Paper conveying device

A paper feeding device and paper feeding roller technology, applied in the directions of transportation and packaging, winding strips, thin material handling, etc., can solve the problems such as the intermittent operation of the paper path, the inability to carry out the paper-breaking die-cutting operation, and the limitation of the operation speed. , to achieve the effect of ensuring normal continuous work, high work efficiency and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are described in detail below:

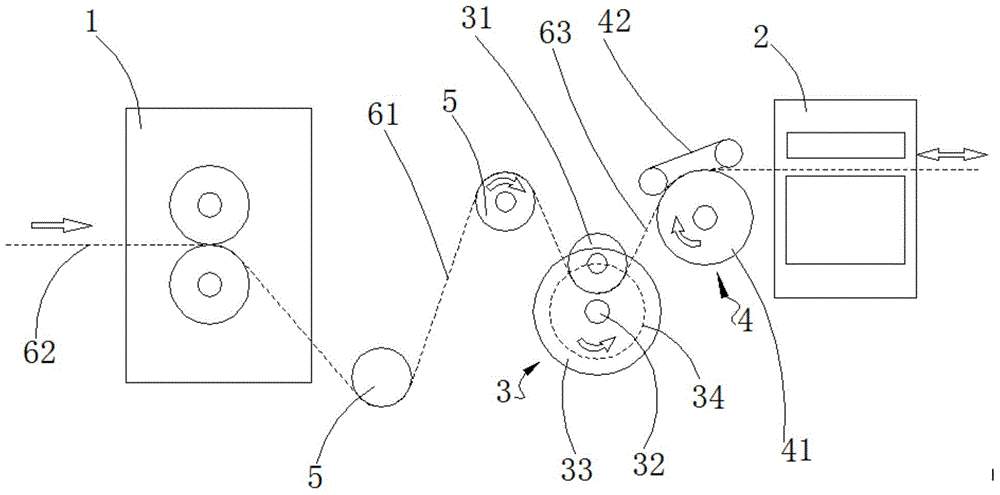

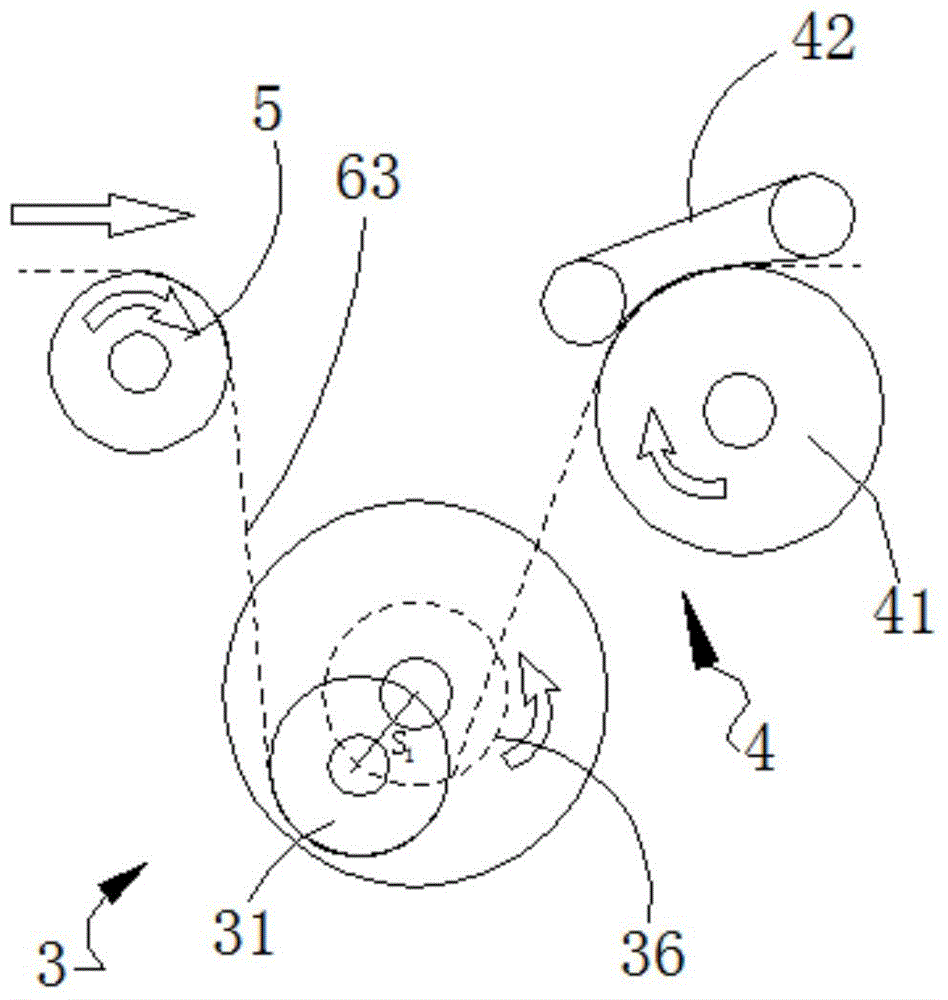

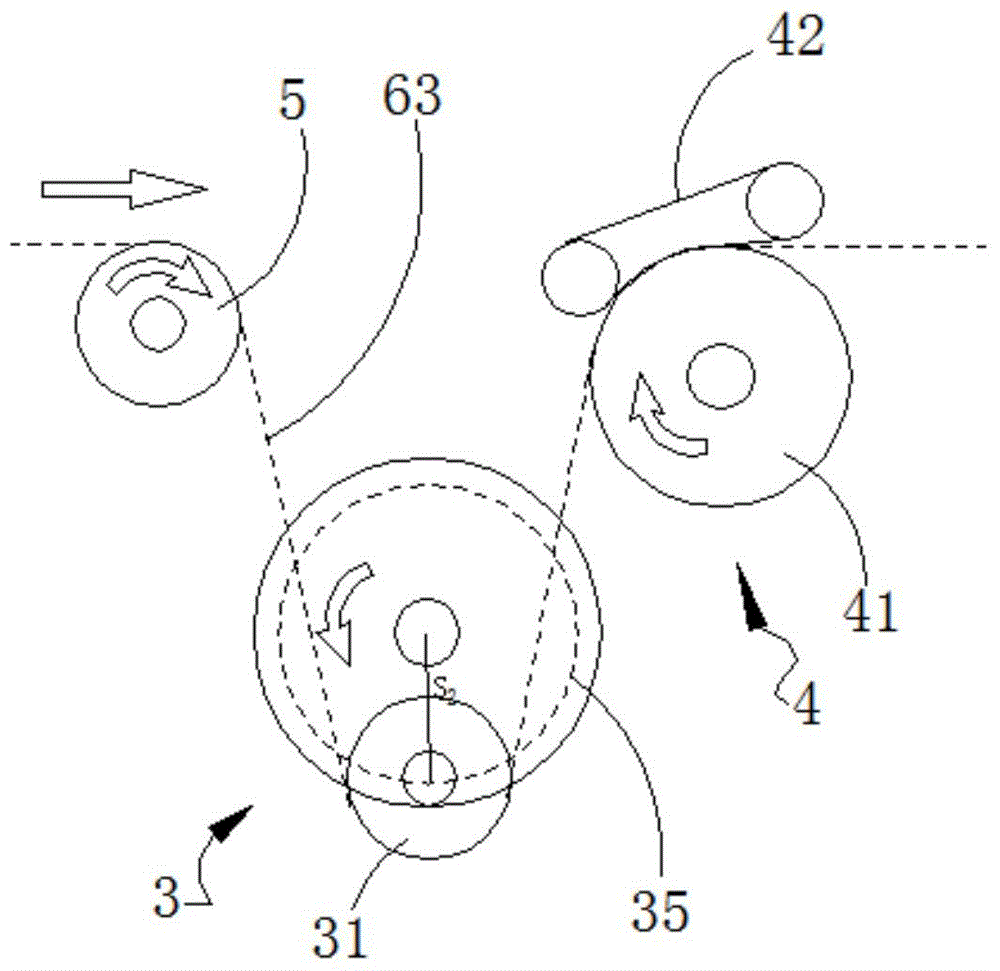

[0036] Such as figure 1 As shown, it is a structural schematic diagram of the paper feeding device according to the present invention. The paper feeding device according to the present invention includes a continuous working unit 1 for continuously operating the paper path, which is arranged in sequence in the paper path running direction, for The intermittent working unit 2 for die-cutting or bronzing operation on the paper path. In the embodiment of the present invention, the intermittent working unit 2 includes a flat-press die-cutting unit and / or a flat-press hot stamping unit. An eccentric control device 3 for changing the length of the paper path is provided between the continuous working unit 1 and the intermittent working unit 2. When the intermittent working unit 2 is working, the eccentric control device 3 makes the continuous working unit The first paper path 61 between the unit 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com