Method for weakening strength of hard rock

A hard rock and strength technology, applied in the field of hard rock strength weakening, can solve the problems of weakening, affecting the driving speed of rock roadway, and wear of cutting parts of fully mechanized excavation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

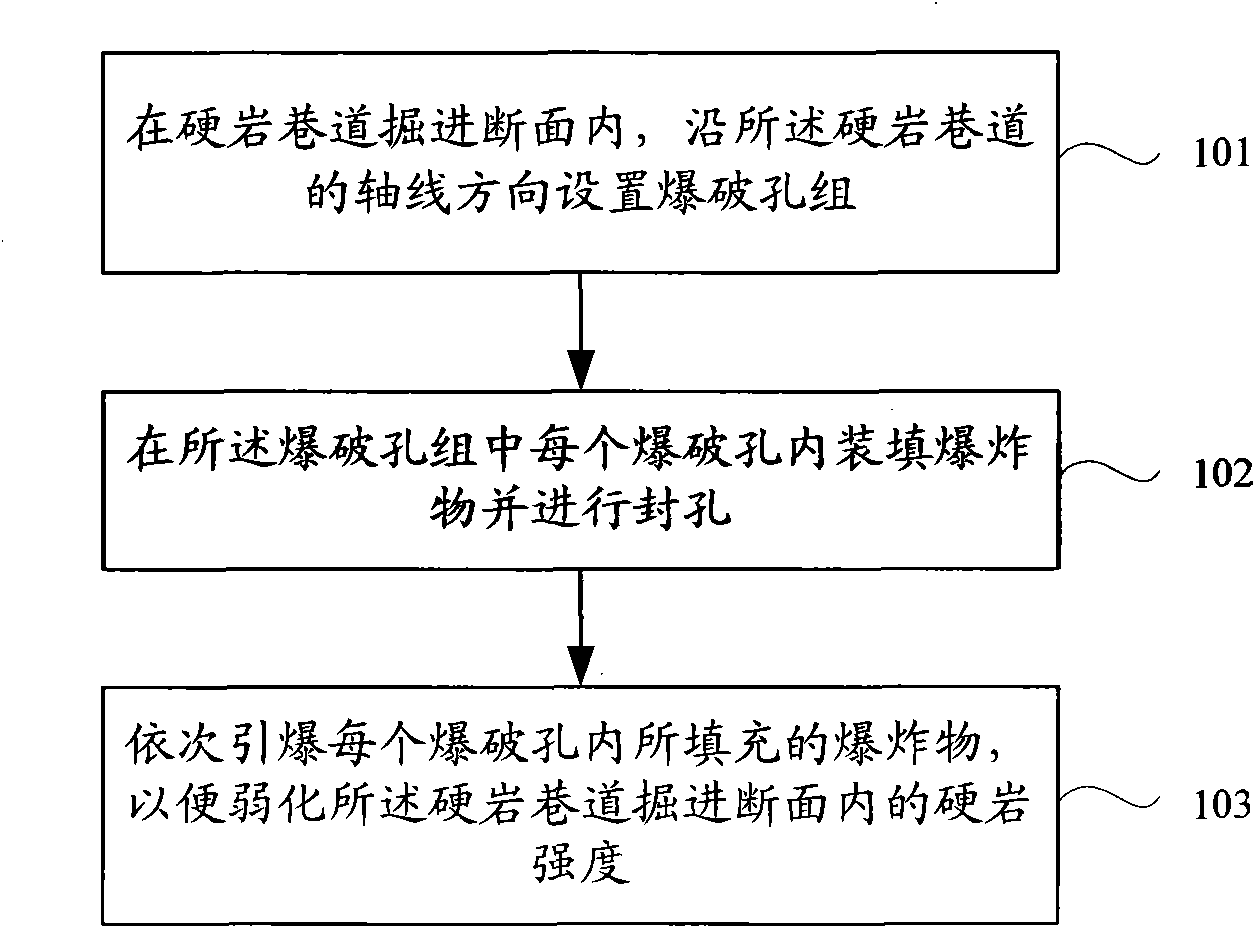

[0017] figure 1 It is a schematic flow diagram of the hard rock strength weakening method of the present invention. Such as figure 1 As shown, the vertical shaft uncovering method of this embodiment includes:

[0018] Step 101: Set a blast hole group along the axis of the hard rock roadway in the tunneling section of the hard rock roadway;

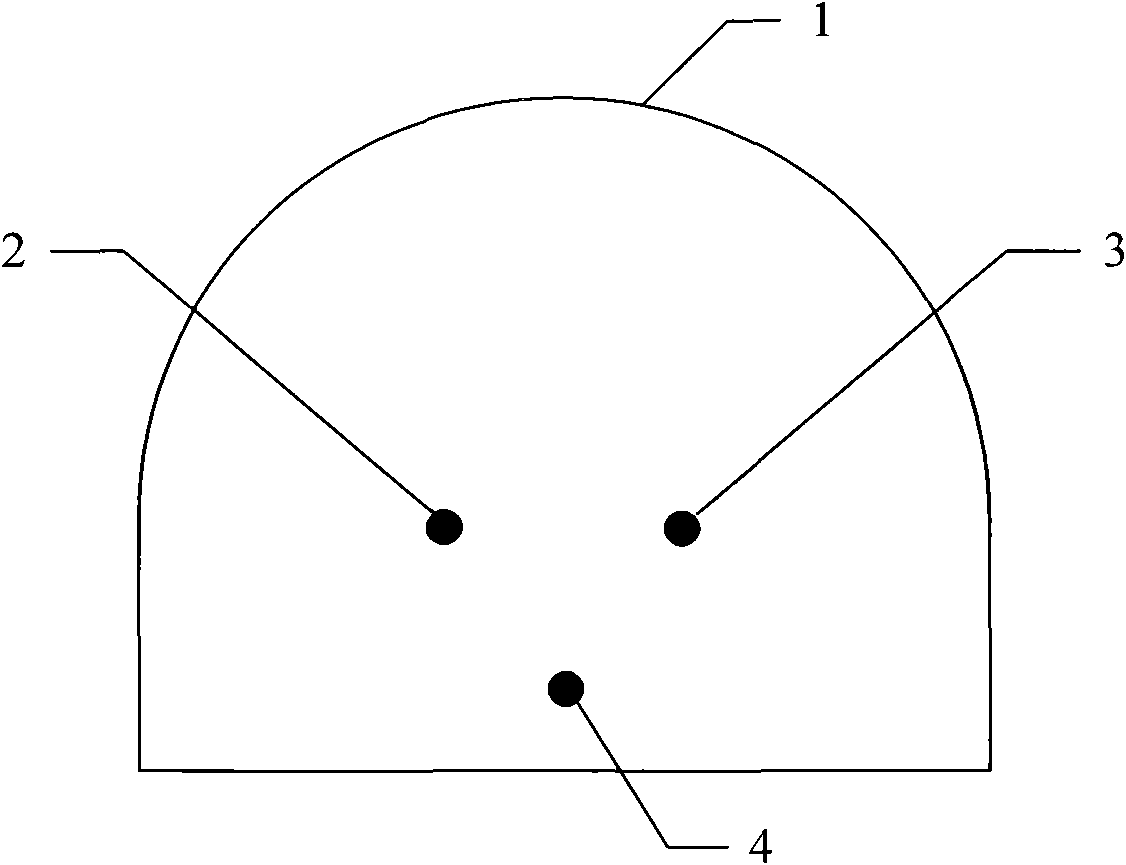

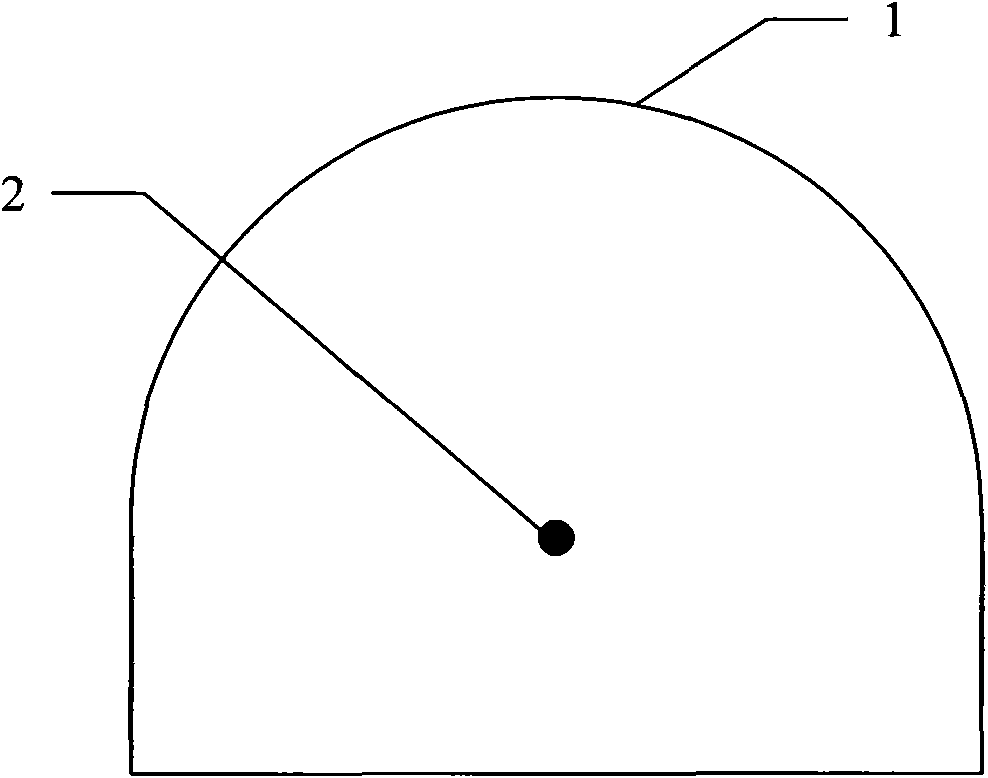

[0019] figure 2 It is a schematic diagram of the rock tunnel section after the blast hole group is set in the hard rock tunnel driving section of the present invention. When the comprehensive excavation equipment encounters hard rocks with a Platts coefficient of 8 or greater in the actual rock tunnel excavation project (the hard rocks involved in this embodiment are all hard rocks with a Platts coefficient of 8 or greater), the construction personnel Firstly, the fully mechanized excavation equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com