Methods and apparatus for pyrolyzing material

a technology of pyrolysis and materials, applied in the field of materials processing, can solve the problems of large portion of materials still discarded, significant environmental problems, and fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

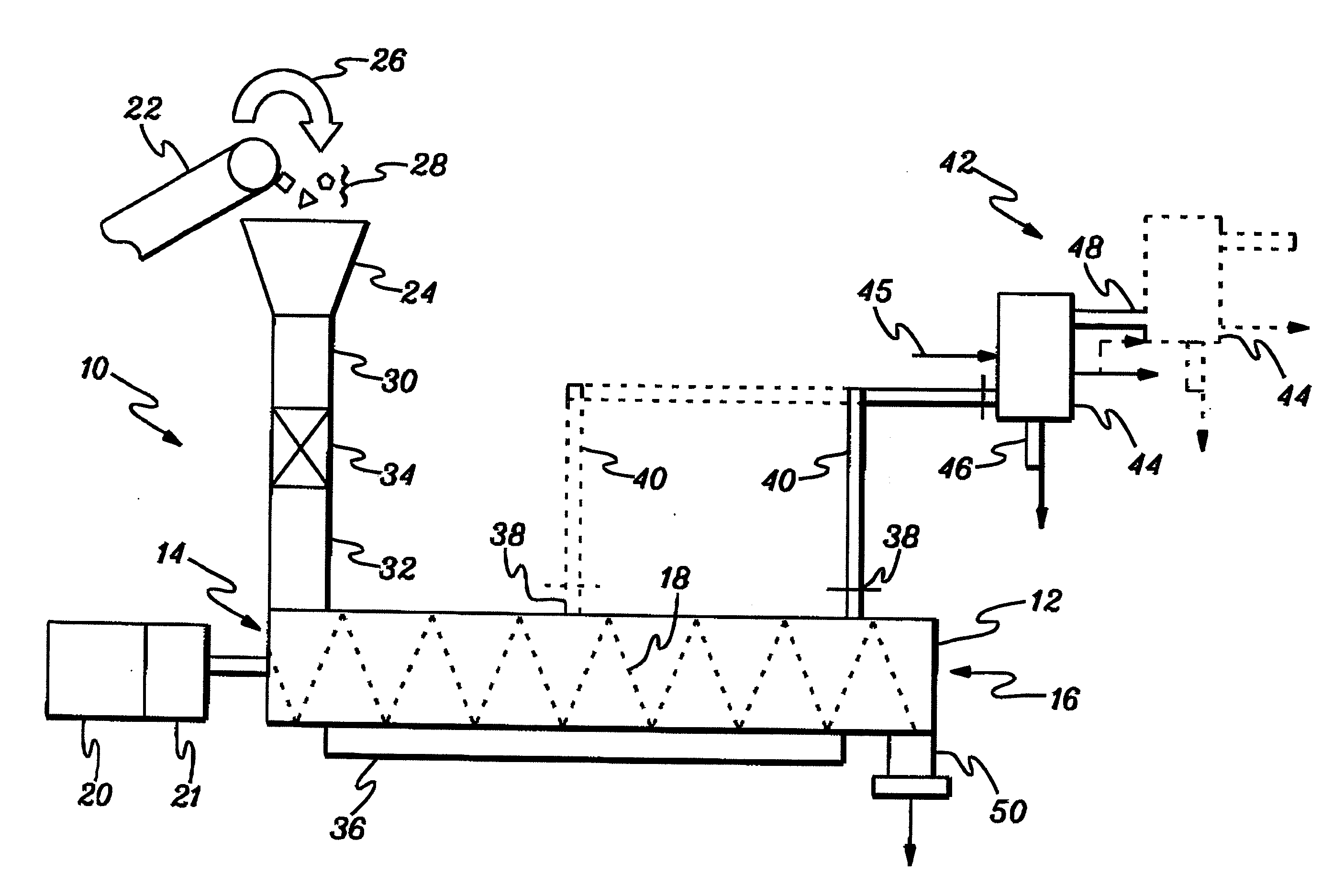

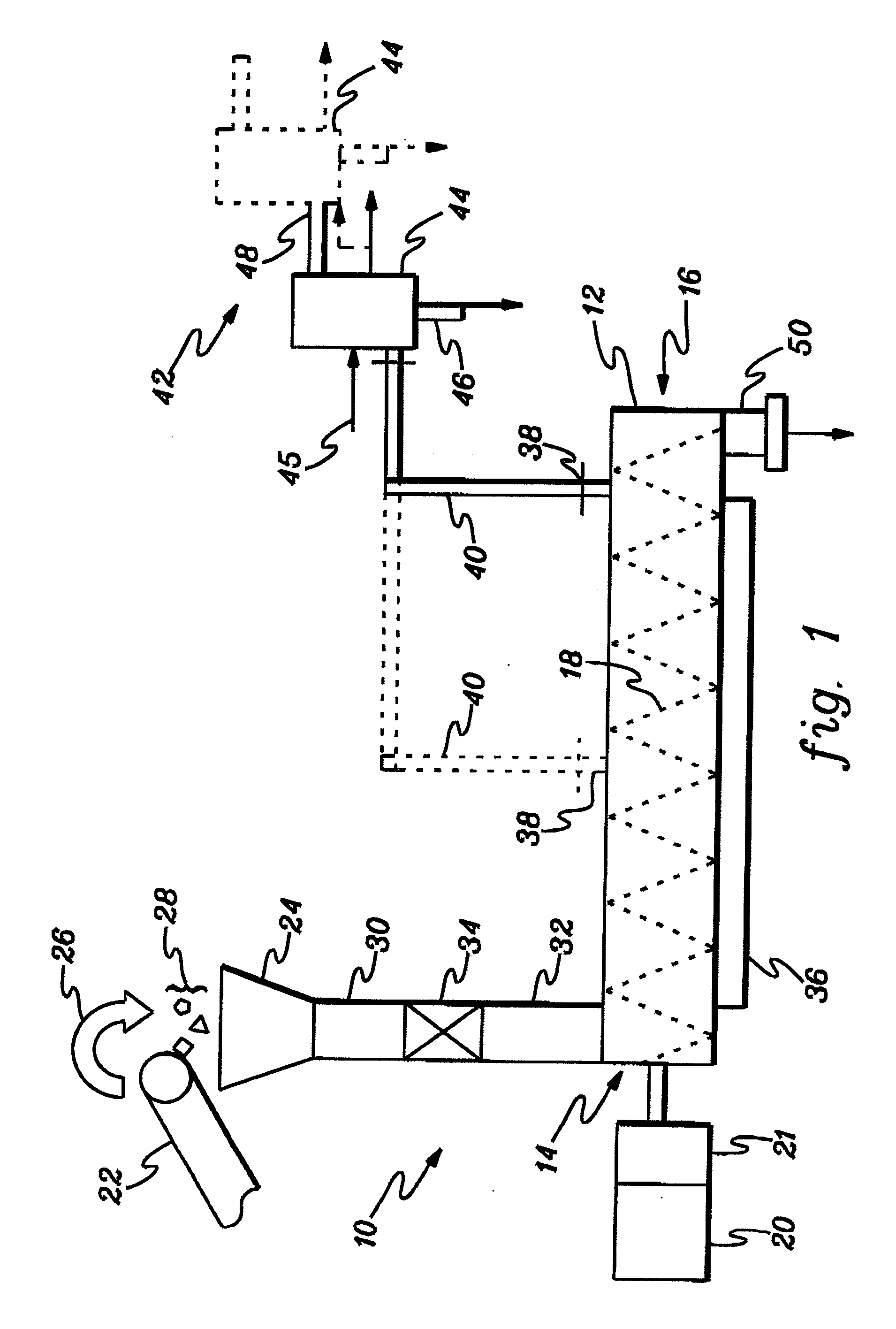

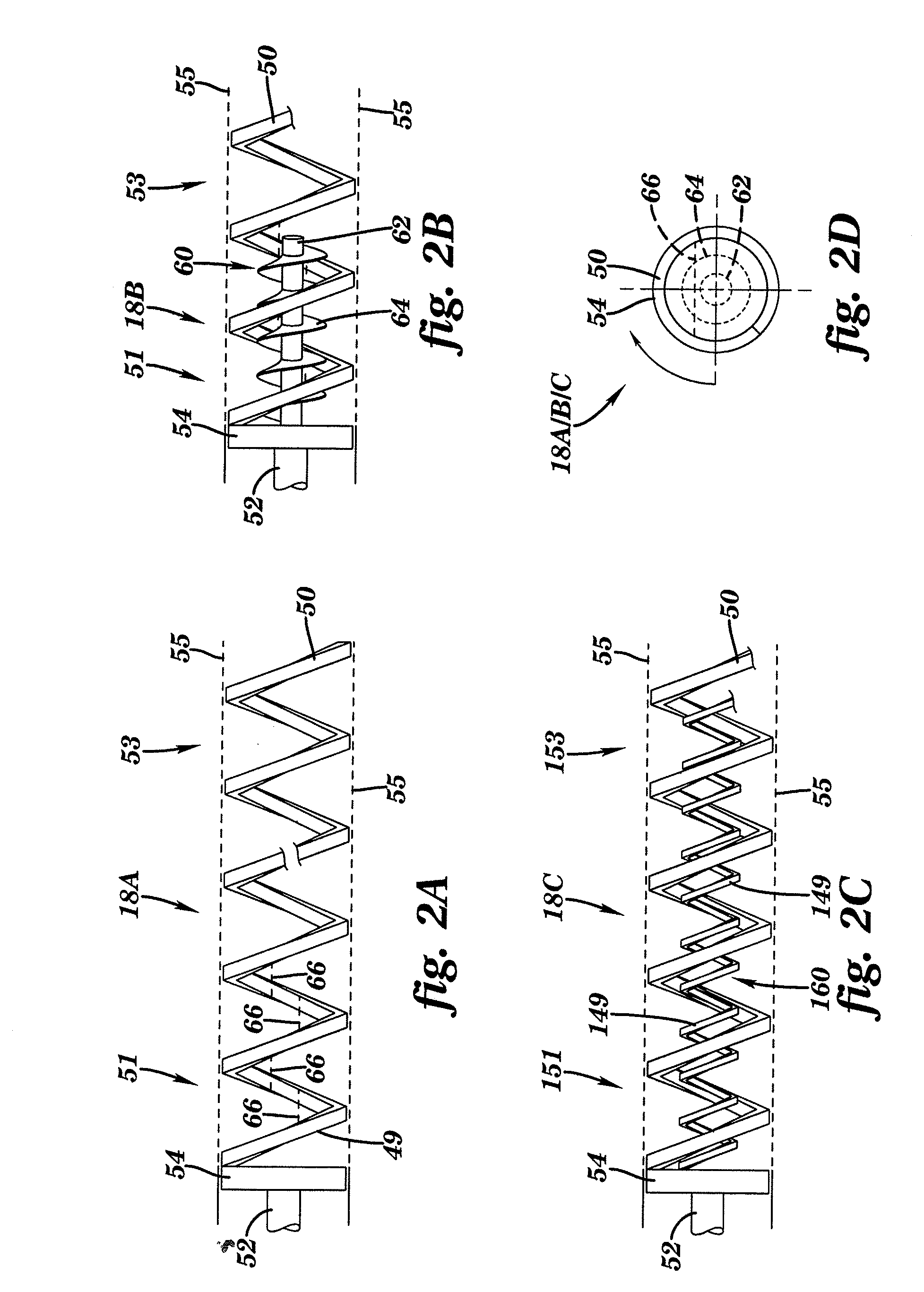

[0029]Aspects of the present invention comprise apparatus and processes for treating feed materials, for example, feed materials containing carbon, hydrogen, and oxygen compounds to produce usable hydrocarbon materials and other substances. In one preferred aspect, the feed material may be used tires, that is, used automobile and truck tires, although a wide variety of other feed materials containing compounds containing carbon, hydrogen, and oxygen material may be used in addition to or in lieu of used tires. Used tires are preferred because of their composition (particularly the recoverable components thereof), cost (used tires are frequently obtainable at a no cost or for a nominal fee, other than costs of transportation and handling) and the environmental mandates against improper disposal. However, other material such as plastics, polymers, rubbers, and other organic / petroleum-based materials are also suitable. In some instances, even when processing the preferred feeds (that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com