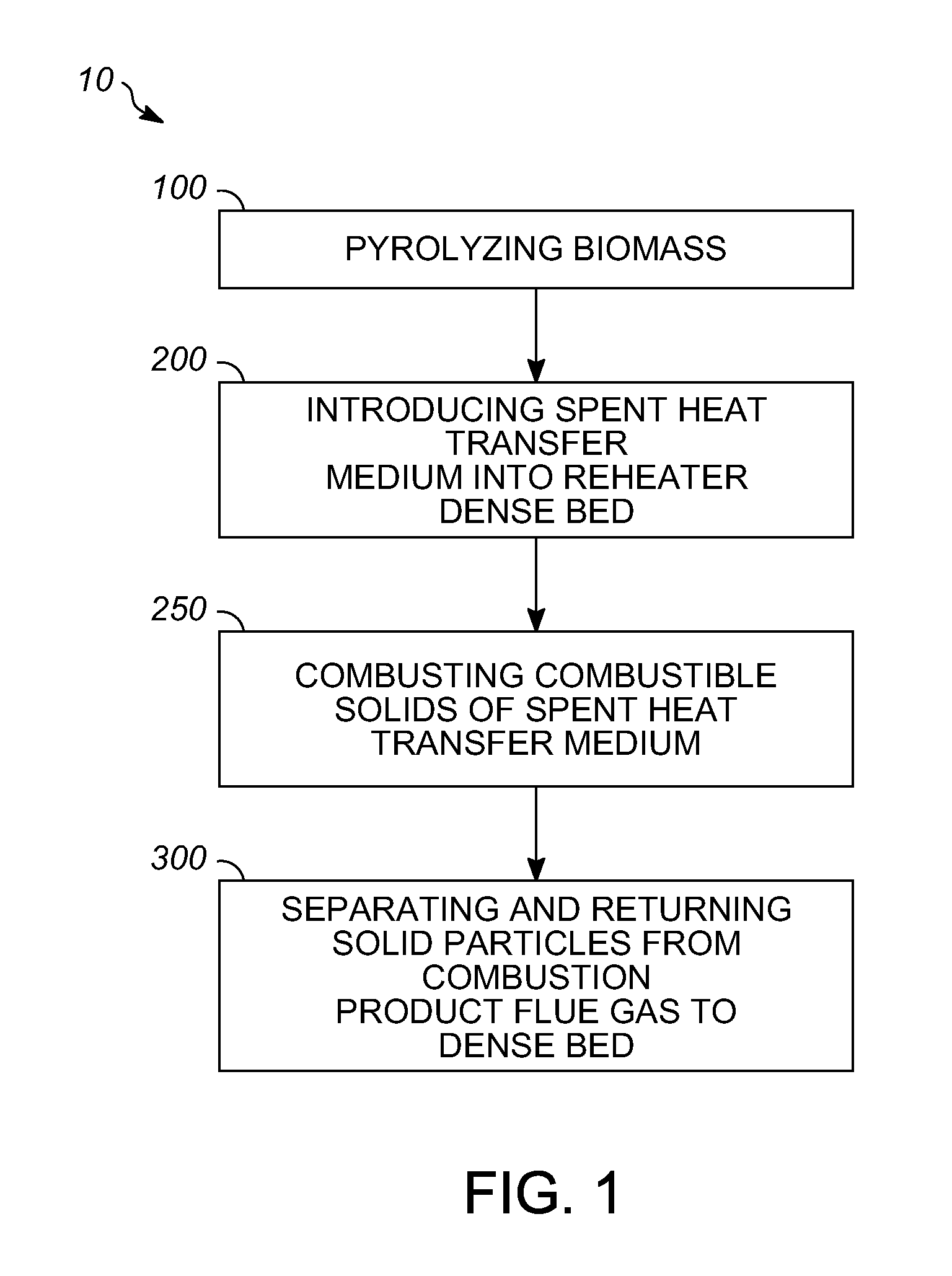

Processes for controlling afterburn in a reheater and for controlling loss of entrained solid particles in combustion product flue gas

InactiveUS20110284359A1Combustible gas coke oven heatingDirect heating destructive distillationFlue gasProcess engineering

Processes for controlling afterburn in a reheater and loss of entrained solid particles in reheater flue gas are provided. Carbonaceous biomass feedstock is pyrolyzed using a heat transfer medium forming pyrolysis products and a spent heat transfer medium comprising combustible solid particles. The spent heat transfer medium is introduced into a fluidizing dense bed. The combustible solid particles of the spent heat transfer medium are combusted forming combustion product flue gas in a dilute phase above the fluidizing dense bed. The combustion product flue gas comprises flue gas and solid particles entrained therein. The solid particles are separated from the combustion product flue gas to form separated solid particles. At least a portion of the separated solid particles are returned to the fluidizing dense bed.

Owner:ENSYN RENEWABLES

Methods and apparatuses for rapid thermal processing of carbonaceous material

ActiveUS20130062184A1Rapid heat treatmentCombustible gas coke oven heatingDirect heating destructive distillationHeat carrierThermal treatment

Embodiments of methods and apparatuses for rapid thermal processing of carbonaceous material are provided herein. The method comprises the step of contacting a carbonaceous feedstock with heated inorganic heat carrier particles at reaction conditions effective to rapidly pyrolyze the carbonaceous feedstock to form a product stream comprising pygas, pyrolysis oil, and solids. The solids comprise char and cooled inorganic heat carrier particles. The reaction conditions include a reactor pressure of about 70 kPa gauge or greater.

Owner:ENSYN RENEWABLES

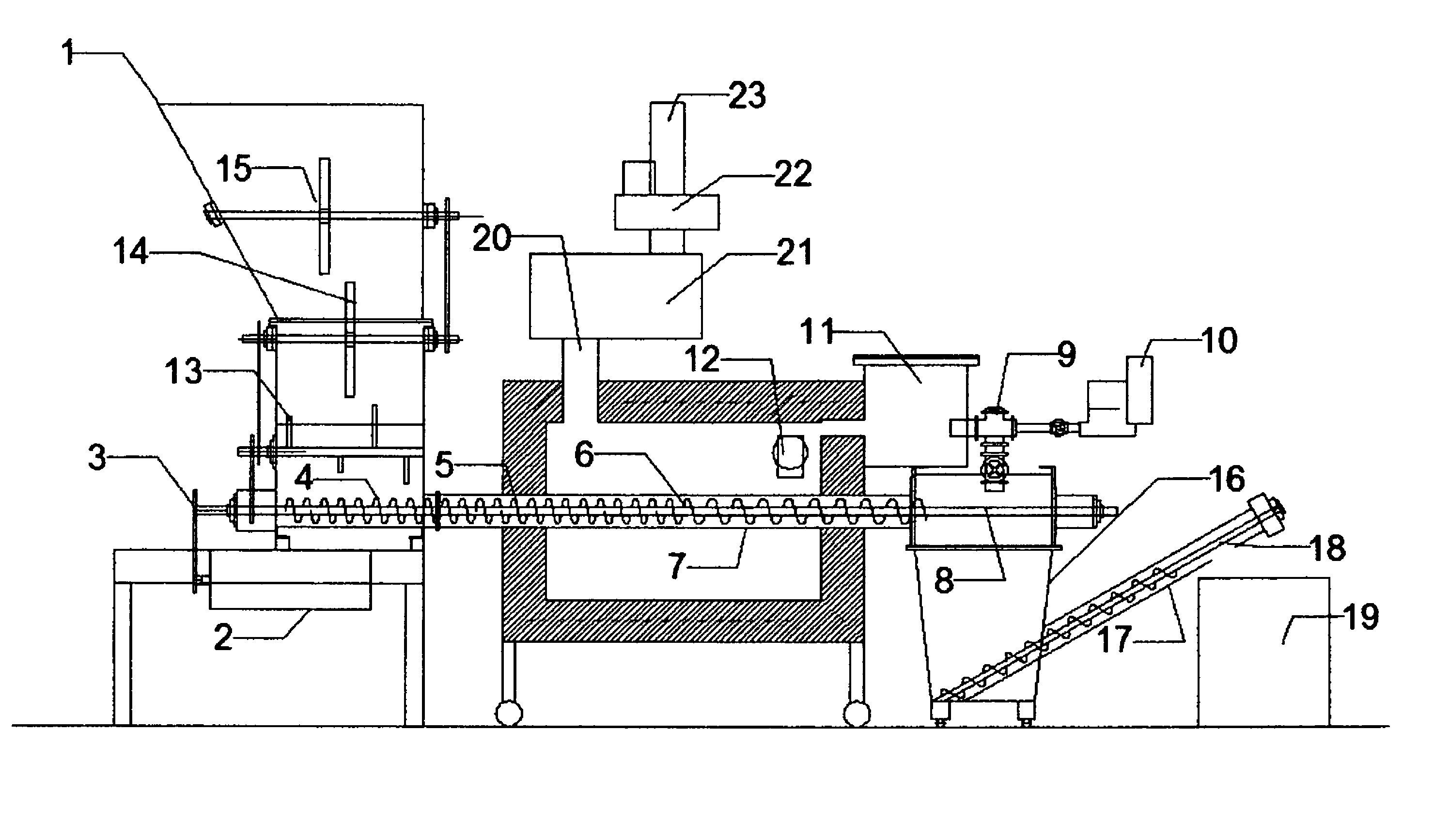

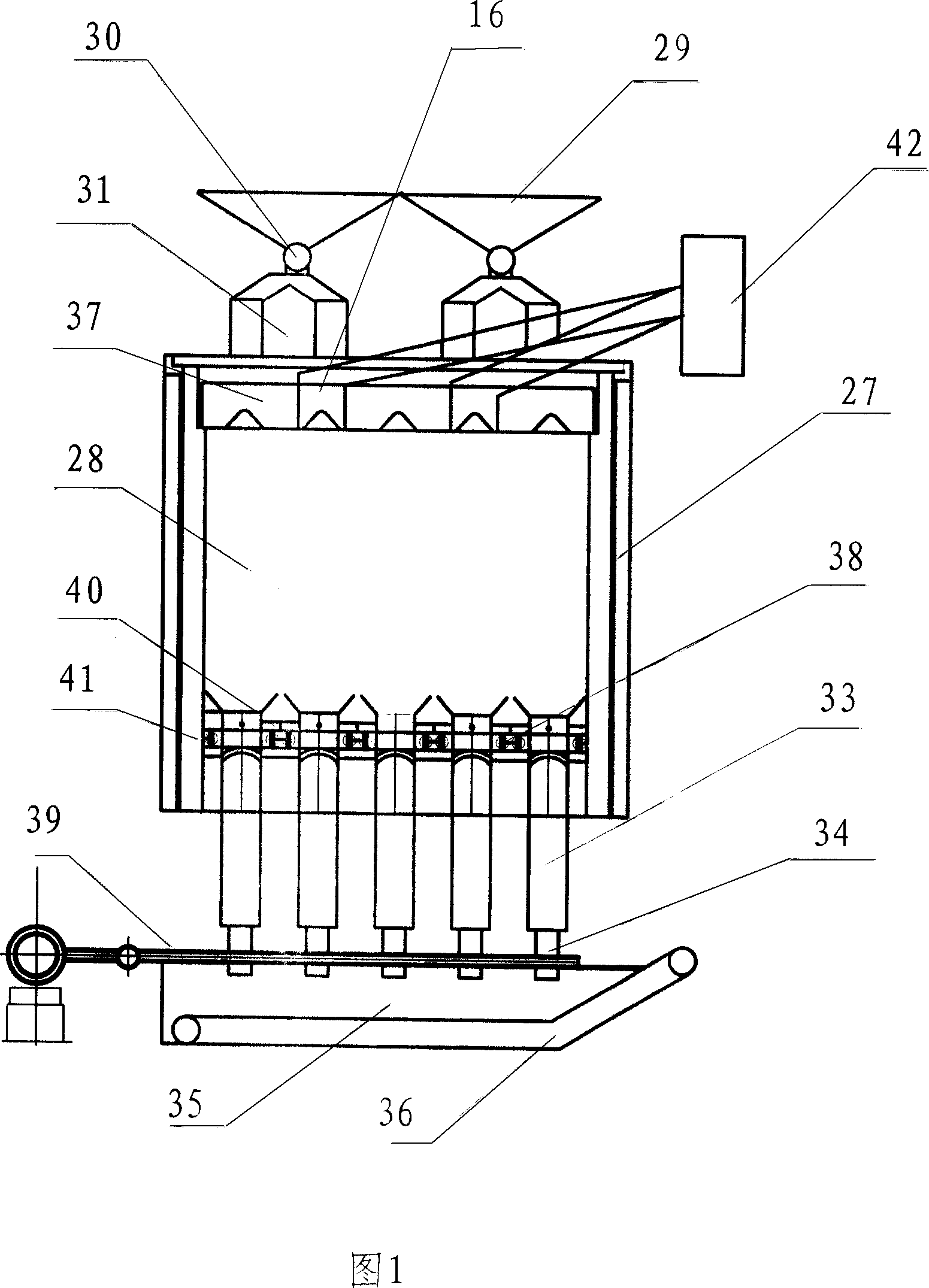

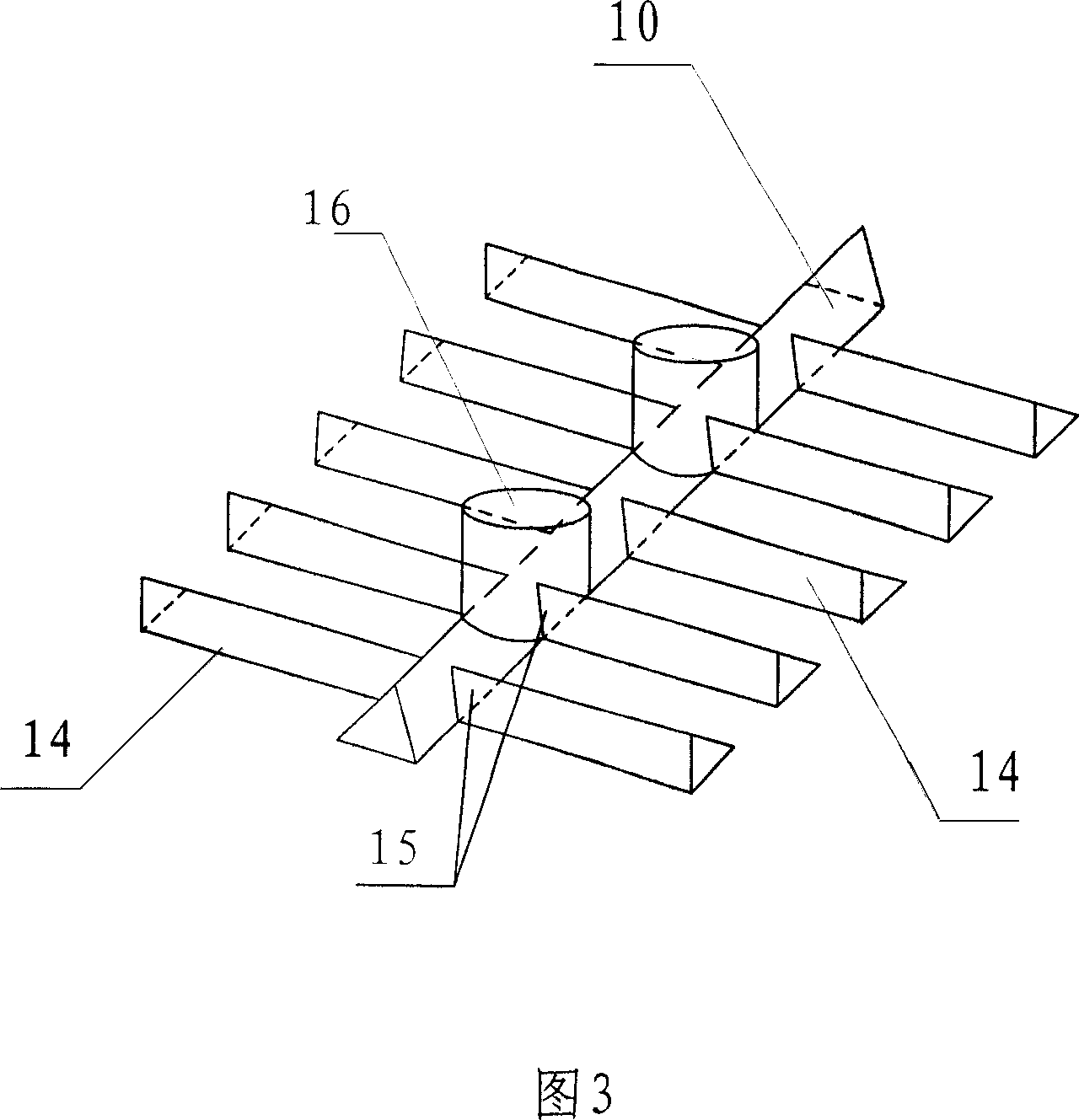

Low-temperature coal carbonization kiln

ActiveCN1966609AIncrease effective volumeHigh yieldRetortsDischarging devicesAutomatic controlCarbonization

The invention disclosed a kind of low temperature coal dry distillating square stove which includes stove body, coal cup, dant-pushing machine and branch admixer. On the top of the hearth there is installed the gas collecting umbrella, inside the stove it is cavity structure; on the bottom of the cavity there are installed several rows of emitting gas walls, every row of emitting gas wall is parallel to the interval between two side umbrella of the gas collecting umbrella; the consecutive emitting gas walls are pedestalled by arch wall; on both sides of the emitting gas walls there are two branch admixer respectively; the bottom of the stove connects the dant discharging box, the bottom of which connects the dant leading slot; the bottom of the dant leading slot is dant-pushing machine, the bottom of which is aqua sealing slot, in the slot there is scraper machine. The invention adopts the heating scheme of endo-burnning and calor internus which can heat uniformly. The gas collecting umbrella and accessory coalbox can make the material and gas-collecting uniformly while the dant-pushing machine can make the product uniform. The advantage of the invention: it can bring into full play of the producing ability and decrease the investment as well as increase the benefits; besides, it is easy to operate, it needs less people and can be controlled automatically.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

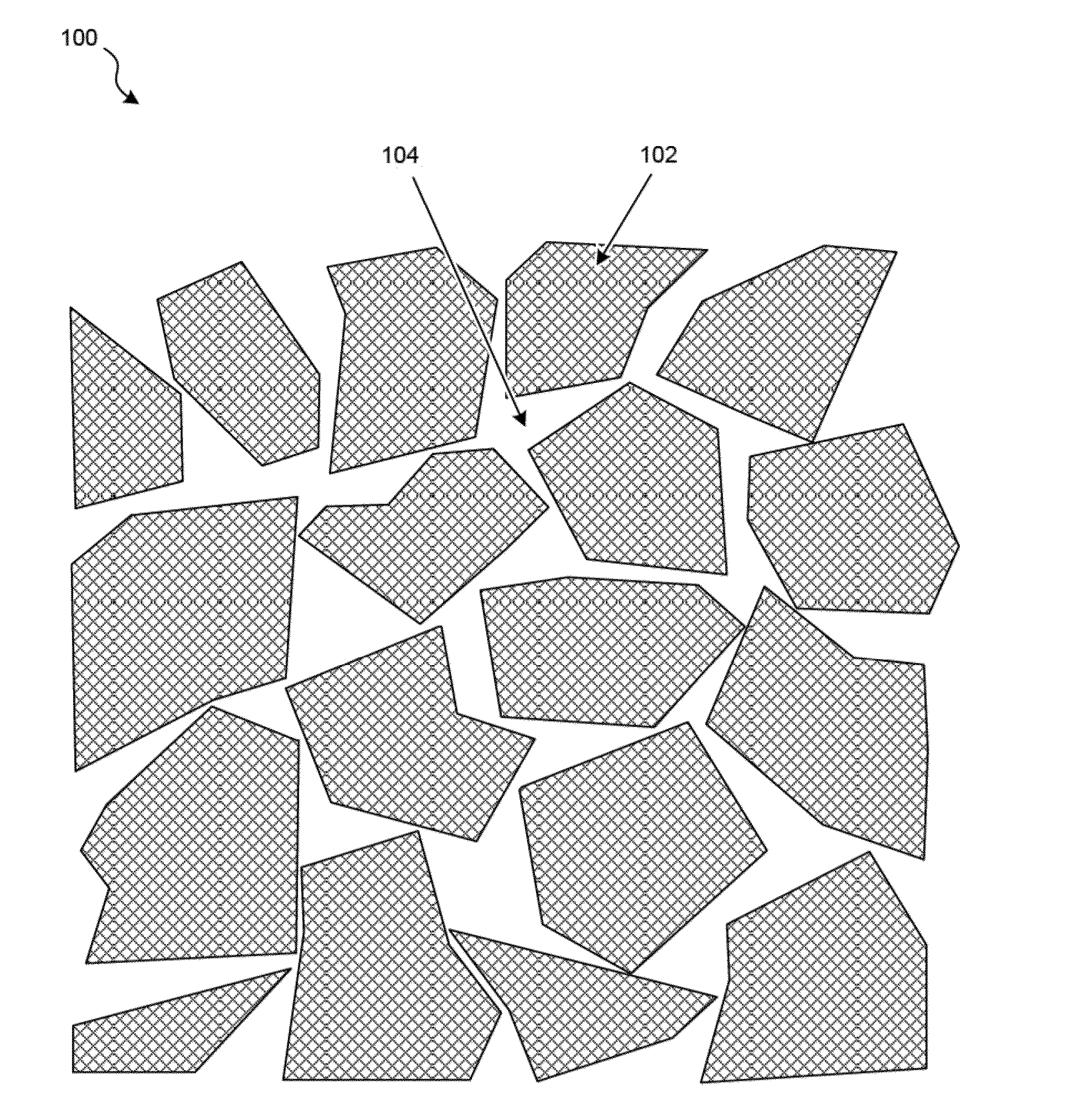

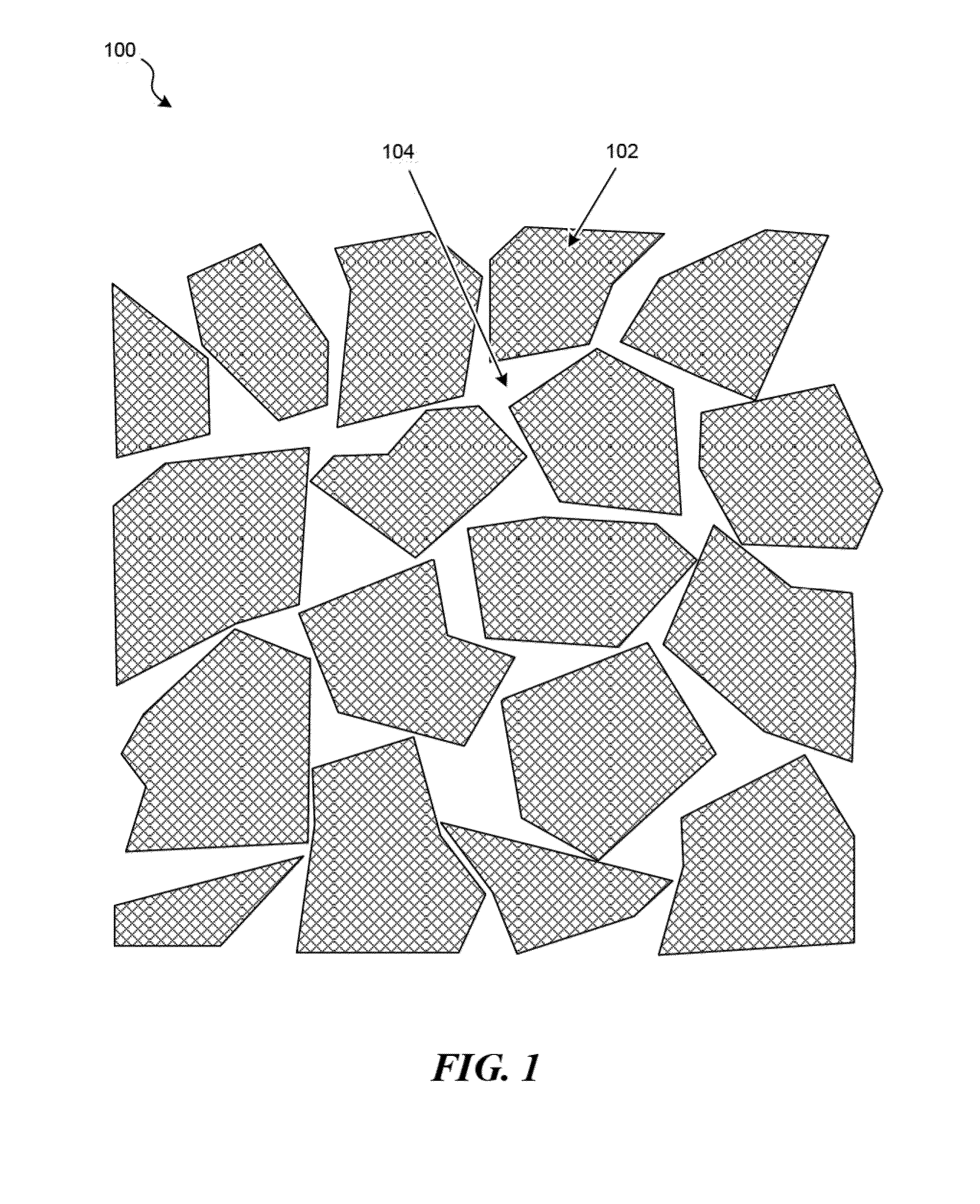

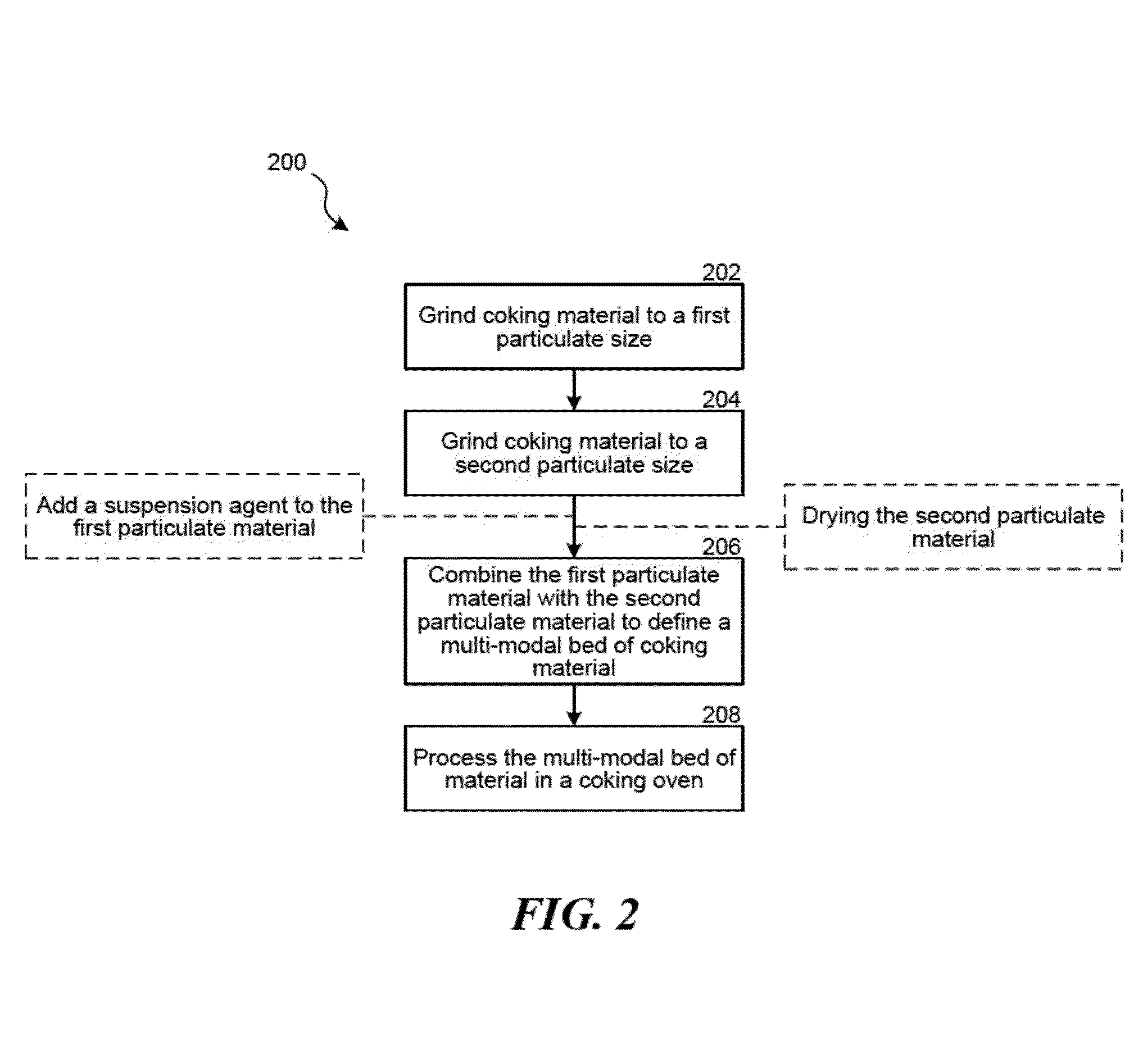

Multi-modal beds of coking material

The present technology is generally directed to providing beds of coking material to charge a coking oven. In various embodiments, a quantity of first particulate material, having a first particulate size and bulk density, is combined with a second particulate material, having a second particulate size and bulk density, to define a multi-modal bed of coking material. The multi-modal bed of coking material exhibits an optimized bulk density that is greater than an ideal bulk density predicted by a linear combination of the bulk densities of the individual materials.

Owner:SUNCOKE TECH & DEV LLC

Pyrolysis systems, methods, and resultants derived therefrom

ActiveUS8282787B2Fit closelyWithout undesired degradation of communication system performanceLayered productsUsing liquid separation agentNon wettingActivated carbon filtration

A system and process for gasification of a carbonaceous feedstock uses pyrolysis to produce a gas product, which may include methane, ethane, and other desirable hydrocarbon gases, and a solids product, which includes activated carbon or carbon. The gas product may then be filtered using at least a portion of the activated carbon from the solids product as a filtering medium. In an embodiment, at least some of the noxious chemicals are sequestered or removed from the gas product in one or more filtering steps using the activated carbon as a filtering medium. In a further embodiment, the filtering steps are performed in stages using activated carbon at different temperatures. A high-temperature pyrolysis system that produces activated carbon may be combined with another high-temperature pyrolysis system that does not produce activated carbon to provide filtering of noxious compounds using activated carbon from the first high-temperature pyrolysis system. A high-temperature pyrolysis system may be combined with one or more low-temperature feedstock conversion processes such that waste heat from the high-temperature pyrolysis system is used to operate the low-temperature process. A novel non-wetting carbon having pores fused with silica can be produced from using the system and process.

Owner:TUCKER RICHARD D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com