Patents

Literature

129results about How to "Meet printing needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet light-cured offset printing ink with LED as light source

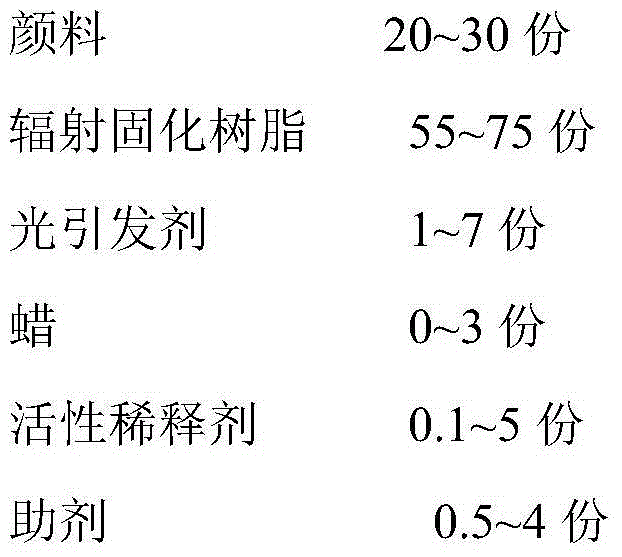

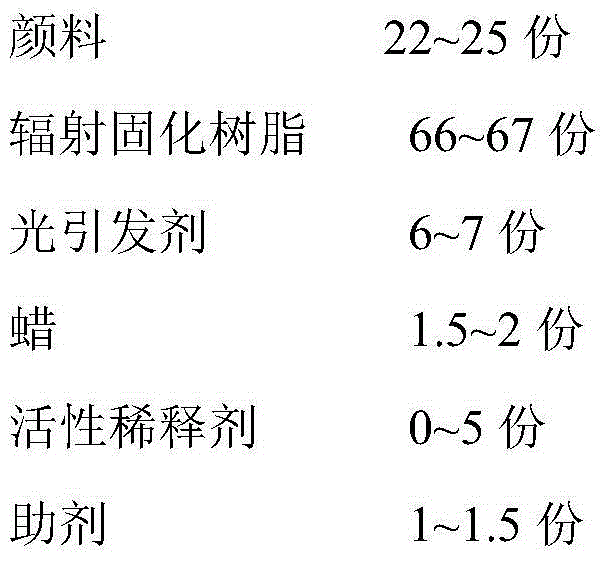

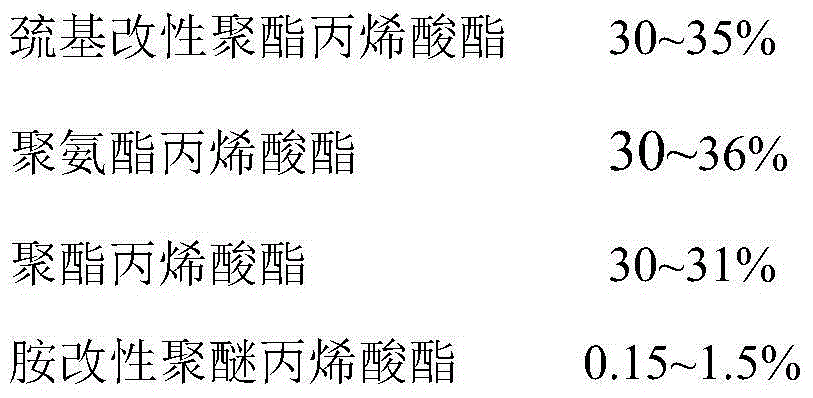

The invention discloses an ultraviolet light-cured offset printing ink with LED as a light source. The ultraviolet light-cured offset printing ink comprises, by weight, 20 to 30 parts of pigment, 55 to 75 parts of radiation-cured resin, 1 to 7 parts of a photoinitiator, 0 to 3 parts of wax, 0.1 to 5 parts of an active diluent and 0.5 to 4 parts of an auxiliary agent. The UV-LED light-cured printing ink has the following characteristics: the printing ink is applicable to offset printing; electric energy consumed in curing is about 1 / 4 of electric energy consumed by a common ultraviolet lamp; emission of CO2 is substantially reduced; ozone is not generated; etc. The printing ink is completely dried under the printing condition of a curing speed of 40 to 200 m / min and enables printed lines to be clear; and after curing, each performance index (adhesion, friction resistance, chemical resistance and the like) of the printing ink accords with requirements on printing of securities.

Owner:CHINA BANKNOTE INK +1

Ceramic ink and preparation method and applications thereof

ActiveCN105384449AEnhanced steric hindranceAvoid reunionImpression capsCeramic shaping apparatusSolid phasesGlycerol

The invention discloses a ceramic ink, which comprises the following raw materials in percentage by mass: 57-57% of ceramic powder, 1-5% of a dispersant, 8-30% of glycerol, 8-35% of water and 5-20% of an organic solvent; and the pH value of the ceramic ink is 8-12, and the dispersant is composed of ammonium polyacrylate and polyvinylpyrrolidone in a mass ratio of 1:5 to 5:1. The invention also discloses a preparation method of the ceramic ink and the application of the ceramic ink in the ink-jet printing of false teeth. According to the invention, the dispersion and ink stability of the ceramic ink are improved by a binary dispersant, and then the solid phase content of the ceramic ink is increased to 20-40 vol. %, so that the ceramic ink can be used for directly printing ceramic products such as false teeth and the like through ink-jet printing, and the relative density of ceramic products is more than 98%.

Owner:HUAZHONG UNIV OF SCI & TECH

Digital printing process for polyester-cotton fabric

InactiveCN107090724ASolve contaminationColorfulDry-cleaning apparatus for textilesGrip property fibresCooking & bakingDisperse dye

The invention relates to a digital printing process for a polyester-cotton fabric. The digital printing process comprises the following process steps: (1) sizing a polyester-cotton fabric; (2) digital printing: carrying out spray printing according to a pattern requirement of rip printing software, generating cyan by virtue of color card generation software (C:100, M:100, Y:100 and K:100), and carrying out unreeling and sequential digital printing on the fabric reeled in the step (1), wherein a printer comprises a first spray head and a second spray head, the first spray head is used for spraying and printing disperse dye ink, the second spray head is used for spraying and printing active dye ink, and a printing condition is that bidirectional four channels are adopted; (3) high-temperature baking: baking the digital-printed fabric in the step (2) at 180-190 DEG C for 40-50 seconds; (4) cotton-cloth steaming; (5) a washing and soaping process: carrying out open-width washing on the fabric processed in the step (4); and (6) shaping and drying: adding a softening agent and a color fixation agent into the fabric processed in the step (5) for shaping, and drying at a temperature of 150-160 DEG C, wherein the speed of a drying vehicle is 40m / min-50m / min.

Owner:杭州科迈数码纺织技术有限公司

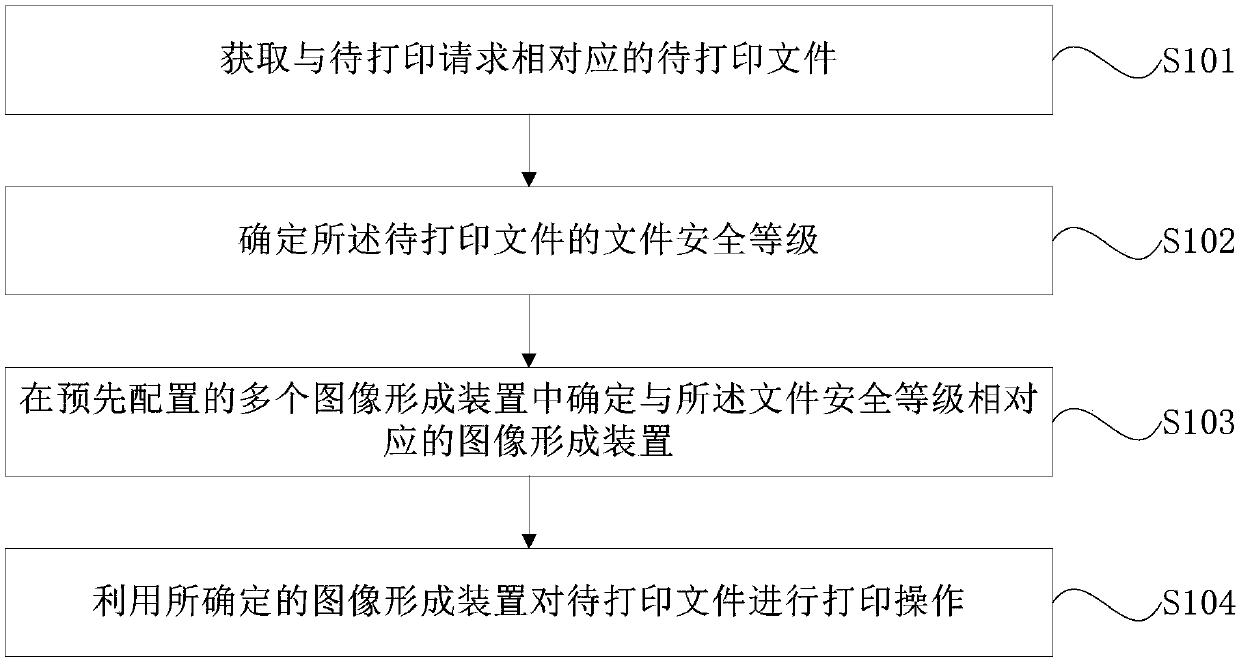

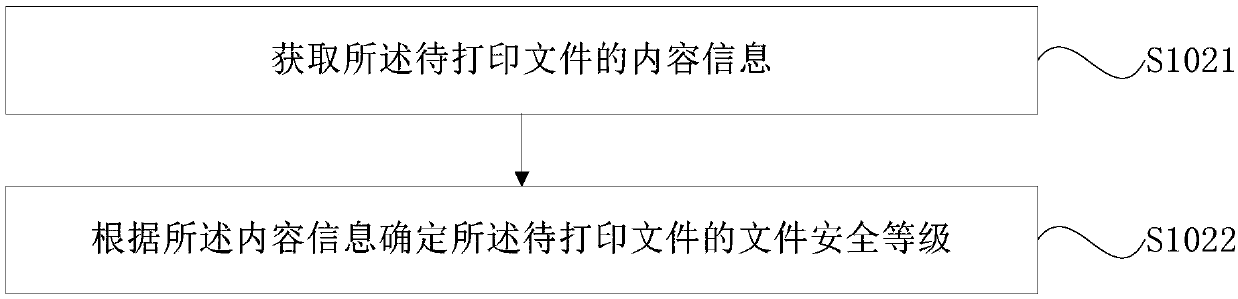

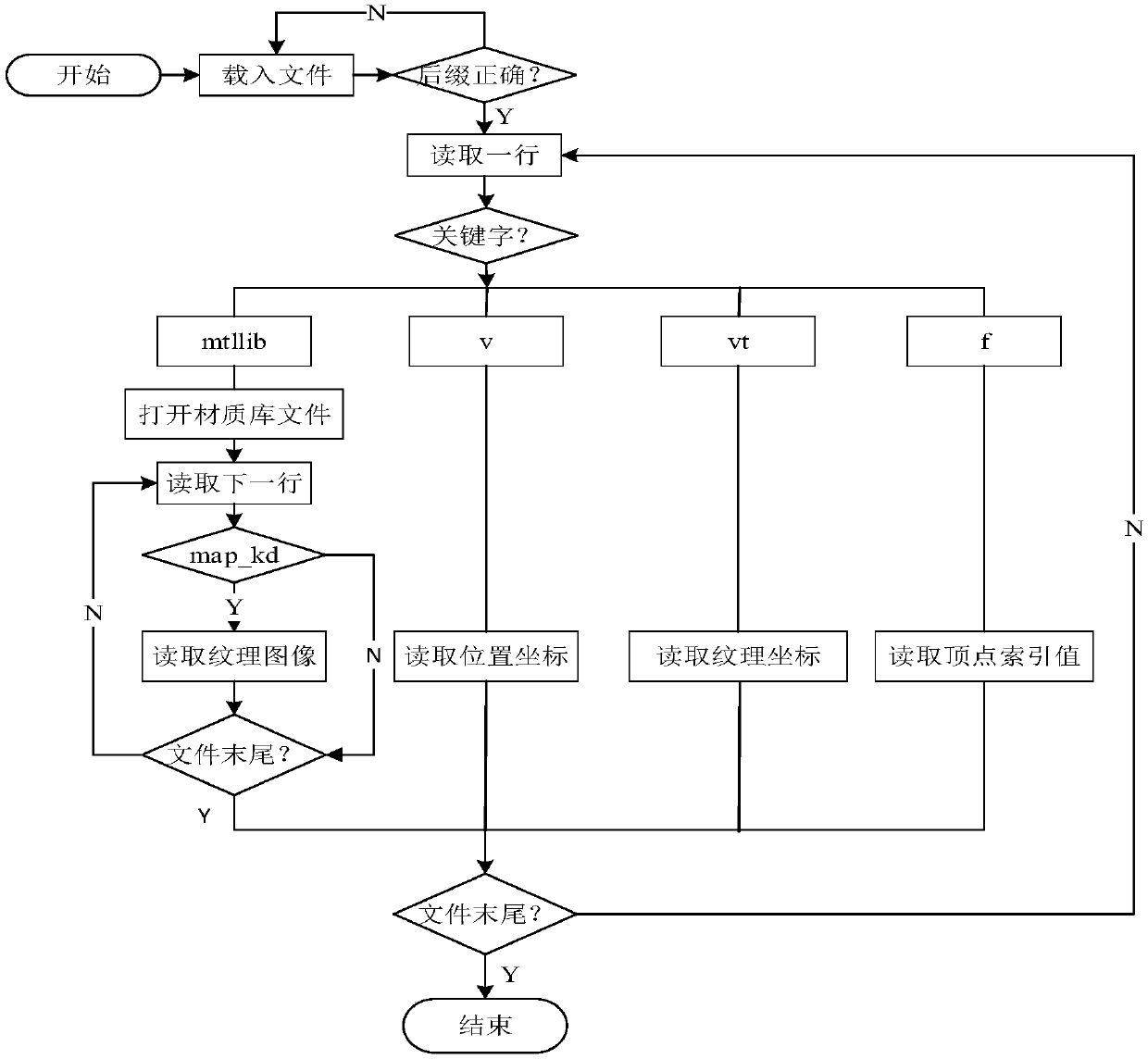

Safe printing method and system

InactiveCN107562392AEnsure safetyImprove printing efficiencyDigital data protectionDigital output to print unitsComputer scienceFile format

The invention provides a safe printing method and system. The method includes the steps of obtaining a to-be-printed file corresponding to a printing request; determining the file safety level of theto-be-printed file; determining an image forming device corresponding to the file safety level in multiple pre-allocated image forming devices; utilizing the determined image forming device to conductprinting operation on the to-be-printed file. According to the safe printing method and system, the file safety level of the to-be-printed file is determined firstly, the image forming device corresponding to the file safety level is determined secondly, and after the image forming device is determined, the image forming device is utilized to conduct printing operation on the to-be-printed file,and therefore the printing demands of different users can be met, and the safety of the file information can be effectively ensured; meanwhile, the printing efficiency of various files is improved, the practicability of the safe printing method is thus ensured, and moreover, since the users do not need to set the image forming device in a manual mode, more convenience is provided for the users.

Owner:ZHUHAI SEINE TECH CO LTD

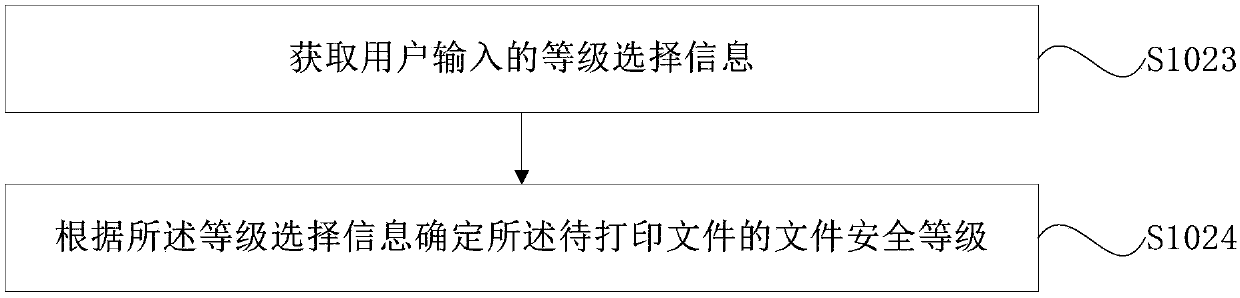

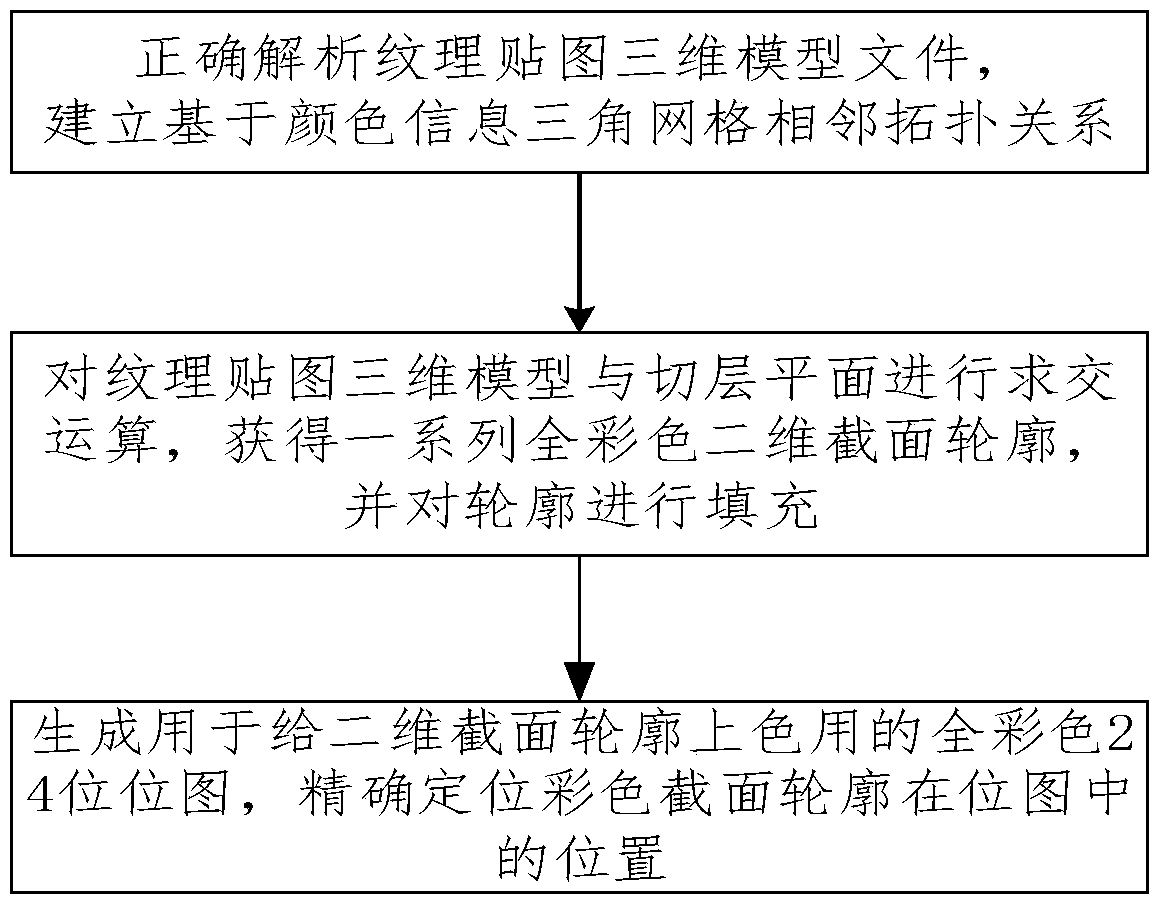

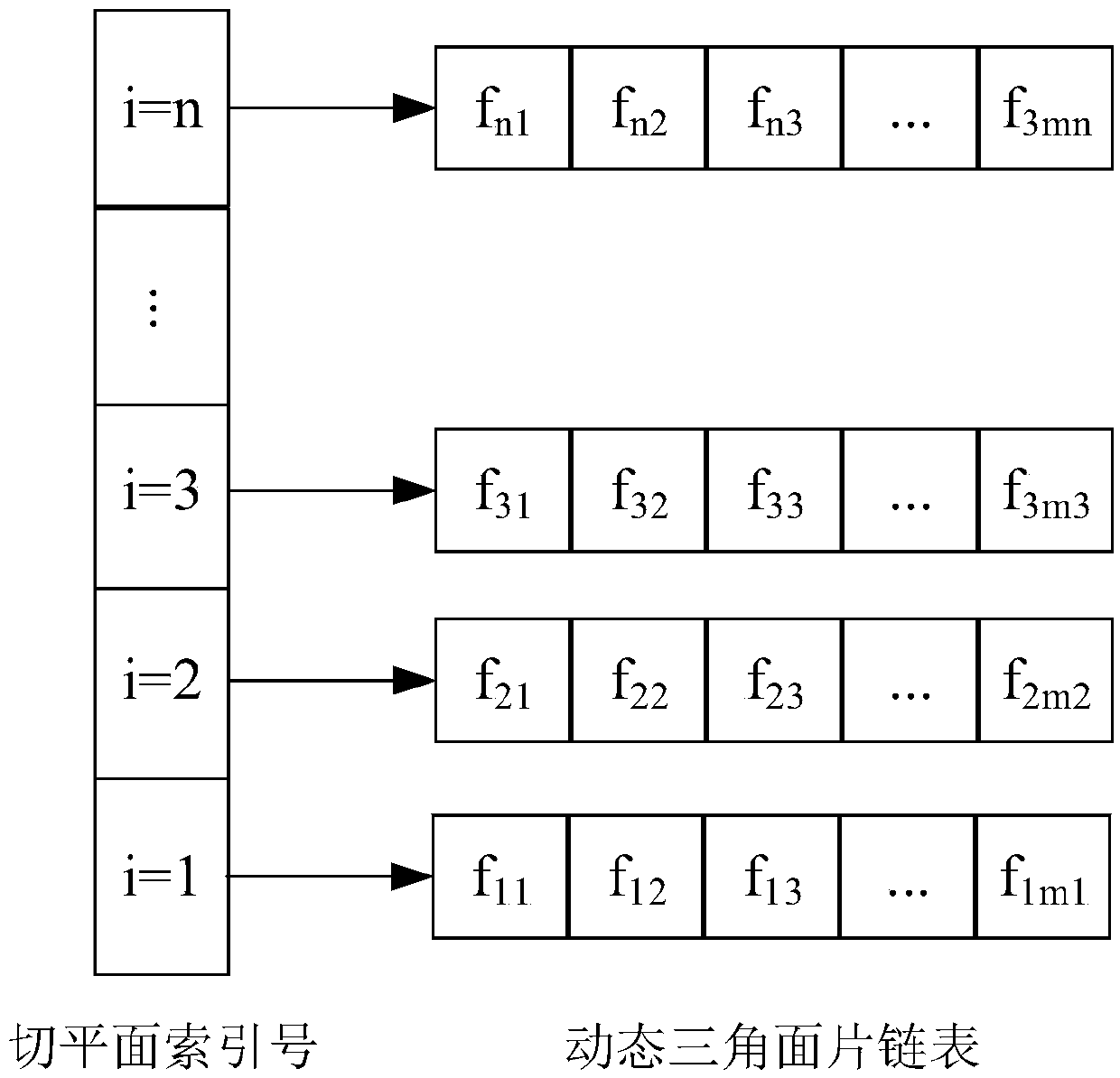

Full-color layered slicing algorithm based on three-dimensional model of texture mapping

ActiveCN110757804AOvercoming the defects of manual coloringMeet printing needsAdditive manufacturing apparatusManufacturing data aquisition/processingAlgorithmSlicing

The invention relates to a full-color layered slicing algorithm based on a three-dimensional model of texture mapping. The full-color layered slicing algorithm based on the three-dimensional model oftexture mapping includes the steps that a three-dimensional model file of texture mapping is analyzed, a triangular mesh adjacent topological relation based on color information is established, and fast query of triangular mesh adjacent information of the color information is realized; the fast intersection operation of color information triangular meshes and a tangent plane is realized, positioncoordinates and texture coordinates of all vertexes in each layer are obtained, the vertexes are connected in sequence to form a full-color two-dimensional contour, and the full-color two-dimensionalcontour is filled; and a full-color bitmap is generated, the position of the full-color contour in the bitmap is precisely located according to the position of a colourless model in a printing platform, the thickness of the contour is increased appropriately, and the function of layer-upon-layer printing and layer-upon-layer coloring is achieved. The full-color layered slicing algorithm based on the three-dimensional model of texture mapping has high slicing efficiency, the surface colors of the model are realistic, the reduction degree is high, the aftertreatment process of coloring the modelis omitted, the requirement for proficiency of operators is greatly reduced, the forming quality of parts is improved, and a real sense of color three-dimensional printing is realized.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

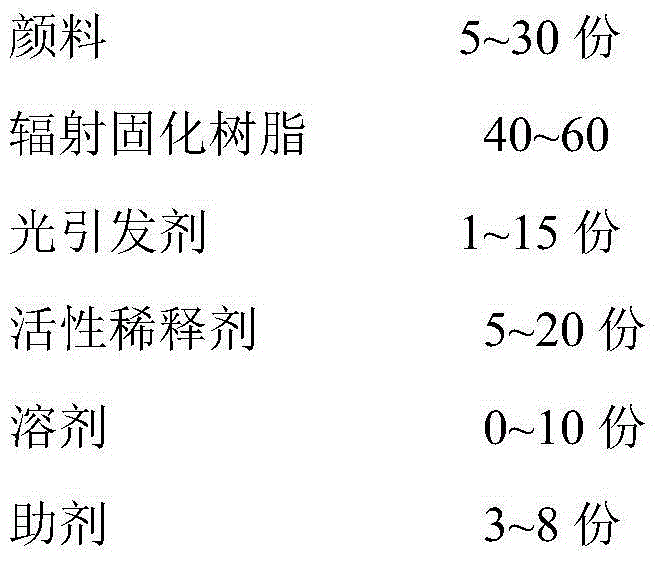

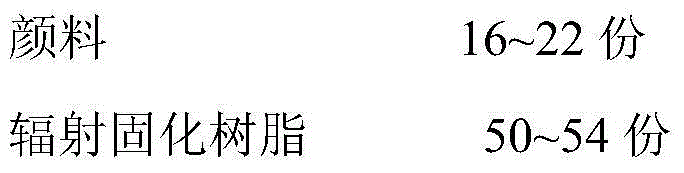

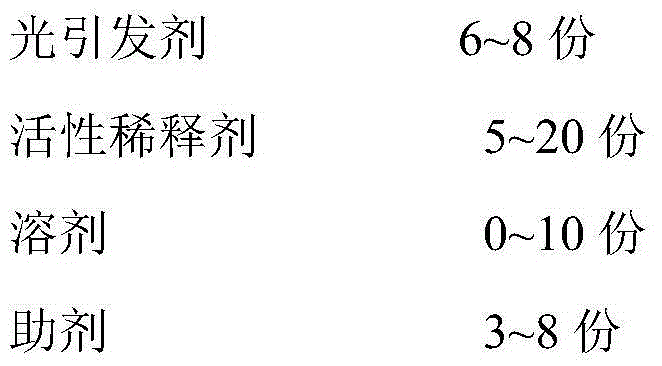

Ultraviolet-cured rotary silk-screen printing ink with LED as light source

The invention discloses an ultraviolet-cured rotary silk-screen printing ink with LED as a light source. The ultraviolet-cured rotary silk-screen printing ink comprises, by weight, 5 to 30 parts of pigment, 40 to 60 parts of radiation-cured resin, 1 to 15 parts of a photoinitiator, 5 to 20 parts of an active diluent, 0 to 10 parts of a solvent and 3 to 8 parts of an auxiliary agent. Electric energy consumed in curing of a silk-screen printing ink composition provided by the invention is about 1 / 4 of electric energy consumed by a common ultraviolet lamp; emission of CO2 is substantially reduced; and ozone is not generated. The silk-screen printing ink composition provided by the invention has viscosity of 50 to 350 mpa.s, overcomes problems in drying of a thick ink layer under irradiation of a low-power ultraviolet lamp and realizes instant drying under the rotary silk-screen printing condition of a high speed of 40 to 200 m / min; moreover, bonding between an ink film and a substrate is firm, and after curing, , each performance index (adhesion, friction resistance, chemical resistance and the like) of the printing ink accords with requirements on printing of securities.

Owner:CHINA BANKNOTE INK +1

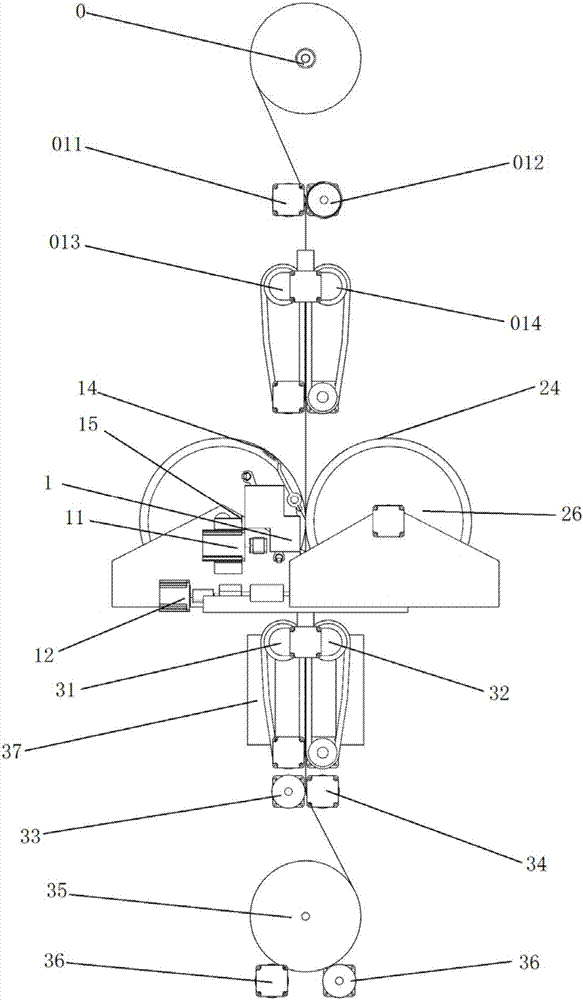

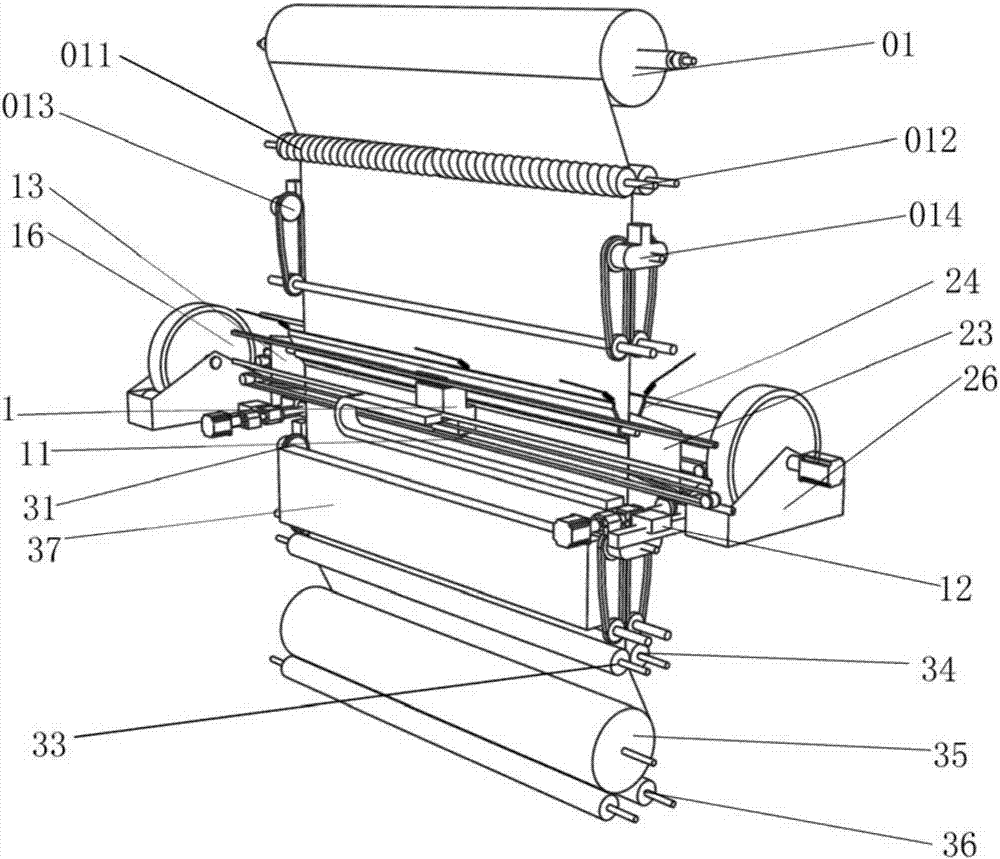

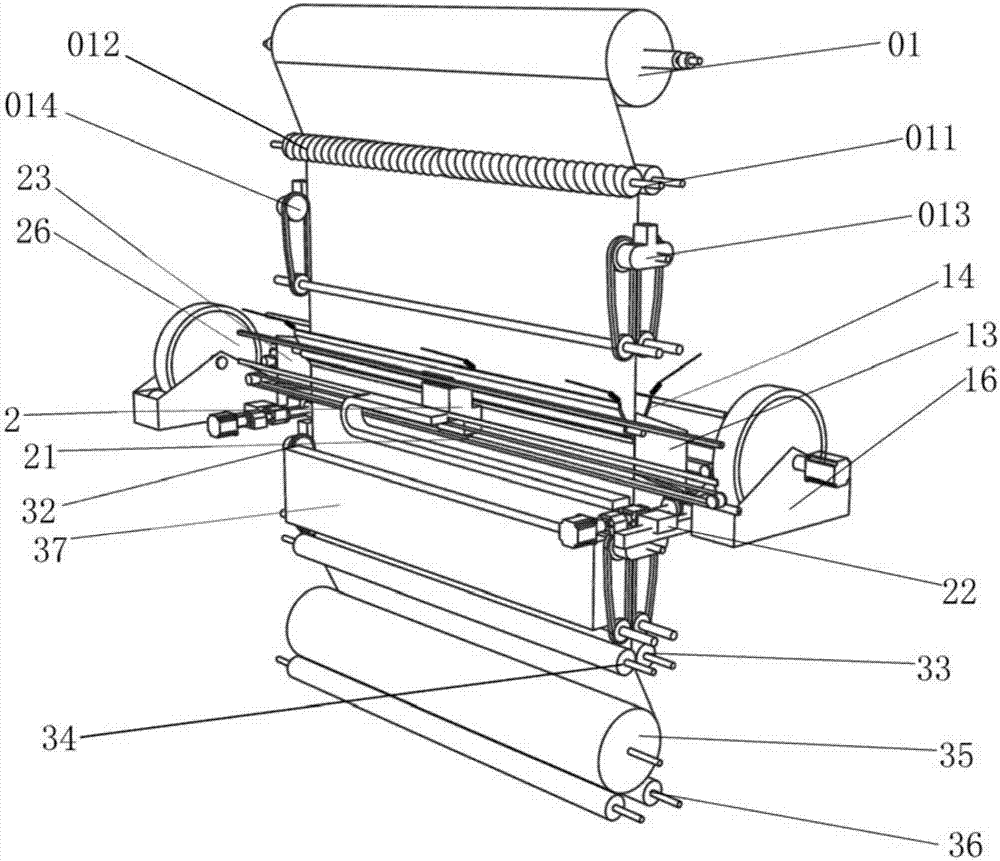

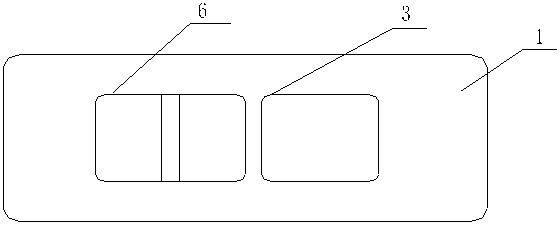

Two-sided printer adopting vertical printing manner

The invention discloses a two-sided printer adopting a vertical printing manner. The two-sided printer comprises a support. A cloth feeding mechanism, a printing mechanism and a cloth collecting mechanism are arranged on the support. The printing mechanism comprises a first printing assembly and a second printing assembly. The first printing assembly is used for conducting printing on the first face of fabric and comprises a first spray nozzle and a first spray nozzle movement servo system, wherein the first spray nozzle is used for discharging ink, and the first spray nozzle movement servo system controls the first spray nozzle to move. The second printing assembly is used for conducting printing on the second face of the fabric and comprises a second spray nozzle and a second spray nozzle movement servo system, the second spray nozzle is used for discharging ink, and the second spray nozzle movement servo system controls the second spray nozzle to move. By means of the two-sided printer with the ink outlet direction of the first spray nozzle and the ink outlet direction of the second spray nozzle located on the same horizontal plane, the existing printing manner is changed, two-sided synchronous same-position printing or two-sided synchronous different-position printing can be achieved, overlapping of patterns on two sides can be achieved particularly when textiles or silk products are printed, and printing requirements can also be met when the two-sided printer is applied to printing of various other types of fabric.

Owner:朱辛伟

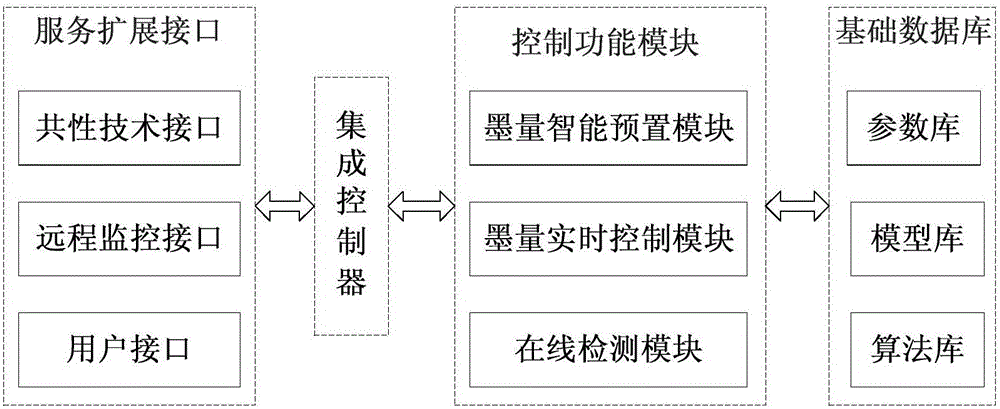

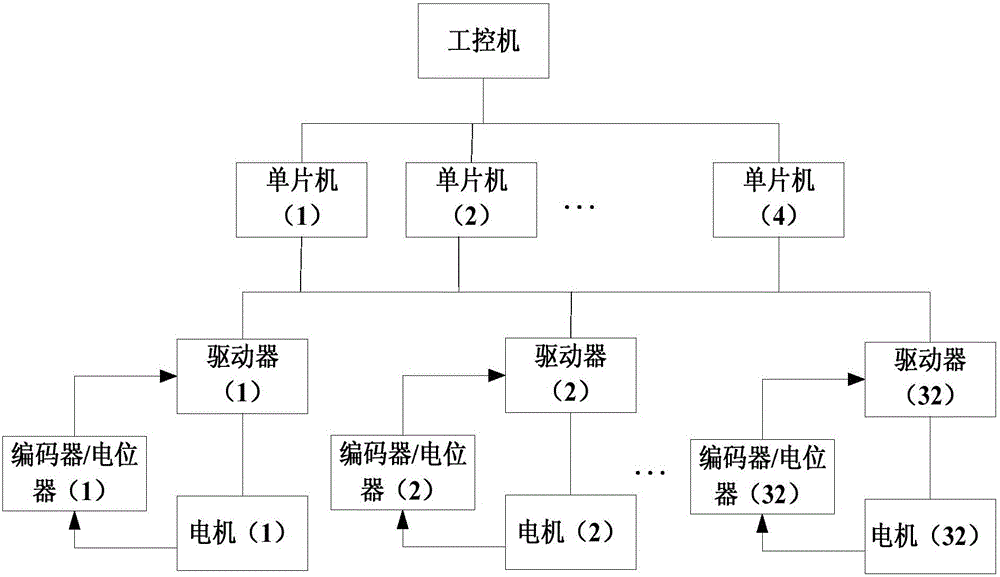

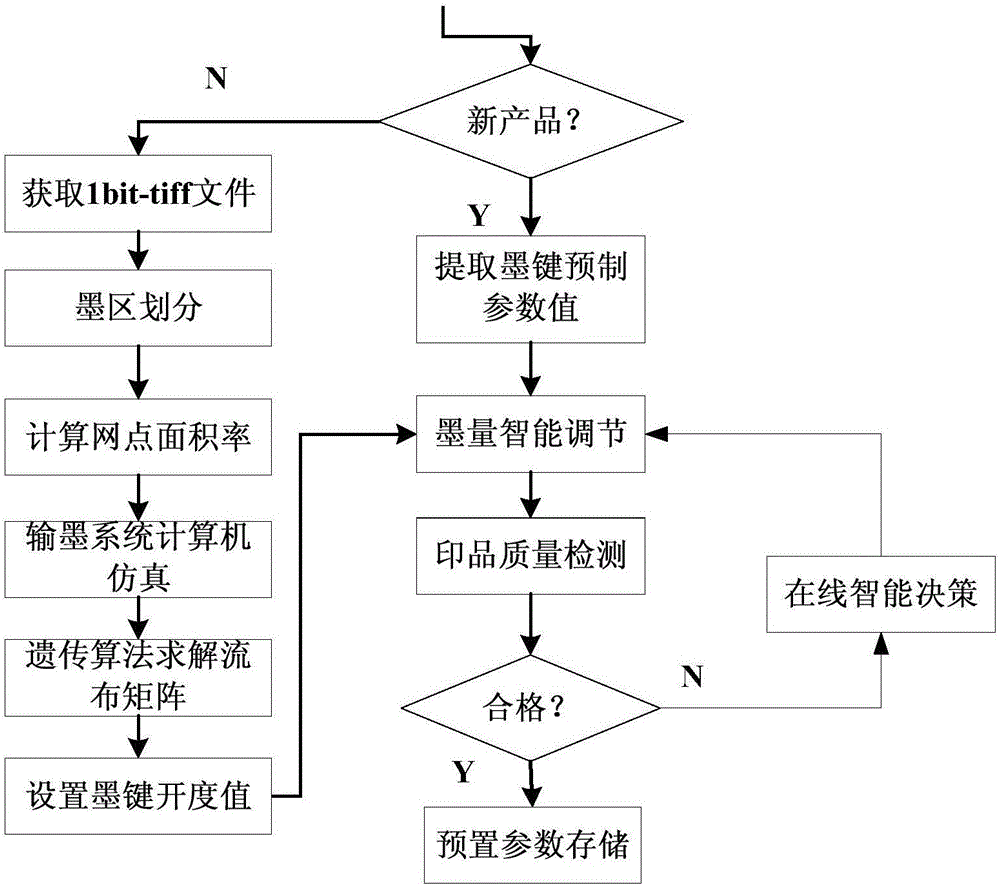

Intelligent ink supply control system for metal sheet printing and method thereof

The invention discloses an intelligent ink supply control system for metal sheet printing and a method thereof. The intelligent ink supply control system comprises a service expansion interface, an integrated controller, a control function module and a foundation database which are connected in sequence, wherein the service expansion interface has the function of completing communication with data of an external user and data of a local user and comprises a generic technology interface, a remote monitoring interface and a user interface; the integrated controller has the functions of completing driving control over 32 ink keys, driving control over a motor through a single chip microcomputer and real-time control over ink key opening degree; the control function module completes intelligent preset of the ink quantity, detection and monitoring of the thickness of an ink layer, fault diagnosis, maintenance and remote diagnosis which are achieved through an industrial PC; the foundation database has the functions of completing storing, invoking and editing of process parameters and printing standard patterns, and the functions are achieved by using a data server through a database programming language. According to the intelligent ink supply control system for metal sheet printing and the method thereof, the intelligent ink supply control system which is high in quality, low in consumption and fully automatic and intelligent in operation is provided for metal sheet printing equipment.

Owner:NANJING UNIV OF SCI & TECH

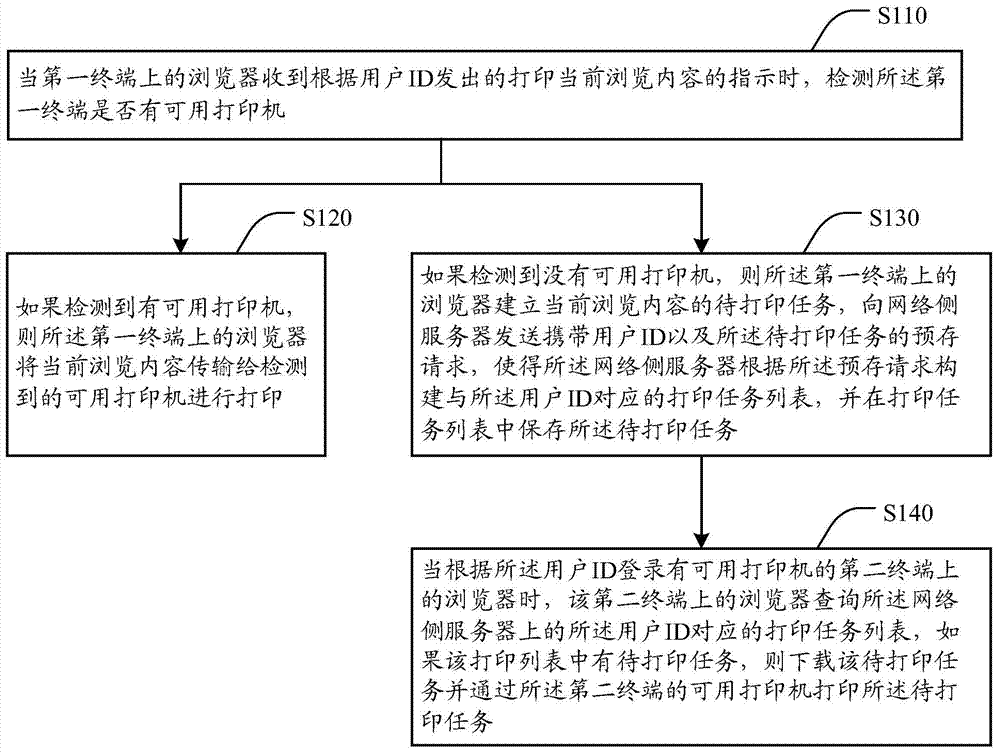

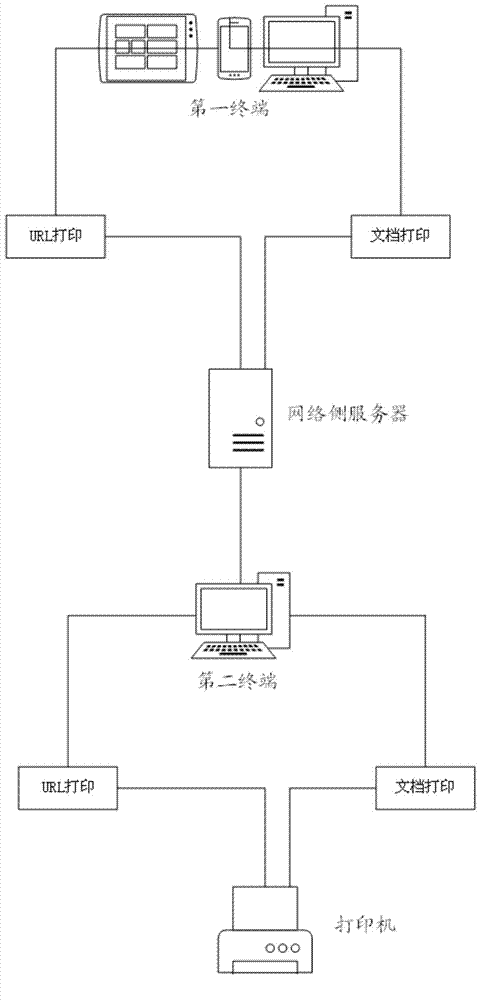

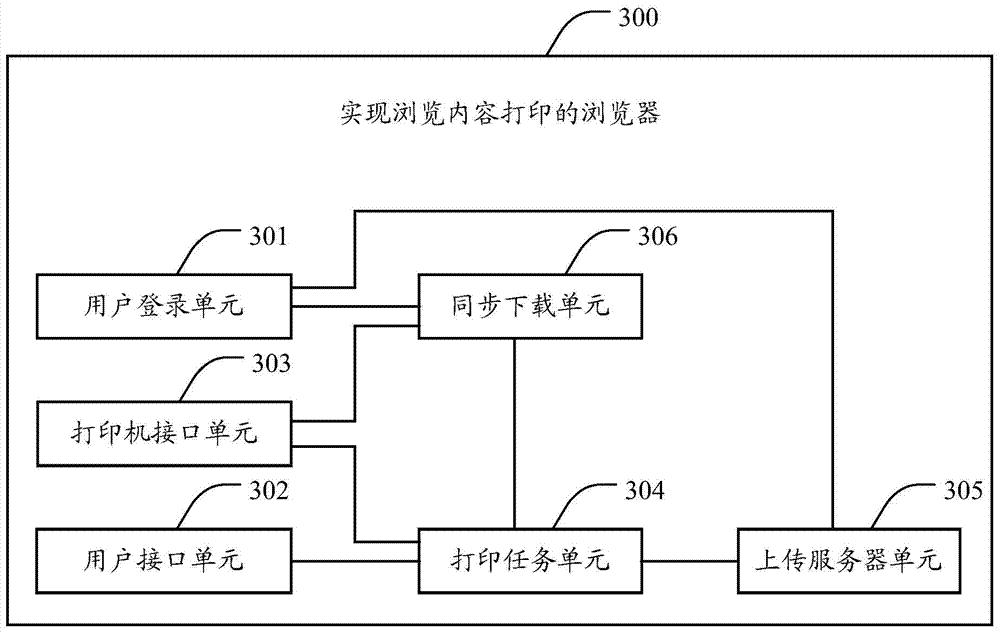

Browser, method and system for realizing browsed content printing

ActiveCN103577129AMeet printing needsSpecial data processing applicationsDigital output to print unitsComputer terminalUser identifier

The invention discloses a browser, method and system for realizing browsed content printing. The method comprises the following steps: when a browser at a first terminal receives printing indication sent out according to the ID of a user, if the fact that no printer is available is detected, a to-be-printed task is established, a pre-store request carrying the user ID and the to-be-printed task is sent to a network side server, so as to enable the network side server to establish a printing task list corresponding to the user ID and save the to-be-printed task; when the user ID logs in a browser at a second terminal provided with an available printer, the browser inquires the printing task list corresponding to the user ID on the network side server, and the to-be-printed task is downloaded and printed by the available printer of the second terminal. According to the technical scheme provided by the invention, during webpage browsing, if no printer is available, the browsed content can be uploaded to the network side server, then the browser is logged in again to print the uploaded content under the condition that a printer is available, and the requirement for printing browsed contents can be met.

Owner:BEIJING QIHOO TECH CO LTD

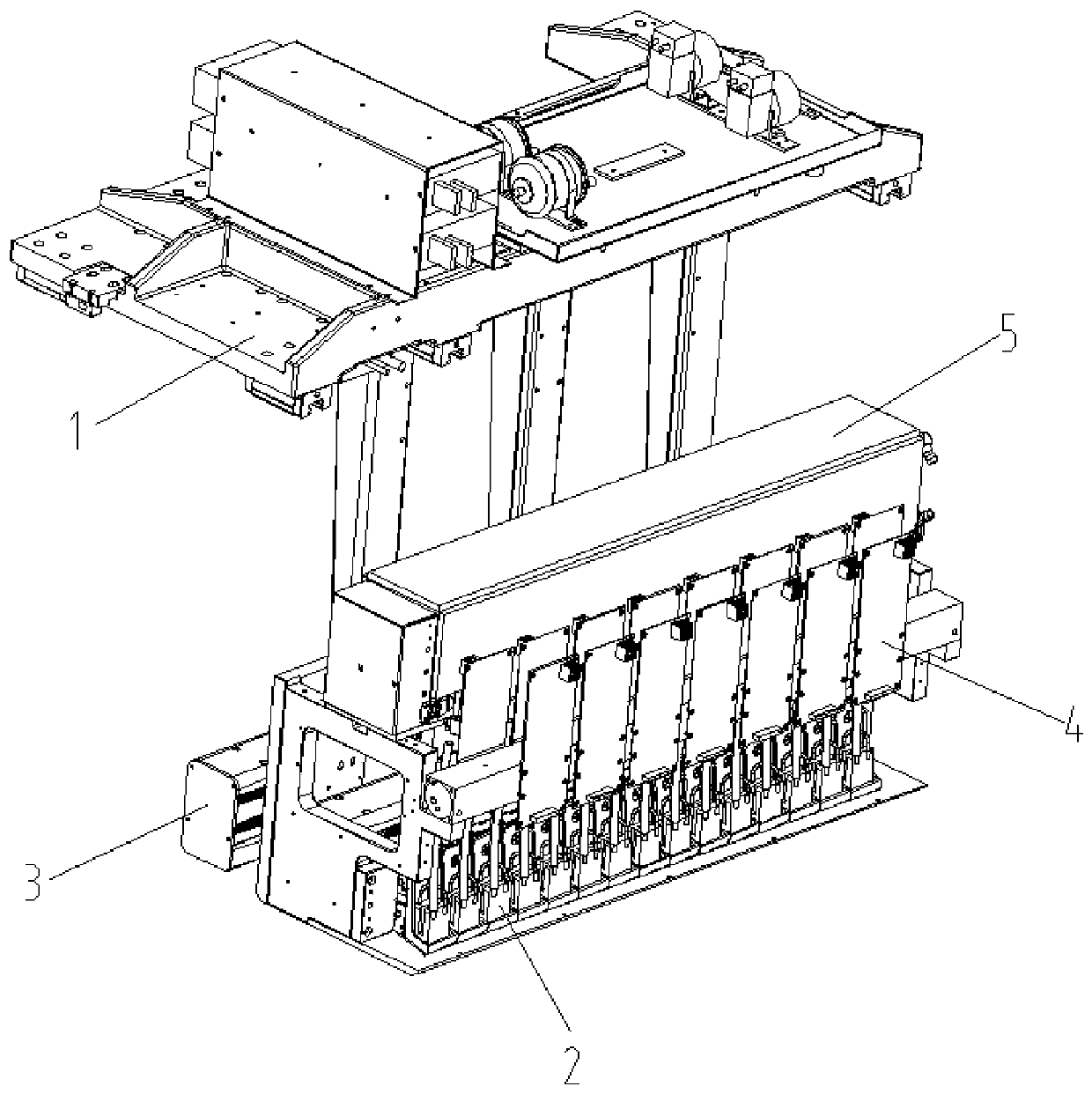

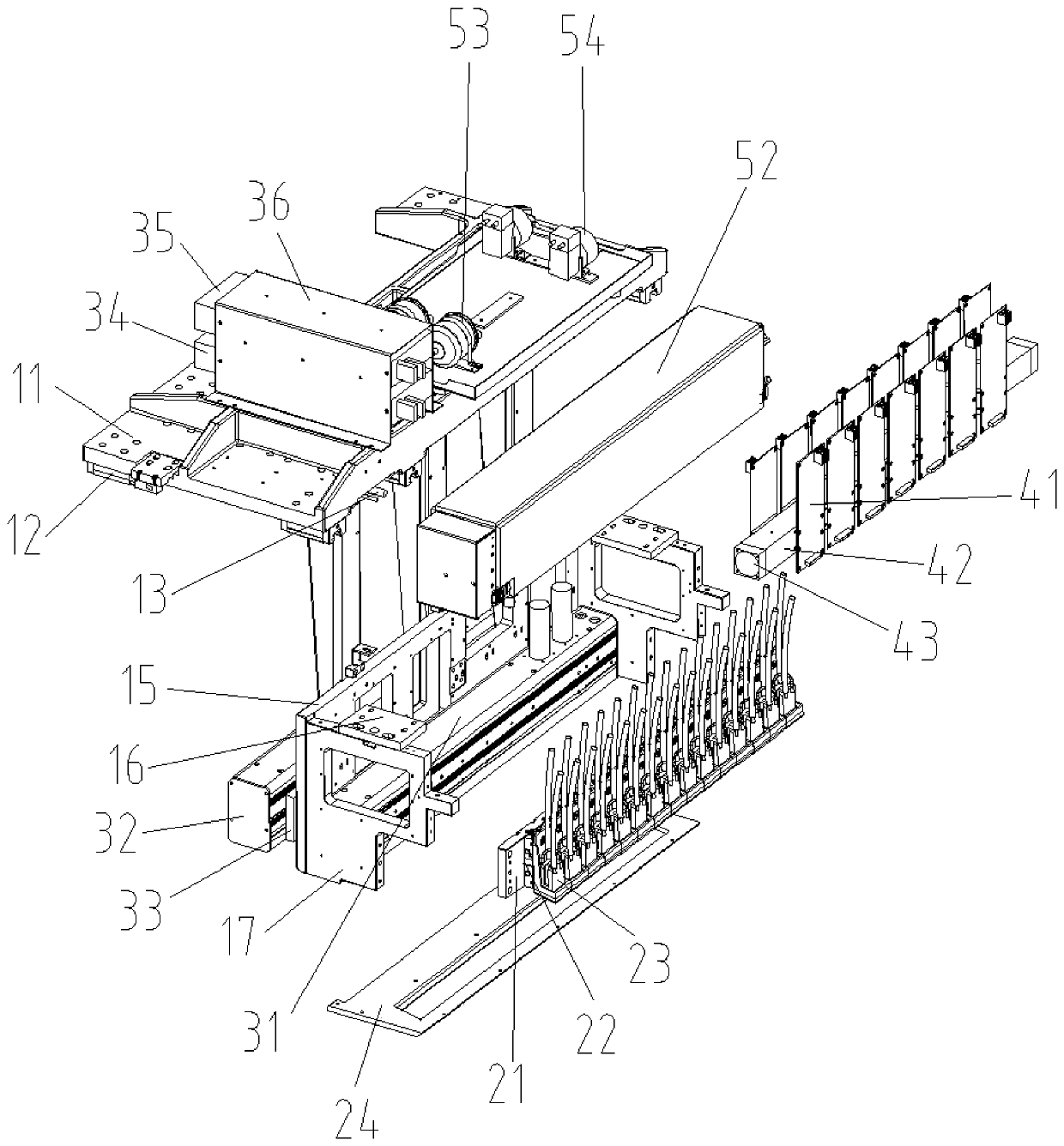

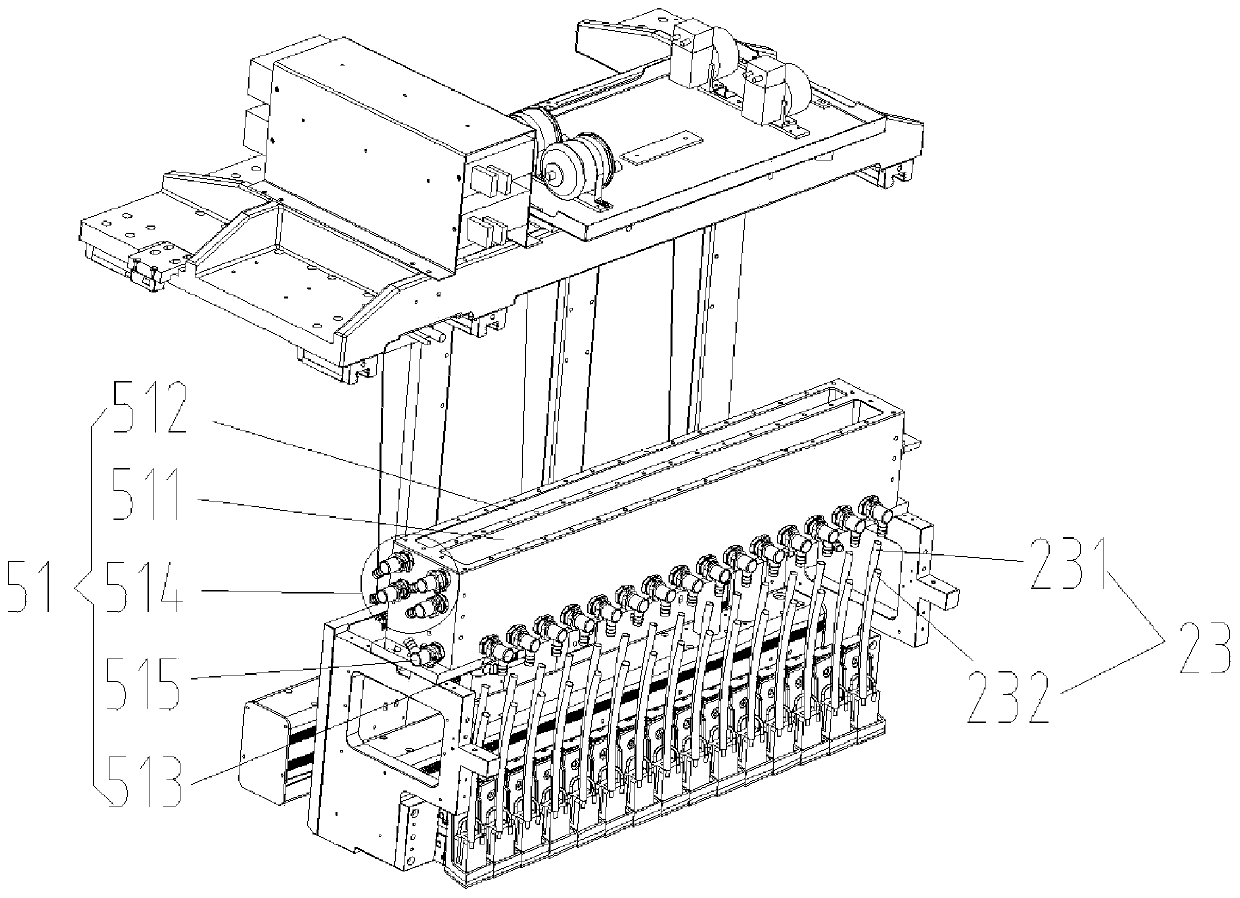

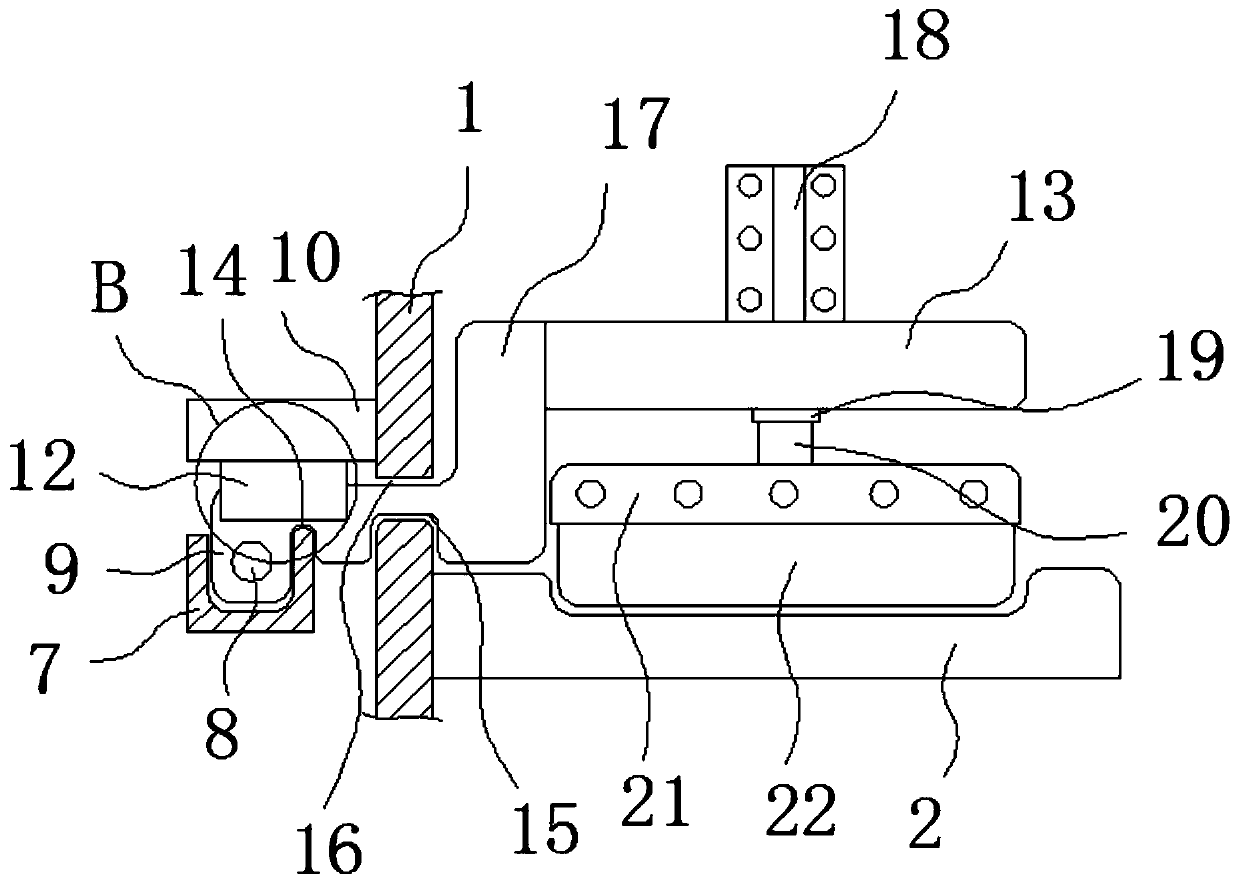

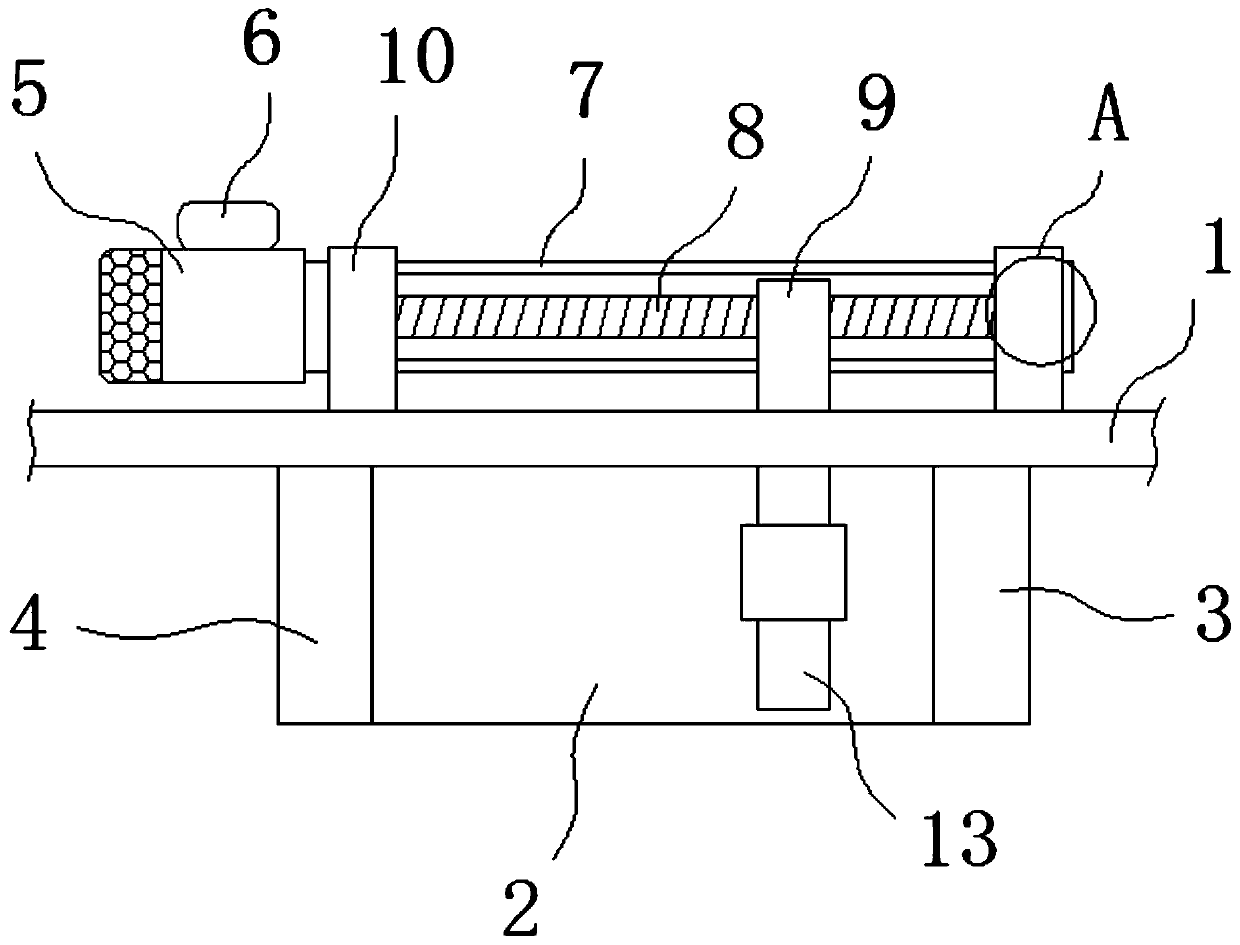

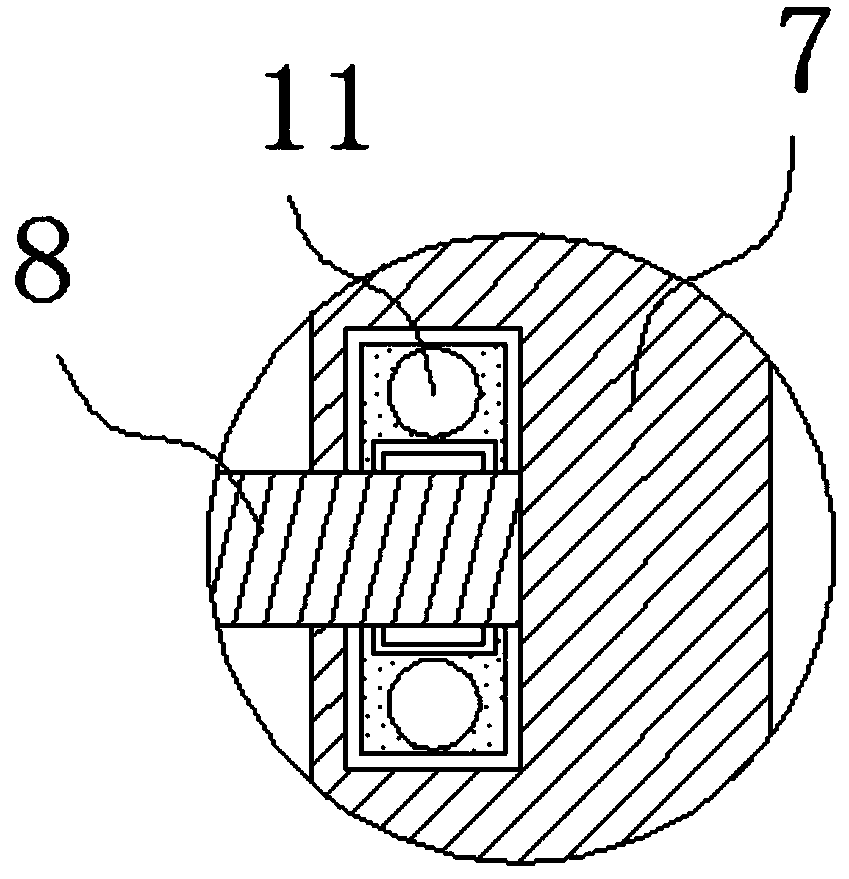

Ink-jet printing trolley and ink-jet printing device

PendingCN111376615AThe structure is evenly stressedGuaranteed uptimeTypewritersOther printing apparatusMechanical engineeringElectrical and Electronics engineering

The invention discloses an ink-jet printing trolley and an ink-jet printing device. The ink-jet printing trolley comprises a trolley support assembly, an ink-jet printing module, a curing module, a spray head control module and an ink supply device. The trolley support assembly is slidably arranged on an equipment cross beam for bearing the ink-jet printing module, the curing module, the spray head control module and the ink supply device. The ink-jet printing module is sued for printing images and texts on a printing medium. The curing module is used for curing the printed images and texts. The spray head control module is used for controlling the ink-jet printing module to print. The ink supply device is used for supplying ink to the ink-jet printing module. Relatively more spray heads can be loaded conveniently and rapidly, so that a relatively wider circuit board can be covered by single scanning of the trolley. The quantity of the arranged spray heads can be changed according to actual demand, and the printing demands on different width circuit boards can be met. The ink-jet printing trolley is balanced in structural stress and stable to operate, and can guarantee printing with high efficiency and high quality. The modules are conveniently detached and maintained at ordinary time.

Owner:선전진신테크놀로지컴퍼니리미티드

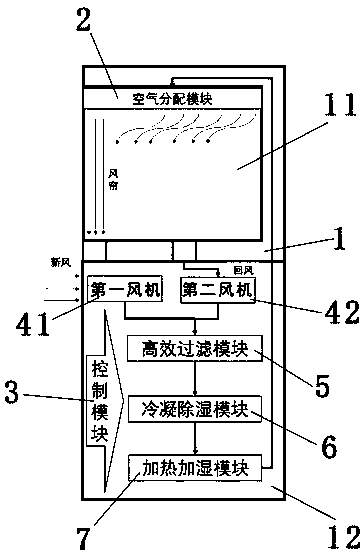

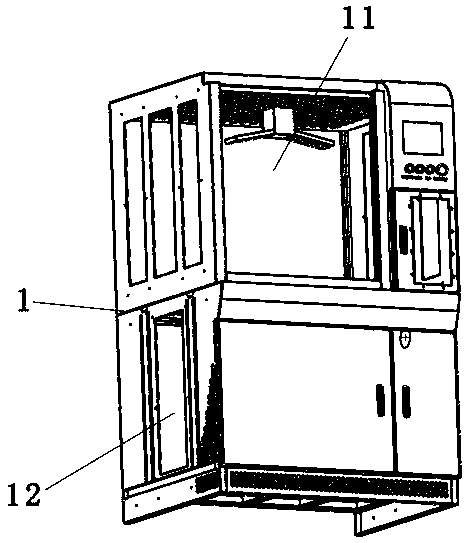

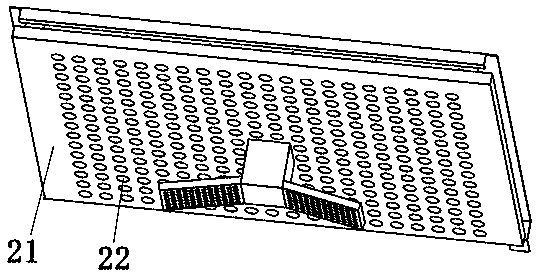

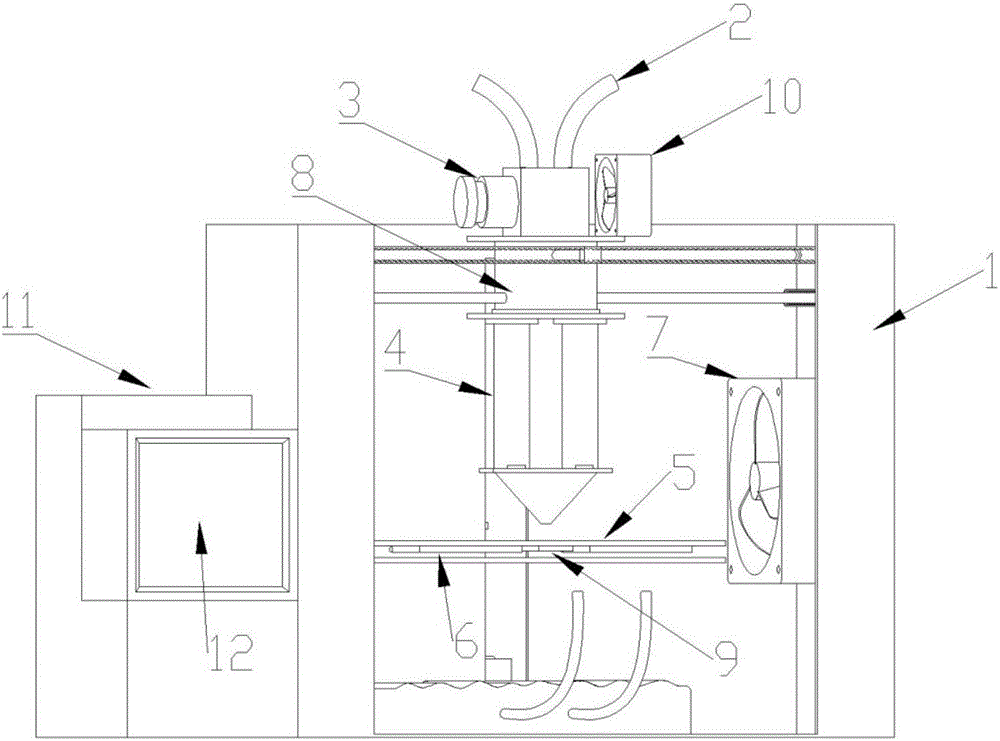

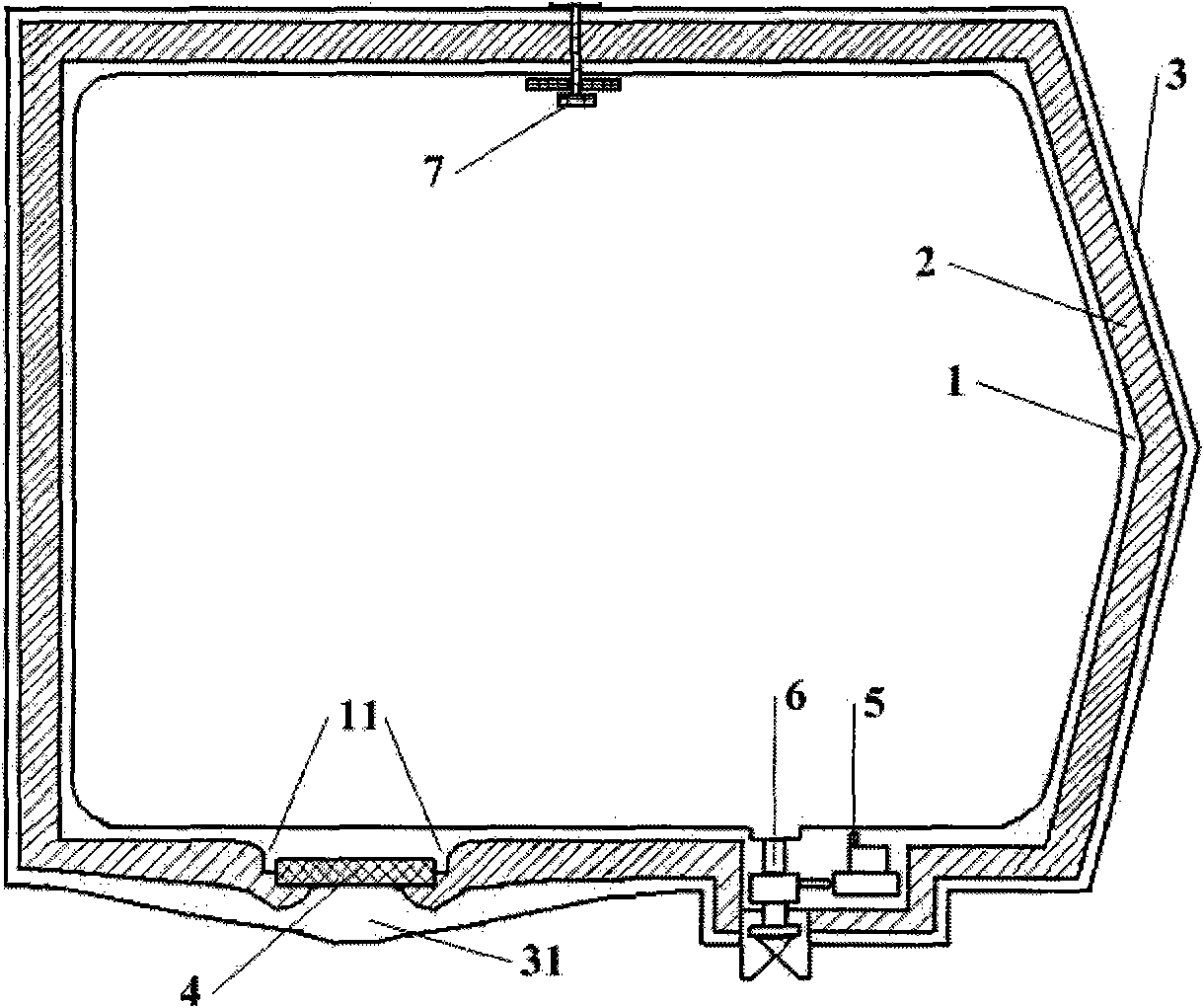

Integrated biological 3D printer printing cavity body environment control system and control method

ActiveCN109055207AMeet printing needsMeet the needs of different regionsBioreactor/fermenter combinationsAdditive manufacturing apparatusStable stateAir volume

The invention provides an integrated biological 3D printer printing cavity body environment control system and a control method. The system comprises a control module, a ventilating module, a high-efficiency filtering module, a condensing and dehumidifying module, a heating and humidifying module and an air distributing module, wherein the ventilating module, the high-efficiency filtering module,the condensing and dehumidifying module, the heating and humidifying module and the air distributing module are sequentially connected; the air distributing module is arranged at the top of a biological 3D printer printing cavity body, the ventilating module is communicated with the inside of the printing cavity body and the outside of a biological 3D printer, and the ventilating module, the high-efficiency filtering module, the condensing and dehumidifying module, the heating and humidifying module and the air distributing module are all connected with the control module. The system disclosedby the invention can achieve integrated control on temperature, humidity, aseptic environment, air speed, air volume and wind direction in the biological 3D printer printing cavity body; furthermore,the environment in the printing cavity body is kept in a stable state, and a high-accuracy biological 3D printing requirement can be met.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

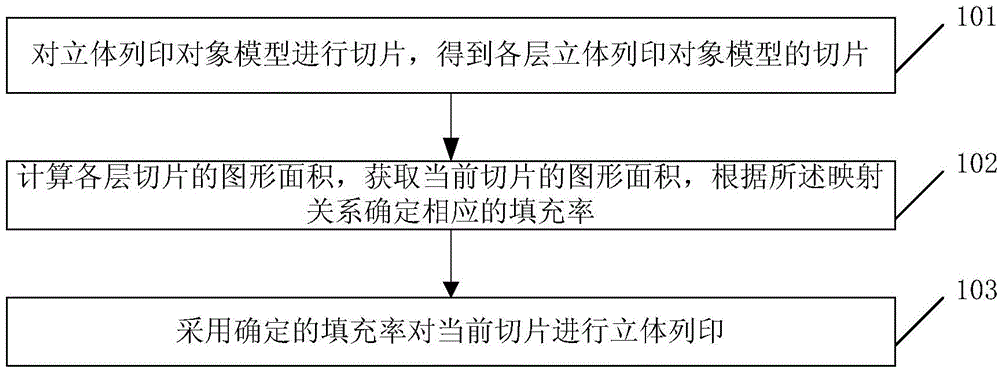

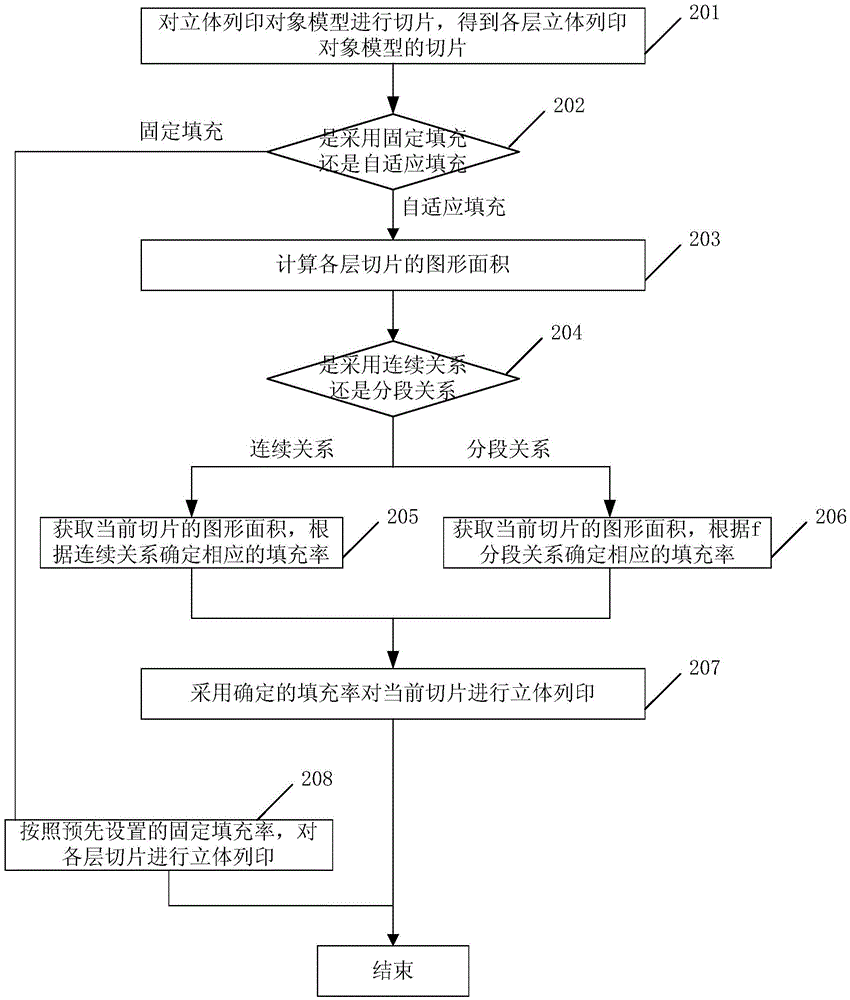

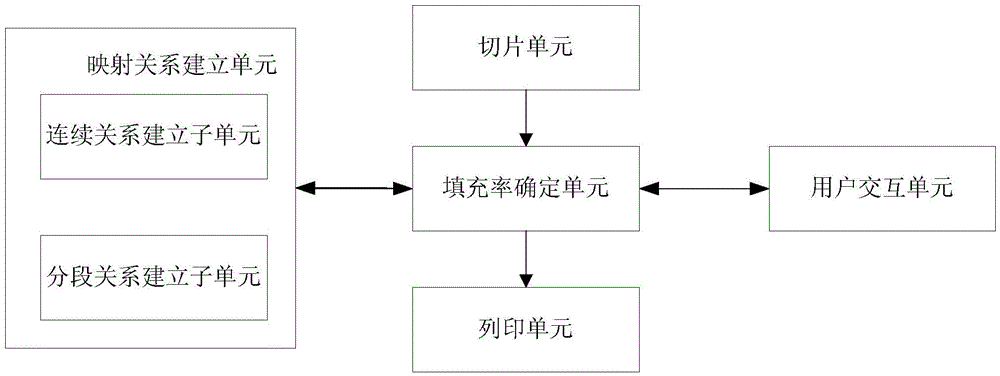

Line printing method and device for three-dimensional line printing machine

ActiveCN104802412AHigh strengthImprove printing qualityAdditive manufacturing apparatusGraphicsFilling rate

The invention discloses a line printing method and device for a three-dimensional line printing machine, wherein according to the method, a mapping relationship between the pattern area and the filling rate is built, wherein the smallest pattern area corresponds to the greatest filling rate. The method also comprises the steps of slicing a three-dimensional line printing object model to obtain slices of each layer of the three-dimensional line printing object model; calculating the pattern area of the slices of each layer; obtaining the pattern area of the current slice, and determining the corresponding filling rate according to the mapping relationship; adopting the current filling rate for carrying out three-dimensional line printing on the current slices. The method and the device adopting the technical scheme have the advantages that the intensity of fine and small parts in the three-dimensional line printing object model can be enhanced, and the line printing quality is improved.

Owner:INVENTECSHANGHAI TECH +2

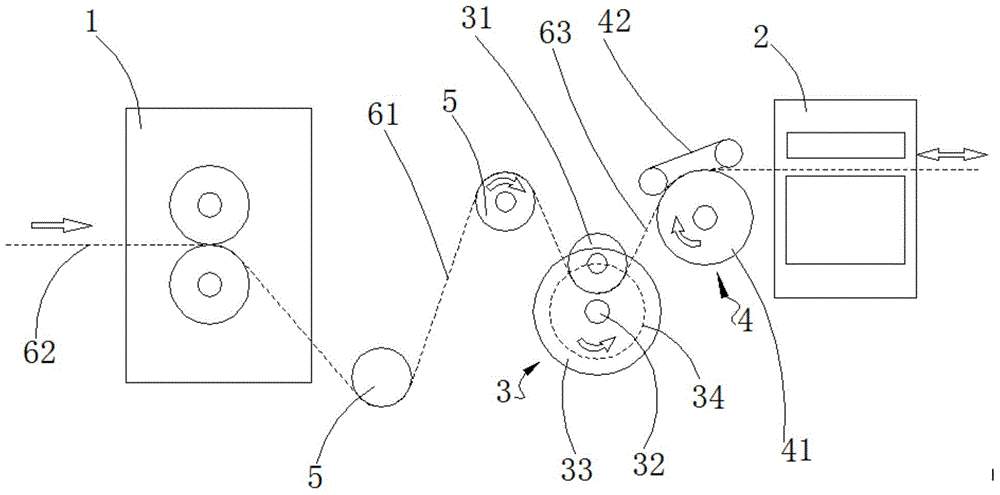

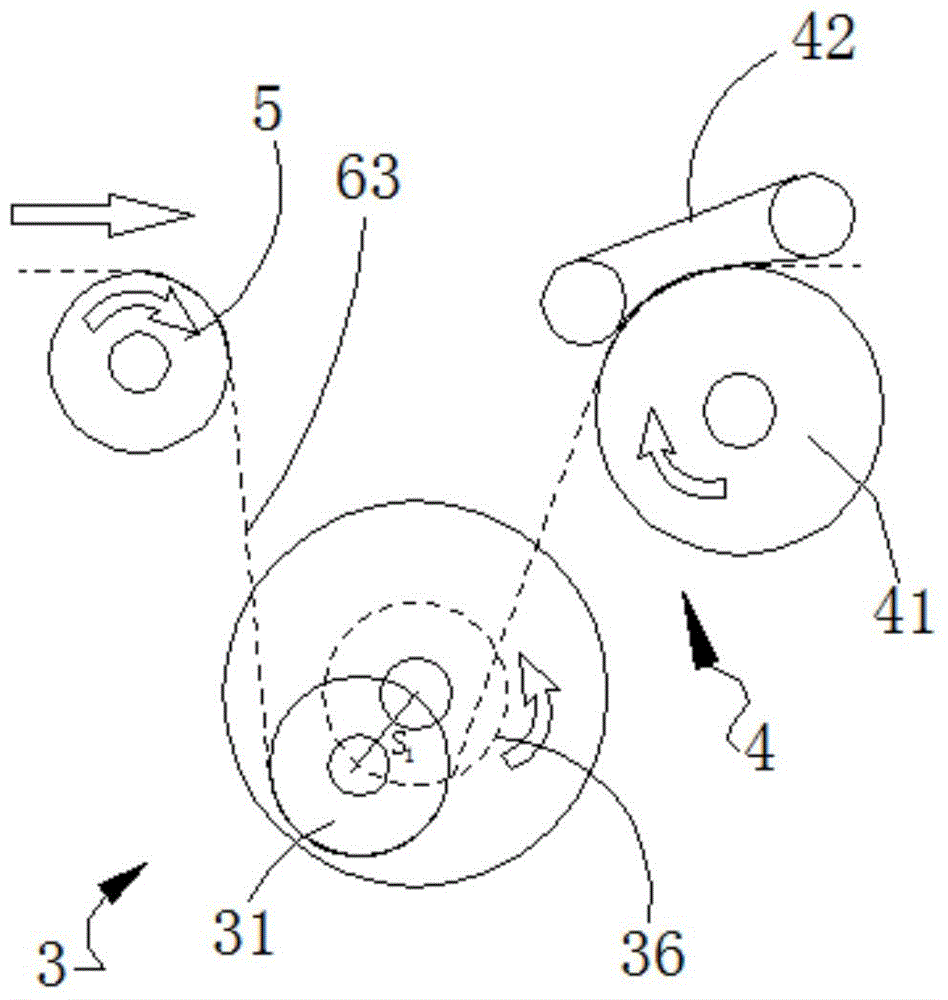

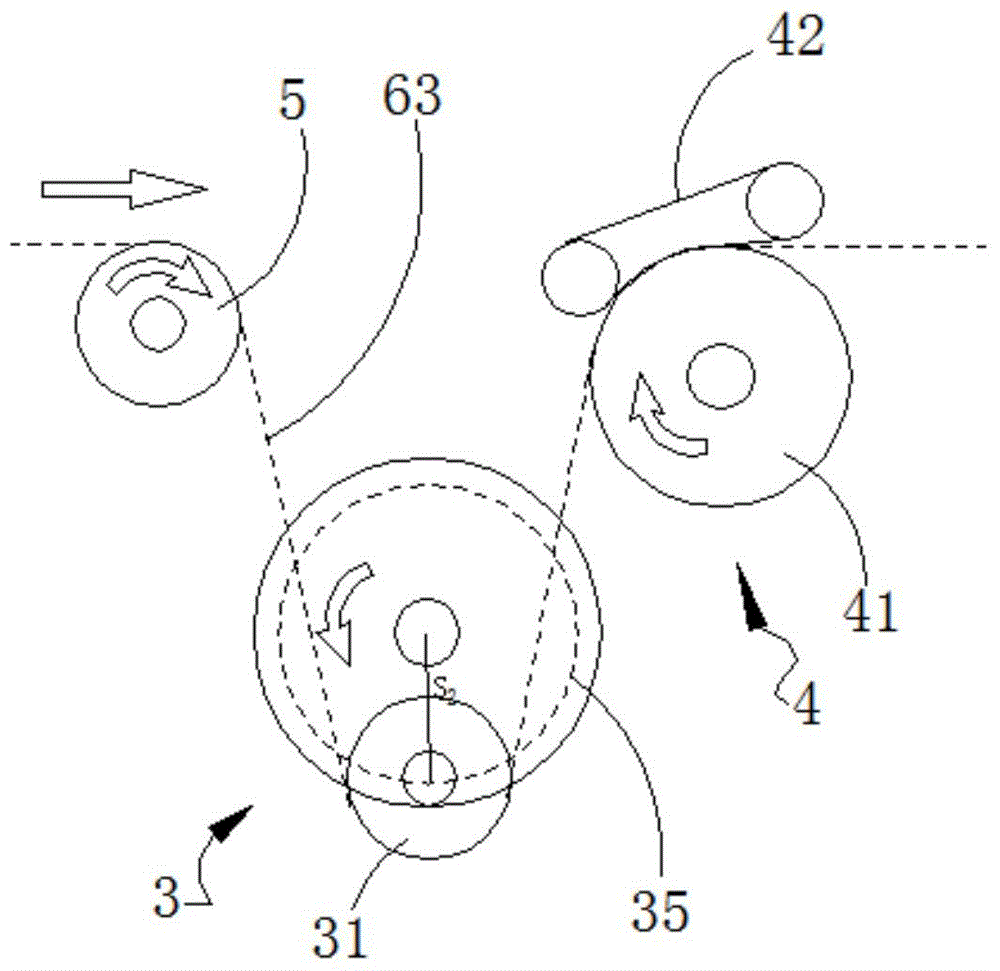

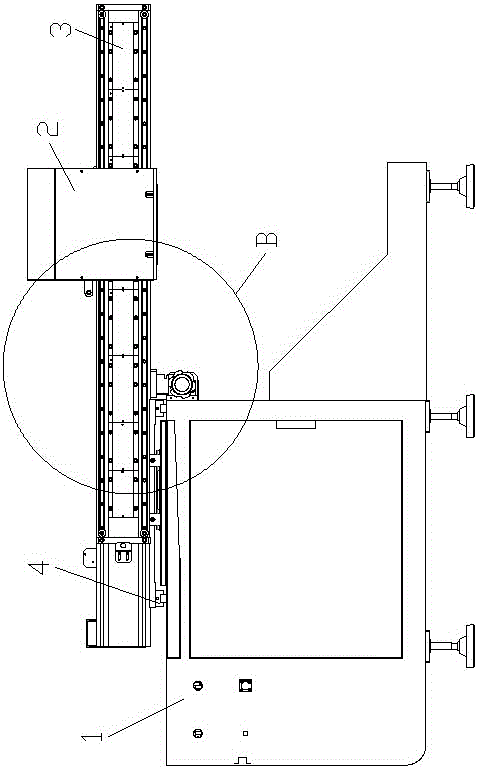

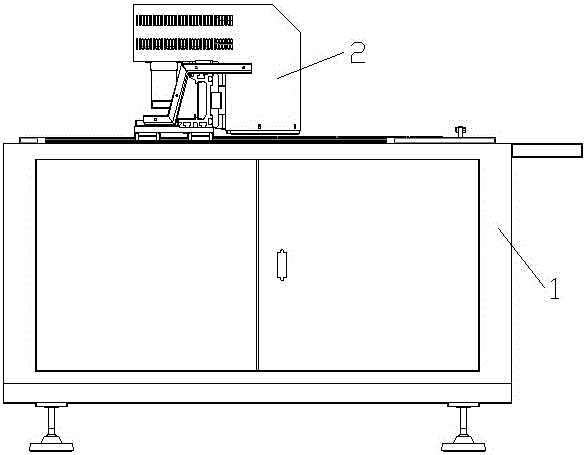

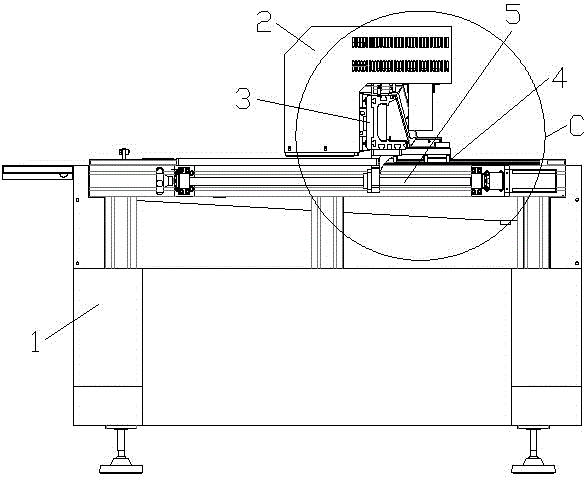

Paper conveying device

The invention discloses a paper conveying device, comprising a continuous working unit and an intermittent work unit; an eccentric control device is arranged between the continuous work unit and the intermittent work unit; when the intermittent work unit works, the eccentric control device gradually lengthens a first paper path between the continuous work unit and the intermittent work unit; the eccentric control device for changing the length of the first paper path is arranged between the continuous work unit and the intermittent work unit, and is used for gradually lengthening the first paper path, so the speed of a third paper path entering the intermittent work unit is slowed, and the intermittent work unit has enough time to perform operations such as die cutting or gold stamping on the third paper path entering the intermittent work unit. While being operated at a high speed, the paper conveying device can perform intermittent operations such as die cutting and gold stamping on the paper path, the paper conveying device meets the printing demands of a long order form, the obtained printed paper product has high quality and the work efficiency is high.

Owner:广州互通气动机器工程有限公司

T-shirt printing system adopting rotary bracket and cantilever beam spray printing device and T-shirt printing method

InactiveCN105774213AConvenient digital printingEasy maintenanceScreen printersTypewritersEngineeringCantilever

The invention relates to a T-shirt printing system adopting a rotary bracket and a cantilever beam spray printing device and a T-shirt printing method. At present, the T-shirt printing system adopting the rotary bracket and the cantilever beam spray printing device and the T-shirt printing method by which the T-shirt printing efficiency and the T-shirt printing quality can be greatly improved have not been invented. The T-shirt printing system comprises the rotary bracket; and a plurality of T-shirt supporting plates which can rotate along with the rotary bracket are arranged on the rotary bracket. The T-shirt printing system is characterized by further comprising the cantilever beam spray printing device; the cantilever beam spray printing device comprises a spray printing device rack, a printing mechanism and a cantilever beam; and one end of the cantilever beam is arranged on the spray printing device rack through a group of cantilever beam guide rail components, and an outrigger structure is formed at the other end of the cantilever beam and is directly erected at one side, facing the T-shirt supporting plates, of the spray printing device rack, so that actual printing areas of the T-shirt supporting plates are positioned in a printing area of the cantilever beam spray printing device. According to the T-shirt printing system and the T-shirt printing method disclosed by the invention, the T-shirt printing efficiency and the T-shirt printing quality can be greatly improved.

Owner:HANGZHOU HONGHUA DIGITAL TECH

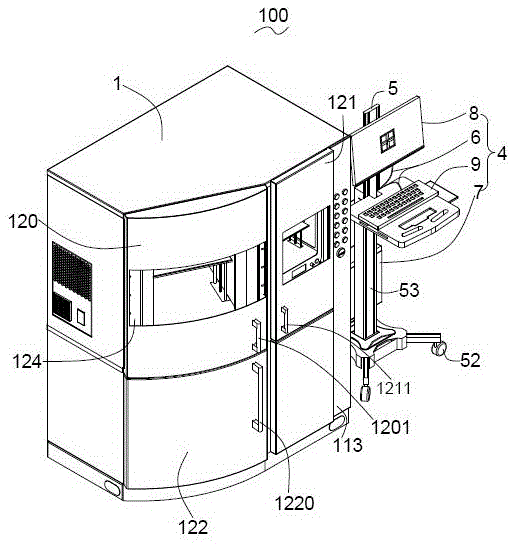

Reaction type 3D printer

ActiveCN106393669AEasy to operateEasy maintenance3D object support structuresManufacturing data aquisition/processingMulti materialControl system

The invention provides a reaction type 3D printer which is characterized in that the reaction type 3D printer comprises a housing, and a discharge device, an air flow control system, a forming chamber, an exhaust system, a movement control system and an operation panel that are located in the housing; the discharge device comprises a mixer, and two or more storage needle cylinders; the air flow control system comprises an air delivery pipe and an electromagnetic valve or an electromagnetic valve or an electromagnetic switch for controlling on-off of high pressure air; the forming chamber is internally provided with a forming substrate; the exhaust system comprises a cooling device (like a cooling ventilating fan) and a tail gas exhaust device (like a ventilating fan) for exhausting reaction tail gas; and the movement control system is used for controlling movement of various components. Compared with the prior art, the reaction type 3D printer is wide in material application range, simple to operate, and easy to maintain and popularize, and can meet the printing requirements of 3D printing on multi-material printing.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

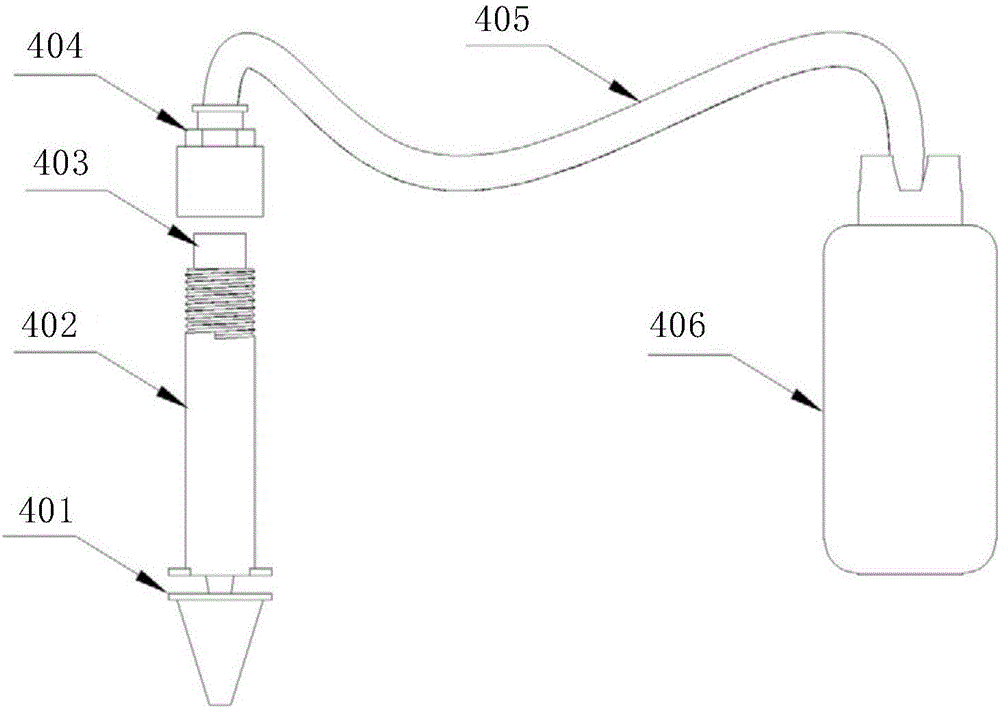

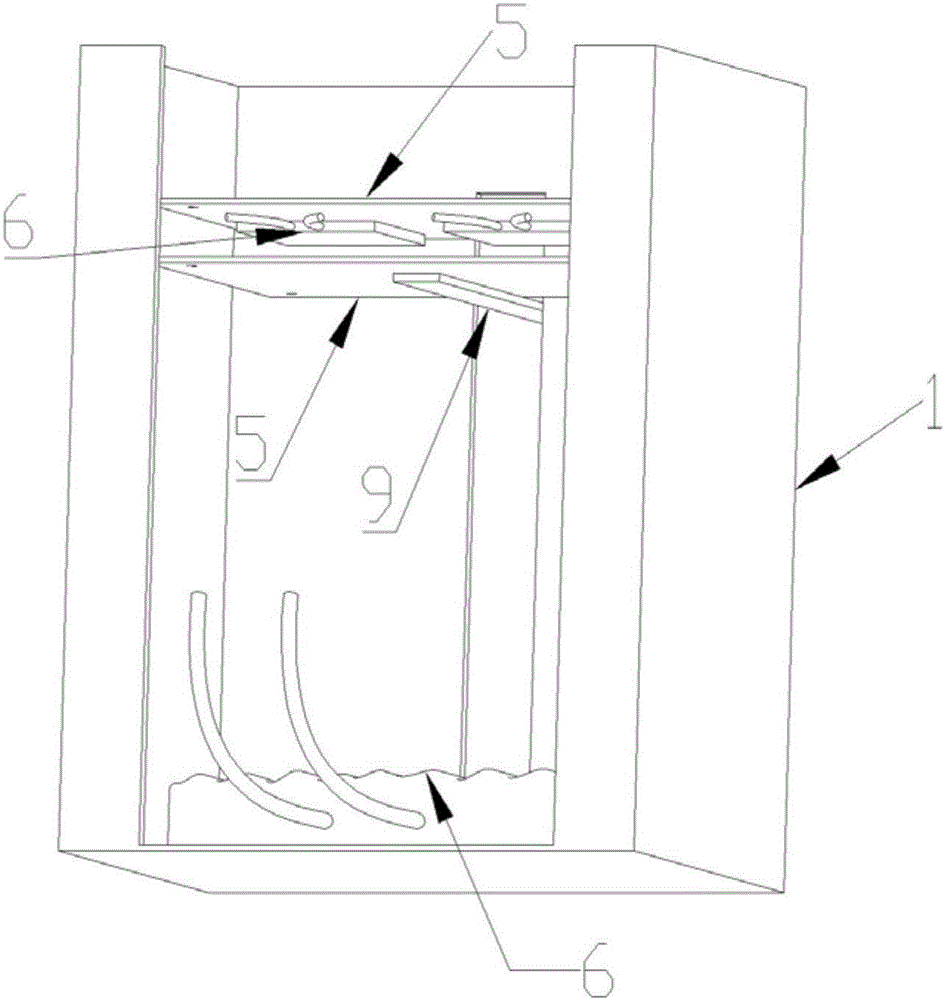

3D printing conveying device for pasty materials

ActiveCN108454096AMeet printing needsHigh precisionAdditive manufacturing apparatusFeeding arrangmentsEngineeringPiston

The invention discloses a 3D printing conveying device for pasty materials. The 3D printing device for the pasty materials comprises a material bed, a forming mechanism, a supply mechanism and a bottom plate which is installed at the bottom of the material bed, the forming mechanism and the supply mechanism are adjacently arranged on the material bed, and the forming mechanism comprises a replaceable forming cylinder, a base plate and a first piston plate; the base plate and the first piston plate are slidingly arranged on the inner wall of the forming cylinder from top to bottom in sequence,the supply mechanism comprises a supply cylinder which is adjacent to the forming cylinder, a second piston plate slidingly arranged on the inner wall of the supply cylinder and a supply plate installed at the top of the supply cylinder through screws, and the first piston plate and the second piston plate are vertically connected with one or more thrust cylinders respectively. The 3D printing conveying device for the pasty materials helps the supply amount in the supply cylinder to meet the printing requirement, the printing precision is improved, the structural design is reasonable, and theapplicability is high.

Owner:ZRAPID TECH CO LTD

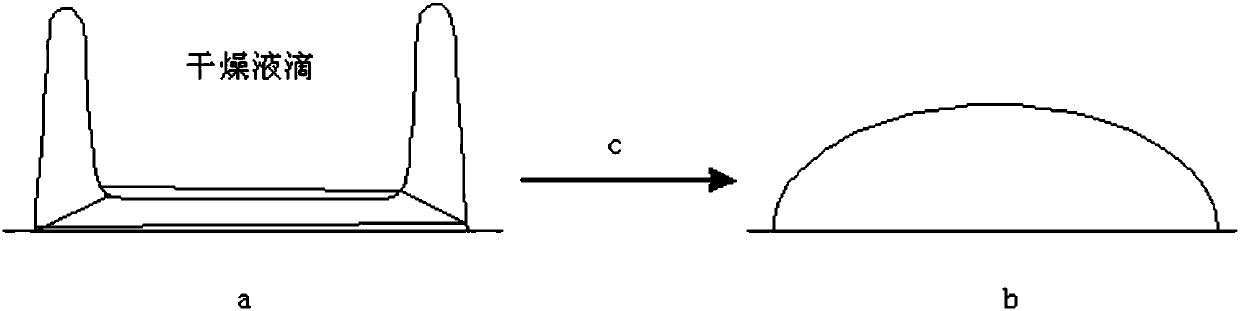

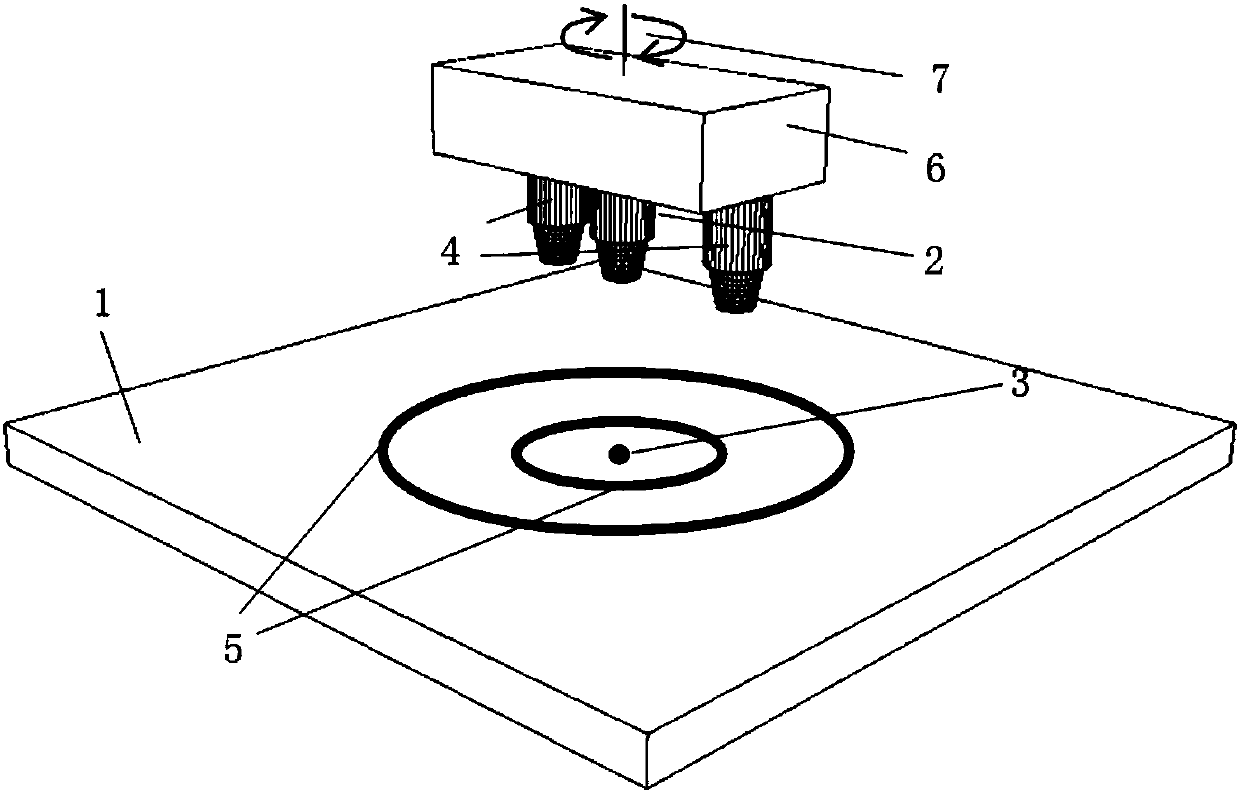

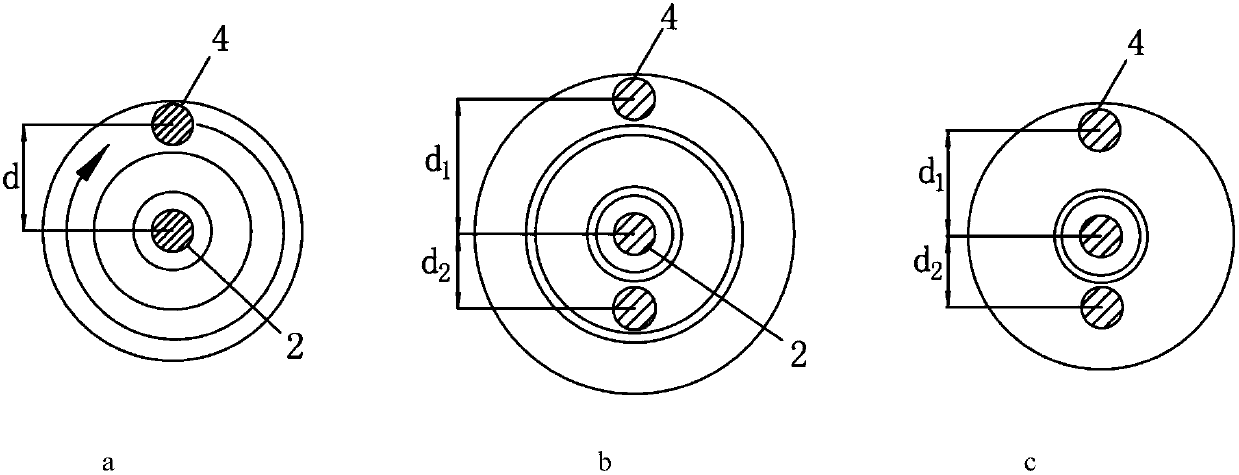

Punctate pattern ink-jet printing system and method

ActiveCN108016135ASimple designWettability requirements are not highDuplicating/marking methodsSolvent evaporationEvaporation

The invention discloses a punctate pattern ink-jet printing system and method. The system comprises a printing substrate, a nozzle device and a rotary shaft. The nozzle device is arranged above the printing substrate and comprises an ink printing nozzle, solvent printing nozzles and a printing nozzle moving assembly. The ink printing nozzle and the solvent printing nozzles are mounted on the printing nozzle moving assembly. The rotary shaft is connected with the printing nozzle moving assembly. According to an evaporitic micro-environment form control mechanism, by printing an ink pattern andsolvent patterns simultaneously, solvents evaporate finally, the ink print patter is left only, ink evaporation is affected by solvent evaporation, and the purpose of form control can be achieved at last, so that the problem of 'coffer-ring' occurring to punctate pattern ink-jet printing is solved, and the different ink even form printing demands are met.

Owner:SOUTH CHINA UNIV OF TECH

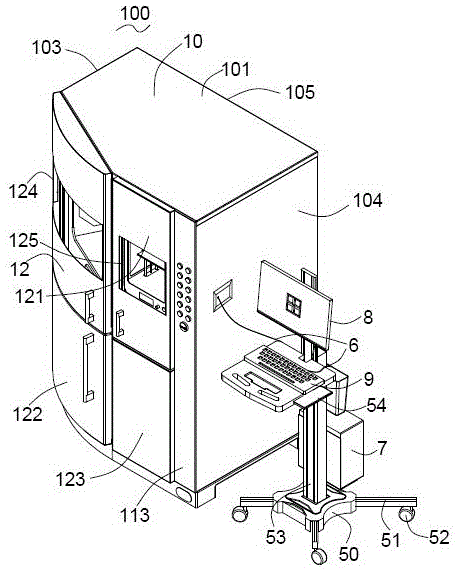

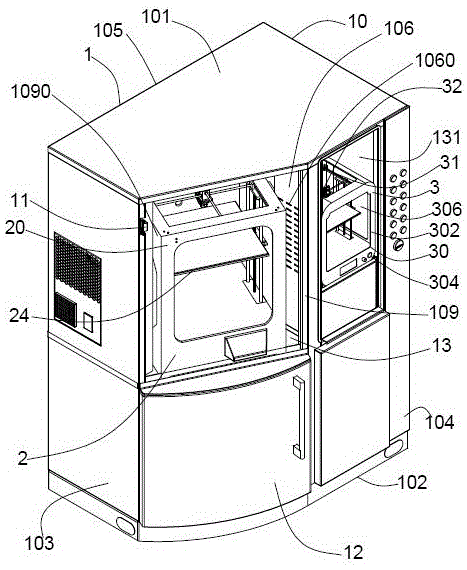

3D printing device

InactiveCN105034392ALow costReduce printing timeAdditive manufacturing apparatusComputer control systemEngineering

The invention provides a 3D printing device which is used for printing surgical implants or surgical models. The 3D printing device comprises a shell, a first printer, a second printer and a computer control system electrically connected with the first printer and the second printer at the same time, wherein the first printer and the second printer are assembled in the shell. The shell comprises a box body and a door body assembly assembled on the box body through a rotating shaft. The shell is provided with a containing space defined by the box body and the door body assembly, wherein the containing space is used for containing the first printer and the second printer. The first printer and the second printer are controlled by the same operation system of the computer control system. The first printer and the second printer contained in the shell of the 3D printing device can work at the same time under the control of the same operation system to print products with different sizes, the printing time is saved, and the working efficiency is improved; the printers can also work independently to meet different printing requirements. In addition, the 3D printing device is controlled by the same operation system, and cost can be reduced.

Owner:SHANGHAI XINJIAN MEDICAL TECH

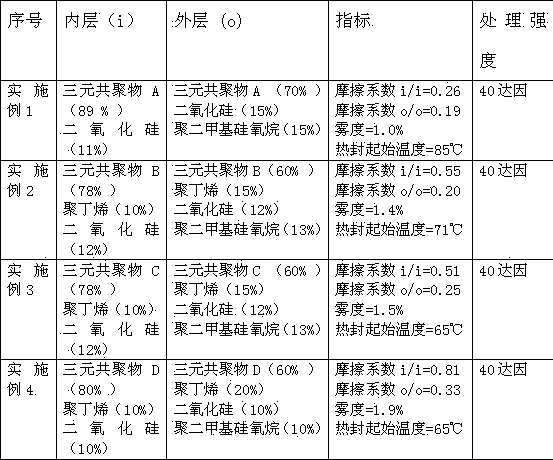

Cigarette logo permeable printing packaging film for replacing cigarette paper carton and preparation method of packaging film

The invention discloses a cigarette logo permeable printing packaging film for replacing a cigarette paper carton and a preparation method of the packaging film. The packaging film comprises an outer layer, an inner layer and a core layer between the inner layer and the outer layer, wherein the core layer consists of polypropylene homopolymer, hydrocarbon resin and master batch; both the outer layer and the inner layer are made from low-temperature heat-seal films, and each low-temperature heat-seal film consists of master batch and a copolymer. The film disclosed by the invention is prepared by adopting a multi-layer coextrusion two-way stretching method, and the heat-seal temperature of the packaging film is 60-95 DEG C; when the cigarette carton is packaged through the packaging film, the inner layer is free from heat seal with a small box packaging outer layer, and simultaneously has a printable function. By using the packaging film disclosed by the invention, exiting cigarette paper carton packaging can be completely replaced, the adhesive consumption amount and the paper consumption are reduced in cigarette packaging, the packaging cost of a cigarette factory is reduced, and simultaneously purposes of energy conservation and environmental protection can be achieved.

Owner:YUNNAN KUNLENE FILM IND

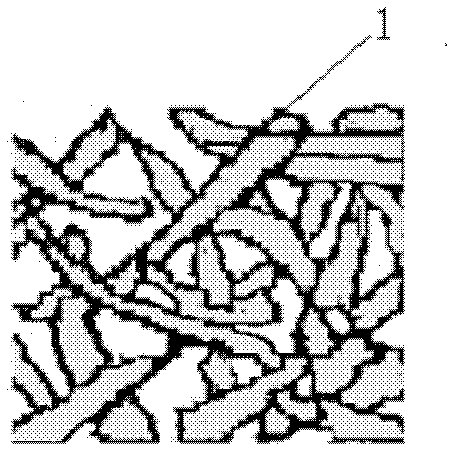

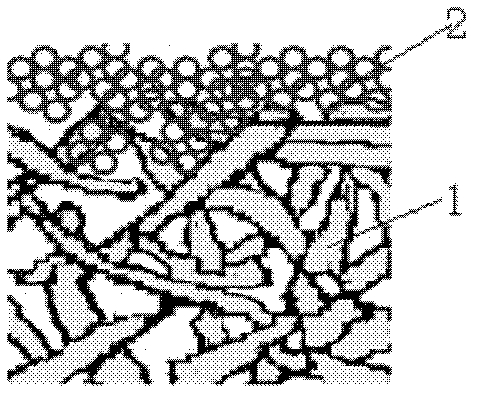

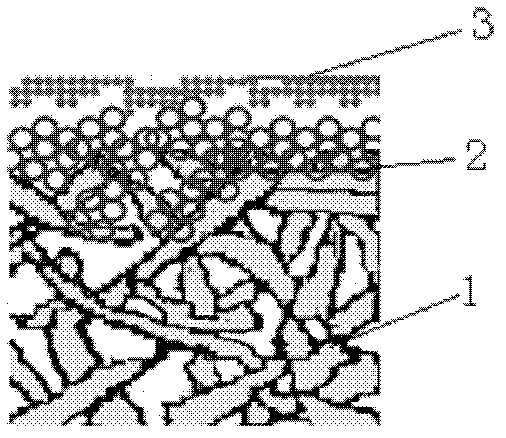

Coating newsprint and making method thereof

InactiveCN102587193AEasy to manufactureReduced whiteness requirementsCoatings with pigmentsPaper/cardboardFiberRegenerating fibers

The invention provides coating newsprint and a making method thereof. The newsprint has the following specifications: the fixed weight is 45-49g / m<2>, whiteness is 59-63%, transverse tear index is larger than 5.5m N.m<2> / g, opaqueness is larger than 95%, surface strength is larger than 1.0m / s, average smoothness of the front side and the back side is larger than 60S, the smoothness difference of the front side and the back side is less than 20%, and the longitudinal breakage length is larger than 1500m. The making method of the coating newsprint comprises the following steps of: preparing 100% regenerated fiber deinked pulp completely made from No.8 waste paper and adding auxiliary materials including retention aid, dyes and cationic starch to obtain material pulp; distributing pulp by using a headbox, forming at a neat part, carrying out composite squeezing in a four-roller three-pressing region, primary drying, surface mineral pigment coating and finishing, post-drying, reeling by using reeling machine and external re-reeling. The making method is simple, the coat of coating newsprint per ton is reduced by 250-280 yuan; the surface whiteness of the product is greatly improved, the surface of the product is smooth and fine, the ink absorption rate of the product is moderate; the printability is improved; ink consumption during printing can be reduced 10-15wt%; the printed pictures have bright color and clear wire marks; and the made coating newsprint can meet printing requirements of common newspapers and periodicals and high-quality colored newspapers and periodicals.

Owner:WUHAN CHENMING HANYANG PAPER

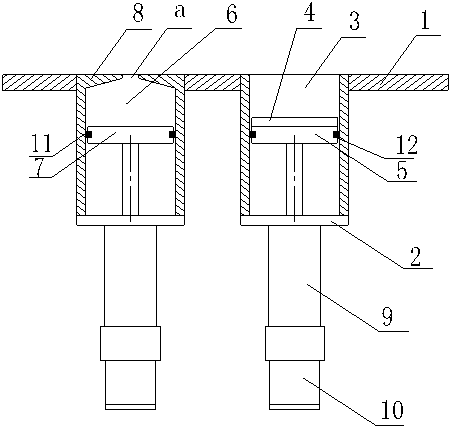

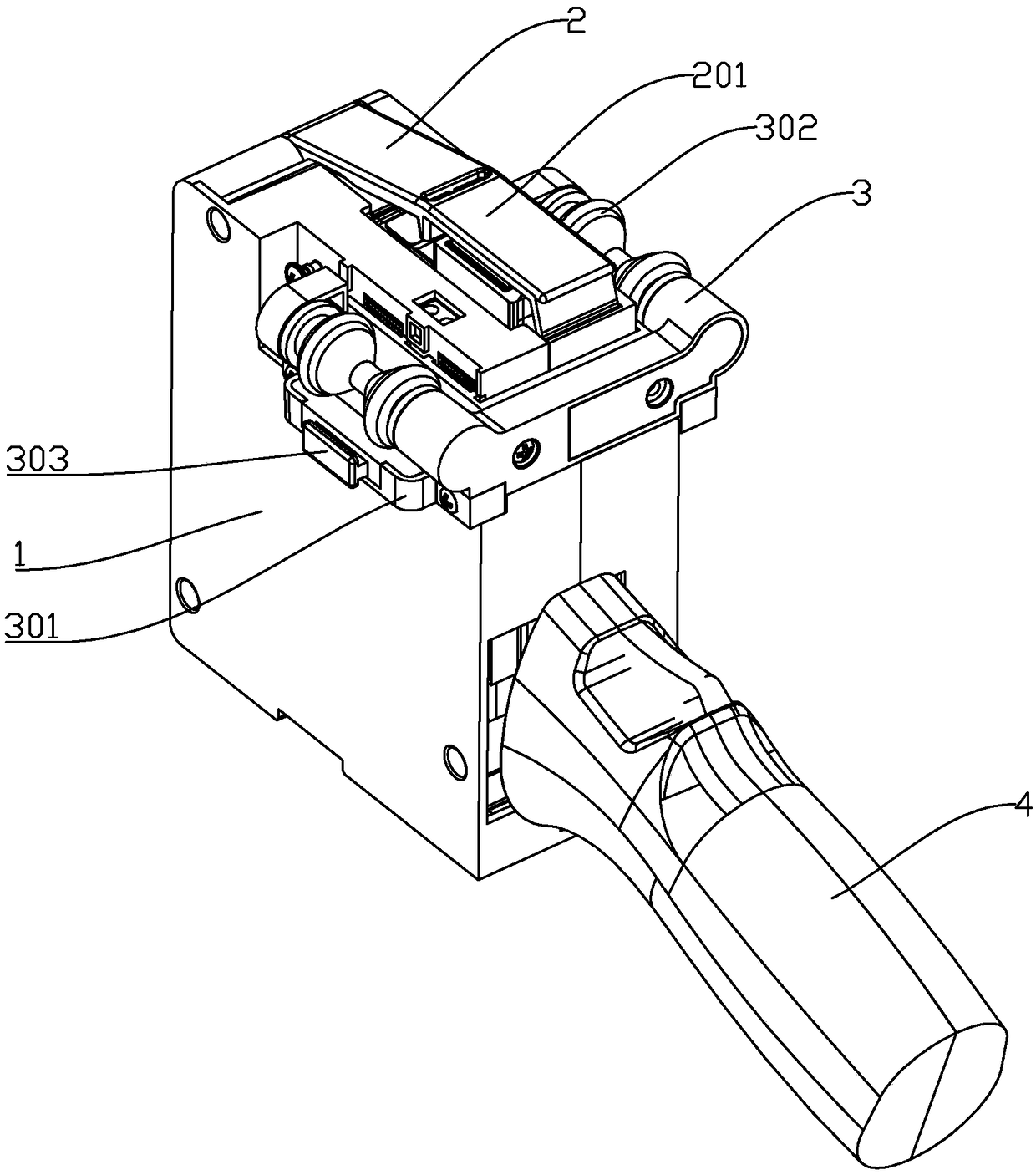

Adjustable printing device

PendingCN109397888AAvoid contact with occludersImprove print qualityTypewritersOther printing apparatusControl circuit

The present invention discloses an adjustable printing device. The adjustable printing device comprises a body, the body is internally provided with a control circuit board and an ink box storing ink,the lower end of the body is provided with a printing head electrically connected with the control circuit board, and an ink outlet is arranged at the ink box corresponding to the printing head. Roller modules are symmetrically arranged at two sides of the printing head of the body, the roller modules are installed on the body through a regulation mechanism and can regulate the installation height through the regulation mechanism to achieve regulation of a distance from the working surface of the printing head. The roller modules can regulate the distance extruded out of the printing workingend through the regulation mechanism and can return to the side of the body through regulation of the regulation mechanism so as to fit different surfaces to be printed and meet the printing demands of different printing articles, and when the surface to be printed is small and there is a shielding object around, the roller modules can be returned to and located at the side of the body so as to prevent the roller modules from butting against the shielding object, effectively improve the printing quality and widen the application range.

Owner:ZHONGSHAN SANZANG ELECTRONICS TECH

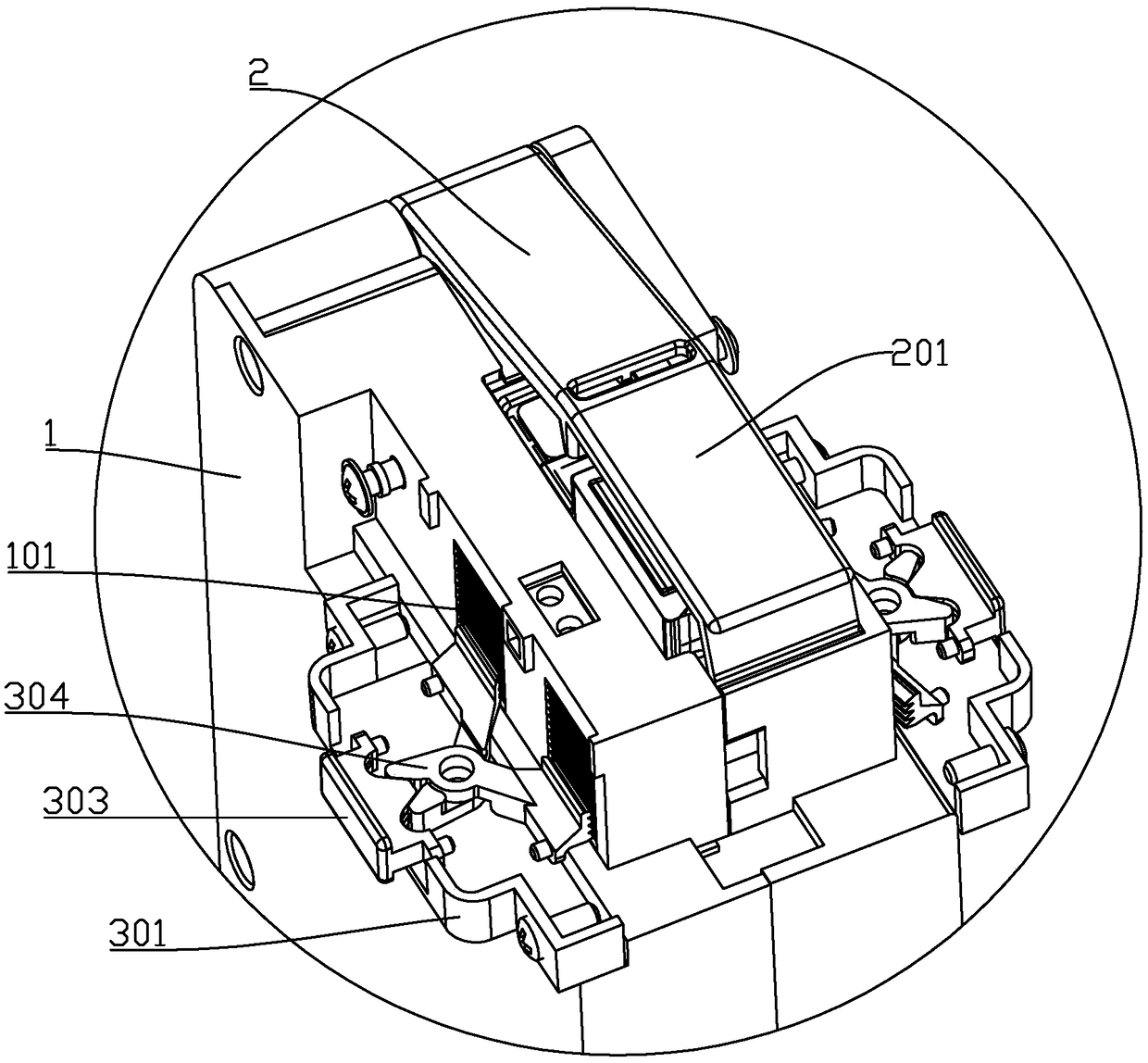

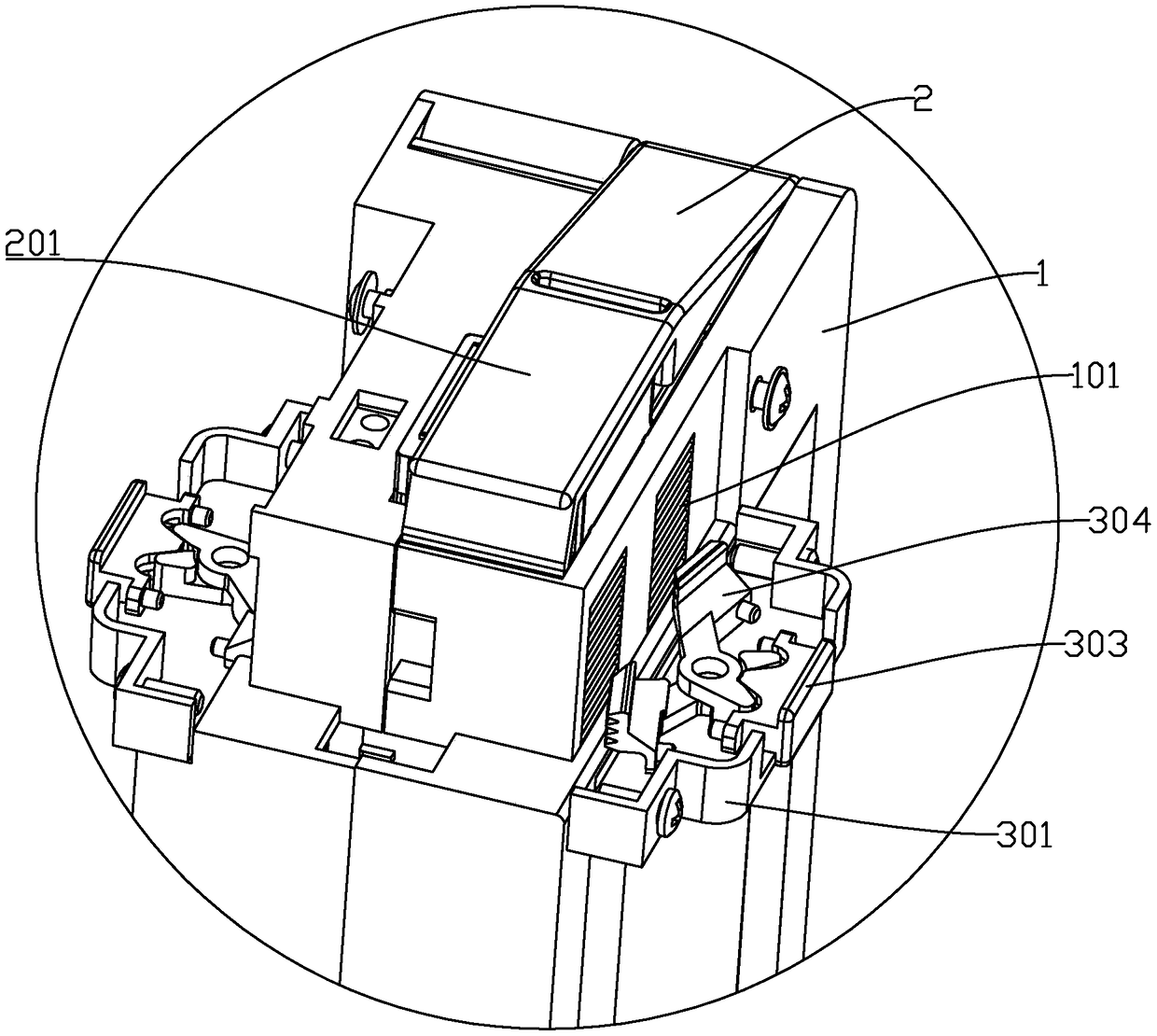

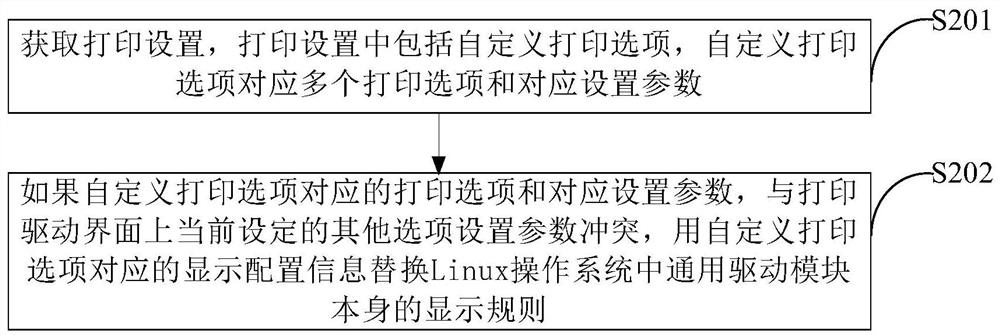

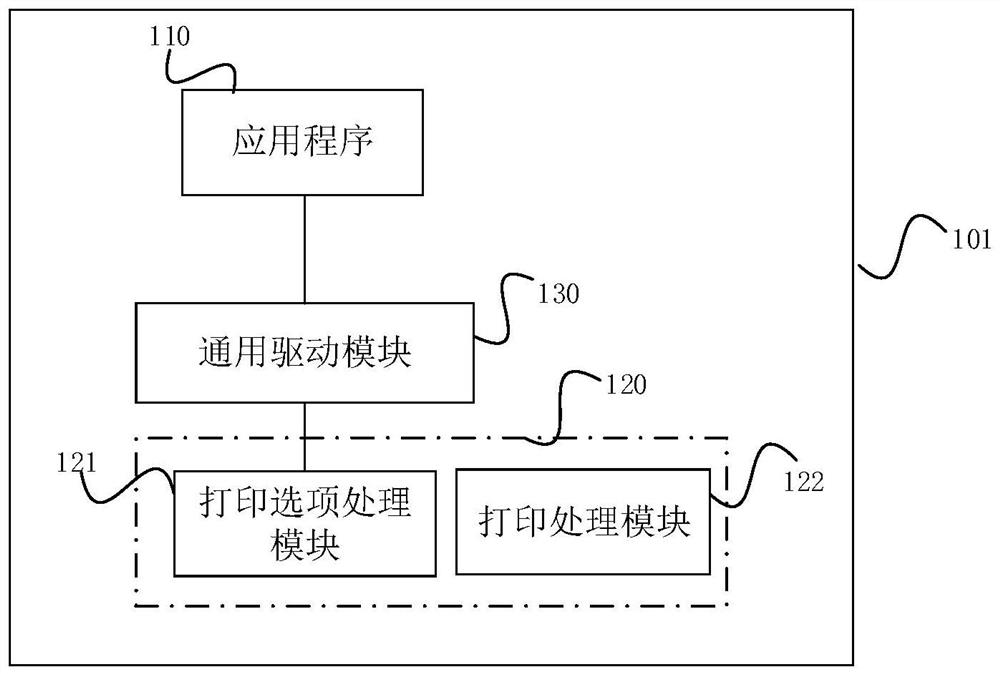

Printing control method and device, electronic equipment and storage medium

PendingCN111949233AAutomate settingsMeet printing needsDigital output to print unitsTerminal equipmentProcess engineering

The invention provides a printing control method and device, electronic equipment and a storage medium, the printing control method is applied to terminal equipment, the terminal equipment carries a Linux operating system, the method comprises the steps of acquiring printing settings, wherein the printing settings comprise custom printing options, and the custom printing options correspond to multiple printing options and corresponding setting parameters; and if the printing option corresponding to the custom printing option and the corresponding setting parameter conflict with other option setting parameters currently set on a printing drive interface, replacing a display rule of a universal drive module in the Linux operating system with display configuration information corresponding tothe custom printing option. Selection of customized printing options is provided for the user, when conflicts occur among the parameters of the printing options, the display rule of the universal driving module in the Linux operating system is not followed any more, the display configuration information corresponding to the custom printing options is used instead, and the conflicts among the options are solved.

Owner:ZHUHAI PANTUM ELECTRONICS

Temperature-regulating ink box

InactiveCN102069645AImprove temperature adaptabilityMeet printing needsPrintingSurface layerHigh heat

The invention provides a temperature-regulating ink box used for an ink-jet printer. The shell of the ink box is divided into three layers: an inner container, a heat insulating layer and an outer surface layer, wherein the inner container and the outer surface are made of a metal material with excellent heat conductivity; the heat insulating layer is made of a material with excellent heat insulation; and a temperature-regulating chip and a temperature sensor are embedded in the shell. When a printer works, a master control chip of the printer senses the temperature of ink through the temperature sensor and controls the temperature-regulating chip according to the temperature so as to regulate the temperature of the ink through the temperature-regulating chip. The temperature-regulating ink box can be used for improving the temperature adaptive capacity of the printer and can meet the printing requirement in high-temperature and high-cold environments.

Owner:FOREVER TECH

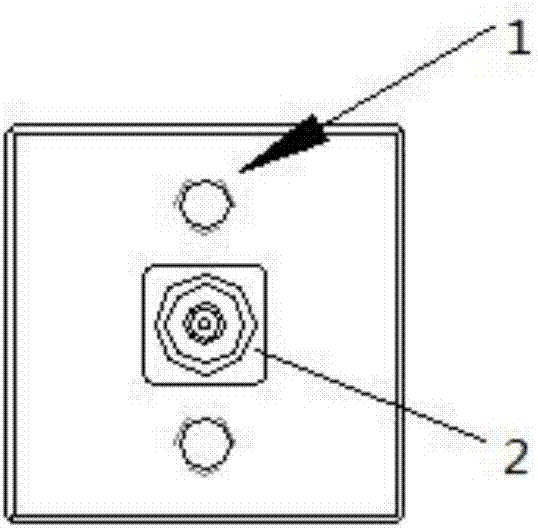

Vibrating piezoelectric spray head system

PendingCN107097409AEasy to disassemble and repairSolve scrap3D object support structuresApplying layer meansFluid viscosityEngineering

The invention discloses a vibrating piezoelectric spray head system. The vibrating piezoelectric spray head system comprises a liquid storage cavity. A liquid supply connector is arranged above the liquid storage cavity. A liquid outlet is formed in the bottom of the liquid storage cavity. A piezoelectric ceramic vibrating mechanism used for vibrating so as to spray fluid is arranged at the bottom of the liquid storage cavity. The piezoelectric ceramic vibrating mechanism comprises an annular piezoelectric ceramic vibrating piece and a metal piece, wherein the annular piezoelectric ceramic vibrating piece and the metal piece are bonded together, convex conical holes communicating with the liquid outlet are formed in the annular piezoelectric ceramic vibrating piece and the metal piece, and a vibrating signal of the piezoelectric ceramic vibrating mechanism is guided in through an electrode on one side of the annular piezoelectric ceramic vibrating piece and an electrode on one side of the metal piece. Compared with the prior art, the vibrating piezoelectric spray head system is large in vibrating amplitude, and the problems that an existing printer spray head is prone to being blocked due to the fact that the fluid viscosity is large and is scrapped when severely blocked can be effectively solved.

Owner:GUIZHOU UNIV

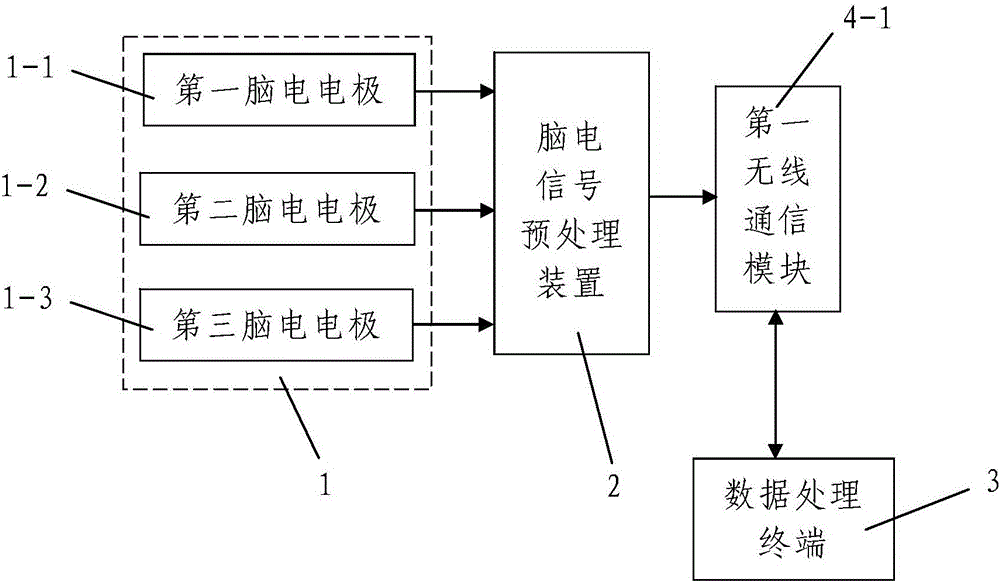

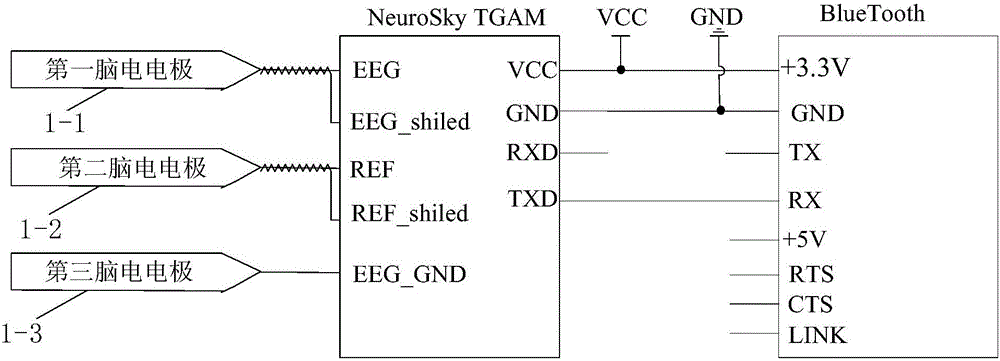

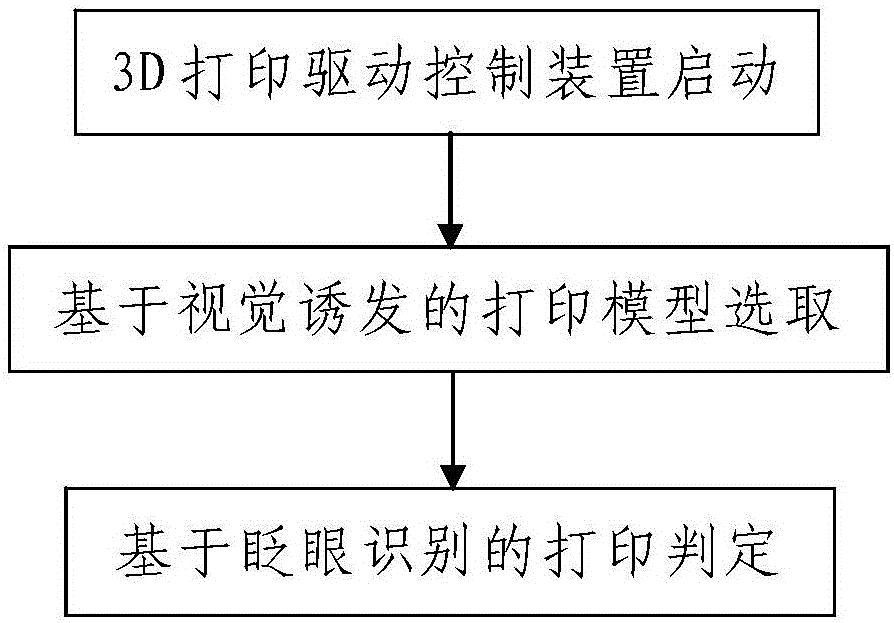

3D printer control method based on winking recognition and vision induction

InactiveCN106476281ASimple structureReasonable designAdditive manufacturing apparatusManufacturing data aquisition/processingModel selectionVision based

The invention discloses a 3D printer control method based on winking recognition and vision induction. The 3D printer control method comprises: 1, 3D printing drive control device starting, wherein a 3D printing drive control device is started, is a 3D printing drive control device based on a brain-machine interface, and comprises an EEG extraction device, an EEG pretreatment device for sampling and pretreating the signal extracted by the EEG extraction device, and a data processing terminal for communicating with the EEG pretreatment device, the data processing terminal comprises a data processer and a display device, and the data processer is connected to a 3D printer; 2, printing model selection based on vision induction; and 3, printing judgment based on winking recognition. According to the present invention, the method has characteristics of simple steps, reasonable design, convenient achieving, good use effect and simple and rapid 3D printer control, and is suitable for people having limb movement disorder and language dysfunction.

Owner:XIAN UNIV OF SCI & TECH

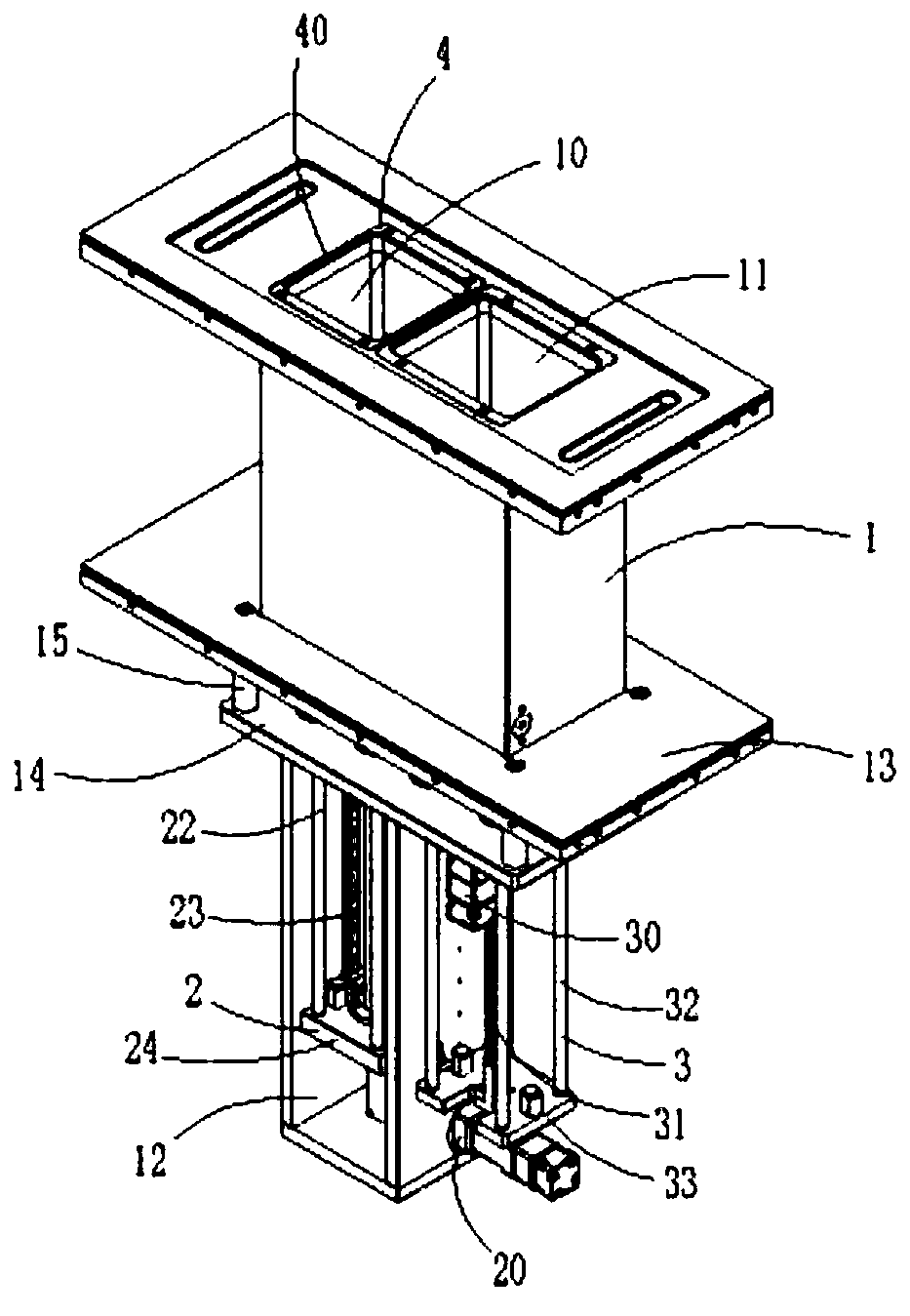

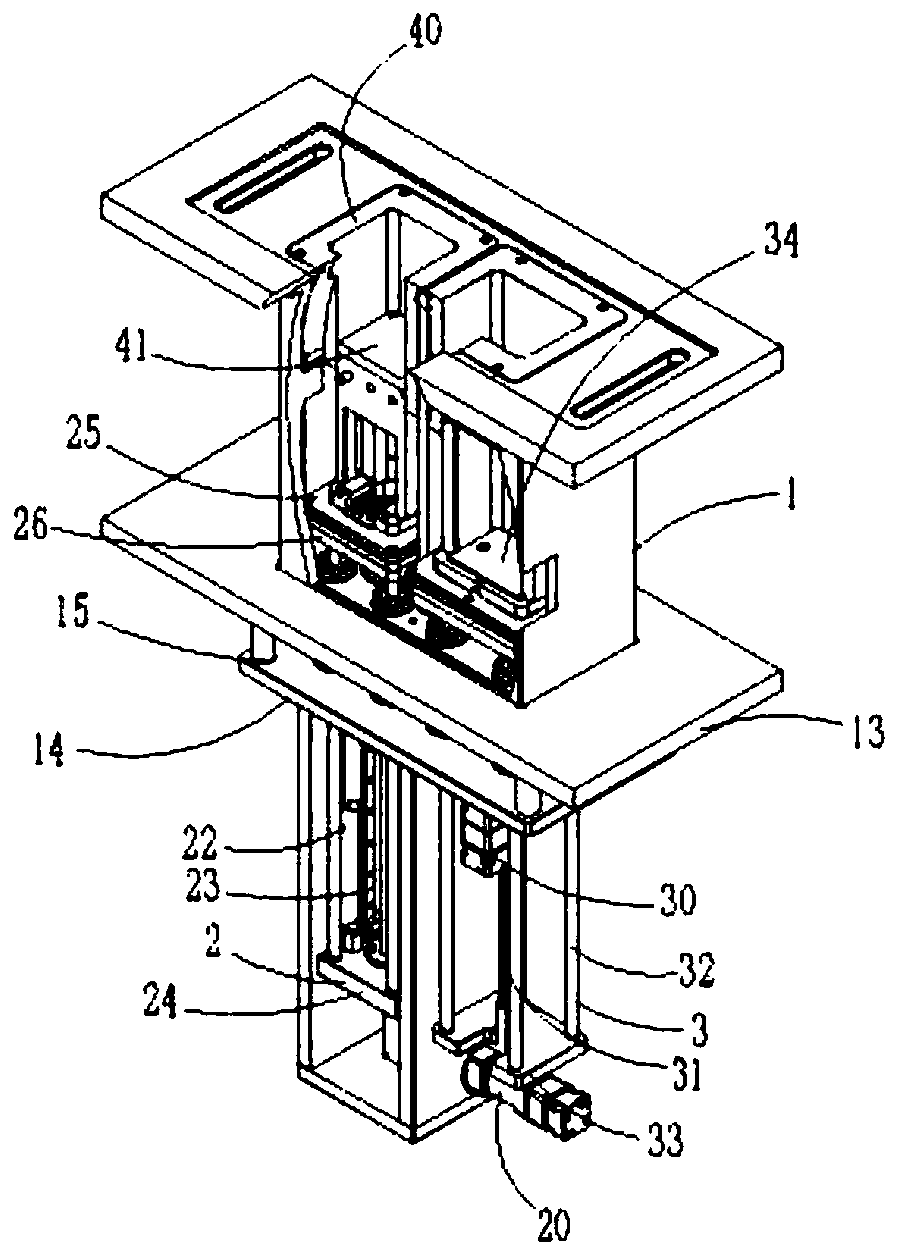

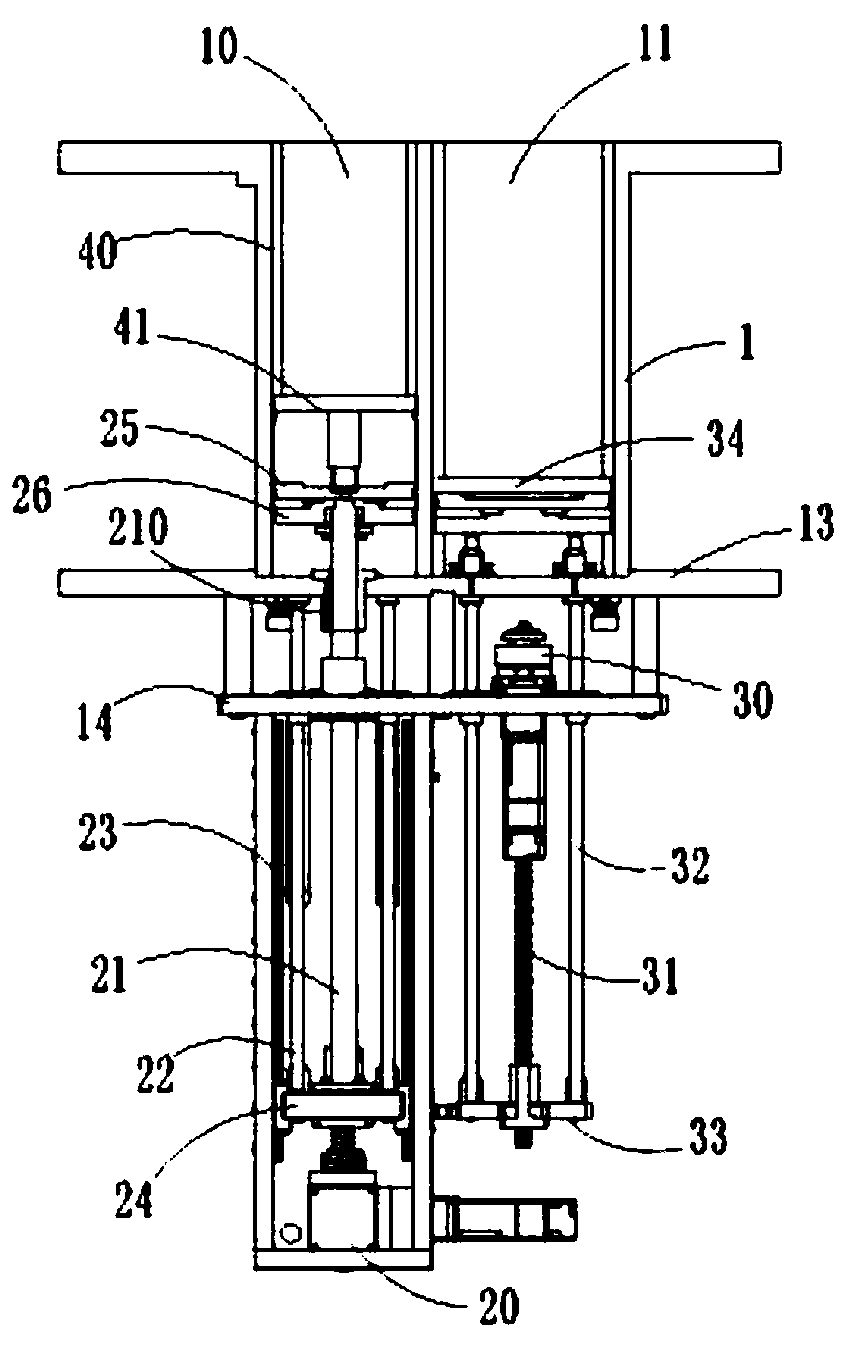

Cylinder diameter-adjustable lifting device

PendingCN111097909AImprove forming qualityLong laying timeAdditive manufacturing apparatusIncreasing energy efficiencyElectric machineryStructural engineering

The invention discloses a cylinder diameter-adjustable lifting device. The cylinder diameter-adjustable lifting device comprises a lifting cabin outside cylinder, a forming cabin lifting mechanism, apowder feeding cabin lifting mechanism and a diameter-variable mechanism, wherein the forming cabin lifting mechanism comprises a forming cabin lifting motor, a forming cabin screw, a forming cabin guide pillar, a forming cabin lifting supporting plate and a forming cabin lifting base plate, the forming cabin lifting motor provides power for the forming cabin screw, and the forming cabin lifting motor is used for driving the forming cabin lifting supporting plate, the forming cabin guide pillar and the forming cabin lifting base plate to ascend; the powder supply cabin lifting mechanism comprises a powder supply lifting motor, a powder supply cabin screw, a powder supply lifting supporting plate and a powder supply base plate, the powder supply cabin lifting motor provides power for the powder supply cabin screw and is used for pushing the powder supply lifting supporting plate and the powder supply cabin guide pillar to ascend, and then the powder supply base plate is driven to ascend. The diameter-variable mechanism is used for narrowing a printing width, the cylinder diameter-adjustable lifting device is reasonable in structural design, can meet the requirements of research anddevelopment, production and manufacturing can be further considered, and the cylinder diameter-adjustable lifting device is suitable for massive popularization.

Owner:西安朗悦智能科技有限公司 +2

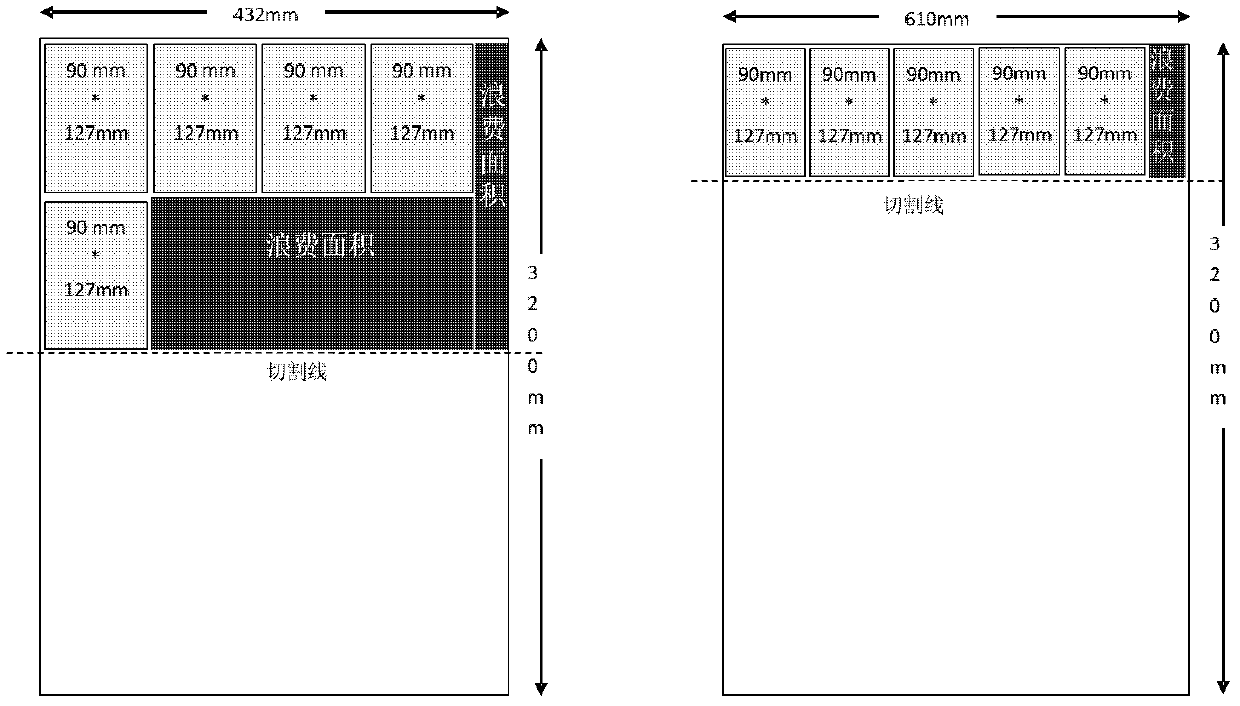

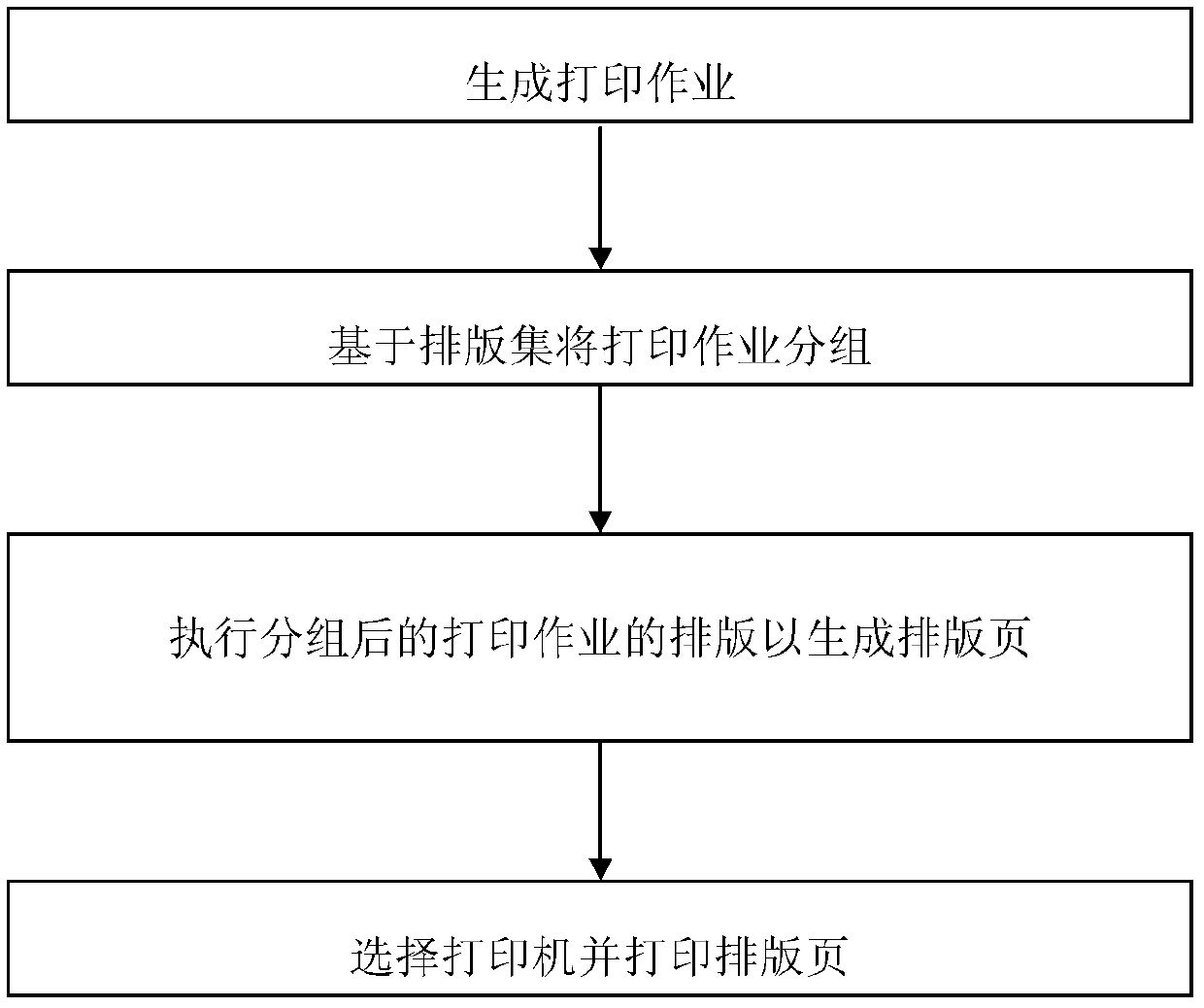

Typesetting method and typesetting equipment

InactiveCN103377181AMaximize UtilizationReduce use lossNatural language data processingSpecial data processing applicationsComputer scienceUtilization rate

The invention provides a typesetting method and typesetting equipment. The method includes that multiple typesetting sets form mutually-different typesetting set sequences, a sequence of the typesetting set sequences is acquired, each typesetting set relates to all or part of parameters of a printer or all or part of joint parameters of multiple printers, and each printer corresponds to one or multiple typesetting sets; the typesetting set sequences are selected from the sequence of the typesetting set sequences, and objects to be processed are grouped into corresponding typesetting sets in each typesetting set sequence in the chosen typesetting set sequences according to the chosen typesetting set sequences; the objects after being grouped are typeset, a score of each typesetting set sequence in the chosen typesetting set sequences is calculated on the basis of one or multiple preset parameters relating to expected typesetting results; final typesetting results of the objects to be processed are determined on the basis of the scores of the chosen typesetting set sequences. By the typesetting method and / or the typesetting equipment, utilization rate of printing resources can be maximized and cost can be lowered.

Owner:CANON KK

Preparation method of steel plate for printing

ActiveCN106079846AReduce production processImprove performanceLamination ancillary operationsLaminationPunchingLaser engraving

The invention discloses a preparation method of a steel plate for printing. The preparation method comprises the following steps that (1) the flat steel plate is fetched and subjected to laser cutting and / or laser punching, and printing patterns are formed on the steel plate; (2) the front surface and the back surface of the steel plate are subjected to roughness treatment, so that the roughness of the front surface and the back surface of the steel plate reaches a certain level; (3), the front surface and the back surface of the steel plate are each covered with a cyclic polymer film through hot pressing or chemical attachment; and (4) the portion, in the area of the printing patterns on the steel plate, of each cyclic polymer film is subjected to gasify stripping through ultraviolet laser engraving. According to the preparation method of the steel plate for printing, the steel plate replaces a screen mesh, the material and structure of a screen are changed, the manufacturing procedures of the screen are decreased, labor input is reduced, and the performance of the screen is improved.

Owner:CANGHE PRECISION IND SUZHOU +1

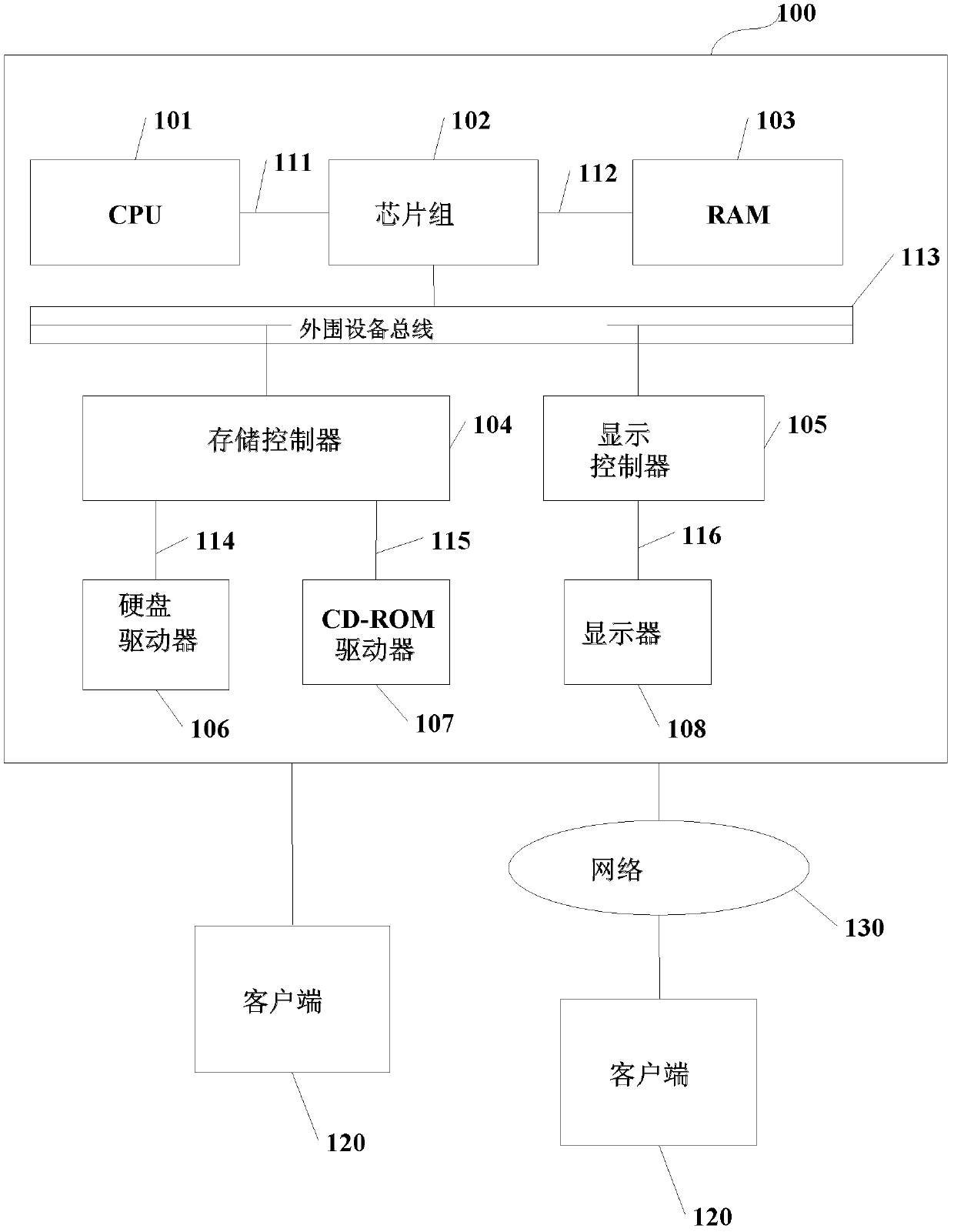

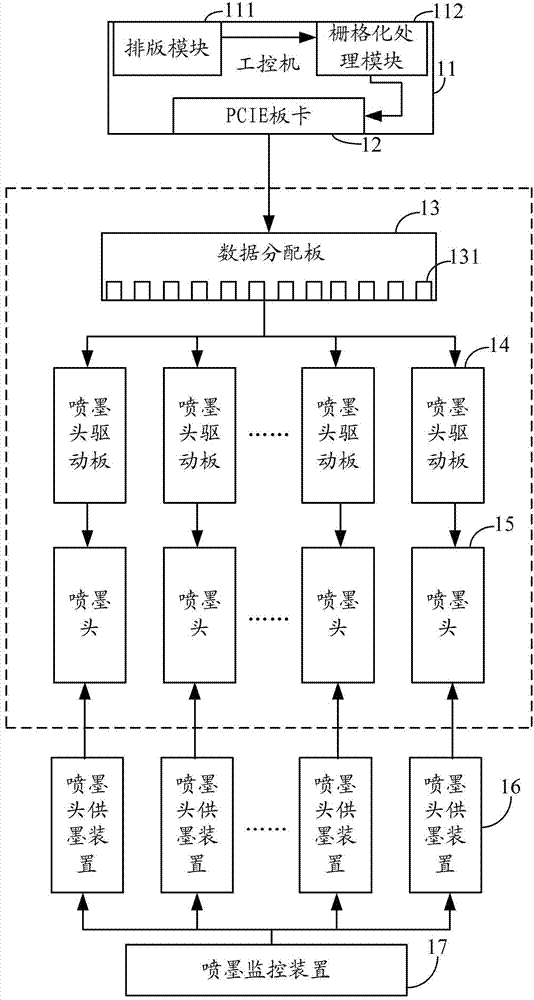

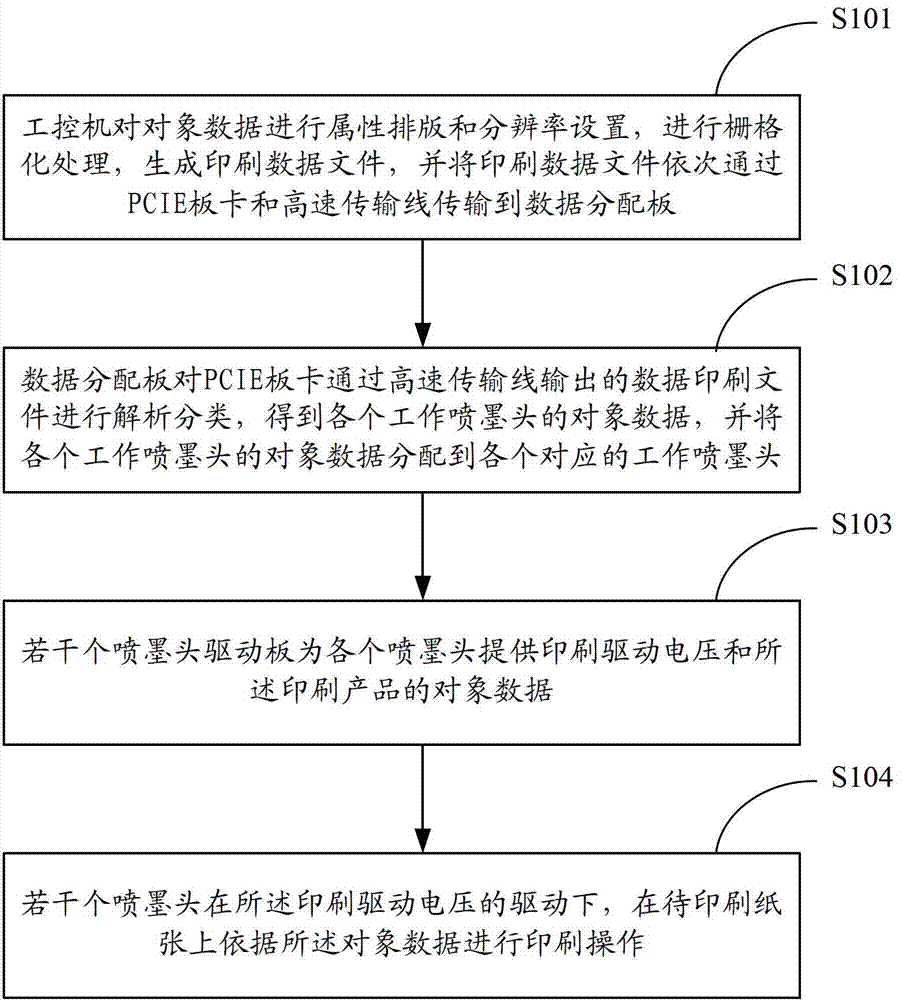

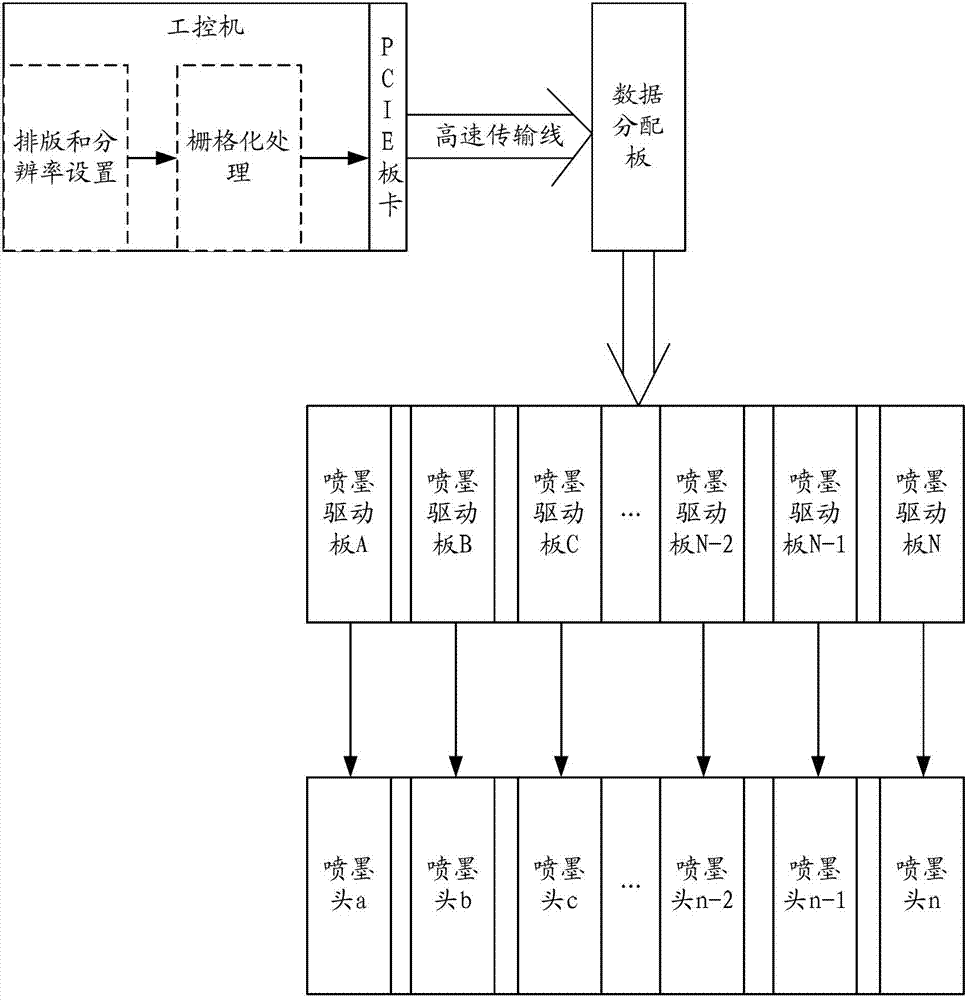

Digital printing system and digital printing method

InactiveCN103399718ARealize printingImprove printing efficiencyDigital output to print unitsData fileEngineering

The invention relates to the technical field of digital ink jet printing, and provides a digital printing system and a digital printing method. The system comprises an industrial personal computer, a data distribution board, a plurality of ink gun driving boards and ink guns. The industrial personal computer is provided with a PCIE (peripheral component interface express) board card, is used for performing typesetting and resolution setting on object data of printing products, performing rasterization and generating and outputting printing data files. The data distribution board is provided with a plurality of data transmission interfaces and transmits the data printing files to the corresponding ink gun driving boards through data transmission lines. The ink gun driving boards drive the corresponding ink guns to print. The data transmission interfaces arranged on the data distribution board can be connected with the ink gun driving boards through the data transmission lines, and a printer is subjected to ink gun module extension so as to meet multi-resolution printing requirements. The object data of different-resolution printing products can be acquired on one printer, equipment utilization rate of the printer is increased effectively, and time and resources are saved.

Owner:潍坊东航印刷科技股份有限公司

3D printing feeding and powder spreading device

InactiveCN110884118ASmooth slidingPrevent excessive travel twisting forceAdditive manufacturing apparatus3D object support structuresElectric machineryStructural engineering

The invention discloses a 3D printing feeding and powder spreading device. The 3D printing feeding and powder spreading device comprises a printer body. A powder spreading plate is mounted at the front end of the printer body. A stepping motor is mounted at the rear end of the printer body. The stepping motor is in threaded connection with a sliding block through a lead screw. The sliding block isclamped to the side edge of a lead screw box and a sliding groove through a first clamping groove and a second clamping groove correspondingly. A powder spreading roll is welded to the sliding blockthrough a second connecting plate. An electric cylinder is mounted on the powder spreading roll. The output end of the electric cylinder is connected with a silica gel scraping plate. Two limiting plates are welded to the rear end of the printer body through a first connecting plate. The 3D printing feeding and powder spreading device can protect the powder spreading roll in motion against damagecaused by collision. Moreover, a spring and a rubber plate can achieve the buffering function, and the silica gel scraping plate can be adjusted to rise and drop through the electric cylinder. The 3Dprinting feeding and powder spreading device is suitable for spreading different thicknesses of powder. The sliding block is provided with the multiple clamping grooves and clamped to the lead screw box and the sliding groove. Accordingly, torsion force of the powder spreading roll to the stepping motor is reduced.

Owner:ANHUI CHUNGU 3D PRINTING INTELLIGENT EQUIP IND TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com